Page 1

www.basler.com

+1 618.654.2341 (USA)

info@basler.com

INTRODUCTION

BE3 ac current relays provide current monitori ng and protection in

both single-phase and three-phase systems. They are used in

applications such as motor protection, load det ect i on, and generator

control. Undercurrent, overcurrent, and c ombined ov er/underc urrent

units are available. BE3 ac current relays operate when the

adjustable trip point is reached. A time delay c ontrol i s provided with

an adjustment of 0 to 10 seconds (relay operating time is typically

200 milliseconds). This time delay may be used to prevent false

tripping when there are slight variations in the sensed current . On

overcurrent units, the output relay energizes when the input signal

exceeds the trip point. On undercurrent units, the output relay deenergizes when the input signal goes below the trip point. A red

LED indicates the state of the output relay. A green LED indicates

the condition of the power supply.

SPECIFICATIONS

Inputs

Operating Power

All units require external operating power.

Nominal Voltage: 120 Vac, 240 Vac, 380 Vac, 480 Vac,

or 24 Vdc

Current Sensing

Nominal: 5 Aac

Range: 0.2 to 10 Aac

Overload Withstand: 50 Aac for 3 s

Frequency: 50, 60, or 400 Hz

Burden: <0.5 VA per phase

Setpoint

Undercurrent Range: Adjustable 0 to 80% (±3%) of

nominal

Overcurrent Range: Adjustable 40 to 120% (±3%) of

nominal

Repeatability: Better than 0.5% of full span

Time Delay: Adjustable 1 to 10 sec

Operating Time: 200 ms typical

Differential: Fixed at 5% of nominal

Outputs

Relay Type: D.P.D.T.

AC Rating: 250 V, 5 A, non-resistive,

1200 VA

DC Rating: 125 V, 1 A, resistive, 120 W

Mechanical Life: 5 million operations

Temperature

Operating Temperature: 0°C (32°F) to 60°C (140°F)

Functional Temperature: –25°C (–13°F) to 70°C (158°F)

Storage Temperature: –40°C (–40°F) to 70°C (158°F)

Temperature Coefficient: 0.03% per °C (300 ppm/°C)

Humidity

Relative Humidity: 95% non-condensing

Physical

Mounting: DIN rail 1.38” by 0.29” (35 mm by 7.5

mm)

Model

Case: Complies with IEC 529, DIN 40050,

Case Material: Complies with UL 94VO

BE3-37, BE3-51, and BE3-37/51

BS 5490

Weight

Single Unit: 0.88 lb (0.4 kg)

Combined Unit: 1.32 lb (0.6 kg)

Size

Single Unit: 2.17” wide (55 mm)

Combined Unit: 3.93” wide (100 mm)

Agency

cULus Listed to UL 508 and CSA C22.2 No. 14

CE compliant

GOST-R certified per the relevant standards of Gosstandart of

Russia

OPERATION

BE3-37 and BE3-51 ac current relays have two external, useradjustable controls marked SET and DELAY . The BE3-37/51 has

four controls: UNDER SET, UNDER DELAY, OVER SET, and

OVER DELAY. The SET control adjusts the relay trip point. An

overcurrent trip causes the relay output to energize when the

current rises above the SET threshold. The overcurrent SET level is

adjustable from 40 to 120% (±3%) of nominal input. An undercurrent

trip causes the relay output to de-energize when the current

decreases below the SET threshold. The undercurrent SET level is

adjustable from 0 to 80% (±3%) of nominal input. Time delay is the

amount of time that elapses after the trip point is reached and when

the output relay operates.

Setting Example

A BE3-51 relay has the following settings:

SET - 120%

DELAY - 4 seconds

A trip occurs when the sensing c urrent rises above six am peres for

four seconds. Reset occurs when the current decreases below 5.75

amperes (5% of nominal below trip setting).

INSTALLATION

BE3 ac current sensing relays are designed for mounting on

standard DIN rails that c omply t o DIN-EN 50022. Mounting involves

hooking the top edge of the cutout on the base of the case over one

edge of the DIN rail. The opposite side of the cutout contai ning the

release clip is then pushed over t he opposite side of the DIN rail. To

remove or reposition the relay, lever the release clip and move the

relay as required. BE3 relays should be installed in a dry, vibrationfree location where the ambient temperature does not exceed the

operating temperature range. Connections to the relay should be

made using wire that meets applicable codes and is properly sized

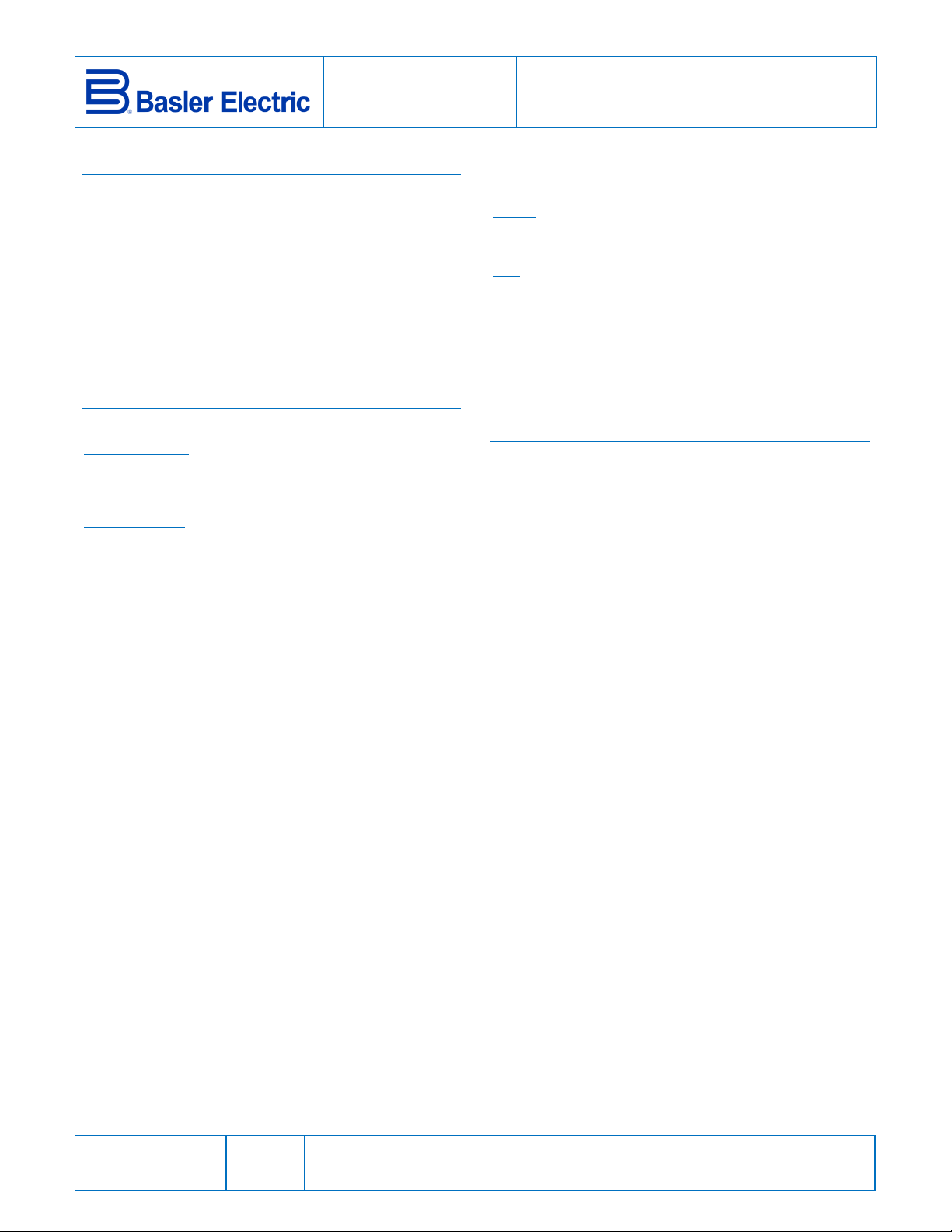

for the application. Figure 1 shows the t erminal connections for the

BE3-37, BE3-51, and BE3-37/51 ac current relays.

CALIBRATION

The calibration marks on the faceplate have a maximum error of

10% and are provided only as guides. Proper cali bration requires

using an accurate ammeter in series wit h the current source. Use

the following procedure to calibrate your relay.

Overcurrent

1. Adjust the SET control fully clockwise (CW) and the DELAY

control fully counterclockwise (CCW).

2. Apply the desired trip current to the relay.

Publication

9319900990

Revision

D

Instructions

Date

03/14

Copyright

2014

Page 2

3. Slowly adjust the SET control CCW until the relay trips. (allow

for the 200 ms operating time).

4. Remove the applied current (do not change the current level)

and set the DELAY control to the desired time delay.

5. Apply the trip current to the relay and measure the time to trip.

6. Adjust the DELAY and repeat Steps 4 and 5 until the desired

time delay is achieved.

Undercurrent

1. Adjust the SET and DELAY controls fully CCW.

2. Decrease the applied sensing current f rom the nominal value

until the desired tripping current is reached.

3. Slowly adjust the SET control CW until the relay trips (allow for

the 200 ms operating time).

FIGURES

4. Set the DELAY control to the desired time delay and apply

nominal current to the relay.

5. Step down the applied current from nominal to a level just

below the trip level set in Step 3.

6. Adjust the DELAY and repeat Steps 4 and 5 until the desired

time delay is achieved.

MAINTENANCE

BE3 relays are solid-state devices that require no maintenance. In

the event that your relay requires repair, contact Basler Electric,

Highland, IL, USA for return authorization.

ORDERING INFORMATION

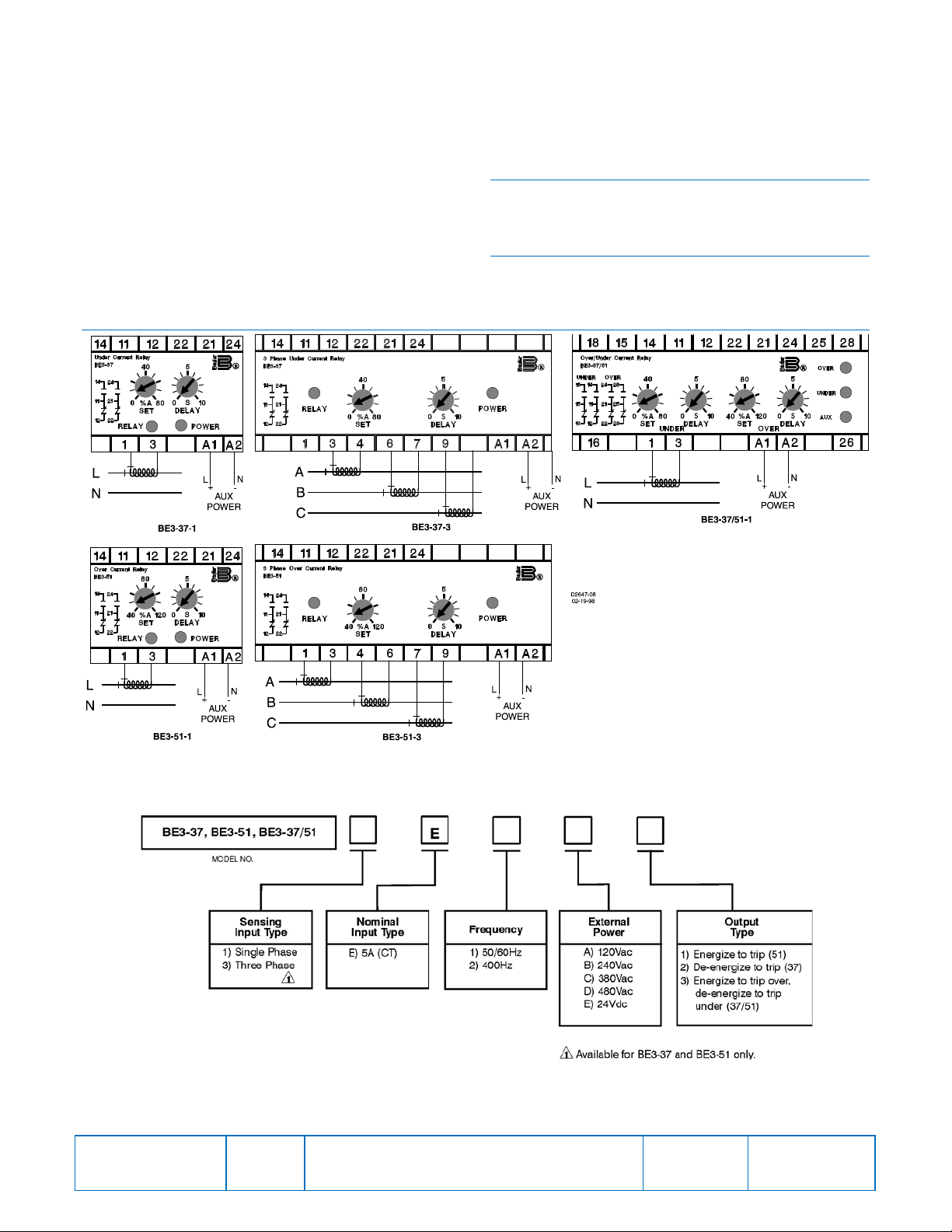

Figure 2 shows the BE3 ac current relay style numbers.

Publication

9319900990

Figure 1. BE3-37, BE3-51, BE3-37/51 AC Current Connections

Figure 2. BE3-37, BE3-51, BE3-37/51 Style Number Identification Chart

Revision

D

Instructions

Date

03/14

Page

2 of 2

Loading...

Loading...