Page 1

SXV 450 – 550

Van Den Bosch Replica

Page 2

SUMMARY TABLE WITH TECHNICAL DATA

FRONT FORK

Type Marzocchi Shiver 50

Travel 267mm

Std. adjustment hydraulic brake under compression 20 clicks from all closed

Std. adjustment hydraulic brake under extension 20 clicks from all closed

Steering angle with centred bushings 25°

Steering angle with eccentric bushings 24° - 26°

Fork offset with centred bushings 14mm

Fork offset with eccentric bushings 11mm - 17mm

REAR SHOCK ABSORBER

Type Mono Sachs racing

Travel 120mm

Std. spring elasticity (K) 5.8 kgf/mm

Std. adjustment hydraulic brake under compression at high speed 10 clicks from all closed

Std. adjustment hydraulic brake under compression at low speed 15 clicks from all closed

Std. adjustment hydraulic brake under extension 20 clicks from all closed

STM CLUTCH

Calibration of primary standard spring SXV VDB 450 (wet race) 120 kg

Calibration of primary supplied spring SXV VDB 450 130 kg

Calibration of secondary standard spring SXV VDB 450 (wet race) 30 kg

Calibration of secondary supplied spring SXV VDB 450 40 kg

Calibration of primary standard spring SXV VDB 550 (wet race) 130 kg

Calibration of primary supplied spring SXV VDB 550 140 kg

Calibration of secondary standard spring SXV VDB 550 (wet race) 30 kg

Calibration of secondary supplied spring SXV VDB 550 40 kg

Wear limit clutch pack 35.00mm

PINION/SPROCKET

Standard pinion SXV VDB 450 z=13

Supplied pinion SXV VDB 450 z=14

Standard sprocket SXV VDB 450 z=45

Supplied sprocket SXV VDB 450 z=44, z=46

Standard pinion SXV VDB 550 z=15

Supplied pinion SXV VDB 550 z=14

Standard sprocket SXV VDB 550 z=46

Supplied sprocket SXV VDB 550 z=45, z=47

Page 3

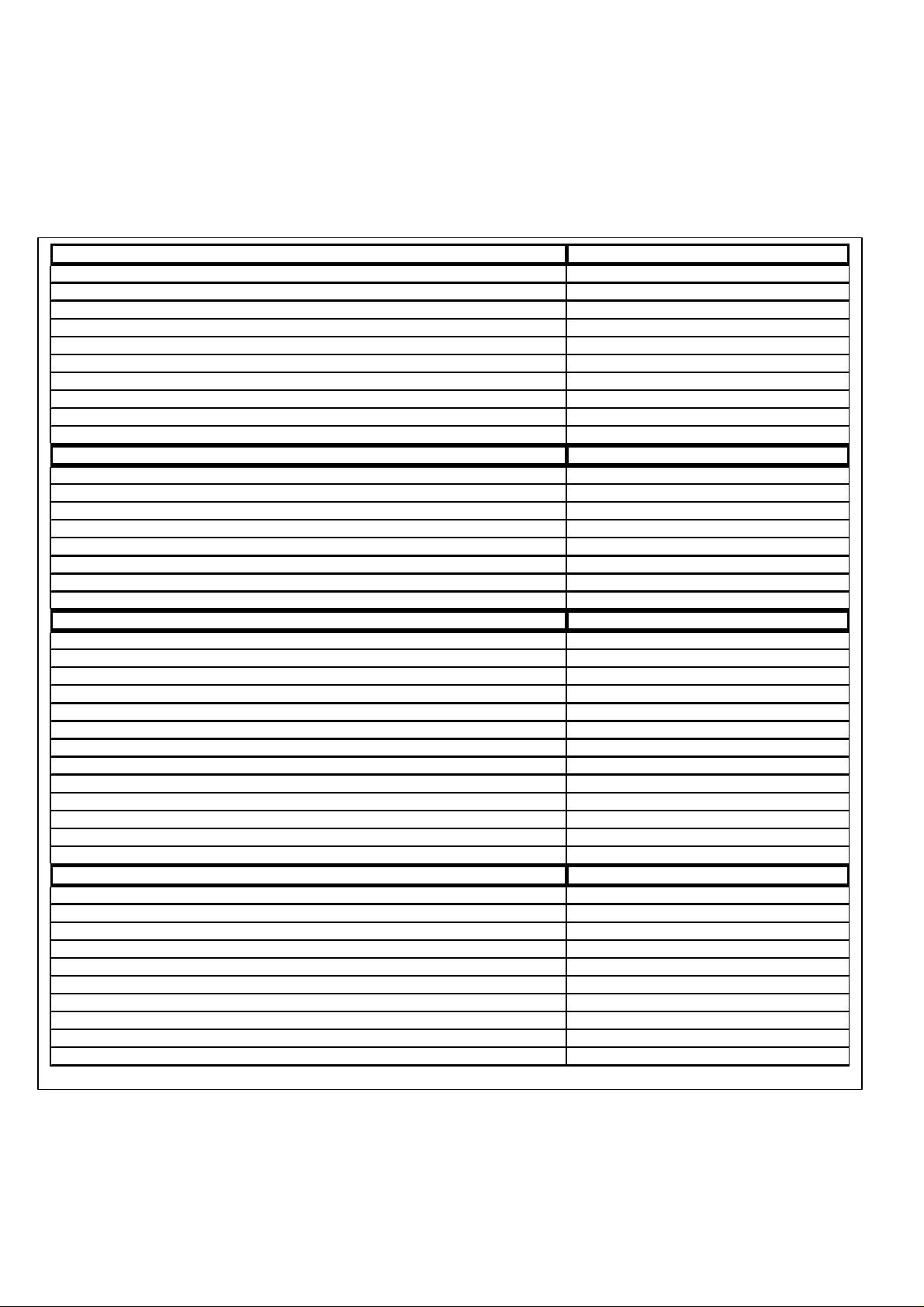

STARTING THE VEHICLE

This vehicle, having been designed for exclusive use in

competitions, is equipped with a small and lightweight

battery, sufficient for amperages needed during warm startups and for the normal operation of the engine.

For cold start it is necessary to use the external battery that

comes with as an accessory to the vehicle.

• Remove the saddle.

• Disconnect the jack from the regular battery and connect

it to the external battery.

• Feed the injection circuit of the vehicle by connecting the

key jack on the handlebar.

• Start the engine using the ignition button on the right

side of the handlebar.

• With the engine running, disconnect the external battery

and reconnect the installed battery.

• To turn off the vehicle just press the off button on the left

side of the handlebar.

WARNING

After use the key jack has to be disconnected.

Page 4

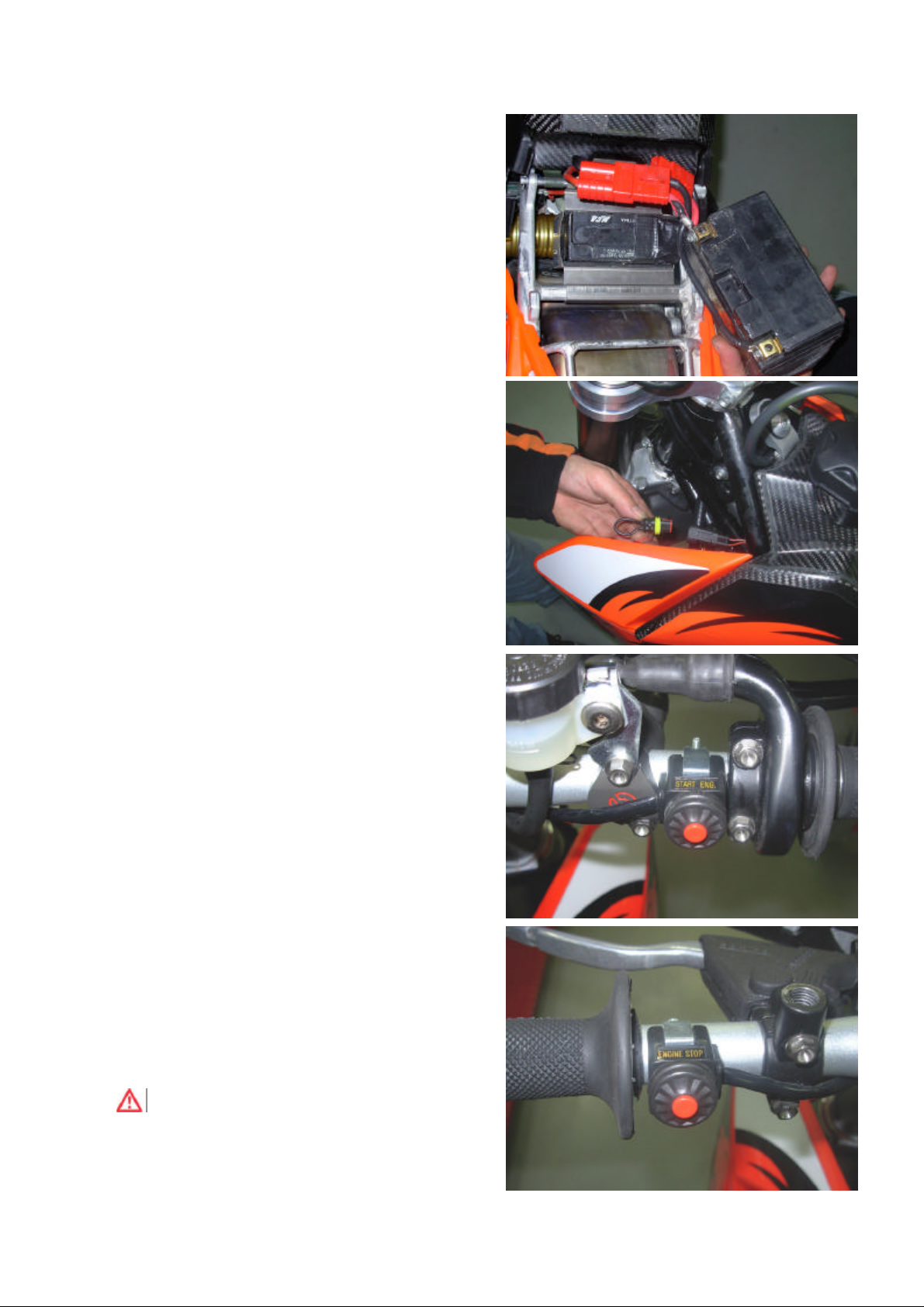

REMOTE ADJUSTMENT OF THE POSITION OF THE FRONT BRAKE

LEVER

• The vehicle is prearranged for a remote adjustment of

the distance of the front brake lever from the handlebar.

• Use the adjustment knob on the left handlebar until the

desired distance is obtained.

Page 5

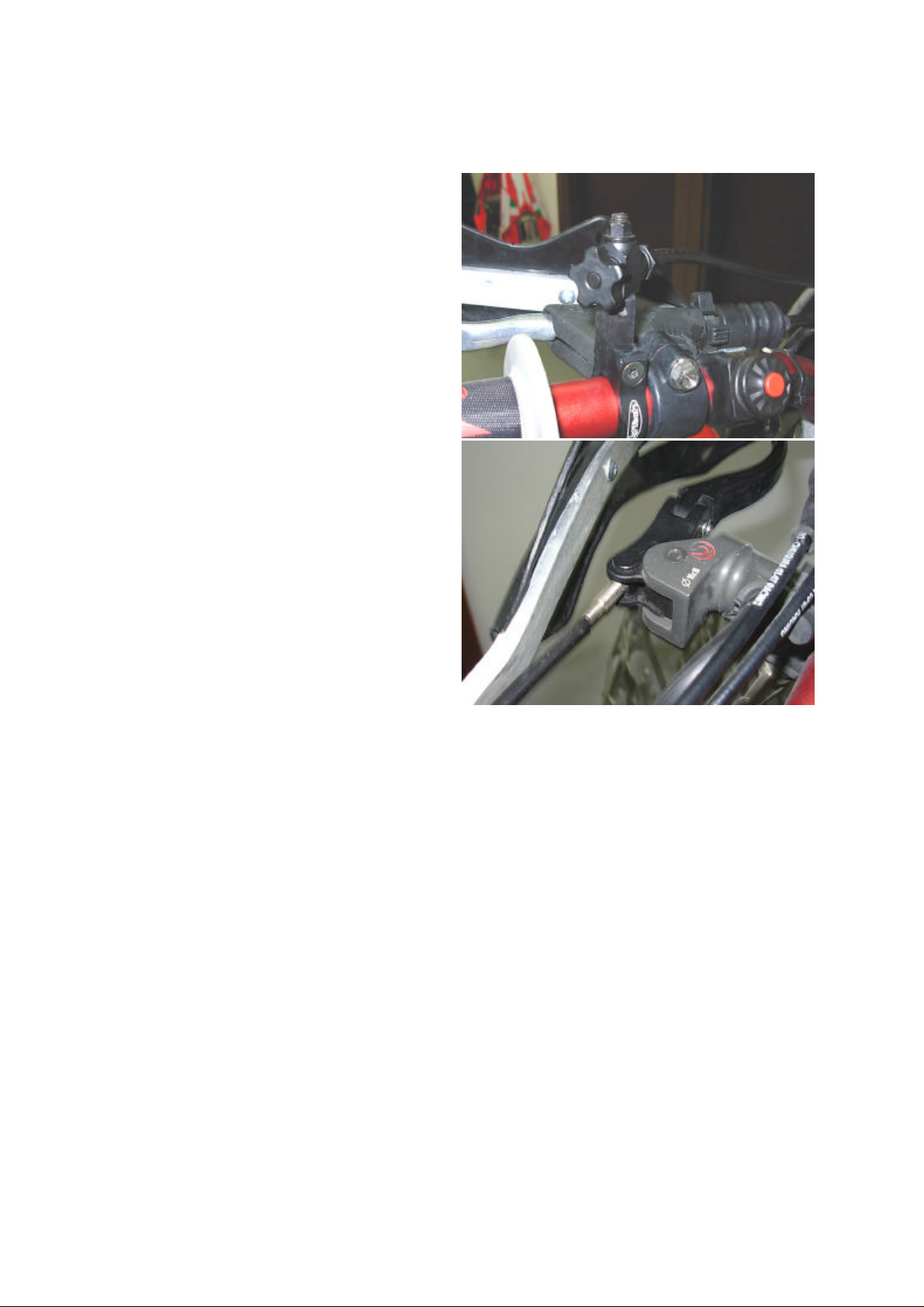

STARTING DEVICE

• The vehicle is set up for locking the fork under

compression as a launch control.

• Press the fork all the way.

• Press on the locking pin.

• Release the fork so that the pin engages on the slot of

the ring mounted on the fork.

• Release the pin.

Page 6

ASYMMETRIC CHAIN TENSIONER PADS

DIRECTION

OF TRAVEL

DIRECTION

OF TRAVEL

• The vehicle is provided with two different chain

sprockets.

• It is possible to replace the chain sprocket and to rotate

the chain tensioner pads without having to adjust the

slack of the chain again.

• Mount the chain tensioner pads in the direction indicated

when installing the sprocket with more teeth.

• Mount the chain tensioner pads in the direction indicated

when installing the sprocket with less teeth.

WARNING

Changing the direction of the chain tensioner

pads corresponds to 1 tooth of the sprocket.

Page 7

FRONT FORK

ADJUSTMENT OF THE HYDRAULIC BRAKE

• In order to adjust the hydraulic brake under compression

operate on the screw shown to the side.

• In order to adjust the hydraulic brake in extension

operate on the screw shown to the side.

DE-AERATION OF THE FRONT FORK

• To extract the air from the clutch stem, remove the dust

cap on each one of the fork legs.

• With the help of a screwdriver open the bleed valve until

the air inside is completely expelled.

Page 8

ADJUSTMENT OF THE STEERING ANGLE

WARNING

To adjust the steering angle the eccentric

bushings must be first assembled.

• Loosen the headstock nut.

• Loosen the screw that closes the upper plate.

• By operating on both fork legs, loosen the tightening

screws on the upper plate.

• Slightly lift the upper plate, by pulling it out by a few

millimetres from the fork legs.

Page 9

• Using a hook spanner, loosen the bearings preload ring

nut.

• The ring nut to work on is the upper one, immediately

below the steering plate.

WARNING

At this stage do not work on the ring nut for

adjusting the steering angle, located

immediately under the bearings preload ring

gear.

• Loosen the screw that locks the lower eccentric ring nut.

• Loosen the screw that locks the upper eccentric ring nut.

Page 10

• Using a hook spanner, turn the upper eccentric ring nut

by 180°.

WARNING

Accurately line up the notch on the ring nut with

the point where the tubes of the frame meet

(vehicle axis).

• Restore the vehicle following, in reverse, the procedure

just described.

FORK OFFSET ADJUSTMENT

• Loosen the headstock nut.

• Loosen the screw that closes the upper plate.

• Loosen the screw that closes the lower plate.

Page 11

• Operating on the square drive nut, turn the headstock

strut by 180°.

• Minimum offset reference.

WARNING

Precisely line up the notch on the eccentric

bushing with the reference on the steering plate.

• Maximum offset reference.

WARNING

Precisely line up the notch on the eccentric

bushing with the reference on the steering plate.

Page 12

REAR MONO-ABSORBER

ADJUSTMENT OF THE HYDRAULIC BRAKE

• In order to adjust the hydraulic brake under compression

turn the gold screw inside the blue knob.

• To adjust the threshold of intervention of the bypass

valve (hydraulic brake in high speed compression)

operate on the blue knob.

• In order to adjust the hydraulic brake in extension

operate on the screw shown to the side.

SPRING PRELOAD ADJUSTMENT (NEGATIVE)

• Loosen the locking screw of the spring pre-load

adjustment ring.

• Using the adjustment pin provided, act on the ring nut

until the desired spring preload is obtained.

• At the end of the operation, tighten the locking screw.

Page 13

B

ADJUSTMENT OF THE VEHICLE HEIGHT

• The height of the vehicle can be adjusted on 3 different

positions.

• The adjustment is obtained by replacing or by turning

the position of the bushing shown in the picture.

• Two are the available bushings:

A: Bushing for medium height

B: Eccentric bushing for max. or min. height (depending

on the direction of the assembly)

A

Page 14

ANTIHUPPING CLUTCH

DISASSEMBLY OF THE CLUTCH FROM THE

ENGINE

• Remove the six screws that secure the ergal flange.

• Remove the ergal flange.

• Lock the clutch with the lock wrench (provided) and

remove the nut.

• Pull out the clutch unit from the main shaft of the gear

box and continue the disassembly on the bench.

• Remove the central cup.

Page 15

• Remove the thrust ring.

• Remove the outside spring.

• Remove the clutch pressure plate and the complete

pack of disks.

• Remove the inside spring.

Page 16

• Remove the ring.

• Remove the disc drum

• Remove the six steel balls.

WARNING

The steel balls have to be greased before

reassembly.

• The two springs can be replaced with springs with a

different elastic constant K to adapt the response of the

clutch to its requirements.

Loading...

Loading...