Page 1

Documentation

EP9214-0023 and EP9224-0023

Power Distribution for EtherCAT Box Modules

Version:

Date:

2.3.1

2018-04-10

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................5

1.1 Notes on the documentation........................................................................................................... 5

1.2 Safety instructions .......................................................................................................................... 6

1.3 Documentation issue status............................................................................................................ 7

2 Product overview.......................................................................................................................................8

2.1 EtherCAT Box - Introduction........................................................................................................... 8

2.2 EP9214 - Introduction ................................................................................................................... 10

2.3 EP9224 - Introduction ................................................................................................................... 11

2.4 Technical data .............................................................................................................................. 12

3 Mounting and cabling .............................................................................................................................13

3.1 Mounting ....................................................................................................................................... 13

3.1.1 Dimensions ......................................................................................................................13

3.1.2 Mounting ..........................................................................................................................14

3.1.3 Nut torque for connectors ................................................................................................15

3.2 EtherCAT ...................................................................................................................................... 16

3.2.1 EtherCAT connection.......................................................................................................16

3.2.2 EtherCAT - Fieldbus LEDs...............................................................................................18

3.3 Power supply ................................................................................................................................ 20

3.3.1 Power Connection............................................................................................................20

3.3.2 Power LEDs .....................................................................................................................22

3.3.3 Power cable conductor losses M8 ...................................................................................23

3.3.4 Power cable 7/8" ..............................................................................................................24

3.3.5 Conductor losses 7/8" ......................................................................................................26

3.3.6 Power outputs ..................................................................................................................27

3.4 Cabling.......................................................................................................................................... 28

3.5 Status LEDs and status bits.......................................................................................................... 30

3.6 Monitoring and reset contacts....................................................................................................... 31

4 Comissioning and Configuration...........................................................................................................32

4.1 Inserting into the EtherCAT network............................................................................................. 32

4.2 Configuration via TwinCAT ........................................................................................................... 35

4.3 Operation with or without EtherCAT master ................................................................................. 43

4.4 Switch of behavior ........................................................................................................................ 44

4.4.1 Switch-off characteristics .................................................................................................44

4.4.2 Current limitation, switching the load circuits off ..............................................................46

4.4.3 Setting the current limitation ............................................................................................47

4.4.4 Status LEDs and status bits.............................................................................................48

4.5 EP9214-0023................................................................................................................................ 50

4.5.1 EP9214-0023 - Object description ...................................................................................50

4.5.2 EP9214-0023 - Process image ........................................................................................65

4.6 EP9224-0023................................................................................................................................ 66

4.6.1 EP9224-0023 - Diagnostic functions................................................................................66

4.6.2 EP9224-0023 - Object description ...................................................................................79

4.6.3 EP9224-0023 - Process image ......................................................................................106

4.7 Restoring the delivery state ........................................................................................................ 107

5 Appendix ................................................................................................................................................109

5.1 General operating conditions...................................................................................................... 109

5.2 EtherCAT Box- / EtherCATPBox - Accessories........................................................................ 110

EP9214-0023 and EP9224-0023 3Version: 2.3.1

Page 4

Table of contents

5.3 Support and Service ................................................................................................................... 111

EP9214-0023 and EP9224-00234 Version: 2.3.1

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

Intended audience

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning these components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE®, XFC® and XTS® are registered

trademarks of and licensed by Beckhoff Automation GmbH.

Other designations used in this publication may be trademarks whose use by third parties for their own

purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, DE102004044764, DE102007017835 with corresponding applications or

registrations in various other countries.

The TwinCAT Technology is covered, including but not limited to the following patent applications and

patents: EP0851348, US6167425 with corresponding applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

EP9214-0023 and EP9224-0023 5Version: 2.3.1

Page 6

Foreword

1.2 Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

Description of symbols

In this documentation the following symbols are used with an accompanying safety instruction or note. The

safety instructions must be read carefully and followed without fail!

DANGER

WARNING

CAUTION

Attention

Note

Serious risk of injury!

Failure to follow the safety instructions associated with this symbol directly endangers the

life and health of persons.

Risk of injury!

Failure to follow the safety instructions associated with this symbol endangers the life and

health of persons.

Personal injuries!

Failure to follow the safety instructions associated with this symbol can lead to injuries to

persons.

Damage to the environment or devices

Failure to follow the instructions associated with this symbol can lead to damage to the environment or equipment.

Tip or pointer

This symbol indicates information that contributes to better understanding.

EP9214-0023 and EP9224-00236 Version: 2.3.1

Page 7

1.3 Documentation issue status

Version Comment

2.3.1 • chapter Switch of behavior updated

• Nut torque for connectors updated

2.3.0 • Cabling added

2.2.0 • Operation with or without EtherCAT master updated

2.1.0 • Power Connection updated

2.0.0 • migration

• chapter mounting and cabling updated

• chapter nut torque for connectors extended

• chapter switch off behavior updated

• object descriptions updated

1.1.0 • EP9224-0023 added

1.0.0 • first release

0.1 • preliminary version (only German available)

Firm and hardware version

Foreword

The documentation refers to the firm and hardware status that was valid at the time it was prepared.

The properties of the modules are subject to continuous development and improvement. Modules having

earlier production statuses cannot have the same properties as modules with the latest status. Existing

properties, however, are always retained and are not changed, so that these modules can always be

replaced by new ones.

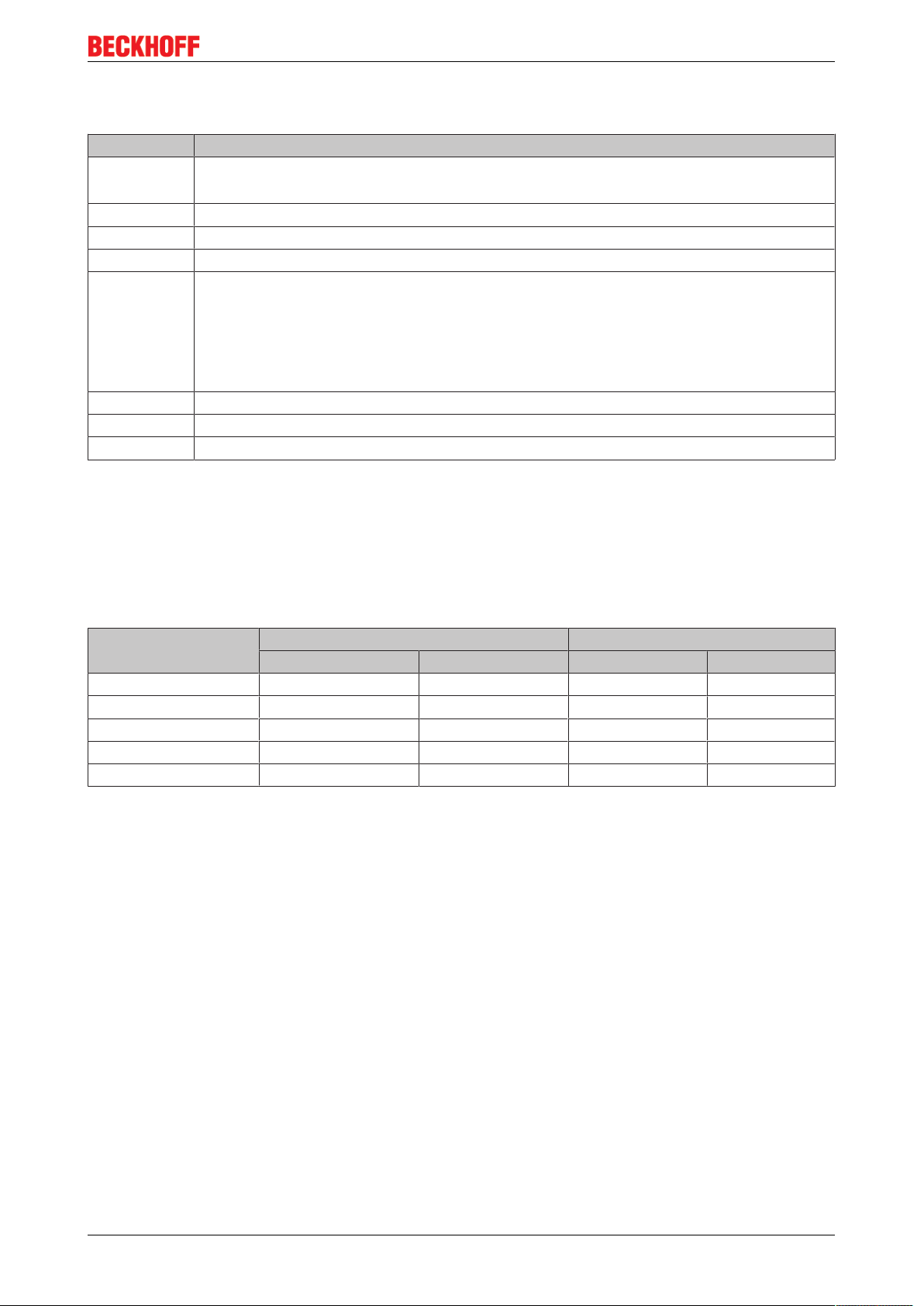

Documentation

version

2.1.0 09 11 04 10

2.0.0 09 10 04 10

1.1.0 09 06 04 06

1.0.0 07 03 - -

0.1 07 03 - -

The firmware and hardware version (delivery state) can be found in the batch number (D number) printed at

the side of the EtherCAT Box.

Syntax of the batch number (D number)

WWYYFFHH

WW - week of production (calendar week)

YY - year of production

FF - firmware version

HH - hardware version

EP9214-0023 EP9224-0023

firmware hardware firmware hardware

Example with ser. no.: 55 09 01 00:

55 - week of production 55

09 - year of production 2009

01 - firmware version 01

00 - hardware version 00

EP9214-0023 and EP9224-0023 7Version: 2.3.1

Page 8

Product overview

2 Product overview

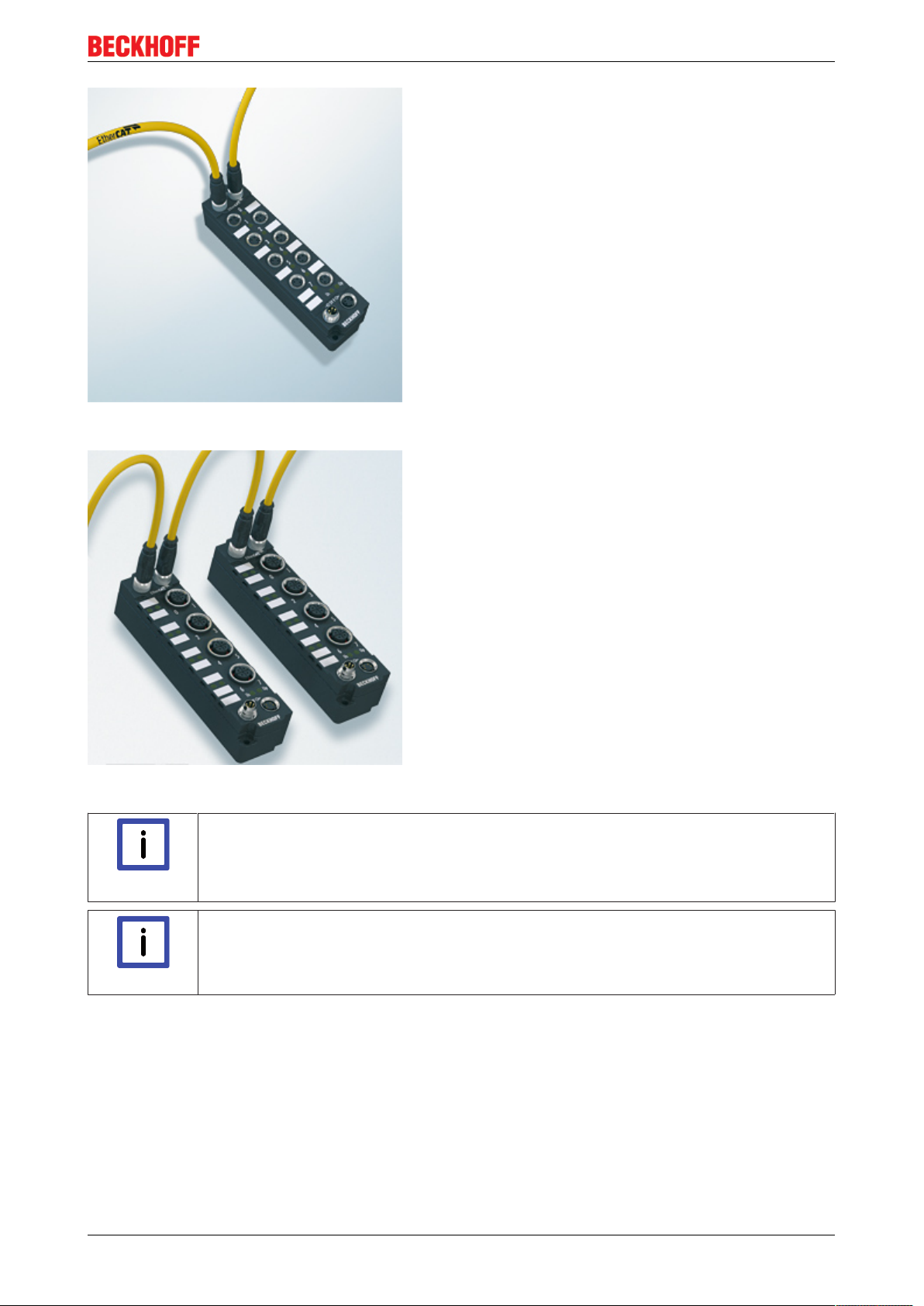

2.1 EtherCAT Box - Introduction

The EtherCAT system has been extended with EtherCAT Box modules with protection class IP67. Through

the integrated EtherCAT interface the modules can be connected directly to an EtherCAT network without an

additional Coupler Box. The high-performance of EtherCAT is thus maintained into each module.

The extremely low dimensions of only 126x30x26.5 mm (hxw xd) are identical to those of the Fieldbus

Box extension modules. They are thus particularly suitable for use where space is at a premium. The small

mass of the EtherCAT modules facilitates applications with mobile I/O interface (e.g. on a robot arm). The

EtherCAT connection is established via screened M8connectors.

Fig.1: EtherCAT Box Modules within an EtherCAT network

The robust design of the EtherCAT Box modules enables them to be used directly at the machine. Control

cabinets and terminal boxes are now no longer required. The modules are fully sealed and therefore ideally

prepared for wet, dirty or dusty conditions.

Pre-assembled cables significantly simplify EtherCAT and signal wiring. Very few wiring errors are made, so

that commissioning is optimized. In addition to pre-assembled EtherCAT, power and sensor cables, fieldconfigurable connectors and cables are available for maximum flexibility. Depending on the application, the

sensors and actuators are connected through M8 or M12connectors.

The EtherCAT modules cover the typical range of requirements for I/O signals with protection class IP67:

• digital inputs with different filters (3.0ms or 10μs)

• digital outputs with 0.5 or 2A output current

• analog inputs and outputs with 16bit resolution

• Thermocouple and RTD inputs

• Stepper motor modules

XFC (eXtreme Fast Control Technology) modules, including inputs with time stamp, are also available.

EP9214-0023 and EP9224-00238 Version: 2.3.1

Page 9

Fig.2: EtherCAT Box with M8 connections for sensors/actuators

Product overview

Fig.3: EtherCAT Box with M12 connections for sensors/actuators

Basic EtherCAT documentation

You will find a detailed description of the EtherCAT system in the Basic System Documen-

Note

tation for EtherCAT, which is available for download from our website (www.beckhoff.com)

under Downloads.

XML files

You will find XML files (XML Device Description Files) for Beckhoff EtherCAT modules on

Note

our website (www.beckhoff.com) under Downloads, in the Configuration Files area.

EP9214-0023 and EP9224-0023 9Version: 2.3.1

Page 10

Product overview

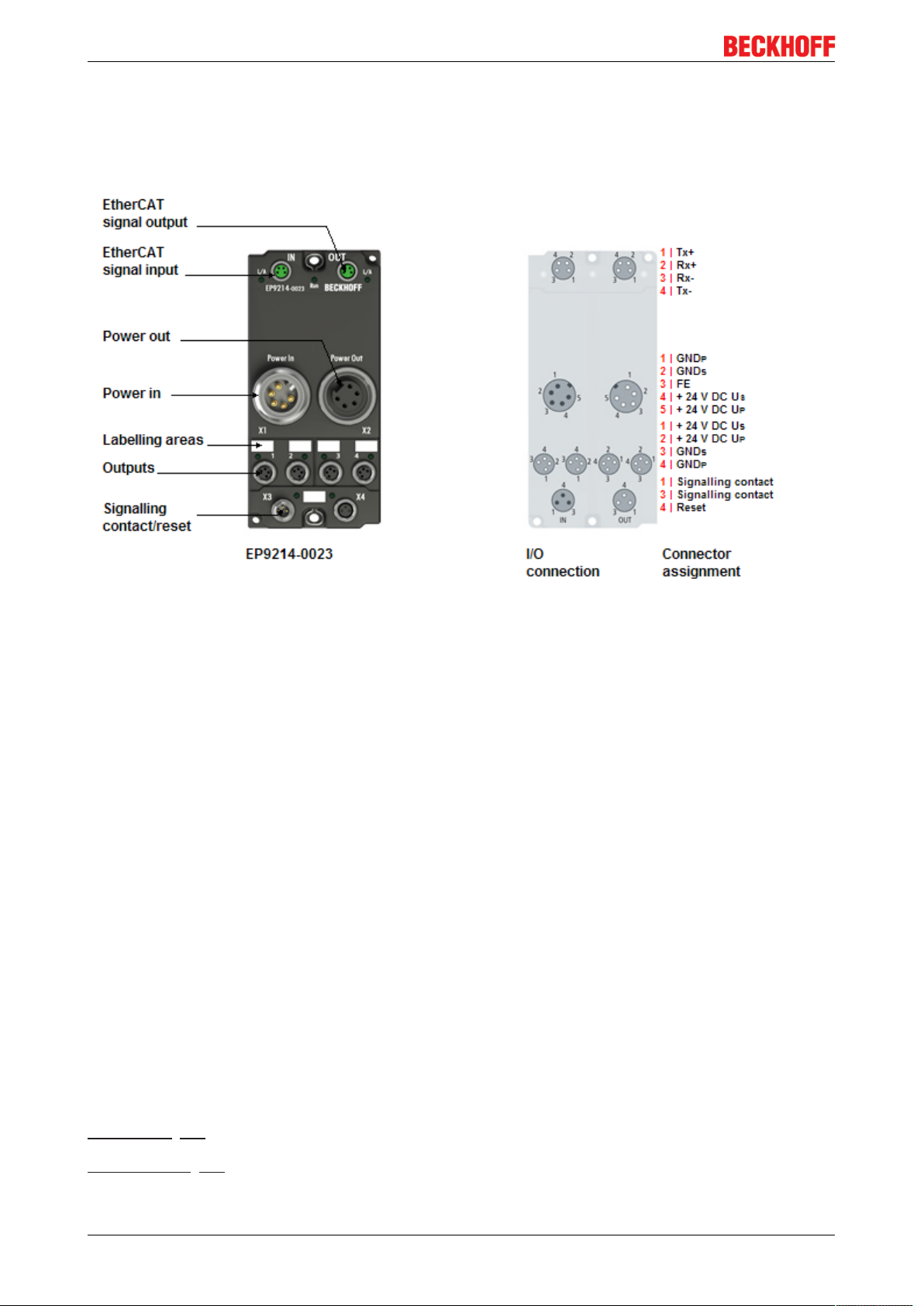

2.2 EP9214 - Introduction

Fig.4: EP9214

Power distribution for EtherCAT Box (24VDC)

The EP9214-0023 enables connection of four power supply branches. In each branch the current

consumption for the control voltage US and the peripheral voltage UP is monitored, limited, and, if necessary,

switched off.

The power distribution is supplied via a 7/8" connector with up to 16A (per voltage supply US/UP). Several

modules can be configured in a cascade arrangement. In the event of a short-circuit in one of the four

outputs, the affected output is switched off. The supply for the other branches remains active. The switch-off

and control is done in such a way that the input voltage does not fall below 21V or other modules are going

down, caused by undervoltage.

During startup consumers with large capacities can be added without problem.

The master can read diagnostic messages from the individual channels via the EtherCAT interface.

Independent switching of individual consumer branches is also possible via the EtherCAT master.

In delivery state the eight outputs of the box (4 times Us, 4 times Up) are activated to enable operation

without EtherCAT.

After an error caused the switch off of a channel, this channel remains switched of when you try to switch it

on again and has to be set back actively by the EtherCAT master or a hardware reset at the box (lower M8

socket).

Quick links

Installation [}13]

Configuration [}32]

EP9214-0023 and EP9224-002310 Version: 2.3.1

Page 11

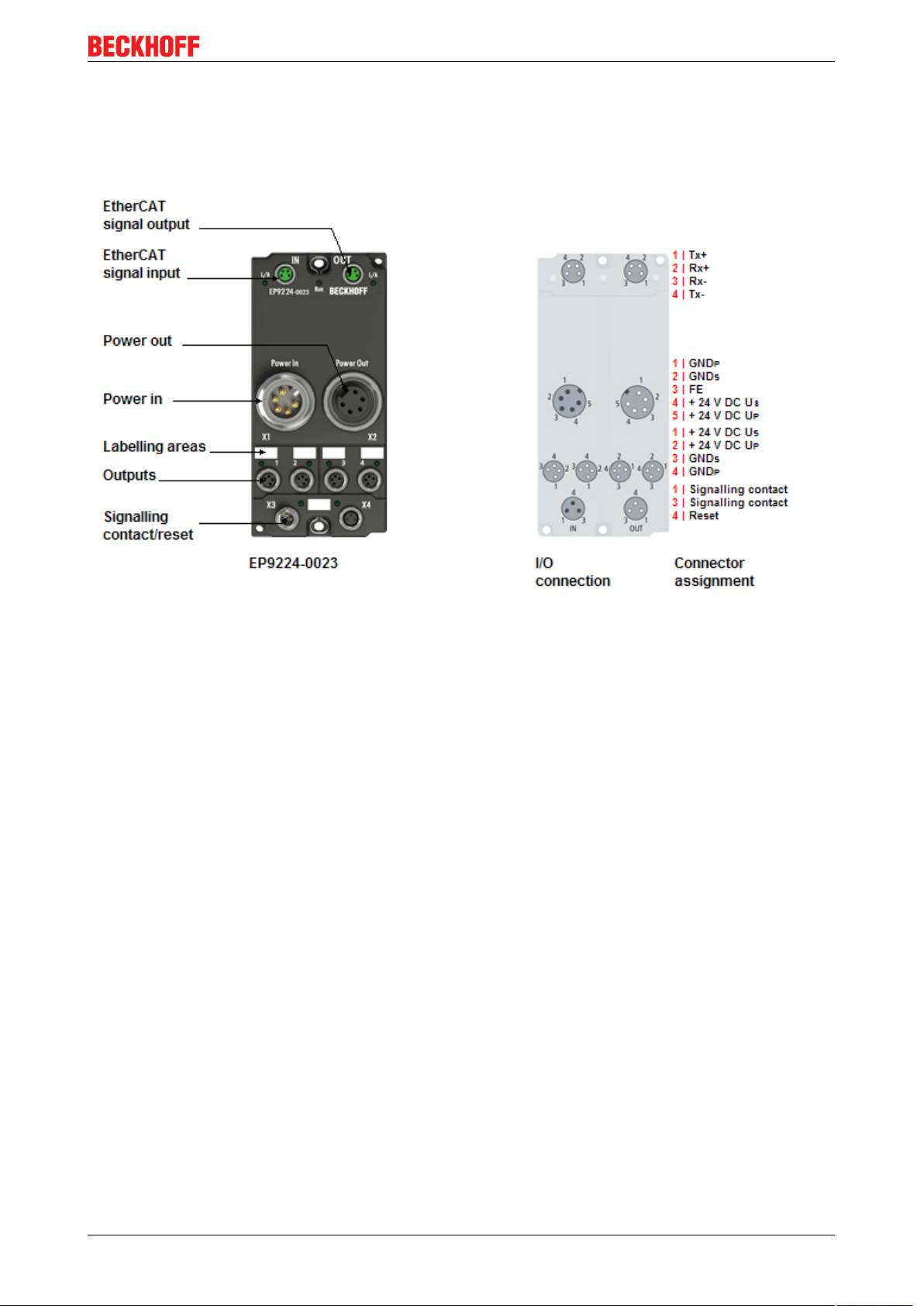

2.3 EP9224 - Introduction

Product overview

Fig.5: EP9224

Power distribution for EtherCAT Box (24VDC) with data logging

The EP9224-0023 enables connection of four power supply branches. In each branch the current

consumption for the control voltage US and the peripheral voltage UP is monitored, limited, and, if necessary,

switched off.

The power distribution is supplied via a 7/8" connector with up to 16 A (per voltage supply US/UP). Several

modules can be configured in a cascade arrangement. In the event of a short-circuit in one of the four

outputs, the affected output is switched off. The supply for the other branches remains active. The switch-off

and control is done in such a way that the input voltage does not fall below 21 V or other modules are going

down, caused by undervoltage.

During startup consumers with large capacities can be added without problem.

The master can read diagnostic messages from the individual channels via the EtherCAT interface.

Independent switching of individual consumer branches is also possible via the EtherCAT master.

In delivery state the eight outputs of the box (4 times Us, 4 times Up) are activated to enable operation

without EtherCAT.

After an error caused the switch off of a channel, this channel remains switched of when you try to switch it

on again and has to be set back actively by the EtherCAT master or a hardware reset at the box (lower M8

socket).

Additional to this basic functionality that is also provided by EP9214, the EP9224 displays the voltage values

of PowerIn supply and all current values of inputs and outputs within the process data.

The box has got an internal log file, that is writing the system values continuously into a ring buffer. This data

logging has to be activated at the startup.

In error case it is stopped, so a history of the system parameters from before the error case can be read out.

This enables a much quicker error localization.

EP9214-0023 and EP9224-0023 11Version: 2.3.1

Page 12

Product overview

Quick links

Installation [}13]

Configuration [}35]

2.4 Technical data

Technical data EP9214-0023 EP9224-0023

Rated voltage 24VDC (-15%/ +20%)

Power supply Feed: Plug 7/8", max. 16A for each Us/Up

Onward connection: Socket 7/8", max. 16A for each Us/Up

Number of load outputs 4 x M8, for each Us and Up

Voltage drop VON in the load

circuits

Parallel connection of several load

outputs

Overload switch-off dependent on selected load curve (20ms at 3xIN, see time/current

Temperature switch-off Internal temperature switch-off

Switch-on delay 10, 100 or 200ms (adjustable via CoE)

Selectivity in case of an error, the channel concerned is switched off

Signalling contact 1

Reset contact 1

Connections for signal and reset

contacts

Fieldbus EtherCAT

Fieldbus connection 2 x M8 sockets, screened, marked green

Electrical isolation Control voltage/fieldbus: 500V

Supply of the module circuitry from the control voltage Us

Current consumption of the module

circuitry

Process image Inputs: 5 x 16bit

Data logging - 40 samples ( 1ms - 1000ms

Permissible ambient temperature

during operation

Permissible ambient temperature

during storage

Vibration / shock resistance conforms to EN60068-2-6 / EN60068-2-27

EMC immunity/emission conforms to EN61000-6-2 / EN61000-6-4

Dimensions 126mm x 60mm x 40 mm

Weight approx. 450g

Installation position variable

Protection class IP65, IP66, IP67 (according to EN 60529)

Approvals CE, UL in preparation

90mV / Ampere

not permissible

characteristics)

in : 1 x M8 plug

out : 1 x M8 socket

typically 110mA from Us,

typically 40mA from Up

Outputs: 5 x 16bit

-25°C ... +60°C

-25 °C... +85°C

Inputs: 16x16Bit

Outputs: 5x16Bit

sample time)

EP9214-0023 and EP9224-002312 Version: 2.3.1

Page 13

3 Mounting and cabling

3.1 Mounting

3.1.1 Dimensions

Mounting and cabling

Fig.6: Dimensions of the EtherCAT Box Modules

All dimensions are given in millimeters.

EP9214-0023 and EP9224-0023 13Version: 2.3.1

Page 14

Mounting and cabling

Housing properties

EtherCAT Box lean body wide body

Housing material PA6 (polyamide)

Casting compound Polyurethane

Mounting two fastening holes Ø3mm for M3 two fastening holes Ø3mm for M3

two fastening holes Ø4,5mm for M4

Metal parts Brass, nickel-plated

Contacts CuZn, gold-plated

Power feed through max. 4A

Installation position variable

Protection class IP65, IP66, IP67 (conforms to EN 60529) when screwed together

Dimensions

(HxWxD)

Weight approx. 125g, depending on module

ca. 126 x 30 x 26,5mm ca. 126 x 60 x 26,5mm

approx. 250g, depending on module type

type

3.1.2 Mounting

EP9214 modules are mounted using two M3 bolts in the mounting holes located in the corners or using two

M4 bolts in the centrally located mounting holes.

The bolts must be longer than 15 mm. The mounting holes in the modules have no thread.

Protect connectors against soiling

Protect all module connections from soiling during installation!The protection classes IP65,

Note

IP66, IP67 (in accordance with EN 60529) are ensured only if all connectors are wired or

sealed! Unused connectors must be sealed with suitable protective caps (see Beckhoff catalogue for connector sets and protective caps)!

Cooling plate

The EP9214 module has a cooling plate on the underside. For the effective dissipation of

Note

Note when mounting that the overall height is increased further by the fieldbus connections. See the

Accessories section

the resultant power loss, the box must be bolted to a metal base, e.g. the machine bed, if

possible making contact over the entire surface.A temperature-related automatic switch-off

of the box can occur if care is not taken to ensure that the power loss from the module is

dissipated via the cooling plate. A corresponding temperature error bit is then set!

EP9214-0023 and EP9224-002314 Version: 2.3.1

Page 15

Mounting and cabling

3.1.3 Nut torque for connectors

M8 connectors

It is recommended to pull the M8 connectors tight with a nut torque of 0.4 Nm. When using the torque control

screwdriver ZB8800 is also a max. torque of 0.5Nm permissible.

Fig.7: EtherCAT Box with M8 connectors

M12 connectors

It is recommended to pull the M12 connectors tight with a nut torque of 0.6 Nm.

Fig.8: EtherCAT Box with M8 and M12 connectors

EP9214-0023 and EP9224-0023 15Version: 2.3.1

Page 16

Mounting and cabling

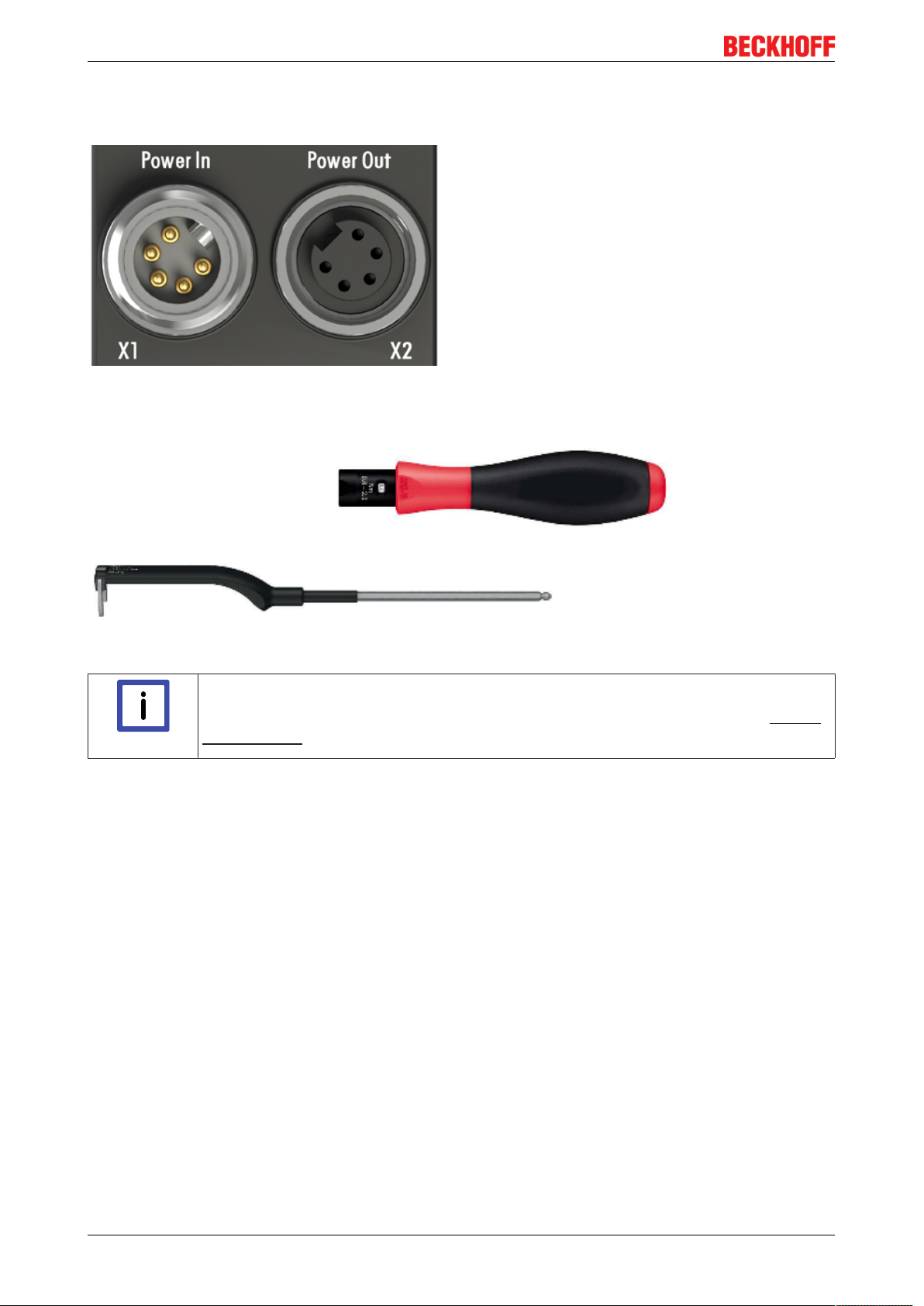

7/8" plug connectors

We recommend fastening the 7/8" plug connectors with a torque of 1.5Nm.

Fig.9: 7/8" plug connectors

Torque socket wrenches

Fig.10: ZB8801 torque socket wrench

Ensure the right torque

Use the torque socket wrenches available by Beckhoff to pull the connectors tight (ZB8800,

Note

ZB8801-0000)!

3.2 EtherCAT

3.2.1 EtherCAT connection

For the incoming and ongoing EtherCAT connection,

• the EtherCAT Box (EPxxxx) has two M8 sockets, marked in green

• the Coupler Box (FBB-x110) has two M12 sockets

EP9214-0023 and EP9224-002316 Version: 2.3.1

Page 17

Fig.11: EtherCAT Box: M8 (30mm housing)

Mounting and cabling

Fig.12: EtherCAT Box: M8 60mm housing (EP9214 for example )

Fig.13: Coupler Box: M12

Assignment

There are various different standards for the assignment and colors of connectors and cables for Ethernet/

EtherCAT.

EP9214-0023 and EP9224-0023 17Version: 2.3.1

Page 18

Mounting and cabling

Ethernet/EtherCAT Plug connector Cable Standard

Signal Description M8 M12 RJ45

Tx + Transmit Data+ Pin 1 Pin 1 Pin 1 yellow

Tx - Transmit Data- Pin 4 Pin 3 Pin 2 orange

Rx + Receive Data+ Pin 2 Pin 2 Pin 3 white

Rx - Receive Data- Pin 3 Pin 4 Pin 6 blue

1

ZB9010, ZB9020,

ZB9030, ZB9032,

ZK1090-6292,

ZK1090-3xxx-xxxx

2

2

2

2

ZB9031 and old

versions

of ZB9030, ZB9032,

ZK1090-3xxx-xxxx

orange/white

orange

blue/white

3

blue

3

3

3

TIA-568B

white/orange

orange

white/green

green

Shield Shield Housing Shroud Screen Screen Screen

1

) colored markings according to EN 61918 in the four-pin RJ45 connector ZS1090-0003

2

) wire colors according to EN 61918

3

) wire colors

Assimilation of color coding for cable ZB9030, ZB9032 and ZK1090-3xxxxxxxx (with M8 connectors)

Note

For unification the prevalent cables ZB9030, ZB9032 and ZK1090-3xxx-xxxx this means

the pre assembled cables with M8 connectors were changed to the colors of EN61918 (yellow, orange, white, blue).So different color coding exists. But the electrical properties are

absolutely identical.

EtherCAT connectors

The following connectors can be supplied for use in Beckhoff EtherCAT systems.

Designation Plug connector Comment

ZS1090-0003 RJ45 four-pin, IP20, for field assembly

ZS1090-0004 M12 four-pin, IP67, for field assembly

ZS1090-0005 RJ45 eight-pin, IP20, for field assembly, suitable for GigaBit Ethernet

ZS1090-0006 M8 male four-pin, IP67, for field assembly, for ZB903x cable

ZS1090-0007 M8 female four-pin, IP67, for field assembly, for ZB903x cable

ZS1090-1006 M8 male four-pin, IP67, for field assembly up to OD = 6.5mm

ZS1090-1007 M8 female four-pin, IP67, for field assembly up to OD = 6.5mm

3.2.2 EtherCAT - Fieldbus LEDs

Fig.14: EtherCAT-LEDs

EP9214-0023 and EP9224-002318 Version: 2.3.1

Page 19

LED display

LED Display Meaning

IN L/A off no connection to the preceding EtherCAT module

Lit LINK: connection to the preceding EtherCAT module

flashing ACT: Communication with the preceding EtherCAT module

OUT L/A off no connection to the following EtherCAT module

Lit LINK: connection to the following EtherCAT module

flashing ACT: Communication with the following EtherCAT module

Run off Status of the EtherCAT module is Init

flashes quickly Status of the EtherCAT module is pre-operational

flashes slowly Status of the EtherCAT module is safe-operational

Lit Status of the EtherCAT module is operational

EtherCAT statuses

The various statuses in which an EtherCAT module may be found are described in the Ba-

Note

sic System Documentation for EtherCAT, which is available for download from our website

(www.beckhoff.com) under Downloads.

Mounting and cabling

EP9214-0023 and EP9224-0023 19Version: 2.3.1

Page 20

Mounting and cabling

3.3 Power supply

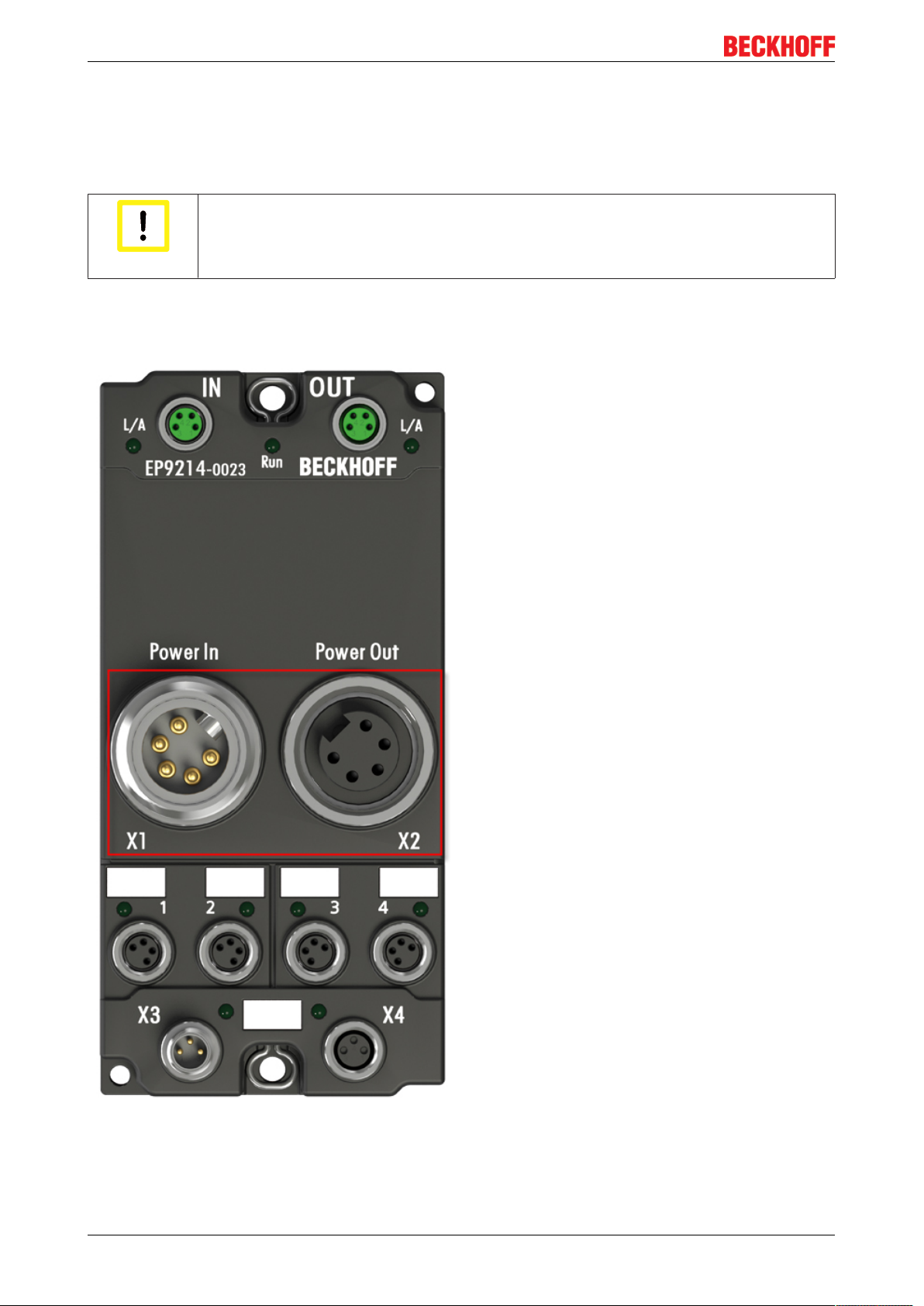

3.3.1 Power Connection

Use cables with suitable cross-sections!

Ensure that the cross-sections of the cables employed are suitable for the load circuit in-

Attention

The supply voltages are fed and relayed onward via two 7/8" connectors in the center of the modules:

• Power In: left-hand 7/8" plug for the feed-in of supply voltages

• Power Out: right-hand 7/8" socket for the onward feeding of supply voltages

puts and outputs and the respective rated current being used!

Fig.15: EP9214-0023 - 7/8" connectors

The contacts of the 7/8" plug connectors can conduct a maximum current of 16A (40°C).

Two LEDs next to the device identifier label indicate the status of the supply voltages.

EP9214-0023 and EP9224-002320 Version: 2.3.1

Page 21

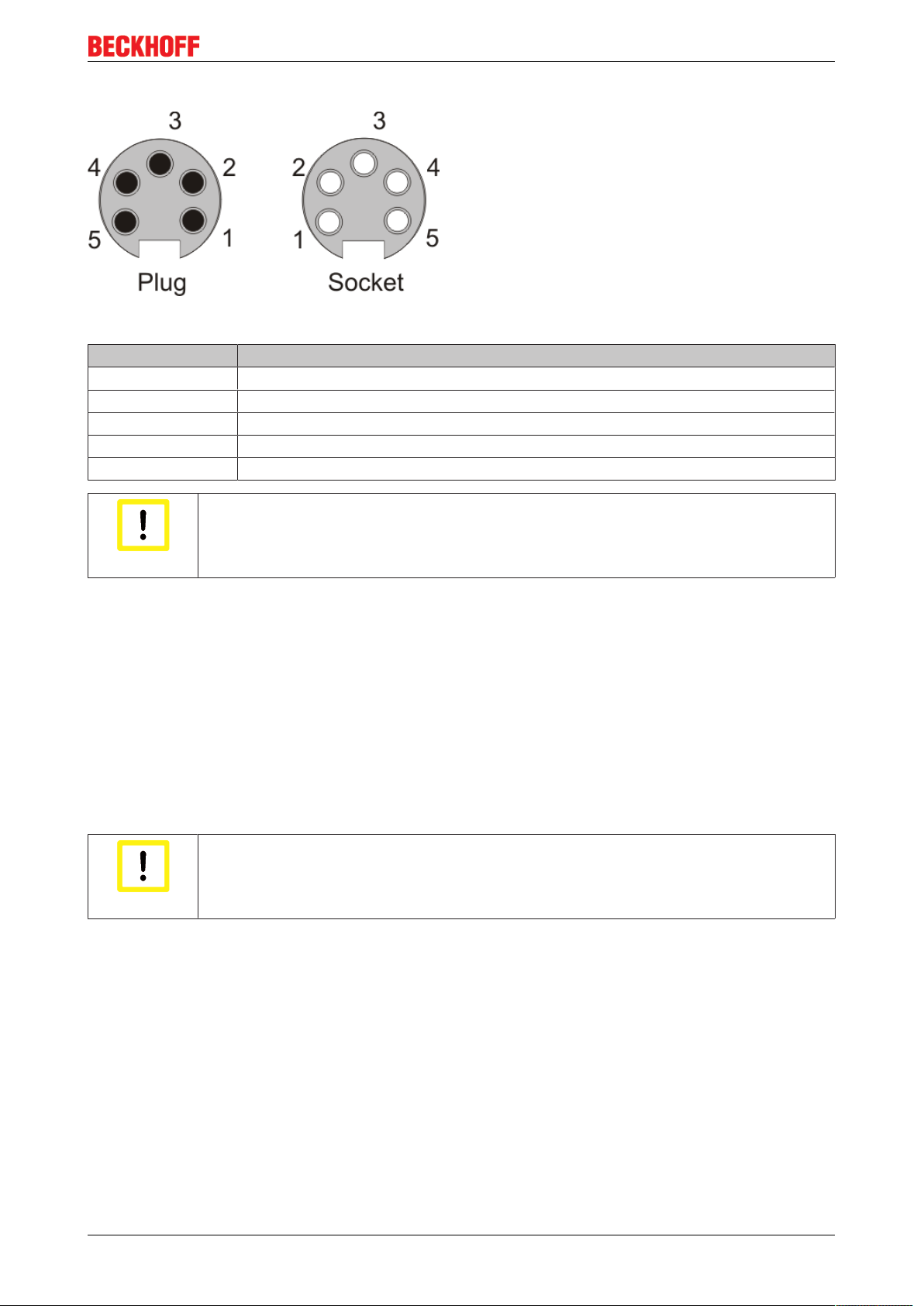

Pin assignment

Fig.16: Pin assignment of 7/8" plug connectors

Contact Voltage

1 GND Up

2 GND Us

3 FE (Functional earth), (as well as contact at central mounting holes)

4 Control voltage Us, +24V

5 Peripheral voltage Up, +24V

DC

DC

Mounting and cabling

Do not confuse the power output with the EtherCAT connection!

Never connect the power cables (M8, 24 VDC) to the green-marked EtherCAT sockets of

the EtherCAT Box Modules. This can cause the destruction of the modules!

Attention

Control voltage Us: 24V

DC

The fieldbus and the processor logic are supplied from the 24 VDC control voltage Us. The control voltage is

electrically isolated from the fieldbus circuitry.

Peripheral voltage Up: 24V

DC

The peripheral voltage Up is monitored and fed to the power outputs, but is not used in the EP9214.

Redirection of the supply voltages

The power connections Power In and Power Out are bridged in the module. Hence, the supply voltages Us

and Up can be passed from EtherCAT Box to EtherCAT Box in a simple manner.

Observe the maximum current of the 7/8" plug connectors!

Also ensure when relaying the supply voltages Us and Up onward that the maximum per-

Attention

missible current of 16 A / 40 °C for each 7/8" plug connector is not exceeded!

EP9214-0023 and EP9224-0023 21Version: 2.3.1

Page 22

Mounting and cabling

3.3.2 Power LEDs

Status-LEDs for the power supply

LED Display Meaning

Us (control voltage) off The power supply voltage, Us, is

not present

Green illuminated The power supply voltage, Us, is

present

Up (peripheral voltage) off The power supply voltage, Up, is

not present

Green illuminated The power supply voltage, Up, is

present

EP9214-0023 and EP9224-002322 Version: 2.3.1

Page 23

Mounting and cabling

3.3.3 Power cable conductor losses M8

The ZK2020-xxxx-yyyy power cables should not exceed the total length of 15m at 4A (with continuation).

When planning the cabling, note that at 24V nominal voltage, the functionality of the module can no longer

be assured if the voltage drop reaches 6V. Variations in the output voltage from the power supply unit must

also be taken into account.

Fig.17: Power cable conductor losses

Example

8m power cable with 0.34mm² cross-section has a voltage drop of 3.2V at 4A.

EP92x4 Power Distribution Modules

With EP9214 and EP9224 Power Distribution Modules intelligent concepts for voltage sup-

Note

ply are available. Further information may be found under www.beckhoff.com/EP9224.

EP9214-0023 and EP9224-0023 23Version: 2.3.1

Page 24

Mounting and cabling

3.3.4 Power cable 7/8"

Fig.18: Power cable 7/8"

Technical data

Technical data

Rated voltage according to IEC61076-2-101 300V (according to IEC61076-2-101)

Contamination level according to IEC60664-1 3/2 (according to IEC60664-1)

Insulation resistance IEC60512-2 >109W

Current carrying capacity according to

IEC60512-3

Volume resistance according to IEC60512-2 < 5mW

Protection class conforms to IEC60529 IP65/66/67, when screwed together

Permissible ambient temperature -30°C to +80°C

Material properties TPE-U (PUR) halogen-free according to DINVDE0472

Approbations UL

Cable outside diameter 7.80 ± 0.20mm

Bending radius min. 6xD (external diameter)

Parameter Max. speed 5m/s, max. acceleration 10m/s²

Number of cycles At least 10million cycles with a max. travel path of 20

16A at 40°C (according to IEC60512-3)

Part815,

flame-retardant according to cULus 20549

meters

EP9214-0023 and EP9224-002324 Version: 2.3.1

Page 25

Ordering data

Mounting and cabling

Order identifier Power cable Screw type

connector

ZK2030-1200-0010 Straight socket, open end 7/8" 5-pin 1,50mm

Contacts Cross-sec-

tion

2

Length

1.00m

ZK2030-1200-0030 3.00m

ZK2030-1200-0050 5.00m

ZK2030-1200-0100 10.00m

ZK2030-1400-0010 Angled socket, open end 1.00m

ZK2030-1400-0030 3.00m

ZK2030-1400-0050 5.00m

ZK2030-1400-0100 10.00m

ZK2030-1112-0010 Straight socket, straight

ZK2030-1112-0030 3.00m

plug

1.00m

ZK2030-1112-0050 5.00m

ZK2030-1112-0100 10.00m

ZK2030-1314-0010 Angled socket, angled

ZK2030-1314-0030 3.00 m

plug

1.00m

ZK2030-1314-0050 5.00m

ZK2030-1314-0100 10.00m

Further available power cables and the associated data sheets can be found in the Beckhoff catalogue or on

our website (http://www.beckhoff.com).

EP9214-0023 and EP9224-0023 25Version: 2.3.1

Page 26

Mounting and cabling

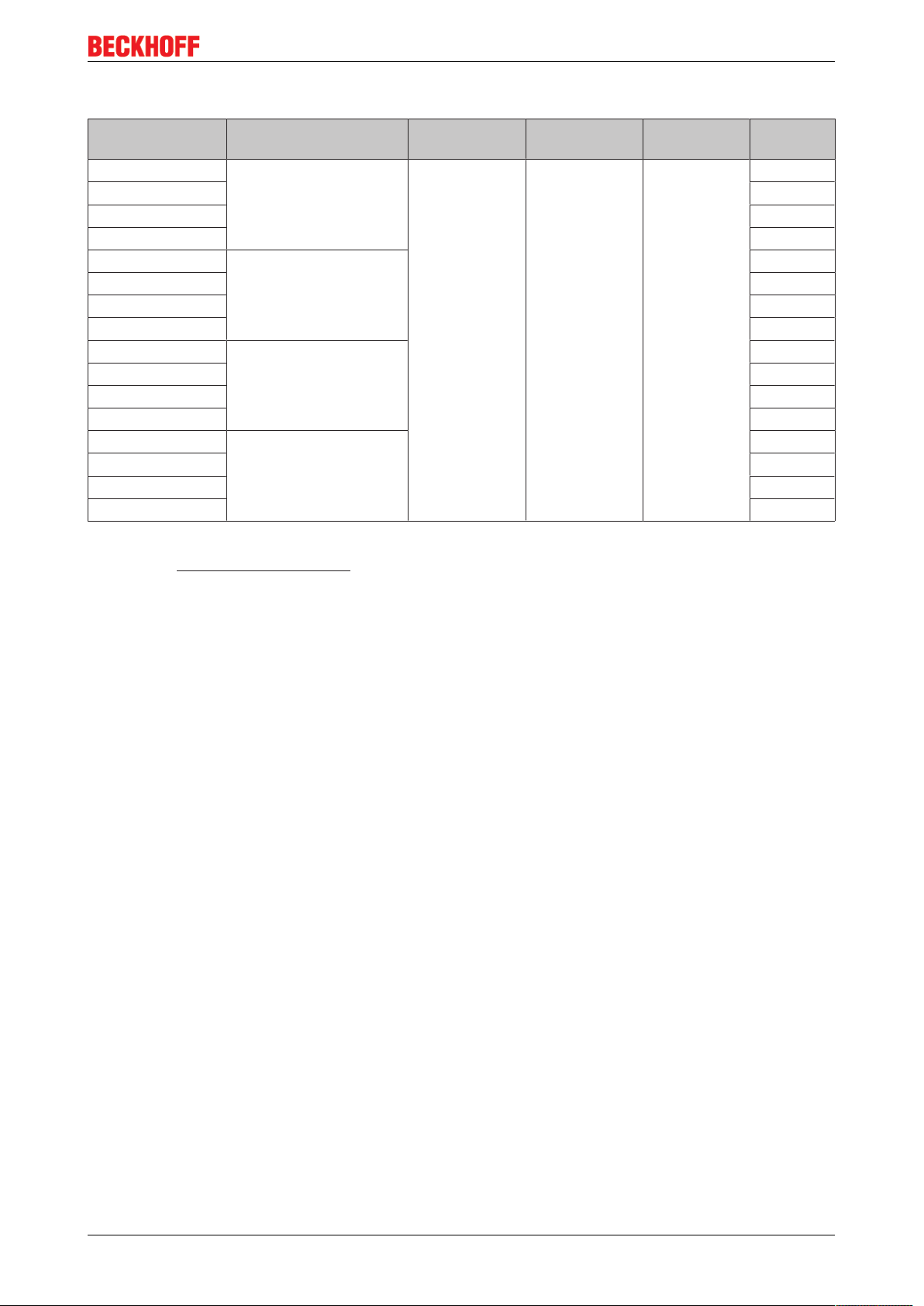

3.3.5 Conductor losses 7/8"

In the case of the power cables ZK2030-xxxx-yyy, a total length of 15m should not be exceeded at 16A.

When wiring, note that with a rated voltage of 24V the function of the modules can no longer be guaranteed

from a voltage drop of 6V. Variations in the output voltage from the power supply unit must also be taken

into account.

Fig.19: ZK2030-xxxx-yyy - Conductor losses

Alternatively, larger cable cross-section can be used, e.g. 2.5mm2.

EP9214-0023 and EP9224-002326 Version: 2.3.1

Page 27

Mounting and cabling

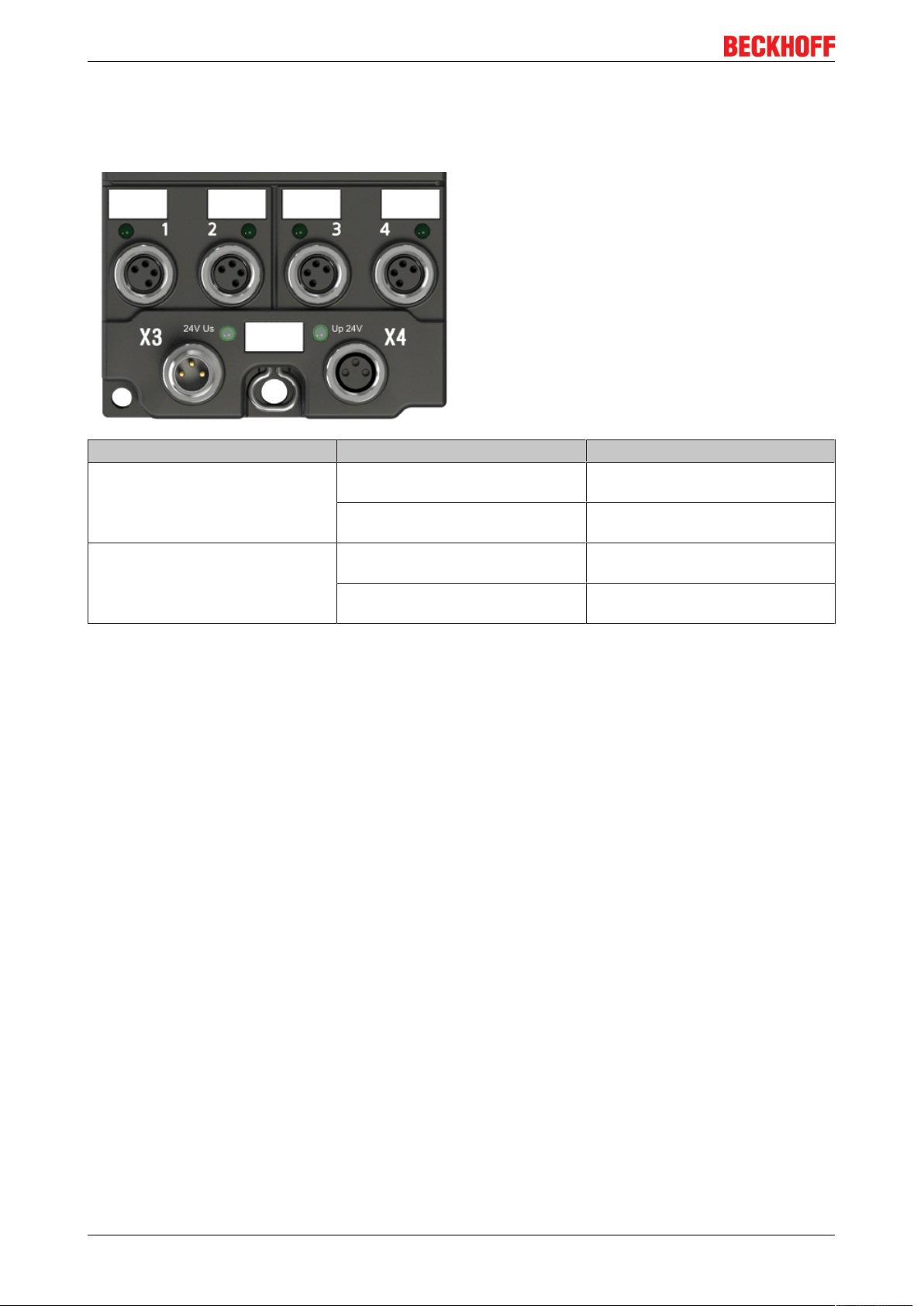

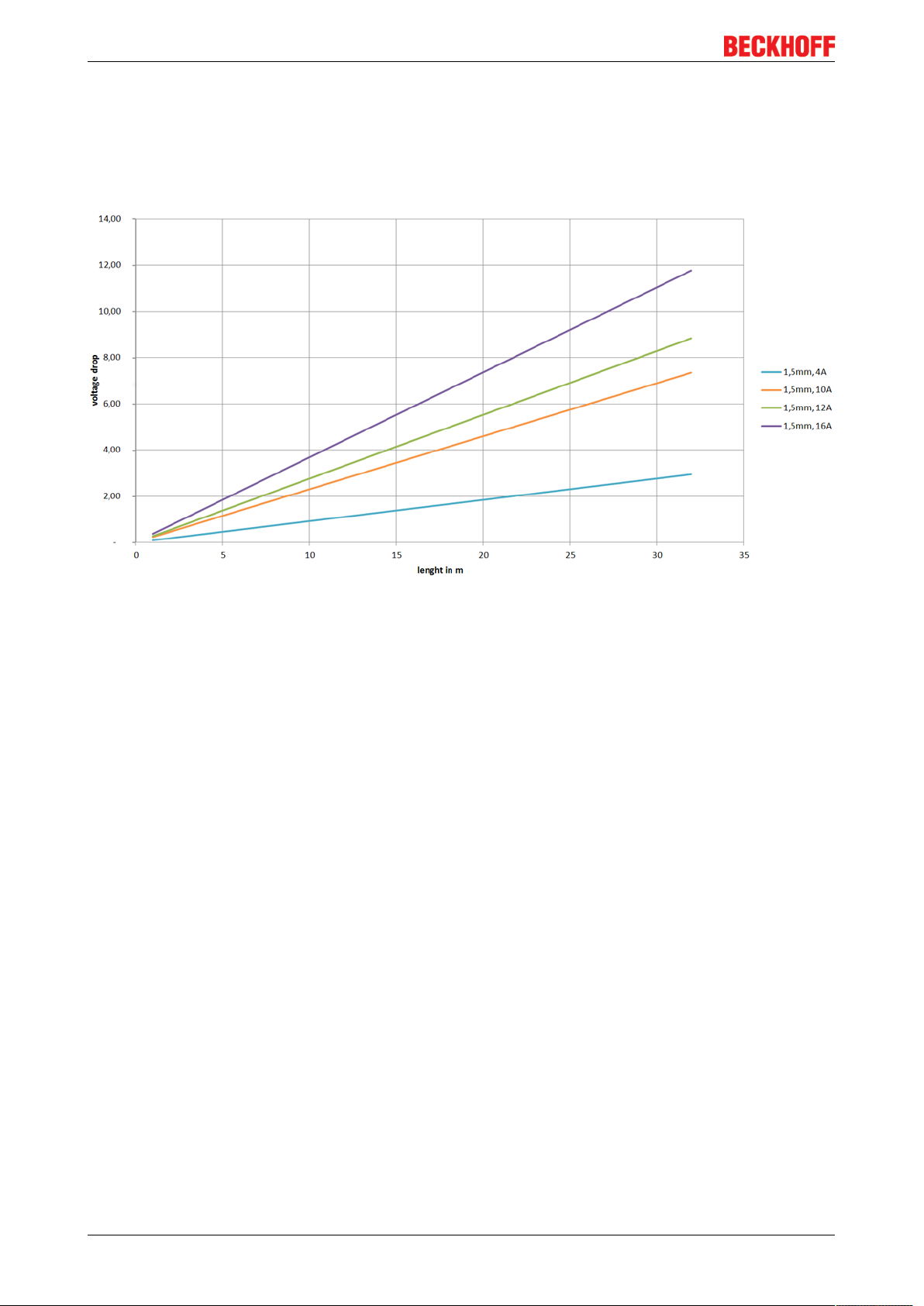

3.3.6 Power outputs

The supply voltages are output via four 4-pole M8 sockets in the lower third of the modules (1, 2, 3 and 4).

Fig.20: M8 sockets

Pin assignment

Fig.21: Pin assignment of the M8 sockets

Contact Voltage

1 Control voltage Us, +24V

2 Peripheral voltage Up, +24V

DC

DC

3 GNDs* *) can be internally connected to one another depending on the connected

4 GNDp*

module: see individual module descriptions

The contacts of the M8 plug connectors can conduct a maximum current of 4A.

A LED indicates the status of the power outputs.

Do not confuse the power outputs with the EtherCAT connection

Never connect the power cables (M8, 24VDC) to the green-marked EtherCAT sockets of the

Attention

EP9214-0023 and EP9224-0023 27Version: 2.3.1

EtherCAT Box Modules. This can cause the destruction of the modules!

Page 28

Mounting and cabling

Control voltage Us: 24V

DC

Power is supplied to the fieldbus, the processor logic, the inputs and the sensors from the control voltage Us

(24VDC). The control voltage is electrically isolated from the fieldbus circuitry.

Peripheral voltage Up: 24V

DC

The peripheral voltage Up (24VDC) supplies the digital outputs; it can be brought in separately. Hence, if the

load voltage is switched off, the fieldbus function as well as the supply and function of the inputs are

retained.

Electrical isolation

The grounds of the control voltage (GNDs) and peripheral voltage (GNDp) are electrically isolated from each

other in order to ensure the electrical isolation of the peripheral devices on Up from the control voltage.

The electrical isolation can be nullified

If you connect digital and analog EtherCAT Box Modules directly to one another via fourpole power lines, then there may no longer be any electrical isolation due to the connected

Attention

boxes!

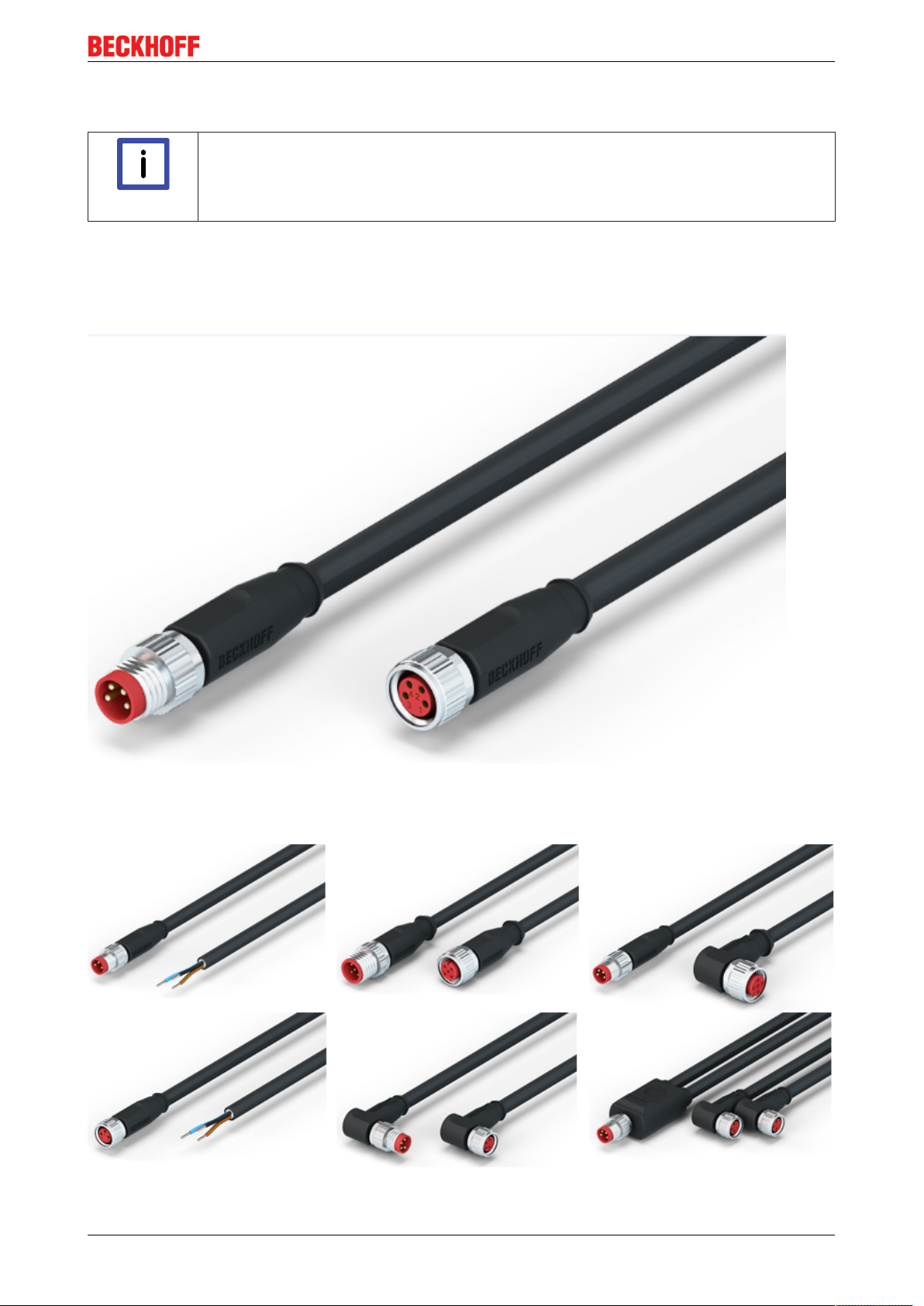

3.4 Cabling

A list of EtherCAT cables, power cables, sensor cables, Ethernet/EtherCAT connectors and fieldconfigurable connectors can be found under the following link: http://download.beckhoff.com/download/

document/catalog/main_catalog/german/Beckhoff_EtherCAT-Box-Zubehoer.pdf

The corresponding data sheets can be found under the following link:

https://beckhoff.de/default.asp?ethercat-box/ethercat_box_cables.htm?id=690338951657421

EtherCAT cables

Fig.22: ZK1090-3131-0xxx

EP9214-0023 and EP9224-002328 Version: 2.3.1

Page 29

Mounting and cabling

For connecting EtherCAT devices, only use shielded Ethernet cables with a minimum specification of

category5 (CAT5) according to EN50173 or ISO/IEC11801.

Wiring recommendations

Detailed recommendations for EtherCAT cabling can be found in the documentation "De-

Note

EtherCAT uses four cable wires for signal transmission.

Due to automatic cable detection (auto-crossing) symmetric (1:1) or cross-over cables can be used between

EtherCAT devices from Beckhoff.

Power cable

sign recommendations for EtherCAT/Ethernet infrastructure", which is available for download from www.beckhoff.de.

Fig.23: ZK2020-3132-0xxx

Sensor cables

Fig.24: Selection of Beckhoff sensor cables

EP9214-0023 and EP9224-0023 29Version: 2.3.1

Page 30

Mounting and cabling

3.5 Status LEDs and status bits

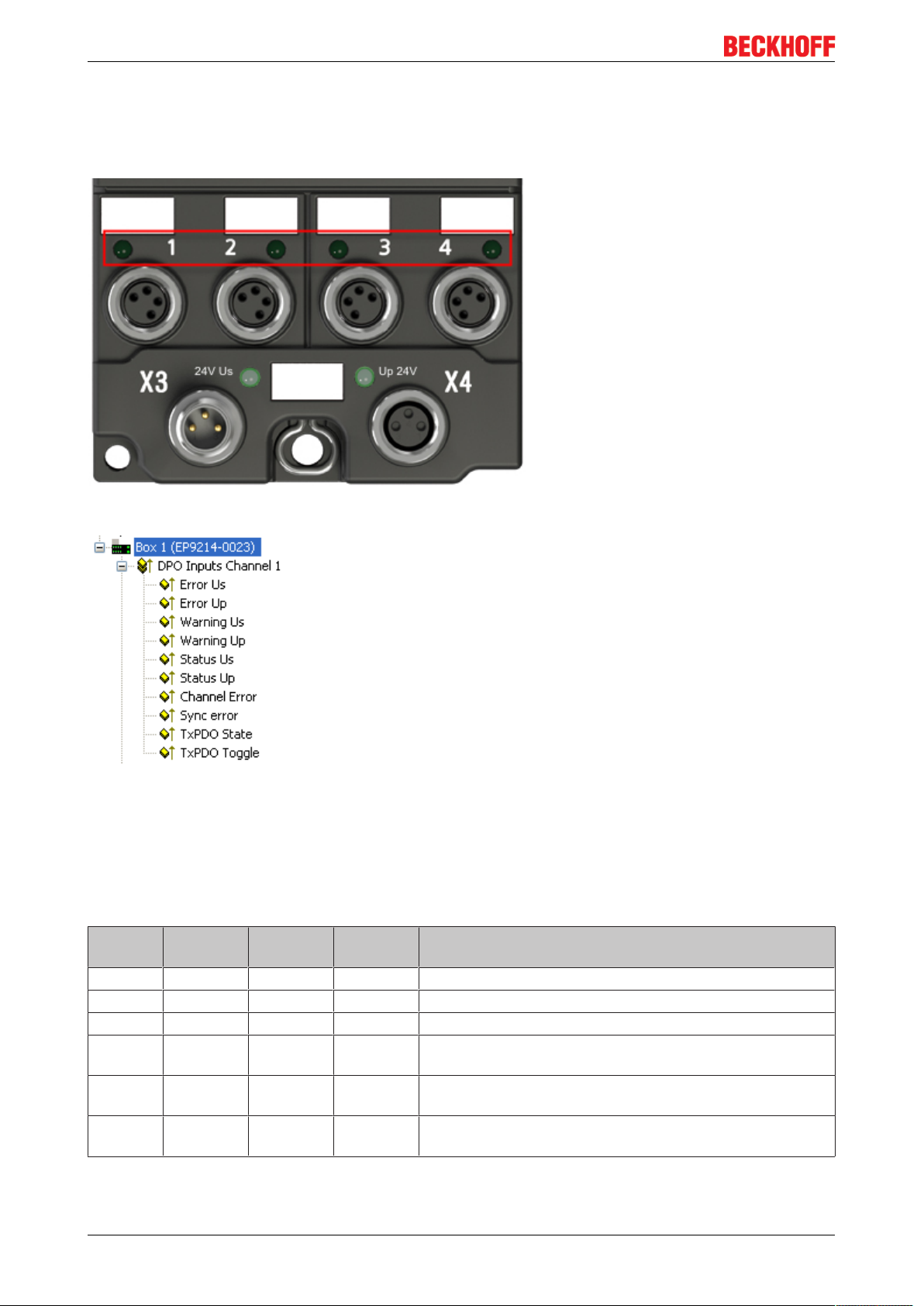

Below is a table showing the meaning of the status LEDs and status bits for the power outputs (EP9214 for

example):

Fig.25: EP9214 - status LEDs

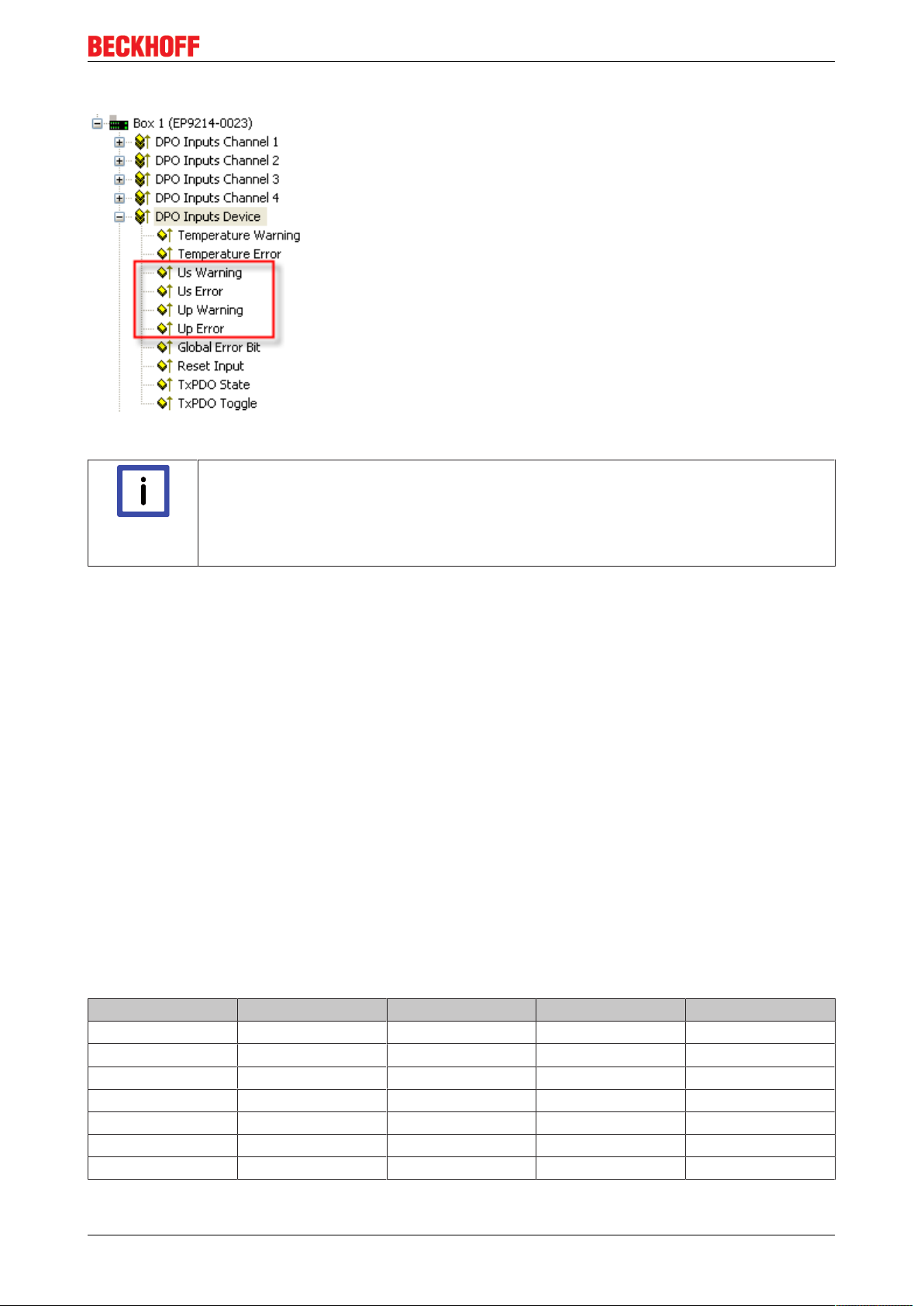

Fig.26: EP9214 - status bits

Initialization

When switching on the voltage supply to the EP9214/ EP9224, all green LEDs and then all red LEDs are

switched on briefly to test the LEDs.

The LED is valid for both voltages and currents (Us and Up; OR).

LED Status

Us / Up

Off 0 0 0 The output is ready

Green 1 0 0 The output is just switching on

Green 1 0 0 The output is switched on. Normal operating status.

Flashing

green

Flashing

red

Red 0 0 1 The output has been deactivated and can be returned to a

1 1 0 The output is still operating, but will switch off if conditions

0 1 1 The output has been switched off. Switching on again is not

Warning Error

Us / Up

Description

remain unchanged (Warning Ux).

yet possible (waiting time of 20seconds)

normal state by a reset.

EP9214-0023 and EP9224-002330 Version: 2.3.1

Page 31

Mounting and cabling

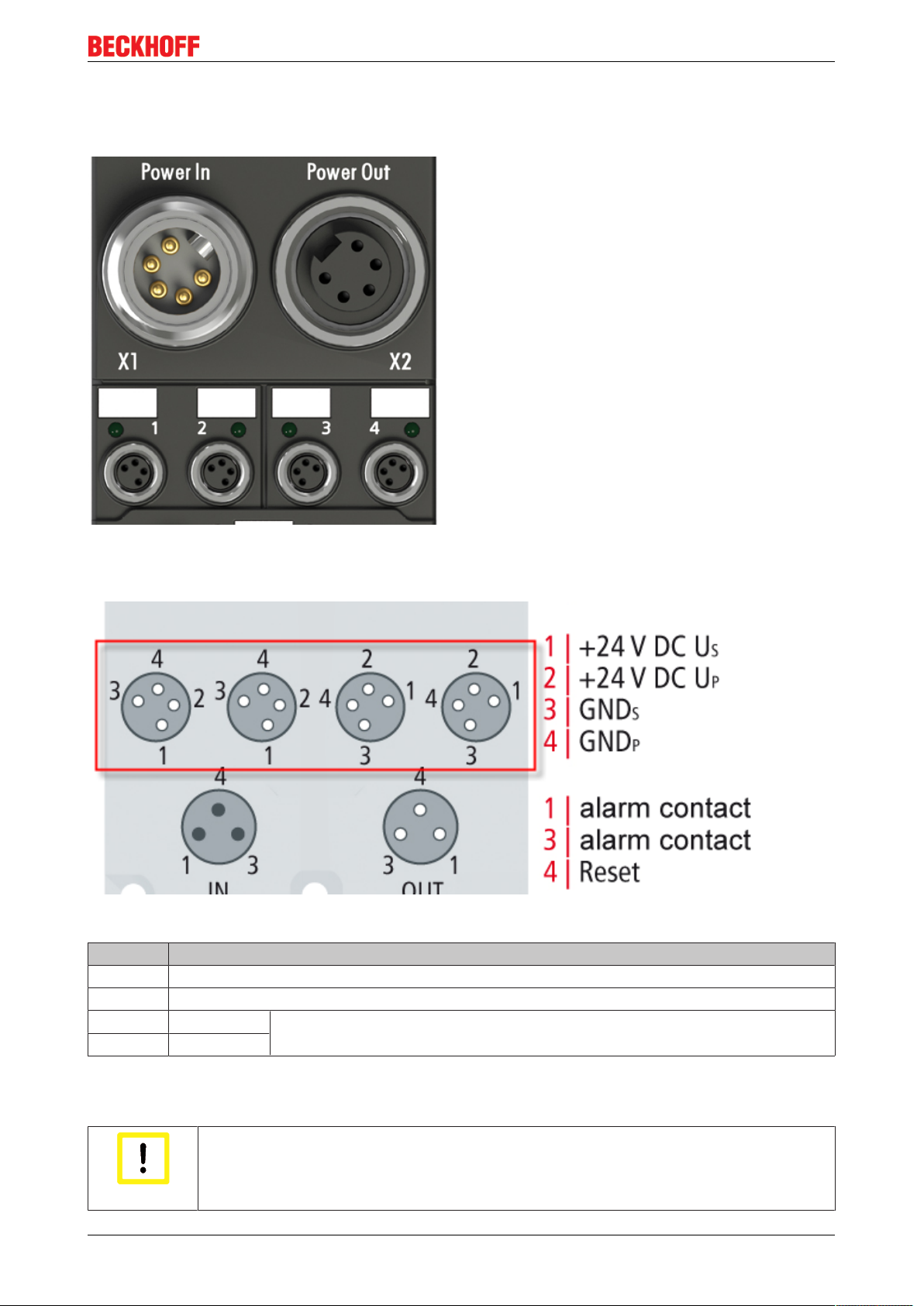

3.6 Monitoring and reset contacts

The EP9214 has a monitoring contact (signal contact) and a reset contact. These contacts are fed out via an

M8 plug and an M8 socket.

The contacts of this M8 plug and M8 socket are wired together 1:1.

Fig.27: EP9214 - Monitoring and reset connectors

Pin assignment

Fig.28: EP9214 - Monitoring and reset contacts

Contact Meaning

Pin 1 and 3:

Monitoring

Pin 4: Reset all errors are reset by applying 24VDC to the Reset contact.

The contacts of the M8 plug connectors can conduct a maximum current of 4A.

Potential-free signalling contact (normally open contact), closes on application of the

supply voltage and if an error occurs in one of the eight load circuits

EP9214-0023 and EP9224-0023 31Version: 2.3.1

Page 32

Comissioning and Configuration

4 Comissioning and Configuration

4.1 Inserting into the EtherCAT network

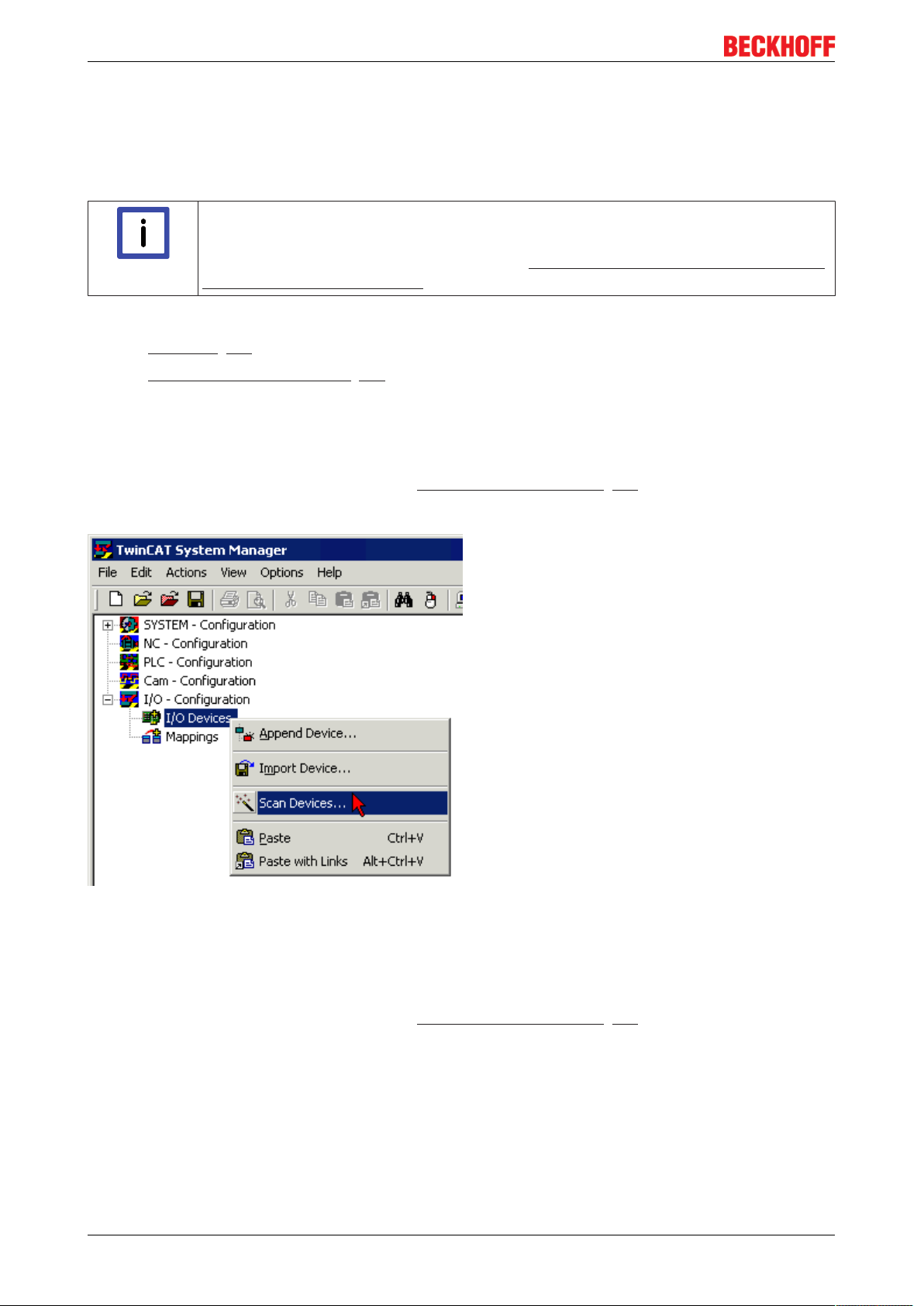

Installation of the latest XML device description

Please ensure that you have installed the latest XML device description in TwinCAT. This

Note

At the Beckhoff TwinCAT System Manager the configuration tree can be build in two different ways:

• by scanning [}32] for existing hardware (called "online") and

• by manual inserting/appending [}32] of fieldbus devices, couplers and slaves.

Automatic scanning in of the box

• The EtherCAT system must be in a safe, de-energized state before the EtherCAT modules are

connected to the EtherCAT network!

• Switch on the operating voltage, open the TwinCAT System Manager [}35] (Config mode), and scan

in the devices (see Fig. 1). Acknowledge all dialogs with "OK", so that the configuration is in "FreeRun"

mode.

can be downloaded from the Beckhoff website (http://www.beckhoff.de/english/download/

elconfg.htm?id=1983920606140) and installed according to the installation instructions.

Fig.29: Scanning in the configuration (I/O Devices -> right-click -> Scan Devices...)

Appending a module manually

• The EtherCAT system must be in a safe, de-energized state before the EtherCAT modules are

connected to the EtherCAT network!

• Switch on the operating voltage, open the TwinCAT System Manager [}35] (Config mode)

• Append a new I/O device. In the dialog that appears select the device EtherCAT (Direct Mode), and

confirm with OK.

EP9214-0023 and EP9224-002332 Version: 2.3.1

Page 33

Comissioning and Configuration

Fig.30: Appending a new I/O device (I/O Devices -> right-click -> Append Device...)

Fig.31: Selecting the device EtherCAT

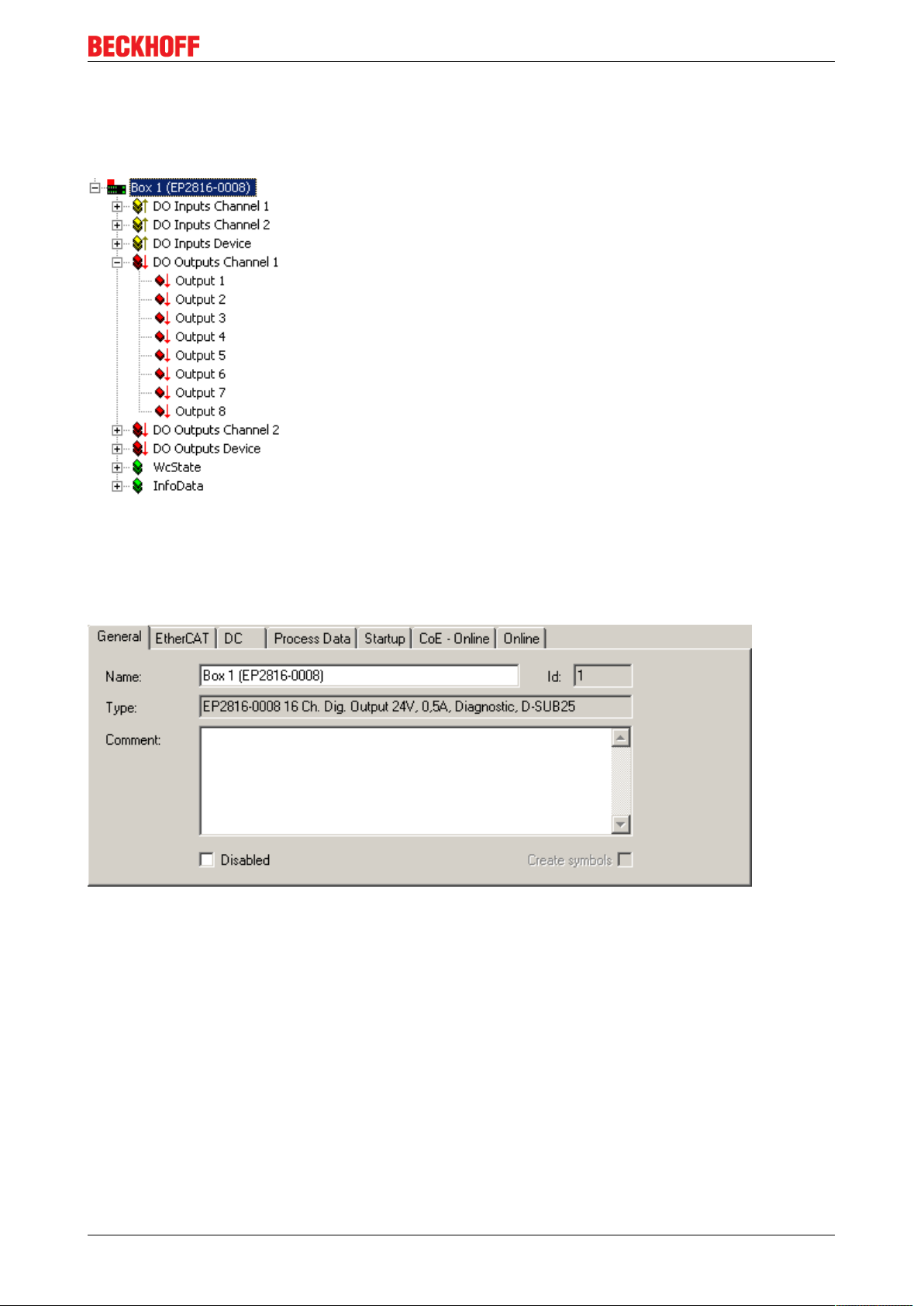

• Append a new box.

Fig.32: Appending a new box (Device -> right-click -> Append Box...)

• In the dialog that appears select the desired box (e.g. EP2816-0008), and confirm with OK.

EP9214-0023 and EP9224-0023 33Version: 2.3.1

Page 34

Comissioning and Configuration

Fig.33: Selecting a Box (e.g. EP2816-0008)

Fig.34: Appended Box in the TwinCAT tree

EP9214-0023 and EP9224-002334 Version: 2.3.1

Page 35

Comissioning and Configuration

4.2 Configuration via TwinCAT

In the left-hand window of the TwinCAT System Manager, click on the branch of the EtherCAT Box you wish

to configure (EP2816-0008 in this example).

Fig.35: Branch of the EtherCAT box to be configured

In the right-hand window of the TwinCAT System manager, various tabs are now available for configuring

the EtherCAT Box.

General tab

Fig.36: General tab

Name Name of the EtherCAT device

Id Number of the EtherCAT device

Type EtherCAT device type

Comment Here you can add a comment (e.g. regarding the system).

Disabled Here you can deactivate the EtherCAT device.

Create symbols Access to this EtherCAT slave via ADS is only available if this checkbox is

activated.

EP9214-0023 and EP9224-0023 35Version: 2.3.1

Page 36

Comissioning and Configuration

EtherCAT tab

Fig.37: EtherCAT tab

Type EtherCAT device type

Product/Revision Product and revision number of the EtherCAT device

Auto Inc Addr. Auto increment address of the EtherCAT device. The auto increment address can

be used for addressing each EtherCAT device in the communication ring through

its physical position. Auto increment addressing is used during the start-up phase

when the EtherCAT master allocates addresses to the EtherCAT devices. With

auto increment addressing the first EtherCAT slave in the ring has the address

0000

. For each further slave the address is decremented by 1 (FFFF

hex

, FFFE

hex

etc.).

EtherCAT Addr. Fixed address of an EtherCAT slave. This address is allocated by the EtherCAT

master during the start-up phase. Tick the checkbox to the left of the input field in

order to modify the default value.

Previous Port Name and port of the EtherCAT device to which this device is connected. If it is

possible to connect this device with another one without changing the order of the

EtherCAT devices in the communication ring, then this combobox is activated and

the EtherCAT device to which this device is to be connected can be selected.

Advanced Settings This button opens the dialogs for advanced settings.

hex

The link at the bottom of the tab points to the product page for this EtherCAT device on the web.

Process Data tab

Indicates the configuration of the process data. The input and output data of the EtherCAT slave are

represented as CANopen process data objects (PDO). The user can select a PDO via PDO assignment and

modify the content of the individual PDO via this dialog, if the EtherCAT slave supports this function.

EP9214-0023 and EP9224-002336 Version: 2.3.1

Page 37

Comissioning and Configuration

Fig.38: Process Data tab

Sync Manager

Lists the configuration of the Sync Manager (SM).

If the EtherCAT device has a mailbox, SM0 is used for the mailbox output (MbxOut) and SM1 for the mailbox

input (MbxIn).

SM2 is used for the output process data (outputs) and SM3 (inputs) for the input process data.

If an input is selected, the corresponding PDO assignment is displayed in the PDO Assignment list below.

PDO Assignment

PDO assignment of the selected Sync Manager. All PDOs defined for this Sync Manager type are listed

here:

• If the output Sync Manager (outputs) is selected in the Sync Manager list, all RxPDOs are displayed.

• If the input Sync Manager (inputs) is selected in the Sync Manager list, all TxPDOs are displayed.

The selected entries are the PDOs involved in the process data transfer. In the tree diagram of the System

Manager these PDOs are displayed as variables of the EtherCAT device. The name of the variable is

identical to the Name parameter of the PDO, as displayed in the PDO list. If an entry in the PDO assignment

list is deactivated (not selected and greyed out), this indicates that the input is excluded from the PDO

assignment. In order to be able do select a greyed out PDO, the currently selected PDO has to be

deselected first.

EP9214-0023 and EP9224-0023 37Version: 2.3.1

Page 38

Comissioning and Configuration

Activation of PDO assignment

• the EtherCAT slave has to run through the PS status transition cycle (from pre-opera-

Note

PDO list

List of all PDOs supported by this EtherCAT device. The content of the selected PDOs is displayed in the

PDO Content list. The PDO configuration can be modified by double-clicking on an entry.

Column Description

Index PDO index.

Size Size of the PDO in bytes.

Name Name of the PDO.

If this PDO is assigned to a Sync Manager, it appears as a variable of the slave with this

parameter as the name.

Flags F Fixed content: The content of this PDO is fixed and cannot be changed by the System

Manager.

M Mandatory PDO. This PDO is mandatory and must therefore be assigned to a Sync Manager!

Consequently, this PDO cannot be deleted from the PDO Assignment list

SM Sync Manager to which this PDO is assigned. If this entry is empty, this PDO does not take part in

the process data traffic.

SU Sync unit to which this PDO is assigned.

tional to safe-operational) once (see Online tab [}41]),

• and the System Manager has to reload the EtherCAT slaves ( button)

PDO Content

Indicates the content of the PDO. If flag F (fixed content) of the PDO is not set the content can be modified.

Download

If the device is intelligent and has a mailbox, the configuration of the PDO and the PDO assignments can be

downloaded to the device. This is an optional feature that is not supported by all EtherCAT slaves.

PDO Assignment

If this check box is selected, the PDO assignment that is configured in the PDO Assignment list is

downloaded to the device on startup. The required commands to be sent to the device can be viewed in the

Startup [}38] tab.

PDO Configuration

If this check box is selected, the configuration of the respective PDOs (as shown in the PDO list and the

PDO Content display) is downloaded to the EtherCAT slave.

Startup tab

The Startup tab is displayed if the EtherCAT slave has a mailbox and supports the CANopen over EtherCAT

(CoE) or Servo drive over EtherCAT protocol. This tab indicates which download requests are sent to the

mailbox during startup. It is also possible to add new mailbox requests to the list display. The download

requests are sent to the slave in the same order as they are shown in the list.

EP9214-0023 and EP9224-002338 Version: 2.3.1

Page 39

Fig.39: Startup tab

Column Description

Transition Transition to which the request is sent. This can either be

• the transition from pre-operational to safe-operational (PS), or

• the transition from safe-operational to operational (SO).

If the transition is enclosed in "<>" (e.g. <PS>), the mailbox request is fixed and cannot be

modified or deleted by the user.

Protocol Type of mailbox protocol

Index Index of the object

Data Date on which this object is to be downloaded.

Comment Description of the request to be sent to the mailbox

Comissioning and Configuration

Move Up This button moves the selected request up by one position in the list.

Move Down This button moves the selected request down by one position in the list.

New This button adds a new mailbox download request to be sent during startup.

Delete This button deletes the selected entry.

Edit This button edits an existing request.

CoE - Online tab

The additional CoE - Online tab is displayed if the EtherCAT slave supports the CANopen over EtherCAT

(CoE) protocol. This dialog lists the content of the object directory of the slave (SDO upload) and enables the

user to modify the content of an object from this list. Details for the objects of the individual EtherCAT

devices can be found in the device-specific object descriptions.

EP9214-0023 and EP9224-0023 39Version: 2.3.1

Page 40

Comissioning and Configuration

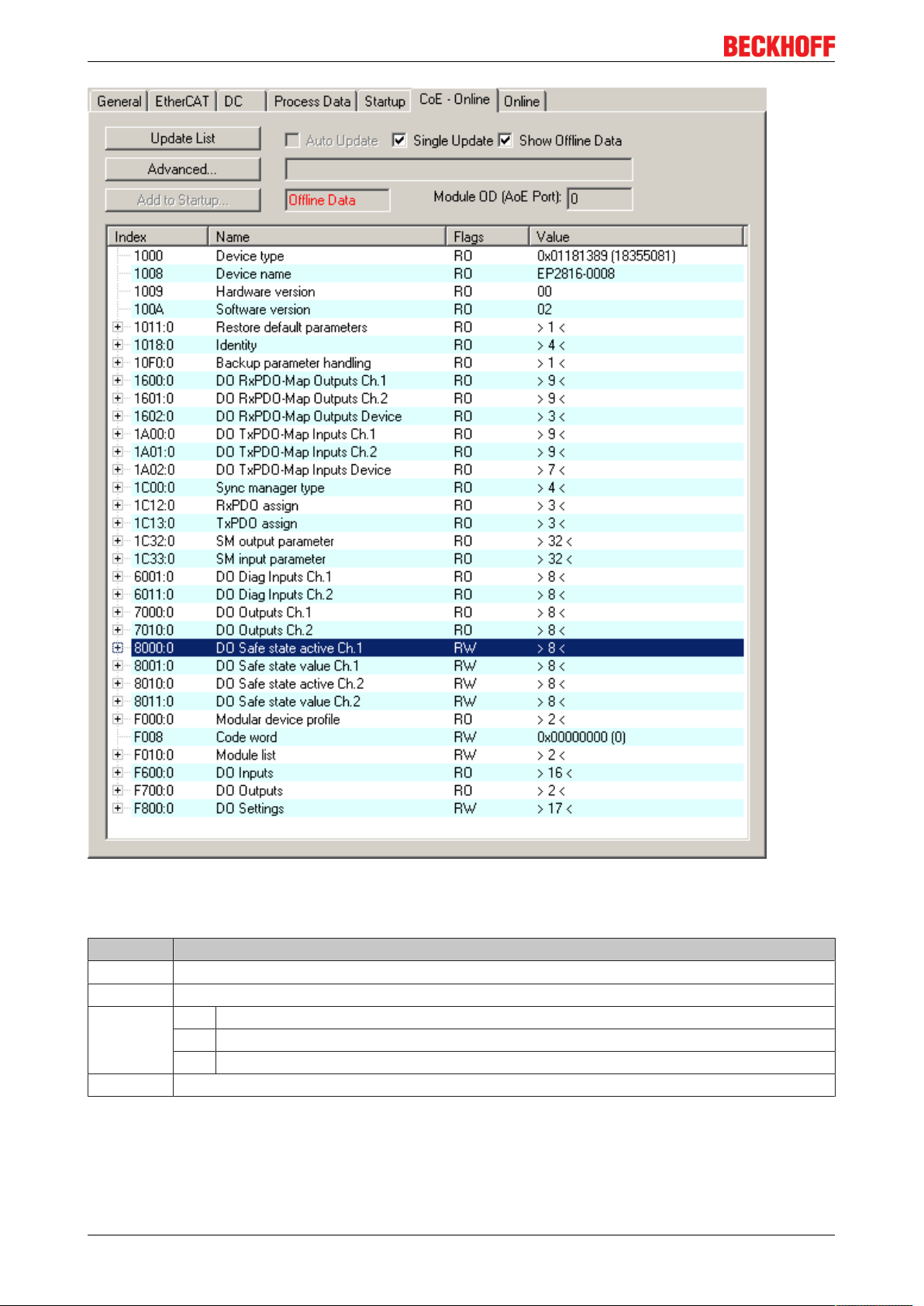

Fig.40: CoE - Online tab

Object list display

Column Description

Index Index and subindex of the object

Name Name of the object

Flags RW The object can be read, and data can be written to the object (read/write)

RO The object can be read, but no data can be written to the object (read only)

P An additional P identifies the object as a process data object.

Value Value of the object

Update List The Update list button updates all objects in the displayed list

Auto Update If this check box is selected, the content of the objects is updated automatically.

Advanced The Advanced button opens the Advanced Settings dialog. Here you can specify which

objects are displayed in the list.

EP9214-0023 and EP9224-002340 Version: 2.3.1

Page 41

Comissioning and Configuration

Fig.41: Advanced settings

Online

- via SDO information

Offline

- via EDS file

Online tab

If this option button is selected, the list of the objects included in the object

directory of the slave is uploaded from the slave via SDO information. The list

below can be used to specify which object types are to be uploaded.

If this option button is selected, the list of the objects included in the object

directory is read from an EDS file provided by the user.

Fig.42: Online tab

EP9214-0023 and EP9224-0023 41Version: 2.3.1

Page 42

Comissioning and Configuration

State Machine

Init This button attempts to set the EtherCAT device to the Init state.

Pre-Op This button attempts to set the EtherCAT device to the pre-operational state.

Op This button attempts to set the EtherCAT device to the operational state.

Bootstrap This button attempts to set the EtherCAT device to the Bootstrap state.

Safe-Op This button attempts to set the EtherCAT device to the safe-operational state.

Clear Error This button attempts to delete the fault display. If an EtherCAT slave fails during

change of state it sets an error flag.

Example: An EtherCAT slave is in PREOP state (pre-operational). The master now

requests the SAFEOP state (safe-operational). If the slave fails during change of

state it sets the error flag. The current state is now displayed as ERR PREOP. When

the Clear Error button is pressed the error flag is cleared, and the current state is

displayed as PREOP again.

Current State Indicates the current state of the EtherCAT device.

Requested State Indicates the state requested for the EtherCAT device.

DLL Status

Indicates the DLL status (data link layer status) of the individual ports of the EtherCAT slave. The DLL status

can have four different states:

Status Description

No Carrier / Open No carrier signal is available at the port, but the port is open.

No Carrier / Closed No carrier signal is available at the port, and the port is closed.

Carrier / Open A carrier signal is available at the port, and the port is open.

Carrier / Closed A carrier signal is available at the port, but the port is closed.

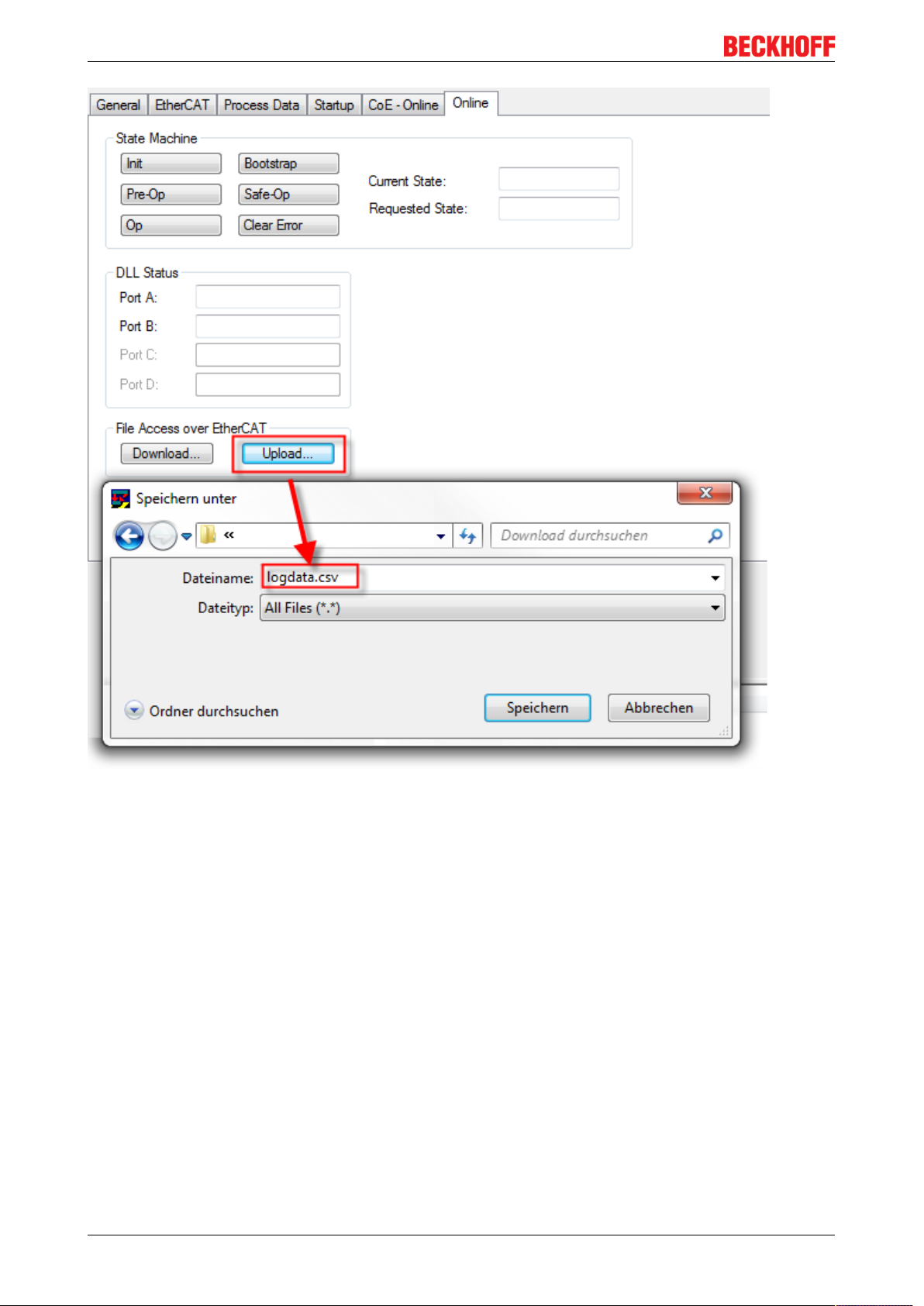

File Access over EtherCAT

Download With this button a file can be written to the EtherCAT device.

Upload With this button a file can be read from the EtherCAT device.

EP9214-0023 and EP9224-002342 Version: 2.3.1

Page 43

Comissioning and Configuration

4.3 Operation with or without EtherCAT master

The EP92x4 is preset in the factory and delivered with a set rated current of 4.0A and all eight channels

switched on.

The channels switch on automatically during commissioning

In the basic setting the rated current of the EP92x4 is 4A per channel. Shortly after the

Attention

This is preset by the CoE object 0xF707:01

EP92x4 is supplied with voltage, all channels are switched on with a delay of 100ms each.

Fig.43: CoE object 0xF707:01 - Enable Control via Fieldbus

If the EP92x4 is operated on an EtherCAT master, the basic setting or the bootup can be adapted.

This is done via the variable DPO Outputs Device -> Enable control via Fieldbus in the process data.

At the next power-on of the box the load circuits will then be switched on depending on the settings in the

CoE objects.

Customize all parameters when EtherCAT is used for the first time

If the EP92x4 operated for the first time with EtherCAT connection, all parameters need to

Note

be adjusted.

Without EtherCAT connection the outputs switch in default status

After the EP92x4 was configured with an EtherCAT master you can disconnect the Ether-

Attention

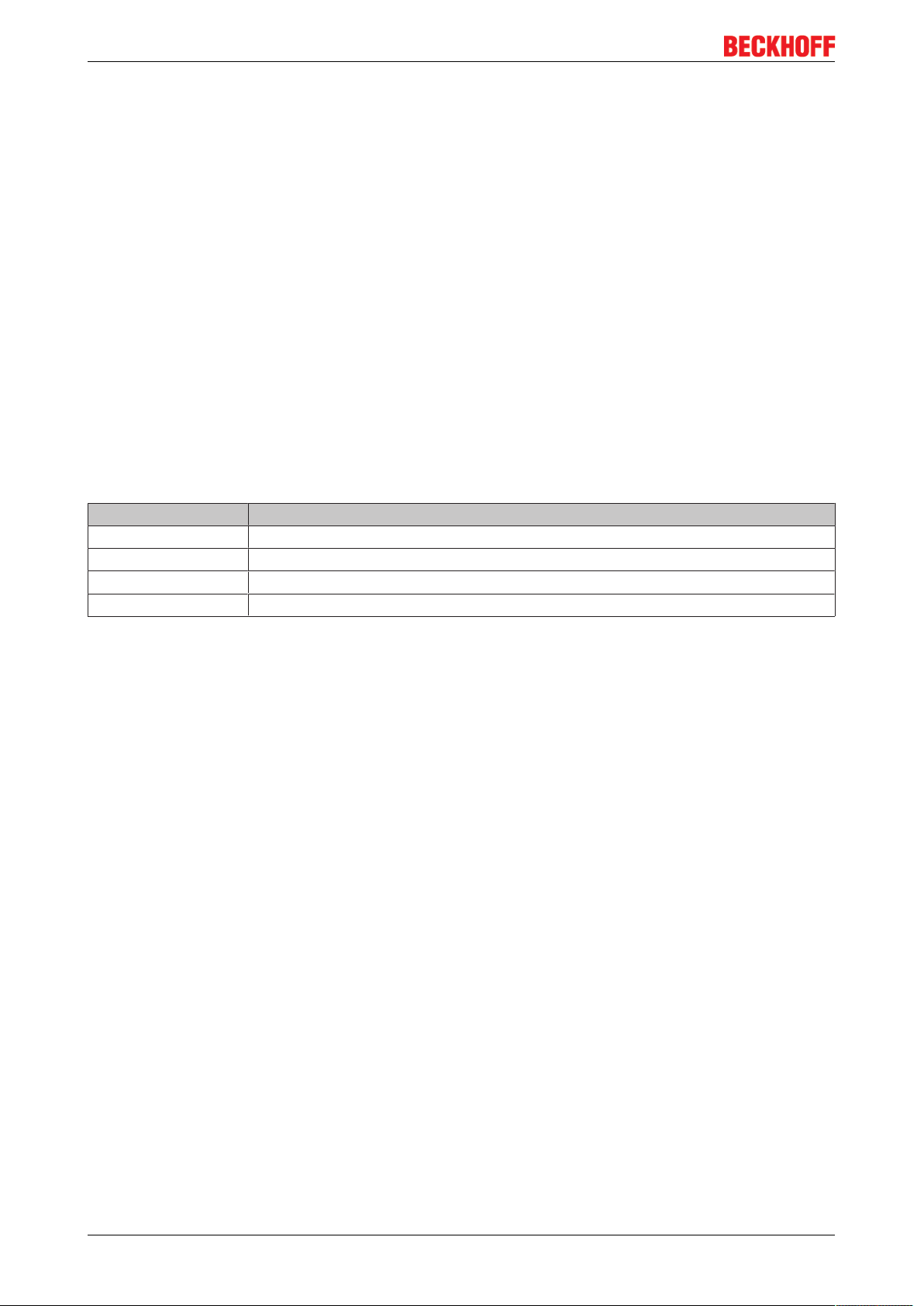

Example for parametrizing the outputs when using EtherCAT

Via the tab “CoE – Online” you can adjust different settings of the box module. For example, it is possible to

adjust the “Nominal Current US” (Index: 8000:12), by double-clicking to the respective parameter opens the

“Set Value Dialog” (see following figure).

CAT connection. But in this case the parameters of all outputs switch in the default status.

When the connection is restored to the EtherCAT master, the previously set values are

available again.

EP9214-0023 and EP9224-0023 43Version: 2.3.1

Page 44

Comissioning and Configuration

Fig.44: Adjust the “DPO Settings Ch.1” with EtherCAT connection

If the EtherCAT connection is disconnected, the option “Show Offline Data” should be activated. Then the

default values of the parameters are displayed.

4.4 Switch of behavior

4.4.1 Switch-off characteristics

The EP9214 EtherCAT Box selectively protects all connected 24VDC load circuits. This is done via various

electronic circuits, additionally protected by a 7A micro-fuse.

Selective switch-off means that the load circuits are individually monitored and if a channel is exceeded, only

that channel is switched off.

This ensures the function of the remaining consumers connected to the higher-level power supply unit.

General functional principle

The EP9214 EtherCAT Box monitors the current for each of the 8 output channels. 4xUs, 4xUp. Switching

off takes place depending on the selected nominal current and release characteristic.

Superordinate to all is the hardware switch-off, which responds if

• 7A is reached for 50ms

• there is a short-circuit for 50ms

• the capacitive load and thus the start-up current of the connected devices is too high

Due to the intelligent current limitation an output current exceeding 7A is not possible under operating

conditions. The additionally installed 7A micro fuse thus blows only if the upstream electronic switch-off is

already defective.

The nominal current can be set for each channel individually between 1A and 4A.

EP9214-0023 and EP9224-002344 Version: 2.3.1

Page 45

Fig.45: Setting the nominal current

Comissioning and Configuration

All set characteristics are referenced to the set nominal current. The following table shows the response time

of the monitoring in relation to the nominal current and characteristic.

Nominal current Very fast acting Fast acting Slow acting Time delay

100% 1h - - 110% 1h 4h - 120% 7min 4h - 150% 30s 30min 1h 4h

210% 500ms 20s 20s 100s

275% 500ms 1s 20s 10s

300% 20ms 100ms 1s 3s

If overcurrent (≥ nominal current) is detected and it is foreseeable that the current monitoring will trip if

conditions remain unchanged, then a warning is given both in the process data and in form of a flashing

LED. An output switch-off due to overcurrent is indicated by a red LED.

If one of the outputs was switched off due to a diagnosis, it must be reactivated by an active RESET.

Restart after power OFF/ON

If an output was switched off due to an error, then an active reset by the RESET contact or

Note

Switching on can be done either via EtherCAT or by applying 24V to the RESET contact. To protect the

circuitry, a RESET can take place maximally every 20seconds. Faster successive edges are ignored.

the fieldbus is necessary. Switching off and on again is not sufficient! To protect the electronic a RESET can be done at maximum all 20seconds.

Switch-on delay of load circuits 1 to 4 without fieldbus control

Here is a table of the startup times, adjustable in the CoE object 0xF80E:11

Description Switch-on delay

Fast 10ms

Moderate 100ms

Slow 200ms

EP9214-0023 and EP9224-0023 45Version: 2.3.1

Page 46

Comissioning and Configuration

4.4.2 Current limitation, switching the load circuits off

The switch-off behavior of the individual load circuits can be adapted to the application.

The following modes can be set individually for each channel:

• Very fast acting

• Fast acting

• Slow acting

• Time delay

Release time (switch-off time) of the modes

Rated current Very fast acting Fast acting Slow acting Time delay

100% 1h - - 110% 1h 4h - 120% 7min 4 h - 150% 30s 30min 1h 4h

210% 500ms 20sec 20s 100s

275% 500ms 1sec 20s 10s

300% 20ms 100ms 1s 3s

The release time depends on the set rated current.

Following the switch-off of a channel it is necessary to reactivate it after rectification of the cause of the error.

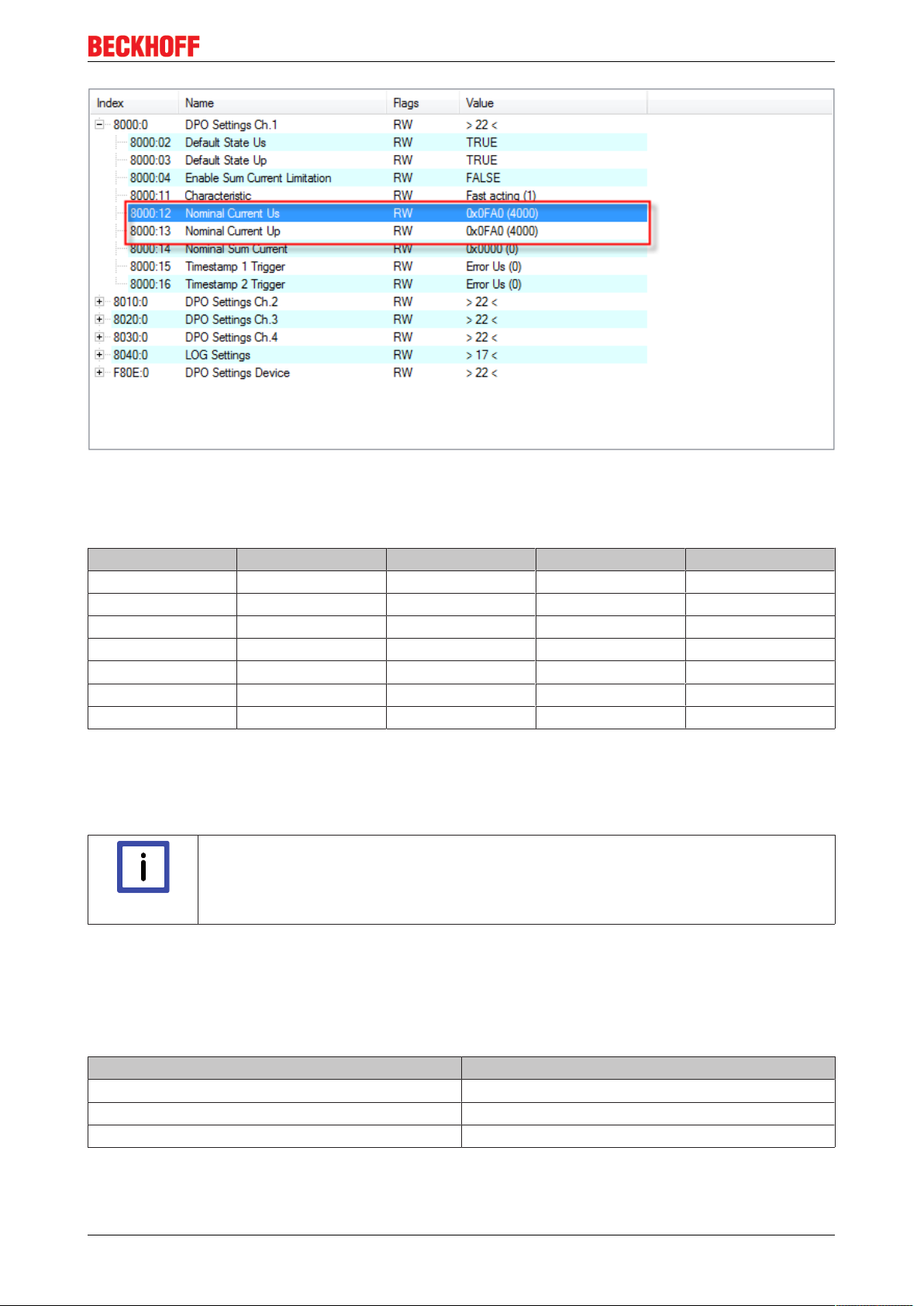

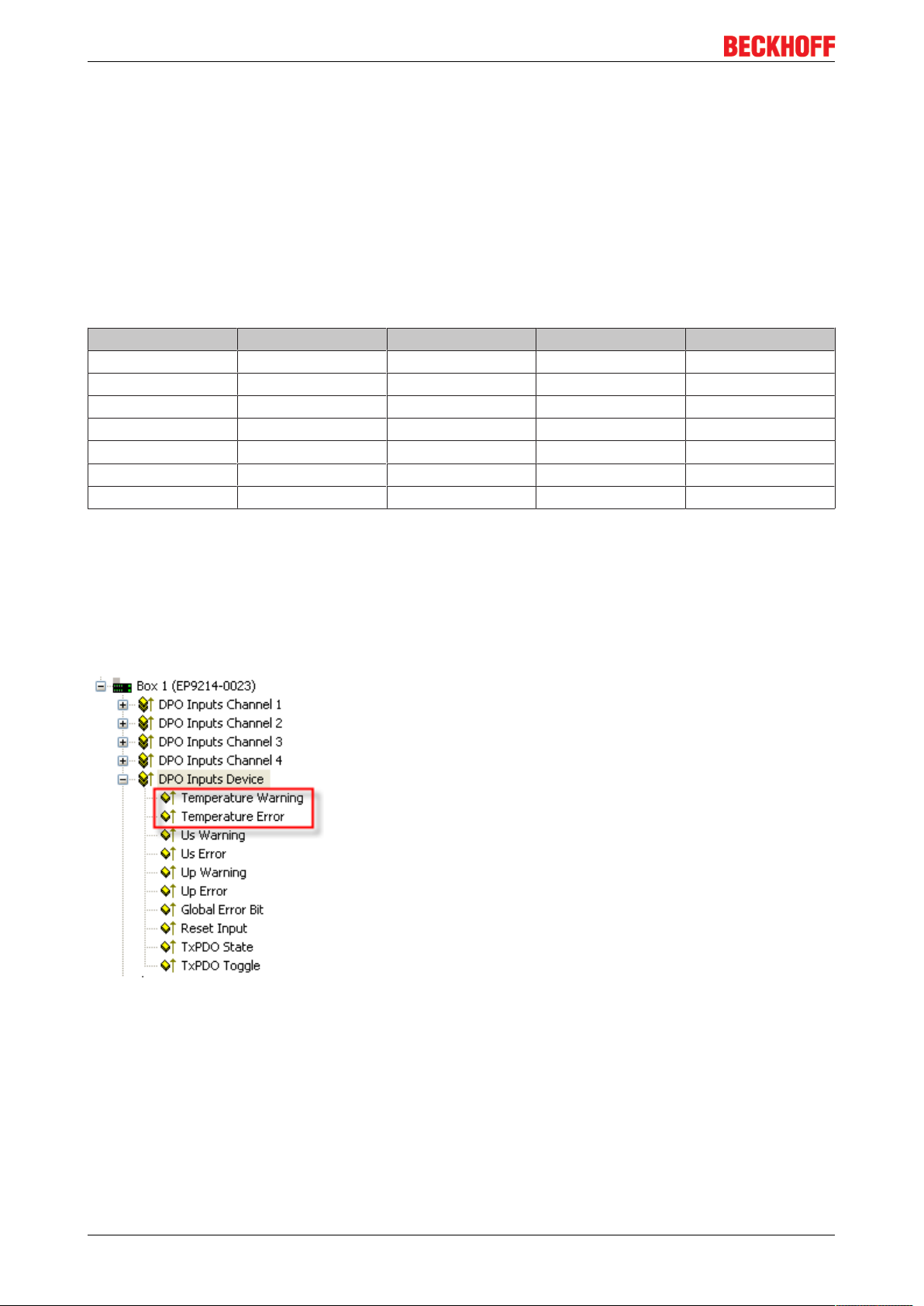

Switch-off of the box due to overtemperature

The EP9214 is internally protected against overheating. A warning is given in the process data if a

temperature of about 80°C is reached.

Fig.46: Temperature Warning and Temperature Error bits

On reaching 85°C all load circuits are switched off in order to protect the hardware against destruction. In

this case the Temperature Error bit is set.

So that the permitted temperature is not exceeded, the box is to be mounted with its rear wall on the flattest

possible thermally conductive surface.

Switch off of the box due to undervoltage

Since undervoltage impairs the function of the safety mechanisms, a warning is given in the process data

from an input voltage of 21.5V. If the voltage falls below 18V all outputs are switched off and the Error bit is

set.

EP9214-0023 and EP9224-002346 Version: 2.3.1

Page 47

Undervoltage is detected independently for Us and Up.

Fig.47: Undervoltage bits

Switching on again

Switching off due to undervoltage and overtemperature is equivalent to the response of the

Note

current monitoring, but applies to the entire box and all outputs. The error must be reset by

setting the process data GLOBAL RESET or by power off/ restart of the module, furthermore the temperature must have fallen below 75°C!

Comissioning and Configuration

Switching load circuits on again after switch-off

This takes place either via the process data by EtherCAT or by the reset input directly on the box.

Also see about this

2 EP9214-0023 - Process image [}65]

2 Monitoring and reset contacts [}31]

4.4.3 Setting the current limitation

The switch-off behavior of the individual load circuits can be adapted to the application.

The following modes can be set individually for each channel:

• Very fast acting

• Fast acting

• Slow acting

• Time delay

Release time (switch-off time) of the modes

Rated current Very fast acting Fast acting Slow acting Time delay

100% 1h - - 110% 1h 4h - 120% 7min 4 h - 150% 30s 30min 1h 4h

210% 500ms 20sec 20s 100s

275% 500ms 1sec 20s 10s

300% 20ms 100ms 1s 3s

EP9214-0023 and EP9224-0023 47Version: 2.3.1

Page 48

Comissioning and Configuration

The release time depends on the set rated current.

CoE parameters for setting the current limiting characteristic

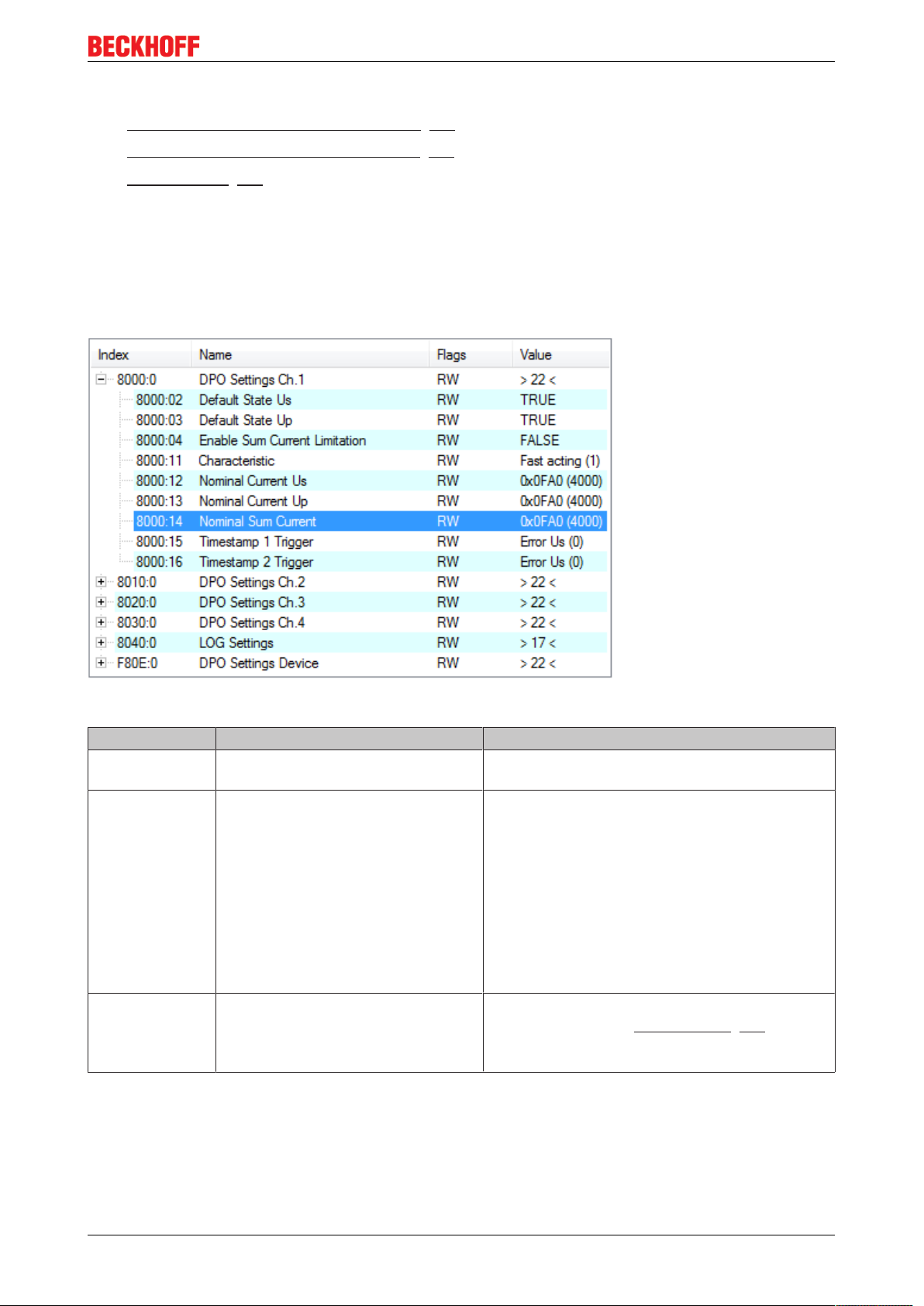

Fig.48: CoE parameters for setting the current limiting characteristic

Meaning of the parameters

Index Name Meaning

0x80n0:02 Default State Us TRUE: in case of operation without fieldbus the load circuit Us of

channel n is automatically switched on

FALSE: in case of operation without fieldbus the load circuit Us of

channel n remains switched off

0x80n0:02 Default State Up TRUE: in case of operation without fieldbus the load circuit Up of

channel n is automatically switched on

FALSE: in case of operation without fieldbus the load circuit Up of

channel n remains switched off

0x80n0:11 Characteristic Release time depending on rated current

0x80n0:12 Nominal Current Us Specification of the rated current of Us in mA

0x80n0:13 Nominal Current Up Specification of the rated current of Up in mA

Switching load circuits on again after switch-off

This takes place either via the process data [}65] by EtherCAT or by the reset input [}31] directly on the

box.

4.4.4 Status LEDs and status bits

Below is a table showing the meaning of the status LEDs and status bits for the power outputs (EP9214 for

example):

EP9214-0023 and EP9224-002348 Version: 2.3.1

Page 49

Fig.49: EP9214 - Status bits

Comissioning and Configuration

Fig.50: EP9214 - status bits

Initialization

When switching on the voltage supply to the EP9214/EP9224, all green LEDs and then all red LEDs are

switched on briefly to test the LEDs.

The LED is valid for both voltages and currents (Us and Up; OR).

LED Status

Us / Up

Off 0 0 0 The output is ready

Green 1 0 0 The output is just switching on

Green 1 0 0 The output is switched on. Normal operating

Flashing green 1 1 0 The output is still operating, but will switch off if

Flashing red 0 1 1 The output has been switched off. Switching on

Red 0 0 1 The output has been deactivated and can be

Warning Error

Us / Up

Description

status.

conditions remain unchanged (Warning Ux).

again is not yet possible (waiting time of

20seconds)

returned to a normal state by a reset.

EP9214-0023 and EP9224-0023 49Version: 2.3.1

Page 50

Comissioning and Configuration

4.5 EP9214-0023

4.5.1 EP9214-0023 - Object description

Parameterization

Terminals' parameterization will be conducted by the CoE tab (double-click on the referring

Note

Note

The CoE overview contains objects for different intended applications:

• Objects required for parameterization during commissioning

• Objects intended for regular operation e.g. through ADS access

• Objects for indicating internal settings (may be fixed)

• Further profile-specific objects indicating inputs, outputs and status information

object) or the Process data tab (PDO assignment)

EtherCAT XML Device Description

The description correspond to the display of the CoE objects from the EtherCAT XML Device Description. It is strongly recommended to download the latest revision of the corresponding XML file from the Beckhoff website (http://www.beckhoff.com/english/default.htm?

download/elconfg.htm) and follow the installation instructions.

The following section first describes the objects require for normal operation, followed by a complete

overview of missing objects.

4.5.1.1 Objects for parameterization

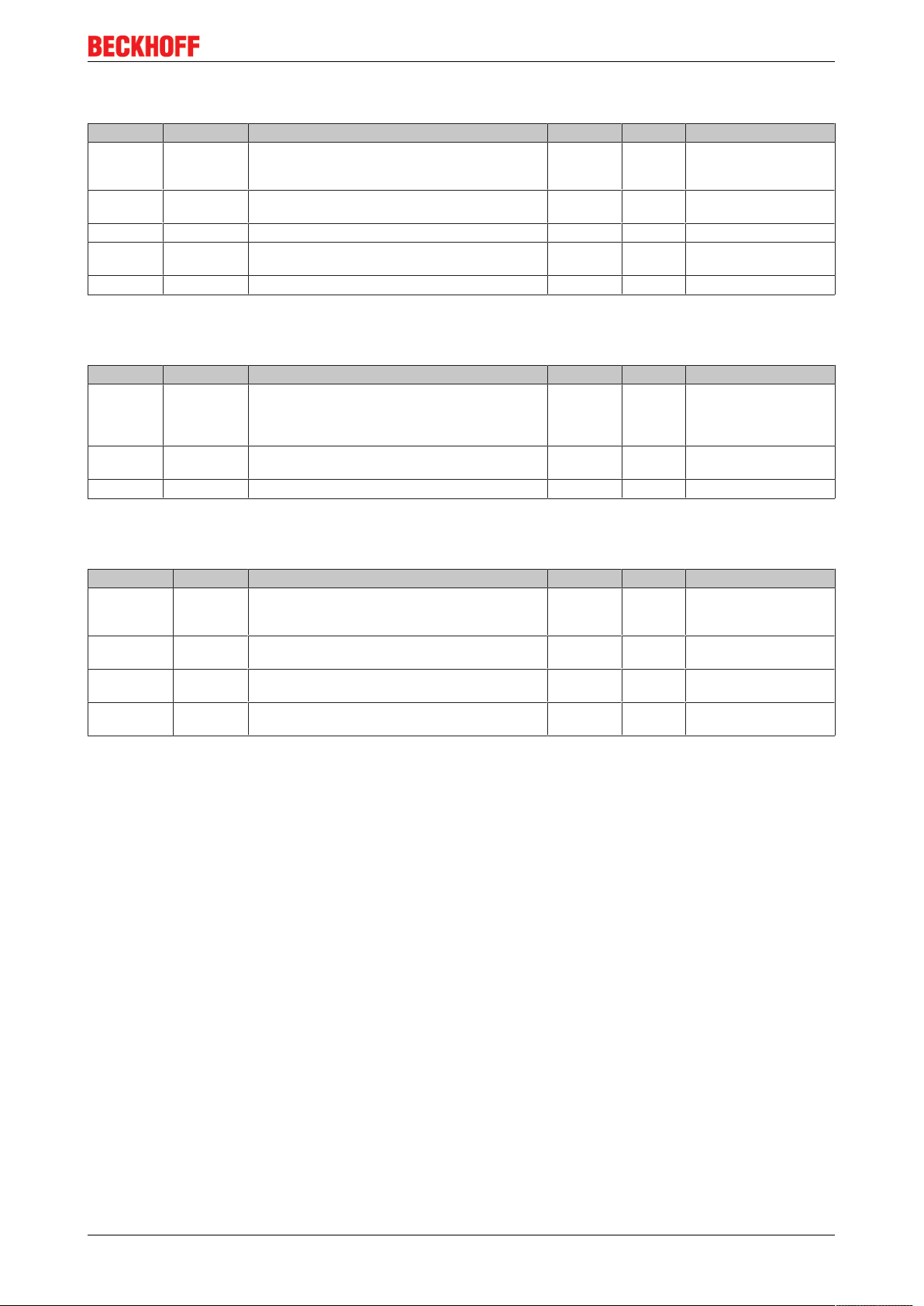

4.5.1.1.1 Index 1011 Restore default parameters

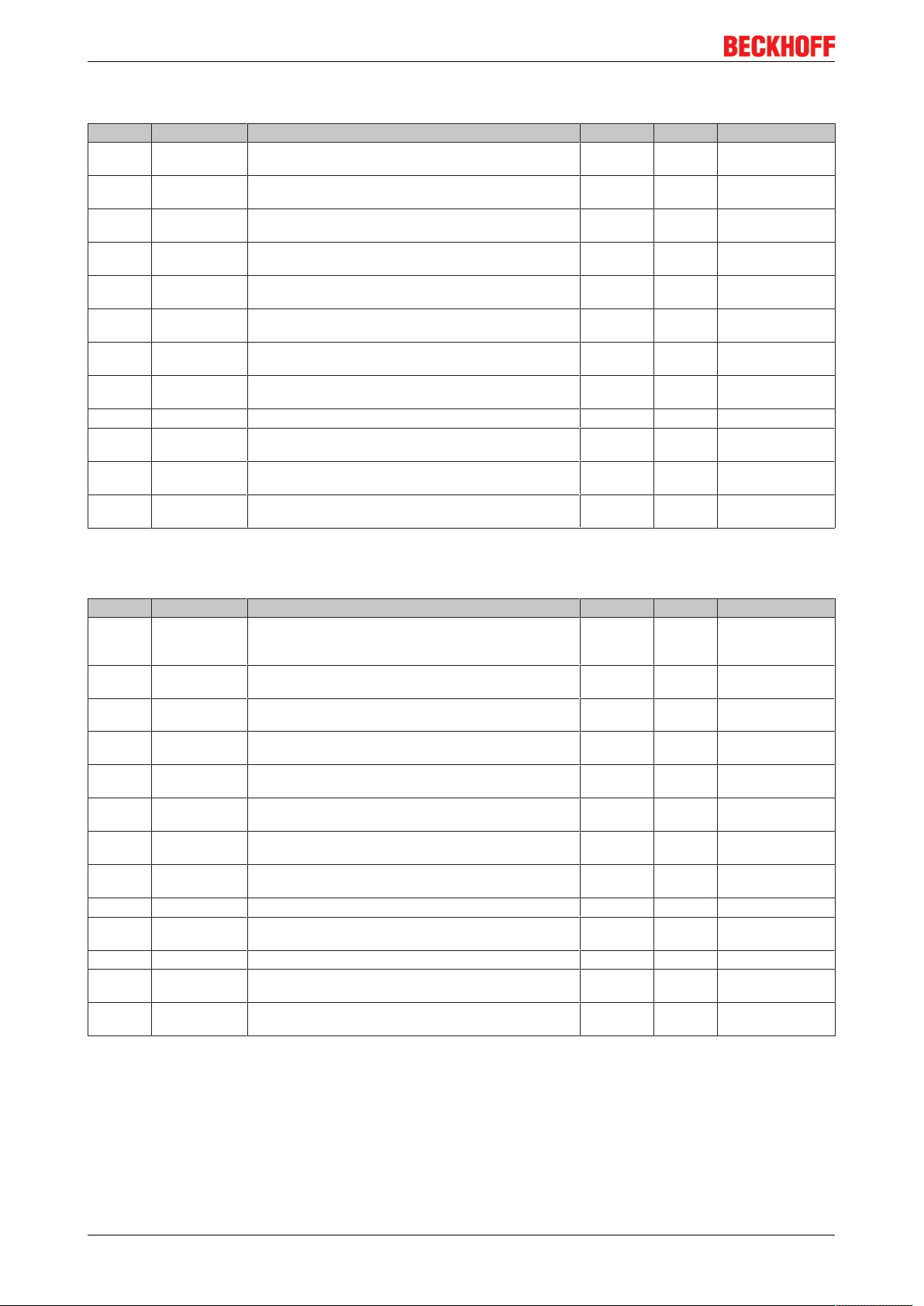

Index Name Meaning Data type Flags Default

1011:0 Restore default

parameters

1011:01 SubIndex 001 If this object is set to "0x64616F6C" in the set value dialog,

4.5.1.1.2 Index 8000 DPO Settings Ch.1

Index Name Meaning Data type Flags Default

8010:0 DPO Settings

Ch.1

8010:02 Default State Us The output adopts this value if F707:01 is not set boolean RW 0x01 (1

8010:03 Default State Up The output adopts this value if F707:01 is not set boolean RW 0x01 (1

8010:11 Characteristic Specifies the characteristic with which the current monitor-

8010:12 Nominal CurrentUsNominal maximum current at the output UINT16 RW 0x0FA0 (4000

Making default settings UINT8 RO 0x01 (1

all backup objects are reset to their delivery state.

ing reacts:

0

: very fast acting

dec

1

: fast acting

dec

2

: slow acting

dec

3

: time delay

dec

UINT32 RW 0x00000000 (0

UINT8 RO 0x13 (19

UINT16 RW 0x0001 (1

)

dec

)

dec

)

dec

)

dec

dec

)

dec

)

)

dec

8010:13 Nominal CurrentUpNominal maximum current at the output UINT16 RW 0x0FA0 (4000

EP9214-0023 and EP9224-002350 Version: 2.3.1

)

dec

Page 51

Comissioning and Configuration

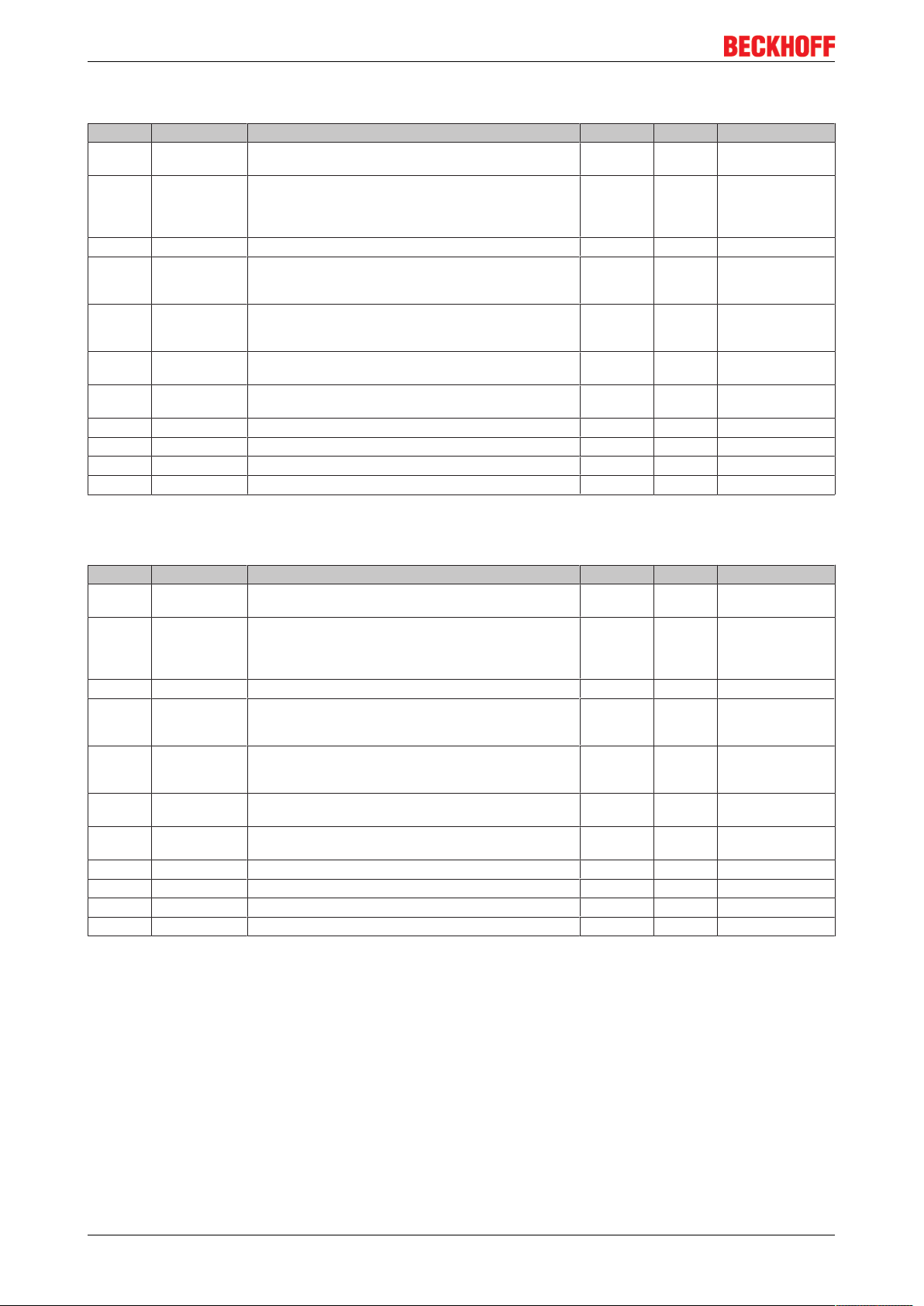

4.5.1.1.3 Index 8010 DPO Settings Ch.2

Index Name Meaning Data type Flags Default

8010:0 DPO Settings

Ch.2

8010:02 Default State Us The output adopts this value if F707:01 is not set boolean RW 0x01 (1

8010:03 Default State Up The output adopts this value if F707:01 is not set boolean RW 0x01 (1

8010:11 Characteristic Specifies the characteristic with which the current monitor-

ing reacts:

0

: very fast acting

dec

1

: fast acting

dec

2

: slow acting

dec

3

: time delay

dec

8010:12 Nominal CurrentUsNominal maximum current at the output UINT16 RW 0x0FA0 (4000

UINT8 RO 0x13 (19

dec

dec

UINT16 RW 0x0001 (1

)

dec

)

)

dec

)

)

dec

8010:13 Nominal CurrentUpNominal maximum current at the output UINT16 RW 0x0FA0 (4000

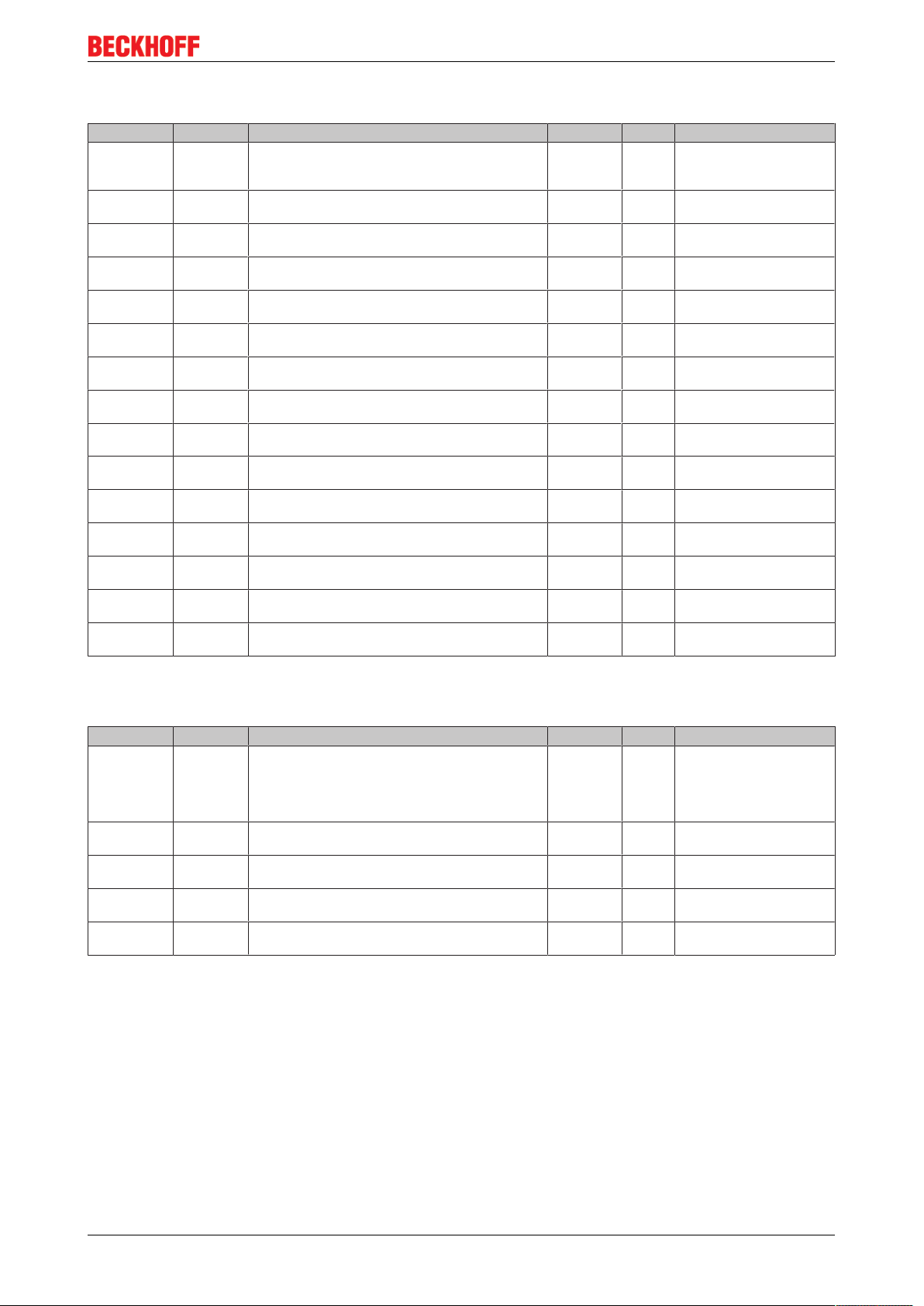

4.5.1.1.4 Index 8020 DPO Settings Ch.3

Index Name Meaning Data type Flags Default

8020:0 DPO Settings

Ch.3

8020:02 Default State Us The output adopts this value if F707:01 is not set boolean RW 0x01 (1

8020:03 Default State Up The output adopts this value if F707:01 is not set boolean RW 0x01 (1

8020:11 Characteristic Specifies the characteristic with which the current monitor-

ing reacts:

0

: very fast acting

dec

1

: fast acting

dec

2

: slow acting

dec

3

: time delay

dec

UINT8 RO 0x13 (19

dec

dec

UINT16 RW 0x0001 (1

)

dec

)

)

dec

8020:12 Nominal CurrentUsNominal maximum current at the output UINT16 RW 0x0FA0 (4000

8020:13 Nominal CurrentUpNominal maximum current at the output UINT16 RW 0x0FA0 (4000

4.5.1.1.5 Index 8030 DPO Settings Ch.4

Index Name Meaning Data type Flags Default

8030:0 DPO Settings

Ch.4

8030:02 Default State Us The output adopts this value if F707:01 is not set boolean RW 0x01 (1

8030:03 Default State Up The output adopts this value if F707:01 is not set boolean RW 0x01 (1

8030:11 Characteristic Specifies the characteristic with which the current monitor-

ing reacts:

0

: very fast acting

dec

1

: fast acting

dec

2

: slow acting

dec

3

: time delay

dec

8030:12 Nominal CurrentUsNominal maximum current at the output UINT16 RW 0x0FA0 (4000

UINT8 RO 0x13 (19

dec

dec

UINT16 RW 0x0001 (1

)

dec

)

)

dec

)

dec

)

)

dec

)

dec

)

)

dec

8030:13 Nominal CurrentUpNominal maximum current at the output UINT16 RW 0x0FA0 (4000

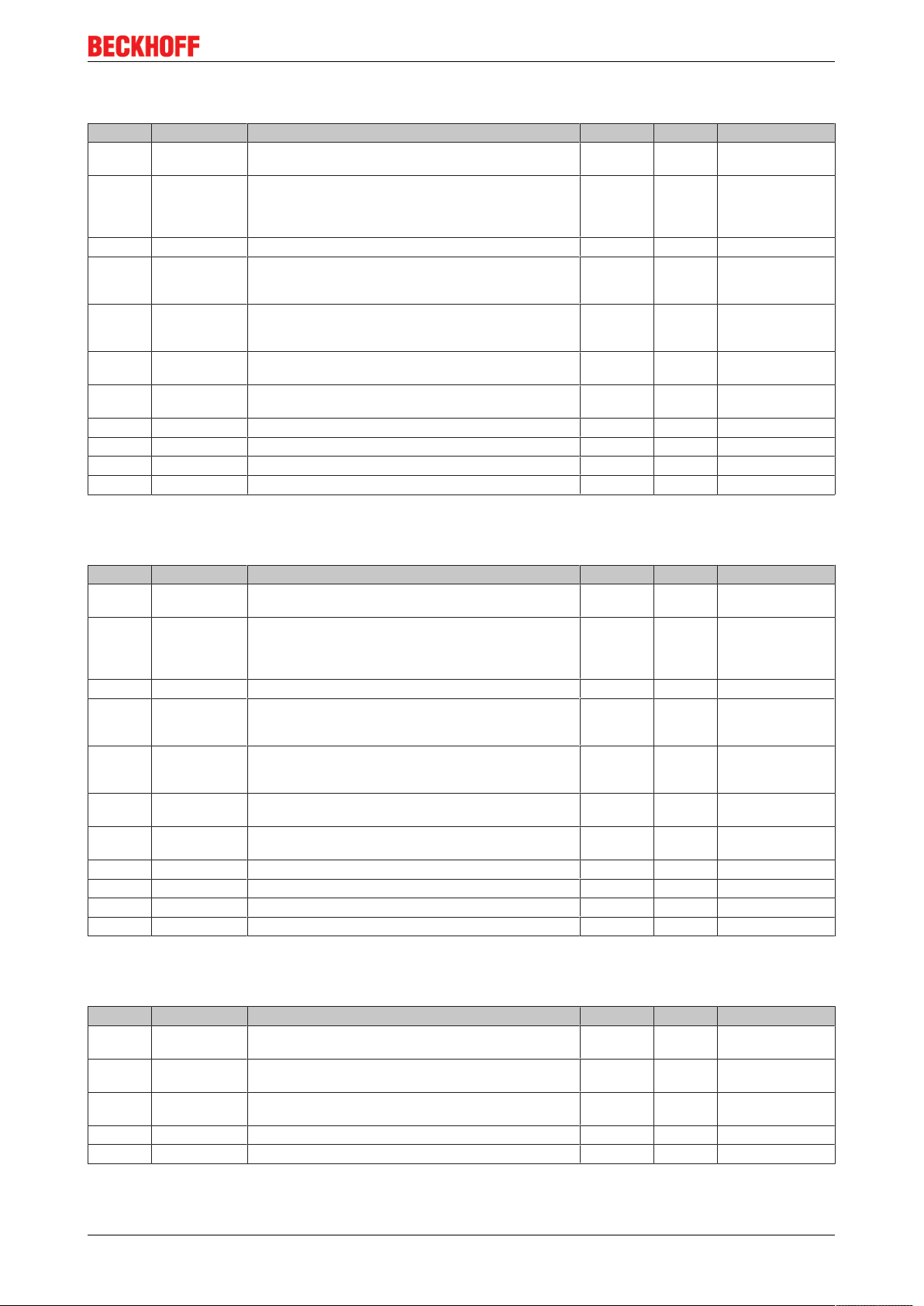

4.5.1.1.6 Index F707 DPO Outputs Device

Index Name Meaning Data type Flags Default

F707:0 DPO Outputs

Device

F707:01 Enable Control

Via Fieldbus

0

: All outputs are set to their default values (80X0:02,

bin

80X0:03)

1

: All outputs are set according to their PDOs (70X0:01,

bin

70X0:02)

F707:04 Global Reset All error bits are reset boolean RO 0x00 (0

UINT8 RO 0x04 (4

boolean RO 0x00 (0

)

dec

)

dec

)

dec

EP9214-0023 and EP9224-0023 51Version: 2.3.1

)

dec

Page 52

Comissioning and Configuration

4.5.1.1.7 Index F80E DPO Settings Device

Index Name Meaning Data type Flags Default

F80E:0 DPO Settings

UINT8 RO 0x11 (17

Device

F80E:11 Startup Delay Sets the time that is kept between two switch-on proce-

UINT16 RW 0x0001 (1

dures:

1

: fast (10ms)

dec

2

: moderate (100ms)

dec

3

: slow (200ms)

dec

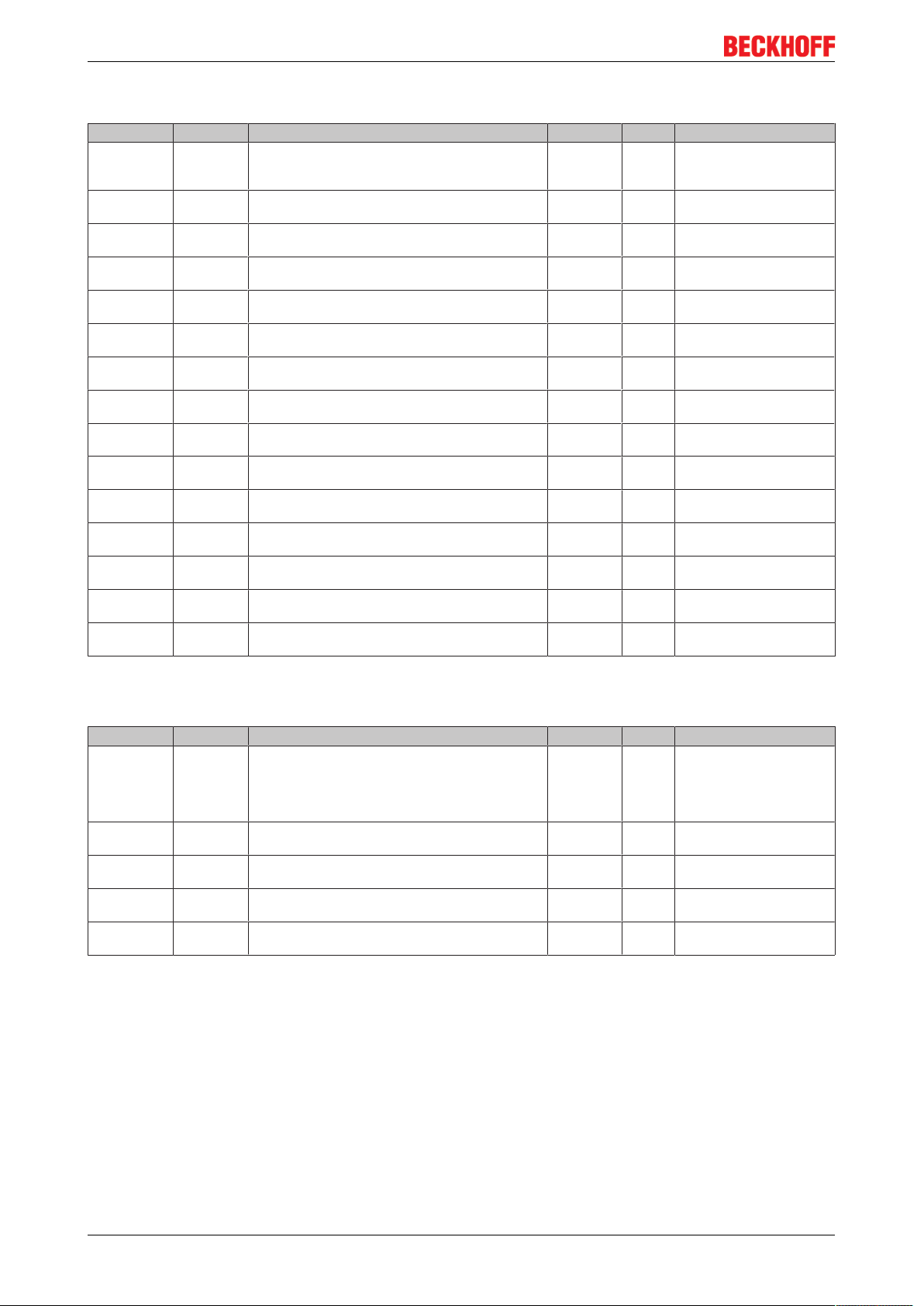

4.5.1.2 Standard objects

The standard objects have the same meaning for all EtherCAT slaves.

4.5.1.2.1 Index 1000 Device type

Index Name Meaning Data type Flags Default

1000:0 Device type Device type of the EtherCAT slave: The low word contains

the CoE profile used (5001). The high word contains the

module profile according to the modular device profile.

UINT32 RO 0x010E1389

(17699721

)

dec

)

dec

)

dec

4.5.1.2.2 Index 1008 Device name

Index Name Meaning Data type Flags Default

1008:0 Device name Device name of the EtherCAT slave STRING RO EP9214-0023

4.5.1.2.3 Index 1009 Hardware version

Index Name Meaning Data type Flags Default

1009:0 Hardware ver-

Hardware version of the EtherCAT slave STRING RO

sion

4.5.1.2.4 Index 100A Software version

Index Name Meaning Data type Flags Default

100A:0 Software ver-

Firmware version of the EtherCAT slave STRING RO 06

sion

4.5.1.2.5 Index 1018 Identity

Index Name Meaning Data type Flags Default

1018:0 Identity Information for identifying the slave UINT8 RO 0x04 (4

1018:01 Vendor ID Vendor ID of the EtherCAT slave UINT32 RO 0x00000002 (2

1018:02 Product code Product code of the EtherCAT slave UINT32 RO 0x23FE4052

(603865170

1018:03 Revision Revision numberof the EtherCAT slave; the low word (bit

UINT32 RO 0x00000000 (0

0-15) indicates the special terminal number, the high word

(bit 16-31) refers to the device description

1018:04 Serial number Serial number of the EtherCAT slave; the low byte (bit 0-7)

UINT32 RO 0x00000000 (0

of the low word contains the year of production, the high

byte (bit 8-15) of the low word contains the week of production, the high word (bit 16-31) is 0

)

dec

dec

)

dec

)

)

dec

)

dec

EP9214-0023 and EP9224-002352 Version: 2.3.1

Page 53

Comissioning and Configuration

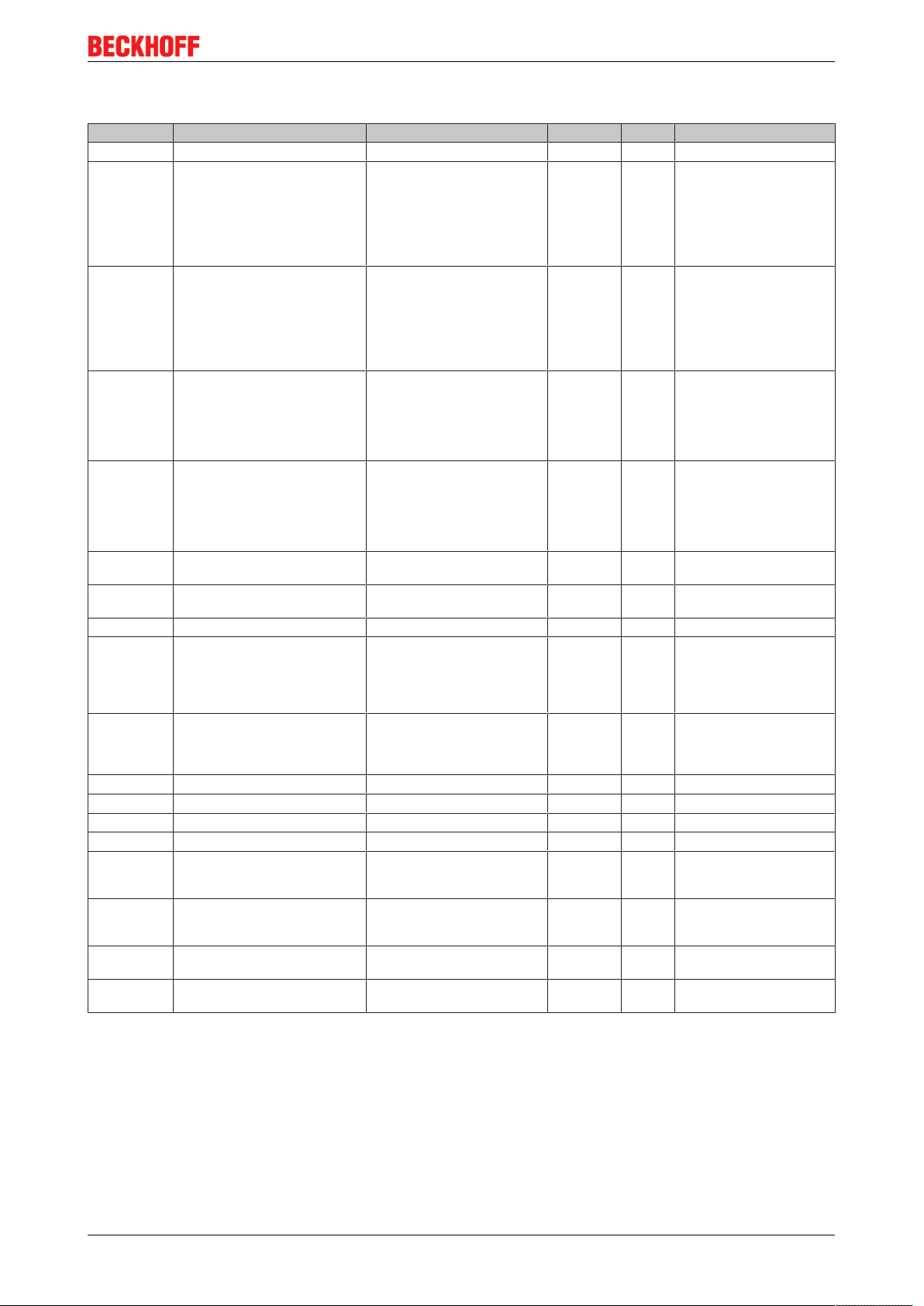

4.5.1.2.6 Index 10F0 Backup parameter handling

Index Name Meaning Data type Flags Default

10F0:0 Backup parame-

ter handling

Information for standardized loading and saving of backup

entries

UINT8 RO 0x01 (1

)

dec

10F0:01 Checksum Checksum across all backup entries of the EtherCAT slave UINT32 RO 0x00000000 (0

4.5.1.2.7 Index 1600 DPO RxPDO-Map Outputs Ch.1

Index Name Meaning Data type Flags Default

1600:0 DPO RxPDO-

Map Outputs

Ch.1

1600:01 SubIndex 001 1. PDO Mapping entry (object 0x7000 (DPO Outputs Ch.1),

1600:02 SubIndex 002 2. PDO Mapping entry (object 0x7000 (DPO Outputs Ch.1),

1600:03 SubIndex 003 3. PDO Mapping entry (2 bits align) UINT32 RO 0x0000:00, 2

1600:04 SubIndex 004 4. PDO Mapping entry (object 0x7000 (DPO Outputs Ch.1),

1600:05 SubIndex 005 5. PDO Mapping entry (object 0x7000 (DPO Outputs Ch.1),

1600:06 SubIndex 006 6. PDO Mapping entry (10 bits align) UINT32 RO 0x0000:00, 10

PDO Mapping RxPDO 1 UINT8 RO 0x06 (6

UINT32 RO 0x7000:01, 1

entry 0x01 (Output Us))

UINT32 RO 0x7000:02, 1

entry 0x02 (Output Up))

UINT32 RO 0x7000:05, 1

entry 0x05 (Reset Us))

UINT32 RO 0x7000:06, 1

entry 0x06 (Reset Up))

)

dec

)

dec

4.5.1.2.8 Index 1601 DPO RxPDO-Map Outputs Ch.2

Index Name Meaning Data type Flags Default

1601:0 DPO RxPDO-

Map Outputs

PDO Mapping RxPDO 2 UINT8 RO 0x06 (6

)

dec

Ch.2

1601:01 SubIndex 001 1. PDO Mapping entry (object 0x7010 (DPO Outputs Ch.2),

UINT32 RO 0x7010:01, 1

entry 0x01 (Output Us))

1601:02 SubIndex 002 2. PDO Mapping entry (object 0x7010 (DPO Outputs Ch.2),

UINT32 RO 0x7010:02, 1

entry 0x02 (Output Up))

1601:03 SubIndex 003 3. PDO Mapping entry (2 bits align) UINT32 RO 0x0000:00, 2

1601:04 SubIndex 004 4. PDO Mapping entry (object 0x7010 (DPO Outputs Ch.2),

UINT32 RO 0x7010:05, 1

entry 0x05 (Reset Us))

1601:05 SubIndex 005 5. PDO Mapping entry (object 0x7010 (DPO Outputs Ch.2),

UINT32 RO 0x7010:06, 1

entry 0x06 (Reset Up))

1601:06 SubIndex 006 6. PDO Mapping entry (10 bits align) UINT32 RO 0x0000:00, 10

4.5.1.2.9 Index 1602 DPO RxPDO-Map Outputs Ch.3

Index Name Meaning Data type Flags Default

1602:0 DPO RxPDO-

Map Outputs

Ch.3

1602:01 SubIndex 001 1. PDO Mapping entry (object 0x7020 (DPO Outputs Ch.3),

1602:02 SubIndex 002 2. PDO Mapping entry (object 0x7020 (DPO Outputs Ch.3),

1602:03 SubIndex 003 3. PDO Mapping entry (2 bits align) UINT32 RO 0x0000:00, 2

1602:04 SubIndex 004 4. PDO Mapping entry (object 0x7020 (DPO Outputs Ch.3),

1602:05 SubIndex 005 5. PDO Mapping entry (object 0x7020 (DPO Outputs Ch.3),

1602:06 SubIndex 006 6. PDO Mapping entry (10 bits align) UINT32 RO 0x0000:00, 10

PDO Mapping RxPDO 3 UINT8 RO 0x06 (6

UINT32 RO 0x7020:01, 1

entry 0x01 (Output Us))

UINT32 RO 0x7020:02, 1

entry 0x02 (Output Up))

UINT32 RO 0x7020:05, 1

entry 0x05 (Reset Us))

UINT32 RO 0x7020:06, 1

entry 0x06 (Reset Up))

)

dec

EP9214-0023 and EP9224-0023 53Version: 2.3.1

Page 54

Comissioning and Configuration

4.5.1.2.10 Index 1603 DPO RxPDO-Map Outputs Ch.4

Index Name Meaning Data type Flags Default

1603:0 DPO RxPDO-

Map Outputs

PDO Mapping RxPDO 4 UINT8 RO 0x06 (6

)

dec

Ch.4

1603:01 SubIndex 001 1. PDO Mapping entry (object 0x7030 (DPO Outputs Ch.4),

UINT32 RO 0x7030:01, 1

entry 0x01 (Output Us))

1603:02 SubIndex 002 2. PDO Mapping entry (object 0x7030 (DPO Outputs Ch.4),

UINT32 RO 0x7030:02, 1

entry 0x02 (Output Up))

1603:03 SubIndex 003 3. PDO Mapping entry (2 bits align) UINT32 RO 0x0000:00, 2

1603:04 SubIndex 004 4. PDO Mapping entry (object 0x7030 (DPO Outputs Ch.4),

UINT32 RO 0x7030:05, 1

entry 0x05 (Reset Us))

1603:05 SubIndex 005 5. PDO Mapping entry (object 0x7030 (DPO Outputs Ch.4),

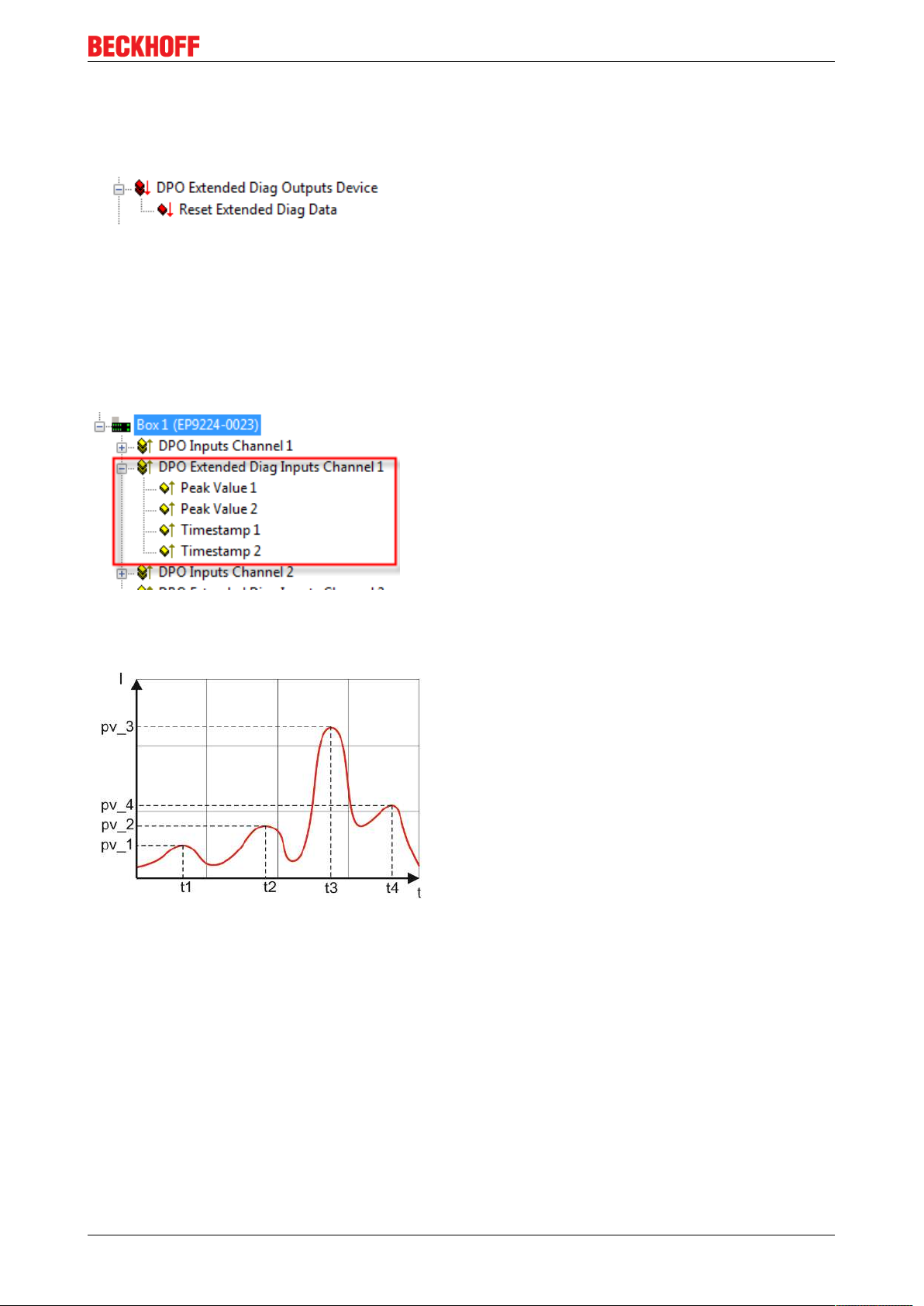

UINT32 RO 0x7030:06, 1