Page 1

25/05/04 Page 1 of 4 3782582

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office – ARB corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

ARB WINCH BULL BAR TO SUIT

MITSUBISHI CHALLENGER No 3435010

WARNING

FOR VEHICLES EQUIPPED WITH SRS AIRBAG

WHEN INSTALLED IN ACCORDANCE WITH THESE INSTRUCTIONS, THE FRONT

PROTECTION BAR DOES NOT AFFECT OPERATION OF THE SRS AIRBAG.

TAKE NOTE OF THE FOLLOWING:

• THIS PRODUCT MUST BE INSTALLED EXACTLY AS PER THESE INSTRUCTIONS USING ONLY THE

HARDWARE SUPPLIED.

• DO NOT USE THIS PRODUCT FOR ANY VEHICLE MAKE OR MODEL, OTHER THAN THOSE SPECIFIED

BY ARB.

• DO NOT REMOVE LABELS FROM THIS BULL BAR.

• THIS PRODUCT OR ITS FIXING MUST NOT BE MODIFIED IN ANY WAY.

BULL BAR FITTING KIT No 6171295

USE

PART No

QTY

DESCRIPTION

IMPACT ABSORBERS

3751726L&R

PAIR

IMPACT ABSORBER

6151045

8

M10 X 25mm BOLT

4581048

8

M10 SPRING WASHER

4581040

12

M10 FLAT WASHER

6151021

2

M8 X 20mm BOLT

4581044

2

M8 FLAT WASHER

6151132

2

M8 FLANGE NUT

AIR DEFLECTOR

6521027

1

AIR DELFECTOR

6151021

4

M8 X 20mm BOLT

6151132

4

M8 FLANGE NUT

4581044

4

M8 FLAT WASHER

IMPACT ABSORBER TO

6151230

2

7/16” X 4” BOLT

VEHICLE CHASSIS

4581041

4

7/16” FLAT WASHER

4581042

2

7/16” SPRING WASHER

6151124

2

7/16” NUT

CONTROL BOX BRKT &

3751619

1

BRKT CONTROL BOX

NUMBER PLATE

6151017

4

M6 X 16mm BOLT

6151046

4

M6 FLAT WASHER

6151128

4

M6 FLANGE NUT

180302

4

CABLE TIES

3500170

1

BUFFER KIT (LH & RH WITH

FLANGE NUTS)

Page 2

25/05/04 Page 2 of 4 3782582

TOOLS REQUIRED

Basic tool kit including a torque wrench plus one deep reach socket (Koken; Part No. 4305M), drill and 8mm drill

bit. 12mm drill bit for winch bull bar.

FITTING THE 9,000lb WINCH

1. Place the bull bar on a suitable stand.

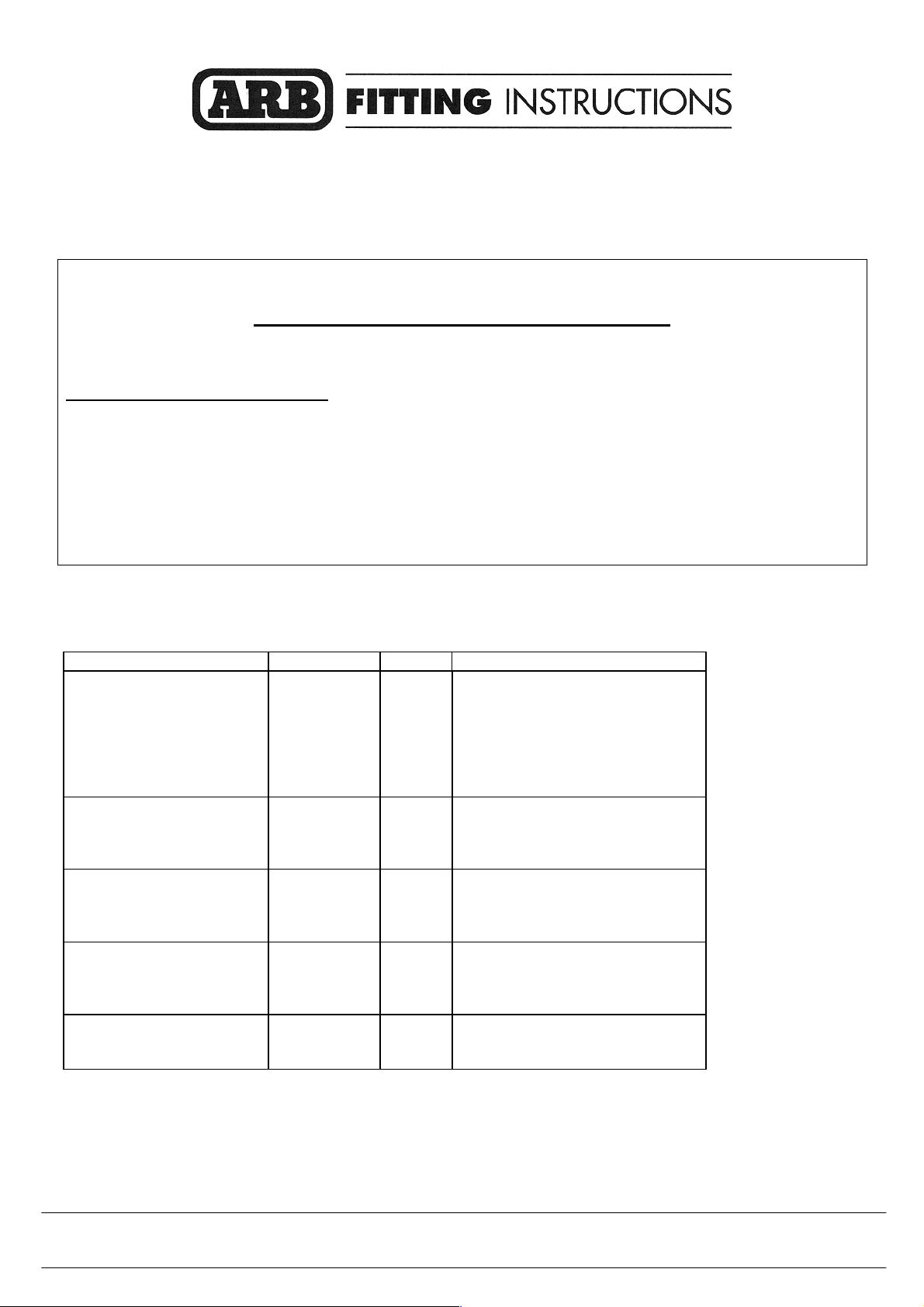

2. To place the winch clutch handle in a convenient location the winch gearbox must be rotated 2 hole spacings,

72 degrees, in an anti-clockwise direction when viewed from the gearbox end. Place the winch on its end and

remove all gearbox bolts. Gently raise the gearbox just enough to rotate it. Do not completely remove the

gearbox and avoid damaging the gasket. Refit all bolts and tighten. (Refer to diagram 1.) NOTE: The winch

handle is positioned at the top of the bull bar.

DIAGRAM 1 DIAGRAM 2

3. To place the winch motor in the correct location the winch motor must be rotated 90 degrees, in a clockwise

direction when viewed from the motor end. Place the winch on its end and remove the two motor retaining

bolts. Gently raise the motor just enough to rotate it. Do not completely remove the motor and avoid damaging

the gasket. Refit all bolts and tighten. (Refer to diagram 2.)

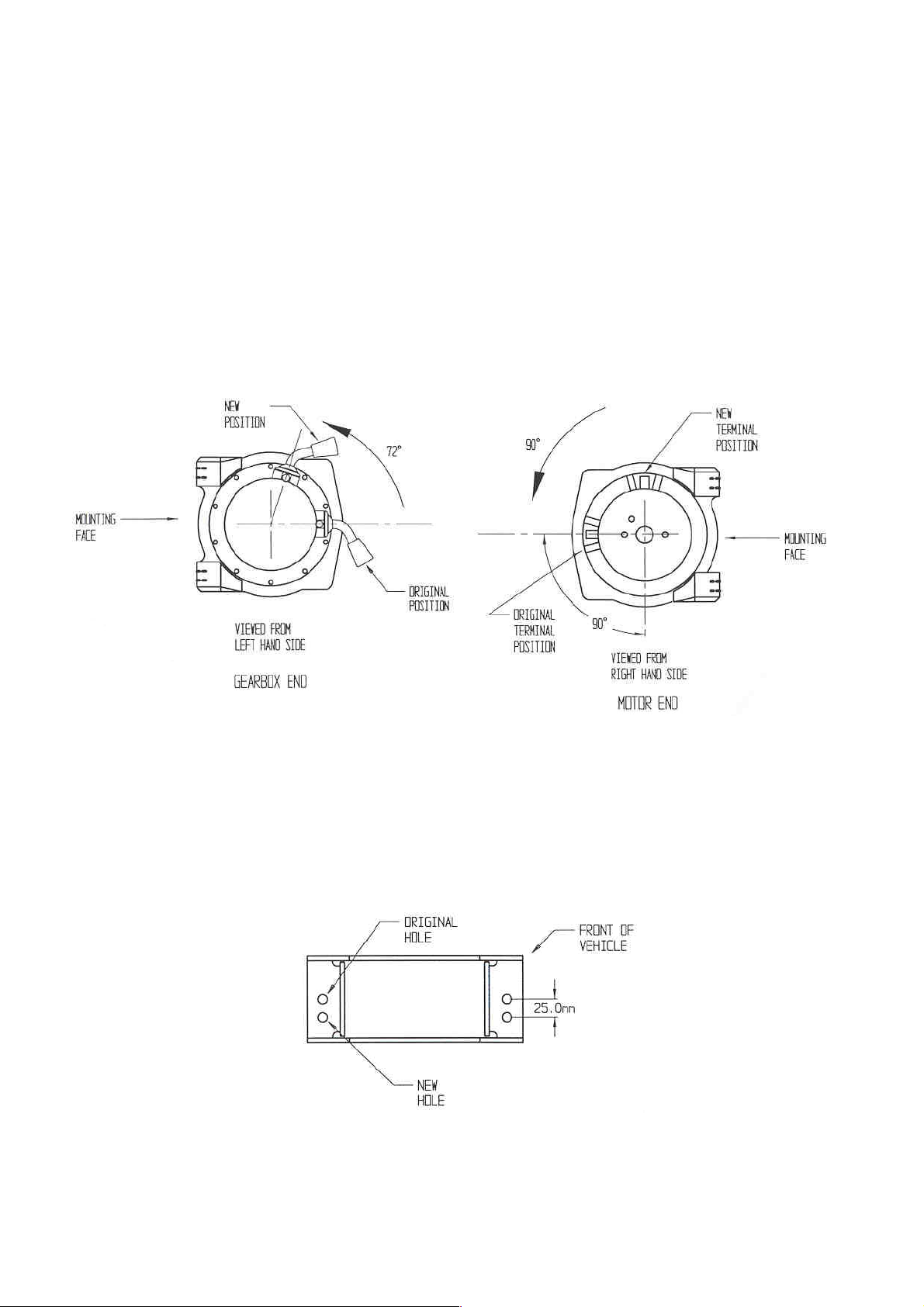

4. The roller fairlead must have new holes drilled to allow for correct wire rope angle. Using a 12mm diameter

drill bit, redrill the roller fairlead as shown. (Refer to diagram 3.)

DIAGRAM 3

Page 3

25/05/04 Page 3 of 4 3782582

5. Fit the control box bracket to the bull bar using two M6 x 16mm bolts, flat washers and flange nuts.

6. Fit the control box to the control box bracket using the two 1/4” nuts, flat washers and spring washers (supplied

in Warn kit). Centralise the control box in the cut-out then tighten nuts firmly.

NOTE: The gearbox is situated on the left hand side of the bull bar (as viewed from inside the vehicle). The cable

spools from the bottom.

7. Fit the winch and roller fairlead into the bull bar using bolts from the winch kit and four M10 washers from the

ARB bolt kit.

8. Connect the winch control box cables to the winch motor. Refer to the Warn handbook for additional

information. Connect the long winch + & - cables to the vehicle after the bull bar is installed. Refer to the

Warn winch manual for vehicle wiring instructions.

9. NOTE: Ensure that these cables are installed well clear of sharp, hot or moving objects. Secure the winch

cables to the bull bar with the cable ties supplied.

FITTING THE BULL BAR TO THE VEHICLE

10. Assemble the two buffers on to the bull bar using the eight M6 flange nuts supplied.

11. Remove bumper bar from the vehicle. (Refer to diagram 4 for removal details.)

DIAGRAM 4

12. Remove the indicators and number plate from the bumper bar.

13. Fit the number plate to the bull bar using the two M6 x 16mm bolts, flat washers and flange nuts.

14. Remove the chassis extensions from both sides of the front of the chassis. Retain the four bolts and discard

both extensions. (Refer to diagram 5.)

Page 4

25/05/04 Page 4 of 4 3782582

DIAGRAM 5 DIAGRAM 6

15. Secure the impact absorber to the front of the chassis using the original chassis extension M10 bolts. Fit the

two 7/16” X 4” bolts through the lower hole in the bracket and finger tighten all the bolts. (Refer to diagram 6.)

16. Lift the bar onto the impact absorber brackets and fasten using the eight M10 x 25mm bolts, flat and spring

washers.

17. Align the bull bar to the vehicle and tighten the bolts retaining the impact absorbs to the chassis to the specified

torque. Drill an 8mm hole in the chassis using the hole in the impact absorber as a guide. Fit the two M8 x

20mm bolts, flat washers and flange nuts and tighten to the specified torque.

18. Fit the indicators into the cut out in the bull bar and connect the indicator looms to the existing indicator loom.

NOTE: Fitting the indicators will be accessed from underneath the bar. Test to ensure the indicators function

correctly.

19. Bolt the air deflector to the underside of the bull bar with the air intake opening facing forward using four M8 x

20mm bolts, flat washers and flange nuts.

TORQUE SETTINGS:

M8 BOLTS

8.6 NM

M10 BOLTS

44 NM

Loading...

Loading...