Page 1

Hardware Data Sheet

ET1200

Slave Controller

Section I – Technology

(Online at http://www.beckhoff.com)

Section II – Register Description

(Online at http://www.beckhoff.com)

Section III – Hardware Description

Pinout, Interface description, electrical

and mechanical specification, ET1200

features and registers

Version 1.8

Date: 2014-07-07

Page 2

DOCUMENT ORGANIZATION

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE® and XFC® are registered trademarks of and licensed by

Beckhoff Automation GmbH. Other designations used in this publication may be trademarks whose use by third parties for their

own purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following German patent applications and patents:

DE10304637, DE102004044764, DE102005009224, DE102007017835 with corresponding applications or registrations in

various other countries.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under development. For that

reason the documentation is not in every case checked for consistency with performance data, standards or other

characteristics. In the event that it contains technical or editorial errors, we retain the right to make alterations at any time and

without warning. No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Copyright

© Beckhoff Automation GmbH 07/2014.

The reproduction, distribution and utilization of this document as well as the communication of its contents to others without

express authorization are prohibited. Offenders will be held liable for the payment of damages. All rights reserved in the event of

the grant of a patent, utility model or design.

DOCUMENT ORGANIZATION

The Beckhoff EtherCAT Slave Controller (ESC) documentation covers the following Beckhoff ESCs:

ET1200

ET1100

EtherCAT IP Core for Altera® FPGAs

EtherCAT IP Core for Xilinx® FPGAs

ESC20

The documentation is organized in three sections. Section I and section II are common for all Beckhoff

ESCs, Section III is specific for each ESC variant.

The latest documentation is available at the Beckhoff homepage (http://www.beckhoff.com).

Section I – Technology (All ESCs)

Section I deals with the basic EtherCAT technology. Starting with the EtherCAT protocol itself, the

frame processing inside EtherCAT slaves is described. The features and interfaces of the physical

layer with its two alternatives Ethernet and EBUS are explained afterwards. Finally, the details of the

functional units of an ESC like FMMU, SyncManager, Distributed Clocks, Slave Information Interface,

Interrupts, Watchdogs, and so on, are described.

Since Section I is common for all Beckhoff ESCs, it might describe features which are not available in

a specific ESC. Refer to the feature details overview in Section III of a specific ESC to find out which

features are available.

Section II – Register Description (All ESCs)

Section II contains detailed information about all ESC registers. This section is also common for all

Beckhoff ESCs, thus registers, register bits, or features are described which might not be available in

a specific ESC. Refer to the register overview and to the feature details overview in Section III of a

specific ESC to find out which registers and features are available.

Section III – Hardware Description (Specific ESC)

Section III is ESC specific and contains detailed information about the ESC features, implemented

registers, configuration, interfaces, pinout, usage, electrical and mechanical specification, and so on.

Especially the Process Data Interfaces (PDI) supported by the ESC are part of this section.

Additional Documentation

Application notes and utilities like pinout configuration tools for ET1200 can also be found at the

Beckhoff homepage.

III-II Slave Controller – ET1200 Hardware Description

Page 3

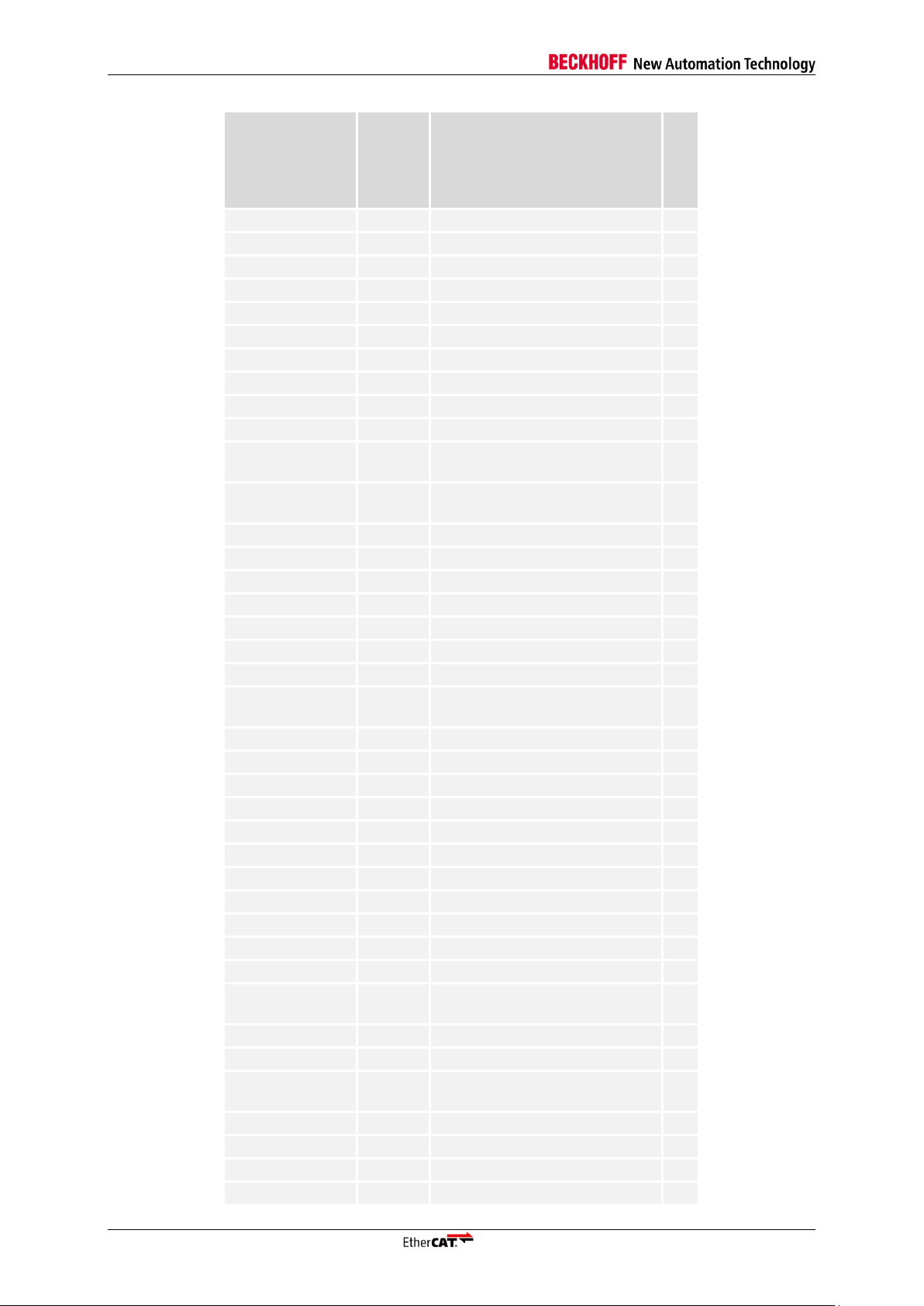

DOCUMENT HISTORY

Version

Comment

0.1

Initial release

0.2

Editorial changes

0.3

Register overview, PDI, Electrical and mechanical spec

0.4

Abbreviations, editorial changes

0.5

Removed RJ45 description (will become part of Section I)

EEPROM_LOADED pull-down resistor recommendation added

Frame processing order example corrected

I2C EEPROM interface description added

MII management interface description added

Corrected Process RAM size in Register Overview

Revision/Build information added

Recommendations for unused input pins added (should not be left open)

EEPROM_SIZE description corrected from Kbyte to Kbit, possible EEPROM

sizes range from 16 Kbit to 4 Mbit

RoHS compliance added

Autonegotiation is mandatory for ESCs

Description of power supply options added

Electrical characteristics added

SPI_IRQ delay added

TX Shift timing diagram and description added

Pin overview table corrected

Internal 27 kΩ PU/PD resistors at EBUS-RX pins added

LED polarity depending on configuration pin setting described

Recommendation for voltage stabilization capacitors added

Description of Digital I/O behavior on watchdog expiration enhanced

EBUS ports are open failsafe

Reset example schematic added

Ethernet PHY requirements and PHY connection schematic added

MI_DATA pull-up requirement added

Editorial changes

1.0

RUN, LINKACT/x) and PERR(x) LED activity level corrected: active high if

pulled down, active low if pulled up

TX Shift description: timing figures corrected, minor changes, moved to MII

Interface chapter

Pin/Signal description overview added

PERR(x) LEDs are only for testing/debugging

Electrical characteristics enhanced

DC Characteristics enhanced: added V

Reset Core

, VID, VIC

Digital I/O and SPI timing characteristics revised

DC SYNC/LATCH signal description and timing characteristics added

MII Interface chapter and MII timing characteristics added

EBUS Interface chapter added

PHY requirements, EEPROM Interface description and MII Management

Interface description moved to Section I

Ambient temperature range instead of junction temperature range

Editorial changes

DOCUMENT HISTORY

Slave Controller – ET1200 Hardware Description III-III

Page 4

DOCUMENT HISTORY

Version

Comment

1.1

Clarified I/O voltage with respect to I/O power supply (only 3.3V I/O with

V

CCI/O

=3.3V, and no 5V input tolerance unless V

CCI/O

=5V)

Update to ET1200 stepping 1

Added/revised OSC_IN, CLK25OUT, and MII TX signal timings

Added soldering profile

PHY address configuration changed

Added feature detail overview, removed redundant feature details

PDI and DC SYNC/LATCH signals are not driven until EEPROM is loaded

Editorial changes

1.2

PHY address configuration chapter added, configuration revised

Enhanced link detection for MII available depending on PHY address

configuration

Ethernet Management Interface: read and write times were interchanged

Editorial changes

1.3

Added reset timing figure and power-on value sample time

Direction of Distributed Clocks SYNC/LATCH signals is configurable

Information on CLK25OUT/CPU_CLK clock output during reset added

Description of internal PU/PD resistors at EBUS_RX pins enhanced

Power supply example schematic clarified

Enhanced package information: MSL and plating material

Digital I/O PDI: added SOF/OUTVALID description

SPI PDI: Read busy signaling not recommended

Editorial changes

1.4

OSC_IN/OSC_OUT pin capacitance added, crystal connection note extended

Release Notes added

Input threshold voltage for OSC_IN added

Renamed Err(x) LED to PERR(x)

Digital I/O PDI: OE_CONF functionality in bidirectional mode corrected

Digital I/O PDI: output event description corrected (EOF mode and WD_TRIG

mode)

SPI PDI: access error if SPI_DI not 1 in the last read byte (not SPI_DO)

AC timing: forwarding delay figures added

Editorial changes

1.5

AC timing: forwarding delay figures MII to MII added

Reset timing figure corrected

Maximum soldering profile added

SPI PDI updated

SII EEPROM interface is a point-to-point connection

Editorial changes

1.6

Update to ET1200-0002

Editorial changes

1.7

Enhanced Link Detection must not be activated if EBUS ports are used

Enhanced Link Detection for MII ports requires PHY address offset = 0

Digital Output principle schematic updated

Chip label updated

Editorial changes

1.8

Update to ET1200-0003

Enhanced Link Detection for MII ports supports PHY address offset 0 and 16

Enhanced Link Detection for MII ports can be disabled at any time

Enhanced Link Detection for EBUS ports is always disabled

MII management interface issues additional MCLK cycle after write accesses

Remote link down signalling time configurable 0x0100[22]

Editorial changes

III-IV Slave Controller – ET1200 Hardware Description

Page 5

CONTENTS

CONTENTS

1 Overview 1

1.1 Frame processing order 2

1.2 Scope of this document 3

1.3 Revision/Build History 3

2 Features and Registers 4

2.1 Features 4

2.2 Register Overview 7

3 Pin Description 10

3.1 Overview 10

3.1.1 Pin Overview 10

3.1.2 Signal Overview 11

3.1.3 PDI Signal Overview 12

3.2 Configuration Pins 13

3.2.1 Chip mode 13

3.2.2 CPU_CLK MODE 13

3.2.3 TX Shift 13

3.2.4 CLK25OUT Enable 14

3.2.5 PHY Address Offset 14

3.2.6 SII EEPROM Size 14

3.3 General ET1200 Pins 15

3.4 SII EEPROM Interface Pins 15

3.5 Distributed Clocks SYNC/LATCH Pins, MII Management Data 16

3.6 LED Signals 16

3.7 Physical Ports and PDI Pins 17

3.7.1 MII Interface 18

3.7.2 EBUS Interface 18

3.7.3 PDI Pins 18

3.7.4 Port 0/1 and PDI[17:8] Signals 19

3.7.5 PDI[7:0] Signals 20

3.8 PDI Signal Pinout depending on selected PDI 20

3.8.1 Digital I/O Pin Out 21

3.8.2 SPI Pin Out 21

3.8.3 EBUS/MII bridge port (Logical port 3) 22

3.9 Power Supply 23

4 MII Interface 24

4.1 MII Interface Signals 24

4.2 PHY Address Configuration 25

4.3 TX Shift Compensation 26

4.4 Timing specifications 27

Slave Controller – ET1200 Hardware Description III-V

Page 6

CONTENTS

5 EBUS/LVDS Interface 28

5.1 EBUS Interface Signals 28

6 PDI Description 29

6.1 PDI Deactivated 29

6.2 Digital I/O Interface 30

6.2.1 Interface 30

6.2.2 Configuration 30

6.2.3 Digital Inputs 30

6.2.4 Digital Outputs 31

6.2.5 Bidirectional mode 32

6.2.6 Output Driver 32

6.2.7 SyncManager Watchdog 32

6.2.8 SOF 33

6.2.9 OUTVALID 33

6.2.10 Timing specifications 33

6.3 SPI Slave Interface 35

6.3.1 Interface 35

6.3.2 Configuration 35

6.3.3 SPI access 35

6.3.4 Commands 36

6.3.5 Address modes 36

6.3.6 Interrupt request register (AL Event register) 36

6.3.7 Write access 37

6.3.8 Read access 37

6.3.9 SPI access errors and SPI status flag 37

6.3.10 EEPROM_LOADED 37

6.3.11 Timing specifications 38

7 Distributed Clocks SYNC/LATCH Signals 43

7.1 Signals 43

7.2 Timing specifications 43

8 SII EEPROM Interface (I²C) 44

8.1 Signals 44

8.2 Timing specifications 44

9 Example Schematics 45

9.1 Clock Adoption 45

9.2 Power supply 46

9.3 Dual purpose configuration input/LED output pins 47

9.4 PHY Connection 47

9.5 LVDS termination 48

9.6 RBIAS resistor 48

9.7 Reset Logic 48

III-VI Slave Controller – ET1200 Hardware Description

Page 7

CONTENTS

10 Electrical Specifications and Timings 49

10.1 Absolute Maximum Ratings 49

10.2 Electrical Characteristics 49

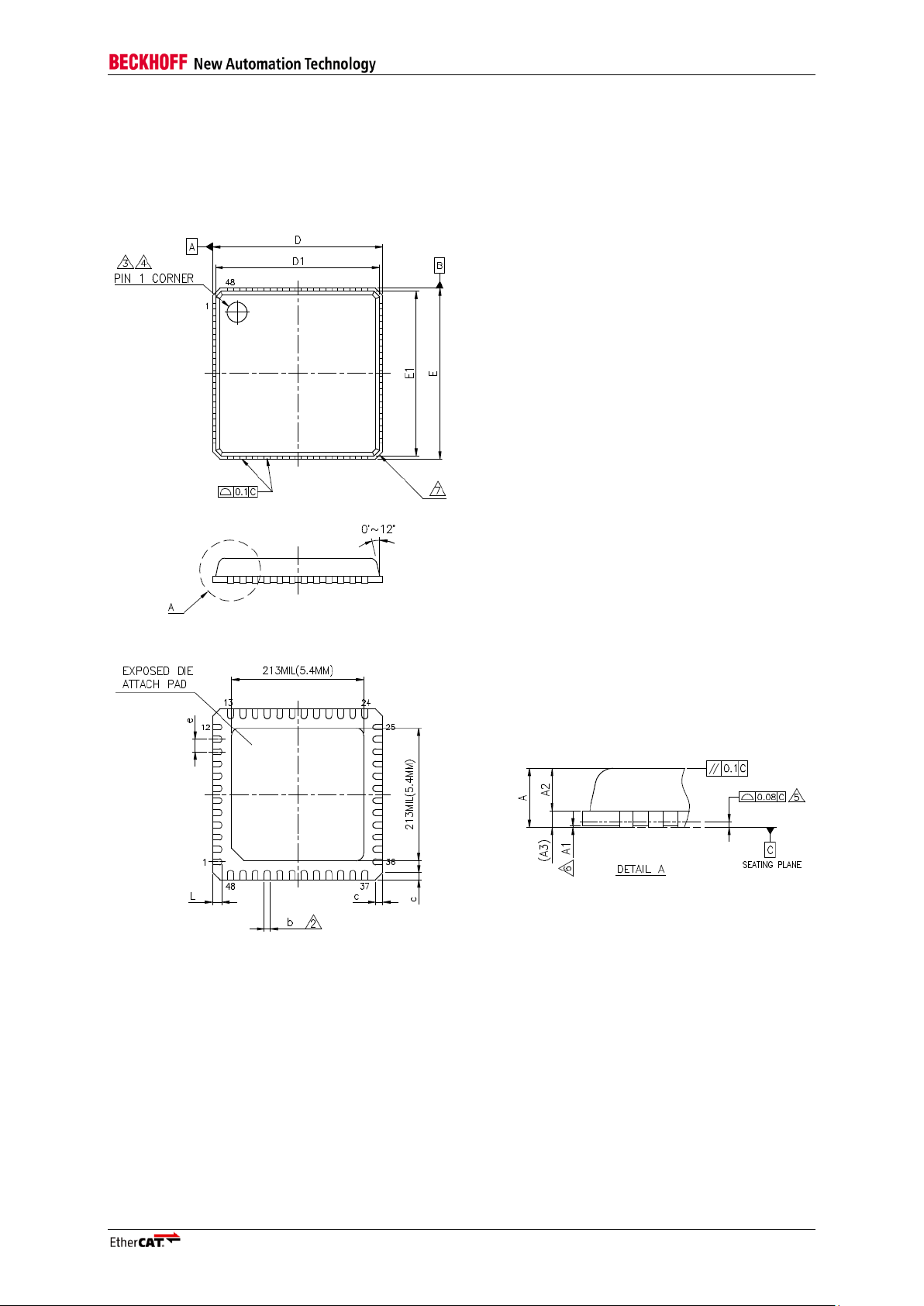

11 Mechanical Specifications 55

11.1 Package Information 55

11.2 Moisture Sensitivity and Storage 57

11.3 Soldering Profile 58

11.4 Ordering codes 59

12 Appendix 60

12.1 Support and Service 60

12.1.1 Beckhoff’s branch offices and representatives 60

12.2 Beckhoff Headquarters 60

Slave Controller – ET1200 Hardware Description III-VII

Page 8

TABLES

TABLES

Table 1: ET1200 Main Features .............................................................................................................. 1

Table 2: Frame Processing Order ........................................................................................................... 2

Table 3: Revision/Build History................................................................................................................ 3

Table 4: ET1200 Feature Details ............................................................................................................ 4

Table 5: Legend ....................................................................................................................................... 6

Table 6: Legend ....................................................................................................................................... 7

Table 7: Register Overview ..................................................................................................................... 7

Table 8: Pin Overview ........................................................................................................................... 10

Table 9: Signal Overview ....................................................................................................................... 11

Table 10: PDI signal overview ............................................................................................................... 12

Table 11: Chip Mode ............................................................................................................................. 13

Table 12: CPU_CLK Mode .................................................................................................................... 13

Table 13: TX Shift .................................................................................................................................. 13

Table 14: CLK_25OUT Enable .............................................................................................................. 14

Table 15: PHY Address Offset .............................................................................................................. 14

Table 16: SII EEPROM Size .................................................................................................................. 14

Table 17: General pins .......................................................................................................................... 15

Table 18: SII EEPROM pins .................................................................................................................. 15

Table 19: DC SYNC/LATCH and MII Management pins ....................................................................... 16

Table 20: LED pins ................................................................................................................................ 16

Table 21: Combinations of Chip modes and PDIs ................................................................................ 17

Table 22: Port 0/1 and PDI signals (Configuration and chip mode 00) ................................................. 19

Table 23: Port 0/1 and PDI signals (chip modes 10/11) ........................................................................ 19

Table 24: PDI pins ................................................................................................................................. 20

Table 25: Mapping of Digital I/O Interface ............................................................................................. 21

Table 26: Mapping of SPI Interface ....................................................................................................... 21

Table 27: Mapping of EBUS Bridge signals .......................................................................................... 22

Table 28: Mapping of MII Bridge signals ............................................................................................... 22

Table 29: Power supply options (all voltages nomal) ............................................................................ 23

Table 30: Power supply ......................................................................................................................... 23

Table 31: MII Interface signals .............................................................................................................. 25

Table 32: TX Shift Timing characteristics .............................................................................................. 26

Table 33: MII timing characteristics ....................................................................................................... 27

Table 34: EBUS Interface signals ......................................................................................................... 28

Table 35: Available PDIs for ET1200 .................................................................................................... 29

Table 36: ET1200 Digital I/O signals ..................................................................................................... 30

Table 37: Digital I/O timing characteristics ET1200 .............................................................................. 33

Table 38: SPI signals ............................................................................................................................. 35

Table 39: SPI commands CMD0 and CMD1 ......................................................................................... 36

Table 40: Address modes ...................................................................................................................... 36

Table 41: Interrupt request register transmission .................................................................................. 36

Table 42: SPI timing characteristics ET1200 ........................................................................................ 38

Table 43: Read/Write timing diagram symbols ...................................................................................... 39

Table 44: Distributed Clocks signals ..................................................................................................... 43

Table 45: DC SYNC/LATCH timing characteristics ET1200 ................................................................. 43

Table 46: I²C EEPROM signals ............................................................................................................. 44

Table 47: EEPROM timing characteristics ............................................................................................ 44

Table 48: Absolute Maximum Ratings ................................................................................................... 49

Table 49: Operating Conditions ............................................................................................................. 49

Table 50: DC Characteristics ................................................................................................................. 50

Table 51: DC Characteristics (Supply current) ...................................................................................... 51

Table 52: AC Characteristics ................................................................................................................. 52

Table 53: Forwarding Delays ................................................................................................................. 54

Table 54: Absolute Maximum Storage Conditions ................................................................................ 57

Table 55: Example Soldering Profile ..................................................................................................... 59

III-VIII Slave Controller – ET1200 Hardware Description

Page 9

FIGURES

FIGURES

Figure 1: ET1200 Block Diagram ............................................................................................................ 1

Figure 2: Frame Processing .................................................................................................................... 2

Figure 3: MII Interface signals ............................................................................................................... 24

Figure 4: TX Shift Timing Diagram ........................................................................................................ 26

Figure 5: MII timing RX signals.............................................................................................................. 27

Figure 6: EBUS Interface Signals .......................................................................................................... 28

Figure 7: ET1200 Digital I/O Signals ..................................................................................................... 30

Figure 8: Digital Output Principle Schematic ......................................................................................... 31

Figure 9: Bidirectional mode: Input/Output connection (R=4.7 kΩ recommended) .............................. 32

Figure 10: Digital Input: Input data sampled at SOF, I/O can be read in the same frame .................... 34

Figure 11: Digital Input: Input data sampled with LATCH_IN ................................................................ 34

Figure 12: Digital Output timing ............................................................................................................. 34

Figure 13: Bidirectional Mode timing ..................................................................................................... 34

Figure 14: SPI master and slave interconnection.................................................................................. 35

Figure 15: Basic SPI_DI/SPI_DO timing (*refer to timing diagram for relevant edges of SPI_CLK) .... 39

Figure 16: SPI read access (2 byte addressing, 2 byte read data) with BUSY and separate status

reading ................................................................................................................................................... 40

Figure 17: SPI write access (2 byte addressing, 1 byte write data) ...................................................... 41

Figure 18: SPI write access (3 byte addressing, 1 byte write data) ...................................................... 42

Figure 19: Distributed Clocks signals .................................................................................................... 43

Figure 20: LatchSignal timing ................................................................................................................ 43

Figure 21: SyncSignal timing ................................................................................................................. 43

Figure 22: I²C EEPROM signals ............................................................................................................ 44

Figure 23: Quartz crystal connection ..................................................................................................... 45

Figure 24: Quartz crystal Clock source for ET1200 and Ethernet PHYs .............................................. 45

Figure 25: Oscillator clock source for ET1200 and Ethernet PHYs ...................................................... 46

Figure 26: ET1200 power supply........................................................................................................... 46

Figure 27: Dual purpose configuration input/LED output pins ............................................................... 47

Figure 28: PHY Connection ................................................................................................................... 47

Figure 29: LVDS termination ................................................................................................................. 48

Figure 30: RBIAS resistor ...................................................................................................................... 48

Figure 31: Reset Logic .......................................................................................................................... 48

Figure 32: Reset Timing ........................................................................................................................ 53

Figure 33: Package Outline ................................................................................................................... 55

Figure 34: Dimensions ........................................................................................................................... 56

Figure 35: Notes .................................................................................................................................... 56

Figure 36: Chip Label ............................................................................................................................ 56

Figure 37: Maximum Soldering Profile .................................................................................................. 58

Figure 38: Example Soldering Profiles .................................................................................................. 58

Slave Controller – ET1200 Hardware Description III-IX

Page 10

ABBREVIATIONS

(x)

Logical Port x

[z]

Bit z

{y}

Physical Port y

µC

Microcontroller

ADR

Address

AL

Application Layer

BD

Bidirectional

BHE

Bus High Enable

CMD

Command

DC

Distributed Clock

Dir.

Pin direction

DL

Data Link Layer

ECAT

EtherCAT

EMC

Electromagnetic Compatibility

EMI

Electromagnetic Interference

EOF

End of Frame

EP

Exposed Pad

ESC

EtherCAT Slave Controller

ESI

EtherCAT Slave Information

FMMU

Fieldbus Memory Management Unit

GPI

General Purpose Input

GPO

General Purpose Output

I

Input

I/O

Input or Output

IRQ

Interrupt Request

LDO

Low Drop-Out regulator

LI-

LVDS RX-

LI+

LVDS RX+

LO-

LVDS TX-

LO+

LVDS TX+

MAC

Media Access Controller

MDIO

Management Data Input / Output

MI

(PHY) Management Interface

MII

Media Independent Interface

MISO

Master In – Slave Out

MOSI

Master Out – Slave In

n.a.

not available

n.c.

not connected

O

Output

PD

Pull-down

PDI

Process Data Interface

PLL

Phase Locked Loop

PU

Pull-up

QFN

Quad Flat package No leads

SII

Slave Information Interface

SM

SyncManager

SOF

Start of Frame

SPI

Serial Peripheral Interface

UI

Unused Input (PDI: PD, others: GND)

WD

Watchdog

WPD

Weak Pull-down, sufficient only for configuration signals

WPU

Weak Pull-up, sufficient only for configuration signals

ABBREVIATIONS

III-X Slave Controller – ET1200 Hardware Description

Page 11

Overview

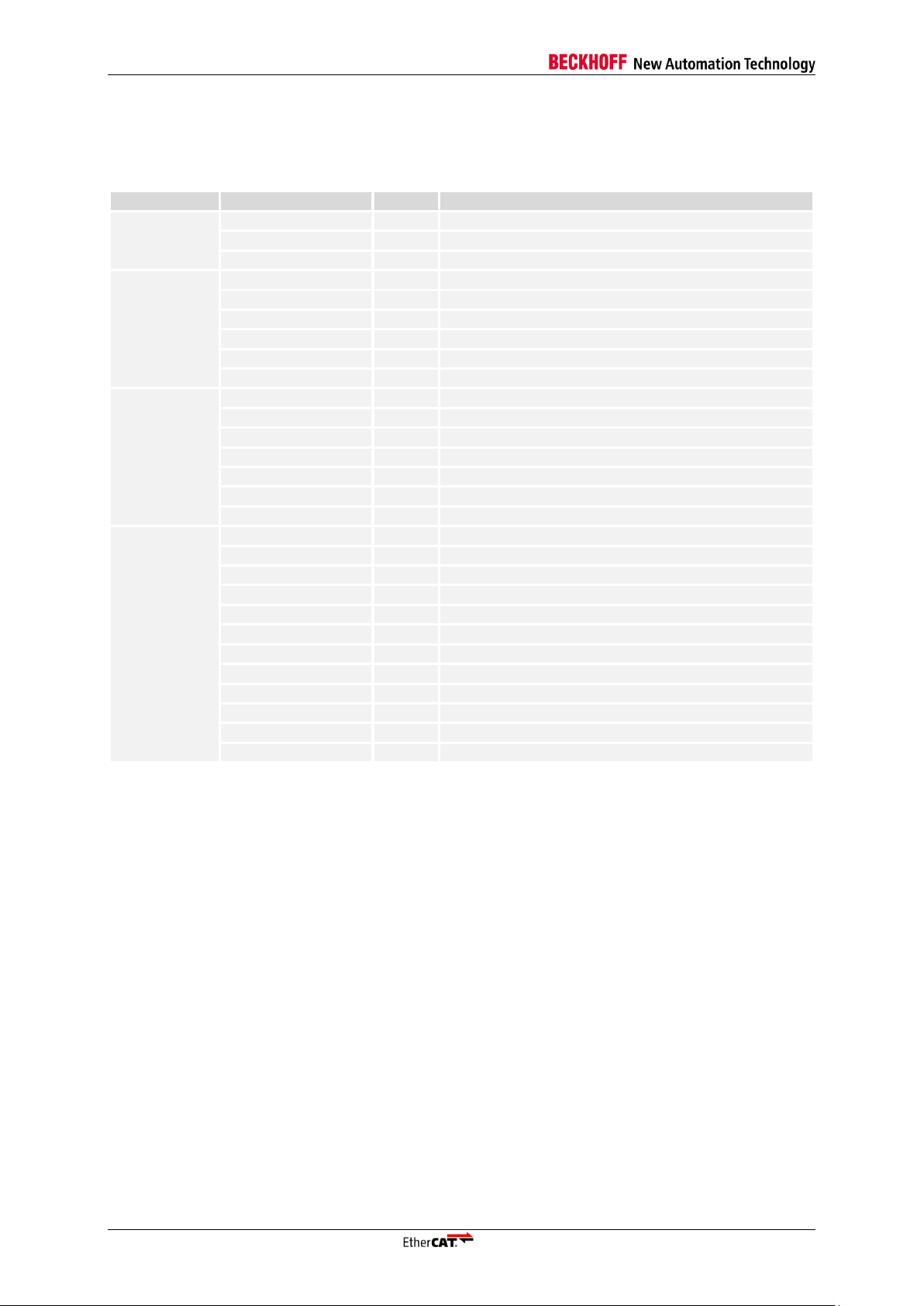

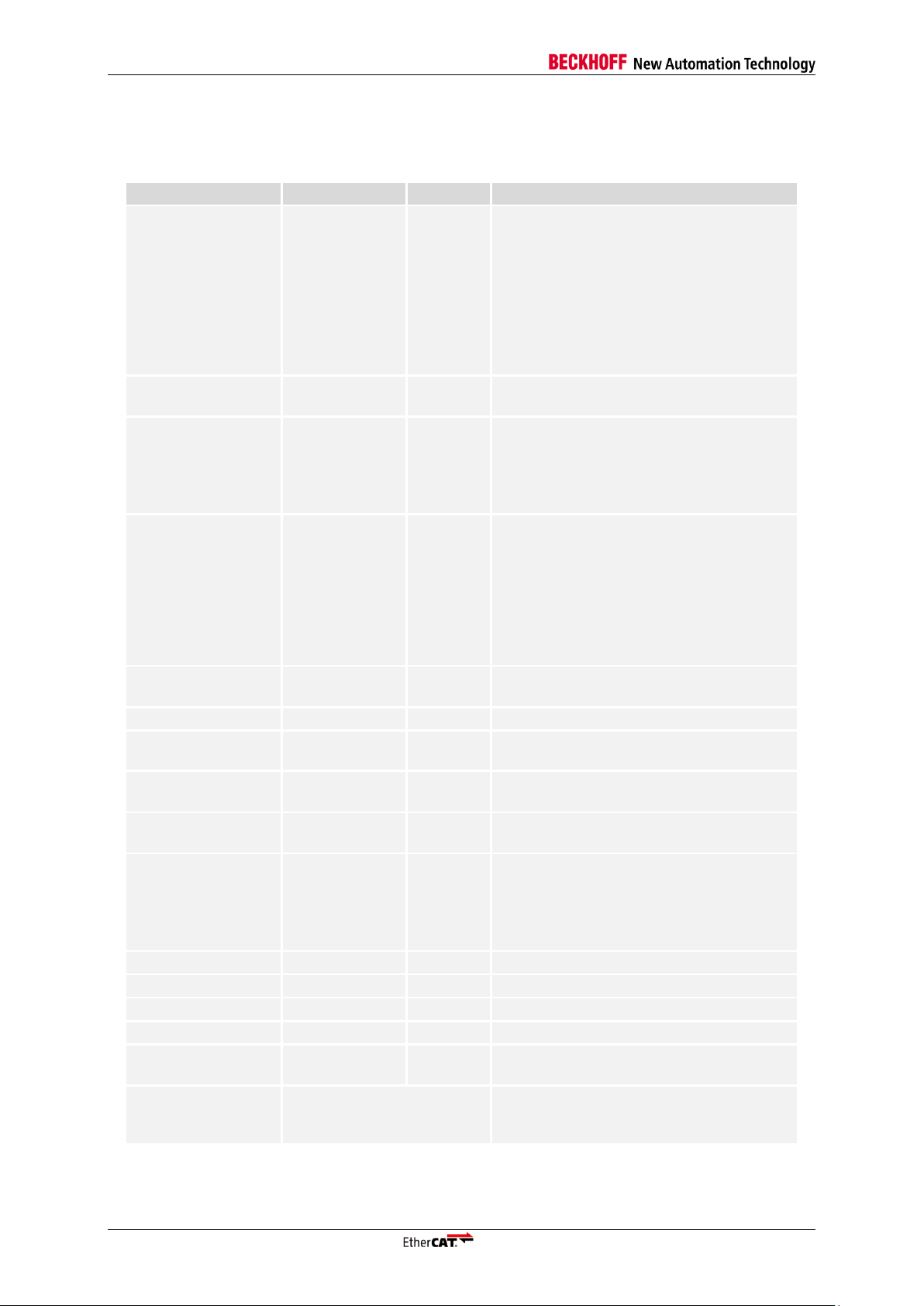

Feature

ET1200

Ports

2 permanent ports, optional one additional bridge port (each EBUS or

MII, max. one MII port)

FMMUs

3

SyncManagers

4

RAM

1 Kbyte

Distributed Clocks

Yes, 64 bit

Process Data Interfaces

16 Bit Digital I/O (unidirectional/bidirectional)

SPI Slave

Power supply

Two integrated voltage regulators (LDO) for I/O (5V to 3.3V) and logic

core/PLL (5V/3.3V to 2.5V), optional external power supply for I/O and

logic core/PLL.

I/O

3.3V compatible I/O

Package

QFN48 (7x7 mm2)

Other features

Internal 1GHz PLL

Clock output for external devices (10, 20, 25 MHz)

ECAT

Processing

Unit

AutoForwarder +

Loopback

SyncManager

FMMU

ESC address space

User RAMRegisters Process RAM

EEPROM

Distributed

Clocks

Monitoring Status

Reset

PHY

Management

Reset

SYNC LEDsI²C EEPROM

PHY MI

SPI / Digital I/O0 1 3

EBUS/MII ports

LATCH

PDI

ECAT Interface PDI Interface

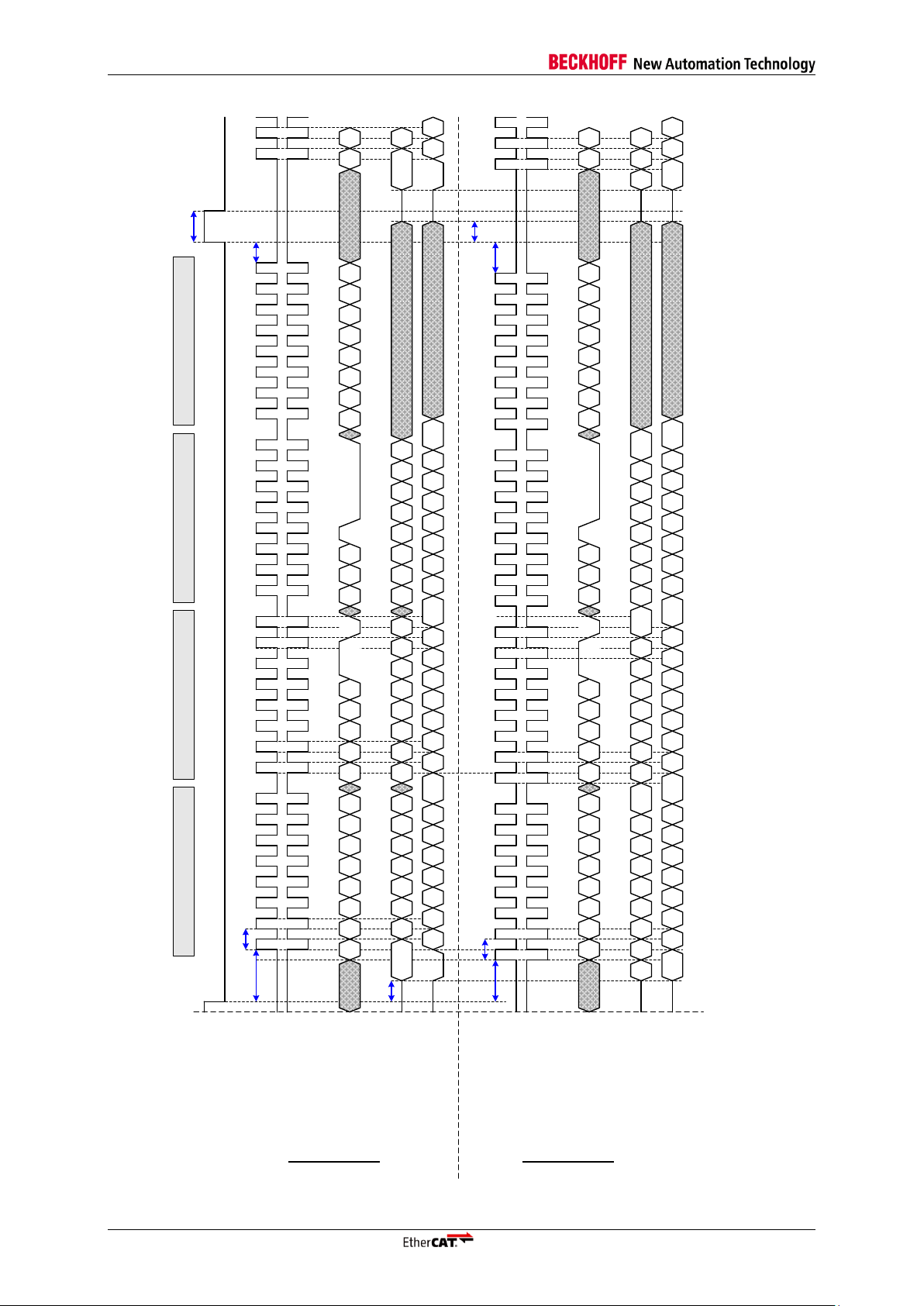

1 Overview

The ET1200 ASIC is an EtherCAT Slave Controller (ESC). It takes care of the EtherCAT

communication as an interface between the EtherCAT fieldbus and the slave application. The ET1200

supports different applications, from simple digital I/O nodes without external logic up to designs with a

µController and Distributed Clocks.

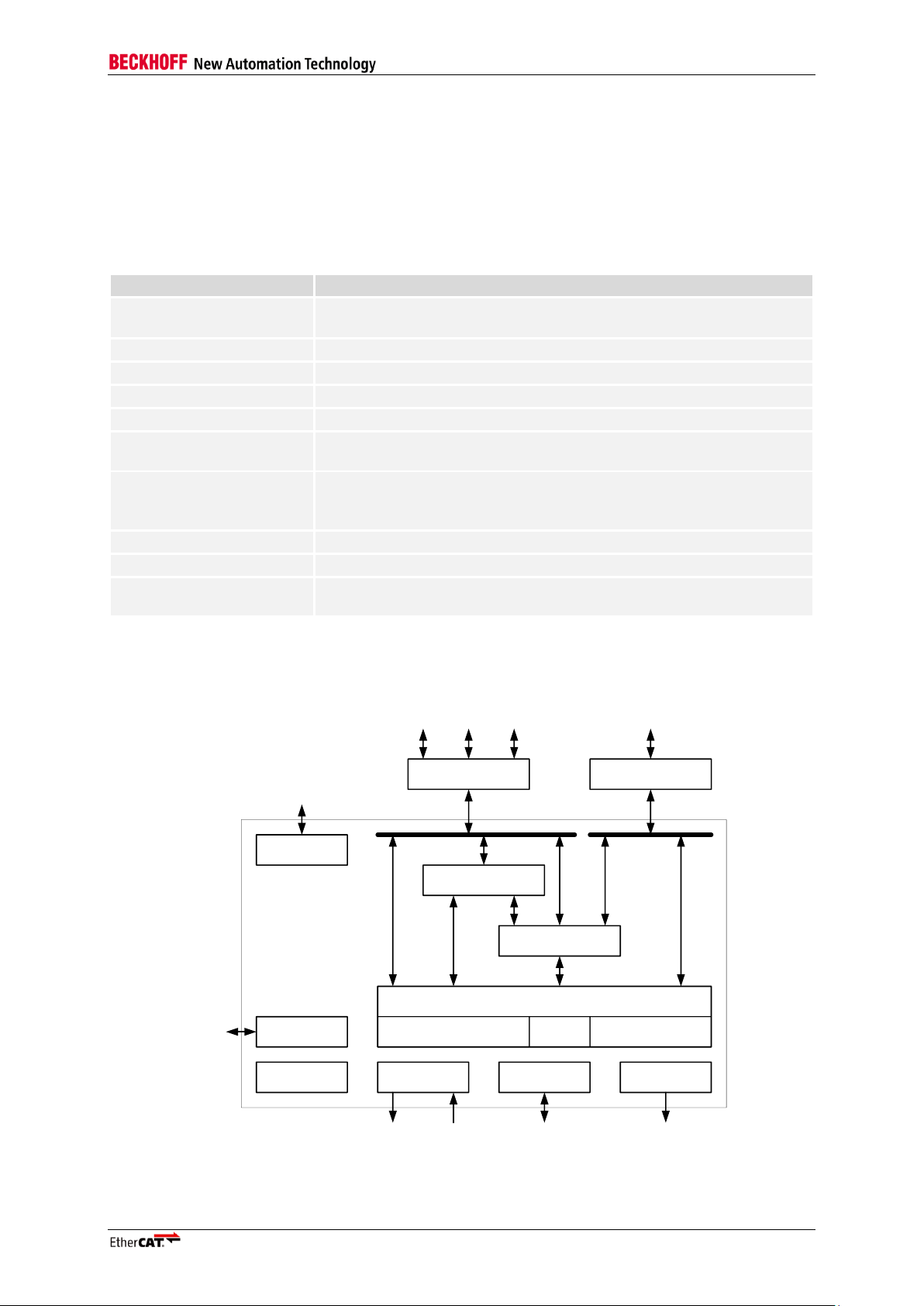

Table 1: ET1200 Main Features

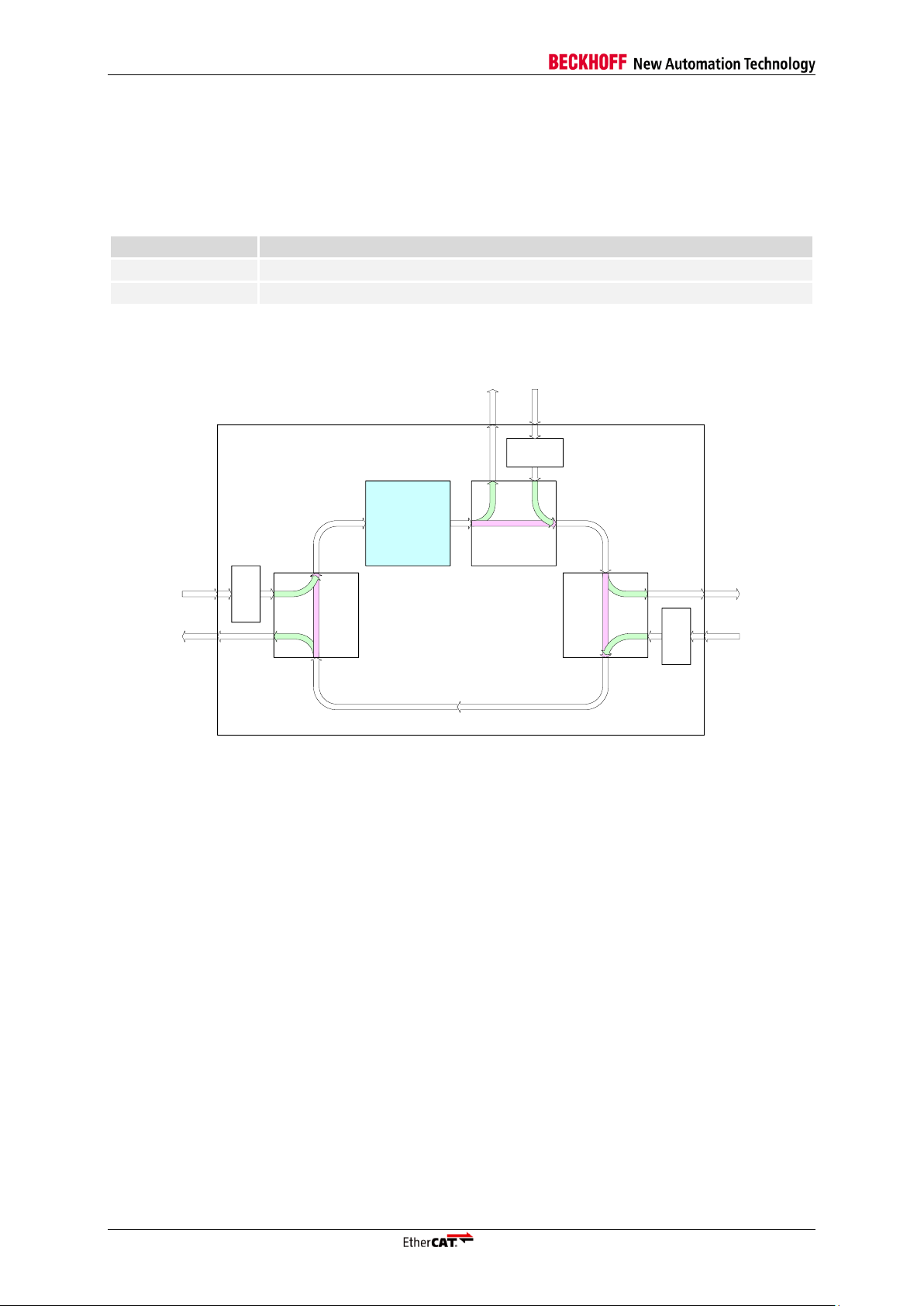

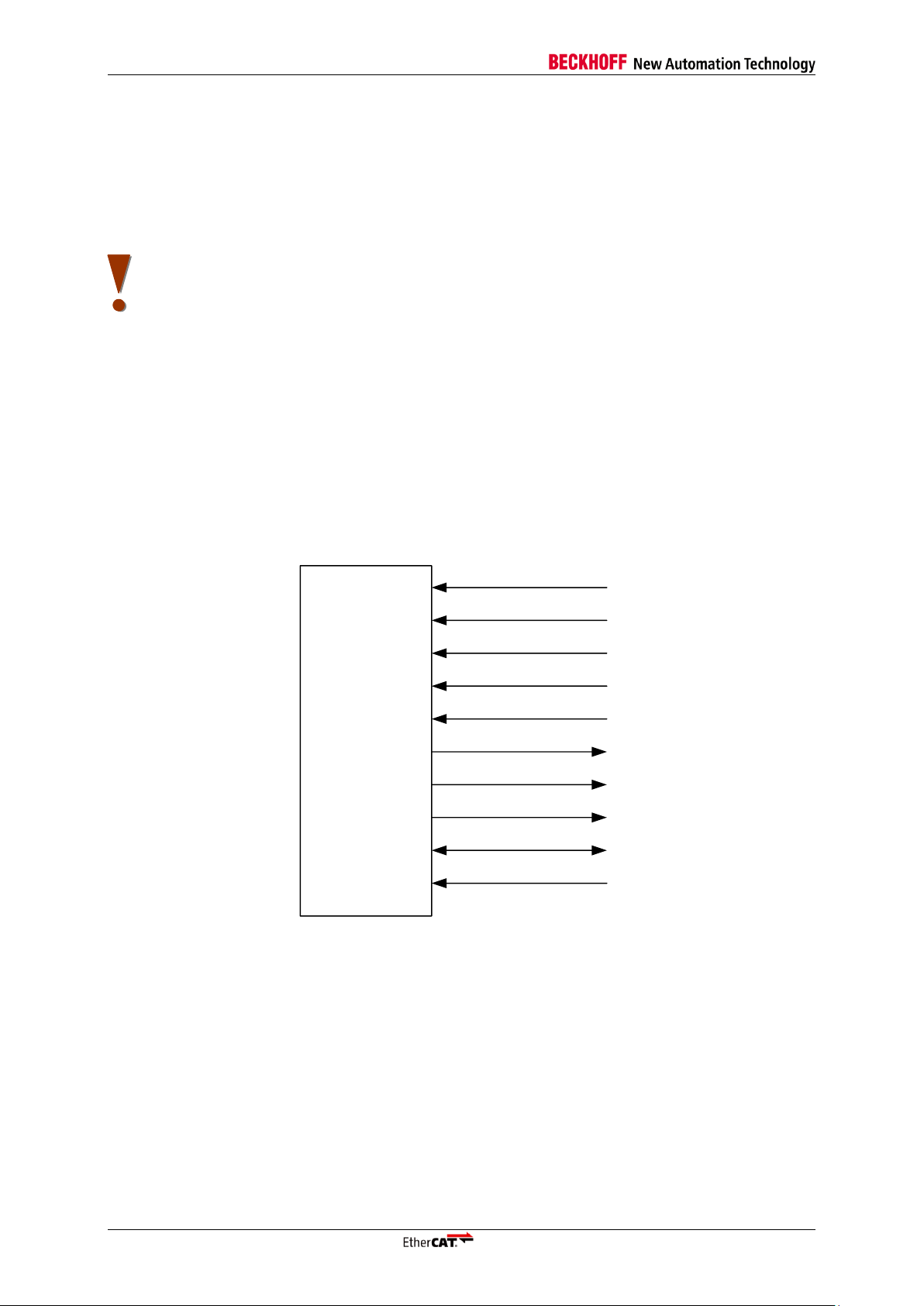

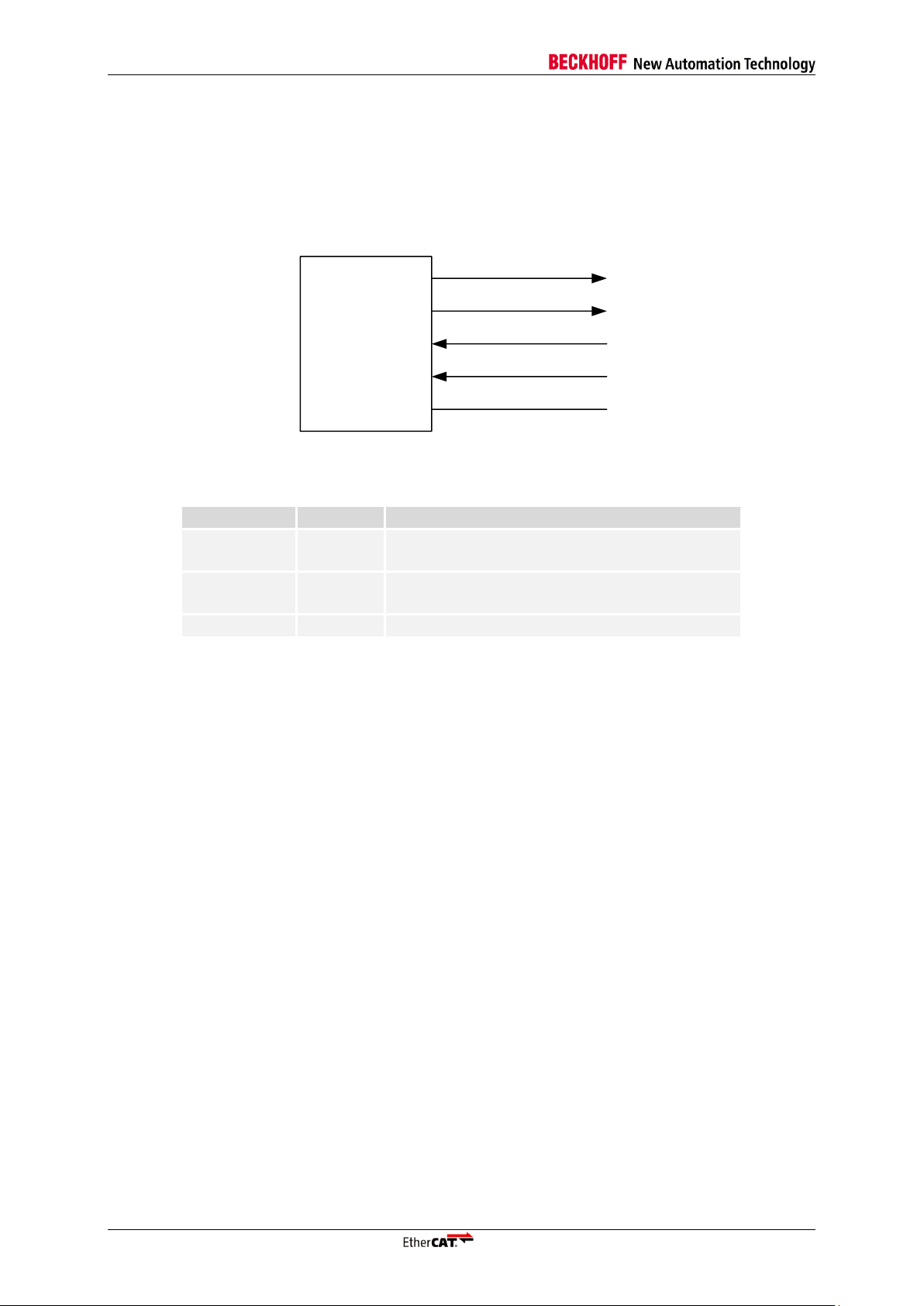

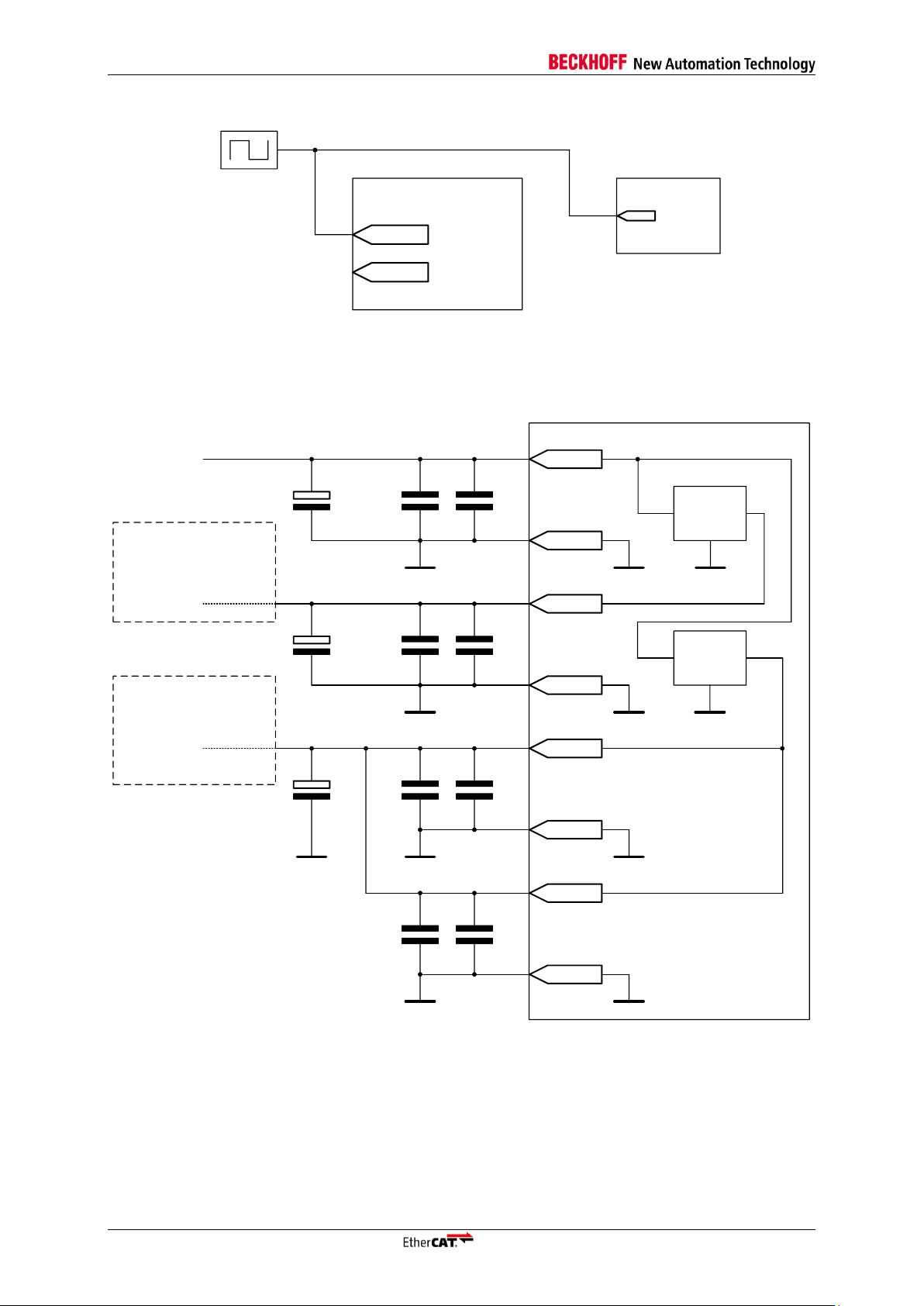

The general functionality of the ET1200 EtherCAT Slave Controller (ESC) is shown in Figure 1:

Slave Controller – ET1200 Hardware Description III-1

Figure 1: ET1200 Block Diagram

Page 12

Overview

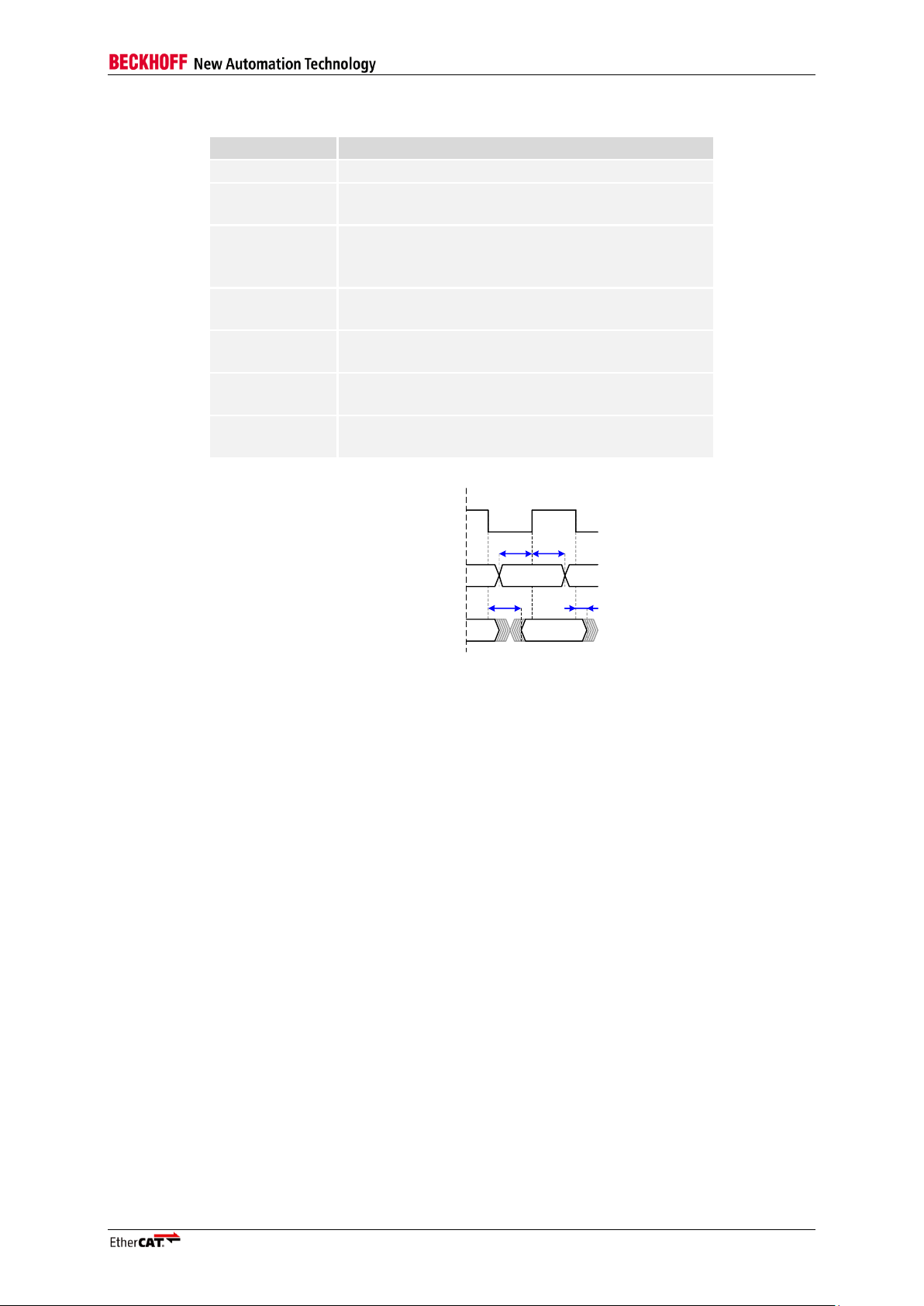

Number of Ports

Frame processing order

2

0→EtherCAT Processing Unit→1 / 1→0

3

0→EtherCAT Processing Unit→3 / 3→1 / 1→0

1

Port 1

Auto-

Forwarder

1

Port 3

Auto-

Forwarder

Port 0

Auto-

Forwarder

Loopback function

EtherCAT

Processing Unit

Loopback function

Loopback function

ET1200

port 1 closed

port 1 open

port 3 open

port 3 closed

port 0 open

or all ports

closed

port 0 closed

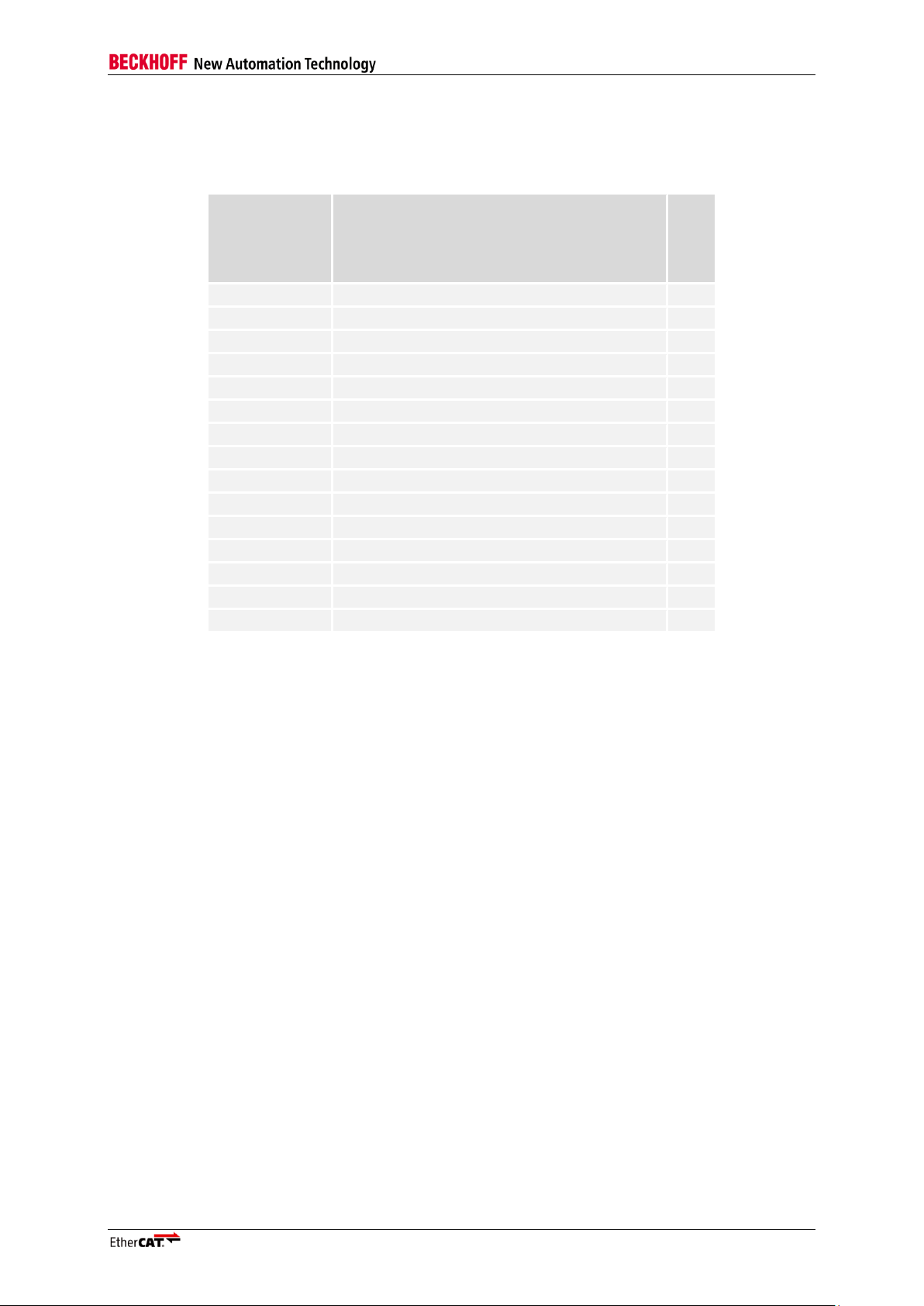

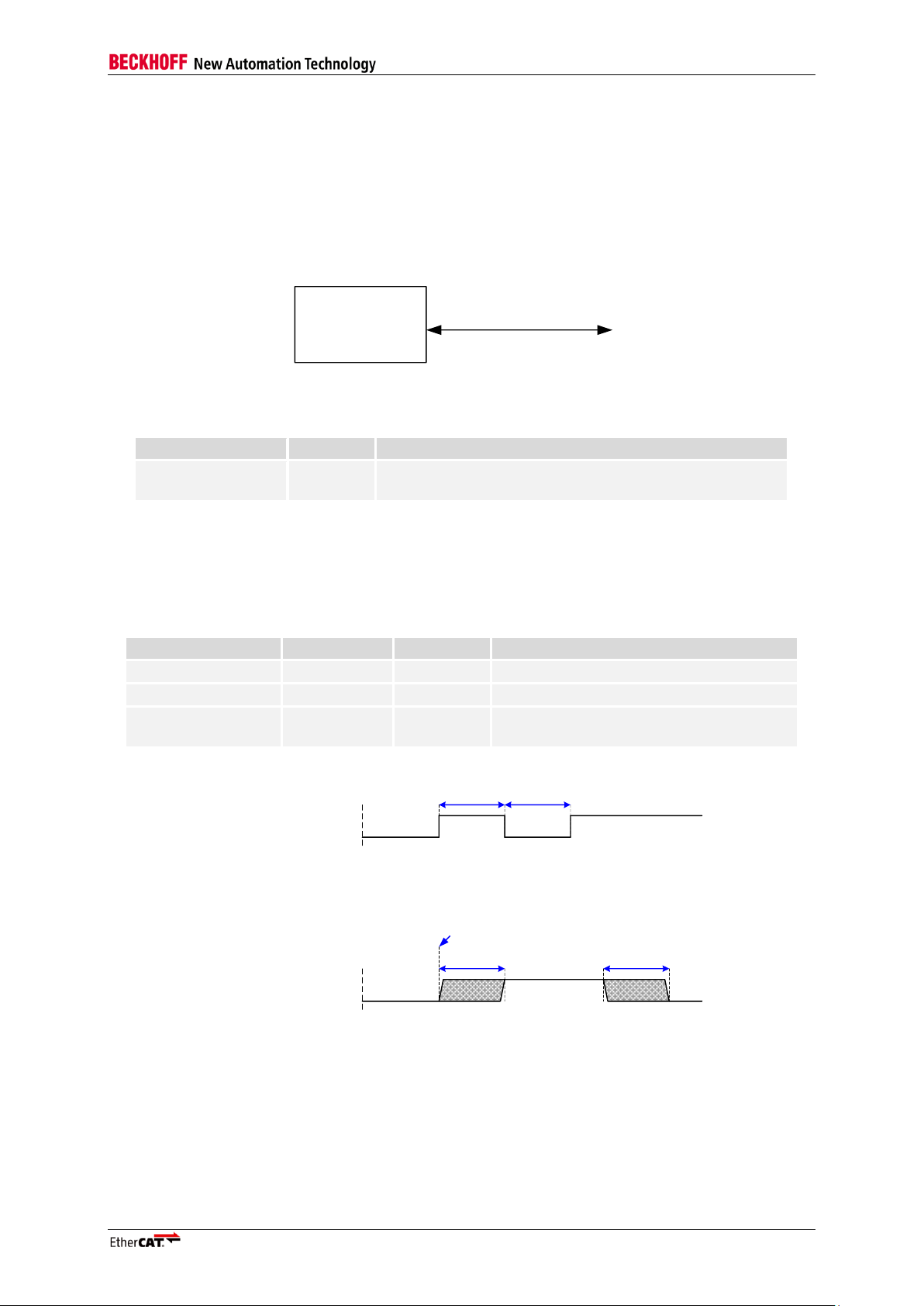

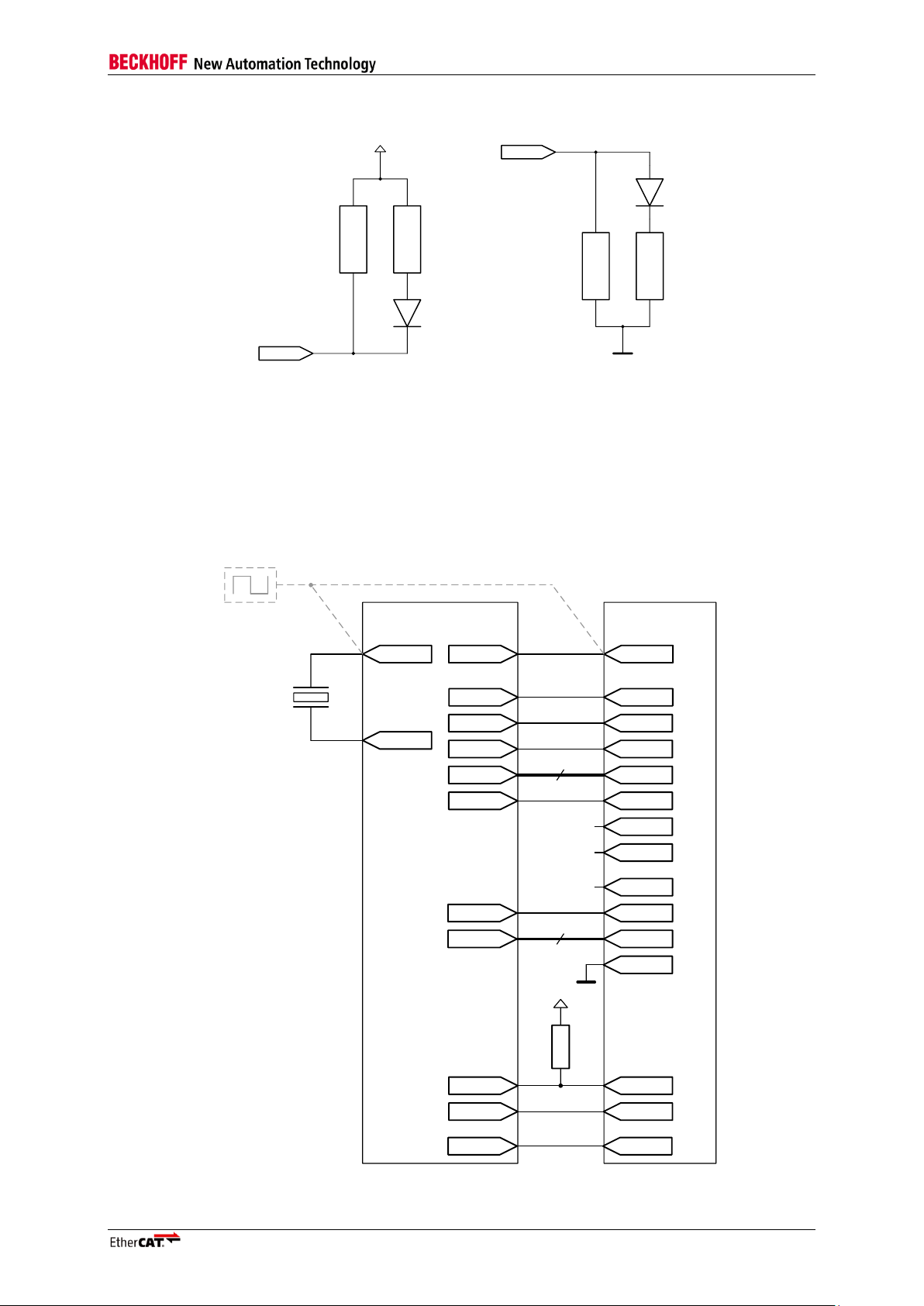

1.1 Frame processing order

The ET1200 supports two ports (logical ports 0 and 1) or three ports (logical ports 0, 1, and 3). The

frame processing order of the ET1200 depends on the number of ports (logical port numbers are

used):

Table 2: Frame Processing Order

Figure 2 shows the frame processing in general:

Figure 2: Frame Processing

III-2 Slave Controller – ET1200 Hardware Description

Page 13

Overview

Revision

Register 0x0001

Build

Register 0x0002:0x0003

Stepping

0x00

0x0000

ET1200-0000 or

ET1200-0001

0x00

0x0002

ET1200-0002

0x00

0x0003

ET1200-0003

1.2 Scope of this document

This documentation refers to stepping ET1200-0003.

1.3 Revision/Build History

Table 3: Revision/Build History

The stepping code is printed on the devices, do not confuse the stepping code with the ordering

codes.

Slave Controller – ET1200 Hardware Description III-3

Page 14

Features and Registers

Feature

ET1200

-0003

EtherCAT Ports

2-3

Permanent ports

2

Optional Bridge port 3 (EBUS or MII)

c

EBUS ports

1-3

MII ports

0-1

RMII ports

-

RGMII ports

-

Port 0

-

Ports 0, 1

x

Ports 0, 1, 2

-

Ports 0, 1, 3

x

Ports 0, 1, 2, 3

-

Slave Category

Full Slave

Position addressing

x

Node addressing

x

Logical addressing

x

Broadcast addressing

x

Physical Layer General Features

FIFO Size configurable (0x0100[18:16])

x

FIFO Size default from SII EEPROM

-

Auto-Forwarder checks CRC and SOF

x

Forwarded RX Error indication, detection

and Counter (0x0308:0x030B)

x

Lost Link Counter (0x0310:0x0313)

x

Prevention of circulating frames

x

Fallback: Port 0 opens if all ports are

closed

x

VLAN Tag and IP/UDP support

x

Enhanced Link Detection per port

configurable

-

EBUS Features

Low Jitter

x

Enhanced Link Detection supported

-

Enhanced Link Detection compatible

X

EBUS signal validation

X

LVDS Transceiver internal

X

LVDS sample rate [MHz]

1,000

Remote link down signaling time

configurable 0x0100[22]

x

General Ethernet Features (MII/RMII/RGMII)

MII Management Interface

(0x0510:0x051F)

x

Supported PHY Address Offsets

0/16

Individual port PHY addresses

-

Port PHY addresses readable

-

Link Polarity configurable

-

Enhanced Link Detection supported

x

FX PHY support (native)

-

PHY reset out signals

-

Link detection using PHY signal (LED)

x

MI link status and configuration

-

MI controllable by PDI (0x0516:0x0517)

-

MI read error (0x0510.13)

-

MI PHY configuration update status

(0x0518.5)

-

MI preamble suppression

-

Additional MCLK

x

Gigabit PHY configuration

-

Gigabit PHY register 9 relaxed check

-

FX PHY configuration

-

Transparent Mode

-

Feature

ET1200

-0003

MII Features

CLK25OUT as PHY clock source

x

Bootstrap TX Shift settings

x

Automatic TX Shift setting (with TX_CLK)

-

TX Shift not necessary (PHY TX_CLK as

clock source)

-

FIFO size reduction steps

1

PDI General Features

Increased PDI performance

-

Extended PDI Configuration

(0x0152:0x0153)

x

PDI Error Counter (0x030D)

-

PDI Error Code (0x030E)

-

CPU_CLK output (10, 20, 25 MHz)

x

SOF, EOF, WD_TRIG and WD_STATE

independent of PDI

-

Available PDIs and PDI features

depending on port configuration

x

PDI selection at run-time (SII EEPROM)

x

PDI active immediately (SII EEPROM

settings ignored)

-

PDI function acknowledge by write

-

PDI Information register 0x014E:0x014F

-

Digital I/O PDI

x

Digital I/O width [bits]

8/16

PDI Control register value

(0x0140:0x0141)

4

Control/Status signals:

2/0

1,2

LATCH_IN

x2

SOF

x2

OUTVALID

x2

WD_TRIG

x2

OE_CONF

-

OE_EXT

-

EEPROM_

Loaded

-

WD_STATE

-

EOF

-

Granularity of direction configuration [bits]

2

Bidirectional mode

x

Output high-Z if WD expired

x

Output 0 if WD expired

-

Output with EOF

x

Output with DC SyncSignals

x

Input with SOF

x

Input with DC SyncSignals

x

1

2

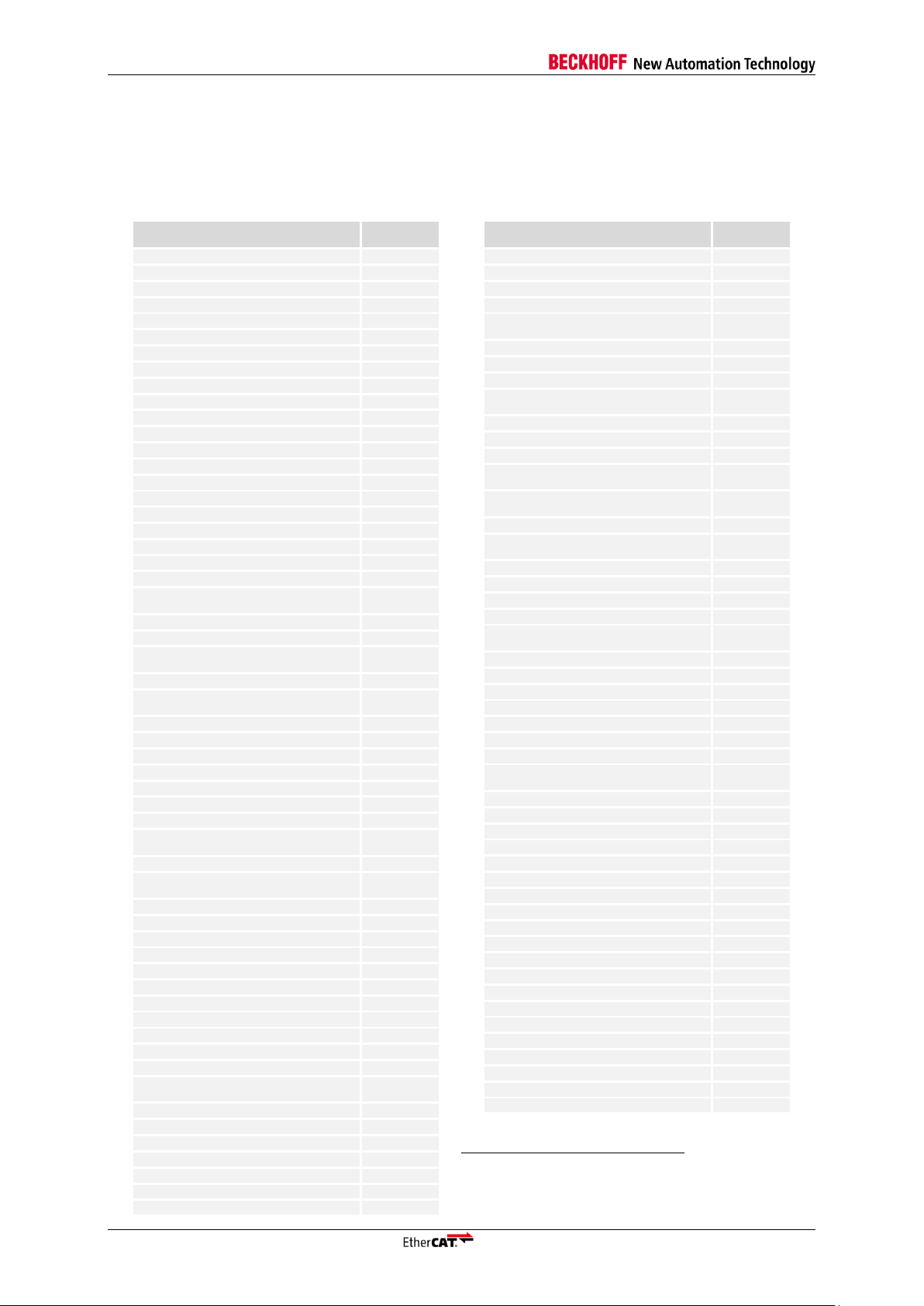

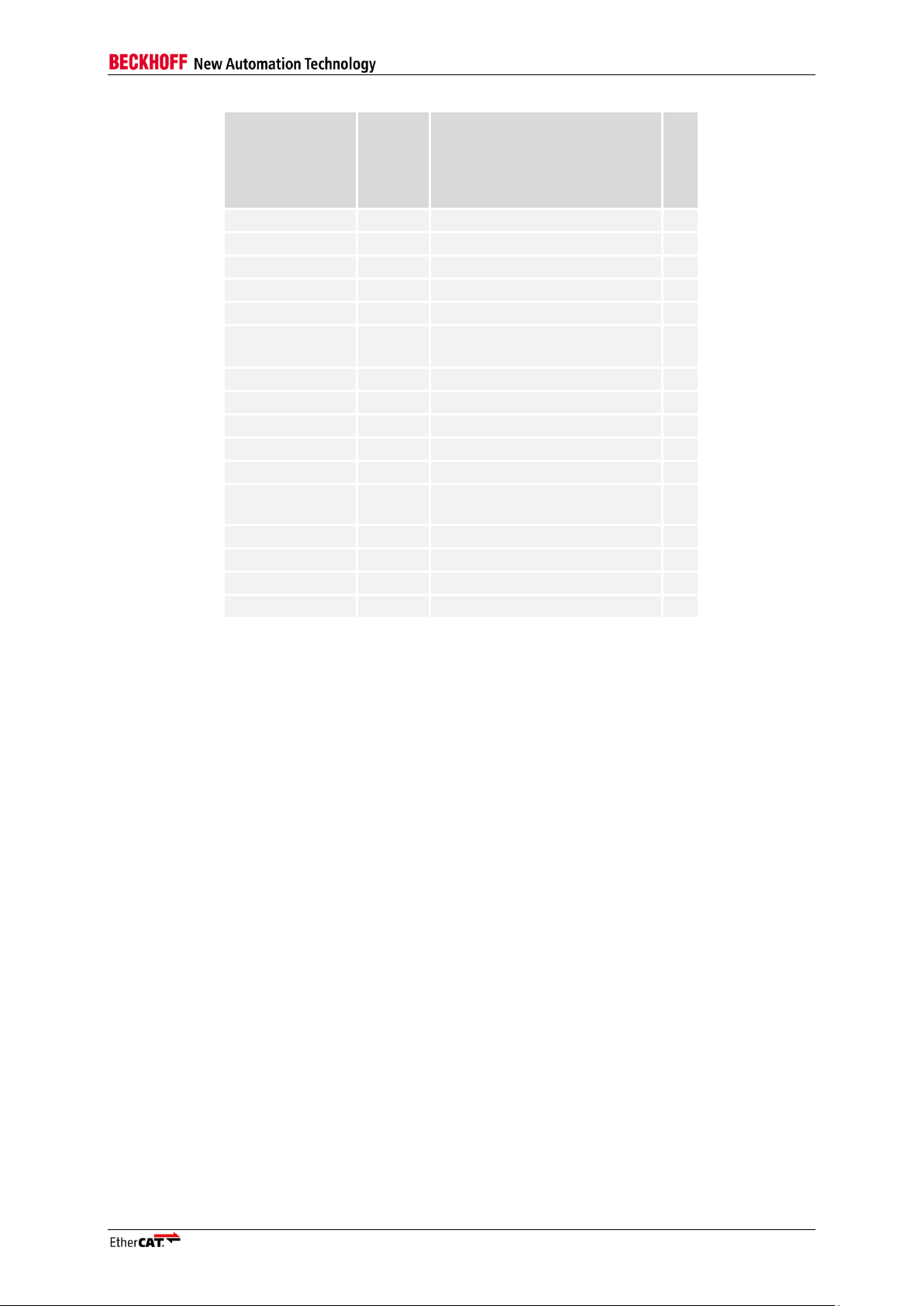

2 Features and Registers

2.1 Features

Table 4: ET1200 Feature Details

III-4 Slave Controller – ET1200 Hardware Description

Shared control/status signals: LATCH_IN/SOF and

OUT_VALID/WD_TRIGGER

Availability depending on port configuration

Page 15

Features and Registers

Feature

ET1200

-0003

SPI Slave PDI

x

Max. SPI clock [MHz]

6-20 (SPI

mode dep.)

SPI modes configurable (0x0150[1:0])

x

SPI_IRQ driver configurable (0x0150[3:2])

x

SPI_SEL polarity configurable (0x0150.4)

x

Data out sample mode configurable

(0x0150.5)

x

Busy signaling

x

Wait State byte(s)

-

Number of address extension byte(s)

1

2/4 Byte SPI master support

-

Extended error detection (read busy

violation)

-

SPI_IRQ delay

x

Status indication

x

EEPROM_

Loaded signal

x

Asynchronous µController PDI

-

Synchronous µController PDI

-

EtherCAT Bridge (port 3, EBUS/MII)

x

General Purpose I/O

x

GPO bits

0-12

GPI bits

-

GPIO available independent of PDI or port

configuration

-

GPIO available without PDI

-

Concurrent access to GPO by ECAT and

PDI

x

ESC Information

Basic Information (0x0000:0x0006)

x

Port Descriptor (0x0007)

x

ESC Features supported (0x0008:0x0009)

x

Extended ESC Feature Availability in User

RAM (0x0F80 ff.)

-

Write Protection (0x0020:0x0031)

x

Data Link Layer Features

ECAT Reset (0x0040)

x

PDI Reset (0x0041)

-

ESC DL Control (0x0100:0x0103) bytes

4

EtherCAT only mode (0x0100.0)

x

Temporary loop control (0x0100.1)

x

FIFO Size configurable (0x0100[18:16])

x

Configured Station Address

(0x0010:0x0011)

x

Configured Station Alias (0x0100.24,

0x0012:0x0013)

x

Physical Read/Write Offset

(0x0108:0x0109)

x

Application Layer Features

Extended AL Control/Status bits

(0x0120[15:5], 0x0130[15:5])

x

AL Status Emulation (0x0140.8)

x

AL Status Code (0x0134:0x0135)

x

Interrupts

ECAT Event Mask (0x0200:0x0201)

x

AL Event Mask (0x0204:0x0207)

x

ECAT Event Request (0x0210:0x0211)

x

AL Event Request (0x0220:0x0223)

x

SyncManager activation changed

(0x0220.4)

x

SyncManager watchdog expiration

(0x0220.6)

-

Error Counters

RX Error Counter (0x0300:0x0307)

x

Forwarded RX Error Counter

(0x0308:0x030B)

x

ECAT Processing Unit Error Counter

(0x030C)

-

PDI Error Counter (0x030D)

-

Lost Link Counter (0x0310:0x0313)

x

Feature

ET1200

-0003

Watchdog

Watchdog Divider configurable

(0x0400:0x0401)

x

Watchdog Process Data

x

Watchdog PDI

x

Watchdog Counter Process Data (0x0442)

x

Watchdog Counter PDI (0x0443)

x

SII EEPROM Interface (0x0500:0x050F)

EEPROM sizes supported

1 Kbyte-

4 Mbyte

EEPROM size reflected in 0x0502.7

x

EEPROM controllable by PDI

x

EEPROM Emulation by PDI

-

Read data bytes (0x0502.6)

8

Internal Pull-Ups for EEPROM_CLK and

EEPROM_DATA

x

FMMUs

3

Bit-oriented operation

x

SyncManagers

4

Watchdog trigger generation for 1 Byte

Mailbox configuration independent of

reading access

x

SyncManager Event Times (+0x8[7:6])

-

Buffer state (+0x5[7:6])

-

Distributed Clocks

x

Width

64

Sync/Latch signals

1-23

SyncManager Event Times

(0x09F0:0x09FF)

-

DC Receive Times

x

DC Time Loop Control controllable by PDI

-

DC activation by EEPROM

(0x0140[11:10])

-

Propagation delay measurement with

traffic (BWR/FPWR 0x900 detected at

each port)

-

LatchSignal state in Latch Status register

(0x09AE:0x09AF)

-

SyncSignal Auto-Activation (0x0981.3)

-

SyncSignal 32 or 64 bit Start Time

(0x0981.4)

-

SyncSignal Late Activation (0x0981[6:5])

-

SyncSignal debug pulse (0x0981.7)

-

SyncSignal Activation State 0x0984)

-

Reset filters after writing filter depth

-

ESC Specific Registers (0x0E00:0x0EFF)

Product and Vendor ID

-

POR Values

x

FPGA Update (online)

-

Process RAM and User RAM

Process RAM (0x1000 ff.) [Kbyte]

1

User RAM (0x0F80:0x0FFF)

x

Extended ESC Feature Availability in User

RAM

-

Additional EEPROMs

1

SII EEPROM (I²C)

x

FPGA configuration EEPROM

-

LED Signals

RUN LED

x

RUN LED override

-

Link/Activity(x) LED per port

x

PERR(x) LED per port

x

Device ERR LED

-

STATE_RUN LED

-

3

Slave Controller – ET1200 Hardware Description III-5

SYNC/LATCH[1] available if no MII port is used.

Page 16

Features and Registers

Feature

ET1200

-0003

Optional LED states

RUN LED: Bootstrap

x

RUN LED: Booting

-

RUN LED: Device identification

-

RUN LED: loading SII EEPROM

-

Error LED: SII EEPROM loading error

-

Error LED: Invalid hardware configuration

-

Error LED: Process data watchdog timeout

-

Error LED: PDI watchdog timeout

-

Link/Activity: port closed

-

Link/Activity: local auto-negotiation error

-

Link/Activity: remote auto-negotiation error

-

Link/Activity: unknown PHY auto-

negotiation error

-

LED test

-

Clock supply

Crystal

x

Crystal oscillator

x

TX_CLK from PHY

x

25ppm clock source accuracy

x

Internal PLL

x

Feature

ET1200

-0003

Power Supply Voltages

1-3

I/O Voltage

3.3 V

x

3.3V / 5V tolerant

-

5 V

(x)

Core Voltage

2.5V

Internal LDOs

2

LDO supply voltage

3.3V/5V

Core Voltage

x

I/O Voltage

x

Package

QFN48

Size [mm²]

7x7

Original Release date

11/2006

Configuration and Pinout calculator (XLS)

x

Register Configuration

fixed

Symbol

Description

x

available

-

not available

c

configurable

Table 5: Legend

III-6 Slave Controller – ET1200 Hardware Description

Page 17

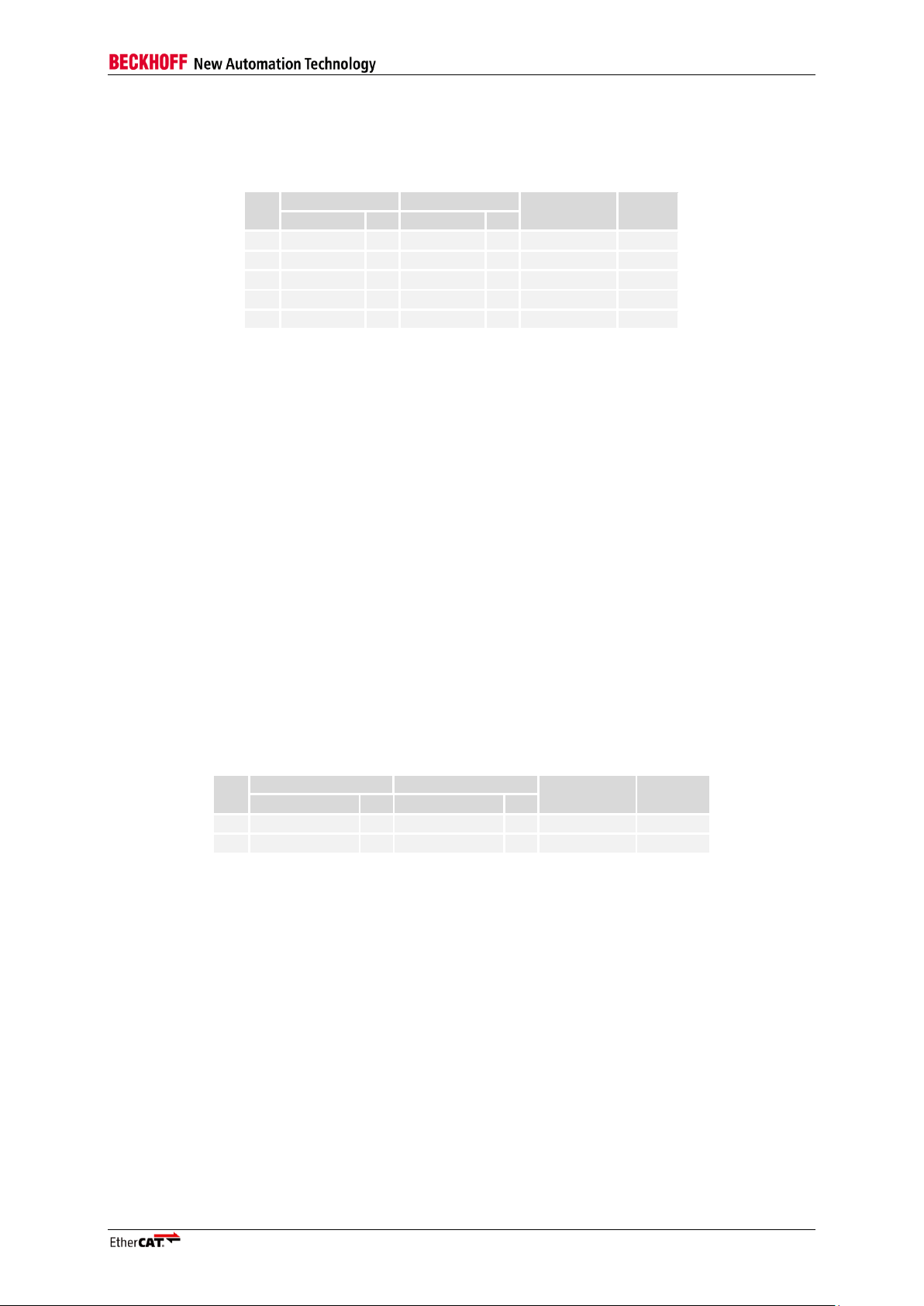

Features and Registers

Symbol

Description

x

Available

-

Not available

Address

Length

(Byte)

Description

ET1200

0x0000

1

Type x 0x0001

1

Revision

x

0x0002:0x0003

2

Build x 0x0004

1

FMMUs supported

x

0x0005

1

SyncManagers supported

x

0x0006

1

RAM Size

x

0x0007

1

Port Descriptor

x

0x0008:0x0009

2

ESC Features supported

x

0x0010:0x0011

2

Configured Station Address

x

0x0012:0x0013

2

Configured Station Alias

x

0x0020

1

Write Register Enable

x

0x0021

1

Write Register Protection

x

0x0030

1

ESC Write Enable

x

0x0031

1

ESC Write Protection

x

0x0040

1

ESC Reset ECAT

x

0x0041

1

ESC Reset PDI

-

0x0100:0x0101

2

ESC DL Control

x

0x0102:0x0103

2

Extended ESC DL Control

x

0x0108:0x0109

2

Physical Read/Write Offset

x

0x0110:0x0111

2

ESC DL Status

x

0x0120

5 bits

[4:0]

AL Control

x

0x0120:0x0121

2

AL Control

x

0x0130

5 bits

[4:0]

AL Status

x

0x0130:0x0131

2

AL Status

x

0x0134:0x0135

2

AL Status Code

x

0x0138

1

RUN LED Override

-

0x0139

1

ERR LED Override

-

0x0140

1

PDI Control

x

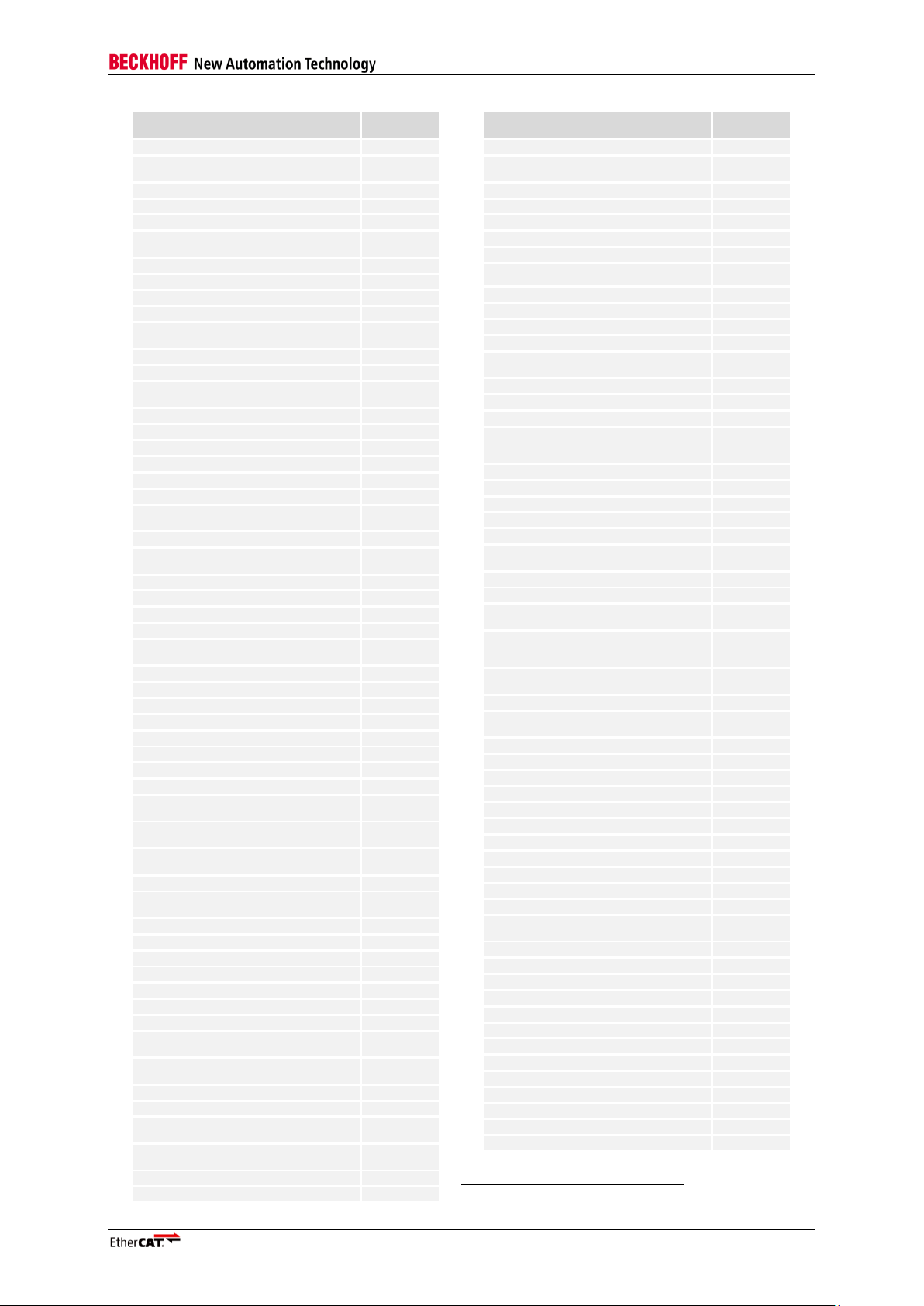

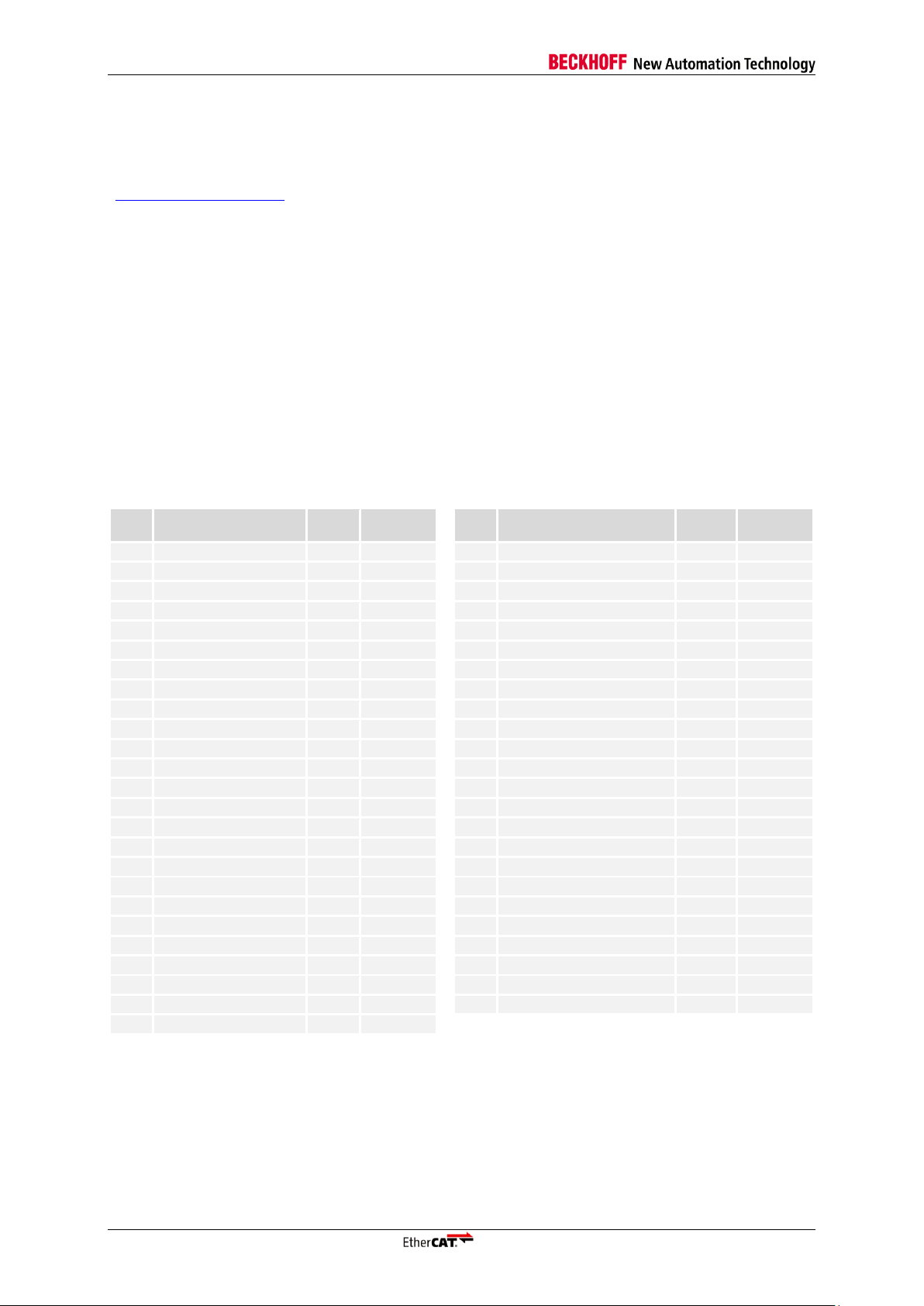

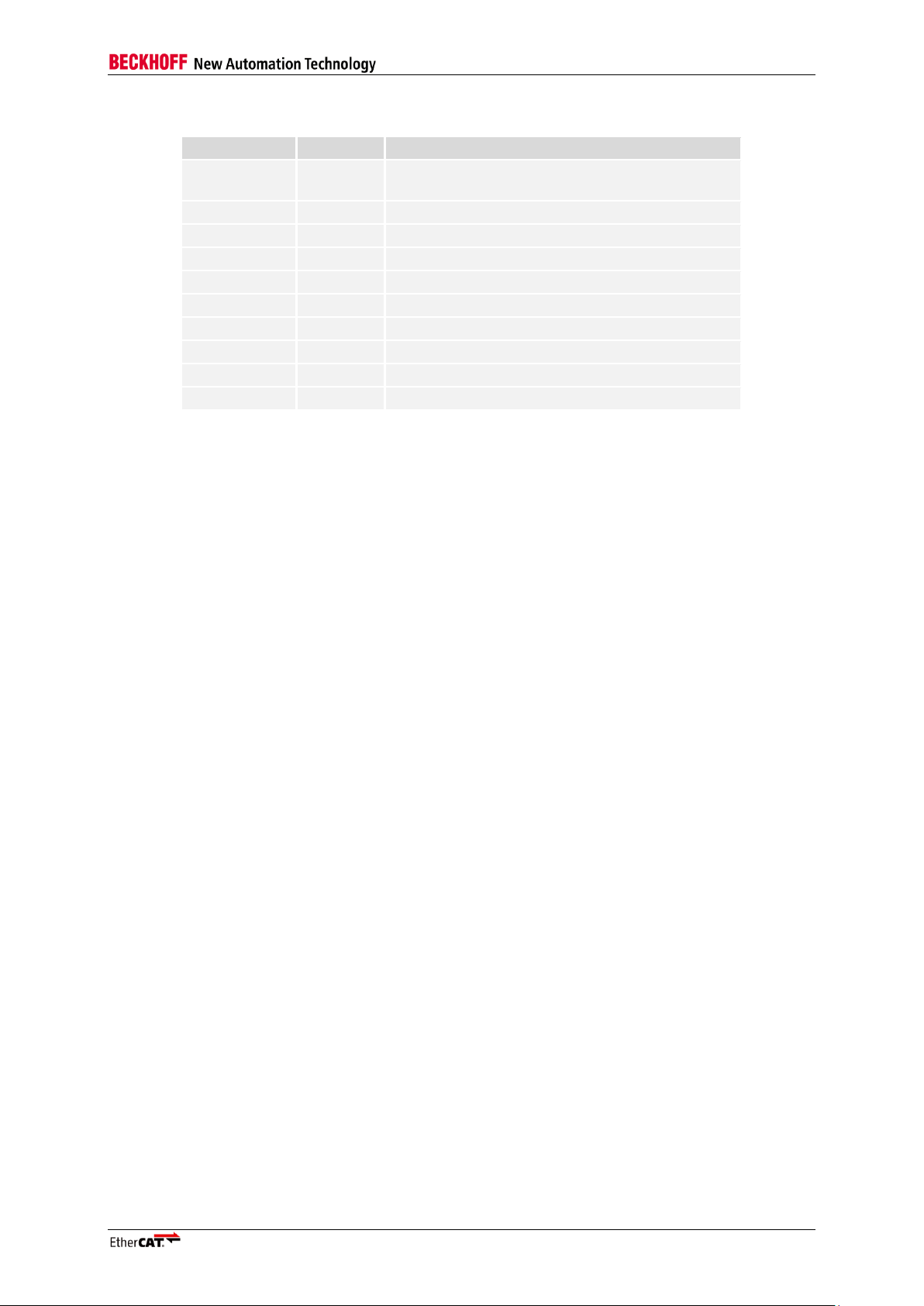

2.2 Register Overview

An EtherCAT Slave Controller (ESC) has an address space of 64 Kbyte. The first block of 4 Kbyte

(0x0000:0x0FFF) is dedicated for registers. The process data RAM starts at address 0x1000, its size

is 1 Kbyte (end address 0x13FF).

Table 7 gives an overview of the available registers.

Table 6: Legend

Table 7: Register Overview

Slave Controller – ET1200 Hardware Description III-7

Page 18

Features and Registers

Address

Length

(Byte)

Description

ET1200

0x0141

1

ESC Configuration

x

0x014E:0x014F

2

PDI Information

-

0x0150

1

PDI Configuration

x

0x0151

1

DC Sync/Latch Configuration

x

0x0152:0x0153

2

Extended PDI Configuration

x

0x0200:0x0201

2

ECAT Event Mask

x

0x0204:0x0207

4

PDI AL Event Mask

x

0x0210:0x0211

2

ECAT Event Request

x

0x0220:0x0223

4

AL Event Request

x

0x0300:0x0307

4x2

Rx Error Counter[3:0]

x

0x0308:0x030B

4x1

Forwarded Rx Error

counter[3:0]

x

0x030C

1

ECAT Processing Unit Error

Counter

0x030D

1

PDI Error Counter

-

0x030E

1

PDI Error Code

-

0x0310:0x0313

4x1

Lost Link Counter[3:0]

x

0x0400:0x0401

2

Watchdog Divider

x

0x0410:0x0411

2

Watchdog Time PDI

x

0x0420:0x0421

2

Watchdog Time Process Data

x

0x0440:0x0441

2

Watchdog Status Process Data

x

0x0442

1

Watchdog Counter Process

Data

x

0x0443

1

Watchdog Counter PDI

x

0x0500:0x050F

16

SII EEPROM Interface

x

0x0510:0x0515

6

MII Management Interface

x

0x0516:0x0517

2

MII Management Access State

-

0x0518:0x051B

4

PHY Port Status[3:0]

-

0x0600:0x06FC

16x13

FMMU[15:0]

3

0x0800:0x087F

16x8

SyncManager[15:0]

4

0x0900:0x090F

4x4

DC – Receive Times[3:0]

x

0x0918:0x091F

8

DC – Receive Time EPU

x

0x0920:0x0935

24

DC – Time Loop Control Unit

x

0x0910:0x0917

8

DC – System Time

x

0x0936

1

DC – Receive Time Latch

mode

x

0x0980

1

DC – Cyclic Unit Control

x

0x0981

1

DC – Activation

x

0x0982:0x0983

2

DC – Pulse length of

SyncSignals

x

0x0984

1

DC – Activation Status

-

0x098E:0x09A7

26

DC – SYNC Out Unit

x

0x09A8

1

DC – Latch0 Control

x

0x09A9

1

DC – Latch1 Control

x

III-8 Slave Controller – ET1200 Hardware Description

Page 19

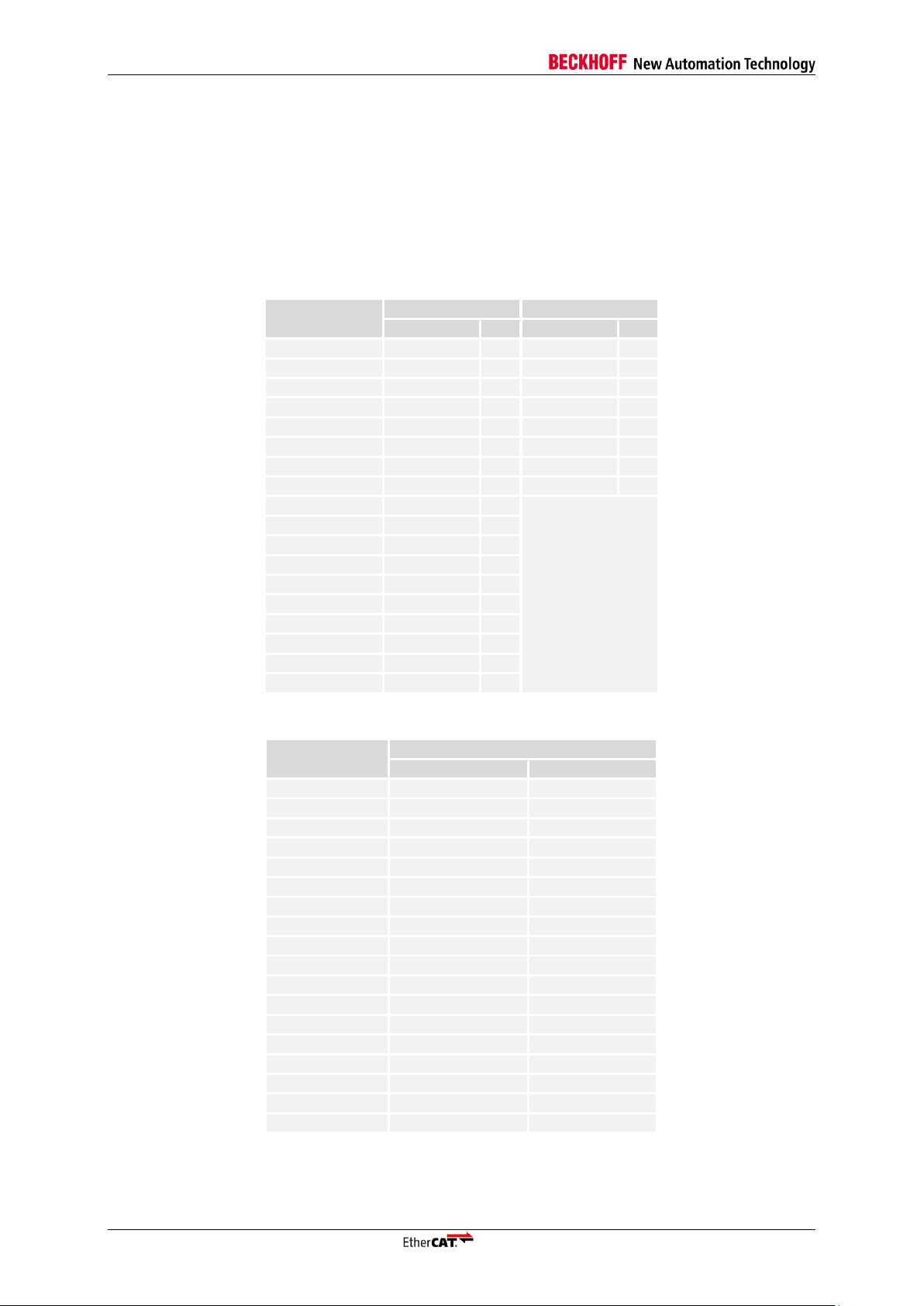

Features and Registers

Address

Length

(Byte)

Description

ET1200

0x09AE

1

DC – Latch0 Status

x

0x09B0:0x09B7

8

DC – Latch0 Positive Edge

x

0x09B8:0x09BF

8

DC – Latch0 Negative Edge

x

0x09C0:0x09C7

8

DC – Latch1 Positive Edge

x

0x09C7:0x09CF

8

DC – Latch1 Negative Edge

x

0x09F0:0x09F3

0x09F8:0x09FF

12

DC – SyncManager Event

Times

-

0x0E00:0x0E03

4

Power-On Values (Bits)

8

0x0E00:0x0E07

8

Product ID

-

0x0E08:0x0E0F

8

Vendor ID

-

0x0E10

1

ESC Health Status

-

0x0F00:0x0F03

4

Digital I/O Output Data

x

0x0F10:0x0F17

8

General Purpose Outputs

[Byte]

2

0x0F18:0x0F1F

8

General Purpose Inputs [Byte]

-

0x0F80:0x0FFF

128

User RAM

x

0x1000:0x1003

4

Digital I/O Input Data

io

0x1000 ff.

Process Data RAM [Kbyte]

1

Slave Controller – ET1200 Hardware Description III-9

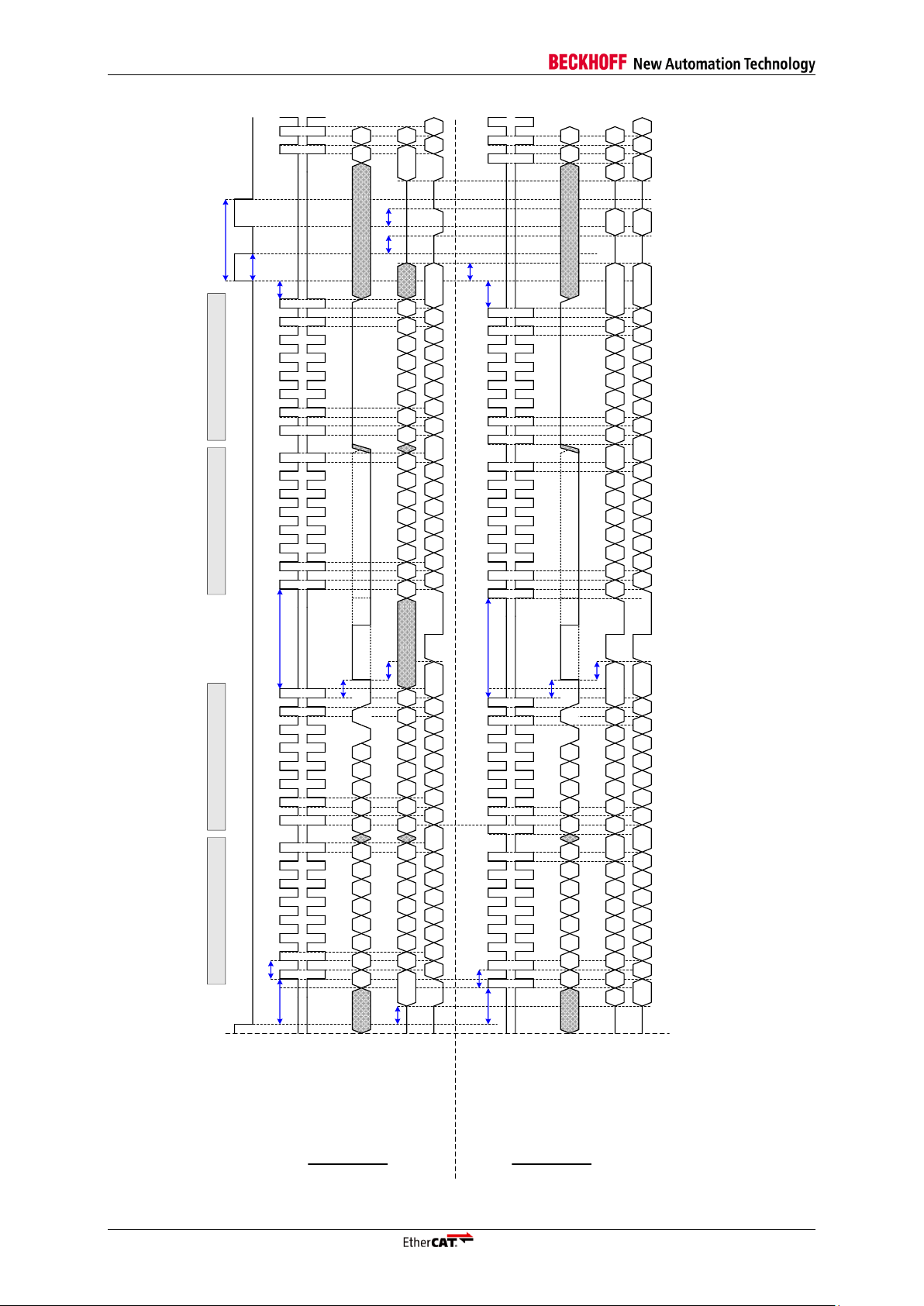

Page 20

Pin Description

Pin

Pin name

Dir.

Int.

PU/PD

Pin

Pin name

Dir.

Int.

PU/PD

EP

GND 25

RBIAS

1

TESTMODE

I

WPD

26

Reset

BD

WPU

2

EBUS{1}-RX-/LINK_MII

LI-/I

27 kΩ PU

27

PDI[17]/RX_D[3]

BD 3

EBUS{1}-RX+/RX_ERR

LI+/I

27 kΩ PD

28

PDI[16]/RX_D[2]

BD

4

EBUS{0}-TX-

LO-

29

PDI[15]/RX_D[1]

BD

5

EBUS{0}-TX+

LO+

30

PDI[14]/RX_D[0]

BD 6

V

CC I/O

I/O

31

PDI[13]/RX_DV

BD 7

GND

I/O

I/O*

32

PDI[12]/RX_CLK

BD 8

EBUS{0}-RX-

LI-

27 kΩ PU

33

PDI[11]/TX_D[3]/C25_SHI[1]

BD

9

EBUS{0}-RX+

LI+

27 kΩ PD

34

PDI[10]/TX_D[2]/C25_SHI[0]

BD 10

EBUS{1}-TX-/MI_CLK

LO-/O

35

PDI[9]/TX_D[1]/C25_ENA

BD

11

EBUS{1}-TX+/TX_ENA

LO+/O

36

PDI[8]/TX_D[0]/PHYAD_OFF

BD 12

PERR(0)/CLK_MODE[0]

BD

WPD

37

PDI[7]/CPU_CLK

BD 13

PERR(1)/CLK_MODE[1]

BD

WPD

38

PDI[6]/CLK25OUT

BD 14

VCC 39

PDI[5]

BD

15

GND 40

PDI[4]

BD 16

LINKACT(0)/MODE[0]

BD

WPD

41

V

CC Core

(2,5V)

17

LINKACT(1)/MODE[1]

BD

WPD

42

GND

Core

18

RUN/EEPROM_SIZE

BD

WPD

43

PDI[3]

BD/LI-

27 kΩ PU

19

EEPROM_CLK

BD

3.3 kΩ PU

44

PDI[2]

BD/LI+

27 kΩ PD

20

EEPROM_DATA

BD

3.3 kΩ PU

45

PDI[1]

BD/LO-

21

OSC_IN I 46

PDI[0]

BD/LO+

22

OSC_OUT

O

47

SYNC/LATCH[0]

BD

23

GND

PLL

48

SYNC/LATCH[1]/MI_DATA

BD

24

Vcc

PLL

(2,5V)

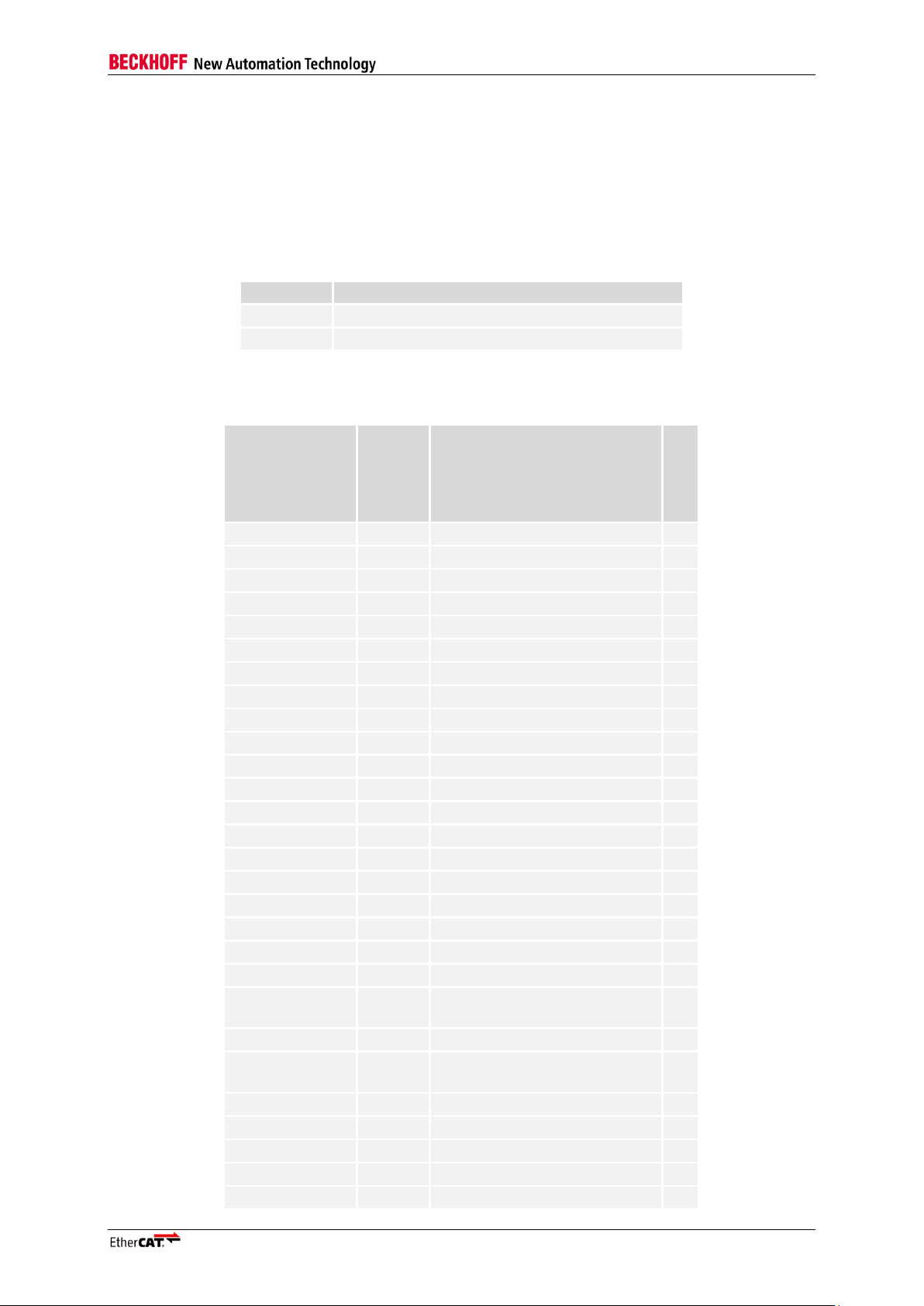

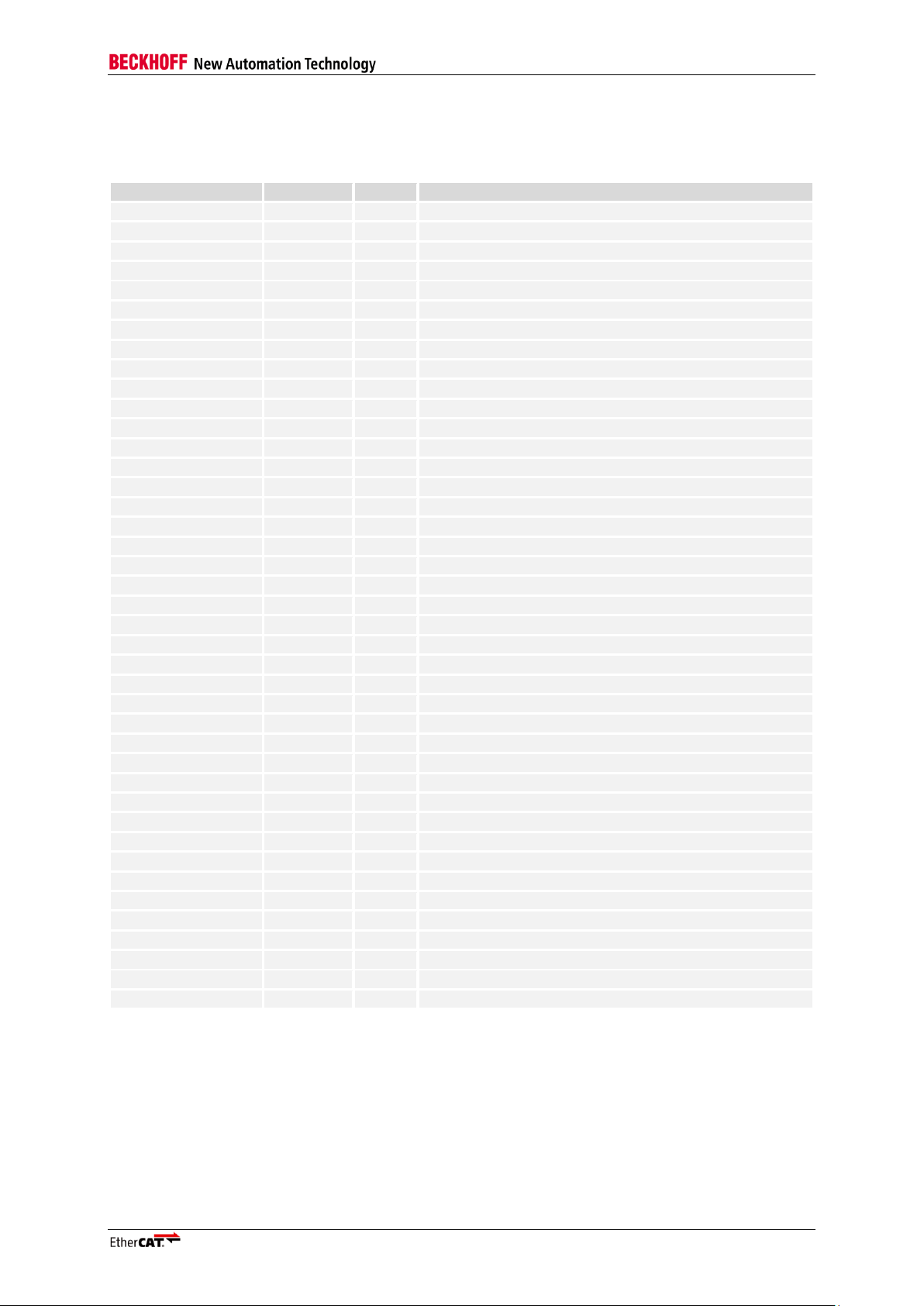

3 Pin Description

For pin configuration there is a table calculation file (ET1200 configuration and pinout V<version>.xls)

available to make pin configuration easier. This file can be downloaded from the Beckhoff homepage

(http://www.beckhoff.com). This documentation supersedes the table calculation file.

Input pins should not be left open/floating. Unused input pins (denoted with direction UI) without

external or internal pull-up/pull-down resistor should not be left open. Unused configuration pins

should be pulled down if the application allows this (take care of configuration signals in the PDI[17:0]

area when bidirectional Digital I/O is used). Unused PDI[17:0] input pins should be pulled down, all

other input pins can be connected to GND directly.

Pull-up resistors must connect to V

be powered via the resistors and the internal clamping diodes as long as V

, not to a different power source. Otherwise the ET1200 could

CC I/O

is below the other

CC I/O

power source.

Internal pull-up/pull-down resistor values shown in the pinout tables are nominal.

3.1 Overview

3.1.1 Pin Overview

Table 8: Pin Overview

NOTE: EP is the exposed center pad at the bottom of the ET1200.

III-10 Slave Controller – ET1200 Hardware Description

Page 21

Pin Description

Signal

Type

Dir.

Description

C25_ENA

Configuration

I

CLK25OUT Enable: Enable CLK25OUT

C25_SHI[1:0]

Configuration

I

TX Shift: Shifting/phase compensation of MII TX signals

CLK_MODE[1:0]

Configuration

I

CPU_CLK configuration

CLK25OUT

MII O 25 MHz clock source for Ethernet PHY

CPU_CLK

PDI O Clock signal for µController

EBUS{1:0}-RX-

EBUS

LI-

EBUS LVDS receive signal -

EBUS{1:0}-RX+

EBUS

LI+

EBUS LVDS receive signal +

EBUS{1:0}-TX-

EBUS

LO-

EBUS LVDS transmit signal -

EBUS{1:0}-TX+

EBUS

LO+

EBUS LVDS transmit signal +

EEPROM_CLK

EEPROM

BD

EEPROM I2C Clock

EEPROM_DATA

EEPROM

BD

EEPROM I2C Data

EEPROM_SIZE

Configuration

I

EEPROM size configuration

PERR(1:0)

LED O Port receive error LED output (for testing)

GND

Power

Ground

GND

Core

Power

Core logic ground

GND

I/O

Power

I/O ground

GND

PLL

Power

PLL ground

LINK_MII(1:0)

MII I PHY signal indicating a link

LINKACT(1:0)

LED O Link/Activity LED output

MI_CLK

MII O PHY Management Interface clock

MI_DATA

MII

BD

PHY Management Interface data

MODE[1:0]

Configuration

I

Chip Mode, port configuration

OSC_IN

Clock

I

Clock source (crystal/oscillator)

OSC_OUT

Clock

O

Clock source (crystal)

PDI[17:0]

PDI

BD

PDI signal, depending on EEPROM content

PHYAD_OFF

Configuration

I

Ethernet PHY Address Offset

RBIAS

EBUS

BIAS resistor for LVDS TX current adjustment

RESET

General

BD

Open collector Reset output/Reset input

RUN

LED O Run LED controlled by AL Status register

RX_CLK

MII I MII receive clock

RX_D[3:0]

MII I MII receive data

RX_DV

MII I MII receive data valid

RX_ERR

MII I MII receive error

SYNC/LATCH[1:0]

DC

I/O

Distributed Clocks SyncSignal output or LatchSignal input

TESTMODE

General

I

Reserved for testing, connect to GND

TX_D[3:0]

MII O MII transmit data

TX_ENA

MII O MII transmit enable

V

CC

Power

Device power (LDO input)

V

CC Core

Power

Core logic power

V

CC I/O

Power

I/O power

V

CC PLL

Power

PLL power

3.1.2 Signal Overview

Table 9: Signal Overview

Slave Controller – ET1200 Hardware Description III-11

Page 22

Pin Description

PDI

Signal

Dir.

Description

Digital I/O

I/O[15:0]

I/O/BD

Input/Output or Bidirectional data

LATCH_IN/SOF

I/O

External data latch signal/Start of Frame

OUTVALID/WD_TRIG

O

Output data is valid/Output event/ Watchdog Trigger

SPI

EEPROM_LOADED

O

PDI is active, EEPROM is loaded

SPI_CLK

I

SPI clock

SPI_DI

I

SPI data MOSI

SPI_DO

O

SPI data MISO

SPI_IRQ

O

SPI interrupt

SPI_SEL

I

SPI chip select

EBUS Bridge

EBUS(3)-RX-

LI-

EBUS LVDS receive signal -

EBUS(3)-RX+

LI+

EBUS LVDS receive signal +

EBUS(3)-TX-

LO-

EBUS LVDS transmit signal -

EBUS(3)-TX+

LO+

EBUS LVDS transmit signal +

PERR(3)

O

Error LED output (for testing)

LINKACT(3)

O

Link/Activity LED output

GPO[11:0]

O

General purpose output

MII Bridge

TX_D(3)[3:0]

O

MII transmit data

TX_ENA(3)

O

MII transmit enable

RX_CLK(3)

I

MII receive clock

RX_D(3)[3:0]

I

MII receive data

RX_DV(3)

I

MII receive data valid

RX_ERR(3)

I

MII receive error

LINK_MII(3)

I

PHY signal indicating a link

LINKACT(3)

O

Link/Activity LED output

PERR(3)

O

Error LED output (for testing)

GPO[1]

O

General purpose output

MI_CLK

O

PHY Management Interface clock

CLK25OUT

O

25 MHz clock source for Ethernet PHY

3.1.3 PDI Signal Overview

Table 10: PDI signal overview

III-12 Slave Controller – ET1200 Hardware Description

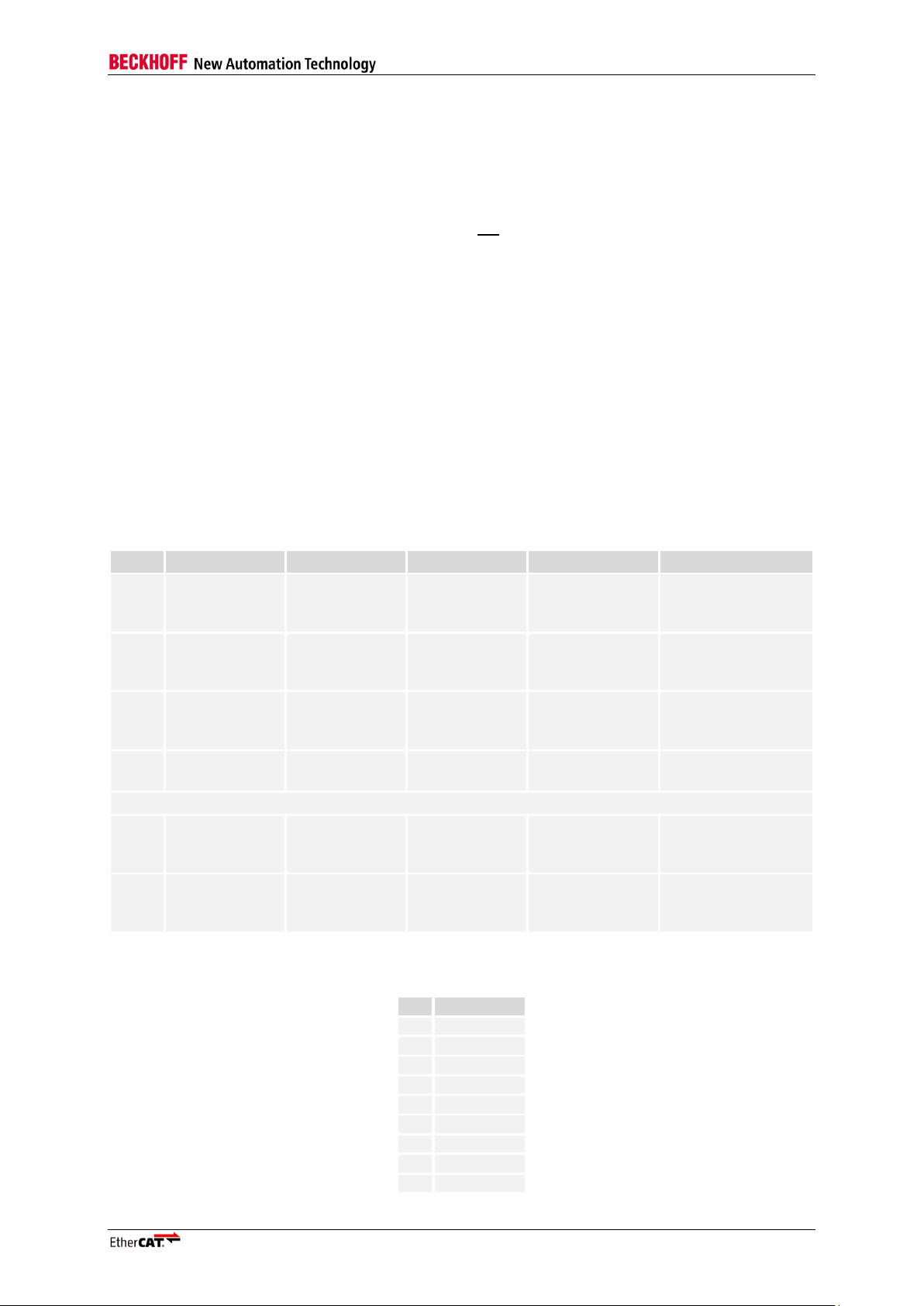

Page 23

Pin Description

Description

Config signal

Pin name

Register

MODE[1:0] Values

Chip Mode

MODE[0]

LINKACT(0)/MODE[0]

0x0E00[0]

00 = EBUS/EBUS (port 0 = EBUS, port 1 = EBUS)

01 = reserved

10 = MII/EBUS (port 0 = MII, port 1 = EBUS)

11 = EBUS/MII (port 0 = EBUS, port 1 = MII)

MODE[1]

LINKACT(1)/MODE[1]

0x0E00[1]

Description

Config signal

Pin name

Register

Values

CPU_CLK MODE

CLK_MODE[0]

PERR(0)/CLK_MODE[0]

0x0E00[2]

00 = off, PDI[7]/CPU_CLK available for PDI

01 = 25 MHz clock output at PDI[7]/CPU_CLK

10 = 20 MHz clock output at PDI[7]/CPU_CLK

11 = 10 MHz clock output at PDI[7]/CPU_CLK

CLK_MODE[1

PERR(1)/CLK_MODE(1)

0x0E00[3]

Description

Config signal

Pin name

Register

Values

TX Shift

C25_SHI[0]

PDI[10]/TX_D[2]/C25_SHI[0]

0x0E00[4]

00 = MII TX signals not delayed

01 = MII TX signals delayed by 10 ns

10 = MII TX signals delayed by 20 ns

11 = MII TX signals delayed by 30 ns

C25_SHI[1]

PDI[11]/TX_D[3]/C25_SHI[1]

0x0E00[5]

4

3.2 Configuration Pins

The configuration pins are used to configure the ET1200 at power-on with pull-up or pull down

resistors. At power-on the ET1200 uses these pins as inputs to latch the configuration4. After poweron, the pins have their operation functionality which has been assigned to them, and therefore pin

direction changes if necessary. The power-on phase finishes before the nRESET pin is released. In

subsequent reset phases without power-on condition, the configuration pins still have their operation

functionality, i.e., the ET1200 configuration is not latched again and output drivers remain active.

The configuration value 0 is realized by a pull-down resistor, a pull-up resistor is used for a 1. Since

some configuration pins are also used as LED outputs, the polarity of the LED output depends on the

configuration value.

3.2.1 Chip mode

Chip mode configures the type of the two permanent ports 0 and 1. It is shown in Table 11. The Chip

mode affects the number of available PDI signals.

Chip mode is shown in Table 11.

Table 11: Chip Mode

3.2.2 CPU_CLK MODE

CLK_MODE is used to provide a clock signal to an external microcontroller. If CLK_MODE is not 00,

CPU_CLK is available on PDI[7], thus this pin is not available for PDI signals anymore.

The CPU_CLK MODE is shown in Table 12.

Table 12: CPU_CLK Mode

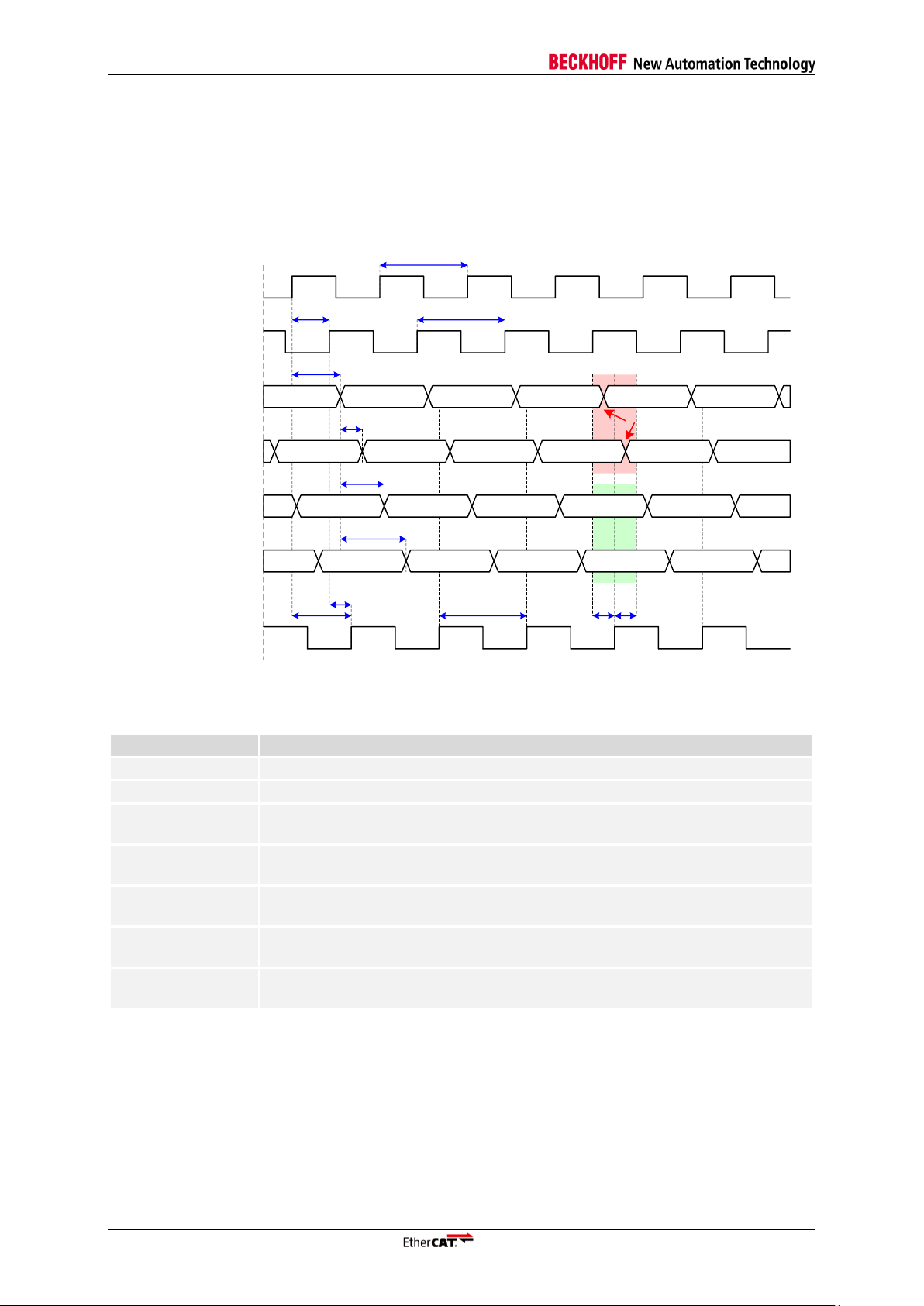

3.2.3 TX Shift

Phase shift (0/10/20/30ns) of MII TX signals (TX_ENA, TX_D[3:0]) can be attained via the C25_SHI[x]

signals. TX Shift settings are explained in Table 13. It is recommended to support all C25_SHI[1:0]

configurations by hardware options to enable later adjustments.

Table 13: TX Shift

Take care of proper configuration: External devices attached to dual-purpose configuration pins might interfere

sampling the intended configuration if they are e.g. not properly powered at the sample time (external device

keeps configuration pin low although a pull-up resistor is attached). In such cases the ET1200 power-on value

sampling time can be delayed by delaying power activation.

Slave Controller – ET1200 Hardware Description III-13

Page 24

Pin Description

Description

Config

signal

Pin name

Register

Values

CLK25OUT

Enable

C25_ENA

PDI[9]/TX_D[1]/C25_ENA

0x0E00[6]

0 = disable, PDI[6]/CLK25OUT is available for

PDI

1 = enable, PDI[6]/CLK25OUT is 25 MHz clock

output (MODE 10/11 only)

Description

Config signal

Pin name

Register

Values

PHY Address Offset

PHYAD_OFF

PDI[8]/TX_D[0]/PHYAD_OFF

0x0E00[7]

0 = PHY address offset 0

1 = PHY address offset 16

Description

Config signal

Pin name

Register

Values

EEPROM Size

EEPROM_SIZE

RUN/EEPROM_SIZE

0x0502[7]

0 = 1 address byte (1 Kbit to 16 Kbit EEPROM)

1 = 2 address bytes (32 Kbit to 4 Mbit EEPROM)

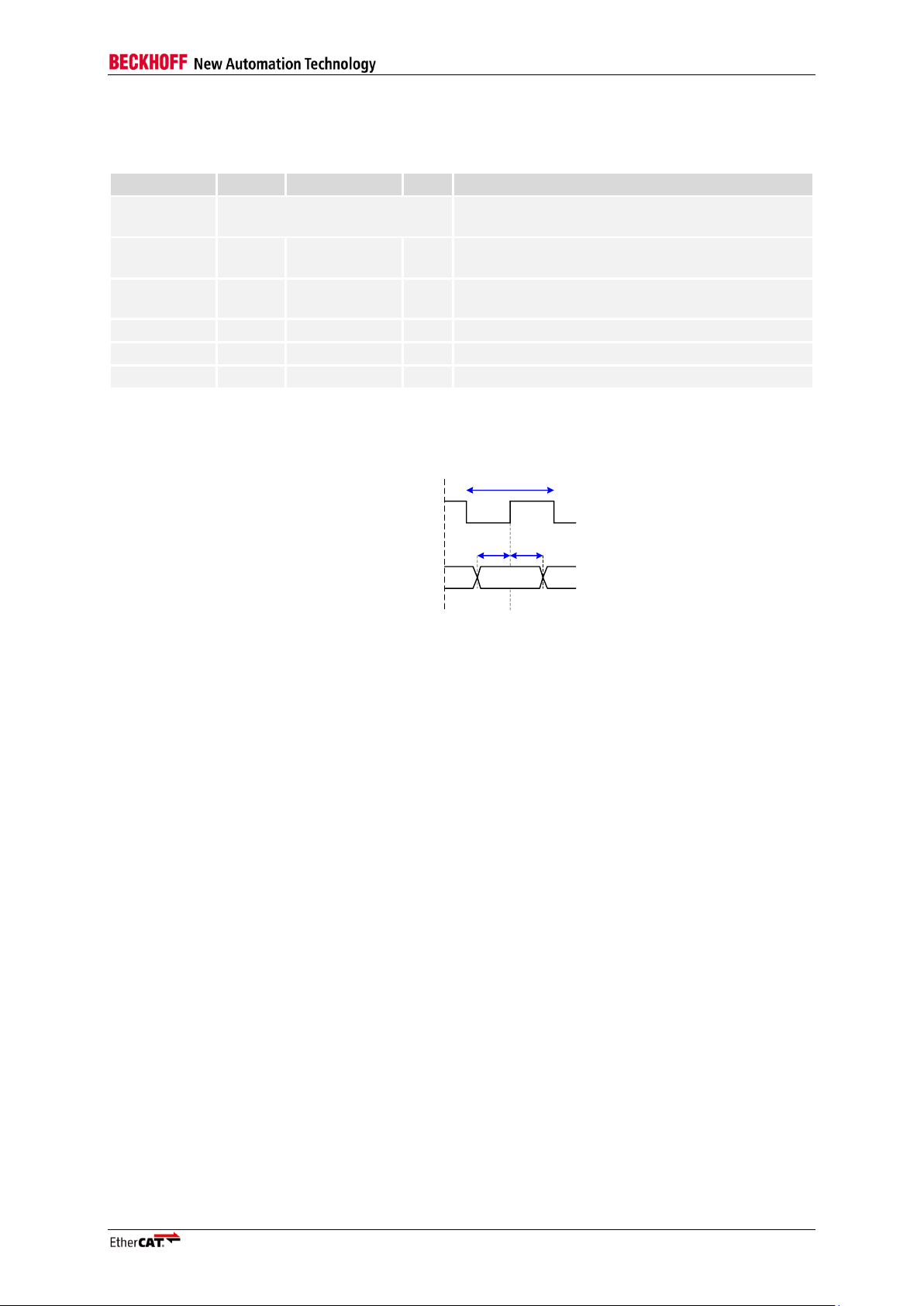

3.2.4 CLK25OUT Enable

A 25MHz clock for the Ethernet PHY can be made available by the ET1200 on pin PDI[6]. This is only

relevant for MODE 10 or 11. For MODE 00 with MII bridge port 3, CLK25OUT is available at PDI[6]

anyway. CLK25OUT is not available in MODE 00 if MII bridge port 3 is not configured, CLK25OUT

Enable is ignored.

CLK_25OUT Enable is explained in Table 14.

Table 14: CLK_25OUT Enable

3.2.5 PHY Address Offset

The ET1200 supports two PHY address offset configurations, either 0 or 16. Refer to chapter 4.2 for

details on PHY address configuration.

PHY Address Offset is explained in Table 15.

Table 15: PHY Address Offset

3.2.6 SII EEPROM Size

EEPROM_SIZE determines the size of the EEPROM (and the number of I²C address bytes).

EEPROM_SIZE is sampled at the beginning of the EEPROM access. EEPROM_ SIZE is shown in

Table 16.

Table 16: SII EEPROM Size

III-14 Slave Controller – ET1200 Hardware Description

Page 25

Pin Description

Pin

Pin

Signal

Configuration

Internal

PU/PD

Name

Dir

Name

Dir

21

OSC_IN

I

OSC_IN I

22

OSC_OUT

O

OSC_OUT O

26

RESET

BD

RESET

BD WPU

25

RBIAS

RBIAS

1

TESTMODE

I

TESTMODE

I WPD

Pin

Pin

Signal

Configuration

Internal

PU/PD

Name

Dir

Name

Dir

19

EEPROM_CLK

BD

EEPROM_CLK

BD 3.3 kΩ PU

20

EEPROM_DATA

BD

EEPROM_DATA

BD 3.3 kΩ PU

3.3 General ET1200 Pins

Table 17: General pins

OSC_IN

Connection to external crystal or oscillator input (25 MHz). An oscillator as the clock source for both

ET1200 and the Ethernet PHY is mandatory if an MII port is used and CLK25OUT cannot be used as

the clock source for the PHY. The 25 MHz clock source should have an initial accuracy of 25ppm or

better.

OSC_OUT

Connection to external crystal. Should be left open if an oscillator is connected to OSC_IN.

RESET

The open collector RESET input/output (active low) signals the reset state of ET1200. The reset state

is entered at power-on, if the power supply is to low, or if a reset was initiated using the reset register

0x0040. ET1200 also enters reset state if RESET pin is held low by external devices.

RBIAS

Bias resistor for LVDS TX current adjustment, should be 11 kΩ connected to GND.

TESTMODE

Reserved for testing, should be connected to GND.

3.4 SII EEPROM Interface Pins

Table 18: SII EEPROM pins

EEPROM_CLK

EEPROM I²C clock signal (open collector output).

EEPROM_DATA

EEPROM I²C data signal (open collector output).

Slave Controller – ET1200 Hardware Description III-15

Page 26

Pin Description

Pin

Pin

No MII port used

MII port used

Configuration

Internal

PU/PD

Name

Dir

Signal

Dir

Signal

Dir

47

SYNC/LATCH[0]

BD

SYNC/LATCH[0]

I/O

SYNC/LATCH[0]

I/O

48

SYNC/LATCH[1]/MI_DATA

BD

SYNC/LATCH[1]

I/O

MI_DATA

BD

Pin

Pin

Signal

Configuration

Internal

PU/PD

Name

Dir

Name

Dir

18

RUN/EEPROM_SIZE

BD

RUN O EEPROM_SIZE

WPD

16

LINKACT(0)/MODE[0]

BD

LINKACT(0)

O

MODE[0]

WPD

12

PERR(0)/CLK_MODE[0]

BD

PERR(0)

O

CLK_MODE[0]

WPD

17

LINKACT(1)/MODE[1]

BD

LINKACT(1)

O

MODE[1]

WPD

13

PERR(1)/CLK_MODE[1]

BD

PERR(1)

O

CLK_MODE[1]

WPD

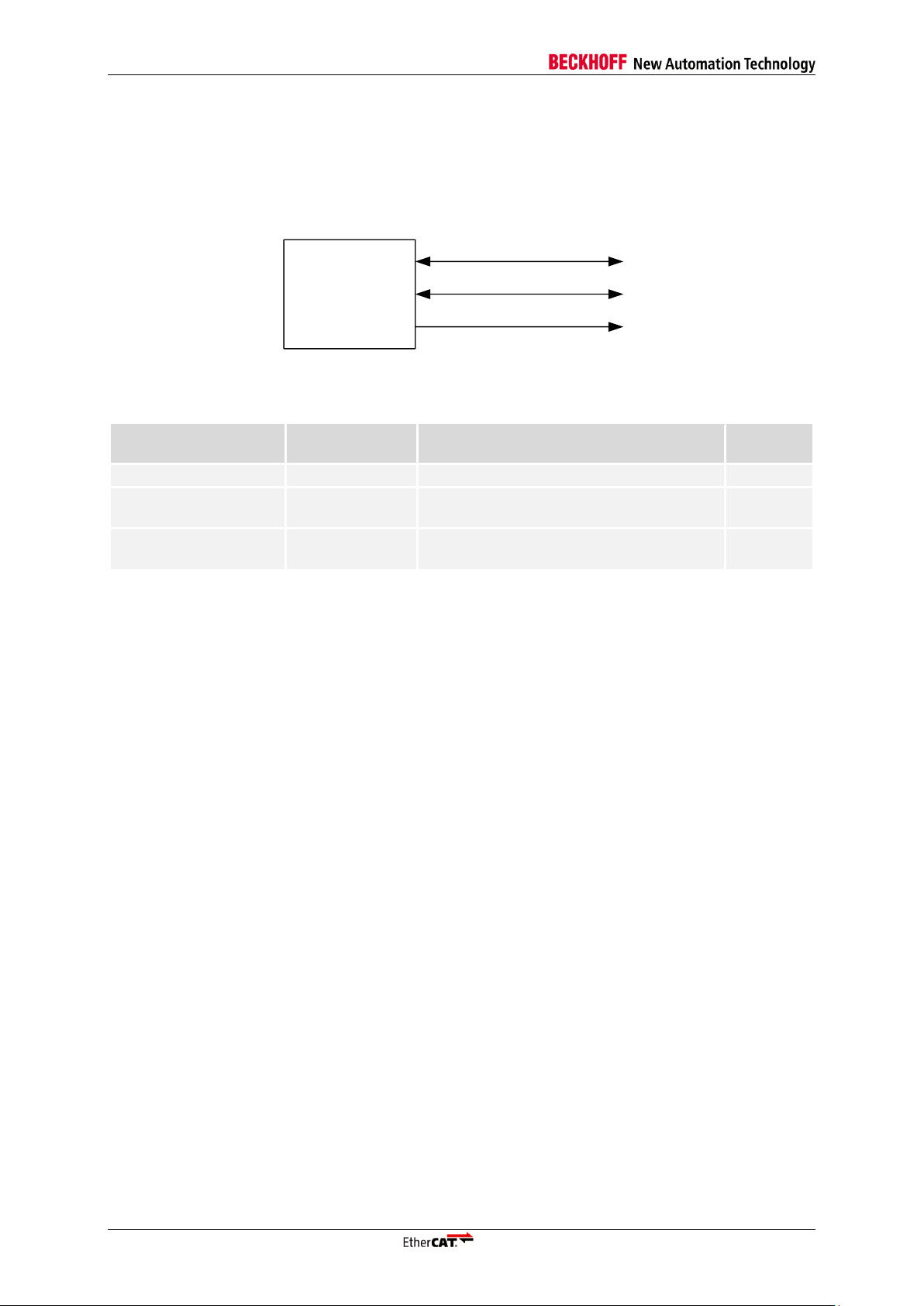

3.5 Distributed Clocks SYNC/LATCH Pins, MII Management Data

Table 19: DC SYNC/LATCH and MII Management pins

SYNC/LATCH[x]/MI_DATA

SYNC/LATCH[x] are Distributed Clocks SyncSignal output or LatchSignal input, depending on SII

EEPROM configuration. If an MII port is used, SYNC/LATCH[1]/MI_DATA becomes MI_DATA, which

is the Ethernet PHY management interface data signal. SYNC/LATCH signals are not driven (high

impedance) until the EEPROM is loaded (MI_DATA is independent of the EEPROM loaded state).

NOTE: MI_DATA must have a pull-up resistor (4.7kΩ recommended for ESCs).

3.6 LED Signals

All LED signals are also used as configuration signals. The polarity of each LED signal depends on

the configuration: LED is active high if pin is pulled down for configuration, and active low if pin is

pulled up. Refer to the example schematics for LED connection details.

Table 20: LED pins

RUN/EEPROM_SIZE

SII EEPROM_SIZE configuration (either 1 Kbit-16 Kbit or 32 Kbit-4 Mbit) sampled at the beginning of

the EEPROM access. Otherwise RUN LED signal, usually. RUN is active high if pin is pulled down,

and active low if pin is pulled up. Refer to example schematics for connection details. RUN LED

should be green.

LINKACT(x)/MODE(x)

Chip MODE configuration pin at power-on, Link/Activity LED output (off=no link, on=link without

activity, blinking=link and activity) for logical port x afterwards. LINKACT(x) is active high if pin is pulled

down, and active low if pin is pulled up. Refer to example schematics for connection details.

Link/Activity LED should be green.

PERR(x)/CLK_MODE(x)

CPU_CLK Mode configuration pin at power-on, Error LED output for logical port x afterwards.

PERR(x) is active high if pin is pulled down, and active low if pin is pulled up. Refer to example

schematics for connection details.

NOTE: PERR(x) LEDs are not part of the EtherCAT indicator specification. They are only intended for testing and

debugging. The PERR(x) LED flashes once if a physical layer receive error occurs. Do not confuse PERR(x)

LEDs with application layer ERR LED, this is not supported by the ESCs and has to be controlled by a

µController.

III-16 Slave Controller – ET1200 Hardware Description

Page 27

Pin Description

Chip mode

SPI

Digital I/O

EBUS bridge

(log. port 3)

MII bridge

(log. port 3)

MODE 00

SPI

+12 Bit GPO

16 Bit I/O

+ control/status

signals

EBUS bridge

+12 Bit GPO

MII bridge

+CLK25OUT +1

Bit GPO

MODE 10/11

SPI

+12 Bit GPO

8 Bit I/O

EBUS bridge +2

Bit GPO

Not available

3.7 Physical Ports and PDI Pins

The ET1200 pin out is optimized in order to achieve an optimum of size and features. To obtain this,

there is a number of pins where either communication or PDI functionality can be assigned to,

depending on the chip mode. The selected chip mode might reduce PDI possibilities

The ET1200 has 18 PDI pins, PDI[17:0]. They are structured in two groups: PDI[7:0] and PDI[17:8].

PDI[7:0] are always available for PDI signals, PDI[17:8] are available for PDI signals in MODE 00, in

MODE 10/11 they are used for MII signals.

Possible Chip mode / PDI combinations

Table 21: Combinations of Chip modes and PDIs

Slave Controller – ET1200 Hardware Description III-17

Page 28

Pin Description

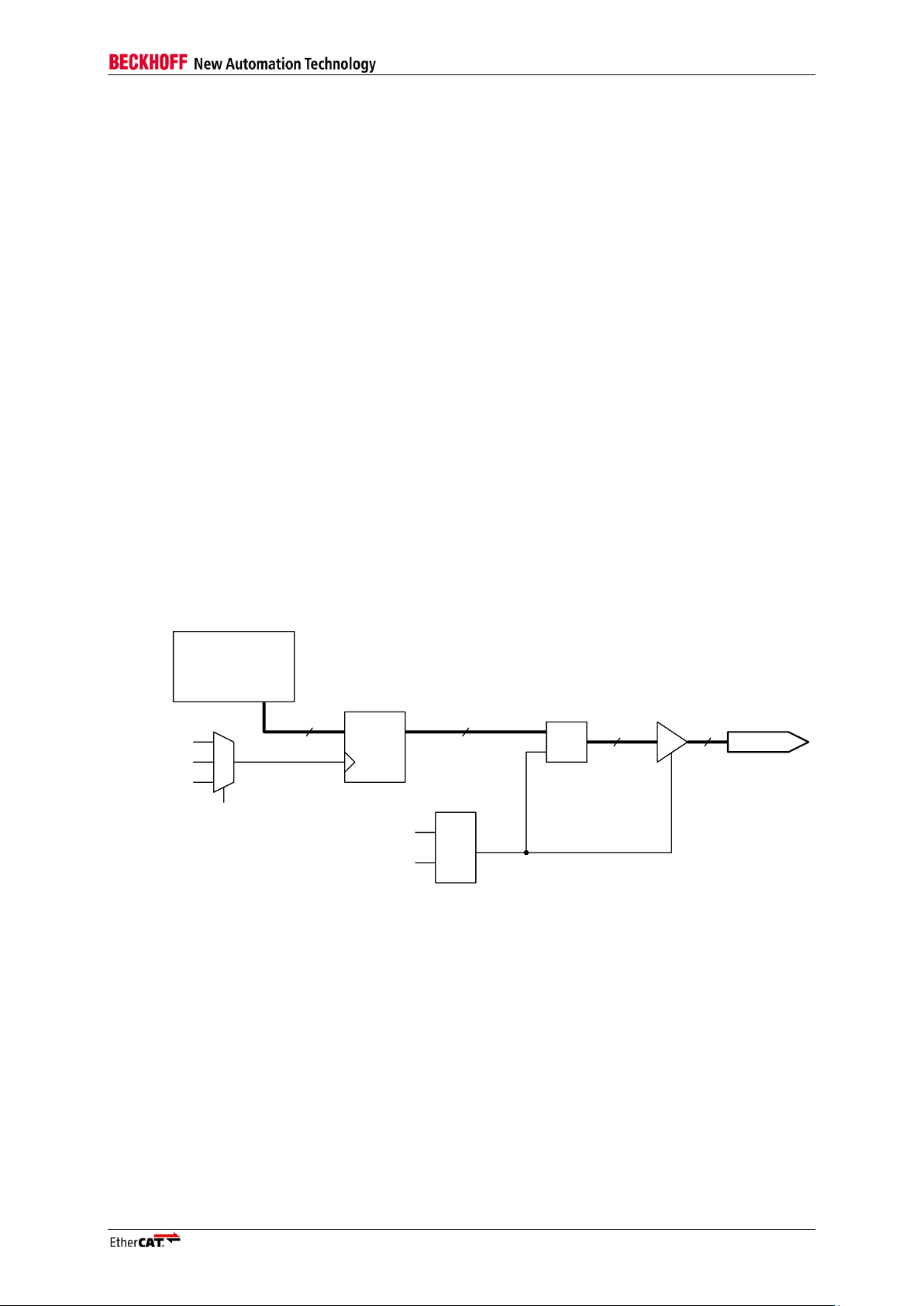

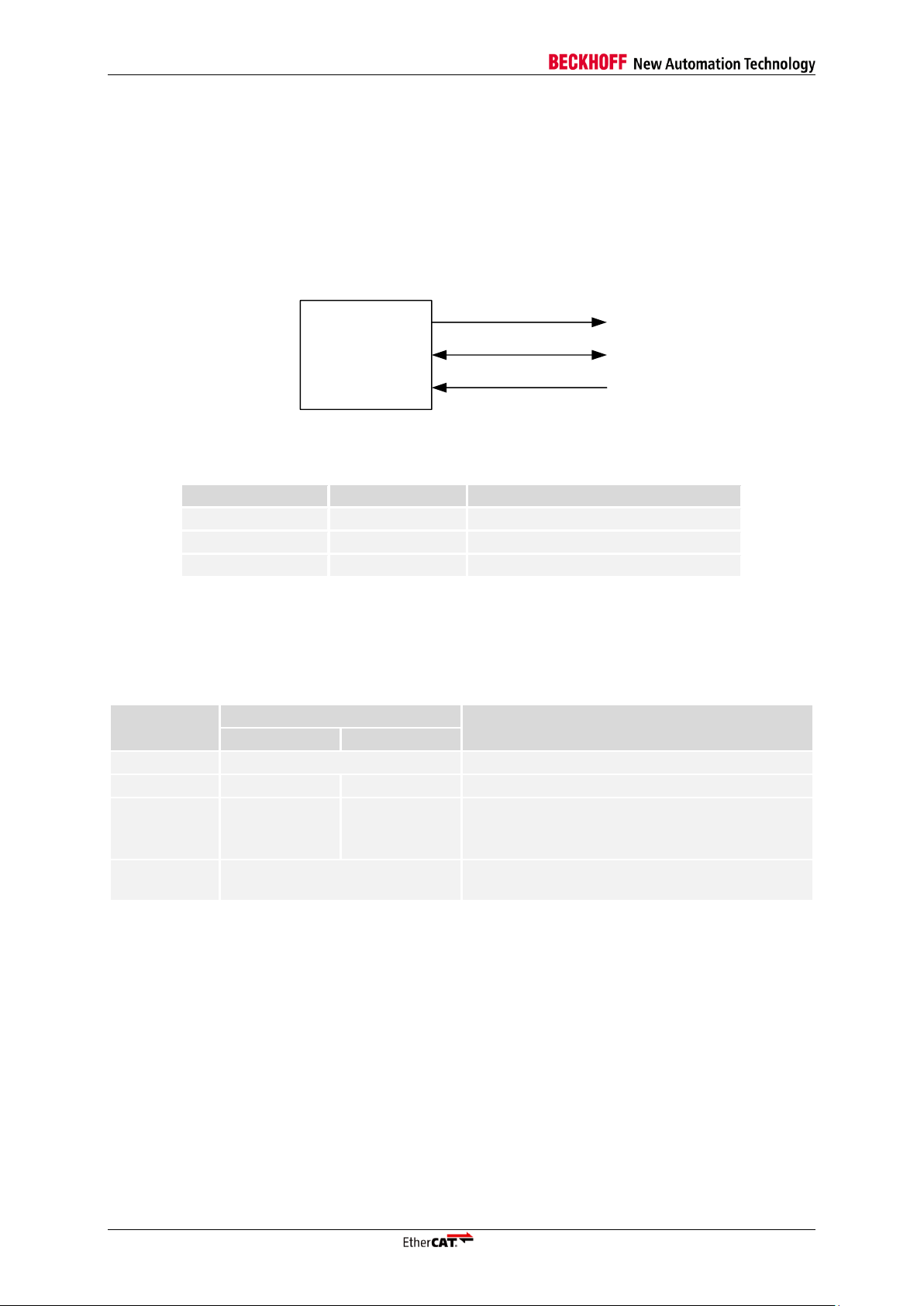

3.7.1 MII Interface LINK_MII(x)

Input signal provided by the PHY if a 100 Mbit/s (Full Duplex) link is established. LINK_MII(x) is active

low.

RX_CLK(x)

MII Receive Clock.

RX_DV(x)

MII receive data valid.

RX_D(x)[3:0]

MII receive data.

RX_ERR(x)

MII receive error.

TX_ENA(x)

MII transmit enable output.

TX_D(x)[3:0]

MII transmit data.

MI_CLK

PHY Management Interface clock.

3.7.1.1 CLK25OUT Signal CLK25OUT

The ET1200 has to provide an Ethernet PHY with a 25 MHz clock signal (CLK25OUT) if a 25 MHz

crystal is used for clock generation. In case a 25 MHz oscillator is used, CLK25OUT is not necessary,

because the Ethernet PHY and the ET1200 can share the oscillator output. CLK25OUT is not

available at PDI[6]/CLK25OUT in chip mode 00 unless the MII bridge port is configured via SII

EEPROM. With the MII bridge port, CLK25OUT is available regardless of C25ENA. For chip modes

10/11, PDI[7] may be configured to deliver CLK25OUT by pulling up the PDI[9]/TX_D[1]/C25ENA

configuration signal.

CLK25OUT provides a clock signal – if configured – during external or ECAT reset, clock output is

only turned off during power-on reset.

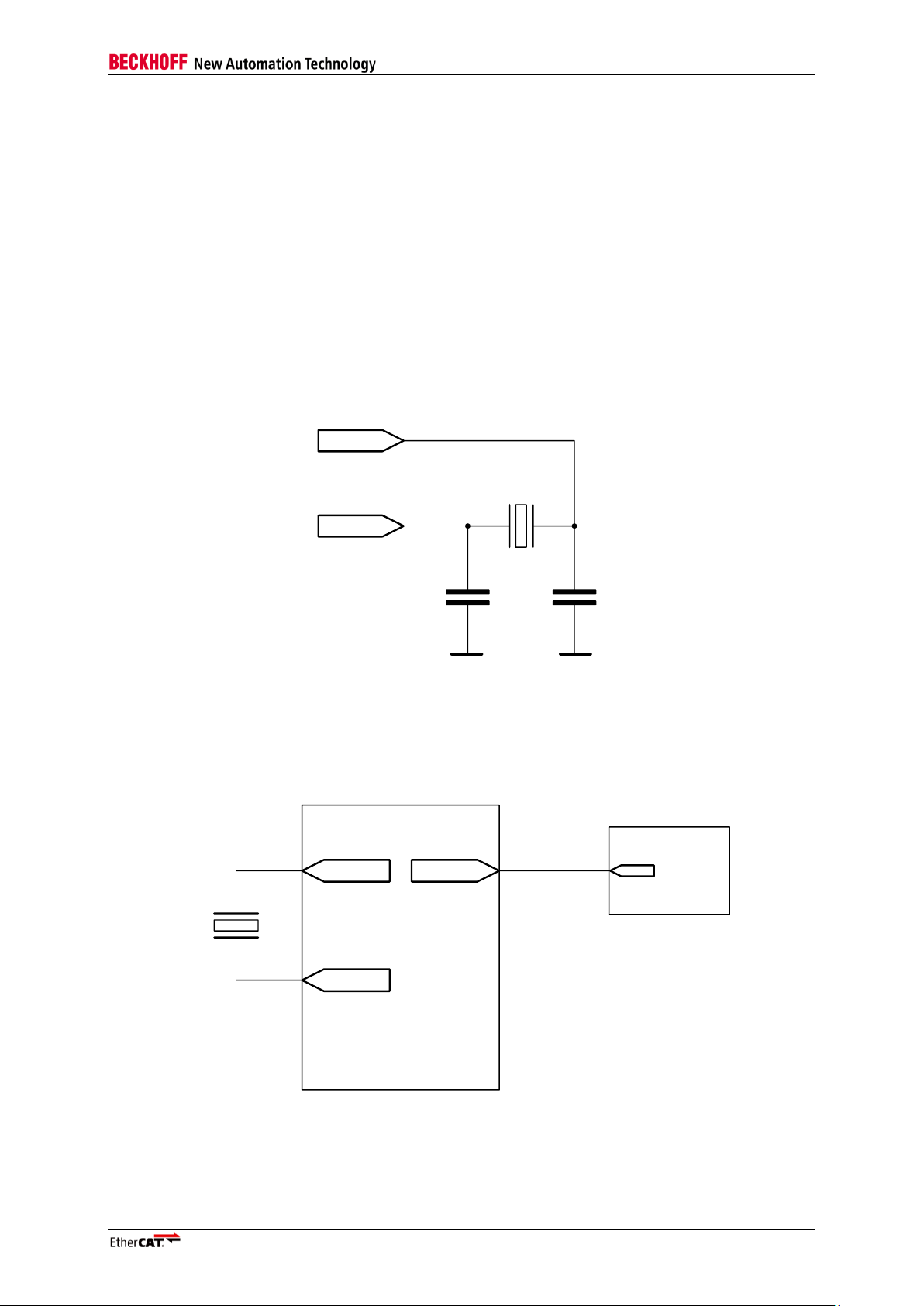

3.7.2 EBUS Interface

The EBUS ports of the ET1200 are open failsafe, i.e., the ET1200 detects if an EBUS port is

unconnected and closes the port internally (no physical link).

EBUS(x)-RX+/EBUS(x)-RX-

EBUS LVDS receive signals. EBUS_RX+ pins incorporate a pull-down resistor R

pins incorporate a pull-up resistor R

, even if the pins are not configured for EBUS.

LI-

and EBUS_RX-

LI+

EBUS(x)-TX+/EBUS(x)-TX-

EBUS LVDS transmit signals.

3.7.3 PDI Pins PDI[x]

The function of PDI[x] signals depends on the configuration stored in the device SII EEPROM. PDI

signals are not driven (high impedance) until the EEPROM is loaded. This has to be taken into

account especially for Digital Outputs.

PDI signals are not driven (high impedance) if no PDI is configured (PDI Control register

0x0140=0x00).

III-18 Slave Controller – ET1200 Hardware Description

Page 29

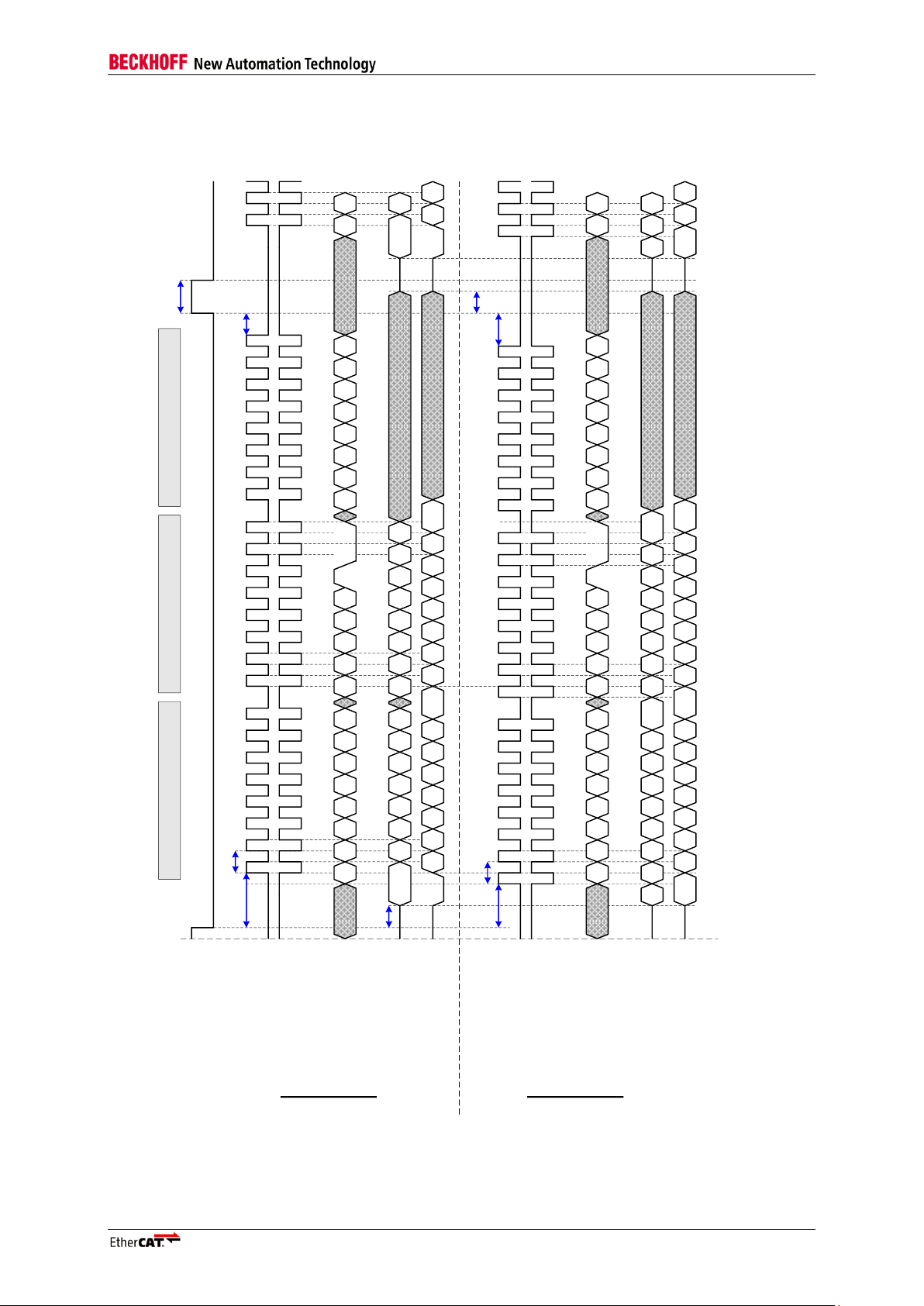

Pin Description

Pin

Pin

Configuration

MODE[1:0]=00

Internal

PU/PD

Name

Dir

Signal

Dir.

36

PDI[8]/TX_D[0]/PHYAD_OFF

BD

PHYAD_OFF

PDI[8]

BD

35

PDI[9]/TX_D[1]/C25_ENA

BD

C25_ENA

PDI[9]

BD

34

PDI[10]/TX_D[2]/C25_SHI[0]

BD

C25_SHI[0]

PDI[10]

BD

33

PDI[11]/TX_D[3]/C25_SHI[1]

BD

C25_SHI[1]

PDI[11]

BD 32

PDI[12]/RX_CLK

BD

PDI[12]

BD

31

PDI[13]/RX_DV

BD

PDI[13]

BD

30

PDI[14]/RX_D[0]

BD

PDI[14]

BD

29

PDI[15]/RX_D[1]

BD

PDI[15]

BD

28

PDI[16]/RX_D[2]

BD

PDI[16]

BD

27

PDI[17]/RX_D[3]

BD

PDI[17]

BD 2

EBUS{1}-RX-/LINK_MII

LI-/I

EBUS(1)-RX-

LI-

27 kΩ PU

3

EBUS{1}-RX+/RX_ERR

LI+/I

EBUS(1)-RX+

LI+

27 kΩ PD

10

EBUS{1}-TX-/MI_CLK

LO-/O

EBUS(1)-TX-

LO-

11

EBUS{1}-TX+/TX_ENA

LO+/O

EBUS(1)-TX+

LO+

8

EBUS{0}-RX-

LI- EBUS(0)-RX-

LI-

27 kΩ PU

9

EBUS{0}-RX+

LI+ EBUS(0)-RX+

LI+

27 kΩ PD

4

EBUS{0}-TX-

LO-

EBUS(0)-TX-

LO-

5

EBUS{0}-TX+

LO+

EBUS(0)-TX+

LO+

Pin

Pin

MODE[1:0]=10

MODE[1:0]=11

Internal

PU/PD

Name

Dir

Signal

Dir.

Signal

Dir.

36

PDI[8]/TX_D[0]/PHYAD_OFF

BD

TX_D(0)[0]

O

TX_D(1)[0]

O

35

PDI[9]/TX_D[1]/C25_ENA

BD

TX_D(0)[1]

O

TX_D(1)[1]

O

34

PDI[10]/TX_D[2]/C25_SHI[0]

BD

TX_D(0)[2]

O

TX_D(1)[2]

O

33

PDI[11]/TX_D[3]/C25_SHI[1]

BD

TX_D(0)[3]

O

TX_D(1)[3]

O

32

PDI[12]/RX_CLK

BD

RX_CLK(0)

I

RX_CLK(1)

I

31

PDI[13]/RX_DV

BD

RX_DV(0)

I

RX_DV(1)

I 30

PDI[14]/RX_D[0]

BD

RX_D(0)[0]

I

RX_D(1)[0]

I

29

PDI[15]/RX_D[1]

BD

RX_D(0)[1]

I

RX_D(1)[1]

I

28

PDI[16]/RX_D[2]

BD

RX_D(0)[2]

I

RX_D(1)[2]

I

27

PDI[17]/RX_D[3]

BD

RX_D(0)[3]

I

RX_D(1)[3]

I

2

EBUS{1}-RX-/LINK_MII

LI-/I

LINK_MII(0)

I

LINK_MII(1)

I

27 kΩ PU

3

EBUS{1}-RX+/RX_ERR

LI+/I

RX_ERR(0)

I

RX_ERR(1)

I

27 kΩ PD

10

EBUS{1}-TX-/MI_CLK

LO-/O

MI_CLK

O

MI_CLK O

11

EBUS{1}-TX+/TX_ENA

LO+/O

TX_ENA(0)

O

TX_ENA(1)

O

8 EBUS{0}-RX-

LI-

EBUS(1)-RX-

LI-

EBUS(0)-RX-

LI-

27 kΩ PU

9

EBUS{0}-RX+

LI+

EBUS(1)-RX+

LI+

EBUS(0)-RX+

LI+

27 kΩ PD

4

EBUS{0}-TX-

LO-

EBUS(1)-TX-

LO-

EBUS(0)-TX-

LO-

5

EBUS{0}-TX+

LO+

EBUS(1)-TX+

LO+

EBUS(0)-TX+

LO+

CPU_CLK

The ET1200 can provide a clock signal for µControllers on pin PDI[7]/CPU_CLK. The CPU_CLK

output setting is controlled by the CLK_MODE configuration pin. If CPU_CLK is enabled, PDI[7] is not

available for the PDI, i.e., I/O[7] is not available for Digital I/O PDI.

CPU_CLK provides a clock signal – if configured – during external or ECAT reset, clock output is only

turned off during power-on reset.

3.7.4 Port 0/1 and PDI[17:8] Signals

Table 22 and Table 23 show the port 0/1 and PDI signals used for ports 0 and 1.

Table 22: Port 0/1 and PDI signals (Configuration and chip mode 00)

Table 23: Port 0/1 and PDI signals (chip modes 10/11)

Slave Controller – ET1200 Hardware Description III-19

Page 30

Pin Description

Pin

Pin

PDI, C25ENA=0,

CLK_MODE=00

PDI, C25ENA=1,

CLK_MODE/=00

Internal

PU/PD

Name

Dir.

Signal

Dir.

Signal

Dir.

46

PDI[0]

BD/LO+

PDI[0]

BD/LO+

PDI[0]

BD/LO+

45

PDI[1]

BD/LO-

PDI[1]

BD/LO-

PDI[1]

BD/LO-

44

PDI[2]

BD/LI+

PDI[2]

BD/LI+

PDI[2]

BD/LI+

27 kΩ PD

43

PDI[3]

BD/LI-

PDI[3]

BD/LI-

PDI[3]

BD/LI-

27 kΩ PU

40

PDI[4]

BD

PDI[4]

BD

PDI[4]

BD 39

PDI[5]

BD

PDI[5]

BD

PDI[5]

BD

38

PDI[6]/CLK25OUT

BD

PDI[6]

BD

CLK25OUT

O

37

PDI[7]/CPU_CLK

BD

PDI[7]

BD

CPU_CLK

O

3.7.5 PDI[7:0] Signals

Table 24 shows the PDI[7:0] signals. The direction of all PDI pins depends on the PDI configuration

stored in the SII EEPROM.

Table 24: PDI pins

3.8 PDI Signal Pinout depending on selected PDI

The PDI signal pinout depends on the selected PDI (SII EEPROM). The PDI selection and PDI signal

pinout is subject to restrictions introduced by the port configuration. Digital I/O and SPI PDI are

available in any configuration – although the I/O width can be reduced depending on the configuration.

The MII bridge port PDIs is only available in chip mode 00.

Refer to PDI descriptions for further PDI and PDI signal descriptions.

The SPI PDI supports additional general purpose output signals, which are not part of the SPI PDI

description:

GPO[x]

General purpose output signals.

III-20 Slave Controller – ET1200 Hardware Description

Page 31

Pin Description

PDI Signal

MODE[1:0]=00

MODE[1:0]=10/11

Signal

Dir.

Signal

Dir.

PDI[0]

I/O[0]

BD

I/O[0]

BD

PDI[1]

I/O[1]

BD

I/O[1]

BD

PDI[2]

I/O[2]

BD

I/O[2]

BD

PDI[3]

I/O[3]

BD

I/O[3]

BD

PDI[4]

I/O[4]

BD

I/O[4]

BD

PDI[5]

I/O[5]

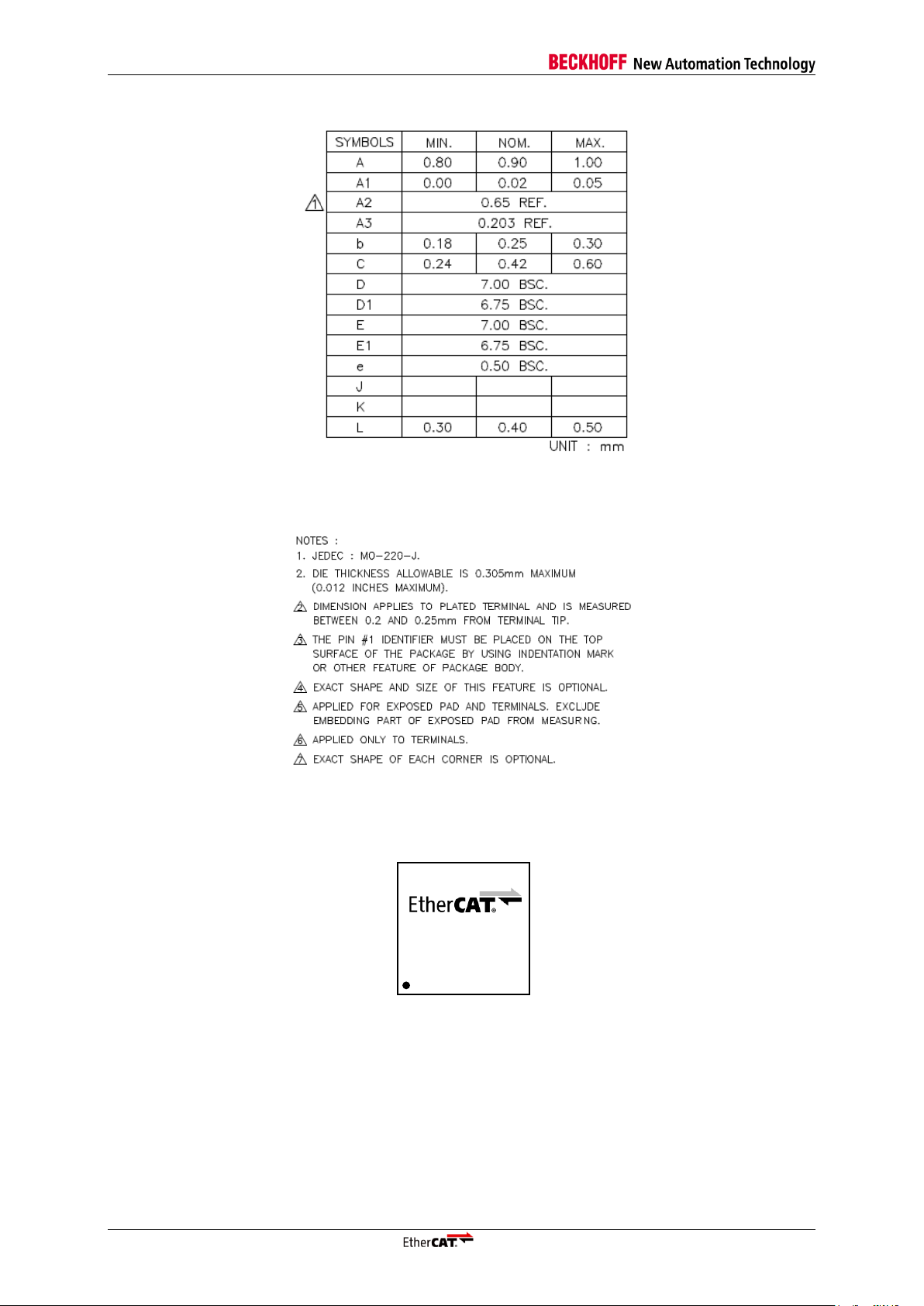

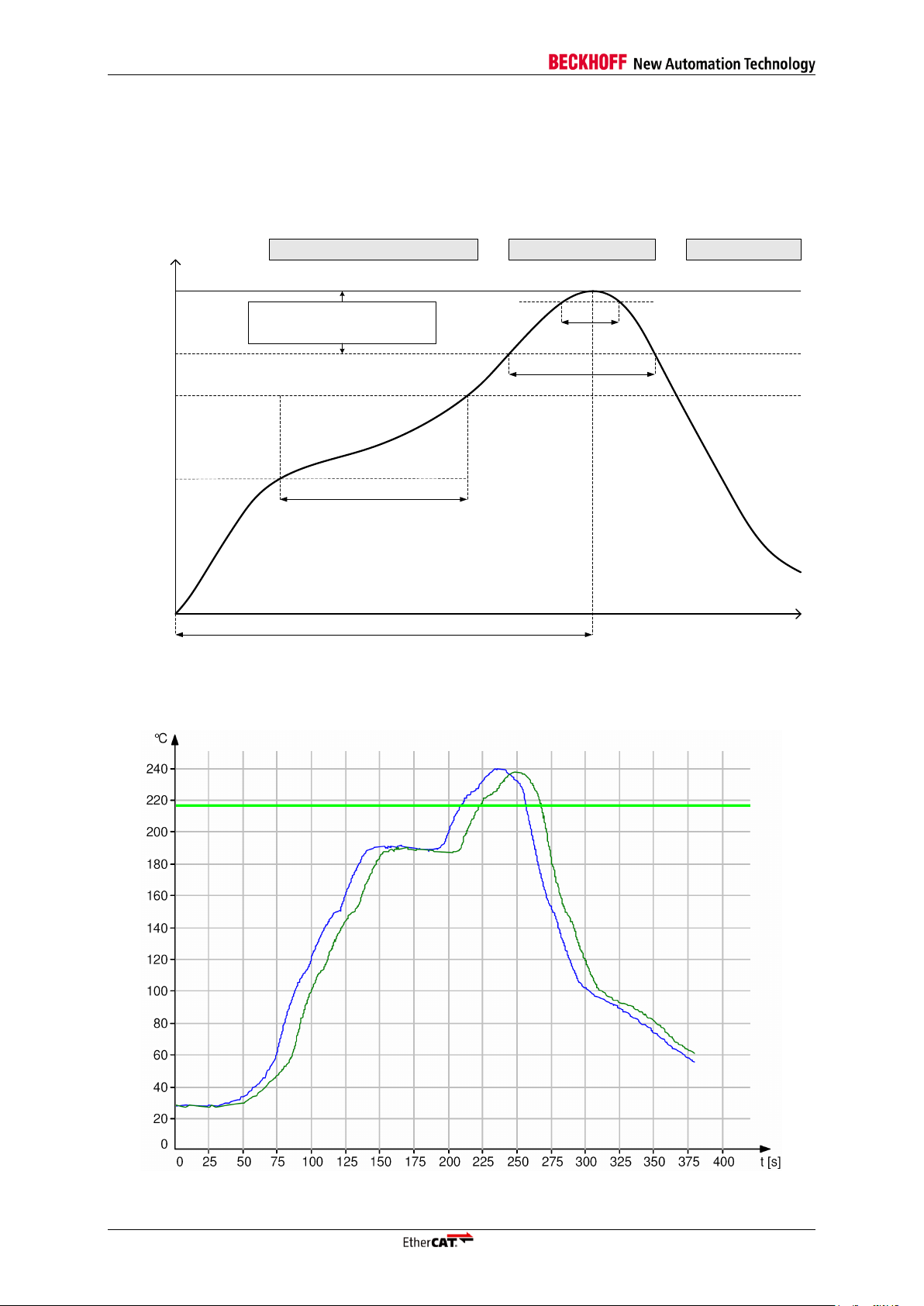

BD