Part Number:

Product

3915030 F/KIT 6172445

ARB SAHARA BAR

Description:

Suited to

TOYOTA TUNDRA YEAR MODELS 07 ON

vehicle/s:

WARNING

REGARDING VEHICLES EQUIPPED WITH SRS AIRBAG:

When installed in accordance with these instructions, the front protection bar does not affect operation of

the SRS airbag.

ALSO, NOTE THE FOLLOWING:

♦

This product must be installed exactly as per these instructions using only the hardware supplied.

♦

In the event of damage to any bull bar component, contact your nearest authorised ARB stockist.

Repairs or modifications to the impact absorption system must not be attempted.

♦

Do not use this product for any vehicle make or model, other than those specified by ARB.

♦

Do not remove labels from this bull bar.

♦

This product or its fixing must not be modified in any way.

♦

The installation of this product may require the use of specialized tools and/or techniques

♦ It is recommended that this product is only installed by trained personnel

♦

These instructions are correct as at the publication date. ARB Corporation Ltd. cannot be held

responsible for the impact of any changes subsequently made by the vehicle manufacturer

♦

During installation, it is the duty of the installer to check correct operation/clearances of all

components

♦

Work safely at all times

♦

Unless otherwise instructed, tighten fasteners to specified torque

ARB 4x4 ACCESSORIES

Corporate Head Office

42-44 Garden St Tel: +61 (3) 9761 6622

Kilsyth, Victoria Fax: +61 (3) 9761 6807

AUSTRALIA 3137

Australian enquiries sales@arb.com.au

North & South American enquiries sales@arbusa.com

Other international enquiries exports@arb.com.au

www.arb.com.au

Last Rev Date: 29/10/2008 Page 1 of 24 Fitting instructions# 3783321

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

GENERAL CARE AND MAINTENANCE

By choosing an ARB Bar, you have bought a product that is one of the most sought after 4WD products in

the world. Your bar is a properly engineered, reliable, quality accessory that represents excellent value.

To keep your bar in original condition it is important to care and maintain it following these

recommendations:

Prior to exposure to the weather your bar should be treated to a Canuba based polish on all exposed

surfaces. It is recommended that this is performed on a six monthly basis or following exposure to

salt, mud, sand or other contaminants.

As part of any Pre Trip Preparation, or on an annual basis, it is recommended that a thorough visual

inspection of the bar is carried out, making sure that all bolts and other components are torqued to the

correct specification. Also check that all wiring sheaths, connectors, and fittings are free of damage.

Replace any components as necessary. This service can be performed by your local authorised ARB

Stockist.

To maintain the polished alloy frame, wash and chamois dry regularly using car wash specific products

Polish the alloy surfaces with Briteshine® or similar products

Small scratches can be removed by using Autosol® metal polish or similar

FITTING REQUIREMENTS

REQUIRED TOOLS FOR FITMENT OF PRODUCT:

Metric socket and spanner sets 8-25mm range

Screwdrivers, Philips and Flat blade Dia 22.0 (7/8”) holesaw

Power Drill 13mm (1/2”) capacity Dia 7.0mm (5/16”) and 10.0mm (25/64”) drill bits

Allen (Hex) Key Set

Hacksaw Scriber Centre punch

Files, round, square and flat Hammer 300mm Rule

External Circlip pliers

HAVE AVAILABLE THESE SAFETY ITEMS WHEN FITTING PRODUCT

:

Protective eyewear

NOTE: ‘WARNING’ notes in the fitting procedure relate to OHS situations, where to avoid a

potentially hazardous situation it is suggested that protective safety gear be worn or a safe work

procedure be employed. If these notes and warnings are not heeded, injury may result.

Hearing protection

FASTENER TORQUE SETTINGS:

SIZE Torque Nm Torque lbft

M6 9Nm 7lbft

M8 22Nm 16lbft

M10 44Nm 32lbft

M12 77Nm 57lbft

Last Rev Date: 29/10/2008 Page 2 of 24 Fitting instructions# 3783321

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

OPTIONAL LIGHT SETS TO SUIT THIS PRODUCT:

♦

FOG LAMP SET P# 6821201, ADD FOR NON FACTORY FOG VEHICLES ONLY P#MD02 LOOM

KIT, P#180209 SWITCH AND P#180215 SWITCH CAP FOR FOGS

♦

UP TO IPF 900 SERIES FOG OR DRIVING LIGHT SETS

♦

IPF 840 FYS FOG LIGHTS CAN BE FITTED TO LOWER PAN AREA

AVAILABLE BUFFER/FRAME SETS:

♦

BUFFER SET ONLY, BLANK BUFFERS P#5100150 OR

♦ FRAME, P#5115030 FRAME ASSEMBLY PLUS P#5100140 BUFFER SET WITH HOLES

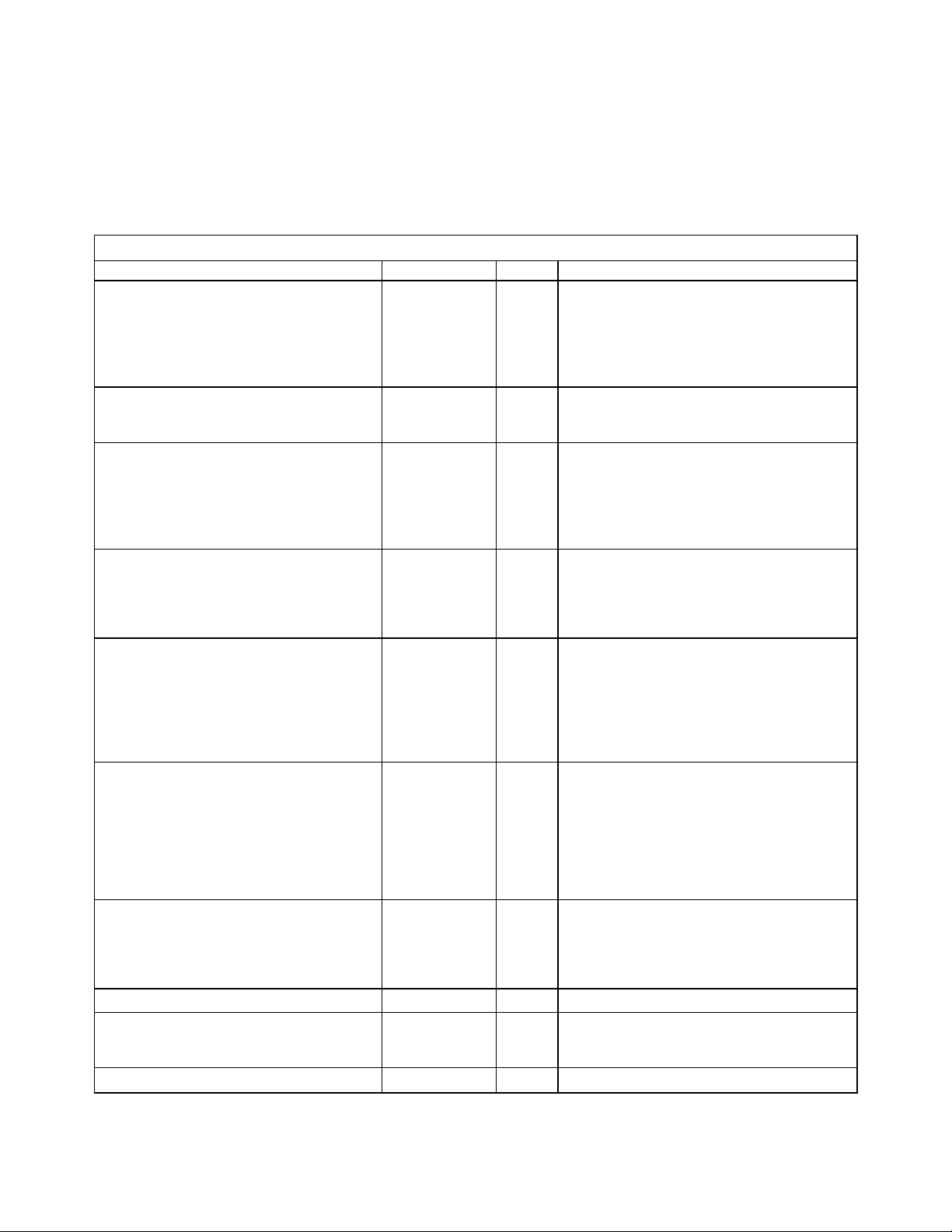

PARTS LISTING

APPLICATION. PART NO. QTY DESCRIPTION

Mount Brackets To Chassis

Brace Assembly

Bull Bar To Mount Bracket Assy

Stone Tray to Bull Bar

Light Surround To Bull Bar

Winch To Bull Bar

Winch Hole Cover Fitment

(If Not Fitting Winch)

Buffer fasteners

Number Plate To Bull Bar

Miscellaneous

3757559R

3757559L

6151428

6151429

6151396

5846400

4681264

6151357

6151321

6151357

6151321

6151255

6151189

4581049

4581050

6522677

6151303

6151234

4581063

4581047

3163015

6821151R

6821151L

6821152

180701

180302

6821192

3756499

6151234

4581045

4581047

6151132

180302

EG50

6151074

6151128

6151256

6191013

6522695

4581304

6151128 12 Nut M6 Flanged

6821189

6151384

6781408

3162152 2 Plug Blanking Dia 16

1

1

2

2

2

2

1

7

7

2

2

6

6

12

6

1

6

6

6

6

1

1

1

2

6

4

2

1

2

2

2

2

10

2

2

2

2

1

1

4

2

2

1

Bracket Mount RHS

Bracket Mount LHS

Flange Nut M12

Chassis Stud M12 x 265 x 1.75

Nut Clevis

Packer M12 x 8mm

Brace

SEMS Bolt M10 x 1.5 x 30mm

Nut Flanged M10 x 1.5

SEMS Bolt M10 x 1.5 x 30mm

Nut Flanged M10 x 1.5

Bolt M12 x 1.75 x 40mm

Nut M12 x 1.75

Washer Flat M12

Washer Spring M12

Stone Tray

Nut Cage 8mm

Bolt M8 x 25mm BZ

Washer Flat M8 x25.4 x 3

Washer Spring M8

Light Surround

Indicator Assembly RH

Indicator Assembly LH

Loom

Scotch Locks

Cable Tie

Bulb 12V 10W BA15S

Bracket Control Box Univ.

Bolt M8 x 25 BZ

Washer Flat M8 BZ

Washer Spring M8 BZ

Nut M8 Flanged

Cable Tie

Grommet Dia 50mm

Bolt 3/8 x 1 3/4

Nut Flange M6

Screw M6 St/Stl Button Head

Extrusion Winch Cover

Panel Winch Cover

Washer M6 st stl

Grommet round

Screw self tapping pan head

Tape double sided

Last Rev Date: 29/10/2008 Page 3 of 24 Fitting instructions# 3783321

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

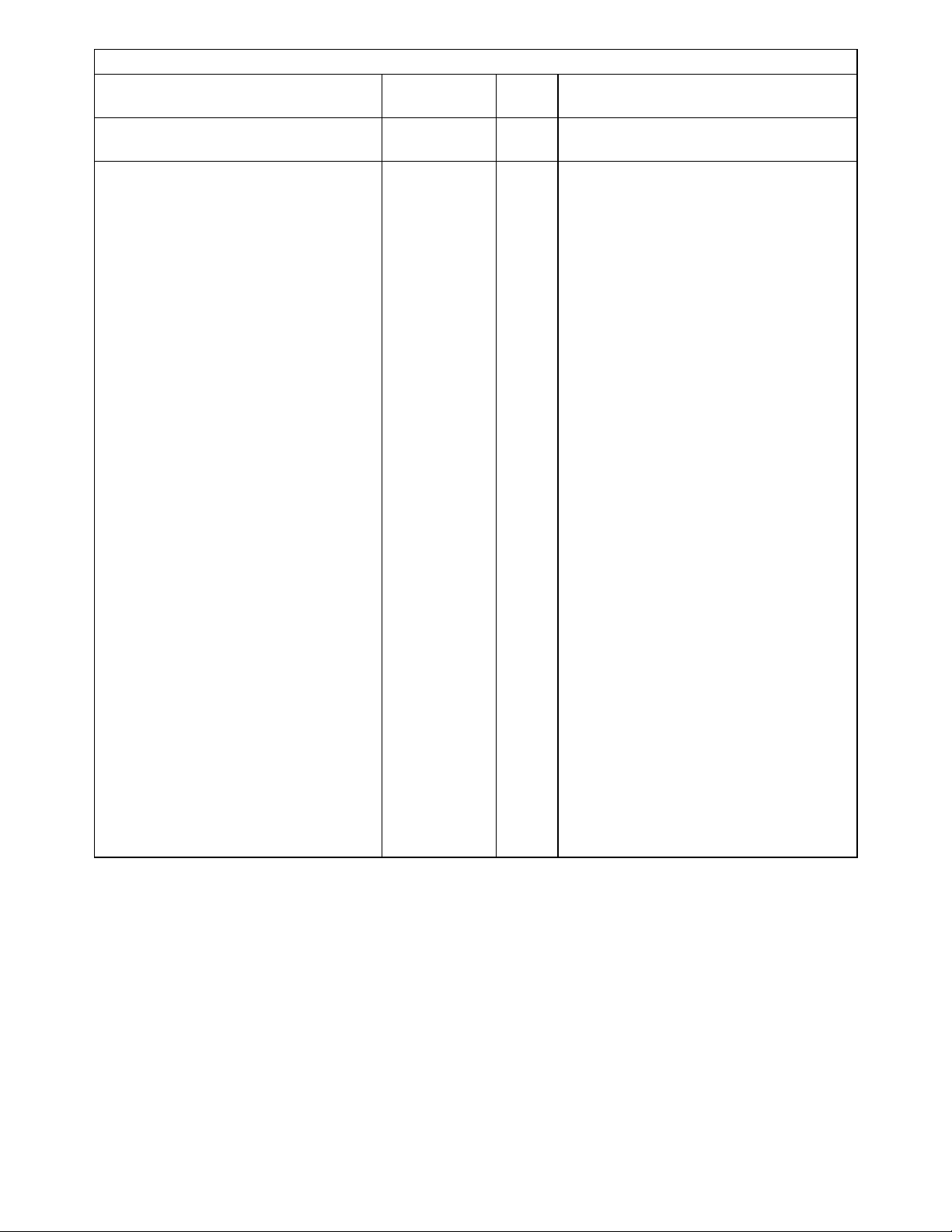

Opt: Blank Buffers Only Kit

P#5100150

Opt: Buffers Suit Frame

P# 5100140

Opt: Frame Assy

Kit P#5115030

NOTE:

♦

WHEN FITTING FRAME ASSEMBLY ONLY, LABEL FOR FRAME TILT OPERATION FOR HOOD

CLEARANCE MUST BE APPLIED TO TOP FACE OF SAHARA BUMPER IN THE POSITION IDENTIFIED

IN THESE FITTING INSTRUCTIONS. FAILURE TO APPLY THIS PERMANENT LABEL AT SAHARA

BUMPER FITMENT INDEMNIFIES ARB CORPORATION OF ANY LIABILITY ARISING FROM THE

OPERATION OR USE OF THIS PRODUCT.

♦

KIT CONTAINS M6 FLANGE NUTS TO SUIT FITMENT OF BUFFERS. WHEN FITTING FRAME

ASSEMBLY WITH BUFFERS, REQUIRED FITTING KIT COMPONENTS COME WITH FRAME.

♦

FACTORY FOGS CANNOT BE REUSED WITH THIS BAR, INSTEAD FIT ARB FOG LAMP KIT 6821201

(SEE NOTE P3).

PARTS LISTING CONT.

3163016R

3163016L

3163017R

3163017L

3757574R

3757574L

3757571

3757692

4581308

4581309

6151046

4581072

4581045

4581040

4581288

6151042

4581047

4581048

6151068

6151234

6151232

6151364

6151417

6151127

6151162

6151212

6151122

6151132

6151321

4558427

5670001

5670002

5670003

5670004

5670005

6564507

2125214

1 1 Buffer Large Sahara

Buffer Large Sahara

1 1 Buffer Large with hole Sahara

Buffer Large with hole Sahara

Bracket Hinge

1

Bracket Hinge

1

Bracket Wedge Pad Support

2

Bracket Slam Latch Operation

1

Washer Nylon 16.0 ID x 30 OD x 3

2

Washer Nylon 8.0 ID

1

Washer Flat M6

2

Washer Flat M6 Large

4

Washer Flat M8 BZ

6

Washer Flat M10

4

Washer Flat M10 Large

2

Washer Spring M6

2

Washer Spring M8 BZ

5

Washer Spring M10

6

Bolt ¼ UNC x 1”

2

Bolt M8 x 25 BZ

5

Bolt M10 x 30

2

Screw Cap M10 x 30 ZP

4

Screw M4 x 16 CSK HD ZP

4

Nut M4 Nyloc

4

Nut M6 Nyloc

4

Nut M8 Nyloc

1

Nut 5/16UNC

1

Nut M8 Flanged

4

Nut M10 Flanged

2

Link Arm Slam Latch

1

Striker

1

Latch Slam

1

Connector Clip 4mm Wire

2

Wedge Pad Urethane

2

Spring Lever Return

1

Bush Pivot Bracket

2

Sticker Frame Tilt Operation

1

Last Rev Date: 29/10/2008 Page 4 of 24 Fitting instructions# 3783321

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

REMOVAL OF BUMPER

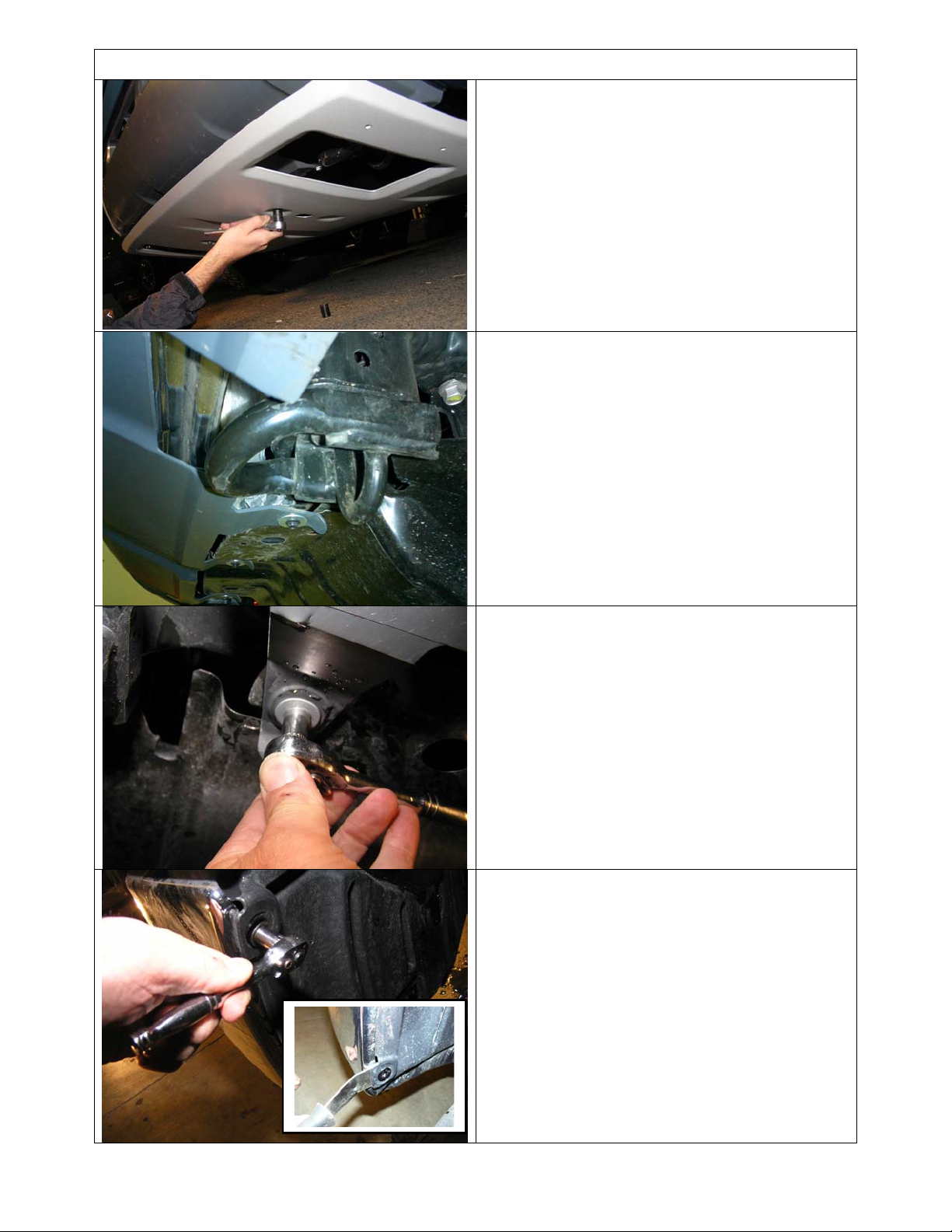

1. If fitted, remove factory bash plate

2. Remove tow hooks and bolts, set aside to be

refitted.

3. Remove lower bumper retaining screws.

4. Remove all lower fender liner retaining

screws to bumper.

Last Rev Date: 29/10/2008 Page 5 of 24 Fitting instructions# 3783321

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

REMOVAL OF BUMPER

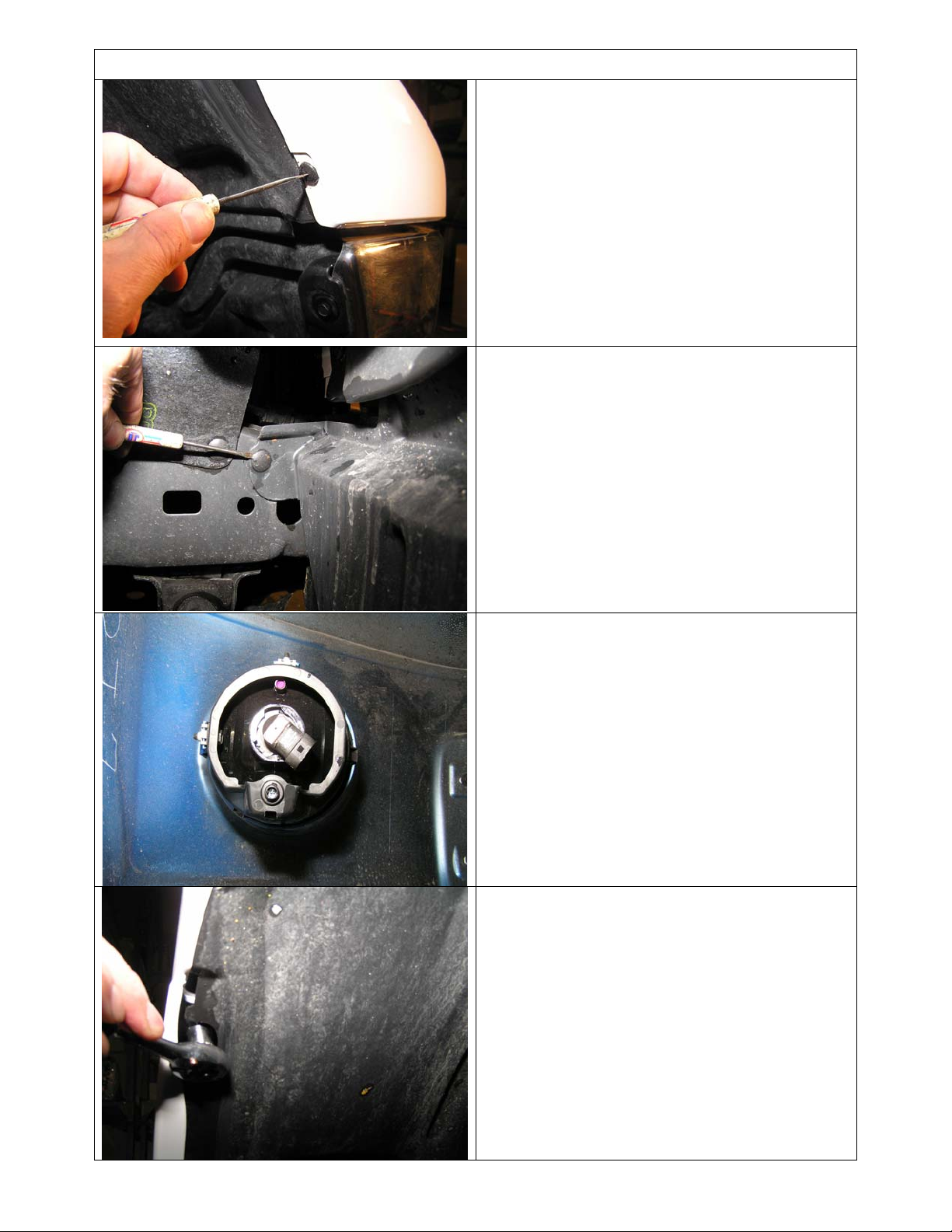

5. Remove upper fender liner retaining scrivets.

6. Prise out lower fender liner plastic push in

plugs. Remove lower fender liner completely,

they will not be reused.

7. If OE fog lights and/or parking sensors fitted

in bumper, undo electrical connections.

8. Remove bumper wing retaining screws in

upper wheel arch area.

Last Rev Date: 29/10/2008 Page 6 of 24 Fitting instructions# 3783321

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

REMOVAL OF BUMPER

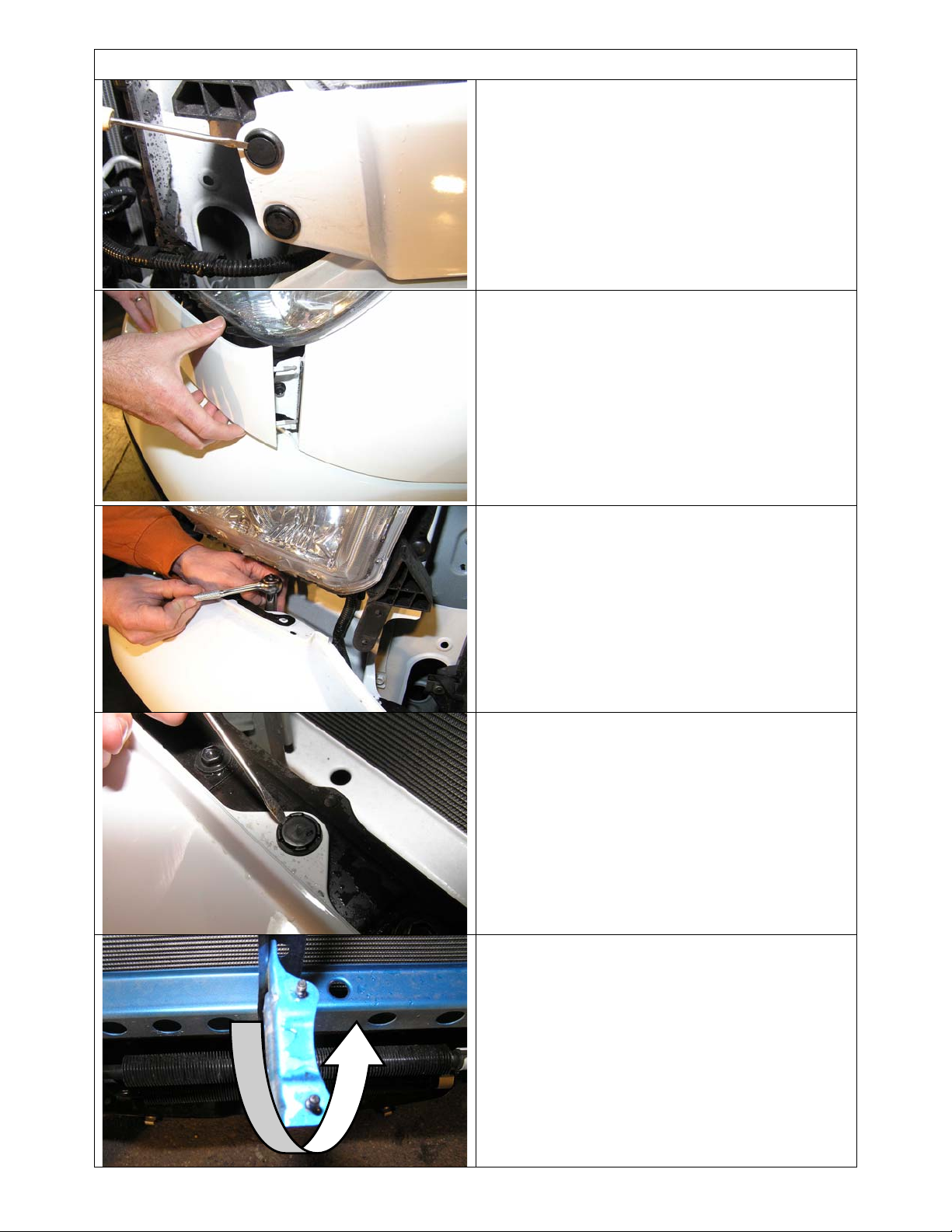

9. Remove push in plugs from trim piece under

headlamp.

10. Carefully prise the trim pieces free by pulling

them forward and twisting to release plugs

out of retaining sockets.

11. Remove screws retaining bumper located

under headlamp area.

12. Remove plugs securing upper bumper tabs.

13. If winch is to be fitted to bull bar, bend the

forward facing section of vertical brace

around and rearwards to prevent interference

from winch operation.

Last Rev Date: 29/10/2008 Page 7 of 24 Fitting instructions# 3783321

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

REMOVAL OF BUMPER

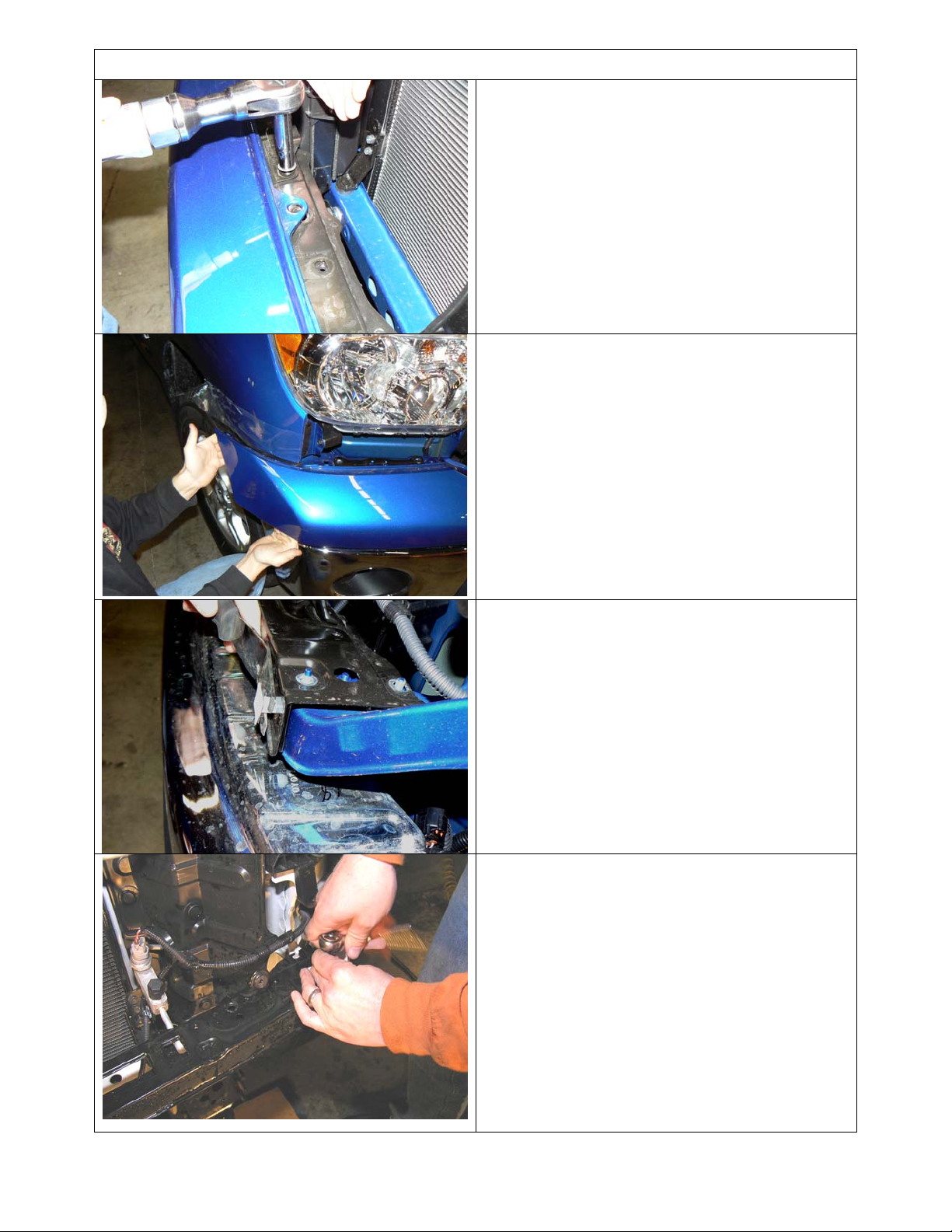

14. Remove screws located along top of cross

member retaining upper bumper metal frame.

Removal of bumper.

15. Pull outward and slightly forward on bumper

cover in upper wheel arch area to unclip tab

on bumper cover from retaining bracket on

fender. The bumper and cover should now

be released. Carefully remove bumper and

set aside.

Hint: This operation is best performed with two

people, one on each end of the bumper.

16. Remove plastic plugs in cross member.

17. Remove cross member and set aside.

Last Rev Date: 29/10/2008 Page 8 of 24 Fitting instructions# 3783321

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Loading...

Loading...