Page 1

Application Note ET9300

(EtherCAT Slave Stack Code)

Version 1.7

Date: 2015-01-13

Page 2

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE® and

XFC® are registered trademarks of and licensed by Beckhoff Automation GmbH.

Other designations used in this publication may be trademarks whose use by third

parties for their own purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following

German patent applications and patents: DE10304637, DE102004044764,

DE102005009224, DE102007017835 with corresponding applications or

registrations in various other countries.

Disclaimer

The documentation has been prepared with care. The products described are,

however, constantly under development. For that reason the documentation is not in

every case checked for consistency with performance data, standards or other

characteristics. In the event that it contains technical or editorial errors, we retain the

right to make alterations at any time and without warning. No claims for the

modification of products that have already been supplied may be made on the basis

of the data, diagrams and descriptions in this documentation.

Copyright

© Beckhoff Automation GmbH

The reproduction, distribution and utilization of this document as well as the

communication of its contents to others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the

event of the grant of a patent, utility model or design.

LEGAL NOTICE

II Application Note ET9300

Page 3

Version

Comment

1.0

Start document

1.1

Chapter 4 “Hardware access”.

Define descriptions; prototypes changed

1.2

Add chapter 5 Application

Add chapter 9 Tool

Add chapter 9 TestApplication

Enhance Hardware access (chapter 4)

update name references

Enhance EoE chapter

1.3

TestApplication; chapter9 :Update object/entry description (0x2020.1, 0x3003, 0x3004 and

0x3007)

Update “HW_GetTimer()” description

SSC Tool: Edit file information

Update SSC Structure

Add “Find Setting” dialog description

Update naming in Object chapter

1.4

SSCTool:

- Remove Wizard

- Add Configuration handling

1.5

Editorial changes

Add “Getting Started” chapter

Add description for hardware adaption

Test Application:

- Add new test description

- Enhance/update application description

- Describe mechanism to control the behaviors

Enhance Application chapter

- Add setting description

- Interface variables

- Guide to create an application

Add “Synchronization” chapter

Hardware chapter: Sync1_Isr() description added

Update SSC configuration references

Add “EEPROM Handling” chapter

- EEPORM Emulation

- EEPROM Programming

1.6

Editorial changes

Update object list of test application

Update SSC Tool description (chapter 12) according version 1.3.1

1.7

Chapter 6.5.2 : Add offline object dictionary enhancement

Add new mailbox test behaviors

Indicate obsolete hardware functions

Editorial changes

Update SSC Tool screenshots and GUI description

Add further test object in the test application

Add object design rules

Update references if TwinCAT 3 is used

Add SSC OD Tool description

Add optional EEPROM interface functions.

Add Bootloader information

DOCUMENT HISTORY

Stack Code. For annotations or comments to this document please send an email to

EthercatSSC@beckhoff.com.

Application Note ET9300 1

NOTE: This document makes no claim to be complete regarding to the containing topics or the Slave

Page 4

CONTENTS

1 References 7

2 Terms, Definition, Abbreviation 8

2.1 Abbreviation 8

3 Getting Started 9

3.1 SSC Tool 9

3.2 Default SSC files 9

4 Code Structure 11

5 Hardware Access 12

5.1 Interrupt Handler 16

5.2 Interface Functions/Macros 16

5.2.1 Generic 17

5.2.2 Read Access 20

5.2.3 Write Access 23

6 Application 26

6.1 Application Settings 26

6.2 SSC Functions 26

6.3 Interface Functions 27

6.3.1 Generic 27

6.3.2 EtherCAT State Machine 28

6.3.3 Process data handling 30

6.4 Interface Variables 30

6.5 Create an Application 31

6.5.1 Adding a new Application 31

6.5.2 Examples 31

7 Objects 41

7.1 Design/Structure Rules 41

7.2 Define local memory 41

7.3 Entry descriptions 42

7.4 Object name 42

7.5 Object description 43

7.6 Index Ranges 44

7.7 Implementation examples 45

7.7.1 Usage of Object Deftype ENUM 45

8 Mailbox 47

8.1 FoE (File Transfer over EtherCAT) 47

8.1.1 Testing FoE 47

8.2 EoE (Ethernet over EtherCAT) 47

8.2.1 Implementation 47

8.2.2 EoE Examples 49

9 Synchronization 55

2 Application Note ET9300

Page 5

9.1 Supported Sync Modes 55

9.1.1 FreeRun 57

9.1.2 SyncManager 57

9.1.3 SyncManager/Sync0 58

9.1.4 SyncManager/Sync0/Sync1 58

9.1.5 Sync0 59

9.1.6 Sync0/Sync1 59

9.1.7 Subordinated Cycles 59

10 CiA402 drive profile 61

10.1 Objects 61

10.2 State machine 62

10.3 Operation modes 64

10.4 TwinCAT setup 65

10.4.1 Automatic network setup 66

10.4.2 Manual network setup 67

10.4.3 NC parameter setup 69

11 TestApplication 71

11.1 Slave Behavior Control 71

11.1.1 Test Control Object 71

11.1.2 User RAM 0xF80:0xF83 72

11.2 ESM Tests (0x2000 – 0x200F) 72

11.3 Mailbox Tests (0x2010 – 0x201F) 73

11.4 CoE Tests (0x2020 – 0x202F) 73

11.5 FoE Tests (0x2030 – 0x203F) 73

11.6 Generic Objects 74

12 Tool 77

12.1 Default Startup Dialogs 77

12.2 Main User Interface Elements 78

12.2.1 Tool Bar 78

12.2.2 Windows 82

12.3 Create Files 83

12.4 Local SSC Update 84

12.5 Project Update 85

12.6 Import Configurations 85

13 OD Tool 87

13.1 Console application 87

13.2 SSC Tool Integration 87

13.3 PDO mapping and SM assign objects 88

13.4 Syntax 88

13.4.1 Comment 88

13.4.2 Object Index 88

Application Note ET9300 3

Page 6

13.4.3 ObjectCode 88

13.4.4 SI (Subindex) 89

13.4.5 DataType 89

13.4.6 Default/Min/Max 90

13.4.7 M/O/C, B/S and rx/tx 90

13.4.8 Access 90

13.5 ENUM 90

14 EEPROM Handling 92

14.1 EEPROM Emulation 92

14.2 EEPROM Programming 92

14.2.1 EEPROM Programmer User Elements 92

15 Bootloader 94

Appendix 95

Support and Service 95

Beckhoff’s branch offices and representatives 95

Beckhoff Headquarters 95

Beckhoff Support 95

Beckhoff Service 95

EtherCAT Technology Group (ETG) Headquarters 95

4 Application Note ET9300

Page 7

FIGURES

Figure 1: EtherCAT Slave Stack Code .................................................................................................. 11

Figure 2: File-Stack Association ............................................................................................................ 11

Figure 3: RxPdo data of an EtherCAT slave ......................................................................................... 36

Figure 4: EL9800 Application object ranges.......................................................................................... 45

Figure 5: Send EoE datagram ............................................................................................................... 48

Figure 6: Receive EoE datagram .......................................................................................................... 49

Figure 7: EoE Example 1 (Schema) ...................................................................................................... 50

Figure 8: Network card settings ............................................................................................................. 51

Figure 9: Access EtherCAT Slave Settings ........................................................................................... 51

Figure 10: EoE EtherCAT Slave Settings .............................................................................................. 52

Figure 11: Ping Command Window ....................................................................................................... 52

Figure 12: EoE Example 2 (Schema) .................................................................................................... 53

Figure 13: Enable IP Routing WinXP .................................................................................................... 53

Figure 14: Enable IP Routing WinCE .................................................................................................... 54

Figure 15: ESC Interrupt Signals ........................................................................................................... 55

Figure 16: Free Run .............................................................................................................................. 57

Figure 17: SyncManager Synchronization ............................................................................................ 57

Figure 18: SM/Sync0 Synchronization .................................................................................................. 58

Figure 19: SM/Sync0/Sync1 Synchronization ....................................................................................... 58

Figure 20: Sync0 Synchronization ......................................................................................................... 59

Figure 21: Sync0/Sync1 Synchronization .............................................................................................. 59

Figure 22: Subordinated Cycles ............................................................................................................ 60

Figure 23: CiA402 state transitions and option codes ........................................................................... 63

Figure 24: Axis configuration ................................................................................................................. 65

Figure 25: Set device variable without PLC link .................................................................................... 66

Figure 26: Scan for new EtherCAT devices with TwinCAT 2 ................................................................ 66

Figure 27: Scan for new EtherCAT devices with TwinCAT 3 ................................................................ 67

Figure 28: TwinCAT 2 CiA402 axis setup ............................................................................................. 67

Figure 29: TwinCAT 3 CiA402 axis setup ............................................................................................. 68

Figure 30: Add CiA402 device ............................................................................................................... 68

Figure 31: Link multiple variables .......................................................................................................... 69

Figure 32: Encoder scaling .................................................................................................................... 70

Figure 33: Velocity scaling..................................................................................................................... 70

Figure 34: Configurator Main User Interface ......................................................................................... 77

Figure 35: Configurator File Menu ......................................................................................................... 78

Figure 36: Create New Project .............................................................................................................. 78

Figure 37: Configurator Project Menu ................................................................................................... 78

Figure 38: Find Setting Dialog ............................................................................................................... 79

Figure 39: Tool Menu ............................................................................................................................ 79

Figure 40: Tool Options ......................................................................................................................... 80

Figure 41: Configurator Locked Setting ................................................................................................. 80

Figure 42: Configurations List................................................................................................................ 81

Figure 43: Configurator Help Menu ....................................................................................................... 81

Figure 44: Configurator Project Information .......................................................................................... 82

Figure 45: Configurator File Context Menu ........................................................................................... 82

Figure 46: Configurator Slave Settings ................................................................................................. 83

Figure 47: Configurator Create Files ..................................................................................................... 84

Figure 48: Configurator Slave Stack Code Update ............................................................................... 84

Figure 49: Configurator Project Update Dialog ..................................................................................... 85

Figure 50: New Project | Import Configuration ...................................................................................... 86

Figure 51: Options | Import Configuration ............................................................................................. 86

Figure 52: SSC OD Tool workflow ........................................................................................................ 87

Figure 53: Excel application definition example .................................................................................... 87

Figure 54: Application file comment ...................................................................................................... 88

Figure 55: EEPROM Programming Tool ............................................................................................... 92

Figure 56: EEPROM Programmer | File ................................................................................................ 93

Figure 57: EEPROM Programmer | Slaves ........................................................................................... 93

Figure 58: EEPROM Programmer | List Elements ................................................................................ 93

Application Note ET9300 5

Page 8

TABLES

Table 1: Hardware Related Settings ..................................................................................................... 12

Table 2: Recommended Hardware Configurations ............................................................................... 14

Table 3: Application Related Settings ................................................................................................... 26

Table 4: TSDOINFOENTRYDESC member variables .......................................................................... 42

Table 5: "TOBJECT" member variables ................................................................................................ 43

Table 6: Basic object index ranges ....................................................................................................... 44

Table 7: Supported Sync Modes ........................................................................................................... 56

Table 8: Object definitions in file cia402appl.h ................................................................................ 61

Table 9: State machine .......................................................................................................................... 64

Table 10: Linking of device and NC variables ....................................................................................... 68

Table 11: Test Object ............................................................................................................................ 71

Table 12: Test Object Entry ................................................................................................................... 71

Table 13: Test Control Object................................................................................................................ 71

Table 14: Test Control Object Entries ................................................................................................... 72

Table 15: Test Application | ESC Register 0xF80:0xF83 ...................................................................... 72

Table 16: Test Object 0x2000 (ESM Group 1) ...................................................................................... 72

Table 17: Test Object 0x2010 (Mailbox Group 1) ................................................................................. 73

Table 18: Test Object 0x2020 (CoE Group 1) ....................................................................................... 73

Table 19: Test Object 0x2030 (FoE Group 1) ....................................................................................... 73

Table 20: Generic Objects ..................................................................................................................... 74

Table 21: PDO mapping and SM assign object generation .................................................................. 88

Table 22: Base Data Types ................................................................................................................... 89

Table 23: Entry access rights ................................................................................................................ 90

Table 24: Enum definition ...................................................................................................................... 91

Table 25: Enum usage .......................................................................................................................... 91

Table 26: EEPROM Emulation Settings ................................................................................................ 92

6 Application Note ET9300

Page 9

1 References

[1] ETG.6010 Implementation Guideline for the CiA402 Drive Profile

(www.ethercat.org/ETG6010)

[2] ETG.1000 part 6 Application Layer protocol specification (www.ethercat.org/ETG1000)

[3] Application Note EL9800

[4] ETG.2000 Slave Information Specification (www.ethercat.org/ETG2000)

[5] ETG 5001 Modular Device Profile Specification (www.ethercat.org/ETG5001)

[6] ET1100 Datasheet

[7] ETG.1020 Protocol Enhancements (www.ethercat.org/ETG1020)

[8] EtherCAT Slave Quick Design Guide

(http://download.beckhoff.com/download/Document/EtherCAT/Development_products/EtherC

AT_Slave_Design_Quick_Guide.pdf)

Application Note ET9300 7

Page 10

Abbreviation

Description

AL

Application Layer

CoE

CANopen application profile over EtherCAT

CANopen™ is a registered trademark of CAN in

Automation e.V., Nuremberg, Germany

CiA402

CANopen™ Drive Profile specified in IEC 61800-7-201;

CANopen™ and CiA™ are registered trademarks of CAN

in Automation e.V., Nuremberg, Germany

csp

cycle synchronous position

csv

cycle synchronous velocity

DC

Distributed Clocks

EoE

Ethernet over EtherCAT

ESC

EtherCAT Slave Controller

FoE

File Transfer over EtherCAT

GPO

General Purpose Output

NC

Numeric Control

PDI

Process data interface

PDO

Process Data Object

PLC

Programmable Logic Controller

SI

SubIndex

SII

Slave Information Interface

SM

Sync Manager

SPI

Serial Peripheral Interface

SSC

Slave Stack Code

2 Terms, Definition, Abbreviation

Base Datatypes -- CoE Datatypes defined in ETG.1000.6

Entry – in conclusion with object single element,

in conclusion with object dictionary the objects

Subindex -- describes a single element (entry) of an object

Object dictionary – the object dictionary is a list of objects. Within this list each object is uniquely

identified by an (object) index.

2.1 Abbreviation

8 Application Note ET9300

Page 11

3 Getting Started

This is a step by step instruction how to start the EtherCAT slave development with the Slave Stack

Code (SSC).

There is also an EtherCAT Slave Design Quick Guide available in the downloaded SSC archive.

In general two possibilities are available either using the SSC Tool (3.1 SSC Tool) or the default SSC

files (3.2 Default SSC files).

3.1 SSC Tool

1. Download the Slave Stack Code here.

NOTE: To download the SSC the ETG member login and an EtherCAT Vendor ID is required.

If you are not an ETG member click here or if you do not have an EtherCAT Vendor ID click

here.

2. Unzip the downloaded archive.

3. Install "EtherCAT Slave Stack Code Tool.msi".

4. Start the SSC Tool (Start -> Program Files -> EtherCAT Slave Stack Code Tool -> SSC Tool).

5. Acknowledge the usage agreement.

6. Enter your Vendor ID and company name.

7. Create a new project (File -> New)

8. Select ...

a. the default SSC configuration.

b. a custom platform/application configuration. If a configuration file is available it can

also be added via the "Import" button.

NOTE: If the SSC shall be executed on a third party platform, e.g. Texas Instruments AM335x

or Renesas R-IN32M3, it is recommended to use the corresponding configuration.

9. If the default SSC configuration was selected the hardware settings should be adapted

according to the target platform (Project Navigation -> "Hardware").

10. Select the slave application (Project Navigation -> "Application").

11. Save the project (File -> Save).

12. If Doxygen is installed a source code documentation can be created automatically (Tool ->

Options -> Create Files -> Create Documentation).

13. Create the slave files (Project -> Create new Slave Files).

14. Click "Start".

15. Create a slave project with the target platform specific IDE, import the generated source files

and run the slave binary. For further details see the IDE/SDK documentation of the platform

vendor.

16. Make the ESI file available in the ESI cache of the EtherCAT configuration tool/master.

17. Connect the slave platform and the EtherCAT configuration tool and create a network.

18. Run the network configuration.

3.2 Default SSC files

1. Download the Slave Stack Code here.

NOTE: To download the SSC the ETG member login and an EtherCAT Vendor ID is required.

If you are not an ETG member click here or if you do not have an EtherCAT Vendor ID click

here.

2. Unzip the downloaded archive.

3. Create a slave project with the target platform specific IDE, import the SSC files and run the

slave binary. For further details see the IDE/SDK documentation of the platform vendor.

4. Adapt the settings in ecat_def.h to the target platform and application.

Application Note ET9300 9

Page 12

5. Create an ESI file according to the settings in step 4.

6. Make the ESI file available in the ESI cache of the EtherCAT configuration tool/master.

7. Connect the slave platform and the EtherCAT configuration tool and create a network.

8. Run the network configuration.

10 Application Note ET9300

Page 13

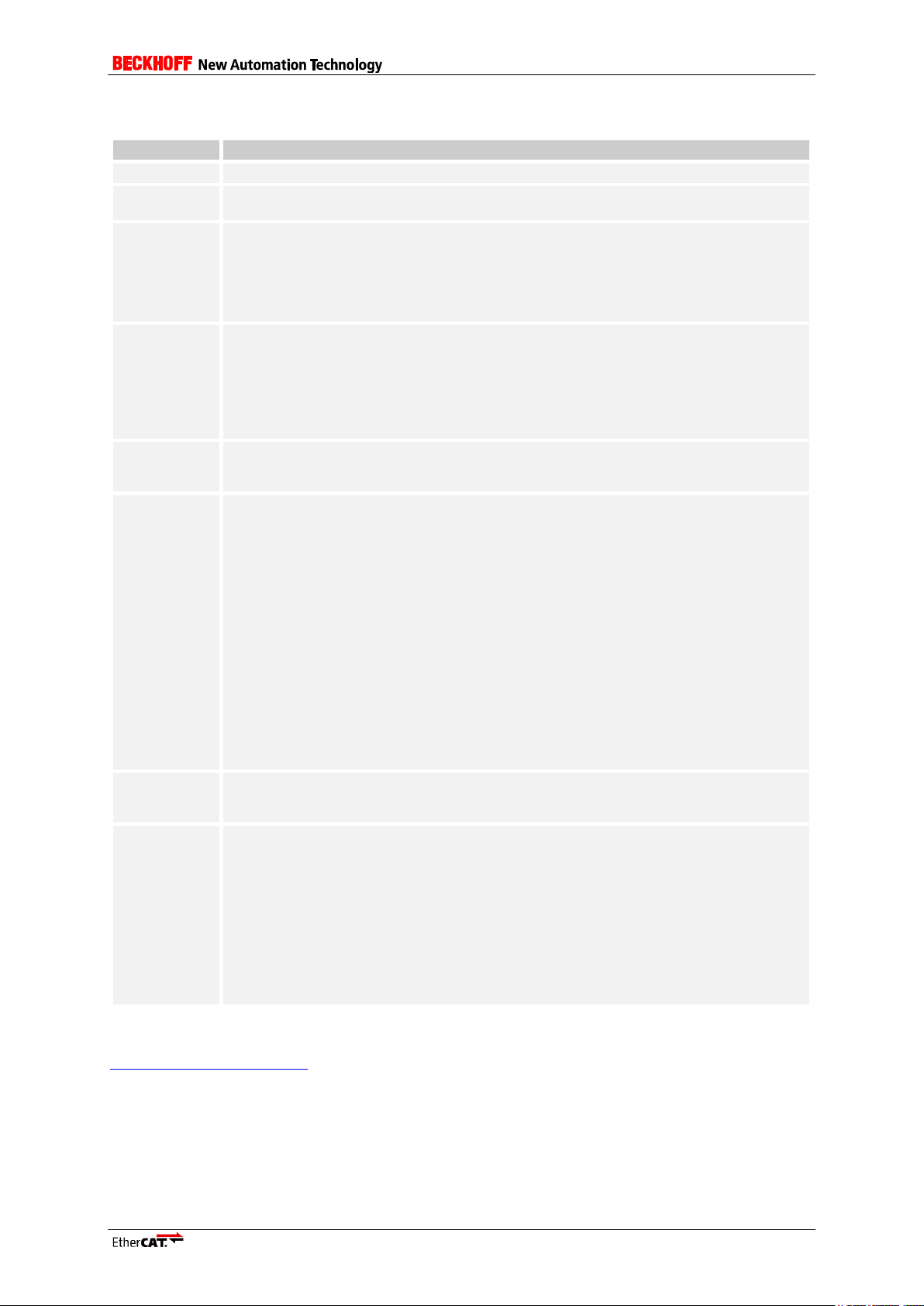

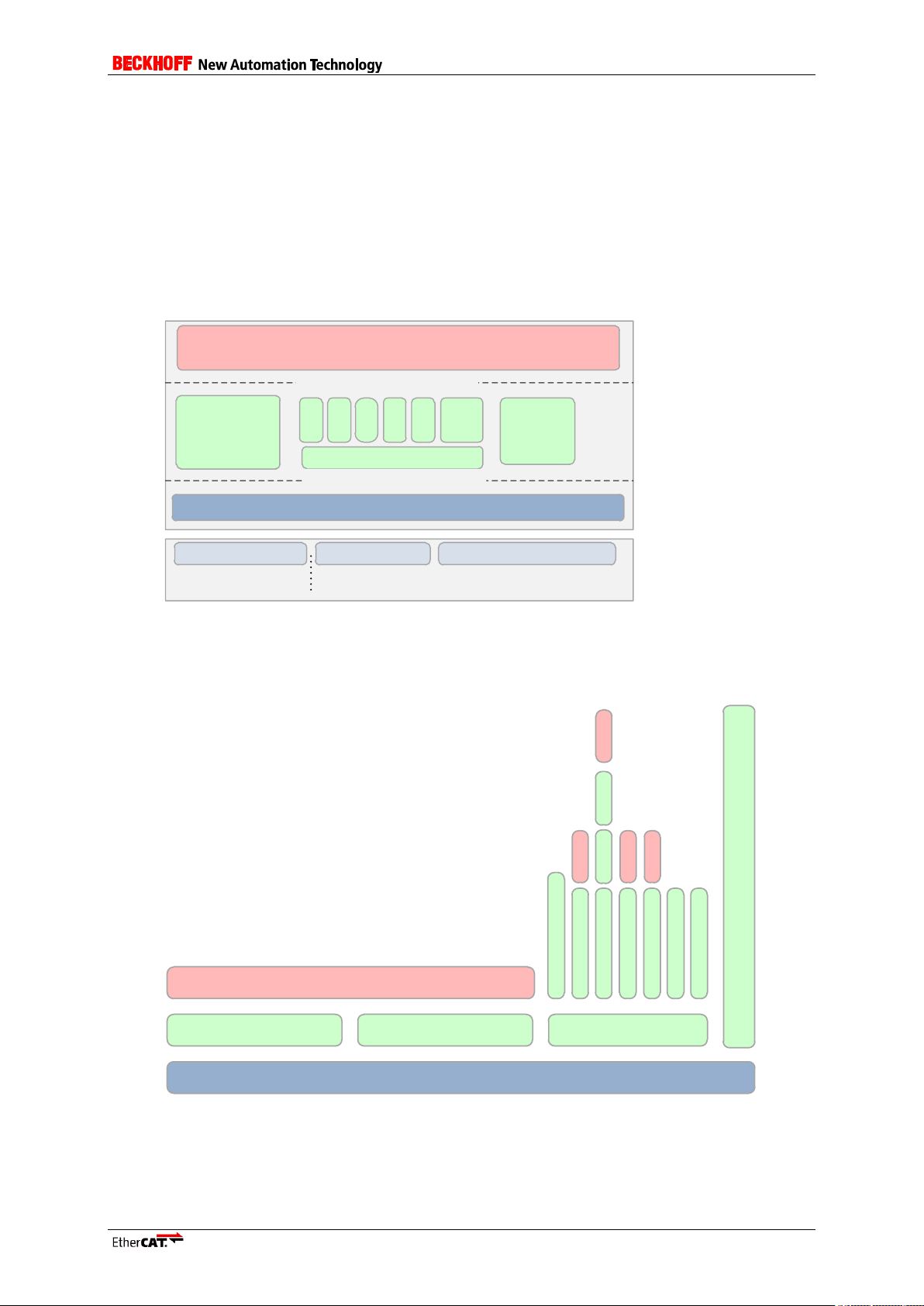

PDI and hardware abstraction

EtherCAT

State

Machine

Mailbox

Process

data

AoE

CoE

FoE

SoE

VoE

EoE

Application

e.g. CiA402 Drive Profile

Mailbox Process data

Register ESC address space (DPRAM)

0x0000 0x1000

User

Application

Generic

EtherCAT stack

Hardware

access

EtherCAT Slave

Controller (extract)

Application function set

Hardware function set

User application files (el9800appl.*,cia402appl.*,... )

PDI and hardware access functions (el9800hw.*; mcihw.*;fc1100hw.*)

Sate machine (ecatslv.*)

Slave configuration header (ecat_def.h)

Mailbox handling (mailbox.*)Process data handling (ecatappl.*)

Emergency (emcy.*)

AoE (ecataoe.*)

CoE (ecatcoe.*)

FoE (ecatfoe.*)

SoE (ecatsoe.*)

VoE

sdoserv.* objdef.*

aoeappl.*

coeappl.*

foeappl.*

EoE (ecateoe.*)

eoeappl.*

4 Code Structure

The EtherCAT slave stack as seen in Figure 1 consists of three parts:

- PDI/Hardware abstraction

- Generic EtherCAT stack

- User application

The functions and macros which shall be provided by the hardware access layer (Hardware function

set) are defined in chapter 5 Hardware Access. The behavior of the generic EtherCAT stack is

described in ETG.1000 Specification [2] . The functions which shall be provided by the application

(Application function set) are defined in chapter 6 Application.

Figure 1: EtherCAT Slave Stack Code

Figure 2 shows the association between the Slave Stack Code layers and the source files.

The structure of the code can be adapted to the application specific requirements by using the Slave

Stack Code Tool (chapter 12).

Figure 2: File-Stack Association

Application Note ET9300 11

Page 14

Define

Description

EL9800_HW

Hardware access if the slave code is executed on the PIC mounted on

EL9800 EtherCAT Evaluation Kit from Beckhoff Automation GmbH. It

includes PIC initialization and ESC access via SPI. This configuration

could also be used if the SSC needs to be adapted to any other 8 or

16Bit µC which accesses the ESC via SPI.

PIC24

Activates the configuration for the Microchip PCI24HJ128GP306 µC

which is mounted on the EL9800 EtherCAT Evaluation board since

Revision 4A. This setting shall only active if define “EL9800_HW” is

also set.

PIC18

Activates the configuration for the Microchip PIC18F452 µC which is

mounted on the EL9800 EtherCAT Evaluation board, Revision 2. This

setting shall only active if define “EL9800_HW” is also set.

MCI_HW

Generic MCI implementation. Can be used if any kind of memory

interface face is used to access the ESC.

FC1100_HW

Specific hardware implementation for the FC1100 PCI EtherCAT slave

card from Beckhoff. Used on Win32 operating system.

CONTROLLER_16BIT

This setting shall be used if the slave code is built for a 16Bit µC.

CONTROLLER_32BIT

This setting shall be used if the slave code is built for a 32Bit µC.

ESC_16BIT_ACCESS

If this setting is set, then only 16Bit aligned accesses will be performed

on the ESC.

ESC_32BIT_ACCESS

If this setting is set, then only 32Bit aligned accesses will be performed

on the ESC.

MBX_16BIT_ACCESS

If this setting is set, then the slave code will only access mailbox data

16Bit aligned. If the mailbox data is copied to the local µC memory and

the define “CONTROLLER_16BIT” is set, then this define should also

be set.

BIG_ENDIAN_16BIT

These define needs to be set if the µC always accesses external

memory 16Bit wise. It works in big endian format and the switching of

Low Byte and High Byte is done in hardware.

BIG_ENDIAN_FORMAT

This setting shall be set if the µC works in big endian format.

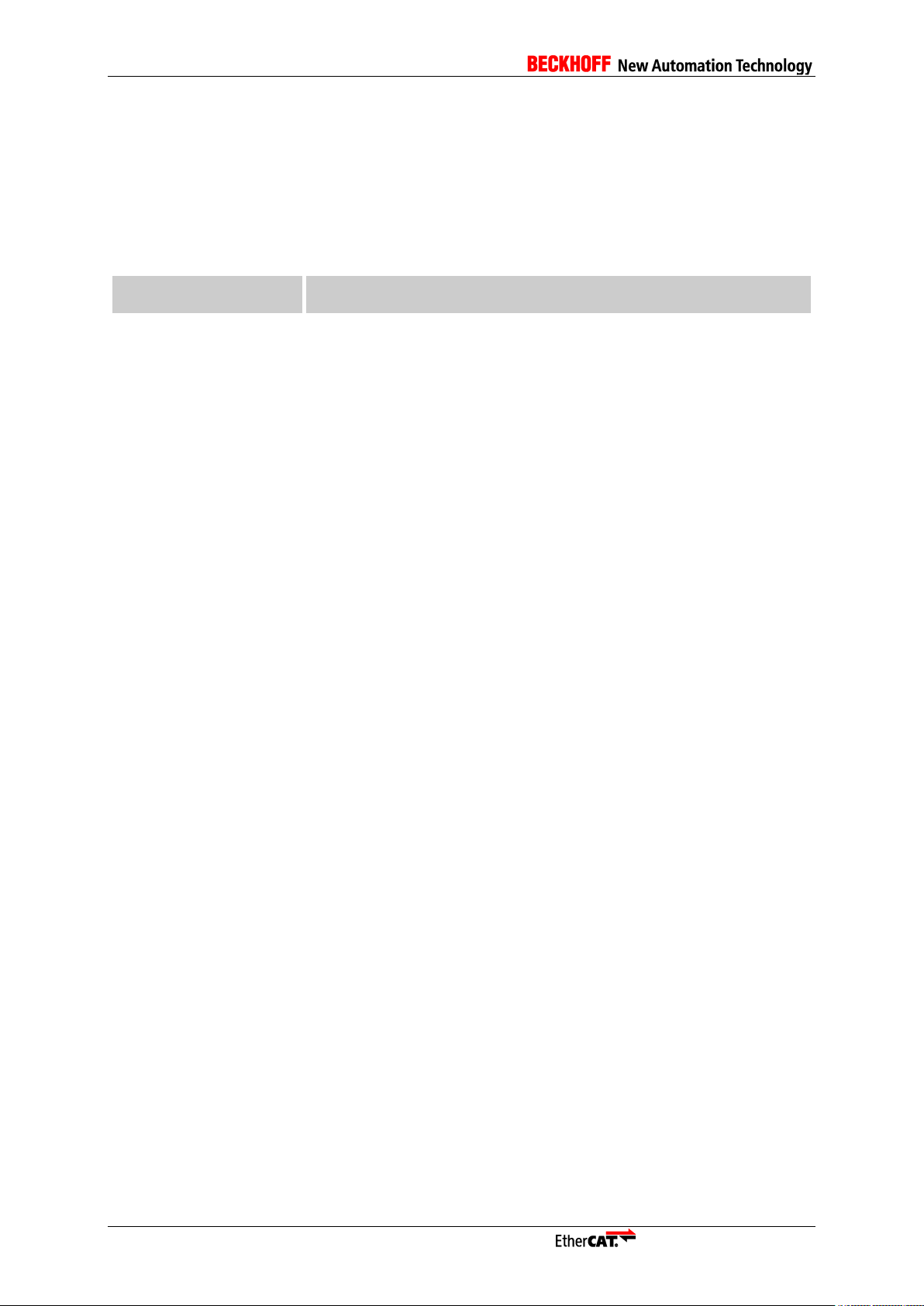

5 Hardware Access

The Slave Stack Code is executable on multiple platforms and controller architectures. This chapter

describes the available hardware implementations/settings and how to implement a new user specific

hardware access.

To support multiple hardware architectures the SSC includes multiple settings to fulfill the specific

hardware requirements. Table 1: Hardware Related Settings includes a list of the defined hardware

settings (located in ecat_def.h or in the SSC Tool).

Table 1: Hardware Related Settings

The settings “EL9800_HW”, “PIC24”, “PIC18”, MCI_HW”, “FC1100_HW” are used to activate a

predefined hardware access implementation. An extract of platforms/ µC is listed in Table 2:

Recommended Hardware Configurations including the recommended settings. Some of the

configurations can also be selected if a new project is created with the SSC Tool (see comment). If

none of these settings are used, then user specific hardware access files need to be added to the

12 Application Note ET9300

Page 15

slave project.

In general the hardware access implementation needs to support the following features:

- ESC read/write access

- Timer supply (at least 1ms base tick)

- Calling of timer handler every 1ms (only required if timer interrupt handling is supported

,“ECAT_TIMER_INT” set to 1)

- Calling the interrupt specific functions (only required if synchronization is supported)

o PDI ISR (required if “AL_EVENT_SUPPORTED” set to 1)

o SYNC0 ISR (required if “DC_SUPPORTED” set to 1)

Application Note ET9300 13

Page 16

Platform

EL9800

_HW

PIC24 PIC18 MCI_HW FC1100_HW CONTROLLER_16BIT CONTROLLER_32BIT ESC_16BIT_ACCESS ESC_32BIT_ACCESS MBX_16BIT_ACCESS BIG_ENDIAN_16BIT BIG_ENDIAN_FORMAT

Comment

Microchip PIC18F452

Generic : 8Bit µC ; SPI ESC

access

1 0 1 0 0 0 0 0 0 0 0 0 The stack is ready to use if the PIC 18 on the EL9800 EtherCAT Evaluation board

is used. Otherwise there might be requirements to adapt the hardware access

Microchip

PIC24HJ128GP306

Generic: 16Bit µC; SPI ESC

access

1 1 0 0 0 1 0 1 0 1 0 0 The stack is ready to use if the PIC 24 on the EL9800 EtherCAT Evaluation board

is used. Otherwise there might be requirements to adapt the hardware access.

x86

(OS Windows)

0 0 0 0 1 0 1 0 1 0 0 0 The stack is ready to use if the stack shall run on a Win32 OS in user mode.

Otherwise changes in hardware access might be required.

The setting “FC1100_HW” is a adapted implementation based on “MCI_HW

Texas Instruments Sitara

AM335x

0 0 0 0 0 0 0 0 0 0 0 0 To use the SSC on TI AM335x chips the hardware access files from the TI SDK

need to be added to the project. The files can be added to the slave project via the

patch file (delivered with the SDK), by selecting the TI configuration in the SSC

Tool or by adding the files manually.

Altera® NIOS®II

(ESC connected via Avalon

bus)

0 0 0 1 0 x x x x x 0 0 x: depends on the NIOS® configuration in the SOPC builder.

In general the following points need to be adapted:

- define “MAKE_PTR_TO_ESC”

- ISRs for Timer/PDI interrupt and Sync0 (depends on the supported features)

- Implement timer access functions and macros

Depending on the platform configuration further changes may be required.

Table 2: Recommended Hardware Configurations

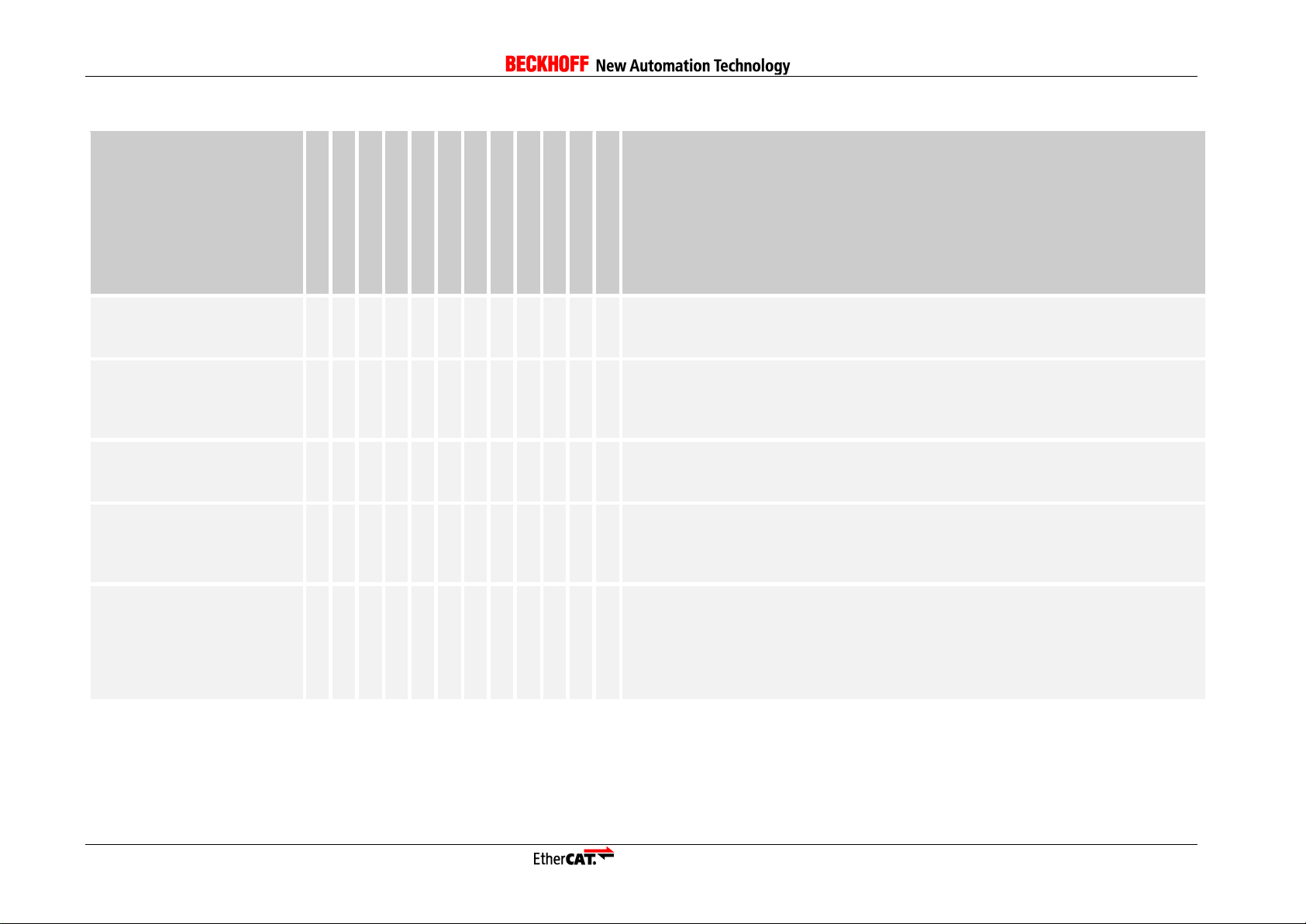

14 Application Note ET9300

Page 17

Platform

EL9800

_HW

PIC24 PIC18 MCI_HW FC1100_HW CONTROLLER_16BIT CONTROLLER_32BIT ESC_16BIT_ACCESS ESC_32BIT_ACCESS MBX_16BIT_ACCESS BIG_ENDIAN_16BIT BIG_ENDIAN_FORMAT

Comment

Xilinx Microblaze™

(ESC connected via PLB)

0 0 0 1 0 x x x x x x 0 x: depends on the Microblaze™ configuration.

In general the following points need to be adapted:

- define “MAKE_PTR_TO_ESC”

- ISRs for Timer/PDI interrupt and Sync0 (depends on the supported features)

- Implement timer access functions and macros

Depending on the platform configuration further changes may be required.

Renesas - RIN32M3

0 0 0 0 0 0 0 0 0 0 0 0 To use the SSC on Renesas RIN32M3 chip the chip specific hardware access files

need to be added to the project. The files are added automatically if the Renesas

PIN32M3 configuration is selected in the SSC Tool.

Application Note ET9300 15

Page 18

Prototype:

void ECAT_CheckTimer (void)

Parameter

void

Return

void

Description

This function needs to be called every 1ms from a timer ISR

(ECAT_TIMER_INT = 1). If no timer interrupt is supported this function is called

automatically when 1ms is elapsed (based on the provided timer).

Prototype:

void PDI_Isr (void)

Parameter

void

Return

void

Description

This function need to be called from the PDI ISR. For the PDI specific pin

naming and the interrupt generation logic please refer to [6] . To support PDI

interrupt handling it is also required to set “AL_EVENT_ENABLED” to 1.

Prototype:

void Sync0_Isr (void)

Parameter

void

Return

void

Description

This function needs to be called from the Sync0 ISR. The Sync0 interrupt is

generated by the DC Unit of the ESC. It is currently not supported by default to

map the Sync0 signal to the PDI interrupt. To support Dc synchronization

“DC_SUPPORTED” need to be set.

Prototype:

void Sync1_Isr (void)

Parameter

void

Return

void

Description

This function needs to be called from the Sync1 ISR. The Sync1 interrupt is

generated by the DC Unit of the ESC. It is currently not supported by default to

map the Sync1 signal to the PDI interrupt. To support Dc synchronization

“DC_SUPPORTED” need to be set.

5.1 Interrupt Handler

The following functions are provided by the generic Slave Stack Code (defined in ecatappl.h) and

need to be called from the hardware access layer.

5.2 Interface Functions/Macros

The functions and macros listed in this chapter need to be implemented by the hardware access layer.

16 Application Note ET9300

Page 19

5.2.1 Generic

Prototype:

UINT16 HW_Init(void)

Parameter

void

Return

0 if initialization was successful

> 0 if error has occurred while initialization

Description

Initializes the host controller, process data interface (PDI) and allocates

resources which are required for hardware access.

Prototype:

void HW_Release(void)

Parameter

void

Return

void

Description

Release allocated resources.

Prototype:

UINT16 HW_GetALEventRegister(void)

Parameter

void

Return

Content of register 0x220-0x221

Description

Get the first two bytes of the AL Event register (0x220-0x221).

Prototype:

UINT16 HW_GetALEventRegister_Isr(void)

Parameter

void

Return

Content of register 0x220-0x221

Description

This function should be implemented if a special function for ESC access from

interrupt service routines is required; otherwise this function is defined as

HW_GetALEventRegister.

Get the first two bytes of the AL Event register (0x220-0x221).

Prototype:

void HW_ResetALEventMask(UINT16 intMask)

Parameter

“intMask” Interrupt mask (disabled interrupt shall be zero)

Return

void

Description

Performs a logical AND with the AL Event Mask register (0x0204 : 0x0205).

This function is only required if “AL_EVENT_ENABLED” is set.

NOTE: This function is only required for SSC 5.10 or older.

Application Note ET9300 17

Page 20

Prototype:

void HW_SetALEventMask(UINT16 intMask)

Parameter

“intMask” Interrupt mask (enabled interrupt shall be one)

Return

void

Description

Performs a logical OR with the AL Event Mask register (0x0204 : 0x0205).

This function is only required if “AL_EVENT_ENABLED” is set.

NOTE: This function is only required for SSC 5.10 or older.

Prototype:

void HW_SetLed(UINT8 RunLed,UINT8 ErrLed)

Parameter

“RunLed” EtherCAT Run LED state

“ErrLed” EtherCAT Error LED state

Return

void

Description

Updates the EtherCAT Run and Error LEDs (or EtherCAT Status LED).

Prototype:

void HW_RestartTarget(void)

Parameter

void

Return

void

Description

Resets the hardware. This function is only required if

“BOOTSTRAPMODE_SUPPORTED” is set.

Prototype:

void HW_DisableSyncManChannel(UINT8 channel)

Parameter

“channel” SyncManager channel

Return

void

Description

Disables selected SyncManager channel. Sets bit 0 of the corresponding 0x807

register.

NOTE: This function is only required for SSC 5.10 or older.

Prototype:

void HW_EnableSyncManChannel (UINT8 channel)

Parameter

“channel” SyncManager channel

Return

void

Description

Enables selected SyncManager channel. Resets bit 0 of the corresponding

0x807 register.

NOTE: This function is only required for SSC 5.10 or older.

18 Application Note ET9300

Page 21

Prototype:

TSYNCMAN * HW_GetSyncMan(UINT8 channel)

Parameter

“channel” SyncManager channel

Return

Pointer to the SyncManager channel description. The SyncManager description

structure size is always 8 Byte, the content of “TSYNCMAN” differs depending

on the supported ESC access.

Description

Gets the content of the SyncManager register from the stated channel. Reads 8

Bytes starting at 0x800 + 8*channel.

NOTE: This function is only required for SSC 5.10 or older.

Prototype:

UINT32 HW_GetTimer(void)

Parameter

void

Return

Current timer value

Description

Reads the current register value of the hardware timer. If no hardware timer is

available the function shall return the counter value of a multimedia timer. The

timer ticks value (increments / ms) is defined in “ECAT_TIMER_INC_P_MS”.

This function is required if no timer interrupt is supported (“ECAT_TIMER_INT”

= 0) and to calculate the bus cycle time.

Prototype:

void HW_ClearTimer(void)

Parameter

void

Return

void

Description

Clears the hardware timer value.

Prototype:

UINT16 HW_EepromReload (void)

Parameter

void

Return

0 <> Error during EEPORM reload

0 = EEPROM load correct

Description

This function is called if an EEPROM reload request is triggered by the master.

Only required if EEPROM Emulation is supported and the function pointer

“pAPPL_EEPROM_Reload” is not set.

Application Note ET9300 19

Page 22

Prototype:

void HW_EscRead(MEM_ADDR *pData, UINT16 Address, UINT16 Len )

Parameter

“pData”

Pointer to local destination buffer. Type of the pointer depends

on the host controller architecture (specified in ecat_def.h or

the SSC Tool).

“Address”

EtherCAT Slave Controller address. Specifies the offset within

the ESC memory area in Bytes. Only valid addresses are

used depending on 8Bit/16Bit or 32 Bit ESC access (specified

in ecat_def.h or the SSC Tool).

“Len”

Access size in Bytes

Return

void

Description

Reads from the EtherCAT Slave Controller. This function is used to access

ESC registers and the DPRAM area.

Prototype:

void HW_EscReadIsr(MEM_ADDR *pData, UINT16 Address, UINT16 Len )

Parameter

“pData”

Pointer to local destination buffer. Type of the pointer depends

on the host controller architecture (specified in ecat_def.h or

the SSC Tool).

“Address”

EtherCAT Slave Controller address. Specifies the offset within

the ESC memory area in Bytes. Only valid addresses are

used depending on 8Bit/16Bit or 32 Bit ESC access (specified

in ecat_def.h or the SSC Tool).

“Len”

Access size in Bytes

Return

void

Description

This function should be implemented if a special function for ESC access from

interrupt service routines is required; otherwise this function is defined as

“HW_EscRead”.

Reads from the EtherCAT Slave Controller. This function is used to access

ESC registers and the DPRAM area.

Prototype:

void HW_EscReadDWord(UINT32 DWordValue, UINT16 Address)

Parameter

“DWordValue”

Local 32Bit variable where the register value shall be stored.

“Address”

EtherCAT Slave Controller address. Specifies the offset within

the ESC memory area in Bytes. Only valid 32Bit addresses

are used..

Return

void

Description

Reads two words from the specified address of the EtherCAT Slave Controller.

5.2.2 Read Access

20 Application Note ET9300

Page 23

Prototype:

void HW_EscReadDWordIsr(UINT32 DWordValue, UINT16 Address)

Parameter

“DWordValue”

Local 32Bit variable where the register value shall be stored.

“Address”

EtherCAT Slave Controller address. Specifies the offset within

the ESC memory area in Bytes. Only valid 32Bit addresses

are used.

Return

void

Description

This function should be implemented if a special function for ESC access from

interrupt service routines is required; otherwise this function is defined as

“HW_EscReadWord”.

Reads two words from the specified address of the EtherCAT Slave Controller.

Prototype:

void HW_EscReadWord(UINT16 WordValue, UINT16 Address)

Parameter

“WordValue”

Local 16Bit variable where the register value shall be stored.

“Address”

EtherCAT Slave Controller address. Specifies the offset within

the ESC memory area in Bytes. Only valid 16Bit addresses

are used.

Return

void

Description

Reads one word from the specified address of the EtherCAT Slave Controller.

Only required if “ESC_32BIT_ACCESS” is not set.

Prototype:

void HW_EscReadWordIsr(UINT16 WordValue, UINT16 Address)

Parameter

“WordValue”

Local 16Bit variable where the register value shall be stored.

“Address”

EtherCAT Slave Controller address. Specifies the offset within

the ESC memory area in Bytes. Only valid 16Bit addresses

are used.

Return

void

Description

This function should be implemented if a special function for ESC access from

interrupt service routines is required; otherwise this function is defined as

“HW_EscReadWord”.

Reads one word from the specified address of the EtherCAT Slave Controller.

Only required if “ESC_32_BIT_ACCESS” is not set.

Application Note ET9300 21

Page 24

Prototype:

void HW_EscReadByte(UINT8 ByteValue, UINT16 Address)

Parameter

“ByteValue”

Local 8Bit variable where the register value shall be stored.

“Address”

EtherCAT Slave Controller address. Specifies the offset within

the ESC memory area in Bytes.

Return

void

Description

Reads one byte from the EtherCAT Slave Controller.

Only required if “ESC_16BIT_ACCESS” and “ESC_32BIT_ACCESS” are not

set.

Prototype:

void HW_EscReadByteIsr(UINT8 ByteValue, UINT16 Address)

Parameter

“ByteValue”

Local 8Bit variable where the register value shall be stored.

“Address”

EtherCAT Slave Controller address. Specifies the offset within

the ESC memory area in Bytes.

Return

void

Description

This function should be implemented if a special function for ESC access from

interrupt service routines is required; otherwise this function is defined as

“HW_EscReadByte”.

Reads one byte from the EtherCAT Slave Controller.

Only required if “ESC_16BIT_ACCESS” and “ESC_32BIT_ACCESS” are not

set.

Prototype:

void HW_EscReadMbxMem(MEM_ADDR *pData, UINT16 Address,

UINT16 Len )

Parameter

“pData”

Pointer to local destination mailbox buffer. Type of the pointer

depends on the host controller architecture (specified in

ecat_def.h or the SSC Tool).

“Address”

EtherCAT Slave Controller address. Specifies the offset within

the ESC memory area in Bytes. Only valid addresses are

used depending on 8Bit/16Bit or 32 Bit ESC access (specified

in ecat_def.h or the SSC Tool).

“Len”

Access size in Bytes

Return

void

Description

Reads data from the ESC and copies to slave mailbox memory. If the local

mailbox memory is also located in the application memory this function is equal

to “HW_EscRead”.

22 Application Note ET9300

Page 25

5.2.3 Write Access

Prototype:

void HW_EscWrite(MEM_ADDR *pData, UINT16 Address, UINT16 Len )

Parameter

“pData”

Pointer to local source buffer. Type of the pointer depends on

the host controller architecture (specified in ecat_def.h or the

SSC Tool).

“Address”

EtherCAT Slave Controller address. Specifies the offset within

the ESC memory area in Bytes. Only valid addresses are

used depending on 8Bit/16Bit or 32 Bit ESC access (specified

in ecat_def.h or the SSC Tool).

“Len”

Access size in Bytes

Return

void

Description

Writes from the EtherCAT Slave Controller. This function is used to access

ESC registers and the DPRAM area.

Prototype:

void HW_EscWriteIsr(MEM_ADDR *pData, UINT16 Address,

UINT16 Len )

Parameter

“pData”

Pointer to local source buffer. Type of the pointer depends on

the host controller architecture (specified in ecat_def.h or the

SSC Tool).

“Address”

EtherCAT Slave Controller address. Specifies the offset within

the ESC memory area in Bytes. Only valid addresses are

used depending on 8Bit/16Bit or 32 Bit ESC access (specified

in ecat_def.h or the SSC Tool).

“Len”

Access size in Bytes

Return

void

Description

This function should be implemented if a special function for ESC access from

interrupt service routines is required; otherwise this function is defined as

“HW_EscWrite”.

Writes from the EtherCAT Slave Controller. This function is used to access ESC

registers and the DPRAM area.

Prototype:

void HW_EscWriteDWord(UINT32 DWordValue, UINT16 Address)

Parameter

“DWordValue”

Local 32Bit variable which contains the data to be written to

the ESC memory area.

“Address”

EtherCAT Slave Controller address. Specifies the offset within

the ESC memory area in Bytes. Only valid 32Bit addresses

are used.

Return

void

Description

Writes one word to the EtherCAT Slave Controller.

Application Note ET9300 23

Page 26

Prototype:

void HW_EscWriteDWordIsr(UINT32 DWordValue, UINT16 Address)

Parameter

“DWordValue”

Local 32Bit variable which contains the data to be written to

the ESC memory area.

“Address”

EtherCAT Slave Controller address . Specifies the offset

within the ESC memory area in Bytes. Only valid 32Bit

addresses are used.

Return

void

Description

This function should be implemented if a special function for ESC access from

interrupt service routines is required; otherwise this function is defined as

“HW_EscWriteWord”.

Writes two words to the EtherCAT Slave Controller.

Prototype:

void HW_EscWriteWordIsr(UINT16 WordValue, UINT16 Address)

Parameter

“WordValue”

Local 16Bit variable which contains the data to be written to

the ESC memory area.

“Address”

EtherCAT Slave Controller address. Specifies the offset within

the ESC memory area in Bytes. Only valid 16Bit addresses

are used.

Return

void

Description

This function should be implemented if a special function for ESC access from

interrupt service routines is required; otherwise this function is defined as

“HW_EscWriteWord”.

Writes one word to the EtherCAT Slave Controller. Only required if

“ESC_32BIT_ACCESS” is not set.

Prototype:

void HW_EscWriteWord(UINT16 WordValue, UINT16 Address)

Parameter

“WordValue”

Local 16Bit variable which contains the data to be written to

the ESC memory area.

“Address”

EtherCAT Slave Controller address. Specifies the offset within

the ESC memory area in Bytes. Only valid 16Bit addresses

are used.

Return

void

Description

Writes one word to the EtherCAT Slave Controller. Only required if

“ESC_32BIT_ACCESS” is not set.

Prototype:

void HW_EscWriteByte (UINT8 ByteValue, UINT16 Address)

Parameter

“ByteValue”

Local 8Bit variable which contains the data to be written to

the ESC memory area.

24 Application Note ET9300

Page 27

Prototype:

void HW_EscWriteByteIsr(UINT8 ByteValue, UINT16 Address)

Parameter

“ByteValue”

Local 8Bit variable which contains the data to be written to

the ESC memory area

“Address”

EtherCAT Slave Controller address. Specifies the offset

within the ESC memory area in Bytes.

Return

void

Description

This function should be implemented if a special function for ESC access from

interrupt service routines is required; otherwise this function is defined as

“HW_EscWriteByte”.

Writes one byte to the EtherCAT Slave Controller.

Only defined if “ESC_16BIT_ACCESS” and “ESC_32BIT_ACCESS” are

disabled.

Prototype:

void HW_EscWriteMbxMem(MEM_ADDR *pData, UINT16 Address,

UINT16 Len )

Parameter

“pData”

Pointer to local source mailbox buffer. Type of the pointer

depends on the host controller architecture (specified in

ecat_def.h or the SSC Tool).

“Address”

EtherCAT Slave Controller address. Specifies the offset

within the ESC memory area in Bytes. Only valid addresses

are used depending on 8Bit/16Bit or 32 Bit ESC access

(specified in ecat_def.h or the SSC Tool).

“Len”

Access size in Bytes.

Return

void

Description

Writes data from the slave mailbox memory to ESC memory. If the local

mailbox memory is also located in the application memory this function is equal

to “HW_EscWrite”.

“Address”

EtherCAT Slave Controller address.Specifies the offset within

the ESC memory area in Bytes.

Return

void

Description

Writes one byte to the EtherCAT Slave Controller.

Only defined if “ESC_16BIT_ACCESS” and “ESC_32BIT_ACCESS” are

disabled.

Application Note ET9300 25

Page 28

Define

Description

TEST_APPLICATION

This application supports almost all SSC features.

Furthermore it is possible to force specific application

behavior (see chapter 9).

NOTE: this application shall not be used as basis for the

application development.

EL9800_APPLICATION

Application based on the EL9800 EtherCAT Evaluation

Board. 8(4) LEDs: 8(4) switches; 16Bit analog input

CiA402_DEVICE

Sample Implementation for the CiA402 Drive Profile. This

application supports 2 modular Axis. See chapter 8 for

further information.

SAMPLE_APPLICATION

Hardware independent application. Recommend

application is if no SSC Tool configuration is available for

the target platform.

SAMPLE_APPLICATION_INTERFACE

Sample application for Win32 to create a dynamic link

library.

Prototype:

UINT16 MainInit(void)

Parameter

Void

Return

0 if initialization was successful

> 0 if error has occurred while initialization

Description

Initialize the generic slave stack.

This function should be called after the platform including operating system and

ESC is ready to use.

Prototype:

void MainLoop(void)

Parameter

Void

Return

Void

Description

This function handles the low priority function like EtherCAT state machine

handling, mailbox protocols and if no synchronization is enabled also the

application.

This function shall be called cyclically from the application.

6 Application

This chapter includes an overview over the default (sample) applications, the application interface and

a guideline how to start the own application development.

6.1 Application Settings

The SSC contains a list of (sample) applications which can be used for master/slave testing or as

basis for the application development. The corresponding settings are listed in Table 3: Application

Related Settings (located in ecat_def.h or in the SSC Tool).

Table 3: Application Related Settings

6.2 SSC Functions

These functions are provided by the generic stack and shall be called from the application layer. The

functions are declared in the header “applInterface.h”.

26 Application Note ET9300

Page 29

Prototype:

void ECAT_StateChange(UINT8 alStatus, UINT16 alStatusCode)

Parameter

alStatus

Requested Al Status

alStatusCode

AL Status Code. (if != 0 the error flag indication will be set)

Return

Void

Description

This function shall be called by the application to trigger state transition in case

of an application error or to complete a pending transition.

If the function was called due to an error it shall be again if the error is gone.

NOTE: state requests to a higher state than the current state are not allowed.

6.3 Interface Functions

Prototype:

void APPL_Application(void)

Parameter

Void

Return

void

Description

This function is called by the synchronization ISR or from the mainloop if not

synchronization is activated.

Prototype:

UINT16 APPL_GetDeviceID (void)

Parameter

Void

Return

Explicit Device ID which is written to the AL Status Code register.

Description

This function is called if the master requests the Explicit Device ID.

Only required if the slave supports Explicit Device ID handling

(EXPLICIT_DEVICE_ID).

Prototype:

UINT16 (* pAPPL_EEPROM_Read)(UINT32 wordaddr)

Parameter

Wordaddr start word address within the EEPROM memory

Return

0 if the operation was successful.

greater 0 an error has occurred

Description

This is an optional function and only required if EEPROM_EMULATION is

enabled and no EEPROM content is created (CREATE_EEPROM_CONTENT

== 0)

This function shall copy EEPROM data to the ESC EEPROM data register

(0x508:0x50F/0x50B).

The EEPROM data starting at the specified word address and the length

specified with "EEPROM_READ_SIZE".

The data shall be copied to the ESC EEPROM buffer (ESC offset 0x508)

6.3.1 Generic

Application Note ET9300 27

Page 30

Prototype:

UINT16 (* pAPPL_EEPROM_Write)(UINT32 wordaddr)

Parameter

Wordaddr start word address within the EEPROM memory

Return

0 if the operation was successful.

greater 0 an error has occurred

Description

This is an optional function and only required if EEPROM_EMULATION is

enabled and no EEPROM content is created (CREATE_EEPROM_CONTENT

== 0)

This function shall copy data from the ESC EEPROM data register

(0x508:0x50F/0x50B) to the EEPROM memory.

The EEPROM data starting at the specified word address and the length

specified with "EEPROM_WRITE_SIZE".

Prototype:

UINT16 (* pAPPL_EEPROM_Reload)(void)

Parameter

Void

Return

0 if the operation was successful.

greater 0 an error has occurred

Description

This is an optional function and only required if EEPROM_EMULATION is

enabled and no EEPROM content is created (CREATE_EEPROM_CONTENT

== 0). In case that this function is implemented the function

“HW_EepromReload()” is not used.

This function shall copy the EEPROM reload information to the ESC EEPROM

data register (0x508:0x50F/0x50B).

Read the ESC data sheet for the reload information (e.g. Beckhoff IPCore ESC

Datasheet section II, clause 3.45.1)

Prototype:

UINT16 APPL_StartMailboxHandler(void)

Parameter

Void

Return

See generic ESM return code description

Description

This function is called during the state transition from INIT to PREOP or INIT to

BOOT.

6.3.2 EtherCAT State Machine

Each ESM function returns a 16Bit Value which reflects the result of the state transition.

Return value:

0 Indicates a successful transition. Define : ALSTATUSCODE_NOERRO

0xFF Indicates a pending state transition (the application need to complete the transition by

calling ECAT_StateChange). Define : NOERROR_INWORK

Other Indicates the reason for the failed transition. See [2] for a list of valid return codes.

28 Application Note ET9300

Page 31

Prototype:

UINT16 APPL_StopMailboxHandler(void)

Parameter

Void

Return

See generic ESM return code description

Description

This function is called during the state transition from PREOP to INIT or BOOT

to INIT.

Prototype:

UINT16 APPL_StartInputHandler (UINT16 *pIntMask)

Parameter

pIntMask Value for register 0x204 (AL Event Mask).

Return

See generic ESM return code description

Description

This function is called during the state transition from PREOP to SAFEOP

(even if no input process data is available).

Prototype:

UINT16 APPL_StopInputHandler (void)

Parameter

Void

Return

See generic ESM return code description

Description

This function is called during the state transition from SAFEOP to PREOP(even

if no input process data is available).

Prototype:

UINT16 APPL_StartOutputHandler (void)

Parameter

Void

Return

See generic ESM return code description

Description

This function is called during the state transition from SAFEOP to OP (even if

no output process data is available).

Prototype:

UINT16 APPL_StopOutputHandler (void)

Parameter

Void

Return

See generic ESM return code description

Description

This function is called during the state transition from OP to SAFEOP(even if no

output process data is available).

Application Note ET9300 29

Page 32

Prototype:

UINT16 APPL_GenerateMapping (UINT16 *pInputSize, UINT16

*pOutputSize)

Parameter

Pointer to two 16bit variables to store the process data size.

pInputSize : Input process data (Slave -> Master).

pOutputSize : Output process data (Master - > Slave).

Return

See generic ESM return code description

Description

This function is called when the transition from PREOP to SAFEOP is

requested by the EtherCAT master. This function shall calculate the process

data size in bytes The values are required to check the SyncManager settings

and for the generic process data handling.

Prototype:

Void APPL_AckErrorInd(UINT16 stateTrans)

Parameter

stateTrans : Indicates the current state transition .

Return

Void

Description

This function is called when the master acknowledge and Error.

Prototype:

void APPL_InputMapping(UINT16 *pData)

Parameter

pData Pointer to the input process data.

Return

Void

Description

This function is called after the application call to map the input process data to

the generic stack (The generic stack will copy the data to the SM buffer).

Prototype:

void APPL_OutputMapping(UINT16 *pData)

Parameter

pData Pointer to the output process data.

Return

Void

Description

This function is called before the application call to get the output process data.

Name

ApplicationObjDic

Type

Array of structure TOBJECT (see 7.5 for structure definition)

Description

Only required if the slave supports CoE. The variable shall be defined in the

application header file. This array contains the application specific objects. The

last element of this array shall have the index 0xFFFF.

6.3.3 Process data handling

6.4 Interface Variables

30 Application Note ET9300

Page 33

Name

pEEPROM

Type

UINT8 *

Description

Pointer to the EEPROM buffer, it is only required if EEPROM emulation is

enabled (ESC_EEPROM_EMULATION = 1).

It is defined in ecatappl.h and shall be set by the application during power up

(before MainInit() is called). The size of the EEPROM buffer is defined by the

setting ESC_EEPROM_SIZE (default 2048)

6.5 Create an Application

A user specific application can either be created from the scratch, by adapting an existing sample

application or import/create an application definition file (see chapter 13).

The default SSC sample applications are listed at the beginning of this chapter. Other (sample)

applications might be available by other vendors and can be added to the slave project manually, by

patch file of the application vendor or the SSC Tool. See chapter 6.5.1 for details.

How to configure…

no mailbox support:

It is recommended that each complex EtherCAT slave supports at least the CoE mailbox

protocol.

To disable the mailbox handling all protocol settings shall be set to 0 ( “AOE_SUPPORTED”,

“COE_SUPPORTED”, “EOE_SUPPORTED”, “FOE_SUPPORTED”, “SOE_SUPPRTED” and

“VOE_SUPPORTED”).

NOTE: Even if no mailbox is supported the SyncManager0 and SyncManager1 shall just be

disabled and reserved for mailbox communication. If the SM are removed the SSC need to be

adapted.

input/output only device:

To create a input/output only EtherCAT slave set either “MAX_PD_INPUT_SIZE” or

“MAX_PD_OUTPUT_SIZE” to 0. Otherwise these settings shall be set to the maximum

process data size.

NOTE: The not used process data Sync Manager shall just be disabled. If the SM is removed

the SSC need to be adapted.

6.5.1 Adding a new Application The most comfortable way to add a new application to the SSC is using the SSC Tool. Just create a

new project and define an application by selecting “Tool->Application->Create new”. The syntax for

the opened table is described in chapter 13. A step-by-step instruction is available in the EtherCAT

Slave Quick Design Guide ([8] ).

To add a new application manually to the slave project all default sample applications need to be

disabled (see 6.1). Afterwards the header file including the function definitions need to be included in

the files “coeappl.c”, “ecatappl.c” and “ecatslv.c” (see “APPLICATION_FILE” comment). The

corresponding ESI file needs to be created from the scratch or by adapting an existing one.

Adding an application via a patch file please refer to the instructions of the application vendor. The

ESI file should be provided with the application source files.

6.5.2 Examples

6.5.2.1 Sample Application process data enhancement

This example base on the SSC version 5.01 and describes how to add new process data to the

default sample application (SAMPLE_APPLICATION).

The default sample application provides the following process data:

- 32Bit Input Counter (0x6000)

Application Note ET9300 31

Page 34

- 32Bit Output Counter (0x7010)

If the Output Counter is 0 the Input Counter is incremented with every application cycle by 1,

otherwise the Input Counter is the Output Counter +1.

Process data of the new application:

- 32Bit Input Counter (0x6000)

- 32Bit Result (0x6010)

- Output Values (0x7010)

SI1: Value1 (32Bit)

SI2: Value2 (32Bit)

0x6010 is the sum of 0x7010.1 and 0x7010.2. 0x6000 is incremented with every application

cycle.

Initial Steps:

The initial steps describe how to create the basic sample application for the Beckhoff EL9800

EtherCAT evaluation board. Proceed with the “Adaption steps” if the basic sample application

already exists (even if it was created for another platform).

1. Follow the steps 1-7 in chapter 3.1SSC Tool.

2. Select the custom configuration “EL9800 | 8Bit Digital I/O, 16Bit Analog Input”

3. Select group “Application”

a. Set “EL9800_APPLICATION” to 0

b. Set “SAMPLE_APPLICATION” to 1

4. Save the project and create new slave files (Project -> “Create new Slave Files”)

5. Program the slave EEPROM based on the created ESI file (see “APPLICATION NOTE EL9800”

for further details)

6. Create an MPLAB project with the create source files (see “APPLICATION NOTE EL9800” for

further details)

Adaption steps:

1. File: sampleappl.h

Create the entry description, the object name and the variable for the “32Bit Result” process data.

/**************************************************************************

* Object 0x6010: result object

**************************************************************************/

#ifdef _OBJD_

/* Entry description */

OBJCONST TSDOINFOENTRYDESC OBJMEM EntryDesc0x6010 = {DEFTYPE_UNSIGNED32,

0x10, ACCESS_READ | OBJACCESS_TXPDOMAPPING};

/* Object name */

OBJCONST UCHAR OBJMEM aName0x6010[] = "Result";

#endif //#ifdef _OBJD_

/* Variable to handle the object data */

PROTO UINT32 ResultObj6010;

2. File: sampleappl.h

Change the existing definition of object 0x7010 (32Bit Output Counter) to a record object which

handles more than one process data (the new object shall include two variables (entries)).

The variable for the entry description is changed to an array and the description for SubIndex0

and for the second variable is added.

The name variable is enhanced by the names for the entries (each “subname” is terminated by

“\000” and the whole string is terminated by “\377”).

For the object data itself a structure including a variable for the subindex0 and the two process

data variables is defined.

See chapter 11 for detailed information regarding the definitions.

32 Application Note ET9300

Page 35

/**************************************************************************

* Object 0x7010: output values object

**************************************************************************/

#ifdef _OBJD_

OBJCONST TSDOINFOENTRYDESC OBJMEM asEntryDesc0x7010[] = {

/* Entry description of Subindex0 */

{DEFTYPE_UNSIGNED8, 0x08, ACCESS_READ},

/* Entry description of the first entry “Value1” */

{DEFTYPE_UNSIGNED32, 0x20, ACCESS_READ | OBJACCESS_RXPDOMAPPING},

/* Entry description of the second entry “Value2” */

{DEFTYPE_UNSIGNED32, 0x20, ACCESS_READ | OBJACCESS_RXPDOMAPPING}};

/* Name of the object and the entries */

OBJCONST UCHAR OBJMEM aName0x7010[] = "Output

values\000Value1\000Value2\000\377";

#endif //#ifdef _OBJD_

/* Structure to handle the object data*/

typedef struct OBJ_STRUCT_PACKED_START {

UINT16 u16SubIndex0;

UINT32 Value1;

UINT32 Value2;

} OBJ_STRUCT_PACKED_END

TOBJ7010;

PROTO TOBJ7010 OutputData

#ifdef _SAMPLE_APPLICATION_

= {0x02, 0x00, 0x00}

#endif

;

3. File: sampleappl.h

Add information about the new process data to the PDO mapping objects.

The changed code is marked bold red.

NOTE: This step is required to have consistent process data information.

Definition for RxPDO (0x1601) (handling the output process data)

/**************************************************************************

* Object 0x1601: RxPDO

**************************************************************************/

#ifdef _OBJD_

OBJCONST TSDOINFOENTRYDESC OBJMEM asEntryDesc0x1601[] = {

{DEFTYPE_UNSIGNED8, 0x8, ACCESS_READ },

{DEFTYPE_UNSIGNED32, 0x20, ACCESS_READ},

/* reference to the new process data. The information does NOT describe the

process data itself, that means if the process data is an UNSIGNED8 value

the deftype in this description is still UNSIGNED32*/

{DEFTYPE_UNSIGNED32, 0x20, ACCESS_READ}};

/* Only the object name is described all entries are automatically names as

“SubIndex 000” (000 is incremented for each entry) */

OBJCONST UCHAR OBJMEM aName0x1601[] = "RxPDO-Map\000\377";

#endif //#ifdef _OBJD_

typedef struct OBJ_STRUCT_PACKED_START {

UINT16 u16SubIndex0;

/* Add one additional array element for the reference to the new process

data */

UINT32 aEntries[2];

} OBJ_STRUCT_PACKED_END

TOBJ1601;

PROTO TOBJ1601 RxPDOMap

Application Note ET9300 33

Page 36

#ifdef _SAMPLE_APPLICATION_

= {2/*the object has now two entries*/, {0x70100120,0x70100220/* Reference

to object 0x07010 Subindex2 and 32Bit length */}}

#endif

;

Definition for TxPDO (0x1A00) (handling the input process data)

/**************************************************************************

* Object 0x1A00: TxPDO

**************************************************************************/

#ifdef _OBJD_

OBJCONST TSDOINFOENTRYDESC OBJMEM asEntryDesc0x1A00[] = {

{DEFTYPE_UNSIGNED8, 0x8, ACCESS_READ },

{DEFTYPE_UNSIGNED32, 0x20, ACCESS_READ},

/* reference to the new process data. The information does NOT describe the

process data itself, that means if the process data is an UNSIGNED8 value

the deftype in this description is still UNSIGNED32*/

{DEFTYPE_UNSIGNED32, 0x20, ACCESS_READ}};

/* Only the object name is described all entries are automatically names as

“SubIndex 000” (000 is incremented for each entry) */

OBJCONST UCHAR OBJMEM aName0x1A00[] = "TxPDO-Map\000\377";

#endif //#ifdef _OBJD_

typedef struct OBJ_STRUCT_PACKED_START {

UINT16 u16SubIndex0;

/* Add one additional array element for the reference to the new process

data */

UINT32 aEntries[2];

} OBJ_STRUCT_PACKED_END

TOBJ1A00;

PROTO TOBJ1A00 TxPDOMap

#ifdef _SAMPLE_APPLICATION_

= {2/*the object has now two entries*/, {0x60000020,0x60100020/* Reference

to object 0x06010 Subindex0 and 32Bit length */}}

#endif

;

4. File: sampleappl.h

Add/Update the references in the object dictionary

TOBJECT OBJMEM ApplicationObjDic[] = {

/* Object 0x1601 */

{NULL,NULL, 0x1601, {DEFTYPE_PDOMAPPING, 2 | (OBJCODE_REC << 8)},

asEntryDesc0x1601, aName0x1601, &RxPDOMap, NULL, NULL, 0x0000 },

/* Object 0x1A00 */

{NULL,NULL, 0x1A00, {DEFTYPE_PDOMAPPING, 2 | (OBJCODE_REC << 8)},

asEntryDesc0x1A00, aName0x1A00, &TxPDOMap, NULL, NULL, 0x0000 },

…

/* Object 0x6010 */

{NULL,NULL, 0x6010, {DEFTYPE_UNSIGNED32, 0 | (OBJCODE_VAR << 8)},

&EntryDesc0x6010, aName0x6010, &ResultObj6010, NULL, NULL, 0x0000 },

/* Object 0x7010 */

{NULL,NULL, 0x7010, {DEFTYPE_RECORD, 2 | (OBJCODE_REC << 8)},

asEntryDesc0x7010, aName0x7010, &OutputData, NULL, NULL, 0x0000 },

{NULL,NULL, 0xFFFF, {0, 0}, NULL, NULL, NULL, NULL}};

5. File: sampleappl.c

Update the expected process data size (which is similar to the size of the corresponding

34 Application Note ET9300

Page 37

SyncManager).

NOTE: if one of the values mismatch with the information in the ESI file the slave will abort the

state transition from PreOP to SafeOP with the Error code 0x1E or 0x1D (depending on the wrong

value)

UINT16 APPL_GenerateMapping(UINT16 *pInputSize,UINT16 *pOutputSize)

{

/* 32Bit cyclic counter (0x6000) and 32Bit Result (*0x6010)/

*pInputSize = 8;

/*32Bit Value1 (0x7010.1) and 32Bit Value2 (0x7010.2)*/

*pOutputSize = 8;

return ALSTATUSCODE_NOERROR;

}

6. File: sampleappl.c

Update the input process data mapping function to copy also the new process data.

void APPL_InputMapping(UINT16* pData)

{

MEMCPY(pData,&InputCounter,SIZEOF(InputCounter));

/* Increment the data pointer to write the next process data (pData refers

to the buffer which is copied to the ESC memory controlled by SyncManager 3

(input process data) */

pData +=2;

/* Copy the value the result */

MEMCPY(pData,&ResultObj6010,SIZEOF(ResultObj6010));

}

7. File: sampleappl.c

Update the output process data mapping function to update the variables handling the output

process data.

void APPL_OutputMapping(UINT16* pData)

{

/* Update the variable “Value1” */

MEMCPY(&OutputData.Value1,pData,SIZEOF(OutputData.Value1));

/* Increment the data pointer to write the next process data (pData refers

to the buffer which is copied to the ESC memory controlled by SyncManager 3

(input process data) */

pData += 2;

/* Update the variable “Value2” */

MEMCPY(&OutputData.Value2,pData,SIZEOF(OutputData.Value2));

}

8. File: sampleappl.c

Update the Application.

void APPL_Application(void)

{

/*Hardware independent sample application*/

ResultObj6010 = OutputData.Value1 + OutputData.Value2;

InputCounter++;

}

9. File: ESI file (in xml format)

Update the entries of the RxPdo and TxPdo elements according to step 3.

<RxPdo Mandatory="true" Fixed="true" Sm="2">

Application Note ET9300 35

Page 38

<Index>#x1601</Index>

<Name>RxPDO</Name>

<Entry>

<Index>#x7010</Index>

<SubIndex>1</SubIndex>

<BitLen>32</BitLen>

<Name>Value1</Name>

<DataType>UDINT</DataType>

</Entry>

<Entry>

<Index>#x7010</Index>

<SubIndex>2</SubIndex>

<BitLen>32</BitLen>

<Name>Value2</Name>

<DataType>UDINT</DataType>

</Entry>

</RxPdo>

<TxPdo Mandatory="true" Fixed="true" Sm="3">

<Index>#x1a00</Index>

<Name>TXPDO</Name>

<Entry>

<Index>#x6000</Index>

<SubIndex>0</SubIndex>

<BitLen>32</BitLen>

<Name>32Bit Input</Name>

<DataType>UDINT</DataType>

</Entry>

<Entry>

<Index>#x6010</Index>

<SubIndex>0</SubIndex>

<BitLen>32</BitLen>

<Name>Result</Name>

<DataType>UDINT</DataType>

</Entry>

</TxPdo>

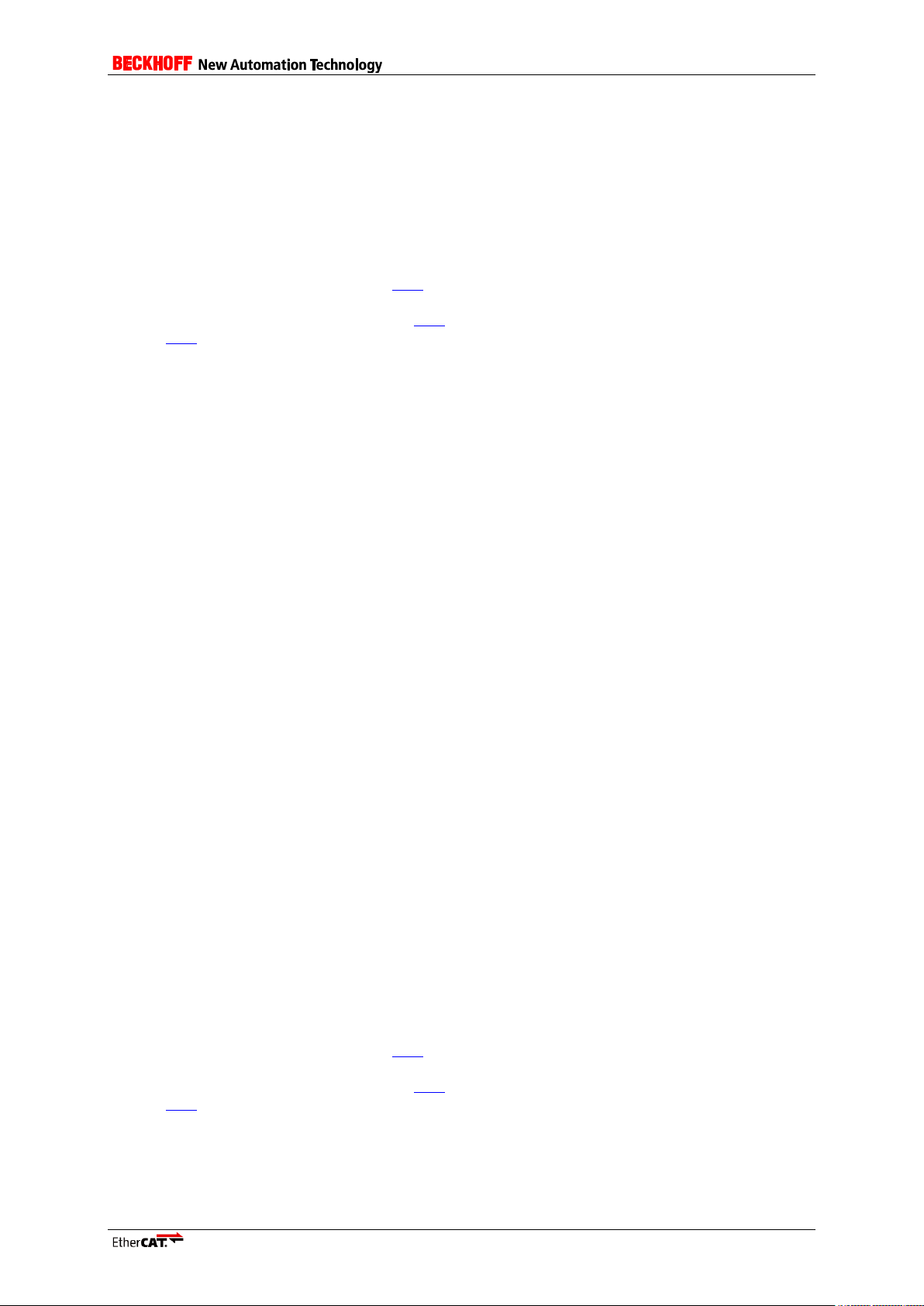

The information is used by the master to calculate the size of the SyncManager (it shall be equal to

the size specified in step 5) and to display the process data to the user (Figure 3: RxPdo data of an

EtherCAT slave).

Figure 3: RxPdo data of an EtherCAT slave

10. File: ESI file

Update the default size of SyncManager according the total bit size of the RxPdo/TxPdo entries

<Sm MinSize="34" MaxSize="192" DefaultSize="128" StartAddress="#x1000"

ControlByte="#x26" Enable="1">MBoxOut</Sm>

<Sm MinSize="34" MaxSize="192" DefaultSize="128" StartAddress="#x1400"

ControlByte="#x22" Enable="1">MBoxIn</Sm>

36 Application Note ET9300

Page 39

<Sm DefaultSize="8" StartAddress="#x1800" ControlByte="#x64"

Enable="1">Outputs</Sm>

<Sm DefaultSize="8" StartAddress="#x1c00" ControlByte="#x20"

Enable="1">Inputs</Sm>

11. File: ESI file

Update the offline object dictionary (element: “Profile/Dictionary”).

a. Add object 0x6010 (no structure definition is required for this object because it contains

only a single base data type value).

<Object>

<Index>#x6010</Index>

<Name>Result</Name>

<Type>UDINT</Type>

<BitSize>32</BitSize>

<Info>

<DefaultData>00000000</DefaultData>

</Info>

<Flags>

<Access>ro</Access>

<Category>o</Category>

<PdoMapping>T</PdoMapping>

</Flags>

</Object>

b. Add the new structure of object 0x7010 to the DataType definitions.

<DataType>

<Name>DT7010</Name>

<BitSize>80</BitSize>

<SubItem>

<SubIdx>0</SubIdx>

<Name>SubIndex 000</Name>

<Type>USINT</Type>

<BitSize>8</BitSize>

<BitOffs>0</BitOffs>

<Flags>

<Access>ro</Access>