Page 1

ARB WINCH/NONWINCH BULLBAR

TO SUIT HJ100 IFS

(To suit October 2002 on)

PRODUCT No. 32/3413190

FITTING KITS 6172338, 6172342

WARNING

FOR VEHICLES EQUIPPED WITH SRS AIRBAG

WHEN INSTALLED IN ACCORDANCE WITH THESE INSTRUCTIONS, THE

FRONT PROTECTION BAR DOES NOT AFFECT OPERATION OF THE SRS

AIRBAG.

TAKE NOTE OF THE FOLLOWING:

• THIS PRODUCT MUST BE INSTALLED EXACTLY AS PER THESE

INSTRUCTIONS USING ONLY THE HARDWARE SUPPLIED.

• IN THE EVENT OF DAMAGE TO ANY BULL BAR COMPONENT, CONTACT

YOUR NEAREST AUTHORISED ARB STOCKIST. REPAIRS OR

MODIFICATIONS TO THE IMPACT ABSORPTION SYSTEM MUST NOT BE

ATTEMPED.

• DO NOT USE THIS PRODUCT FOR ANY VEHICLE MAKE OR MODEL, OTHER

THAN THOSE SPECIFIED BY ARB.

• DO NOT REMOVE LABELS FROM THIS BULL BAR.

• THIS PRODUCT OR ITS FIXING MUST NOT BE MODIFIED IN ANY WAY.

OPTIONAL LIGHT SETS TO SUIT THIS PRODUCT:

-ARB 6821201 Fog Light Kit Suit 3163015

-Up to IPF 900 SERIES FOG OR DRIVING LIGHT SETS

30/04/08 Page 1 of 13 3786407

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

WA: (08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: ( 03) 6331 4190

Head Office – ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

Page 2

USE

MOUNT BRACKETS TO 6151099 2 BOLT M14 X 40mm

VEHICLE 4581052 2 WASHER SPRING M14

6151299 2 BOLT M10 X 1.5 X 100mm

6151040 2 BOLT M10 X 1.25 X 30

4581048 4 WASHER SPRING M10

4581040 6 WASHER FLAT M10

6151026 2 NUT 10 X 1.5

3756493L 1 BRACKET IMPACT ABSORBER LHS

3756493R 1 BRACKET IMPACT ABSORBER RHS

4721520 2 TUBE CRUSH

BULLBAR TO MOUNT ASSY 6151232 8 BOLT M10 X 30X 1.5

4581288 4 WASHER FLAT M10 LARGE

4581040 4 WASHER M10 FLAT

4581048 8 WASHER M10 SPRING

6151026 4 NUT M10

6151304 4 NUT M10 CAGED

WINCH 8/9000/10,000 LB 4581040 4 WASHER FLAT 3/8”

6151074 2 BOLT 3/8” X 1 ¾”

4581041 2 WASHER FLAT 7/16”

NUMBER PLATE 3751451 1 NUMBER PLATE BRACKET

6151180 4 BOLT M6 X 16

6151046 4 WASHER FLAT M6

6151128 4 NUT FLANGE M6

CONTROL BOX 3751564 1 CONTROL BOX BRACKET

6151021 2 BOLT M8 X 20MM

6151132 2 NUT FLANGE M8

4581044 2 WASHER M8

BUFFERS TO BAR 6151128 12 NUT FLANGE M6

6162470R 1 BUFFER UPRIGHT RH

6162470L 1 BUFFER UPRIGHT LH

WINCH CABLES BLB560 2 BLACK CABLE

BLR 560 1 RED CABLE

CABLE TIES 180302 8 CABLE TIES

AIR DEFLECTOR 3314477 1 AIR DEFLECTOR

6151300 4 NUT M6 CAGED

6151180 4 BOLT M6 X 20

6151046 4 WASHER FLAT

4581036 4 WASHER SPRING

INDICATORS TO BAR 3163015 1 COMBINATION LIGHT SURROUND KIT

3314478 1 PAN COVER INTERCOOLER

TURBO DIESEL MODEL 6151128 5 NUT FLANGE M6

FIT KIT 6171775 6151180 5 BOLT M6 X 20

6151046 5 WASHER FLAT M6

PART No

180701 6 SCOTCH LOCK

6821151L 1 TURN SIGNAL / CLEARANCE LIGHT

6821151R 1 TURN SIGNAL / CLEARANCE LIGHT

6821152 2 WIRING LOOM

QTY DESCRIPTION

Tools Required

10mm, 14mm, 13mm 18mm, 19mm, 22mm Spanners and Sockets. Phillips

head screwdriver, drill & 10mm drill bit, hacksaw or angle grinder and 50mm,

100m socket extension.

29/04/08 Page 2 of 13 3786407

Page 3

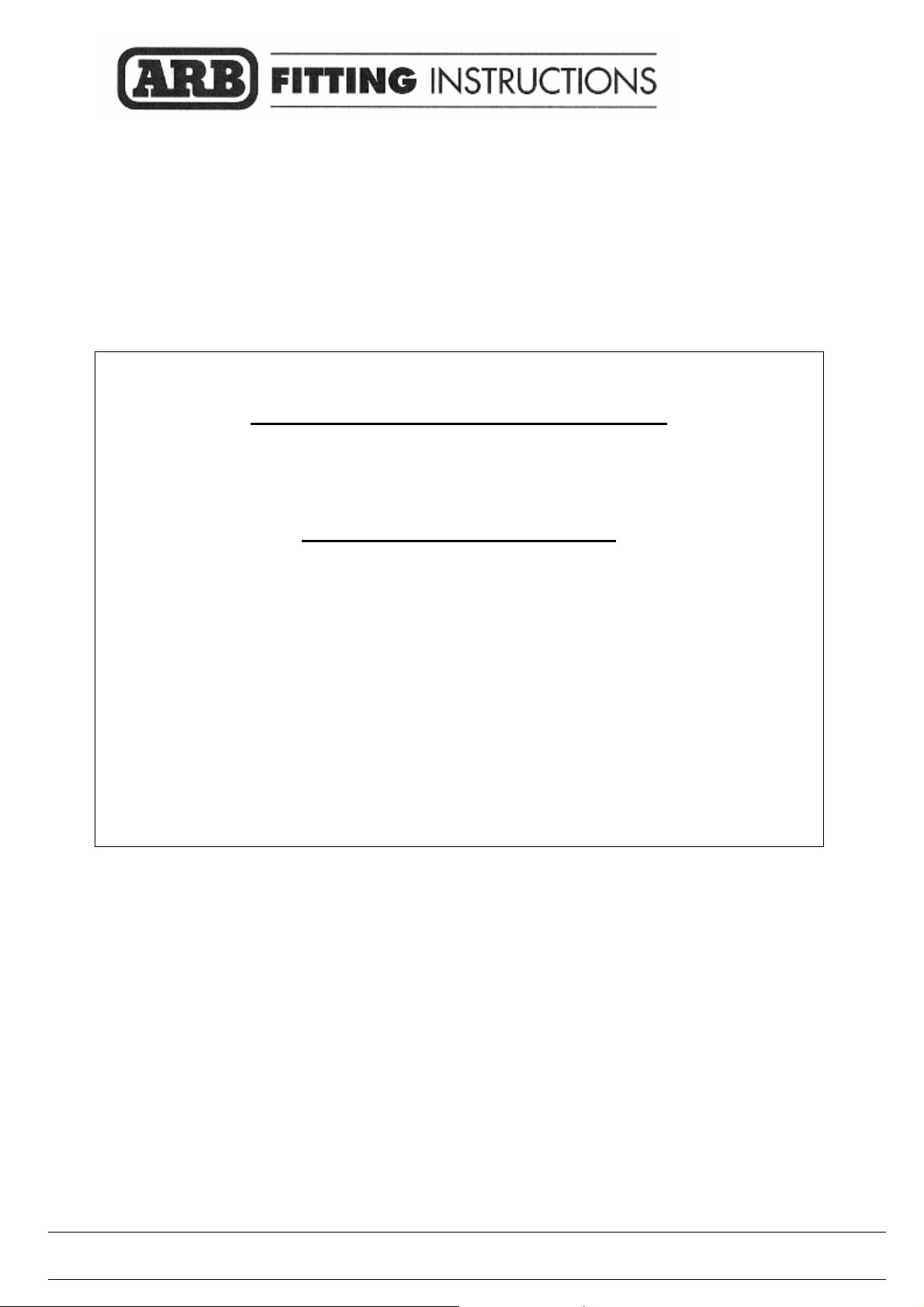

1. Remove the bumper bar and grille

from vehicle.

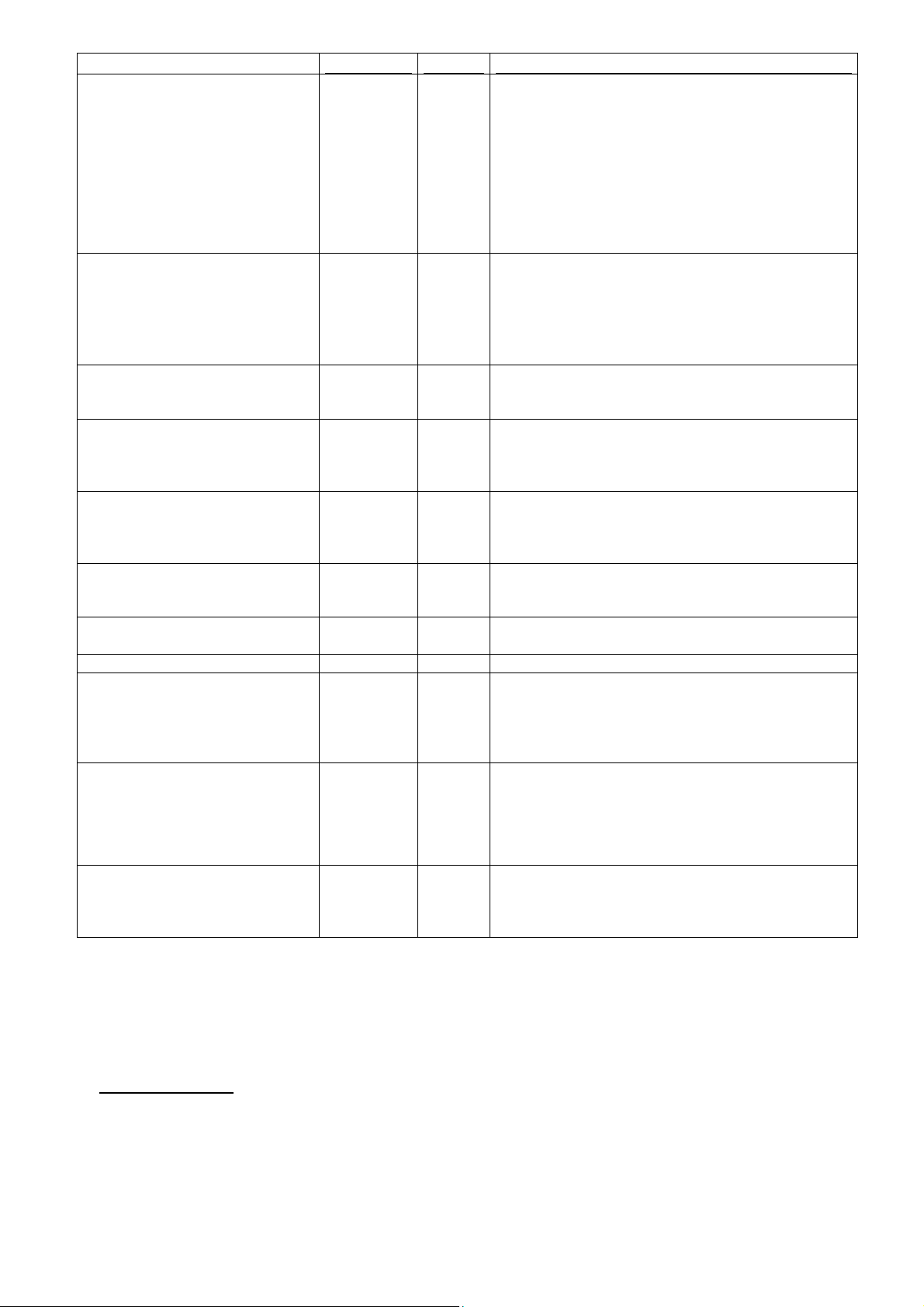

2. Remove the cross member bracket

and tow brackets and tie downs.

Remove the 4 front 8mm bolts that

secure the vehicle stone tray.

3. To fit chassis brackets to chassis rails,

cut off the lower section of chassis

mount.

4. Mark out a line level with the bottom

of chassis rail, and cut off using a

hacksaw or a angle grinder and touch

up bare metal with paint.

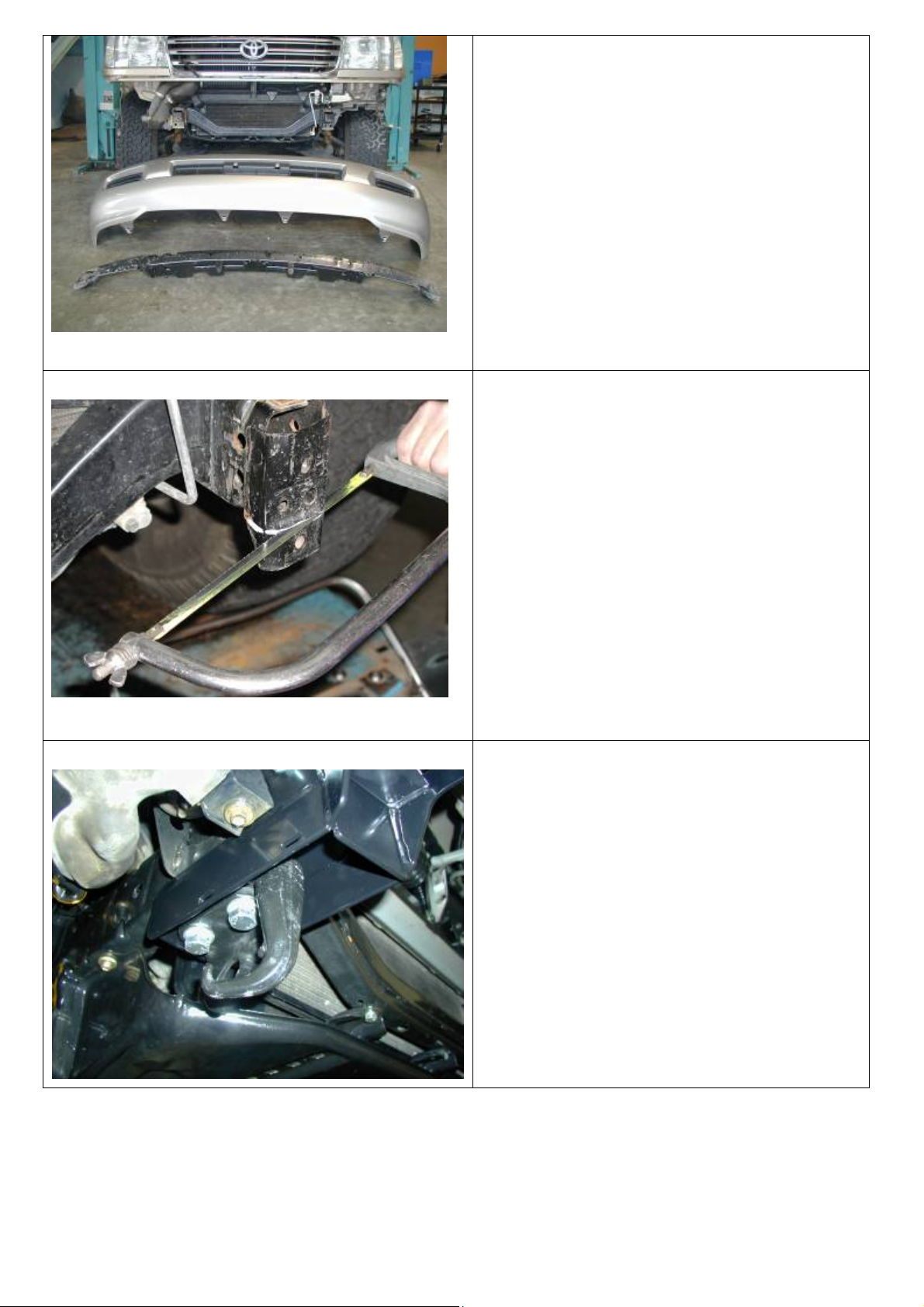

5. Fit chassis brackets to vehicle and

secure as follows.

6. On RHS of vehicle, refit tie down

bracket, tow hook, original 14mm

long bolts and washers to underside

of chassis bracket, finger tighten

only.

Note: Swap tie down brackets left to

right so they mount as shown.

29/04/08 Page 3 of 13 3786407

Page 4

7. On LHS of vehicle secure chassis

bracket and tie down bracket to

vehicle using 14mm x 40 bolts and

spring washers supplied in bolt kit.

(finger tighten only)

8. Using a 13mm drill bit, drill through

chassis rails using hole in impact

absorber as a template. Fit crush

tube, 100mm x10mm bolt, 10mm

washers and nuts through both sides

of chassis brackets. (Finger tighten

only)

9.Fit a 10mm fine thread x 30mm bolt

and washers in the front of chassis

brackets.

10. When all bolts are fitted, the width

of the chassis brackets at bolting

surface should be 860mm. When

measurement is correct, tighten all

bolts securely. Fit 10mm caged nuts

into each chassis bracket. (2 per side)

29/04/08 Page 4 of 13 3786407

Page 5

TO FIT A WINCH BAR.

ORIGINAL

VIEWED FROM

LHS OF VEHICLE

ROTATED

ORIGINAL

11.To fit a 8/9/9.5/000lb winch, rotate

gearbox 144° counterclockwise.

12.Stand winch upright and undo the

capped head screws and by lifting the

gearbox only a couple of millimeters,

rotate the gearbox. Once in position,

refit all screws and tighten firmly.

WARNING

Do not lift gear box more than a couple

of millimeters.

13. To fit a 10/12000 winch, rotate

gearbox 72° clockwise. Both winches

are viewed from gearbox end and

cable spools from the bottom of both

winches.

VIEWED FROM

RHS OF VEHICLE

ROTATED

14. Drill out roller fairlead 25mm

lower than original hole using a

12mm drill bit.

15. 8/9000lb winches use top holes

when fitted to bar

8.

New holes

16. 10/12000lb winches use lower holes

when fitted to bar

29/04/08 Page 5 of 13 3786407

Page 6

17. Remove the cover from the control

box.

18. The three main power cables that go

from winch to control box, must be

changed over using longer cables from

bolt kit. Make sure that you identify the

colour codes on the new cables before

replacing the cover.

(This must be done for all winches to be

fitted to the bull bar)

If fitting XP 9.5 winch, leave

cover open and continue to step

19. For any other winch,

advance to step 25.

19. For XP 9.5 winch, remove the two

cap screws, nuts and spacer washers that

hold the four solenoids in place.

29/04/08 Page 6 of 13 3786407

Page 7

20. Remove the four solenoids from the

base of the control box using the copper

bus bar as an aid and hold to one side.

21. Remove the two bolts in the base of

the control box and reposition them into

the more centralised holes

Before

After

22. Place the 4 solenoids over the 2 metal

stands that are facing upwards. Make

sure they line up with the holes in the

base.

29/04/08 Page 7 of 13 3786407

Page 8

23. Replace the 2 cap screws, washers

and nuts removed in step 19 above into

original holes.

24. Replace the black cover and refit the

three cover screws (DO NOT OVER

TIGHTEN)

25. Fit control box bracket to bar using

8mm hardware.

26. Fit buffers to bull bar using 6mm

hardware.

27. Fit control box to control box

bracket and pull wires through top

cutouts.

28. Fit 8/9000lb winch to top hole

pattern in rear of bar. Secure top

holes of winch using 1 ½” x 3/8”

bolts, spring and flat washers, and

lower holes with 1 ¾” x 3/8’ bolts

through roller fairlead original top

holes. When all bolts are fitted,

tighten firmly.

29. Connect power wires to winch motor

as per Warn instruction manual

(Clutch handle on LHS of

vehicle)

29/04/08 Page 8 of 13 3786407

Page 9

30. Fit 10/12000lb winch to lower hole

pattern in rear of bar. Secure top

and lower holes of winch using 1 ½”

x 7/6” bolts, spring and flat washers,

through roller fairlead drilled lower

holes. When all bolts are fitted,

tighten firmly.

31. Connect power wires to winch motor

as per Warn instruction manual.

(clutch handle on RHS of vehicle)

32. When fitting roller fairlead to bar,

remove circlips and push vertical

pins upward so you can push

vertical rollers sideways to enable

you to place a socket to the bolt

33. When all bolts are tighten, replace

pins and circlips.

29/04/08 Page 9 of 13 3786407

Page 10

34. Before fitting bar to chassis brackets

on vehicle, cable tie all winch power

cables well clear of all moving parts.

When bar is fitted to vehicle, fit leads to

battery and cable tie clear of all moving

parts.

35. Fit 6mm caged nuts into square holes

in lower section of bar.

36. With the help of a friend, lift bar in

between the chassis brackets and

secure to caged nuts using 10mm x

30mm bolts, large HD washers and

spring washers.

29/04/08 Page 10 of 13 3786407

Page 11

37. Adjust bar so there is a 15mm plus

gap around the periphery of the

front of the vehicle.

38. Tighten all 4 bolts until the washers

start to deform.

39. Using a 10mm drill bit. Drill out

pinning holes using holes in bar as a

template. Secure using 10mm x

30mm bolts, washers and 10mm

nuts. Tighten all bolts firmly.

40. Top hole through light aperture in

bar

41. Lower hole through bottom of bar

upright.

29/04/08 Page 11 of 13 3786407

Page 12

42. When bar is secured to vehicle, fit

splash pan using 6mm caged nuts on

lower lip of bar, and to where the

stone tray 8mm bolts were removed

earlier, when all bolts are in place

tighten securely.

43. Assemble and install combination

light surrounds (p/n 3163015) as per

instructions no. 3786421 supplied with

surround kit. Note: Optional fog lamps

can be installed at this point as per

fitting instruction no. 3783315 supplied

with fog lamp kit no. 6821201.

Wire the combination lamp to the

vehicles indicator and clearance lamps.

Caution: Cable tie all cables together

and keep all cables clear of sharp edges

and moving parts.

44. For turbo diesel models, a cover

shield for intercooler pipes must be

fitted.

45. Cover shield fits to chassis bracket,

lower lip of bar and to the tag on the

tube inside the bar.

29/04/08 Page 12 of 13 3786407

Page 13

y

46. Fit number plate to bar.

Winch Bar

If

ou have a slimline number plate

attach it directly to the top pan with

the fasteners provided.

If you have a standard number plate,

fasten it to the top pan using the

bracket and fasteners provided.

Non Winch Bar

Fasten the number plate to the lower

pan using the fasteners provided.

29/04/08 Page 13 of 13 3786407

Loading...

Loading...