Page 1

User s

Manual

Page 2

276

TABLE OF CONTENTS

1. GENERAL INFORMATION

2. OPERATING INSTRUCTIONS

3. USEFUL INFORMATION

-2-

IMPORTANT!

Please read this manual carefully.

For additional information, please consult the

“Installation and Servicing Instructions.”

Make sure to keep the manuals provided with

the appliance so that they can be used by the

end-user, installer or our authorised engineer.

Every attempt has been made to avoid

errors of any kind in this User's Manual, the

Management invites customers to inform of

any inaccuracies which they may find.This

will help to improve our service.

Page 3

276 -3-

Dear Customer,

Thank you for choosing an ARISTON boiler.

We guarantee that your boiler is a reliable and technically sound

product.

This User's Manual provides detailed instructions and

recommendations for proper installation, use and maintenance.

Remember to keep this manual in a safe place for future reference.

Your local MTS Servicing Centre is at your complete disposal for all

requirements.

GROUP

GUARANTEE

The guarantee on this appliance is valid for 12 months from

the first day of installation.

Repairs to the electric, water or gas circuits may be carried

out only by your local authorised MTS Servicing Centre.

Page 4

276

-4-

GENERAL DATA

Thermal Capacity min/max kW 8 / 24 8 / 24

Usable Thermal Power min/max (30/40°C) kW 8.8 / 26.1 8.8 / 26.1

Usable Thermal Power min/max (60/80°C) kW 7.9 / 23.3 7.9 / 23.3

Usable Thermal Power min/max (30/50°C) kW - / 24.5 - / 24.5

Power for Hot Water Production min/max kW 7.9 / 23.3 7.9 / 23.3

Efficiency at Nominal Thermal Capacity (60/80°C) % 97.3 97.3

24 MFFI 24 RFFI SYSTEM

TECHNICAL INFORMATION

Page 5

276 -5-

CENTRAL HEATING

Temperature min/max (High Temperature range) °C 42 / 82 42 / 82

Temperature min/max (Low Temperature range) °C 30 / 75 30 / 75

Maximum Heating Pressure bar 3 3

Expansion Vessel Capacity l 7 7

DOMESTIC HOT WATER

Temperature min/max °C 36 / 56 36 / 56

Pressure of Water for Domestic Use min/max bar 0.2 / 8-10 0.2 / 8-10

Heating Temperature min/max (Low Temperature range) °C 30 / 75 30 / 75

Temperature of Water for Domestic Use min/max °C 36 / 56 36 / 56

Flow Rate ∆T=30°C l/min 11.1 N/A

Flow Rate ∆T=35°C l/min 9.6 N/A

Page 6

276

ELECTRICAL DATA

Electrical Supply V/Hz 230/50 230/50

Power Consumption W 130 130

Protection of Electrical System IP 4XD 4XD

CATEGORY

Nominal Pressure/Natural Gas (G20) (boiler at maximum) mbar 20 20

Nominal Pressure/LPG (G30-31) (boiler at maximum) mbar 30 30

-6-

24 MFFI 24 RFFI SYSTEM

TECHNICAL INFORMATION (CONT’D)

Page 7

276 -7-

1. GENERAL INFORMATION

This is a combined appliance for the production of central heating (C.H.) and

domestic hot water (D.H.W.).

This appliance must be used only for the purpose for which it is designed.

The manufacturer declines all liability for damage caused by improper or

negligent use.

Do not allow children or inexperienced persons to use the appliance without

supervision.

If you smell gas in the room, do not turn on light switches, use the telephone or

any other object which might cause sparks.

Open doors and windows immediately to ventilate the room.

Shut the gas mains tap (on the gas meter) or the valve of the gas cylinder and

call your Gas Supplier immediately.

If you are going away for a long period of time, remember to shut the mains gas

tap or the gas cylinder valve.

Before any intervention within the boiler it is first necessary to cut off the

electrical power supply by turning the external switch to “OFF”.

This manual may be kept in the front panel of the boiler.

Page 8

276

-8-

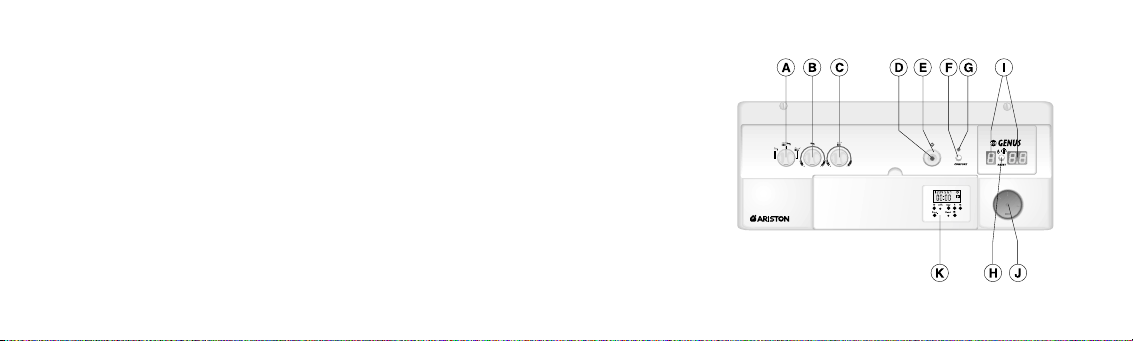

CONTROL PANEL

A. Selector Knob for

Summer/Winter/Flue Test Modes

B. Domestic Hot Water Temperature

Adjustment Knob

C. Central Heating Temperature

Adjustment Knob

D. On/Off L.E.D.

E. On/Off Knob

F. "COMFORT"/Heating Only

Function Push-button

G. “COMFORT"/Heating Only

Function L.E.D.

H. Reset Button

I. Multi-function Display

J. Heating System Pressure Gauge

K. Time Clock

Page 9

276 -9-

HELPFUL SUGGESTIONS

To get the most out of your boiler, we have provided you with some useful advice on

proper use and maintenance:

- Periodically check the system pressure using the pressure

gauge “J” and make sure that the pressure is between 1.0 and

1.5 bar (the blue part on the gauge) when the system is off and

cool.If the pressure is below the minimum recommended value,

the pressure must be brought into the acceptable range.Consult

your installer for checking and refilling the system.

If the pressure level drops on a frequent basis, it is likely that there is a water leak

in the system. If this is the case, your installer must inspect the system.

2. OPERATING INSTRUCTIONS

CAUTION

Installation, start-up, adjustments and maintenance must be performed by

a competent person only in accordance with the current Gas Safety

(Installation & Use) Regulations and the instructions provided. Improper

installation may cause damage or injury to individuals, animals and

personal property,for which the manufacturer will not be held liable.

To ensure efficient and safe operation it is recommended that the boiler is

serviced annually by a competent person.

If it is known or suspected that a fault exists on the appliance, it must not

be used until the fault has been corrected by a competent person.

J

Page 10

276 -10-

- The outer panels of the boiler's case must only be cleaned with a damp cloth,

do not use abrasive cleaners. The Control panel can be wiped with either a

damp or dry cloth. Spray polishes must not be used on the control panel

surface or knobs. Care must be taken in preventing any liquid entering the

appliance.

- If the water is exceptionally hard, install a water softener so that the efficiency

of the boiler remains the same over time, as this will consume less gas.

- To improve comfort levels and take full advantage of the heat produced by the

boiler, it is recommended that an external thermostat be installed.

A programmable timer for the thermostat is also recommended to schedule

when the boiler will turn on and off during the course of the day (or week), and

an outdoor sensor to optimise operating times.

- When the boiler is not in use for prolonged periods shut it down by pushing

button “E”, the red light “D” will go out; close the gas and water isolation

valves.

I

MPORTANT!

This will disable the anti-frost device - if the period of disuse is very cold it will

also be necessary to drain the heating system of water.

If you wish to leave the anti-frost device active, it is necessary to leave the

boiler on: this will not safeguard from possible "blocks" which may impair this

function.

- It is good practice to clean and service the appliance and central heating

system every year.

Call an Authorised Service Centre.

Page 11

276 -11-

code.

To reset the ignition system, the reset button “H”

must be pressed. Should the system fail to light a

second time, check to make sure that the gas cock

is open. If the problem persists, contact one of our

Authorised Service Centres.

Before starting the boiler, check the following:

- The water pressure on the pressure gauge “J”;

- That the gas cock and the inlet for domestic water are

open.

These models are equipped with electronic ignition which

utilises contact ionisation.

T o mak e the boiler oper ational, simply press theswitch “E”.

The red L.E.D.“D” will then tur n on. At this point the boiler

is ready for use: a centralised electronic control unit will automatically light the

main burner when needed without any intervention from the outside.If the burner

does not light within the pre-set safety time limit, the display will show an error

START-UP PROCEDURE

E

J

H

Page 12

Installation without an external thermostat:

- Turn on the power supply to the boiler by pressing the

switch “E”; the red L.E.D.“D” will then turn on;

- Turn the “A” selector knob to < >;

- Regulate the temperature of the heating system water in

the boiler by turning the “C” knob.The temperature can

vary between 42°C and about 82°C;

276

-12-

WINTER AND SUMMER OPERATING MODES

The boiler is fitted with a selector knob “A” which allows

you to switch between winter < > and summer < >

operating modes and vice versa

When the knob is set to < >, the boiler can serve the

dual purpose of providing heat or hot water for domestic

use. The supply of domestic hot water always takes

precedence over central heating.

When the knob is set to < >, the boiler cuts out the heating

system and only provides domestic hot water (when needed).

TURNING ON THE HEATING

A

E

D

Page 13

276 -13-

Installation with an external thermostat:

- Turn the “A” selector knob to < >;

- Turn on the power supply to the boiler by pressing the switch

“E”; the red L.E.D.“D” will then illuminate;

- Turn the thermostat knob “C” to the highest temperature

setting.

- In this instant the boiler is controlled by a time clock and

outdoor sensor; COMO (programmable thermostat) with or without an outdoor

sensor; CCM with or without outdoor sensor i.e depending on internal or

external temperature. At that point, the main burner will turn off and the

circulation pump will stop (if a pump overrun period has not been set, see

section 3.6.6. of the “I

NSTALLATION INSTRUCTIONS”).

- The temperature of the heating system water in the boiler

can be regulated on the alpha-numerical display. With this

type of installation, the heating thermostat acts on ambient

temperature directly.

H

A

C

C

Page 14

276

-14-

TURNING OFF THE HEATING

ENERGY SAVING SUGGESTIONS

To improve comfort and take full advantage of the heat produced by the boiler, it

is recommended that an external thermostat (remote control) be installed.

There are two control systems available:

- Timer and room temperature control only.

- Timer , room temperature and outdoor temperature sensor control.

Installation without an external thermostat:

To turn off the heating, turn the “A” selector knob to < >.The

boiler will still provide domestic hot water.

Installation with an external thermostat:

To turn off the heating, turn the “A” selector knob to < >.The

boiler will still provide hot water for domestic use. With an

external thermostat, there are a number of ways to turn off the

heating. For additional information, please consult the relative

manual.

A

A

Page 15

276 -15-

It is recommended that the temperature knob for the

domestic hot water is not set to a high temperature and

then mixed with cold water. Setting the thermostat to

medium temperature is preferable (see figure).

PRODUCTION OF DOMESTIC HOT WATER

Turn on the power to the boiler by pressing the switch “E”;

the red L.E.D.will then illuminate.

- With these settings, the boiler is already ready for use,

regardless of the position of the “A” selector knob.

- Turn the “B” knob to select the temperature for the hot

water (between 44°C and about 56°C depending on the

flow rate of the water).

ADJUSTING THE TEMPERATURE OF THE DOMESTIC HOT WATER

B B

Page 16

276

-16-

COMFORT FUNCTION 24 MFFI

HEATING ONLY BUTTON 24 RFFI SYSTEM

The supply of water for domestic use can become more

convenient by means of the “COMFORT” function, which

maintains the secondary exchanger at a preset temperature

when the boiler is not running; thereby allowing a quicker

delivery of domestic water when required. This function is

activated by pressing the “F” button on the control panel.

When the function is on, a green L.E.D.on the control panel will

illuminate.

N

OTE:If the “COMFORT” function is on during the pump overrun period, it will be temporarily

deactivated. The green L.E.D. will remain on to indicate that the boiler will resume the

“COMFORT” mode once the pump overrun period is complete.

This function can be activated by pressing the “F” button on

the control panel.When the function is on, a green L.E.D.on

the control panel will illuminate.This means that the external

cylinder is not kept at the set temperature and that only the

anti-frost protection is on.When the temperature falls below

5°C, the boiler ignites and heats the water until the

temperature exceeds 10°C.

F

F

Page 17

276 -17-

- Diagnostics Stage (precedes all other functions)

0 No Request for Heat

C Heating, Burner Off

C. Heating, Burner On

c Pump Overrun for Heating

d Water for Domestic Use, Burner Off

d. Water for Domestic Use, Burner On

h Pump Overrun for Water for Domestic Use

b Storage Cylinder, Burner Off (SYSTEM version)

b. Storage Cylinder, Burner On (SYSTEM version)

NOTE: the flashing dot on the left-hand display always indicates “burner off”;

the still dot indicates “bur ner on”.

The right-hand display (two-digit) shows:

- in heating mode: temperature of heating system flow;

- in domestic hot water mode: temperature domestic hot water.

SHUTDOWN PROCEDURE

To turn off the main burner, simply press the switch “E”;

the red L.E.D.“D” will then turn off. As a precautionary

measure, it is recommended that the gas cock located

on the bottom of the boiler, is also turned off.

When the system is operating, i.e. while the boiler is fulfiling its normal functions,the

left-hand display will show a series of letters indicating the following functions:

DISPLAY:VIEWING NORMAL FUNCTIONS

LEFT RIGHT

Page 18

276

-18-

TIME CLOCK

The steps marked with the symbol are necessary to carr y out a switching

program.

PREPARING FOR OPERATION

Activate the “Reset” switch to reset the time switch to its default settings (activate

using a pencil or similar pointed instrument). Do this:

- every time you wish to “Reset” the time switch;

- to erase all switching times and the current time of day

After approximately two seconds the following display appears:

Weekdays blinks

Input time Enter minutes

Enter

switching time

Summer and

winter time

setting

Reset

Enter weekdays

Enter the hour

Manual switch

Page 19

276 -19-

ENTER CURRENT TIME AND WEEKDAY

Keep the “ ” key pressed down. During the summer

time period press the +/-1h key once.

Enter the hour using the “h” key.

Enter the minutes using the “m” key.

Enter the day using the “Day”key.

1 = Mon ....... 7 = Sun

Release the “ ” key .

The colon now blinks once a second.

AM/PM

TIME DISPLAY

If you press the “+/-h” and “h” keys at the same time, the time display switches

into the AM/PM mode.

NOTE

: If you keep the “h” and “m”keys pressed down for more than 2 seconds,

the display will enter fast forward scroll mode.

ENTERING THE SWITCHING TIMES

If your entry is incomplete, the segments not yet

selected will blink in the display.

You have 20 memory locations available.Each switching

time takes up one memory location.

Keep pressing the “Prog” key until a free memory

location is shown in the display “-- : --”.

Program ON or OFF with the “”key:

“”= ON - “”= OFF.

Page 20

276 -20-

Enter the hour using “h”; enter the minutes using “m”.

If a switching command is to be carried out every day (1 2 3 4 5 6 7) then store

using the “”key, otherwise select the days it is to be carried out on by using

the “Day” key.

When the day selection is left blank, the programmed switching instruction

operates at the same time every day.

1 2 3 4 5 6 7 Monday ..... Sunday

1 2 3 4 5 6 Monday ..... Saturday

1 2 3 4 5 Monday ..... Friday

1 2 3 4 5 6 7 Saturday ..... Sunday

1 Monday

..... (selection of single days)

7 Sunday

Store using the “”key or push “Prog” key if you are going to continue

programming.The time switch enters the automatic operating mode and displays

the current time of day. Begin any further entr y of a switching time with the

“Prog” switch.

If necessary, once you have finished programming and have returned to the

current time display, by pressing the “”button, the timer will not automatically

switch to the current programmed status until the next timed setting.You can put

the timer into the correct mode with the “”key.

Page 21

276 -21-

ADDITIONAL FUNCTIONS

Switching from summer time to winter and vice versa.

Press the “+/-1h” key once.

M

ANUAL OVERRIDE KEY

With the “”key you can change the current switching settings at any time.

The switching program already entered is not altered.

= ON

= OFF

= OFF

= ON

= ON

= OFF

AUTOMATIC

OPERATION

MANUAL

OPERATION

CONTINUOUS

OPERATION

[ ]

The switching times

correspond to the program

entered.

If the current switching mode

is changed manually, the

next switching time will be

carried out automatically

again according to the

entered switching program.

You can only return to

automatic mode from the

continuously ON and

continuously OFF switching

modes by pressing the

“”key.

Page 22

276 -22-

Pressing the “Prog” key displays the programmed

switching times until the first free memory location

appears in the display “-- : --”.

If you now press the “Prog” key once again, the

number of free memory locations will be displayed,

e.g. “Fr 20”. If all memory locations are occupied, the

display “Fr 00” appears.

C

HANGING THE PROGRAMMED SWITCHING TIMES

Press the “Prog” key repeatedly until the switching time you want to change is

displayed. You can now enter the new data. See “E

NTERING THE SWITCHING TIMES”.

NOTES ON STORING SWITCHING TIMES:

If you end your entry of the switching times by pressing the “Prog” key, the

switching time you have entered will be stored and the next memory location

displayed.

Entry of further switching times is also carried out as described in “E

NTERING THE

SWITCHING TIMES”.

In addition, a complete switching command is stored automatically after around

90 seconds provided no other key is pressed.

The time switch then enters the automatic operating mode and displays the

current time again.

Page 23

276 -23-

3. USEFUL INFORMATION

BOILER SHUTDOWN

The boiler is equipped with safety devices which intervene in certain situations

to shutdown the boiler.Some of these situations are signalled by the boiler and

can be corrected by the user.

SHUTDOWN DUE TO IGNITION FAILURE

This anomaly is indicated by “A01” on the display.

To reset the boiler, press and then release the “H”

button.

At this point, the electronic ignition system will

attempt to light the burner again.

Should the boiler fail to ignite a second time,

check that the external gas cock is open.If the

problem persists, contact an Authorised

Service Centre.

DELETING INDIVIDUAL SWITCHING TIMES

Press the “Prog” key repeatedly until the switching time you wish to delete is

shown in the display.

Then set to “--” using the “h” or “m” key and keep the “”key pressed down

for around 3 seconds.

The switching time is now erased and the current time is displayed.

H

Page 24

276

SHUTDOWN DUE TO OVERHEATING

This anomaly is indicated by “E03” on the

display. The boiler has shutdown because the

safety thermostat detected that the boiler

temperature has exceeded the maximum limit.

To reset this state, wait until the boiler has

cooled and press the button “H”.

If the safety thermostat operates on a frequent

basis, contact one of our Authorised Service

Centres.

This anomaly is indicated by “A21” on the display.

One of the possible causes of this shutdown situation

could be the lack of water in the boiler or water

circulation failure in the primary heating circuit.

Check the system pressure on the pressure gauge “J”

and, if it is less than 0.5 bar, try bringing the system

pressure up to a mean value of 1.0 bar by opening the

water inlet valve.Then reset by turning the boiler off and

then back on by pressing the button “H”.

-24-

SHUTDOWN DUE TO INSUFFICIENT

WATER CIRCULATION

J

H

Page 25

276 -25-

If this situation persists, contact one of our Authorised Service Centres.

OTHER SHUTDOWN SITUATIONS

Should a shutdown situation indicated on the display by the following letters and

figures occur, E04, E05, E08, E20, E21, E22, E23, E56, E64, E66, E74, E99 contact one of

our Authorised Service Centres.

If instead the display shows one of the shutdown situations indicated by the

following letters and figures, A02, A03, A07, A19, A20, A22, A99, try resetting the boiler

by pressing the reset button “H”.If the boiler shuts off again, contact one of our

Authorised Service Centres.

H

Page 26

276

FLUE TEST FEATURE

(ONLY FOR AUTHORISED PERSONNEL)

The “A” Summer/Winter/Flue Test selector knob can be

set to < > to bypass temperature adjustment on the

heating circuit for the purpose of analysing the fumes

produced by combustion. To access this mode, open a

water tap so that the flow rate is no less than 8 litres per

minute. Then push the “A” selector knob in and turn it

from < > or < > to the < > position.

-26-

CAUTION!

The flue test function makes the boiler run continuously at its maximum power.

This condition should be used exclusively by authorised personnel.

TEST MODE

The P.C.B.allows for the boiler to be pushed at its maximum or minimum thermal

capacity. For the relevant information, refer to section 3.7.5.of the “INSTALLATION

INSTRUCTIONS”.

N.B. Should the boiler not be used for a long period of time, the condensate

trap must be filled up again before re-starting the boiler. Failure to add

water to the trap is dangerous because exhaust fumes could be released

into the environment.

A

Page 27

276 -27-

Page 28

23 99 84 1378 000

RAFICA E STAMPA SERIART - FABRIANO (AN) ITALIA TEL.0039+732+23069

Manufacturer: Merloni TermoSanitari SpA - Italy

Commercial subsidiary: MTS (GB) LIMITED

MTS Building

Hughenden Avenue

High Wycombe

Bucks HP13 5FT

Telephone: (01494) 755600

Fax:(01494) 459775

Technical Service Hot Line: (01494) 539579

Loading...

Loading...