Page 1

Hardware Data Sheet

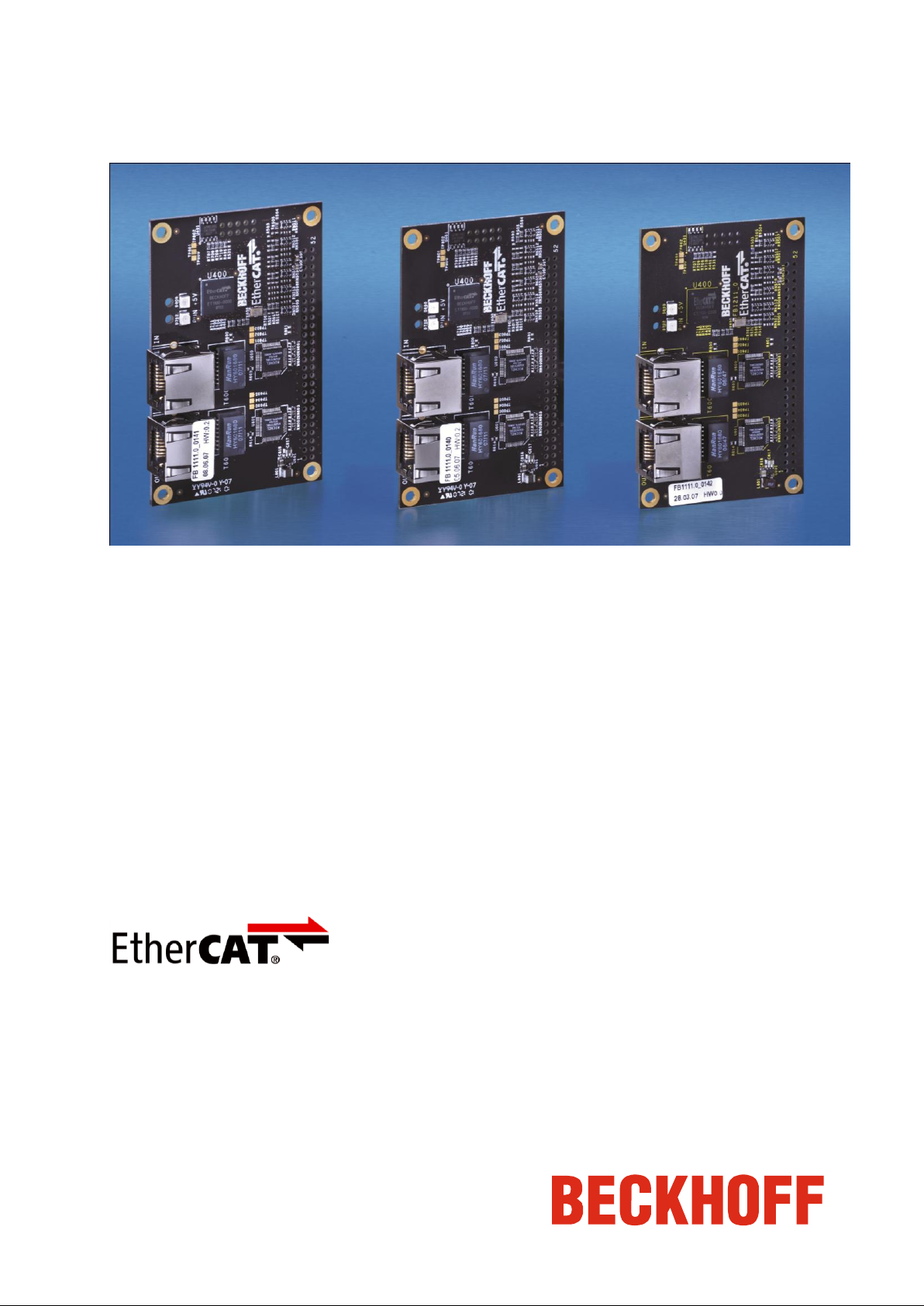

FB1111-0140

FB1111-0141

FB1111-0142

Piggyback Controller

Boards

Version 2.2

Date: 2011-12-04

Page 2

CONTENTS

CONTENTS

1 Foreword 1

1.1 Notes on the Documentation 1

1.1.1 Liability Conditions 1

1.2 Safety Instructions 1

1.2.1 Safety Rules 1

1.2.2 State at Delivery 1

1.2.3 Personnel Qualification 1

1.2.4 Description of Safety Symbols 1

1.3 Documentation Issue Status 2

2 Overview 3

2.1 Indicator LEDs 3

2.2 Variant Differentiation 3

3 Process Data Interfaces 4

3.1 PDI Configuration 4

3.2 Power Supply 6

3.3 Pinout 6

3.4 Using the FB1111-0142 in SPI- or µC-Mode 8

4 Component Placement Specification 10

4.1 Placed/Unplaced Components 10

4.2 Power Test Pads 10

4.3 FB1111-0142 – 32 bit In/Out digital Interface 11

4.3.1 Top Side of FB1111-0142 11

4.3.2 Bottom side of FB1111-0142 12

4.4 FB1111-0141 – Serial Peripheral Interface 13

4.4.1 Top side of FB1111-0141 13

4.4.2 Bottom side of FB1111-0141 14

4.5 FB1111-0140 – 8/16 bit asynchronous Microcontroller Interface 15

4.5.1 Top side of FB1111-0140 15

4.5.2 Bottom side of FB1111-0140 16

5 Interfacing with the EL9820 Evaluation Kit 17

5.1.1 Left side pin header definition 18

5.2 EL9820 stacking examples 19

6 Electrical Specification 20

6.1 Ratings 20

6.2 EMC – Electro magnetic compatibility 20

7 Mechanical Specification 21

7.1 Board Dimensions 21

7.2 Physical Connector Specification 22

7.3 Recommended Panel Opening 22

II FB1111 Piggyback Controller Board

Page 3

CONTENTS

7.4 Top/Bottom Side Component Height Definition 23

8 Appendix 25

8.1 Support and Service 25

8.1.1 Beckhoff’s branch offices and representatives 25

8.2 Beckhoff Headquarters 25

FB1111 Piggyback Controller Board III

Page 4

TABLES

TABLES

Table 1: Indicator LEDs ........................................................................................................................... 3

Table 2: Variants of the FB1111-014X .................................................................................................... 3

Table 3: Process data interfaces in combination with the EL9803.......................................................... 4

Table 4: Resistors for PDI Mapping ........................................................................................................ 4

Table 5: Networks for PDI Mapping ........................................................................................................ 5

Table 6: Pinout for different PDI Configurations ...................................................................................... 6

Table 7 Pinout of the FB1111-0142 in SPI and µC Mode ....................................................................... 8

Table 8: Power Test Pads ..................................................................................................................... 10

Table 9 Pin description of 8 pin right angle header ............................................................................... 18

Table 10: Typical Ratings ...................................................................................................................... 20

IV FB1111 Piggyback Controller Board

Page 5

FIGURES

FIGURES

Figure 1: Overview of the FB1111-014X ................................................................................................. 3

Figure 2: PDI Connector Power Pin Distribution ..................................................................................... 6

Figure 3: Example for placed/unplaced components ............................................................................ 10

Figure 4: Pads of resistor networks and single resistors ....................................................................... 10

Figure 5: EL9803 Adapter board – Top Side ......................................................................................... 17

Figure 6: EL9803 Adapter board – Bottom Side ................................................................................... 18

Figure 7: Left side right angle header pinout ......................................................................................... 18

Figure 8: Microcontroller Configuration with EL9803 ............................................................................ 19

Figure 9: SPI Configuration with EL9803 .............................................................................................. 19

Figure 10: Connection to GND-Earth .................................................................................................... 20

Figure 11: Board dimensions of the FB1111 – Top View ...................................................................... 21

Figure 12: Recommended Panel Opening ............................................................................................ 22

Figure 13: Component height zones for the top side of FB1111-014X ................................................. 23

Figure 14: Component height zones for the bottom side of FB1111-014X ........................................... 24

FB1111 Piggyback Controller Board V

Page 6

ABBREVIATIONS

µController

Microcontroller

as.

Asynchronous

DC

Direct Current

EEPROM

Electrically Erasable Programmable Read Only Memory. Non-volatile memory used

to store ESC configuration and description.

ESC

EtherCAT Slave Controller

EtherCAT

Real-time Standard for Industrial Ethernet Control Automation Technology

GND-Earth

Ground-Earth

LED

Light Emitting Diode, used as an indicator

PCB

Printed Circuit Board

PDI

Process Data interface

SPI

Serial Peripheral Interface

RJ45

FCC Registered Jack, standard Ethernet connector (8P8C)

ABBREVIATIONS

VI FB1111 Piggyback Controller Board

Page 7

Foreword

Danger

This symbol is intended to highlight risks for the life or health of personnel.

Warning

This symbol is intended to highlight risks for equipment, materials or the environment.

Note

This symbol indicates information that contributes to better understanding.

1 Foreword

1.1 Notes on the Documentation

This description is only intended for the use of trained specialists in control and automation engineering who are familiar with the applicable national standards. It is essential that the following notes and

explanations are followed when installing and commissioning these components.

1.1.1 Liability Conditions

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

The documentation has been prepared with care. The products described are, however, constantly

under development. For that reason the documentation is not in every case checked for consistency

with performance data, standards or other characteristics. None of the statements of this manual represents a guarantee (Garantie) in the meaning of § 443 BGB of the German Civil Code or a statement

about the contractually expected fitness for a particular purpose in the meaning of § 434 par. 1 sentence 1 BGB. In the event that it contains technical or editorial errors, we retain the right to make alterations at any time and without warning. No claims for the modification of products that have already

been supplied may be made on the basis of the data, diagrams and descriptions in this documentation.

© This documentation is copyrighted. Any reproduction or third party use of this publication, whether in

whole or in part, without the written permission of Beckhoff Automation GmbH, is forbidden.

1.2 Safety Instructions

1.2.1 Safety Rules

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

1.2.2 State at Delivery

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH.

1.2.3 Personnel Qualification

This description is only intended for the use of trained specialists in control and automation engineering who are familiar with the applicable national standards.

1.2.4 Description of Safety Symbols

The following safety symbols are used in this operating manual. They are intended to alert the reader

to the associated safety instructions.

FB1111 Piggyback Controller Board 1

Page 8

Foreword

Version

Comment

0.1

First Version

0.2

Figure for PDI Connector supply added

PDI-Pinout checked and modified

Section for electrostatic protection added

Figures of component placement updated.

0.3

Description of EL9803 added

Figures illustrating component heights added

0.4

Foreword added

Format corrections

0.5

Corrections in figures

0.6

Errors in sections 4 removed

1.0

First official release

1.1

Modification of component height values in chapter 7.4

1.2

Dimension added in Figure 10

1.3

Table added in chapter 3

Figure added in chapter 4

Modifications in chapter 5

1.4

Operating- and storage temperature recommendations

1.5

EEPROM reprogramming information added in chapter 3

1.6

R525 changed to “placed” for SPI-PDI in Table 4

1.7

1.8

Comment in chapter 3 concerning EL9800_A

1.9

CPU_CLK_IN signal for synchronous µ-Controller interface in Table 6 added

2.0

PIN 30 changed to D[9] in Table 6

2.1

Pinout of FB1111-0142 in SPI- and µC-Mode added

2.2

Ethernet PHYs changed.

1.3 Documentation Issue Status

2 FB1111 Piggyback Controller Board

Page 9

Overview

IN

TR 0

ET1100

+5VRUN

Port 0

E²P

Link 1 Link 0

PHY

0

PDI Configuration

Area

PDI Connector

OUT

TR 1

Port 1

PHY

1

LED

Comment

+5V

Indicates 5V power supply

RUN

RUN indicator (LED) for application state

Link 0

Link/Act Indicator (LED) for port 0

Link 1

Link/Act Indicator (LED) for port 1

Product Code

Sub Code

PDI Interface

Comment

FB1111

0140

µController

16/8 bit asynchronous Microcontroller Interface

FB1111

0141

SPI

Serial Peripheral Interface (Slave)

FB1111

0142

Digital IO

32 bit In/Out digital interface

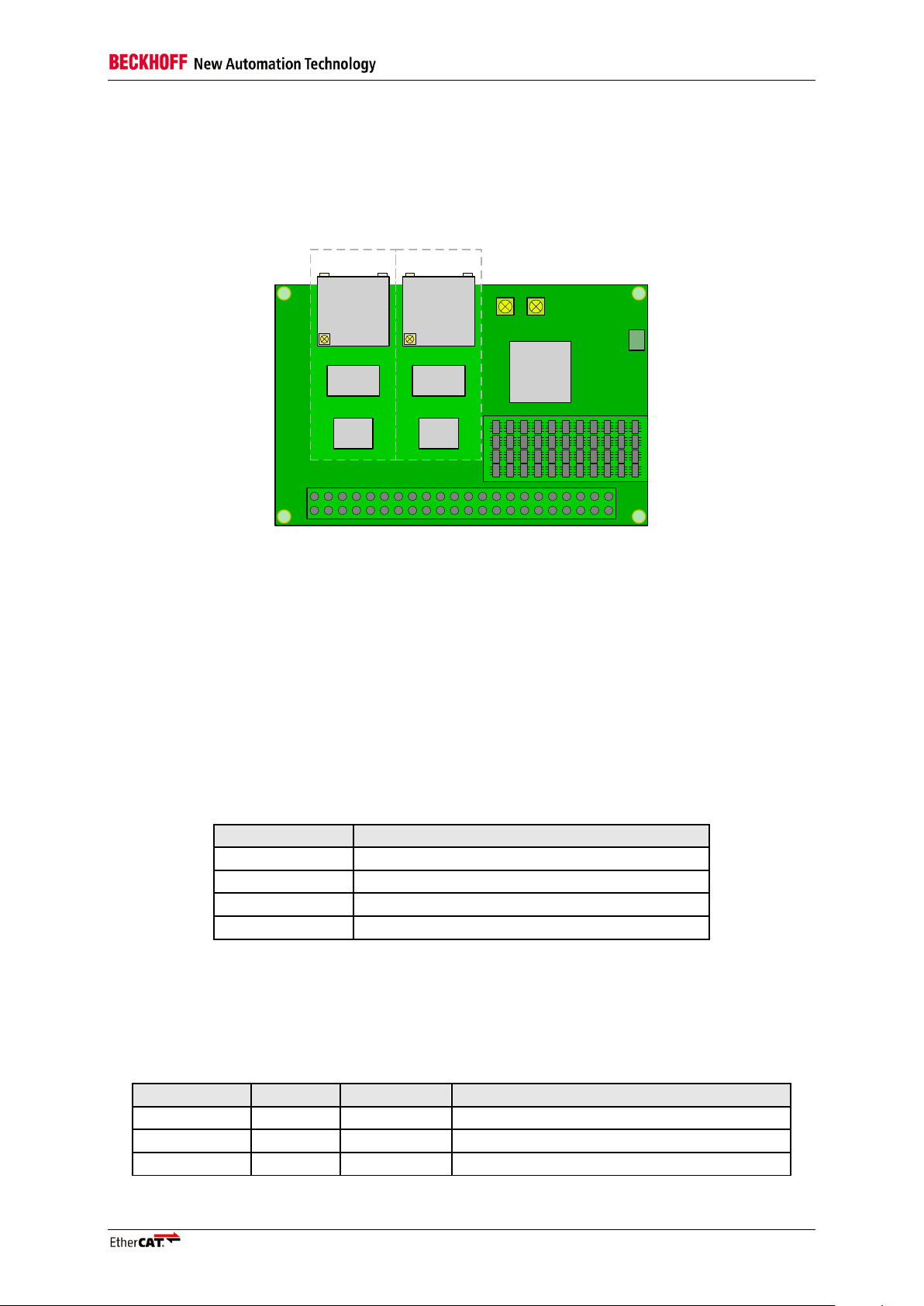

2 Overview

The EtherCAT Piggyback controller boards FB1111-014X combine an ET1100 EtherCAT Slave Controller, two EtherCAT ports and a PDI-Connector on a printed circuit board. The Piggyback controller

boards can as well be used for EtherCAT evaluation purposes as assembled into customer end products. Three variants with different Process Data Interfaces (PDIs) are existing in order to cooperate

with the most commonly known hardware interfaces like digital IO, SPI and Microcontroller.

Figure 1: Overview of the FB1111-014X

The board is structured in areas for Port 0 and Port 1, the PDI Connector, a PDI Configuration Area,

EEPROM, LEDs, and the ET1100 EtherCAT Slave Controller. While the EtherCAT port configuration,

LEDs, ET1100 and EEPROM are identical for the different variants of the FB1111-014X, the PDI Configuration Area differs in order to achieve different PDI Connector pinouts. Each EtherCAT port in Figure 1 combines a PHY, magnetics and an RJ45 connector. The PDI Configuration Area is a field of

resistors. Different pinouts on the PDI connector can be achieved by different resistor combinations in

this area. (See chapter 3.)

2.1 Indicator LEDs

Four LEDs for information about the device status are available on all three variants of the FB1111.

Table 1 is giving an overview over the indicator LEDs on the PCB.

Table 1: Indicator LEDs

2.2 Variant Differentiation

The three variants of the FB1111-014X are corresponding to three different PDI configurations. The

type of PDI interface can be identified by the last position in the product code. In Table 2 the variants

of the FB1111-014X are listed with respect to the different PDI interfaces.

FB1111 Piggyback Controller Board 3

Table 2: Variants of the FB1111-014X

Page 10

Process Data Interfaces

Piggyback Variant

Digital IO

µ-Controller

SPI

FB1111-0140

X

FB1111-0141

X

FB1111-0142

X

FB1111-0142

with EL9803 in

µC-Position

FB1111-0142

with EL9803 in

SPI-Position

Designator

Value

Footprint

0142 - 32bit Digital IO

0141 - SPI

0140 - 16bit as. µC

R500

0R

0603 X X R501

4.7k

0603 X R502

0R

0603 X

R503

4.7k

0603 X R504

0R

0603 X X R505

4.7k

0603

X

R506

0R

0603 X

R507

0R

0603 X X R508

0R

0603

X

R509

0R

0603 X R510

0R

0603 X

R511

0R

0603

X

R512

0R

0603 X R513

0R

0603

X

R514

0R

0603 X

X

Note

Usage of the EL9803 adaptor board becomes obsolete, if the FB1111-014X is

used in combination with the EL9800_4A evaluation board.

3 Process Data Interfaces

The Process Data Interface is used to communicate with external hardware. The printed circuit board

of the FB1111 supports three different PDI configurations. Thus the FB1111-0142 can be converted

into the FB1111-0140 and FB1111-0141 by replacing resistors in the PDI Configuration Area. As the

EL9820 Evaluation Kit contains the EL9803 adapter board, manual modification of the FB1111-0142 is

unnecessary. Using the EL9803, the SPI and µ-Controller interfaces can be realized without modifying

the FB1111-0142 piggyback controller board. Anyhow for in system testing manual modification of the

PDI Configuration Area may be necessary. Therefore in chapter 0 resistor mapping is listed. According to this mapping the signal pinout on the process data interface connector is shown in chapter 3.3.

Table 3 gives an overview about the FB1111-014X and EL9803 combinations. In chapter 5 detailed

information about the usage of the EL9803 in combination with the FB1111-0142 piggyback controller

board is given.

Table 3: Process data interfaces in combination with the EL9803

The Process Data Interface can be changed by reprogramming the EtherCAT configuration EEPROM

using TwinCAT.

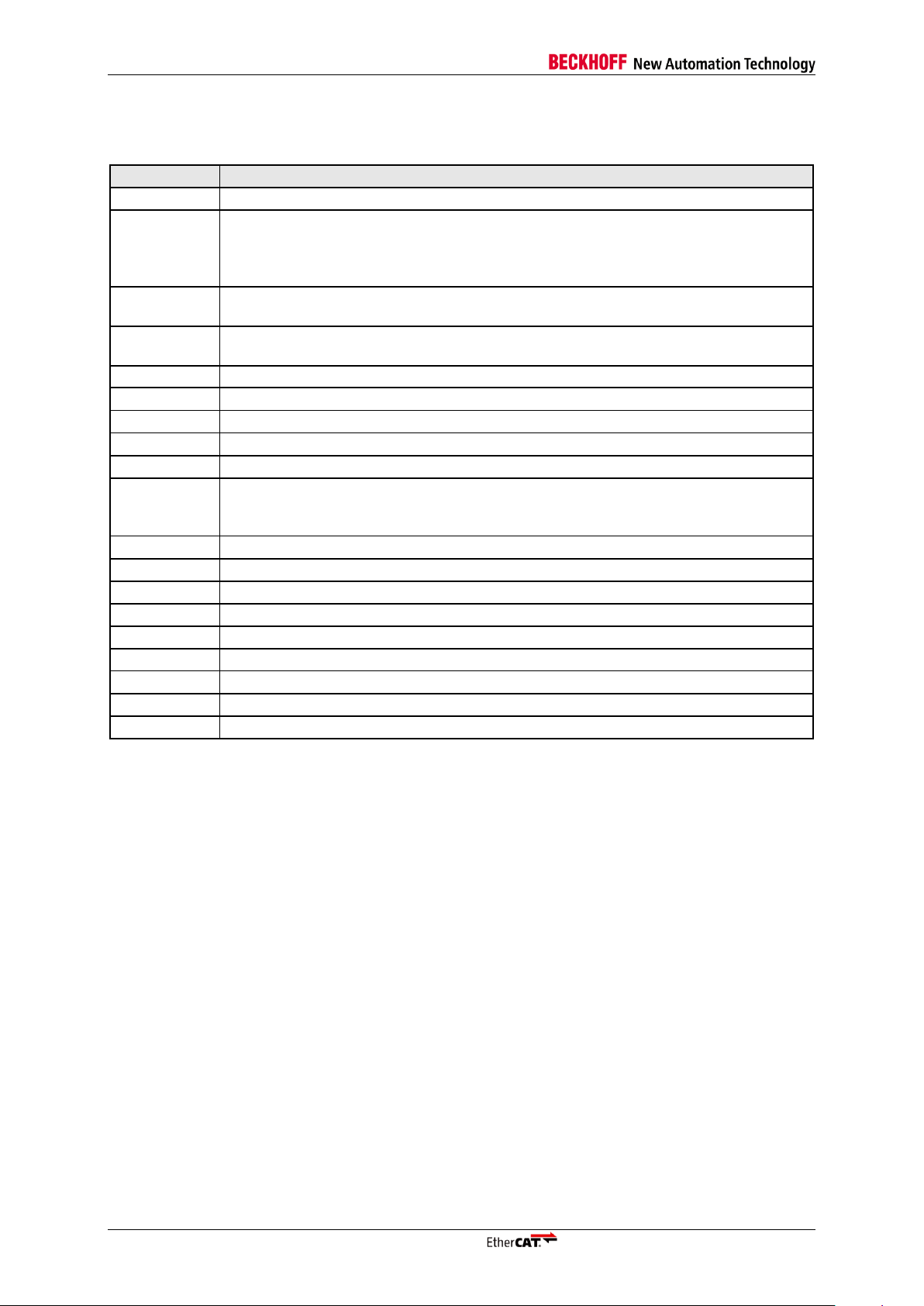

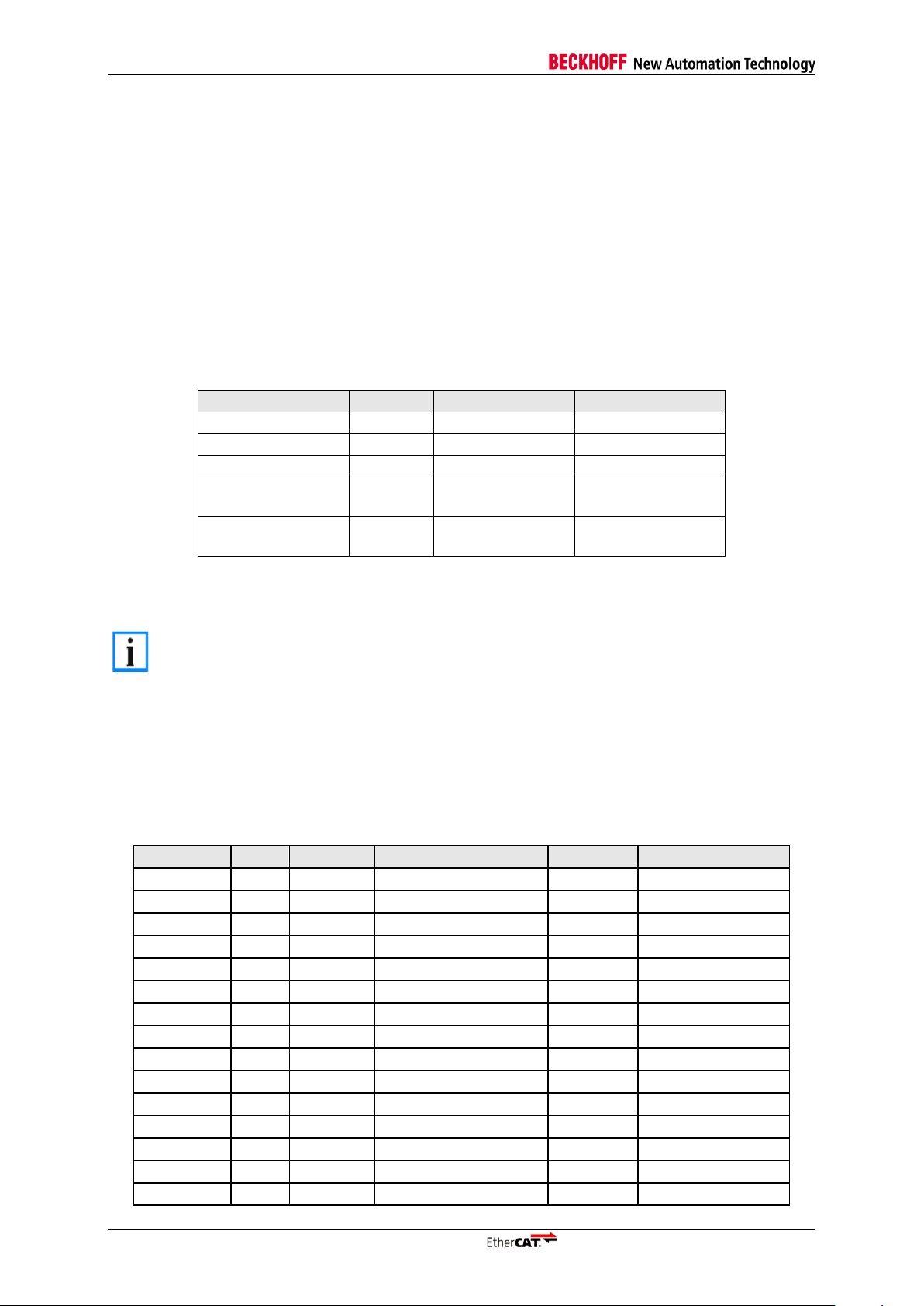

3.1 PDI Configuration

Table 4 and Table 5 are showing the resistor and resistor network configuration for the different PDI

interfaces. Additionally to the designator (first column) the value (second column) and the footprint of

the desired resistor (third column) are listed. In the following columns a “X” is set, if the associated

resistor has to be placed on the PCB.

Table 4: Resistors for PDI Mapping

4 FB1111 Piggyback Controller Board

Page 11

Process Data Interfaces

Designator

Value

Footprint

0142 - 32bit Digital IO

0141 - SPI

0140 - 16bit as. µC

R515

0R

0603 X R516

0R

0603 X R517

0R

0603 X

X

R518

0R

0603 X R519

0R

0603 X R520

0R

0603 X

R521

0R

0603 X X R522

0R

0603 X R523

0R

0603

X

R524

0R

0603 X R525

0R

0603 X X R526

0R

0603

X

R527

0R

0603 X R528

0R

0603 X R529

0R

0603 X

R530

0R

0603 X R531

4.7k

0603

X

Designator

Value

Footprint

0142 - 32bit Digital IO

0141 - SPI

0140 - 16bit as. µC

RN500

4Y0R

1206 X RN501

4Y0R

1206 X RN502

4Y0R

1206 X

RN503

4Y0R

1206 X RN504

4Y0R

1206 X RN505

4Y0R

1206 X

RN506

4Y0R

1206 X RN507

4Y0R

1206 X X RN508

4Y0R

1206 X

X

RN509

4Y0R

1206 X X RN510

4Y0R

1206 X

X

RN511

4Y0R

1206 X X RN512

4Y0R

1206 X X RN513

4Y0R

1206 X

Note

4Y0R refers to a network of four independent resistors with 0R resistance. For

example resistors from PHYCOMP of the type ARV241 1206 0R can be used.

Warning

Incorrect modification of the resistor configuration can cause serious damage to

the FB1111 EtherCAT piggyback controller board. Modification of the PDI Configuration is on the users own risk and therefore not covered by warranty.

Table 5: Networks for PDI Mapping

FB1111 Piggyback Controller Board 5

Page 12

Process Data Interfaces

1

10

19

28

37

46

47 49

50

PHY 1 PHY 0

PDI Configuration Area

VCC (5V)

+3.3V

GND

1 Pin Number

Pin number

Port

0142 - 32bit Digital IO

0141 - SPI

0140 - 16bit as. µC

1

GND

2

PA0

I/O[0]

GPI[6]

A[0]

3

PA1

I/O[1]

GPI[5]

A[1]

4

PA2

I/O[2]

GPI[4]

A[2]

5

PA3

I/O[3]

GPO[7]

A[3]

6

PA4

I/O[4]

GPO[6]

A[4]

7

PA5

I/O[5]

GPO[5]

A[5]

8

PA6

I/O[6]

GPO[4]

A[6]

9

PA7

I/O[7]

GPI[3]

A[7]

10

GND

11

PB0

I/O[8]

GPI[2]

A[8]

12

PB1

I/O[9]

GPI[1]

A[9]

13

PB2

I/O[10]

GPI[0]

A[10]

14

PB3

I/O[11]

GPO[3]

A[11]

15

PB4

I/O[12]

GPO[2]

A[12]

16

PB5

I/O[13]

EEPROM Loaded

17

PB6

I/O[14]

GPO[1]

A[13]

18

PB7

I/O[15]

GPI[11]

CPU_CLK_IN

3.2 Power Supply

Figure 2 shows the distribution of the power pins on the PDI Connector from top side view.

Figure 2: PDI Connector Power Pin Distribution

The Pins 47 and 49 have to be supplied with +5V V

Pin 50 is a 3.3V Output from one DC-DC con-

CC.

verter on the FB1111-014X. The power supply on the FB1111-014X is divided in two sections. One

converter is supplying the PHYs for port 0 and 1. The second DC-DC converter supplies the ET1100

ASIC and all other parts on the printed circuit board. In consequence, the maximum current that can

be driven through the 3.3V output (Pin 50) is limited to 100mA. The GND pins, which are marked blue,

have to be connected to a ground plane on the supplying PCB. All in- and outputs are 3.3V compatible. Applying higher voltages will cause serious damage to the device.

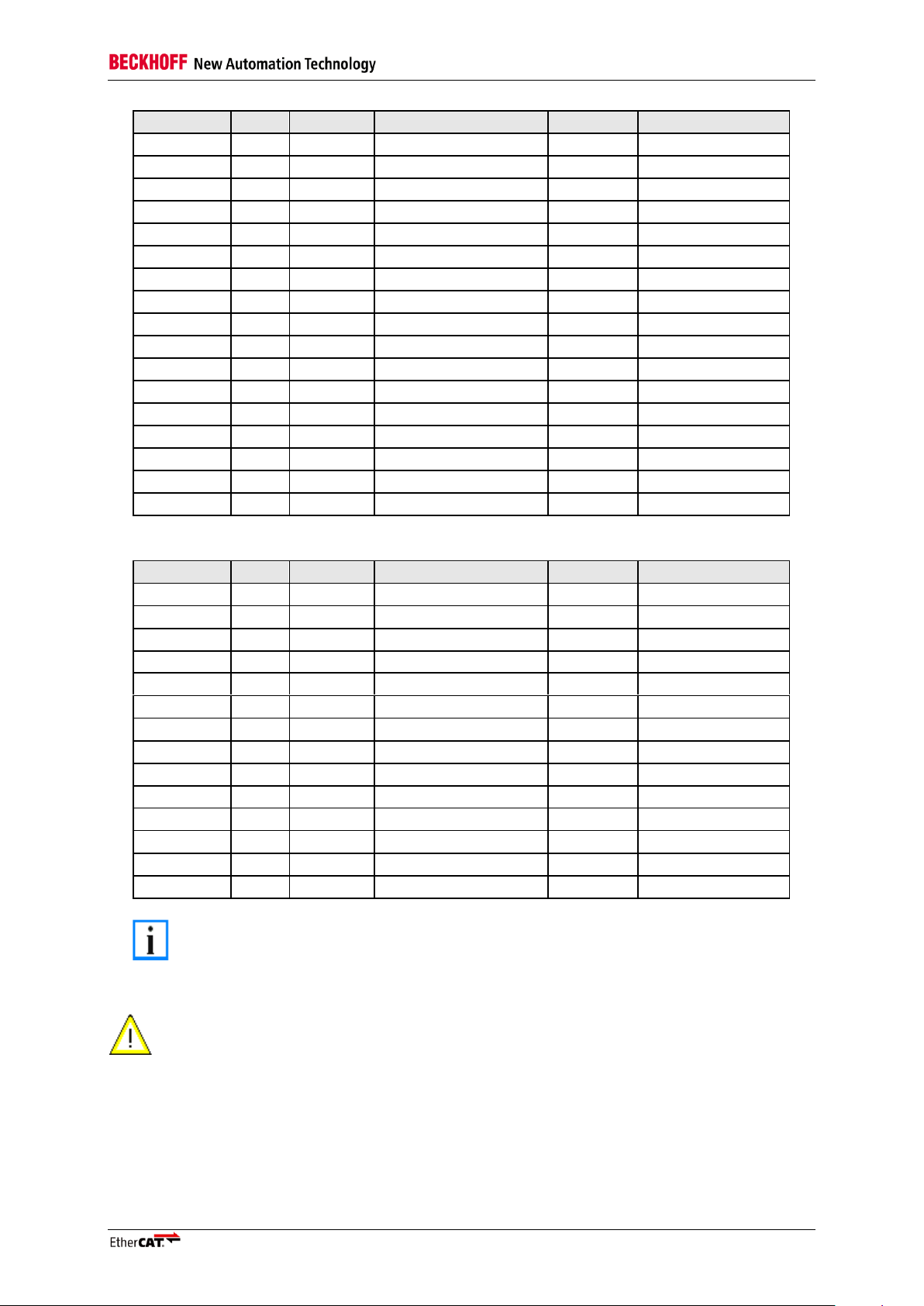

3.3 Pinout

Table 6: Pinout for different PDI Configurations

6 FB1111 Piggyback Controller Board

Page 13

Process Data Interfaces

Pin number

Port

0142 - 32bit Digital IO

0141 - SPI

0140 - 16bit as. µC

19

GND

20

PC0

I/O[16]

GPI[7]

D[0]

21

PC1

I/O[17]

GPO[8]

D[1]

22

PC2

I/O[18]

SPI_SEL

D[2]

23

PC3

I/O[19]

GPO[10]

D[3]

24

PC4

I/O[20]

GPO[11]

D[4]

25

PC5

I/O[21]

GPI[8]

D[5]

26

PC6

I/O[22]

SPI_INT

D[6]

27

PC7

I/O[23]

GPI[10]

D[7]

28

GND

29

PD0

I/O[24]

SPI_D_IN

D[8]

30

PD1

I/O[25]

GPO[13]

D[9]

31

PD2

I/O[26]

SPI_D_OUT

D[10]

32

PD3

I/O[27]

GPO[15]

D[11]

33

PD4

I/O[28]

GPI[12]

D[12]

34

PD5

I/O[29]

GPI[13]

D[13]

35

PD6

I/O[30]

GPI[14]

D[14]

36

PD7

I/O[31]

GPI[15]

D[15]

37

GND

38

PE0

WD_TRIGGER

SPI_CLK

nCS

39

PE1

OUT_VALID

N.C.

nRD

40

PE2

SOF

N.C.

nWR

41

PE3

N.C.

N.C.

nBHE

42

PE4

SYNC[0]/LATCH[0]

43

PE5

SYNC[1]/LATCH[1]

44

PE6

LATCH_IN

N.C.

nINT

45

PE7

OE

N.C.

nBUSY

46

GND

47

VCC

48

N.C.

49

VCC (5V Input)

50

3.3V Out

51

PF0

OE_CONF

GPO[0]

A[14]

52

PF1

CLK25_OUT

N.C.

A[15]

FB1111 Piggyback Controller Board 7

Page 14

Process Data Interfaces

Pin number

Port

SPI

16bit as. µC

1 GND

GND

2

PA0

SPI_CLK

CS

3

PA1

SPI_SEL

RD

4

PA2

SPI_DI

WR

5

PA3

SPI_DO

BUSY

6

PA4

SPI_IRQ

IRQ

7

PA5

N.C.

BHE

8

PA6

EEPROM Loaded

9

PA7

N.C.

ADR[15]

10

GND

11

PB0

GPO[0]

ADR[14]

12

PB1

GPO[1]

ADR[13]

13

PB2

GPO[2]

ADR[12]

14

PB3

GPO[3]

ADR[11]

15

PB4

GPI[0]

ADR[10]

16

PB5

GPI[1]

ADR[9]

17

PB6

GPI[2]

ADR[8]

18

PB7

GPI[3]

ADR[7]

19

GND

20

PC0

GPO[4]

ADR[6]

21

PC1

GPO[5]

ADR[5]

22

PC2

GPO[6]

ADR[4]

23

PC3

GPO[7]

ADR[3]

24

PC4

GPI[4]

ADR[2]

25

PC5

GPI[5]

ADR[1]

26

PC6

GPI[6]

ADR[0]

27

PC7

GPI[7]

DATA[0]

28

GND

29

PD0

GPO[8]

DATA[1]

30

PD1

GPO[9]

DATA[2]

31

PD2

GPO[10]

DATA[3]

32

PD3

GPO[11]

DATA[4]

33

PD4

GPI[8]

DATA[5]

34

PD5

GPI[9]

DATA[6]

35

PD6

GPI[10]

DATA[7]

36

PD7

GPI[11]

CPU_CLK_IN

37

GND

38

PE0

GPO[15]

DATA[11]

39

PE1

GPO[14]

DATA[10]

40

PE2

GPO[12]

DATA[8]

41

PE3

GPI[14]

DATA[14]

3.4 Using the FB1111-0142 in SPI- or µC-Mode

The FB1111-0142 supplies all process data signals of the ET1100 on its PDI connector. Therefore the

FB1111-0142 can be configured to operate in SPI- or µC-Mode. In these cases the pinout of the

FB1111-0142 differs from the other piggyback controller board variants. The following table (Table 7)

shows the signal definitions on the FB1111-0142s PDI connector.

Table 7 Pinout of the FB1111-0142 in SPI and µC Mode

8 FB1111 Piggyback Controller Board

Page 15

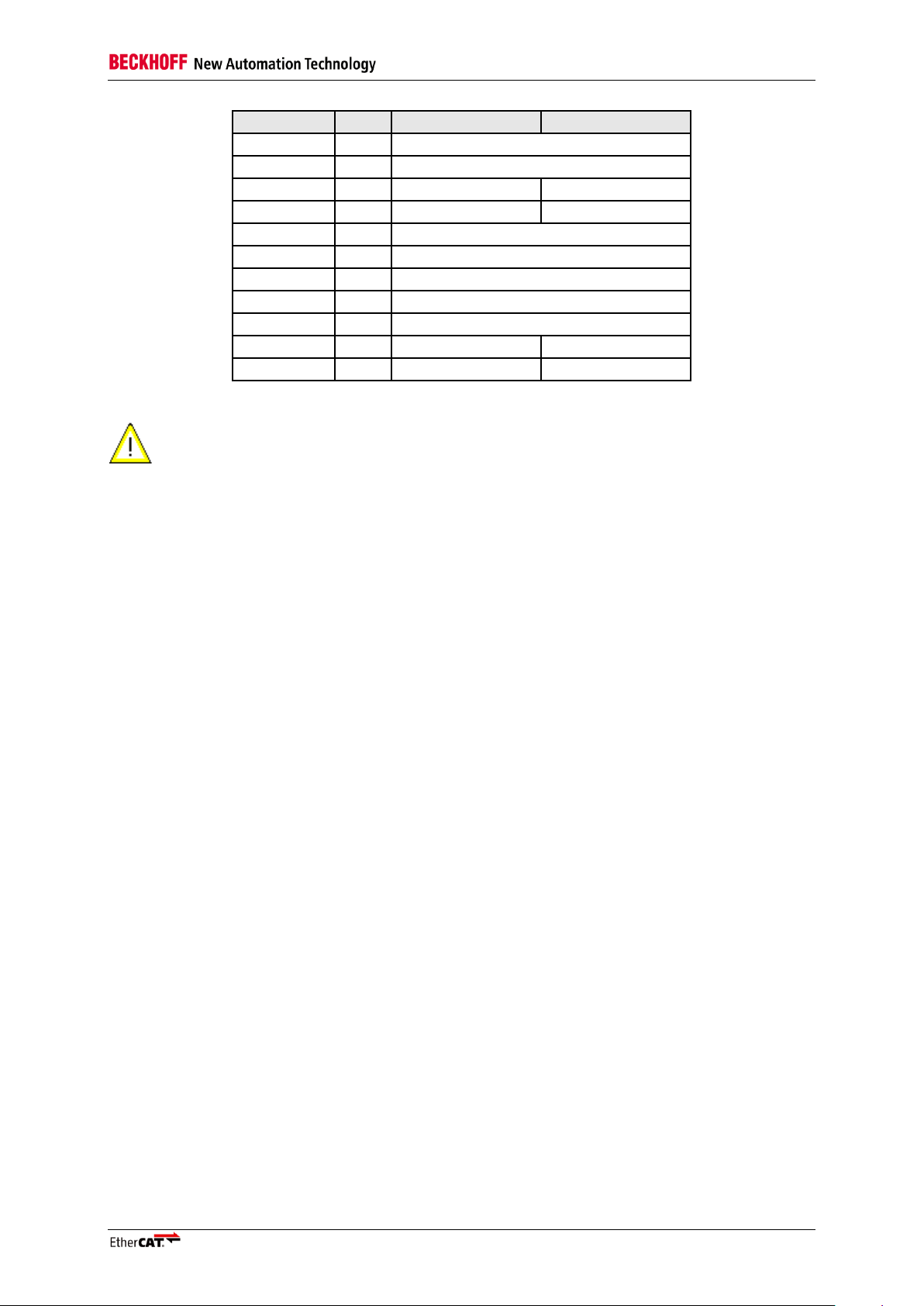

Process Data Interfaces

Pin number

Port

SPI

16bit as. µC

42

PE4

SYNC[0]/LATCH[0]

43

PE5

SYNC[1]/LATCH[1]

44

PE6

GPI[12]

DATA[12]

45

PE7

GPO[13]

DATA[9]

46

GND

47

VCC

48

N.C

49

VCC (5V Input)

50

3.3V Out

51

PF0

GPI[13]

DATA[13]

52

PF1

GPI[14]

DATA[15]

Warning

Due to the different pinouts the piggyback controller boards FB1111-0140 and

FB1111-0141 cannot be replaced by a FB1111-0142 programmed either in SPIor µC-Mode.

FB1111 Piggyback Controller Board 9

Page 16

Component Placement Specification

R500

R501

R502

R503

R504

R505

RN501

RN500

R500 R501

R503R502

R505R504

Designator

Signal

Connected To

TP800

+2.5V Core

ET1100

TP604

+3.3V

+3.3V

TP605

GND

GND

4 Component Placement Specification

In the following chapters the component placement specification in terms of reference designators and

component values are listed for the three variants of the FB1111 EtherCAT piggyback controller

board.

4.1 Placed/Unplaced Components

As the variants of the FB1111 are all based on one printed circuit board, the different PDI configurations are achieved by alternative component placements. Figure 3 is an example for placed and unplaced components. Designators for placed components are surrounded by a rectangle. Components

that are not mounted for a specific variant are also referenced by a designator, but without the surrounding rectangle.

Figure 3: Example for placed/unplaced components

Most of the resistor pairs within the PDI configuration area are sharing one pad with each other. When

modifying the resistor configuration care have to be taken in order to connect the corresponding pads

with each other correctly. An example is shown in Figure 4 for single resistors as for an resistor network.

Figure 4: Pads of resistor networks and single resistors

4.2 Power Test Pads

Table 8: Power Test Pads

10 FB1111 Piggyback Controller Board

Page 17

Component Placement Specification

4.3 FB1111-0142 – 32 bit In/Out digital Interface

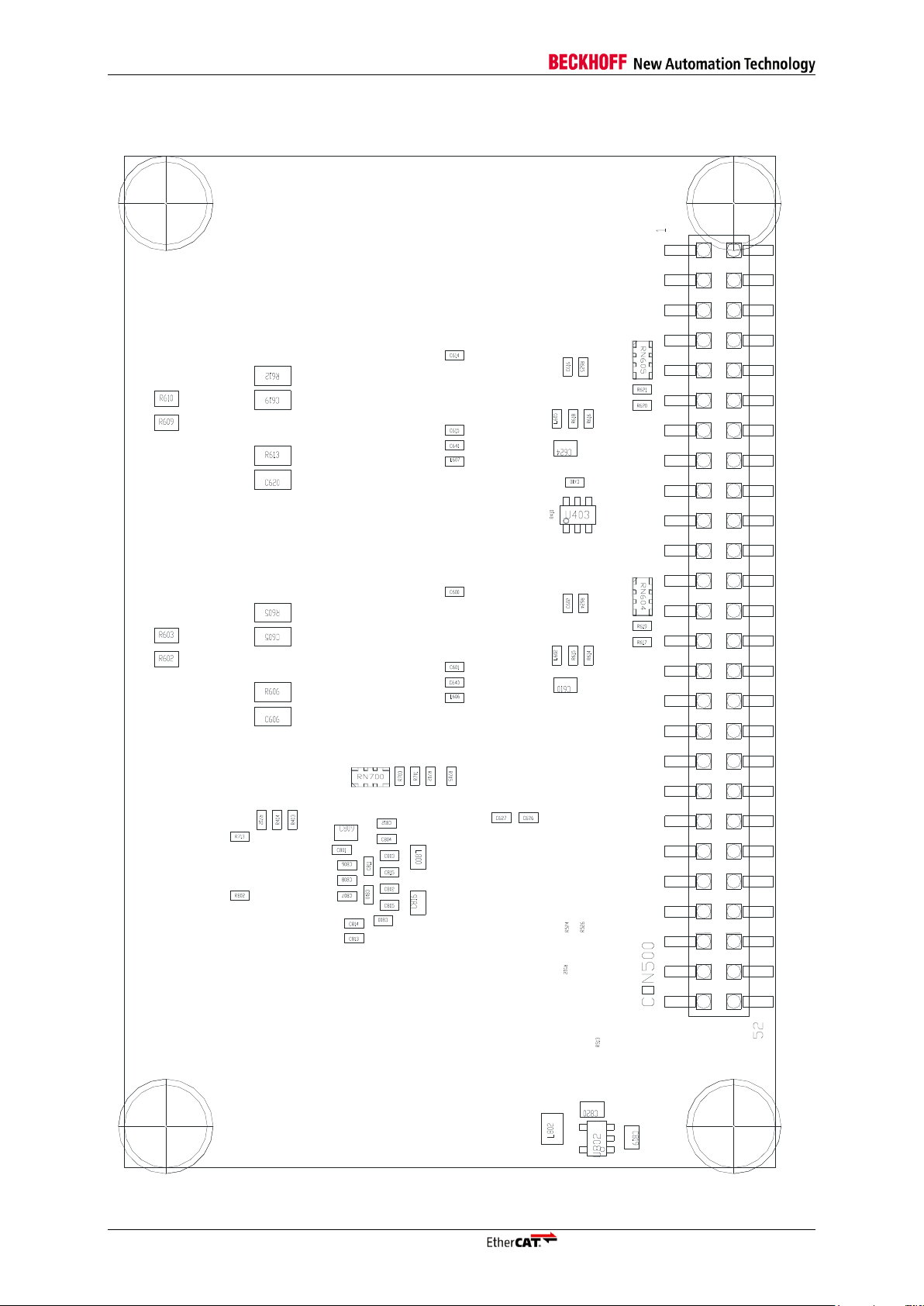

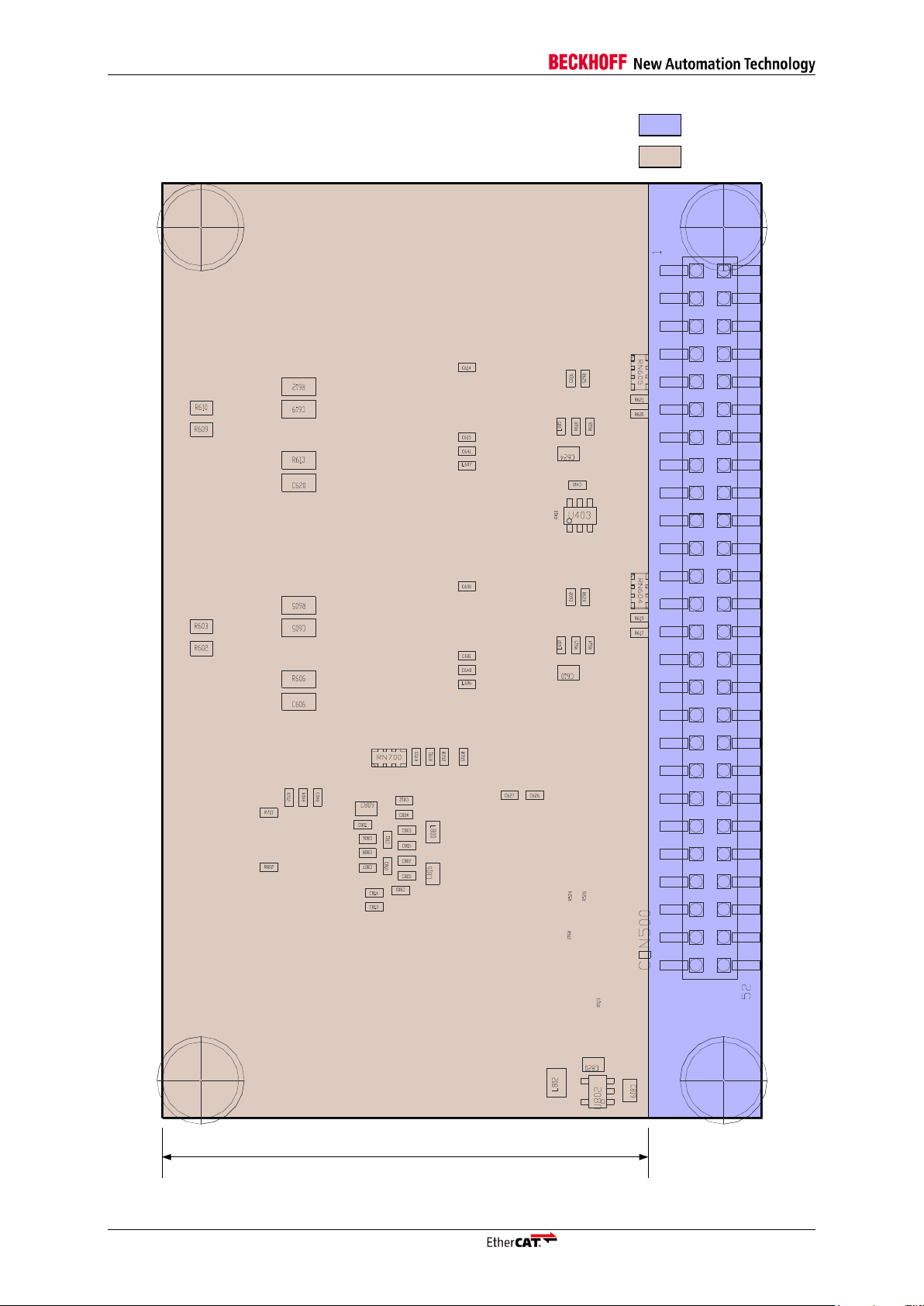

4.3.1 Top Side of FB1111-0142

FB1111 Piggyback Controller Board 11

Page 18

Component Placement Specification

4.3.2 Bottom side of FB1111-0142

12 FB1111 Piggyback Controller Board

Page 19

Component Placement Specification

4.4 FB1111-0141 – Serial Peripheral Interface

4.4.1 Top side of FB1111-0141

FB1111 Piggyback Controller Board 13

Page 20

Component Placement Specification

4.4.2 Bottom side of FB1111-0141

14 FB1111 Piggyback Controller Board

Page 21

Component Placement Specification

4.5 FB1111-0140 – 8/16 bit asynchronous Microcontroller Interface

4.5.1 Top side of FB1111-0140

FB1111 Piggyback Controller Board 15

Page 22

Component Placement Specification

4.5.2 Bottom side of FB1111-0140

16 FB1111 Piggyback Controller Board

Page 23

Interfacing with the EL9820 Evaluation Kit

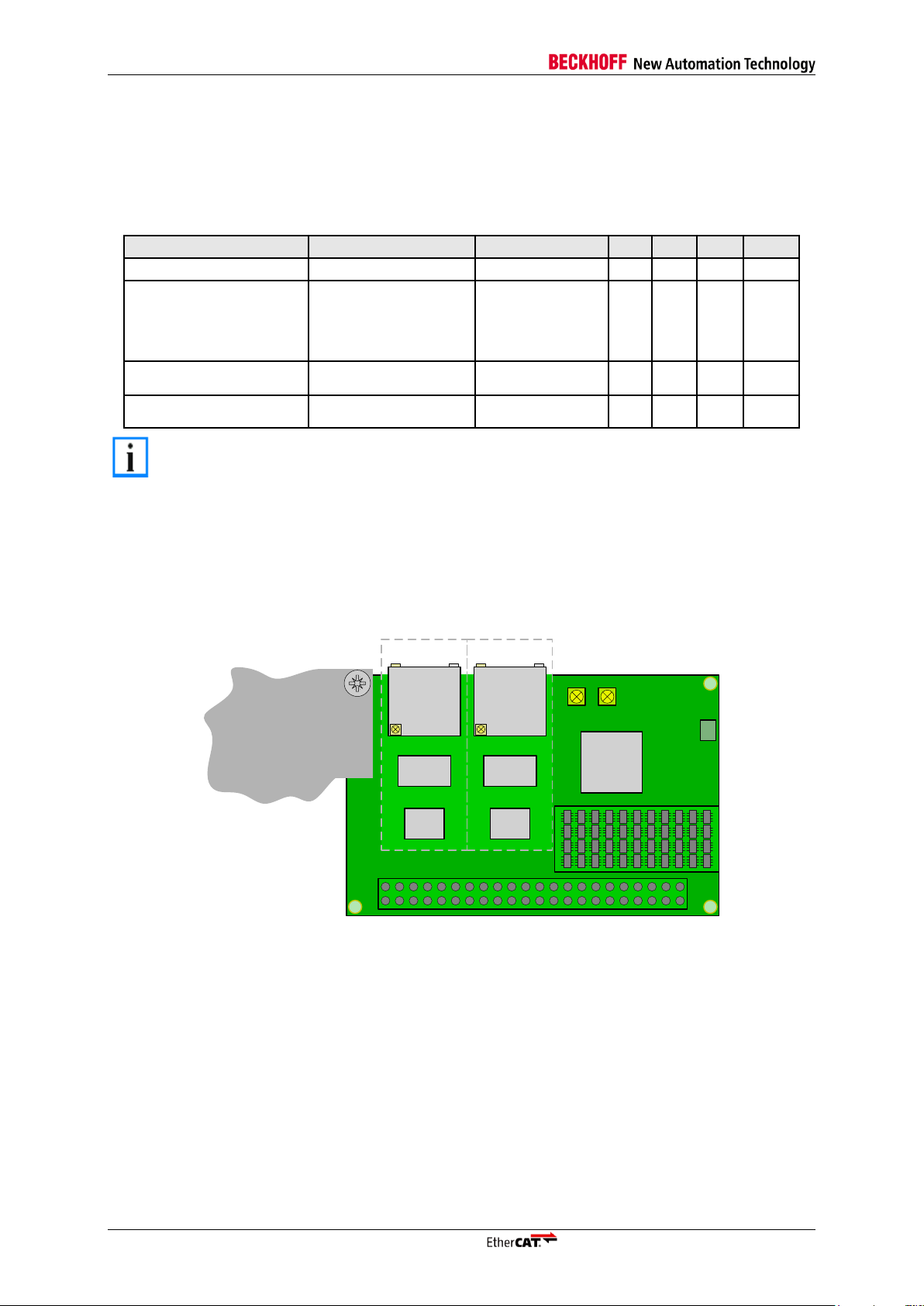

5 Interfacing with the EL9820 Evaluation Kit

As the FB1111 piggyback controller board variant with the sub code 0142 (32 bit In/Out digital Interface) uses all available signals on the PDI connector, it can be programmed to implement the two

remaining PDIs.

Figure 5: EL9803 Adapter board – Top Side

Due to the different PDI connector pinouts in comparison with the variants 0141 and 0140 an additional board is needed, that maps the physical digital PDI signals to the Microcontroller, respectively SPI,

interface of the EL9820 Evaluation Kit. Therefore the EL9803 adapter board can be used to realize all

three available PDIs on the EL9820 Evaluation Kit with just one FB1111-0142.

Figure 5 shows the top side of the EL9803 Adapter Board. The FB1111-0142 has to be placed on the

position, labelled with “FB1111” on the top most right of Figure 5. The adapter board is delivered with

spacer pins at the position, where the FB1111-0142 has to be attached at.

The EL9820 Evaluation Kit connects with the EL9803 Adapter Board from the bottom side (Figure 6)

of the of the adapter board. The holes labelled with “As uC” and “SPI” are referencing the position of

the EL9820 Evaluation Board for the desired Process Data Interface. In addition to the labelled position holes two LEDs are placed on the board (bottom right edge of Figure 5). The left LED indicates

physical SPI mapping between EL9820 and EL9803. The right one indicates asynchronous Microcontroller interfacing.

Only 50 PDI signals are provided by the EL9820 Evaluation Kit in comparison to the 52 signals of the

EtherCAT piggyback controller board FB1111-0142, respectively the EL9803 Adapter Board. The

boards FB1111-0142 and EL9803 are supporting full functionality of the EtherCAT Evaluation Kit

EL9820. The additional pins will be used in future versions of the EL9820.

FB1111 Piggyback Controller Board 17

Page 24

Interfacing with the EL9820 Evaluation Kit

VCC

GND

+3.3V

PDI4

PDI9

PDI8

PDI7

PDI6

Pin name

0141 - SPI

0140 - 16bit as. µC

PDI4

SPI_IRQ

IRQ

PDI6

EEPROM_Loaded

PDI7

n.c.

ADR[15]

PDI8

GPO[0]

ADR[14]

PDI9

GPO[1]

ADR[13]

Figure 6: EL9803 Adapter board – Bottom Side

The PCB colour may vary between green, black and red.

5.1.1 Left side pin header definition

Figure 7: Left side right angle header pinout

Figure 7 shows the pinout of the header on left side of the EL9803’s top. Depending on the selected

process data interface, the definition of the pins PDI4 and PDI6 to PDI9 are differing. The pin names

given here are based on the ET1100 PDI pinout. Thus detailed information about pin description and

electrical specification of these pins can be found in the ET1100 Hardware Data Sheet that can be

downloaded from the company’s website. An overview of the pinout is given in the following table.

18 FB1111 Piggyback Controller Board

Table 9 Pin description of 8 pin right angle header

Page 25

Interfacing with the EL9820 Evaluation Kit

5.2 EL9820 stacking examples

In this chapter the two stacking alternatives of the EL9803 Adapter Board on the EL9820 Evaluation

Kit is shown. Figure 8 represents the asynchronous microcontroller configuration, while Figure 9

demonstrates the SPI configuration of the three boards.

Figure 8: Microcontroller Configuration with EL9803

Figure 9: SPI Configuration with EL9803

FB1111 Piggyback Controller Board 19

Page 26

Electrical Specification

Note

Additional information about the ratings, operation conditions and DC characteristics can be found in the EtherCAT ET1100 hardware data sheet.

IN

TR 0

ET1100

+5VRUN

Port 0

E²P

GND-Earth

Link 1 Link 0

PHY

0

PDI Configuration

Area

PDI Connector

OUT

TR 1

Port 1

PHY

1

Symbol

Parameter

Condition

Min

Typ

Max

Units

VCC

Board Supply Voltage

4.0

5.0

5.5

V

ICC

Board Supply Current

1 Port

2 Ports

1 Port + full PDI

2 Ports + full PDI

100

140

190

300

350

700

mA

Storage

Storage temperature

-65 105

°C

Ambient

Ambient temperature

-40 70

°C

6 Electrical Specification

6.1 Ratings

Table 10: Typical Ratings

6.2 EMC – Electro magnetic compatibility

For proper protection against damage caused by electrostatic discharge, the top left mounting hole of

the EtherCAT piggyback controller board has to be connected to a massive panel or plate that is connected with GND-Earth. The remaining three holes have to be used for mechanical fixation of the piggyback controller board.

Figure 10: Connection to GND-Earth

Suitable screw dimensions are: M3x6 DIN-7985.

20 FB1111 Piggyback Controller Board

Page 27

Mechanical Specification

Note 1

Pin 1

Pin 52

IN

OUT

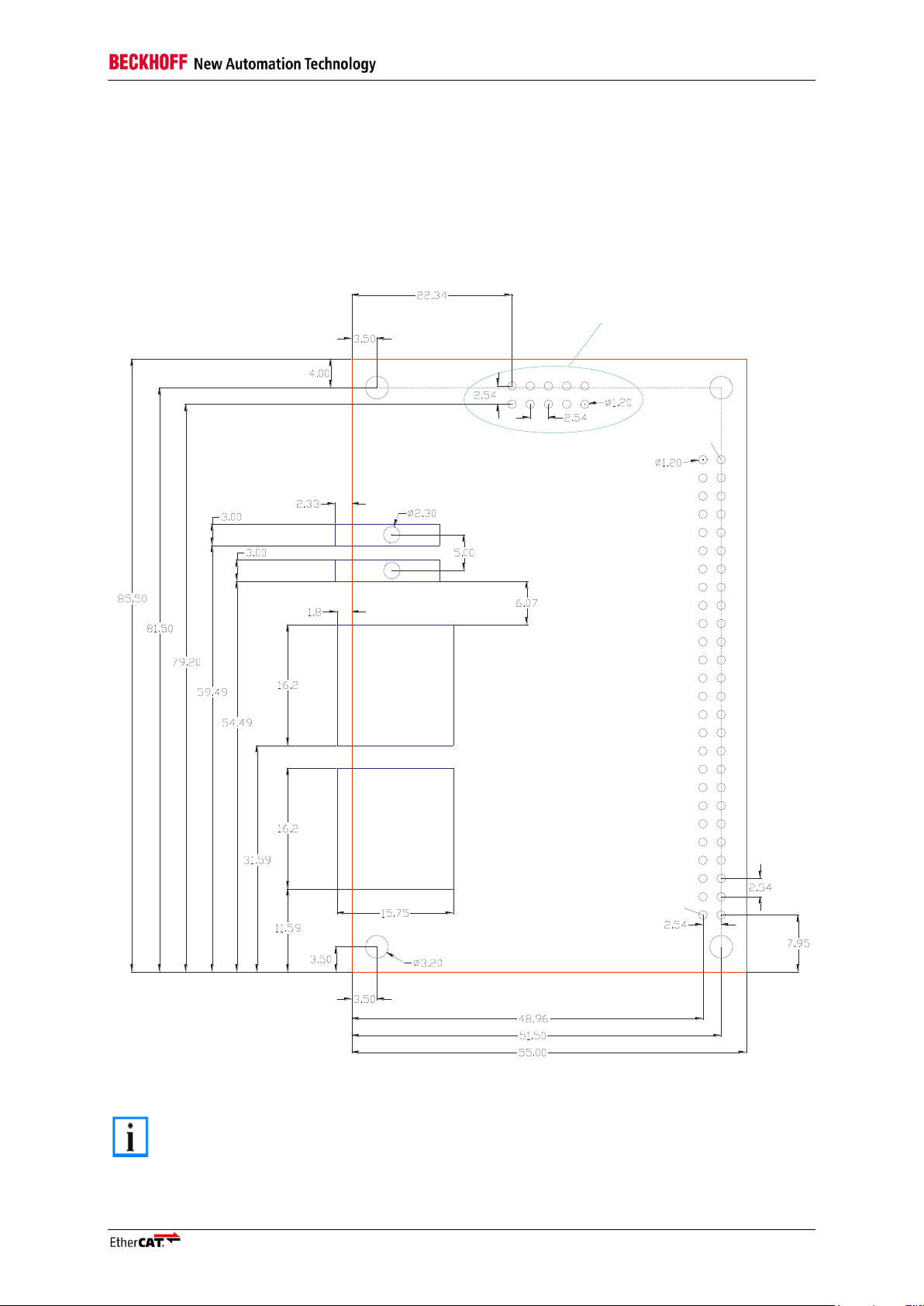

Note

The ten holes encapsulated by the ellipsoid in Figure 11 don’t have to be taken

into account, when the piggyback controller board is integrated into a third party

customer device. The holes are only mechanical and therefore do not have any

electrical connection.

7 Mechanical Specification

As the EtherCAT piggyback controller board FB1111-014x can be assembled with customer hardware

to complex end user devices, board dimensions and assembly recommendations have to be taken in

account. In 7.1 the board dimensions including mounting and contact hole positions and diameters

from top view are shown. Panel opening recommendations are shown in section 7.2. All dimensions

are drawn in millimeters.

7.1 Board Dimensions

Figure 11: Board dimensions of the FB1111 – Top View

FB1111 Piggyback Controller Board 21

Page 28

Mechanical Specification

14.1

17.4

2.6

RUN+5V

5.0

7.3

2.54

Ø3.00

OUTIN

7.2 Physical Connector Specification

The Board to Board connector (CON500) can be connected as well from the bottom as from the top

side of the FB1111-014X. The bottom side low profile socket is equivalent to the Samtec

(www.samtec.com) product with the manufacturer number CLH-126-F-D-BE-P-TR. Insertion depth

from top side is 4.7 mm, respectively 3.2 mm from bottom side. A suitable pin header for the low profile socket can also be received from Samtec. The TSM series is suitable for the socket. As an example the pin header with the part number TSM-126-02-L-DV can be used to connect the EtherCAT piggyback controller board FB1111-014x.

7.3 Recommended Panel Opening

Figure 12: Recommended Panel Opening

In Figure 12 the dimensions of a typical panel opening is illustrated. The two ports and the LED break

throughs have to be labelled as shown in the figure.

22 FB1111 Piggyback Controller Board

Page 29

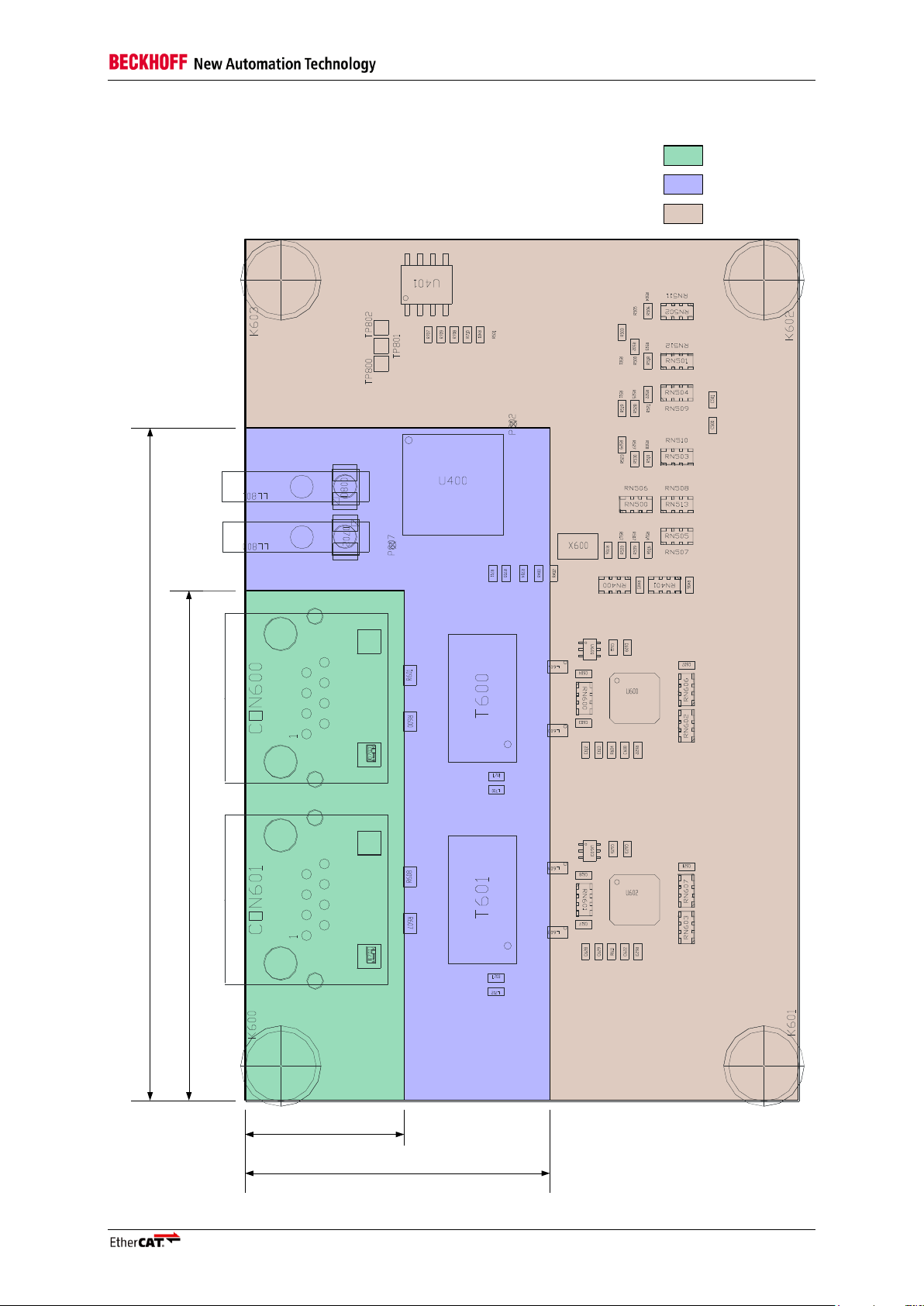

Mechanical Specification

13.5 mm

6 mm

3 mm

51

67

16

30

7.4 Top/Bottom Side Component Height Definition

Figure 13: Component height zones for the top side of FB1111-014X

FB1111 Piggyback Controller Board 23

Page 30

Mechanical Specification

4 mm

3 mm

45

Figure 14: Component height zones for the bottom side of FB1111-014X

24 FB1111 Piggyback Controller Board

Page 31

Appendix

8 Appendix

8.1 Support and Service

Beckhoff and their partners around the world offer comprehensive support and service, making available fast and competent assistance with all questions related to Beckhoff products and system solutions.

8.1.1 Beckhoff’s branch offices and representatives

Please contact your Beckhoff branch office or representative for local support and service on Beckhoff

products!

The addresses of Beckhoff's branch offices and representatives round the world can be found on her

internet pages: http://www.beckhoff.com

You will also find further documentation for Beckhoff components there.

8.2 Beckhoff Headquarters

Beckhoff Automation GmbH

Eiserstr. 5

33415 Verl

Germany

phone: + 49 (0) 5246/963-0

fax: + 49 (0) 5246/963-198

e-mail: info@beckhoff.com

web: www.beckhoff.com

Beckhoff Support

Support offers you comprehensive technical assistance, helping you no only with the application of

individual Beckhoff products, but also with other, wide-ranging services:

support

design, programming and commissioning of complex automation systems

and extensive training program for Beckhoff system components

hotline: + 49 (0) 5246/963-157

fax: + 49 (0) 5246/963-9157

e-mail: support@beckhoff.com

Beckhoff Service

The Beckhoff Service Center supports you in all matters of after-sales service:

on-site service

repair service

spare parts service

hotline service

hotline: + 49 (0) 5246/963-460

fax: + 49 (0) 5246/963-479

e-mail: service@beckhoff.com

FB1111 Piggyback Controller Board 25

Loading...

Loading...