Page 1

FCC Part 15.247

Transmitter Certification

Direct Sequence Spread Spectrum Transmitter

Test Report

FCC ID: UID-WRMTM5

FCC Rule Part: 15.247

ACS Report Number: 06-0200-15C

Manufacturer: Sercomm

Applicant: ARRIS International, Inc.

Model: TM552 WRM

Installation Guide

5015 B.U. Bowman Drive Buford, GA 30518 USA Voice: 770-831-8048 Fax: 770-831-8598

Page 2

Q

TM552 WRM INSTALLATION GUIDE

n

s

)

WORKING INSTRUCTION

組裝段

機種別/版本 文件編號

MODEL NAME/REV. Doc. NO.

TM552 WRM M3-701-C06VPA023

1.Confirm 5M checklist before assembly: 5M(manpower,machine,material,method,measurement), any abnormal, please inform the line leader.

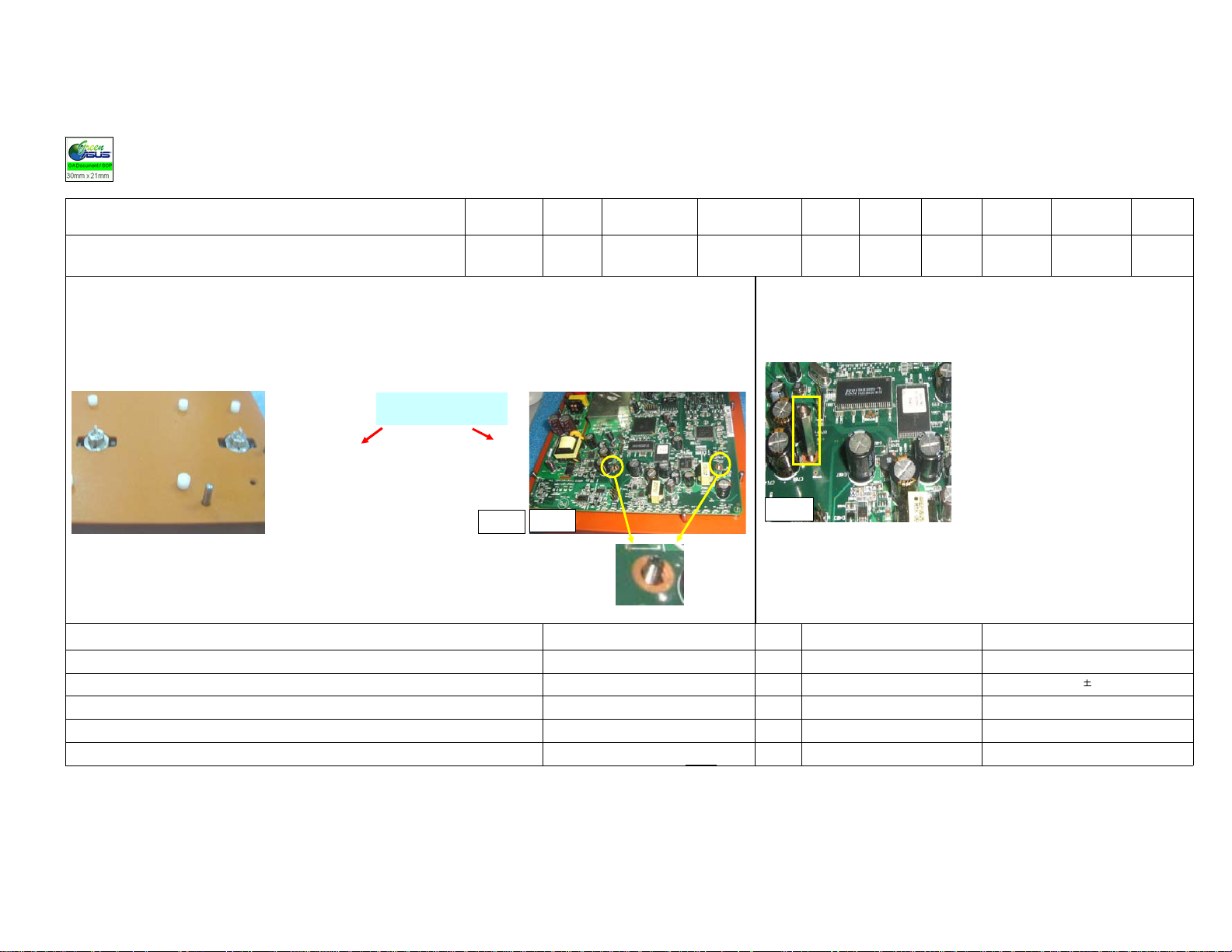

2.Take two screws and check if any damages on the them. If not, put the two screws onto the fixture with screw head down. (Photo 1)

3.Put the motherboard on the fixture. Let two screws on the fixture already go through the through holes of the motherboard. (Photo 2)

Put the 2 screws with screw

head down on the fixture

作業名稱 : 鎖主板

站別/站數 作業人數 安全防護 文件版本 發行日期 擬案 機構會簽 製造組長會簽 核准

Station NO. Person Safety Protection Doc. Rev. Issue Date Prepared Approved2 Approved2 Approved1

2/12 1

wear ESD gloves and

wrist strap,button

slevees

主件料號:80-BETNGN-00P

REV02 2006/9/6 Laurie Wang

4.Take two metal stand offs and make sure there is no damage on them. If so, put the metal

stand offs onto the two screws and use hex driver to fasten them. (Photo 3)

5. Confirm 5S checklist after operate,any abnormal inform line leader.

Photo 1

料號

Part NO.

13GMAPXD050W screw Assembly fixture

13GB4710M510-1 metal stand off

Photo 2

品名

Descriptio

數量

2

2

耗材(品名/料號/規格)

T

Consumers

治工具(品名/料號/規格)

Fixture &Tool

Hex driver (Torque:2.8, 0.2kg.f*cm, #5 driver

head

photo 3

Page 3

p,

Q

工作指導書

n

s

WORKING INSTRUCTION

組裝段

機種別/版本 文件編號

MODEL NAME/REV. Doc. NO.

TM552 WRM M3-701-C06VPA023

1.Confirm 5M checklist before assembly: 5M (manpower, machine, material, method, measurement), if any abnormal, please inform the line leader.

2. Take WRM and check whether any missing or scratch on the WRM to make sure the pins of LAN JACK, antenna connecter & reset button

are good. Also make sure that solder side is not scrathced or the WRM FW and S/N label is legible, if anything defect, just put it into defect

box.

3.Take 1 plastic stand off and inspect it to make sure no bending and no scratched. And then, fasten the small foot of the plastic stand off to the

bottom side of WRM (Photo 1)

4.Get the WRM and carefully aim at the 2x 12 pin holes to the pin header (location on P601) on the mother board and then plug the pins into

the holes.

作業名稱 : 組裝网卡&主板

站別/站數 作業人數 安全防護 文件版本 發行日期 擬案 機構會簽 製造組長會簽 核准

Station NO. Person Safety Protection Doc. Rev. Issue Date Prepared Approved2 Approved2 Approved1

3/12 1

wear ESD gloves

and wrist

stra

button slevees

主件料號:80-BETNGN-00P

REV02 2006/9/6 Laurie Wang

5. Click the other end of plastic stand off to the through hole near RJ-11 on the mother

board (photo 3).

6. Align the PTH of the WRM with the two metal stand offs.(Photo 4)

Plug the plastic

stand off in

Photo 1

Small foot

2x 12 pin holes on WRM

Photo 2

料號

Part NO.

13GB4710P560-1 plastic stand off

品名

Descriptio

2 x 12 Pin

header (P601)

Photo 3

Photo 4

7. Check whether the plastic stand was opposite after inserting.Check method:

(1)VI the size of plastic stand's two ends

(2)Whether end is loose when plastic stand off is pluged to WRM and to mother

board, it

shows it's plugged upside down.

數量

1

耗材(品名/料號/規格)

T

Consumers

治工具(品名/料號/規格)

Fixture &Tool

Page 4

p,

Q

工作指導書

n

s

g

)

WORKING INSTRUCTION

組裝段

機種別/版本 文件編號

MODEL NAME/REV. Doc. NO.

TM552 WRM M3-701-C06VPA023

1.Confirm 5M checklist before assembly: 5M (manpower, machine, material, method, measurement), if any abnormal, please inform the line leader.

2.Take the assembled WRM and mother board from the production line,check whether the plastic stand off is clipped good, the 2x12 pins are

plugged good (all the pins need to go through the holes.) (Photo 1)

3.Get two screws and put them to the PTH of the WRM. Use electric screw driver to fasten the screws. (Photo 2)

作業名稱 : 鎖网卡&主板

站別/站數 作業人數 安全防護 文件版本 發行日期 擬案 機構會簽 製造組長會簽 核准

Station NO. Person Safety Protection Doc. Rev. Issue Date Prepared Approved2 Approved2 Approved1

4/12 1

wear ESD gloves

and wrist

stra

button slevees

fasten screws on

主件料號:80-BETNGN-00P

REV02 2006/9/6

Laurie Wang

4.Modify the torgue value of electric screw driver before operating.

5.Put the locked board on the production line.

6.Confirm 5S checklist after operate,any abnormal inform line leader.

Photo 1

料號

Part NO.

13GMAPXD050W screw assembly fixture

04G030002100 WRM

Descriptio

品名

Photo 2

數量

2

1

耗材(品名/料號/規格)

T

Consumers

治工具(品名/料號/規格)

Fixture &Tool

electric screw driver (torque:2.8

0.2k

.f*cm,#1 screw driver head

圖二

Page 5

NOTICE TO USER

h

e

g

.

y

g

n

.

d

p

FCC Class B:

“NOTE: This equipment has been tested and found to comply wit

the limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation.

This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interferenc

will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of

the following measures:

Reorient or relocate the receivin

Increase the separation between the equipment and receiver

Connect the equipment into an outlet on a circuit

different from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for

help.”

Warning: Changes or modifications to this device not expressly

approved by ARRIS International, Inc. could void the user’s

authorit

to operate the equipment.

RF Exposure

In accordance with FCC requirements of human exposure to

radiofrequency fields, the radiating element shall be installed such

that a minimum separation distance of 20cm shall be maintained

from the user and/or

IC:

This Class B digital apparatus meets all requirements of the

Canadian Interference Causing Equipment Regulations. Operatio

is subject to the following two conditions:(1) this device may not

cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause

undesired operation

eneral population

antenna.

Cet appareillage numérique de la classe B répond à toutes les

exigences de l'interférence canadienne causant des règlements

d'équipement. L'opération est sujette aux deux conditions

suivantes: (1) ce dispositif peut ne pas causer l'interférence

nocive, et (2) ce dispositif doit accepter n'importe quelle

interférence reçue, y compris l'interférence qui peut causer

l'opération peu désirée.

NOTES:

1

This device has been designed to operate with the antennas liste

below, and having a maximum gain of 1.8dBi. Antennas not

included in this list or having a gain greater than 1.8dBi are strictly

prohibited for use with this device. The required antenna

edance is 50 ohms.

im

2

To reduce potential radio interference to other users, the antenna

type and its gain should be so chosen that the equivalent

isotropically radiated power (EIRP) is not more than that required

for successful communication. The approved antennas used with

this device are 1. C147-510023-A and 2. C66-510003-A.

Loading...

Loading...