Page 1

Documentation

EP7211

Servomotor module with OCT

Version:

Date:

1.0

2019-08-01

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................5

1.1 Notes on the documentation..............................................................................................................5

1.2 Safety instructions .............................................................................................................................6

1.3 Documentation issue status ..............................................................................................................7

2 Product overview.......................................................................................................................................8

2.1 EtherCAT Box - Introduction..............................................................................................................8

2.2 EP7211-x034 - Introduction.............................................................................................................10

2.3 Technical data .................................................................................................................................11

2.4 Scope of supply ...............................................................................................................................12

2.5 Technology ......................................................................................................................................13

3 Mounting and cabling..............................................................................................................................15

3.1 Mounting .........................................................................................................................................15

3.1.1 Dimensions ...................................................................................................................... 15

3.1.2 Fixing ............................................................................................................................... 16

3.1.3 Functional earth (FE) ....................................................................................................... 16

3.2 Cabling ............................................................................................................................................17

3.2.1 Power supply ................................................................................................................... 18

3.2.2 EtherCAT ......................................................................................................................... 20

3.2.3 Motor, brake and feedback system.................................................................................. 22

3.2.4 Hardware Enable / Safe Torque Off ................................................................................ 24

3.2.5 Touch Probe .................................................................................................................... 27

4 Commissioning........................................................................................................................................29

4.1 Activate motor output stage.............................................................................................................29

4.2 Configuration in TwinCAT................................................................................................................29

4.3 Start-up and parameter configuration..............................................................................................30

4.3.1 Integration into the NC configuration ............................................................................... 30

4.3.2 Settings with the Drive Manager...................................................................................... 34

4.3.3 Settings in the CoE register ............................................................................................. 39

4.3.4 NC settings ...................................................................................................................... 42

4.3.5 Commissioning without NC, status word/control word..................................................... 48

4.3.6 Settings for the automatic configuration .......................................................................... 51

4.3.7 Configure end position monitoring ................................................................................... 53

4.3.8 Homing ............................................................................................................................ 54

4.3.9 Touch Probe .................................................................................................................... 57

4.4 Drive profiles....................................................................................................................................61

4.5 Operation modes .............................................................................................................................62

4.5.1 Overview.......................................................................................................................... 62

4.5.2 CSV ................................................................................................................................. 63

4.5.3 CST.................................................................................................................................. 66

4.5.4 CSTCA............................................................................................................................. 69

4.5.5 CSP ................................................................................................................................. 72

4.6 Process data MDP 742....................................................................................................................76

4.7 DS402 process data ........................................................................................................................80

EP7211 3Version: 1.0

Page 4

Table of contents

4.8 Object description (MDP 742) .........................................................................................................84

4.8.1 Restore object.................................................................................................................. 84

4.8.2 Configuration data ........................................................................................................... 84

4.8.3 Configuration data (vendor-specific)................................................................................ 91

4.8.4 Command object.............................................................................................................. 91

4.8.5 Input data......................................................................................................................... 91

4.8.6 Output data ...................................................................................................................... 93

4.8.7 Information / diagnosis data............................................................................................. 95

4.8.8 Standard objects.............................................................................................................. 98

4.9 Object description (DS402) ...........................................................................................................107

4.9.1 Configuration data ......................................................................................................... 108

4.9.2 Configuration data (vendor-specific).............................................................................. 113

4.9.3 Command object ........................................................................................................... 113

4.9.4 Input/output data............................................................................................................ 114

4.9.5 Information / diagnosis data .......................................................................................... 119

4.9.6 Standard objects............................................................................................................ 122

5 Appendix ................................................................................................................................................129

5.1 General operating conditions.........................................................................................................129

5.2 Firmware Update EL/ES/EM/ELM/EPxxxx ....................................................................................130

5.2.1 Device description ESI file/XML..................................................................................... 131

5.2.2 Firmware explanation .................................................................................................... 134

5.2.3 Updating controller firmware *.efw................................................................................. 135

5.2.4 FPGA firmware *.rbf....................................................................................................... 136

5.2.5 Simultaneous updating of several EtherCAT devices.................................................... 140

5.3 EtherCAT Box- / EtherCATPBox - Accessories ..........................................................................141

5.4 Servo technology - accessories.....................................................................................................141

5.5 General note on the introduction of the Beckhoff Identification Code (BIC) ..................................142

5.6 Support and Service ......................................................................................................................144

EP72114 Version: 1.0

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

Intended audience

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning these components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCATG®, EtherCATG10®, EtherCATP®, SafetyoverEtherCAT®,

TwinSAFE®, XFC®, XTS® and XPlanar® are registered trademarks of and licensed by Beckhoff Automation

GmbH. Other designations used in this publication may be trademarks whose use by third parties for their

own purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, EP1456722, EP2137893, DE102015105702 with corresponding

applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

EP7211 5Version: 1.0

Page 6

Foreword

1.2 Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

Description of instructions

In this documentation the following instructions are used.

These instructions must be read carefully and followed without fail!

DANGER

Serious risk of injury!

Failure to follow this safety instruction directly endangers the life and health of persons.

WARNING

Risk of injury!

Failure to follow this safety instruction endangers the life and health of persons.

CAUTION

Personal injuries!

Failure to follow this safety instruction can lead to injuries to persons.

NOTE

Damage to environment/equipment or data loss

Failure to follow this instruction can lead to environmental damage, equipment damage or data loss.

Tip or pointer

This symbol indicates information that contributes to better understanding.

EP72116 Version: 1.0

Page 7

Foreword

1.3 Documentation issue status

Version Comment

1.0 • First release

0.4 • Preliminary version

0.3 • Updates

0.2 • Technical data updated

0.1 • First draft

Firmware and hardware versions

This documentation refers to the firmware and hardware version that was applicable at the time the

documentation was written.

The module features are continuously improved and developed further. Modules having earlier production

statuses cannot have the same properties as modules with the latest status. However, existing properties

are retained and are not changed, so that older modules can always be replaced with new ones.

The firmware and hardware version (delivery state) can be found in the batch number (D-number) printed on

the side of the EtherCATBox.

Syntax of the batch number (D-number)

D: WW YY FF HH

WW - week of production (calendar week)

YY - year of production

FF - firmware version

HH - hardware version

Beckhoff Identification Code (BIC)

The Beckhoff Identification Code contains additional information about the delivery state of the module:

General note on the introduction of the Beckhoff Identification Code (BIC) [}142].

Example with D no. 29 10 02 01:

29 - week of production 29

10 - year of production 2010

02 - firmware version 02

01 - hardware version 01

EP7211 7Version: 1.0

Page 8

Product overview

2 Product overview

2.1 EtherCAT Box - Introduction

The EtherCAT system has been extended with EtherCAT Box modules with protection class IP67. Through

the integrated EtherCAT interface the modules can be connected directly to an EtherCAT network without an

additional Coupler Box. The high-performance of EtherCAT is thus maintained into each module.

The extremely low dimensions of only 126x30x26.5 mm (hxw xd) are identical to those of the Fieldbus

Box extension modules. They are thus particularly suitable for use where space is at a premium. The small

mass of the EtherCAT modules facilitates applications with mobile I/O interface (e.g. on a robot arm). The

EtherCAT connection is established via screened M8connectors.

Fig.1: EtherCAT Box Modules within an EtherCAT network

The robust design of the EtherCAT Box modules enables them to be used directly at the machine. Control

cabinets and terminal boxes are now no longer required. The modules are fully sealed and therefore ideally

prepared for wet, dirty or dusty conditions.

Pre-assembled cables significantly simplify EtherCAT and signal wiring. Very few wiring errors are made, so

that commissioning is optimized. In addition to pre-assembled EtherCAT, power and sensor cables, fieldconfigurable connectors and cables are available for maximum flexibility. Depending on the application, the

sensors and actuators are connected through M8 or M12connectors.

The EtherCAT modules cover the typical range of requirements for I/O signals with protection class IP67:

• digital inputs with different filters (3.0ms or 10μs)

• digital outputs with 0.5 or 2A output current

• analog inputs and outputs with 16bit resolution

• Thermocouple and RTD inputs

• Stepper motor modules

XFC (eXtreme Fast Control Technology) modules, including inputs with time stamp, are also available.

EP72118 Version: 1.0

Page 9

Fig.2: EtherCAT Box with M8 connections for sensors/actuators

Product overview

Fig.3: EtherCAT Box with M12 connections for sensors/actuators

Basic EtherCAT documentation

You will find a detailed description of the EtherCAT system in the Basic System Documentation for

EtherCAT, which is available for download from our website (www.beckhoff.com) under Downloads.

EtherCAT XML Device Description

You will find XML files (XML Device Description Files) for Beckhoff EtherCAT modules on our website (www.beckhoff.com) under Downloads, in the Configuration Files area.

EP7211 9Version: 1.0

Page 10

Product overview

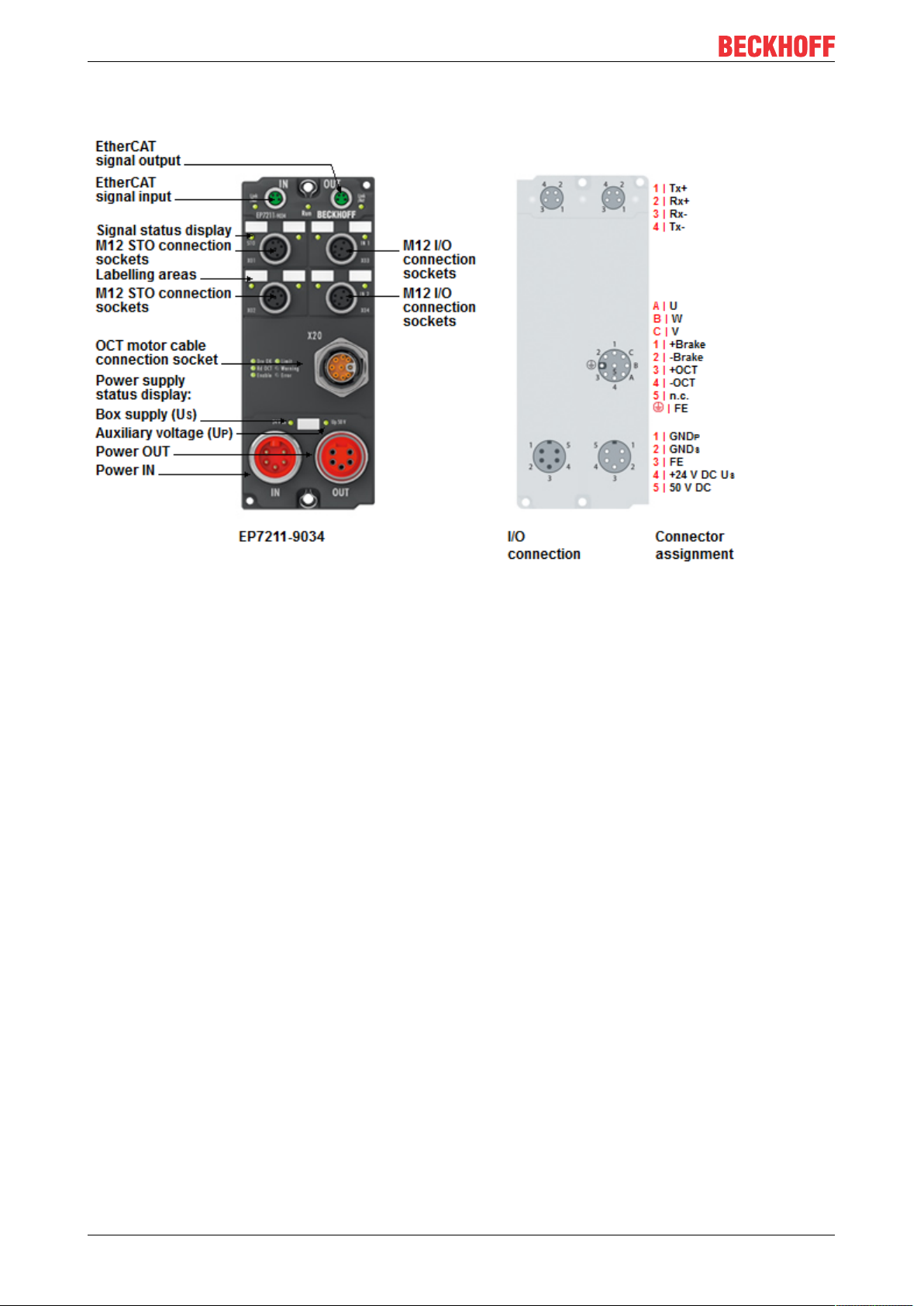

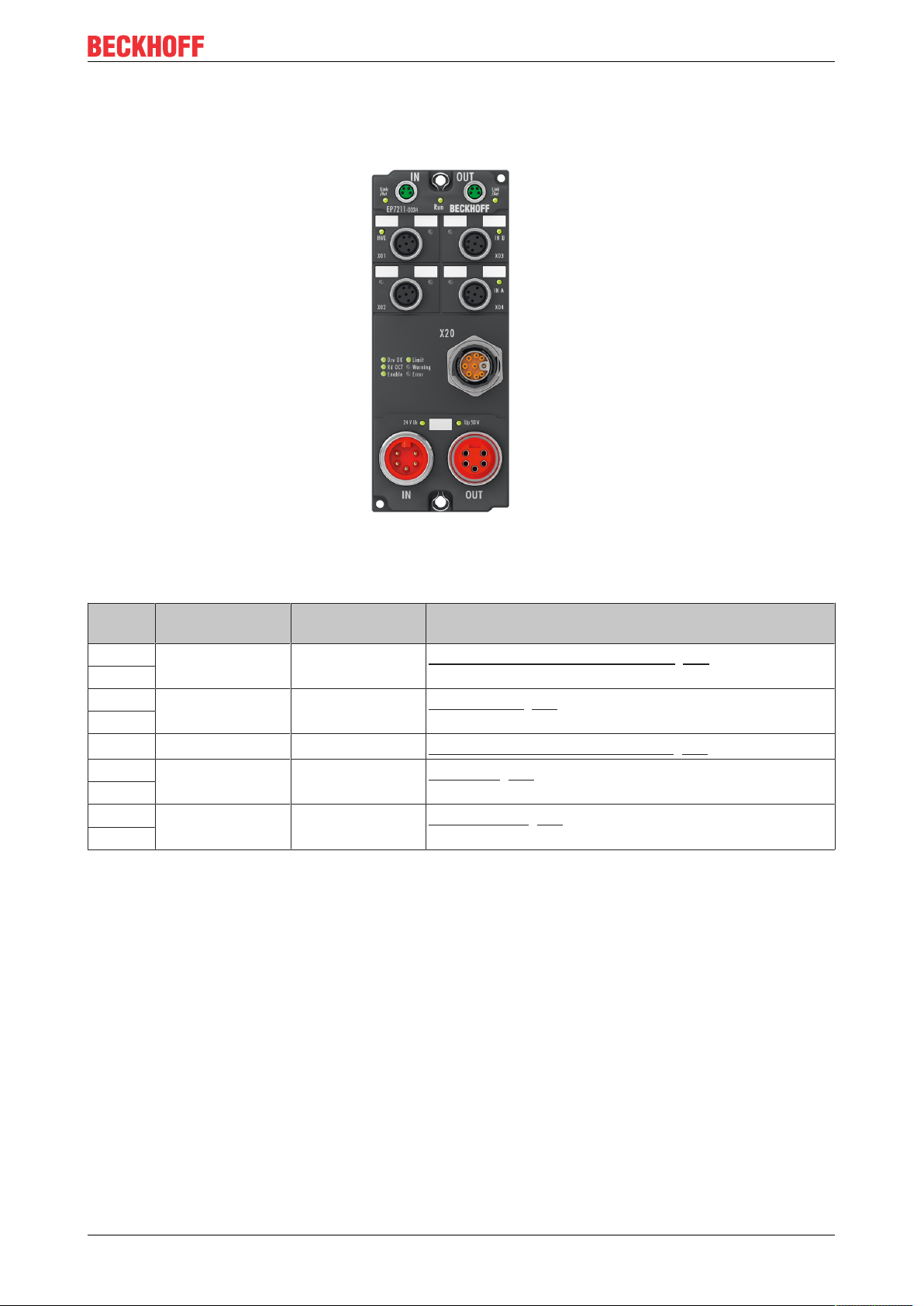

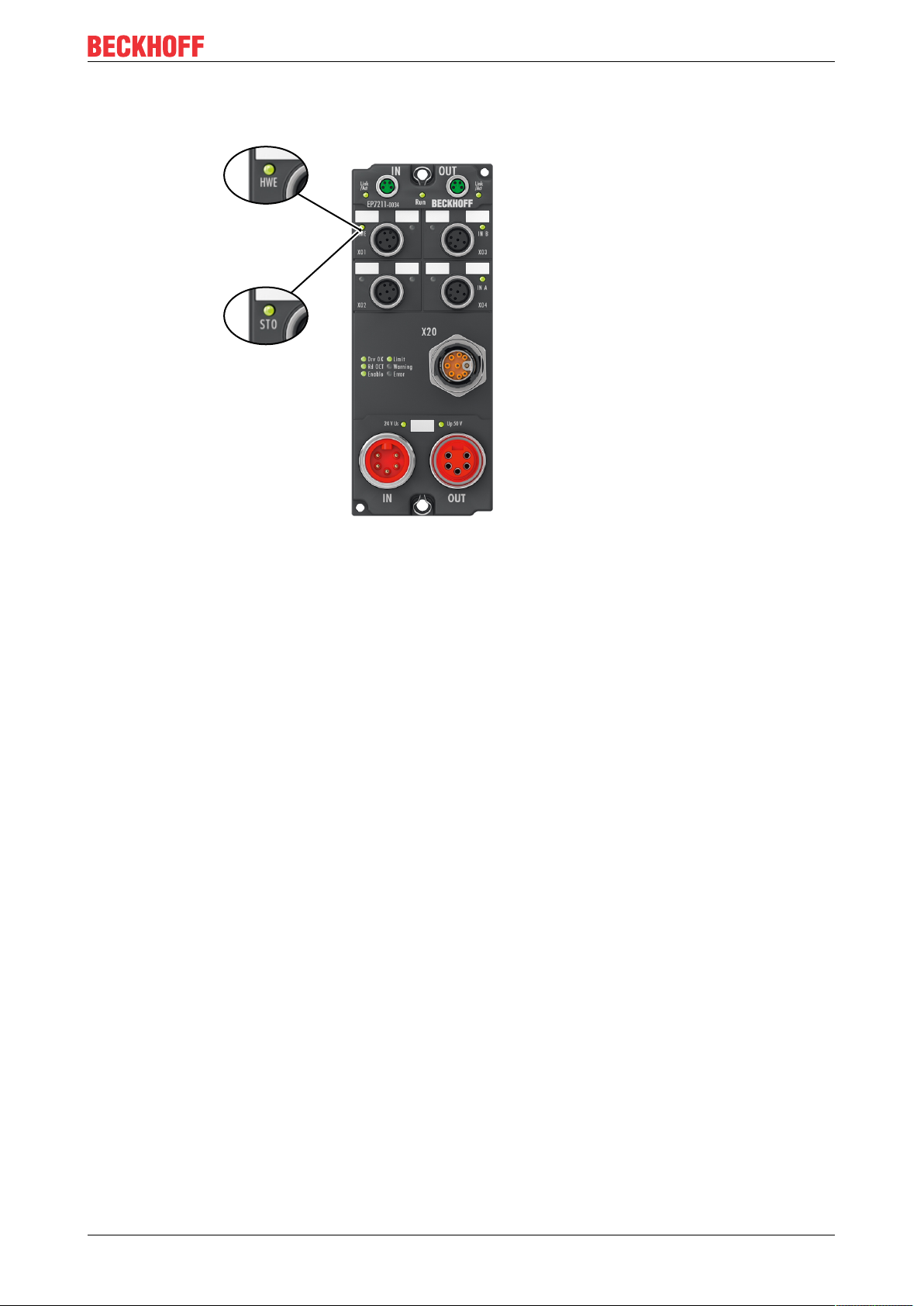

2.2 EP7211-x034 - Introduction

Fig.4: EP7211-9034

The EP7211-x034 EtherCAT Box is a single-channel servo drive for synchronous servomotors with OCT

feedback system.

It is intended for operation with motors from the AM81xx series. These motors have an electronic

identification plate. EP7211-x034 can read the electronic identification plate in order to set the motor

parameters in TwinCAT automatically.

The EP7211-9034 variant supports the "Safe Torque Off" (STO) function. This variant is non-reactive and

can be used in a safety application.

Process-side interfaces of EP7211-x034:

• Motor

• Motor brake

• OCT communication:

◦ Feedback

◦ Electronic identification plate readout

• 2 x touch probe

• Hardware Enable (EP7211-0034): digital input for activating the output stage

• Safe Torque Off (EP7211-9034)

The motor is connected via a hybrid cable. The hybrid cable contains the wires for the motor phases, the

brake and the OCT communication.

EP7211-x034 can be controlled via the MDP742 or alternatively the DS402 drive profile.

EP721110 Version: 1.0

Page 11

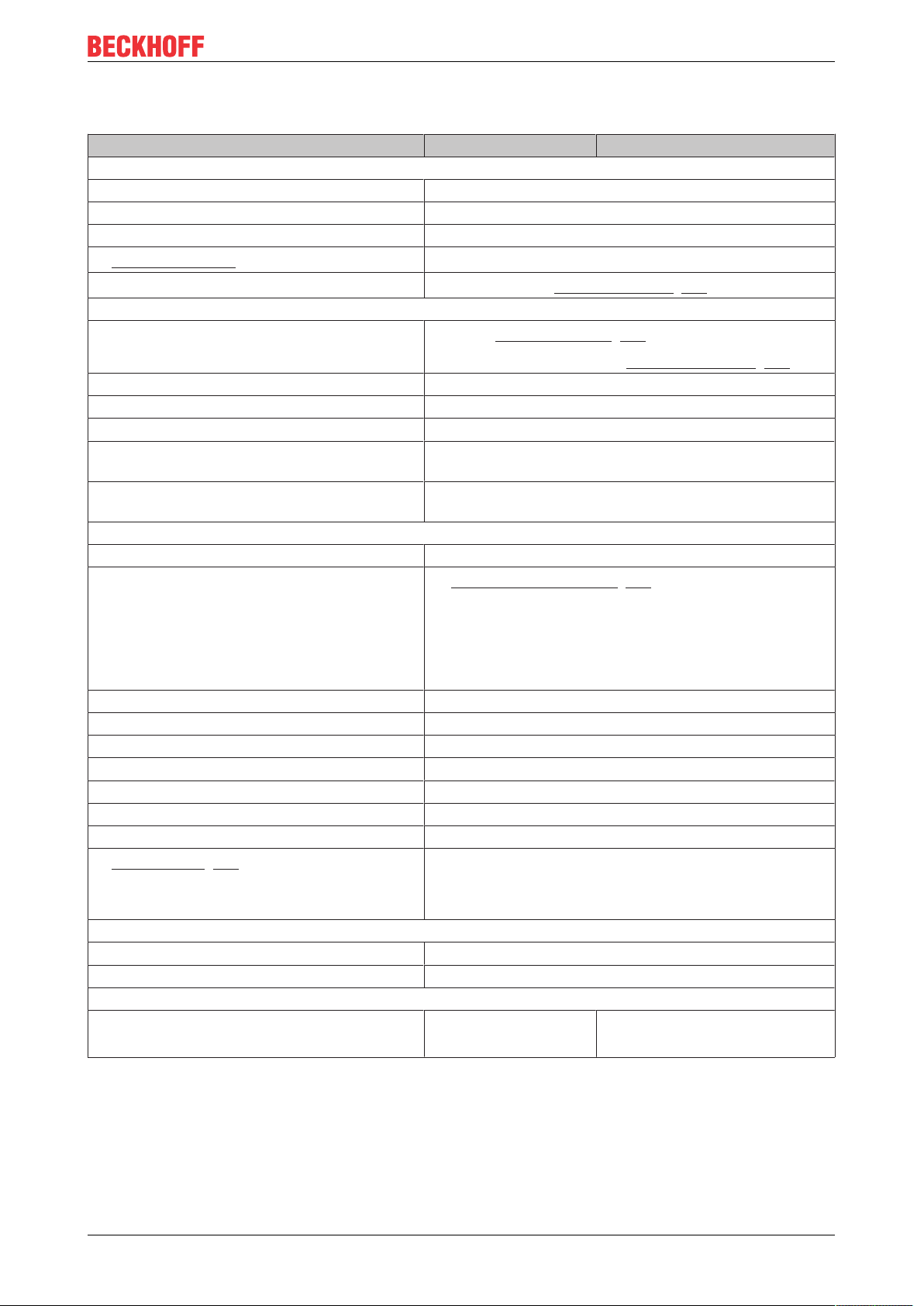

2.3 Technical data

Technical data EP7211-0034 EP7211-9034

Fieldbus

Fieldbus EtherCAT

Connection 2 x M8 socket (green)

Electrical isolation 500V (fieldbus / IO)

Distributed Clocks

Process image

Supply

Connection

Control voltage U

DC link supply voltage U

S

P

Supply of the module electronics from the control voltage U

Current consumption of the module

electronics

Current consumption from the

DC link supply voltage

Motor

Motor type Synchronous servomotor

Connection

Power rating P

Nominal output current I

Peak output current I

n

n

peak

Output frequency range 0..599Hz

PWM clock frequency 16kHz

Current controller frequency 32kHz

Speed controller frequency 16kHz

Drive profile [}61]

Motor brake

Output voltage 24VDC from the control voltage U

Output current max. 0.5A, short-circuit protected

Digital inputs

Interfaces 2 x touch probe

Yes

Dependent on the operation mode [}62]

Feed: 1 x 7/8" plug, 5-pin [}18]

Downstream connection: 1 x 7/8" socket, 5-pin [}18]

24VDC (-15% / +20%)

48VDC (8 - 50VDC), not protected against polarity reversal

S

typ. 120mA

typ. 50mA

1 x iTec socket, 9-pin, M23 [}22]

Hybrid connector for:

• 1 x motor

• 1 x feedback (OCT encoder)

• 1 x brake

max. 276W

4.5A

rms

9.0A

for 1s

rms

Alternatively:

• MDP 742 (default)

• CiA DS402

S

2 x touch probe

1 x Hardware Enable

1 x Safe Torque Off (STO)

Product overview

EP7211 11Version: 1.0

Page 12

Product overview

Technical data EP7211-0034 EP7211-9034

Environmental conditions

Permissible ambient temperature

during operation

Permissible ambient temperature

during storage

Vibration/ shock resistance conforms to EN60068-2-6/ EN60068-2-27

EMC immunity/emission conforms to EN61000-6-2/ EN61000-6-4

EMC category Category C3 (auxiliary filter required)

Protection class IP65, IP66, IP67 (conforms to EN 60529)

Mechanics

Dimensions 150mmx 60mmx 26.5mm (without plug connectors)

Weight approx.500g

Installation position variable

Approvals and conformity

Approvals CE, UL in preparation

-25°C ... +60°C

-40°C ... +85°C

Category C2, C1 in preparation (auxiliary filter required)

2.4 Scope of supply

Make sure that the following components are included in the scope of delivery:

• 1x EtherCAT Box EP7211-0034 / EP7211-9034

• 2x protective caps for EtherCAT socket (mounted)

• 1x protective cap for 7/8" socket (mounted)

• 10X labels, blank (1 strip of 10)

EP721112 Version: 1.0

Page 13

Product overview

2.5 Technology

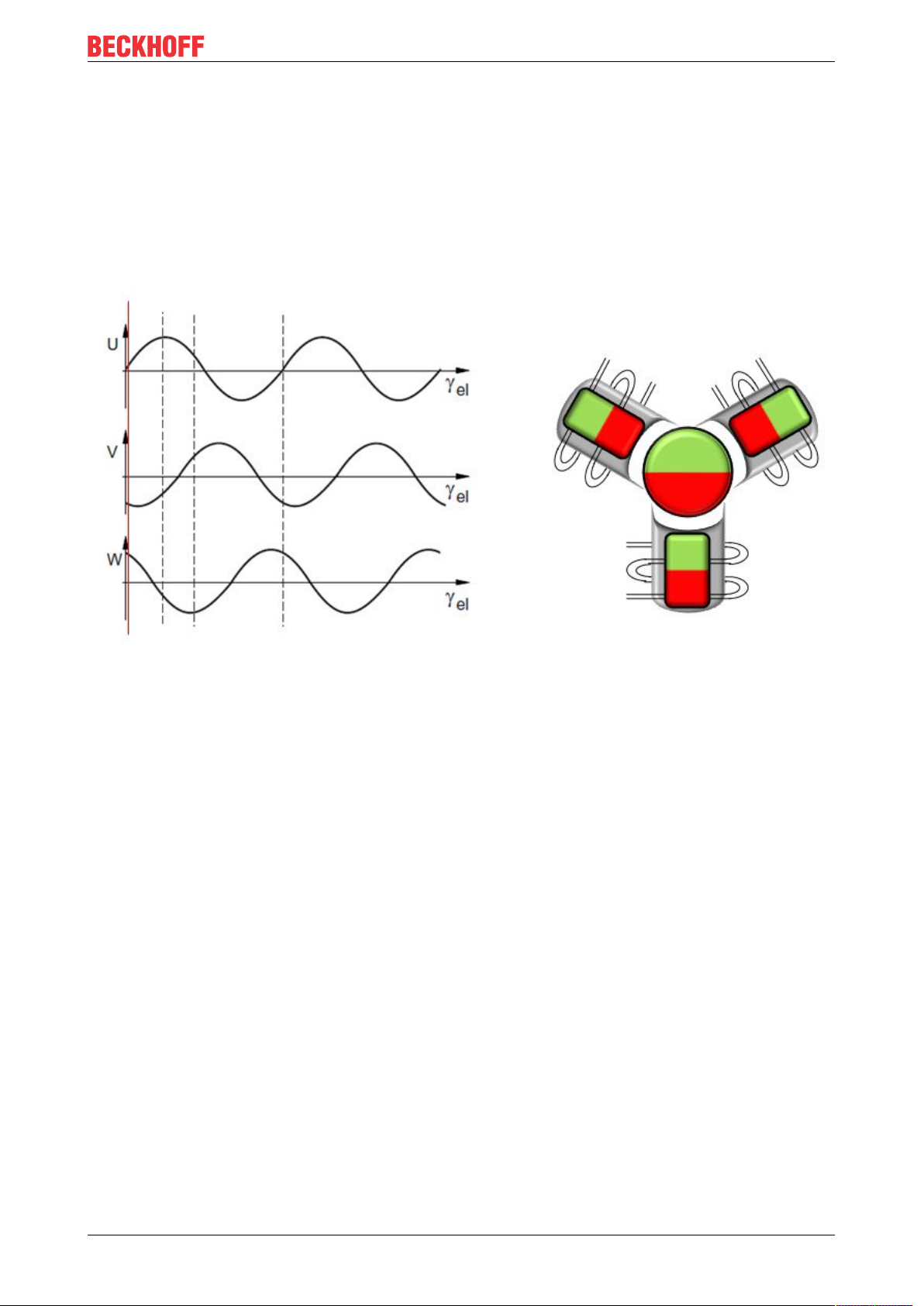

Servomotor

The servomotor is an electrical motor. Together with a servo drive the servomotor forms a drive. The

servomotor is operated in a closed control loop with position, torque or speed control.

EP7211-x034 supports control of permanent magnet synchronous motors. These consist of 3 coils which are

offset by 120° and a permanent magnet rotor.

Fig.5: Three synchronous motor coils, each offset by 120°

One Cable Technology (OCT)

In the servomotors from the AM8100-xF2 x series the feedback signals are transmitted directly via the power

supply cable, so that power and feedback system are combined in a single motor connection cable. With the

use of the One Cable technology, the information is sent reliably and without interference through a digital

interface. Since a cable and plug are omitted at both the motor and controller end, the component and

commissioning costs are reduced.

Thermal I²T motor model

The thermal I²T motor model represents the thermal behavior of the motor winding taking into account the

absolute thermal resistance Rth and the thermal capacity Cth of motor and the stator winding.

The model assumes that the motor reaches its maximum continuous operating temperature T

continuous operation with rated current I

. This temperature corresponds to 100% motor load. During

nom

nom

during

operation at rated current the motor model reaches a load of 63% after a time of τth=Rth∙Cth and slowly

reaches its continuous operating temperature.

If the motor is operated with a current that is greater than the rated current, the model reaches 100% load

more quickly.

If the load of the I²T model exceeds 100%, the requested set current is limited to the rated current, in order to

protect the motor winding thermally. The load reduces to a maximum of 100%. If the current falls below the

rated current, the load falls below 100% and the set current limitation is cancelled.

For a motor that has been cooled to ambient temperature, the time for reaching 100% load with a set current

that exceeds the rated current can be estimated with τth∙I

nom

²/I

actual

².

The actual load must be known for exact calculation of the time when the 100% load threshold is exceeded.

EP7211 13Version: 1.0

Page 14

Product overview

Fig.6: Limitation to the rated motor current

EP721114 Version: 1.0

Page 15

3 Mounting and cabling

150

60

141

Ø 4.5

3.1 Mounting

3.1.1 Dimensions

Mounting and cabling

Fig.7: Dimensions

All dimensions are given in millimeters.

Housing features

Housing material PA6 (polyamide)

Sealing compound polyurethane

Mounting two fastening holes Ø4.5mm for M4

Metal parts brass, nickel-plated

Contacts CuZn, gold-plated

Power feed through max. 16A at 40°C (according to IEC 60512-3)

Mounting position variable

Protection class IP65, IP66, IP67 (conforms to EN60529) when screwed together

Dimensions (HxWxD) approx. 150 x 60 x 26.5mm (without connectors)

EP7211 15Version: 1.0

Page 16

Mounting and cabling

FE

FE

3.1.2 Fixing

NOTE

Protect connectors against soiling!

Protection class IP67 can only be guaranteed if all cables and connectors are connected.

Protect the connections against soiling during mounting.

Mount the module with two M4 screws in the centrally located fastening holes.

The bolts must be longer than 15mm. The fastening holes in the modules have no thread.

Note when mounting that the overall height is increased further by the fieldbus connections. See chapter

Accessories.

3.1.3 Functional earth (FE)

All existing connections for the functional earth must be connected to earth:

• Fastening holes

• "FE" cores in the supply cables

Functional earth via the fastening holes

The fastening holes [}16] also serve as connections for the functional earth (FE).

Make sure that the box is earthed with low impedance via both fastening screws.

Fig.8: Functional earth via the fastening holes

Functional earth via the supply lines

The pins of the supply connectors [}18] marked with "FE" are directly connected to the functional earth

potential of the fastening holes.

Connect the functional earth of the "FE" cores in accordance with the following instructions:

• If the remote station is a device with a 7/8" connector: connect the devices with a pre-configured cable.

Possible types of preconfigured cables:

◦ Beckhoff ZK2030-1112-0xxx

◦ Beckhoff ZK2030-1114-0xxx

◦ Beckhoff ZK2030-1314-0xxx

• Otherwise: Earth the "FE" core with low impedance as near as possible to the remote station.

EP721116 Version: 1.0

Page 17

3.2 Cabling

X60 X61

X20

X04

X03

X02

X01

X40 X41

Mounting and cabling

Fig.9: Connector overview

Name Connector

type

X01 M12 0.6Nm

Tightening

torque

1)

Function

Hardware Enable / Safe Torque Off [}24]

X02

X03 M12 0.6Nm

1)

Touch Probe [}27]

X04

X20 iTec M23 -

X40 M8 0.4Nm

1)

Motor, brake and feedback system [}22]

EtherCAT [}20]

X41

X60 7/8" 1.5Nm

Power supply [}18]

X61

1)

Mount connectors on these plug connectors using a torque wrench, e.g. ZB8801 from Beckhoff.

EP7211 17Version: 1.0

Page 18

Mounting and cabling

1

2

3

4

5

IN

5

4

3

2

1

OUT

3.2.1 Power supply

3.2.1.1 Connection

Two 7/8" connectors at the low-end of the modules are used for feeding and routing the supply voltages:

• "IN" (male): left connector for feeding the supply voltages

• "OUT" (female): right connector for downstream connection

Fig.10: 7/8" connector pin assignment

NoteDefect possible through polarity reversal. The input for the DC link voltage Up is not protected

against polarity reversal. Ensure that the polarity is correct.

Pin Name Comment Core colors

1 GND

2 GND

P

S

GND to U

GND to U

P

S

Black

Blue

3 FE Functional earth Grey

4 +24 VDC U

5 +48 VDC U

1)

The core colors apply to cables of the type: Beckhoff ZK203x-xxxx.

S

P

Control voltage U

DC link voltage U

S

P

Brown

White

1)

EP721118 Version: 1.0

Page 19

Mounting and cabling

3.2.1.2 Status LEDs

The status of the supply voltages is signaled by two LEDs. A Status LED lights up green when the respective

supply voltage is present on the connector for the supply.

Fig.11: Power supply Status LEDs

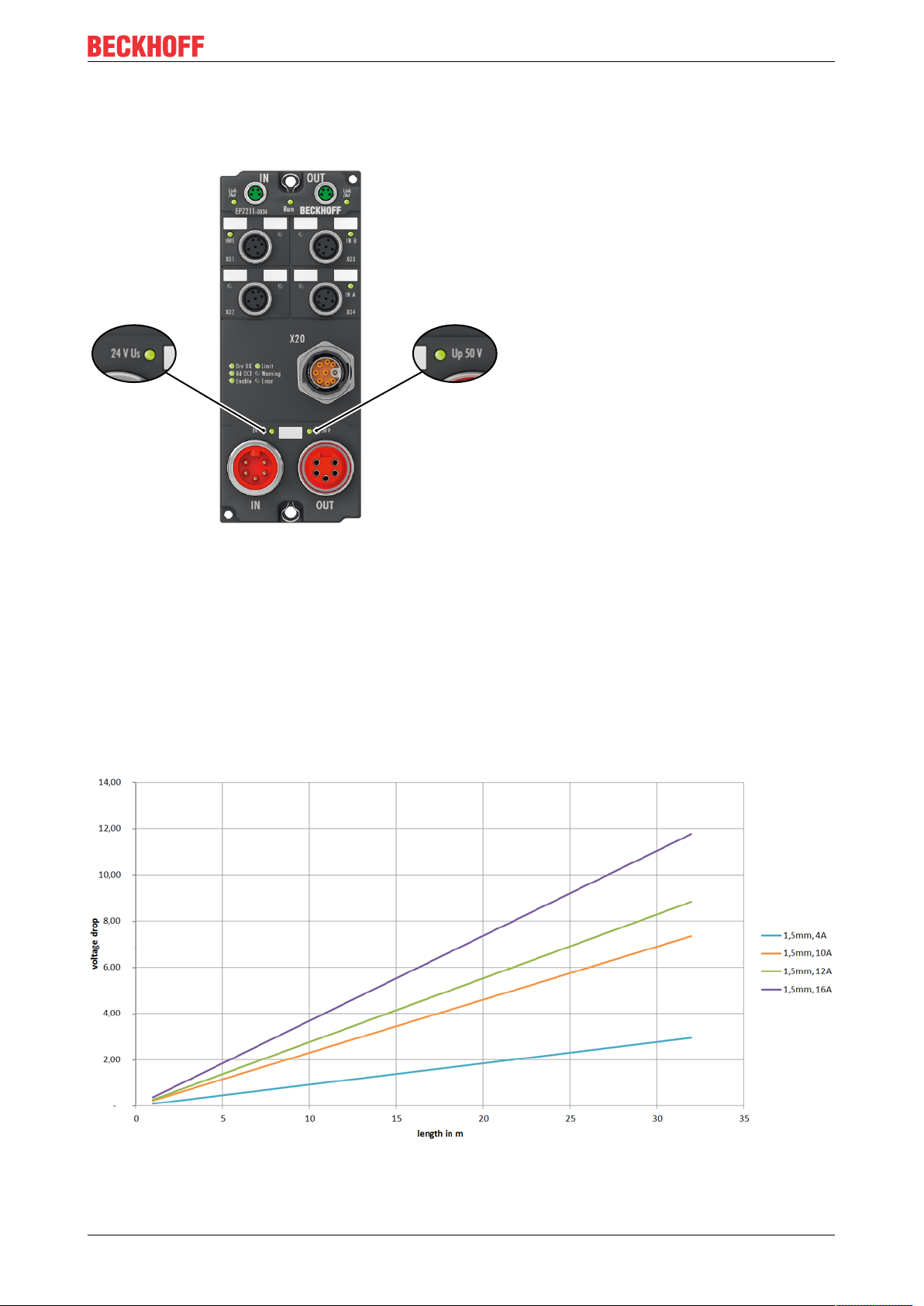

3.2.1.3 Conductor losses

Take into account the voltage drop on the supply line when planning a system. Avoid the voltage drop being

so high that the supply voltage at the box lies below the minimum permissible value. See Technical data.

Variations in the voltage of the power supply unit must also be taken into account.

The following graph illustrates the dependence of the voltage drop on the core cross-section, current and

cable length:

Fig.12: Losses on the supply line

EP7211 19Version: 1.0

Page 20

Mounting and cabling

3.2.2 EtherCAT

3.2.2.1 Connection

EtherCAT Boxes (EPxxxx) have two green M8 sockets for the incoming and outgoing EtherCAT

connections.

Fig.13: EtherCAT connection

Fig.14: M8 socket pin assignment

Assignment

There are various different standards for the assignment and colors of connectors and cables for EtherCAT.

EtherCAT Plug connector Cable Standard

Signal M8 M12 RJ45

Tx + Pin 1 Pin 1 Pin 1 yellow

Tx - Pin 4 Pin 3 Pin 2 orange

Rx + Pin 2 Pin 2 Pin 3 white

Rx - Pin 3 Pin 4 Pin 6 blue

Shield Housing Shroud Shield Shield Shield

1

) colored markings according to EN 61918 in the four-pin RJ45 connector ZS1090-0003

2

) wire colors according to EN 61918

3

) wire colors

1

ZB9010, ZB9020,

ZB9030, ZB9032,

ZK1090-6292,

ZK1090-3xxx-xxxx

2

2

2

2

ZB9031 and old versions of ZB9030,

ZB9032,

ZK1090-3xxx-xxxx

orange/white

orange

blue/white

3

blue

3

3

3

TIA-568B

white/orange

orange

white/green

green

Assimilation of color coding for cable ZB9030, ZB9032 and ZK1090-3xxxx-xxxx (with

M8 connectors)

For unification, the prevalent cables ZB9030, ZB9032 and ZK1090-3xxx-xxxx were changed to the

colors of EN61918 (yellow, orange, white, blue). So different color coding exists. But the electrical

properties are absolutely identical.

EP721120 Version: 1.0

Page 21

3.2.2.2 Status LEDs

Mounting and cabling

Fig.15: EtherCAT Status LEDs

L/A (Link/Act)

A green LED labelled "L/A" or “Link/Act” is located next to each EtherCAT/EtherCATP socket. The LED

indicates the communication state of the respective socket:

LED Meaning

off no connection to the connected EtherCAT device

lit LINK: connection to the connected EtherCAT device

flashes ACT: communication with the connected EtherCAT device

Run

Each EtherCAT slave and each EtherCATP slave has a green LED labelled "Run". The LED signals the

status of the slave in the EtherCAT network:

LED Meaning

off Slave is in "Init" state

flashes uniformly Slave is in "Pre-Operational“ state

flashes sporadically Slave is in "Safe-Operational" state

lit Slave is in "Operational" state

A description of the EtherCAT slave states can be found under

https://infosys.beckhoff.com/content/1033/ethercatsystem/1036980875.html?id=8582353789396071752.

EP7211 21Version: 1.0

Page 22

Mounting and cabling

C

B

A

5

1

2

4

3

3.2.3 Motor, brake and feedback system

3.2.3.1 Connection

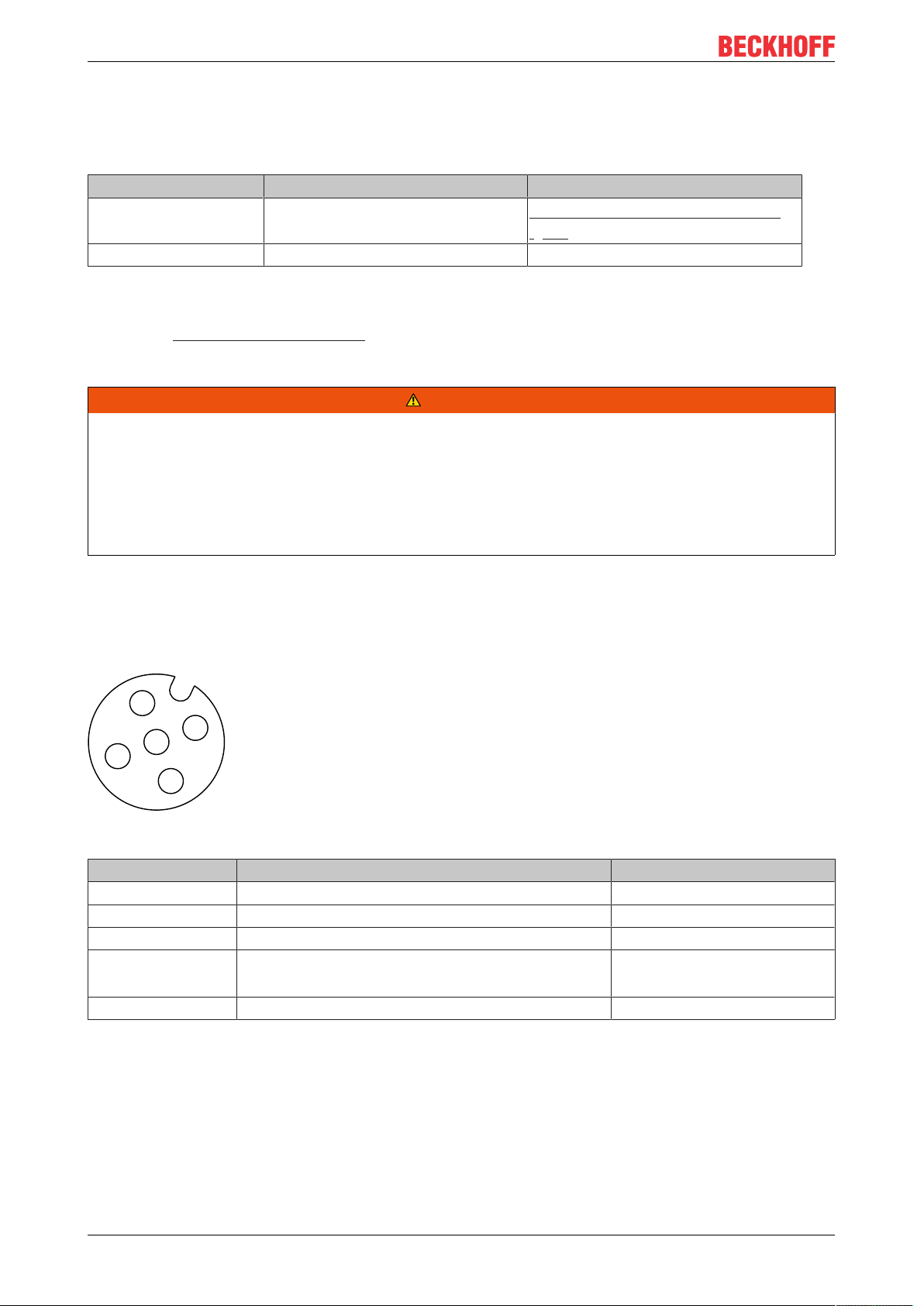

Fig.16: iTec socket pin assignment

Pin Name Comment Core colors

1 Brake + Motor brake + Red

2 Brake - Motor brake - Black

3 OCT + Data and supply for the OCT feedback system White

4 OCT - Data and supply for the OCT feedback system Blue

5 - A U Motor phase U Black

B W Motor phase W Grey

C V Motor phase V Brown

FE, shield Functional earth, cable shield green-yellow

1)

The core colors apply to the ZK470x-xxxx motor cables from Beckhoff.

1)

EP721122 Version: 1.0

Page 23

3.2.3.2 Status LEDs

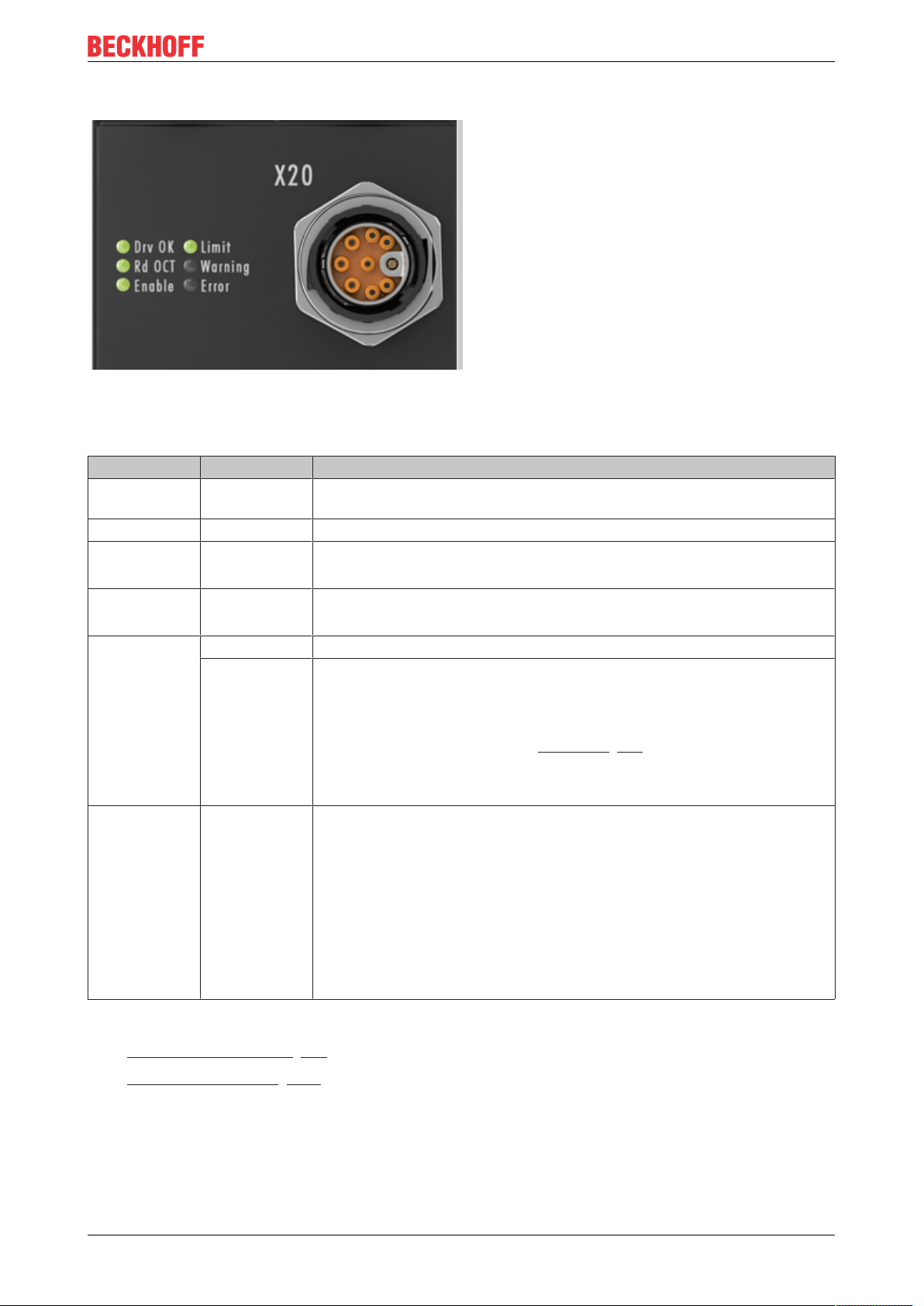

Fig.17: Status LEDs of the motor connection

LED Displays

LED Display Meaning

Drv OK green

illuminated

Rd OCT flashing green The electronic identification plate is being read.

Enable green The driver stage is enabled.

Limit orange Limit reached (e.g. torque or speed limit).

Warning flashes Error while reading the electronic identification plate.

orange Warning. The "Warning" threshold value is exceeded.

The driver stage is ready for operation.

The LED is linked with bits 1 and 2 of the Status word1).

The LED is linked with bit 11 of the Status word1).

Possible reasons:

• Motor load (I²T) is higher than 100%

Mounting and cabling

• The motor output stage is not activated [}29]

• Maximum operating temperature exceeded

The LED is linked with bit 7 of the Status word1).

Error red Error. The “Error” threshold value is exceeded.

Possible reasons:

• Overcurrent

• STO triggered with active axis

• Voltage not available

• Feedback not connected

• Max. temperature (100 °C) exceeded

The LED is linked with bit 3 of the Status word1).

1)

Status word in the CoE directory:

• Device profile MDP742 [}92] (default)

• Device profile DS402 [}114]

EP7211 23Version: 1.0

Page 24

Mounting and cabling

1

2

3

4

5

3.2.4 Hardware Enable / Safe Torque Off

EP7211-0034 and EP7211-9034 differ from each other by the purpose of use of the digital input "Hardware

Enable" / "Safe Torque Off":

Hardware variant Designation of the digital input Purpose of use of the digital input

EP7211-0034 Hardware Enable (HWE)

EP7211-9034 Safe Torque Off (STO) Safe Torque Off

Safe Torque Off (STO)

Refer to the Application Guide TwinSAFE if you wish to use the EP7211-9034 in a safety application: an

application example with "Safe Torque Off" for EL72x1-9014 is described in chapter 2.27. EP7211-9034 can

be used instead of EL72x1-9014 in this application example if you observe the following note:

WARNING

Wiring of the STO

The wiring between EL2904 and the STO input of EP7211-9034 must be done with a separate sheathed

cable in order to be able to assume a fault exclusion for the cross-circuit or external power supply of the

wiring between EL2904 and EP7211-9034. Alternatively, the wiring is to be protected individually by an

earth connection.

The evaluation of this wiring and the evaluation of whether the fault exclusion is permissible must be done

by the machine manufacturer or user.

Activation of the motor output stage

[}29]

3.2.4.1 Connection

Connect the "Hardware Enable" / "Safe Torque Off" signal to the X01 or alternatively the X02 socket. The

X01 and X02 sockets have the same configuration and are bridged 1:1 inside the box.

Fig.18: M12 socket pin assignment

Pin Signal Core colors

1 n.c. Brown

2 n.c. White

3 n.c. Blue

4 EP7211-0034: Hardware Enable

EP7211-9034: Safe Torque Off

5 FE (Functional earth) Grey

1)

The core colors apply to cables of the types ZK2000-5xxx, ZK2000-6xxx and ZK2000-7xxx from Beckhoff.

Black

1)

EP721124 Version: 1.0

Page 25

3.2.4.2 Status LEDs

EP7211-9034

EP7211-0034

Mounting and cabling

Fig.19: Status LEDs for HWE/STO

EP7211-0034

The green LED with the name "HWE" (Hardware Enable) lights when a high level is present on the

corresponding pin of X01 or X02.

→ The motor output stage is activated.

EP7211-9034

The green LED with the name "STO" (Safe Torque Off) lights when a high level is present on the

corresponding pin of X01 or X02.

→ The motor output stage is activated.

EP7211 25Version: 1.0

Page 26

Mounting and cabling

EP7211

HWE /

STO

EP7211

Box 1 Box 2

...

Cable

Cable

Cable

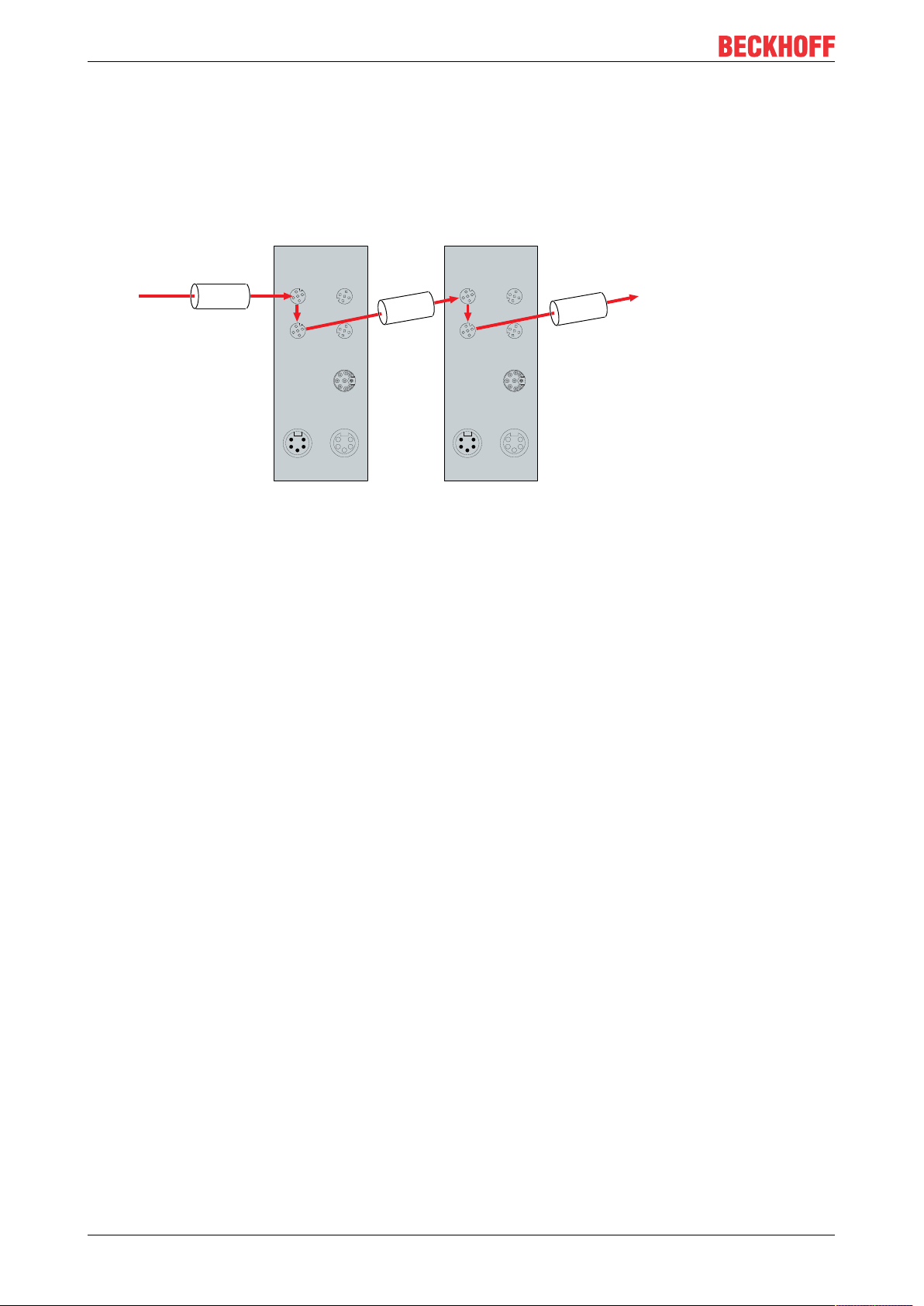

3.2.4.3 Cabling

The X01 and X02 sockets have the same configuration and are bridged 1:1 inside the box. This makes it

possible to forward the signal for "Hardware Enable" / "Safe Torque Off" from one box to the next.

Sample:

Fig.20: Sample: forwarded HWE/STO signal

EP721126 Version: 1.0

Page 27

Mounting and cabling

1

2

3

4

5

3.2.5 Touch Probe

3.2.5.1 Connection

Connect touch probes to the sockets X03 and X04. The X03 and X04 sockets have the same configuration

and are bridged 1:1 inside the box.

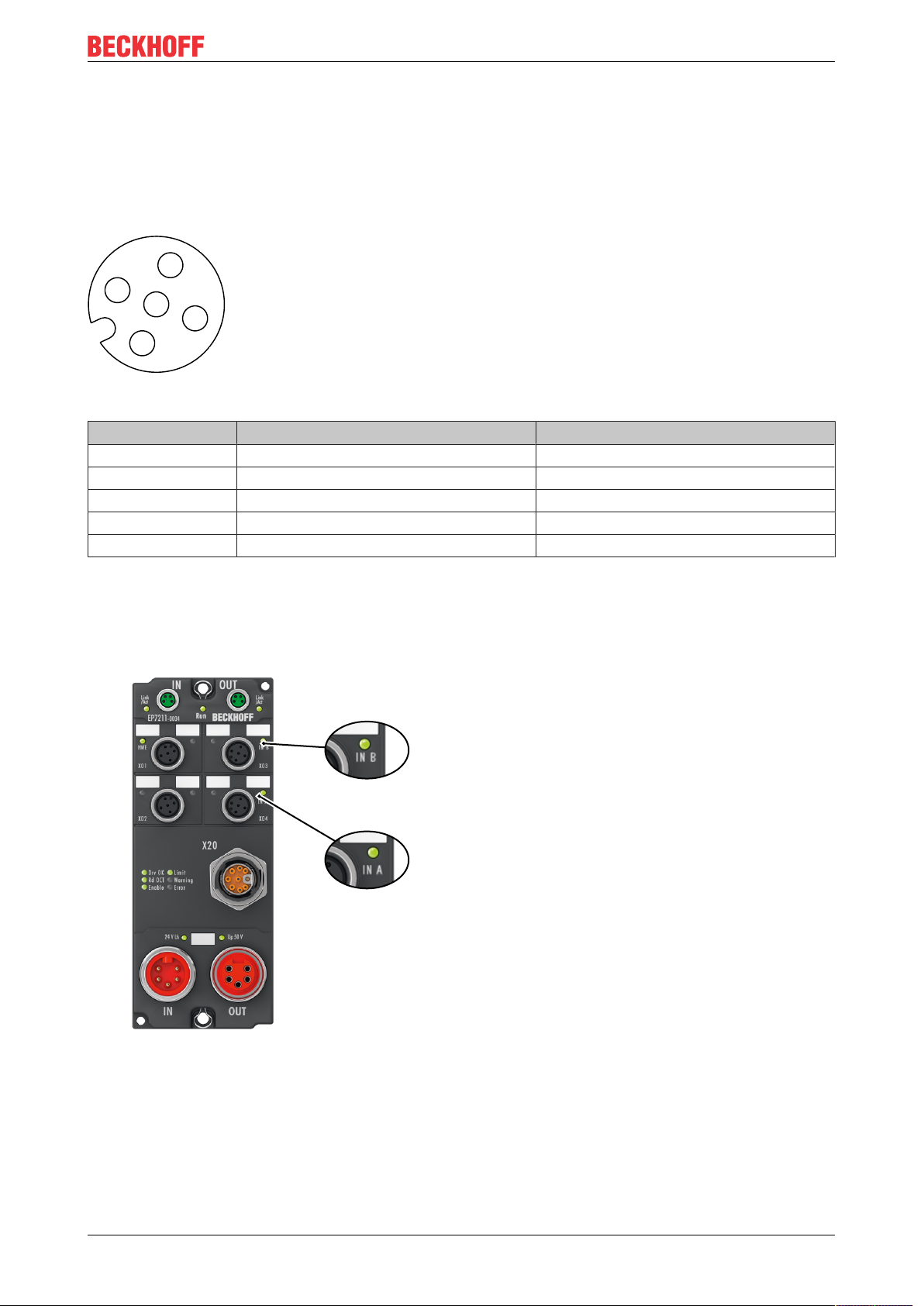

Fig.21: M12 socket pin assignment

Pin Signal Core colors

1 US: +24V

DC

Brown

1)

2 IN B = TP2 White

3 GND

S

Blue

4 IN A = TP1 Black

5 n.c. Grey

1)

The core colors apply to cables of the types ZK2000-5xxx, ZK2000-6xxx and ZK2000-7xxx from Beckhoff.

3.2.5.2 Status LEDs

Fig.22: Touch probe Status LEDs

The green LEDs with the names "IN A" and "IN B" light when a high level is present on the corresponding

pins of X03 or X04:

• IN A = TP1

• IN B = TP2

EP7211 27Version: 1.0

Page 28

Mounting and cabling

X03

X04

Cable

X03

X04

Cable

Cable

3.2.5.3 Cabling

The X03 and X04 sockets have the same configuration and are bridged 1:1 inside the box. This enables the

touch probes to be wired in two ways:

• One common cable (connection to X03 or X04)

• One cable per touch probe (connection to X03 and X04)

EP721128 Version: 1.0

Page 29

Commissioning

4 Commissioning

4.1 Activate motor output stage

Activate the motor output stage by applying a high level to the digital input Hardware Enable / Safe Torque

Off [}24].

4.2 Configuration in TwinCAT

An EtherCAT Box must be configured in TwinCAT so that its functions can be used in a PLC program.

The following link will take you to a quick start guide describing the configuration of an EtherCAT Box in

TwinCAT:

https://infosys.beckhoff.com/content/1033/epioconfiguration/index.html?id=6991403443235907429

EP7211 29Version: 1.0

Page 30

Commissioning

4.3 Start-up and parameter configuration

4.3.1 Integration into the NC configuration

(Master: TwinCAT 2.11 R3)

Installation of the latest XML device description

Please ensure that you have installed the corresponding latest XML device description in TwinCAT.

This can be downloaded from the Beckhoff Website and installed according to the installation in-

structions.

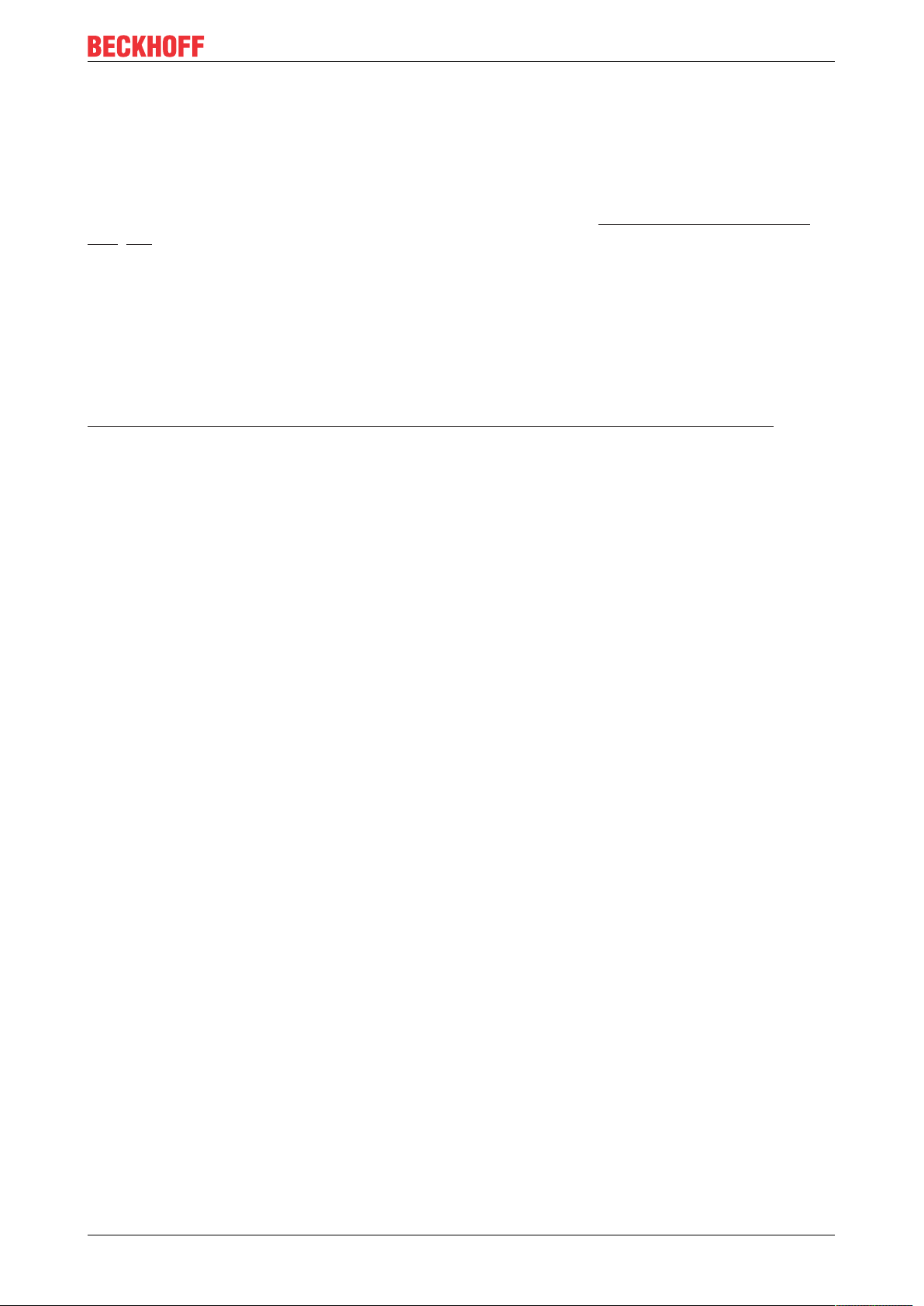

Integration into the NC can be accomplished as follows:

• The box must already have been added manually under I/O devices or have been scanned in by the

system (see section Configuration in TwinCAT [}29]).

Adding an axis automatically

• TwinCAT detects the new axes automatically once the IO modules have been successfully scanned.

The user is asked whether the detected axes should be added

automatically (see Fig. Axis detected). If this is confirmed, all axes are automatically liked to the NC.

Fig.23: Axis detected

• Several parameters have to be set before the motor can be started up. The values can be found in the

chapter Settings in the CoE register [}39].

Set these parameters before continuing with the motor commissioning.

EP721130 Version: 1.0

Page 31

Commissioning

Adding an axis manually

• First add a new task. Right-click on NC configuration and select "Append Task..." (see Fig. Adding a

new task).

• Rename the task if required and confirm with OK.

Fig.24: Adding a new task

• Right-click on Axes, then add a new axis (see Fig. Adding a new axis).

Fig.25: Adding a new axis

• Select Continuous Axis type and confirm with OK (see Fig. Selecting and confirming the axis type).

EP7211 31Version: 1.0

Page 32

Commissioning

Fig.26: Selecting and confirming the axis type

• Left-click your axis to select it. On the Settings tab, select "Link To..." (see Fig. Linking the axis with the

box).

Fig.27: Linking the axis with the box

• Select the appropriate box (CANopen DS402, EtherCAT CoE) and confirm with "OK".

Fig.28: Selection of the correct box

• All main links between the NC configuration and the box are set automatically (see Fig. Automatic

linking of all main variables)

EP721132 Version: 1.0

Page 33

Commissioning

Fig.29: Automatic linking of all main variables

• Several parameters have to be set before the motor can be started up. The values can be found in the

chapters Settings in the CoE register [}39] and NC settings [}42].

Set these parameters before continuing with the motor commissioning.

EP7211 33Version: 1.0

Page 34

Commissioning

4.3.2 Settings with the Drive Manager

(Master TwinCAT 2.11 R3)

The data given here serve as an example for a servomotor type AM8131-0F20-0000 from Beckhoff

Automation. For other motors the values may vary, depending on the application.

Table of contents

Start-up with the Drive Manager [}34]

Setting further parameters with the Drive Manager [}38]

Integral velocity controller component Tn [}38]

Proportional velocity controller component Kp

The TwinCAT Drive Manager is available for download in the AX5000 download package.

The TwinCAT Drive Manager for parameterizing an EL7211 is integrated in the System Manager, so that no

separate configuration tool is required. Once an EP7211 has been detected or entered, the TwinCAT Drive

Manager is available on the "Configuration" tab.

The following points are intended to enable you to start up the EP7211 quickly. More detailed information on

the Drive Manager can be found in the corresponding documentation "AX5000 Introduction in the

TCDrivemanager"

Start-up with the Drive Manager

• The box must already have been added manually under I/O devices or have been scanned in by the

system (see chapter Configuration in TwinCAT [}29])

• The box must already have been integrated in the NC (see chapter Integration into the NC

configuration [}30])

• Select the Drive Manager tab of the EP7211.

• Select the connected voltage under Power Management.

Fig.30: Selecting the connected voltage

• You can subsequently scan or select the connected motor under Channel A > Configuration > Motor

and Feedback. If you decide to use automatic scanning, click on Scan motor and feedback. The

electronic identification plate of the AM81xx-x2xx motor will then be read automatically. To do this it is

necessary for automatic scanning of the motor to be activated in the box (Index 0x8008 [}85], MDP

or Index 0x2018 [}113], DS402)

EP721134 Version: 1.0

Page 35

Commissioning

Fig.31: Automatic scanning of the connected motor

• If you decide to manually input the connected motor, please click on Select Motor.

Fig.32: Selecting the connected motor

• Select the suitable motor in the selection window and confirm with Ok.

EP7211 35Version: 1.0

Page 36

Commissioning

Fig.33: List of available motors

• Confirm the next dialog box with OK. All required parameters are automatically entered in the NC, and

the scaling factor is calculated. If this is not confirmed, these settings have to be entered manually. See

section NC settings [}42].

Fig.34: Confirmation of the automatic NC settings parameters

• The scaling can be determined under Scalings and NC Parameters. A motor revolution is defined as

360° as an example. All required parameters are adjusted automatically. The setting only becomes

active once the configuration is activated.

EP721136 Version: 1.0

Page 37

Commissioning

Fig.35: Adapting the scaling

All main parameters for the commissioning the motor are now set. The motor can now be commissioned with

the NC, for example. A brief description can be found in section "Commissioning the motor with the NC". Or

the NC can be addressed from the PLC. A sample program has been added in the documentation for this

also.

Some parameters can be adjusted manually for your particular application.

EP7211 37Version: 1.0

Page 38

Commissioning

Setting further parameters with the Drive Manager

The values specified here are exemplary, although in most cases they have led to excellent results.

Depending on the application, other values may yield better results.

These values can be changed during operation. Click on Download to apply the values.

Integral velocity controller component Tn

• Reduce the value, until the motor starts to oscillate slightly. Then increase the value by 10%.

Fig.36: Adapting Tn

Proportional velocity controller component Kp

• Increase the value, until the motor starts to oscillate slightly. Then reduce the value to 80%.

Fig.37: Adapting Kp

EP721138 Version: 1.0

Page 39

Commissioning

4.3.3 Settings in the CoE register

(Master TwinCAT 2.11 R3)

The data given here serve as an example for a servomotor type AM8131-0F20-0001 from Beckhoff

Automation. For other motors the values may vary, depending on the application.

Table of contents

Settings in the CoE register [}39]

Settings in the CoE register [}41]

Setting further parameters [}41]

Settings in the CoE register [}41]

Torque limitation [}41]

Settings in the CoE register [}41]

Settings in the CoE register [}41]

Inserting the motor XML file

Downloading the motor XML files

The motor XML files are available for download from the Beckhoff website.

To facilitate commissioning of the EP7211, motor XML files have been created for the servomotors that are

supported by the EP7211. The XML files can be read in the System Manager.

All CoE parameters and DS402 parameters are then set as required.

• To read the motor XML file, select the EP7211 and open the Startup tab. Right-click in the empty field

and select Import from XML...(see Fig. Importing the motor XML file).

Fig.38: Importing the motor XML file

• Select the motor XML file that matches the connected motor (see Fig. Selecting the correct motor XML

file)

EP7211 39Version: 1.0

Page 40

Commissioning

Fig.39: Selecting the correct motor XML file

• All required parameters are then set, and the motor can be put into operation (see Fig. CoE

parameters of the motor XML file).

Fig.40: CoE parameters of the motor XML file

Startup list

Any further application-specific settings should also be implemented in the Startup list. Otherwise

the modified settings will be overwritten next time the box starts up.

EP721140 Version: 1.0

Page 41

Commissioning

Adaptation of current and voltage

NOTE

The motor may overheat!

In order to prevent overheating of the connected motor, it is important to adjust the output voltage of the

box to the actually connected voltage.

This requires the index 0x8010:19 [}86] (0x2002:19 [}108], DS402 profile) "Nominal DC Link Voltage" of

the connected voltage to be set accordingly

Setting further parameters

Single-turn bits (MDP742: Index 0x8000:12 [}84] / DS402: Index 0x2010:12 [}112])/

Multi-turn bits (MDP742: Index 0x8000:13 [}84] / DS402: Index 0x2010:13 [}112])

Here the user can specify how many single-turn and multi-turn bits the box should display. A total of 32bits

are available. These 32bits can be subdivided as required.

The standard setting is 20 single-turn bits and 12 multi-turn bits.

Single-turn bits: number of bits relating to the resolution of one rotor rotation.

Multiturn bits: after a rotor rotation the multi-turn bits are incremented by one.

The motor may overheat!

If the number of single-turn bits is changed, the scaling factor [}44] in the NC has to be adjusted.

Fig.41: Multi-turn / single-turn bits

Torque limitation (MDP742: Index 0x7010:0B [}94] / DS402: Index 0x6072:0 [}116])

Limits the current / torque to this value. The value is specified in 1000th of the rated current.

Integral velocity controller component Tn (MDP742: Index 0x8010:14 [}86] / DS402: Index

0x2002:14 [}108])

The values specified here are exemplary, although in most cases they have led to excellent results.

Depending on the application, other values may yield better results.

• Reduce the value, until the motor starts to oscillate slightly. Then increase the value by 10%.

Proportional velocity controller component Kp (MDP742: Index 0x8010:15 [}86] / DS402: Index

0x2002:15 [}108])

The values specified here are exemplary, although in most cases they have led to excellent results.

Depending on the application, other values may yield better results.

EP7211 41Version: 1.0

Page 42

Commissioning

• Increase the value, until the motor starts to oscillate slightly. Then reduce the value to 80%.

4.3.4 NC settings

(Master TwinCAT 2.11 R3)

The data given here serve as an example for a servomotor type AM8122-0F20-0000 from Beckhoff

Automation. For other motors the values may vary, depending on the application.

Table of contents

Definition of the unit [}42]

Selecting the maximum velocity [}43]

Dead time compensation [}43]

NC settings [}44]

NC settings [}44]

Calculation of the scaling factor [}45]

Scaling output [}45]

NC settings [}45]

Commissioning the motor with the NC

Several important parameters are required for the commissioning with the NC. These should be set as

follows before commissioning. A fundamental factor for setting the following parameters is the unit in which

the NC is set to operate. For the following parameters it was assumed that one revolution corresponds to

360°.

Definition of the unit

The unit can be defined in the Settings tab for the axis.

Fig.42: Definition of the unit

EP721142 Version: 1.0

Page 43

Commissioning

Selecting the maximum velocity

The maximum permitted velocity is calculated based on the maximum motor speed (name plate) and the

distance, in this case in relation to 360° per second.

Fig.43: Adjusting the reference velocity

The reference velocity matches the maximum permitted velocity.

Below that separate values for the maximum and minimum velocity for manual NC mode can be set.

Dead time compensation

The dead time compensation can be adjusted on the Time Compensation tab of Axis1_ENC.

It should theoretically be 3 cycles of the NC cycle time, although in practice 4 cycles are preferable.

Therefore, the settings of the parameters Time Compensation Mode Encoder should be ‚ON (with velocity) )‘

and Encoder Delay in Cycles ‘4’.

Fig.44: Dead time compensation parameter

EP7211 43Version: 1.0

Page 44

Commissioning

Setting the encoder mask

The maximum values for the encoder mask can be set in the Parameter tab for the Axis1_ENC encoder

settings. EP7211 provides a maximum of 32bits for the encoder.

The parameter Encoder Mask (maximum encoder value) can be used to set the maximum number of

available bits. By default this is set to 0xFFFF FFFF, which corresponds to 32bits (20 single-turn bits and 12

multi-turn bits). The calculation is based on the following equation.

The parameter Encoder Sub Mask (absolute range maximum value) indicates how many bits of the

maximum encoder value are single-turn bits. The default setting is 20 (and therefore 12 multi-turn bits). The

calculation is based on the following equation.

Further calculation example with 13 single-turn bits and 8 multi-turn bits.

Fig.45: Setting the encoder mask

Scaling factor

The scaling factor can be changed by selecting "Axis 1_Enc" and tab Parameter in the NC (see Setting the

Scaling Factor). The value can be calculated with the formulas specified below. The calculation is based on

the assumption that one revolution corresponds to 360°.

The number of single-turn bits is taken into account in the calculation of the scaling factor. As indicated

above, the default setting for EP7211 is 20 single-turn bits. This value is also used for calculating the scaling

factor. If the single-turn bit value is changed, the scaling factor must be adjusted.

EP721144 Version: 1.0

Page 45

Calculation of the scaling factor

Commissioning

Fig.46: Setting the Scaling Factor

Scaling output

Enter the value 32 in the Parameter tab for the drive settings under Output Scaling (Velocity).

Fig.47: Output scaling

Position lag monitoring

The position lag monitoring function checks whether the current position lag of an axis has exceeded the

limit value. The position lag is the difference between the set value (control value) and the actual value

reported back. If the box parameters are set inadequately, the position lag monitoring function may report an

error when the axis is moved. During commissioning it may therefore be advisable to increase the limits of

the Position lag monitoring slightly.

EP7211 45Version: 1.0

Page 46

Commissioning

NOTE

Damage to equipment, machines and peripheral components possible!

Setting the position lag monitoring parameters too high may result in damage to equipment, machines and

peripheral components.

Fig.48: Lag monitoring

Commissioning the motor with the NC

• Once the parameters are set, the motor is basically ready for operation. Individual further parameters

have to be adapted to the respective application.

• To commission the axis, activate the configuration (Ctrl+Shift+F4), select the axis, select tab Online

and enable the axis under Set.

• Set all tick marks and set Override to 100% (see Fig. Enabling an axis). The axis can then be moved.

EP721146 Version: 1.0

Page 47

Commissioning

Fig.49: Enabling an axis

You can now move the axis with the function keys F1, F2 (Backward) or F3, F4 (Forward).

You can adjust the Kv factor in order to approach a suitable factor. Set the value to 0 initially in order to set

the correct reference velocity. For calculating the reference velocity please refer to section "Selecting the

maximum velocity [}43]". The calculation provides a relatively precise value, although the value may have to

be corrected slightly. To this end move the motor with a Kv factor of 0 until the actual velocity matches the

setpoint velocity.

Alternatively you can control the axis via the Functions tab. An example is provided below.

• Select as Reversing Sequence as the start type.

• Enter the required Target Position2, e.g. 12000°.

• Enter the required Target Velocity, e.g. 12000°/s.

• Enter the required Target Position1, e.g. 0°.

• Enter the required Idle Time, e.g. 2 s.

• Select Start.

EP7211 47Version: 1.0

Page 48

Commissioning

Fig.50: Reversing Sequence

The motor now turns to position 2, remains there for 2 seconds and returns to position 1. This is repeated

until Stop is pressed.

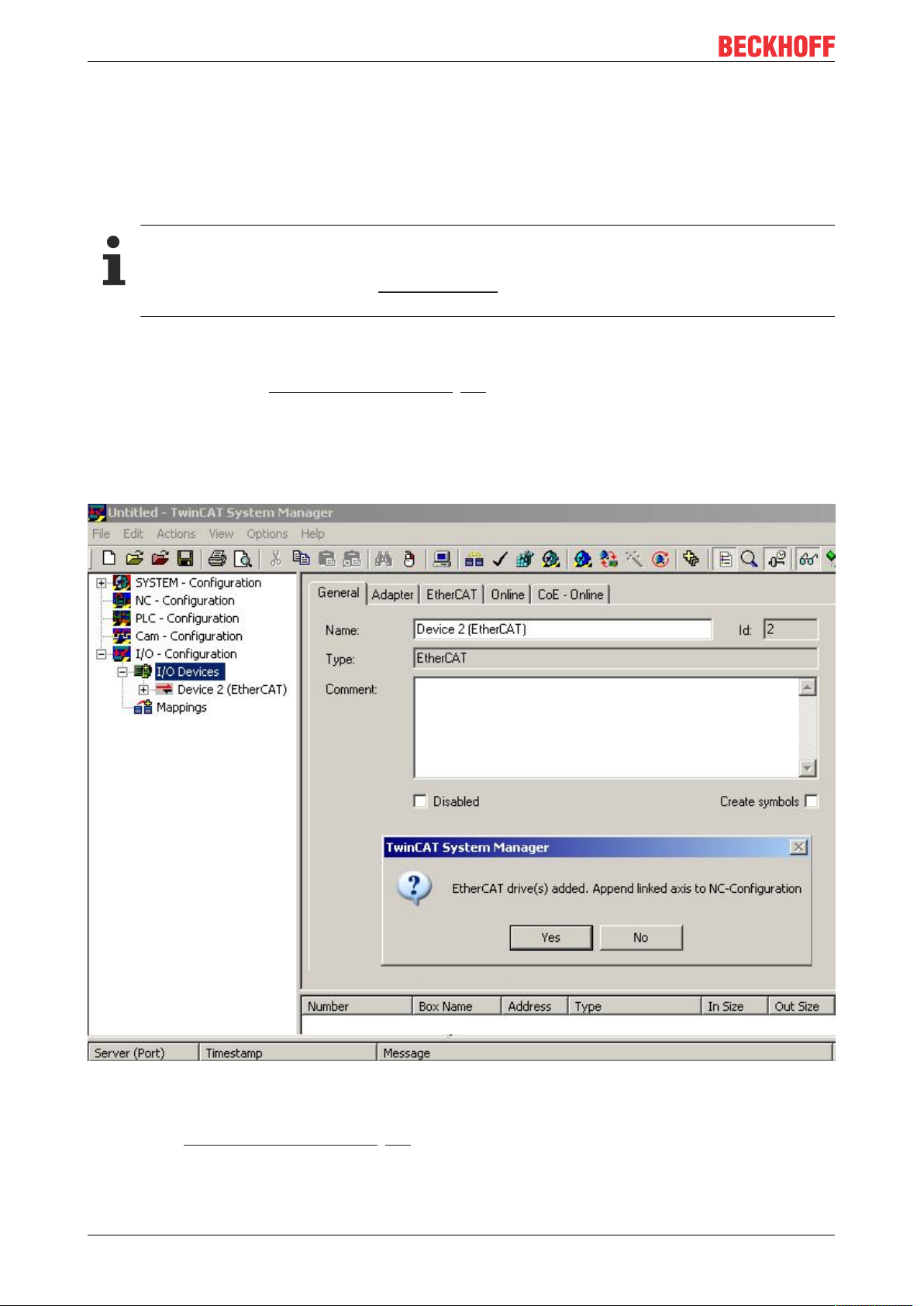

4.3.5 Commissioning without NC, status word/control word

(Master: TwinCAT 2.11 R3)

In principle, the operating modes CST, CSTCA, CSV and CSP can be used without TwinCAT NC.

Output stage enabled via control word

The output stage has to be enabled for each operation mode. To this end enter the following values in the

specified order via the PLC control word (MDP742 [}94] / DS402 [}114]) (see Fig. DS402 State Machine).

The respective status messages are output in the status word (MDP742 [}92] / DS402 [}114]).

0

hex

80

(Fault reset)

hex

6

(Shutdown)

hex

7

(Switch on)

hex

F

(Enable operation)

hex

EP721148 Version: 1.0

Page 49

Commissioning

Fig.51: DS402 State Machine

EP7211 49Version: 1.0

Page 50

Commissioning

CST - cyclic synchronous torque

Select Cyclic synchronous torque mode in index 0x7010:03 [}94] Modes of operation (MDP) or 0x6060:0

[}115] Modes of operation (DS402). In the respective process data, the Predefined PDO Assignment: 'Cyclic

synchronous torque mode (CST)' should also be selected (see Process data MDP 742 [}76] or DS402

process data [}80]). The configuration then has to be reloaded in order to activate the selection.

Index 0x6010:03 [}92] Modes of operation display (MDP) or index 0x6061:0 [}115] Modes of operation

display (DS402) can be used to check the actual mode of the box.

Via the PLC a defined torque can be defined in the variable Target torque as a basis for the box control. The

torque is specified in 1000th of the rated current. A value of 1000

, for example, corresponds to the set

dec

index 0x8011:12 [}89] Rated current (MDP) or index 0x6075:0 [}116] Motor rated current (DS402). The

value 1

corresponds to one 1000th of the rated current.

dec

CSTCA - cyclic synchronous torque with commutation angle

Select Cyclic synchronous torque mode with commutation angle in index 0x7010:03 [}94] Modes of

operation (MDP) or index 0x6060:0 [}115] Modes of operation (DS402). In the respective process data, the

Predefined PDO Assignment: 'Cyclic synchronous torque mode with commutation angle mode (CSTCA)'

should also be selected (see Process data MDP 742 [}76] or DS402 process data [}80]). The configuration

then has to be reloaded in order to activate the selection.

Index 0x6010:03 [}92] Modes of operation display (MDP) or index 0x6061:0 [}115] Modes of operation

display (DS402) can be used to check the actual mode of the box.

Via the PLC a defined torque can be set in the Target torque variable as a basis for the box control and the

angle to be maintained with the set torque can be specified in the Commutation angle variable. The torque is

specified in 1000th of the rated current. A value of 1000

0x8011:12 [}89] Rated current (MDP) or index 0x6075:0 [}116] Motor rated current (DS402). The value 1

, for example, corresponds to the set index

dec

dec

corresponds to one 1000th of the rated current.

The angle value must be converted, 65536

corresponds to 360°.

dec

CSV - cyclic synchronous velocity

Select Cyclic synchronous velocity in index 0x7010:03 [}94] Modes of operation (MDP) or index 0x6060:0

[}115] Modes of operation (DS402). In the respective process data, the Predefined PDO Assignment: 'Cyclic

synchronous velocity mode (CSV)' should also be selected (see Process data MDP 742 [}76] or DS402

process data [}80]). The configuration then has to be reloaded in order to activate the selection.

Index 0x6010:03 [}92] Modes of operation display (MDP) or index 0x6061:0 [}115] Modes of operation

display (DS402) can be used to check the actual mode of the box.

Via the PLC a defined speed can be set in the variable Target velocity 0x7010:06 [}94] (MDP) or 0x60FF:0

[}118] (DS402) as a basis for the box control. The constant value Velocity encoder resolution in CoE object

0x9010:14 [}97] (MDP) or 0x6090:0 [}117] (DS402) corresponds to 1 revolution per second. If this value is

entered under Target velocity, the motor speed is 1 rpm. The velocity can be increased by entering a

suitable multiple of the Velocity encoder resolution value under Target velocity.

CSP - cyclic synchronous position

Select Cyclic synchronous position in index 0x7010:03 [}94] Modes of operation (MDP) or index 0x6060:0

[}115] Modes of operation (DS402).

In the respective process data, the Predefined PDO Assignment: 'Cyclic synchronous position mode (CSP)'

should also be selected (see Process data MDP 742 [}76] or DS402 process data [}80]). The configuration

then has to be reloaded in order to activate the selection.

Index 0x6010:03 [}92] Modes of operation display (MDP) or index 0x6061:0 [}115] Modes of operation

display (DS402) can be used to check the actual mode of the box.

Via the PLC a defined position can be set in the variable Target position 0x7010:05 [}94] (MDP) or

0x607A:0 [}116] (DS402) to which the motor is to drive. The calculated scaling factor is taken as the basis

for the calculation of the position. The value entered in the Target position variable must be multiplied by the

calculated scaling factor.

EP721150 Version: 1.0

Page 51

Commissioning

4.3.6 Settings for the automatic configuration

(Master TwinCAT 2.11 R3)

The EP7211 offers the option of automatically configuring the connected motor from the AM81xx series. The

electronic identification plate integrated in the motor is read and the necessary parameters of the box are

adapted accordingly.

The automatic configuration is switched off on delivery. The user has the possibility to adapt the automatic

configuration according to the flow chart shown below (see fig. Flow chart for the automatic configuration).

Overwriting of the parameters during automatic configuration

The parameters manually changed by the user in the parameter list of the automatic configuration

are automatically overwritten at the next start-up if automatic configuration is switched on.

• The automatic configuration can be switched on in the index 0x8001:01 [}85] (0x2018:01 [}113],

DS402 Profile) Enable autoconfig.

• In the index 0x8008:02 [}85] (0x2018:02 [}113], DS402 Profile) Reconfig identical motor, the user

can decide in the case of replacing an identical motor whether the box should automatically reconfigure the motor (setting = true) or whether the motor should be operated with the stored settings

(setting = false). The deactivation of this function can be advantageous, for example, if the user has

specially adjusted the motor to his application and does not want to lose these settings after replacing

the motor.

• In the index 0x8008:03 [}85] (0x2018:03 [}113], DS402 Profile) Reconfig non-identical motor , the

user can decide in the case of replacing a non-identical motor whether the box should automatically reconfigure the motor (setting = true) or whether the motor should be operated with the stored settings

(setting = false).

EP7211 51Version: 1.0

Page 52

Commissioning

Fig.52: Flow chart for the automatic configuration

EP721152 Version: 1.0

Page 53

Parameter list of the automatic configuration

The following parameters are affected by the automatic configuration.

Index (hex) Name Meaning

MDP 407 Profile DS402 Profile

8010:12 [}86] 2002:12 [}108]

8010:13 [}86] 2002:13 [}108]

8011:11 [}89] 2003:11 [}111]

8011:12 [}89] 2003:12 [}111]

8011:13 [}89] 2003:13 [}111]

8011:15 [}89] 2003:15 [}111]

8011:16 [}89] 2003:16 [}111]

8011:18 [}89] 2003:18 [}111]

8011:19 [}89] 2003:19 [}111]

8011:1B [}89] 2003:1B [}111]

8011:2B [}89] 2003:2B [}111]

8011:2C [}89] 2003:2C [}111]

8011:2D [}89] 2003:2D [}111]

8012:11 [}90] 2004:11 [}112]

8012:12 [}90] 2004:12 [}112]

8012:14 [}90] 2004:14 [}112]

Current loop integral time is calculated according to the symmetrical optimum

Current loop proportional gain is calculated according to the symmetrical optimum

Max. current is adopted directly from the electronic identification

plate of the connected motor

Rated current is adopted directly from the electronic identification

plate of the connected motor

Motor pole pairs is adopted directly from the electronic identification

plate of the connected motor

Commutation offset is always set to -90°

Torque constant is adopted directly from the electronic identification

plate of the connected motor

Rotor moment of inertia is adopted directly from the electronic identification

plate of the connected motor

Winding inductance is adopted directly from the electronic identification

plate of the connected motor

Motor speed limitation Calculation of the max. speed of the connected motor

Motor temperature warn level is adopted directly from the electronic identification

plate of the connected motor

Motor temperature error level is adopted directly from the electronic identification

plate of the connected motor

Motor thermal time constant is adopted directly from the electronic identification

plate of the connected motor

Release delay is adopted directly from the electronic identification

plate of the connected motor

Application delay is adopted directly from the electronic identification

plate of the connected motor

Brake moment of inertia is adopted directly from the electronic identification

plate of the connected motor

Commissioning

4.3.7 Configure end position monitoring

Software end position monitoring

The TwinCAT NC can be used to set software end position monitoring for EP7211 to ensure the safety of the

system. The axis does not move beyond the set position (maximum/minimum end position). End position

monitoring can be activated in the Parameter tab for the corresponding axis.

Fig.53: Pull-down menu for activating end position monitoring

EP7211 53Version: 1.0

Page 54

Commissioning

4.3.8 Homing

(Master TwinCAT 2.11 R3)

The data given here serve as an example for a servomotor type AM8131-0F20-0000 from Beckhoff

Automation. For other motors the values may vary, depending on the application.

Table of contents

Referencing [}54]

Function block "MC_Home" [}54]

Homing [}55]

Referencing

Referencing does not work via the online commissioning tab of the axis (see Fig. Online homing in the NC).

Fig.54: Online homing in the NC

Function block "MC_Home"

• Referencing must be done from the PLC. The function block MC_Home from the TC MC2 Lib is used

for this purpose.

• The following minimum configuration is required in MC_Home.

◦ HomingMode enables selection of mode to be used for referencing.

◦ Execute is used to initiate homing.

◦ bCalibrationCam, which has to be linked with your reference cam, is used to stop homing.

EP721154 Version: 1.0

Page 55

Commissioning

Fig.55: Configuration of the MC_Home block

• The following figure Extract from the functional description for MC_Home shows an extract from the

functional description of MC_Home. Full information can be found in the corresponding functional

description.

Fig.56: Extraction from the functional description for MC_Home

Reference modes

• EP7211 can be operated with the following NC reference modes (see Fig. Selection of the reference

modes in the NC).

• Default: Is suitable as a general setting and for most applications.

Once the motor reaches the reference cam, the direction is reversed. The declining cam signal causes

the motor to stop. The reference position is then set.

• Software Sync: The C track is modelled virtually.

EP7211 55Version: 1.0

Page 56

Commissioning

Fig.57: Selection of the reference modes in the NC

The velocity to be used for homing can also be set in the NC (Fig. Setting the reference velocity).

Fig.58: Setting the reference velocity

EP721156 Version: 1.0

Page 57

Commissioning

4.3.9 Touch Probe

(Master TwinCAT 2.11 R3)

Functional description

The touch probe function saves the current position of the motor when a signal edge is detected on a digital

input [}27].

The process data objects required for this can be activated on the Process data tab (see figs. Touch Probe

inputs and Touch Probe outputs).

EP7211 57Version: 1.0

Page 58

Commissioning

Fig.59: Touch Probe inputs

EP721158 Version: 1.0

Page 59

Commissioning

Fig.60: Touch Probe outputs

EP7211 59Version: 1.0

Page 60

Commissioning

Step-by-step

TP1 is used here as an example for the description of the function.

• TP1 Enable must be set to true in order to generally activate the Touch Probe function.

• Subsequently, you must decide whether the position is to be saved on a positive edge at input 1 (TP1

Enable pos edge = true), on a negative edge (TP1 Enable neg edge = true), or in both cases (both set

to ‘true’).

• With TP1 Continuous you can decide whether the position is to be saved only at the first event (TP1

Continuous = false) or whether this should take place at every event (TP1 Continuous = true).

For example, if TP1 Continous and TP1 Enablepos edge are set, the position is saved on each positive

edge at input 1 of the box.

If TP1 Enable neg edge is set and TP1 Continuous is not set, the position will only be saved on the first

negative edge at input 1 of the box. If you wish to repeat this procedure, you must first deactivate TP1

Enable and then activate it again. Then the position is saved again on the first negative edge.

• The TP1 Trigger mode has no function with the EP7211.

• The saved position of the positive edge can be read in the inputs of the process data under TP1 Pos

position, that of the negative edge under TP1 Neg position.

• The variables under Touch probe status are for the diagnosis.

• The Touch Probe inputs must be addressed with a 1-wire +24V signal.

EP721160 Version: 1.0

Page 61

Commissioning

4.4 Drive profiles

The EP7211 supports the MDP742 and DS402 drive profiles. Both drive profiles contain the same

parameters. The drive profiles define the presentation of the parameters in TwinCAT and the index, under

which the respective parameters are arranged in the object directory.

• The CoE objects in the MDP742 (Modular Device Profile) are allocated in the way that is common for

the Beckhoff IO modules.

• The DS402 drive profile is specified in IEC61800-7-200 (CiA402) and uses a different allocation of the

object directory structure.

The drive state machine in both profiles is based on the CiA402 State Machine [}48], which means the

functional behavior is identical.

The box is supplied ex factory with the MDP742 drive profile.

Changing the drive profile

You can change the drive profile by carrying out an EEPROM Update [}131]. Select the EEPROM

description on the basis of the following table.

Variant of the EP7211 Drive profile EEPROM description

EP7211-0034 MDP742 EP7211-0034

DS402 EP7211-0035

EP7211-9034 MDP742 EP7211-9034

DS402 EP7211-9035

The EEPROM description is at the same time the name of the IO module in the IO tree.

The CoE object description and the process data of the drive profiles are different. The motor XML files that

match the set profile must be used.

EP7211 61Version: 1.0

Page 62

Commissioning

4.5 Operation modes

4.5.1 Overview

Operation modes CST, CSTCA, CSV and CSP are supported. The operation mode is set in the CoE

directory in index 0x7010:03 [}94] Modes of operation (MDP) or index 0x6060:0 [}115] Modes of operation

(DS402). In the respective process data the user can additionally select the respective Predefined PDO

Assignment. All required variables are then in the process data.

CSV [}63] - cyclic synchronous velocity (velocity control)

The EP7211-x034 operates in the cyclic velocity interface in the CSV operation mode. A defined velocity can

be set via the Target velocity variable.

CST [}66] - cyclic synchronous torque (torque control)

The EP7211-x034 operates in the cyclic torque interface in the CST operation mode. A defined torque can

be set via the Target torque variable.

CSTCA [}69] - cyclic synchronous torque with commutation angle (torque control with commutation

angle)

This operation mode is also intended for use with the cyclic torque interface. In addition the user can specify

the commutation angle. The variable Commutation angle can be used to set an angle which is to be

maintained with a defined torque set in variable Target torque.

CSP [}72] - cyclic synchronous position (position control)

The EP7211-x034 operates in the cyclic position interface in the CSP operation mode. A defined position

can be set via the Target position variable.

For further information on the three operation modes described above please refer to section Commissioning

without NC [}48].

EP721162 Version: 1.0

Page 63

Commissioning

4.5.2 CSV

The EP7211-x034 operates in the cyclic velocity interface in the CSV operation mode. A defined velocity can

be set via the Target velocity variable.

Step-by-Step

• Add the box to the configuration as described in the chapter Configuration in TwinCAT [}29].

• Link the box with the NC as described in the chapter Integration into the NC configuration [}30].

• Import the motor XML file into the Startup directory as described in the chapter Settings in the CoE

[}39].

• Set the mode of operation in the CoE directory to Cyclic synchronous velocity mode (CSV), Fig.

Selection of the mode of operation.

Fig.61: Selection of the mode of operation

• Under Predefined PDO assignment, also select Cyclic synchronous velocity mode (CSV), Fig.

Selecting a predefined PDO assignment.

EP7211 63Version: 1.0

Page 64

Commissioning

Fig.62: Selecting a predefined PDO assignment

• Activate the configuration (Ctrl+Shift+F4)

• Run through the State Machine of the box. There are two ways to do this:

◦ If you use the TwinCAT NC.

The State Machine is run through automatically by the NC. You can enable the axis in the Online

tab of the axis.

Set all tick marks and set Override to 100% (see Fig. Set enables). The axis can then be moved.

EP721164 Version: 1.0

Page 65

Commissioning

Fig.63: Set enables

◦ If you don’t use the TwinCAT NC.

In this case you must run through the State Machine manually. To do this, follow the instructions in

the chapter Commissioning without the NC [}48].

• The cyclic variable Target velocity (Fig. Torque specification) can be used to specify a defined velocity.

The value in the index 0x9010:14 [}97] (0x6090 [}117], DS402) Velocity encoder resolution

corresponds to 1rpm.

Fig.64: Torque specification

EP7211 65Version: 1.0

Page 66

Commissioning

4.5.3 CST

The EP7211-x034 operates in the cyclic torque interface in the CST operation mode. A defined torque can

be set via the Target torque variable.

Step-by-Step

• Add the box to the configuration as described in the chapter Configuration in TwinCAT [}29].

• Link the box with the NC as described in the chapter Integration into the NC configuration [}30].

• Import the motor XML file into the Startup directory as described in the chapter Settings in the CoE

[}39].

• Set the mode of operation in the CoE directory to Cyclic synchronous torque mode (CST), Fig.

Selection of the mode of operation

Fig.65: Selection of the mode of operation

• Under Predefined PDO assignment, also select Cyclic synchronous torque mode (CST), Fig. Selecting

a predefined PDO assignment

EP721166 Version: 1.0

Page 67

Commissioning

Fig.66: Selecting a predefined PDO assignment

• Activate the configuration (Ctrl+Shift+F4)

• Run through the State Machine of the box. There are two ways to do this:

◦ If you use the TwinCAT NC.

The State Machine is run through automatically by the NC. You can enable the axis in the Online

tab of the axis.