Avdel GENESIS NG3 User Manual

Hydro-Pneumatic Power Tool

Druckluftgerät

Outil oléo-pneumatique

Attrezzo oleopneumatico

Genesis

®

G3

Instruction Manual

Manuel d’instructions

Betriebsanleitung

Manuale d’istruzione

3

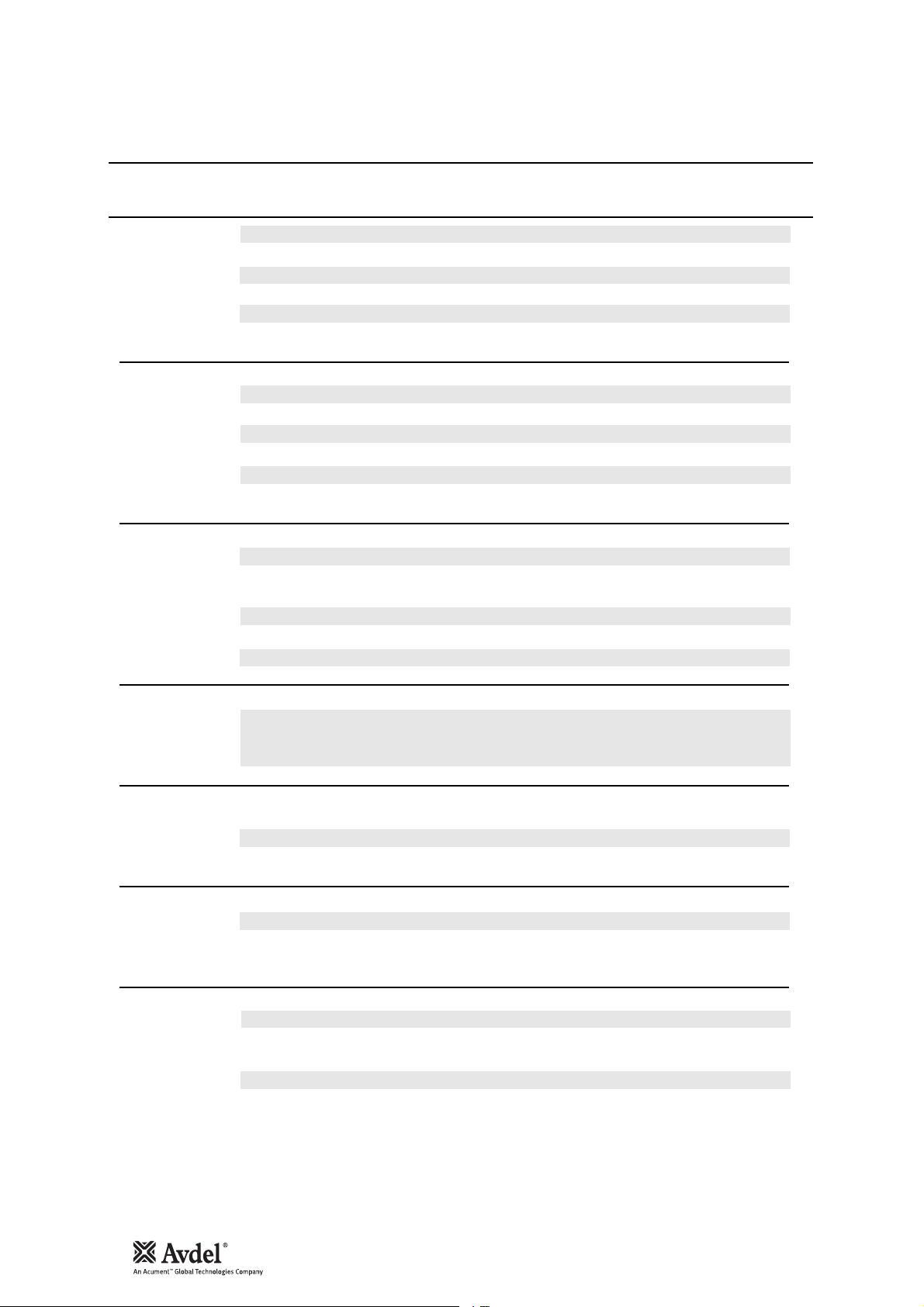

Safety Instructions 4

Specifications

Tool Specification 5

Tool Dimensions 5

Intent of Use

Range of Fasteners 6

Part Numbering 6

Putting into Service

Air Supply 7

Operating Procedure 7

Nose Assemblies

Fitting Instructions 8

Servicing Instructions 8

Nose Tips 9 - 12

Type 1 Standard 9

Avseal

®

II Nose Tips 10

Type 2 Limited Access 11

Type 3 Aerospace 11

Type 4 Monobolt

® -

Extended 12

Type 5 Avtainer

®

12

Type 6 Monobolt

®

- Interlock

®

12

Accessories

Stem Deflector 13

Preparing the Base Tool for use with Stem Deflector 13

Extension 13

Swivel Heads 14

Straight Swivel Head capability 14

Preparing the Base Tool for Right-Angle and Straight 15

Swivel Head Attachment

Right-Angle Swivel Head capability 15

Swivel Head Fitting Instructions 16

Swivel Head Servicing Instructions 17

Constant Components 17

Servicing the Tool

Daily / Weekly 18

Moly Lithium Grease EP 3753 Safety Data 18

Molykote

®

55m Grease Safety Data 19

Molykote

®

111 Grease Safety Data 19

Service Kit 20

Maintenance 20

Nose Equipment 20

Dismantling the Tool 21

Head Assembly 21

Pneumatic Piston Assembly 22

Air Valve 22

Rotary Valve 23

Trigger 23

Stop Plate Assembly (71213-03900) 24

General Assembly of Base Tool

General Assembly 26

Parts List 27

Priming

Oil Details 28

Hyspin

®

VG 32 Oil Safety Data 28

Priming Kit 28

Priming Procedure 29

Fault Diagnosis

Symptom, Possible Cause and Remedy 30

Français 33

Deutsch 63

Italiano 93

Avdel UK Limited policy is one of continuous product development and improvement and we reserve the right to change the specification of any product without prior notice.

LIMITED WARRANTY

Avdel make the limited warranty that its products will be free of defects in

workmanship and materials which occur under normal operating conditions. This

Limited Warranty is contingent upon: (1) the product being installed, maintained and

operated in accordance with product literature and instructions and (2) confirmation by

Avdel of such defect, upon inspection and testing. Avdel makes the forgoing limited

warranty for a period of twelve (12) months following Avdel’s delivery of the product to

the direct purchaser from Avdel. In the event of any breach of the forgoing warranty,

the sole remedy shall be to return the defective Goods for replacement or refund for

the purchase price at Avdel’s option. THE FORGOING EXPRESS LIMITED WARRANTY

AND REMEDY ARE EXCLUSIVE AND ARE IN LIEU OF ALL OTHER WARRANTIES AND

REMEDIES. ANY IMPLIED WARRANTY AS TO QUALITY, FITNESS FOR PURPOSE, OR

MERCHANTABILITY ARE HEREBY SPECIFICALLY DISCLAIMED AND EXCLUDED BY AVDEL.

Contents

English

4

Safety Instructions

1 Do not use outside the design intent.

2 Do not use equipment with this tool/machine other than that recommended and supplied by Avdel UK Limited.

3 Any modification undertaken by the customer to the tool/machine, nose assemblies, accessories or any equipment supplied by Avdel UK

Limited or their representatives, shall be the customer’s entire responsibility. Avdel UK Limited will be pleased to advise upon any

proposed modification.

4 The tool/machine must be maintained in a safe working condition at all times and examined at regular intervals for damage and function

by trained competent personnel. Any dismantling procedure shall be undertaken only by personnel trained in Avdel UK Limited procedures.

Do not dismantle this tool/machine without prior reference to the maintenance instructions. Please contact Avdel UK Limited with your

training requirements.

5 The tool/machine shall at all times be operated in accordance with relevant Health and Safety legislation. In the U.K. the “Health and

Safety at Work etc. Act 1974” applies. Any question regarding the correct operation of the tool/machine and operator safety should be

directed to Avdel UK Limited.

6 The precautions to be observed when using this tool/machine must be explained by the customer to all operators.

7 Always disconnect the airline from the tool/machine inlet before attempting to adjust, fit or remove a nose assembly.

8 Do not operate a tool/machine that is directed towards any person(s) or the operator.

9 Always adopt a firm footing or a stable position before operating the tool/machine.

10 Ensure that vent holes do not become blocked or covered.

11 The operating pressure shall not exceed 7 bar.

12 Do not operate the tool if it is not fitted with a complete nose assembly or swivel head unless specifically instructed otherwise.

13 Care shall be taken to ensure that spent stems are not allowed to create a hazard.

14 Vacuum Air MUST be turned off using the Trigger before removing the Stem Collector Bottle which MUST be emptied when half full.

15 The Tool MUST NOT be operated with the Stem Collector Bottle removed.

16 If the nG3 tool is fitted with a stem deflector, it should be rotated until the aperture is facing away from the operator and other person(s)

working in the vicinity.

17 When using the tool, the wearing of safety glasses is required both by the operator and others in the vicinity to protect against fastener

ejection, should a fastener be placed ‘in air’. We recommend wearing gloves if there are sharp edges or corners on the application.

18 Take care to avoid entanglement of loose clothes, ties, long hair, cleaning rags etc. in the moving parts of the tool which should be kept

dry and clean for best possible grip.

19 When carrying the tool from place to place keep hands away from the trigger/lever to avoid inadvertent start up.

20 Excessive contact with hydraulic fluid oil should be avoided. To minimize the possibility of rashes, care should be taken to wash

thoroughly.

21 C.O.S.H.H. data for all hydraulic oils and lubricants is available on request from your tool supplier.

This instruction manual must be read with particular attention to the following safety rules, by any person

installing, operating, or servicing this tool.

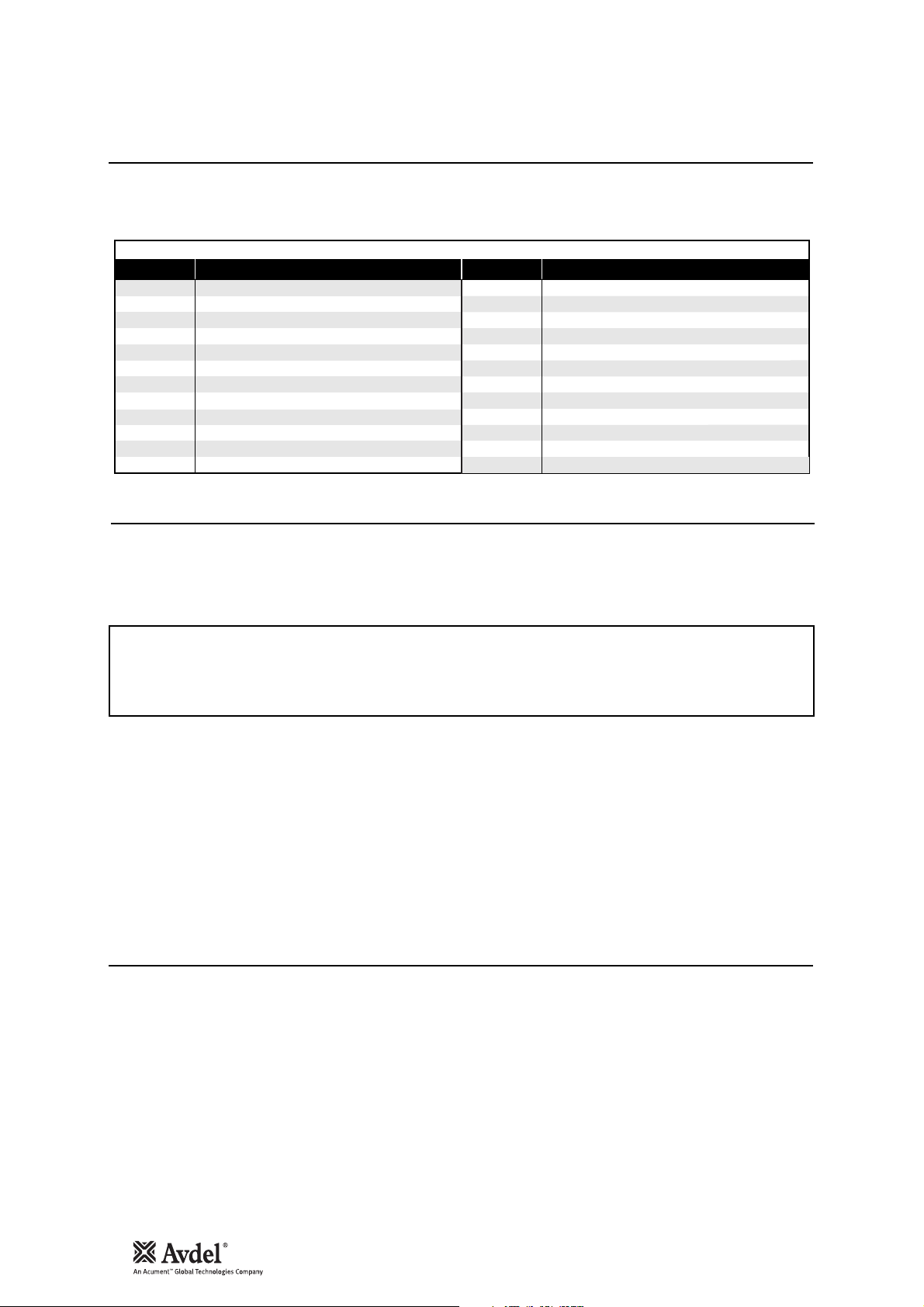

Tool Specification

Specifications

5

Air Pressure Minimum - Maximum 5-7 bar (72.5 - 101.5 psi)

Free Air Volume Required @ 5.5 bar 4.3 litres (0.15 cuft)

Stroke Minimum 26 mm (1.02 in)

Pull Force @ 5.5 bar 12.9 kN (2900 lbf)

Cycle Time Approximately 1.2 seconds

Noise Level 75 dB(A)

Weight Including nose equipment 2.25 Kg

Vibration Less than 2.5 m/s

2

(8.2 ft/s

2

)

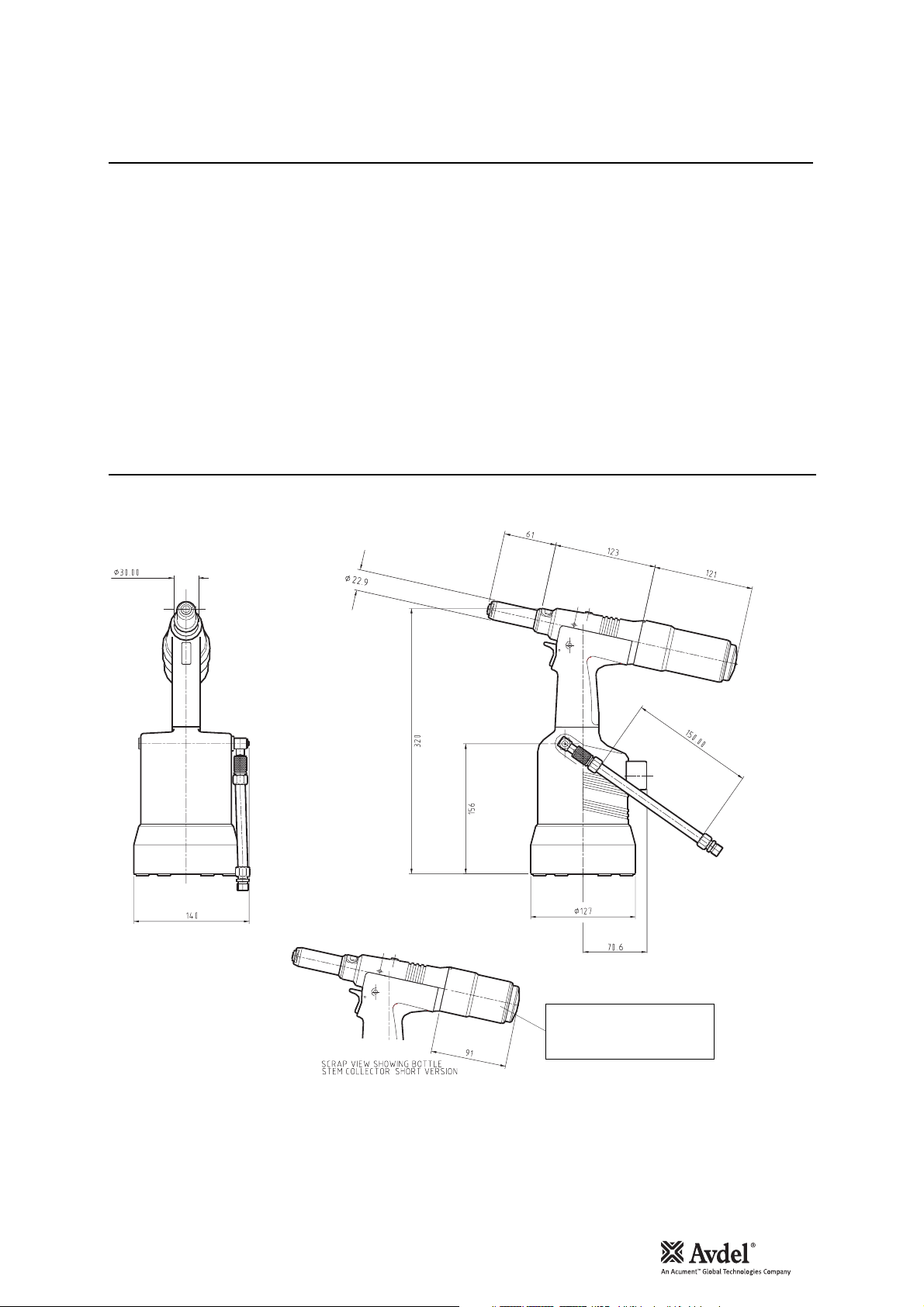

Dimensions in millimetres

Tool Dimensions

Note: Stem Collector Short

Version Bottle is an accessory

part number 71213-03810.

English

6

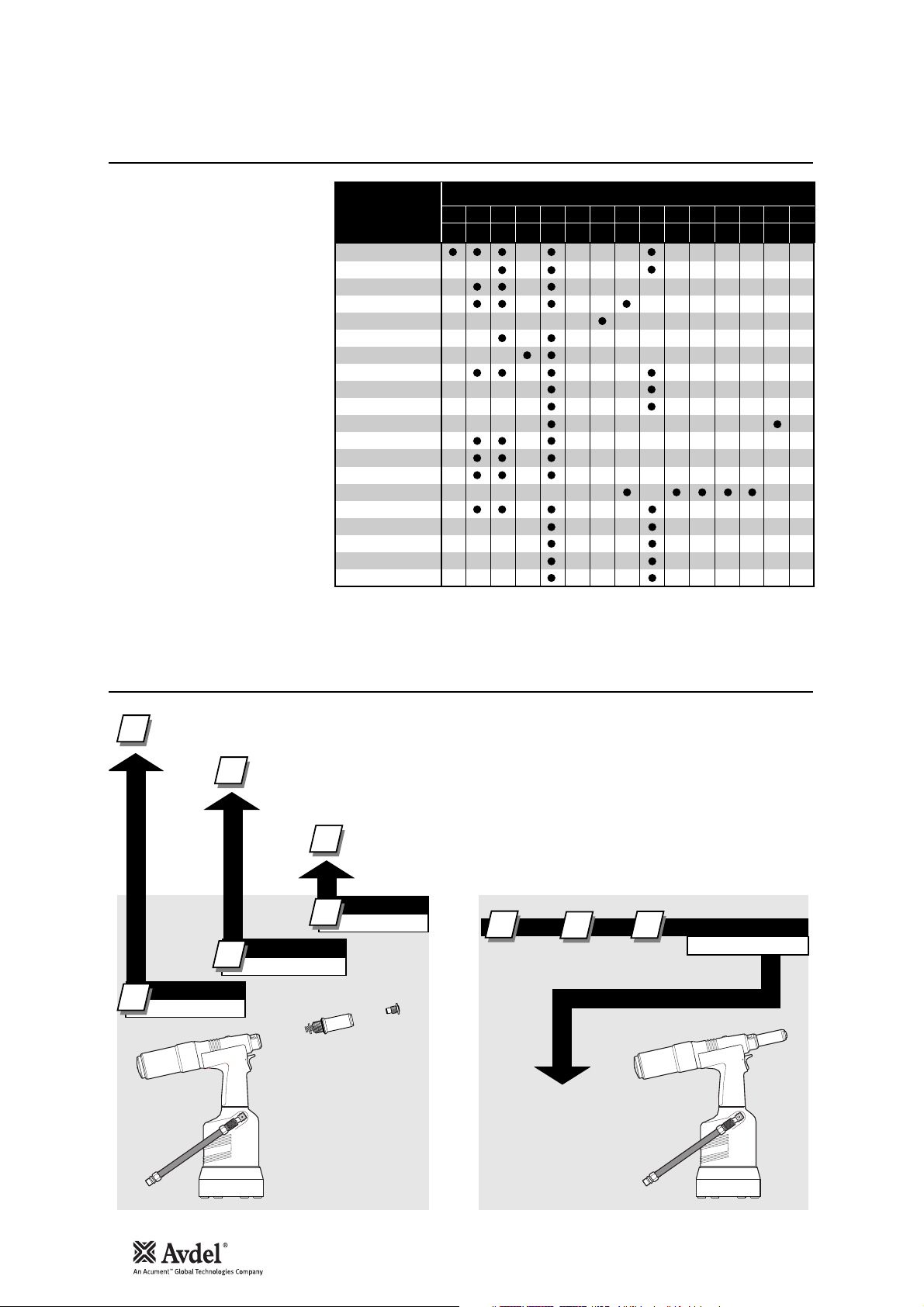

Intent of Use

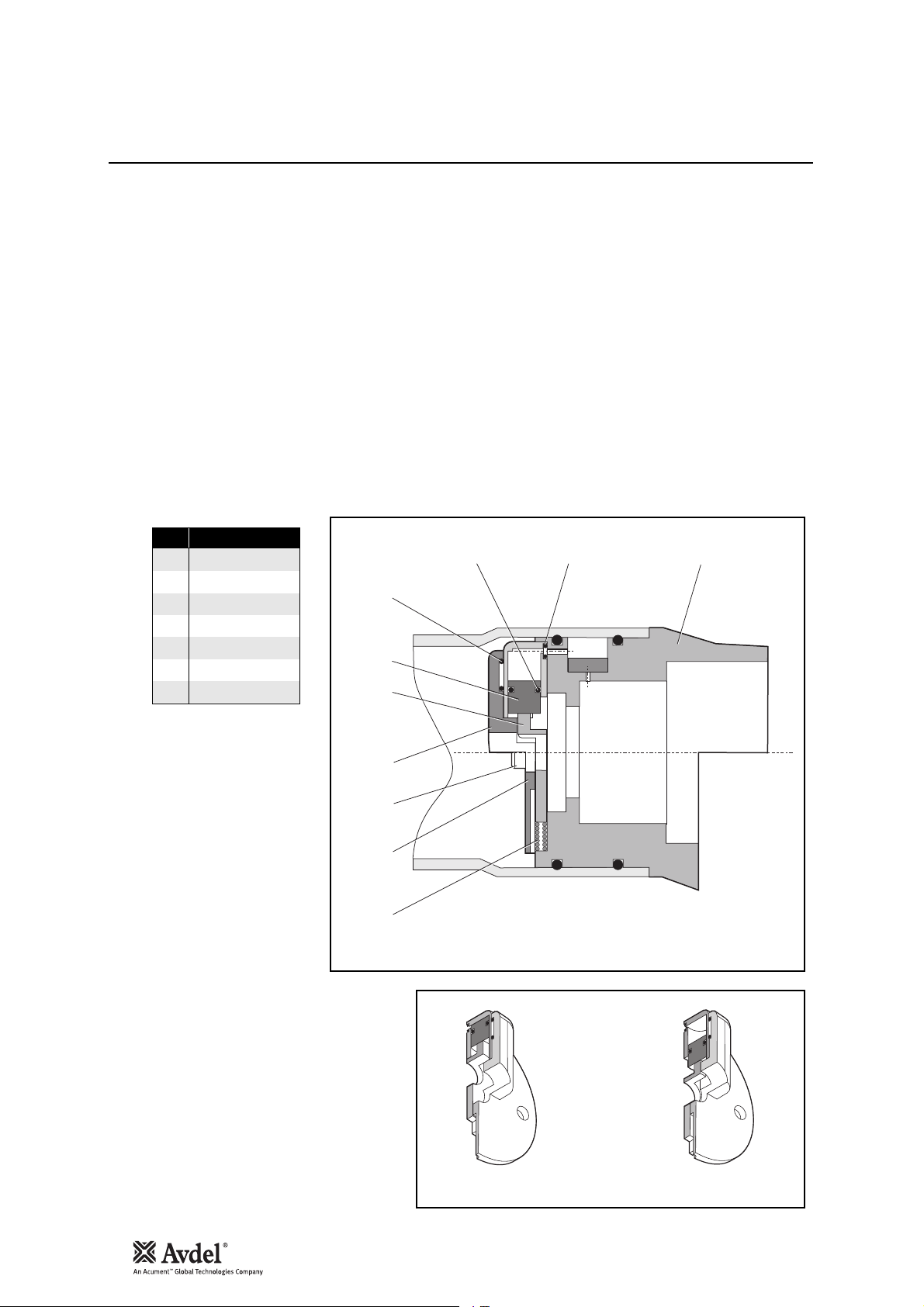

nG3 is a hydro-pneumatic tool designed

to place Avdel

®

breakstem fasteners at

high speed making it ideal for batch or

flow-line assembly in a wide variety of

applications throughout all industries. It

can place all fasteners listed opposite.

The tool features a vacuum system for

fastener retention and trouble free

collection of the spent stems

regardless of tool orientation.

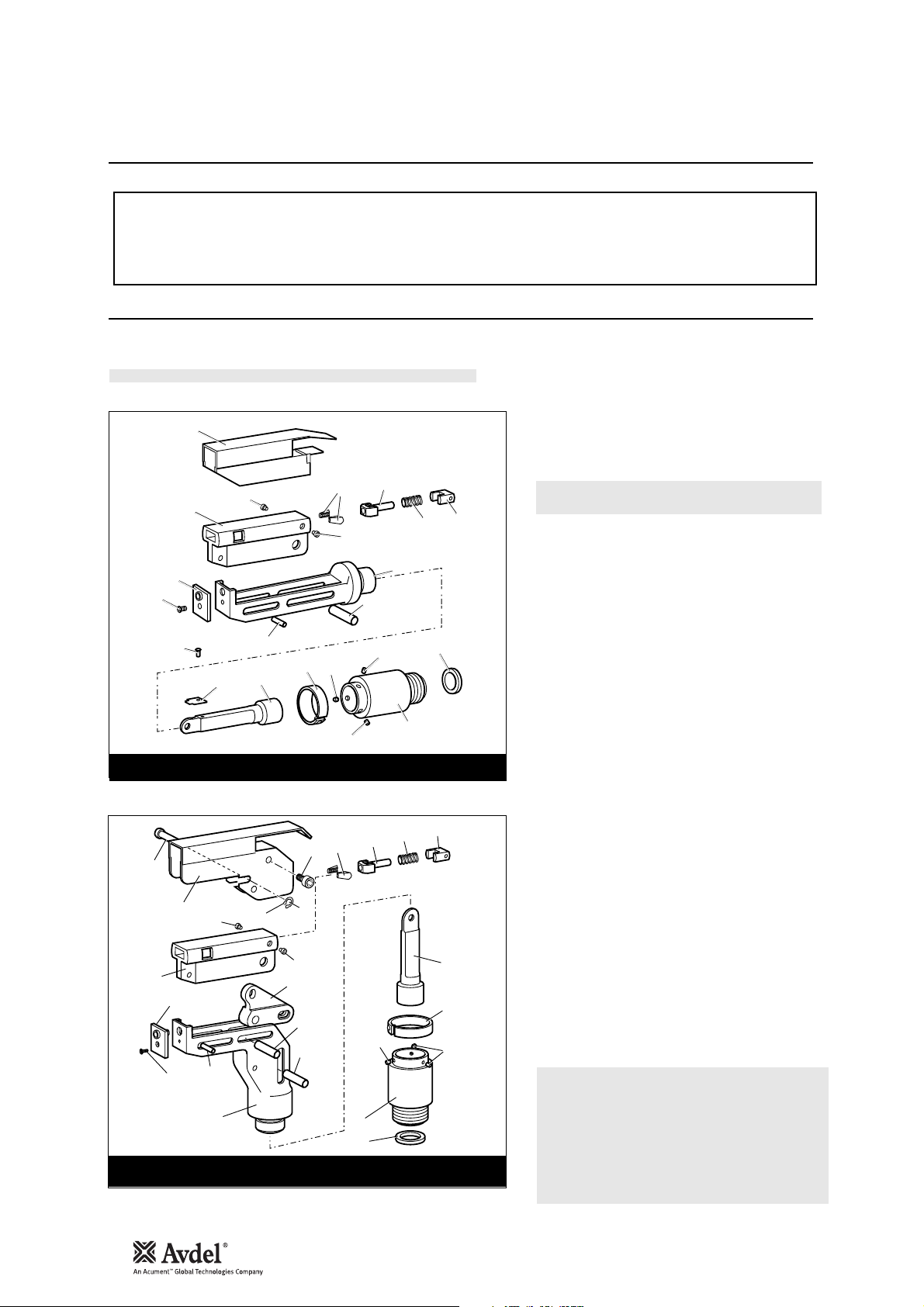

A complete tool is made up of

three separate elements which will

be supplied individually. See

diagram below.

NOSE EQUIPMENT MUST BE

FITTED AS DESCRIBED ON PAGE 8.

MM

Pollici

AVEX

®

STAVEX

®

AVINOX

®

II

AVIBULB

®

ETR

BULBEX

®

T-LOK

®

AVDEL

®

SR

MONOBOLT

®

INTERLOCK

®

AVTAINER

®

AVDEL

®

MBC

®

MBC/LC

®

AVSEAL

®

II

Q

™ RIVET

T

™ RIVET

CHERRYMATE™

KLAMPTITE™

KLAMPTITE™KTR

3 3.2 4.0 4.3 4.8 5 5.2 6 6.4 6.5 7 8 9 9.5 10

–

1

/8

5

/32 –

3

/16 – – –

1

/4 – – – –

3

/8 –

TIPO

RIVETTO

DIMENSIONI ( )

COMPLETE TOOL

71223-00 . . .

*

BASE TOOL

1

1

2

3

1

NOSE ASSEMBLY

NOSE TIP

2

71223-02000

71210-15000

see note 3

2

3

++=

3

The part number of the base tool remains the same whichever nose assembly, or nose tip is fitted. See the General Assembly

pages 26 and 27. If a swivel head is fitted, the same base tool must be adapted. See details pages 14-15.

The nose tip part number relates to a specific fastener. If access to the application is

restricted, some extended nose tips are available. See table pages 11 and 12.

This single nose assembly will allow placing of non-aerospace fasteners by simply selecting the appropriate

nose tip from the range of Type 1 Nose Tips. Other nose assemblies are available for applications with

restricted access, for aerospace and special fasteners. See table page 11. A nose assembly can be

substituted by a swivel head (see pages 14 and 15). In this case the nose tip is part of the swivel head.

* ADD 3 DIGITS FROM THE

LAST COLUMN OF A NOSE

TIP TABLE ON PAGE 9 - 12.

FOR TOOLS WITH SWIVEL

HEADS USE TABLE PAGES 14-

15.

Range of Fasteners

Part Numbering

7

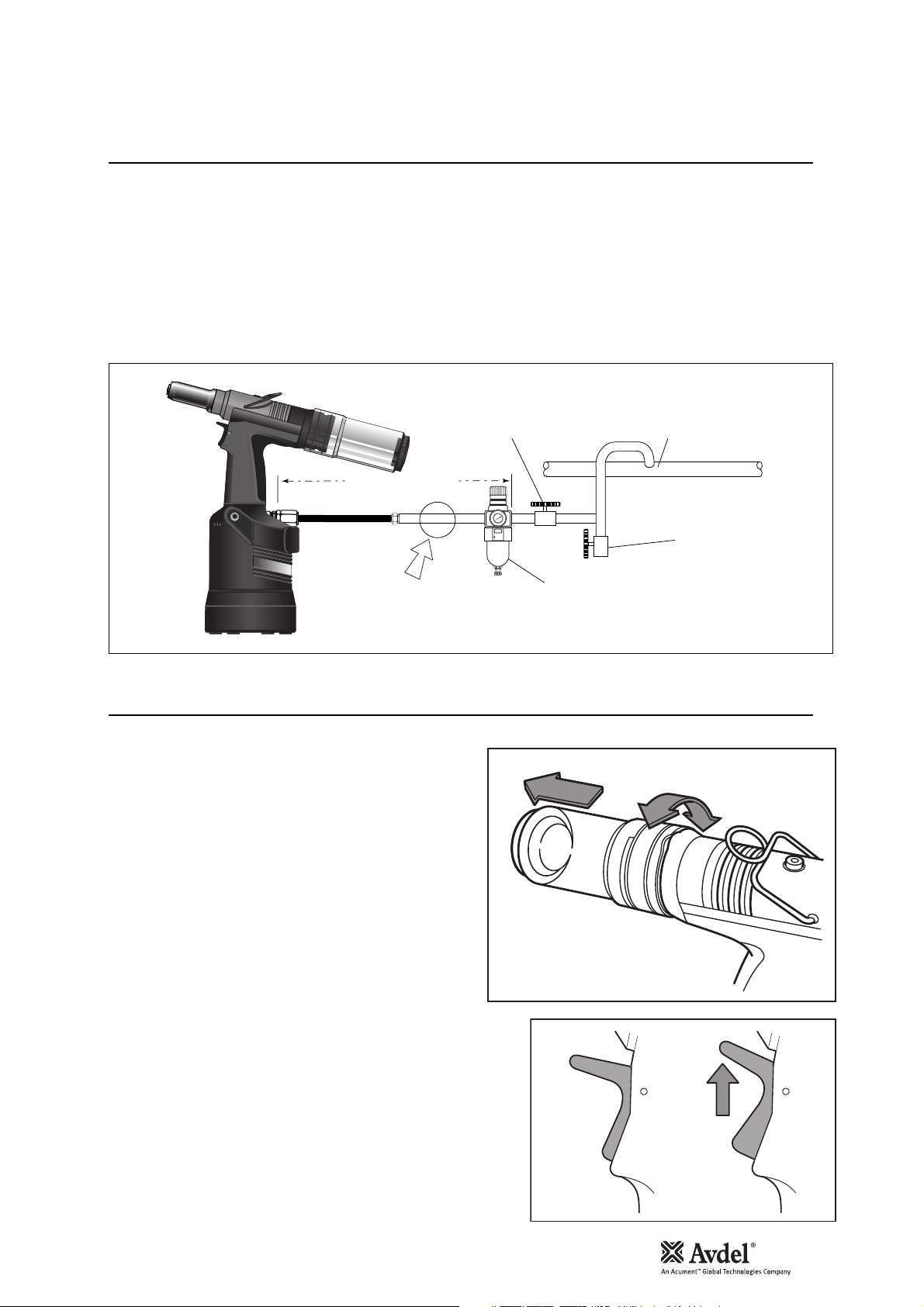

All tools are operated with compressed air at an optimum pressure of 5.5 bar. We recommend the use of pressure regulators and filtering

systems on the main air supply. These should be fitted within 3 metres of the tool (see diagram below) to ensure maximum tool life and

minimum tool maintenance.

Air supply hoses should have a minimum effective working pressure rating of 150% of the maximum pressure produced in the system or

10 bar, whichever is the highest. Air hoses should be oil resistant, have an abrasion resistant exterior and should be armoured where

operating conditions may result in hoses being damaged. All air hoses MUST have a minimum bore diameter of 6.4 millimetres or

1

/4 inch.

8

6

4

2

0

10

12

14

16

TAKE OFF POINT

FROM

MAIN SUPPLY

STOP COCK

(USED DURING MAINTENANCE

OF FILTER/REGULATOR OR LUBRICATION UNITS)

MAIN SUPPLY

DRAIN POINT

AIR LUBRICATION

PERMISSABLE

PRESSURE REGULATOR

AND FILTER (DRAIN DAILY)

3 METRES MAXIMUM

• Ensure that the correct nose assembly suitable for the fastener is

fitted.

• Connect the tool to the air supply.

• Insert the fastener stem into the nose of the tool. If using a

standard nose assembly, the fastener should remain held in by the

vacuum system.

• Bring the tool with the fastener to the application so that the

protruding fastener enters squarely into the hole of the

application.

• Fully actuate the trigger. The tool cycle will broach the fastener

and with standard nose assemblies the broken stem will be

projected to the rear of the tool into the collector bottle.

• A partial rotation and pull movement removes the collector bottle.

The Trigger should be lifted to cut-off the vacuum supply air prior

to removing the collector bottle.

Putting into Service

Air Supply

Operating Procedure

• To minimise air consumption, the trigger should be ‘lifted” to cut-off the

vacuum air supply if the tool is not to be used for a period of time.

Lift Trigger to

cut-off the

vacuum air

supply.

English

Do not use tool when Stem

Collector Bottle is removed

8

Nose Assemblies

* Item included in the nG3 Service Kit. For complete list see page 20.

Fitting Instructions

IMPORTANT

Nose assemblies do NOT include nose tips. Nose tips must be ordered separately.

A complete tool must always be fitted with the correct nose assembly and nose tip for your fastener and must be ordered separately,

refer to the ‘NOSE TIPS’ tables on pages 9 to 12.

If your application presents no access restriction use a Type ‘1’ Nose Tip unless you are placing aerospace fasteners which requires a

Type ‘3’ Nose Tip or Avtainer

®

fasteners a Type 5 Nose Tip.

Dimensions ‘A’ and ‘B’ in the following Nose Tip tables will help you assess the suitability of a particular nose tip.

You should also check that the dimensions of the nose casing will not restrict access to your application. If access is restricted Type

‘2’ Nose Tips are available for some fasteners. Refer to the table on page 11.

It is essential that nose assembly and nose tip are compatible with the fastener prior to operating the tool.

The Type 4 Nose Tip is an alternative to place

1

/4 in Monobolt

®

. Refer to the table on page 12.

Swivel heads are available as an alternative to nose assemblies as well as an extension when further reach is required.

See pages 14 to 17 in the ‘Accessories’ section.

Nose assemblies should be serviced at weekly intervals. You should hold some stock of all internal components of the nose assembly and

nose tips as they will need regular replacement.

Use Spanner 07900-00849 (supplied with the tool) to assist when servicing the nose assembly.

• Remove the nose equipment using the reverse procedure to the ‘Fitting instructions’.

• Any worn or damaged part should be replaced.

• Clean and check wear on Jaws.

• Ensure that neither the Jaw Spreader nor the Front Spring Guide is distorted.

• Check Spring 7 is not distorted.

• Assemble according to fitting instructions above.

IMPORTANT

The air supply must be disconnected when fitting or removing nose assemblies.

Item numbers in bold refer to nose assembly components in all 5 nose tip tables.

• Lightly coat Jaws 4 with Moly Lithium grease*.

• Drop Jaws 4 into Jaw Housing 3 or Chuck Collet 9 depending on which nose assembly you are using.

• Insert Jaw Spreader 5 into Jaw Housing 3 or insert Front Spring Guide 10 into Chuck Collet 9.

• Locate Buffer 6 on Jaw Spreader 5.

• Locate Spring 7 onto Jaw Spreader 5 or onto Front Spring Guide 10.

• Screw Rear Spring Guide 11 into Chuck Collet 9.

• Fit Locking Ring 8 onto the Jaw Spreader Housing of the tool.

• Holding tool pointing down, screw the assembled Jaw Housing or Chuck Collet onto the Jaw Spreader Housing and tighten with spanner*.

• Screw the nose tip into Nose Casing 1 and tighten with spanner*.

• Place Nose Casing 1 over Jaw Housing 3 or Chuck Collet 9 and screw onto the tool, tightening with spanner*.

Servicing Instructions

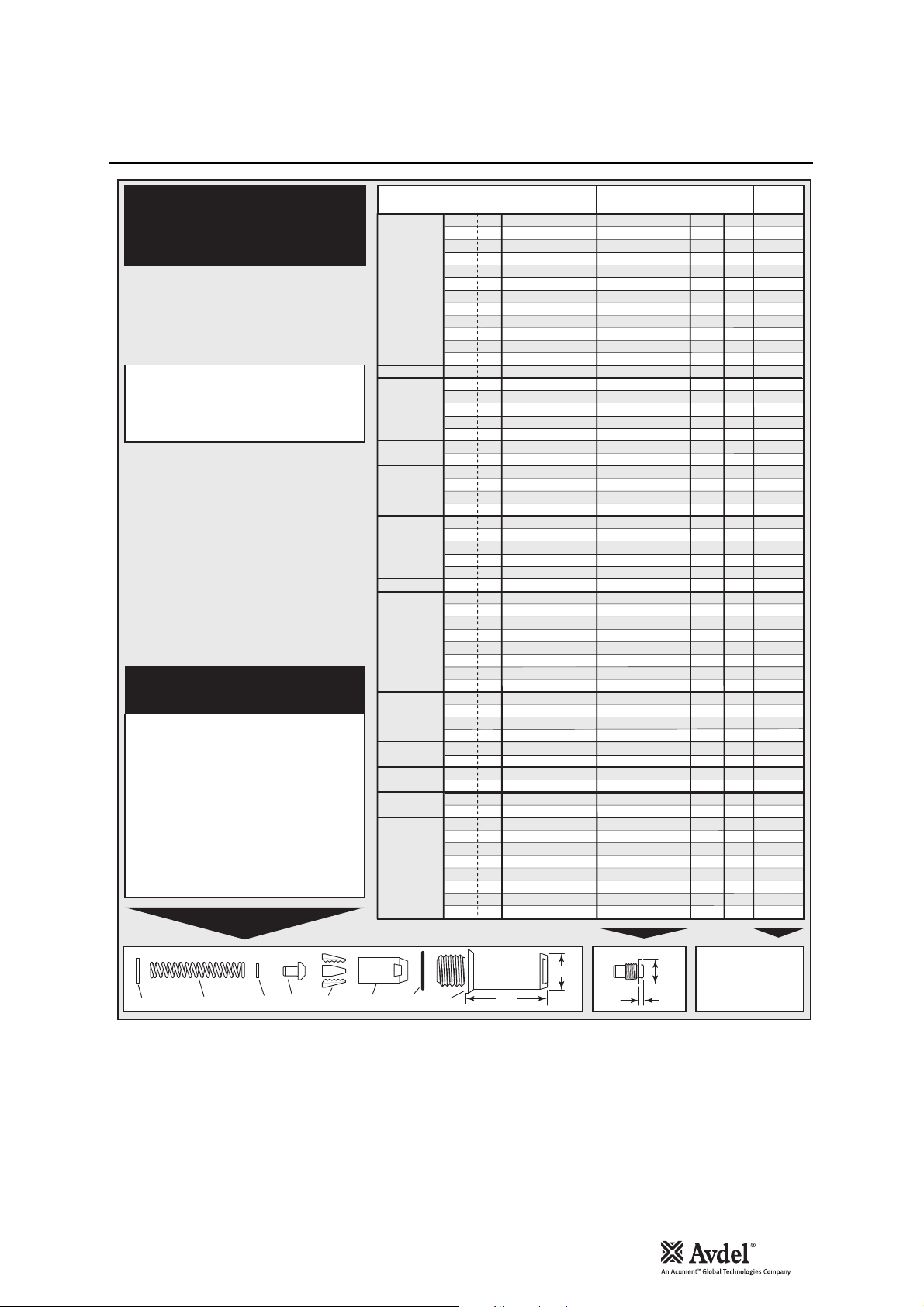

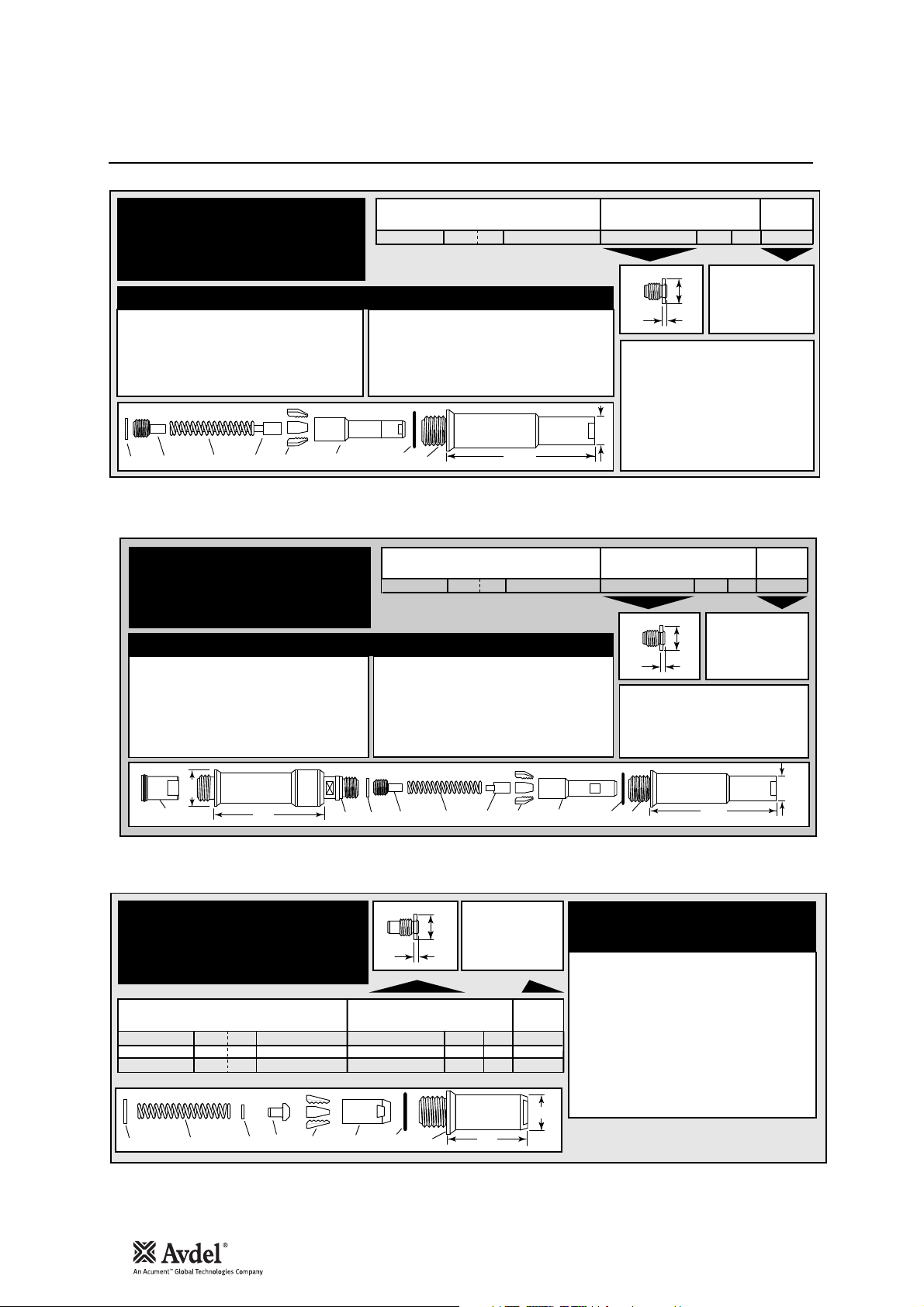

Nose Tips

Nose Assemblies

9

1

In inches then in millimetres.

2

Head forming nose tips for use with countersunk heads

ONLY.

TYPE 1

NOSE TIPS

NOSE ASSEMBLY

part nº 71210-15000

FASTENER

MATERIAL

Ø

1

NOSE TIP (mm)

see

below

PART Nº 'A' 'B'NAME

Al Alloy

Steel

Al Alloy

Al Alloy

Al Alloy

Steel

Al Alloy

Al Alloy

Al Alloy

Steel

Al Alloy

Al Alloy

Any

Al Alloy

Al Alloy

Stainless Steel

Stainless Steel

Stainless Steel

Steel

Steel

Steel

Steel

Steel

Steel

Any

Any

Any

Any

Any

Any

Steel

Steel

Steel

Steel

Steel

Stainless Steel

Stainless Steel

Stainless Steel

Any

Any

Any

Any

Any

Any

Any

Any

Any

Any

Al Alloy

Al Alloy

Al Alloy/Steel

Al Alloy/Steel

Al Alloy

Al Alloy

Al Alloy/Steel

Al Alloy/Steel

1

/

8

1

/

8

1

/

8

–

5

/

32

5

/

32

5

/

32

3

/

16

3

/

16

3

/

16

3

/

16

1

/

4

3

/

16

5

/

32

3

/

16

1

/

8

5

/

32

3

/

16

–

3

/

16

1

/

8

5

/

32

3

/

16

–

1

/

8

5

/

32

3

/

16

3

/

16

1

/

4

3

/

16

1

/

8

5

/

32

3

/

16

3

/

16

3

/

16

1

/

8

5

/

32

3

/

16

1

/

8

5

/

32

3

/

16

1

/

4

3

/

16

1

/

4

3

/

16

1

/

4

3

/

16

1

/

4

3

/

16

3

/

16

3

/

16

3

/

16

1

/

4

1

/

4

1

/

4

1

/

4

4.8

3.3

2.9

4.8

3.3

2.8

3.3

2.8

3.3

3.3

4.1

3.3

4.1

3.3

2.8

3.3

2.8

4.8

3.3

3.3

3.3

2.8

4.8

3.3

4.8

3.3

5.7

5.7

3.3

2.8

3.3

2.8

2.8

3.3

2.8

3.3

2.8

2.8

4.8

3.3

3.3

3.3

3.3

3.3

4.8

4.8

2.8

3.3

6.35

6.35

6.35

6.35

6.65

6.65

6.65

6.65

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

19.0

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

19.0

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

71210-05002

71210-16070

07340-06401

2

71210-05002

71210-16070

07381-04701

07340-06501

2

07381-04701

07340-04800

07490-04401

07340-06601

2

07612-02001

71210-16020

71210-16070

07381-04701

71210-16070

07381-04701

07498-01401

07340-06201

07340-06201

71210-16070

07381-04701

07498-01401

07612-02001

71210-05002

71210-16070

07348-07001

71210-16050

71220-60001

07381-04701

71210-16070

07381-04701

07381-04701

07340-04800

07381-04701

71210-16070

07381-04701

07381-04701

71210-05002

07340-06201

07340-06201

07612-02001

07340-06201

07612-02001

71220-16060

71220-16061

07381-04701

07612-02001

703-A-25-6TA

703-B-21

703-A-25-6T

703-B-26

743-A-25-8TA

703-B-21

743-A-25-8T

743-B-26

3.2

3.2

3.2

3.0

4.0

4.0

4.0

4.8

4.8

4.8

4.8

6.4

4.8

4.0

4.8

3.2

4.0

4.8

4.3

4.8

3.2

4.0

4.8

6

3.2

4.0

4.8

4.8

6.4

4.8

3.2

4.0

4.8

4.8

4.8

3.2

4.0

4.8

3.2

4.0

4.8

6.4

4.8

6.4

4.8

6.4

4.8

6.4

4.8

4.8

4.8

4.8

6.4

6.4

6.4

6.4

AVEX

®

Large flange

MONOBOLT

®

BULBEX

®

AVINOX

®

II

T-LOK

®

AVIBULB

®

AVDEL

®

SR

Countersunk

INTERLOCK

®

STAVEX

®

Large flange

Countersunk

Q

™

RIVET

CHERRYMATE™

KLAMPTITE™

KTR

KLAMPTITE™

T

™

RIVET

Large flange

Large flange

Large flange

Large flange

…001

…004

…003

…001

…004

…010

…009

…010

…016

…017

…015

…021

…200

…004

…010

…004

…010

…082

…120

…120

…004

…010

…082

…021

…001

…004

…062

…064

…063

…010

…004

…010

…010

…016

…010

…004

…010

…010

…001

…120

…120

…021

…120

…021

…500

…501

…010

…021

…380

…381

…383

…384

…385

…386

…387

…388

A

B

ITEM DESCRIPTION PART Nº

1 NOSE CASING 07340-00306

2 'O' RING 07003-00067

3 JAW HOUSING 07340-00304

4 JAWS 71210-15001

5 JAW SPREADER 07498-04502

6 BUFFER 71210-05001

7 SPRING 07500-00418

8 LOCKING RING 07340-00327

* In ADDITION to the nose assembly shown below,

an extra long nose assembly is available to place

1

/

4

" Monobolt

®

in applications with restricted

access. See type 4 NOSE TIP table.

COMPLETE TOOL

PART NUMBER :

precede with

71223-00

8 7 6 5 4 23 1

61

22.9

English

10

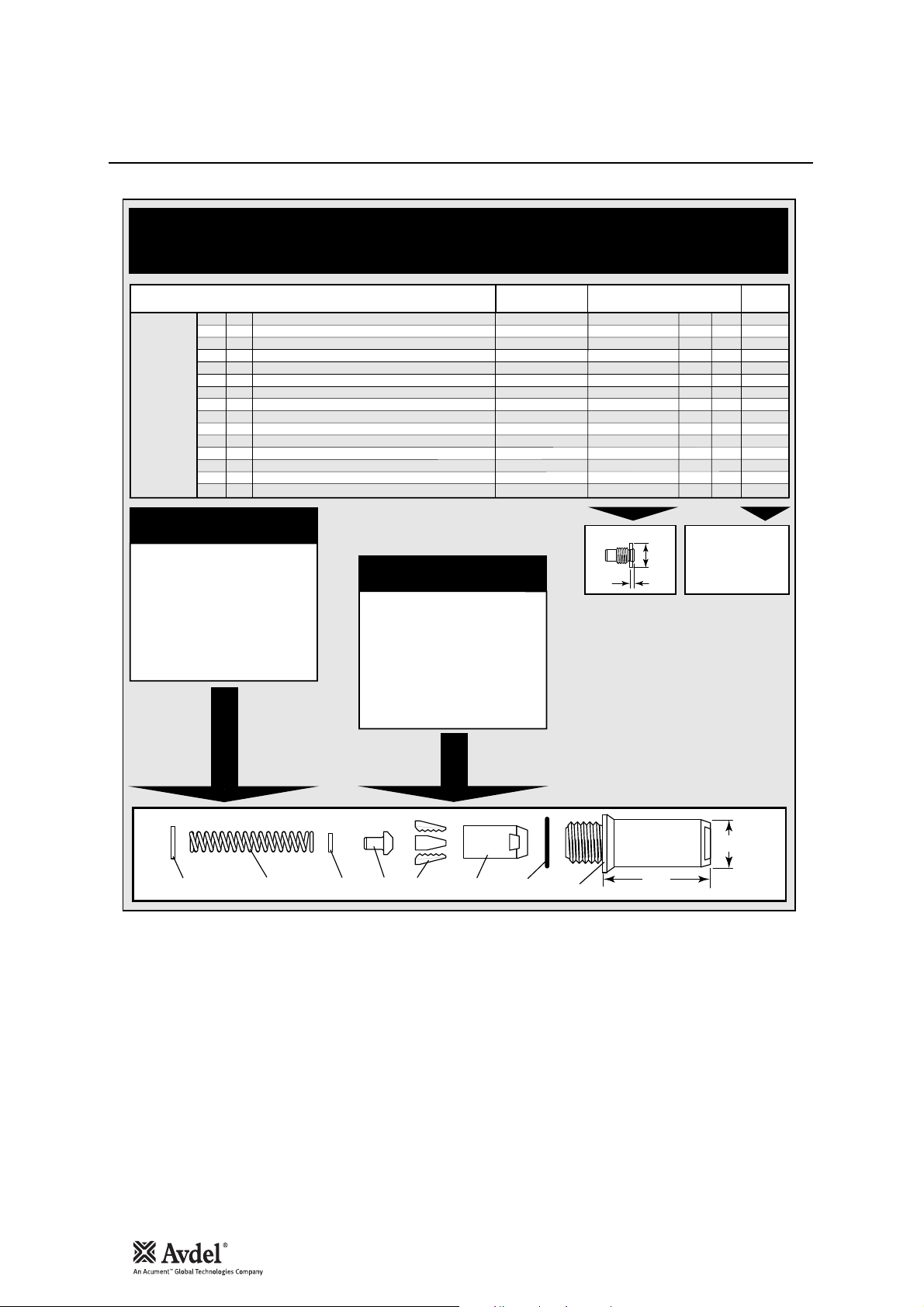

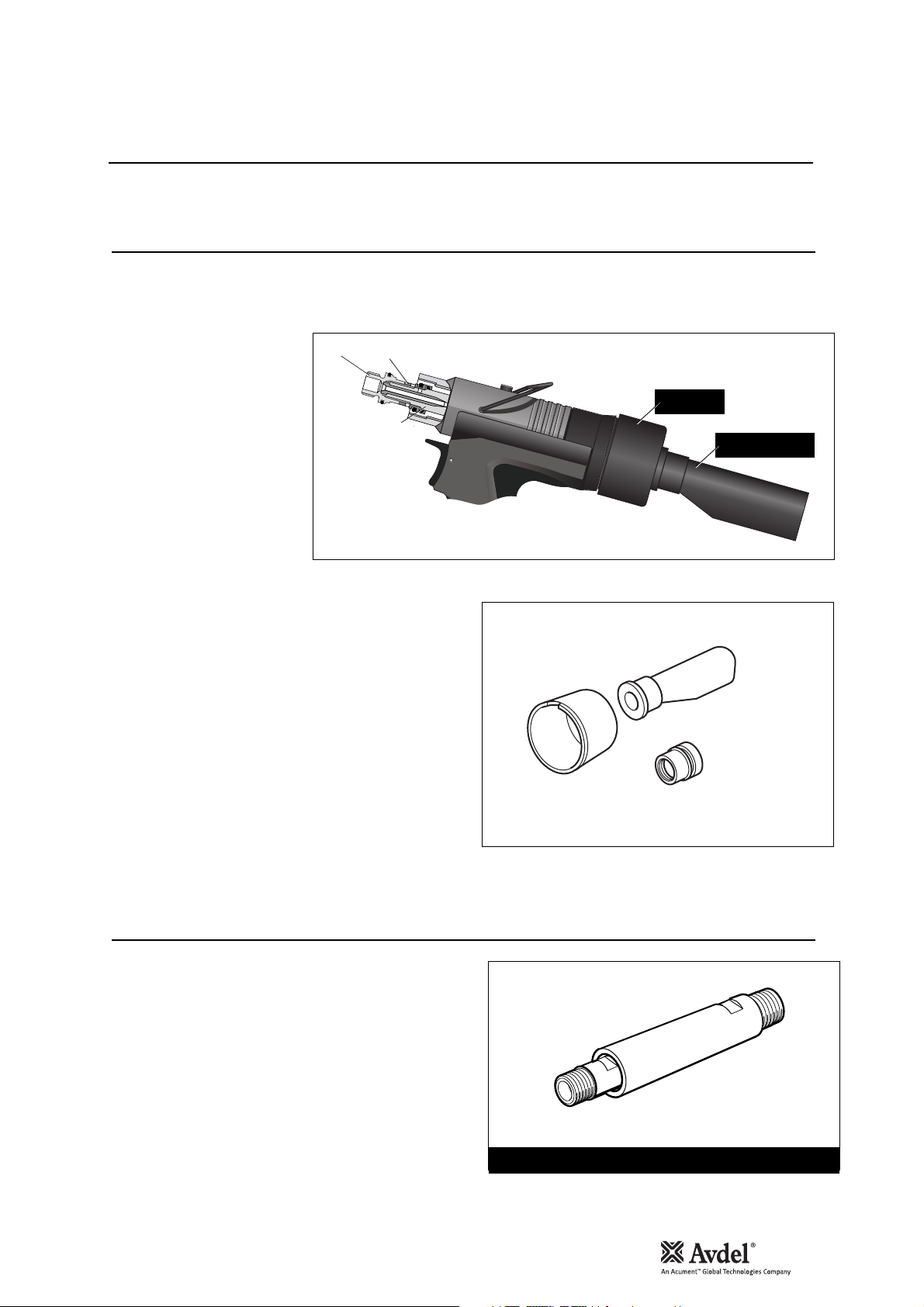

Nose Assemblies

Nose Tips

AVSEAL

®

II

NOSE TIPS

FASTENER

MATERIAL

Ø

NOSE TIP (mm)

see

below

PART Nº 'A' 'B'

NAME

Standard Al. Alloy - Flush Nose Tip

Standard Al. Alloy - 2mm Extended Nose Tip

Standard Al. Alloy - 8mm Extended Nose Tip

Standard Al. Alloy - Flush Nose Tip

Standard Al. Alloy - 2mm Extended Nose Tip

Standard Al. Alloy - 8mm Extended Nose Tip

Standard Al. Alloy - Flush Nose Tip

Standard Al. Alloy - 2mm Extended Nose Tip

Standard Al. Alloy - 8mm Extended Nose Tip

Standard & Low Pressure - Flush Nose Tip

Standard & Low Pressure - 2mm Ext Nose Tip

Standard & Low Pressure - 8mm Ext Nose Tip

Low Pressure Al. Alloy - Flush Nose Tip

Low Pressure Al. Alloy - 2mm Ext Nose Tip

Low pressure Al. Alloy - 8mm Ext Nose Tip

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

2.5

5.4

11.4

2.5

5.4

11.4

2.5

5.4

11.4

2.5

5.4

11.4

3.3

5.4

11.4

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

14.3

14.3

14.3

12AF

12AF

12AF

71210-16104

71210-16108

71210-16112

71210-16114

71210-16115

71210-16116

71210-16105

71210-16109

71210-16113

71220-16102

71220-16103

71220-16104

71220-16105

71220-16106

71220-16107

71210-16100

71210-16100

71210-16100

71210-16100

71210-16100

71210-16100

71210-16100

71210-16100

71210-16100

71220-16100

71220-16100

71220-16100

71220-16100

71220-16100

71220-16100

6.0

6.0

6.0

6.5

6.5

6.5

7.0

7.0

7.0

8.0

8.0

8.0

9.0

9.0

9.0

AVSEAL

®

II

… 407

… 408

… 409

… 413

… 414

… 415

… 410

… 411

… 412

… 413

… 414

… 415

… 430

… 431

… 432

A

B

COMPLETE TOOL

PART NUMBER :

precede with 71223-00.

NOSE ASSEMBLY

part nº 71210-16100

ITEM DESCRIPTION PART Nº

1 NOSE CASING 07340-00306

2 'O' RING 07003-00067

3 JAW HOUSING 07340-00304

4 JAWS 71210-16101

5 JAW SPREADER 07498-04502

6 BUFFER 71210-05001

7 SPRING 07500-00418

8 LOCKING RING 07340-00327

NOSE ASSEMBLY

part nº 71220-16100

ITEM DESCRIPTION PART Nº

1 NOSE CASING 07340-00306

2 'O' RING 07003-00067

3 JAW HOUSING 07612-02003

4 JAWS 71220-16120

5 JAW SPREADER 07498-04502

6 BUFFER 07498-03003

7 SPRING 07500-00418

8 LOCKING RING 07340-00327

8 7 6 5 4 23 1

61

22.9

NOSE

ASSEMBLY

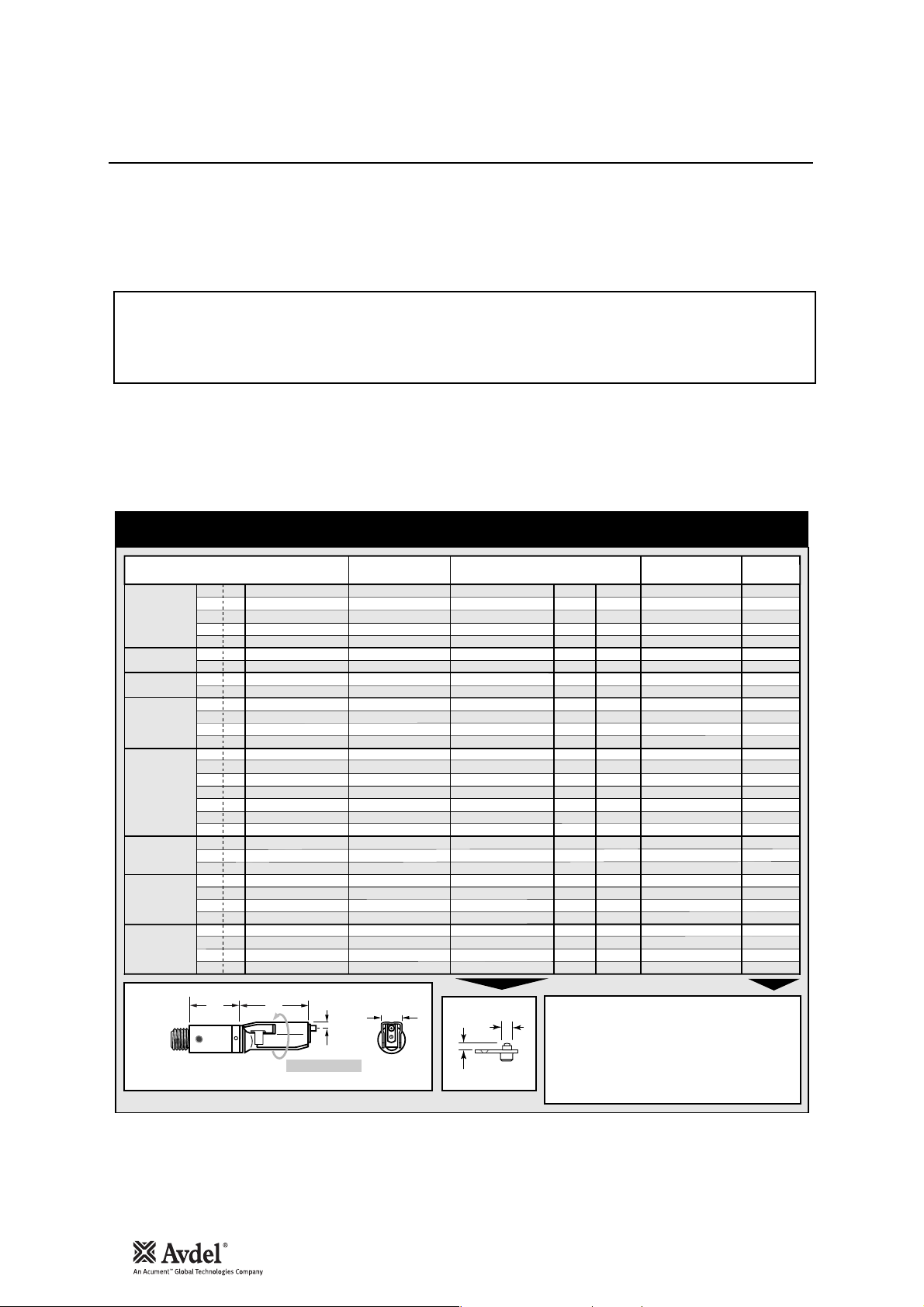

Nose Assemblies

Nose Tips

TYPE 3

NOSE TIPS

COMPLETE TOOL

PART NUMBER :

precede with

71223-00

1

In inches then in millimetres.

O

Oversize

NOSE ASSEMBLY

part nº 71210-15300

TYPE 3 NOSE TIPS ARE SPECIFICALLY FOR THE AEROSPACE

FASTENERS LISTED BELOW.

FASTENER

MATERIAL

Ø

1

NOSE TIP (mm) see

below

PART Nº 'A' 'B'NAME

Al Alloy

Al Alloy

O

Stainless Steel

Al Alloy

Al Alloy

O

Stainless Steel

Al Alloy

Al Alloy

O

Any

Any

Al Alloy

Any

Any

Al Alloy

1

/

8

1

/

8

1

/

8

5

/

32

5

/

32

5

/

32

3

/

16

3

/

16

1

/

8

5

/

32

3

/

16

1

/

8

5

/

32

3

/

16

2.5

2.5

3.3

2.5

2.5

3.3

2.5

2.5

4.8

5.0

5.1

4.6

4.6

4.6

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

12.7

71210-16030

71210-16031

71210-16032

71210-16033

71210-16034

71210-16035

71210-16036

71210-16037

07340-06701

07340-06801

07340-06901

07344-04701

07344-04701

07344-04701

3.2

3.2

3.2

4.0

4.0

4.0

4.8

4.8

3.2

4.0

4.8

3.2

4.0

4.8

AVDEL

®

MBC

®

MBC L/C

®

…283

…284

…285

…288

…289

…290

…293

…294

…300

…305

…310

…320

…320

…320

A

B

8 7 6 5 423

ITEM DESCRIPTION PART Nº

1 NOSE CASING 07344-02001

2 'O' RING 07003-00067

3 JAW HOUSING 07340-00304

4 JAWS 71210-15001

5 JAW SPREADER 07498-04502

6 BUFFER 71210-05001

7 SPRING 07500-00418

8 LOCKING RING 07340-00327

9 JAW SPREADER HOUSING 71210-02101

10 'O' RING 07003-00277

9 10

1

56.3

22.9

Note: Items 9 and 10 are not required when assembling Type 2 or Type 3 Nose Tip to the Base Tool nG3 (71223-02000).

1

In inches then in millimetres.

COMPLETE TOOL

PART NUMBER :

precede with

71223-00

NOSE ASSEMBLY

part nº 71210-15200

A

B

TYPE 2 NOSE TIPS ARE EXTENDED

TO ALLOW ACCESS INTO

APPLICATIONS WHERE TYPE 1

NOSE TIPS WILL NOT REACH.

TYPE 2

NOSE TIPS

8 7 6 5 4239 10

1

58.3

22.9

FASTENER

MATERIAL

Ø

1

NOSE TIP (mm)

see

below

PART Nº 'A' 'B'NAME

Aluminium Alloy

Steel

Aluminium Alloy

Steel

Aluminium Alloy

Steel

Aluminium Alloy

Aluminium Alloy

Steel

Steel

Steel

Steel

Steel

Stainless Steel

Stainless Steel

Stainless Steel

Steel

Steel

Steel/Brass

1

/

8

1

/

8

5

/

32

5

/

32

3

/

16

3

/

16

5

/

32

3

/

16

–

3

/

16

1

/

8

5

/

32

3

/

16

1

/

8

5

/

32

3

/

16

1

/

8

5

/

32

–

12.95

11.4

11.4

10.0

10.0

11.8

11.4

10.0

10.0

10.0

11.4

10.0

10.0

11.4

10.0

10.0

11.4

10.0

10.0

9.5

9.5

9.5

12.7

12.7

12.7

9.5

12.7

12.7

12.7

9.5

12.7

12.7

9.5

12.7

12.7

9.5

12.7

12.7

07340-02805

07340-02806

07340-02806

07340-02807

07340-02807

07340-07301

07340-02806

07340-02807

07241-07101

07241-07101

07340-02806

07340-02807

07340-02807

07340-02806

07340-02807

07340-02807

07340-02806

07340-02807

07340-02807

3.2

3.2

4.0

4.0

4.8

4.8

4.0

4.8

4.3

4.8

3.2

4.0

4.8

3.2

4.0

4.8

3.2

4.0

5.2

AVEX

®

BULBEX

®

T-LOK

®

STAVEX

®

AVIBULB

®

E.T.R

…002

…008

…008

…014

…014

…018

…008

…014

…121

…121

…008

…014

…014

…008

…014

…014

…008

…014

…014

ITEM DESCRIPTION PART Nº

1 NOSE CASING 07340-02804

2 'O' RING 07003-00067

3 JAW HOUSING 07340-00304

4 JAWS 71210-15001

5 JAW SPREADER 07498-04502

6 BUFFER 71210-05001

7 SPRING 07500-00418

8 LOCKING RING 07340-00327

9 JAW SPREADER HOUSING 71210-02101

10 'O' RING 07003-00277

Note: Items 9 and 10 are not required when assembling Type 2 or Type 3 Nose Tip to the Base Tool nG3 (71223-02000).

11

English

12

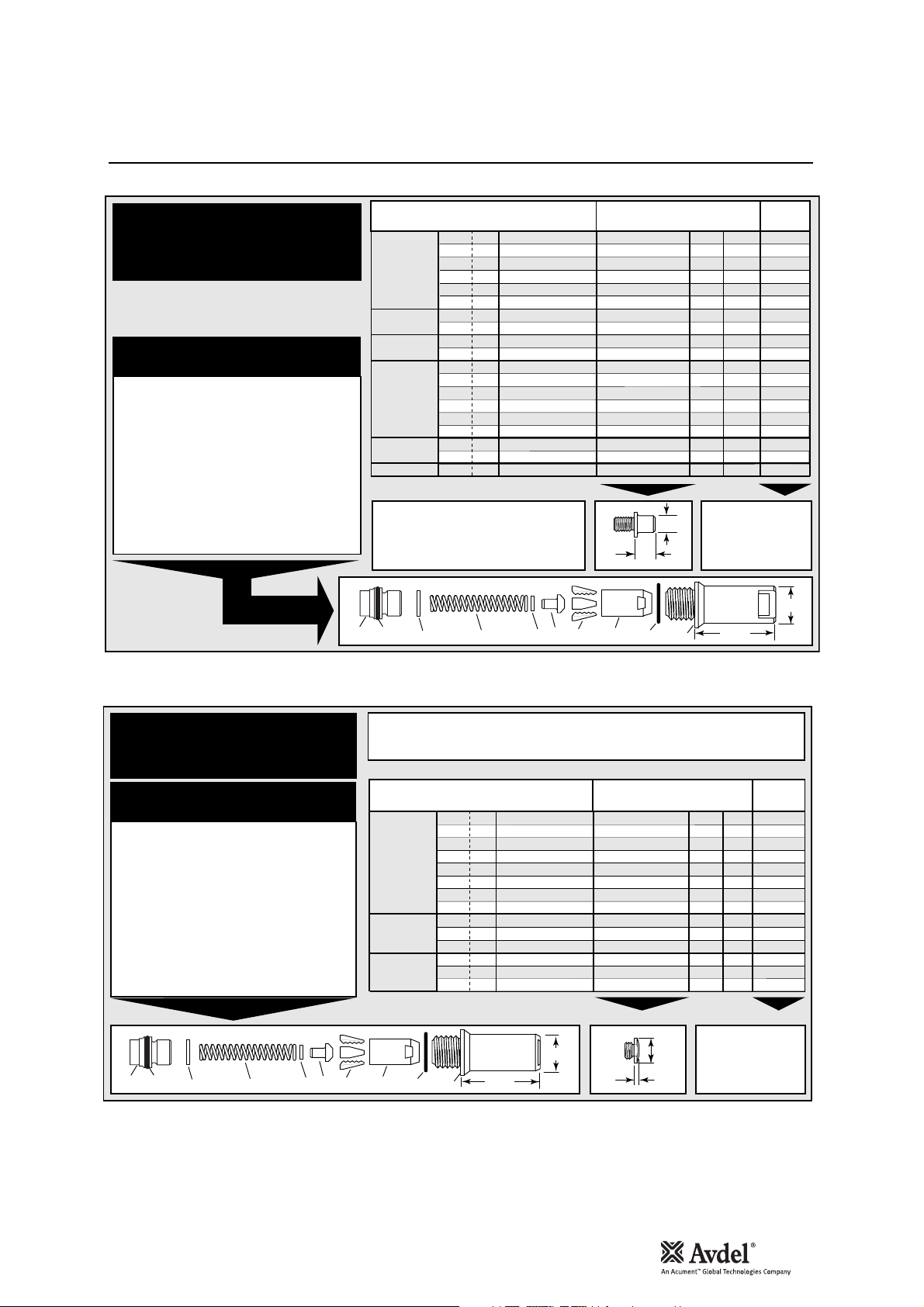

Nose Tips

Nose Assemblies

TYPE 4

NOSE TIP

COMPLETE TOOL

PART NUMBER :

precede with

71223-00

1

1

In inches then in millimetres

NOSE ASSEMBLY

part nº 71220-15400

ITEM DESCRIPTION PART Nº

1 NOSE CASING 07498-00501

2 'O' RING 07003-00067

9 CHUCK COLLET 07498-00502

4 JAWS 07497-03002

ITEM DESCRIPTION PART Nº

10 FRONT SPRING GUIDE 07498-00507

7 SPRING 07500-02005

11 REAR SPRING GUIDE 07498-00503

8 LOCKING RING 07340-00327

FITTED TO THIS LONG NOSE

ASSEMBLY, THE TYPE 4 NOSE TIP

WILL ALLOW THE PLACING OF

1

/4 " MONOBOLT

®

FASTENERS

IN APPLICATIONS REQUIRING

VERY DEEP ACCESS.

FASTENER

MATERIAL

Ø

1

NOSE TIP (mm) see

below

PART Nº 'A' 'B'NAME

Any

1

/

4

4.114.3

71220-16021

6.4

MONOBOLT

®

…202

11 7 10 4298

A

B

20.6

98.5

13

TYPE 5

NOSE TIP

COMPLETE TOOL

PART NUMBER :

precede with

71223-00

1

1

In inches then in millimetres

NOSE ASSEMBLY

part nº 71220-15500

ITEM DESCRIPTION PART Nº

1 NOSE CASING 07498-00501

2 'O' RING 07003-00067

9 CHUCK COLLET 07498-00801

4 JAWS 07220-02302

10 FRONT SPRING GUIDE 07498-00803

ITEM DESCRIPTION PART Nº

7 SPRING 07500-02005

11 REAR SPRING GUIDE 07498-00503

8 LOCKING RING 07340-00327

12 SIDE EJECTION ADAPTOR 07498-00900

THERE IS ONLY ONE TYPE 5 NOSE

TIP, SPECIFICALLY DESIGNED TO

PLACE AVTAINER

®

FASTENERS WITH

THIS SPECIAL NOSE ASSEMBLY.

FASTENER

MATERIAL

Ø

1

NOSE TIP (mm) see

below

PART Nº 'A' 'B'NAME

Steel

3

/

8

4.119.1

07498-00802

9.6

AVTAINER

®

…243

98.5

20.6

90

12 11 7 10 4298

A

B

28.6

13 71233-20200

VAC SHUT-OFF STOP NUT ASSY

NOSE ASSEMBLY

part nº 71230-15800

A

B

8 7 6 5 4 23 1

61

22.9

... 201

... 261

... 261

1

In inches then in millimetres

FASTENER

MATERIAL

Ø

1

NOSE TIP (mm) see

above

PART Nº 'A' 'B'NAME

1

/

4

1

/

4

1

/

4

MONOBOLT

®

INTERLOCK

®

STAVEX

®

TYPE 6

NOSE TIPS

ITEM DESCRIPTION PART Nº

1 NOSE CASING 07340-00306

2 'O' RING 07003-00067

3 CHUCK COLLET 07612-02003

4 JAWS 07612-02002

5 JAW SPREADER 07498-04502

6 BUFFER 07498-03003

7 SPRING 07500-00418

8 LOCKING RING 07340-00327

Any

Any

Any

4.1

3.6

3.6

14.3

14.3

14.3

71220-16021

07612-02001

07612-02001

6.4

6.4

6.4

COMPLETE TOOL

PART NUMBER

PRECEDED WITH:

71223-00

ADAPTOR

71213-20101

STEM DEFLECTOR

07340-00342

SEALED NUT

71213-02200

Stem Deflector

Accessories

The stem deflector is a very simple alternative to the standard stem collector and allows access in restricted areas. To replace the

stem collector with the stem deflector proceed as follows:

Item numbers in bold refer to the general assembly drawing and parts list on pages 26 and 27.

INNER

71210-20301

OUTER

71210-20302

EXTENSION PART NUMBER: 71210-20300

Fitted between the tool and the nose assembly the extension allows

access into deep channels.

• To fit the extension, remove any nose assembly components.

• Screw the inner extension to Jaw Spreader Housing 41.

• Screw the outer onto Head Assembly 58.

• Fit the nose assembly onto the extension.

• Loosen Locknut 40 using

16mm AF Spanner.

• Unscrew and remove both Jaw

Spreader Housing 41 and

Locknut 40.

• Replace Locknut 40 with

‘Sealed’ Nut 71213-02200,

screw ‘Sealed’ Nut onto Piston

36 to disable Vacuum System.

• Jaw Spreader Housing 41

must be tightened onto Piston

36, finally tightening ‘Sealed’

Nut against it.

• Remove Stop Plate Assembly

(page 24) by unscrewing

Screws 89 (2off).

Extension

Preparing the Base Tool for use with Stem Deflector

07340-00342

STEM DEFLECTOR

71213-20101

ADAPTOR

41

40

36

The airline must be disconnected before any servicing or dismantling.

‘Sealed’ Nut 71213-02200 replaces Locknut 40 (to cut-off air supply to Vacuum System) as follows:

13

English

• Fit Stem Deflector (07340-00342) into Adaptor (71213-20101).

• Push the assembled Stem Deflector and Adaptor over Bottle

Adaptor 32 and align with the cut-out feature.

14

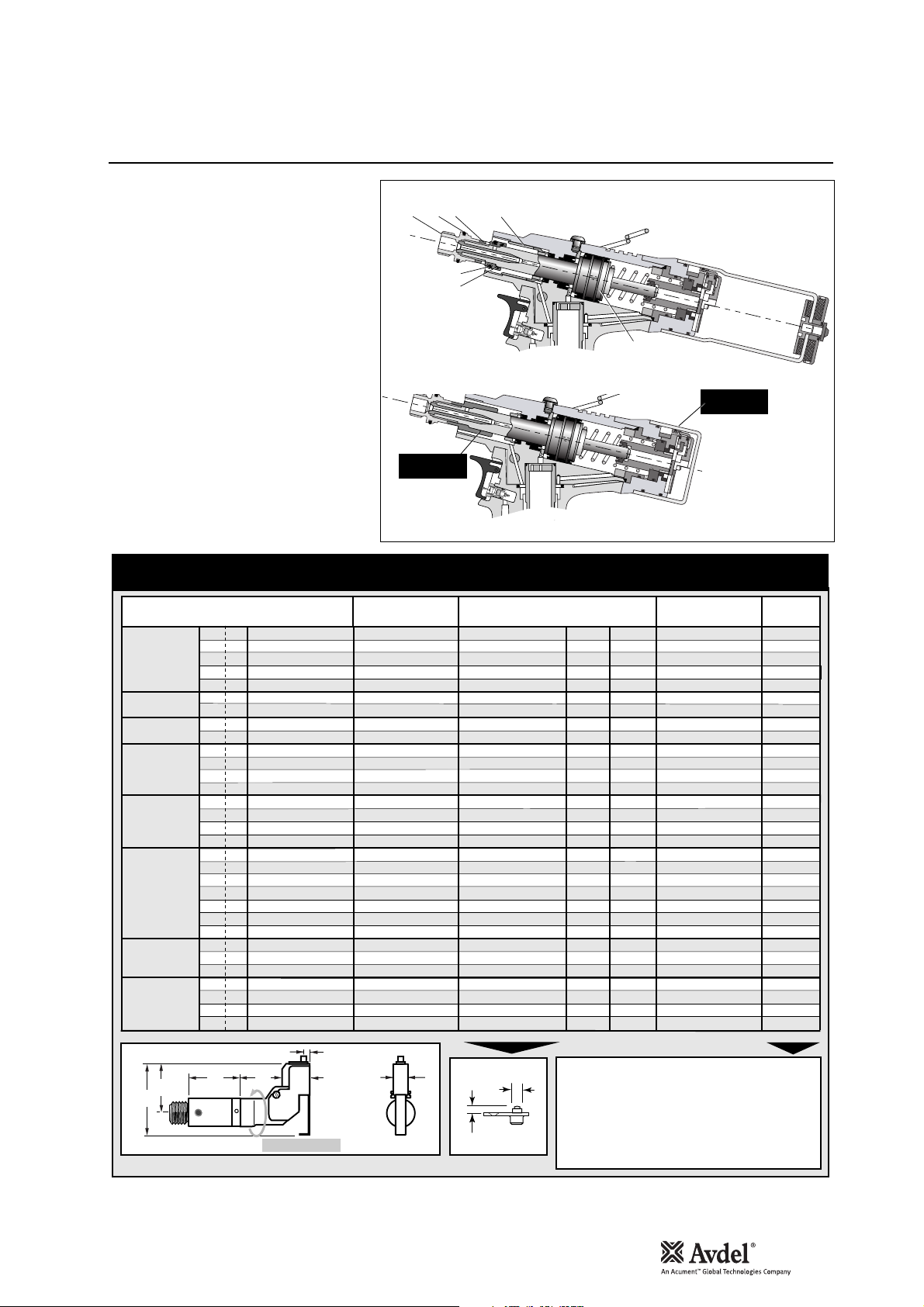

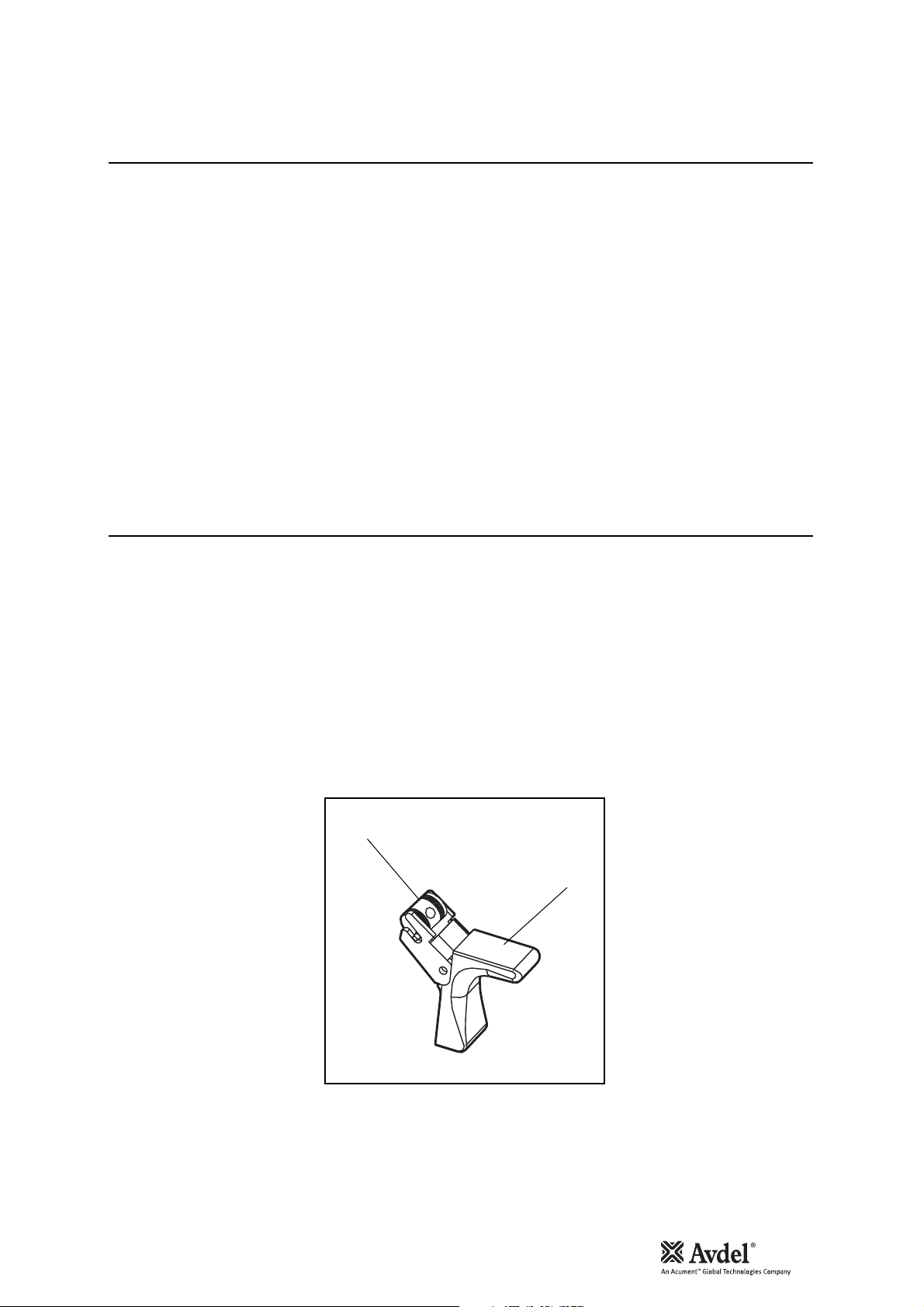

Swivel Heads

Accessories

Instead of a nose assembly, a swivel head can be fitted to a base tool. It allows 360° rotation of the tool about the nose tip and

allows access into many applications otherwise too restrictive. There are two types of swivel heads: the straight swivel head with the

nose tip slightly offset from the centre line of the tool head and the right-angle swivel head with the nose tip on a perpendicular axis to

the head of the tool. See drawings below for dimensions and pages 16 and 17 for detail.

IMPORTANT

PRIOR to fitting a swivel head, the base tool must be adapted. See Preparing the base tool opposite.

In contrast to nose assemblies part numbers of swivel heads do INCLUDE a nose tip as shown below.

Swivel heads are supplied separately for fitting to a base tool forming a complete tool. See table below for part numbers. Jaws and

nose tips vary depending on the fastener to be placed but all other components remain the same within each type of swivel head. See

the ‘capability’ tables below and page 15. For the ‘Constant Components’ table see page 17.

'A’ and ‘B’ dimensions will help you assess the accessibility of your application.

1

In inches then in millimetres.

2

Long nose tip for deep placing.

O

Oversize

FASTENER

MATERIAL

Ø

1

NOSE TIP (mm)SWIVEL HEAD

PART Nº

JAWS

see

below

'A' 'B'NAME

Al Alloy

Steel

Al Alloy

Steel

Al Alloy

Al Alloy

Al Alloy

Stainless Steel

Stainless Steel

Al Alloy

Al Alloy

Al Alloy

Al Alloy

Al Alloy

Al Alloy O

Stainless Steel

Al Alloy

Al Alloy O

Al Alloy

Al Alloy O

Al Alloy

Al Alloy

Al Alloy

Al Alloy

Al Alloy

Al Alloy O

Al Alloy

Steel

Steel

Stainless Steel

Stainless Steel

1

/

8

1

/

8

5

/

32

5

/

32

3

/

16

5

/

32

3

/

16

1

/

8

5

/

32

–

–

–

–

1

/

8

1

/

8

1

/

8

5

/

32

5

/

32

3

/

16

3

/

16

1

/

8

5

/

32

3

/

16

1

/

8

5

/

32

5

/

32

3

/

16

3.81

3.81

3.81

3.81

3.81

3.81

3.81

3.81

3.81

1.95

4.11

2.00

4.11

1.17

1.17

3.81

0.84

0.84

0.25

0.25

1.9

2.36

2.46

2.03

2.03

2.03

2.03

3.81

3.81

3.81

3.81

7.87

7.87

7.87

7.87

7.87

7.87

7.87

7.87

7.87

6.35

6.35

7.62

7.62

5.08

5.08

5.08

6.6

6.6

8.13

8.13

4.75

6.35

7.92

7.87

7.87

7.87

7.87

7.87

7.87

7.87

7.87

07345-03000

07345-03100

07345-03100

07345-03200

07345-03200

07345-03100

07345-03200

07345-03100

07345-03200

71213-06000

71213-06600

71213-06100

71213-06700

07345-03300

07494-03600

07494-03000

07345-03400

07494-03700

07345-03500

07494-03800

07345-04000

07345-04100

07345-04200

07345-04700

07345-04700

07345-04800

07345-04800

07345-03100

07345-03200

07345-03100

07345-03200

PART Nº

07340-00213

07340-00213

07340-00213

07490-04602

07490-04602

07340-00213

07490-04602

07340-00213

07490-04602

07340-00213

07340-00213

07340-00213

07340-00213

07340-00229

07340-00229

07340-00213

07340-00229

07340-00229

07498-04401

07498-04401

07340-00229

07340-00229

07498-04401

07340-00229

07340-00229

07498-04401

07498-04401

07340-00213

07490-04602

07340-00213

07490-04602

PART Nº

07345-03600

07345-03700

07345-03700

07345-03800

07345-03800

07345-03700

07345-03800

07345-03700

07345-03800

71213-16401

71213-16402

2

71213-16403

71213-16404

2

07345-03301

07494-03601

07494-03011

07345-03401

07494-03701

07345-03501

07494-03801

07165-00701

07165-00702

07165-00703

07345-04701

07345-04701

07345-04701

07345-04701

07345-03700

07345-03800

07345-03700

07345-03800

3.2

3.2

4.0

4.0

4.8

4.0

4.8

3.2

4.0

4

4

5

5

3.2

3.2

3.2

4.0

4.0

4.8

4.8

3.2

4.0

4.8

3.2

4.0

4.0

4.8

3.2

4.0

3.2

4.0

AVEX

®

BULBEX

®

AVINOX

®

II

AVSEAL

®

II

AVDEL

®

MBC

®

MBC

®

L/C

STAVEX

®

…001

…004

…004

…010

…010

…004

…010

…004

…010

…160

…180

…161

…181

…283

…284

…285

…288

…289

…293

…294

…300

…305

…310

…320

…320

…327

…327

…004

…010

…004

…010

COMPLETE TOOL PART NUMBER :

precede with 71223-30

(the stop nut and safety cap are included)

IMPORTANT:

in contrast to complete tools

with nose assemblies, those fitted with swivel heads

include the nose tip as a part of the head.

STRAIGHT SWIVEL HEAD capability

A

B

360

°

rotation

56

92

6

20

1

/

8

1

/

8

5

/

32

5

/

32

FASTENER

MATERIAL

Ø

1

NOSE TIP (mm)SWIVEL HEAD

PART Nº

JAWS

see

below

'A' 'B'NAME

Aluminium Alloy

Steel

Aluminium Alloy

Steel

Aluminium Alloy

Aluminium Alloy

Aluminium Alloy

Stainless Steel

Stainless Steel

Aluminium Alloy

Aluminium Alloy

Aluminium Alloy

Aluminium Alloy

Steel

Steel

Stainless Steel

Stainless Steel

Aluminium Alloy

Aluminium Alloy O

Stainless Steel

Aluminium Alloy

Aluminium Alloy O

Aluminium Alloy

Aluminium Alloy O

Aluminium Alloy

Aluminium Alloy

Aluminium Alloy

Aluminium Alloy

Aluminium Alloy

Aluminium Alloy O

Aluminium Alloy

1

/

8

1

/

8

5

/

32

5

/

32

3

/

16

5

/

32

3

/

16

1

/

8

5

/

32

–

–

–

–

1

/

8

5

/

32

1

/

8

5

/

32

1

/

8

1

/

8

1

/

8

5

/

32

5

/

32

3

/

16

3

/

16

1

/

8

5

/

32

3

/

16

1

/

8

5

/

32

5

/

32

3

/

16

3.81

3.81

3.81

3.81

3.81

3.81

3.81

3.81

3.81

1.95

4.11

2.00

4.11

3.81

3.81

3.81

3.81

1.17

1.17

3.81

0.84

0.84

0.25

0.25

1.9

2.36

2.46

2.03

2.03

2.03

2.03

7.87

7.87

7.87

7.87

7.87

7.87

7.87

7.87

7.87

6.35

6.35

7.62

7.62

7.87

7.87

7.87

7.87

5.08

5.08

5.08

6.6

6.6

8.13

8.13

4.75

6.35

7.92

7.87

7.87

7.87

7.87

07346-03000

07346-03100

07346-03100

07346-03200

07346-03200

07346-03100

07346-03200

07346-03100

07346-03200

71213-04000

71213-04700

71213-04100

71213-04800

07346-03300

07495-03600

07495-03000

07346-03400

07495-03700

07346-03500

07495-03800

07346-04000

07346-04100

07346-04200

07346-04500

07346-04500

07346-04600

07346-04600

PART Nº

07340-00213

07340-00213

07340-00213

07490-04602

07490-04602

07340-00213

07490-04602

07340-00213

07490-04602

07340-00213

07340-00213

07340-00213

07340-00213

07340-00213

07490-04602

07340-00213

07490-04602

07340-00229

07340-00229

07340-00213

07340-00229

07340-00229

07498-04401

07498-04401

07340-00229

07340-00229

07498-04401

07340-00229

07340-00229

07498-04401

07498-04401

PART Nº

07345-03600

07345-03700

07345-03700

07345-03800

07345-03800

07345-03700

07345-03800

07345-03700

07345-03800

71213-16401

71213-16402

2

71213-16403

71213-16404

2

07345-03700

07345-03800

07345-03700

07345-03800

07345-03301

07494-03601

07494-03011

07345-03401

07494-03701

07345-03501

07494-03801

07165-00701

07165-00702

07165-00703

07345-04701

07345-04701

07345-04701

07345-04701

3.2

3.2

4.0

4.0

4.8

4.0

4.8

3.2

4.0

4

4

5

5

3.2

4.0

3.2

4.0

3.2

3.2

3.2

4.0

4.0

4.8

4.8

3.2

4.0

4.8

3.2

4.0

4.0

4.8

AVEX

®

BULBEX

®

AVINOX

®

II

AVSEAL

®

II

STAVEX

®

AVDEL

®

MBC

®

MBC

®

L/C

…001

…004

…004

…010

…010

…004

…010

…004

…010

…160

…180

…161

…181

…004

…010

…004

…010

…283

…284

…285

…288

…289

…293

…294

…300

…305

…310

…320

…320

…327

…327

RIGHT-ANGLE SWIVEL HEAD capability

1

In inches then in millimetres.

2

Long nose tip for deep placing. O

Oversize

COMPLETE TOOL PART NUMBER :

precede with 71223-40

(the stop nut and safety cap are included)

IMPORTANT:

in contrast to complete tools

with nose assemblies, those fitted with swivel

heads include the nose tip as a part of the head.

7.6

32

20

52

56

74

97

A

B

360

°

rotation

07346-03100

07346-03200

07346-03100

07346-03200

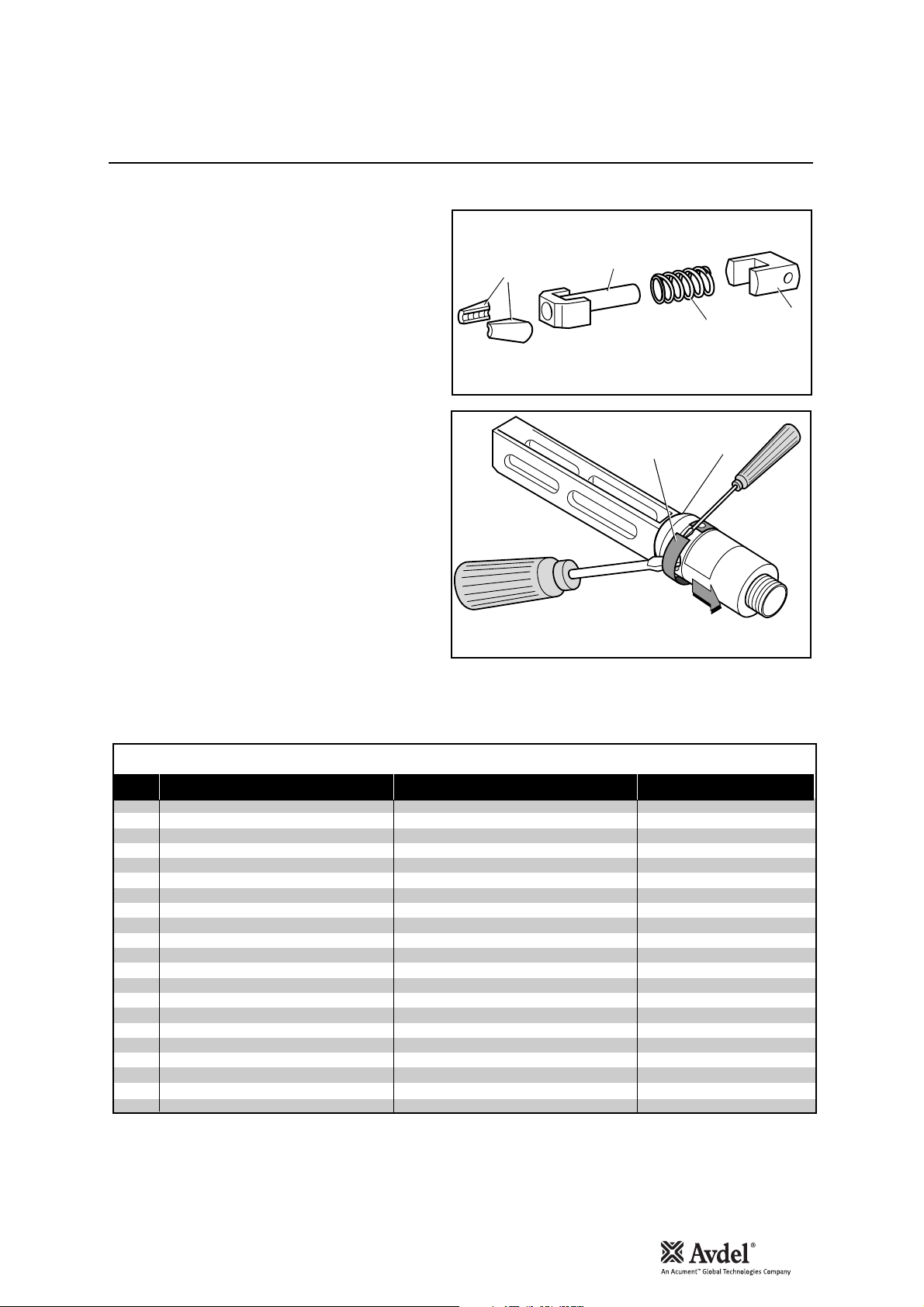

41 12 40 52

19

15

36

View with 25 removed

and stop nut

replacing removed

items 19, 15, 52, 40

71213-20200

STOP NUT

71213-20201

SAFETY CAP

• Disconnect the air supply.

• Remove any nose assembly items.

• Remove Stem Collector Bottle Assembly 25

(71213-03800).

• Replace assembly 25 with Safety Cap

(71213-20201)

• Unscrew Jaw Spreader Housing 41 and

remove with ‘O’ Ring 12, Locknut 40*, ‘O’

Rings 19* and 15*, and Seal Housing 52*.

Do not refit these items (*).

• Screw Stop Nut (71213-20200) onto the

front of Head Piston 36 as far as it will go by

hand.

• Fit Jaw Spreader Housing 41 and ‘O’ Ring 12,

tighten onto Head Piston 36, finally tighten

Stop Nut against Jaw Spreader Housing 41.

The tool is now ready to be fitted with a

swivel head, see page below.

Item numbers in bold refer to the general

assembly drawing and parts list on pages 26 and

27.

Base tool to receive a nose assembly

Base tool to receive a swivel head

Preparing the Base Tool for Right-Angle and Straight Swivel Head Attachment

Accessories

15

English

16

Accessories

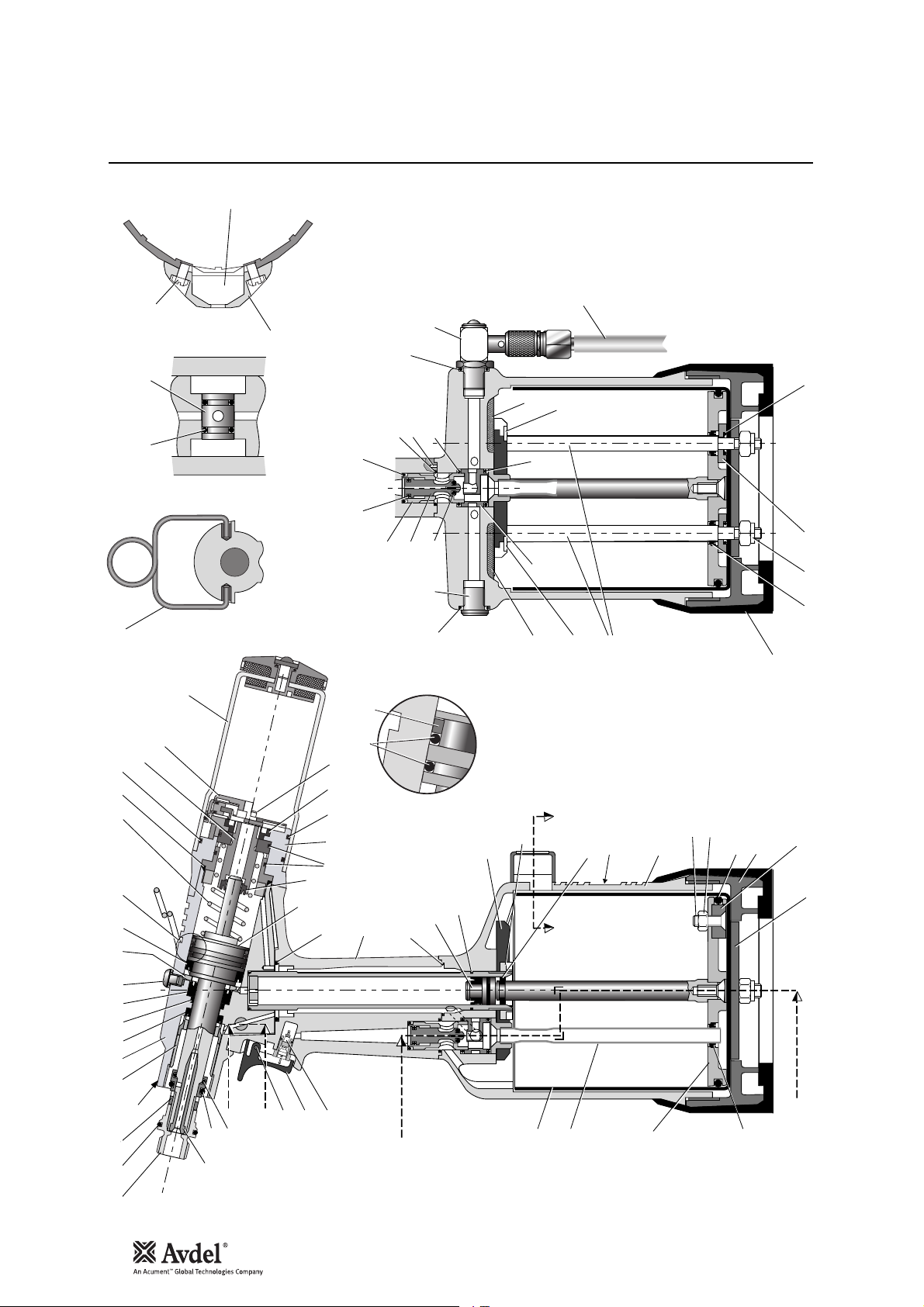

The fitting and servicing procedures for both types of head are almost identical. Differences are clearly indicated.

IMPORTANT

PRIOR to fitting a swivel head, the base tool must be adapted. See Preparing the base tool opposite.

The air supply must be disconnected when fitting or removing swivel heads.

A Fit Locking Ring 10 over Jaw Spreader Housing 41*

(71210-02101). *See pages 26 and 27.

B Coat Screw 13 with thread locking adhesive and use to

secure Nose Tip 14 onto Body 5.

C Lightly lubricate items 17, 18, 19, 20 and insert into

Jaw Carrier 3 as shown. Secure with Screws 16.

D Position Lever 4 into Body 5 and hold in place with pin

15 through the hole of Body 5 (not a slot).

E Lubricate the sides of the Jaw Carrier Assembly and

insert into Body 5.

F Lubricate Rollers 8 and ENSURE that they will freely

rotate in the holes of Adaptor 9. If necessary ream the

holes.

G Position Spring Clip 7 over Adaptor 9 past the holes for

the rollers and rotate until the locating peg is aligned

with the corresponding hole in Adaptor 9 (smallest

hole).

H Fit Adaptor 9 over the end of Body 5 and drop Rollers 8

into place. Push Spring Clip 7 over Rollers 8.

I Insert Spindle 11 through Adaptor 9 into Jaw Carrier 3

until the hole lines up with slot in Body 5. Temporarily

hold in place with Pin 6.

J Insert Pin 12 through the front slot of Body 5 into Jaw

Carrier 3.

K Hold the assembly vertical to prevent all pins dropping

out and slide the jaw carrier assembly back and forth a

few times to ensure free movement. Go to M

.

L Remove Screws 23 (4 off) and guard 1. On a straight

swivel head also remove Screw 21 and Platform 22.

M Push Pin(s) 6 out and let Spindle 11 drop out. Screw

Spindle 11 onto the Jaw Spreader Housing of the tool,

leaving the small screw fixing hole uppermost for

straight swivel. Tighten gently with a tommy bar.

N Screw the assembly over Spindle 11 onto the tool

handle. Replace Pin(s) 6.

O On straight swivel heads attach Platform 22 onto the

top of the Spindle with Screw 21. Deburr the back end

of Platform 22 so that it cannot catch on Guard 1.

P Snap Guard 1 over the assembly, align screw holes in

guard with tapped holes in body assembly.

Q Insert Pivot Pin 15 through slots in guard and hole in

body. Fit Circlip 2 onto pivot pin so that the circlip seats

in groove provided.

R Coat the thread of Screws 23 (4 off) with thread locking

adhesive and screw into body assembly securing guard

to body assembly.

Swivel Head Fitting Instructions

The following procedure will allow you to assemble and fit either of the swivel heads to the tool. If you order a complete swivel head

rather than individual components, you will only need to start at stage ‘L’.

All moving parts should be lubricated. Unless stated otherwise use Moly Lithium grease (details page 18).

When on grey tint, instructions refer only to the right-angle swivel head. Item numbers in bold refer to illustrations below.

16

1

3

12

14

13

16

6

5

21

22

11

7

9

8

8

8

10

17

18

19

20

STRAIGHT SWIVEL HEAD

2

1

15

9

8

8

10

7

11

17

23

18

19

20

3

16

16

4

12

14

13

6

6

5

RIGHT-ANGLE HEAD

Swivel Head Servicing Instructions

Accessories

5

7

17

18

19

20

Swivel heads should be serviced at weekly intervals.

• Remove the complete head using the reverse procedure to

the ‘Fitting instructions’ omitting step ‘L’.

• If Guard 1 is at all damaged it must be replaced by a new

one.

• Any worn or damaged parts should be replaced.

• Pay particular attention to jaw carrier items in the upper

illustration opposite as follows:

Check wear on Jaws 17.

Check that Jaw Spreader Tube 18 is not distorted.

Check that Spring 19 is neither broken or distorted.

Check that Spring Guide 20 is not damaged.

• Check that spring clip 7 is not distorted. When removing

Spring Clip 7, use two screwdrivers as shown in the lower

illustration opposite.

• Check for excessive wear on slots of Body 5.

• Assemble according to fitting instructions.

Item numbers in bold refer to Swivel Head illustrations on

this page. Guard 1 refers to illustration on page 16.

While nose tips and jaws will vary for each swivel head, other components remain constant within each type of head. See table below

For nose tips and jaws part numbers see within the table on pages 9 to 12.

CONSTANT COMPONENTS

ITEM DESCRIPTION STRAIGHT SWIVEL RIGHT-ANGLE SWIVEL

1

2

3

4

5

6

7

8

9

10

11

12

13

15

16

18

19

20

21

22

23

GUARD

CIRCLIP

JAW CARRIER

LEVER

BODY

PIVOT PIN

SPRING CLIP

ROLLER

ADAPTOR

LOCKING RING

SPINDLE

DOWEL PIN

SCREW

PIVOT PIN

SCREW

JAW SPREADER

SPRING

SPRING GUIDE

SCREW

PLATFORM

SCREW

07494-05000

-

07494-03026

-

07494-03015

07343-02207

07495-03900

07007-00039

07345-03001

07345-03003

07345-03002

07007-00038

07342-02207

-

07494-03028

07346-03101

07165-00305

07494-03027

07001-00368

07345-00401

-

07495-03003

07004-00105

07494-03026

07495-03004

07495-03002

07343-02207

07495-03900

07007-00039

07345-03001

07345-03003

07345-03002

07007-00038

07342-02207

07343-02207

07494-03028

07346-03101

07165-00305

07494-03027

–

–

07210-00804

17

English

18

Servicing the Tool

• Daily, before use or when first putting the tool into service, pour a few drops of clean, light lubricating oil into the air inlet of the tool

if no lubricator is fitted on air supply. If the tool is in continuous use, the air hose should be disconnected from the main air supply

and the tool lubricated every two to three hours.

• Check for air leaks. If damaged, hoses and couplings should be replaced.

• If there is no filter on the pressure regulator, bleed the air line to clear it of accumulated dirt or water before connecting the air hose

to the tool. If there is a filter, drain it.

• Check that the nose assembly or swivel head is correct for the fastener to be placed.

• Check the stroke of the tool meets the minimum specification (page 5). The last step of the Priming Procedure on page 29 explains

how to measure the stroke.

• Either a stem collector or a stem deflector must be fitted to the tool unless using a swivel head.

• Check that Base Cover 31 is fully tightened onto Body 30.

• Stem Collector Bottle: ‘O’ Rings 20 and 28 to be checked for wear, cleaned and lubricated with Molykote

®

55m.

• Dismantle and clean the nose assembly with special attention to the jaws. Lubricate with Moly Lithium grease before assembling.

• Check for oil leaks and air leaks in the air supply hose and fittings.

Grease can be ordered as a single item, the part number is shown in the Service Kit page 19.

First Aid

SKIN:

As the grease is completely water resistant it is best removed with an approved emulsifying skin cleaner.

INGESTION:

Ensure the individual drinks 30ml Milk of Magnesia, preferably in a cup of milk.

EYES:

Irritant but not harmful. Irrigate with water and seek medical attention.

Fire

FLASH POINT: Above 220°C.

Not classified as flammable.

Suitable extinguishing media: CO

2

, Halon or water spray if applied by an experienced operator.

Environment

Scrape up for burning or disposal on approved site.

Handling

Use barrier cream or oil resistant gloves

Storage

Away from heat and oxidising agent.

Item numbers in bold refer to the general assembly drawing and parts list on pages 26 and 27.

IMPORTANT

Read Safety Instructions on page 4.

The employer is responsible for ensuring that tool maintenance instructions are given to the appropriate personnel.

The operator should not be involved in maintenance or repair of the tool unless properly trained.

The tool shall be examined regularly for damage and malfunction.

Daily

Weekly

Moly Lithium Grease EP 3753 Safety Data

Molykote

®

55m Grease Safety Data

First Aid

SKIN:

Flush with water. Wipe off.

INGESTION:

No first aid should be needed.

EYES:

Flush with water.

Fire

FLASH POINT: Above 101.1°C. (closed cup)

Explosive Properties: No

Suitable Extinguishing Media: Carbon Dioxide Foam, Dry Powder or fine water spray.

Water can be used to cool fire exposed containers.

Environment

Do not allow large quantities to enter drains or surface waters.

Methods for cleaning up: Scrape up and place in suitable container fitted with a lid. The spilled product produces an extremely

slippery surface.

Harmful to aquatic organisms and may cause long-term adverse effects in the aquatic environment. However, due to the physical

form and water - insolubility of the product the bioavailability is negligible.

Handling

General ventilation is recommended. Avoid skin and eye contact.

Storage

Do not store with oxidizing agents. Keep container closed and store away from water or moisture.

First Aid

SKIN:

No first aid should be needed.

INGESTION:

No first aid should be needed.

EYES:

No first aid should be needed.

INHALATION:

No first aid should be needed.

Fire

FLASH POINT: Above 101.1°C. (closed cup)

Explosive Properties: No

Suitable Extinguishing Media: Carbon Dioxide Foam, Dry Powder or fine water spray.

Water can be used to cool fire exposed containers.

Environment

No adverse effects are predicted.

Handling

General ventilation is recommended. Avoid eye contact.

Storage

Do not store with oxidizing agents. Keep container closed and store away from water or moisture.

Molykote

®

111 Grease Safety Data

Servicing the Tool

19

English

20

Service Kit

For an easy complete service, Avdel

®

offers the complete service kit below.

PART Nº DESCRIPTIONPART Nº DESCRIPTION

SERVICE KIT : 71210-99990 Spanners are specified in inches and across flats unless otherwise stated

07900-00667 PISTON SLEEVE

07900-00692 TRIGGER VALVE EXTRACTOR

07900-00670 BULLET

07900-00672 'T' SPANNER

07900-00706 'T' SPANNER SPIGOT

07900-00684 GUIDE TUBE

07900-00685 INSERTION ROD

07900-00351 3 MM ALLEN KEY

07900-00469 2.5 MM ALLEN KEY

07900-00158 2 MM PIN PUNCH

07900-00224 4 MM A/F ALLEN KEY

07900-00734 STOP NUT - MAXLOK

07900-00164 CIRCLIP PLIERS

07900-00008

7

/16 x

1

/2 SPANNER

07900-00012

9

/16 x

5

/8 SPANNER

07900-00015

5

/8 x

11

/16 SPANNER

07900-00686 PEG SPANNER

07900-00677 SEAL EXTRACTOR

07900-00698 STOP NUT

07900-00700 PRIMING PUMP

07992-00020 GREASE - MOLY LITHIUM E.P.3753

07992-00075 GREASE - MOLYKOTE 55M

07900-00755 GREASE - MOLYKOTE 111

®

®

®

®

Servicing the Tool

Maintenance

The airline must be disconnected before any servicing or dismantling is attempted unless specifically instructed otherwise.

It is recommended that any dismantling operation be carried out in clean conditions.

Before proceeding with dismantling, empty the oil from the tool following the first three steps of the ‘Priming Procedure’ on page 28.

Prior to dismantling the tool it is necessary to remove the nose equipment. For instructions see the nose assemblies section, pages 9

to 12 or if a swivel head was fitted pages 14 and 15.

For a complete service of the tool, we advise that you proceed with dismantling of sub-assemblies in the order shown.

After any dismantling REMEMBER to prime the tool and to fit an appropriate nose assembly or swivel head.

(Annually or every 500,000 cycles whichever is the soonest)

Annually or every 500,000 cycles the tool should be completely dismantled and new components should be used where worn,

damaged or recommended. All ‘O’ rings and seals should be renewed and lubricated with Molykote

®

55m grease for pneumatic

sealing or Molykote

®

111 for hydraulic sealing.

IMPORTANT

Read Safety Instructions on page 4.

The employer is responsible for ensuring that tool maintenance instructions are given to the appropriate

personnel.

The operator should not be involved in maintenance or repair of the tool unless properly trained.

Nose Equipment

• Unscrew Nose Casing 1 and Nose Tip.

• Unscrew Jaw Housing 3 and remove Jaws 4, Jaw Spreader 5, Spring 7 and Buffer 6.

• Inspect all components. Renew all damaged or worn parts.

• Clean all parts and apply Moly Lithium Grease EP 3753 (07992-00020) to taper bore of Jaw Housing.

• Insert Jaws 4, Jaw Spreader 5, Spring 7 and Buffer 6 into Jaw Housing 3 and assemble onto Jaw Spreader Housing 41*.

• Screw Nose Tip into Nose Casing and tighten.

Item numbers in bold refer to Nose Tip Tables on pages 9 to 12.

41* refers to illustration on page 25.

Dismantling the Tool

Servicing the Tool

Before dismantling the tool the oil must be emptied from it.

• With the air supply switched OFF at ON/OFF Valve Assembly 62 remove Bleed Screw 1 and Bonded Seal 6.

• Insert tool over a suitable container, switch air supply ON and actuate tool.

• Oil will expel from bleed screw orifice into container.

• Switch air supply OFF after all oil is expelled.

This operation must have the Bleed Screw orifice facing away from the person performing this operation.

• Twist and pull off Stem Collector Bottle Assembly 25. See illustration on page 7.

• Remove Stop Plate Assembly 104 by unscrewing Screws 89 2 off.

• Unscrew Retaining Nut 50.

• Pull off Bottle Adaptor Assembly 32 together with ‘O’ Rings 20 and 28.

• Remove End Cap Assembly 35 together with ‘O’ Ring 97 and Lip Seal 9.

• Remove Spring 91.

• Loosen Locknut 40 with a spanner* and unscrew Jaw Spreader Housing 41 together with ‘O’ Ring 12.

• Remove Locknut 40 together with ‘O’ Rings 19 and 15, withdraw Vacuum Sleeve 42..

• Push Head Piston 36 to the rear and out of Head Assembly 58 taking care not to damage the cylinder bore

• Using circlip pliers* remove Seal Retainer 43. Push Lip Seal 8 and Bearing Tape 26 to the rear and out of Head Assembly 58 taking

care not to damage the cylinder bore.

• Remove Seal Housing 52 and Lip Seal 2.

Assemble in reverse order noting the following points:

• Place Lip Seal 8 onto the insertion rod* ensuring correct orientation. Locate the guide tube* into the head of the tool and push the

insertion rod* with the seal in place through the guide tube*. Pull the insertion rod* out and then the guide tube*.

• The chamfered edge of Seal Retainer 43 must face forward with the gap at the bottom.

• After fitting Lip Seal 11, ‘O’ Rings 18 and Bearing Tape 27 onto the Head Piston 36 ensuring correct orientation, lubricate the cylinder

bore and place the piston sleeve* into the back of Head Assembly 58. Slide the bullet* onto the threaded part of Head Piston 36 and

push the piston with the seals through the piston sleeve* as far as it will go. Slide the bullet* off the piston and remove piston sleeve*.

• Jaw Spreader Housing 41 must be fully tightened onto Head Piston 36 before tightening Locknut 40 against it.

• Reprime in accordance with the instructions on page 29.

* Item included in the nG3 Service Kit. For complete list see page 20.

Item numbers in bold refer to the general assembly drawing and parts list on pages 26 and 27.

Head Assembly

21

English

22

• Remove ‘ON/OFF’ valve assembly 62.

• Clamp the body of the inverted tool ACROSS THE AIR INLET BOSSES in a vice fitted with soft jaws.

• Pull off Rubber Boot 48.

• Using the peg spanner* unscrew Base Cover 31.

• Unscrew Nyloc Nuts 67 (2 off) and remove Base Plate Assembly 65.

• Remove Cylinder Liner 37 together with Sealing Washers 29 (2 off) and ‘O’ Rings 66 (2 off).

• Remove Pneumatic Piston Assembly 57 together with ‘O’ Ring 75, Lip Seal 90 (3 off) and Guide Ring 51.

• Engage the Seal Extractor* into Seal Assembly 63 and withdraw Seal Assembly from intensifier tube of the Head Assembly 58.

Assemble in reverse order to dismantling.

* seals should be checked for damage and replaced as necessary. Lubricate Pneumatic seals with Molykote

®

55m Grease and Hydraulic

seals with Molykote

®

111 Grease.

Dismantling

•

Remove Pneumatic Piston Assembly 57 as described above in Pneumatic Piston Assembly.

• Using Spanner (07900-00672), and Location Spigot (07900-00671). Unscrew Clamp Nut 39 and remove together with Top Plate

Assembly 44 together with Tie Rods 56, Transfer Tube Assembly 61, ‘O’ Rings 14 and Silencer 53.

• Remove tool from vice and separate Body 30 from Handle Assembly 64. Remove ‘O’ ring 17.

• Push out the Valve Seat 34, from the Body 30, together with ‘O’ Rings 14.

• Pull out Valve Spool Assembly 59 from Handle Assembly 64. Remove ‘O’ Ring 7 from handle counterbore.

Assembly

Assemble in reverse order to Dismantling Instructions

• Seals should be checked for damage and replaced if necessary, lubricated with Molykote

®

55M Grease.

• Apply Loctite

®

243 to Clamp Nut 39 and tighten to torque 11ftlb (14.91 Nm)

IMPORTANT

Check the tool against daily and weekly servicing.

Priming is ALWAYS necessary after the tool has been dismantled and prior to operating.

* Item included in the nG3 Service Kit. For complete list see page 20.

Item numbers in bold refer to the general assembly drawing and parts list on pages 26 and 27.

Pneumatic Piston Assembly

Servicing the Tool

Air Valve

Servicing the Tool

Dismantling

• Using a 4mm pin punch (07900-00158) drive Trigger Pin 46 out and remove Trigger Assembly 33.

• Remove Pneumatic Piston Assembly 57 as described in Pneumatic Piston Assembly, see page 22.

• Using Spanner (07900-00672), and Location Spigot (07900-00671), unscrew Clamp Nut 39 and remove together with Top Plate

Assembly 44 together with Tie Rods 56, Transfer Tube Assembly 61, Seperate Body 30 from Handle Assembly 64. Remove ‘O’

Rings 16 and 17.

• Seperate Head Assembly 58 from Handle Assembly 64. NOTE ORIENTATION OF ROTARY VALVE 38

• Push out Rotary Valve 38 together with ‘O’ Rings 5.

Assemble in reverse order to Dismantling Instructions noting the following:

• Seals should be checked for damage and replaced if necessary, lubricated with Molykote

®

55m grease.

• Ensure Rotary Valve 38 is assembled in correct orientation, align pins with forks on the Trigger 33.

See illustration below.

Rotary Valve

Dismantling

• Using a 4mm pin punch (07900-00158) drive Trigger Pin 46 out and remove Trigger 33.

• Unscrew Trigger Valve 21 using trigger valve extractor (0900-00692).

Assemble in reverse order to Dismantling Instructions noting the following:

• When assembling Trigger 33 the trigger forks locate on the pins each side of the Rotary Valve 38.

• Ensure Rotary Valve 38 is orientated correctly. See illustration below.

Trigger

38

33

Item numbers in bold refer to the general assembly drawing and parts list on pages 26 and 27.

23

English

24

CLOSED

OPEN

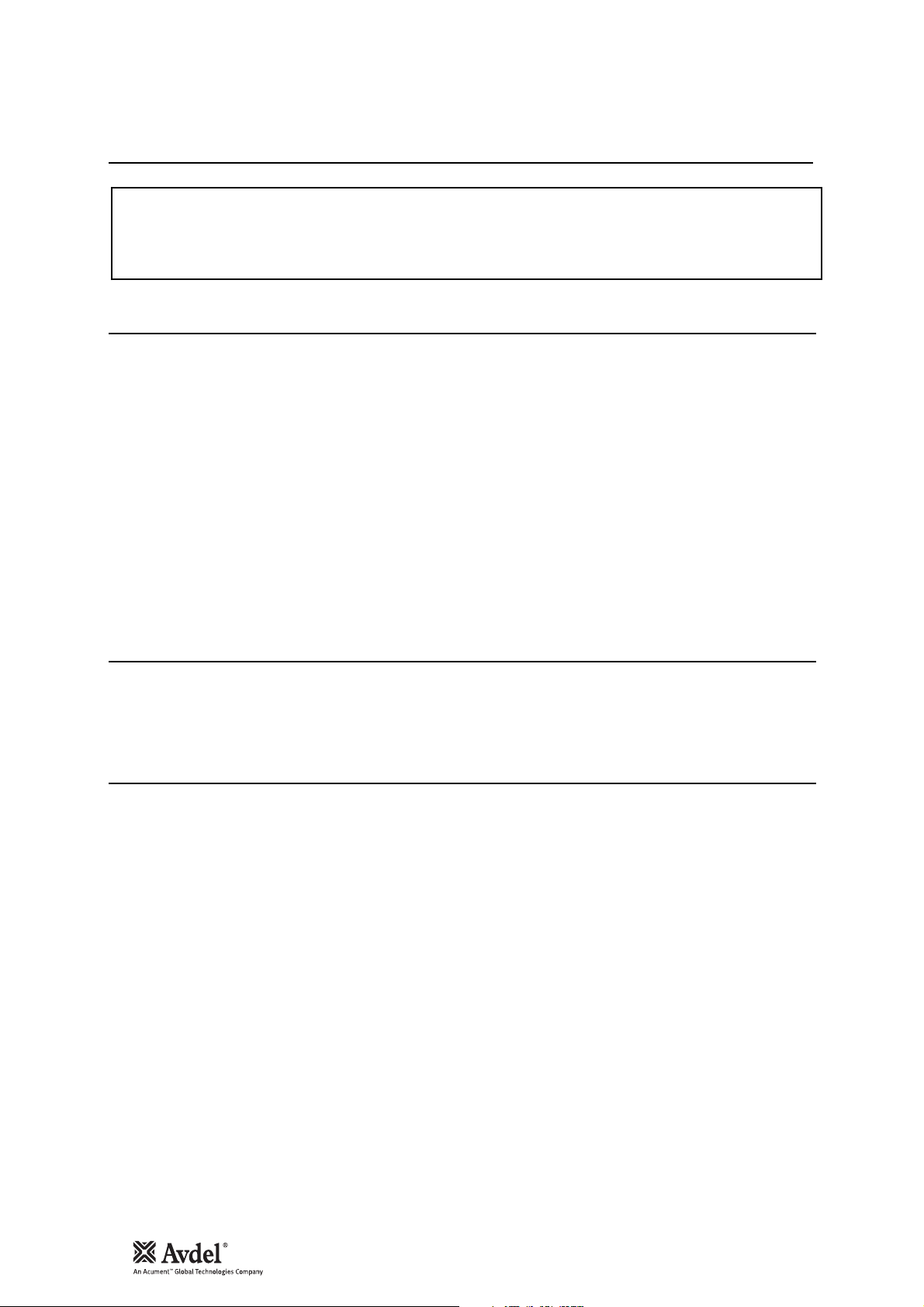

Stop Plate Assembly (71213-03900)

Servicing the Tool

Assembly (see illustration below)

• Place ‘O’ Ring 2 into the recess in Housing 5 retain in position using grease Molykote

®

55.

• Assemble ‘O’ Ring 4 onto Piston 1 and push assembly into Housing 5 making sure it is in as far as it will go.

• Position the slot in Piston 1 parallel to the step face in Housing 5.

• Slide Plate Shut Off 3 into the assembled parts 1, 2, 4, and 5. Retain parts in place using grease Molykote

®

55.

• Place ‘O’ Ring 4 into the recess of Cover Plate 6 retain in position using grease Molykote

®

55.

• Place spring 7 into position locate using the recesses in both Plate Shut Off 3 and Bottle Adaptor Assembly 32*.

• Position the above assembled parts onto Bottle Adaptor Assembly 32*.

• Secure in position using two Screws 89*.

*see pages 26 and 27.

1 PISTON

2 ‘O’ RING

3 PLATE SHUT OFF

4 ‘O’ RING

5 HOUSING

6 COVER PLATE

7 SPRING

ITEM DESCRIPTION

2

1

3

4

4

5

6

7

32*

89*

Notes

25

English

26

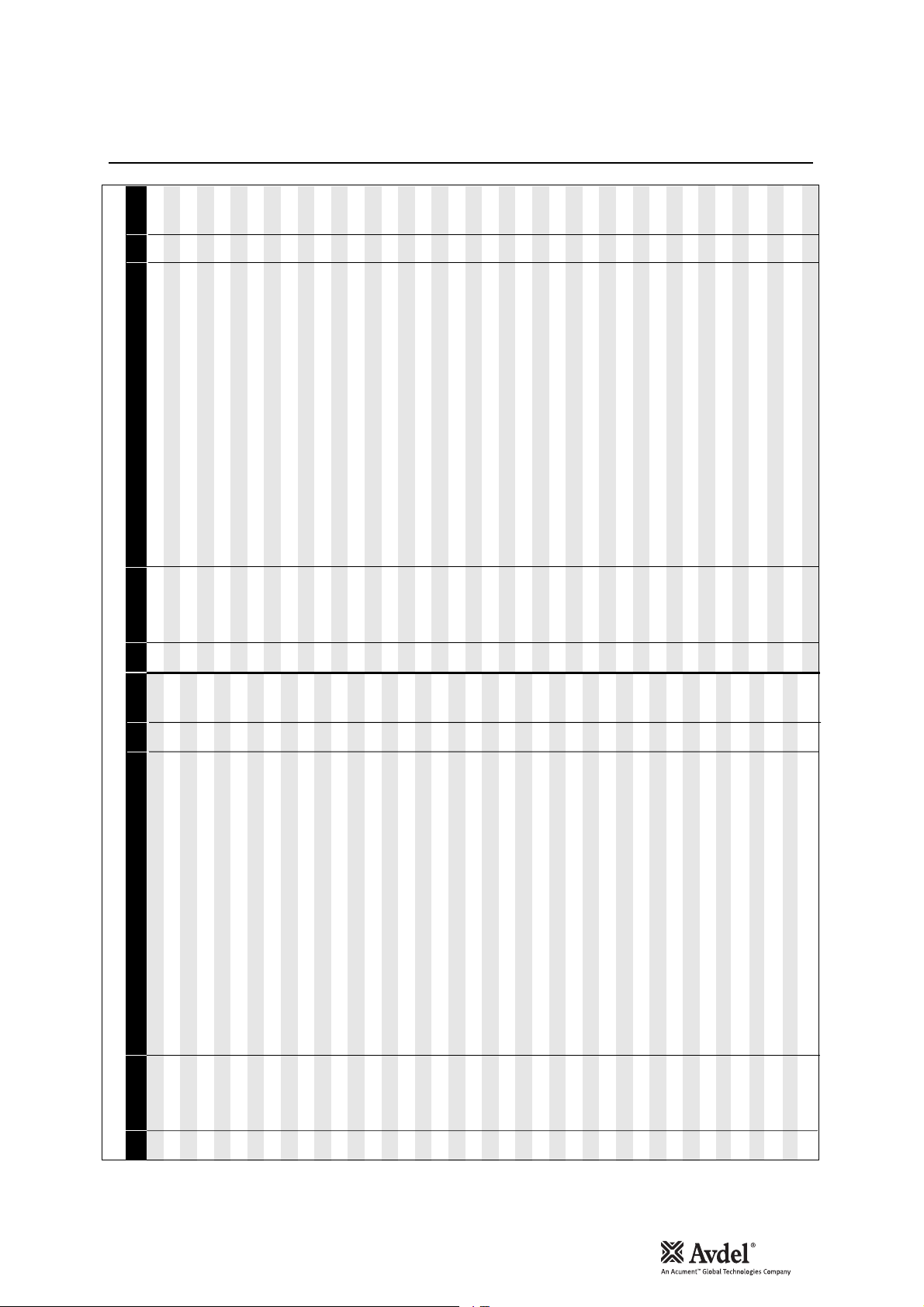

General Assembly of Base Tool 71223-02000

B - B

A - A

385

49

30

31

75

17

16

A

A

Assy 61

37

Assy 57

90

39

44

51

B

B

41 12 40 1,6 4352

Assy

58

2 8

17

64 Assy

21

46

Assy 33

42

19

15

35 Assy

36

9

91

13

28 11

'X'

26

A

8920

104 Assy

25 Assy

50

79

80

65 Assy

53

14

53

34

14

7

98

99

Assy 59

96

4

22

14

23

62 Assy

24

56

48

90 67 29 66

77

97 32

100

4

76

76

Suspension

Ring

H - H

45

71

74

73

72

HH HH

Detail 'X'

27

18

63 Assy

Parts List for 71223-02000

01

02

04

05

06

07

08

09

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

07001-00405

07003-00333

07003-00127

07003-00189

07003-00194

07003-00271

07003-00273

07003-00274

07003-00341

07003-00277

07003-00278

07003-00281

07003-00204

07003-00287

07003-00288

07003-00342

07003-00310

07003-00415

07005-00088

07005-01274

07008-00010

07007-00224

71213-03800

71213-02021

71213-02022

07003-00416

71221-02006

71223-02001

71221-02002

71213-03000

71213-02008

71210-02009

71213-02025

71223-02121

71221-02008

71213-02012

71210-02014

71210-02103

71210-02101

71220-02102

M5x5 HEX SOCKET BUTTON HD BLEED SCREW

LIP SEAL

'O' RING

'O' RING

M5 BONDED SEAL

'O' RING

LIP SEAL

LIP SEAL

LIP SEAL

'O' RING

'O' RING

'O' RING

'O' RING

'O' RING

'O' RING

'O' RING

'O' RING

'O' RING

TRIGGER VALVE

1/8" BSP PLUG

6" FLEXIBLE HOSE

3mm DIAx10mm SPIROL PIN

STEM COLLECTOR BOTTLE ASSEMBLY

BEARING TAPE - PISTON ROD

BEARING TAPE - PISTON

'O' RING

SEALING WASHER

BODY MACHINED

BASE COVER

BOTTLE ADAPTOR ASSEMBLY

TRIGGER ASSEMBLY

VALVE SEAT

END CAP ASSEMBLY

HEAD PISTON

CYLINDER LINER

ROTARY VALVE

CLAMP NUT

LOCKNUT

JAW SPREADER HOUSING

VACUUM SLEEVE

1

1

2

2

1

1

1

1

1

1

1

3

1

1

2

2

1

1

1

1

1

2

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

43

44

45

46

48

49

50

51

52

53

56

57

58

59

61

62

63

64

65

66

67

71

72

73

74

75

76

77

79

80

89

90

91

96

97

98

99

100

103

104

71210-02019

71213-02010

71210-02022

71210-02024

71221-02007

71223-02027

71213-02028

71210-03205

71210-02104

71210-02031

71221-02004

71221-03210

71213-03320

71210-03400

71230-03600

71210-03700

71210-03800

71213-02013

71221-02014

07003-00027

07002-00108

71221-20105

71221-20101

71221-20103

71221-20102

07003-00280

07002-00163

07007-01993

71221-20104

07002-00098

07001-00677

07003-00274

07490-03002

07003-00268

07003-00398

07003-00042

71210-03401

07007-01503

07900-00842

71213-03900

SEAL RETAINER

TOP PLATE ASSEMBLY

SUSPENSION RING

TRIGGER PIN

RUBBER BOOT

LABEL

RETAINING NUT

GUIDE RING

SEAL HOUSING

SILENCER

TIE ROD

PNEUMATIC PISTON ASSEMBLY

HEAD ASSEMBLY

VALVE SPOOL ASSEMBLY

TRANSFER TUBE ASSEMBLY

ON/OFF VALVE ASSEMBLY

INTENSIFIER SEAL ASSEMBLY

HANDLE ASSEMBLY

BASE PLATE ASSEMBLY

'O' RING

M6 NYLOC NUT

MODIFIED COUNTER

COUNTER MOULDING

MOULDING RETAINING NUT

SPECIAL M4 SCREW

'O' RING

WASHER

CENTRE POLE MAGNET

M5 X 19 COUNTERSUNK SCREW

M5 NYLOK NUT

SCREW

LIP SEAL

SPRING

'O' RING

'O' RING

'O' RING

VALVE BODY

LABEL BOOK SYMBOL

TOOL INSTRUCTION MANUAL

STOP PLATE ASSEMBLY

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

2

2

1

1

2

2

1

2

1

1

1

2

3

1

1

2

1

1

1

1

1

ITEM PART Nº DESCRIPTION ITEM PART Nº DESCRIPTION

71223-02000 PARTS LIST * These are minimum recommended levels of spares based on regular servicing

QTY SPARES

QTY SPARES

27

English

28

Priming

Priming is ALWAYS necessary after the tool has been dismantled and prior to operating. It may also be necessary to restore the full stroke

after considerable use, when the stroke may be reduced and fasteners are not fully placed by one operation of the trigger.

The recommended oil for priming is Hyspin

®

VG32 available in 0.5 litre (part number 07992-00002) or one gallon containers (part number

07992-00006). Please see safety data below.

First Aid

SKIN: