Aprilia SXV450, SXV 550 Upgrade Book 2008

UPGRADE BOOK

APRILIA SXV 450-550

Replica VAN DEN BOSCH

MY 08

ENGLISH VERSION

CONTENTS

SUMMARY TABLE OF TECHNICAL DATA 3

VEHICLE START-UP 4

REMOTE ADJUSTMENT OF THE POSITION OF THE FRONT BRAKE LEVER 5

CHANGING ECU MAPPING 5

ACTIVATION/DEACTIVATION OF THE ELECTRONIC TRASMISSION 6

STARTING DEVICE 6

ASYMMETRIC CHAIN TENSIONER PADS 7

FRONT FORK 8

REAR MONO SHOCK ABSORBER 13

SADDLE SUPPORT CHASSIS 14

STM SLIPPERING CLUTCH 15

2

SUMMARY TABLE OF TECHNICAL DATA

FRONT FORK

Type Marzocchi Shiver 50

Travel 267 mm

Std. adjustment hydraulic brake under compression 20 clicks from all closed

Std. adjustment hydraulic brake under extension 20 clicks from all closed

Steering angle with centred bushings 25°

Steering angle with eccentric bushings 24° - 26°

Fork offset with centred bushings 14 mm

Fork offset with eccentric bushings 11 mm – 17 mm

REAR SHOCK ABSORBER

Type Mono Sachs racing

Travel 120 mm

Std. spring elasticity (K) 6 kgf/mm

Std. adjustment hydraulic brake under compression at high speed 7 clicks from all closed

Std. adjustment of the hydraulic brake under compression at low speed 12 clicks from all closed

Std. adjustment hydraulic brake under extension 15 clicks from all closed

STM CLUTCH

Calibration of primary standard spring SXV VDB 450 (wet race) 120 kg

Calibration of primary supplied spring SXV VDB 450 130 kg

Calibration of secondary standard spring SXV VDB 450 (wet race) 30 kg

Calibration of secondary supplied spring SXV VDB 450 40 kg

Calibration of primary standard spring SXV VDB 550 (wet race) 130 kg

Calibration of primary supplied spring SXV VDB 550 140 kg

Calibration of secondary standard spring SXV VDB 550 (wet race) 30 kg

Calibration of secondary supplied spring SXV VDB 550 40 kg

Wear limit clutch pack 35 mm

FRONT / REAR CHAIN SPROCKETS

Standard pinion SXV VDB 450 z=14

Supplied pinion SXV VDB 450 z=15

Standard sprocket SXV VDB 450 z=45

Supplied sprocket SXV VDB 450 z=44, z=46

Standard pinion SXV VDB 550 z=16

Supplied pinion SXV VDB 550 z=15

Standard sprocket SXV VDB 550 z=46

Supplied sprocket SXV VDB 550 z=45, z=47

3

VEHICLE START-UP

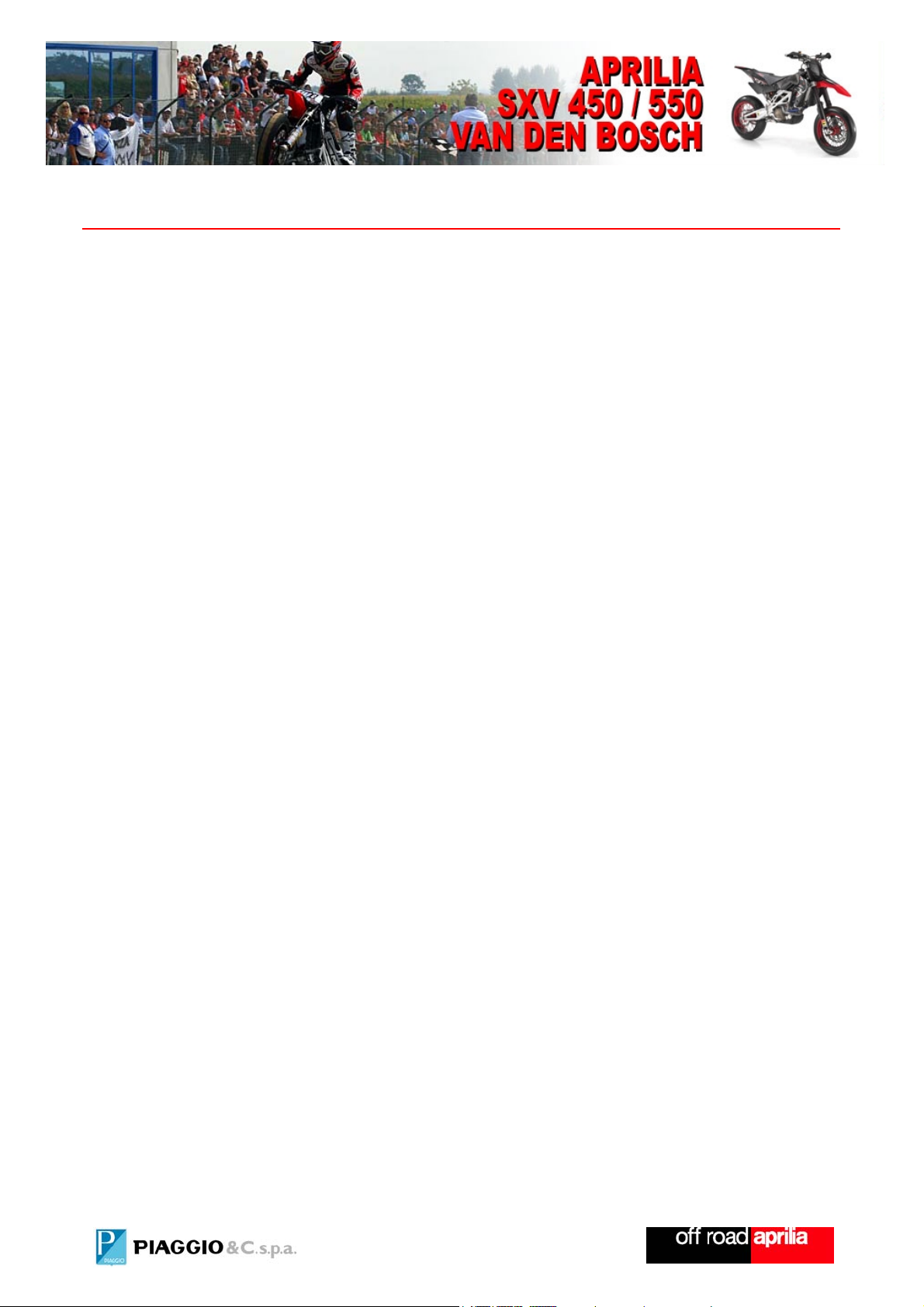

This vehicle, having been designed for exclusive

use in competitions, is equipped with a small and

lightweight battery, sufficient for amperages

needed during warm start-up and for the normal

operation of the engine.

For cold start it is necessary to use the external

battery that comes with as an accessory to the

vehicle.

Remove the saddle.

Disconnect the jack from the regular battery and

connect it to the external battery.

Feed the injection circuit of the vehicle by

connecting the key jack on the handlebar.

Start the engine using the ignition button on the

right side of the handlebar.

With the engine running, disconnect the external

battery and reconnect the installed battery.

To turn off the vehicle just press the off button

on the left side of the handlebar.

WARNING

After use the key jack has to be

disconnected.

4

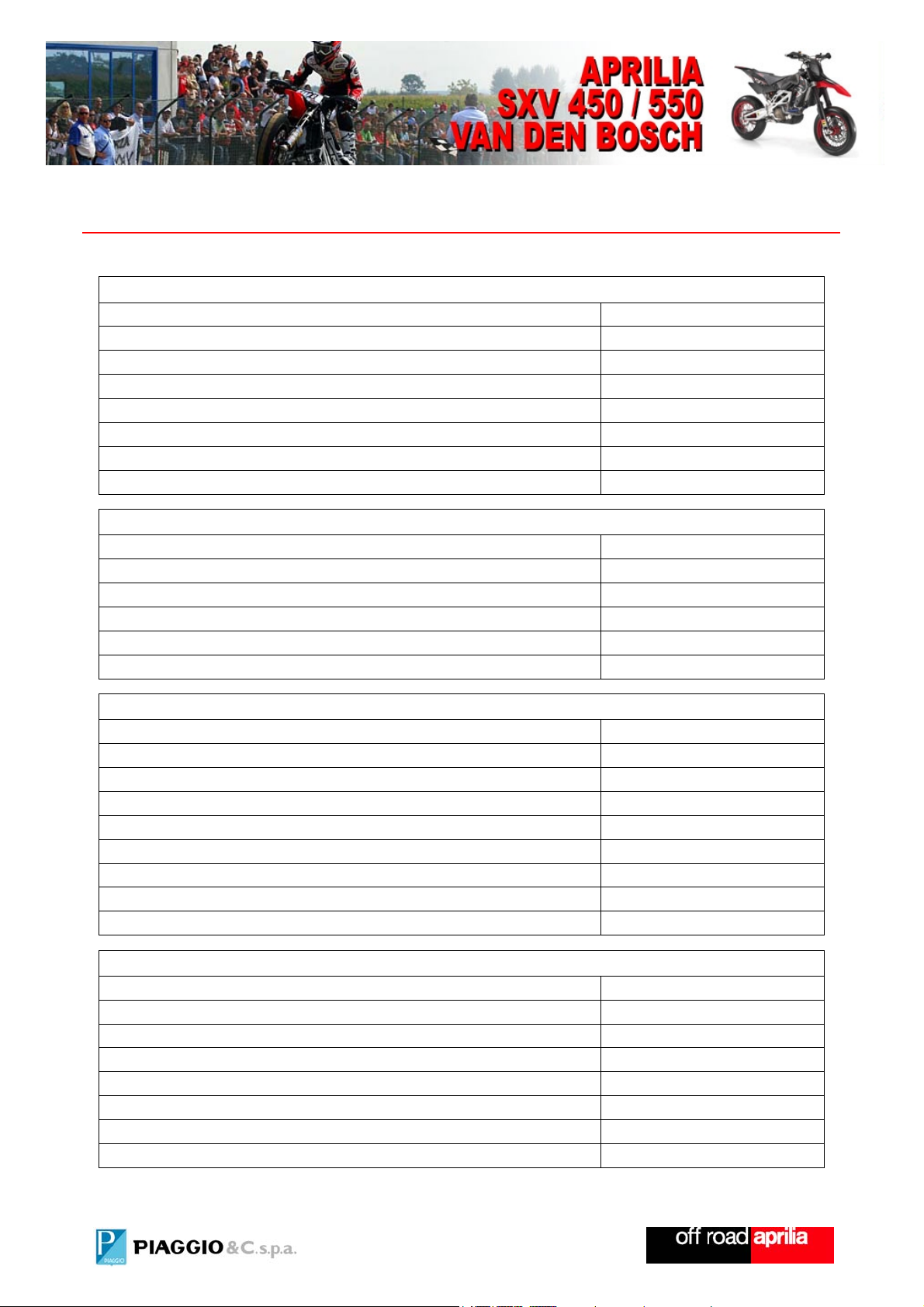

REMOTE ADJUSTMENT OF THE POSITION OF THE FRONT BRAKE LEVER

The vehicle is prearranged for a remote

adjustment of the distance of the front brake

lever from the handlebar.

Use the adjustment knob on the left handlebar

until the desired distance is obtained.

CHANGING ECU MAPPING

The vehicle offers the possibility of choosing

between two different mappings of the control

unit.

The mapping change can be accomplished while

the vehicle is in motion.

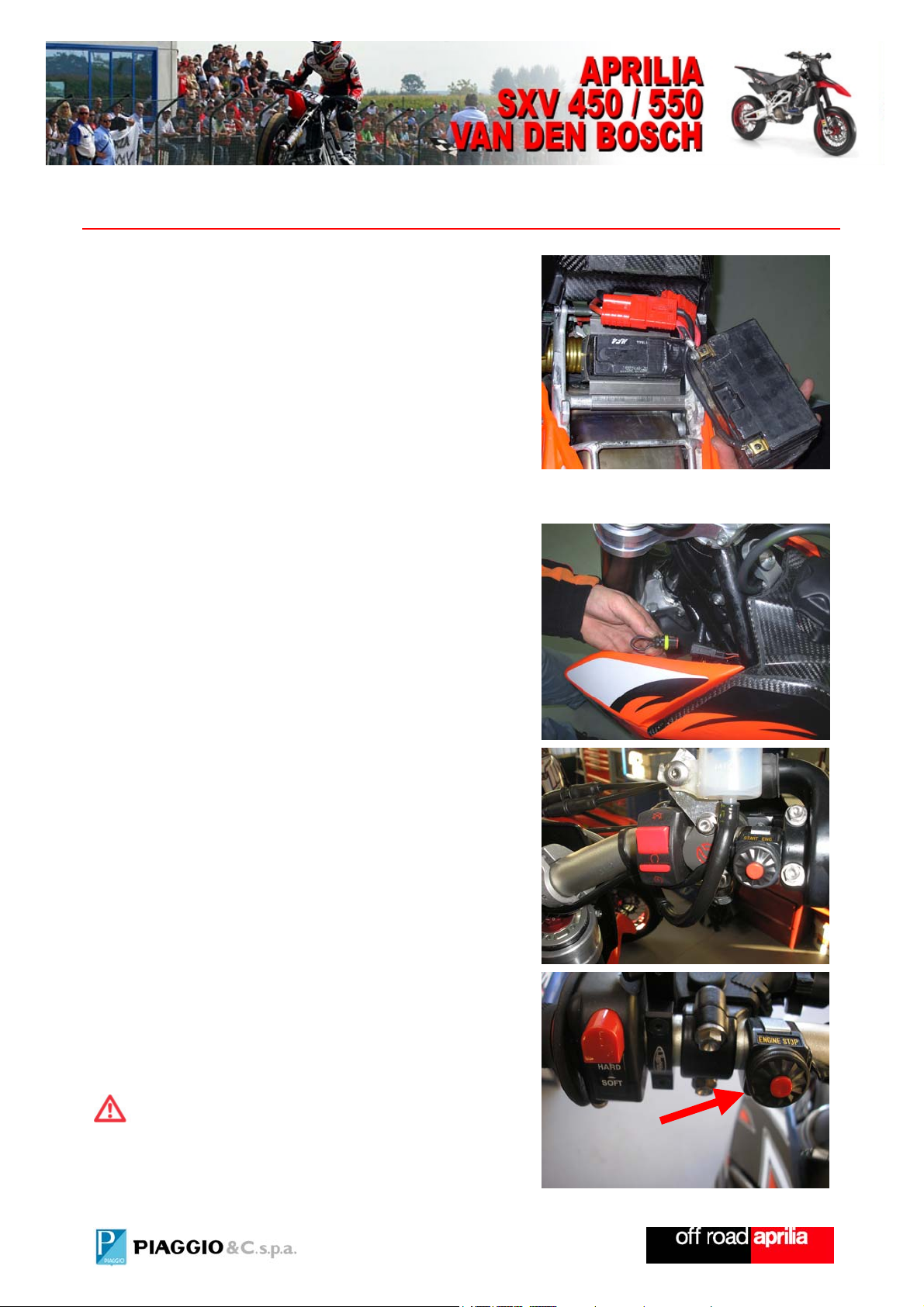

Push the button on the left side of the handlebar

to chose between HARD and SOFT modes.

5

ACTIVATION/DEACTIVATION OF THE ELECTRONIC TRASMISSION

The vehicle is supplied with an electronic

control mechanism for the gear ratio.With the

electronic control mechanism activated, it is

possible to change the ratio upward without the

aid of friction and while keeping the throttle

control open.

Push the button on the right side of the handlebar

to activate or deactivate the electronic control

mechanism:

1 - Device OFF

2 - Device ON

1

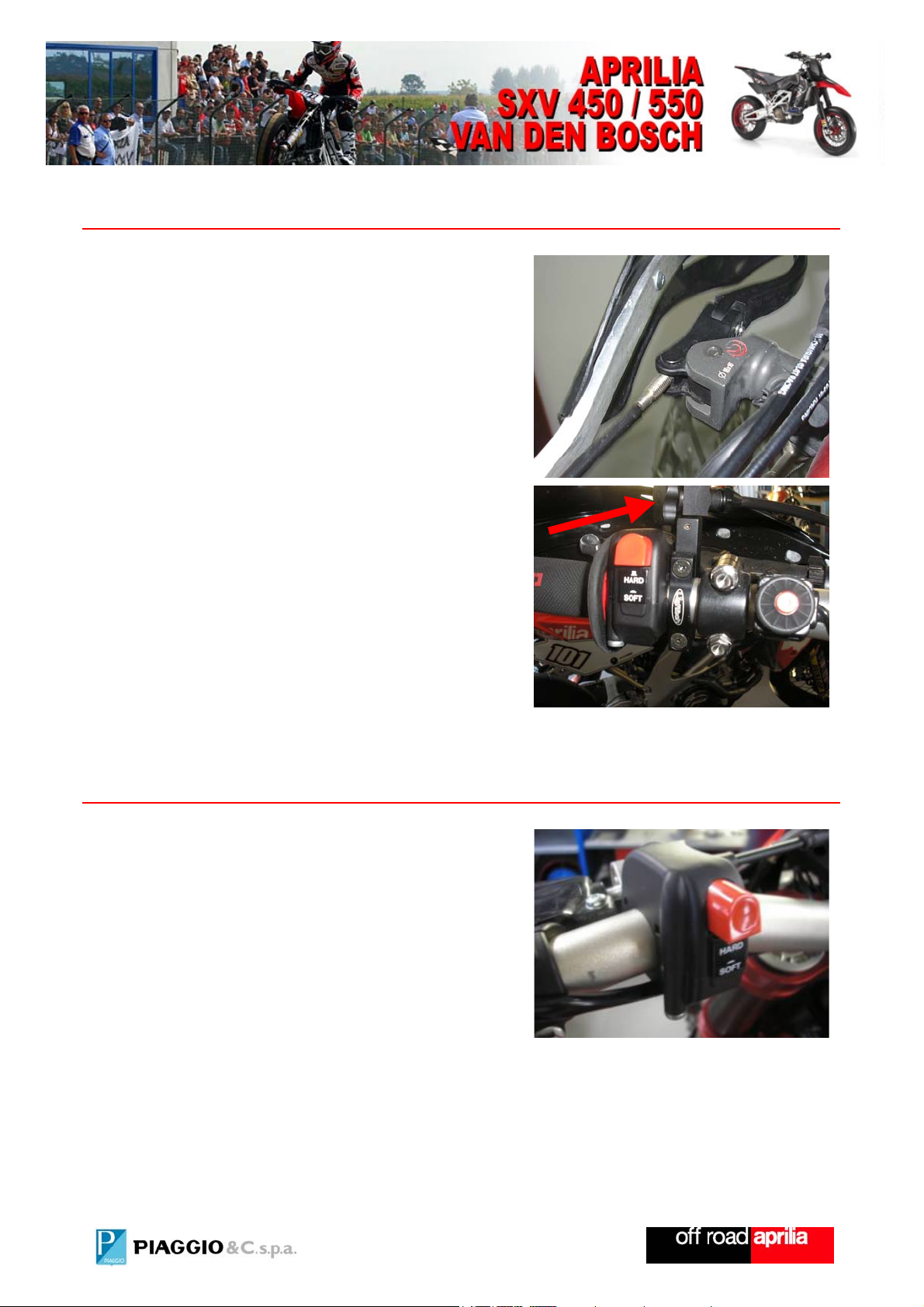

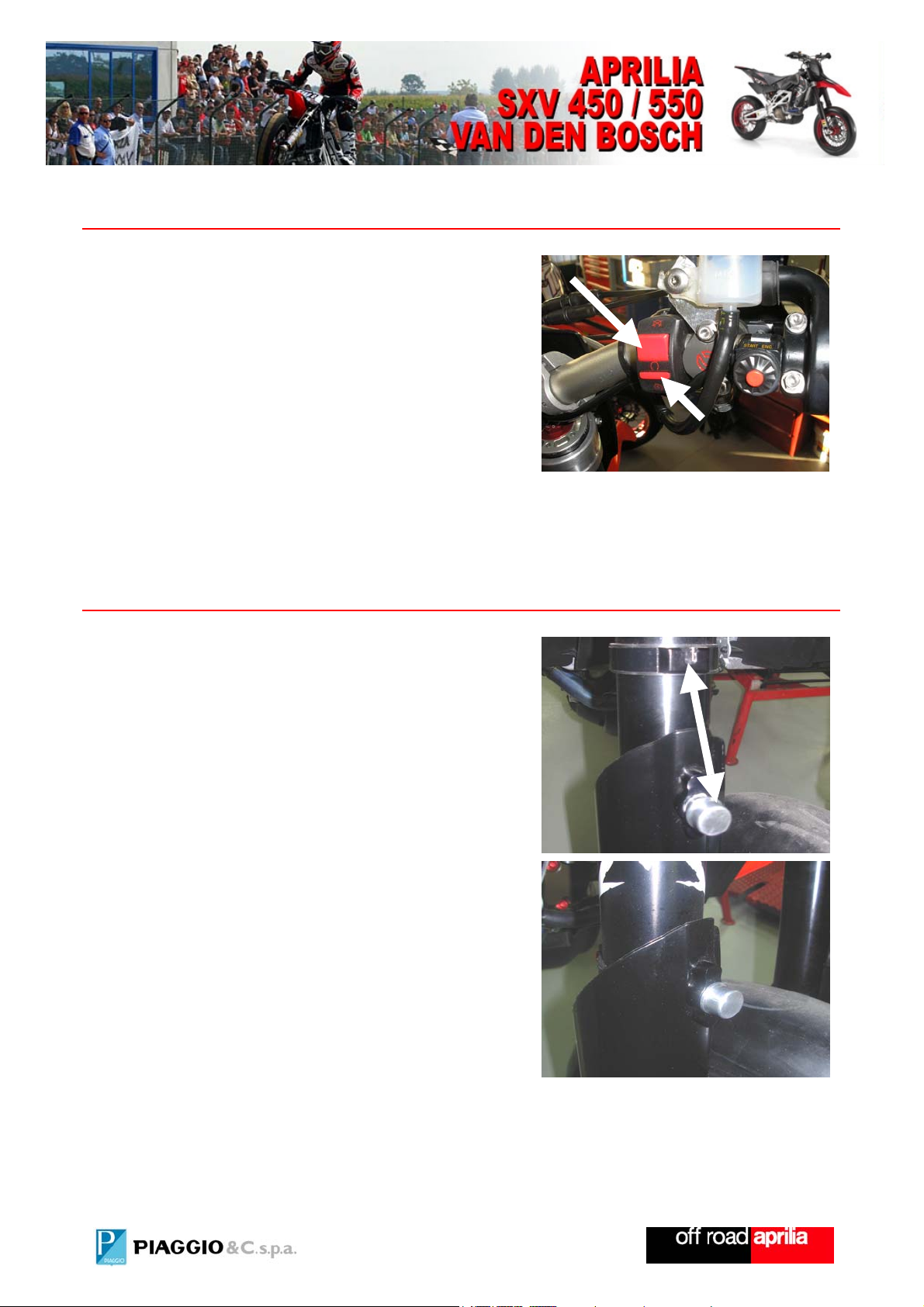

STARTING DEVICE

FITTING

The distance between two components should be:

D = 11 mm

D

= 13 mm

MAX

USE

The vehicle is set up for locking the fork under

compression as a launch control.

Press the fork all the way.

Press on the locking pin.

Release the fork so that the pin engages on the

slot of the ring mounted on the fork.

Release the pin.

2

D

6

Loading...

Loading...