Page 1

ARB TACOMA COMBO BULL BAR 2005 ONWARDS.

• PART No 3423030

WARNING

FOR VEHICLES EQUIPPED WITH SRS AIRBAG

WHEN INSTALLED IN ACCORDANCE WITH THESE INSTRUCTIONS, THE FRONT

PROTECTION BAR DOES NOT AFFECT OPERATION OF THE SRS AIRBAG.

TAKE NOTE OF THE FOLLOWING:

• THIS PRODUCT MUST BE INSTALLED EXACTLY AS PER THESE INSTRUCTIONS

USING ONLY THE HARDWARE SUPPLIED.

• IN THE EVENT OF DAMAGE TO ANY BULL BAR COMPONENT, CONTACT YOUR

NEAREST AUTHORISED ARB STOCKIST. REPAIRS OR MODIFICATIONS TO THE

IMPACT ABSORPTION SYSTEM MUST NOT BE ATTEMPED.

• DO NOT USE THIS PRODUCT FOR ANY VEHICLE MAKE OR MODEL, OTHER THAN

THOSE SPECIFIED BY ARB.

• DO NOT REMOVE LABELS FROM THIS BULL BAR.

• THIS PRODUCT OR ITS FIXING MUST NOT BE MODIFIED IN ANY WAY.

Tools Required For Bar Fitment: Basic Tool Kit, ½” socket set , Cir-Clip pliers, Drill, 10mm bit

and ¼” socket set

05-09-05 Page 1 of 15 3783174

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

WA:(08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

Head Office – ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

Page 2

USE. PART NO.

Chassis Mount Assembly

Bull Bar To Chassis Mount

Assembly

Stone Tray to Bull Bar

Buffers To Bull Bar

Indicators To Bull Bar

Licence Plate To Bull Bar

Miscellaneous

3756781

3756794L

3756794R

6151095

6151135

4516049

4581050

4581007

6151104

6151139

6151133

4581040

4581048

6151232

6151026

6151304

6151232

4581040

4581048

6151026

6542063

6151300

6151180

4581072

4581036

3162470R

3162470L

6151128

6821151R

6821151L

6821116

6151308

6821152

180701

6151128

6151046

6151180

3751313

EG50

180302

BLB850

6151074

QTY DESCRIPTION

1

1

1

4

4

6

6

6

2

2

2

10

6

4

4

6

10

14

10

4

1

8

8

8

8

1

1

12

1

1

4

4

2

6

4

4

4

1

2

10

3

4

Bracket Mount Assembly

Bracket Tension LHS

Bracket Tension RHS

Bolt M12 x 1.25 x 35mm

Nut M12 x 1.25

Washer Flat ½”

Washer Spring ½”

Washer Flat M12 x 4mm HD (Large )

Bolt ½”x 4”UNC

Nut ½’UNCNut M10 x 1.25

Nut M10 x 1.25

Washer Flat M10

Washer Spring M10

Bolt M10 x 1.5 x 30mm

Nut M10 x 1.5

Nut Cage M10 x 1.5

Bolt M10 x 1.5 x 30mm

Washer Flat M10 x 2mm

Washer Spring M10

Nut M10 x 1.5

Stone Tray

Nut Cage 6mm

Bolt M6 x 20mm

Washer Flat M6

Washer Spring M6

Buffer Standard RHS

Buffer Standard LHS

Nut Flange M6

Indicator Kit, RHS

Indicator Kit, LHS

Nylon Plug

Screw, Self Drilling

Wiring Loom

Scotch Lock

Nut Flange M6

Washer Flat M6

Bolt M6 x 20mm

Bracket Number Plate

Rubber Grommet 3/8” ID

Cable Ties

Cable Black 850mm

3/8” x 13/4” UNC Bolts

01-09-06 Page 2 of 15 3783174

Page 3

Bracket Control Box to

Bull Bar

3751564

6151021

4581044

6151132

1

2

2

2

Bracket control box mount

Bolt M8 x 20mm

Washer Flat M8

Nut Flange M8

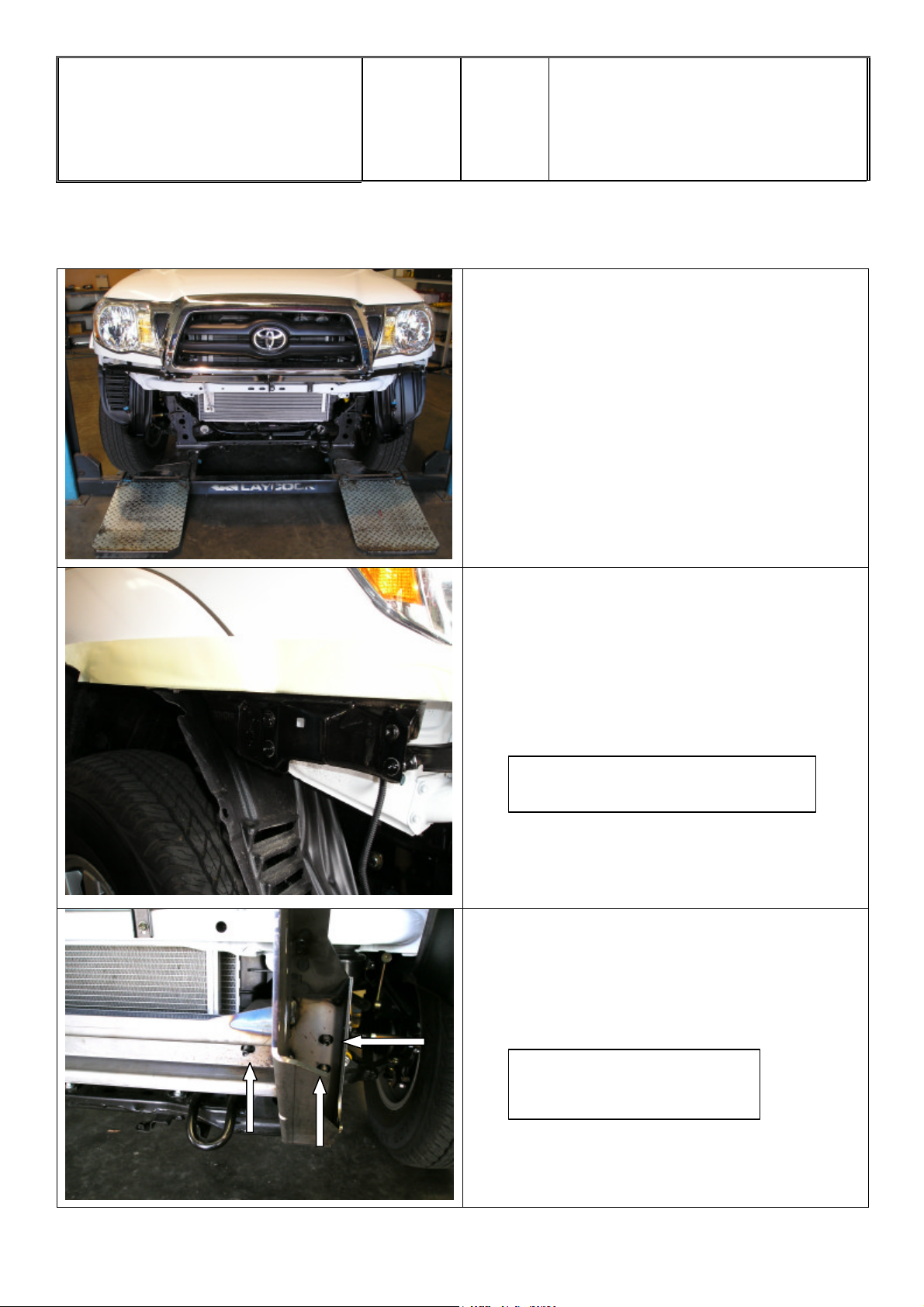

1. Remove front bumper cover from

vehicle.

2. Remove side bumper supports from

both guards.

3. It is recommended that you paint satin

black under guard line.

Photo is of RHS of vehicle.

4. Fit bracket mounting assembly to front

of vehicle using the 6 x 10mm studs to

locate on.

ARROWS INDICATE STUDS

ON LHS OF VEHICLE

01-09-06 Page 3 of 15 3783174

Page 4

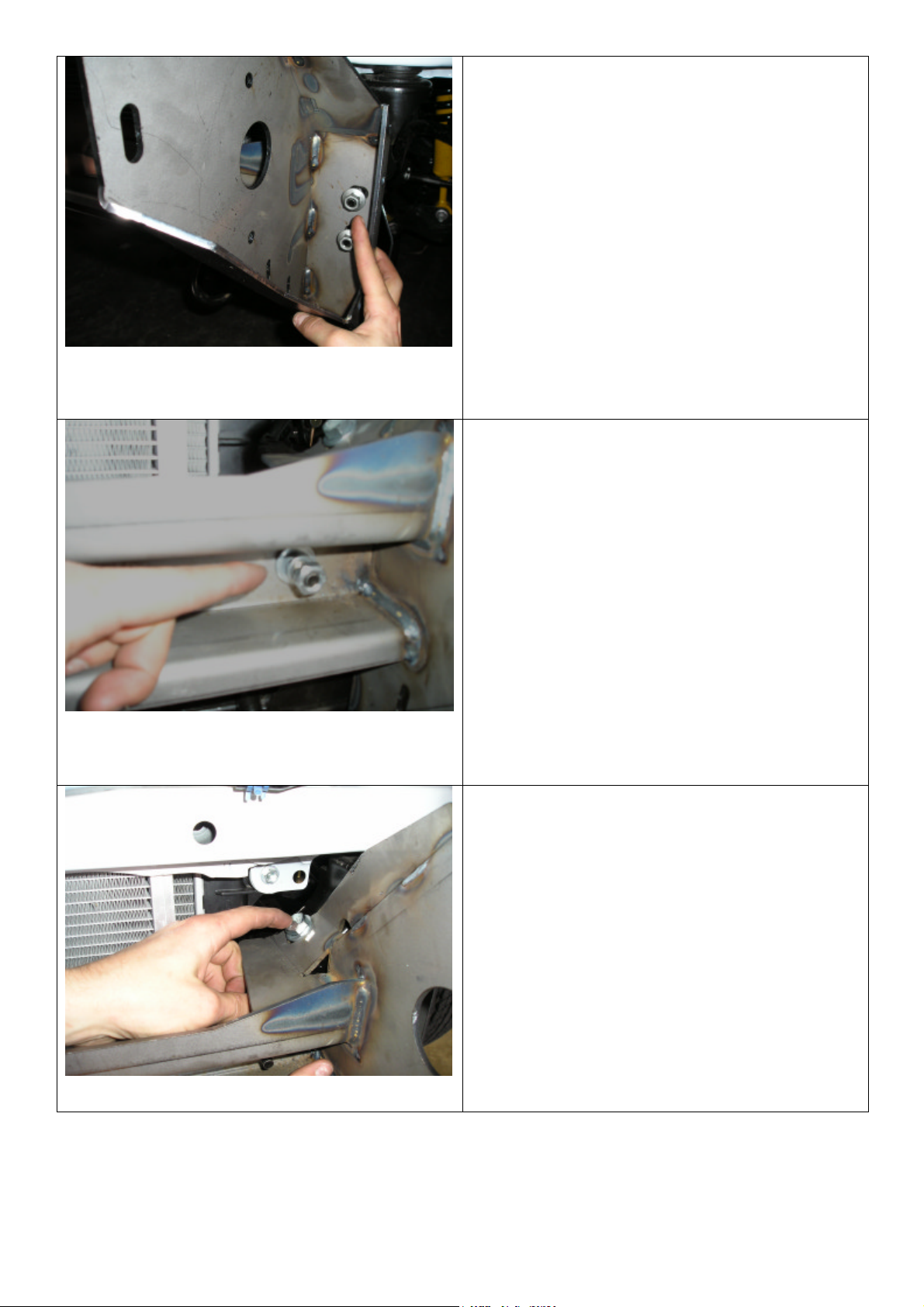

5. Fit original 10mm nuts to the outside

fixing points . See Photo:

6. Fit 10mm x 1.25mm nuts ( fine thread)

spring washers and flat washers ( from

bull bar bolt kit ) to both the centre

studs. See Photo:

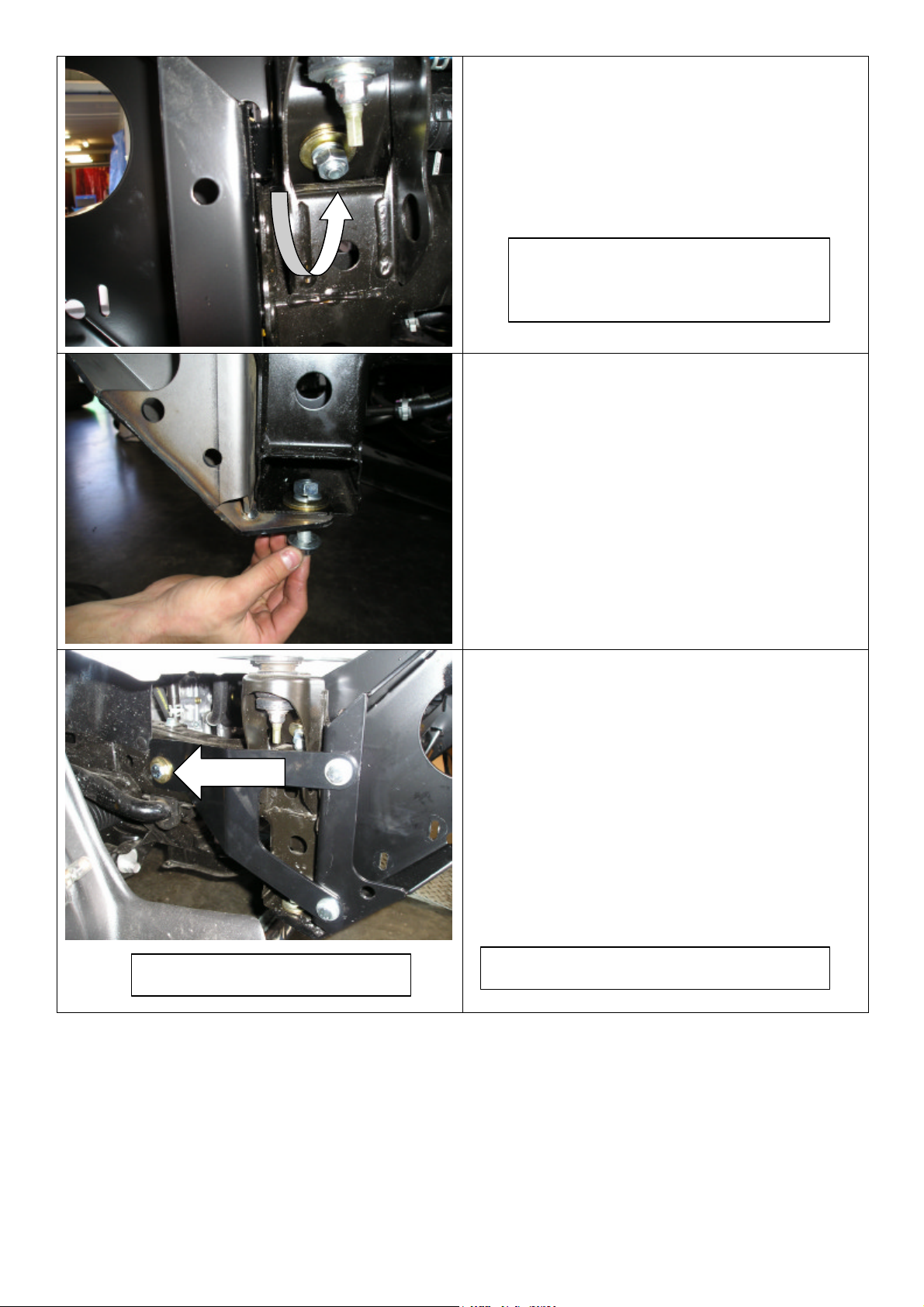

7. Fit 12 x 35mm x 1.25 (fine thread)

bolt,12mm flat washer through top

rearward bracket passing through body

mount.

See Photo:

01-09-06 Page 4 of 15 3783174

Page 5

8. Secure from underneath using large

12mm gold coloured flat washer,12mm

spring washer and 12mm nut to both

sides of vehicle.

See Photo:

PHOTO VIEWED FROM UNDER

LHS OF VEHICLE

9. Secure lower fixing point by passing

through lower bracket in a upward

motion, using M12 bolt, 12mm flat

washer and secure from the top using

large gold coloured 12mm flat

washer,12mm spring washer and

12mm nut ( fine thread ) to each side of

vehicle. When all bolts are fitted,

tighten securely.

PHOTO IS OF RHS OF VEHICLE

10 Lastly fit tension brackets to each side

of vehicle. The two front fixing bolts are

M10 x 30mm,flat washers, spring washers

and M10 nuts. The rear bolt is 4” x ½’

which is passed through the chassis from

outside of vehicle and fitted with a large

gold 12mm washer and a ½’Nyloc nut on

the inside of vehicle. When all bolts are

fitted, tighten front 10mm bolts securely

and tighten rear ½” bolt to a torque setting

of 30ft lb ( NO MORE )

ARROW INDICATES THE ½” BOLT

01-09-06 Page 5 of 15 3783174

Page 6

11. If vehicle is fitted with fog lights,

remove globes from sockets and cable tie

fog light loom to vehicle panel.

ie There is no provision for

fog lights in the bull bar

PHOTO IS LHS OF VEHICLE

12. Cable tie under guard plastic

moulding up to vehicle front pan.

13. Fit M10 caged nuts to the inside of

mounting surface of bull bar.

( 3 to each side of bull bar. )

PHOTO IS OF INSIDE LHS OF BULL BAR.

01-09-06 Page 6 of 15 3783174

Page 7

14….Fit white nylon plugs into square holes.

PHOTO IS OF INSIDE LHS OF BULL BAR.

15. Align indicator/parker light above

white nylon plugs and secure to bull bar

using self tapping screws.

16 .Fit M6 caged nuts to inside lower flange

of inside of bar.

17..Fit two to each side.

THESE CAGED NUTS ARE TO BOLT ON

SPLASH PAN.

01-09-06 Page 7 of 15 3783174

Page 8

n 8/9/9.5/000lb winch, rotate

18. Fit buffers to bar and secure from inside

of bull bar using 6mm flange nuts. Six to

each side of vehicle.

DO NOT OVER TIGHTEN

ORIGINAL

VIEWED FROM

LHS OF VEHICLE

ROTATED

TO FIT A WINCH BAR

19 . To fit a

gearbox 72° counterclockwise.

Stand winch upright and undo the capped

head screws and by lifting the gearbox only

a couple of millimetres, rotate the gearbox.

Once in position, refit all screws and

tighten firmly.

WARNING: Do not lift gearbox more

than a couple of millimeters.

01-09-06 Page 8 of 15 3783174

20. Remove the cover from the control box.

21. Replace the three main power cables that

go from winch to control box. Make sure that

you identify the colour codes on the new

cables before closing control box cover.

This must be done for whatever winch is to

be fitted to the bull bar.

Page 9

22. Bolt control box bracket to top of bar

using 8mm hardware.

23. Fit rubber grommet to RHS of bar.

24. Drill two new 13mm holes in the roller

fairlead provided in the kit, as shown on

the adjacent picture.

25. Place the winch on a table with the feet

facing up and using an assistant;

carefully lift the bull bar on top of the

winch.

26. Attach the winch to the bull bar using

two 1 ½” x 3/8” bolts from the winch

fitting kit, 3/8” spring washer and 3/8”

flat washers in the top holes.

01-09-06 Page 9 of 15 3783174

Page 10

.

27. Position the roller fairlead, and remove

the circlips from the lower of the verticle

rollers and push the pins up to give access

to the lower bolts.

28. Fix the roller fairlead to the bar using the

1 ¾” x 3/8” bolts, spring and flat washers.

29. When all bolts are fitted and tighten, refit

vertical roller pins back into roller fairlead

and refit circlips.

30. Fit number plate bracket to bar using

6mm hardware.

01-09-06 Page 10 of 15 3783174

Page 11

GROUND WIRE

31. Fit control box to control box bracket and

pass cables through rubber grommet.

32. Fit all 3 cables to their correct terminals

and tighten. Refer to Warn installation

instruction when wiring up winch. Fit

plastic boots over terminals. Cable tie

cables to brace as per photo to clear of

all moving parts. Fit ground wire under

winch tie rod. ( See Photo )

33. With the help of a friend, lift bull bar on

to chassis mount bracket and align holes

with 10mm caged nuts already fitted. ( 3

each side )

34. Secure using M10 x 30mm bolt,M10

spring washer and M10 flat washer.

01-09-06 Page 11 of 15 3783174

ARROWS INDICATE WHICH HOLES

TO USE IN SECTION VIEW DRAWING

SECTION VIEW IS LHS OF VEHICLE.

Page 12

6MM CAGED NUTS

35. Align bull bar so there is a 15mm to

20mm gap around periphery under front

vehicle panels, then tighten all bolts

securely.

36. Finally, using the existing 2 holes as a

template. Drill through using a M10 drill

bit and secure using the balance of the

10mm hardware.

(These bolts are to lock the bull bar to the

chassis mounting bracket )

37. Fit M6 caged nuts to the inside of the

flanges on the splash pan.

01-09-06 Page 12 of 15 3783174

Page 13

ARROWS INDICATE M6 BOLT POSITION

38. Fit splash pan to lower flange of bull bar

using M6 x 20mm bolts,6mm spring

washers and 6mm large flat washers.

Finger tighten only.

39 . Fit splash pan to bull bar sides using

M6 x 20mm bolts,6mm spring washers and

6mm large flat washers. Finger tighten only.

40. When all bolts are fitted tighten

securely

41. Fit number plate to number plate

bracket using M6 hardware.

42. Driving lights can be fitted at this stage

and can be tighten using a ratchet and

socket which fits through the gap as per

arrow

01-09-06 Page 13 of 15 3783174

Page 14

43. There is two positions for the number

plate to be fitted to the bull bar.

44. Top arrow is position to bolt number

plate for a winch bar.

45. Lower arrow is position to bolt number

plate for a non winch bar.

FUNCTION INDICATOR

INDICATOR GREEN GREEN /

EARTH BLACK WHITE/BLACK WHITE/BLACK

PARK LAMP RED GREEN GREEN

HARNESS

VEHICLE COMBINATION LAMP

RIGHT LEFT

GREEN / BLACK

YELLOW

46. There is a provision on both sides

of bar for a HiLift to be used.

47. Finally fit indicator/parker light

loom extension to light and wire to

vehicle main light loom using scotch

locks as per table.

01-09-06 Page 14 of 15 3783174

Page 15

01-09-06 Page 15 of 15 3783174

Loading...

Loading...