Beckett CF2300A User Manual

MODELMODEL

MODEL

MODELMODEL

2300

Oil

CF

Instruction Manual

Low/High Operation

Firing rate: 7.0 – 19.9 GPH

Motor voltage: 120 / 60 Hz std.

2300A

Burner

Thank you

Beckett burner. With proper care and

regular maintenance, it will provide

years of trouble-free service. Please

take a few minutes to read the section

entitled “T o the owner” inside this

manual. Then, keep the manual in a

safe place where it can be easily

located if needed by your professional

service technician.

for purchasing a

Instruction Manual – Model CF2300A Oil Burner

Please . . . read this page first

Hazard definitions

The following will be used throughout this manual to bring attention to hazards and their risk factors, or to special information.

Denotes presence of a hazard which, if

ignored, will result in severe personal injury,

death or substantial property damage.

Denotes presence of a hazard which, if

ignored, could result in severe personal injury ,

death or substantial property damage.

Denotes presence of a hazard which, if

ignored, could result in minor personal injury

or property damage.

To the owner —

Installation and adjustment of the burner

requires technical knowledge and the use of

combustion test instruments. Do not tamper

with the unit or controls. Call your qualified

service technician. Incorrect operation of the

burner could result in severe personal injury,

death or substantial property damage.

Have your equipment inspected and adjusted

at least annually by your qualified service

technician to assure continued proper

operation.

Never attempt to use gasoline in your heating

appliance or to store gasoline or combustible

materials near the heating equipment. This

could result in an explosion or fire, causing

severe personal injury, death or substantial

property damage.

Intended to bring special attention to

information, but not related to personal injury

or property damage.

To the owner —

Never burn garbage or refuse in your heating

appliance or try to light the burner by tossing

burning material into the appliance. This

could result in severe personal injury, death

or substantial property damage.

Never attempt to use crankcase or waste oil in

your heating appliance. This could damage

the fuel unit or heating equipment, resulting

in risk of severe personal injury, death or

substantial property damage.

Never restrict air openings on the burner or to

the room in which the appliance is located.

This could result in fire hazard or flue gas

leakage, causing severe personal injury, death

or substantial property damage.

To the installer —

Read all instructions before proceeding.

Follow all instructions completely. Failure to

follow these instructions could result in

equipment malfunction, causing severe

personal injury, death or substantial property

damage.

This equipment must be installed, adjusted

and started only by a qualified service

technician – an individual or agency, licensed

and experienced with all codes and

ordinances, who is responsible for the

installation and adjustment of the equipment.

The installation must comply with all local

codes and ordinances and with the National

Fire Protection Standard for Oil-Burning

Equipment, NFPA 31 (or CSA B139-M91).

High altitude installations — Accepted industry practice requires no derate of burner capacity up to 2,000 feet

above sea level. For altitudes higher than 2,000 feet, derate burner capacity 4% for each 1000 feet above sea level.

2

To the installer —

Concealed damage - If you discover damage

to the burner or controls during unpacking,

notify the carrier at once and file the

appropriate claim.

Contacting Beckett for service information

or parts - Please record the burner serial number

(and have available when calling or writing).

You will find the serial number on the

Underwriters Laboratories label, located on

the left rear of the burner.

50 Hz motors — The burner ratings, air

settings and nozzle ratings are based on

standard 60 hz motors (at 3450 rpm). Derate

all ratings 20% when using 50 hz motors.

Consult factory for specific application data.

Form 6104 BCF-23-R0399

Instruction Manual – Model CF2300A Oil Burner

Warranty

Beckett warrants its equipment to those who

have purchased it for resale, including your

dealer. If you have any problems with your

equipment or its installation, you should

contact your dealer for assistance.

Refer to warranty sheet in literature packet

included with burner for details.

Specifications

Fuels #1 or #2 Fuel Oil

Firing range 7.0 to 19.9 GPH

Motor ¾ HP 3450 RPM

120/60 hz standard

12.5 amps @ 120 VAC

Optional voltages:

(60 hz or 50 hz) –

• 240/1-PH

• 208/240/480/3-PH

Ignition Trans. 120V/12,000V

Housing Cast aluminum

Fuel unit 100 - 300 PSIG

Oil nozzle 45° - 70° solid

Shipping wt. 90 lbs.

Dimensions See Figure 7 (Page 7)

Contents

Please . . . read this page first ................ 2

Pre-installation checklist........................... 4

Mount the burner .......................................... 6

Connect fuel line(s) ...................................... 8

Wire the burner ............................................ 10

Sequence of operation - typical ............ 11

Prepare the burner for start-up ............. 11

Start the burner .......................................... 14

Maintenance and service......................... 15

Replacement parts................... Back cover

(See NOTICE on opposite page for 50 hz motor applications.)

Agency approvals

• Underwriters Laboratories has certified

this burner to comply with ANSI

Standard 296 and has listed it for use

with No. 1 or No. 2 fuel oil as specified

in ASTM D396. State and local

approvals appear on the burner rating

label.

• Certified by ULC.

• Approved by Commonwealth of

Massachusetts - State Fire Marshall.

• Accepted by N.Y.C. M.E.A.

• Other approvals may be available and

must be specified at time of order.

Form 6104 BCF-23-R0399

Before you begin . . .

The following resources will give you additional information

for your installation. We suggest that you consult these

resources whenever possible. Pay particular attention to the

appliance manufacturer’s instructions.

Appliance manufacturer’ s instructions — Alw ays follow

the appliance manufacturer’s instructions for burner

installation, equipment and setup.

1–800–OIL–BURN — Beckett’s technical services hot-line.

www.beckettcorp.com — Beckett’ s website.

3

Instruction Manual – Model CF2300A Oil Burner

Rated

gph @

100 psig

Pressure - pounds per square inch

125 150 175 250 275 300

4.50 5.04 5.51 5.95 7.11 7.46 7.79

5.00 5.59 6.12 6.61 7.91 8.29 8.66

5.50 6.15 6.74 7.28 8.70 9.12 9.53

6.00 6.71 7.35 7.94 9.49 9.95 10.39

6.50 7.27 7.96 8.60 10.28 10.78 11.26

7.00 7.83 8.57 9.26 11.07 11.61 12.12

7.50 8.39 9.19 9.92 11.86 12.44 12.99

8.00 8.94 9.80 10.58 12.65 13.27 13.86

9.00 10.06 11.02 11.91 14.23 14.92 15.59

10.00 11.18 12.25 13.23 15.81 16.58 17.32

11.00 12.30 13.47 14.55 17.39 18.24 19.05

12.00 13.42 14.70 15.87 18.97 19.90 20.78

Pre-installation checklist

❏ Combustion air supply

• The burner requires combustion air and ventilation air for

reliable operation. Assure that the building and/or combustion air openings comply with National Fire Protection

Standard for Oil-Burning Equipment, NFPA 31. For appliance/burner units in confined spaces, the room must have

an air opening near the top of the room plus one near the

floor, each with a free area at least one square inch per

1,000 Btu/hr input of all fuel burning equipment in the

room. For other conditions, refer to NFP A 31 (CSA B1139M91 in Canada).

• If there is a risk of the space being under negative pressure

or of exhaust fans or other devices depleting available air

for combustion and ventilation, the appliance/burner

should be installed in an isolated room provided with outside combustion air.

❏ Clearances

• With the burner installed in the appliance, there must be

adequate space in front of and on the sides of the burner to

allow access and operation. Verify that the clearance dimensions comply with all local codes and with the appliance manufacturer's recommendations.

❏ Vent system

• The flue gas venting system must be in good condition

and must comply with all applicable codes.

❏ Electrical supply

• Verify that the power connections available are correct for

the burner. All power must be supplied through fused disconnect switches.

❏ Verify burner components —

• Burner box, Model CF2300A

• Air tube assembly (selected per following)

• Mounting flange kit

• Pedestal mounting assembly kit (recommended)

• Oil nozzle, per Table 1 — Use only 45° to 70° solid pat-

tern nozzles unless otherwise shown by appliance manufacturer.

Find the required firing rate in the 300 psig column (high

fire rate).

Select the corresponding nozzle from column 1 (Rated

gph @ 100 psig).

❏ Fuel supply

• The fuel supply piping and tank must provide #1 or #2

fuel oil at pressure or vacuum conditions suitable for the

fuel unit (oil pump) on the burner. Refer to fuel unit literature in the literature envelope in the b urner carton to verify

allowable suction pressure.

When fuel supply is level with or higher than burner

fuel unit —

• When the fuel unit is not required to lift the oil, the installation is usually suitable for either a one-pipe or two-pipe

oil system. The oil pressure at the inlet of the fuel unit must

not exceed 3 psig.

• The fuel unit is shipped with the by-pass plug installed.

Leave the by-pass plug installed for all low/high firing

burners, regardless whether one-pipe (with by-pass loop)

or two-pipe. See Figure 8 for installation of the by-pass

loop required for one-pipe fuel supply installations. See

Figure 9 for connections to the fuel unit for two-pipe fuel

supply installations.

When fuel supply is below the burner fuel unit —

• Use a two-pipe oil system when the fuel unit must lift the

oil more than 8 feet if burner is equipped with a B fuel unit

— or more than 2 feet if burner is equipped with an H fuel

unit. The return line provided by the two-pipe system is

needed to purge the air from the fuel lines and minimize

the likelihood of air-related problems during operation.

T able 1 – Nozzle capacities at various pressures

4

Form 6104 BCF-23-R0399

Instruction Manual – Model CF2300A Oil Burner

2304

E

D

G

T

2°

1

F

A.T.C. Codes

(A.T.C. = Air Tube Combination)

Tube KG Tube KS

(Dim T) (Dim D) (Dim F) (Dim T) (Dim D) (Dim F)

All — 6¹⁄₂” 2¹⁵⁄₁₆” All — 8¹⁄₈” 3¹¹⁄₁₆”

6¾” CF 66 KG 6¾” CF 66 KS

— — 8¾” CF 86 KS

10¼” CF 102 KG 11” CF 110 KS

13¾” CF 136 KG 14½” CF 144 KS

17¾” CF 176 KG 18½” CF 184 KS

Firebox

pressure

(In. w.c.)

Tube KG Tube KS

No reserve

air

10%

turndown

No reserve

air

10%

turndown

0.0 19.9 GPH 19.9 GPH 19.9 GPH 19.9 GPH

0.2 19.2 GPH 19.1 GPH 19.7 GPH 19.6 GPH

0.4 18.5 GPH 18.3 GPH 19.5 GPH 19.3 GPH

0.6 17.9 GPH 17.6 GPH 19.4 GPH 19.1 GPH

0.8 17.2 GPH 16.8 GPH 19.2 GPH 18.8 GPH

1.0 16.5 GPH 16.0 GPH 19.0 GPH 18.5 GPH

Note: 10% turndown indicates sufficient reserve air to reduce th e CO2 in the

flue to 90% of its value.

Note:

The above ratings may vary 5% due to variations in actual job conditions.

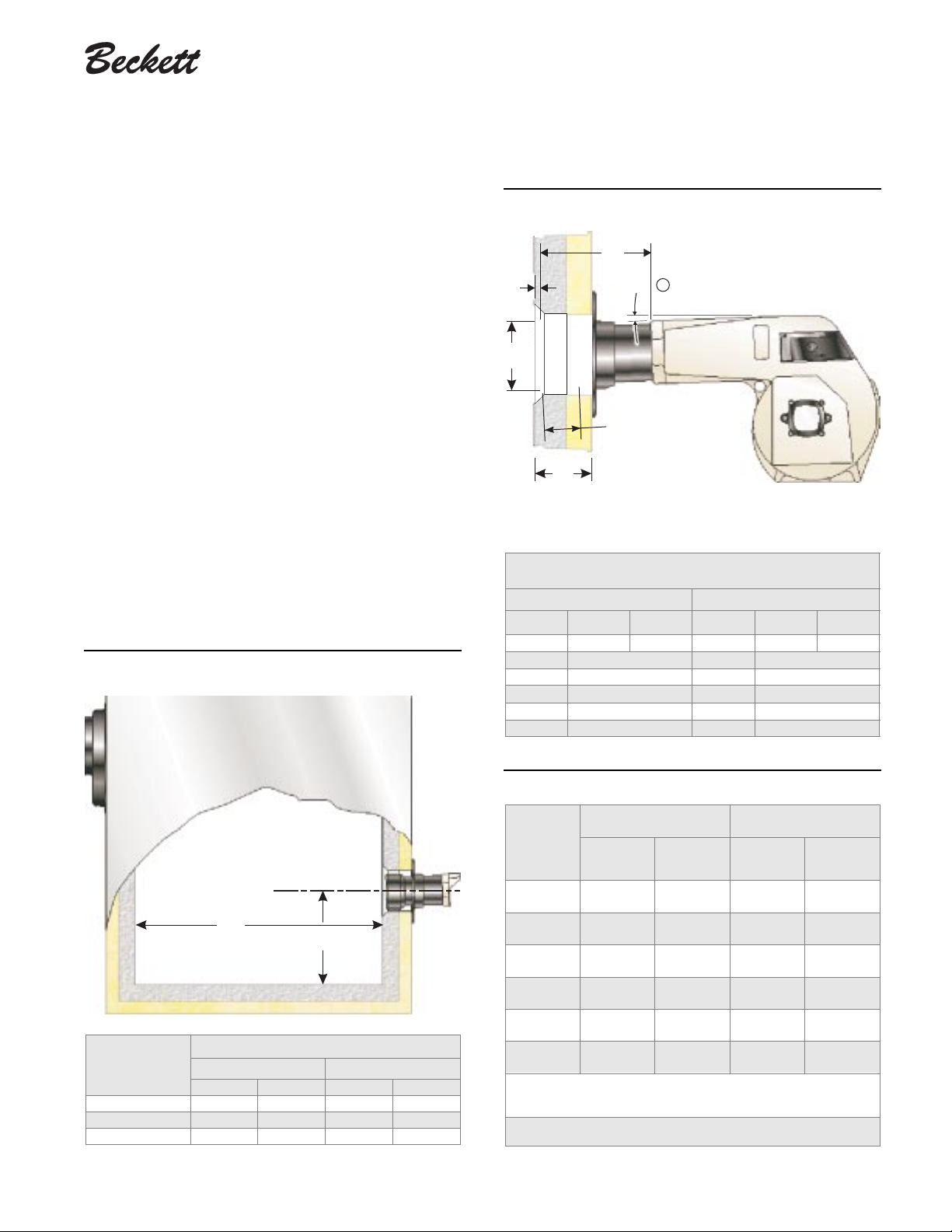

❏ Verify firing rate

• Refer to appliance manufacturer’s instructions (if available) for firing rate and nozzle selection. Otherwise, the

maximum recommended firing rate for the burner depends

on the length of the firing chamber and the distance from

the burner center to the chamber floor . Verify that the chamber dimensions are at least as large as the minimum values

given in Figure 1. If the appliance dimensions are smaller

than recommended, reduce the firing rate accordingly.

❏ Verify air tube

• The information in this section may be disregarded if the

air tube is supplied by the appliance manufacturer.

• Two tube arrangements are available –

Tube KG — 7.0 to 19.9 GPH per Table 2

Tube KS — 10.0 to 19.9 GPH per Table 2

• Maximum firing capacity depends on the firebox pressure.

Use Table 2 to verify the correct air tube type for the firing

rate required. Use Tube KS only when Tube KG cannot

provide the firing rate required.

• See Figure 2 to verify the correct air tube length and air

tube combination code.

Figure 2 – Air tube mounting dimensions

E Insertion depth

G Air tube to inside of chamber

– 0.25" ± 0.125"

T Air tube length

D Tube diameter

① Install the burner with a 2° pitch as shown.

Figure 1 – Min. combustion chamber dimensions

L

A

Firing rate

5 to 10 gph 8.0" 35.0" 8.0" 40.0"

10 to 15 gph 9.0" 40.0" 9.0" 50.0"

15 to 20 gph 11.0" 55.0" 11.0" 60.0"

Minimum dimensions

(refractory-lined) (wet-base boilers)

A L A L

Form 6104 BCF-23-R0399

T able 2 – Air tube capacity vs. firebox pressure

2305

5

Loading...

Loading...