Page 1

Hardware Data Sheet Section I

Slave Controller

Section I – Technology

EtherCAT Protocol, Physical Layer,

EtherCAT Processing Unit, FMMU,

SyncManager, SII EEPROM, Distributed

Clocks

Section II – Register Description

(Online at http://www.beckhoff.com)

Section III – Hardware Description

(Online at http://www.beckhoff.com)

Version 2.2

Date: 2014-07-07

Page 2

DOCUMENT ORGANIZATION

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE® and XFC® are registered trademarks of and licensed by

Beckhoff Automation GmbH. Other designations used in this publication may be trademarks whose use by third parties for their

own purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following German patent applications and patents:

DE10304637, DE102004044764, DE102005009224, DE102007017835 with corresponding applications or registrations in

various other countries.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under development. For that

reason the documentation is not in every case checked for consistency with performance data, standards or other

characteristics. In the event that it contains technical or editorial errors, we retain the right to make alterations at any time and

without warning. No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Copyright

© Beckhoff Automation GmbH 07/2014.

The reproduction, distribution and utilization of this document as well as the communication of its contents to others without

express authorization are prohibited. Offenders will be held liable for the payment of damages. All rights reserved in the event of

the grant of a patent, utility model or design.

DOCUMENT ORGANIZATION

The Beckhoff EtherCAT Slave Controller (ESC) documentation covers the following Beckhoff ESCs:

ET1200

ET1100

EtherCAT IP Core for Altera® FPGAs

EtherCAT IP Core for Xilinx® FPGAs

ESC20

The documentation is organized in three sections. Section I and section II are common for all Beckhoff

ESCs, Section III is specific for each ESC variant.

The latest documentation is available at the Beckhoff homepage (http://www.beckhoff.com).

Section I – Technology (All ESCs)

Section I deals with the basic EtherCAT technology. Starting with the EtherCAT protocol itself, the

frame processing inside EtherCAT slaves is described. The features and interfaces of the physical

layer with its two alternatives Ethernet and EBUS are explained afterwards. Finally, the details of the

functional units of an ESC like FMMU, SyncManager, Distributed Clocks, Slave Information Interface,

Interrupts, Watchdogs, and so on, are described.

Since Section I is common for all Beckhoff ESCs, it might describe features which are not available in

a specific ESC. Refer to the feature details overview in Section III of a specific ESC to find out which

features are available.

Section II – Register Description (All ESCs)

Section II contains detailed information about all ESC registers. This section is also common for all

Beckhoff ESCs, thus registers, register bits, or features are described which might not be available in

a specific ESC. Refer to the register overview and to the feature details overview in Section III of a

specific ESC to find out which registers and features are available.

Section III – Hardware Description (Specific ESC)

Section III is ESC specific and contains detailed information about the ESC features, implemented

registers, configuration, interfaces, pinout, usage, electrical and mechanical specification, and so on.

Especially the Process Data Interfaces (PDI) supported by the ESC are part of this section.

Additional Documentation

Application notes and utilities like pinout configuration tools for ET1100/ET1200 can also be found at

the Beckhoff homepage.

I-II Slave Controller – Technology

Page 3

DOCUMENT HISTORY

Version

Comment

1.0

Initial release

1.1

Chapter Interrupts – AL Event Request: corrected AL Event Mask register

address to 0x0204:0x0207

EtherCAT Datagram: Circulating Frame bit has position 14 (not 13)

PHY addressing configuration changed

Loop control: a port using Auto close mode is automatically opened if a valid

Ethernet frame is received at this port

EEPROM read/write/reload example: steps 1 and 2 swapped

EEPROM: Configured Station Alias (0x0012:0x0013) is only taken over at first

EEPROM load after power-on or reset

SyncManager: Watchdog trigger and interrupt generation in mailbox mode with

single byte buffers requires alternating write and read accesses for some ESCs,

thus buffered mode is required for Digital I/O watchdog trigger generation

National Semiconductor DP83849I Ethernet PHY deprecated because of large

link loss reaction time and delay

Added distinction between permanent ports and Bridge port (frame processing)

Added PDI chapter

PDI and DC Sync/Latch signals are high impedance until the SII EEPROM is

successfully loaded

Editorial changes

1.2

PHY address configuration revised. Refer to Section III for ESC supported

configurations

Added Ethernet Link detection chapter

Added MI Link Detection and Configuration, link detection descriptions updated

Added EEPROM Emulation for EtherCAT IP Core

Added General Purpose Input chapter

Corrected minimum datagram sizes in EtherCAT header figure

Editorial changes

1.2.1

Chapter 5.1.1: incompatible PHYs in footnote 1 deleted

1.3

Added advisory for unused MII/RMII/EBUS ports

Ethernet PHY requirements revised: e.g., configuration by strapping options,

recommendations enhanced. Footnote about compatible PHYs removed,

information has moved to the EtherCAT Slave Controller application note “PHY

Selection Guide”.

Frame Error detection chapter enhanced

FIFO size reduction chapter enhanced

EBUS enhanced link detection chapter enhanced

Ethernet PHY link loss reaction time must be faster than 15 µs, otherwise use

Enhanced link detection

Enhanced link detection description corrected. Enhanced link detection does

not remain active if it is disabled by EEPROM and EBUS handshake frames are

received

ARMW/FRWM commands increase the working counter by 1

Editorial changes

1.4

Update to EtherCAT IP Core Release 2.1.0/2.01a

Added restriction to enhanced link configuration: RX_ER has to be asserted

outside of frames (IEEE802 optional feature)

ESC power-on sequence for IP Core corrected

Removed footnote on t

Diff

figures, refer to Section III for actual figures

Editorial changes

DOCUMENT HISTORY

Slave Controller – Technology I-III

Page 4

DOCUMENT HISTORY

Version

Comment

1.5

EEPROM Read/Write/Reload example: corrected register addresses

Updated/clarified PHY requirements, PHY link loss reaction time is mandatory

Enhanced Link Detection can be configured port-wise depending on ESC

Added DC Activation and DC Activation State features for some ESCs

ESC10 removed

Editorial changes

1.6

Fill reserved EEPROM words of the ESC Configuration Area with 0

Interrupt chapter: example for proper interrupt handling added

Use Position Addressing only for bus scanning at startup and to detect newly

attached devices

System Time PDI controlled: detailed description added

Added MII back-to-back connection example

Renamed Err(x) LED to PERR(x)

Editorial changes

1.7

Link status description enhanced

Clarifications for DC System Time and reference between clocks and registers

Chapter on avoiding unconnected Port 0 configurations added

Direct ESC to standard Ethernet MAC MII connection added

MI link detection and configuration must not be used without LINK_MII signals

Added criteria for detecting when DC synchronization is established

SII EEPROM interface is a point-to-point connection

PHY requirements: PHY startup should not rely on MDC clocking, ESD

tolerance and baseline wander compensation recommendations added

Editorial changes

1.8

Update to EtherCAT IP Core Release 2.3.0/2.03a

EEPROM acknowledge error (0x0502[13]) can also occur for a read access

ERR and STATE LED updated

Editorial changes

1.9

EtherCAT state machine: additional AL status codes defined

EtherCAT protocol: LRD/LRW read data depends on bit mask

Updated EBUS Enhanced Link Detection

Updated FMMU description

Loop control description updated

EtherCAT frame format (VLAN tag) description enhanced

Update to EtherCAT IP Core Release 2.3.2/2.03c

2.0

Update to EtherCAT IP Core Release 2.4.0/2.04a

SII/ESI denotation now consistent with ETG

Updated AL Status codes

Editorial changes

2.1

Update to EtherCAT IP Core Release 3.0.0/3.00a

Update to ET1100-0003 and ET1200-0003

RUN/ERR LED description enhanced

Added RGMII and FX operation

Added Gigabit Ethernet PHY chapter

Updated FIFO size configuration (default from SII)

Updated PHY address configuration

Added PDI register function acknowledge by write

Added propagation delay measurement in reverse mode (especially ET1200)

Enhanced ERR_LED description

Editorial changes

2.2

Update to EtherCAT IP Core Release 3.0.6/3.00g

Added resetting Distributed Clocks Time Loop Control filters to the

synchronization steps

Extended Back-to-Back MII connection schematic

Clarified EBUS standard link detection restrictions

Editorial changes

I-IV Slave Controller – Technology

Page 5

DOCUMENT HISTORY

Slave Controller – Technology I-V

Page 6

CONTENTS

CONTENTS

1 EtherCAT Slave Controller Overview 1

1.1 EtherCAT Slave Controller Function Blocks 2

1.2 Further Reading on EtherCAT and ESCs 3

1.3 Scope of Section I 3

2 EtherCAT Protocol 4

2.1 EtherCAT Header 4

2.2 EtherCAT Datagram 5

2.3 EtherCAT Addressing Modes 6

2.3.1 Device Addressing 7

2.3.2 Logical Addressing 7

2.4 Working Counter 8

2.5 EtherCAT Command Types 9

3 Frame Processing 12

3.1 Loop Control and Loop State 12

3.2 Frame Processing Order 14

3.3 Permanent Ports and Bridge Port 15

3.4 Shadow Buffer for Register Write Operations 15

3.5 Circulating Frames 15

3.5.1 Unconnected Port 0 16

3.6 Non-EtherCAT Protocols 16

3.7 Special Functions of Port 0 16

4 Physical Layer Common Features 17

4.1 Link Status 17

4.2 Selecting Standard/Enhanced Link Detection 18

4.3 FIFO Size Reduction 19

4.4 Frame Error Detection 19

5 Ethernet Physical Layer 20

5.1 Requirements to Ethernet PHYs 20

5.2 PHY reset and Link partner notification/loop closing 20

5.3 MII Interface 21

5.4 RMII Interface 22

5.5 RGMII Interface 22

5.5.1 RGMII In-Band Link Status 22

5.6 Link Detection 22

5.6.1 LINK_MII Signal 22

5.6.2 MI Link Detection and Configuration 23

5.7 Standard and Enhanced MII Link Detection 23

5.8 EtherCAT over Optical Links (FX) 24

5.8.1 Link partner notification and loop closing 24

I-VI Slave Controller – Technology

Page 7

CONTENTS

5.8.2 Far-End-Fault (FEF) 24

5.8.3 ESCs with native FX support 25

5.8.4 ESCs without native FX support 25

5.9 Gigabit Ethernet PHYs 25

5.10 MII Management Interface (MI) 26

5.10.1 PHY Addressing/PHY Address Offset 26

5.10.2 Logical Interface 28

5.10.3 MI Protocol 29

5.10.4 Timing specifications 29

5.11 MII management example schematic 30

5.12 Ethernet Termination and Grounding Recommendation 31

5.13 Ethernet Connector (RJ45 / M12) 32

5.14 Back-to-Back MII Connection 33

5.14.1 ESC to ESC Connection 33

5.14.2 ESC to Standard Ethernet MAC 34

6 EBUS/LVDS Physical Layer 35

6.1 Interface 35

6.2 EBUS Protocol 36

6.3 Timing Characteristics 36

6.4 Standard EBUS Link Detection 37

6.5 Enhanced EBUS Link Detection 37

6.6 EBUS RX Errors 38

6.7 EBUS Low Jitter 38

6.8 EBUS Connection 38

7 FMMU 39

8 SyncManager 41

8.1 Buffered Mode 42

8.2 Mailbox Mode 43

8.2.1 Mailbox Communication Protocols 43

8.3 PDI register function acknowledge by Write 44

8.4 Interrupt and Watchdog Trigger Generation, Latch Event Generation 44

8.5 Single Byte Buffer Length / Watchdog Trigger for Digital Output PDI 45

8.6 Repeating Mailbox Communication 45

8.7 SyncManager Deactivation by the PDI 46

9 Distributed Clocks 47

9.1 Clock Synchronization 47

9.1.1 Clock Synchronization Process 49

9.1.2 Propagation Delay Measurement 50

9.1.3 Offset Compensation 55

9.1.4 Resetting the Time Control Loop 56

9.1.5 Drift Compensation 56

Slave Controller – Technology I-VII

Page 8

CONTENTS

9.1.6 Reference between DC Registers/Functions and Clocks 58

9.1.7 When is Synchronization established? 59

9.1.8 Clock Synchronization Initialization Example 59

9.2 SyncSignals and LatchSignals 60

9.2.1 Interface 60

9.2.2 Configuration 60

9.2.3 SyncSignal Generation 61

9.2.4 LatchSignals 64

9.2.5 ECAT or PDI Control 65

9.3 System Time PDI Controlled 66

9.4 Communication Timing 68

10 EtherCAT State Machine 70

10.1 EtherCAT State Machine Registers 71

10.1.1 AL Control and AL Status Register 71

10.1.2 Device Emulation 71

10.1.3 Error Indication and AL Status Code Register 71

11 SII EEPROM 72

11.1 SII EEPROM Content 73

11.2 SII EEPROM Logical Interface 74

11.2.1 SII EEPROM Errors 75

11.2.2 SII EEPROM Interface Assignment to ECAT/PDI 76

11.2.3 Read/Write/Reload Example 77

11.2.4 EEPROM Emulation 77

11.3 SII EEPROM Electrical Interface (I2C) 78

11.3.1 Addressing 78

11.3.2 EEPROM Size 78

11.3.3 I²C Access Protocol 79

11.3.4 Timing specifications 80

12 Interrupts 82

12.1 AL Event Request (PDI Interrupt) 82

12.2 ECAT Event Request (ECAT Interrupt) 83

12.3 Clearing Interrupts Accidentally 83

13 Watchdogs 84

13.1 Process Data Watchdog 84

13.2 PDI Watchdog 84

14 Error Counters 85

14.1 Frame error detection 86

14.2 Errors and Forwarded Errors 86

15 LED Signals (Indicators) 87

15.1 RUN LED 87

15.1.1 RUN LED override 87

I-VIII Slave Controller – Technology

Page 9

CONTENTS

15.2 ERR LED 88

15.2.1 ERR LED override 88

15.3 STATE LED and STATE_RUN LED Signal 89

15.4 LINKACT LED 89

15.5 Port Error LED (PERR) 90

16 Process Data Interface (PDI) 91

16.1 PDI Selection and Configuration 91

16.2 PDI register function acknowledge by write 92

16.3 General Purpose I/O 93

16.3.1 General Purpose Inputs 93

16.3.2 General Purpose Output 93

17 Additional Information 94

17.1 ESC Clock Source 94

17.2 Power-on Sequence 94

17.3 Write Protection 95

17.3.1 Register Write Protection 95

17.3.2 ESC Write Protection 95

17.4 ESC Reset 95

18 Appendix 96

18.1 Support and Service 96

18.1.1 Beckhoff’s branch offices and representatives 96

18.2 Beckhoff Headquarters 96

Slave Controller – Technology I-IX

Page 10

TABLES

TABLES

Table 1: ESC Main Features ................................................................................................................... 1

Table 2: EtherCAT Frame Header........................................................................................................... 4

Table 3: EtherCAT Datagram .................................................................................................................. 6

Table 4: EtherCAT Addressing Modes .................................................................................................... 6

Table 5: Working Counter Increment ...................................................................................................... 8

Table 6: EtherCAT Command Types .................................................................................................... 10

Table 7: EtherCAT Command Details ................................................................................................... 11

Table 8: Registers for Loop Control and Loop/Link Status ................................................................... 13

Table 9: Frame Processing Order ......................................................................................................... 14

Table 10: Link Status Description .......................................................................................................... 17

Table 11: Registers for Enhanced Link Detection ................................................................................. 18

Table 12: Registers for FIFO Size Reduction ........................................................................................ 19

Table 13: Special/Unused MII Interface signals .................................................................................... 21

Table 14: Registers used for Ethernet Link Detection ........................................................................... 22

Table 15: PHY Address configuration matches PHY address settings ................................................. 27

Table 16: PHY Address configuration does not match actual PHY address settings ........................... 27

Table 17: MII Management Interface Register Overview ...................................................................... 28

Table 18: MII Management Interface timing characteristics .................................................................. 29

Table 19: Signals used for Fast Ethernet .............................................................................................. 32

Table 20: EBUS Interface signals ......................................................................................................... 35

Table 21: EBUS timing characteristics .................................................................................................. 36

Table 22: Example FMMU Configuration .............................................................................................. 39

Table 23: SyncManager Register overview ........................................................................................... 41

Table 24: EtherCAT Mailbox Header .................................................................................................... 44

Table 25: Registers for Propagation Delay Measurement .................................................................... 50

Table 26: Parameters for Propagation Delay Calculation ..................................................................... 53

Table 27: Registers for Offset Compensation ....................................................................................... 55

Table 28: Registers for Resetting the Time Control Loop ..................................................................... 56

Table 29: Registers for Drift Compensation .......................................................................................... 57

Table 30: Reference between DC Registers/Functions and Clocks ..................................................... 58

Table 31: Distributed Clocks signals ..................................................................................................... 60

Table 32: SyncSignal Generation Mode Selection ................................................................................ 61

Table 33: Registers for SyncSignal Generation .................................................................................... 62

Table 34: Registers for Latch Input Events ........................................................................................... 65

Table 35: Registers for the EtherCAT State Machine ........................................................................... 71

Table 36: AL Control and AL Status Register Values ........................................................................... 71

Table 37: ESC Configuration Area ........................................................................................................ 73

Table 38: SII EEPROM Content Excerpt ............................................................................................... 74

Table 39: SII EEPROM Interface Register Overview ............................................................................ 74

Table 40: SII EEPROM Interface Errors ................................................................................................ 75

Table 41: I²C EEPROM signals ............................................................................................................. 78

Table 42: EEPROM Size ....................................................................................................................... 78

Table 43: I²C Control Byte ..................................................................................................................... 79

Table 44: I²C Write Access .................................................................................................................... 79

Table 45: I²C Read Access .................................................................................................................... 80

Table 46: EEPROM timing characteristics ............................................................................................ 80

Table 47: Registers for AL Event Request Configuration ..................................................................... 82

Table 48: Registers for ECAT Event Request Configuration ................................................................ 83

Table 49: Registers for Watchdogs ....................................................................................................... 84

Table 50: Error Counter Overview ......................................................................................................... 85

Table 51: Errors Detected by Physical Layer, Auto-Forwarder, and EtherCAT Processing Unit ......... 86

Table 52: RUN LED state indication ...................................................................................................... 87

Table 53: Registers for RUN LED control ............................................................................................. 87

Table 54: Automatic ESC ERR LED state indication ............................................................................ 88

Table 55: Registers for ERR LED control .............................................................................................. 88

Table 56: LINKACT LED States ............................................................................................................ 89

Table 57: Available PDIs depending on ESC ........................................................................................ 91

Table 58: Functions/registers affected by PDI register function acknowledge by write ........................ 92

Table 59: ESC Power-On Sequence ..................................................................................................... 94

Table 60: Registers for Write Protection ............................................................................................... 95

I-X Slave Controller – Technology

Page 11

TABLES

Slave Controller – Technology I-XI

Page 12

FIGURES

FIGURES

Figure 1: EtherCAT Slave Controller Block Diagram .............................................................................. 1

Figure 2: Ethernet Frame with EtherCAT Data ....................................................................................... 4

Figure 3: EtherCAT Datagram ................................................................................................................. 5

Figure 4: Auto close loop state transitions ............................................................................................ 13

Figure 5: Frame Processing .................................................................................................................. 14

Figure 6: Circulating Frames ................................................................................................................. 15

Figure 7: All frames are dropped because of Circulating Frame Prevention ........................................ 16

Figure 8: Write access ........................................................................................................................... 29

Figure 9: Read access ........................................................................................................................... 29

Figure 10: MII management example schematic .................................................................................. 30

Figure 11: Termination and Grounding Recommendation .................................................................... 31

Figure 12: RJ45 Connector ................................................................................................................... 32

Figure 13: M12 D-code Connector ........................................................................................................ 32

Figure 14: Back-to-Back MII Connection (two ESCs) ........................................................................... 33

Figure 15: Back-to-Back MII Connection (ESC and standard MAC)..................................................... 34

Figure 16: EBUS Interface Signals ........................................................................................................ 35

Figure 17: EBUS Protocol ..................................................................................................................... 36

Figure 18: Example EtherCAT Network ................................................................................................ 37

Figure 19: EBUS Connection ................................................................................................................ 38

Figure 20: FMMU Mapping Principle ..................................................................................................... 39

Figure 21: FMMU Mapping Example ..................................................................................................... 40

Figure 22: SyncManager Buffer allocation ............................................................................................ 42

Figure 23: SyncManager Buffered Mode Interaction............................................................................. 42

Figure 24: SyncManager Mailbox Interaction ........................................................................................ 43

Figure 25: EtherCAT Mailbox Header (for all Types) ............................................................................ 44

Figure 26: Handling of a Repeat Request with Read Mailbox .............................................................. 46

Figure 27: Propagation Delay, Offset, and Drift Compensation ............................................................ 49

Figure 28: Propagation Delay Calculation ............................................................................................. 52

Figure 29: Distributed Clocks signals .................................................................................................... 60

Figure 30: SyncSignal Generation Modes ............................................................................................. 61

Figure 31: SYNC0/1 Cycle Time Examples .......................................................................................... 63

Figure 32: System Time PDI Controlled with three steps ..................................................................... 66

Figure 33: System Time PDI Controlled with two steps ........................................................................ 67

Figure 34: DC Timing Signals in relation to Communication ................................................................. 68

Figure 35: EtherCAT State Machine ..................................................................................................... 70

Figure 36: SII EEPROM Layout............................................................................................................. 72

Figure 37: I²C EEPROM signals ............................................................................................................ 78

Figure 38: Write access (1 address byte, up to 16 Kbit EEPROMs) ..................................................... 80

Figure 39: Write access (2 address bytes, 32 Kbit - 4 Mbit EEPROMs) ............................................... 81

Figure 40: Read access (1 address byte, up to 16 Kbit EEPROMs) .................................................... 81

Figure 41: PDI Interrupt Masking and interrupt signals ......................................................................... 82

Figure 42: ECAT Interrupt Masking ....................................................................................................... 83

I-XII Slave Controller – Technology

Page 13

ABBREVIATIONS

µC

Microcontroller

ADR

Address

ADS

Automation Device Specification (Beckhoff)

AL

Application Layer

AMBA®

Advanced Microcontroller Bus Architecture from ARM®

APRD

Auto Increment Physical Read

APWR

Auto Increment Physical Write

APRW

Auto Increment Physical ReadWrite

ARMW

Auto Increment Physical Read Multiple Write

AoE

ADS over EtherCAT

ASIC

Application Specific Integrated Chip

Auto Crossover

Automatic detection of whether or not the send and receive lines are crossed.

Auto Negotiation

Automatic negotiation of transmission speeds between two stations.

Avalon®

On-chip bus for Altera® FPGAs

AXITM

Advanced eXtensible Interface Bus, an AMBA interconnect. Used as On-Chipbus

Big Endian

Data format (also Motorola format). The more significant byte is transferred first

when a word is transferred. However, for EtherCAT the least significant bit is

the first on the wire.

BOOT

BOOT state of EtherCAT state machine

Boundary Clock

A station that is synchronized by another station and then passes this

information on.

Bridge

A term for switches used in standards. Bridges are devices that pass on

messages based on address information.

Broadcast

An unacknowledged transmission to an unspecified number of receivers.

BRD

Broadcast Read

BWR

Broadcast Write

BRW

Broadcast ReadWrite

Cat

Category – classification for cables that is also used in Ethernet. Cat 5 is the

minimum required category for EtherCAT. However, Cat 6 and Cat 7 cables are

available.

CoE

CAN® application layer over EtherCAT

Communication

Stack

A communication software package that is generally divided into successive

layers, which is why it is referred to as a stack.

Confirmed

Means that the initiator of a service receives a response.

CRC

Cyclic Redundancy Check, used for FCS

ABBREVIATIONS

Slave Controller – Technology I-XIII

Page 14

ABBREVIATIONS

Cut Through

Procedure for cutting directly through an Ethernet frame by a switch before the

complete message is received.

Cycle

Cycle in which data is to be exchanged in a system operating on a periodical

basis.

DC

Distributed Clocks

Mechanism to synchronize EtherCAT slaves and master

Delay

Delays can be caused by run-times during transfer or internal delays of a

network component.

Dest Addr

Destination address of a message (the destination can be an individual network

station or a group (multicast).

DHCP

Dynamic Host Configuration Protocol, used to assign IP addresses (and other

important startup parameter in the Internet context).

DL

Data Link Layer, also known as Layer 2. EtherCAT uses the Data Link Layer of

Ethernet, which is standardized as IEEE 802.3.

DNS

Domain Name Service, a protocol for domain name to IP addresses resolution.

EBUS

Based on LVDS (Low Voltage Differential Signaling) standard specified in

ANSI/TIA/EIA-644-1995

ECAT

EtherCAT

EEPROM

Electrically Erasable Programmable Read Only Memory. Non-volatile memory

used to store EtherCAT Slave Information (ESI). Connected to the SII.

EMC

Electromagnetic Compatibility, describes the robustness of a device with regard

to electrical interference from the environment.

EMI

Electromagnetic Interference

Engineering

Here: All applications required to configure and program a machine.

EoE

Ethernet over EtherCAT

EOF

End of Frame

ERR

Error indicator for AL state

Err(x)

Physical Layer RX Error LED for debugging purposes

ESC

EtherCAT Slave Controller

ESI

EtherCAT Slave Information, stored in SII EEPROM

ESM

EtherCAT State Machine

ETG

EtherCAT Technology Group (http://www.ethercat.org)

EtherCAT

Real-time Standard for Industrial Ethernet Control Automation Technology

(Ethernet for Control Automation Technology)

EtherType

Identification of an Ethernet frame with a 16-bit number assigned by IEEE. For

example, IP uses EtherType 0x0800 (hexadecimal) and the EtherCAT protocol

uses 0x88A4.

I-XIV Slave Controller – Technology

Page 15

ABBREVIATIONS

EPU

EtherCAT Processing Unit. The logic core of an ESC containing e.g. registers,

memory, and processing elements.

Fast Ethernet

Ethernet with a transmission speed of 100 Mbit/s.

FCC

Federal Communications Commission

FCS

Frame Check Sequence

FIFO

First In First Out

Firewall

Routers or other network component that acts as a gateway to the Internet and

enables protection from unauthorized access.

FMMU

Fieldbus Memory Management Unit

FoE

File access over EtherCAT

Follow Up

Message that follows Sync and indicates when the Sync frame was sent from

the last node (defined in IEEE 1588).

FPGA

Field Programmable Gate Array

FPRD

Configured Address Physical Read

FPWR

Configured Address Physical Write

FPRW

Configured Address Physical ReadWrite

FRMW

Configured Address Physical Read Multiple Write

Frame

See PDU

FTP

File Transfer Protocol

Get

Access method used by a client to read data from a device.

GND

Ground

GPI

General Purpose Input

GPO

General Purpose Output

HW

Hardware

I²C

Inter-Integrated Circuit, serial bus used for SII EEPROM connection

ICMP

Internet Control Message Protocol: Mechanisms for signaling IP errors.

IEC

International Electrotechnical Commission

IEEE

Institute of Electrical and Electronics Engineers

INIT

INIT state of EtherCAT state machine

Interval

Time span

IP

Internet Protocol: Ensures transfer of data on the Internet from end node to end

node.

Intellectual Property

IRQ

Interrupt Request

ISO

International Standard Organization

Slave Controller – Technology I-XV

Page 16

ABBREVIATIONS

ISO/OSI Model

ISO Open Systems Interconnection Basic Reference Model (ISO 7498):

describes the division of communication into 7 layers.

IT

Information Technology: Devices and methods required for computer-aided

information processing.

LatchSignal

Signal for Distributed Clocks time stamping

LED

Light Emitting Diode, used as an indicator

Link/Act

Link/Activity Indicator (LED)

Little Endian

Data format (also Intel format). The less significant byte is transferred first when

a word is transferred. With EtherCAT, the least significant bit is the first on the

wire.

LLDP

Lower Layer Discovery Protocol – provides the basis for topology discovery and

configuration definition (see IEEE802.1ab)

LRD

Logical Read

LWR

Logical Write

LRW

Logical ReadWrite

LVDS

Low Voltage Differential Signaling

M12

Connector used for industrial Ethernet

MAC

Media Access Control: Specifies station access to a communication medium.

With full duplex Ethernet, any station can send data at any time; the order of

access and the response to overload are defined at the network component

level (switches).

MAC Address

Media Access Control Address: Also known as Ethernet address; used to

identify an Ethernet node. The Ethernet address is 6 bytes long and is assigned

by the IEEE.

Mandatory

Services

Mandatory services, parameters, objects, or attributes. These must be

implemented by every station.

MBX

Mailbox

MDI

Media Dependent Interface:

Use of connector Pins and Signaling (PC side)

MDI-X

Media Dependent Interface (crossed):

Use of connector Pins and Signaling with crossed lines (Switch/hub side)

MI

(PHY) Management Interface

MII

Media Independent Interface: Standardized interface between the Ethernet

MAC and PHY.

Multicast

Transmission to multiple destination stations with a frame – generally uses a

special address.

NOP

No Operation

NVRAM

Non-volatile random access memory, e.g. EEPROM or Flash.

Octet

Term from IEC 61158 – one octet comprises exactly 8 bits.

OP

Operational state of EtherCAT state machine

I-XVI Slave Controller – Technology

Page 17

ABBREVIATIONS

OPB

On-Chip Peripheral Bus

Optional Service

Optional services can be fulfilled by a PROFINET station in addition to the

mandatory services.

OSI

Open System Interconnect

OUI

Organizationally Unique Identifier –the first 3 Bytes of an Ethernet-Address that

will be assign to companies or organizations and can be used for protocol

identifiers as well (e.g. LLDP)

PDI

Process Data Interface or Physical Device Interface: an interface that allows

access to ESC from the process side.

PDO

Process Data Object

PDU

Protocol Data Unit: Contains protocol information (Src Addr, Dest Addr,

Checksum and service parameter information) transferred from a protocol

instance of transparent data to a subordinate level (the lower level contains the

information being transferred).

PE

Protection Earth

PHY

Physical layer device that converts data from the Ethernet controller to electric

or optical signals.

Ping

Frame that verifies whether the partner device is still available.

PLB

Processor Local Bus

PLL

Phase Locked Loop

PREOP

Pre-Operational state of EtherCAT state machine

Priority Tagging

Priority field inserted in an Ethernet frame.

Protocol

Rules for sequences – here, also the sequences (defined in state machines)

and frame structures (described in encoding) of communication processes.

Provider

Device that sends data to other consumers in the form of a broadcast message.

PTP

Precision Time Protocol in accordance with IEEE 1588: Precise time

synchronization procedures.

PTP Master

Indicates time in a segment.

PTP Slave

Station synchronized by a PTP master.

Quad Cable

Cable type in which the two cable pairs are twisted together. This strengthens

the electromagnetic resistance.

RAM

Random Access Memory. ESC have User RAM and Process Data RAM.

Read

Service enabling read access to an I/O device.

Real-Time

Real-time capability of a system to perform a task within a specific time.

Request

Call of a service in the sender/client.

Response

Response to a service on the client side.

Slave Controller – Technology I-XVII

Page 18

ABBREVIATIONS

RJ45

FCC Registered Jack, standard Ethernet connector (8P8C)

RMII

Reduced Media Independent Interface

Router

Network component acting as a gateway based on the interpretation of the IP

address.

RSTP

Rapid Spanning Tree Protocol: Prevents packet from looping infinitely between

switches; RSTP is specified in IEEE 802.1 D (Edition 2004)

RT

Real-time. Name for a real-time protocol that can be run in Ethernet controllers

without special support.

RTC

Real-time Clock chip of PCs

RT Frames

EtherCAT Messages with EtherType 0x88A4.

RX

Receive

RXPDO

Receive PDO, i.e. Process Data that will be received by ESC20

RUN

RUN indicator (LED) for application state

SAFEOP

Safe-Operational state of EtherCAT state machine

Safety

Safety function, implemented by an electric, electronic programmable fail-safe

system that maintains the equipment in a safe state, even during certain critical

external events.

Schedule

Determines what should be transferred and when.

Services

Interaction between two components to fulfill a specific task.

Set

Access method used by a client to write data to a server.

SII

Slave Information Interface

SM

SyncManager

SNMP

Simple Network Management Protocol: SNMP is the standard Internet protocol

for management and diagnostics of network components (see also RFC 1157

and RFC 1156 at www.ietf.org ).

SoE

Servo Profile over EtherCAT

SOF

Start of Frame

Ethernet SOF delimiter at the end of the preamble of Ethernet frames

SPI

Serial Peripheral Interface

Src Addr

Source Address: Source address of a message.

Store and

Forward

Currently the common operating mode in switches. Frames are first received in

their entirety, the addresses are evaluated, and then they are forwarded. This

result in considerable delays, but guarantees that defective frames are not

forwarded, causing an unnecessary increase in the bus load.

STP

Shielded Twisted Pair: Shielded cable with at least 2 core pairs to be used as

the standard EtherCAT cable.

I-XVIII Slave Controller – Technology

Page 19

ABBREVIATIONS

Subnet Mask

Divides the IP address into two parts: a subnet address (in an area separated

from the rest by routers) and a network address.

Switch

Also known as Bridge. Active network component to connect different

EtherCAT participants with each other. A switch only forwards the frames to the

addressed participants.

SyncManager

ESC unit for coordinated data exchange between master and slave µController

SyncSignal

Signal generated by the Distributed Clocks unit

TCP

Transmission Control Protocol: Higher-level IP protocol that ensures secure

data exchange and flow control.

TX

Transmit

TXPDO

Transmit PDO, i.e. Process Data that will be transmitted by ESC20

UDP

User Datagram Protocol: Non-secure multicast/broadcast frame.

UTP

Unshielded Twisted Pair: Unshielded cable with at least 2 core pairs are not

recommended for industrial purpose but are commonly used in areas with low

electro-magnetic interference.

VLAN

Virtual LAN

VoE

Vendor specific profile over EtherCAT

WD

Watchdog

WKC

Working Counter

XML

Extensible Markup Language: Standardized definition language that can be

interpreted by nearly all parsers.

XML Parser

Program for checking XML schemas.

Slave Controller – Technology I-XIX

Page 20

Page 21

EtherCAT Slave Controller Overview

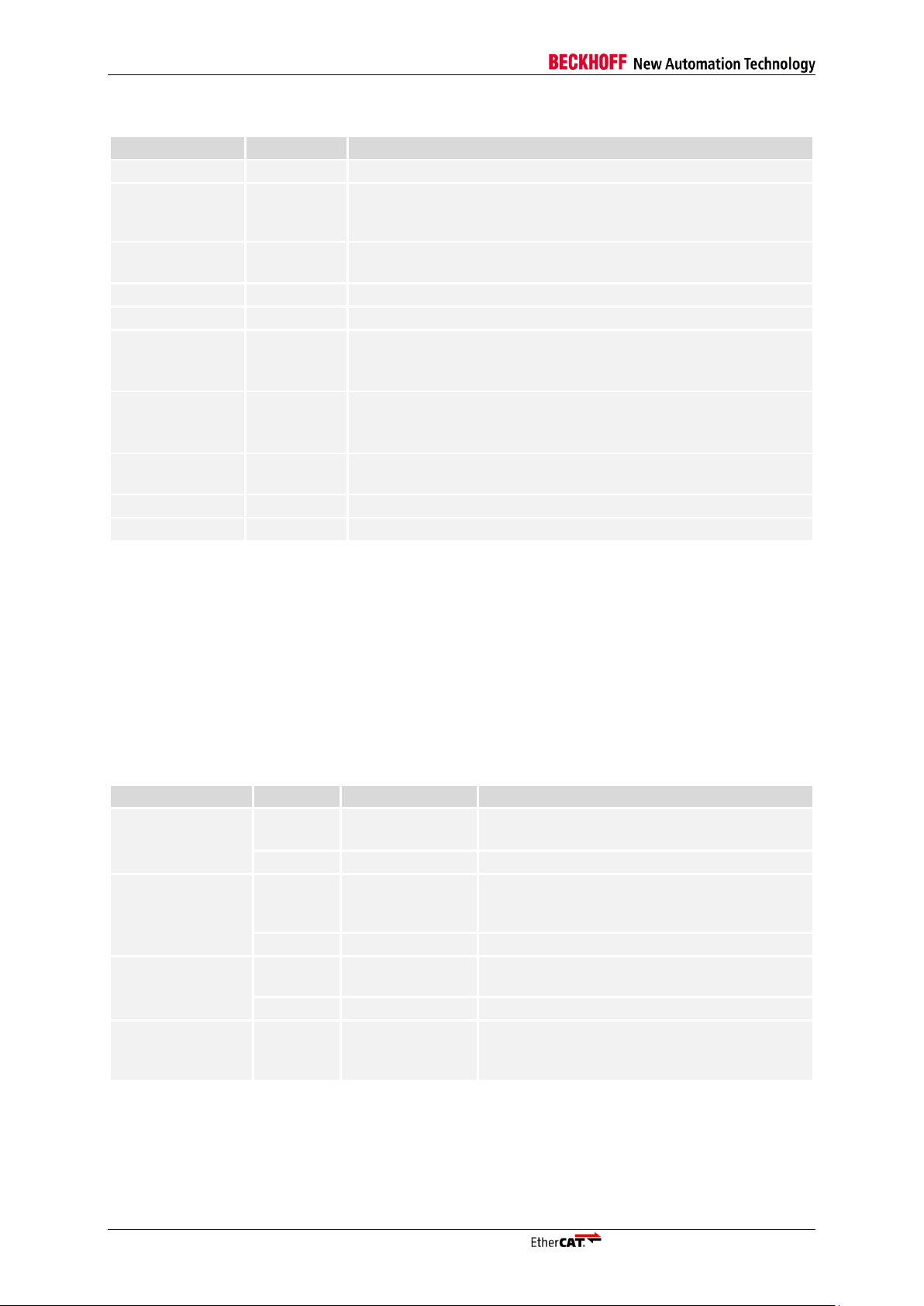

Feature

ET1200

ET1100

IP Core

ESC20

Ports

2-3 (each

EBUS/MII,

max. 1xMII)

2-4 (each

EBUS/MII)

1-3 MII/

1-3 RGMII/

1-2 RMII

2 MII

FMMUs

3 8 0-8 4 SyncManagers

4 8 0-8 4 RAM [Kbyte]

1 8 0-60

4

Distributed Clocks

64 bit

64 bit

32/64 bit

32 bit

Process Data Interfaces

Digital I/O

16 bit

32 bit

8-32 bit

32 bit

SPI Slave

Yes

Yes

Yes

Yes

8/16 bit µController

-

Async/Sync

Async

Async

On-chip bus

- - Yes

-

ECAT

Processing

Unit

AutoForwarder +

Loopback

SyncManager

FMMU

ESC address space

User RAMRegisters Process RAM

EEPROM

Distributed

Clocks

Monitoring Status

Reset

PHY

Management

Reset

SYNC LEDsI²C EEPROM

PHY MI

SPI / µC parallel /

Digital I/O / On-chip bus

0 1 2 3

Ports (Ethernet/EBUS)

LATCH

PDI

ECAT Interface PDI Interface

1 EtherCAT Slave Controller Overview

An EtherCAT Slave Controller (ESC) takes care of the EtherCAT communication as an interface

between the EtherCAT fieldbus and the slave application. This document covers the following

Beckhoff ESCs: ASIC implementations (ET1100, ET1200), functionally fixed binary configurations for

FPGAs (ESC20), and configurable IP Cores for FPGAs (ET1810/ET1815).

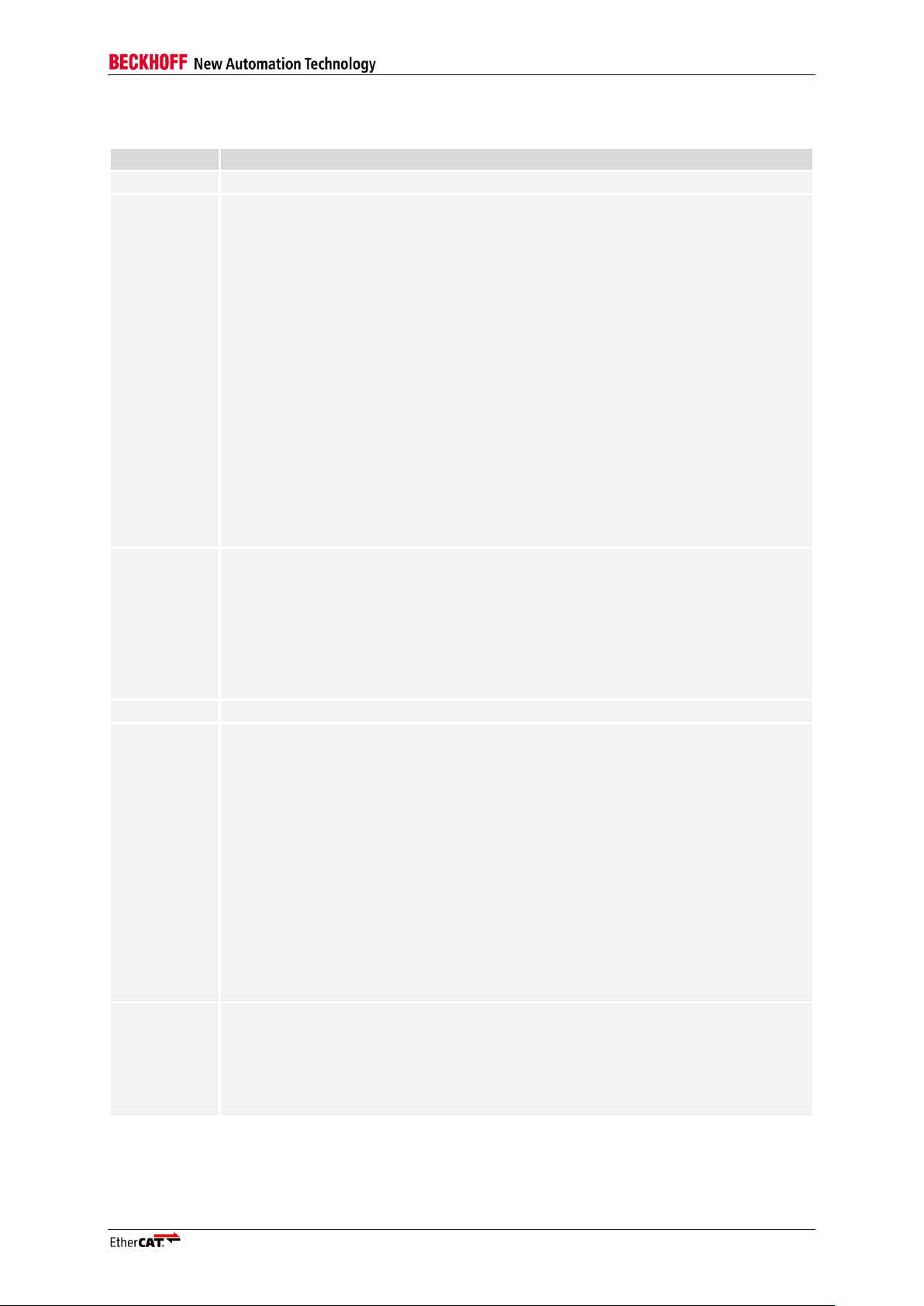

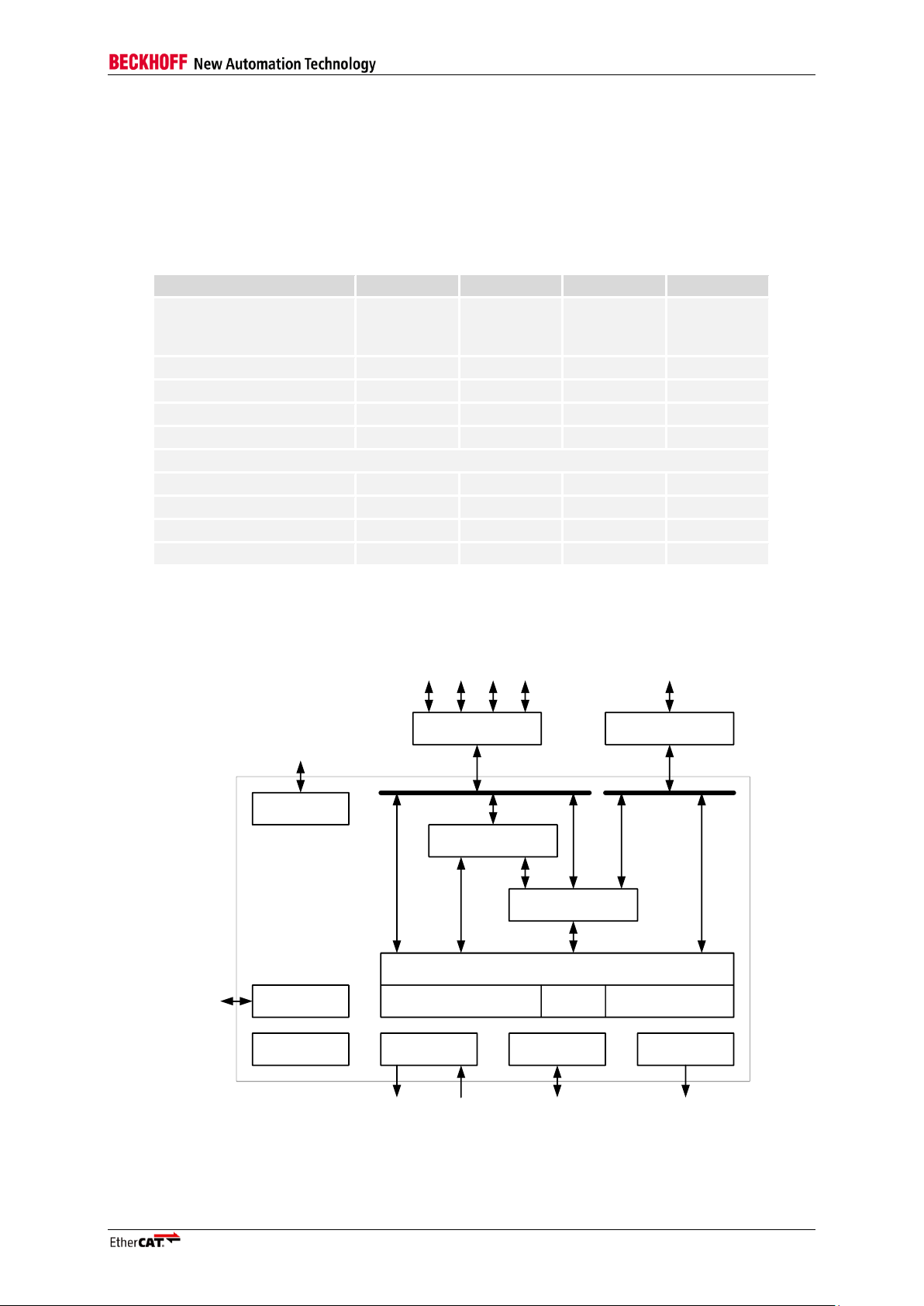

Table 1: ESC Main Features

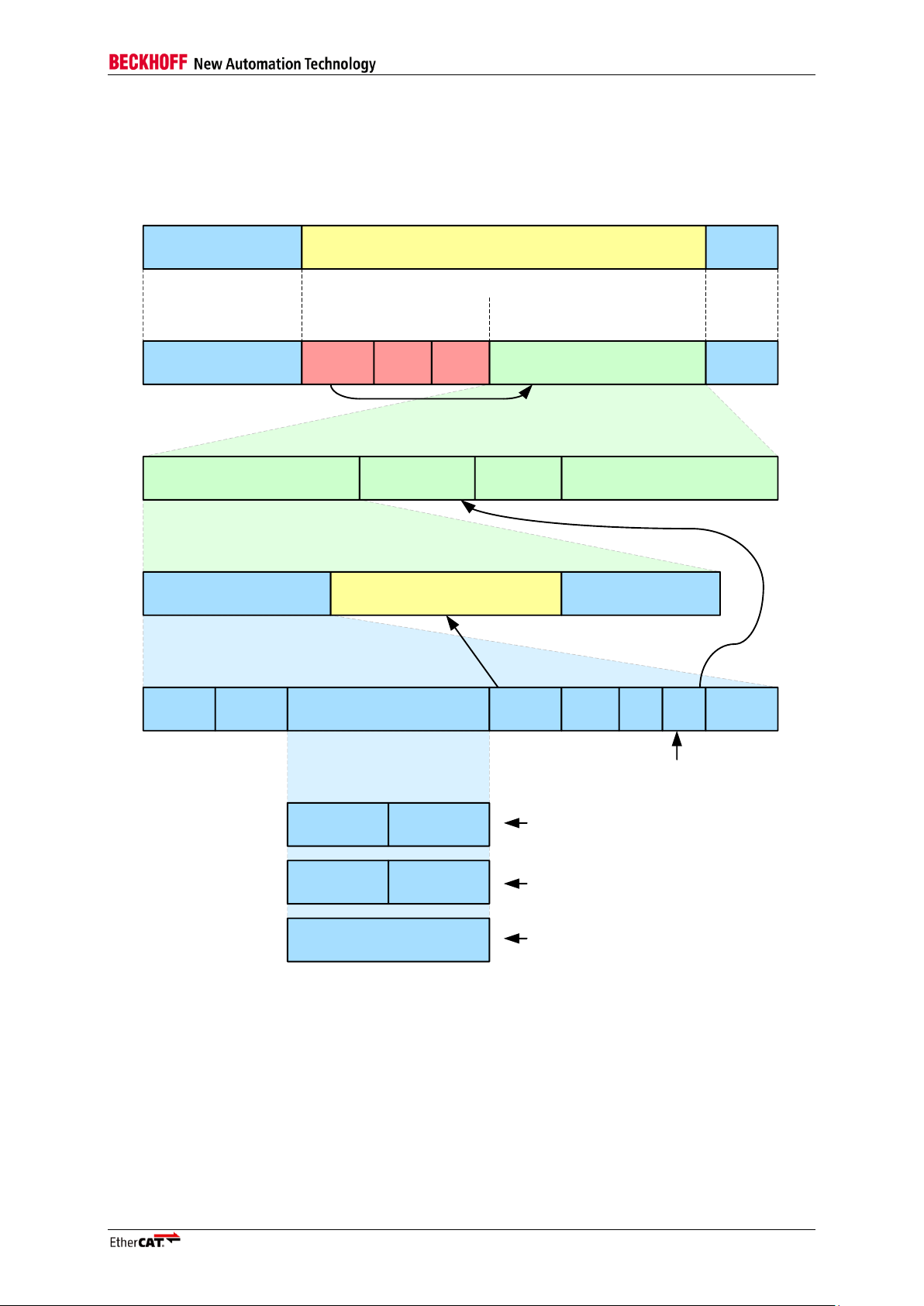

The general functionality of an ESC is shown in Figure 1:

Figure 1: EtherCAT Slave Controller Block Diagram

Slave Controller – Technology I-1

Page 22

EtherCAT Slave Controller Overview

1.1 EtherCAT Slave Controller Function Blocks EtherCAT Interfaces (Ethernet/EBUS)

The EtherCAT interfaces or ports connect the ESC to other EtherCAT slaves and the master. The

MAC layer is integral part of the ESC. The physical layer may be Ethernet or EBUS. The physical

layer for EBUS is fully integrated into the ASICs. For Ethernet ports, external Ethernet PHYs connect

to the MII/RGMII/RMII ports of the ESC. Transmission speed for EtherCAT is fixed to 100 Mbit/s with

Full Duplex communication. Link state and communication status are reported to the Monitoring

device. EtherCAT slaves support 2-4 ports, the logical ports are numbered 0-1-2-3, formerly they were

denoted by A-B-C-D.

EtherCAT Processing Unit

The EtherCAT Processing Unit (EPU) receives, analyses, and processes the EtherCAT data stream. It

is logically located between port 0 and port 3. The main purpose of the EtherCAT Processing unit is to

enable and coordinate access to the internal registers and the memory space of the ESC, which can

be addressed both from the EtherCAT master and from the local application via the PDI. Data

exchange between master and slave application is comparable to a dual-ported memory (process

memory), enhanced by special functions e.g. for consistency checking (SyncManager) and data

mapping (FMMU). The EtherCAT Processing Units contains the main function blocks of EtherCAT

slaves besides Auto-Forwarding, Loop-back function, and PDI.

Auto-Forwarder

The Auto-Forwarder receives the Ethernet frames, performs frame checking and forwards it to the

Loop-back function. Time stamps of received frames are generated by the Auto-Forwarder.

Loop-back function

The Loop-back function forwards Ethernet frames to the next logical port if there is either no link at a

port, or if the port is not available, or if the loop is closed for that port. The Loop-back function of port 0

forwards the frames to the EtherCAT Processing Unit. The loop settings can be controlled by the

EtherCAT master.

FMMU

Fieldbus Memory Management Units are used for bitwise mapping of logical addresses to physical

addresses of the ESC.

SyncManager

SyncManagers are responsible for consistent data exchange and mailbox communication between

EtherCAT master and slaves. The communication direction can be configured for each SyncManager.

Read or write transactions may generate events for the EtherCAT master and an attached µController

respectively. The SyncManagers are responsible for the main difference between and ESC and a

dual-ported memory, because they map addresses to different buffers and block accesses depending

on the SyncManager state. This is also a fundamental reason for bandwidth restrictions of the PDI.

Monitoring

The Monitoring unit contains error counters and watchdogs. The watchdogs are used for observing

communication and returning to a safe state in case of an error. Error counters are used for error

detection and analysis.

Reset

The integrated reset controller observes the supply voltage and controls external and internal resets

(ET1100 and ET1200 ASICs only).

PHY Management

The PHY Management unit communicates with Ethernet PHYs via the MII management interface. This

is either used by the master or by the slave. The MII management interface is used by the ESC itself

for optionally restarting auto negotiation after receive errors with the enhanced link detection

mechanism, and for the optional MI link detection and configuration feature.

Distributed Clock

Distributed Clocks (DC) allow for precisely synchronized generation of output signals and input

sampling, as well as time stamp generation of events. The synchronization may span the entire

EtherCAT network.

I-2 Slave Controller – Technology

Page 23

EtherCAT Slave Controller Overview

Memory

An EtherCAT slave can have an address space of up to 64Kbyte. The first block of 4 Kbyte (0x00000x0FFF) is used for registers and user memory. The memory space from address 0x1000 onwards is

used as the process memory (up to 60 Kbyte). The size of process memory depends on the device.

The ESC address range is directly addressable by the EtherCAT master and an attached µController.

Process Data Interface (PDI) or Application Interface

There are several types of PDIs available, depending on the ESC:

Digital I/O (8-32 bit, unidirectional/bidirectional, with DC support)

SPI slave

8/16 bit µController (asynchronous or synchronous)

On-chip bus (e.g., Avalon® , PLB®, or AXI®, depending on target FPGA type and selection)

General purpose I/O

The PDIs are described in Section III of the particular ESC, since the PDI functions are highly

depending on the ESC type.

SII EEPROM

One non-volatile memory is needed for EtherCAT Slave Information (ESI) storage, typically an I²C

EEPROM. If the ESC is implemented as an FPGA, a second non-volatile memory is necessary for the

FPGA configuration code.

Status / LEDs

The Status block provides ESC and application status information. It controls external LEDs like the

application RUN LED/ERR LED and port Link/Activity LEDs.

1.2 Further Reading on EtherCAT and ESCs

For further information on EtherCAT, refer to the EtherCAT specification ETG.1000, available from the

EtherCAT Technology Group (ETG, http://www.ethercat.org), and the IEC standard “Digital data

communications for measurement and control – Fieldbus for use in industrial control systems”, IEC

61158 Type 12: EtherCAT, available from the IEC (http://www.iec.ch).

Additional documents on EtherCAT can be found on the EtherCAT Technology Group website

(http://www.ethercat.org).

Documentation on Beckhoff Automation EtherCAT Slave Controllers is available at the Beckhoff

website (http://www.beckhoff.com), e.g., data sheets, application notes, and ASIC pinout configuration

tools.

1.3 Scope of Section I

Section I deals with the basic EtherCAT technology. Starting with the EtherCAT protocol itself, the

frame processing inside EtherCAT slaves is described. The features and interfaces of the physical

layer with its two alternatives Ethernet and EBUS are explained afterwards. Finally, the details of the

functional units of an ESC like FMMU, SyncManager, Distributed Clocks, Slave Information Interface,

Interrupts, Watchdogs, and so on, are described.

Since Section I is common for all Beckhoff ESCs, it contains features which might not be available in

every individual ESC. Refer to the feature details overview in Section III of a specific ESC to find out

which features are actually available.

The following Beckhoff ESCs are covered by Section I:

ET1200-0003

ET1100-0003

EtherCAT IP Core for Altera® FPGAs (V3.0.6)

EtherCAT IP Core for Xilinx® FPGAs (V3.00g)

ESC20 (Build 22)

Slave Controller – Technology I-3

Page 24

EtherCAT Protocol

Ethernet Header

Destination Source

EtherType

0x88A4

Destination Source

Destination Source

EtherType

0x0800

Destination Source

EtherType

0x0800

IP Header

UDP Header

dest. port 0x88A4

EtherType

0x88A4

Ethernet Data

EtherCAT Data

EtherCAT Header

FCS

FCS

FCS

FCS

FCSIP HeaderVLAN Tag

Datagrams

EtherCAT Header

EtherCAT Header

Length

Res. Type

48 bit 48 bit 16 bit 32 bit

11 bit 1 bit 4 bit

160 bit 64 bit

32 bit

46-1500 Byte

16-1478 Byte

Datagrams

Datagrams

44-1498 Byte

16-1478 Byte

64-1522 Byte

UDP Header

dest. port 0x88A4

Destination Source

EtherType

0x88A4

FCSEtherCAT Header Datagrams

16 bit 44-1498 Byte

Basic EtherCAT frame

EtherCAT in

UDP/IP frame

Basic EtherCAT frame with

VLAN tag

EtherCAT in UDP/IP frame

with VLAN tag

Basic EtherCAT frame

Ethernet frame

EtherCAT frame header

VLAN Tag

Field

Data Type

Value/Description

Length

11 bit

Length of the EtherCAT datagrams (excl. FCS)

Reserved

1 bit

Reserved, 0

Type

4 bit

Protocol type. Only EtherCAT commands (Type = 0x1) are supported

by ESCs.

1

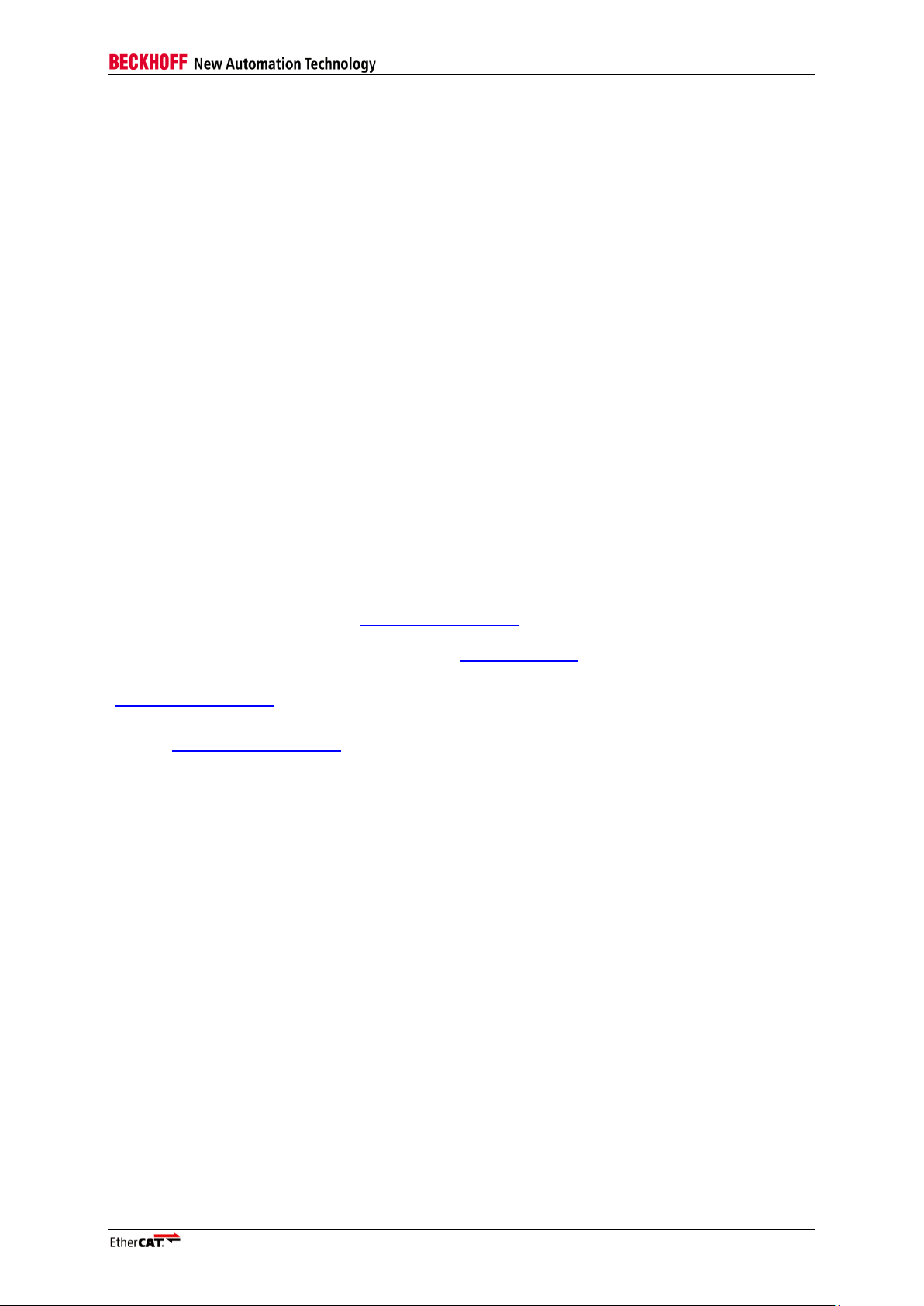

2 EtherCAT Protocol

EtherCAT uses standard IEEE 802.3 Ethernet frames, thus a standard network controller can be used

and no special hardware is required on master side.

EtherCAT has a reserved EtherType of 0x88A4 that distinguishes it from other Ethernet frames. Thus,

EtherCAT can run in parallel to other Ethernet protocols1.

EtherCAT does not require the IP protocol, however it can be encapsulated in IP/UDP. The EtherCAT

Slave Controller processes the frame in hardware. Thus, communication performance is independent

from processor power.

An EtherCAT frame is subdivided into the EtherCAT frame header followed by one or more EtherCAT

datagrams. At least one EtherCAT datagram has to be in the frame. Only EtherCAT frames with Type

1 in the EtherCAT Header are currently processed by the ESCs. The ESCs also support IEEE802.1Q

VLAN Tags, although the VLAN Tag contents are not evaluated by the ESC.

If the minimum Ethernet frame size requirement is not fulfilled, padding bytes have to be added.

Otherwise the EtherCAT frame is exactly as large as the sum of all EtherCAT datagrams plus

EtherCAT frame header.

2.1 EtherCAT Header

Figure 2 shows how an Ethernet frame containing EtherCAT data is assembled.

NOTE: The EtherCAT header length field is ignored by ESCs, they rely on the datagram length fields.

ESCs have to be configured to forward non-EtherCAT frames via DL Control register 0x0100[0].

I-4 Slave Controller – Technology

Figure 2: Ethernet Frame with EtherCAT Data

Table 2: EtherCAT Frame Header

Page 25

EtherCAT Protocol

Datagram Header

FCS

FCS

Data

4 Byte

Position Addressing

1...n Datagrams

44*-1498 Byte

Ethernet header

Ethernet header

Length

Res. Type

11 bit 1 bit 4 bit14 Byte

1st EtherCAT Datagram 2

nd

... n

th

EtherCAT Datagram...

Working Counter

(WKC)

Cmd Idx

Position Offset

Address Offset

Logical Address

Address Len R C M IRQ

10 Byte 0-1486 Byte 2 Byte

8 Bit 8 Bit 32 Bit 11 Bit 16 Bit3 Bit 1 1

16 Bit 16 Bit

Node Addressing

Logical Addressing

* add 1-32 padding bytes if Ethernet frame is shorter than

64 Bytes (Ethernet Header+Ethernet Data+FCS)

Ethernet Data

EtherCAT header

168 6248 590 63 64 79

More EtherCAT Datagrams

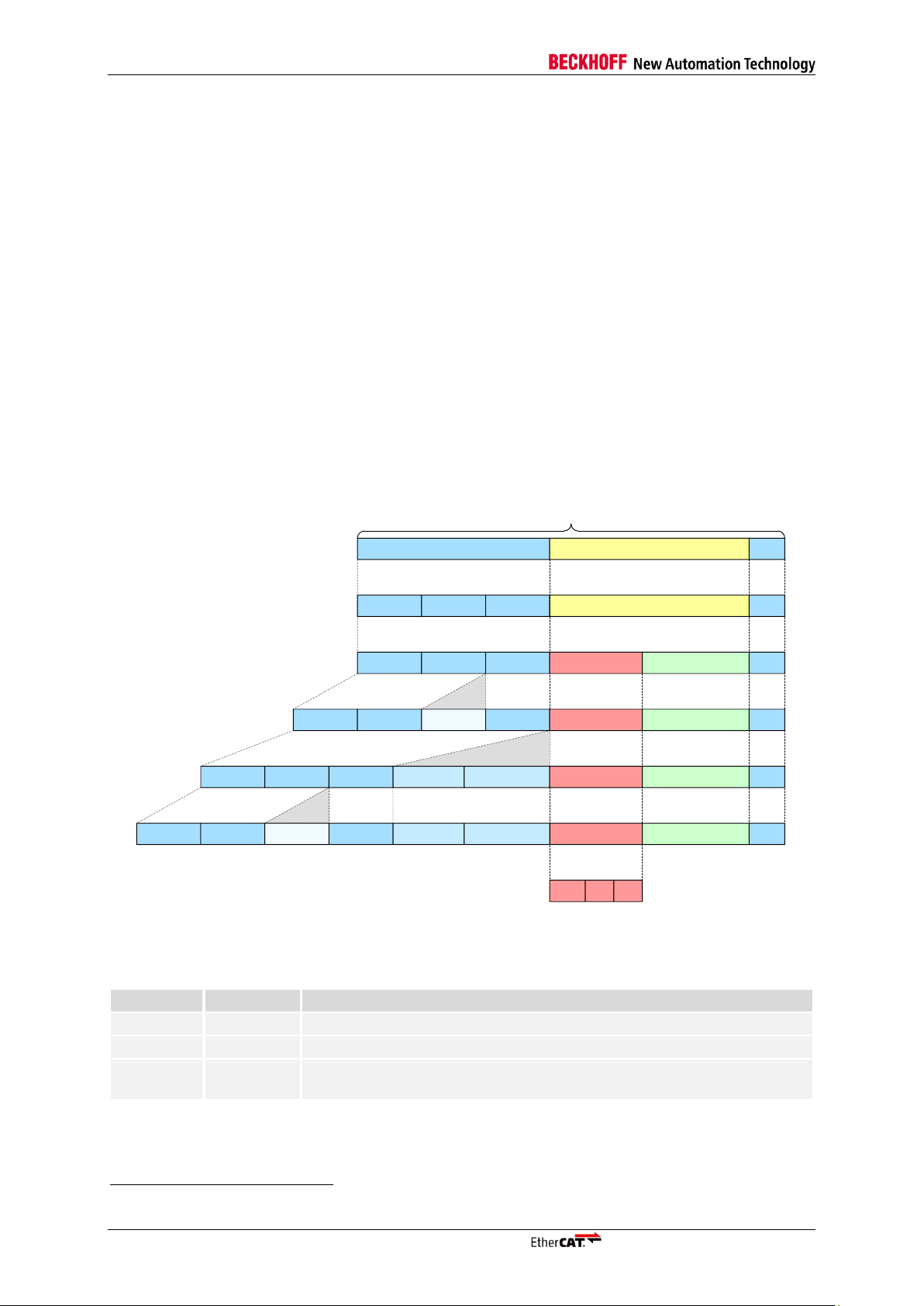

2.2 EtherCAT Datagram

Figure 3 shows the structure of an EtherCAT frame.

Figure 3: EtherCAT Datagram

Slave Controller – Technology I-5

Page 26

EtherCAT Protocol

Field

Data Type

Value/Description

Cmd

BYTE

EtherCAT Command Type (see 2.5)

Idx

BYTE

The index is a numeric identifier used by the master for

identification of duplicates/lost datagrams. It shall not be changed

by EtherCAT slaves

Address

BYTE[4]

Address (Auto Increment, Configured Station Address, or Logical

Address, see 2.3)

Len

11 bit

Length of the following data within this datagram

R

3 bit

Reserved, 0

C

1 bit

Circulating frame (see 3.5):

0: Frame is not circulating

1: Frame has circulated once

M

1 bit

More EtherCAT datagrams

0: Last EtherCAT datagram

1: More EtherCAT datagrams will follow

IRQ

WORD

EtherCAT Event Request registers of all slaves combined with a

logical OR

Data

BYTE[n]

Read/Write Data

WKC

WORD

Working Counter (see 2.4)

Mode

Field

Data Type

Value/Description

Auto Increment

Address

Position

WORD

Each slave increments Position.

Slave is addressed if Position = 0.

Offset

WORD

Local register or memory address of the ESC

Configured

Station Address

Address

WORD

Slave is addressed if Address matches

Configured Station Address or Configured

Station Alias (if enabled).

Offset

WORD

Local register or memory address of the ESC

Broadcast

Position

WORD

Each slave increments Position (not used for

addressing)

Offset

WORD

Local register or memory address of the ESC

Logical Address

Address

DWORD

Logical Address (configured by FMMUs)

Slave is addressed if FMMU configuration

matches Address.

Table 3: EtherCAT Datagram

2.3 EtherCAT Addressing Modes

Two addressing modes of EtherCAT devices are supported within one segment: device addressing

and logical addressing. Three device addressing modes are available: auto increment addressing,

configured station address, and broadcast. EtherCAT devices can have up to two configured station

addresses, one is assigned by the master (Configured Station Address), the other one is stored in the

SII EEPROM and can be changed by the slave application (Configured Station Alias address). The

EEPROM setting for the Configured Station Alias address is only taken over at the first EEPROM

loading after power-on or reset.

Table 4: EtherCAT Addressing Modes

I-6 Slave Controller – Technology

Page 27

EtherCAT Protocol

2.3.1 Device Addressing

The device can be addressed via Device Position Address (Auto Increment address), by Node

Address (Configured Station Address/Configured Station Alias), or by a Broadcast.

Position Address / Auto Increment Address:

The datagram holds the position address of the addressed slave as a negative value. Each slave

increments the address. The slave which reads the address equal zero is addressed and will

execute the appropriate command at receive.

Position Addressing should only be used during start-up of the EtherCAT system to scan the

fieldbus and later only occasionally to detect newly attached slaves. Using Position addressing is

problematic if loops are closed temporarily due to hot connecting or link problems. Position

addresses are shifted in this case, and e.g., a mapping of error register values to devices

becomes impossible, thus the faulty link cannot be localized.

Node Address / Configured Station Address and Configured Station Alias:

The configured Station Address is assigned by the master during start up and cannot be changed

by the EtherCAT slave. The Configured Station Alias address is stored in the SII EEPROM and

can be changed by the EtherCAT slave. The Configured Station Alias has to be enabled by the

master. The appropriate command action will be executed if Node Address matches with either

Configured Station Address or Configured Station Alias.

Node addressing is typically used for register access to individual and already identified devices.

Broadcast:

Each EtherCAT slave is addressed.

Broadcast addressing is used e.g. for initialization of all slaves and for checking the status of all

slaves if they are expected to be identical.

Each slave device has a 16 bit local address space (address range 0x0000:0x0FFF is dedicated for

EtherCAT registers, address range 0x1000:0xFFFF is used as process memory) which is addressed

via the Offset field of the EtherCAT datagram. The process memory address space is used for

application communication (e.g. mailbox access).

2.3.2 Logical Addressing

All devices read from and write to the same logical 4 Gbyte address space (32 bit address field within

the EtherCAT datagram). A slave uses a mapping unit (FMMU, Fieldbus Memory Management Unit)

to map data from the logical process data image to its local address space. During start up the master

configures the FMMUs of each slave. The slave knows which parts of the logical process data image

have to be mapped to which local address space using the configuration information of the FMMUs.

Logical Addressing supports bit wise mapping. Logical Addressing is a powerful mechanism to reduce

the overhead of process data communication, thus it is typically used for accessing process data.

Slave Controller – Technology I-7

Page 28

EtherCAT Protocol

Command

Data Type

Increment

Read command

No success

no change

Successful read

+1

Write command

No success

no change

Successful write

+1

ReadWrite command

No success

no change

Successful read

+1

Successful write

+2

Successful read and write

+3

2.4 Working Counter

Every EtherCAT datagram ends with a 16 Bit Working Counter (WKC). The Working Counter counts

the number of devices that were successfully addressed by this EtherCAT datagram. Successfully

means that the ESC is addressed and the addressed memory is accessible (e.g., protected

SyncManager buffer). EtherCAT Slave Controllers increment the Working Counter in hardware. Each

datagram should have an expected Working Counter value calculated by the master. The master can

check the valid processing of EtherCAT datagrams by comparing the Working Counter with the

expected value.

The Working Counter is increased if at least one byte/one bit of the whole multi-byte datagram was

successfully read and/or written. For a multi-byte datagram, you cannot tell from the Working Counter

value if all or only one byte was successfully read and/or written. This allows reading separated

register areas using a single datagram by ignoring unused bytes.

The Read-Multiple-Write commands ARMW and FRMW are either treated like a read command or like

a write command, depending on the address match.

Table 5: Working Counter Increment

I-8 Slave Controller – Technology

Page 29

EtherCAT Protocol

2.5 EtherCAT Command Types

All supported EtherCAT Command types are listed in Table 6. For ReadWrite operations, the Read

operation is performed before the Write operation.

Slave Controller – Technology I-9

Page 30

EtherCAT Protocol

CMD

Abbr.

Name

Description

0

NOP

No Operation

Slave ignores command

1

APRD

Auto Increment Read

Slave increments address. Slave puts read data

into the EtherCAT datagram if received address is

zero.

2

APWR

Auto Increment Write

Slave increments address. Slave writes data into

memory location if received address is zero.

3

APRW

Auto Increment Read Write

Slave increments address. Slave puts read data

into the EtherCAT datagram and writes the data

into the same memory location if received address

is zero.

4

FPRD

Configured Address Read

Slave puts read data into the EtherCAT datagram

if address matches with one of its configured

addresses

5

FPWR

Configured Address Write

Slave writes data into memory location if address

matches with one of its configured addresses

6

FPRW

Configured Address Read

Write

Slave puts read data into the EtherCAT datagram

and writes data into the same memory location if

address matches with one of its configured

addresses

7

BRD

Broadcast Read

All slaves put logical OR of data of the memory

area and data of the EtherCAT datagram into the

EtherCAT datagram. All slaves increment position

field.

8

BWR

Broadcast Write

All slaves write data into memory location. All

slaves increment position field.

9

BRW

Broadcast Read Write

All slaves put logical OR of data of the memory

area and data of the EtherCAT datagram into the

EtherCAT datagram, and write data into memory

location. BRW is typically not used. All slaves

increment position field.

10

LRD

Logical Memory Read

Slave puts read data into the EtherCAT datagram

if received address matches with one of the

configured FMMU areas for reading.

11

LWR

Logical Memory Write

Slaves writes data to into memory location if

received address matches with one of the

configured FMMU areas for writing.

12

LRW

Logical Memory Read Write

Slave puts read data into the EtherCAT datagram

if received address matches with one of the

configured FMMU areas for reading. Slaves writes

data to into memory location if received address

matches with one of the configured FMMU areas

for writing.

13

ARMW

Auto Increment Read

Multiple Write

Slave increments address. Slave puts read data

into the EtherCAT datagram if received address is

zero, otherwise slave writes the data into memory

location.

14

FRMW

Configured Read Multiple

Write

Slave puts read data into the EtherCAT datagram

if address matches with one of its configured

addresses, otherwise slave writes the data into

memory location.

15-255

reserved

Table 6: EtherCAT Command Types

I-10 Slave Controller – Technology

Page 31

EtherCAT Protocol

CMD

High

Addr. In

High

Addr.

Out

Low

Addr.

Address Match

Data

In

Data

Out

WKC

NOP

untouched

none

untouched

APRD

Position

Pos.+1

Offset

ADP=0

-

Read

+0/1

APWR

Position

Pos.+1

Offset

ADP=0

Write

+0/1

APRW

Position

Pos.+1

Offset

ADP=0

Write

Read

+0/1/2/3

FPRD

Address

Offset

ADP=conf.

station addr.

-

Read

+0/1

FPWR

Address

Offset

ADP=conf.

station addr.

Write

+0/1

FPRW

Address

Offset

ADP=conf.

station addr.

Write

Read

+0/1/2/3

BRD

High Add.

In+1

Offset

all

Data In OR

Read

+0/1

BWR

High Add.

In+1

Offset

all

Write

+0/1

BRW

High Add.

In+1

Offset

all

Write

Data In OR

Read

+0/1/2/3

LRD

Logical address

FMMU

-

(Read AND

bitmask1)

OR

(Data In

AND NOT

bit_mask1)

+0/1

LWR

Logical address

FMMU

Write

+0/1

LRW

Logical address

FMMU

Write

(Read AND

bit_mask1)

OR

(Data In

AND NOT

bit_mask1)

+0/1/2/3

ARMW

Position

Pos.+1

Offset

Read: ADP=0

-

Read

+0/1

Write: ADP/=0

Write

+0/1

FRMW

Address

Offset

Read: ADP=

conf. station

address./alias

-

Read

+0/1

Write: ADP/=

conf. station

address./alias

Write

+0/1

1

Table 7: EtherCAT Command Details

NOTE: Working Counter (WKC) increment depends on address match

by the logical read/write command.

bit_mask depends on FMMU configuration if bit-wise mapping is used: only masked bits are actually addressed

Slave Controller – Technology I-11

Page 32

Frame Processing

3 Frame Processing

The ET1100, ET1200, IP Core, and ESC20 slave controllers only support Direct Mode addressing:

neither a MAC address nor an IP address is assigned to the ESC, they process EtherCAT frames with

any MAC or IP address.

It is not possible to use unmanaged switches between these ESCs or between master and the first

slave, because source and destination MAC addresses are not evaluated or exchanged by the ESCs.

Only the source MAC address is modified when using the default settings, so outgoing and incoming

frames can be distinguished by the master.

NOTE: Attaching an ESC directly to an office network will result in network flooding, since the ESC will reflect any

frame – especially broadcast frames – back into the network (broadcast storm).

The frames are processed by the ESC on the fly, i.e., they are not stored inside the ESC. Data is read

and written as the bits are passing the ESC. The forwarding delay is minimized to achieve fast cycle

times. The forwarding delay is defined by the receive FIFO size and the EtherCAT Processing Unit

delay. A transmit FIFO is omitted to reduce delay times.

The ESCs support EtherCAT, UDP/IP, and VLAN tags. EtherCAT frames and UDP/IP frames

containing EtherCAT datagrams are processed. Frames with VLAN tags are processed by the ESCs,

the VLAN settings are ignored and the VLAN tag is not modified.

The source MAC address is changed for every frame passing the EtherCAT Processing Unit

(SOURCE_MAC[1] is set to 1 – locally administered address). This helps to distinguish between

frames transmitted by the master and frames received by the master.

3.1 Loop Control and Loop State

Each port of an ESC can be in one of two states: open or closed. If a port is open, frames are

transmitted to other ESCs at this port, and frames from other ESCs are received. A port which is

closed will not exchange frames with other ESCs, instead, the frames are forwarded internally to the

next logical port, until an open port is reached.

The loop state of each port can be controlled by the master (ESC DL Control register 0x0100). The

ESCs supports four loop control settings, two manual configurations, and two automatic modes:

Manual open

The port is open regardless of the link state. If there is no link, outgoing frames will be lost.

Manual close

The port is closed regardless of the link state. No frames will be sent out or received at this port, even

if there is a link with incoming frames.

Auto

The loop state of each port is determined by the link state of the port. The loop is open if there is a

link, and it is closed without a link.

I-12 Slave Controller – Technology

Page 33

Frame Processing

open

closed

closed

wait

link lost

a) master writes loop

configuration again to AL Control

register (via another open port)

or

b) a valid Ethernet frame is

received at this port

link lost

link establishd

Register Address

Name

Description

0x0100[15:8]

ESC DL Control

Loop control/loop setting

0x0110[15:4]

ESC DL Status

Loop and link status

0x0518:0x051B

PHY Port status

PHY Management link status

Auto close (manual open)

The port is closed depending on the link state, i.e., if the link is lost, the loop will be closed (auto

close). If the link is established, the loop will not be automatically opened, instead, it will remain closed

(closed wait state). Typically, the port has to be opened by the master explicitly by writing the loop

configuration again to the ESC DL Control register 0x0100. This write access has to enter the ESC via

a different open port. There is an additional fallback option for opening the port: if a valid Ethernet

frame is received at the closed port in Auto close mode, it will also be opened after the CRC is

received correctly, without explicit master interaction.

Figure 4: Auto close loop state transitions

A port is considered open if the port is available, i.e., it is enabled in the configuration, and one of the

following conditions is met:

The loop setting in the DL Control register is Auto and there is an active link at the port.

The loop setting in the DL Control register is Auto close and there is an active link at the port and

the DL Control register was written again after the link was established.

The loop setting in the DL Control register is Auto close and there is an active link at the port and

a valid frame was received at this port after the link was established.

The loop setting in the DL control register is Always open

A port is considered closed if one of the following conditions is met:

The port is not available or not enabled in the configuration.

The loop setting in the DL Control register is Auto and there is no active link at the port.

The loop setting in the DL Control register is Auto close and there is no active link at the port or

the DL Control register was not written again after the link was established

The loop setting in the DL Control register is Always closed

NOTE: If all ports are closed (either manually or automatically), port 0 will be opened as the recovery port.

Reading and writing via this port is possible, although the DL status register reflects the correct status. This can

be used to correct DL control register settings.

Registers used for loop control and loop/link status are listed in Table 8.

Slave Controller – Technology I-13

Table 8: Registers for Loop Control and Loop/Link Status

Page 34

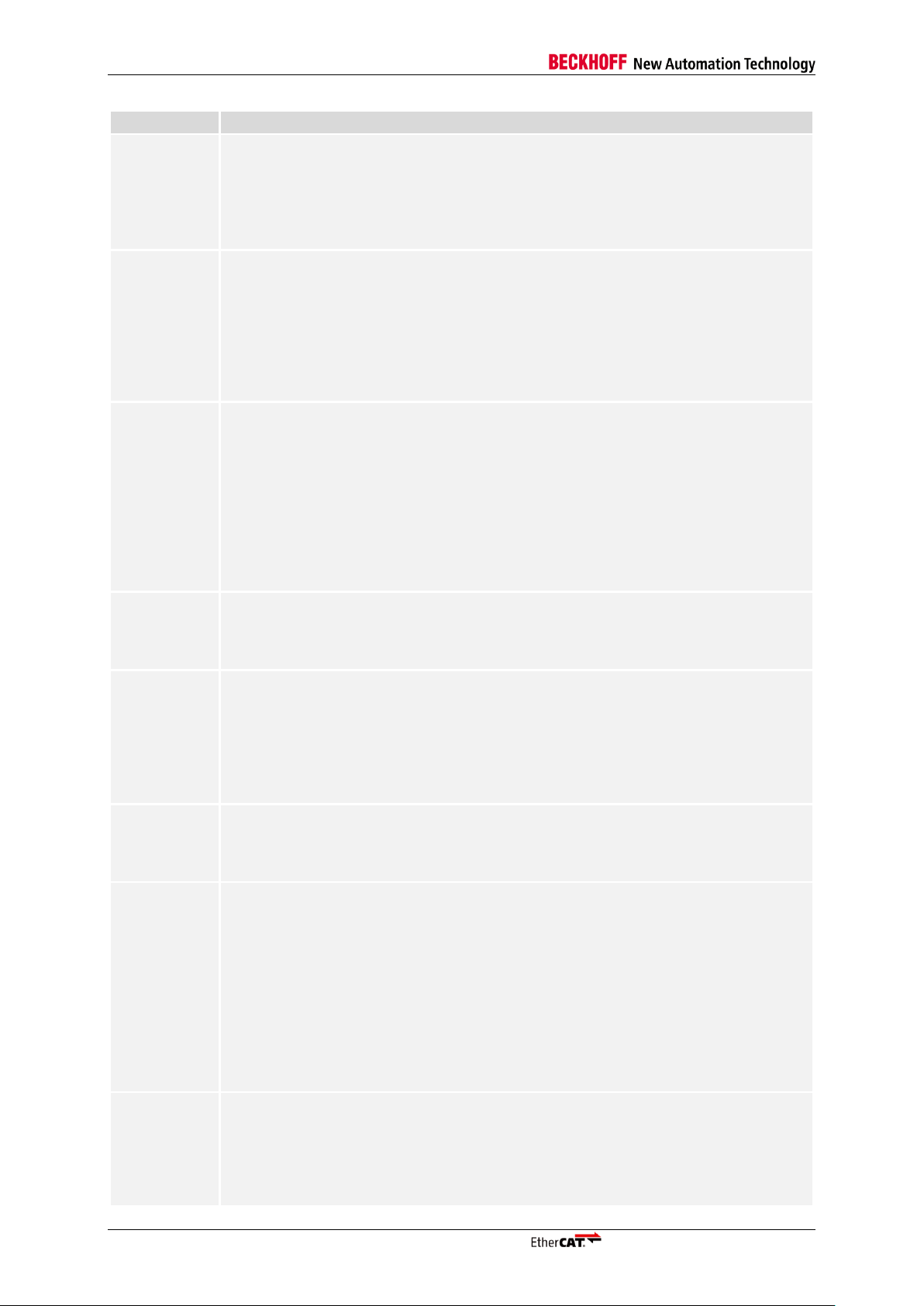

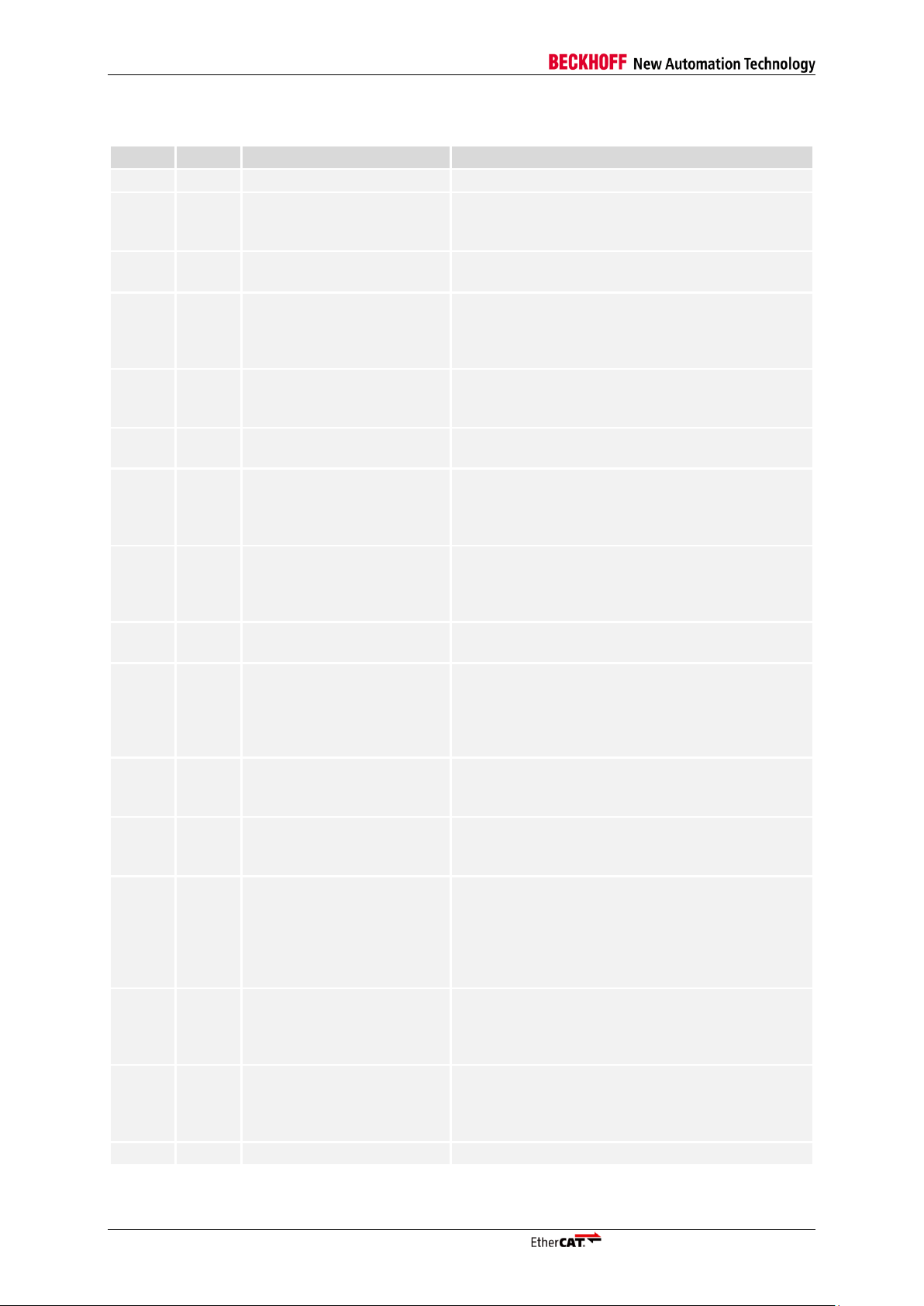

Frame Processing

Number of Ports

Frame processing order

1

0→EtherCAT Processing Unit→0

2

0→EtherCAT Processing Unit→1 / 1→0

3

0→EtherCAT Processing Unit→1 / 1→2 / 2→0 (log. ports 0,1, and 2)

or

0→EtherCAT Processing Unit→3 / 3→1 / 1→0 (log. ports 0,1, and 3)

4

0→EtherCAT Processing Unit→3 / 3→1 / 1→2 / 2→0

1

Port 2

Auto-

Forwarder

Port 1

Auto-

Forwarder

1

Port 3

Auto-

Forwarder

Port 0

Auto-

Forwarder

Loopback function

Loopback function

EtherCAT

Processing Unit

Loopback function