Page 1

Documentation | EN

EP7047-1032

Stepper motor box with incremental encoder and vector control

2020-12-22 | Version: 1.0

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................5

1.1 Notes on the documentation..............................................................................................................5

1.2 Safety instructions .............................................................................................................................6

1.3 Documentation Issue Status..............................................................................................................7

2 Product overview.......................................................................................................................................8

2.1 Introduction........................................................................................................................................8

2.2 Technical data ...................................................................................................................................9

2.3 Scope of supply ...............................................................................................................................10

2.4 Process image.................................................................................................................................11

2.4.1 "Predefined PDO Assignments" ...................................................................................... 11

2.4.2 Process data objects ....................................................................................................... 13

2.5 Technology ......................................................................................................................................18

2.5.1 Stepper motor .................................................................................................................. 19

2.5.2 Selecting a stepper motor................................................................................................ 22

2.5.3 Standard mode ................................................................................................................ 23

2.5.4 Field-oriented control ....................................................................................................... 25

3 Mounting and connections.....................................................................................................................27

3.1 Mounting..........................................................................................................................................27

3.1.1 Dimensions ...................................................................................................................... 27

3.1.2 Fixing ............................................................................................................................... 28

3.1.3 Functional earth (FE) ....................................................................................................... 28

3.2 Connections.....................................................................................................................................29

3.2.1 Connector overview ......................................................................................................... 29

3.2.2 EtherCAT: X40 and X41 .................................................................................................. 30

3.2.3 Supply voltages: X60 and X61......................................................................................... 32

3.2.4 Incremental encoders: X03 or X04 .................................................................................. 34

3.2.5 Limit switch: X05.............................................................................................................. 35

3.2.6 Latch input: X06............................................................................................................... 36

3.2.7 Motor brake: X07 ............................................................................................................. 37

3.2.8 Stepper motor: X08.......................................................................................................... 38

4 Commissioning and configuration ........................................................................................................40

4.1 Integrating EP7047 into a TwinCAT project ....................................................................................40

4.2 Parameterizing EP7047...................................................................................................................41

4.2.1 Open the parameter directory (CoE) ............................................................................... 41

4.2.2 Setting important motor parameters ................................................................................ 42

4.2.3 Setting other important parameters ................................................................................. 44

4.3 Setting the operating mode .............................................................................................................45

4.3.1 Operating modes ............................................................................................................. 46

4.4 Parameterizing the NC axis.............................................................................................................52

4.4.1 Parameterizing the encoder............................................................................................. 54

4.4.2 Parameterizing the controller........................................................................................... 56

4.5 Performing a test run .......................................................................................................................58

4.5.1 Test run with TwinCAT NC .............................................................................................. 58

EP7047-1032 3Version: 1.0

Page 4

Table of contents

4.5.2 Test run without the TwinCAT NC ................................................................................... 59

4.6 Further applications .........................................................................................................................60

4.6.1 Using the "Positioning Interface" ..................................................................................... 60

4.6.2 Linking an NC axis with EP7047...................................................................................... 75

4.6.3 Determining the voltage constant of a motor experimentally........................................... 76

4.6.4 Restoring the delivery state ............................................................................................. 77

4.7 Decommissioning ............................................................................................................................78

5 Diagnosis..................................................................................................................................................79

5.1 Diagnostics – basic principles of diag messages ............................................................................79

5.2 Diag Messages of EtherCAT devices for drive technology .............................................................88

6 CoE parameters .......................................................................................................................................89

6.1 Object directory ...............................................................................................................................89

6.2 Data format of CoE parameters.......................................................................................................91

6.3 Object description............................................................................................................................92

6.3.1 Objects for parameterization............................................................................................ 92

6.3.2 Status objects .................................................................................................................. 96

6.3.3 Standard objects.............................................................................................................. 97

7 Appendix ..................................................................................................................................................99

7.1 General operating conditions...........................................................................................................99

7.2 Accessories ...................................................................................................................................100

7.3 Version identification of EtherCAT devices ...................................................................................101

7.3.1 Beckhoff Identification Code (BIC)................................................................................. 105

7.4 Support and Service ......................................................................................................................107

EP7047-10324 Version: 1.0

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

Intended audience

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning these components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCATG®, EtherCATG10®, EtherCATP®, SafetyoverEtherCAT®,

TwinSAFE®, XFC®, XTS® and XPlanar® are registered trademarks of and licensed by Beckhoff Automation

GmbH. Other designations used in this publication may be trademarks whose use by third parties for their

own purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, EP1456722, EP2137893, DE102015105702 with corresponding

applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

EP7047-1032 5Version: 1.0

Page 6

Foreword

1.2 Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

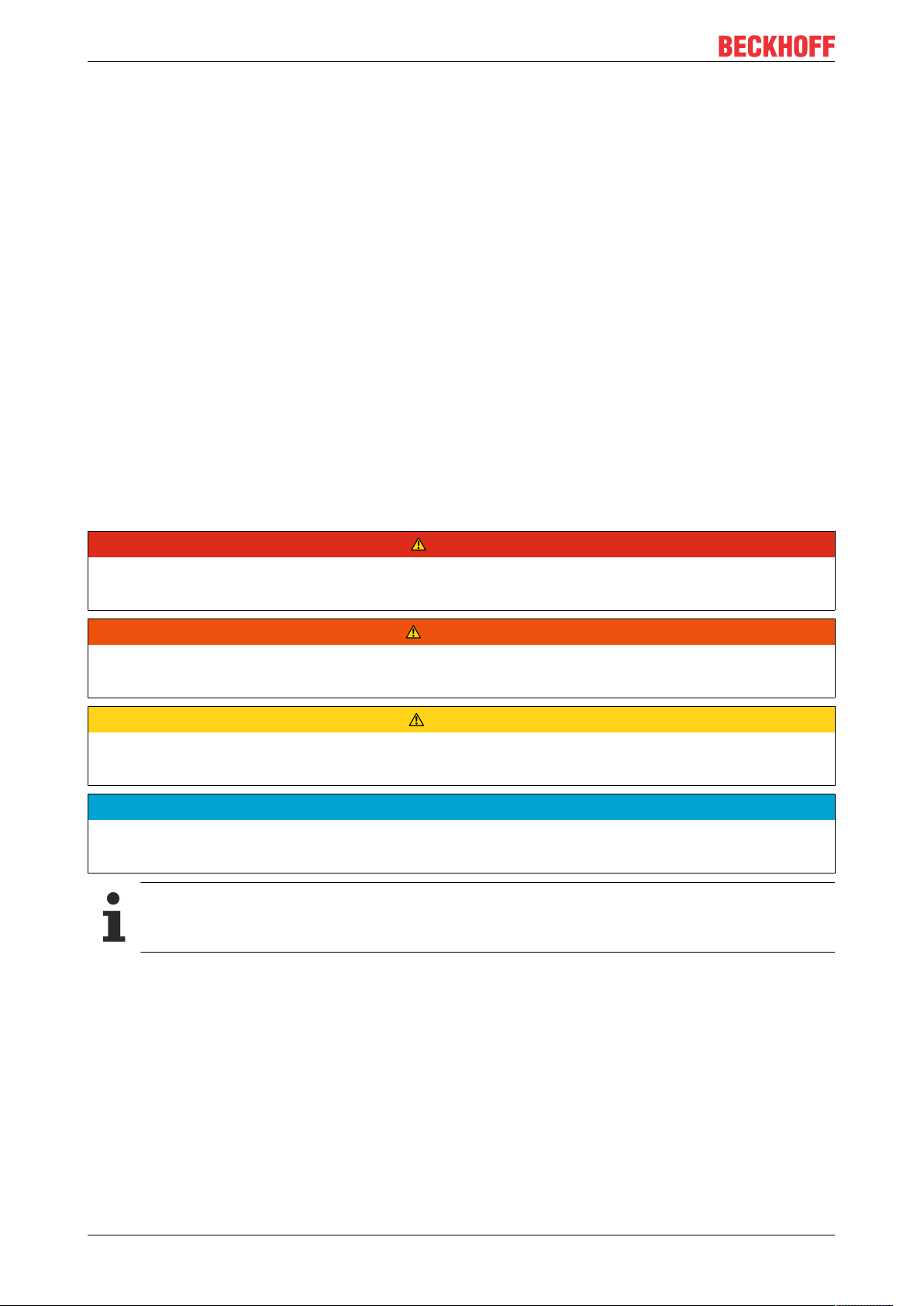

Description of instructions

In this documentation the following instructions are used.

These instructions must be read carefully and followed without fail!

DANGER

Serious risk of injury!

Failure to follow this safety instruction directly endangers the life and health of persons.

WARNING

Risk of injury!

Failure to follow this safety instruction endangers the life and health of persons.

CAUTION

Personal injuries!

Failure to follow this safety instruction can lead to injuries to persons.

NOTE

Damage to environment/equipment or data loss

Failure to follow this instruction can lead to environmental damage, equipment damage or data loss.

Tip or pointer

This symbol indicates information that contributes to better understanding.

EP7047-10326 Version: 1.0

Page 7

Foreword

1.3 Documentation Issue Status

Version Comment

1.0 • First release

Firmware and hardware versions

This documentation refers to the firmware and hardware version that was applicable at the time the

documentation was written.

The module features are continuously improved and developed further. Modules having earlier production

statuses cannot have the same properties as modules with the latest status. However, existing properties

are retained and are not changed, so that older modules can always be replaced with new ones.

Documentation Firmware Hardware

1.0 06 00

The firmware and hardware version (delivery state) can be found in the batch number (D-number) printed on

the side of the EtherCAT Box.

Syntax of the batch number (D-number)

D: WW YY FF HH

WW - week of production (calendar week)

YY - year of production

FF - firmware version

HH - hardware version

Further information on this topic: Version identification of EtherCAT devices [}101].

Example with D no. 29 10 02 01:

29 - week of production 29

10 - year of production 2010

02 - firmware version 02

01 - hardware version 01

EP7047-1032 7Version: 1.0

Page 8

Product overview

2 Product overview

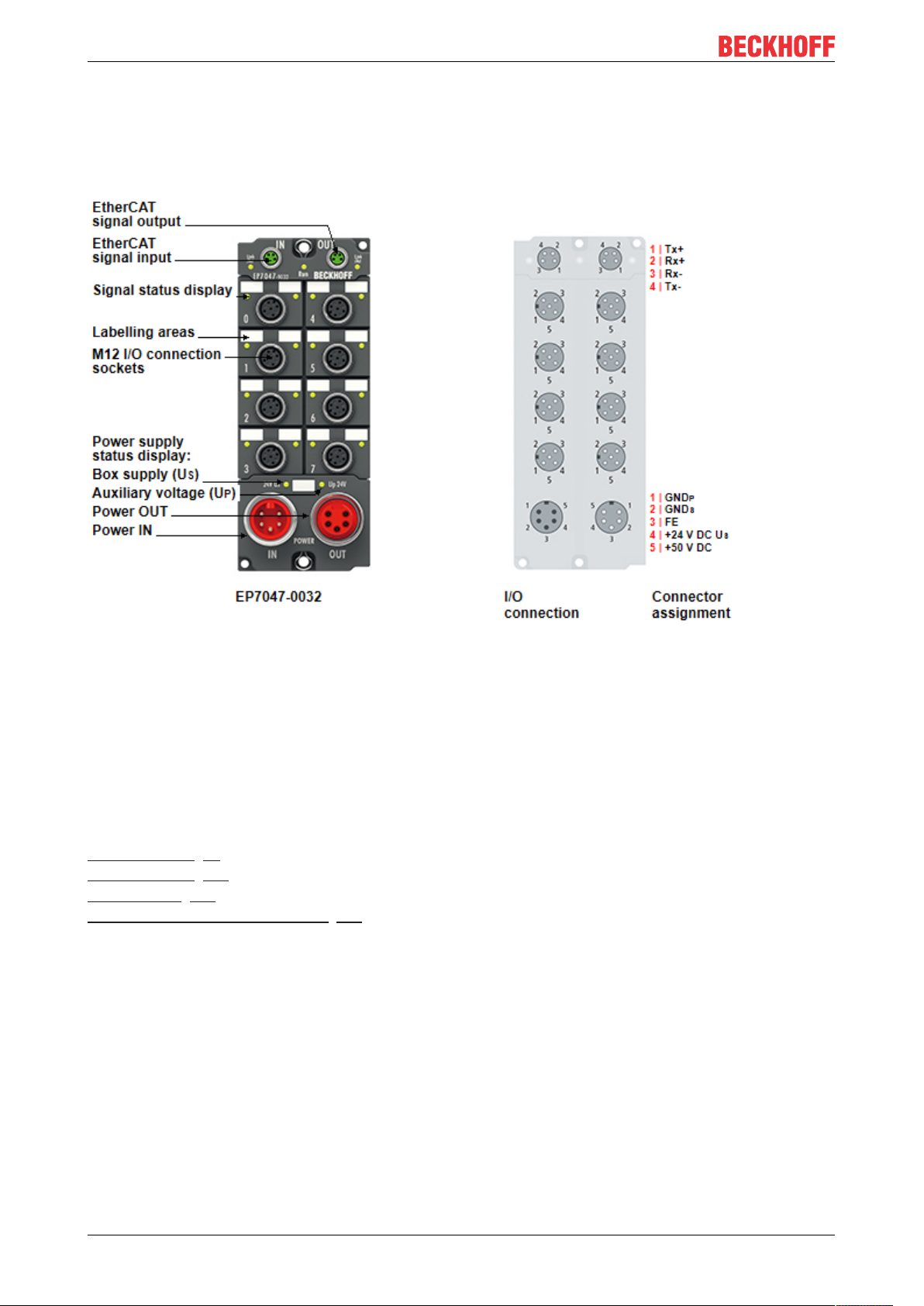

2.1 Introduction

Stepper motor box with incremental encoder and field-oriented control, 48 V DC, 5 A

The EP7047-0032 EtherCAT Box is designed for the medium performance range of stepper motors. The

PWM output stages cover a wide range of voltages and currents. They are housed in the EtherCAT Box,

together with two inputs for limit switches. The EP7047-0032 can be adapted to the motor and the

application with just a few parameters. The torsionally stiff integrated encoder (1024 inc/rev) makes the

AS2000 stepper motor ideal for closed-loop control of the EP7047-0032. Either a 5 V or a 24 V single-ended

version can be used as an encoder.

Quick links

Technical data [}9]

Process image [}11]

Connections [}29]

Commissioning and configuration [}40]

EP7047-10328 Version: 1.0

Page 9

2.2 Technical data

All values are typical values over the entire temperature range, unless stated otherwise.

EtherCAT

Connection 2x M8 socket, 4-pin, green

Electrical isolation 500V

Supply voltages

Connection Input: 7/8" plug, 5-pin

Downstream connection: 7/8" socket, 5-pin

US nominal voltage 24VDC (-15%/ +20%)

US sum current

Current consumption from U

UP nominal voltage 8…48V

UP sum current

Current consumption from U

1)

S

max. 16Aat 40°C

120mA + current consumption of connected devices:

• encoder

• motor brake

• limit switches

1)

P

max. 16A at 40°C

= current consumption of the stepper motor

DC

Product overview

Stepper motor

Motor type 2-phase stepper motor, unipolar or bipolar

Connection 1x M12 socket, 5-pin

Current per phase max. 5A (overload-proof and short-circuit proof)

Maximum step frequency Adjustable:

1000/ 2000/ 4000/ 8000/ 16000 full steps per second

Microstepping up to 64x

2)

Current controller frequency approx. 30 kHz

Resolution approx. 5000 positions per revolution in typical applications

Encoder input

Number 1

encoder type Incremental encoders

Connection 1x M12 socket, 5-pin

Encoder supply Alternatively:

• 5VDC, max 0.5A, short-circuit proof

• 24V

max. 0.5A, not short-circuit proof

DC,

signals A, B, C; single-ended

(C = reference pulse / zero pulse)

Signal voltage "0" -3…2V

Signal voltage "1" 3.7…28V

Pulse frequency max. 400,000 increments per second (4-fold evaluation)

1)

This value corresponds to the current carrying capacity of the connections for the supply voltages.

2)

automatic switching, speed-dependent.

EP7047-1032 9Version: 1.0

Page 10

Product overview

Digital inputs for limit switches

Number 2

Nominal voltage high level 24V

DC

Digital output for the motor brake

Nominal voltage 24VDC from the control voltage U

S

Output current max. 0,5A

Environmental conditions

Ambient temperature during operation -25…+60°C

Ambient temperature during storage -40…+85°C

Vibration/ shock resistance conforms to EN60068-2-6/ EN60068-2-27

EMC immunity/ emission conforms to EN61000-6-2/ EN61000-6-4

Protection class IP65, IP66, IP67 conforms to EN60529

Housing data

Dimensions Wx Hx D 60mmx 150mmx 26,5mm (without connectors)

Weight approx. 440g

Material PA6 (polyamide)

Installation position variable

Approvals

Approvals CE, UL in preparation

2.3 Scope of supply

Make sure that the following components are included in the scope of delivery:

• 1x EP7047-1032 EtherCAT Box

• 1x Protective cap for supply voltage output, 7/8”, black (pre-fitted)

• 2x protective cap for EtherCAT socket, M8, green (pre-assembled)

• 10x labels, blank (1 strip of 10)

Pre-assembled protective caps do not ensure IP67 protection

Protective caps are pre-assembled at the factory to protect connectors during transport. They may

not be tight enough to ensure IP67 protection.

Ensure that the protective caps are correctly seated to ensure IP67 protection.

EP7047-103210 Version: 1.0

Page 11

Product overview

2.4 Process image

The scope of the process image is adjustable.

EP7047-1032 has several predefined variants of the process image: "Predefined PDO Assignments". Select

the "Predefined PDO Assignment" according to the operating mode [}45].

The factory default setting is "Velocity control compact" [}12].

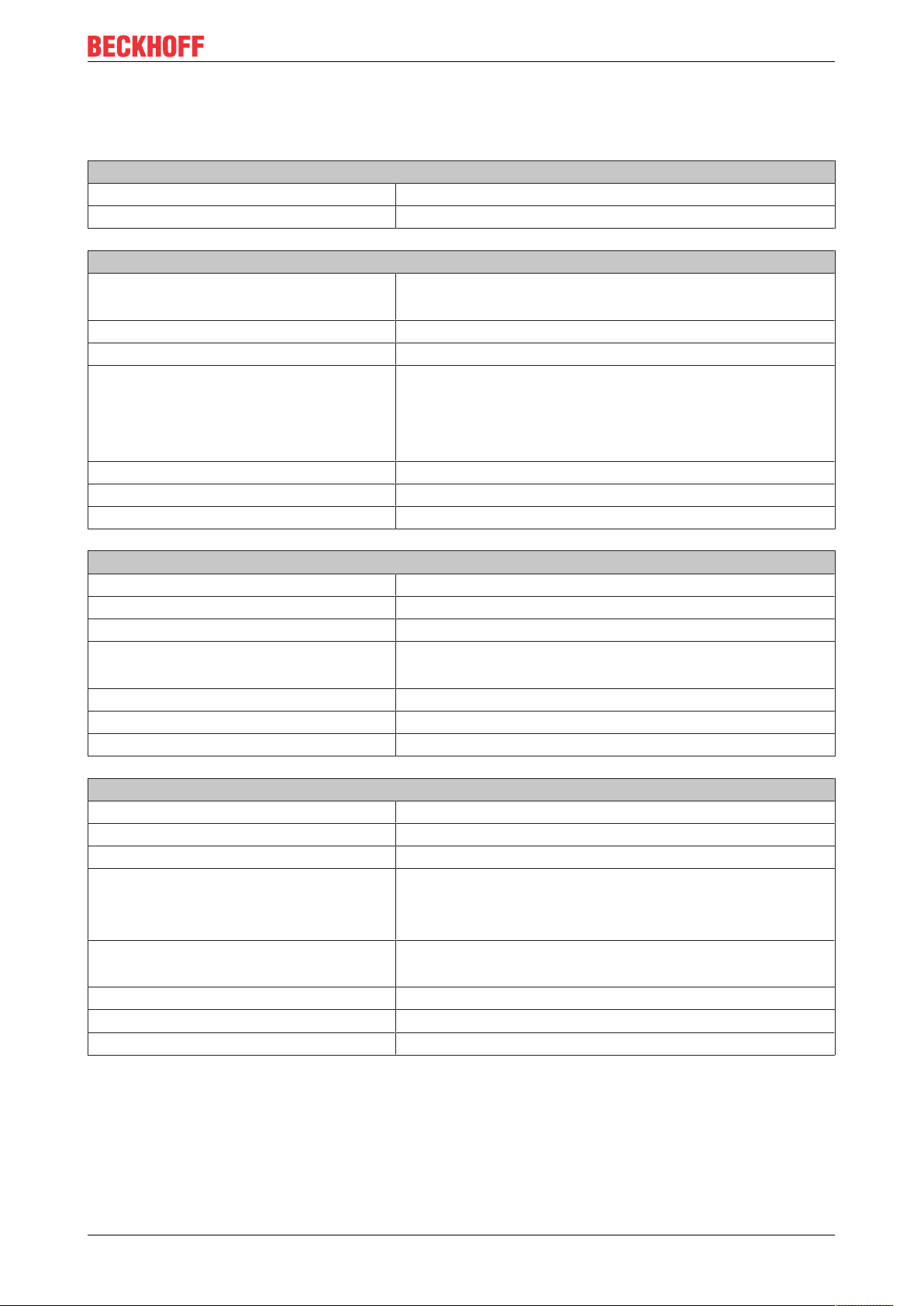

2.4.1 "Predefined PDO Assignments"

Name Process image Process data objects

Position control

ENC Status [}13]

STM Status [}15]

ENC Control [}16]

STM Control [}17]

STM Position [}17]

Positioning interface

Positioning interface (Auto

start)

Positioning interface (Auto

start) with info data

ENC Status [}13]

STM Status [}15]

POS Status [}14]

ENC Control [}16]

STM Control [}17]

POS Control [}16]

ENC Status [}13]

STM Status [}15]

POS Status [}14]

ENC Control [}16]

STM Control [}17]

POS Control [}16]

POS Control 2 [}16]

ENC Status [}13]

STM Status [}15]

EP7047-1032 11Version: 1.0

STM Synchron info data [}15]

POS Status [}14]

ENC Control [}16]

STM Control [}17]

POS Control [}16]

POS Control 2 [}16]

Page 12

Product overview

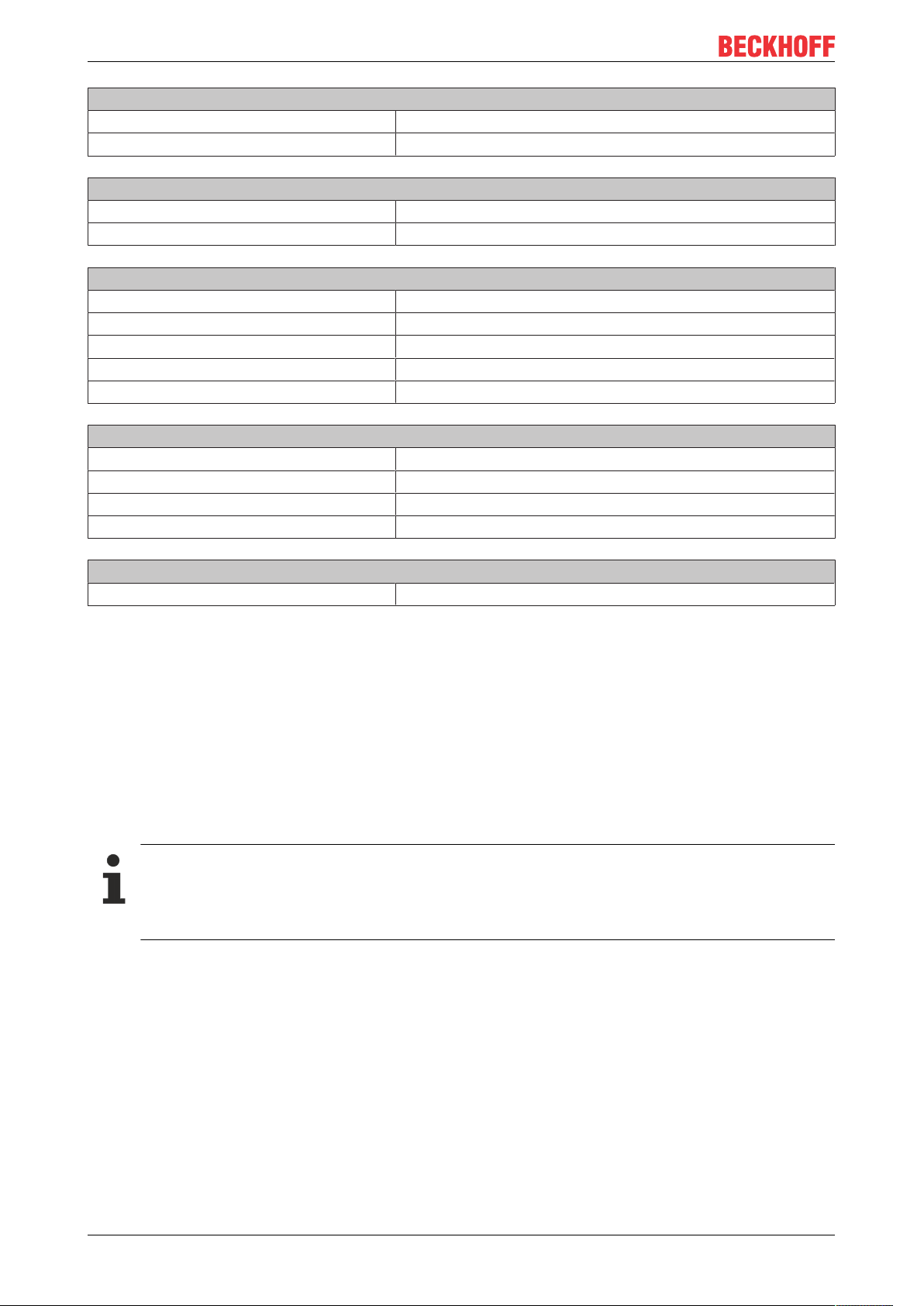

Name Process image Process data objects

Positioning interface compact

ENC Status [}13]

STM Status [}15]

POS Status compact [}14]

ENC Control [}16]

STM Control [}17]

POS Control compact [}16]

Velocity control

Velocity control compact

(Factory setting)

Velocity control compact with

info data

ENC Status [}13]

STM Status [}15]

ENC Control [}16]

STM Control [}17]

STM Velocity [}17]

ENC Status compact [}13]

STM Status [}15]

ENC Control compact [}16]

STM Control [}17]

STM Velocity [}17]

ENC Status compact [}13]

STM Status [}15]

STM Synchron info data [}15]

ENC Control compact [}16]

STM Control [}17]

STM Velocity [}17]

EP7047-103212 Version: 1.0

Page 13

Product overview

2.4.2 Process data objects

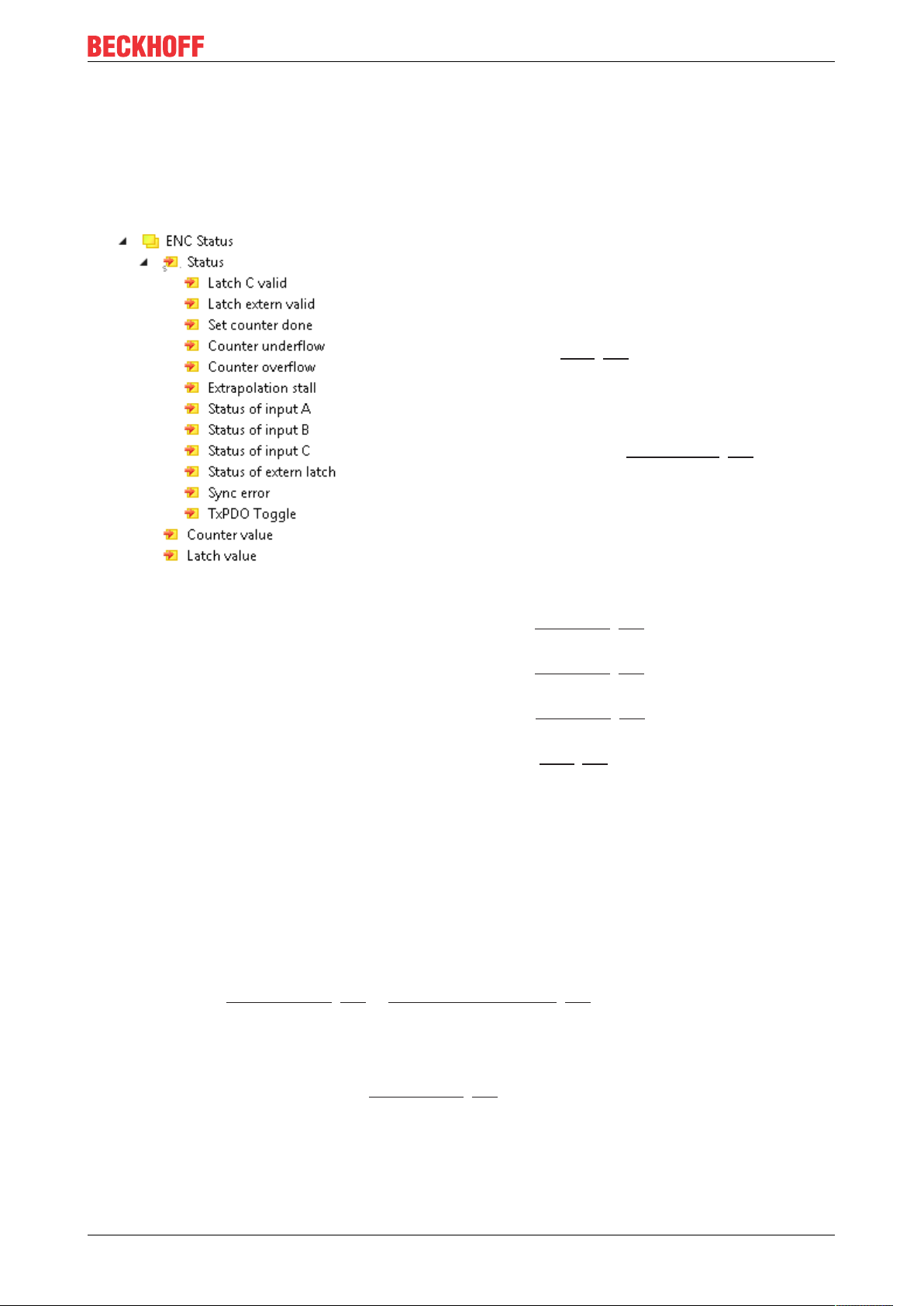

2.4.2.1 "ENC status"

"ENC Status" contains the status variables of the encoder input. "ENC" is the abbreviation for "Encoder".

Status

• Latch C valid: A signal edge has been detected at

encoder signal "C". As a result, the "Counter value"

was written to the variable "Latch value" at the time of

the signal edge.

• Latch extern valid: A signal edge was detected at

the latch input X06 [}36]. As a result, the counter

value was written to the variable "Latch value" at the

time of the signal edge.

• Set counter done: The value from "Set counter

value" was written to the variable "Counter value" after

setting of "Set counter" (ENC Control [}16]).

• Counter underflow: The counter value "Counter

value" has fallen below the value 0.

• Counter overflow: The counter value "Counter value"

has exceeded the maximum value.

• Extrapolation stall: The extrapolated part of the

counter is invalid ("Micro increments").

• Status of input A: Current signal level of encoder

signal "A" (X03 / X04 [}34])

• Status of input B: Current signal level of encoder

signal "B" (X03 / X04 [}34])

• Status of input C: Current signal level of encoder

signal "C" (X03 / X04 [}34])

• Status of extern latch: Current signal level at the

latch input (X06 [}36])

• Sync error: Distributed Clocks synchronization error

in the previous cycle.

• TxPDO Toggle: This bit is inverted each time an input

data update occurs.

1)

1)

Counter value: The current counter value.

Latch value: Counter value stored at the time of the last

signal edge at latch input X06 or encoder signal "C".

1)

The latch function is deactivated in the factory setting. You may activate and configure the latch function in

1)

process data object "ENC Control" [}16] or "ENC Control compact" [}16].

2.4.2.2 "ENC Status compact"

This process data object is identical with "ENC status" [}13], see there.

EP7047-1032 13Version: 1.0

Page 14

Product overview

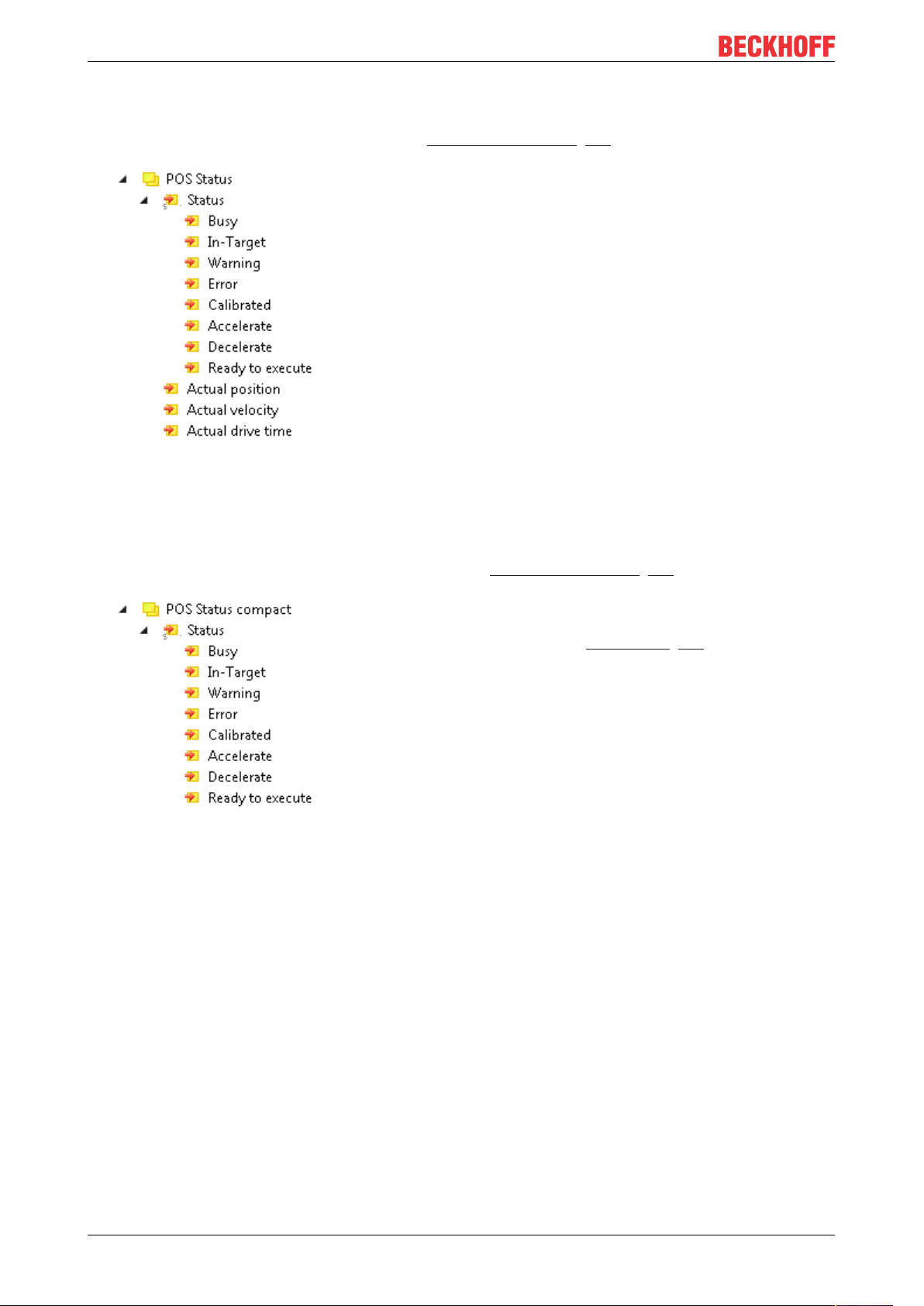

2.4.2.3 "POS Status"

"POS Status" contains the status variables of the Positioning Interface [}60].

Status

• Busy: A motion command is active.

• In-Target: The target position of the motion command

has been reached.

• Warning: Warning message.

• Error: Error message.

• Calibrated: The motor is calibrated.

• Accelerate: The motor accelerates.

• Decelerate: The motor brakes.

• Ready to execute: Ready for a motion command.

Actual position: current set position

Actual velocity: current set velocity

Actual drive time: the elapsed time of the motion

command.

2.4.2.4 "POS Status compact"

"POS Status compact" contains the status variables of the Positioning Interface [}60].

Status

This variable is identical to the "Status" variable in the

process data object "POS Status [}14]". See there.

EP7047-103214 Version: 1.0

Page 15

Product overview

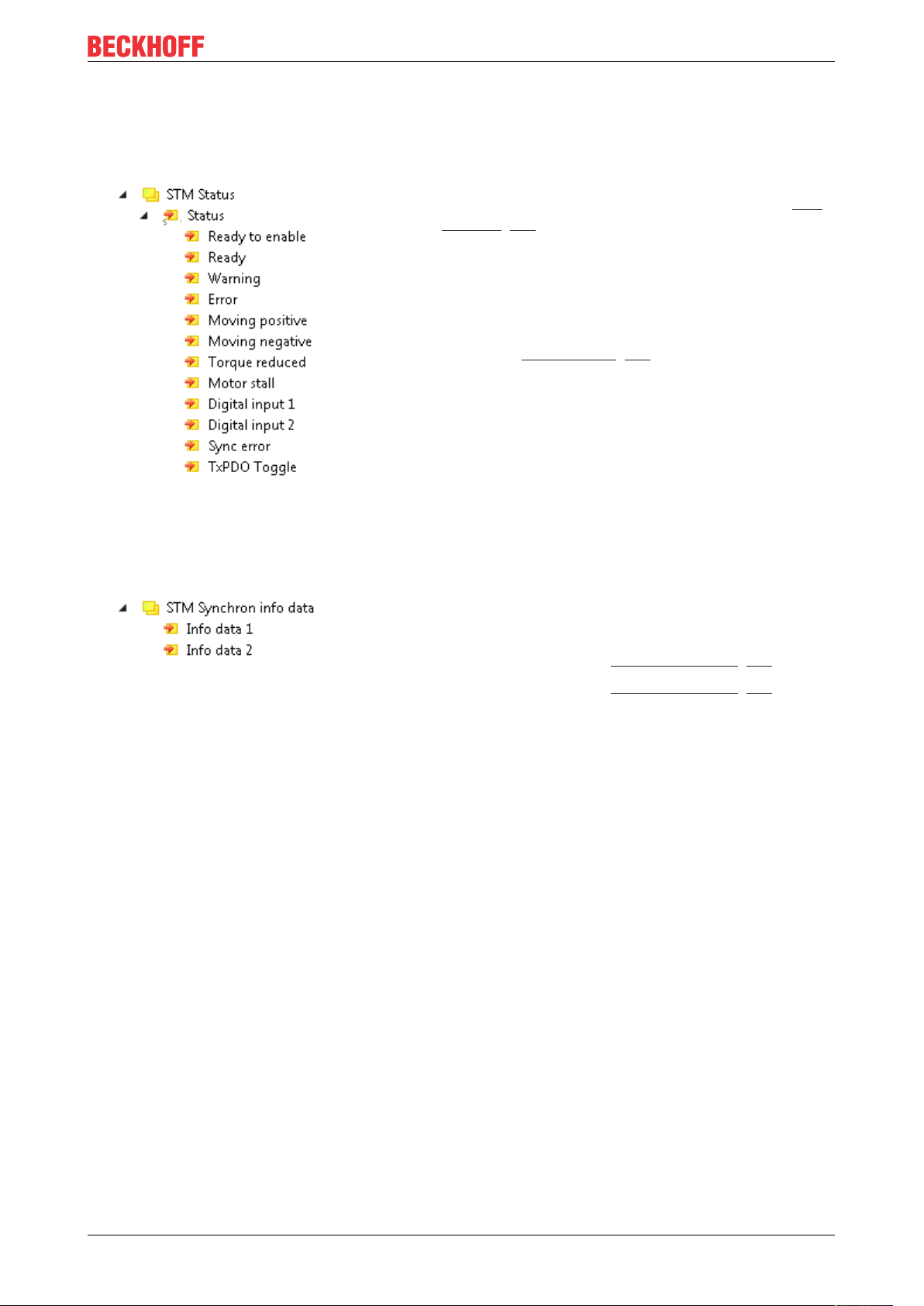

2.4.2.5 "STM Status"

„STM Status" contains the status bits of the stepper motor output stage. "STM" is the abbreviation for

"Stepper Motor".

Ready to enable: The output stage can be enabled. See

output variable "Enable" in the process data object STM

Control [}17].

Ready: The output stage is enabled.

Warning: Warning message.

Error: Error message. The output stage was switched

off due to an error. You can acknowledge the error

message with the output variable "Reset" in the process

data object STM Control [}17]

Moving positive: The speed is greater than 0.

Moving negative: The speed is less than 0.

Motor stall: A loss of step has occurred.

2.4.2.6 "STM Synchronous info data"

"STM" is the abbreviation for "Stepper Motor".

Info data n: Additional information from the box.

You can select what information these variables should

contain:

• Parameter 8012:11

• Parameter 8012:19

Select info data 1 [}94]

hex

Select info data 2 [}94]

hex

EP7047-1032 15Version: 1.0

Page 16

Product overview

2.4.2.7 "ENC Control"

Enable latch C: Activate edge trigger for encoder input

"C".

Enable latch extern on positive edge: Activate edge

trigger for positive signal edges at latch input X06

[}36].

Set counter: Accept the value of the variable "Set

counter value" as the current counter value.

Enable latch extern on negative edge: Activate edge

trigger for negative signal edges at latch input X06

[}36].

Set counter value: Default value for "Set counter".

2.4.2.8 "ENC Control compact"

This process data object is identical with "ENC Control" [}16].

2.4.2.9 "POS Control"

This process data object contains variables for controlling the Positioning Interface [}60].

2.4.2.10 "POS Control 2"

This process data object contains variables for controlling the Positioning Interface [}60].

2.4.2.11 "POS Control compact"

This process data object contains variables for controlling the Positioning Interface [}60].

EP7047-103216 Version: 1.0

Page 17

Product overview

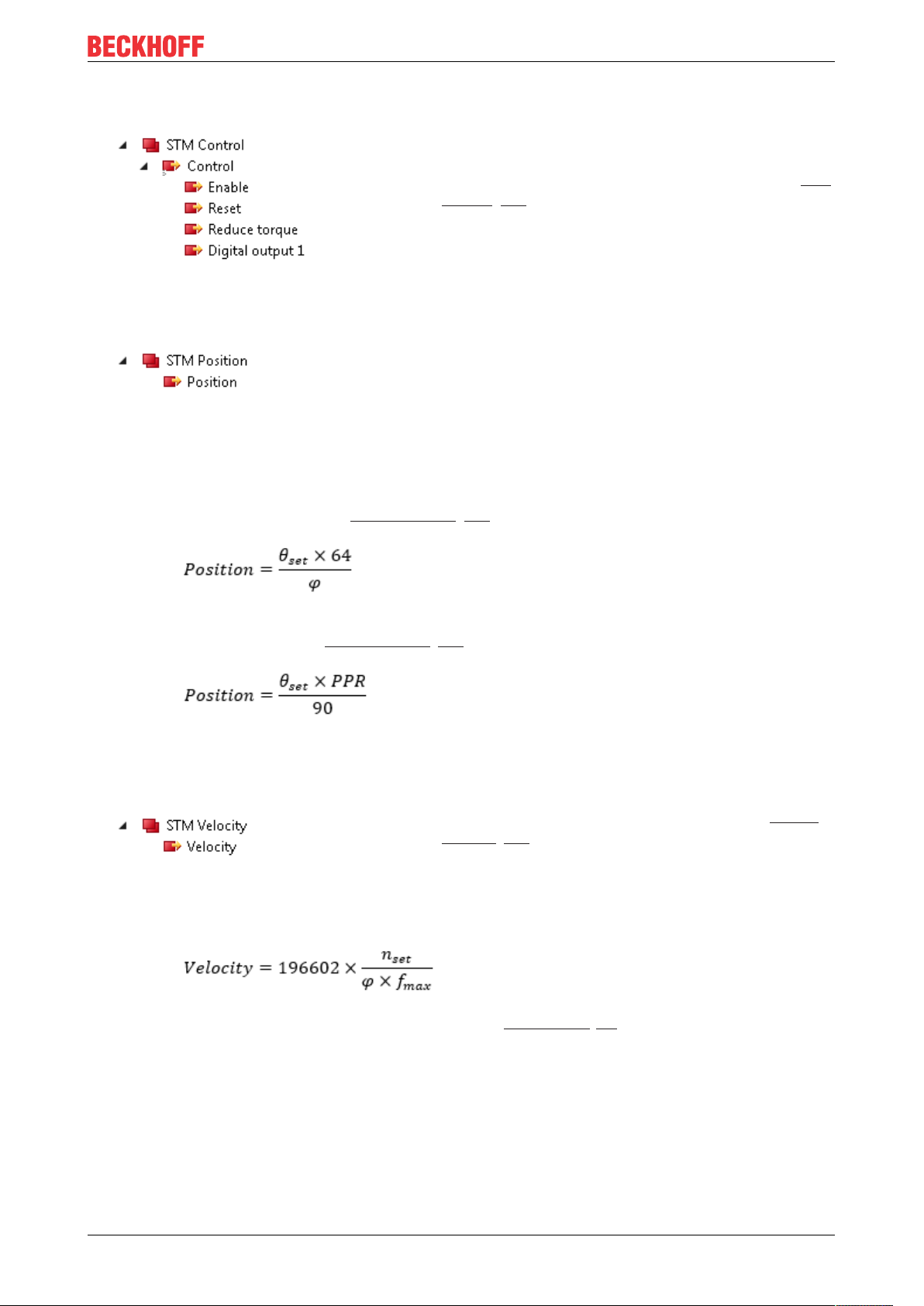

2.4.2.12 "STM Control"

Enable: Enable output stage.

Reset: Acknowledge error message, reset error status.

See input variable "Error" in the process data object STM

Status [}15]

2.4.2.13 "STM Position"

Position: Position setpoint.

Specify the position setpoint in increments.

Conversion from degrees (°) to increments: See below.

Conversion of position setpoints

The formula for converting a position setpoint from degrees (°) to increments depends on whether you are

using an encoder.

• If you are not using an encoder (feedback type [}94] = "Internal counter" ), use this formula:

Position: Setpoint [increments]

Θ

: Setpoint [°]

set

φ: Step angle of the motor [°]

(for AS10xx stepper motors: φ=1.8°)

• If you are using an encoder (feedback type [}94] = "Encoder" ), use this formula:

Position: Setpoint [increments]

Θ

: Setpoint [°]

set

PPR: Resolution of the encoder [increments/revolution]

(for AS10xx stepper motors: inc = 1024)

2.4.2.14 "STM Velocity"

Velocity: Speed setpoint in % of the parameter "Speed

range" [}44].

32767

-100%.

Conversion of speed setpoints

corresponds to 100%, -32767

dec

Velocity: Setpoint [increments/s]

n

: Setpoint [rpm]

set

φ: Step angle of the motor [°]

(for AS10xx stepper motors: φ=1.8°)

f

: "Speed range" [}44] [full steps/s]

max

corresponds to

dec

The speed setpoint can be positive or negative, depending on the desired direction of rotation of the motor.

EP7047-1032 17Version: 1.0

Page 18

Product overview

2.5 Technology

EP7047-1032 provides two basic modes of operation.

• In standard mode [}23] all unipolar and bipolar stepper motors that comply with the specifications of

EP7047-1032 can be controlled. Two currents with sine/cosine curve are provided. The current is

clocked with 64 kHz and resolved with up to 64-fold microstepping to achieve a smooth current.

• Extended mode [}25] is based on field-oriented control. This mode can only be used for stepper

motors from Beckhoff. The current is not only provided, but controlled in a comprehensive manner.

Typical stepper motor problems such as pronounced resonance are therefore finally a thing of the past.

Furthermore, the current is adjusted depending on the load, thereby enabling considerable energy

savings and lower thermal loads at the stepper motor.

Realisation of more demanding positioning tasks

More demanding positioning tasks can be realised via the TwinCAT automation software from Beckhoff. Like

other axes, EP7047-1032 is integrated via the TwinCAT System Manager and can be used like standard

servo axes. Special stepper motor features, such as speed reduction in the event of large following errors,

are automatically taken into account via the stepper motor axis option. The effort for changing from a

servomotor to a stepper motor - and back - is no greater than changing from one fieldbus to another one

under TwinCAT.

The output stages of EP7047-1032 have an overload protection in the form of an overtemperature warning

and switch-off. Together with short circuit detection, diagnostic data are accessible in the process image of

the controller. In addition, this status is displayed by LEDs, along with other information. The output stage is

switched on via an Enable-Bit. The motor current can be set and reduced via a parameter value.

Optimum adaptation to the motor and the implementation of energy-saving features require minimum

programming effort. Since all data are set in the form of parameters in the CoE register, it is easily possible

to replace an EtherCAT device or store certain parameters for transfer to the next project. It is therefore no

longer necessary to transfer certain potentiometer settings or to document DIP switch settings.

EP7047-103218 Version: 1.0

Page 19

Product overview

2.5.1 Stepper motor

Stepper motors are electric motors and are comparable with synchronous motors. The rotor is designed as a

permanent magnet, while the stator consists of a coil package. The frequency of the stator rotary field is

always in a fixed ratio relative to the rotor speed. In contrast to synchronous motors, stepper motors have a

large number of pole pairs. In a minimum control configuration, the stepper motor is moved from pole to pole,

or from step to step.

Stepper motors have been around for many years. They are robust, easy to control, and provide high torque.

In many applications, the step counting facility saves expensive feedback systems. Even with the

increasingly widespread use of synchronous servomotors, stepper motors are by no means "getting long in

the tooth". They are considered to represent mature technology and continue to be developed further in

order to reduce costs and physical size, increase torque and improve reliability. For a standard stepper

motor with 200 full steps, the best possible positioning accuracy is approx. 1.8°.

Today, the most widely used type in industry is the hybrid stepper motor type. In this type of motor the rotor

consists of a toothed iron core with one or a few permanent magnets in the rotor core. The rotor is designed

such that the polarity of successive teeth is inverse. This enables the production of motors with a high

number of steps, which is essential for positioning accuracy, combined with a relatively high torque. The

electrical behaviour of such a hybrid stepper motor is comparable with a multipole synchronous servomotor.

However, thanks to the synchronous toothing of stator and rotor, hybrid stepper motors offer a significantly

higher cogging torque.

Hybrid stepper motors with two or more phases are available on the market. Since EP7047-1032 is designed

for two-phase motors, the description focuses on the two-phase type, with the phases referred as A and B in

this documentation.

Stepper motor parameters

• Mechanical system

Irrespective of the drive and the stepper motor itself, the configuration of the mechanism attached to the

motor shaft has significant influence on the achievable control quality.

Natural resonances, load resonances, gear backlash (loose) and static friction have negative affect on the

controllability of the drive system. This often requires "softer" controller parameterisation, which in turn leads

to a higher position lag in the system. Sliding friction can result in reduced efficiency (due to increased

energy demand), but on the other hand it can have a positive effect on the control stability, due to its

dampening effect.

As a general rule, the "stiffer" the mechanics of a drive system, the easier it is to control, which is beneficial

for achieving a small position lag in the drive system.

• Speed

Stepper motors have low maximum speed, which is usually specified as a maximum step frequency.

• Number of phases

Motors with 2 to 5 phases are common. EP7047-1032 supports 2-phase motors. 4-phase motors are

basically 2-phase motors with separate winding ends. They can be connected directly to EP7047-1032.

• Torque

Refers to the maximum motor torque at different speeds. This parameter is usually represented by a

characteristic curve. Stepper motors have comparatively high torque in the lower speed range. In many

applications, this enables them to be used directly without gearing. Compared with other motors, stepper

motors can quite easily provide a holding moment of the same order of magnitude as the torque.

EP7047-1032 19Version: 1.0

Page 20

Product overview

• Cogging torque

In many cases the stepper motors design results in high cogging torque, which can lead to relatively strong

natural resonance in a motor- and load-dependent speed range. In relation to the cogging torque, increased

inertia often leads to a less strong resonance and smoother operation.

• Mass moment of inertia

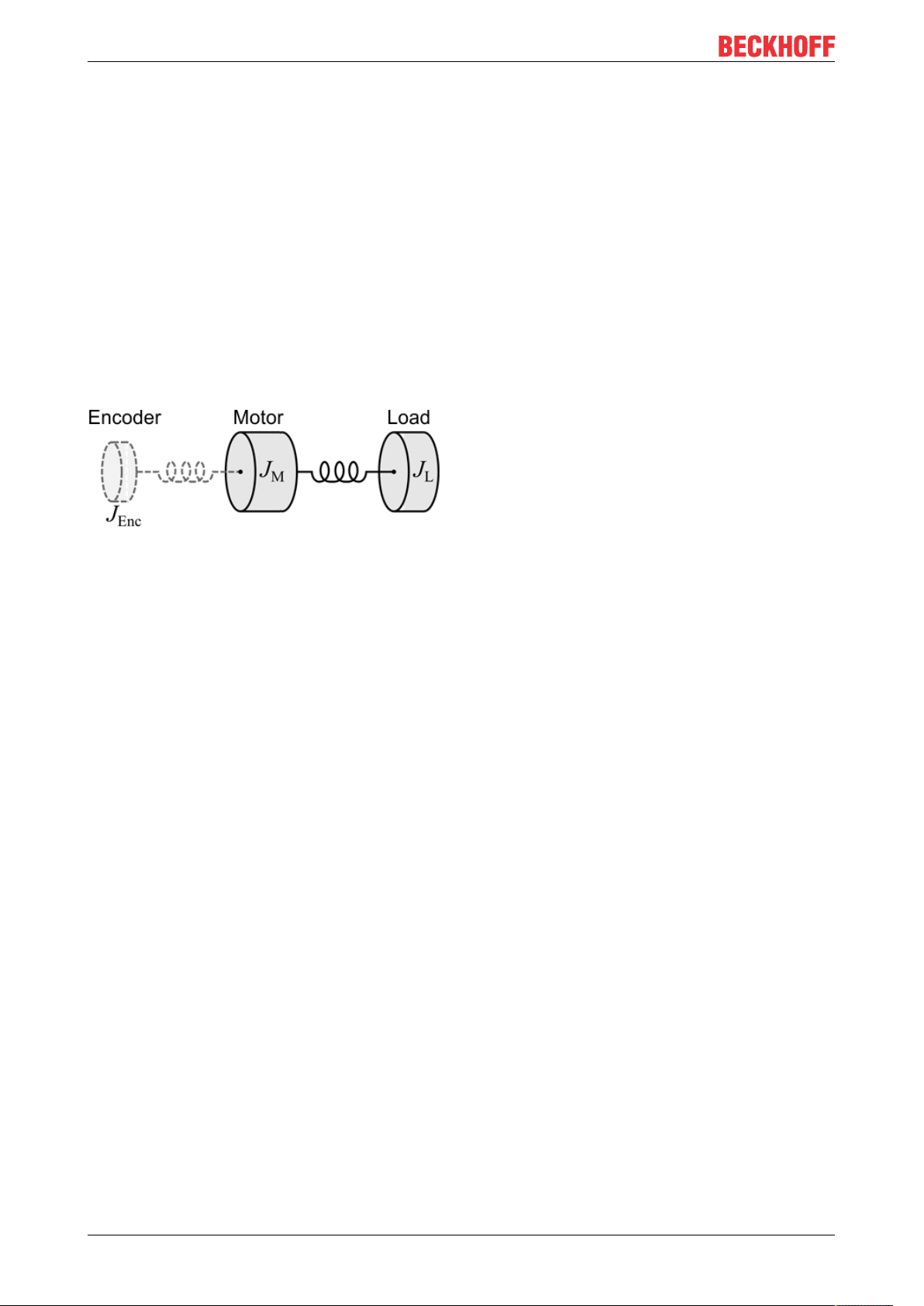

In standard mode, the key parameter of the mechanical system is the mass moment of inertia JΣ. It is

essentially composed of the mass moment of inertia of the stepper motor rotor JM and the mass moment of

inertia of the connected load JL. The friction moment J

and the moment of inertia of the encoder J

fric

can be

Enc

neglected in a first approximation.

JƩ ≈ JM + J

L

The ratio between the load torque and the motor torque is defined by the constant kJ.

kJ ≈ JL / J

M

Fig.1: Simplified representation of the mass moments of inertia

As a first approximation, the coupling of the individual masses over the rotor shaft can be modelled as twomass oscillator. The resonance frequency between the motor and the encoder lies in a relatively high

frequency range, which is usually not relevant for stepper motor drives and is suppressed within the drive by

low-pass filtering. The resonance frequency between the motor and the load is frequently in the range

between 20 and 500 Hz. It is therefore often in the operating range of the drive control. Design measures to

reduce the influence of the load resonance include a small load ratio kJ and a rigid coupling of the motor

shaft to the connected load.

• Resonance

At certain speeds, stepper motors run less smoothly. This phenomenon is particularly pronounced when the

motor runs without coupled load, in which case it may even stop (in standard mode). This is caused by

resonance. A distinction can roughly be made between

• resonances in the lower frequency range up to approx. 250Hz; and

• resonances in the medium to upper frequency range.

Resonances in the medium to upper frequency range essentially result from electrical parameters such as

inductance of the motor winding and supply line capacity. They can be controlled relatively easily through

high pulsing of the control system.

Resonances in the lower range essentially result from the mechanical motor parameters. Apart from their

impact on smooth running, such resonances can lead to significant loss of torque, or even loss of step of the

motor, and are therefore particularly undesirable.

In principle, the stepper motor represents an oscillatory system (comparable to a mass/spring system),

consisting of the moving rotor with a moment of inertia and a magnetic field that creates a restoring force that

acts on the rotor. Moving and releasing the rotor creates a damped oscillation. If the control frequency

corresponds to the resonance frequency, the oscillation is amplified, so that in the worst case the rotor will

no longer follow the steps, but oscillate between two positions.

EP7047-1032 prevents this effect thanks to the field-oriented control (Extended Operation Modes) for all

Beckhoff stepper motors.

EP7047-103220 Version: 1.0

Page 21

Product overview

•Torque constant

In the Extended Operation Modes the torque constant kT is used as an additional parameter for the

mechanical controlled system. It indicates the ratio between the torque-forming motor current and the active

torque at the shaft. However, since the field-oriented operating mode is not common for stepper motors, the

torque constant is usually not listed in the motor data sheet.

Electrical system

• Nominal voltage, supply voltage and winding resistance

Under steady-state conditions, the rated current at the rated voltage depends on the winding resistance. This

voltage should not be confused with the supply voltage of the power output stage. EP7047-1032 applies a

controlled current to the motor winding. If the supply voltage falls below the nominal voltage, the power

output stage can no longer apply the full current, resulting in a loss of torque. It is desirable to aim for

systems with small winding resistance and high supply voltage in order to limit warming and achieve high

torque at high speeds.

• Induced countervoltage

Like servomotors, hybrid stepper motors induce a voltage ui [Vs/rad] in the stator winding of the motor, which

is proportional to the speed. It is also referred to as Back Electromotive Force (BEMF). In conjunction with

the DC link voltage (motor voltage), the induced countervoltage determines the physically achievable

maximum speed of the motor.

The ratio of the magnitude of the induced countervoltage and the motor speed varies depending on the

design and is described via the voltage constant ke.

ui = ke·ω

m

The motor parameter ke [mV/(rad/s)] is required for step loss recognition without encoder.

For stepper motors where the voltage constant is not specified in the data sheet, it can be relatively easily

determined using a digital multimeter. To this end the motor to be measured must be operated (within the

rated speed range) by an auxiliary motor via a coupling with constant speed. The motor phases of the motor

to be measured must be open (not connected or shorted). The multimeter can then be used to determine the

RMS value of the induced countervoltage, and therefore the voltage constant, at one of the two open motor

phases (A or B).

• Step angle

The step angle indicates the angle travelled during each step. Typical values are 3.6°, 1.8° and 0.9°. This

corresponds to 100, 200 and 400 steps per motor revolution. Together with the downstream transmission

ratio, this value is a measure for the positioning accuracy. For technical reasons, the step angle cannot be

reduced below a certain value. Positioning accuracy can only be improved further by mechanical means

(transmission). An elegant solution for increasing the positioning accuracy is the microstepping function. It

enables up to 64 intermediate steps. The smaller "artificial" step angle has a further positive effect: The drive

can be operated at higher speed, yet with the same precision. The maximum speed is unchanged, despite

the fact that the drive operates at the limit of mechanical resolution.

• Winding resistance, winding inductance

The winding inductance and winding resistance of the stepper motor stator determine the electrical motor

time constant Te = L / R, which is a key parameter for current controller configuration.

EP7047-1032 21Version: 1.0

Page 22

Product overview

2.5.2 Selecting a stepper motor

Specifying the stepper motor

1. Determine the required positioning accuracy and hence the step resolution. The first task is to determine the maximum resolution that can be achieved. The resolution can be increased via mechanical

gear reduction devices such as spindles, gearing or toothed racks. The 64-fold microstepping also has

to be taken into account.

2. Determine mass m and moment of inertia (J) of all parts to be moved

3. Calculate the acceleration resulting from the temporal requirements of the moved mass.

4. Calculate the forces from mass, moment of inertia, and the respective accelerations.

5. Convert the forces and velocities to the rotor axis, taking account of efficiencies, moments of friction

and mechanical parameters such as gear ratio. It is often best to start the calculation from the last

component, usually the load. Each further element transfers a force and velocity and leads to further

forces or torques due to friction. During positioning, the sum of all forces and torques acts on the motor shaft. The result is a velocity/torque curve that the motor has to provide.

6. Using the characteristic torque curve, select a motor that meets these minimum requirements. The

moment of inertia of the motor has to be added to the complete drive. Verify your selection. In order to

provide an adequate safety margin, the torque should be oversized by 20% to 30%. The optimisation

is different if the acceleration is mainly required for the rotor inertia. In this case, the motor should be

as small as possible.

7. Test the motor under actual application conditions: Monitor the housing temperatures during continuous operation. If the test results do not confirm the calculations, check the assumed parameters and

boundary conditions. It is important to also check side effects such as resonance, mechanical play,

settings for the maximum operation frequency and the ramp slope.

8. Different measures are available for optimising the performance of the drive: using lighter materials or

hollow instead of solid body, reducing mechanical mass. The control system can also have significant

influence on the behaviour of the drive. EP7047-1032 enables operation with different supply voltages.

The characteristic torque curve can be extended by increasing the voltage. In this case, a current increase factor can supply a higher torque at the crucial moment, while a general reduction of the current can significantly reduce the motor temperature. For specific applications, it may be advisable to

use a specially adapted motor winding.

EP7047-103222 Version: 1.0

Page 23

Product overview

2.5.3 Standard mode

Stepper motors were originally operated with very simple output stages, which were only able to switch the

voltage of the motor phases separately (nowadays current control takes place via PWM with pulse-width

modulation as standard). Initially the motor phases there were controlled individually in turn. A switching

sequence in the positive direction of rotation corresponds to the switching sequence (+A, +B, -A, -B).

Sequential switching results in rather irregular operation in this mode. In order to make the operation

smoother, so-called microstepping was introduced later, in which the four set voltages were extended by

intermediate values (e.g. from a stored sine table). These days, microstepping based on 64 steps is

commonly used.

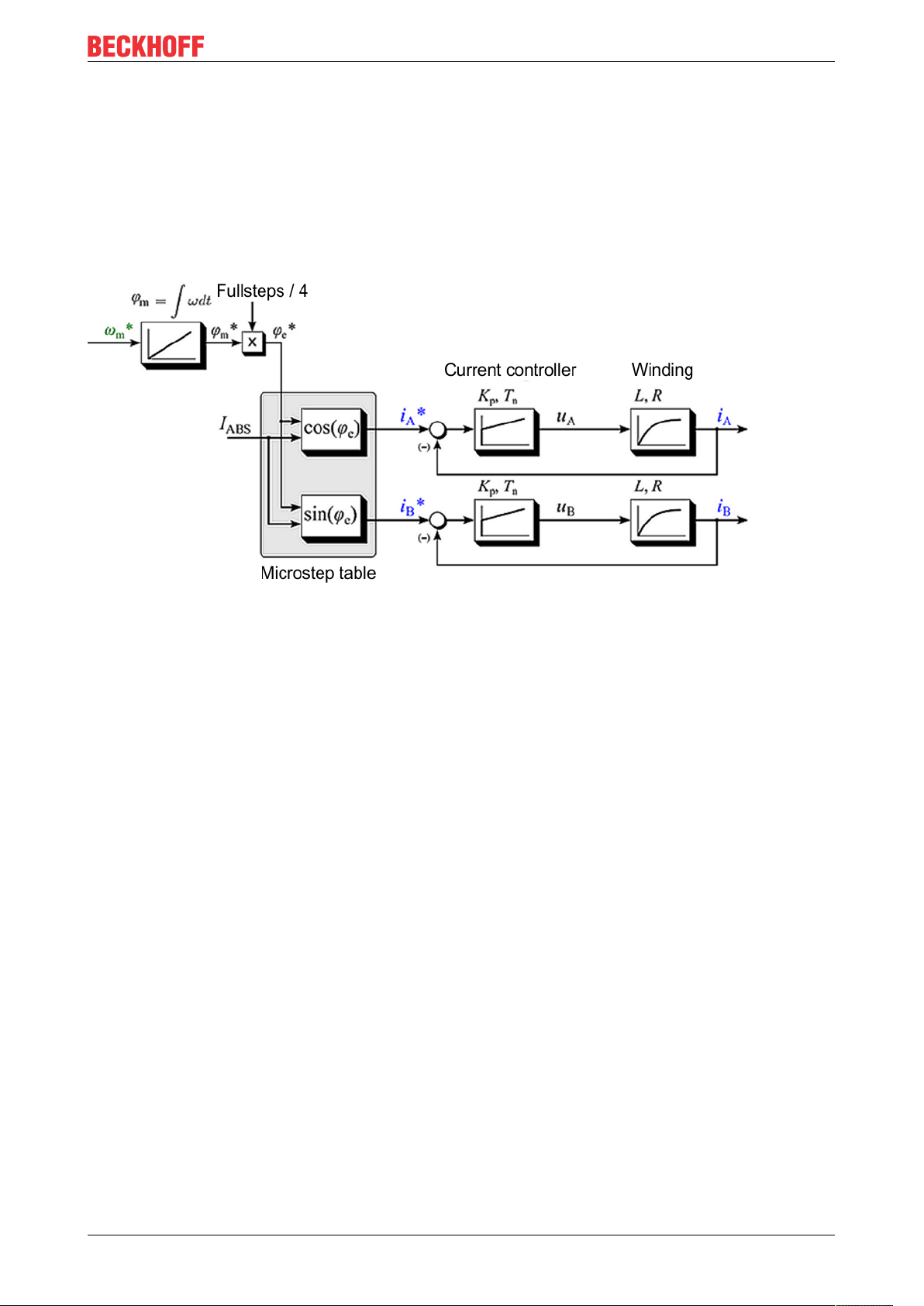

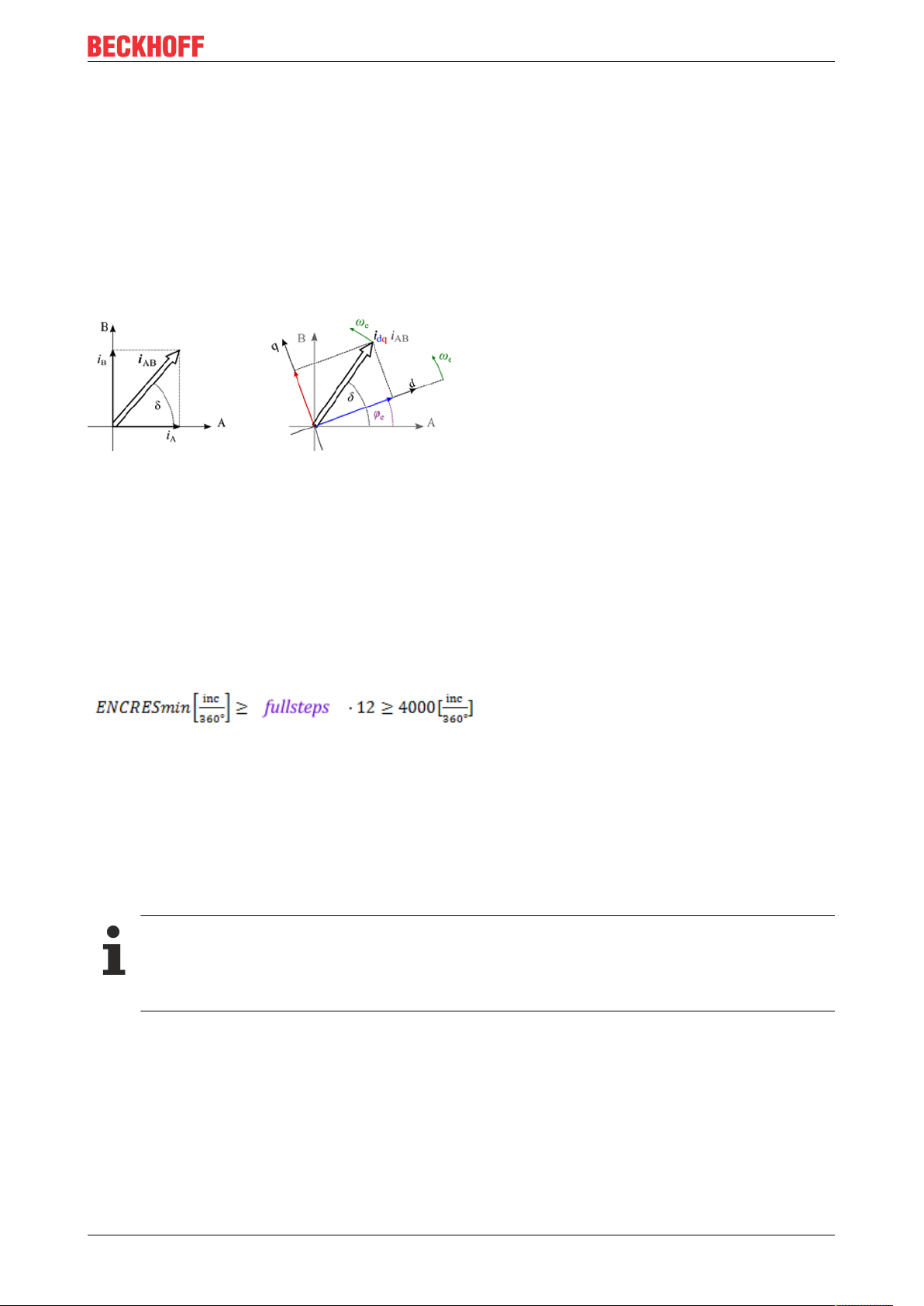

Fig.2: Control structure of a standard stepper motor drive

Neglecting the sampling resulting from the microstepping, the motor current I as function of the electrical

angle φe and of the magnitude of the motor current I

(when using a current controller) can be described as

ABS

follows:

I(φe) = IA+ jIB= I

cos(φe) + jI

ABS

ABS

sin(φe)

Represented by magnitude and angle:

I(φe ) = I

ABS

· e

jφe

It follows that a rotation of the electrical angle φe is equivalent to four full steps. (A stepper motor with 200

full steps therefore has 50 pole pairs).

The shaft aligns itself if a constant current is set with no load at the motor shaft. Within a pole pairs the shaft

points in the direction of the active stator field.

If an external load is applied to the motor shaft, the shaft is turned out of the field direction, resulting in a load

angle (also referred to as angular displacement) (relative to an electric rotation of the angle φe). The load

angle depends on the design of the stepper motor itself, the motor current and the torque acting on the shaft.

The relationship is non-linear!

If the load angle exceeds a motor-dependent maximum value (i.e. if the maximum machine torque under

these boundary conditions is exceeded), the load torque can no longer be maintained by the motor. If the

shaft is turned further out of the rotary field, it "tips", resulting in one or more step losses. The "tip angle" may

vary between motor types. Often, it lies between around 45° and 65°.

EP7047-1032 23Version: 1.0

Page 24

Product overview

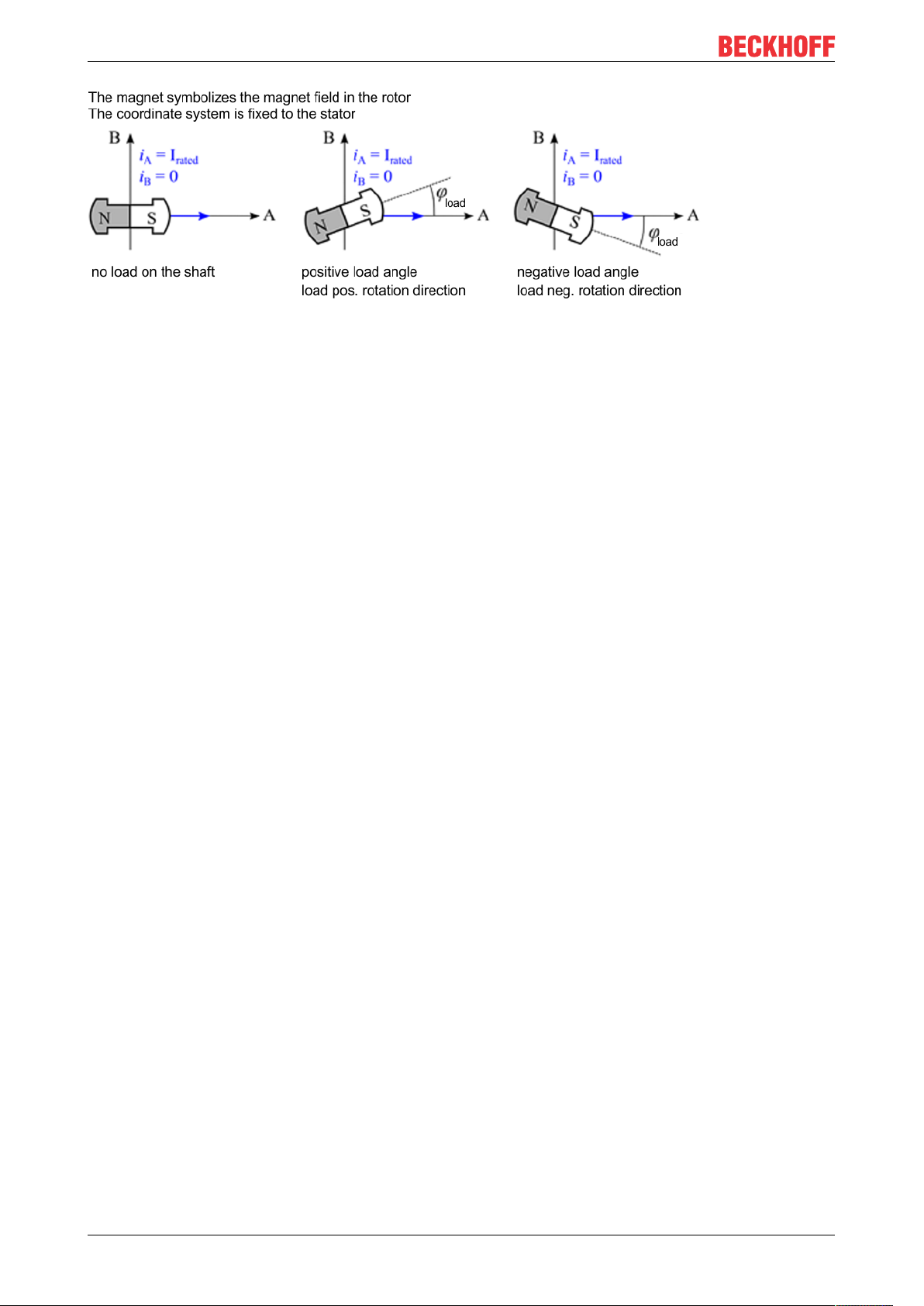

Fig.3: Behaviour of the rotor under load

The load angle is of interest for the user, because it allows conclusions about the load on the shaft. It is

measured by evaluating the induced countervoltage* and can be used to optimise the drive system.

EP7047-103224 Version: 1.0

Page 25

Product overview

2.5.4 Field-oriented control

In the Extended Operation Modes the stepper motor is operated like a servomotor, based on the principle of

field-oriented control.

Function

The operating behaviour of the motor corresponds to that of a traditional DC motor, with commutation via a

mechanical commutator. With a constant exciter field, the torque of the DC machine is directly proportional to

the stator current and can be directly influenced by it. The exciter field is generated, depending on the

machine type, by permanent magnets or, with a separately excited DC machine, for example, via a separate

excitation winding.

Fig.4: Coordinate transformation of field-oriented control

For servomotors and also hybrid stepper motors, initially there is no direct link between the phase currents

and the torque. Field and torque are decoupled mathematically via Park's transformation. Two current

components, "d" for "direct" in field direction and "q" for "quadrature" in torque-forming direction, are

calculated from the phase currents. Via the torque-forming current component iq, the torque of the machine

can now be regulated directly, like for a DC machine.

A prerequisite is that the rotor position is available with sufficiently high accuracy. For a stepper motor the

encoder resolution should be at least 4000 increments per mechanical revolution, in order to achieve

adequate positioning accuracy. The minimum encoder resolution also depends on the number of full steps

and can be calculated approximately as follows.

Fig.5: Calculation of the resolution

Commutation determination for Extended Operation Modes

Because the absolute actual position is not available for incremental encoders, on system start-up there is

no direct reference to the rotor position, which is required for field-oriented operation. Therefore, the

reference between the actual position and the rotor position must be generated at start-up via a commutation

determination process. During this process the rotor is moved forward and back several times up to two full

steps.

Commutation determination

• The maximum current should be set just below the rated motor current.

• During commutation determination the rotor shaft should not be subject to an external torque. If

this condition is not met, the Extended Operation Modes cannot be used.

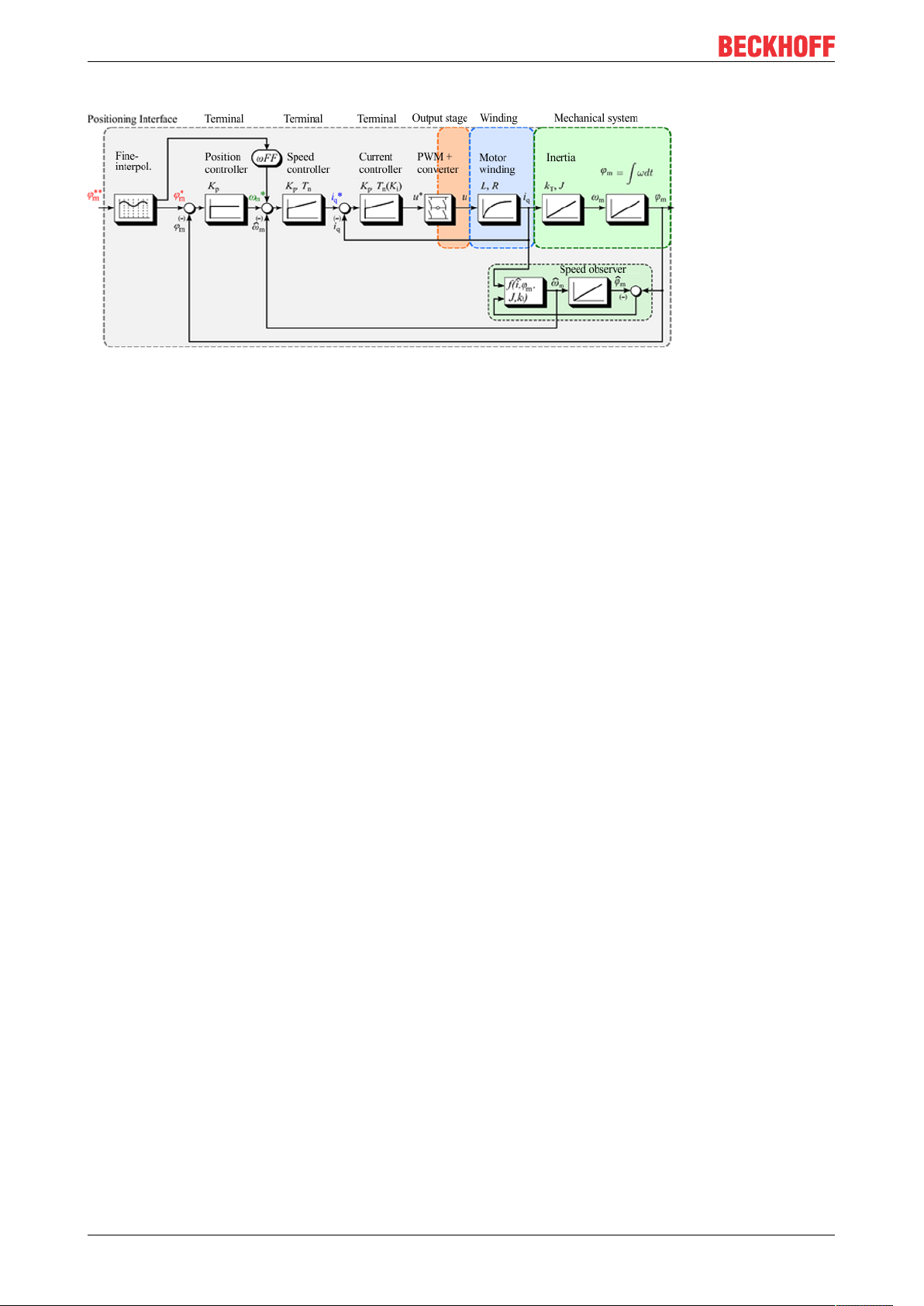

Control structure

The drive control structure is a cascade control structure with a position control loop and a lower-level speed

and current control loop. If a speed setpoint is specified, the external position control loop can be omitted.

EP7047-1032 25Version: 1.0

Page 26

Product overview

Fig.6: Cascade control structure with field-oriented control (Extended Operating modes)

Motor dependency

Due to the fact that the control is strongly dependent on the motor parameters, the controller parameters and

motor behaviour itself, field-oriented control is limited to Beckhoff motors. This mode is not supported for

motors from other manufacturers.

Main advantages compared with standard mode

• Low current consumption (almost full load-dependence)

• High efficiency

• Consistent dynamics compared with standard mode

• Step losses are inherently avoided

Requirement

• Encoder with sufficiently high resolution required (minimum 4000 [INC/360°])

• Slightly higher parametrisation effort required (speed controller)

• Commutation determination at startup (due to incremental encoder)

• Only possible with stepper motors from Beckhoff Automation (AS10xx)

EP7047-103226 Version: 1.0

Page 27

3 Mounting and connections

150

60

141

Ø 4.5

3.1 Mounting

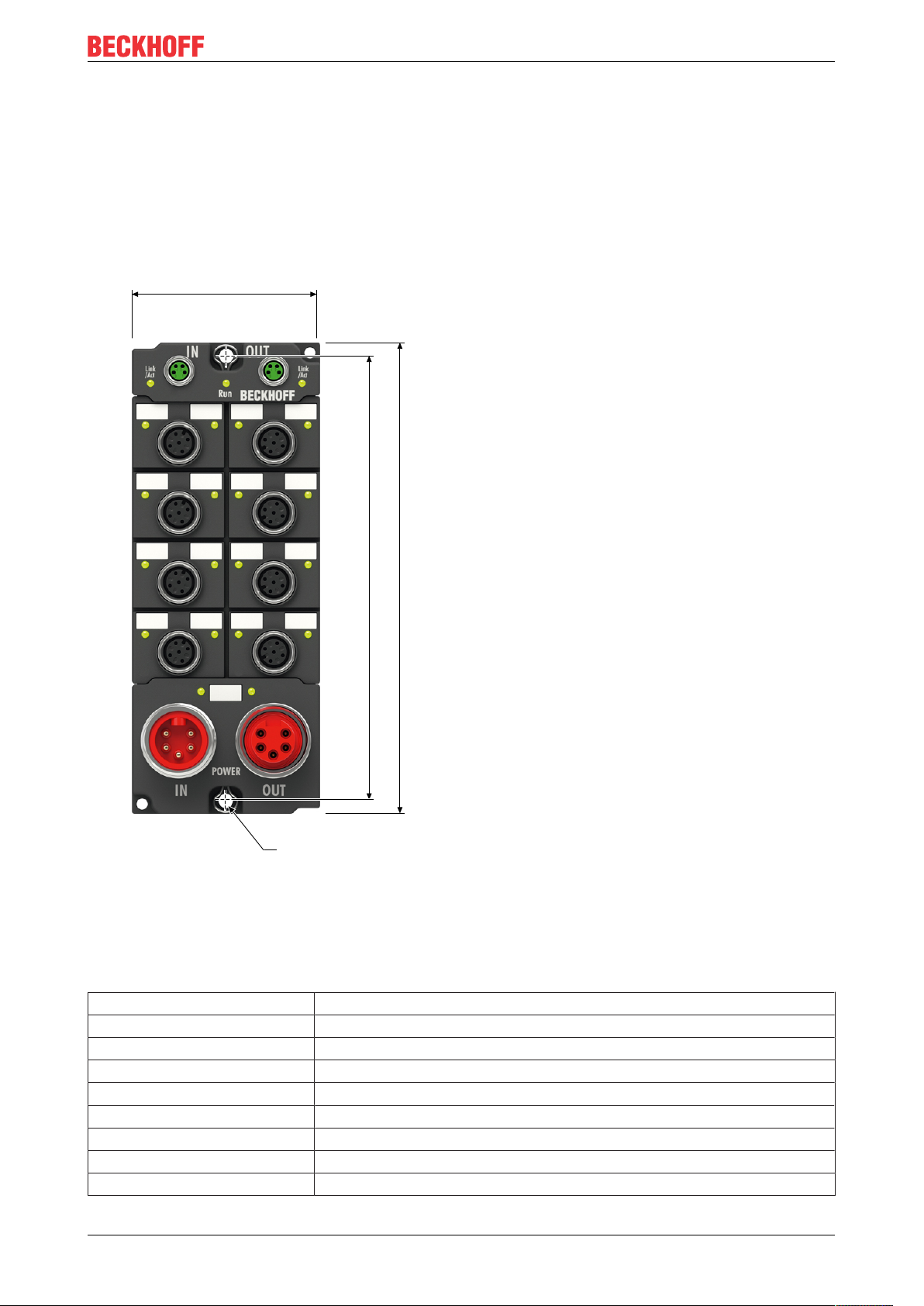

3.1.1 Dimensions

Mounting and connections

Fig.7: Dimensions

All dimensions are given in millimeters.

Housing features

Housing material PA6 (polyamide)

Sealing compound polyurethane

Mounting two fastening holes Ø 4.5 mm for M4

Metal parts brass, nickel-plated

Contacts CuZn, gold-plated

Power feed through max. 16 A at 40°C (according to IEC 60512-3)

Installation position variable

Protection class IP65, IP66, IP67 (conforms to EN 60529) when screwed together

Dimensions (H x W x D) approx. 150 x 60 x 26.5mm (without connectors)

EP7047-1032 27Version: 1.0

Page 28

Mounting and connections

FE

FE

3.1.2 Fixing

NOTE

Dirt during assembly

Dirty connectors can lead to malfunctions. Protection class IP67 can only be guaranteed if all cables and

connectors are connected.

• Protect the plug connectors against dirt during the assembly.

Mount the module with two M4 screws in the centrally located fastening holes.

3.1.3 Functional earth (FE)

The fastening holes [}28] also serve as connections for the functional earth (FE).

Make sure that the box is earthed with low impedance via both fastening screws. You can achieve this, for

example, by mounting the box on a grounded machine bed.

Fig.8: Functional earth via the fastening holes

EP7047-103228 Version: 1.0

Page 29

Mounting and connections

X60 X61

X01

X40 X41

X02

X05

X06

X03

X04

X07

X08

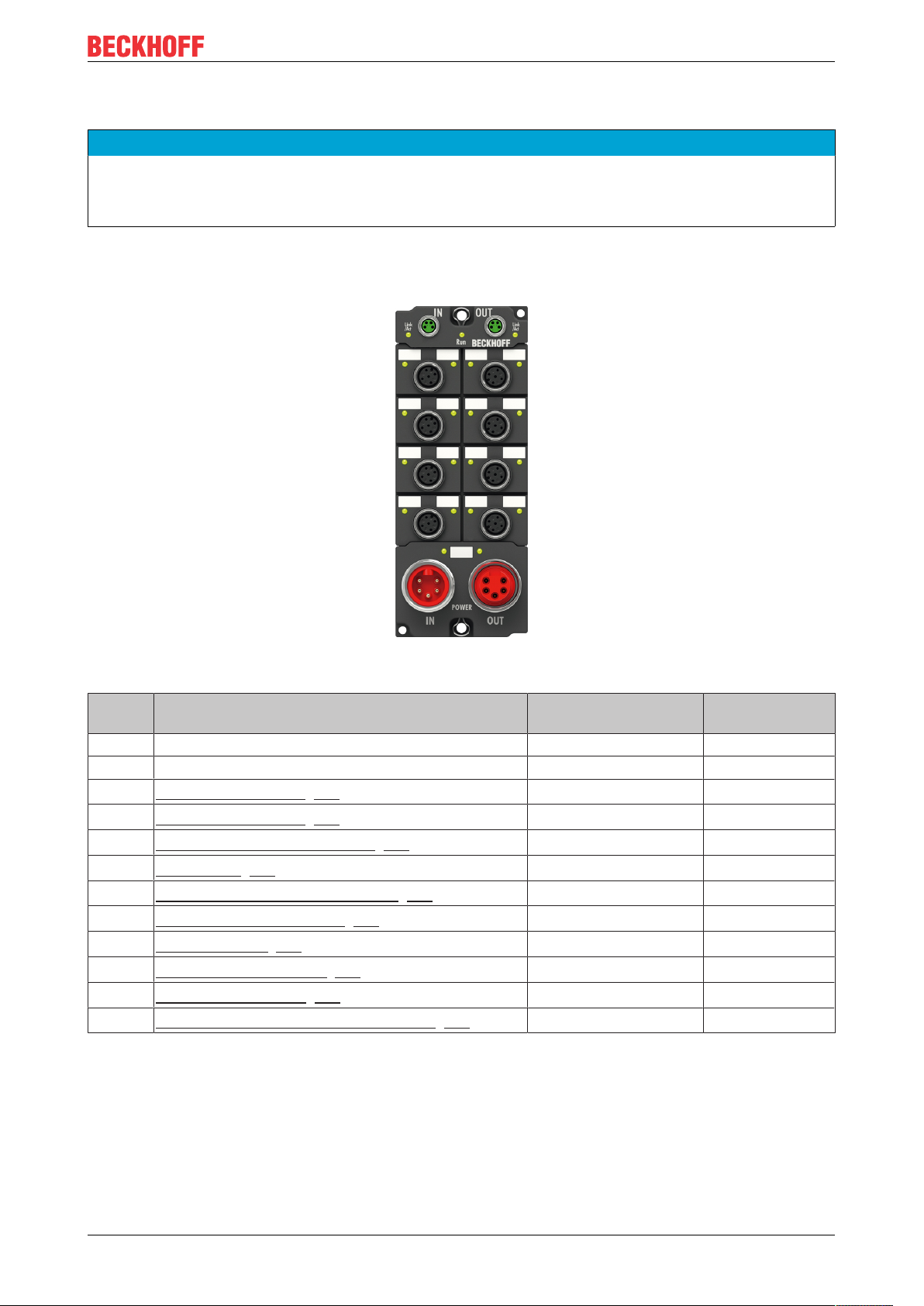

3.2 Connections

NOTE

Risk of confusion with M12 sockets

The M12 sockets X01 to X08 are assigned very different functions. Connecting a plug connector to the

wrong socket can result in damage.

3.2.1 Connector overview

Fig.9: Connector overview

Name Function Connector

type

Tightening

torque

X01 - M12 socket 0.6Nm

X02 - M12 socket 0.6Nm

X03

X04

X05

X06

X07

X08

X40

X41

X60

X61

1)

Mount plugs on these connectors using a torque wrench, e.g. ZB8801 from Beckhoff.

Protective caps

Incremental encoder [}34] with 5 V supply

Incremental encoder [}34] with 24 V supply

Digital inputs for limit switches [}35]

Latch input [}36]

Digital output for the motor brake [}37]

Stepper motor connection [}38]

EtherCAT input [}30]

EtherCAT-Weiterleitung [}30]

Supply voltage input [}32]

Supply voltage downstream connection [}32]

M12 socket 0.6Nm

M12 socket 0.6Nm

M12 socket 0.6Nm

M12 socket 0.6Nm

M12 socket 0.6Nm

M12 socket 0.6Nm

M8 socket 0.4Nm

M8 socket 0.4Nm

7/8“ plug connector 1.5Nm

7/8“ socket 1.5Nm

• Seal unused connectors with protective caps.

• Ensure the correct seating of pre-assembled protective caps.

Protective caps are pre-assembled at the factory to protect connectors during transport. They may not

be tight enough to ensure IP67 protection.

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

EP7047-1032 29Version: 1.0

Page 30

Mounting and connections

3 1

24

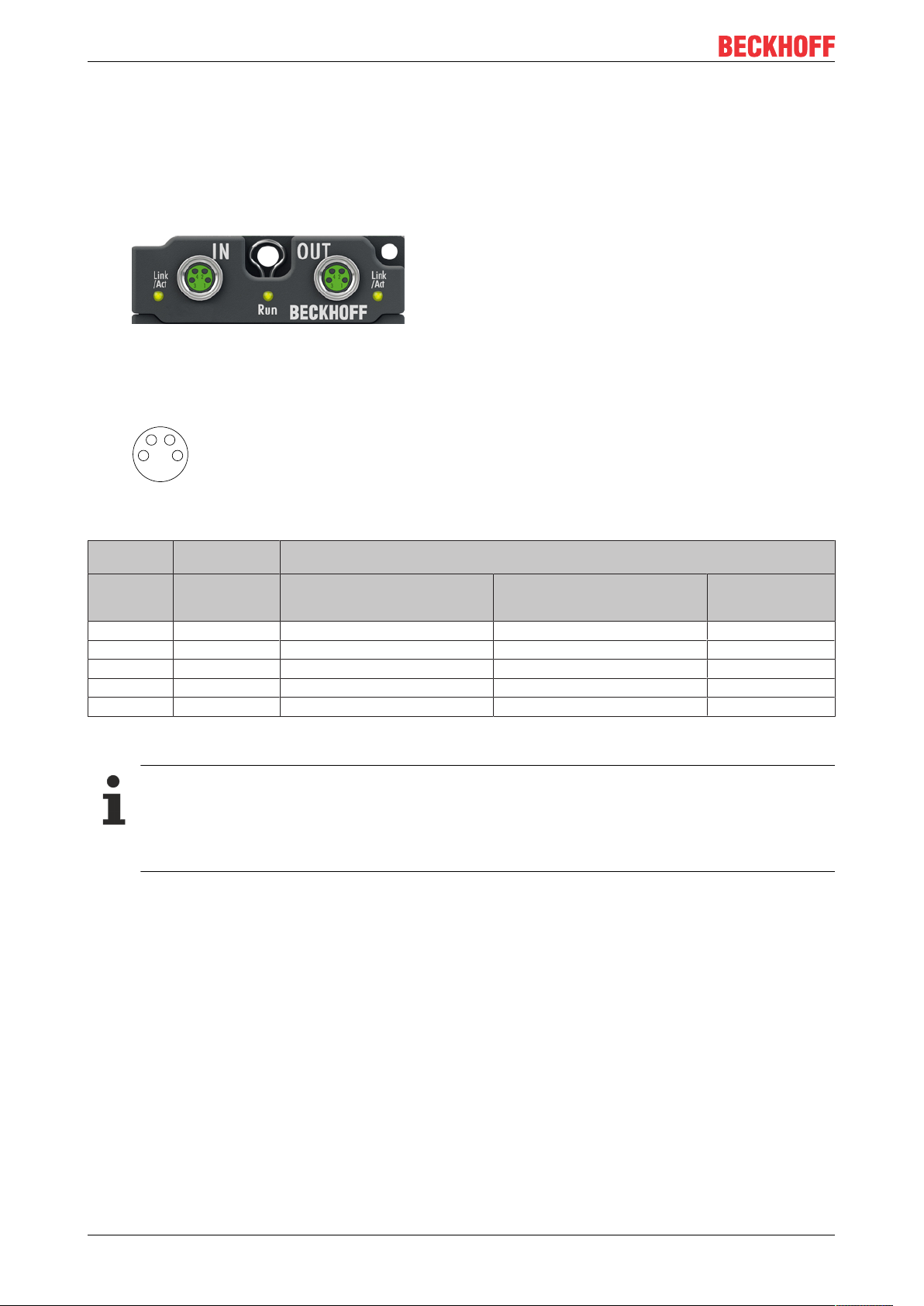

3.2.2 EtherCAT: X40 and X41

3.2.2.1 Connectors

EtherCAT Box Modules have two green M8 sockets for the incoming and downstream EtherCAT

connections.

Fig.10: EtherCAT connectors

Connection

Fig.11: M8 socket

EtherCAT M8

Signal Contact ZB9010, ZB9020, ZB9030, ZB9032,

Tx + 1 yellow

Tx - 4 orange

Rx + 2 white

Rx - 3 blue

Shield Housing Shield Shield Shield

1)

Core colors according to EN61918

connector

Core colors

ZK1090-6292,

ZK1090-3xxx-xxxx

1)

1)

1)

1)

ZB9031 and old versions of

ZB9030, ZB9032, ZK1090-3xxxxxxx

orange/white white/orange

orange orange

blue/white white/green

blue green

TIA-568B

Adaptation of core colors for cables ZB9030, ZB9032 and ZK1090-3xxxx-xxxx

For standardization, the core colors of the ZB9030, ZB9032 and ZK1090-3xxx-xxxx cables have

been changed to the EN61918 core colors: yellow, orange, white, blue. So there are different color

codes in circulation. The electrical properties of the cables have been retained when the core colors

were changed.

EP7047-103230 Version: 1.0

Page 31

Mounting and connections

3.2.2.2 Status LEDs

Fig.12: EtherCAT Status LEDs

L/A (Link/Act)

A green LED labelled "L/A" is located next to each EtherCAT socket. The LED indicates the communication

state of the respective socket:

LED Meaning

off no connection to the connected EtherCAT device

lit LINK: connection to the connected EtherCAT device

flashes ACT: communication with the connected EtherCAT device

Run

Each EtherCAT slave has a green LED labelled "Run". The LED signals the status of the slave in the

EtherCAT network:

LED Meaning

off Slave is in "Init" state

flashes uniformly Slave is in "Pre-Operational“ state

flashes sporadically Slave is in "Safe-Operational" state

lit Slave is in "Operational" state

Description of the EtherCAT slave states

3.2.2.3 Cables

For connecting EtherCAT devices only shielded Ethernet cables that meet the requirements of at least

category5 (CAT5) according to EN50173 or ISO/IEC11801 should be used.

EtherCAT uses four wires for signal transmission.

Thanks to automatic line detection ("Auto MDI-X"), both symmetrical (1:1) or cross-over cables can be used

between Beckhoff EtherCAT.

Detailed recommendations for the cabling of EtherCAT devices

EP7047-1032 31Version: 1.0

Page 32

Mounting and connections

1

2

3

4

5 5

4

3

2

1

Plug

Feed-in

Socket

Forwarding

3.2.3 Supply voltages: X60 and X61

EP7047 requires two supply voltages:

• Control voltage U

• DC link voltage U

S

P

3.2.3.1 Connectors

Two 7/8" connectors at the low-end of the modules are used for feeding and routing the supply voltages:

• "IN" (male): left connector for feeding the supply voltages

• "OUT" (female): right connector for downstream connection

Pin assignment

Fig.13: 7/8" connector pin assignment

NOTE

The input for UP is not protected against reverse polarity.

Defect possible through polarity reversal.

Pin Name Comment Core colors

1 GND

2 GND

P

S

GND to U

GND to U

P

S

Black

Blue

3 FE Functional earth Grey

4 +24 VDC U

5 +48 VDC U

1)

The core colors apply to cables of the type: Beckhoff ZK203x-xxxx.

S

P

Control voltage U

DC link voltage U

S

P

Brown

White

1)

EP7047-103232 Version: 1.0

Page 33

Mounting and connections

Vert. Faktor: 0,45 cm / V

5 10 15 20

2

4

6

8

10

250

0

12

30

Vert. Faktor: 0,45 cm / V

Voltage drop (V)

Cable length (m)

35

8 A

1.5 mm²

4 A

12 A

16 A

3.2.3.2 Status LEDs

The status of the supply voltages is signaled by two LEDs. A Status LED lights up green when the respective

supply voltage is present on the connector for the supply.

3.2.3.3 Conductor losses

Take into account the voltage drop on the supply line when planning a system. Avoid the voltage drop being

so high that the supply voltage at the box lies below the minimum nominal voltage.

Variations in the voltage of the power supply unit must also be taken into account.

Voltage drop on the supply line

EP7047-1032 33Version: 1.0

Page 34

Mounting and connections

1

2

3

4

5

GND

Pin 1

ENC_A

24V

Pin 3

Pin 2

C

B

A

ENC_B

Pin 4

ENC_C

Pin 5

5

4

3

2

1

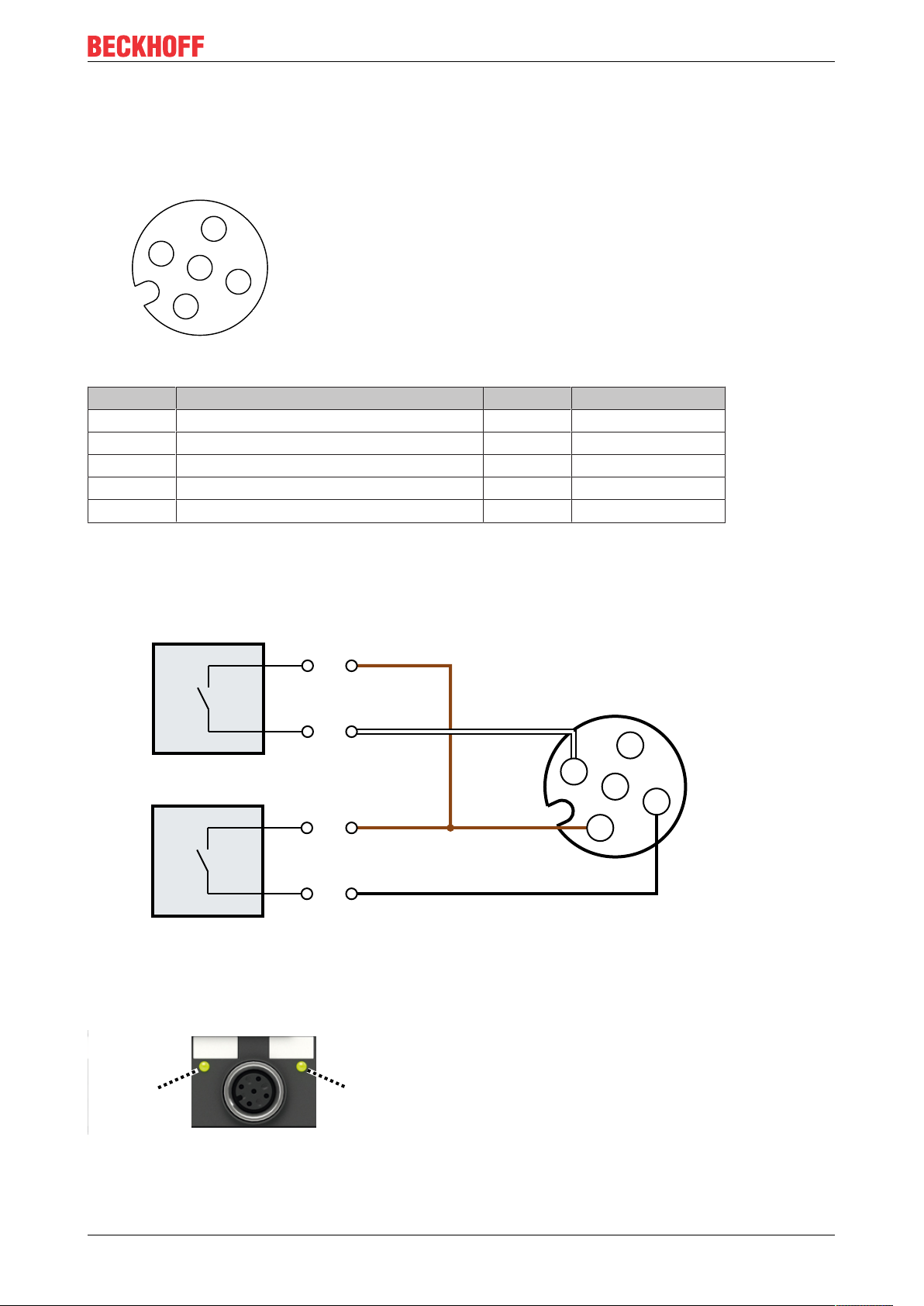

3.2.4 Incremental encoders: X03 or X04

EP7047 has two connectors for incremental encoders, but only one of these may be used:

• X03 for incremental encoders that require 5V supply voltage.

• X04 for incremental encoders that require 24V supply voltage.

NOTE

Only connect one encoder

Connecting two encoders simultaneously can result in damage.

NOTE

The encoder supply at X04 is not short-circuit proof (24V)

Risk of damage due to short circuit.

• Avoid short-circuiting the encoder supply voltage.

Pin assignment

Fig.14: M12 socket

Pin Function X03 X04 Core color

1 0V encoder supply GND

S

2 Encoder supply 5V 24V U

GND

S

S

brown

white

1)

3 Encoder signal input A ENC_A ENC_A blue

4 Encoder signal input B ENC_B ENC_B black

5 Reference pulse / zero pulse ENC_C ENC_C grey

1)

The wire colors apply to M12 encoder cables from Beckhoff: ZK4000-5100-2xxx, ZK4000-5151-0xxx.

Connection example

Fig.15: Connection example: Incremental encoders

EP7047-103234 Version: 1.0

Page 35

3.2.5 Limit switch: X05

1

2

3

4

5

Di1

Pin 4

24V

Pin 1

5

4

3

2

1

Di2

Pin 2

24V

Pin 1

Di1 Di2

You can connect up to two limit switches to X05.

Pin assignment

Fig.16: M12 socket

Mounting and connections

Pin Function Symbol Core color

1 Limit switch supply 24V

DC

US1

2)

brown

1)

2 Digital input2 Di2 white

3 Limit switch supply 0V GND

S

blue

4 Digital input1 Di1 black

5 Functional earth FE grey

1)

The core colors apply to M12 cables from Beckhoff: ZK2000-5xxx, ZK2000-6xxx, ZK2000-7xxx

2)

US1 is branched off from the supply voltage US.

Connection example

Fig.17: Connection example: Two limit switches, two-wire connection

Status LEDs

X05 has two green LEDs. An LED lights up when a high level is detected at the respective input.

Fig.18: Status LEDs for limit switch

EP7047-1032 35Version: 1.0

Page 36

Mounting and connections

1

2

3

4

5

3.2.6 Latch input: X06

Pin assignment

Fig.19: M12 socket

Pin Function Symbol Core color

1 Supply output 24V

DC

US1

2)

brown

1)

2 - - white

3 Supply output 0V

DC

GND

S

blue

4 Latch input LTC black

5 Functional earth FE grey

1)

The core colors apply to M12 cables from Beckhoff: ZK2000-5xxx, ZK2000-6xxx, ZK2000-7xxx

2)

US1 is branched off from the supply voltage US.

EP7047-103236 Version: 1.0

Page 37

3.2.7 Motor brake: X07

1

2

3

4

5

Pin assignment

Fig.20: M12 socket

Mounting and connections

Pin Function Symbol Core color

1)

1 - - brown

2 - - white

3 Ground GND

S

blue

4 Brake output BRK black

5 Functional earth FE grey

1)

The core colors apply to M12 cables from Beckhoff: ZK2000-5xxx, ZK2000-6xxx, ZK2000-7xxx

EP7047-1032 37Version: 1.0

Page 38

Mounting and connections

1

2

3

4

5

A2

A1

B1

5

4

3

2

1

B2

M

3.2.8 Stepper motor: X08

Pin assignment

Fig.21: M12 socket

Pin Function Symbol Core color

1 Motor winding A A1 brown

2 A2 white

3 Motor winding B B1 blue

4 B2 black

5 Functional earth FE grey

1)

The core colors apply to M12 cables from Beckhoff: ZK2000-5xxx, ZK2000-6xxx, ZK2000-7xxx

Connection examples

1)

Fig.22: Connection example: Bipolar stepper motor, serial connection

EP7047-103238 Version: 1.0

Page 39

A2

A1

B1

5

4

3

2

1

B2

M

Fig.23: Connection example: Bipolar stepper motor, parallel connection

A2

A1

B1

5

4

3

2

1

B2

M

Mounting and connections

Fig.24: Connection example: Unipolar stepper motor

In unipolar stepper motors only half of each winding is energized.

EP7047-1032 39Version: 1.0

Page 40

Commissioning and configuration

4 Commissioning and configuration

4.1 Integrating EP7047 into a TwinCAT project

1. Integrate EP7047-1032 as an I/O module in TwinCAT (Quick-Start Guide).

ð A dialog box appears:

You now have two options:

• Click "OK" (recommended) …

◦ … if you want to use the TwinCAT NC functions and you have not yet created the axis to be

controlled in the current TwinCAT project.

• Click "Cancel" …

◦ … if you have already created the axis to be controlled in TwinCAT.

◦ … if you do not want to use the TwinCAT NC functions.

Note: This information is not binding. In other words, you can link an NC axis with EP7047 [}75] at a later

stage or disconnect the link.

When you click "OK":

• In the Solution Explorer under the entry "MOTION", a new NC task "NC-Task 1 SAF" is created if no

NC task is available there yet.

• A new NC axis is created in the NC task under "Axes": „Axisn".

• The newly created NC axis is automatically linked to EP7047.

EP7047-103240 Version: 1.0

Page 41

Commissioning and configuration

1

2

4.2 Parameterizing EP7047

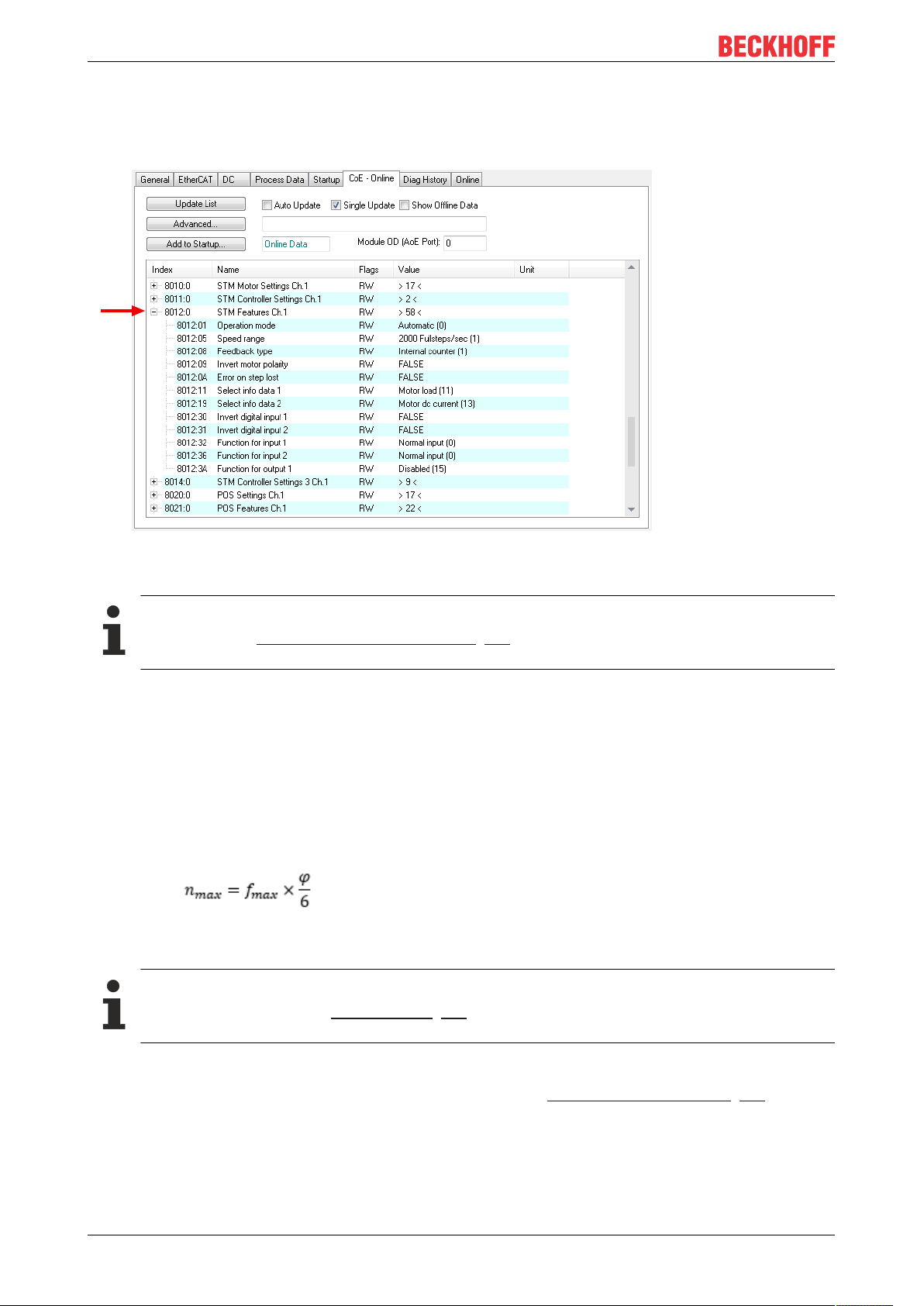

4.2.1 Open the parameter directory (CoE)

1. In the Solution Explorer: double-click EP7047-1032.

2. Click on the "CoE - Online" tab.

ð You will see the CoE directory of EP7047-1032 where you can check and change the parameter values.

Resetting parameters to factory settings

If you do not know whether parameters have already been changed by the present EP7047, you

can reset all parameters to the factory settings [}77].

EP7047-1032 41Version: 1.0

Page 42

Commissioning and configuration

4.2.2 Setting important motor parameters

NOTE

Some motor parameters are not fault-tolerant

Incorrect motor parameters can result in damage.

• Take care when setting the motor parameters.

The motor parameters are stored in CoE object 8010

hex

.

To ensure safe commissioning, it is sufficient to set the following parameters correctly. Further motor

parameters are described under CoE object 8010

: STM Motor Settings Ch.1 [}92].

hex

8010:01 "Maximal current"

The maximum current that the current controller outputs per motor winding.

Unit: mA

Factory setting: 5000

dec

The maximum value that should be entered here is the nominal motor current. The nominal current can

usually be found in the data sheet of the motor.

8010:02 "Reduced current"

Winding current at motor standstill.

Unit: mA

Factory setting: 1000

dec

Criteria for setting this parameter:

• A lower value results in a lower power loss when the motor is at standstill.

• A higher value leads to a higher breakdown torque when the motor is at standstill.

EP7047-103242 Version: 1.0

Page 43

8010:03 "Nominal voltage"

The DC link voltage UP, which you connect to X60 [}32].

Risk of confusion: DC link voltage and nominal motor voltage

• Do not enter the nominal motor voltage here.

Unit: 10mV

Factory setting: 5000

dec

Commissioning and configuration

EP7047-1032 43Version: 1.0

Page 44

Commissioning and configuration

4.2.3 Setting other important parameters

Other important parameters are stored in CoE object 8012

8012:05 "Speed range"

hex

.

When changing "Speed range": adjust "Reference velocity"

Recalculate the parameter "Reference velocity" [}52] if you have changed the parameter "Speed

range".

The "Speed range" parameter has several functions:

• Upper limit of the output step frequency.

• Reference value for speed setpoints:

Speed setpoints are given in % of the "Speed range".

Unit: Full stepspersecond

Factory setting: "2000Fullsteps/sec"

The following formula can be used to determine the maximum achievable speed for a "Speed range":

n

: Maximum achievable speed [rpm]

max

f

: "Speed range" [full steps/s]

max

φ: Step angle of the motor [°]

8012:08 "Feedback type"

When changing the "Feedback type": adjust the "Scaling factor"

Recalculate the parameter Scaling factor [}54] if you have changed the "Feedback type" parameter.

Factory setting: "Internal counter"

• If you are using an encoder, set this parameter to "Encoder". Parameterize the encoder [}54].

• Otherwise set this parameter to "Internal counter".

EP7047-103244 Version: 1.0

Page 45

Commissioning and configuration

4.3 Setting the operating mode

1. Decide which operating mode is required for your application. Selection wizard [}46]

2. Set the operating mode via CoE parameter 8012:01

hex

.

3. Click the "Process data" tab.

4. Select a suitable "Predefined PDO Assignment" for the selected operating mode.

Suitable "Predefined PDO Assignments" for the individual operating modes can be found in chapter

Operating modes [}46].

Note:

- if you have set the "Automatic" [}47] operating mode, the selection of the "Predefined PDO

Assignment" determines the actual operating mode.

- if you select "Positioning Interface [...]", the link to an NC axis is broken.

5. Set all parameters required for the selected operating mode [}46].

EP7047-1032 45Version: 1.0

Page 46

Commissioning and configuration

4.3.1 Operating modes

"Automatic" [}47] (factory setting)

"Velocity direct" [}48]

"Position Controller" [}49]

"Ext. Velocity mode" [}50]

"Ext. Position mode" [}51]

4.3.1.1 Selection wizard

As a rule, the operating modes differ in whether the setpoint is a position or a speed.

Operating modes with position setpoint:

• "Position Controller" [}49]

• "Ext. Position mode" [}51]

Operating modes with speed setpoint:

• "Velocity direct" [}48]

• "Ext. Velocity mode" [}50]

Requirements

Velocity

direct

Position

controller

Ext. Velocity

mode

Ext. Position

mode

Motor from Beckhoff required? No No Yes Yes

Encoder required? No No Yes Yes

Pros and cons

Commutation finding

Velocity

direct

1)

No No Yes Yes

Position

controller

Ext. Velocity

mode

Ext. Position

mode

Control dynamics + + ++ ++

Step loss detection Yes Yes n/a

Load angle detection Yes Yes n/a

2)

3)

n/a

n/a

2)

3)

Load-dependent current No No Yes Yes

Energy efficiency o o ++ ++

Use of the Positioning Interface [}60]

No Yes No Yes

possible

1)

After the output stage is enabled, the rotor slightly moves in both directions.

During commutation determination the rotor shaft should not be subject to an external torque. See also [}25]

2)

Step losses are avoided

3)

The load angle is always 90°.

EP7047-103246 Version: 1.0

Page 47

Commissioning and configuration

4.3.1.2 "Automatic" operating mode

If the "Automatic" operating mode is set, EP7047-1032 selects the actual operating mode according to the

set "Predefined PDO assignment" [}11]:

Predefined PDO Assignment Operation mode

Position Control

Positioning Interface

Positioning Interface (Auto start)

Positioning Interface (Auto start) with info data

Positioning interface compact

Velocity control

Velocity control compact (factory setting)

Velocity control compact with info data

Position controller [}49]

Position controller [}49]

Position controller [}49]

Position controller [}49]

Position controller [}49]

Velocity direct [}48]

Velocity direct [}48]

Velocity direct [}48]

EP7047-1032 47Version: 1.0

Page 48

Commissioning and configuration

4.3.1.3 "Velocity direct" operating mode

Properties

• Speed control

• Specification of the speed via the "Velocity" variable in process data object STM Velocity [}17].

Possible "Predefined PDO Assignments"

• Velocity control [}12]

Parameter

Index

(hex)

8010:03 Nominal voltage The DC link voltage U

Name Description Unit Data

type

P

10 mV UINT 5000

Default

value

8011:01 Kp factor (curr.) Proportional component of the current controller UINT 150

8011:02 Ki factor (curr.) Integral component of the current controller UINT 10

Optional parameters

To use step loss detection and/or load angle detection without encoder, set the following parameters

additionally:

Index

(hex)

8010:05 Motor EMF The voltage constant ke for calculating the back

Name Description Unit Data

type

electromotive force (BEMF)

mV/

(rad/s)

UINT 0

Default

value

The voltage constant can be found in the data

sheet of the motor. Alternatively, you can

determine it experimentally [}76].

8010:0A Motor coil

The winding inductance of the motor. 0.01mH UINT 0

inductance

dec

dec

dec

EP7047-103248 Version: 1.0

Page 49

Commissioning and configuration

4.3.1.4 "Position controller" operating mode

Properties

• Position specification via the variable "Position" in process data object STM Position [}17].

• If you do not want to use the TwinCAT NC, you can use the Positioning Interface [}60].

Possible "Predefined PDO Assignments"

• Position control [}11]

• Positioning interface [}11]

• Positioning interface (Auto start) [}11]

• Positioning interface (Auto start) with info data [}11]

• Positioning interface compact [}12]

Parameter

Index

(hex)

8010:03 Nominal voltage The DC link voltage U

8010:04 Motor coil

Name Description Unit Data

type

P

10 mV UINT 5000

The winding resistance of the motor. 0.01Ω UINT 100

Default

value

resistance

8011:01 Kp factor (curr.) Proportional component of the current controller UINT 150

8011:02 Ki factor (curr.) Integral component of the current controller UINT 10

8014:01 Feed forward

(pos.)

Pre-control of the position controller. UDINT 100000

ec

8014:02 Kp factor (pos.) Proportional component of the position controller. UINT 500

Optional parameters

To use step loss detection and/or load angle detection without encoder, set the following parameters

additionally:

Index

(hex)

8010:05 Motor EMF The voltage constant ke for calculating the back

Name Description Unit Data

type

electromotive force (BEMF)

mV/

(rad/s)

UINT 0

Default

value

The voltage constant can be found in the data

sheet of the motor. Alternatively, you can

determine it experimentally [}76].

8010:0A Motor coil

The winding inductance of the motor. 0.01mH UINT 0

inductance

dec

dec

dec

dec

d

dec

EP7047-1032 49Version: 1.0

Page 50

Commissioning and configuration

4.3.1.5 "Ext. Velocity mode" operating mode

Properties

• Velocity control

• Field-oriented control [}25]

• Specification of the speed via the "Velocity" variable in process data object STM Velocity [}17].

Possible "Predefined PDO Assignments"

• Velocity control [}12]

• Velocity control compact [}12]

• Velocity control compact with info data [}12]

Parameter

Index

(hex)

8010:03 Nominal voltage The DC link voltage U

8010:07 Encoder

Name Description Unit Data

type

10 mV UINT 5000

- UINT 4096

increments (4fold)

P

Number of encoder increments per revolution with

4-fold evaluation.

Usually this is the resolution (ppr) of the encoder

Default

value

multiplied by 4.

8011:01 Kp factor (curr.) Proportional component of the current controller UINT 150

8011:02 Ki factor (curr.) Integral component of the current controller UINT 10

8014:03 Kp factor (velo.) Proportional component of the velocity controller. 0.1mA/

UDINT 50

dec

dec

dec

(rad/s)

8014:04 Tn (velo.) Time constant Tn of the velocity controller. 0.01ms UINT 50000

dec

dec

dec

EP7047-103250 Version: 1.0

Page 51

Commissioning and configuration

4.3.1.6 "Ext. Position mode" operating mode

Properties

• Position control

• Field-oriented control [}25]

• Position specification via the variable "Position" in process data object STM Position [}17].

Possible "Predefined PDO Assignments"

• Position control [}11]

• Positioning Interface [}11]

• Positioning Interface compact [}12]

• Positioning interface (Auto start) [}11]

• Positioning interface (Auto start) with info data [}11]

Parameter

Index

(hex)

8010:03 Nominal voltage The DC link voltage U

8010:04 Motor coil

Name Description Unit Data

type

P

10 mV UINT 5000

The winding resistance of the motor. 0.01Ω UINT 100

Default

value

dec

resistance

8010:07 Encoder

increments (4fold)

Number of encoder increments per revolution with

4-fold evaluation.

Usually this is the resolution (ppr) of the encoder

- UINT 4096

multiplied by 4.

8011:01 Kp factor (curr.) Proportional component of the current controller UINT 150

8011:02 Ki factor (curr.) Integral component of the current controller UINT 10

8014:01 Feed forward

Pre-control of the position controller. UDINT 100000

(pos.)

8014:02 Kp factor (pos.) Proportional component of the position controller. UINT 500

8014:03 Kp factor (velo.) Proportional component of the velocity controller. 0.1mA/

UDINT 50

dec

dec

ec

dec

dec

(rad/s)

8014:04 Tn (velo.) Time constant Tn of the velocity controller. 0.01ms UINT 50000

dec

dec

d

dec