Beckett AFG Oil Burner User Manual

AFG Oil

Burner

Instruction Manual

Types “F” & “M” air tubes

Motor voltage: 120 Vac / 60 Hz

AFG burner with type “F” air tube

Type “L1” head |

Type “V1” head |

AFG

Type “M” air tube combinations

Instruction Manual – Model AFG Oil Burner

Contents

Prepare before installing |

|

Verify specifications ............................................................................................. |

3 |

Be aware of hazard definitions ........................................................................... |

3 |

Check certifications/approvals ........................................................................... |

3 |

Notice special requirements................................................................................ |

3 |

Prepare burner & site |

|

Inspect/prepare installation site .......................................................................... |

4 |

Prepare burner ..................................................................................................... |

5 |

Check/adjust “Z” dimension ............................................................................... |

6 |

Set head position adjusting plate (“V1” head only) ............................................ |

7 |

Adjust, pipe & wire burner |

|

Mount burner on appliance................................................................................. |

8 |

Connect fuel lines ................................................................................................ |

8 |

Wire burner .......................................................................................................... |

8 |

Startup & adjust burner |

|

Startup burner/set combustion......................................................................... |

10 |

Set combustion with instruments ..................................................................... |

10 |

Service & maintain burner |

|

Perform annual maintenance............................................................................ |

10 |

To replace the blower wheel ............................................................................. |

10 |

Replacement parts ............................................................................................. |

11 |

Owner’s information and warranty ................................................................... |

12 |

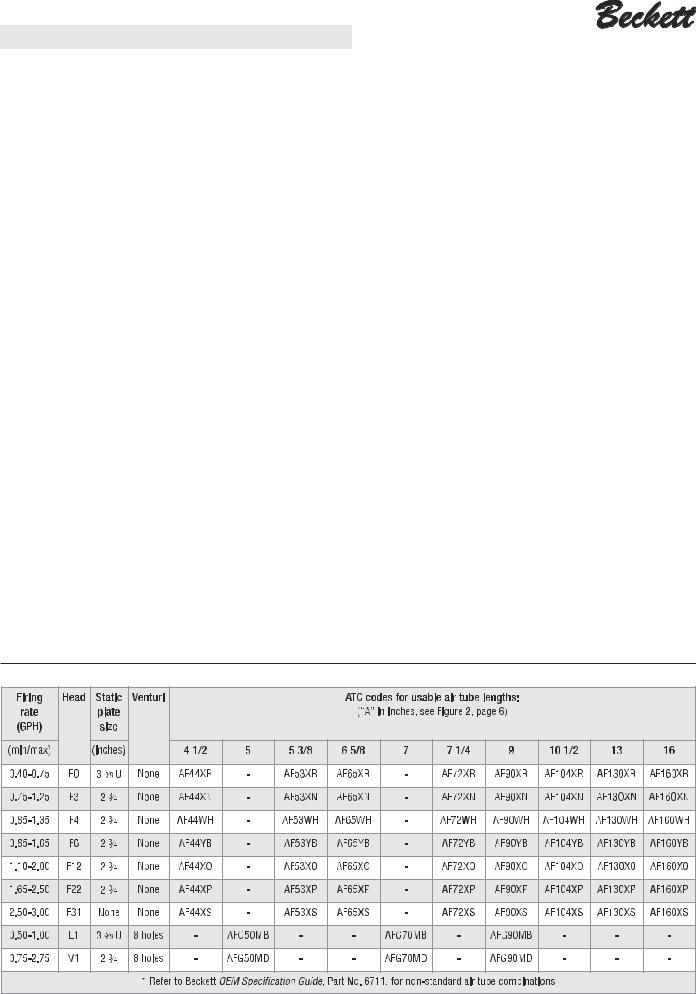

Table 1 — Air tube combination (ATC) codes*

2 |

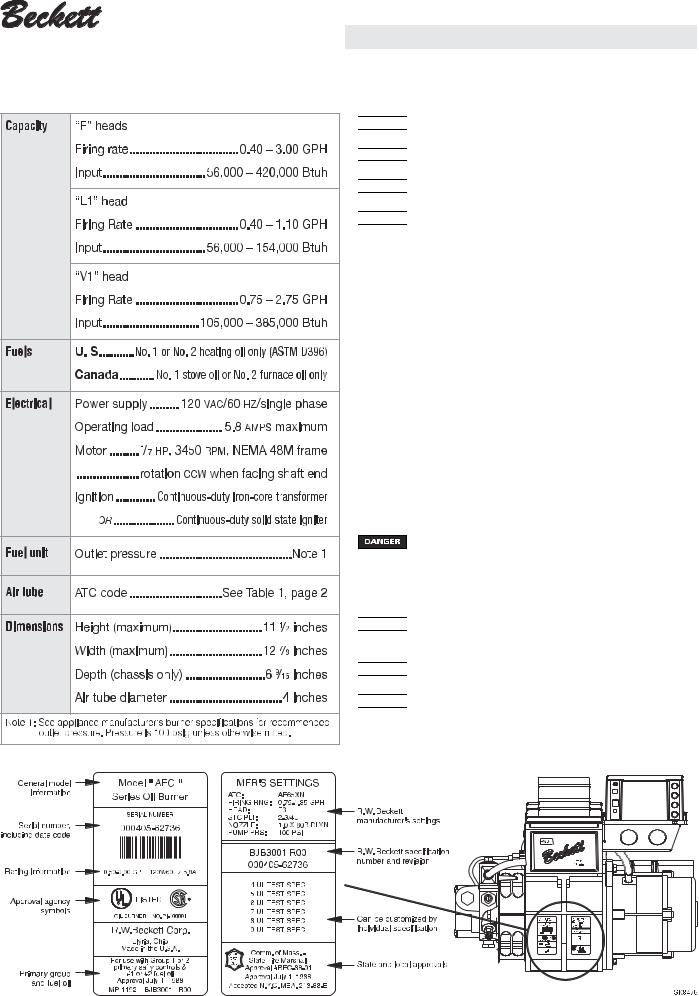

Verify specifications

Instruction Manual – Model AFG Oil Burner

Prepare before installing

Be aware of hazard definitions

Denotes presence of a hazard which, if ignored, will result in severe personal injury, death or substantial property damage.

Denotes presence of a hazard which, if ignored, will result in severe personal injury, death or substantial property damage.

Denotes presence of a hazard which, if ignored, could result in severe personal injury, death or substantial property damage.

Denotes presence of a hazard which, if ignored, could result in severe personal injury, death or substantial property damage.

Denotes presence of a hazard which, if ignored, could result in minor personal injury or property damage.

Denotes presence of a hazard which, if ignored, could result in minor personal injury or property damage.

Intended to bring special attention to information, but not related to personal injury or property damage.

Intended to bring special attention to information, but not related to personal injury or property damage.

Check certifications/approvals

•Underwriters Laboratories has certified this burner to comply with ANSI/UL 296 and has listed it for use with #1 or #2 fuel oil as specified in ASTM D396. Low sulfur #1 and #2 fuel oils reduce heat exchanger deposits with all burners compared to the standard fuels. Reduced deposits extend the service interval for cleaning and improve the efficiency of the appliance over time. Low sulfur fuels reduce particulate and oxides of nitrogen emissions as well. The Oilheat Manufacturers' Association recommends these fuels as the preferred fuels for this burner.

•State and local approvals are shown on burner rating label (see below).

•All oil burners should be installed in accordance with regulations of the latest revision of the National Fire Protection Association Standard NFPA 31 and in complete accordance with all local codes and authorities having jurisdiction. Regulation of these authorities take precedence over the general instructions provided in this installation manual.

•For recommended installation practice in Canada, reference to CSA Standard B139-M91.

Notice special requirements

This equipment must be installed, adjusted and started only by a

– an individual or agency, licensed and experienced with all codes and ordinances, who is responsible for the installation and adjustment of the equipment. The installation must comply with all local codes and ordinances and with the latest revision of the National Fire Protection Standard for Oil-Burning Equipment, NFPA 31 (or CSA B139-M91).

. Follow all instructions completely. Failure to follow these instructions could result in equipment malfunction, causing severe personal injury, death or substantial property damage.

. Follow all instructions completely. Failure to follow these instructions could result in equipment malfunction, causing severe personal injury, death or substantial property damage.

Concealed damage — If you discover damage to the burner or controls during unpacking, notify the carrier at once and file the appropriate claim.

Concealed damage — If you discover damage to the burner or controls during unpacking, notify the carrier at once and file the appropriate claim.

When contacting Beckett for service information — Please record the burner serial number (and have available when calling or writing). You will find the serial number on the Underwriters Laboratories label, located on the left rear of the burner, or the cover mounting plate. See illustration below.

When contacting Beckett for service information — Please record the burner serial number (and have available when calling or writing). You will find the serial number on the Underwriters Laboratories label, located on the left rear of the burner, or the cover mounting plate. See illustration below.

3

Instruction Manual – Model AFG Oil Burner

Prepare burner & site

Inspect/prepare installation site |

Inspect/prepare installation site (continued) |

Chimney or vent |

Clearances to burner and appliance |

•Inspect the chimney or vent, making sure it is properly sized and in good condition for use.

•For those installations not requiring a chimney, such as through-the-wall vented appliances, follow the instructions given by the appliance and power venter (if used) manufacturers.

Direct air supply and sidewall venting

•Some AFG burners are equipped with combustion air boots to allow use of outside air for combustion.

•When sidewall venting appliances, carefully follow appliance and power venter instructions for installation and wiring.

Combustion air supply

See NFPA Standard 31 for complete details.

If the burner is not supplied with a reliable combustion air source, the burner cannot properly burn the fuel. This would result in incomplete combustion, causing sooting and possible emission of carbon monoxide. Severe personal injury, death or substantial property damage could occur.

If the burner is not supplied with a reliable combustion air source, the burner cannot properly burn the fuel. This would result in incomplete combustion, causing sooting and possible emission of carbon monoxide. Severe personal injury, death or substantial property damage could occur.

Appliance located in confined space

The confined space should have two (2) permanent openings: one near the top of the enclosure and one near the bottom of the enclosure. Each opening shall have a free area of not less than (1) one square inch per 1,000 BTU’s per hour of the total input rating of all appliances within the enclosure. The openings shall have free access to the building interior, which should have adequate infiltration from the outside.

Exhaust fans and other air-using devices

Size air openings large enough to allow for all air-using devices in addition to the minimum area required for combustion air. If there is any possibility of the equipment room developing negative pressure (because of exhaust fans or clothes dryers, for example), either pipe combustion air directly to the burner or provide a sealed enclosure for the burner and supply it with its own combustion air supply.

Outside air kit applications

Refer to separate instruction sheet supplied with AFG outside air kit for installation. This optional kit allows combustion air to be piped directly to the burner. (Part number 51747.)

You must install the outside air kit strictly following the kit installation instructions. Do not attempt to install outside air piping without using the AFG outside air kit and instructions. Failure to do so could result in burner or heating appliance failure, causing potential severe personal injury, death or substantial property damage.

You must install the outside air kit strictly following the kit installation instructions. Do not attempt to install outside air piping without using the AFG outside air kit and instructions. Failure to do so could result in burner or heating appliance failure, causing potential severe personal injury, death or substantial property damage.

•Provide space around burner and appliance for easy service and maintenance.

•Check minimum clearances against those shown by the appliance manufacturer and by applicable building codes.

Combustion chamber — Burner retrofitting

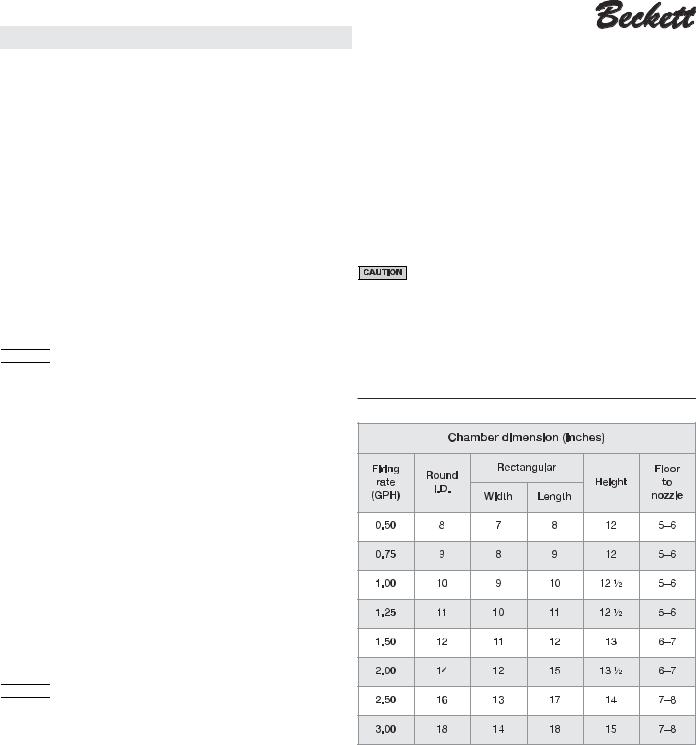

Verify that the appliance combustion chamber provides at least the minimum dimensions given in Table 2.

When retrofitting an appliance that has a stainless steel chamber

— A chamber burnout could result from the use of a high performance burner. Protect the chamber from high temperatures through the use of "wet-pac" or a similar ceramic liner. Some new equipment may contain stainless steel chambers that have been designed and tested by the manufacturer for use with flame retention burners — ceramic protection would not be necessary. Refer to appliance manufacturer’s instructions. Failure to comply could result in damage to heating equipment.

Table 2 — Minimum combustion chamber dimensions

4

Loading...

Loading...