Page 1

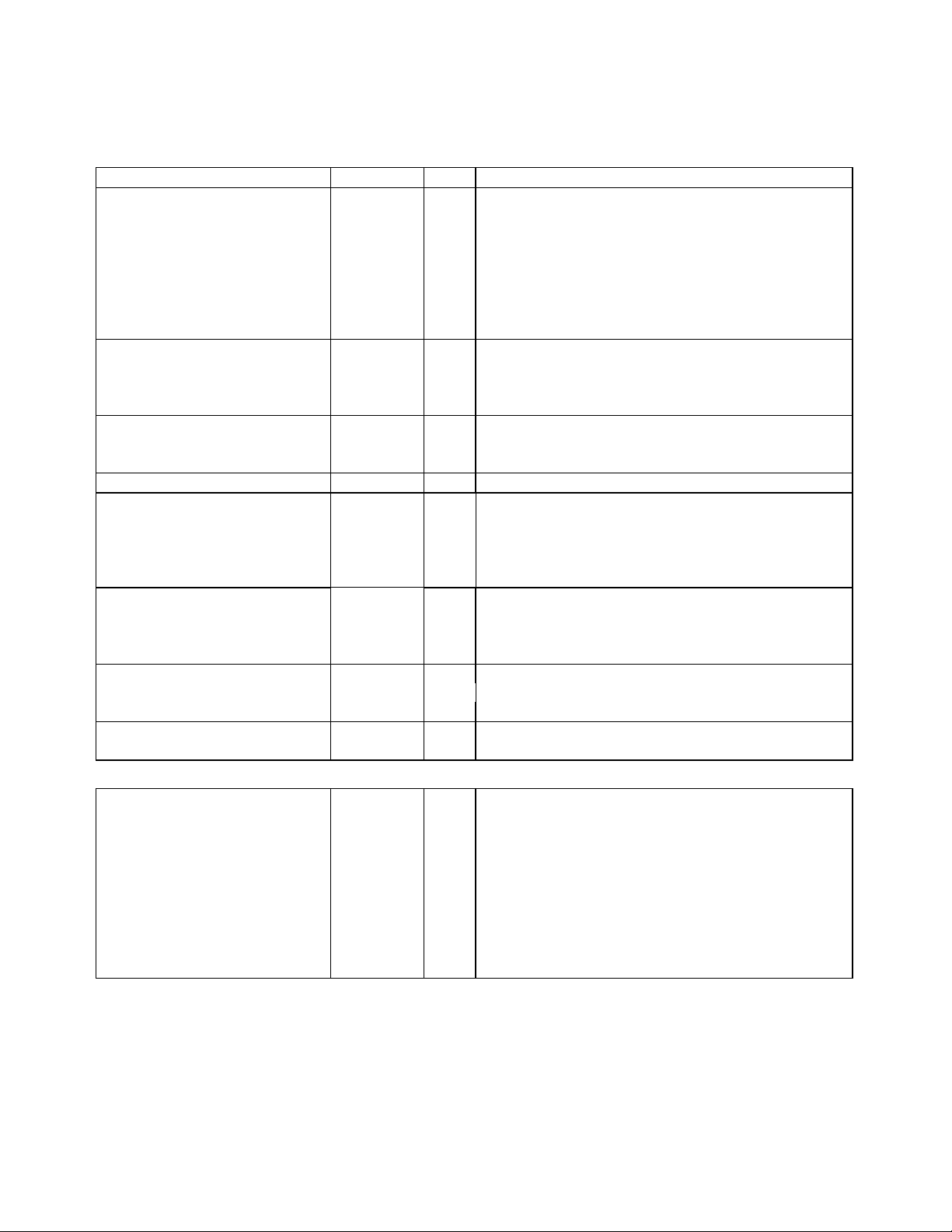

TOYOTA TACOMA (USA)

PRODUCT NUMBER 3423020

WARNING

FOR VEHICLES EQUIPPED WITH SRS AIRBAG

WHEN INSTALLED IN ACCORDANCE WITH THESE INSTRUCTIONS, THE FRONT

PROTECTION BAR DOES NOT AFFECT OPERATION OF THE SRS AIRBAG.

TAKE NOTE OF THE FOLLOWING:

• THIS PRODUCT MUST BE INSTALLED EXACTLY AS PER THESE INSTRUCTIONS

USING ONLY THE HARDWARE SUPPLIED.

• DO NOT USE THIS PRODUCT FOR ANY VEHICLE MAKE OR MODEL, OTHER THAN

THOSE SPECIFIED BY ARB.

• DO NOT REMOVE LABELS FROM THIS BULL BAR.

• THIS PRODUCT OR ITS FIXING MUST NOT BE MODIFIED IN ANY WAY.

30-11-04 Page 1 of 8 3782653

Page 2

FITTING KIT NUMBER 6171370

USE PART No QTY DESCRIPTION

6151096

6151095

IMPACT ABSORBERS 4581050

TO CHASSIS RAILS 4581049

6151138

6151105

3751872L

3751872R

SPLASH PAN 6151021

TO BULL BAR 4581044

3314401

6151132

BULL BAR TO 6151045

IMPACT ABSORBERS 4581048

4581040

BUFFERS TO BULL BAR 6151132

6151021

CONTROL BOX BRACKET 4581044

3751564

6151132

NUMBER PLATE BRACKET 6151017

6151046

6151128

3751542

BUFFERS AND INDICATORS 3500200

3500080

8-9000lb WINCH TO PAN 4581040

180302

THE FOLLOWING PARTS ARE ONLY FOR 2002 MODEL ONWARD

BOLT M12 x 40mm

2

BOLT M12 x 1.25 PITCH X 35mm

2

WASHER SPRING M12

6

WASHER FLAT M12

8

NUT ½” UNC

2

BOLT ½” x 4 ½” UNC

2

IMPACT ABSORBERS

1

IMPACT ABSORBERS

1

BOLT M8 x 20mm

3

WASHER FLAT M8

3

SPLASH PAN

1

NUT FLANGE

3

BOLT M10 x 25mm

6

WASHER SPRING M10

6

WASHER FLAT M10

6

NUT FLANGE M8

4

BOLT M8 x 20mm

2

WASHER FLAT M8

2

CONTROL BOX BRACKET

1

NUT FLANGE M8

2

BOLT M6 x 16mm

4

WASHER FLAT M6

4

NUT FLANGE M6

4

NUMBER PLATE BRACKET

1

BUFFERS KIT

1

ARB INDICATORS

1

WASHER FLAT 3/8”x 1”

4

CABLE TIES

6

CHASSIS EXTENSION 3756405

6151246

4581049

4581050

3756407

5846400

6151294

6151021

4581044

4581046

BRACET CHASSIS EXTENSION

2

BOLT M12 X 1.75 PITCH X 25MM

2

WASHER M12

2

WASHER SPRING M12

2

BRACKET SUMP GUARD SUPPORT ASSY

1

PACKER RECTANGULAR

2

“U” NUT M8

3

BOLT M8 X 20MM

3

WASHER M8

3

WASHER SPRING M8

3

TOOLS REQUIRED

1 BASIC TOOL KIT, DRILL, ½” DRILL BIT. ¾” LONG REACH SOCKET. (IF DRIVING LIGHTS ARE TO BE FITTED)

30 11 04 Page 2 of 8 3782653

Page 3

ASSEMBLY SEQUENCE FOR BULL BAR INSTALLATION.

1. Remove bumper bar, tie down rings, and tow

hook from the vehicle.

2. Remove the crush cans from the front of the

vehicle. (On 2002 models onward, the crush cans

are welded to the sump guard support cross

member which must be removed)

3. Fit the indicators into bar.

4. Fit number plate bracket to bull bar using 6mm

hardware.

5. Fit control box bracket to bull bar using 8mm

hardware.

6. Fit buffers to bull bar using M8 flange nuts

supplied in buffer kit.

NOTE: DO NOT OVER TIGHTEN.

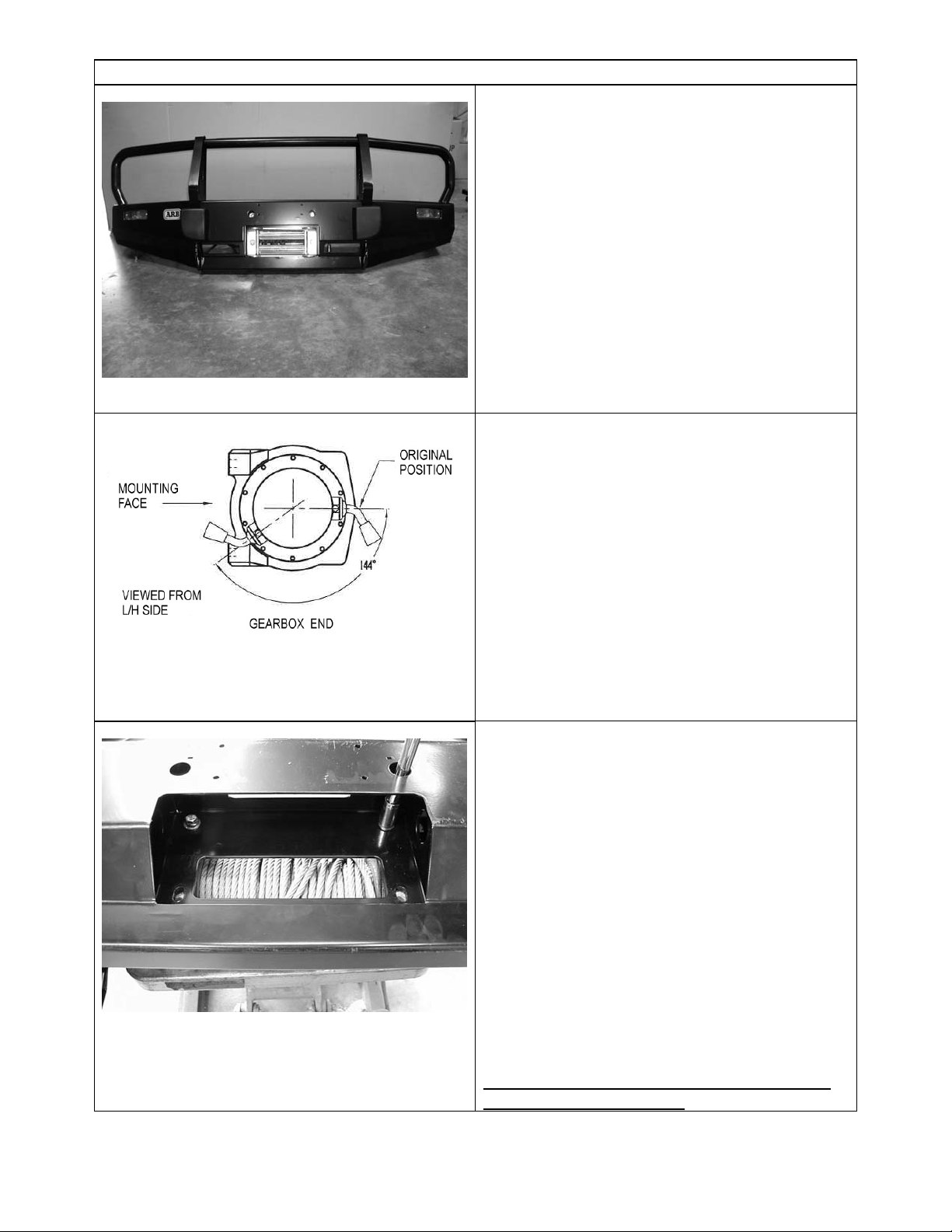

7. To place the clutch handle in the correct

position, the winch gearbox must be rotated 144

degrees (4 hole spacings), in anti- clockwise

direction when viewed from gearbox end. Place the

winch on its end and remove all gearbox bolts.

Gently raise the gearbox just enough to rotate it.

When the correct position is located, refit all bolts

and tighten.

NOTE: Take care not to lift the assembly more

than a couple of millimetres while rotating to

correct position to avoid unmeshing the gears.

See diagram opposite.

8. Once winch is rotated, positioned winch on

bench face up.

9. Lower bull bar on top of winch and align holes

with each other. Using 1 1/4” x 3/8” bolts and flat

washers from bolt kit, secure the two most upper

holes first and finger tighten. Remove top circlips

from vertical rollers of fairlead and remove pins

and rollers, this is done so there is easy access to

lower bolts.

10. Place roller fairlead in bar cutout over lower

holes and fasten using 1 1/2” x 3/8” bolts and 3/8”

flat washers supplied in bolt kit.

11.When all is positioned, tighten all bolts firmly

and replace rollers, pins and circlips back to roller

fairlead.

If fitting the XP 9.5 winch, continue to step 12,

otherwise, jump to step 19.

30 11 04 Page 3 of 8 3782653

Page 4

12.

If fitting the XP 9.5 winch, remove the cover from

the control box.

13. Remove the two cap screws, nuts and spacer

washers that hold the four solenoids in place.

14. Remove the four solenoids from the base of the

control box using the copper bus bar as an aid and

hold to one side.

30 11 04 Page 4 of 8 3782653

Page 5

15. Remove the two bolts in the base of the control

box and reposition them into the more centralised

holes

Before

After

16. Place the 4 solenoids over the 2 metal stands

that are facing upwards. Make sure they line up

with the holes in the base.

17. Replace the 2 cap screws, washers and nuts

removed in step 13 above into original holes.

18. Replace the black cover and refit the three

cover screws (DO NOT OVER TIGHTEN)

30 11 04 Page 5 of 8 3782653

Page 6

19. Fit control box to control box bracket and

tighten firmly.

20. Pull wires through viewer cutout under control

box and wire up as per Warn instruction manual.

21. Tie back cables clear of all moving parts with

cable tie supplied.

22. Place ground earth lead under bolt of winch

tension bar.

FOR 2002 MODELS ONWARD go to step 23.

FOR PREVIOUS MODELS go to step 24. (The parts listed in step 23 will not be required)

23. Push the 3 M8 “U” nuts onto the sump guard

support and bolt the chassis extension and support

to the front of the chassis using 2 M12 x 35mm

fine pitch bolts, flat washers, spring washers and

rectangular packer.

24. Fit impact absorbers to both sides of the

vehicle.

25. On LHSide of vehicle, refit tow hook using

original 12mm bolts.

26.

Prior 2002 models

, fit 12mm x 30mm fine

pitch bolt to the front of the chassis.

2002 models

on, fit 12mm x 25mm course pitch

bolts to the front of the chassis extension.

27. From underneath of bracket, drill right through,

using ½” drill bit and fit 4 ½” bolt upward with

washers and nut.

28.On RHSide of vehicle under impact absorber,

relace tie downs and bolt up using 12mm x 40mm

bolts etc.

29. When all bolts are fitted, finger tighten only.

30 11 04 Page 6 of 8 3782653

Page 7

30. Lift bar into position between impact absorbers

and bolt up using M10 x 25mm bolts, spring and

flat washers. Finger tighten only. (Bolts fit from

inside of bar.)

31. At this stage, firmly tighten all impact absorber

bolts.

32. Adjust bar so that there is a 20mm gap around

the periphery of the vehicle and securely tighten all

remaining bolts throughout.

33. Wire main power leads to battery as per Warn

instructions and cable tie leads securely from all

moving parts with cable ties supplied.

34.Fit number plate to bar using 6mm hardware.

35.Pull winch cable through roller fairlead, and fit

tow hook.

36. Connect the indicator looms to the existing

indicator loom with the Scotchloks supplied. Test

to ensure the indicators function correctly.

37.

Prior 2002 models

. Once bar is correctly fitted,

undo front bolts in splash pan of vehicle, slide bar

plate in between and refit bolts and finger tighten.

2002 models on

, splash pan is bolted to bull bar as

above and bolted to cross member installed in step

23. using 8mm hardware supplied.

38. Using 8mm hardware supplied, bolt plate to

front of underside of bar. When all bolts are fitted,

tighten firmly.

39. If driving lights are to be fitted, use extension

bar with ratchet, ¾” long reach socket to tighten

from cutout in centre pan.

30 11 04 Page 7 of 8 3782653

Page 8

40. Winch handle is operated from this cutout.

30 11 04 Page 8 of 8 3782653

Loading...

Loading...