Page 1

LAND ROVER DISCOVERY 3

ARB BULL BAR AND WINCH BAR

• PART No 3432150 DISCOVERY 3 WINCH BAR

• PART No 3232150 DISCOVERY 3 BULL BAR

WARNING

FOR VEHICLES EQUIPPED WITH SRS AIRBAG

WHEN INSTALLED IN ACCORDANCE WITH THESE INSTRUCTIONS, THE FRONT

PROTECTION BAR DOES NOT AFFECT OPERATION OF THE SRS AIRBAG.

TAKE NOTE OF THE FOLLOWING:

• THIS PRODUCT MUST BE INSTALLED EXACTLY AS PER THESE INSTRUCTIONS

USING ONLY THE HARDWARE SUPPLIED.

• IN THE EVENT OF DAMAGE TO ANY BULL BAR COMPONENT, CONTACT YOUR

NEAREST AUTHORISED ARB STOCKIST. REPAIRS OR MODIFICATIONS TO THE

IMPACT ABSORPTION SYSTEM MUST NOT BE ATTEMPTED.

• DO NOT USE THIS PRODUCT FOR ANY VEHICLE MAKE OR MODEL, OTHER THAN

THOSE SPECIFIED BY ARB.

• DO NOT REMOVE LABELS FROM THIS BULL BAR.

• THIS PRODUCT OR ITS FIXING MUST NOT BE MODIFIED IN ANY WAY.

TOOLS REQUIRED :- METRIC 3/8 DRIVE SOCKET SET, METRIC RING AND OPEN ENDED SPANNERS,

TORX BIT SET, PHILLIPS AND FLAT SCREWDRIVERS, KEY HOLE SAW, DRILL AND 8 &10 mm DRILL BIT ,

SHARP KNIFE AND A WHITE PAINT MARKER .

19-03-08 Page 1 of 18 3783182

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

Head Office – ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

Page 2

USE PART No QTY DESCRIPTION

IMPACT ABSORBER TO

CHASSIS

BULL BAR TO IMPACT

ABSORBER

BUFFERS TO BULL BAR

BAR

FOG LIGHTS AND

INDICATORS TO BULL BAR

WINCH TO BULL BAR

(SUPPLIED WITH FITTING

KIT 6171975 ONLY)

3756789L 1 CHASSIS MOUNT BRACKET ASSEMBLY

3756789R 1 CHASSIS MOUNT BRACKET ASSEMBLY

6151204 4 BOLT M10 x 35 x 1.5p HEX HEAD

6151321 4 NUT FLANGE M10 x 1.5

4581040 4 WASHER FLAT M10

4581048 4 WASHER SPRING M10

6151022 8 BOLT M8 x 25mm HEX HEAD

4581044 8 WASHER FLAT M8

4581046 8 WASHER SPRING M8

CR08 1 SPIRAL WRAP

6151204 8 BOLT M10 x 35 x 1.5p HEX HEAD

6151321 8 NUT FLANGE M10 x 1.5

4581040 8 WASHER FLAT M10

4581048 8 WASHER SPRING M10

3162470L 1 BUFFER 260 x 230 STANDARD

3162470R 1 BUFFER 260 x 230 STANDARD

6151128 12 NUT FLANGE M6

6821116 2 NYLON PLUG LICENCE PLATE TO BULL

6151143 2 SCREW TEK 8-18 x 20mm

6151300 4 CAGE NUT M6

6821116 4 NYLON PLUG

3756792L 1 FOG LIGHT BRACKET

3756792R 1 FOG LIGHT BRACKET

3756778L 1 COVER MOUNT BRACKET

3756778R 1 COVER MOUNT BRACKET

6821151L 1 INDICATOR COMBINATION LAMP

6821151L 1 INDICATOR COMBINATION LAMP

6821152 2 COMBINATION LAMP WIRING LOOM

180701 6 SCOTCH LOCK

6151309 6 CAPTIVE U-TYPE NUT

3162468 2 FOG LIGHT INSERT

6151317 8 SCREW 8-18 x 5/8 PAN HEAD

6151213 4 BOLT M6 x 20mm BLACK ZINK

4581082 4 WASHER FLAT M6 x 20 BLACK ZINK

4581287 4 WASHER SPRING M6 BLACK ZINK

6151308 4 SCREW 8-AB X 1” PAN HEAD

6821198 1 INDICATOR LOOM KIT

3756499 1 CONTROL BOX MOUNT

EG50 2 RUBBER GROMMET

BLB850 3 WINCH LEAD 850mm BLACK

6151074 2 BOLT 3/8” x 1 ¾” HEX HEAD

6151073 2 BOLT 3/8” x 1 ½” HEX HEAD

4581040 4 WASHER FLAT M10

4581048 4 WASHER SPRING M10

6151021 2 BOLT M8 x 20mm

6151132 2 NUT FLANGE M8

4581044 2 WASHER FLAT M8

180302 6 CABLE TIES

19-03-08 Page 2 of 21 3783182

Page 3

USE PART No QTY DESCRIPTION

WASHER BOTTLE

SUPPORT TO IMPACT

ABSORBERS

STONE TRAY TO BULL

BAR

WASHER BOTTLE TRAY

TO BULL BAR

RETAINING FENDER

LINERS TO WASHER

BOTTLE TRAYS

AMBIENT TEMP SENDER

TO IMPACT ABSORBER

MISCELLANEOUS

19-03-08 Page 3 of 21 3783182

3756801 2 WASHER BOTTLE SUPPORT BRACKET

6151301 4 CAGE NUT M8

6151021 4 BOLT M8 x 20mm HEX HEAD

4581044 4 WASHER FLAT M8

4581046 4 WASHER SPRING M8

6151300 2 CAGE NUT M6

6151213 2 BOLT M6 x 20mm BLACK ZINK

4581082 2 WASHER FLAT M6 x 20 BLACK ZINK

4581287 2 WASHER SPRING M6 BLACK ZINK

6542064 1 STONE TRAY

6151300 4 CAGE NUT M6

6151213 6 BOLT M6 x 20mm BLACK ZINK

4581082 6 WASHER FLAT M6 x 20 BLACK ZINK

4581287 6 WASHER SPRING M6 BLACK ZINK

6542065L 1 WASHER BOTTLE TRAY

6542065R 1 WASHER BOTTLE TRAY

6151301 2 CAGE NUT M8

6151300 6 CAGE NUT M6

6151262 2 BOLT M8 x 20mm BLACK ZINK

4581045 2 WASHER FLAT M8 BLACK ZINK

4581047 2 WASHER SPRING M8 BLACK ZINK

6151213 6 BOLT M6 x 20mm BLACK ZINK

4581082 6 WASHER FLAT M6 x 20 BLACK ZINK

4581287 6 WASHER SPRING M6 BLACK ZINK

3757570 4 BRACKET CAGE NUT M6

6151300 10 CAGE NUT M6

6151213 10 BOLT M6 x 20mm BLACK ZINK

4581082 10 WASHER FLAT M6 x 20 BLACK ZINK

4581287 10 WASHER SPRING M6 BLACK ZINK

6151021 1 BOLT M8 x 20mm HEX HEAD

6151132 1 NUT FLANGE M8

4581044 1 WASHER FLAT M8

180302 10 CABLE TIES

3162152 2 ARIAL PLUG

6191009 1 PLASTIC SIDE MOULDING

4721542 1 WASHER BOTTLE HOSE 8mm x 400mm

Page 4

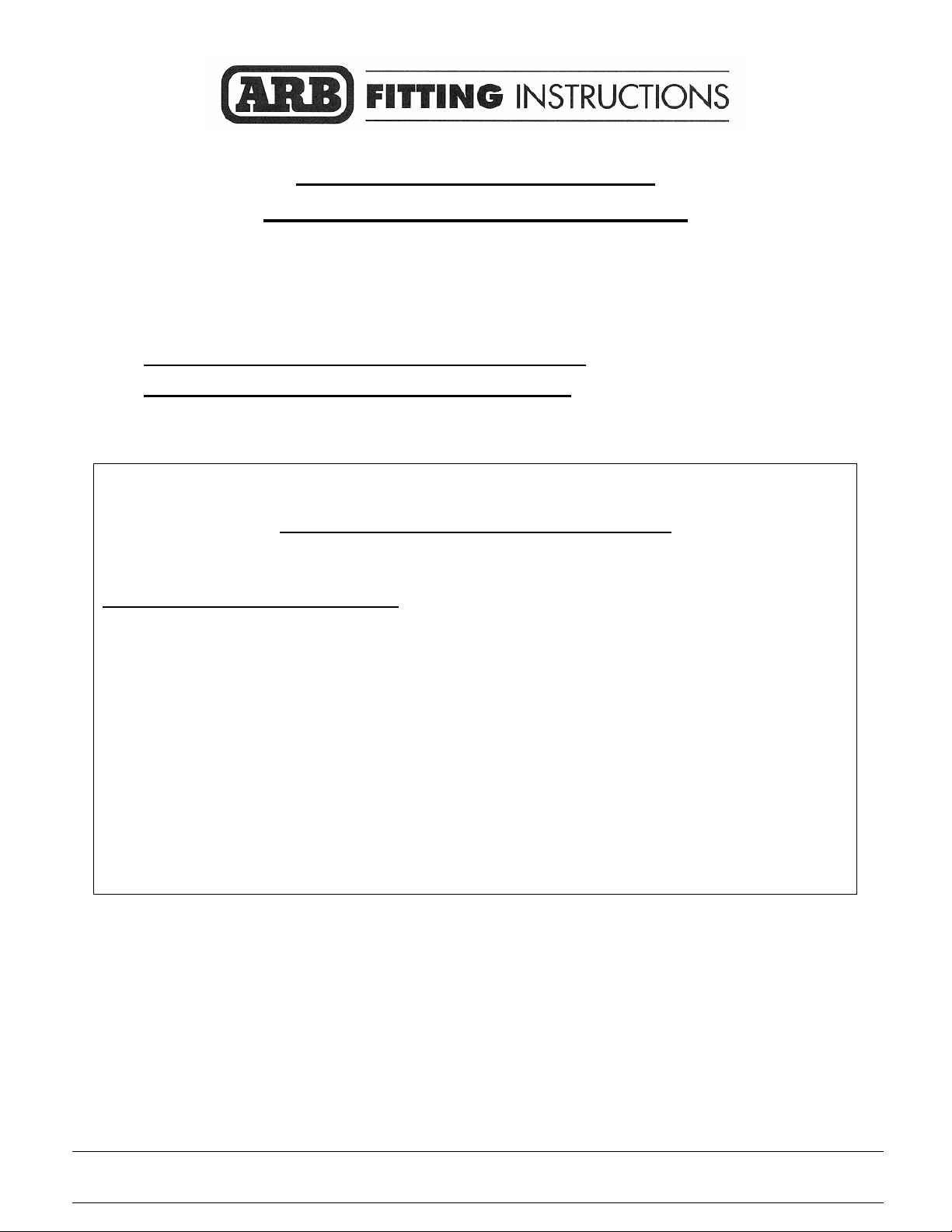

VEHICLE PREPARATION

1. Remove the grill and then the headlights

from the vehicle.

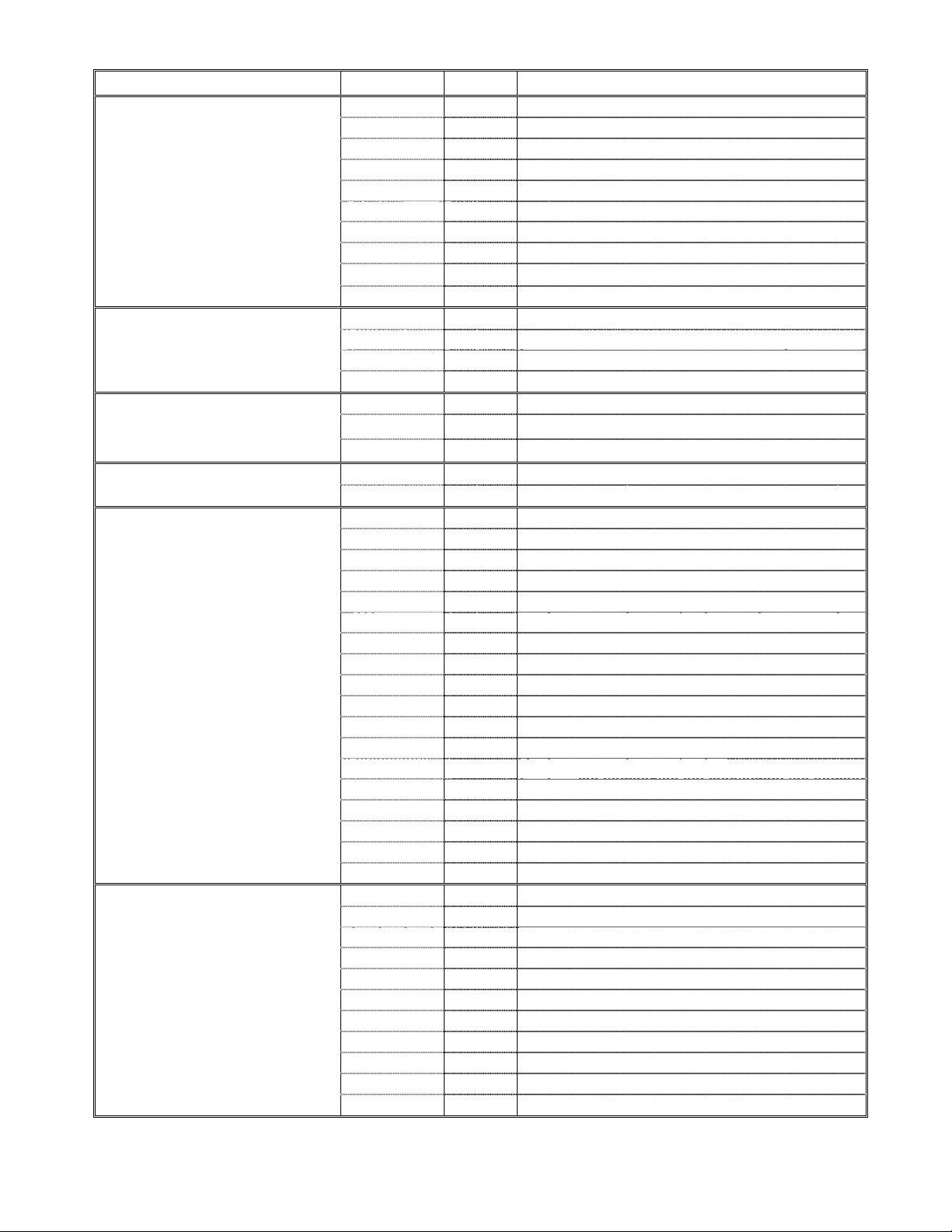

2. Remove the flares from the vehicle.

3. Remove the bumper bar from the vehicle.

4. Remove the two bolts attaching the

bumper cross bar to the washer bottle.

5. Remove the inside plastic brackets and

brake off the inside sections of the outer

plastic brackets.

Remove this

section from both

outside brackets

6. On air suspension models, remove the

solenoid pack attached to the right hand

side of the crossbar.

7. Remove the crossbar from the vehicle.

19-03-08 Page 4 of 21 3783182

Page 5

VEHICLE PREPARATION

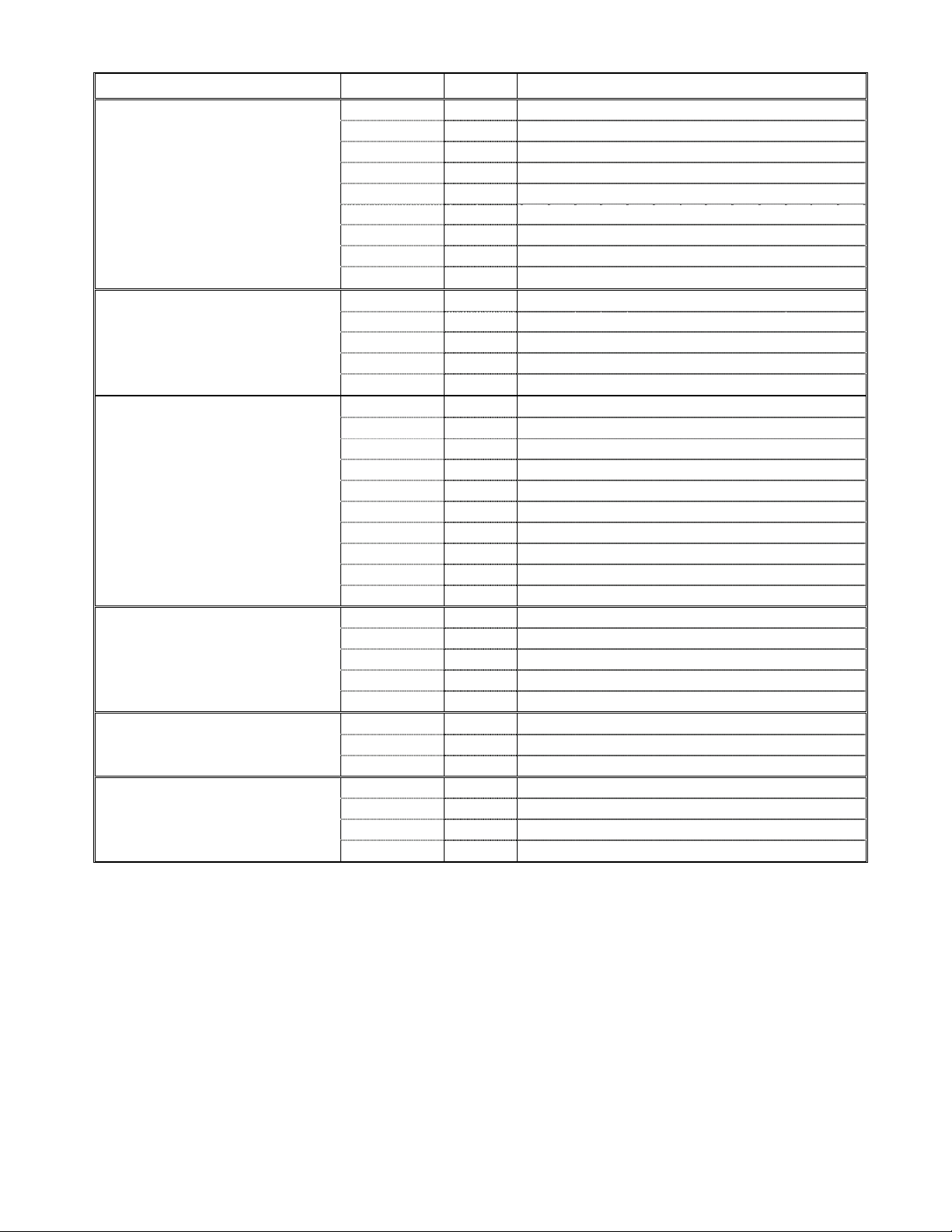

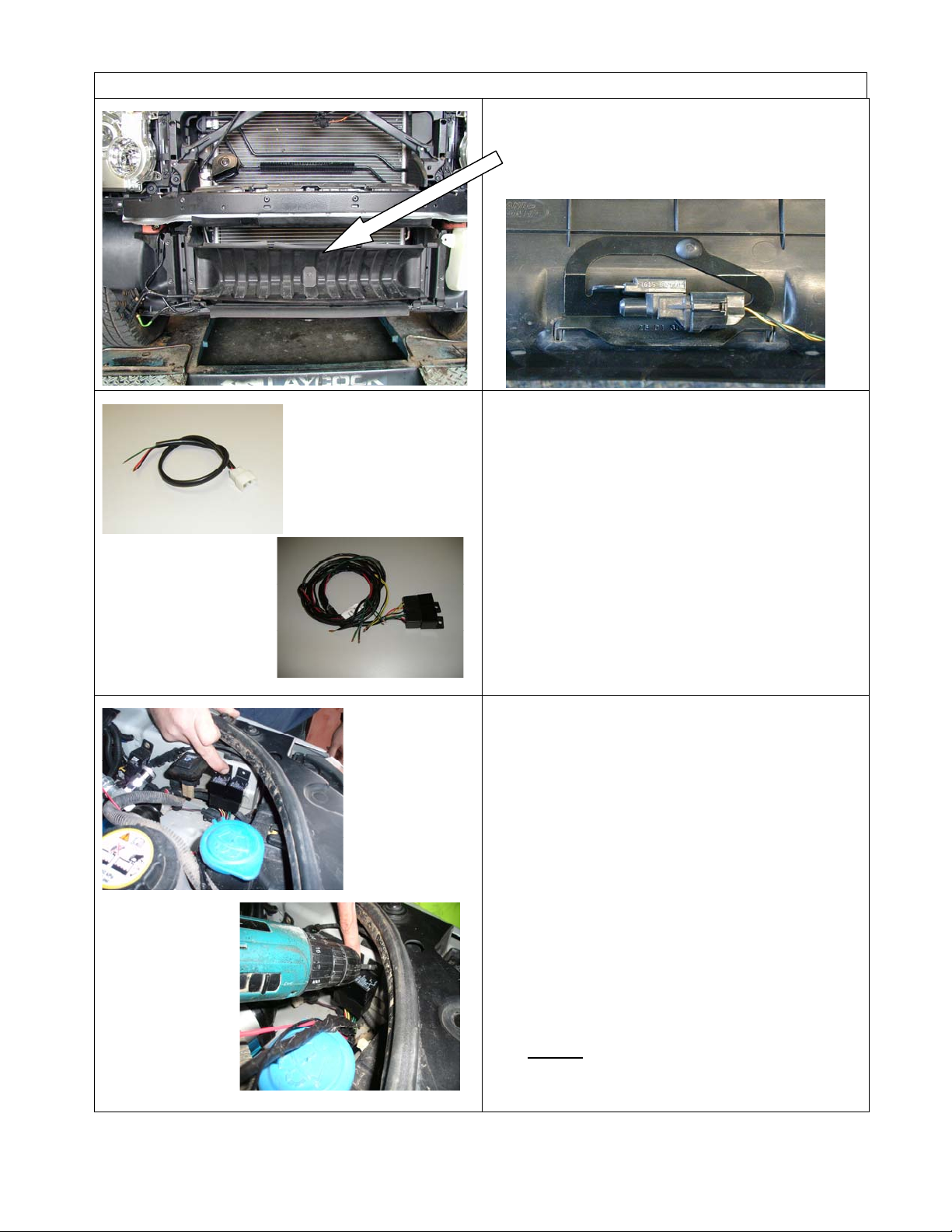

8. Remove the air shield form the vehicle,

and remove the ambient temperature

sender from the air shield.

Short loom .

Longer relay loom .

9. To wire up the indicators from the bull bar

to the vehicle indicators a short loom must

be fitted .

A longer loom with two relays is also to be

fitted in conjunction with the short turn

signal loom .

10. Open the bag containing the long wiring

loom with relays .

Lay the loom across the engine bay from

headlamp to headlamp with the relays on

the Left Hand ( battery ) side of

the vehicle .

Place the relays on the inner guard ( as

shown ) as close as possible to the

battery .

Using a drill and a Phillips head bit attach

the relays to the vehicle with the screws

provided .

Note :any metal part or sharp edges .

Ensure wiring will not rub on

19-03-08 Page 5 of 21 3783182

Page 6

RED WIRE TO

BATTERY POSITIVE

TERMINAL

VEHICLE PREPARATION

BLACK WIRE TO

BATTERY NEGATIVE

TERMINAL

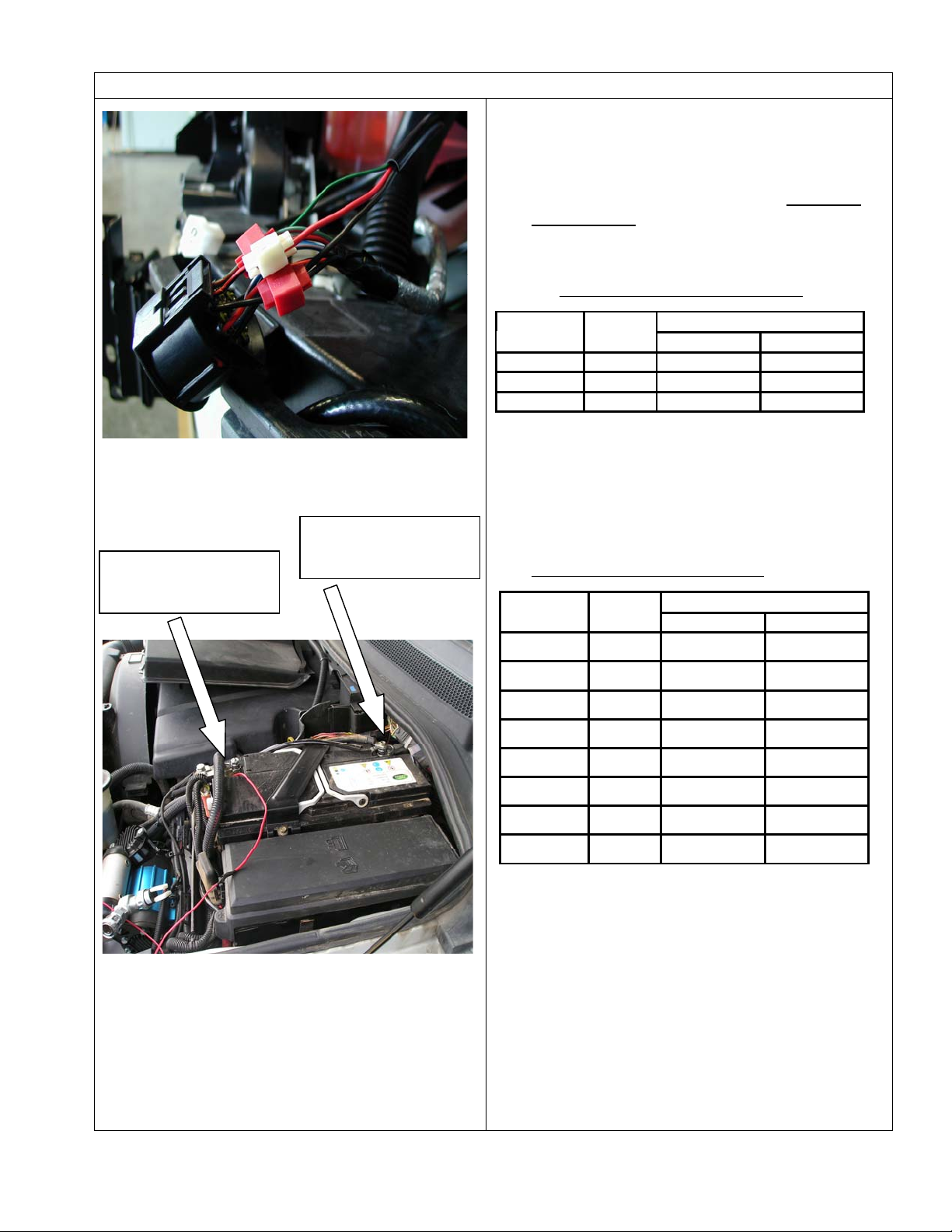

11. Find the clearance , indicator and earth

wires for each headlight using a test lamp.

Removal of the headlamp will make this

easier . Wire the park lamp wire ONLY AT

THIS STAGE

from the short indicator looms

into the head light looms using the scotch

locks provided .

WIRING TABLE FOR SHORT LOOM

FUNCTION INDICATOR

HARNESS

INDICATOR GREEN GREEN / WHITE GREEN / RED

EARTH BLACK BLACK BLACK

PARK LAMP RED RED / ORANGE RED / BLACK

VEHICLE COMBINATION LAMP

RIGHT LEFT

12. The remaining wires from the short loom

( tabled above ) will now in conjunction with

the longer loom - will be both wired into the

vehicles headlamp loom . The table below

lists the colour & function of the longer relay

loom .

WIRING TABLE FOR LONG LOOM

FUNCTION RELAY

BATTERY

POSITIVE

BATTERY

EARTH

VEHICLE RH

INDICATOR

BULL BAR

INDICATOR

BULL BAR

INDICATOR

VEHICLE LH

INDICATOR

BULL BAR

INDICATOR

BULL BAR

INDICATOR

HARNESS

RED ------- ------

BLACK ------- ------

GREEN /

BLACK

GREEN GREEN GREEN

BLACK BLACK BLACK

YELLOW /

BLACK

YELLOW GREEN GREEN

BLACK BLACK BLACK

SHORT INDICATOR HARNESS

RIGHT LEFT

------ ------

------ ------

13. The two wires for each common function

from both looms can now be combined and

scotch locked to the appropriate wire in the

vehicles head lamp loom . Replace the

headlamps back into the vehicle if removed .

14. Wire the positive wire to the battery and the

earth wire to the negative as shown .

19-03-08 Page 6 of 21 3783182

Page 7

VEHICLE PREPARATION

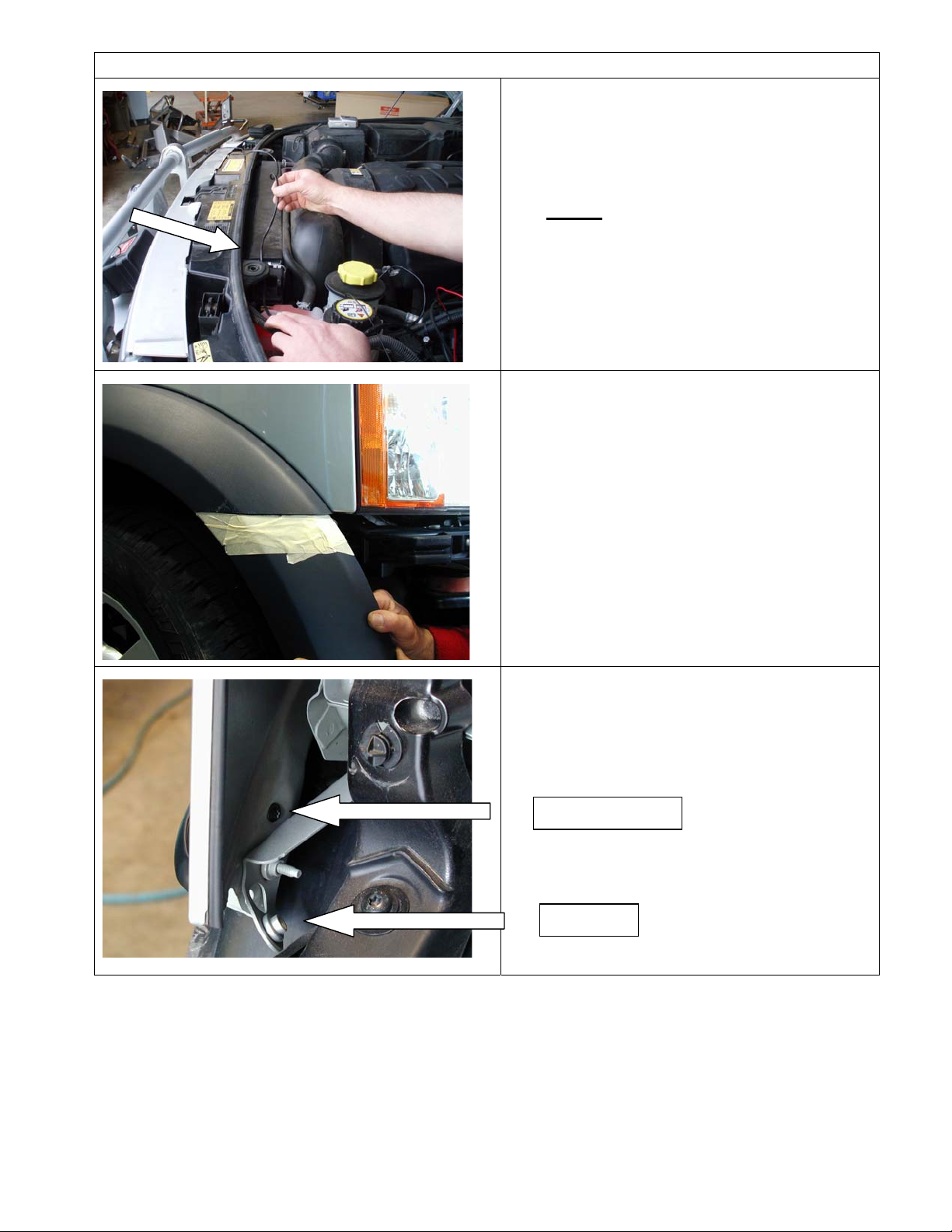

15. With all the wiring connections now

made , feed the harness down so that it

sits neatly and retain in place with the

cable ties provided .

Note :-

Ensure all wiring will not rub or

touch on any metal parts , sharp

edges and hot or moving parts .

16. Replace the headlight and mask the flare

along the line of the headlight.

17. Remove the headlight and remove the

flare.

18. Cut the flare along the line of the

masking tape.

19. Replace the flares making sure to

replace the screw at headlight level.

20. Bend the tag that hangs down below the

line of the guard up and out of the way.

Replace screw

Bend tag

19-03-08 Page 7 of 21 3783182

Page 8

VEHICLE PREPARATION

21. Once satisfied with the cut of the flare,

replace the headlight and the grill.

22. Clean the flare where it has been cut and

attach the plastic side moulding to the

flare.

23. Cut the plastic side moulding with a

Stanley knife along the back edge of the

flare.

24. It is recommended that the lower portion

of the bodywork below the flare cut off be

painted black. Clean the surface with

prep wash then mask the surrounding

area.

If fog lights not fitted go to step 22

25. Using a TORX bit, remove the fog lights

from the bumper bar and keep the six

retaining screws.

26. Remove the fog light wiring loom from

the bumper bar.

19-03-08 Page 8 of 21 3783182

Page 9

VEHICLE PREPARATION

27. Unclip the headlight washer hose from the

nozzle and remove both the headlight

washers and the hose.

If air suspension not fitted go to step 23.

28. Cut the supplied spiral wrap in half. Wind

the spiral wrap around the two lower air

hoses that connect to the suspension

actuators.

19-03-08 Page 9 of 21 3783182

Page 10

BULL BAR SETUP

Nylon plugs

29. Fit both the right and left hand buffers to

the bar using M6 flange nuts. DO NOT

OVER TIGHTEN.

30. Fit 14 M6 cage nuts (10 into the wings

and four into the main pan) and four nylon

plugs to the bar.

M6 cage nuts

31. Install the indicators into the bar using the

self tapping screws (8-AB X 1” pan head)

supplied with the fitting kits. Discard the

screws supplied with the indicators.

NOTE: The indicators should be installed

with the drain holes at the bottom

32. If there are no fog lights fitted to the

vehicle, fit the fog light insert supplied to

the bar. Fit the fog insert bracket to the

fog light insert with the eight pan head

screws as shown opposite.

19-03-08 Page 10 of 21 3783182

Page 11

BULL BAR SETUP

27. Fit the fog light insert assembly to the bar

using two M6 x 20mm black bolts, M6 flat

black washers and M6 black spring washers.

33. For vehicles with fog lights, fit the U-type

nuts to the fog light brackets as shown

opposite.

U-type nuts

34. Using the original TORX head screws

removed with the fog lights earlier; fit the

fog lights into the fog light brackets.

19-03-08 Page 11 of 21 3783182

Page 12

BULL BAR SETUP

Clip the fog light assembly into the indicator

bracket and fix in place using two M6 x

20mm black bolts, M6 flat black washers and

M6 black spring washers.

35. If fitted, re-fit the head light washers into

the bar using the original spring clips.

36. Run the fog light wiring loom through the

bullbar. Remove the plastic clips as

necessary.

Remove

19-03-08 Page 12 of 21 3783182

Page 13

BULL BAR SETUP

37. Replace the small section of hose that

runs between the headlight washers with

the hose supplied in the fitting kit.

38. Run the hose through the bull bar to both

headlight washers.

Replace hose

39. Fit the fog light loom to the fog light and fit

the washer hose to the headlight washer.

Cable tie the head light loom and the

washer hose together making sure they

are away from sharp edges.

This hole can be used

to clip the wiring loom

to the bracket

WINCH FITMENT

IF NOT FITTING A WINCH GO TO STEP 47

40. If fitting a Warn winch, replace the three

cables in the control box marked A, F1

and F2 with the three 850mm cables from

the fitting kit. Mark the new cables as per

the original cables.

19-03-08 Page 13 of 21 3783182

Page 14

g

WINCH FITMENT

41. Remove the cap head screws retaining

the gearbox to the winch drum. Carefully

lift and rotate the gearbox 144 degrees

counter clockwise (four hole spacings)

and re-fit the cap screws.

42. Lay the winch on a suitable surface and

place the bull bar on top so that the wire

rope will feed from the bottom.

43. Using two 3/8” x 1 1/2” bolts, M10 flat and

spring washers, attach the bull bar to the

winch through the top two holes

44. Using a 12mm drill bit, drill two new holes

in the roller fairlead 25mm below the

original holes.

Drill the new

hole 25mm

below ori

inal

19-03-08 Page 14 of 21 3783182

Page 15

WINCH FITMENT

45. Remove the cir-clips from the bottom of

the vertical rollers of the fairlead and push

the pin upwards. Push the vertical rollers

inwards und using two 3/8” x 1 ¾” bolts

M10 flat and spring washers, attach the

roller fairlead to the bar.

46. Replace the circlips on the vertical rollers.

47. Insert the two rubber grommets into the

top face of bull bar.

48. Attach the control box to the control box

bracket.

49. Fit the control box to the bar with two M8

x 20mm bolts, M8 flat washers and M8

flange nuts.

19-03-08 Page 15 of 21 3783182

Page 16

WINCH FITMENT

50. Run the cables through the rubber

grommets and connect to the winch as

per wiring diagram supplied with the

winch.

51. Using cable ties, fix the cables away from

any moving, sharp or hot surfaces.

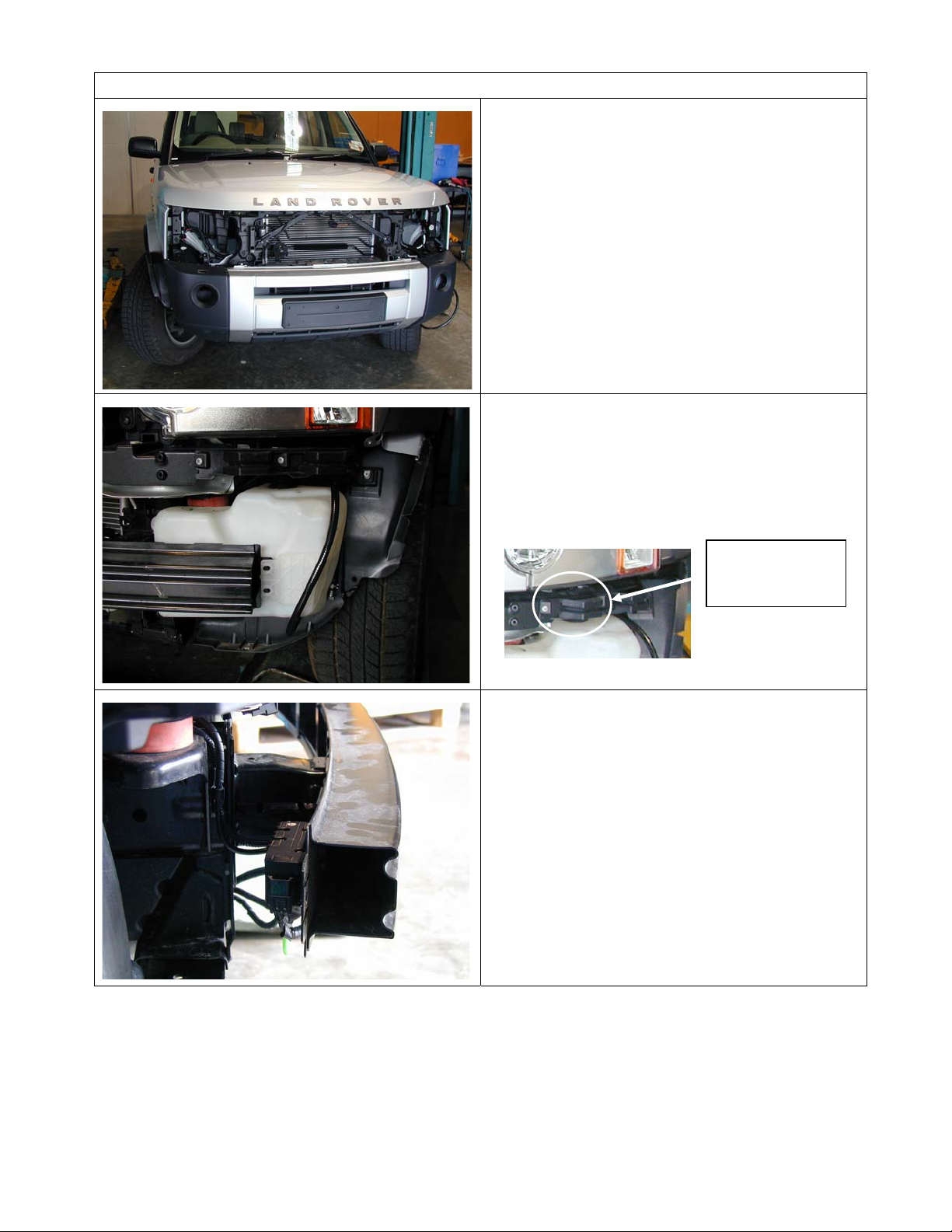

BULL BAR FITMENT TO VEHICLE

52. Fit the six M8 cage nuts to the impact

absorbers.

53. Mount both the impact absorbers to the

vehicle using four (a side) M8 x 25mm

bolts, M8 flat and spring washers in the

front face, two (a side) M10 x 35mm bolts,

M10 flat washers, M10 spring washers

and M10 flange nuts in the underside.(

DO NOT TIGHTEN)

Left hand side

M10 bolts

19-03-08 Page 16 of 21 3783182

Page 17

BULL BAR FITMENT TO VEHICLE

815mm

54. Centralise the mounts so that the surface

that mounts to the bull bar is vertical.

55. The mounts must be positioned so that

there is 815mm gap between the outside

surfaces of the bull bar mounting face.

56. Tighten all the bolts.

57. On the left hand side, the washer bottle

sits in front of the mount face. (Make sure

that the metal spacer in the washer bottle

tag remains in place)

58. On the right hand side, the air lines on air

suspension models run through the gap in

the impact absorber backing plate.

Spacer

59. Install two M6 cage nuts into one of the

Washer bottle brackets.

60. Attach the washer bottle bracket wit the

cage nuts installed to the left hand side

impact absorber using two M8 x 20mm

bolts, M8 flat and spring washers.

61. Fix the washer bottle to the bracket using

two M6 x 20mm black bolts, M6 flat black

washers and M6 black spring washers.

19-03-08 Page 17 of 21 3783182

Page 18

Mount sensor here

BULL BAR FITMENT

62. Attach the washer bottle bracket without

the cage nuts to the right hand side

impact absorber using two M8 x 20mm

bolts, M8 flat and spring washers.

63. On vehicles equipped with air suspension,

attach the solenoid pack to the bracket.

64. Carefully bend the bracket that holds the

temperature sensor to 90 degrees.

65. Re-install the ambient temperature sensor

to the right hand side impact absorber

using a M8 x 20mm bolt, M8 flat washer

and M8 flange nut.

Bend the bracket

along the crease line

to 90 degrees

66. With the help of another person, lift the

bull bar into position and fix in place using

3 (a side) M10 x 35mm bolts, M10 flat

washers, M10 spring washers and M10

flange nuts. Do not tighten.

19-03-08 Page 18 of 21 3783182

Page 19

BULL BAR FITMENT TO VEHICLE

61. Adjust the bar so there is approximately a

10mm gap between the bull bar wing and the

bottom of the flare. When the bar is in the

correct position tighten the bolts.

10mm gap

67. Using a 10mm drill bit; drill the pinning

bolt hole using the hole in the upright as a

guide.

68. Fix in place using a M10 x 35mm bolt,

M10 flat washer, M10 spring washer and

M10 flange nut. Repeat for the other side.

69. Connect the indicators to the indicator

loom. Re-connect the fog light loom,

headlight washer hose and the ambient

temperature sensor.

70. Fit the stone tray to the bar using six M6 x

20mm black bolts, M6 black flat washers

and M6 black spring washers.

M6 black bolts

19-03-08 Page 19 of 21 3783182

Page 20

WASHER BOTTLE GUARD FITMENT TO BULL BAR

71. Fit the washer bottle guards to both sides

of the bull bar .

72. Use the three M6 x 20mm black bolts, M6

black flat washers and M6 black spring

washers to attach the guards to the wing

along the front and side edges .

73. Attach the M8 x 20mm black bolt , M8

black flat washer and M8 black spring

washer to attach the guard to the impact

absorber as shown .

74. On the right hand side of the vehicle ,

Push the out side edge of the fender liner

forward and tuck it in behind the outer

edge of the washer bottle guard .

Using a paint marker mark the upper and

lower holes ( through the guard onto the

fender liner ) .

Repeat the marking of the holes on the

Left hand side of the vehicle.

75. Using a 8 mm drill bit - drill the upper and

lower hole in the right hand side fender

liner .

76. With both the upper and lower holes

marked on the Left hand side , pull the

fender liner rearward – clear of the

washer bottle guard and drill the holes.

WARNING :- DO NOT DRILL THE

LEFT HAND FENDER LINER HOLES

IN PLACE AS THE WASHER BOTTLE

WILL BE PUNCTURED .

19-03-08 Page 20 of 21 3783182

Page 21

WASHER BOTTLE GUARD FITMENT TO BULL BAR

77. Install the cage nut into the cage nut

bracket as shown below .

78. Insert the cage nut bracket up through the

access hole and line up the hole in the

fender liner and bottle guard , use the M6

hardware supplied to bolt the fender liner

to the washer bottle guard .

Repeat for the lower hole and for the Left

hand side . Break off the excess length

of cage nut bracket when finally

secured .

79. Trim the inner guard in line with the lower

edge of the washer bottle cover .

80. Using the washer bottle guard as a

template mark the position of three cage

nuts located on the rear fold with a paint

marker onto the fender liner .

Drill Using a 8 mm drill bit - drill the three

holes .

81. To fit the license plate to the bar, first

push two nylon plugs into the front face of

the top pan. Fit the license plate using two

8-18 x 20mm tek screws .

82. Ensure all lights are functioning correctly

and all bolts are fully tightened .

Also supplied in the kit are two 16mm plugs. The two plastic plugs are for the holes in the top

surface of the wings if no CB aerials are fitted.

19-03-08 Page 21 of 21 3783182

Loading...

Loading...