Page 1

03/12/04 Page 1 of 11 3782893

If you have any queries regarding the installation of this product please contact the distributor from whom it was purchased, or alternatively the ARB office in your state.

Head Office – ARB Corporation Ltd VIC: 42-44 Garden Street, Kilsyth, Victoria, 3137 Tel: (03) 9761 6622 Fax: (03) 9761 6807

WA: (08) 9244 3553 NSW: (02) 9821 3633 ACT: (02) 6280 7475 SA: (08) 8244 5001 QLD: (07) 3872 3872 NT: (08) 8947 2262 TAS: (03) 6331 4190

ARB WINCH/NONWINCH BULLBAR

TO SUIT HJ100 IFS

PRODUCT No. 3413050 (Pre 09/2002)

WARNING

FOR VEHICLES EQUIPPED WITH SRS AIRBAG

WHEN INSTALLED IN ACCORDANCE WITH THESE INSTRUCTIONS, THE

FRONT

PROTECTION BAR DOES NOT AFFECT OPERATION OF THE SRS AIRBAG.

TAKE NOTE OF THE FOLLOWING:

• THIS PRODUCT MUST BE INSTALLED EXACTLY AS PER THESE

INSTRUCTIONS USING ONLY THE HARDWARE SUPPLIED.

• IN THE EVENT OF DAMAGE TO ANY BULL BAR COMPONENT,

CONTACT YOUR NEAREST AUTHORISED ARB STOCKIST. REPAIRS OR

MODIFICATIONS TO THE IMPACT ABSORPTION SYSTEM MUST NOT

BE ATTEMPED.

• DO NOT USE THIS PRODUCT FOR ANY VEHICLE MAKE OR MODEL,

OTHER THAN THOSE SPECIFIED BY ARB.

• DO NOT REMOVE LABELS FROM THIS BULL BAR.

• THIS PRODUCT OR ITS FIXING MUST NOT BE MODIFIED IN ANY WAY.

IMPORTANT

• This bull bar is suitable for Warn 9000lb, 9500lb High Speed,

10000lb, and 12000lb winches. Note: if fitting a 10000lb or 12000lb

winch cable kit 6171397 is required.

Tools Required

10mm, 14mm, 18mm, 19mm, 22mm Spanners and Sockets. Phillips head screwdriver, hacksaw, drill

& 10mm drill bit.

Optional Extras suited for this bar includes a range of IPF driving lights and

durable driving light covers. Contact your nearest ARB stockest for further

information.

Page 2

03/12/04 Page 2 of 11 3782893

FITTING KIT No: - 6171406(Pre 09/2002) 6171752 (09/2002On)

USE

PART No

QTY

DESCRIPTION

MOUNT ASSY TO VEHICLE

6151257

2

BOLT M12 X 200mm

4581049

6

WASHER FLAT

4721469

2

TUBE PACKER

5846282

2

CHANNEL PACKER

4581050

2

WASHER SPRING M12

6151189

2

NUT M12

6151258

2

BOLT M14 X 80mm

4581052

4

WASHER SPRING M14

5846283

4

PACKER 10mm THICK

3756202

1

MOUNT ASSY.

BULLBAR TO MOUNT ASSY

6151255

6

BOLT M12 X 40mm

4581050

6

WASHER SPRING M12

4581007

6

WASHER FLAT M12 LARGE

6151045

2

BOLT M10 X 25mm

4581039

4

WASHER M10 FLAT

4581048

2

WASHER M10 SPRING

6151026

2

NUT M10

WINCH

4581040

4

WASHER 3/8”

CONTROL BOX FITTMENT

3756220

1

CONTROL BOX BRACKET

6151017

2

BOLT M6 X 16MM

6151128

2

NUT FLANGE M6

6151046

2

WASHER M6

ROLLER FAIRLEAD FITTMENT

6151255

2

BOLT M12 X 40mm

4581050

2

WASHER SPRING M12

4581049

4

WASHER FLAT M12

6151189

2

NUT M12

WINCH COVER FITTMENT

6151128

2

NUT FLANGE M6

6151256

2

SCREW M6 S/STEEL BUTTON HEAD

6191001

1

WINCH COVER EXTRUSION

6521036

1

WINCH COVER (Pre 09/2002)

6522018

1

WINCH COVER (09/2002 On)

6151046

2

WASHER M6

BUFFERS

3500170

1

BUFFER KIT WITH 8 M6 NUTS

NUMBER PLATE FITTMENT

6151017

4

BOLT M6 X 16mm

6151128

4

NUT FLANGE M6

3756234

1

BRACKET NUMBER PLATE

6151046

2

WASHER M6

WIRING

3500080

1

INDICATOR KIT

180302

6

CABLE TIE

Page 3

03/12/04 Page 3 of 11 3782893

ASSEMBLY SEQUENCE FOR BULLBAR.

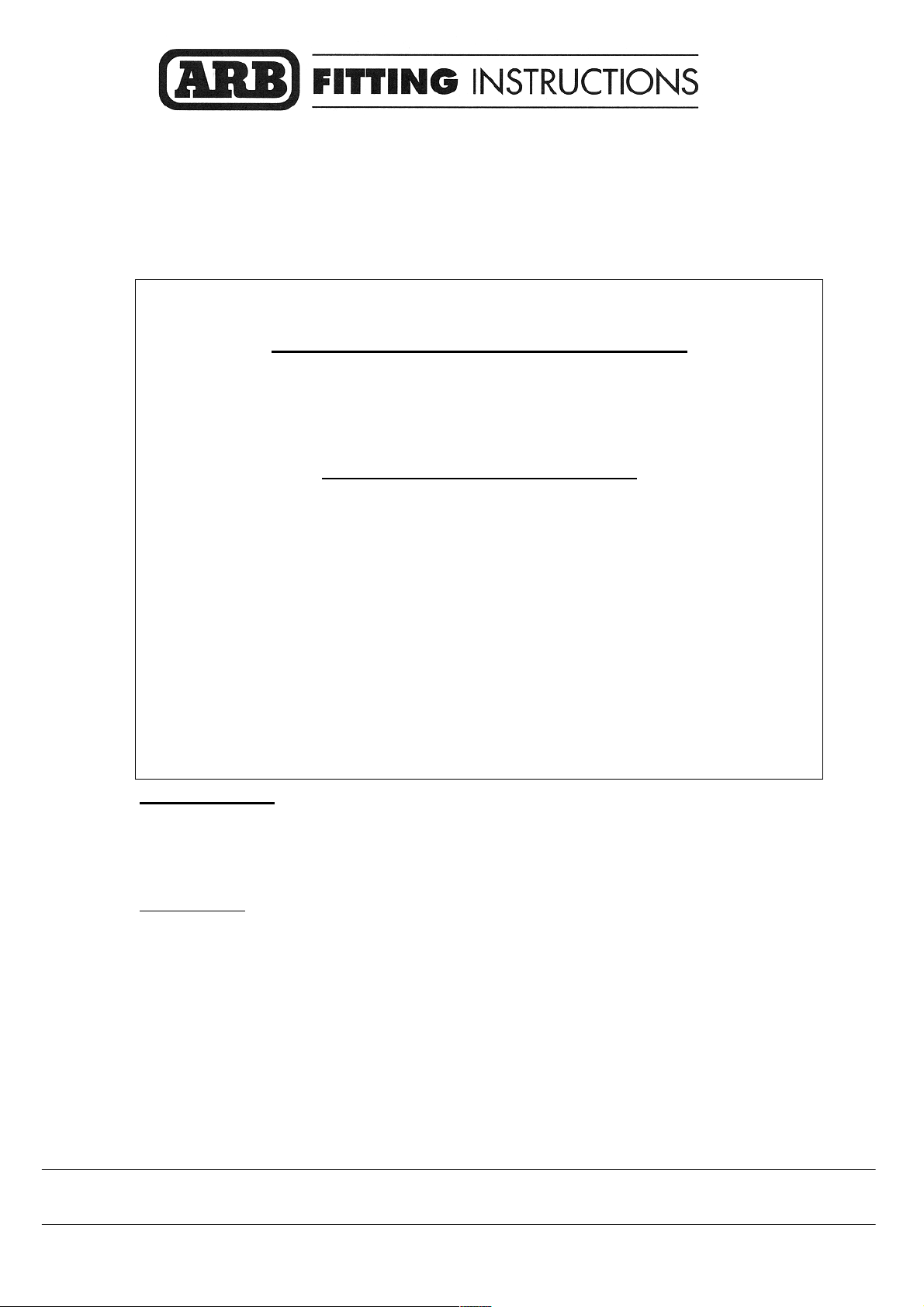

1. 1. Remove the bumper bar and grill.

2. Remove the cross member and tow brackets. See

picture.

3. Bend the sheet metal returns located under the light

area down so they don’t interfere when the bar is

fitted. Mask under the light trim and guard and paint

flat black.

4. Bend the center bracket back approx 90 degrees.

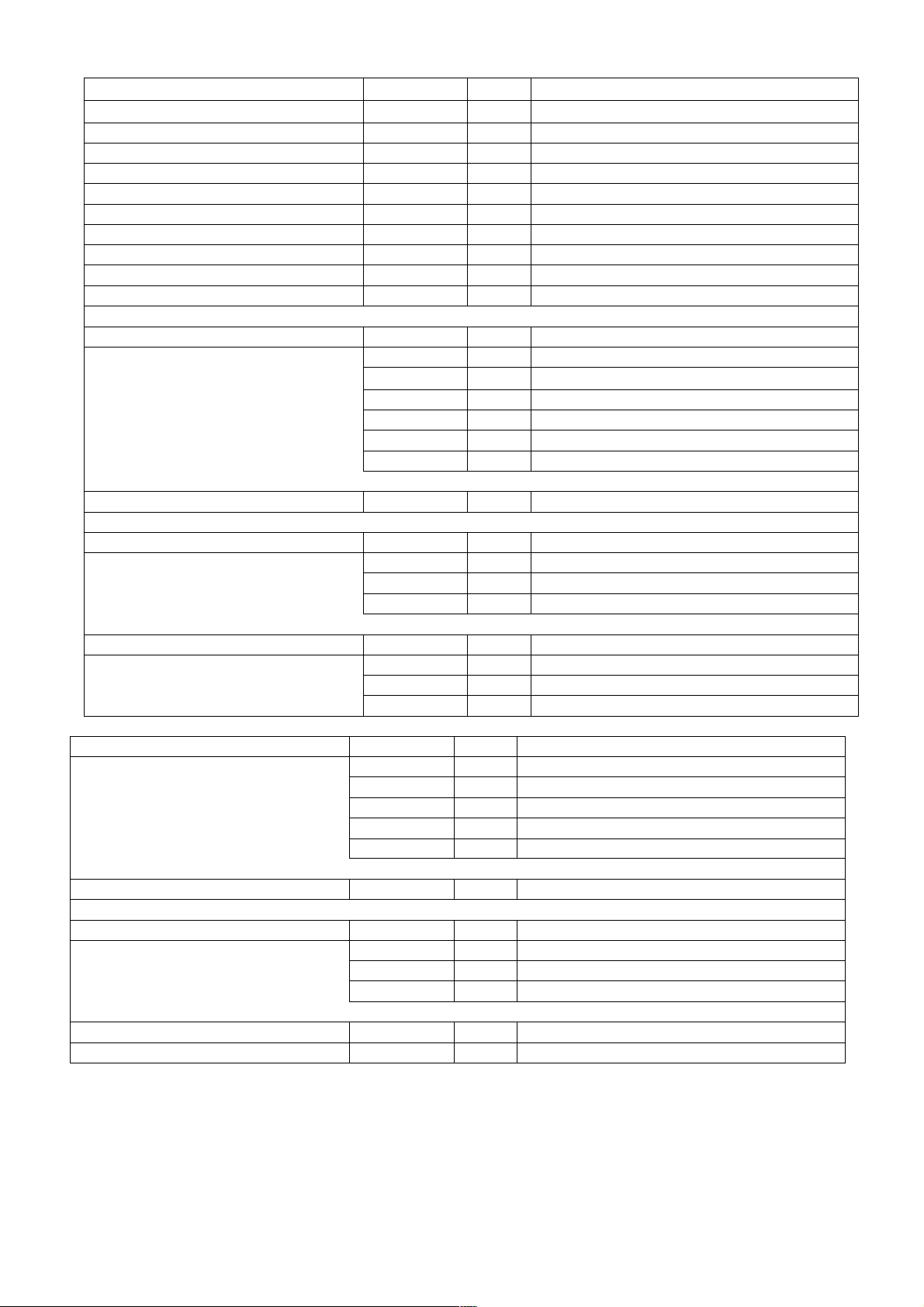

2. 1. Insert the tube packers, one in each chassis arm. Line

the bottom of the tube to the bottom hole of the

chassis rail. Rest the top of the tube to the front of the

chassis rail. The tube should be angled forward.

3. 1. Slide the mount assy. over the chassis rails. Try not

to shake the vehicle too severely as the tube packers

may fall out of place.

2. Insert the channel packers from the rear. Make sure

the hole correspond to the holes in the mount.

3. Push the entire mount as far back as possible.

Page 4

03/12/04 Page 4 of 11 3782893

ASSEMBLY SEQUENCE FOR BULLBAR.

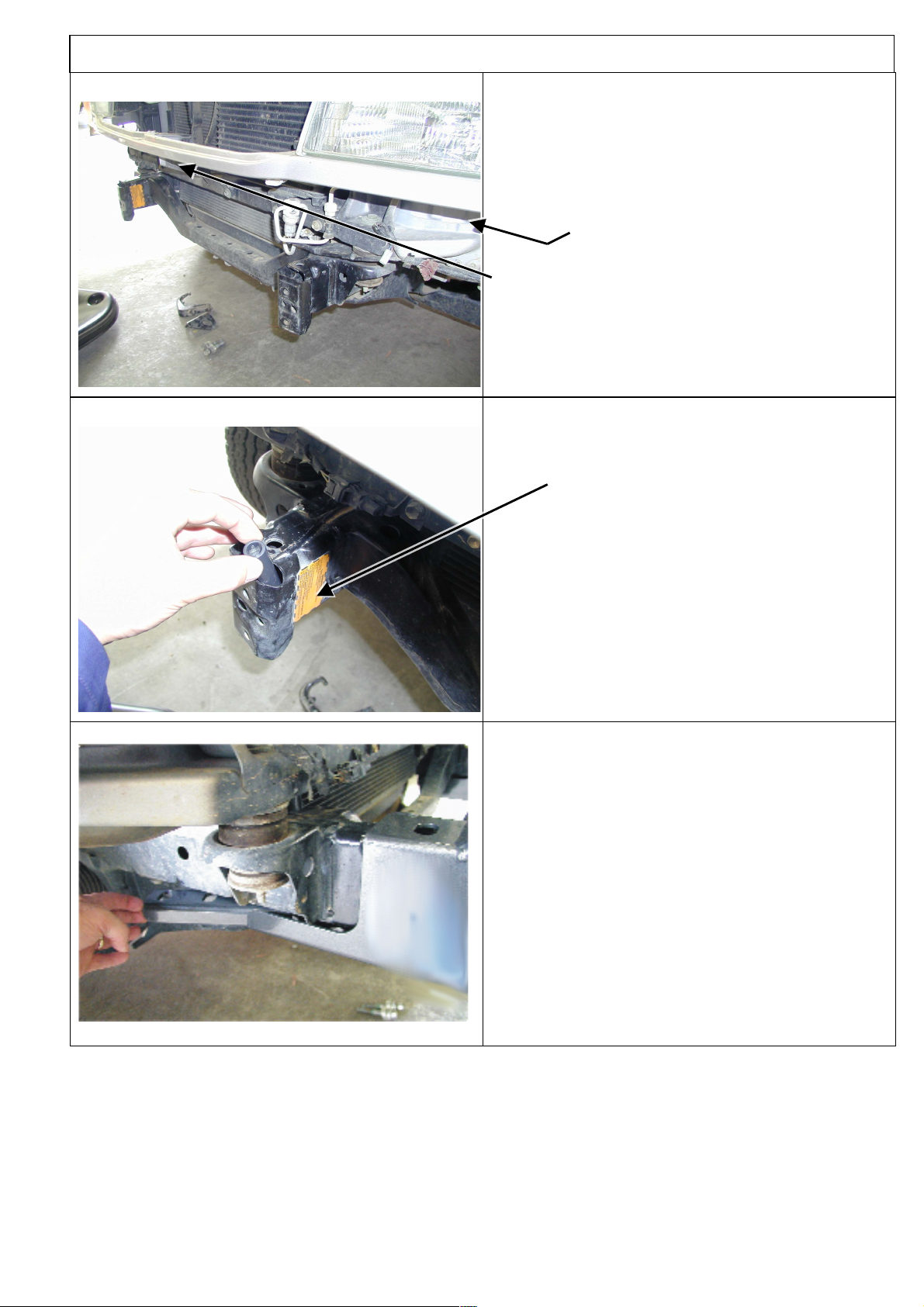

4. 1. Using a long screwdriver insert it through the

bottom hole so it passes through the tube packer.

This may require a visual check from under the

vehicle to see the position of the tube.

2. Using the screwdriver twist around until the packer

is inline with the top hole.

5. 1. Insert the M12 X 200mm bolt through the top hole

using one of the 10mm thick packers. Push through

while removing the screwdriver from underneath

until the bolt locates right through.

Note: For turbo diesel models remove the intercooler

hose to gain access for the M12 X 200mm bolt.

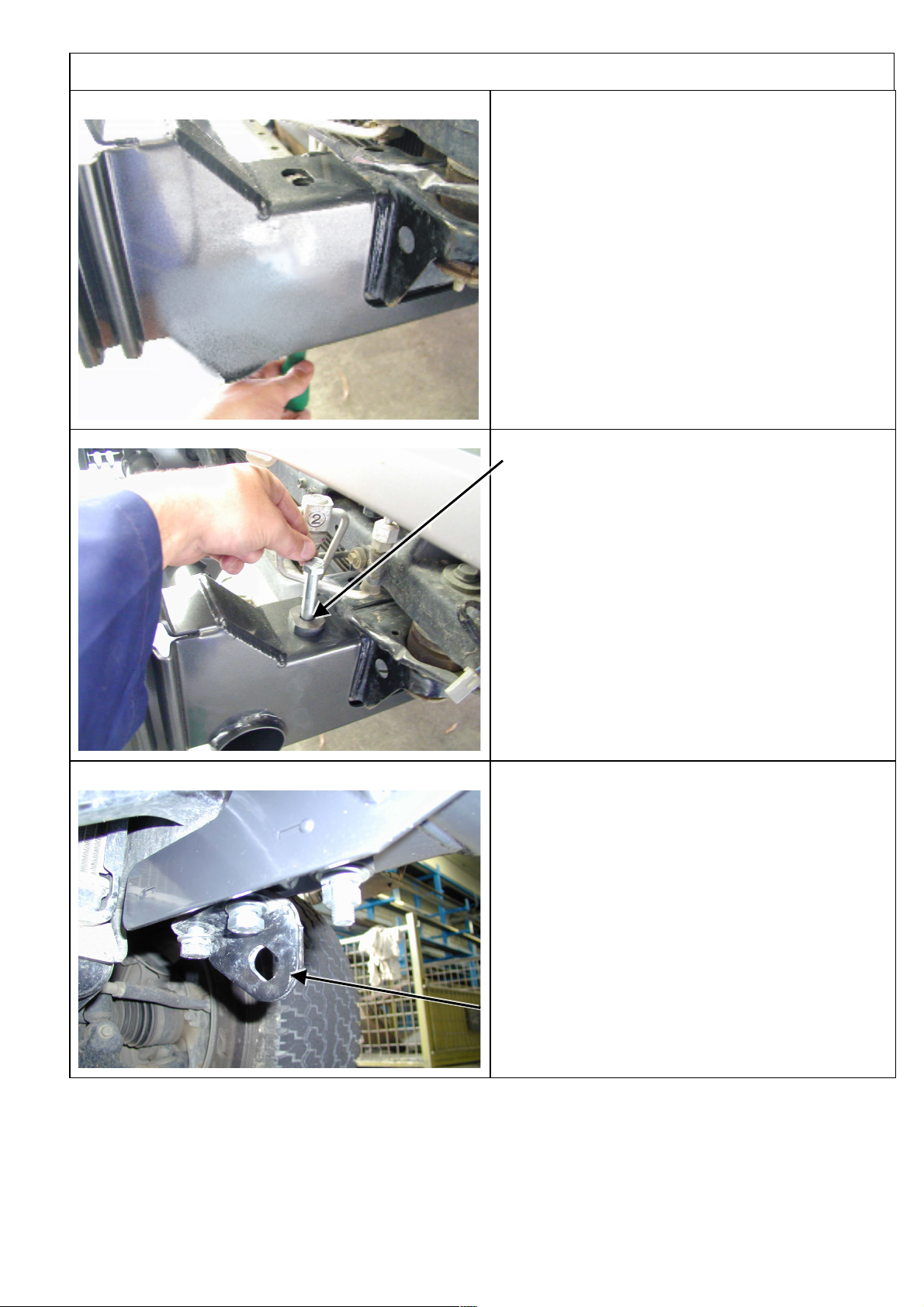

6. 1. Fasten the remainder of the mount using:

2 M14 bolts removed earlier from tow bracket

2 M14 bolts from fitting kit

6 M14 flat washers

4 M14 spring washers

2 10mm thick packers

2 M12 nuts

2 M12 spring washers

Note: Assemble with the tow brackets.

Page 5

03/12/04 Page 5 of 11 3782893

ASSEMBLY SEQUENCE FOR BULLBAR.

7.

1. For pre 09-2002 models use vice grips, multi grips

or pliers bend back the bumper mounting arm

approximately 90 degree’s to clear winch bumper

when assembled.

8. 1. On models built after 09-2002 if you are fitting a

10000lb or 12000lb winch you will need to remove

the upright support and cut a section of it out.

9. 1. Once removed hold the upright in a vice and cut out

the section shown with a hacksaw.

2. Replace the upright and continue fitting the winch.

Page 6

03/12/04 Page 6 of 11 3782893

ASSEMBLY SEQUENCE FOR BULLBAR.

8.

Viewed from passenger side, gearbox end.

9000lb & H/S 9500lb

Viewed from passenger side, motor end.

10000lb & 12000lb

(If fitting with winch)

To place the clutch handle in a convenient location the

winch gearbox must be rotated.

1. Place the winch on its end and remove all gearbox

bolts.

2. Gently raise the motor just enough to rotate it.

3. Do not completely remove the motor and avoid

damaging the gasket.

4. Refit and tighten all bolts.

Note: Take care not to lift the assembly more than a

couple of millimeters while rotating to the desired

position to avoid unmeshing the gears.

9.

(If fitting with winch.)

1. Place the winch on the mount assembly.

2. Bolt from underneath using bolts supplied with

winch and the 3/8” washers supplied in the fitting kit.

Refer to Warn installation instructions for correct

procedure.

Note: If fitting 9000lb or 9500lb high speed winches

mount on the front hole positions. If fitting 10000lb or

12000lb winches mount on the rear hole position.

Fasten the two front bolts first then push the winch to

the back position. Fasten the two rear bolts then tighten

all bolts. Move front lower tie rod to rear lower position

for 10000lb and 12000lb winches.

Page 7

03/12/04 Page 7 of 11 3782893

ASSEMBLY SEQUENCE FOR BULLBAR.

10. (If fitting with winch)

1. Bolt the roller fair lead to the winch bumper using

the M12 X 40mm bolts, washers, spring washers

and nuts.

11. 1. Fasten the indicator lights to the bar.

2. Position the bar on the mounts and fasten the bar to

the mounts using the M12 X 40mm bolts, large washers

and spring washers.

3. Line up the end of the wing to the wheel arch and

leave approximately a 15mm gap between the bar and

the vehicle. Tighten all bolts.

Note: The lower bolt can be accessed through the cutout

at the front of the wing.

12. (If not fitting winch)

1. Wrap rubber extrusion around winch cover.

2. Place washers over the winch cover fixing holes

located on the top middle face of the winch bumper.

3. Place the winch cover on top of the winch bumper

inline with the mount holes.

4. Bolt together using the M6 button head stainless

steel screws and M6 nuts.

Page 8

03/12/04 Page 8 of 11 3782893

ASSEMBLY SEQUENCE FOR BULLBAR.

13.

1. Next step is to lock pin the bar so there is no

movement by drilling a 10mm hole on both sides of

vehicle, fasten with 10mm x 25mm bolts plus 10mm

hardware.

14.

(If fitting with winch)

1. Feed the winch cable through the roller fair lead.

Mount the hook to the end of the cable.

15.

Fitting with winch

Fitting without winch

(If fitting with winch.)

1. Bolt the number plate to the number plate bracket

using the M6 bolts and M6 flange nuts.

2. Bolt the assembly to the bar as shown in the

illustration using the M6 bolts and M6 flange nuts.

(If not fitting with winch.)

1. Bolt the number plate through the top holes using

M6 X 16mm bolts and M6 flange nuts.

Page 9

03/12/04 Page 9 of 11 3782893

ASSEMBLY SEQUENCE FOR BULLBAR.

16. 1. If fitting the XP 9.5 winch, remove the cover from

the control box.

For any other winch, go to step 22.

17. 1. Remove the two cap screws, nuts and spacer washers

that hold the four solenoids in place.

18. 1. Remove the four solenoids from the base of the

control box using the copper bus bar as an aid and hold

to one side.

Page 10

03/12/04 Page 10 of 11 3782893

ASSEMBLY SEQUENCE FOR BULLBAR.

19.

Before

1. Remove the two bolts in the base of the control box

and reposition them into the more centralised holes

After

20. 1. Place the 4 solenoids over the 2 metal stands that are

facing upwards. Make sure they line up with the holes in

the base.

21. 1. Replace the 2 cap screws, washers and nuts removed

in step 17 above into original holes.

2. Replace the black cover and refit the three cover

screws (DO NOT OVER TIGHTEN)

Page 11

03/12/04 Page 11 of 11 3782893

ASSEMBLY SEQUENCE FOR BULLBAR.

22.

(If fitting with winch)

1. Assemble the control box bracket to the control box

using M6 nuts located on the control box bolts.

2. Mount the control box to the bar using M6 X 16

bolts and M6 flange nuts. Fasten the control box to

the front of the cutout on the top pan. This should

leave an opening at the rear for viewing the cable

drum while operating the winch.

Note: If fitting a 10000lb or 12000lb winch cable kit

6171397 is required. Replace the control box cables with

the new longer cables.

23. 1. Fasten the buffers using the M6 flange nuts

supplied.

24.

(If fitting with winch)

Connect the winch control box cables to the winch motor. Refer to the Warn handbook for additional

information. Connect the long winch + & - cables to the vehicle after the bar is installed. Refer to the Warn

winch manual for vehicle wiring instructions. Note: if fitting a 10000lb or 12000lb winch cable kit 6171397 is

required. Use the longer leads to replace ones on control box.

Ensure that these cables are installed well clear of sharp, hot or moving objects. Secure the winch cables

to the vehicle and winch bumper with the supplied cable ties.

25.

Wire the turn signal lights to the vehicle wiring.

Loading...

Loading...