Page 1

Part Number:

Product

3415110/120 F/Kit 6172316

ARB DELUXE WINCH BULL BAR

Description:

Suited to

TOYOTA LANDCRUISER 200 SERIES 2007 ON,

vehicle/s:

Note: 3415110 NO HLC, 3415120 WITH HLC (SAHARA)

WARNING

REGARDING VEHICLES EQUIPPED WITH SRS AIRBAG;

When installed in accordance with these instructions, the front protection bar does not affect operation of

the SRS airbag.

ALSO, NOTE THE FOLLOWING:

♦ This product must be installed exactly as per these instructions using only the hardware supplied.

♦ In the event of damage to any bull bar component, contact your nearest authorised ARB stockist.

Repairs or modifications to the impact absorption system must not be attempted.

♦ Do not use this product for any vehicle make or model, other than those specified by ARB.

♦ Do not remove labels from this bull bar.

♦ This product or its fixing must not be modified in any way.

♦ The installation of this product may require the use of specialized tools and/or techniques

♦ It is recommended that this product is only installed by trained personnel

♦ These instructions are correct as at the publication date. ARB Corporation Ltd. cannot be held

responsible for the impact of any changes subsequently made by the vehicle manufacturer

♦ During installation, it is the duty of the installer to check correct operation/clearances of all

components

♦ Work safely at all times

♦ Unless otherwise instructed, tighten fasteners to specified torque

ARB 4x4 ACCESSORIES

Corporate Head Office

42-44 Garden St Tel: +61 (3) 9761 6622

Kilsyth, Victoria Fax: +61 (3) 9761 6807

AUSTRALIA 3137

Australian enquiries sales@arb.com.au

North & South American enquiries sales@arbusa.com

Other international enquiries exports@arb.com.au

www.arb.com.au

Last Rev Date: 17 SEPTEMBER 2008 Page 1 of 20 Fitting instructions# 3783312

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 2

GENERAL CARE AND MAINTENANCE

By choosing an ARB Bar, you have bought a product that is one of the most sought after 4WD products

in the world. Your bar is a properly engineered, reliable, quality accessory that represents excellent

value. To keep your bar in original condition it is important to care and maintain it following these

recommendations:

Prior to exposure to the weather your bar should be treated to a Canuba based polish on all exposed

surfaces. It is recommended that this is performed on a six monthly basis or following exposure to

salt, mud, sand or other contaminants.

As part of any Pre Trip Preparation, or on an annual basis, it is recommended that a thorough visual

inspection of the bar is carried out, making sure that all bolts and other components are torqued to

the correct specification. Also check that all wiring sheaths, connectors, and fittings are free of

damage. Replace any components as necessary. This service can be performed by your local

authorized ARB Stockist.

FITTING REQUIREMENTS

REQUIRED TOOLS FOR FITMENT OF PRODUCT:

Metric socket and spanner sets 8-25mm range External Circlip pliers

Screwdrivers, Philips and Flat blade Power Jigsaw with blade for plastic cutting

Short Body Power Drill 13mm (1/2”) capacity Dia 7.0mm (5/16”) and 10.5mm (25/64”) drill bits

Tin snips Marking pen

Half round file Soft Hammer

Metric hex key set Loctite© 262 or equiv.

Wide masking tape Stanley knife

Small Spirit Level Tape Measure & 2 x 300mm rulers

If fitting parking sensors: Dia 22.0 (7/8”) hole saw Paint black fast drying

HAVE AVAILABLE THESE SAFETY ITEMS WHEN FITTING PRODUCT:

Protective eyewear

NOTE: ‘WARNING’ notes in the fitting procedure relate to OHS situations, where to avoid a

potentially hazardous situation it is suggested that protective safety gear be worn or a safe work

procedure be employed. If these notes and warnings are not heeded, injury may result.

Hearing protection

FASTENER TORQUE SETTINGS:

SIZE Torque Nm Torque lbft

M6 9Nm 7lbft

M8 22Nm 16lbft

M10 44Nm 32lbft

M12 77Nm 57lbft

OPTIONAL LIGHT SETS TO SUIT THIS PRODUCT:

♦ FOG LAMP SET P# 6821201 ADD GXL ONLY P#MD02 LOOM KIT, P#180209 SWITCH AND

P#180215 SWITCH CAP FOR FOGS

♦ UP TO IPF 900 SERIES FOG OR DRIVING LIGHT SETS

♦ IPF 840 FYS

Last Rev Date: 17 SEPTEMBER 2008 Page 2 of 20 Fitting instructions# 3783312

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FOG LIGHTS CAN BE FITTED TO LOWER PAN AREA

Page 3

APPLICATION. PART NO. QTY DESCRIPTION

Mount Brackets To Chassis

Brace Assembly

Bull Bar To Mount Bracket Assy

Stone Tray to Bull Bar

Winch To Bull Bar

Number Plate To Bull Bar

Wing Inner Panels

Buffers

Lights

Miscellaneous

PARTS LISTING

3757602R

3757602L

4581007

4581050

6151395

6151396

5846400

4681274

6151357

6151321

6151357

6151321

6151255

6151189

4581049

4581050

6522683

6151300

6151213

4581082

4581287

6151270

4721518

3756499

6151234

4581045

4581047

6151132

180302

EG50

6151074

6821189

6151384

6781408

6522685R

6522685L

6151300

6151213

4581082

4581287

6151234

4581045

4581047

6151132

3163018R

3163018L

6151128

3163015

6821151R

6821151L

6821152

180701

180302

6191019

3786342

EG50

5868356

1

1

2

2

2

2

2

1

7

7

2

2

6

6

12

6

1

4

4

6

6

2

2

1

2

2

2

2

8

2

2

2

2

1

1

1

10

10

10

10

2

2

2

2

1

1

12

1PR

1

1

2

6

6

2

1

2

3

Bracket Mount RHS

Bracket Mount LHS

Washer Flat M12 large

Washer Spring M12

Bolt M12 x 240mm

Nut Clevis

Plate M12 Bolt x 8mm

Brace

SEMS Bolt M10 x 1.5 x 30mm

Nut Flanged M10 x 1.5

SEMS Bolt M10 x 1.5 x 30mm

Nut Flanged M10 x 1.5

Bolt M12 x 1.75 x 40mm

Nut M12 x 1.75

Washer Flat M12

Washer Spring M12

Stone Tray

Nut Cage M6

Bolt M6 x 20mm

Washer Flat M6 x 16 x 3

Washer Spring M6

Bolt M6 x 40

Spacer Tube 18mm

Bracket Control Box Univ.

Bolt M8 x 25

Washer Flat M8 BZ

Washer Spring M8 BZ

Nut M8 Flanged

Cable Tie

Grommet Dia 50mm

Bolt 3/8 x 1 3/4

Grommet round

Screw self tapping pan head

Tape double sided

Panel Inner Wing RH

Panel Inner Wing LH

Nut Caged M6

Bolt M6 x 20 Blk

Washer Flat M6 Blk

Washer Spring M6 Blk

Bolt M8

Washer Flat M8

Washer Spring M8

Nut M8 Flanged

Buffer

Buffer

Nut M6 Flanged

Light Surround Set

Indicator

Indicator

Loom

Scotch Locks

Cable Ties

Trim Pinch Weld

Template Bumper Cutting

Grommet Dia 50mm

Packer

Last Rev Date: 17 SEPTEMBER 2008 Page 3 of 20 Fitting instructions# 3783312

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 4

REMOVAL OF BUMPER

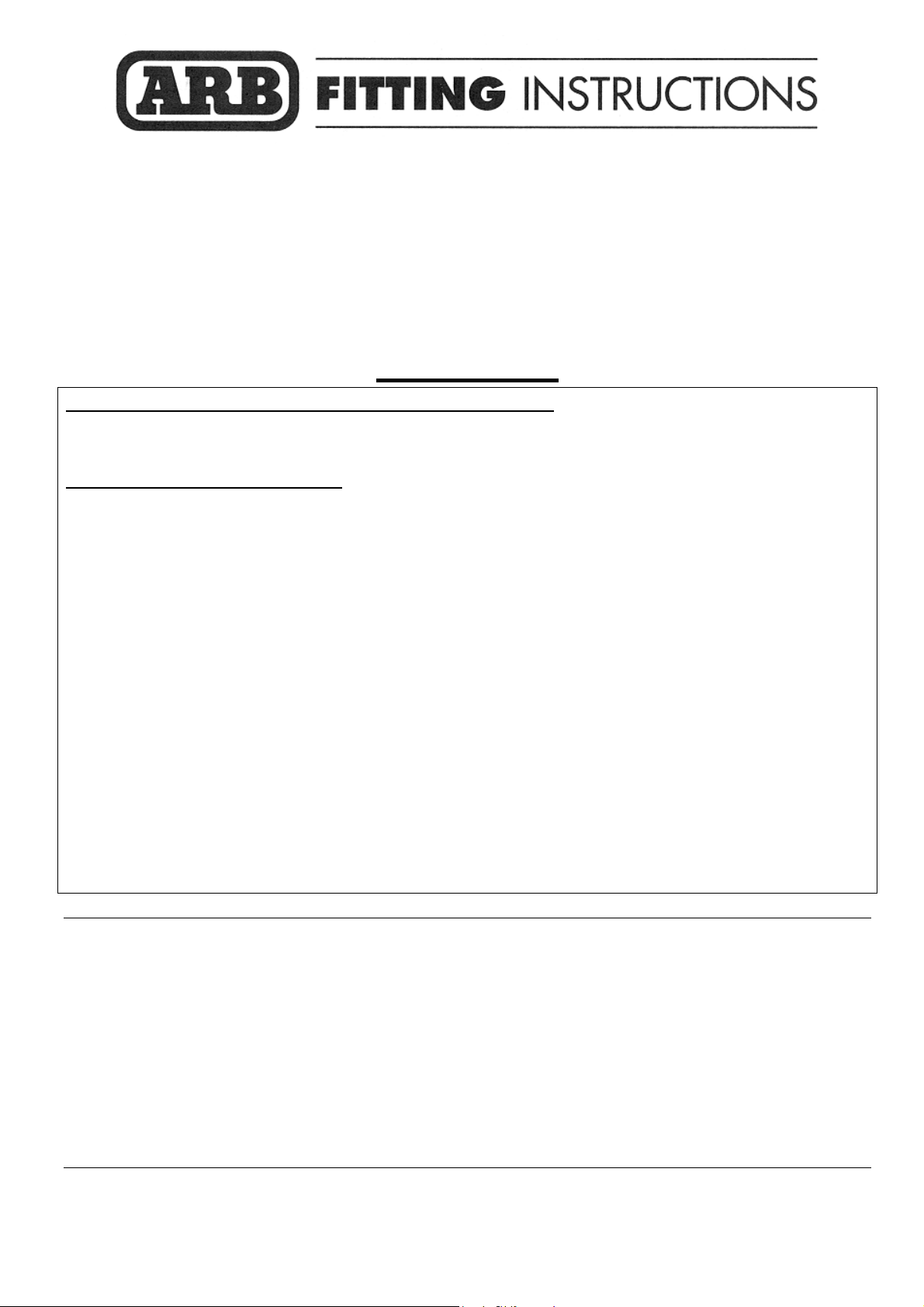

1. Remove number plate

2. Remove number plate mount bracket

3. Remove inner guard bumper retaining

screws three per side using M4 hex key

4. Remove lower trim panel sets each side

which attach to bumper and engine

protective plate area then set aside, they

will not be reused.

Last Rev Date: 17 SEPTEMBER 2008 Page 4 of 20 Fitting instructions# 3783312

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 5

REMOVAL OF BUMPER

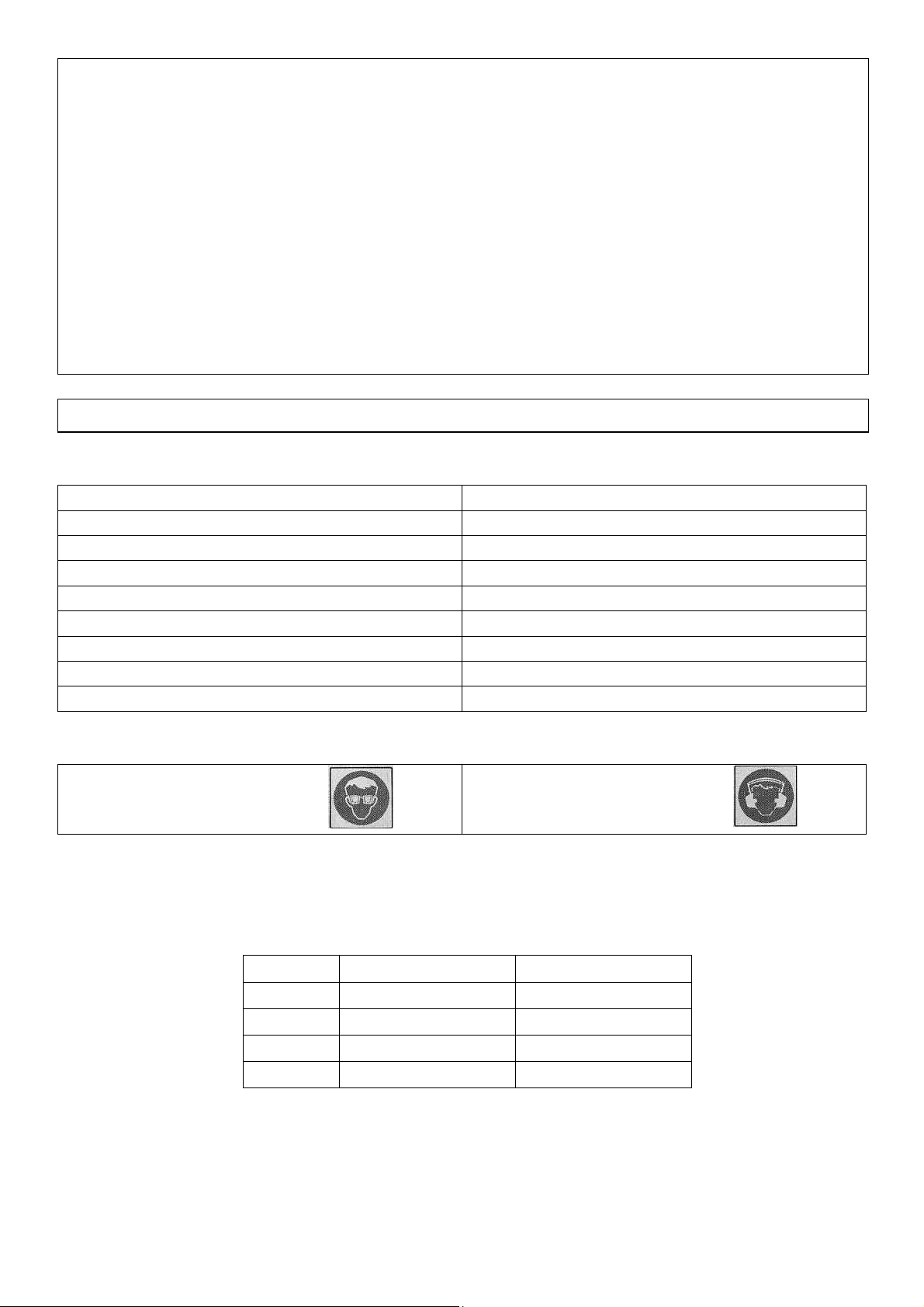

5. When removing lower trim panels, a

plastic nut located on each side will need

to be prized open with a small flat blade

screwdriver to assist removal.

6. Remove lower bumper retaining screws.

7. Remove plastic engine bay cover above

grille area and set aside. Prise open

plastic plugs with small flat blade

screwdriver or similar as shown.

8. Remove 3 X retaining screws from top

of grille

Last Rev Date: 17 SEPTEMBER 2008 Page 5 of 20 Fitting instructions# 3783312

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 6

MASKING BUMPER FOR TRIMMING

9. Apply wide masking tape edge, carefully

aligning 10mm above bumper feature

line as shown. Keep the same line level

through the centre section of the bumper

as shown

Hint: Using a marking pen, run a line or

dashed lines along the feature line on the

bumper to assist in measuring the 10mm

offset for the tape application.

10. Mark out centre cut area of bumper as

shown, 740mm wide x 30mm back from

feature edge.

30mm

11. View of masking tape across bumper for

reference.

12. Apply approx.200mm of masking tape

with edge exactly 90mm from angled

bumper end as shown.

Last Rev Date: 17 SEPTEMBER 2008 Page 6 of 20 Fitting instructions# 3783312

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 7

MASKING BUMPER FOR TRIMMING

13. Cut A3 paper template along identified

cutting line.

NOTE: There is a scale on the sheet to

confirm that the template is 1:1 scale, this

is critical.

14. Apply template to outer corner of RHS

bumper as shown aligning accurately to

features such as the lower line of

headlamp and end of bumper. Tape in

position

Cutting line

15. Transfer cutting line to bumper

16. Apply masking tape aligning edge to

marked cut line as shown

17. Reverse template and apply to LHS of

bumper and follow same steps as RHS.

18. The bumper is now marked out for

cutting.

Last Rev Date: 17 SEPTEMBER 2008 Page 7 of 20 Fitting instructions# 3783312

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 8

REMOVAL OF BUMPER

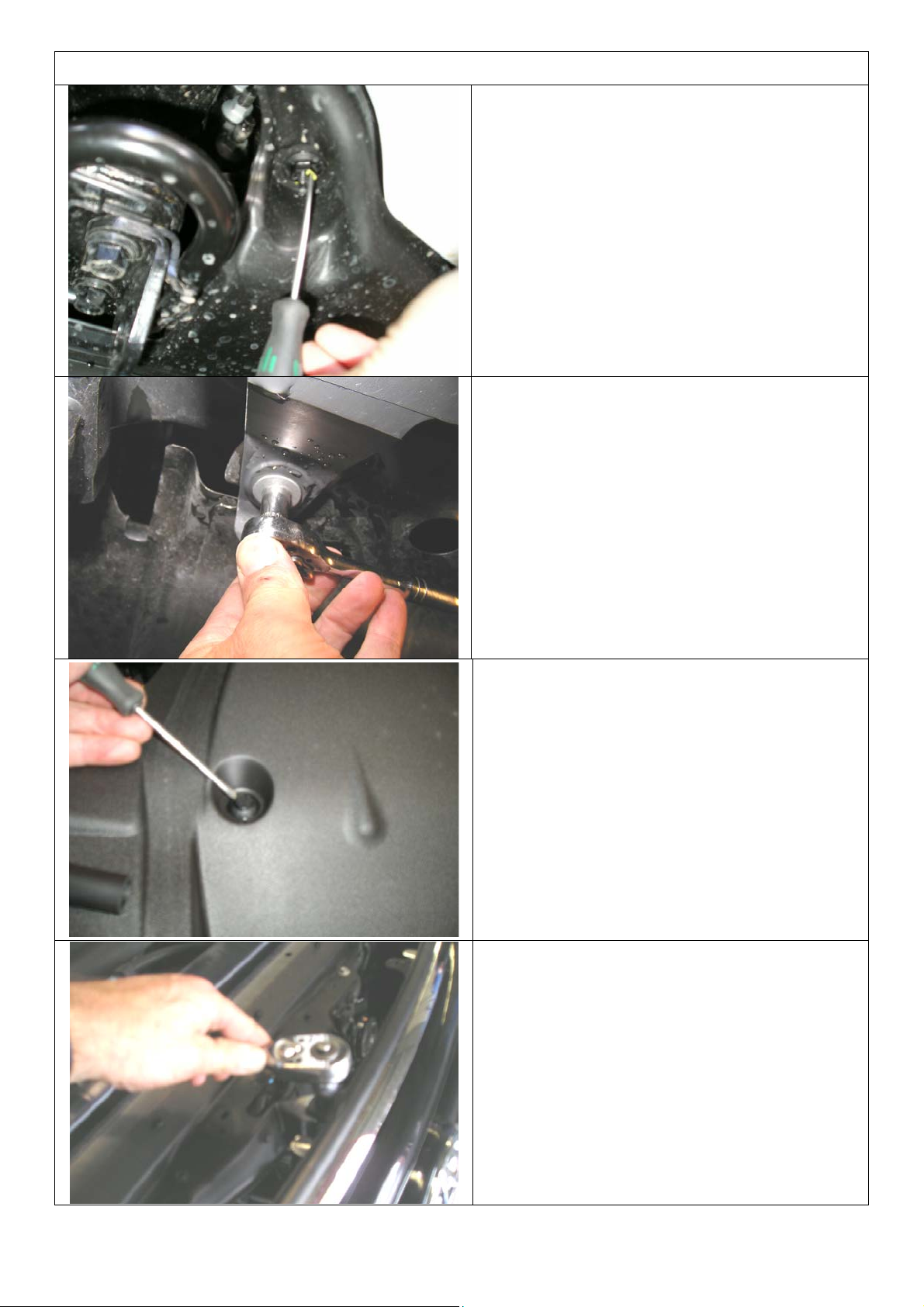

19. Release top of grille. It is retained by 2 x

push in spring clips, located at the outer

top sections below the bolt position.

Hint: You can use a small flat blade

screwdriver to aid in pushing in spring. Fit

spring clips back to grille plugs for easy

replacement.

20. Pull outer returns of bumper outwards

and out of retaining clips.

21. Push bumper down immediately below

headlamp to gain access with a small flat

blade screwdriver and release holding

tab.

NOTE: Take care not to damage painted

edge of bumper

22. Remove plastic plugs securing upper

bumper tabs to cross member.

23. You can now remove the bumper and

place on soft non abrasive rug or similar,

it is best to do this with the help of another

person.

24. If headlight washer system is fitted

disconnect the main line from the vehicle

to the bumper circuit and clamp/crimp it to

prevent washer fluid from leaking out

25. If factory fog lights are fitted, disconnect

the fog light harness from the vehicle by

opening the white flip over clip on the

connector and releasing the loom plug.

Last Rev Date: 17 SEPTEMBER 2008 Page 8 of 20 Fitting instructions# 3783312

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 9

g

REMOVAL OF BUMPER Cont.

26. If fitting 12000lb winch, undo bolt

securing the brace attached to the

centre of grille cross member. See step

61 for picture of bracket.

27. Remove grille from bumper cover by

releasing plastic tabs as shown

28. Remove fog light brackets and set aside,

these will not be reused

29. Remove headlight washer circuit if fitted

and retain for reuse.

30. Remove fog light loom, if fitted, for reuse.

Note, the connections will need to be

removed to fit through the bull bar holes.

Cutting edge

31. Place bumper face up on a bench or

similar so there is sufficient access for the

cutting operation

32. Using a jigsaw, carefully cut along the

edge of the masking tape.

33. Remove burrs from the cut edge of the

bumper, then set aside on the soft non

abrasive surface.

Warning: Cutting

operations can result in

flying debris, safety glasses

should be worn. Work

safely; keep fingers clear of

cuttin

blade.

Cutting line

Last Rev Date: 17 SEPTEMBER 2008 Page 9 of 20 Fitting instructions# 3783312

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 10

PREPARATION FOR MOUNT BRACKETS

34. Remove foam absorber bar and set

aside, this will not be reused

35. Remove crash bar then beam mount

brackets and set aside, retain only M10

flange nuts for reuse.

36. Remove tow hooks and set aside, these

will be reused.

Mark line 60mm

from front face,

other lines as

indicated

37. Mark the lower section of the air scoop

for the power steering radiator as shown.

This is for trimming to clear the mount

brackets.

Note: The 60 mm line from front as indicated

goes right over the top of the scoop and down

the other side, then steps back in the same at

70mm from top, then back to 15mm and down

as shown this side.

38. Remove scoop and cut using jigsaw or

similar and remove burrs.

Warning: Cutting

operations can result in

flying debris, safety glasses

should be worn.

Last Rev Date: 17 SEPTEMBER 2008 Page 10 of 20 Fitting instructions# 3783312

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 11

PREPARATION FOR MOUNT BRACKETS

39. Refit to vehicle, it should now look like

this.

40. Mark out and trim the air deflector on the

LHS of the vehicle using a pair of tin snips

or similar.

Hint: You can do this on the vehicle as shown

below.

41. Fit the cut bumper and secure.

42. Fit the grille

43. Fit pinch weld to each end of the bumper

as shown

44. Secure the wing return in the wheel arch

area with one of the original dome head

screws each side.

45. Fit 2 x large rubber grommets to holes in

uprights inside the upper area of the bull

bar.

46. If fitting fog lamps, factory loom can be

reused and routed through the grommets

in uprights and along inside the lower lip

of the top pan.

47. If headlight cleaner circuit is to be refitted,

run hosing along the underside of the

grille cross member, cable tie in position

as shown Ensure that the tee is

centralised and then cable tie in position

Last Rev Date: 17 SEPTEMBER 2008 Page 11 of 20 Fitting instructions# 3783312

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 12

PREPARATION OF BULL BAR

FITTING WINCH

48. Fit large grommets to holes in top pan

49. Fit control box bracket to control box

studs as shown. Picture also shows

routing of leads through grommets in pan.

50. Using M8 fasteners fit control box

mounting bracket to pan

ORIGINAL

POSITION

POSITION

NEW

51. Prepare winch for fitting by undoing the

cap screws on the gearbox end.

52. Then rotate the end cap and gearbox in a

counter clockwise direction 144° ( four

hole pitches) while looking down at the

gearbox, as shown (for 12000lb winches

rotate clockwise 72°)

53. Tighten the cap screws ensuring the

gearbox handle operates freely.

54. For 8-9500lb only rotate the motor end

90° clockwise (elec. terminals will be up,

see step 59)

NOTE: 12000lb motor is in correct position

as supplied

NOTE: Be careful not to lift the gearbox more

than a few millimetres. Before doing up cap

screws, ensure that the flange faces engage

properly and gaskets are not damaged.

Last Rev Date: 17 SEPTEMBER 2008 Page 12 of 20 Fitting instructions# 3783312

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 13

PREPARATION OF BULL BAR

55. Position the winch with the mount face

facing upward on an adjustable table or

similar and with the assistance of another

person lower the bulbar over the winch.

The winch handle should be in the LHS of

the bull bar for all winches except 12000lb

winch is on the opposite side. The cable

must spool off the bottom of the winch.

NOTE: The 12000lb winch will need to be at

the bottom of the adjustment slots.

Also follow the installation instructions in

the Warn winch handbook accompanying

the winch.

56. Fit the roller fair lead, pull only the end of

the cable through and adjust the position

of winch then bolt up securely. Use the 1

½” long bolts in the top and 1 ¾”in the

lower set through the RFL.

Hint: To increase access to mount bolts in front of

roller fairlead, remove circlips from bottom of each

vertical roller shaft, push shaft up so roller can be

dislodged sideways. Do up bolts in fairlead and

winch, then refit circlip.

57. With the aid of another person, turn the

bull bar over so that the back of the bar is

accessible.

58. Connect up the wires to the winch. Note

that the 12000lb winch requires

supplementary wire kit 3512050. Connect

the longer wires to control box

connections, marking them for correct

connection to motor terminals.

NOTE: Refer to the Warn winch handbook for

wiring instructions to winch and vehicle.

If fitting 12000LB winch only

59. Either relieve the forward section of the

vehicle bracing sheet metal member as

shown to clear winch tie rod, or bend it

back clear of where the winch will be

positioned.

Cut away the entire

forward section at

this line

Last Rev Date: 17 SEPTEMBER 2008 Page 13 of 20 Fitting instructions# 3783312

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 14

PREPARATION OF BULL BAR

60. Fit 4 x M6 cage nuts to bottom inside

face of lower pan in square holes as

shown.

Hint: A small flat blade screwdriver may help to

press nut cage flanges into hole.

Sensors fit on these

outer corners, 90mm

down from top face

in the center of the

corner radius

Hole saw Dia 22.0 (7/8”)

Warning: Cutting operations

can result in flying debris, safety

glasses should be worn.

61. If parking sensors are to be fitted, mark

out the hole positions, located in the

middle of the large corner radius of the

wings and 90mm down from the top face.

(Similar position to original bumper)

Hint: Use two rules across flat faces to find

mid point of radius

62. Once Dia 22 (7/8”) hole is drilled and

fully deburred, check that the hole size is

actually Dia 22.0 – 22.8mm, better if on

larger side. Trial fit sleeve and sensor.

63. Once checked use some fast drying

primer paint to seal bare edges.

64. Carefully slide top section of buffer past

edge of cover strap as shown

65. Adjust buffers so they sit neatly on the

bull bar profile then secure using M6

flange nuts over studs.

NOTE: Do not over tighten nuts as damage

to buffer may result.

Last Rev Date: 17 SEPTEMBER 2008 Page 14 of 20 Fitting instructions# 3783312

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 15

FITTING MOUNT BRACKETS

Hint: Check that the M12 long bolts screw

freely into the clevis nut threads before

assembly.

Packers are supplied to compensate for

body to chassis variation if required

66. Insert clevis bolt with spring, large flat

washers and rectangular 8mm plate

washer through hole in mount bracket

rear flange as shown. Then loose fit

mount brackets to chassis.

67. Secure using existing OE M10 flange

nuts, but do not do up tight.

68. Replace tow hooks using existing bolts

but do not do up tight.

69. Insert clevis nut into rectangular hole in

outboard face of chassis, with the notch in

nut facing toward front of vehicle and

located at the outboard edge of chassis.

NOTE: If KDSS is fitted to vehicle the LHS nut

will have to be loaded to the chassis hole from

the inboard face (engine bay side).

70. The nut when positioned has a slot which

should snugly fit and locate the nut on the

outboard edge of the rectangular chassis

hole. The nut should protrude

approximately 7mm. Screw the clevis bolt

into the clevis nut, do not tighten yet.

71. Tap the outer flange of the mount

brackets until they are hard up against the

tow hook mount area. Nip up the lowest

outboard nut on each bracket. Brackets

should be about 935mm apart

Last Rev Date: 17 SEPTEMBER 2008 Page 15 of 20 Fitting instructions# 3783312

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 16

FITTING BULL BAR TO VEHICLE

72. With the aid of a lift table or one or more

assistants carefully and safely lift, position

and bolt the bull bar to the mounts using 6

x M12 bolts, large flat washers and spring

washers. Centralise the bar to the front of

the vehicle and adjust height.

73. Fit the cross brace to underside of lower

pan and on top of gussets in mount

brackets. Use M10 x 30mm SEMS bolt

and washer sets, flange nuts but do not

do up tight.

74. Adjust the bar height leaving

approximately 15mm gap between top of

wing angled face and the pinch weld on

bumper.

75. Tighten bar mount M12 bolts

15mm gap

76. Tighten M10 flange nuts to chassis studs

to 56Nm.

77. Then tighten up the long M12 tension

bolts, ensuring that the clevis nut location

slot is positioned correctly over the hole

edge in the chassis, protrusion as shown

is approximately 7mm.

78. Tighten brace bolts.

79. Remove each tow hook bolt in turn, apply

loctite © to threads and tighten up.

80. With access through light aperture in

wing, using the M10 pilot holes in mount

brackets (located up 175mm from bottom

face of bar), drill pinning hole through

uprights on bull bar. Fit M10 screw,

washer set and flange nut and do up tight.

Warning: Drilling operations can result in

flying metal debris, safety glasses should be

Last Rev Date: 17 SEPTEMBER 2008 Page 16 of 20 Fitting instructions# 3783312

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 17

FITTING BULL BAR TO VEHICLE

81. If headlight cleaner system to be fitted,

reconnect circuit at main joint to vehicle

and also hoses to tails of spray heads

82. Remove and discard screws and speed

nuts on supplied indicators.

83. Using the 25mm long pan head screws in

the fitting kit, fit indicators to light

surrounds, note that the indicators are

handed and drain holes must be on the

lowest edge.

84. If fitting fog lamps, refer to instructions

supplied with kit.

85. Fit insert assemblies into the wings as

shown

86. Fit the 4 x clamps to secure light

assembly in position.

HINT: You can loose fit the top two screw

and clamp sets before loading the assembly

into the wing to make fit up easier.

Last Rev Date: 17 SEPTEMBER 2008 Page 17 of 20 Fitting instructions# 3783312

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 18

FITTING BULL BAR TO VEHICLE

87. Wire up indicators and parking lamps.

88. Connect red wire from supplied loom to

Running

lamp wiring

Indicator

lamp wiring

HINT: Temporarily undo the battery clamps and

move batteries sideways to gain better access.

NOTE: For GXL use ARB Loom MD02 plus

switch, for VX and Sahara no extra loom or

switching is required. Supplied tails can be joined

to OE loom which is run through bull bar.

green wire from running (parker) lamp.

Connect black wire from supplied loom to

green/yellow indicator wire. Connect

green loom wire to white/black indicator

wire.

89. Use supplied scotch locks for the

electrical connections then secure wiring

with cable ties when complete.

90. Wire up P# 6821201 ARB fog lamps if

fitted. Connect factory loom if fitted.

Check that

sensor fits

flush

Spacer tube

M6 thread in

vehicle tray

91. If parking sensors to be fitted, insert

sleeves first noting that they must be in

the same orientation as in the original

bumper (tab to top RHS down on LHS).

92. Fit sensors checking that they are not too

tight, otherwise correct operation may be

affected (if tight check hole size and

rectify as necessary)

93. Connect to main loom and cable tie

wiring securely

94. Fit stone tray using 4 x M6 bolts and

washer sets at front under bull bar and 2 x

M6 x 40 bolts, washers and 18mm long

tube spacers at two locations into existing

sump guard front section as shown.

95. Fit off winch hook.

Last Rev Date: 17 SEPTEMBER 2008 Page 18 of 20 Fitting instructions# 3783312

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 19

p

FITTING BULL BAR TO VEHICLE

96. If fitting winch apply double sided tape

Split horizontal

Note: LHS shown with 3 of 5 cage nuts inserted.

Fit cage nuts to

inside faces

strip to top back of number plate. If not

fitting winch use top holes in number plate

and no adhesive is required.

97. Fit grommets to slots, with split horizontal

as shown

98. Fit number plate using supplied pan head

screws into grommets.

99. Fit 5 x M6 cage nuts to each wing splash

panel as shown on inside faces.

100. Fit panels up inside wings, secure using

M6 x 20 black bolts and washer sets.

101. Fix folded up slotted flange on panel to

top hole in side of main mount bracket

using M8 bolt set.

Trim this

edge flush

with face of

anel

102. Tuck fender liner into wing return. Trim if

necessary

103. Mark out and drill 2 x Dia 7.0 mm holes in

each fender liner for securing to the

splash panel flange.

Hint: Scribe a line on the liner parallel to the

splash panel, measure and mark the position of

the required holes up from the marked line.

104. Use M6 x 20 black bolts and washer sets

to secure the fender liner to the panels.

105. Trim the fender liner end flush with the

splash panel face as shown.

Warning: Drilling operations can

result in flying debris, safety

glasses should be worn.

Last Rev Date: 17 SEPTEMBER 2008 Page 19 of 20 Fitting instructions# 3783312

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Page 20

NOTE:

♦ Check wiring connections to fitted lights and winch.

♦ Check operation of winch and all lights.

♦ Check operation of headlight washers if fitted

♦ Check operation of parking sensors if fitted

♦ IMPORTANT: Check that all piping and wiring is clear of sharp edges and pinch

points. Adjust any piping to clear the bull bar or mounts by a minimum of 15mm.

FINAL PRODUCT ON VEHICLE

Last Rev Date: 17 SEPTEMBER 2008 Page 20 of 20 Fitting instructions# 3783312

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Loading...

Loading...