Page 1

ARB COMBINATION WINCH/NON-WINCH BULL BARS TO SUIT FORD

F250/350 PICKUPS 2000-2004 AND 2005 MODELS ON.

PRODUCTS No. 3436030/40

FITTING KITS No.6171871, 6171873,

6171926 (SUPP. KIT FOR WINCH FITMENT 3436040

ONLY)

WARNING

FOR VEHICLES EQUIPPED WITH SRS AIRBAG

WHEN INSTALLED IN ACCORDANCE WITH THESE INSTRUCTIONS, THE FRONT

PROTECTION BAR DOES NOT AFFECT OPERATION OF THE SRS AIRBAG.

TAKE NOTE OF THE FOLLOWING:

• THIS PRODUCT MUST BE INSTALLED EXACTLY AS PER THESE INSTRUCTIONS USING

ONLY THE HARDWARE SUPPLIED.

• IN THE EVENT OF DAMAGE TO ANY BULL BAR COMPONENT, CONTACT YOUR

NEAREST AUTHORISED ARB STOCKIST. REPAIRS OR MODIFICATIONS TO THE

IMPACT ABSORPTION SYSTEM MUST NOT BE ATTEMPED.

• DO NOT USE THIS PRODUCT FOR ANY VEHICLE MAKE OR MODEL, OTHER THAN

THOSE SPECIFIED BY ARB.

• DO NOT REMOVE LABELS FROM THIS BULL BAR.

• THIS PRODUCT OR ITS FIXING MUST NOT BE MODIFIED IN ANY WAY.

Note :

1 These winch bumpers are suitable for Warn 10, 12, 15, and 16500lb

winches.

Tools Required

Metric Spanner and Socket set Phillips head screwdriver,

Dia 12.5mm & 10mm drill bits 13mm capacity electric drill.

Plastic trimming cutting tool Allen (Hex) Key Set

Sikaflex - black

13/12/05 Page 1 of 12 3783101

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

WA: (08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

Head Office – ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

Page 2

USE PART No QTY DESCRIPTION

MOUNT BRACKETS TO VEHICLE 3756655L 1 BRACKET BAR MOUNT LHS

3756655R 1 BRACKET BAR MOUNT RHS

3193695 4 PLATE

6151321 8 NUT M10 FLANGED

4581040 8 WASHER M10 X 3mm THICK

6151232 8 SCREW M10 X 30mm

4581048 8 WASHER M10 SPRING

6151305 6 CAGE NUT M12

4581049 6 M12 WASHER FLAT

4581050 6 M12 WASHER SPRING

6151255 6 SCREW M12 X 40

3199818 2 PACKER PLATE

TOW HOOK RELOCATION 4581049 6 M12 WASHER FLAT

4581050 6 M12 WASHER SPRING

6151255 6 SCREW M12 X 40

CONTROL BOX FITTMENT 3756775 1 CONTROL BOX BRACKET UNIV.

(If fitting winch) 3199790 1 PLATE TRIM FOR 16500LB CNTRL BX

6151364 2 SCREW CAP M10X30

4581291 2 WASHER FLAT M10 BZ

6151321 2 NUT M10 FLANGED

180302 8 CABLE TIE

NUMBER PLATE FITTMENT 6151017 2 BOLT M6 X 16mm

6151128 2 NUT FLANGE M6

6781408 1 TAPE DOUBLE SIDED

AIR DEFLECTOR FITTMENT 6151022 3 BOLT M8 x 25

4581063 3 WASHER FLAT M8 x 25.4 x 3

6151301 3 NUT M8 CAGED

6522045 1 PANEL AIR DEFLECTOR

4581046 3 WASHER M8 SPRING

TENSION STRAP 3756432 2 PLATE TENSION STRAP

6151255 4 BOLT M12 X 40mm

4581050 4 WASHER SPRING M12

4581049 8 WASHER FLAT M12

6151189 4 NUT M12

WINCH HOLE COVER FITTMENT 6151128 2 NUT FLANGE M6

(If not fitting winch) 6151256 2 SCREW M6 S/STEEL BUTTON HEAD

6191013 1 EXTRUSION WINCH COVER

6522048 1 PANEL WINCH COVER

6151046 2 WASHER M6

13/12/05 Page 2 of 12 3783101

Page 3

BAR TO MOUNT ASSEMBLY 6151255 6 BOLT M12 X 40mm

4581050 6 WASHER SPRING M12

4581049 12 WASHER FLAT M12

4581048 4 WASHER SPRING M10

6151189 6 NUT M12

6151321 4 NUT M10 FLANGED

6151232 4 BOLT M10 X 30mm

4581040 4 WASHER FLAT 3/8”

INDICATOR ASSY 6821151R 1 INDICATOR ASSY RHS

6821151L 1 INDICATOR ASSY LHS

6151308 4 SCREW SELF TAPPING

6821116 4 NUT NYLON PLUG

6821152 2 LOOM

180701 6 SCOTCH LOCKS

180302 4 CABLE TIE

SUPPLIMENTARY KIT 6171926 FOR WINCH RELIEF FOR 2005ON BAR ONLY

4681176 1 BRACE

3756735 1 BRACKET ANGLE

6151143

8 SELF DRILL SCREW

NOTE: Shipping brackets connecting bull bar

to pallet and associated fasteners are not

intended to be reused in fitted bar assembly.

13/12/05 Page 3 of 12 3783101

Page 4

ASSEMBLY SEQUENCE FOR WINCH BUMPER.

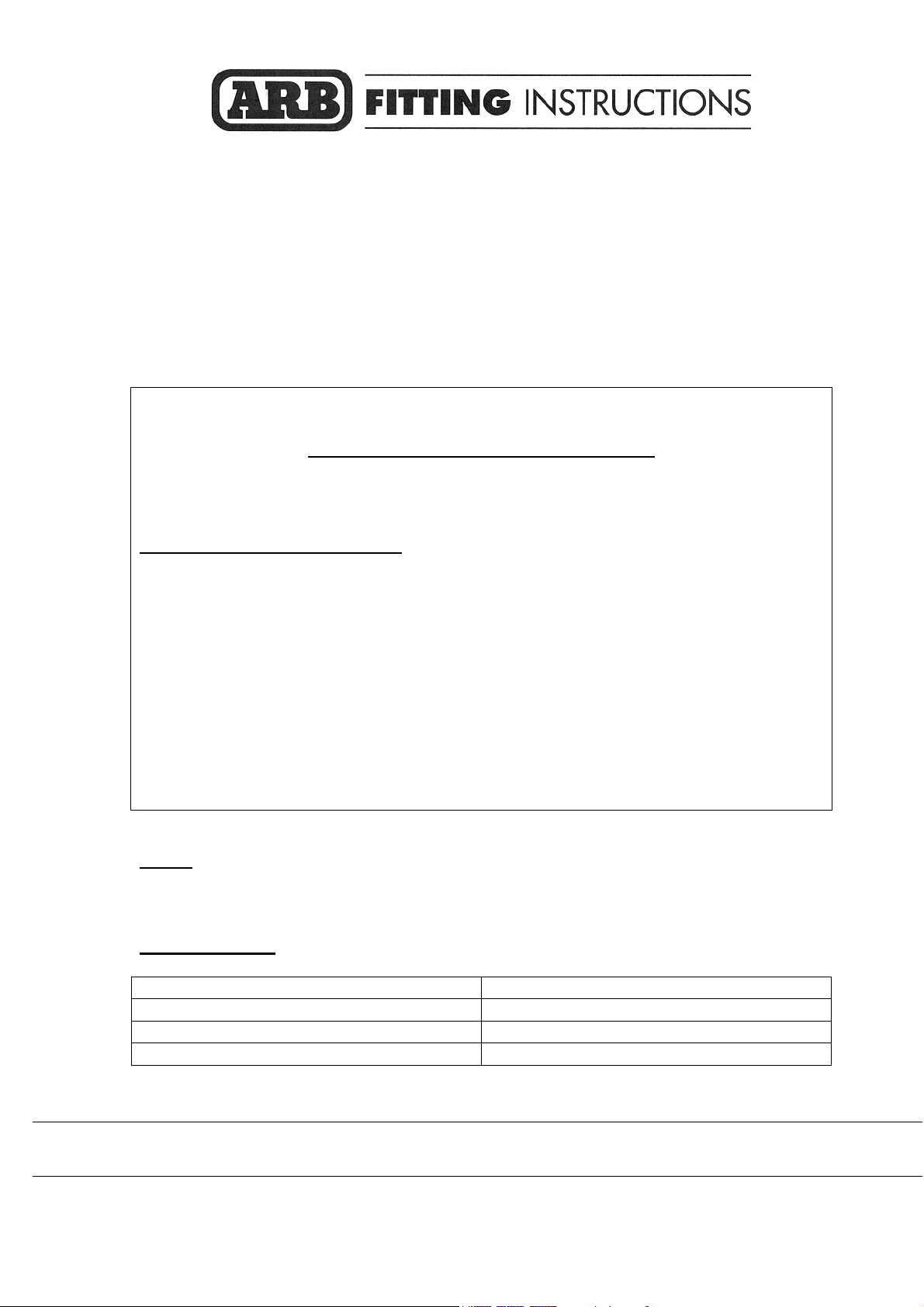

1. Fitting mounting brackets

Remove the bumper and two recovery

hooks.

Fit M12 cage nuts to slots on each mount

bracket as shown; make sure that they can

move laterally along the slots for

adjustment purposes later on.

2. Sit mount brackets in position as shown in

step 3. Check that they sit flush against

flange, if not; the edge of chassis may be

bearing on weld on underside of welded

gusset. Fettle edge of chassis until it

clears bracket.

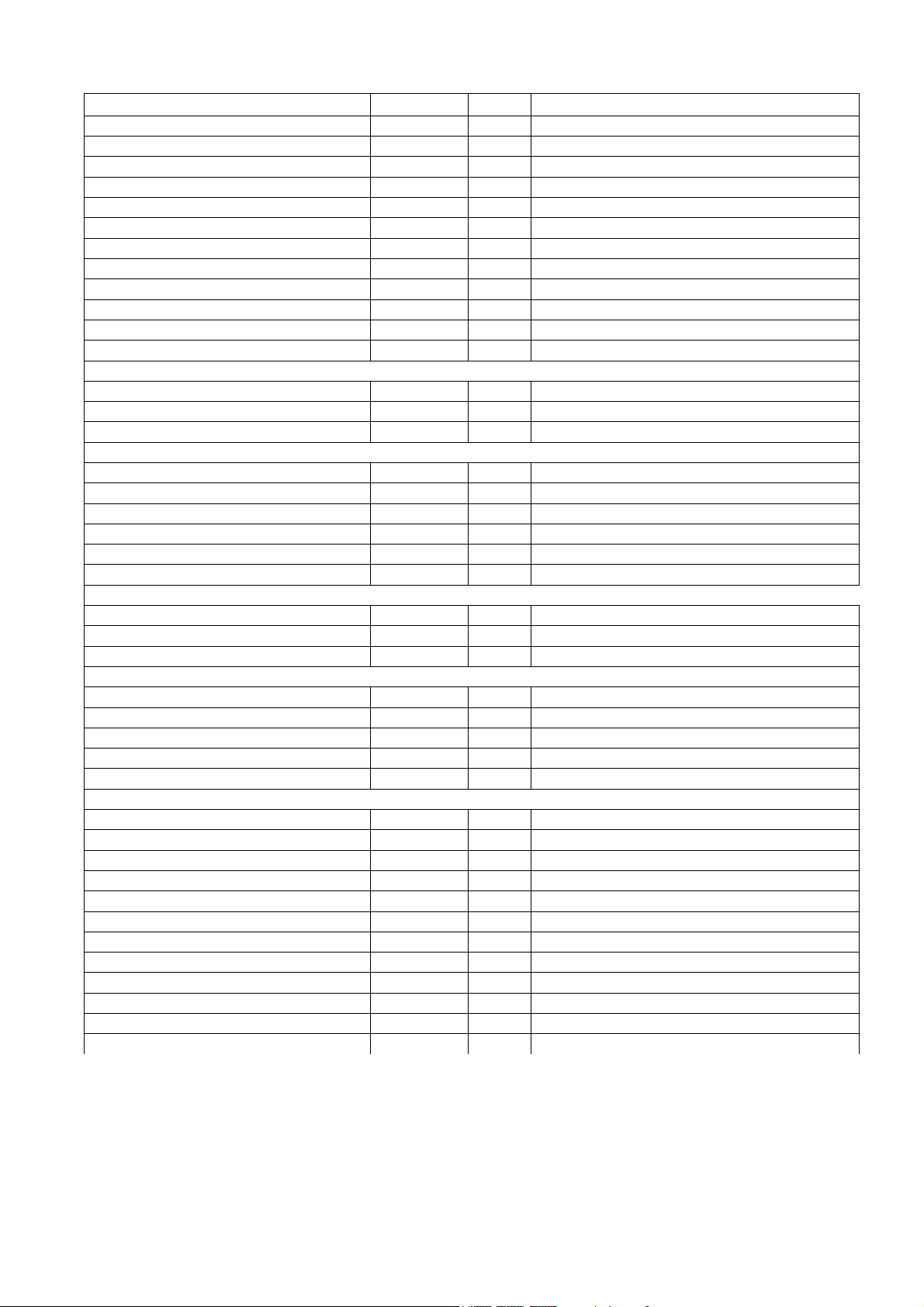

Slide packer into

chassis slot,

adjacent to

rearmost cage nut

position in gusset

There will be an air gap between the

rearmost under face of the gusset to the

lower inside face of chassis. Slide in

packer plate under rearmost bolt position to

support gusset. Using M12 x 40mm bolts,

flat and spring washers, fasten through the

holes in chassis end including packer,

where the recovery hook bolts were

removed.

Do not tighten bolts yet.

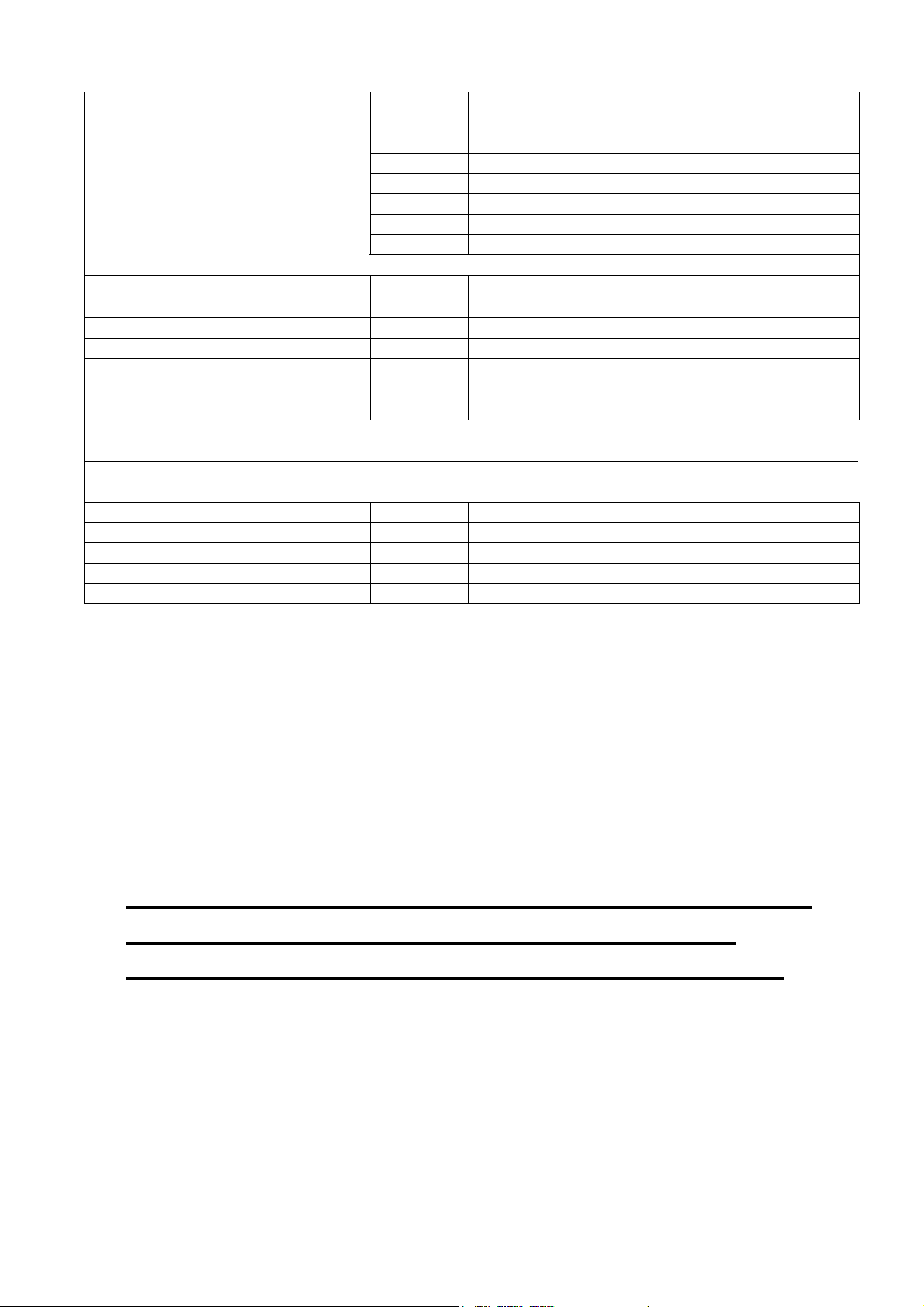

3. Fasten onto the end flanges on chassis

with M10 bolts, large 4mm thick washers,

M10 spring washers, nut plates and M10

flange nuts as shown, lightly tension.

Set the pitch between the flanges at

953mm inside, and locate symmetrically to

the center of the vehicle.

13/12/05 Page 4 of 12 3783101

Page 5

4. With the bull bar mounting brackets now in

place (but not tightened) bolt the tension

strap to the chassis using the hole next to

the horizontal slot.

Using the M12 bolt, flat washers, spring

washer and nut, bolt up the tension strap

as shown.

Note: The tension strap will need to be

bent out slightly, to pass alongside the bull

bar mounting bracket.

As the bolt is tightened the bracket will

bend slightly to allow the strap to sit flat

against the chassis.

5. Bend the end of the strap inward, as

shown, to allow the strap to sit against the

bull bar mounting bracket.

ROTATION

ORIGINAL

POSITION

Drill Dia

12.5mm hole

for pinning

NEW POSITION

Drill through the strap and bracket using a

12.5mm drill bit and bolt up using the same

hardware as described in the above step.

IMPORTANT: STRAP POSITION MUST BE

AS LOW AS PRACTICAL ON MOUNT

BRACKET AS SHOWN

6. If fitting winch.

Rotate clutch handle end

The clutch handle must be repositioned so

it is in a convenient location when mounted

to bar.

Place the winch on its end and remove all

gearbox bolts.

Gently raise the motor just enough to rotate

it. Viewing from the gearbox end, rotate the

gearbox 72deg clockwise.

Do not completely remove the motor and

avoid damaging the gasket.

Refit and tighten all bolts.

Note: Take care not to lift the assembly

more than a couple of millimeters while

rotating to the desired position to avoid unmeshing the gears.

13/12/05 Page 5 of 12 3783101

Page 6

Factory motor position

shown, motor must be

rotated 180°

Rotate motor end 180°.

Undo the 2 x bolts securing the motor in

position, withdraw bolts and rotate motor

180°, so terminals will now face away from

vehicle when mounted. Tighten up

retaining bolts.

7. Fit control box to pan:

• For 10000-12000lb winches, use universal

control box bracket supplied, attaching to

rear of control box mount studs.

• Slide bracket flange under pan and align

with mount slots.

• Fasten in position with 2 x M10 cap

screws, black washers and flange nuts.

• For 15000lb winches, use Warn supplied

control box bracket, attaching to rear of

control box mount studs.

• Slide bracket flange under pan and align

with mount slots.

• Fasten in position with 2 x M10 cap

screws, black washers and flange nuts.

13/12/05 Page 6 of 12 3783101

Page 7

• For 16500lb winches, apply Sikaflex (or

similar product) to rear of control box trim

plate from fitting kit (note orientation critical

to suit final position with control box profile

in pan opening).

• Position trim plate on top of pan centrally

about control box opening and line up with

mount slots.

• Fasten in position with 2 x M10 cap screws

and flange nuts from fitting kit.

8. The roller fair lead may need to be drilled

prior to fitment.

Using a 13.0 mm drill bit drill two holes as

shown in diagram.

9. Viewed from front of vehicle the winch

clutch must be positioned on the LH side.

Cable spools from the bottom. Draw off

some cable so cable crimp can be pulled

through roller fairlead.

Bolt in position with the roller fair lead in

place and the tail of cable through rollers.

Note; To increase access to mount bolts in

front of roller fairlead, remove circlips from

bottom of each vertical roller shaft, push

shaft up so roller can be dislodged

sideways. Do up bolts in fairlead and

winch, then refit circlip.

Connect the winch control box cables to

the winch motor. Refer to the Warn

handbook for additional information.

Connect the long winch + & - cables to the

vehicle after the bar is installed. Refer to

the Warn winch manual for vehicle

wiring instructions.

13/12/05 Page 7 of 12 3783101

Page 8

10. IMPORTANT: For 2005ON vehicles, the

lower grille and rear support frame must be

trimmed for clearance to winch. Cut the

grille as marked, 450mm wide x 50mm

high, and notch 540mm x 25mm high.

Note: Cutting specified should clear most

winches, when putting bull bar in position in

step 17, check that adequate clearance has

been achieved, if not trim more from grille.

11. Cut out the corresponding lower center

section of the grille and headlamp support

frame at 450mm wide.

Once the trimming is complete, fix

reinforcing brace in place with self drilling

screws supplied. Fit the angle bracket to

fix the vertical strut in place as shown.

Fitting with winch

Fitting without winch

12. Fitting number plate – with winch

Peel off one side of the double-sided tape

and adhere to the top rear side of the

number plate. Note: Clean the adhering

surfaces before applying tape with an

alcohol solvent.

Peel off the other side of the tape and bolt

to the winch bumper with the M6 X 16mm

bolts and M6 flange nuts through the lower

holes of the number plate.

Press firmly to the top of the number plate

so the tape can properly adhere.

If not fitting winch.

Bolt the number plate through the top

holes using M6 X 16mm bolts and M6

flange nuts.

If desired the double sided tape can be

used down the sides of the number plate.

13/12/05 Page 8 of 12 3783101

Page 9

If not fitting winch cont.

13. Wrap rubber extrusion around winch cover.

Place washers over the winch cover fixing

holes located on the top middle face of the

winch bumper.

Place the winch cover on top of the winch

bumper inline with the mount holes.

Bolt together using the M6 button head

stainless steel screws and M6 nuts.

14. Fitting indicators

Fit the indicator assemblies noting the RH

and LH designation. Use the nylon nut

plugs and the self tapping screws in the

bolt kit (discard screws, speed nuts and

rubber caps supplied with light assemblies)

Screws enter from the rear of the light body

flange. Position the light with the parker

(clear lens) towards the outside of bull bar.

NOTE: It may be easier, at this stage,

before bull bar is fitted, to temporarily

remove headlight surround or head light

and then connect the wiring looms for

indicators/clearance lamps to original

vehicle wiring through this opening

Ref step 19.

15. Fitting bull bar

Fit M8 cage nuts x 3 off to lower pan

section

13/12/05 Page 9 of 12 3783101

Page 10

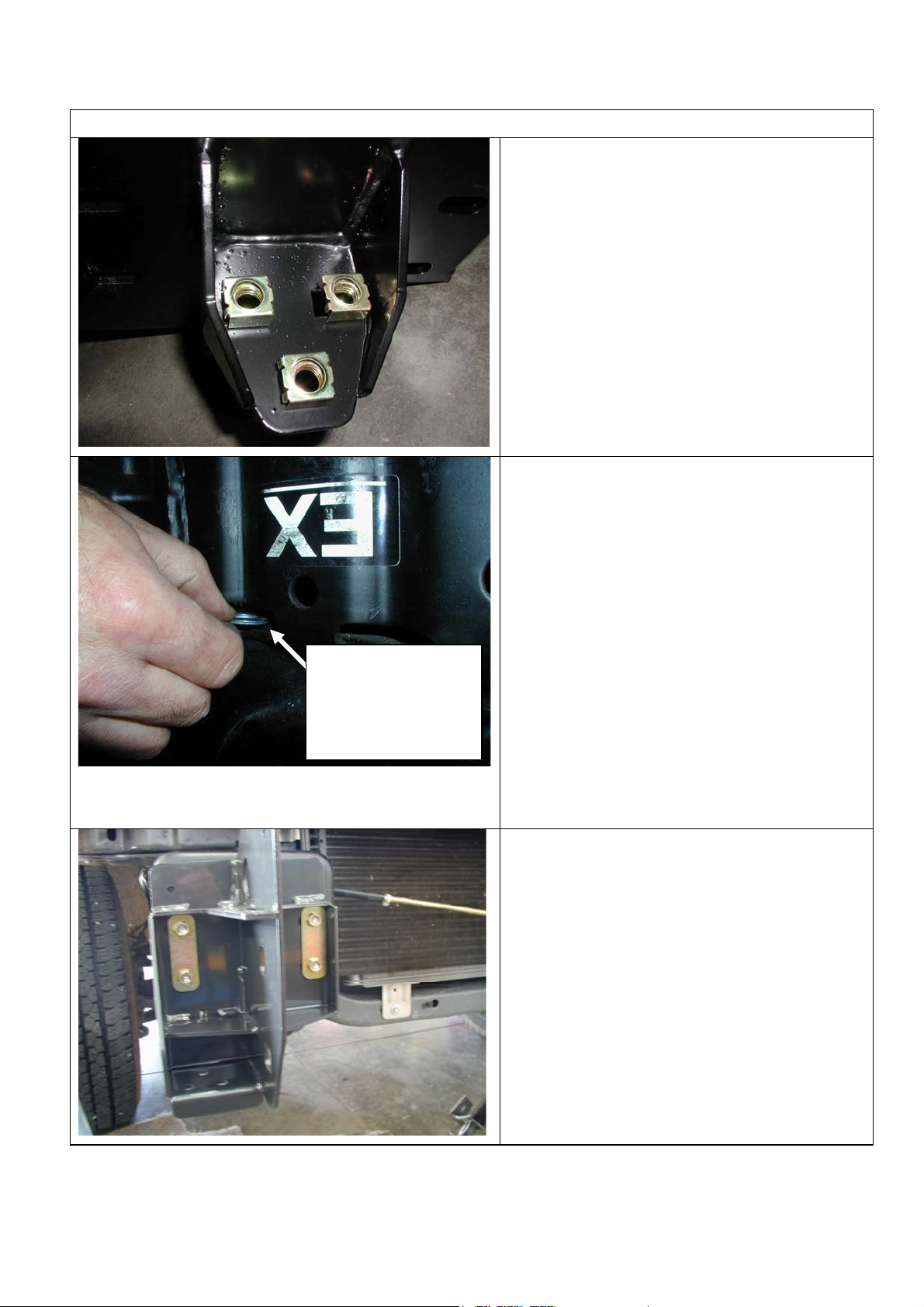

16. On the vehicle, remove the rubber air guide

on the lower cross member area and

discard.

IMPORTANT :- When fitting a winch, on

some models the top power steering cooler

line (steel) will interfere with the winch and

must be bent down to provide clearance as

shown .

Take care when bending the cooler line

tube that you don’t kink it.

Leave the power steering cooler in its

original position.

17. Using two people, three if winch fitted,

position the bar assembly on the vehicle

mounts.

Bolt the bar to the mounts using M12 bolts,

large flat washers and spring washers.

Align the bar to the profile of the guards

and tighten all bolts including the mount

brackets and 3 x bolts through each

original tow point mount.

18. When the bar position is finalised, it must

be pin bolted to the mount brackets. Using

a drill and 10mm drill bit, drill through the

upper and lower Ø10mm pinning holes

located in the mount brackets.

Fasten through holes using M10 bolts, flat

washers, spring washers and flange nuts.

13/12/05 Page 10 of 12 3783101

Page 11

19. Tie the power steering lines to the chassis

away from sharp edges and moving parts

with cable ties provided.

Bolt the air deflector panel to the original

bolts located in the chassis cross member.

20. Bolt the flange of the air deflector to the bar

using M8 bolts, large M8 flat washers and

spring washers.

1

21. Bolt the tow hooks to the mount brackets

using the M12 x 40mm bolts, flat washers

and spring washers.

13/12/05 Page 11 of 12 3783101

Page 12

If fitting with winch

21. With the winch cable through the roller fair

lead. Mount the hook to the end of the

cable.

22. Wire up the indicator and clearance lamp

assemblies. Use scotch locks to splice

cables to existing indicator and clearance

lamp wiring and cable tie securely.

23. If fitting with winch.

Connect the long winch ‘+’ (positive) & ‘-‘

(negative) cables to the vehicle after the bar is

installed.

Refer to the Warn winch manual for vehicle

wiring instructions.

Ensure that these cables are installed well

clear of sharp, hot or moving objects. Secure

the winch cables to the vehicle and winch

bumper with the supplied cable ties.

13/12/05 Page 12 of 12 3783101

Loading...

Loading...