Baldor IP-65, NEMA 4X User Manual

|

ADJUSTABLE SPEED DRIVE |

|

Series 5 Inverter |

|

NEMA 4X, IP-65 |

|

Installation & Operating Manual |

8/01 |

MN781B |

|

TABLE OF CONTENTS |

|

Section |

Page |

|

i. |

Simplified Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 1 |

ii. |

Safety Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 1 |

I. |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 2 |

II. |

Wiring Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 5 |

III. |

Setting Selectable Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 7 |

IV. |

Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 8 |

V. |

Recommended High Voltage Dielectric Withstand Testing (Hi-Pot) . . . . . . . . . . . . . . . |

. . 8 |

VI. |

Control Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 9 |

VII. AC Line Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 10 |

|

VIII. Trimpot Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 10 |

|

IX. |

Diagnostic LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 13 |

X. |

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 13 |

XI. |

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 14 |

Tables |

|

|

1. |

Electrical Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 5 |

2. |

General Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 5 |

3. |

Terminal Block Wiring Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 6 |

4. |

Fault Recovery and Resetting the Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. .10 |

5. |

Control Mode and Status LED Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 12 |

Figures |

|

|

1. |

Control Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 3 |

2. |

Enlarged View of Trimpot Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 3 |

3. |

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 4 |

4. |

Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 6 |

5. |

Remote Main Speed Potentiometer Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 6 |

6. |

Remote Start/Stop Switch Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 6 |

7. |

Start/Stop Function Eliminated (Jumper Installed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 6 |

8. |

Voltage Following Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 7 |

9. |

Enable Circuit Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 7 |

10. |

AC Line Input Voltage Selection (J1 and J2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 7 |

11. |

Motor Horsepower Selection (J3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 7 |

12. |

Reset Mode Selection (J4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 8 |

13. |

Motor Frequency Selection (J5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 8 |

14. |

Motor Frequency Multiplier Selection (J6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 8 |

15. |

Boost Mode Selection (J7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 8 |

16. |

Hi-Pot Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 9 |

17. |

MAX Trimpot Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 10 |

18. |

MIN Trimpot Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 10 |

19. |

ACCEL Trimpot Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 10 |

20. |

DECEL Trimpot Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 11 |

21. |

COMP Trimpot Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 11 |

22. |

CL Trimpot Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 11 |

23. |

I2t Trip Time vs Motor Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. .11 |

24. |

BOOST Trimpot Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 12 |

ii |

|

|

i.SIMPLIFIED OPERATING INSTRUCTIONS

IMPORTANT – You must read these simplified operating instructions before proceeding. These instructions are to be used as a reference only and are not intended to replace the detailed instructions provided herein. You must read the Safety Warning below before proceeding.

! WARNING! Disconnect main power when making connections to the control.

A.AC Line Connection – Connect the AC line to L1 and L2 terminals of Terminal Block TB1 and the ground wire (Earth) to the green ground screw as shown in Figure 4, on page 6, and as described in Section IIA, on page 6, and Section IIB, on page 6. Set Jumpers J1 and J2 to the corresponding AC line input voltage (115 or 208/230 Volts AC).

B.Motor Connection – Connect the motor to U, V and W terminals of Terminal Block TB1 as shown in Figure 4, on page 6, and as described in Section IIC, on page 6.

C.Start/Stop Switch – The control is supplied with a prewired Start/Stop Switch as described in Section IIE, on page 6, which is used to start and stop the control. In Manual Start Mode, this switch must be used to start the control each time the AC power is lost or the control shuts down due to a fault.

D.Jumper Settings – All jumpers are factory set for most applications. Be sure Jumper J3 is set to the correct motor HP. See Section IIIB, on page 7.

E.AC Line Fusing – Install a fuse or circuit breaker in the AC line. Fuse each conductor that is not at ground potential. See Section VII, on page 10, for recommended fuse size.

F.Trimpot Settings – All trimpots have been factory set as shown in Figure 2, on page 3. Trimpots may be readjusted as described in Section VIII, on page 10.

G.Diagnostic LEDs – After power has been applied, observe the LEDs to verify proper control operation as described in Section IX, on page 13.

ii. |

! SAFETY WARNING! Please read carefully |

This product should be installed and serviced by a qualified technician, electrician, or electrical maintenance person familiar with its operation and the hazards involved. Proper installation, which includes wiring, mounting in proper enclosure, fusing or other overcurrent protection, and grounding can reduce the chance of electrical shocks, fires, or explosion in this product or products used with this product, such as electric motors, switches, coils, solenoids, and/or relays. Eye protection must be worn and insulated adjustment tools must be used when working with control under power. This product is constructed of materials (plastics, metals, carbon, silicon, etc.) which may be a potential hazard. Proper shielding, grounding, and filtering of this product can reduce the emission of radio frequency interference (RFI) which may adversely affect sensitive electronic equipment. If further information is required on this product, contact the factory. It is the responsibility of the equipment manufacturer and individual installer to supply this Safety Warning to the ultimate end user of this product. (SW effective 11/1992.)

This control contains electronic Start/Stop circuits that can be used to start and stop the control. However these circuits are never to be used as safety disconnects since they are not failsafe. Use only the AC line for this purpose.

Be sure to follow all instructions carefully. Fire and/or electrocution can result due to improper use of this product.

This product complies with all CE directives pertinent at the time of manufacture. Contact factory for detailed installation and Declaration of Conformity. Installation of a CE approved RFI filter is required. Additional shielded motor cable and/or AC line cables may

be required along with a signal isolator (ID5SI-2).

1

I.INTRODUCTION

The Baldor ID5601-BO Adjustable Speed Drive is a variable speed control in a NEMA-4X / IP65 and watertight enclosure. It is designed to operate 208 - 230 Volt 3-phase AC induction motors through 3.6 Amps RMS. The sine wave coded Pulse Width Modulated (PWM) output, which operates at a frequency of 8 kHz, provides high motor torque, high efficiency and low noise. The control operates from 115 or 208/230 Volt 50/60 Hz single phase AC line input.

Due to its user friendly design, tailoring to specific applications is easily accomplished via selectable jumpers and trimpot adjustments. However, for most applications no adjustments are necessary.

Main features include adjustable RMS Current Limit and I2t Motor Overload Protection. In addition, Adjustable Slip Compensation provides excellent load regulation over a wide speed range. Electronic Inrush Current Limiting eliminates harmful AC line inrush current and Adjustable Linear Acceleration and Deceleration make the drive suitable for soft-start applications. Additional features include holding torque at zero speed and ride-through which provides a smooth recovery to the previous set speed during a momentary power loss.

Standard front panel features include diagnostic LEDs for power on and control status, a Start/Stop Switch, Power On/Off Switch and a Main Speed Potentiometer. Other features include a Barrier Terminal Block to facilitate wiring of the AC line and motor, adjustable trimpots (MAX, MIN, ACCEL, DECEL, COMP, CL, BOOST) and selectable jumpers (line voltage, motor horsepower, auto or manual reset modes, motor frequency, frequency multiplier, fixed or adjustable boost).

Optional accessories include a Forward-Stop-Reverse Switch, Signal Isolator, and Auto/Manual Switch. Quick-connect terminals are provided for easy installation of all accessories.

STANDARD FEATURES

•Motor Overload Protection (I2t)* – Provides motor overload protection which prevents motor burnout and eliminates nuisance trips.

•Electronic Inrush Current Limiting – Eliminates harmful inrush AC line current during startup.

•Dual Voltage Input – The control operates from 115 or 208/230 Volt 50/60 Hz single phase AC line Input.

•Horsepower Selection – The control contains a horsepower selection jumper which eliminates the need to recalibrate the CL trimpot for different motors.

•Short Circuit Protection – Shuts down the control if a short circuit occurs at the motor (phase-to-phase).

•Regeneration Protection – Eliminates tripping due to bus overvoltage caused by rapid deceleration of high inertial loads.

•Slip Compensation with Boost – Provides excellent load regulation over a wide speed range.

•Start/Stop Switch – Provides electronic start and stop.

•Power On/Off Swiitch – Disconects the AC line.

•Ride-Through – Provides smooth recovery to the previous set speed during a momentary power loss.

•Diagnostic LEDs – Power on (POWER) and control status (STATUS).

•Barrier Terminal Block – Facilitates wiring of motor and AC line.

•Protection Features – Undervoltage and overvoltage protection. MOV input transient protection. Microcontroller self-monitoring and auto reboot. Short circuit protected phase-to- phase at motor.

•Industrial Duty Die-Cast Aluminum Case.

•Holding Torque at Zero Speed – Resists motor shaft rotation when the control is in stop mode.

Note: * UL approved as an electronic overload protector for motors.

2

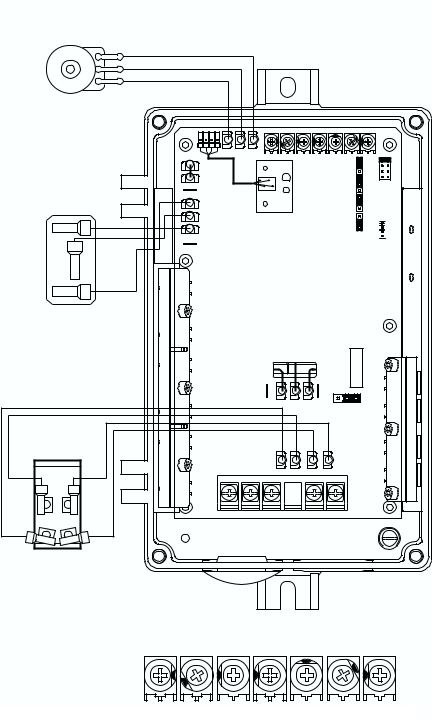

FIGURE 1 – CONTROL LAYOUT

(Illustrates Factory Setting of Jumpers and Approximate Trimpot Settings)

WHITE

ORANGE

VIOLET

MAIN SPEED POTENTIOMETER

(BACK VIEW)

|

CON1 |

|

|

MAX |

MIN ACCEL DECEL COMP CL |

BOOST |

|

|

|

|

|

|

|

|

|

|

P3 |

P2 |

P1 |

|

|

|

|

|

|

|

|

|

|

|

FIX |

|

FWD |

|

|

|

|

|

BOOST |

|

STOP |

|

B |

G |

POWER |

J7 |

ADJ |

|

|

|

1X |

||||

|

|

|

R |

Y |

STATUS |

|

MULT |

|

REV |

|

J6 |

2X |

|||

START/STOP SWITCH |

|

|

|

|

|

|

60HZ |

RUN |

|

|

|

|

|

FREQ |

|

(BACK VIEW) |

|

|

|

|

|

||

|

|

|

|

|

J5 |

50HZ |

|

RED |

COM |

|

LED BOARD |

|

AUTO |

||

STOP |

|

|

|

|

J4 |

MAN |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

J2 |

BLACK |

R/F |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WHITE

NOTES:

1.REV TERMINAL IS USED FOR OPTIONAL FWD-STOP-REV SWITCH.

2.R/F, B- AND B+ TERMINALS ARE USED FOR OPTIONAL ID5SI-2 SIGNAL ISOLATOR.

|

|

|

|

|

|

|

|

|

J1 |

|

|

|

|

B- |

BC- |

BC0 |

BC+ B+ |

115V |

230V |

|

|

|

|

|

|

|

|

||

POWER ON/OFF SWITCH |

|

|

|

|

|

|

|

|

|

BLUE |

WHITE |

|

|

|

L1A |

L1B |

L2A |

L2B |

|

|

TB1 |

|

|

|

|

|

|

|

|

|

MOTOR |

U |

V |

W |

|

|

L1 |

L2 |

AC LINE |

BLUE |

WHITE |

|

|

|

|

|

|

|

|

1HP |

3/4 |

1/2 |

1/4 |

J3 |

115V 230V

115V 230V

FIGURE 2 – ENLARGED VIEW OF TRIMPOT SETTINGS

MAX |

MIN ACCEL DECEL COMP |

CL |

BOOST |

3

Loading...

Loading...