Beckett CF500, 800 User Manual

WARNING

!

Incorrect installation, adjustment, or misuse of this burner could result in death, severe

personal injury, or substantial property damage.

Potential for Fire, Smoke and Asphyxiation Hazards

To the Homeowner or Equipment

Owner:

Please read and carefully follow all instructions

y

provided in this manual regarding your responsibilities

in caring for your heating equipment.

Contact a professional, qualifi ed service agency for

y

installation, start-up or service work.

Save this manual for future reference.

y

6104 BCF5 R07 1

To the Professional, Qualifi ed Installer

or Service Agency:

Please read and carefully follow all instructions provided

y

in this manual before installing, starting, or servicing this

burner or heating system.

The Installation must be made in accordance with all state

y

and local codes having jurisdiction.

Before you begin . . .

The following resources will give you additional

information for your installation. We suggest that

you consult these resources whenever possible. Pay

particular attention to the appliance manufacturer’s

instructions.

Appliance manufacturer’s instructions -Always

follow the appliance manufacturer’s instructions

for burner installation, equipment and set-up.

1–800–OIL–BURN - Beckett’s technical services

hot-line.

www.beckettcorp.com - Beckett’s website.

To the Owner:

Thank you for purchasing a Beckett burner

for use with your heating appliance. Please pay

attention to the Safety Warnings contained within

this instruction manual. Keep this manual for your

records and provide it to your qualifi ed service

agency for use in professionally setting up and

maintaining your oil burner.

Your Beckett burner will provide years of effi cient

operation if it is professionally installed and

maintained by a qualifi ed service technician. If at

any time the burner does not appear to be operating

properly, immediately contact your qualifi ed

service agency for consultation.

We recommend annual inspection/service of

your oil heating system by a qualifi ed service

agency.

Table of Contents

General Information ..............................................2-4

Hazard Defi nitions ..........................................................3

Agency approvals ..........................................................3

Specifi cations .................................................................3

Owner’s Responsibility ..................................................4

Installer/Service Agency Responsibility .........................4

Pre-installation checklist .....................................4-7

Combustion air supply ...................................................4

Clearances .....................................................................4

Fuel supply .....................................................................5

Nozzle pressure .............................................................5

Electrical supply .............................................................5

Vent system ...................................................................5

Verify burner components ..............................................6

Verify fi ring rate ..............................................................6

Verify air tube .................................................................6

Stray light lockout ...........................................................7

Dust and Moisture ..........................................................7

Mount the burner ...................................................7-9

Mount fl anges on air tubes .............................................7

Mount air tube to burner .................................................8

Install Nozzle ..................................................................8

Check Electrode Settings ...............................................8

Install Nozzle Line Assembly .........................................8

Set Dimension Z ............................................................8

Insert Burner ..................................................................8

Fuel Unit By-pass Plug ..................................................9

Oil Supply/Return Lines .................................................9

Burner Fuel Flow ............................................................9

Wire the burner ....................................................... 10

Sequence of operation .......................................10

Resetting to cad cell .............................................10

Prepare the burner for start-up ......................11-12

Start-up checklist .........................................................11

Z Dimension .................................................................11

Initial head position ......................................................11

Initial air settings ..........................................................12

Set appliance limit controls ..........................................12

Prepare the fuel unit for air venting ..............................12

Start the burner..................................................12-13

Starting the burner and venting air ..............................12

CAD Cell resistance check ..........................................13

Set combustion using instruments ...............................13

Maintenance and Service ..................................... 14

Annual Service .............................................................14

Monthly maintenance ...................................................14

Replacement Parts ................................................. 15

Warranty ..................................................Back Cover

2 6104 BCF5 R07

Hazard defi nitions

Indicates an imminently

hazardous situation,

which, if not avoided, will result in death,

serious injury, or property damage.

Indicates a potentially

hazardous situation,

which, if not avoided, could result in death,

severe personal injury, and/or substantial

property damage.

Indicates a potentially

hazardous situation,

which, if not avoided, may result in personal injury or property damage.

Specifi cations

U.S. #1 or #2 Fuel Oil only

Fuels

Firing range

Motor

Igniter. 120V/14,000V

Housing Cast aluminum

Fuel unit 100 - 200 PSIG

Oil nozzle 45° - 70° solid

Shipping wt. 55 lbs.

(ASTM D396)

Canada #1 Stove Oil or #2

Furnace Oil only

CF500: 1.75 to 5.50 GPH

CF800: 3.00 to 8.00 GPH

1/3 HP 3450 RPM

120/60 hz standard

4.8 amps @ 120 VAC

NOTICE

Intended to bring special attention to information,

but not related to personal injury or property

damage.

Note: Within the boundaries of the hazard warning, there

will be information presented describing consequences

if the warning is not heeded and instructions on how to

avoid the hazard.

Agency approvals

UL listed to comply with ANSI/UL296 and certifi ed to

CSA B140.0.

Accepted by N.Y.C. M.E.A.

Other approvals may be

available and must be specifi ed

at time of order.

6104 BCF5 R07 3

Owner’s Responsibility:

Follow These

Instructions Exactly

Failure to follow these instructions,

misuse, or incorrect adjustment of

the burner could lead to equipment

malfunction and result in asphyxiation, explosion or fi re.

Contact a professional, qualifi ed service agency for the

installation, adjustment and service of your oil burning

system. Thereafter, have your equipment adjusted and

inspected at least annually to ensure reliable operation.

This work requires technical training, trade experience,

licensing or certifi cation in some states and the proper

use of special combustion test instruments.

Please carefully read and comply with the following

instructions:

y

Never store or use gasoline or other fl ammable liquids

or vapors near this burner or appliance.

y

Never attempt to burn garbage or refuse in this appliance.

y

Never attempt to light the burner by throwing burning

material into the appliance.

y

Never attempt to burn any fuel not specifi ed and ap-

proved for use in this burner.

y

Never restrict the air inlet openings to the burner or the

combustion air ventilation openings in the room.

Professional Installer/Service Agency

Responsibility:

Follow These

Instructions Exactly

Failure to follow these instructions

could lead to equipment malfunction and result in asphyxiation,

explosion or fi re.

Please read all instructions before proceeding. Follow

y

all instructions completely.

This equipment must be installed, adjusted and started

y

by a qualifi ed service agency that is experienced with

all applicable codes and ordinances and responsible for

the installation and commission of the equipment.

The installation must comply with all local codes and

y

ordinances having jurisdiction and the latest editions of

the NFPA 31 and CSA-B139 & B140 in Canada.

NOTICE

50 Hz motors — The burner ratings, air settings and nozzle

ratings are based on standard 60 hz motors (at 3450 rpm). Derate

all ratings 20% when using 50 hz motors. Consult factory for

specifi c application data.

NOTICE

High altitude installations — Accepted industry practice

requires no derate of burner capacity up to 2,000 feet above

sea level. For altitudes higher than 2,000 feet, derate burner

capacity 2% for each 1000 feet above sea level.

Pre-installation checklist

Combustion air supply

Adequate Combustion

and Ventilation Air

Supply Required

Failure to provide adequate air supply could se-

riously affect the burner performance and result

in damage to the equipment, asphyxiation, explosion or fi re hazards.

The burner cannot properly burn the fuel if it is not

y

supplied with a reliable combustion air source.

Follow the guidelines in the latest editions of the NFP A

y

31 and CSA-B139 regarding providing adequate air for

combustion and ventilation.

The burner requires combustion air and ventilation air

y

for reliable operation. Assure that the building and/or

combustion air openings comply with National Fire

Protection Standard for Oil-Burning Equipment, NFP A 31.

4 6104 BCF5 R07

For appliance/burner units in confi ned spaces, the room

must have an air opening near the top of the room plus

one near the fl oor, each with a free area at least one square

inch per 1,000 Btu/hr input of all fuel burning equipment

in the room. For other conditions, refer to NFPA 31 (CSA

B1139-M91 in Canada).

y

If there is a risk of the space being under negative pressure

or of exhaust fans or other devices depleting available

air for combustion and ventilation, the appliance/burner

should be installed in an isolated room provided with

outside combustion air.

Clearances

With the burner installed in the appliance, there must be

y

adequate space in front of and on the sides of the burner

to allow access and operation. Verify that the clearance

dimensions comply with all local codes and with the

appliance manufacturer’s recommendations.

Fuel supply

Nozzle pressure

Oil Supply Pressure

Control Required

Damage to the pump, fi lter or other compo-

nent seals could cause possible oil leakage

and potential fi re hazard.

The oil supply inlet pressure to the fuel unit cannot

y

exceed 3 psig.

Do NOT install valves in return line.

y

Ensure that a pressure-limiting device is installed in

y

accordance with the latest edition of the NFPA 31.

The fuel supply piping and tank must provide #1 or #2 fuel

y

oil at pressure or vacuum conditions suitable for the fuel

unit (oil pump) on the burner. Refer to fuel unit literature

in the literature envelope in the burner carton to verify

allowable suction pressure.

If fuel supply is level with or higher than fuel unit —

When the fuel unit is not required to lift the oil, the

y

installation is usually suitable for either a one-pipe or twopipe oil system. The oil pressure at the inlet of the fuel unit

must not exceed 3 psig.

Refer to the Mount the Burner Section of this manual for

y

one-pipe or two-pipe fuel supply installation instructions.

If fuel supply is below the fuel unit —

Use a two-pipe oil system when the fuel unit must lift the

y

oil more than 8 feet if burner is equipped with a B fuel

unit. The return line provided by the two-pipe system is

needed to purge the air from the fuel lines and minimize

the likelihood of air-related problems during operation.

Correct Nozzle and Flow

Rate Required

Incorrect nozzles and fl ow rates could

result in impaired combustion, underfi ring, over-fi ring, sooting, puff-back

of hot gases, smoke and potential fi re

or asphyxiation hazards.

Use only nozzles having the brand, fl ow rate (gph),

spray angle and pattern specifi ed by the appliance

manufacturer.

Follow the appliance manufacturer’s specifi cations for

the required pump outlet pressure for the nozzle, since

this affects the fl ow rate.

Nozzle manufacturers calibrate nozzle fl ow rates at

y

100 psig.

This burner utilizes pressures higher than 100 psig, so

y

the actual nozzle fl ow rate will be greater than the gph

stamped on the nozzle body. (Example: A 4.00 gph

nozzle at 140 psig = 4.70 gph.

For typical nozzle fl ow rates at various pressures

y

see accompanying chart.

The fuel unit nozzle port pressure is factory set at 140

y

psig. Some original equipment manufacturer burner applications may call for a lower pressure to obtain a required

fi ring rate. Do not change this pressure unless directed to

do so by the appliance manufacturer.

Electrical supply

Verify that the power connections available are correct for

y

the burner. Refer to Figure 1. All power must be supplied

through fused disconnect switches.

Vent system

The fl ue gas venting system must be in good condition and

y

must comply with all applicable codes.

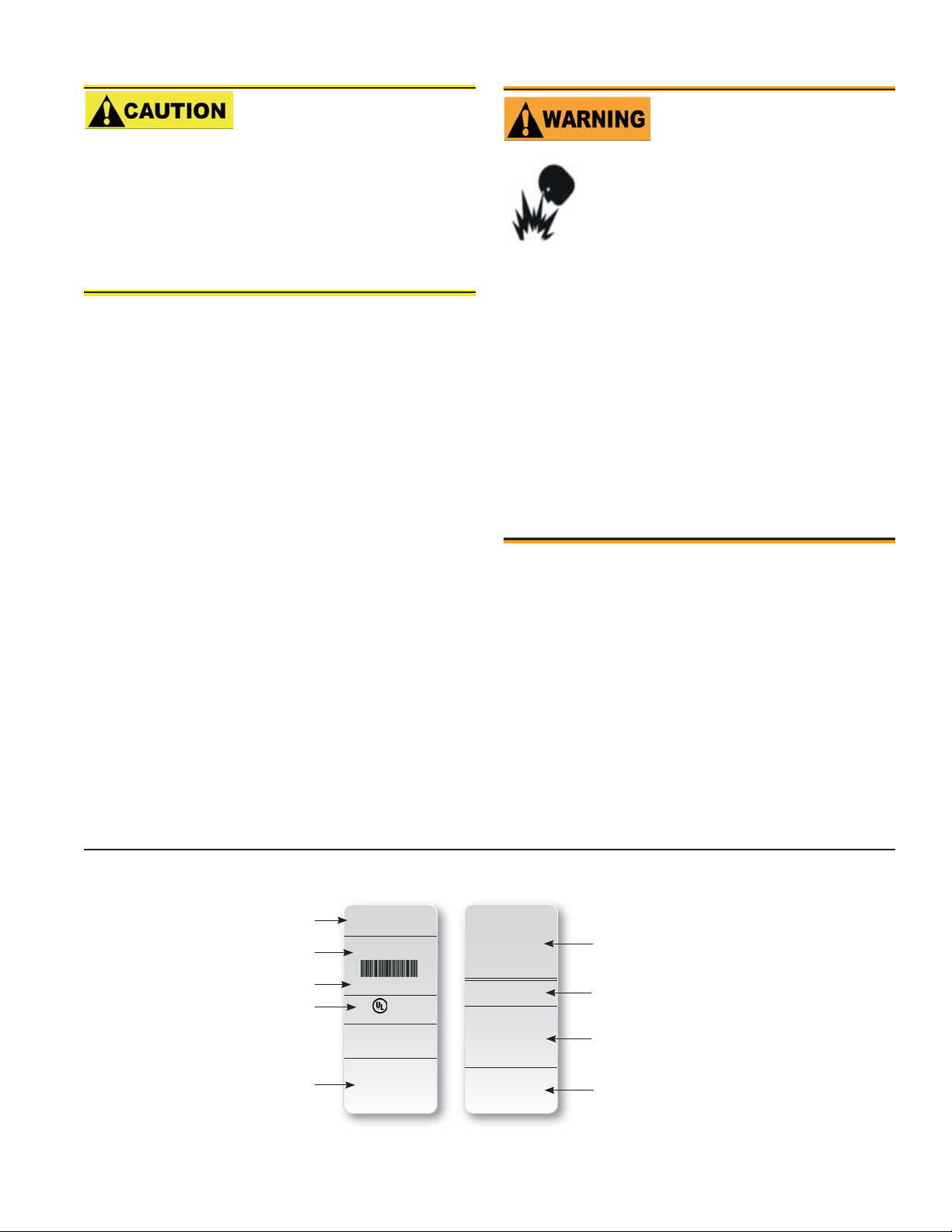

Figure 1. Typical Nameplate

General Model Information

Serial Number,Including Date Code

Rating Information

Approval Agency Symbols

Primary Group and Fuel

Model “XX”

Series (Fuel) Burner

SERIAL NUMBER

050214-00000

Control Circ: 120V/60Hz 4.5A

Motor Circ: 120V/60Hz 4.0A

LISTED

(FUEL) BURNER

R.W. Beckett Corp.

Elyria, Ohio

Made in the U.S.A.

For use with Group 8 . . .

MP 1192 XX000 R00

6104 BCF5 R07 5

MFR’S SETTINGS

X

X

X

X

X

X

XX000 R00

050214-00000

R.W. Beckett Construction & Setting Data

R.W. Beckett Specifi cation

Number and Revision

Boiler Manufacturer and

Model, When Applicable

Additional Codes

L0002

Loading...

Loading...