Page 1

Xserve (Late 2006/Early 2008)

Processor Heat Sink

Replacement Instructions

Follow the instructions in this document carefully. Failure to follow these instructions could

damage your equipment and void its warranty.

Online instructions are available at http://www.apple.com/support/diy/.

Working Safely Inside the Xserve

Always touch the Xserve enclosure to discharge static electricity before you touch any

components inside the Xserve. To avoid generating static electricity, do not walk around the

room until you have nished working inside the server and have replaced the cover. To minimize

the possibility of damage due to static discharge, wear an antistatic wrist strap while you work

inside the Xserve.

Warning: Always shut down the Xserve and disconnect the power cords before opening

it to avoid damaging its internal components or the components you are installing. Don’t

open the server while it is turned on. Even after you shut down the Xserve, its internal

components can be very hot. Let it cool before you open it.

Tools Required

The following tools are required for this procedure:

Phillips #1 screwdriver•

Antistatic wrist strap (if available)•

Alcohol wipe for cleaning processor (supplied with the part)•

Thermal grease syringe for replacing thermal grease on processor (supplied with the part)•

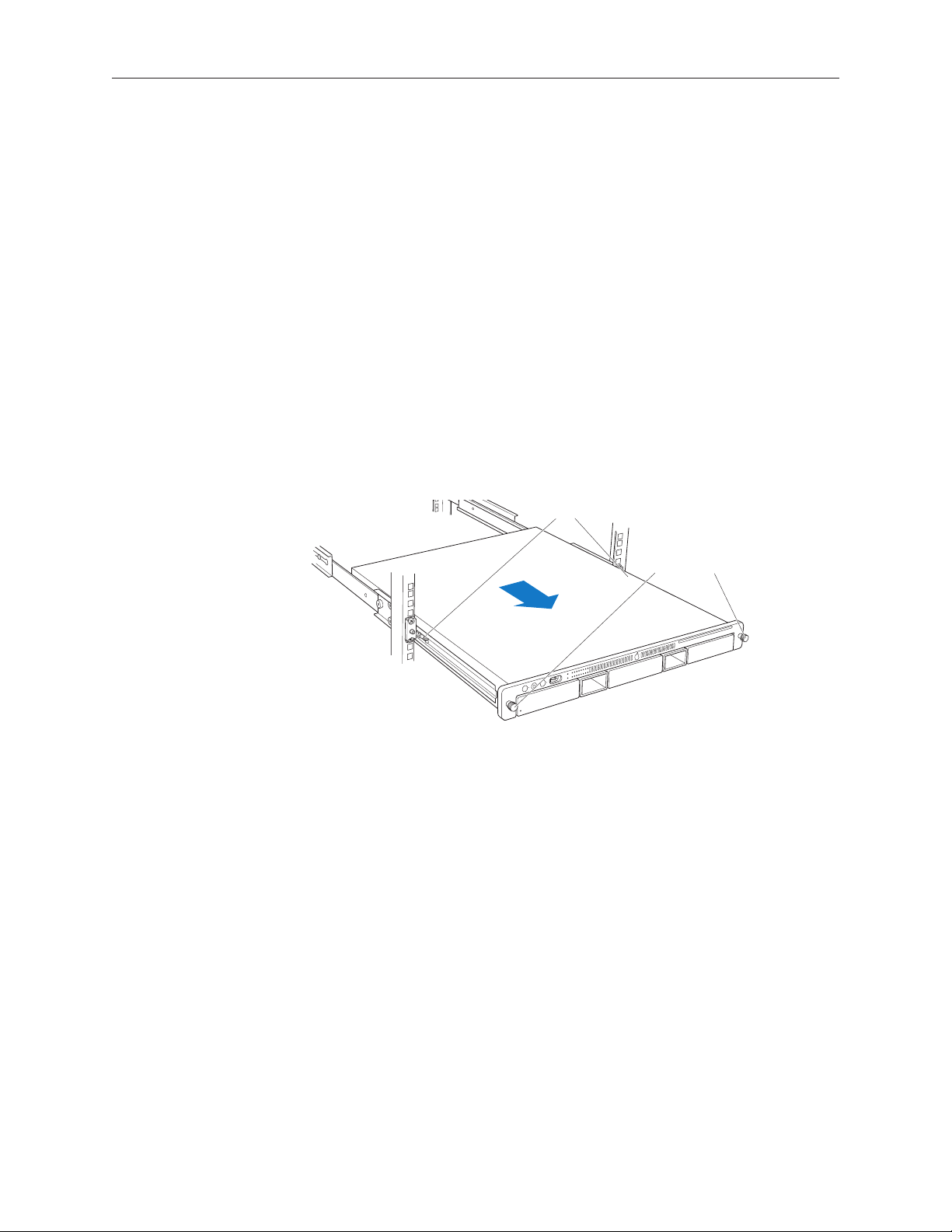

Removing the Xserve from a Rack

Alert users that the server will be unavailable for a period of time. 1.

Shut down the Xserve (see the Xserve User’s Guide for help) and then wait to let the Xserve 2.

internal components cool.

073-1096 Rev. B

Page 2

Warning: Always shut down the Xserve before opening it to avoid damaging its internal

Latches

Thumbscrews

components or the components you want to install or remove. Don’t open the Xserve

or try to install or remove items inside while it is turned on. Even after you shut down

the Xserve, its internal components can be very hot. Let it cool down for 5 to 10 minutes

before you open it.

Unplug all cables from the Xserve. 3.

Note: If you have trouble releasing a cable from the back panel, try using a small screwdriver

or other at tool to depress the tab on the cable connector.

To avoid inadvertently unlatching a drive module during handling, use the enclosure key to 4.

lock the enclosure lock on the front panel.

Touch the server’s metal case to discharge any static electricity. 5.

Loosen the thumbscrews at both ends of the front panel.6.

Grasp the thumbscrews and pull the Xserve forward until the safety latches engage (about 7.

halfway out of the rack).

When the safety latches engage, grip the Xserve where it emerges from the rack, press down 8.

on the latch tabs with your thumbs, and slide the Xserve the rest of the way out of the rack.

Set the Xserve on a at surface and unlock it. 9.

Xserve (Late 2006/Early 2008) Processor Heat Sink Replacement Instructions 2

Page 3

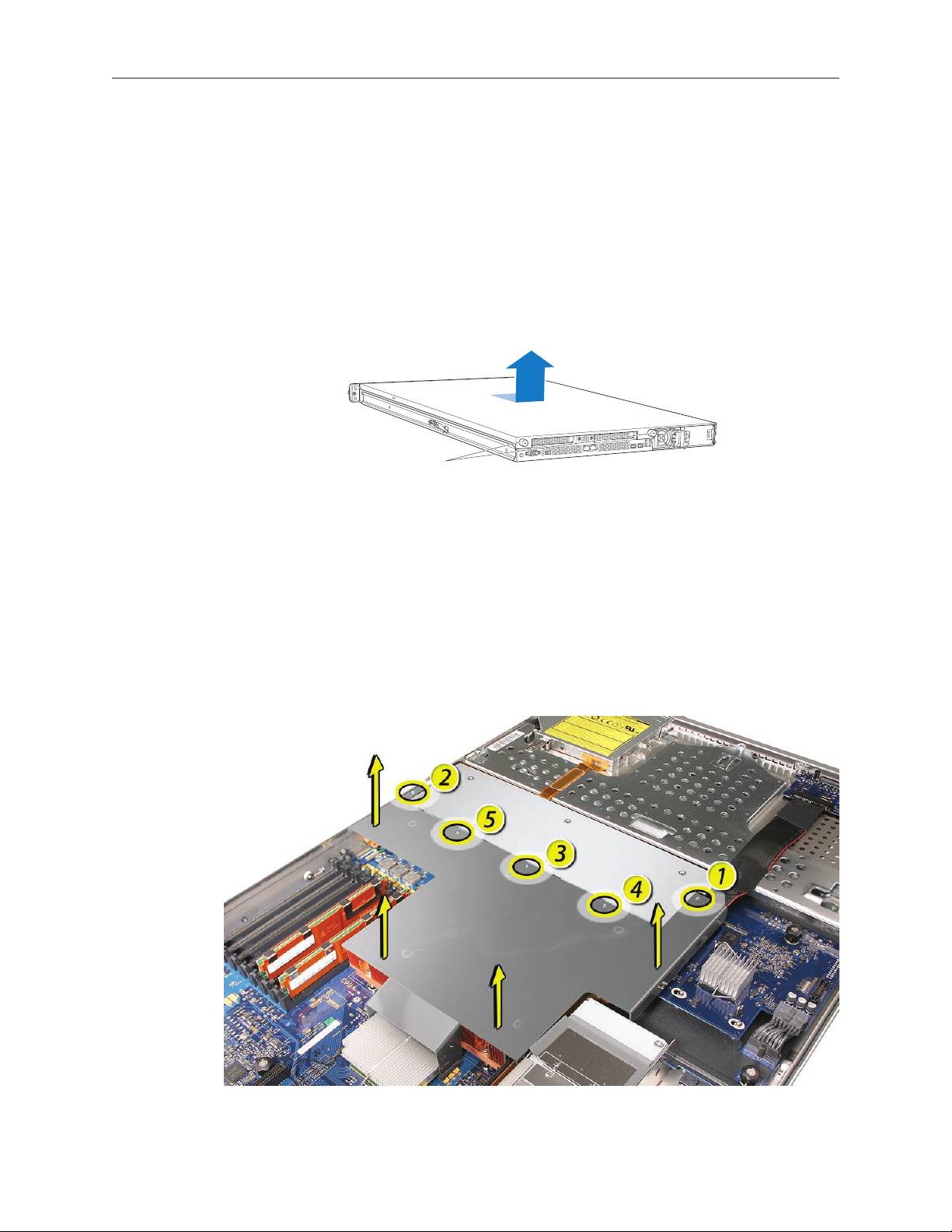

Opening the Xserve

Unscrew the two

captive thumbscrews.

Slide the cover back and lift it off.

Loosen the thumbscrews at the back of the top cover and slide the cover back and up to remove

it. If you have diculty removing the cover, check the enclosure lock on the front panel.

Warning: Even after you shut down the Xserve, its internal components can be very hot. Let

it cool before you open it.

Important: To minimize the possibility of damage to Xserve components due to static discharge,

wear an antistatic wrist strap, if possible, while you work inside the Xserve.

Removing the Installed Processor Heat Sink

Note: Before you can remove a processor heat sink, you must remove the airow duct.

Airow Duct

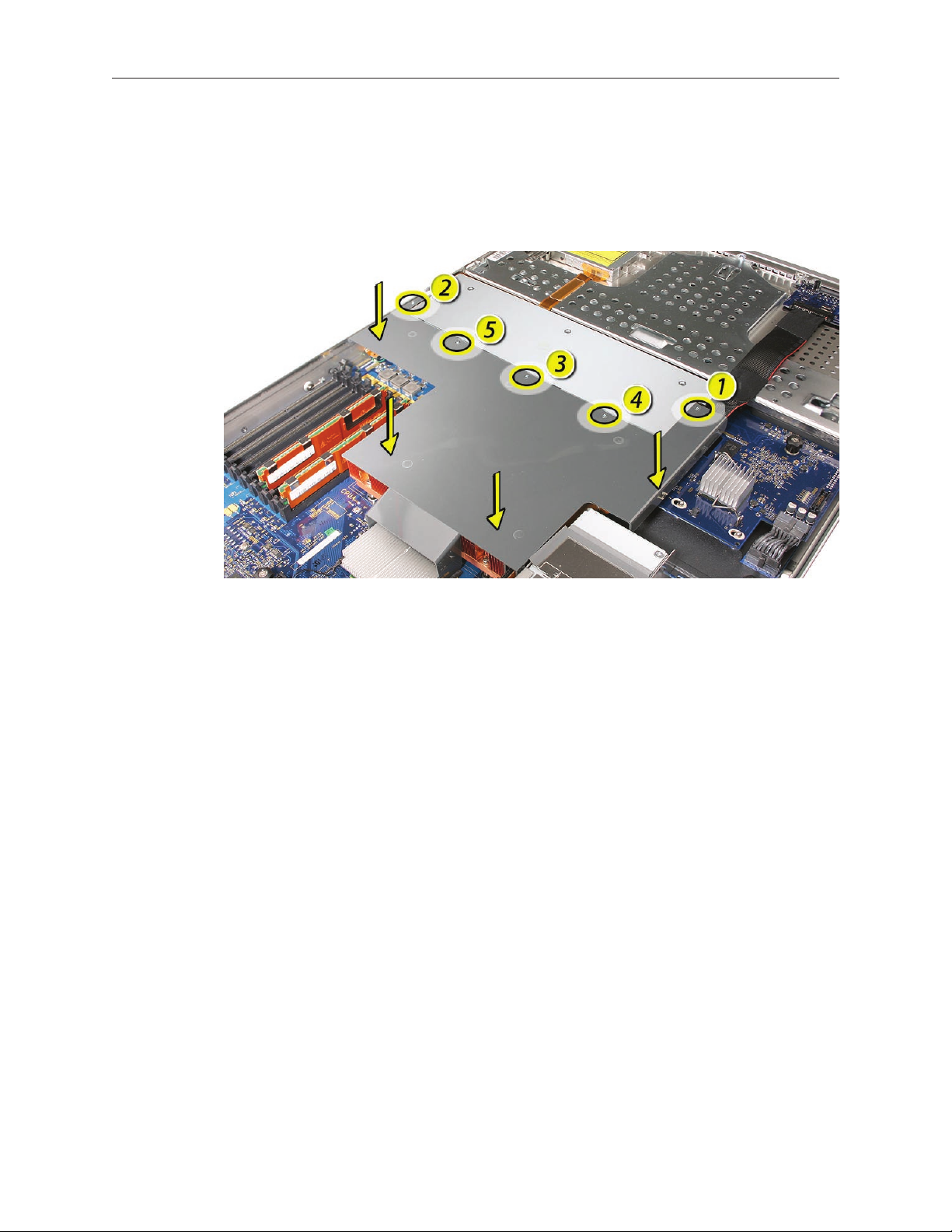

Loosen the ve Phillips screws that fasten the airow duct to the fan array.1.

Pull up on either side of the airow duct, and lift it straight up and out of the Xserve. 2.

Xserve (Late 2006/Early 2008) Processor Heat Sink Replacement Instructions 3

Page 4

Caution: Try not to completely remove the screws from the airow duct. Tiny black rubber

washers hold these screws captive on the underside of the airow duct. If the screws are

completely removed, these washers can easily fall into the enclosure and become lost.

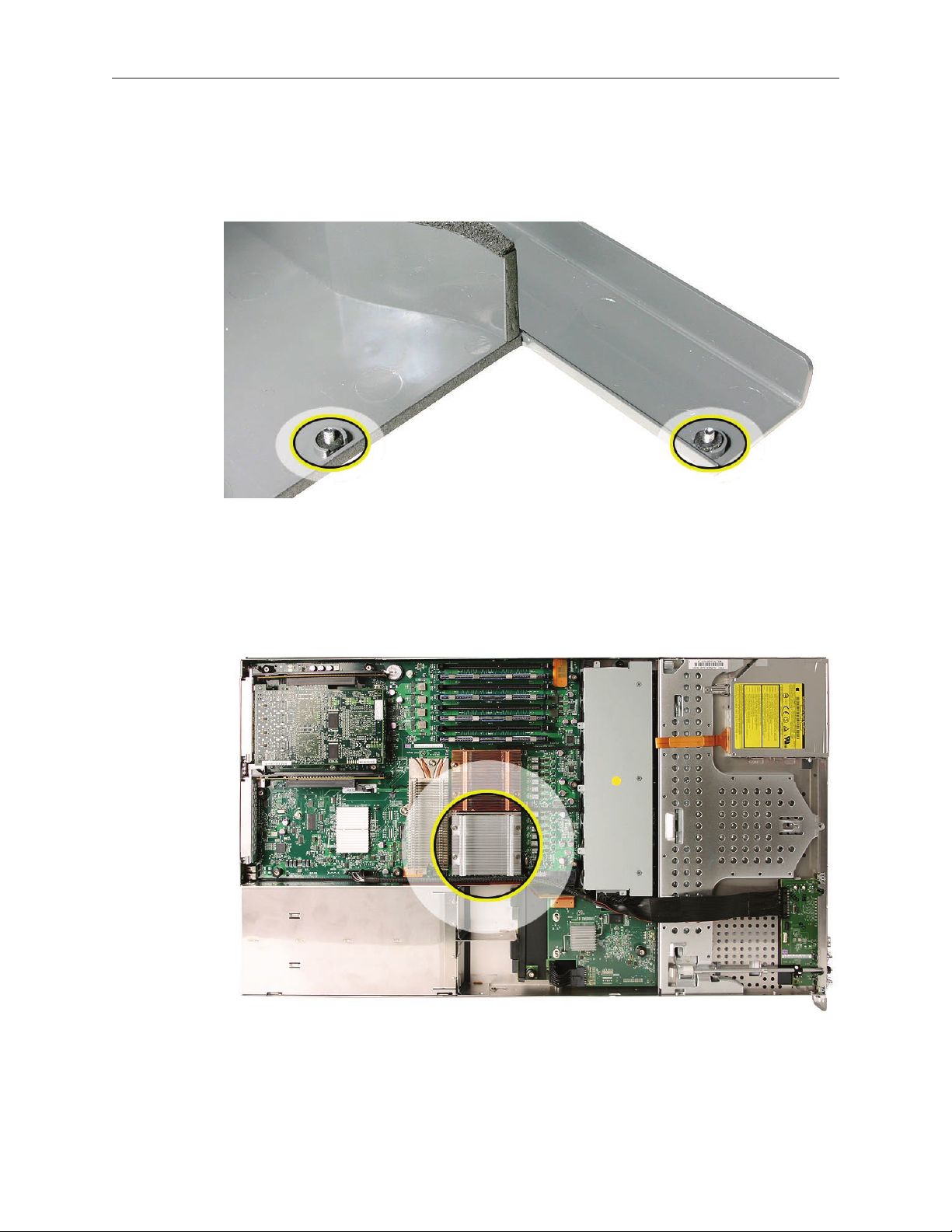

Processor Heat Sink

Note: Server congurations with a single processor have a regular heat sink and a blank heat sink

installed. The blank heat sink is silver colored (as shown below) and should not be removed

except when replacing a logic board.

Xserve (Late 2006/Early 2008) Processor Heat Sink Replacement Instructions 4

Page 5

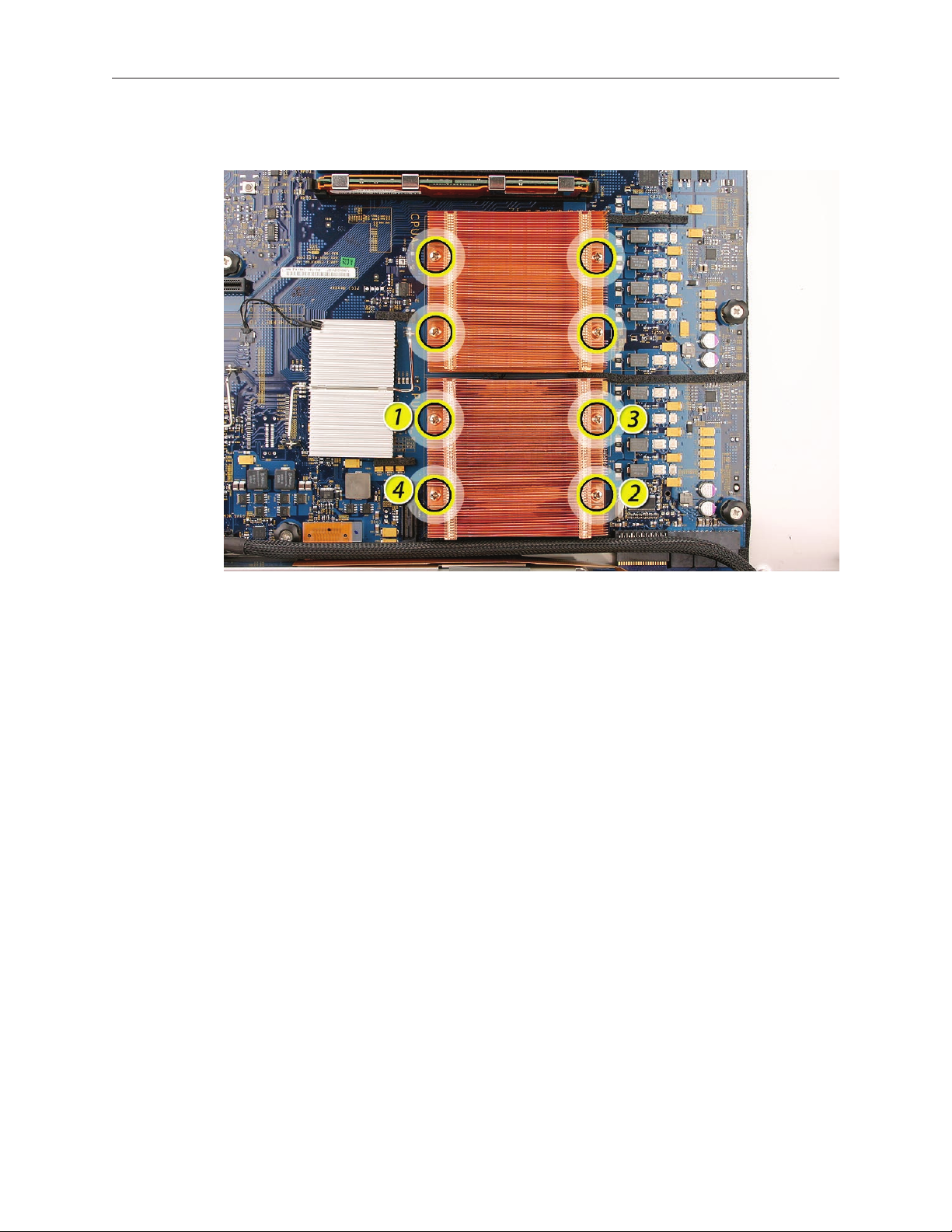

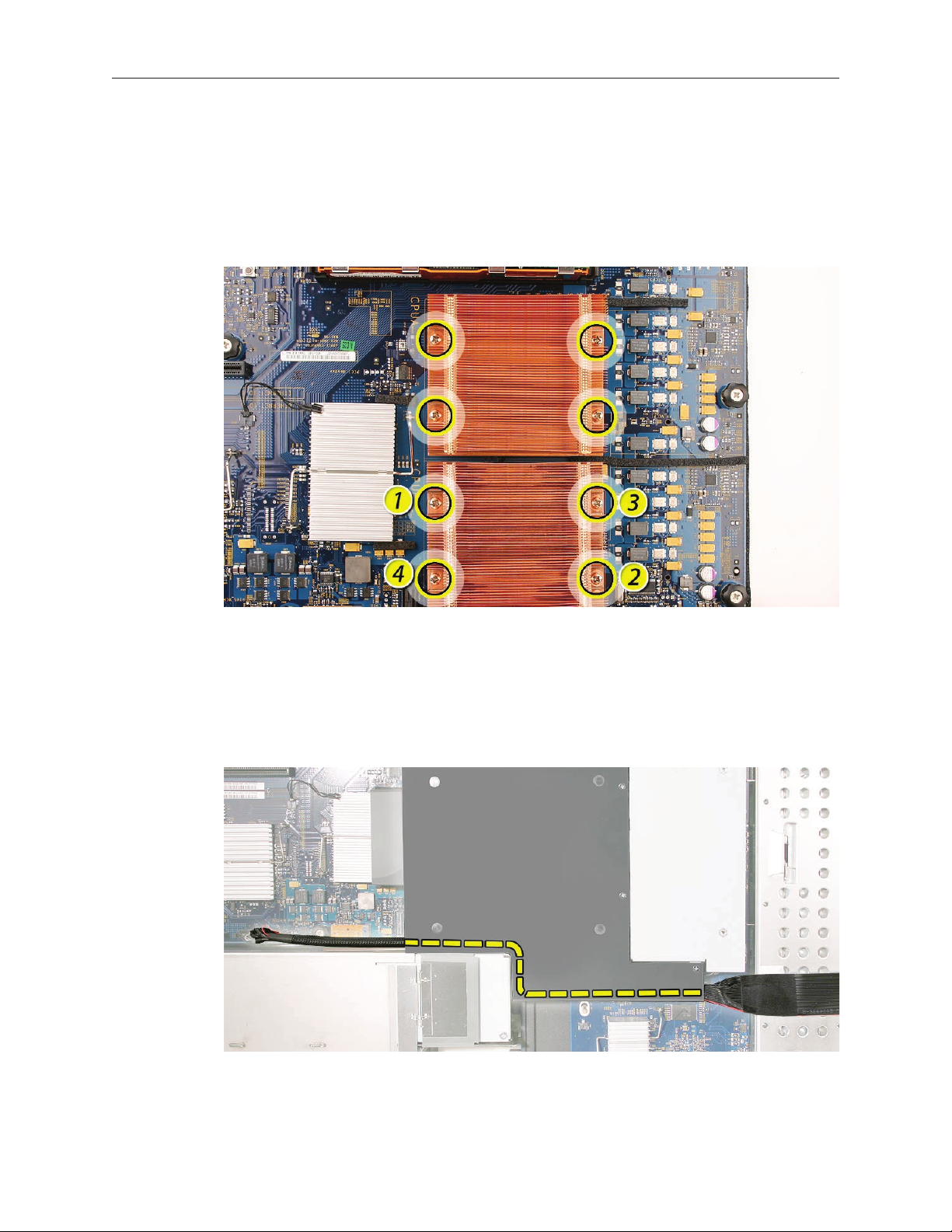

Loosen the four screws securing the heat sink in the order indicated below. 1.

Xserve (Late 2006/Early 2008) Processor Heat Sink Replacement Instructions 5

Page 6

Caution: Whenever you handle the heat sink, handle it from the slotted sides, not the

smooth sides. Grasping the smooth sides of the heat sink can compress its ribs causing

permanent damage.

Xserve (Late 2006/Early 2008) Processor Heat Sink Replacement Instructions 6

Page 7

Caution: Each heat sink is connected to the logic board by a small 2-pin thermal sensor 2.

cable. Lifting the heat sink too quickly can damage the cable or connector. Because of

the tight thermal bond between the processor and heat sink, be especially cautious to

initially lift the heat sink no more than one centimeter (1 cm) o the processor. Do not

pull on the cable as you lift the heat sink enough to disconnect the cable from the logic

board.

Slowly raise the heat sink o the processor just far enough that you can reach the sensor

cable connector.

Pull on the connector, not the cable, to disconnect the sensor cable from the logic board. 3.

Lift the heat sink straight up and out of the enclosure.4.

Xserve (Late 2006/Early 2008) Processor Heat Sink Replacement Instructions 7

Page 8

Installing the Replacement Processor Heat Sink

Note: The thermal bond between the processor heat sink and the processor requires thermal

grease for proper operation. Every time you remove or replace the processor heat sink, you must

replace the thermal grease on the processor below the heat sink. New grease and an alcohol

wipe for cleaning o the old grease are included with the replacement heat sink. Clean the

processor and apply new grease as follows

Release the latch on the metal processor holder for the processor.1.

Rotate the top of the holder to the open position. 2.

Carefully lift the processor out of the holder. 3.

Important: When removing or installing a processor, always hold the processor by three

corners. Be extremely careful not to touch the gold pins on the bottom of the processor, as

this type of connector is very sensitive to contamination. Also be careful not to touch the

gold pins in the processor socket on the logic board.

Xserve (Late 2006/Early 2008) Processor Heat Sink Replacement Instructions 8

Page 9

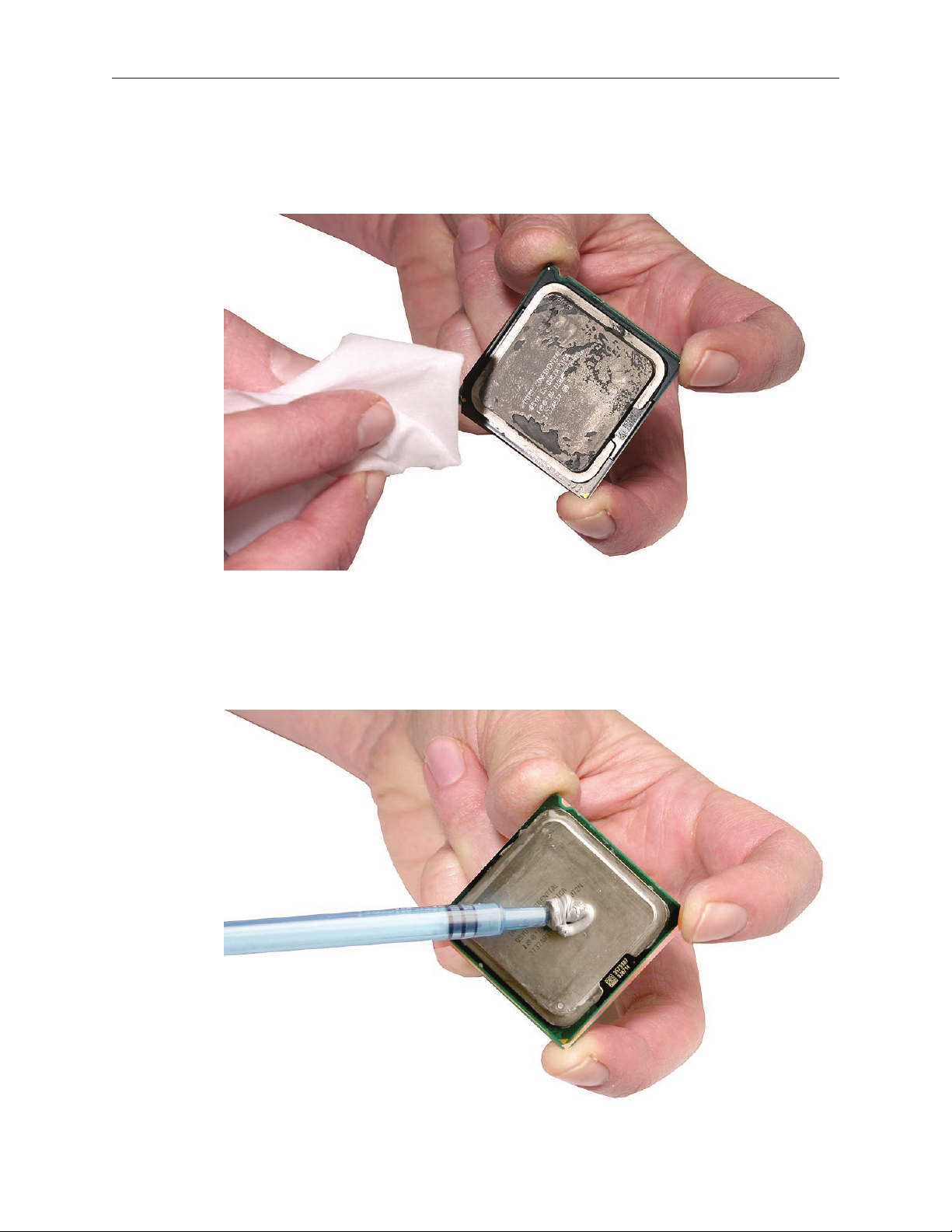

Clean o any existing thermal grease on the top face of the processor using the alcohol wipe 4.

provided with the replacement part, being careful not to get any thermal grease on the

processor contacts.

Apply the entire contents on a single syringe of thermal grease (approximately 4.5 cc) to the 5.

top surface of the processor.

Important: Be sure not to get any grease anywhere on the processor other than the very

top, at surface that directly contacts the heat sink.

Xserve (Late 2006/Early 2008) Processor Heat Sink Replacement Instructions 9

Page 10

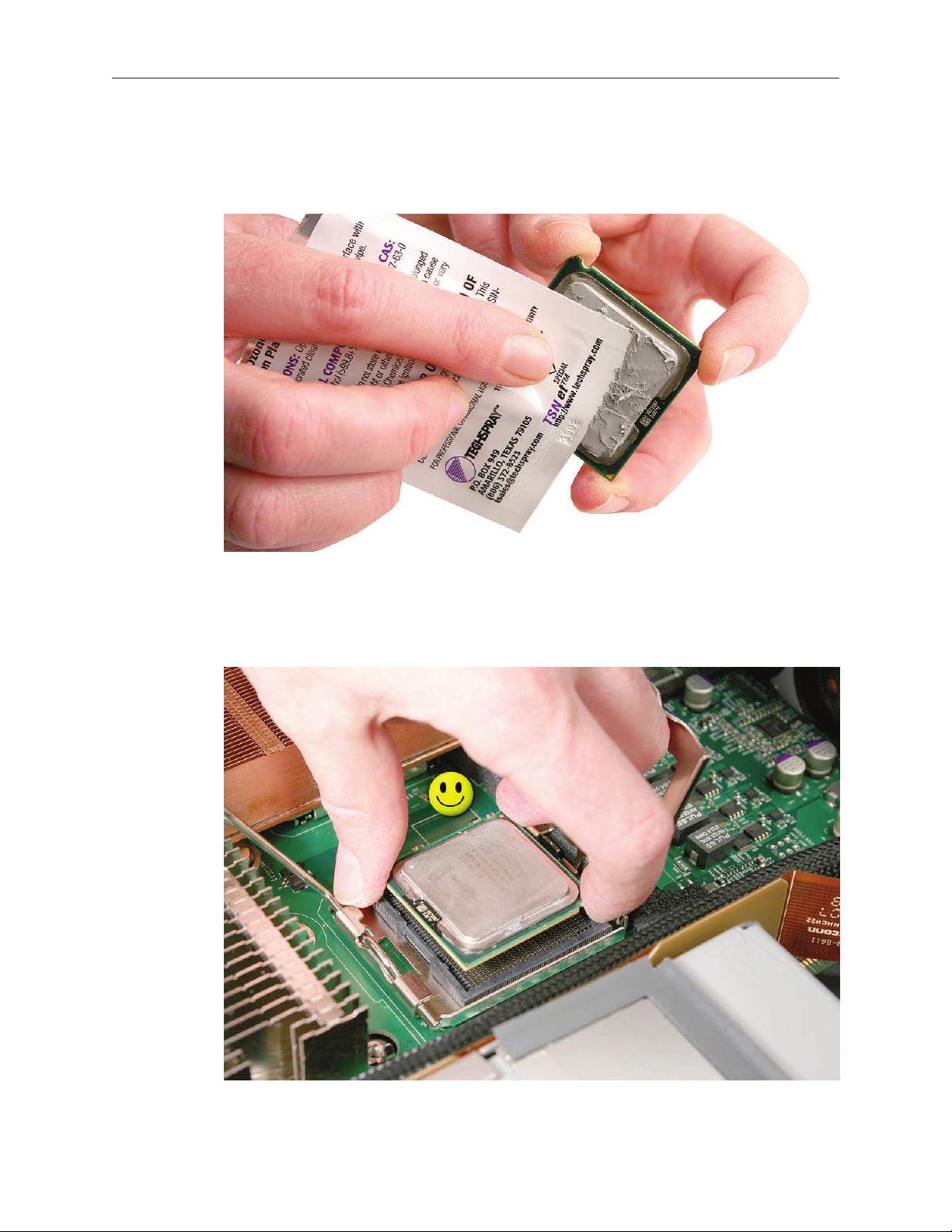

Use the edge of the package that the alcohol wipe came in as a spatula to spread the 6.

thermal grease evenly over the entire top surface of the processor. Scrape o any excess

grease with the package edge, then discard the package.

Holding the processor by three corners only, keep the processor level as you place it into its 7.

holder on the logic board, being careful not to get any thermal grease on the contacts of

either the processor or its socket holder.

Xserve (Late 2006/Early 2008) Processor Heat Sink Replacement Instructions 10

Page 11

Note: When installing the processor on the logic board, align the processor notch with the

tab on the processor holder, as shown. Then lower the processor straight down onto the

socket.

Rotate the top of the holder to the closed position.8.

Engage the latch on the metal processor holder.9.

Holding the heat sink in one hand, reconnect the 2-pin thermal sensor cable for the heat 10.

sink to the logic board.

Note: Make sure the connector on the sensor cable is oriented as shown, with the gold

ngers facing up.

Xserve (Late 2006/Early 2008) Processor Heat Sink Replacement Instructions 11

Page 12

Carefully seat the heat sink over the processor, aligning the four screws with the holes in the 11.

logic board.

Tighten the four captive Phillips mounting screws for the heat sink in the order indicated 12.

below. Do not over-tighten the screws. If you have a torque driver, tighten the screws to 8

inch-pounds; otherwise, try to tighten the screws with equal pressure.

Replacing the Airow Duct

Lower the airow duct into position on the logic board. 1.

Note: When installing the airow duct, be sure to route both the front panel board cable and

the backplane-to-logic board I/O cable inside the channel under the left side of the duct.

Xserve (Late 2006/Early 2008) Processor Heat Sink Replacement Instructions 12

Page 13

Ensure the airow duct ts ush all over, and does not protrude above the enclosure. 2.

Note: Be careful when working with any black foam pieces that are part of the airow duct

or the logic board.

Tighten the ve Phillips screws that fasten the airow duct to the fan array, in the order 3.

shown, to prevent the duct from warping. Do not overtighten the screws.

Closing the Xserve

Replace and secure the cover.1.

Slide the Xserve back into the rack, and tighten the front thumbscrews to secure the Xserve 2.

in the rack.

If the server case was locked, use the enclosure key to lock the security lock on the front 3.

panel.

Warning: Never turn on the server unless all of its internal and external parts are in place

and it is closed. Operating the server when it is open or missing parts can damage it or

cause injury.

Xserve (Late 2006/Early 2008) Processor Heat Sink Replacement Instructions 13

Page 14

Apple Inc.

© 2006, 2008 Apple Inc. All rights reserved.

Under the copyright laws, this document may not be copied, in whole or in part, without the

written consent of Apple.

Every eort has been made to ensure that the information in this document is accurate. Apple is

not responsible for printing or clerical errors.

Apple

1 Innite Loop

Cupertino, CA 95014-2084

USA

+ 1 408 996 1010

http://www.apple.com

Apple, the Apple logo, Mac, Macintosh, and Xserve are trademarks of Apple Inc., registered in the

U.S. and other countries.

Xserve (Late 2006/Early 2008) Processor Heat Sink Replacement Instructions 14

Loading...

Loading...