Page 1

Operation and Maintenance Manual

ML2419A RANGE CALIBRATOR

Anritsu Company

490 Jarvis Drive

Morgan Hill, CA 95037-2809

USA

Part Number: 10585-00007

Copyright 2014 Anritsu Company

Published: March 2014

Revision: B

Page 2

WARRANTY

The Anritsu product(s) listed on the title page is (are) warranted against defects in materials and workmanship for

one (1) year from the date of shipment.

Anritsu’s obligation covers repairing or replacing products which prove to be defective during the warranty period.

Buyers shall prepay transportation charges for equipment returned to Anritsu for warranty repairs. Obligation is

limited to the original purchaser. Anritsu is not liable for consequential damages.

LIMITATION OF WARRANTY

The foregoing warranty does not apply to Anritsu connectors that have failed due to normal wear. Also, the warranty

does not apply to defects resulting from improper or inadequate maintenance, unauthorized modification or misuse,

or operation outside of the environmental specifications of the product. No other warranty is expressed or implied,

and the remedies provided herein are the Buyer’s sole and exclusive remedies.

DISCLAIMER OF WARRANTY

DISCLAIMER OF WARRANTIES. TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, ANRITSU

COMPANY AND ITS SUPPLIERS DISCLAIM ALL WARRANTIES, EITHER EXPRESSED OR IMPLIED,

INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, WITH REGARD TO THE PRODUCT. THE USER ASSUMES THE ENTIRE RISK OF

USING THE PRODUCT. ANY LIABILITY OF PROVIDER OR MANUFACTURER WILL BE LIMITED

EXCLUSIVELY TO PRODUCT REPLACEMENT.

NO LIABILITY FOR CONSEQUENTIAL DAMAGES. TO THE MAXIMUM EXTENT PERMITTED BY

APPLICABLE LAW, IN NO EVENT SHALL Anritsu COMPANY OR ITS SUPPLIERS BE LIABLE FOR ANY

SPECIAL, INCIDENTAL, INDIRECT, OR CONSEQUENTIAL DAMAGES WHATSOEVER (INCLUDING,

WITHOUT LIMITATION, DAMAGES FOR LOSS OF BUSINESS PROFITS, BUSINESS INTERRUPTION, LOSS

OF BUSINESS INFORMATION, OR ANY OTHER PECUNIARY LOSS) ARISING OUT OF THE USE OF OR

INABILITY TO USE THE PRODUCT, EVEN IF Anritsu COMPANY HAS BEEN ADVISED OF THE POSSIBILITY

OF SUCH DAMAGES. BECAUSE SOME STATES AND JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR

LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, THE ABOVE LIMITATION

MAY NOT APPLY TO YOU.

TRADEMARK ACKNOWLEDGMENTS

Anritsu is a trademark of Anritsu Company.

Microsoft Excel is a trademark of the Microsoft Corporation.

Acrobat Reader is a registered trademark of Adobe Corporation.

NOTICE

Anritsu Company has prepared this manual for use by Anritsu Company personnel and customers as a guide for the

proper installation, operation and maintenance of Anritsu Company equipment and computer programs. The

drawings, specifications, and information contained herein are the property of Anritsu Company, and any

unauthorized use or disclosure of these drawings, specifications, and information is prohibited; they shall not be

reproduced, copied, or used in whole or in part as the basis for manufacture or sale of the equipment or software

programs without the prior written consent of Anritsu Company.

UPDATES

Updates, if any, can be downloaded from the Documents area of the Anritsu web site at:

http://www.anritsu.com

For the latest service and sales contact information in your area, please visit:

http://www.anritsu.com/contact.asp

Page 3

Page 4

Notes On Export Management

This product and its manuals may require an Export License or approval by the government of the product

country of origin for re-export from your country.

Before you export this product or any of its manuals, please contact Anritsu Company to confirm whether or

not these items are export-controlled.

When disposing of export-controlled items, the products and manuals need to be broken or shredded to such a

degree that they cannot be unlawfully used for military purposes.

CE Conformity Marking

Anritsu affixes the CE Conformity marking onto its conforming products in accordance with Council Directives

of The Council Of The European Communities in order to indicate that these products conform to the EMC and

LVD directive of the European Union (EU).

C-tick Conformity Marking

Anritsu affixes the C-tick marking onto its conforming products in accordance with the electromagnetic

compliance regulations of Australia and New Zealand in order to indicate that these products conform to the

EMC regulations of Australia and New Zealand.

Page 5

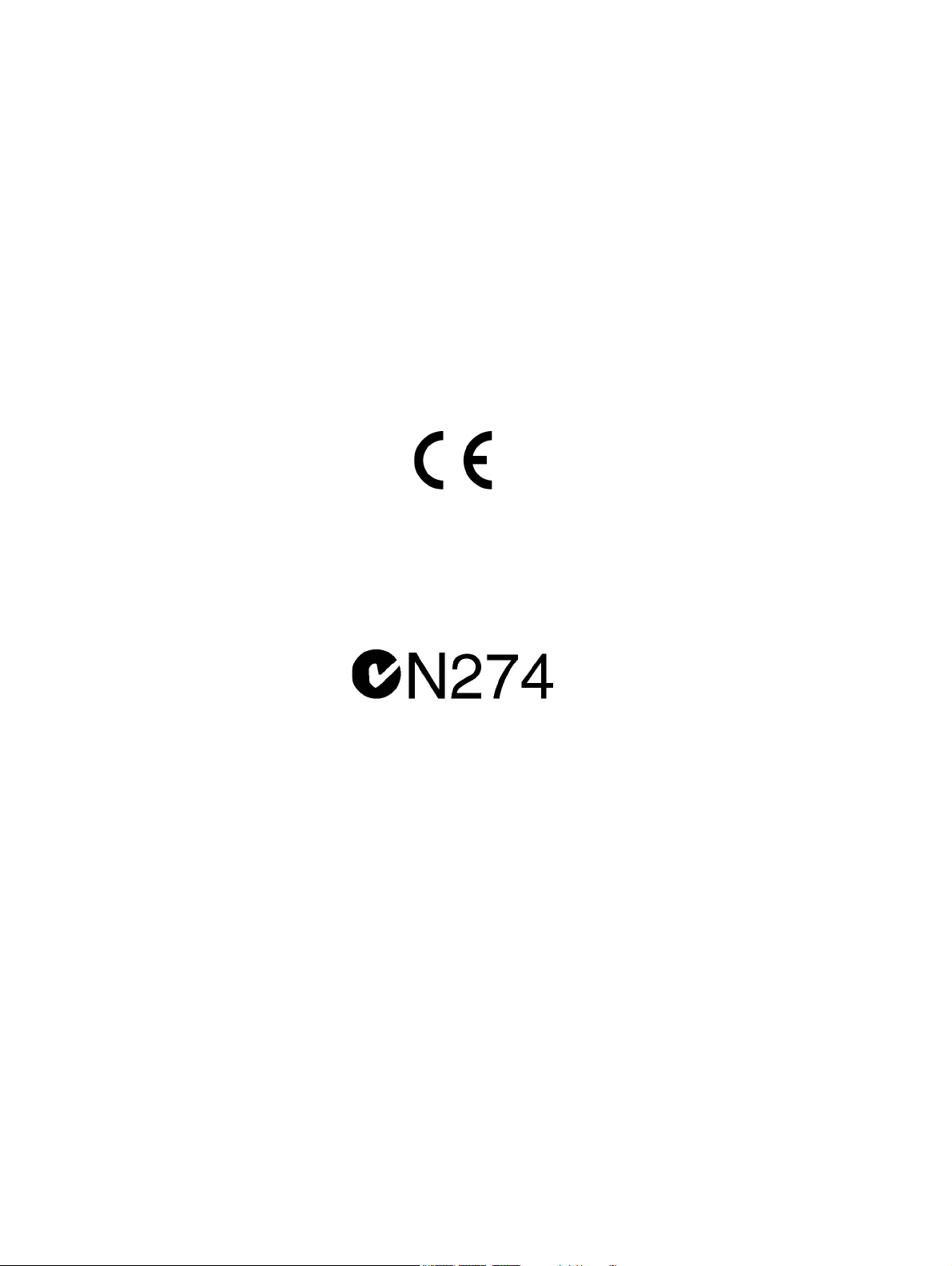

European Parliament and Council Directive 2002/96/EC

Equipment Marked with the crossed-out Wheelie

Bin symbol complies with the European

Parliament and Council Directive 2002/96/EC (the

“WEEE Directive”) in the European Union.

For Products placed on the EU market after

August 13, 2005, please contact your local Anritsu

representative at the end of the product’s useful

life to arrange disposal in accordance with your

initial contract and the local law.

Chinese RoHS Compliance Statement

Page 6

Page 7

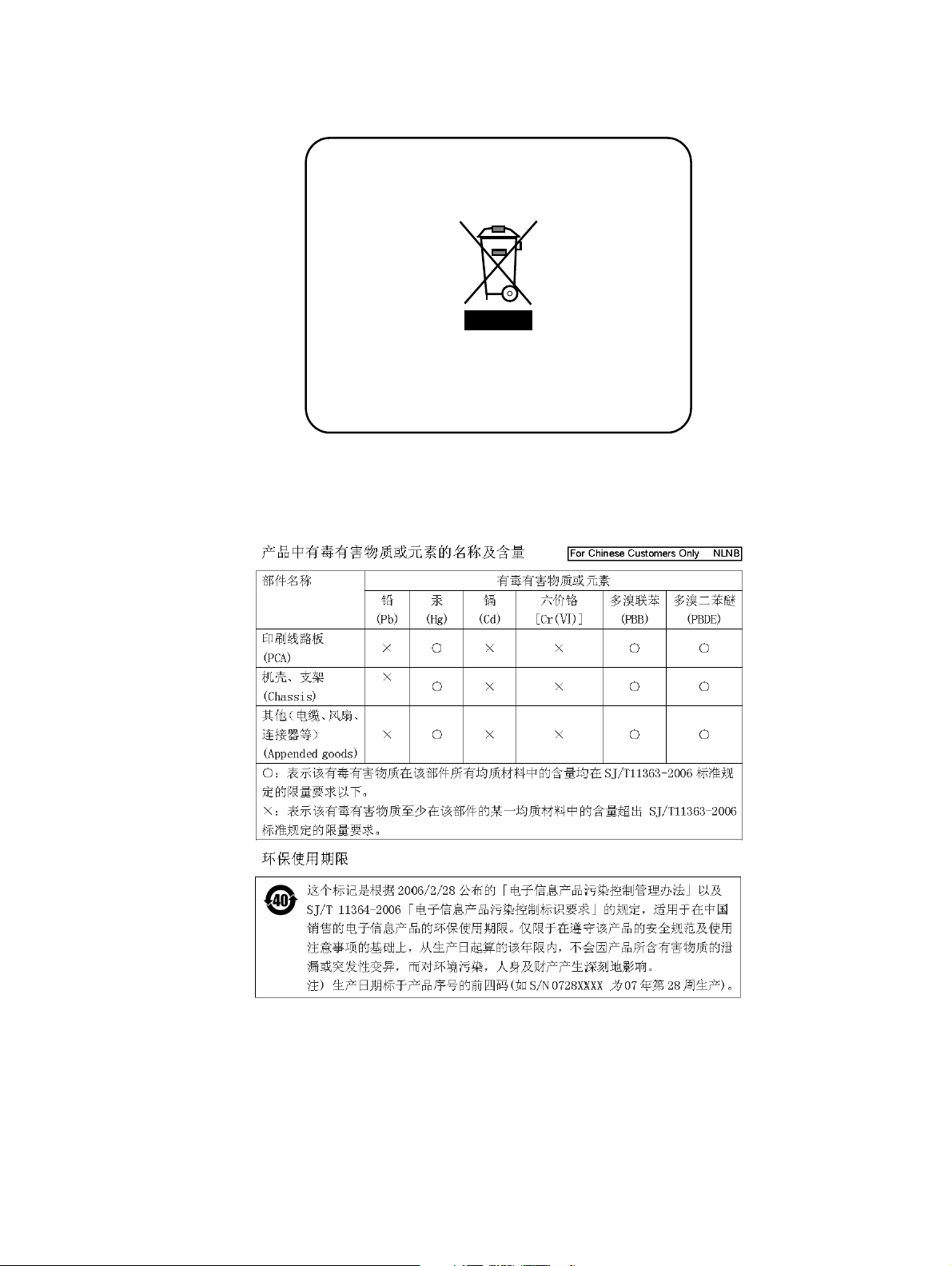

Safety Symbols

To prevent the risk of personal injury or loss related to equipment malfunction, Anritsu Company uses the

following symbols to indicate safety-related information. For your own safety, please read the information

carefully before operating the equipment.

Symbols Used in Manuals

Danger

This indicates a risk from a very dangerous condition or procedure that could result in

serious injury or death and possible loss related to equipment malfunction. Follow all

precautions and procedures to minimize this risk.

Warning

Caution

This indicates a risk from a hazardous condition or procedure that could result in

light-to-severe injury or loss related to equipment malfunction. Follow all precautions

and procedures to minimize this risk.

This indicates a risk from a hazardous procedure that could result in loss related to

equipment malfunction. Follow all precautions and procedures to minimize this risk.

Safety Symbols Used on Equipment and in Manuals

The following safety symbols are used inside or on the equipment near operation locations to provide

information about safety items and operation precautions. Ensure that you clearly understand the meanings of

the symbols and take the necessary precautions before operating the equipment. Some or all of the following

five symbols may or may not be used on all Anritsu equipment. In addition, there may be other labels attached

to products that are not shown in the diagrams in this manual.

This indicates a prohibited operation. The prohibited operation is indicated symbolically

in or near the barred circle.

This indicates a compulsory safety precaution. The required operation is indicated

symbolically in or near the circle.

This indicates a warning or caution. The contents are indicated symbolically in or near

the triangle.

This indicates a note. The contents are described in the box.

These indicate that the marked part should be recycled.

ML2419A OMM PN: 10585-00007 Rev. B Safety-1

Page 8

For Safety

Warning

Warning

Warning

Always refer to the operation manual when working near locations at which

the alert mark, shown on the left, is attached. If the operation, etc., is

performed without heeding the advice in the operation manual, there is a

risk of personal injury. In addition, the equipment performance may be

reduced.

Moreover, this alert mark is sometimes used with other marks and

descriptions indicating other dangers.

When supplying power to this equipment, connect the accessory 3-pin

power cord to a 3-pin grounded power outlet. If a grounded 3-pin outlet is

not available, use a conversion adapter and ground the green wire, or

connect the frame ground on the rear panel of the equipment to ground. If

power is supplied without grounding the equipment, there is a risk of

receiving a severe or fatal electric shock.

This equipment can not be repaired by the operator. Do not attempt to

remove the equipment covers or to disassemble internal components.

Only qualified service technicians with a knowledge of electrical fire and

shock hazards should service this equipment. There are high-voltage parts

in this equipment presenting a risk of severe injury or fatal electric shock to

untrained personnel. In addition, there is a risk of damage to precision

components.

Electrostatic Discharge (ESD) can damage the highly sensitive circuits in

the instrument. ESD is most likely to occur as test devices are being

Caution

Safety-2 PN: 10585-00007 Rev. B ML2419A OMM

connected to, or disconnected from, the instrument’s front and rear panel

ports and connectors. You can protect the instrument and test devices by

wearing a static-discharge wristband. Alternatively, you can ground

yourself to discharge any static charge by touching the outer chassis of the

grounded instrument before touching the instrument’s front and rear panel

ports and connectors. Avoid touching the test port center conductors

unless you are properly grounded and have eliminated the possibility of

static discharge.

Repair of damage that is found to be caused by electrostatic discharge is

not covered under warranty.

Page 9

Table of Contents

Chapter 1—General Information

1-1 Scope of Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-3 Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-4 Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-5 Verification and Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Instrument Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Test Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-6 Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Chapter 2—Installation

2-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2 Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-3 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

AC Line Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Fuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-4 Environmental. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-5 Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-6 Storage and Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Preparation for Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Preparation for Shipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Chapter 3—Connections

3-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-3 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Chapter 4—Operation with an ML2430A Series Power Meter

4-1 Performing a Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2 RF Calibrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4-3 Interpreting the Results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

dB Error Figure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Pass/Fail Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Absolute Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Linearity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Range Change Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4-4 Diagnostic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

ML2419A OMM PN: 10585-00007 Rev. B Contents-1

Page 10

Table of Contents (Continued)

Chapter 5—Operation with an ML248xx or ML249xA Series Power Meter

5-1 Performing a Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2 Interpreting the Results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

dB Error Figure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Pass/Fail Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Absolute Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Linearity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Range Change Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5-3 Using the Diagnostics Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5-4 Using the Range Calibrator Config Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Chapter 6—Maintenance

6-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-2 Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-3 Test Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-4 Test Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-5 Power Supply Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

+12 V Supply Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

–12 V Supply Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

+5 V Supply Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

50 MHz Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-6 Reference Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

High Level Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Positive High Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Balancing VH+ and VH– . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Positive Low Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Low Level Differential Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6-7 Microcontroller Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6-8 Attenuator Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6-9 Reference Zero Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6-10 Low Level Attenuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6-11 High Level Attenuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6-12 Rear Panel Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

5 V Reference Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Trigger Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6-13 ML2419A 50 MHz, 0 dBm Reference Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Scope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Frequency Calibration for the 50 MHz, 0 dBm Reference . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Output Power Level Calibration for the 50 MHz, 0 dBm Reference . . . . . . . . . . . . . . . . . 6-15

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6-14 Post test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Contents-2 PN: 10585-00007 Rev. B ML2419A OMM

Page 11

Appendix A—ML2419A Range Calibrator Specifications

Appendix B—Range Calibrator Verification Spreadsheet Information

B-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B-2 Using the Spreadsheet Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

ML2419A OMM PN: 10585-00007 Rev. B Contents-3

Page 12

Contents-4 PN: 10585-00007 Rev. B ML2419A OMM

Page 13

Chapter 1 — General Information

A

1-1 Scope of Manual

This manual provides installation, operation, and maintenance information for the Anritsu model ML2419A

Range Calibrator.

Figure 1-1. ML2419A Range Calibrator

1-2 Introduction

This chapter provides information to familiarize the user with the basic ML2419A Range Calibrator. Included

is information about the equipment identification number, options, and accessories.

1-3 Identification

The ML2419A identification number is affixed to the rear panel (see Figure 3-2, “ML2419A Rear Panel”

on page 3-2). Please use the complete identification number when ordering parts or corresponding with the

Anritsu Customer Service department.

1-4 Options and Accessories

The ML2419A Range Calibrator is available with the following options:

• 760-209: Hard Side Transit Case

• D41310: Soft Sided Carry Case with shoulder strap

• 2400-82: Rack Mount, single unit

• 2400-83: Rack Mount, side-by-side

Note

ML2419A OMM PN: 10585-00007 Rev. B 1-1

Options 2400-82 and 2400-83 are mutually exclusive.

1.5 meter sensor cables are supplied with the Anritsu ML24xxx Series Power Meter.

Page 14

1-5 Verification and Test Chapter 1 — General Information

1-5 Verification and Test

The ML2419A Range Calibrator provides a traceable series of voltages to facilitate accuracy measurements for

the ML2430A and ML248xx / ML249xA Series Power Meter signal channels. The voltages are produced by

means of a precision voltage reference and a series of switchable attenuators, operated by a microcontroller. All

voltages produced are accurate, stable, and low-noise such that errors inherent in the Range Calibrator itself

do not contribute significantly to the error measurements of the signal channel.

Instrument Control

The Range Calibrator is controlled remotely using the ML24xxx Series Power Meter menu system via the

sensor cables. On connection of a sensor cable, the meter automatically senses the presence of the Range

Calibrator. From this point, the Range Calibrator is controlled using the ML24xxx keypad and displayed

menus.

Test Conditions

The Range Calibrator is intended for use as a calibration instrument, and as such must be operated under

controlled conditions of temperature and humidity in order to meet its specified precision and stability.

All tests must be performed at 25 °C ± 10 °C (77 °F ± 18 °F) and a relative humidity of less than 75 % at 40 °C

(104 °F), non-condensing.

Prior to making any precision measurements, allow the Range Calibrator and the Power Meter to warm up for

a period of 15 minutes from power on. If the power supply is interrupted for any reason, allow a similar settling

period.

1-6 Related Documentation

The procedures in this manual may require reference to the following Power Meter Operation and Remote

Programming manuals and other information provided on the product disc:

• ML2430A Series Operation and Remote Programming Manual: 10585-00001

• ML248xx / ML249xA Operation Manual: 13000-00238

• ML248xx / ML249xA Remote Programming Manual: 13000-00239

• Anritsu Power Meters and Sensors Application and Documentation Disc: 2300-283

The above product disc contains all of the required documentation and spreadsheets specified in this manual.

Updated information can be downloaded from each product page on the Anritsu web site:

http://www.anritsu.com

1-2 PN: 10585-00007 Rev. B ML2419A OMM

Page 15

Chapter 2 — Installation

2-1 Introduction

This section provides information for the initial inspection and preparation for use of the ML2419A Range

Calibrator. Shipping and storage information is also included.

2-2 Initial Inspection

Inspect the shipping container for damage. If the container or cushioning material is damaged, retain until the

contents of the shipment have been checked against the packing list and the instrument has been checked for

mechanical and electrical operation.

If the instrument is damaged mechanically, notify your local sales representative or Anritsu Customer Service

Center. If either the shipping container is damaged or the cushioning material shows signs of stress, notify the

carrier as well as Anritsu. Retain the shipping materials for the carrier's inspection.

2-3 Power Requirements

The ML2419A Range Calibrator is operated from AC line power and is intended as an Installation

(Overvoltage) Category II, Insulation Category I device. A front-panel LED indicates when power is applied.

AC Line Power

The ML2419A Range Calibrator can operate on AC input power of 90 to 132 V or 180 to 264V, 47 Hz to 63 Hz,

6 VA max.

Fuses

The ML2419A Range Calibrator AC input line is protected by an internally mounted fuse. This fuse should

only be changed by qualified service personnel. Replace only with a fuse of the same type and rating:

0.5 A, 250 V, antisurge (T).

Grounding

The ML2419A Range Calibrator must be properly grounded. Failure to ground the instrument could be

hazardous to operating personnel. The instrument is supplied with a three-conductor power cord. The

instrument is properly grounded during AC line operation when the plug is connected to a properly installed

three-prong receptacle. A grounding terminal is also provided on the rear panel.

2-4 Environmental

The ML2419A Range Calibrator is designed to operate within the temperature range of 0 °C to 50 °C

(32 °F to 122 °F) with a maximum relative humidity of 95 % at 40 °C (104 °F), non-condensing.

Full accuracy is specified at 25 °C ± 10 °C (77 °F ± 18 °F), at a maximum relative humidity of 75 % at 40 °C

(104 °F), non-condensing.

ML2419A OMM PN: 10585-00007 Rev. B 2-1

Page 16

2-5 Rack Mounting Chapter 2 — Installation

2-5 Rack Mounting

The ML2419A Range Calibrator can be ordered with rack mounting hardware that allows the unit to be

mounted into a standard 19 inch equipment rack. There are two rack mount option kits available:

• The 2400-82 Rack Mount option allows the installation of a single ML2419A in either the left or

right-side rack position.

• The 2400-83 Rack Mount option allows mounting of two ML2419A Range Calibrators (or one Range

Calibrator and one ML24xxx Series Power Meter) side-by-side.

The instrument itself must be ordered from the factory as a rack mount unit. As such, it will be fitted with rack

mount top and bottom cases that have extra mounting holes so that the rack mount kits can be installed.

Instructions for installing the rack mount kits are supplied with the rack mounting kits.

2-6 Storage and Shipment

The following paragraphs describe preparing the range calibrator for storage and shipment.

Preparation for Storage

Preparing the range calibrator for storage consists of cleaning the unit and packing it with moisture-absorbing

desiccant crystals.

Environmental Requirements

Store the unit in a temperature controlled environment that is maintained between –40 and +70 °C

(–40 to +156 °F), with a maximum humidity of 95 % at 40 °C (104 °F), non-condensing.

Preparation for Shipment

To provide maximum protection against damage in transit, the range calibrator should be repackaged in the

original shipping container. If this container is no longer available and the range calibrator is being returned to

Anritsu for repair, follow the packaging instructions below:

• Use a Suitable Container: Obtain a corrugated cardboard carton with a 275 pound test strength. This

carton should have inside dimensions of no less than six inches larger than the instrument dimensions to

allow for cushioning.

• Protect the Instrument: Wrap the instrument to protect the finish.

• Cushion the Instrument: Cushion the instrument on all sides by tightly packing dunnage or urethane

foam between the carton and the instrument. Provide at least three inches of dunnage on all sides.

• Seal the Container: Seal the carton using either shipping tape or an industrial stapler.

• Address the Container: If the instrument is being returned to Anritsu for service, mark the address of

the appropriate Anritsu service center (refer to

Authorization (RMA) number, and your return address on the carton in a prominent location.

http://www.anritsu.com/contact.asp), the Return Materials

2-2 PN: 10585-00007 Rev. B ML2419A OMM

Page 17

Chapter 3 — Connections

A

3-1 Introduction

This section provides descriptions of the ML2419A Range Calibrator front and rear panels and connectors.

3-2 Front Panel

The front panel is illustrated in Figure 3-1. There are three connectors and an ON/OFF indicator LED on the

front panel.

Figure 3-1. ML2419A Front Panel

AC Power LED: This LED lights whenever AC power is applied to the ML2419A Range Calibrator and the

power switch is in the on position.

50 MHz 0 dBm Connector: This precision output provides a nominal 50 MHz, 0.0 dBm reference signal to

approximate the sensor calibration. For a traceable calibration, use the 50 MHz source on the ML24xxx Series

Power Meter. The 0.0 dBm level is available at this N-type connector whenever the Range Calibrator is

powered on.

Sensor A Connector: This connector is a 12 pin, circular precision connector to be used in conjunction with

1.5 meter power sensor cables.

Sensor B Connector: This connector is a 12 pin, circular precision connector to be used in conjunction with

1.5 meter power sensor cables.

ML2419A OMM PN: 10585-00007 Rev. B 3-1

Page 18

3-3 Rear Panel Chapter 3 — Connections

3-3 Rear Panel

The Rear Panel has four connectors, the AC input voltage selector, and an ID number label.

Figure 3-2. ML2419A Rear Panel

AC Line Power Connector: The ML2419A Range Calibrator can operate on AC input power of 90 to 132 V or

180 to 264V, 47 Hz to 63 Hz, 50 VA max. The Range Calibrator must be properly configured using the voltage

selector for the voltage being applied. No on/off switch is provided, as the unit is powered continuously during

use. A front-panel LED indicates when power is applied.

Output 1 5V Reference: This function is reserved for future use.

Output 2 Trigger: This function is reserved for future use.

Chassis Ground: This grounding terminal can be used to connect the chassis ground of the Range Calibrator

to other equipment as necessary.

The instrument itself is properly grounded when the AC line plug is connected to a properly installed

three-prong receptacle.

ID Number Label: The ML2419A identification number is affixed to the rear panel. Please use the complete

identification number when ordering parts or corresponding with the Anritsu Customer Service department.

3-2 PN: 10585-00007 Rev. B ML2419A OMM

Page 19

Chapter 4 — Operation with an ML2430A

-erom-A

Range Calibrator

ANRITSU

A

B

A and B - more -

Range Calibrator

ANRITSU

Series Power Meter

4-1 Performing a Verification

The performance of the Anritsu ML2430A Series Power Meter’s individual signal channel inputs are verified

using the following procedure. References in this procedure to sensor input B apply to model ML2438A

(dual-channel) power meter only. Before starting this procedure, refer to Section 1-5 “Verification and Test” for

information on the appropriate Test Conditions.

1. Connect the Range Calibrator to the Power Meter using 1.5 meter sensor cables. The inputs to be verified

must be connected to the corresponding connectors on the Range Calibrator; that is, connect Power

Meter connector A to Range Calibrator connector A, and connector B to connector B (ML2438A only).

2. On connection of the sensor cables, the meter automatically detects that a Range Calibrator is present

and displays the performance verification menus.

Figure 4-1. ML2419A Range Calibrator Top Menu (single-channel power meter)

Figure 4-2. ML2419A Range Calibrator Top Menu (dual-channel power meter)

3. The performance verification tests will begin when the soft key for the sensor input to be verified is

selected. For single-channel power meters (ML2437A), press the A soft key. For dual-channel models

(ML2438A), press A, B, or A and B. If the “A and B” soft key is selected, all measurements are first taken

on sensor input A, then repeated for sensor input B. Performance verification tests for each sensor input

are performed in the following sequence:

• The signal channel input is zeroed.

• The Power Meter signal channels are checked at the upper and lower levels of each measurement

range. A null is performed at each range setting prior to every measurement.

ML2419A OMM PN: 10585-00007 Rev. B 4-1

Page 20

4-1 Performing a Verification Chapter 4 — Operation with an ML2430A Series Power Meter

SENSOR

Range calibrator results SensorA

Range (upper) Range (lower)

1 6.996

2 -11.822

3 -25.864

4 -41.806

5 -57.805

1 -11.822

2 -25.771

3 -41.808

4 -57.814

5 -61.727

PRINT REPEAT - exit -

4. When all measurements have been performed on the selected inputs, the results are presented on the

screen and the following soft keys are displayed:

Figure 4-3. ML2419A Range Calibrator Verification Results Menu Example

SENSOR: Toggles the display to show the data for each sensor channel verified. If only one channel has been

verified, the SENSOR soft key shown in Figure 4-3 will not be displayed.

PRINT: The verification data can be printed using the PRINT selection. The data is output through the

ML2430A Series Power Meter rear panel printer port. The printer type will be the same as that selected when

operating the meter in stand-alone mode. Refer to the ML2430A Series Power Meter Operation Manual for

information on print commands and supported printers.

See Figure 4-4 for an example of a printed Range Calibrator Report.

The results of the Range Calibrator tests are available from the power meter via the GPIB, once the

Note

Range Calibrator is disconnected from the power meter. Refer to the description of the RCD

command in the ML2430A Series Power Meter Operation Manual.

REPEAT: The last selected performance verification sequence is repeated.

-exit-: Returns the user to the top-level menu (Figure 4-1 or Figure 4-2).

5. To exit the Range Calibrator mode, disconnect the sensor cables. The Power Meter will reset to the

default mode.

4-2 PN: 10585-00007 Rev. B ML2419A OMM

Page 21

Chapter 4 — Operation with an ML2430A Series Power Meter 4-1 Performing a Verification

Figure 4-4. Example Range Calibrator Report

ML2419A OMM PN: 10585-00007 Rev. B 4-3

Page 22

4-2 RF Calibrator Chapter 4 — Operation with an ML2430A Series Power Meter

4-2 RF Calibrator

The Range Calibrator RF Calibrator output can be used to approximate the 0.0 dBm at 50 MHz reference

calibration of a sensor. Calibration is accomplished using the ML2430A Series Power Meter Cal/Zero menu.

Sensors should be zeroed before being calibrated (refer to the ML2430A Series Power Meter Operation Manual,

part number 10585-00001). Zeroing a power sensor compensates for noise and thermal EMF of the device

under test, and is recommended prior to taking important power readings in the bottom 20 dB of a power

sensor’s dynamic range.

When the sensor is first attached, the message SENSOR x ZERO not done (where x = A or B as appropriate) is

displayed. Perform the sensor zeroing procedure described in the ML2430A Series Power Meter Operation

Manual.

After zeroing the power sensor, perform the following procedure to calibrate the sensor:

1. Connect the sensor to the ML2419A Range Calibrator 50 MHz, 0.0 dBm reference output connector

labeled CALIBRATOR.

2. Press the Cal/Zero front panel key and the Cal 0 dBm soft key, then select the appropriate sensor. Note

that if only one sensor is connected, the A and B selection is not displayed and the calibration process

begins immediately.

3. On successful completion of the calibration operation, the buzzer sounds.

The sensors can also be calibrated using the GPIB CAL command (refer to the programming section of the

ML2430A Series Power Meter Operation Manual).

4-3 Interpreting the Results

The tabular data presented consist of the values read by the meter for each range, with one measurement

taken at each end of each range. For each of these measurements, there is an expected value. These measured

values must meet the specification limits defined in Appendix A, “ML2419A Range Calibrator Specifications”.

dB Error Figure

The Range Calibrator measures the “Zero” level, and the “Upper” and “Lower” limits of each of the five ranges

(both channels on a dual-channel meter). To calculate the dB Error Figure for each level, subtract the expected

level from the measured level.

4-4 PN: 10585-00007 Rev. B ML2419A OMM

Page 23

Chapter 4 — Operation with an ML2430A Series Power Meter 4-3 Interpreting the Results

Pass/Fail Criteria

The meter should be accepted as PASSED if it meets the following conditions applied to the error figures

calculated by the above method.

Note

Table 4 - 1 . Pass / Fail Criteria

Range Specifications (dB)

Range 1 Absolute Error –0.028 ≤ R1U ≤ 0.028

Range 1 Linearity –0.028 ≤ R1U – R1L ≤ 0.028

Ranges 1 – 2 Change –0.028 ≤ R1L – R2U ≤ 0.028

Range 2 Linearity –0.028 ≤ R2U – R2L ≤ 0.028

Ranges 2 – 3 Change –0.028 ≤ R2L – R3U ≤ 0.028

Range 3 Absolute Error –0.028 ≤ R3U ≤ 0.028

Range 3 Linearity –0.028 ≤ R3U – R3L ≤ 0.028

Ranges 3 – 4 Change –0.028 ≤ R3L – R4U ≤ 0.028

Range 4 Linearity –0.028 ≤ R4U – R4L ≤ 0.028

Range 4 – 5 Change –0.075 ≤ R4L – R5U ≤ 0.075

Range 5 Linearity –0.023 ≤ R5U – R5L ≤ 0.023

Note that the provided Excel™ spreadsheet form can also be used to determine pass/fail status.

Refer to Appendix B, “Range Calibrator Verification Spreadsheet Information”.

Absolute Error

The calculated absolute error should be as shown in table above. For example, the calculated absolute errors

for Range 1 Upper (R1U) should be between –0.028 dB and +0.028 dB.

Linearity

The linearity values should be as shown in table above. For example, the Range 1 Lower (R1L) should differ

from Range 1 Upper (R1U) by no less than 0.028 dB.

Range Change Error

The range change error, defined as the difference between the errors for the two dB levels at the overlap

between any two ranges, should be as shown in the table above. For example, the maximum range change

error between Range 1 Lower and Range 2 Upper (R1L – R2U) should be between –0.028 dB and +0.028 dB.

ML2419A OMM PN: 10585-00007 Rev. B 4-5

Page 24

4-4 Diagnostic Mode Chapter 4 — Operation with an ML2430A Series Power Meter

6.990

Range Calibrator Diagnostics

Sensor A

Level Range 1 upper

SENSOR LEVEL ZERO - exit -

dB

4-4 Diagnostic Mode

The Diagnostics mode allows the user to investigate meter problems by holding on any of the fixed level

outputs to examine the results of a particular measurement. From the top-level menu press -more-and DIAGS.

When the Diagnostics option is selected, the SENSOR, LEVEL, and ZERO soft keys become available.

Figure 4-5. ML2419A Diagnostics Menu

SENSOR: Toggles the display to show the measurements for each channel. If only one channel is connected,

the SENSOR soft key shown in Figure 4-5 will not be displayed.

LEVEL: Selects the level to be verified.

ZERO: The selected sensor input is zeroed.

When a SENSOR and LEVEL are selected, the range calibrator outputs the required signal to the appropriate

sensor input on the meter, and the meter continuously measures it. The reading obtained for a particular

range should be the same as when the full set of tests were run (within the specifications listed in

Appendix A, “ML2419A Range Calibrator Specifications”). To obtain an accurate measurement, it is important

to ZERO at each selection of SENSOR and LEVEL.

-exit-: Returns the user to the top-level menu (Figure 4-1 or Figure 4-2).

4-6 PN: 10585-00007 Rev. B ML2419A OMM

Page 25

Chapter 5 — Operation with an ML248xx or ML249xA Series Power Meter

5-1 Performing a Verification

The performance of the ML248xx / ML249xA Series Power Meter’s individual signal channel inputs are

verified using the following procedure. References in this procedure to sensor input B apply to ML248xx and

ML2496A (dual-channel) power meters only. Before starting this procedure, refer to Section 1-5 “Verification

and Test” for information on the appropriate Test Conditions.

1. Connect the Range Calibrator to the Power Meter using 1.5 m sensor cables. The inputs to be verified

must be connected to the corresponding connectors on the Range Calibrator; that is, connect Power

Meter connector A to Range Calibrator connector A, and connector B to connector B (ML248xx and

ML2496A only).

2. On connection of the sensor cables, the power meter automatically detects the Range Calibrator and

displays the following screen.

Figure 5-1. ML2419A Range Calibrator Top Menu

3. Press the soft key of the sensor input to be verified. For single-channel power meters (ML2487x and

ML2495A), press the A soft key. For dual-channel models (ML248xx and ML2496A), press A, B, or

A&B. If the A & B soft key is selected, all measurements are first taken on sensor input A, then

repeated for sensor input B. Performance verification tests for each sensor input are performed in the

following sequence:

a. The signal channel input is zeroed.

b. The Power Meter signal channel are checked at the upper and lower levels of each measurement

range. A null is performed at each range setting prior to every measurement.

ML2419A OMM PN: 10585-00007 Rev. B 5-1

Page 26

5-2 Interpreting the Results Chapter 5 — Operation with an ML248xx or ML249xA Series Power Meter

4. When all measurements have been performed on the selected inputs, the results are presented on the

screen as shown below.

Figure 5-2. ML2419A Range Calibrator Verification Results Menu Example

The figure above shows the results for inputs A and B acquired by pressing the A & B soft key. Once results for

both inputs have been acquired, the information is retained until the power is turned off.

5-2 Interpreting the Results

The tabular data consists of the values read by the meter for each range, with one measurement taken at each

end of each range. For each of these measurements, the expected value must meet the specification limits as

defined in Appendix A, “ML2419A Range Calibrator Specifications”.

dB Error Figure

The Range Calibrator measures the "Zero" level, and the "Upper" and "Lower" limits of each of the five ranges

(both channels on a dual-channel meter). To calculate the dB Error Figure for each level, subtract the expected

level from the measured level.

5-2 PN: 10585-00007 Rev. B ML2419A OMM

Page 27

Chapter 5 — Operation with an ML248xx or ML249xA Series Power Meter 5-2 Interpreting the Results

Pass/Fail Criteria

The meter should be accepted as PASSED if it meets the error and linearity statistics in the following table.

Note

Table 5 - 1 . Pass / Fail Criteria

Range Specifications (dB)

Range 1 Absolute Error –0.020 ≤ R1U ≤ 0.020

Range 1 Linearity –0.040 ≤ R1U – R1L ≤ 0.040

Ranges 1 – 2 Change –0.030 ≤ R1L – R2U ≤ 0.030

Range 2 Linearity –0.040 ≤ R2U – R2L ≤ 0.040

Ranges 2 – 3 Change –0.030 ≤ R2L – R3U ≤ 0.030

Range 3 Absolute Error –0.020 ≤ R3U ≤ 0.020

Range 3 Linearity –0.040 ≤ R3U – R3L ≤ 0.040

Ranges 3 – 4 Change –0.030 ≤ R3L – R4U ≤ 0.030

Range 4 Linearity –0.040 ≤ R4U – R4L ≤ 0.040

Range 4 – 5 Change –0.030 ≤ R4L – R5U ≤ 0.030

Range 5 Linearity –0.040 ≤ R5U – R5L ≤ 0.040

Range 7 Absolute Error –0.030 ≤ R7U ≤ 0.030

Range 8 Absolute Error –0.030 ≤ R8U ≤ 0.030

Range 8 Linearity –0.085 ≤ R8U – R8L ≤ 0.085

Range 9 Absolute Error –0.050 ≤ R9U ≤ 0.050

Range 9 Linearity –0.18 ≤ R9U – R9L ≤ 0.18

Note that the provided Excel™ spreadsheet form can also be used to determine pass/fail status.

Refer to Appendix B, “Range Calibrator Verification Spreadsheet Information”.

Absolute Error

The calculated absolute error should be as shown in table above. For example, the calculated absolute errors

for Range 1 Upper (R1U) should be between –0.020 dB and +0.020 dB.

Linearity

The linearity values should be as shown in table above. For example, the Range 1 Lower (R1L) should differ

from Range 1 Upper (R1U) by no less than 0.040 dB.

Range Change Error

The range change error, defined as the difference between the errors for the two dB levels at the overlap

between any two ranges, should be as shown in the table above. For example, the maximum range change

error between Range 1 Lower and Range 2 Upper (R1L – R2U) should be between –0.030 dB and +0.030 dB.

ML2419A OMM PN: 10585-00007 Rev. B 5-3

Page 28

5-3 Using the Diagnostics Menu Chapter 5 — Operation with an ML248xx or ML249xA Series Power Meter

5-3 Using the Diagnostics Menu

The Diagnostics mode allows the user to investigate meter problems by holding on any of the fixed level

outputs to examine the results of a particular measurement.

1. Connect the Range Calibrator to the Power Meter using 1.5 m sensor cables. The inputs to be verified

must be connected to the corresponding connectors on the Range Calibrator; that is, connect Power

Meter connector A to Range Calibrator connector A, and connector B to connector B (ML248xx and

ML2496A only).

2. Press the Diag soft key to display the Rng Cal Diag group of commands and the Range Calibrator

Diagnostics dialog.

Figure 5-3. ML2419A Range Calibrator Diagnostics Menu

3. Press the Next Level soft key to display the required level. The range calibrator outputs the required

signal to the appropriate sensor input on the meter, and the meter continuously measures it. The

reading obtained for a particular range should be the same as when the full set of tests was run.

4. Press the Zero soft key to zero the residual range for the required level.

5. Press the Exit soft key to close the dialog and return to the main Range Cal menu.

5-4 Using the Range Calibrator Config Menu

The range calibrator config menu houses four commands normally found under the System hard key of the

ML248xx / ML249xA Series Power Meter. These commands have been included so that the user can access

them without the need to disconnect from the range calibrator. The soft keys in the Rng Cal Conf menu are

summarized below. Refer to chapter 5 of this manual for a more detailed explanation.

Identity: Press to display instrument type, serial number, and firmware version details.

Set GPIB Address: Press to display or change the instrument's GPIB address.

Set RS232 Baud Rate: Press to display or change the baud rate.

Screen Dump Mode: Press to retain the display of the soft keys in screen dumps captured remotely using the

supplied ScreenCapture.exe program.

5-4 PN: 10585-00007 Rev. B ML2419A OMM

Page 29

Chapter 6 — Maintenance

6-1 Introduction

This chapter describes the functional test and calibration of the ML2419A Range Calibrator used for

performance verification of the ML24xxx Series Power Meter. Also included is a list of recommended test

equipment.

Procedures in this section should be performed by qualified technical personnel only. These

procedures require access to internal test points and adjustment pots, and care should be taken to

Note

6-2 Recommended Test Equipment

The following test equipment is required to perform the procedures in this chapter.

• A DVM with a DC voltage measurement accuracy of ± 60 ppm ± 1 digit (example: Agilent 34401A)

• General purpose oscilloscope and BNC lead

• Test lead set for DVM

• Frequency Counter (example: Anritsu MF2412B)

• Power Meter (example: Agilent 732A)

• Thermistor Mount Sensor (example: Agilent 478A)

avoid contact with potentially hazardous voltages. No conductors carrying AC voltages are readily

accessible provided the unit is operated correctly with all insulators intact. As there are conductors

carrying AC voltages on the underside of the motherboard, the unit must always be powered with the

rear panel and motherboard firmly in place on the base.

Note Ensure all test equipment is within its calibration period.

6-3 Test Conditions

The Range Calibrator is intended for use as a calibration instrument and must be operated under controlled

conditions of temperature and humidity in order to meet its specified precision and stability. All tests should be

performed at a temperature of 25 °C ± 10 °C (77 °F ± 9 °F) and relative humidity of less than 75 % at 40 °C

(104 °F), non-condensing. Prior to making any precision measurements, allow the Range Calibrator to warm

up for a period of 30 minutes from power on. If the power supply is interrupted for any reason, allow a similar

settling period.

ML2419A OMM PN: 10585-00007 Rev. B 6-1

Page 30

6-4 Test Setup Chapter 6 — Maintenance

6-4 Test Setup

Procedures in this and the following sections should be performed by qualified technical personnel

Caution

With AC power disconnected, open the unit by loosening the six captive screws on the underside

(Figure 6-1, “ML2419A Bottom View” on page 6-3) and separating the top half of the case from the base.

Ensure that the front and rear panels remain firmly in place during this operation.

Apply power to the unit using the AC inlet on the rear panel and verify that the front panel LED is

illuminated. Prior to making any precision measurements, allow the Range Calibrator to warm up for a period

of 30 minutes from power on. If the power supply is interrupted for any reason, allow a similar settling period.

Record all measurements on a copy of the Test Result Sheet provided at the end of this chapter.

only. This procedure requires access to internal test points and adjustment pots, and care should be

taken to avoid contact with potentially hazardous voltages.

6-5 Power Supply Tests

Use a digital voltmeter and the Range Calibrator test lead set, as specified in Section 6-2 “Recommended Test

Equipment” on page 6-1 to perform the following tests. See Figure 6-2, “ML2419A Main PCB” on page 6-4 for

test point, potentiometer, and jumper locations.

+12 V Supply Test

1. Attach the DVM test leads to TP30 and TP31 and “zero” the DVM

2. Using the test lead set, connect the DVM –ve input to TP21 (0V) and the +ve input to TP24.

3. Verify that the +12 V supply is within specification.

SPECIFICATION: +12.15 V ± 0.5 V

–12 V Supply Test

1. Connect the DVM +ve input to TP25.

2. Verify that the –12 V supply is within specification.

SPECIFICATION: –12.17 V ± 0.50 V

+5 V Supply Test

1. Connect the DVM –ve input to TP22 and the +ve input to TP23.

2. Verify that the +5 V supply is within specification.

SPECIFICATION: +5.0 V ± 0.2 V

50 MHz Supply

1. Connect the DVM –ve input to TP26 and the +ve input to TP32.

2. Verify that the 50 MHz supply voltage is within specification.

SPECIFICATION: +24V ± 5 V

6-2 PN: 10585-00007 Rev. B ML2419A OMM

Page 31

Chapter 6 — Maintenance 6-5 Power Supply Tests

LOOSEN THESE SCREWS

Figure 6-1. ML2419A Bottom View

LOOSEN THESE SCREWS

ML2419A OMM PN: 10585-00007 Rev. B 6-3

Page 32

6-5 Power Supply Tests Chapter 6 — Maintenance

CH A

REFZ

ZERO

LEVEL 1

LEVEL 2

LEVEL 3

LEVEL 4

LEVEL 6

LEVEL 7

LEVEL 5

INVERT

START STEP RESET

TP24

TP26

TP25

TP32

TP22

TP23

TP19

TP13

TP15

TP11

TP9

TP17

TP7

TP16

TP12

TP10

TP18

TP8

TP20

TP14

TP27

TP29

J16 J17

J14

J15 J12 J13

TP3

TP5

TP4

TP6

TP30

TP1

R19

R41

R36

TP2

TP21

TP31

J1

J9

J10

J2

J3

J4

J5

FUSE

Figure 6-2. ML2419A Main PCB

6-4 PN: 10585-00007 Rev. B ML2419A OMM

Page 33

Chapter 6 — Maintenance 6-6 Reference Levels

6-6 Reference Levels

The following tests verify the high and low reference levels. Use a DVM and the test leads as specified in

Section 6-2 “Recommended Test Equipment” on page 6-1 to perform these tests. Refer to Figure 6-2, “ML2419A

Main PCB” on page 6-4 for test point, potentiometer, and jumper locations.

Section 6-6 and Section 6-9 require measurement of µV offset voltages while the top cover is

removed. To avoid interference during these measurements, turn off all nonessential equipment

Note

Before performing the reference level tests listed below, “zero” or “null” the DVM with the DVM test leads

attached to TP30 and TP31.

High Level Offsets

1. Attach the DVM –ve lead to TP21 and the +ve lead to TP3.

2. Move the jumper from J1 to J2.

3. Verify the offset voltage measured at TP3 is within specifications, even when the Invert button is pressed.

Record the results.

within close proximity (2 m) of the test.

Prior to making the following measurements, press the RESET button on the Range Calibrator PCB

and ensure that the REFZ LED is not lit. If the REFZ LED is lit, refer to Section 6-7 for information on

controlling the LED.

4. Move the jumper from J2 to J3 and the DVM +ve lead to TP4.

5. Verify the offset voltage measured at TP4 is within specifications, even when the Invert button is pressed.

Record the results.

SPECIFICATION: 0, ±20 µV

Positive High Level

1. Remove the jumper from J3 and return it to J1.

2. Attach the DVM +ve lead to TP1.

3. Adjust R19 to set the measurement as close as possible to +2.5000V, changing to –2.5000V when the

Invert button is pressed.

SPECIFICATION: ±2.5000, ± 0.1 mV.

Balancing VH+ and VH–

The voltage at TP2 should be the inverse of the voltage at TP1. Measure the voltages at TP1 and TP2

alternately while adjusting R19 if necessary to balance the two voltages as close as possible within their

specification. Obtain the best balance possible, including the effect of pressing the Invert button. Record the

final TP1 and TP2 voltages.

SPECIFICATION: ±2.5000, ± 0.1 mV.

ML2419A OMM PN: 10585-00007 Rev. B 6-5

Page 34

6-7 Microcontroller Operation Chapter 6 — Maintenance

Positive Low Level

1. Move the Jumper from J1 to J4, and place the DVM +ve lead on TP5 and the –ve lead on TP21.

Note Zero the DVM at TP30 and TP31 before making the following measurements.

2. Adjust R36 such that the offset voltage measured is balanced about zero when the Invert button is

alternately pressed and released. Obtain the best possible balance within the specification. Record the

results.

SPECIFICATION: 0, ±11 µV.

3. Move the jumper to J5, and the DVM +ve lead to TP6.

4. Repeat the above operation, this time adjusting R41 to obtain the best possible balance about zero at TP6.

Record the results.

SPECIFICATION: 0 ± 11 µV.

Low Level Differential Voltage

1. Move the jumper from J5 back to the park position at J1.

2. Move the DVM +ve lead to TP5 and the DVM –ve lead to TP6.

3. Measure and record the voltages, both with and without the Invert button pressed.

SPECIFICATION: ±279.33 mV ± 0.06 mV

6-7 Microcontroller Operation

On power-up, the Range Calibrator defaults to normal operation, whereby the unit is controlled remotely by

the ML24xxx Series Power Meter. To gain control of the Range Calibrator locally, hold down the START button

and press the PCB RESET button momentarily. Refer to Figure 6-2, “ML2419A Main PCB” on page 6-4 for

switch and LED locations.

To place the Range Calibrator in each of its states sequentially, press the PCB STEP button repeatedly and

note that indication of present state is given by the bank of LEDs on the PCB.

The sequence will step from Channel A, Level ZERO through LEVEL 7 to LEVEL 1, followed by Channel B,

Level ZERO through LEVEL 7 to LEVEL 1. Once all of the states have been stepped through the cycle will

repeat so that it is possible to return to any given state by repeatedly pressing the STEP button.

To operate the Reference Zero function, hold both the START and STEP buttons down together and press the

PCB RESET button momentarily. Now repeated operation of the STEP button will result in a single cycle

through the Channel A and Channel B levels, but with the REFZ LED illuminated indicating that a reference

voltage of 0.0 V has been selected. Once all of the states have been stepped through, the cycle will repeat with

the REFZ LED extinguished, indicating that the normal reference of 5.0 V has been selected.

To return to normal operation, press the PCB RESET button. In this mode, the STEP button will have no effect

since the instrument is waiting for instructions from the ML24XX Power Meter. Control can be switched

between local and remote operation as required without the need to cycle power, avoiding warm-up time

delays.

6-6 PN: 10585-00007 Rev. B ML2419A OMM

Page 35

Chapter 6 — Maintenance 6-8 Attenuator Function

6-8 Attenuator Function

Prior to verification of the attenuation factors, check the basic function of the attenuator control as follows:

Note Zero the DVM at TP30 and TP31 before making any of the following measurements.

1. Attach the DVM –ve lead to TP20 and the +ve lead to TP19.

2. Cycle through each attenuator step with the STEP button and verify the following readings on the DVM.

Use the INVERT button at each step to verify the negative polarity. Record the result.

LEVEL EXPECTED VALUE

7

6

5

4

3

2

1

ZERO

± 208 µV, ± 5 µV

± 512 µV, ± 5 µV

± 2.646 mV, ± 5 µV

± 20.434 mV, ± 5 µV

± 65.552 mV, ± 10 µV

± 802.78 mV, ± 100 µV

± 5.0000V, ± 500 µV

± 0.000 mV,± 5 µV

6-9 Reference Zero Function

To check the Reference Zero function:

1. Hold both the START and STEP buttons down together and press the RESET button momentarily.

2. Verify that the voltage measured with the leads at TP19 and TP20 for each of the Channel A and

Channel B level states is always at zero while the REFZ LED is on.

SPECIFICATION: 0.00mV ±50 µV

Note

ML2419A OMM PN: 10585-00007 Rev. B 6-7

Press the RESET button when this test is completed and ensure that the REFZ LED is off before

proceeding to the next test.

Page 36

6-10 Low Level Attenuators Chapter 6 — Maintenance

6-10 Low Level Attenuators

Note Zero the DVM at TP30 and TP31 before making any of the following measurements.

To check the low level attenuators:

1. Remove the jumpers from JP9 and JP10.

2. Place the DVM +ve lead on TP5 and the –ve lead on TP6.

3. Measure and record the voltage level.

Note Measure and record all voltage levels to four decimal places.

4. Place the leads on TP7 and TP8 and record the voltage level.

5. Divide the first voltage by the second to compare with the expected attenuation factor.

EXPECTED VALUE: 13.6701 ± 0.0027

6. Insert the jumpers on JP12 and JP13.

7. Measure and record the new voltage at TP7 and TP8.

8. Attach the DVM leads to TP9 and TP10 and record the voltage level.

9. Divide the first voltage by the second to compare with the expected attenuation factor.

EXPECTED VALUE: 7.7224 ± 0.0016

10. Insert the jumpers on JP14 and JP15.

11. Measure and record the new voltage at TP9 and TP10.

12. Attach the DVM leads on TP11 and TP12 and record the voltage level.

13. Divide the first voltage by the second to compare with the expected attenuation factor.

EXPECTED VALUE: 5.1651 ± 0.0010

14. Insert the jumpers on JP16 and JP17.

15. Measure and record the new voltage at TP11 and TP12.

16. Attach the DVM –ve test lead to TP14 and the +ve test lead to TP13 and record the voltage level.

17. Divide the first voltage by the second to compare with the expected attenuation factor.

EXPECTED VALUE: 2.4661 ± 0.0005

6-8 PN: 10585-00007 Rev. B ML2419A OMM

Page 37

Chapter 6 — Maintenance 6-11 High Level Attenuators

6-11 High Level Attenuators

Note Zero the DVM at TP30 and TP31 before making any of the following measurements.

To check the high level attenuators:

1. Attach the DVM +ve lead on TP3 and the –ve lead on TP4 and record the voltage level.

Note Measure and record all voltage levels to four decimal places.

2. Attach the leads on TP15 and TP16 and record the voltage level.

3. Divide the first voltage by the second to compare with the expected attenuation factor.

EXPECTED VALUE: 6.2281 ± 0.0013

4. Remove the jumpers from J16 and J17 and insert them on J18 and J19.

5. Measure and record the new voltage at TP15 and TP16.

6. Attach the leads on TP17 and TP18 and record the voltage level.

7. Divide the first voltage by the second to compare with the expected value.

EXPECTED VALUE: 12.2471 ± 0.0025

Remove the jumpers from J18 and J19 and return them to J9 and J10 once these measurements are

Note

complete. Failure to do this will lead to incorrect operation of the Low Level attenuator chain.

(Correct operation may be verified by repeating the operations described in Section 6-6 “Reference

Levels” on page 6-5.

6-12 Rear Panel Functions

The following paragraphs describe the rear panel functions.

5 V Reference Output

Refer to Section 6-7 “Microcontroller Operation” for information on the Range Calibrator using the on-board

push-button switches.

1. Attach the DVM +ve lead on TP29 and the DVM –ve lead on TP27.

2. Verify that the voltage measured at TP29 is +5 V when any level is selected other than level ZERO.

Record the result.

EXPECTED VALUE: +5.000 V, ± 1 mV

3. Confirm that when level ZERO is selected, the voltage at TP29 is 0 V. Record the result.

EXPECTED VALUE: 0 V, ± 1 mV

ML2419A OMM PN: 10585-00007 Rev. B 6-9

Page 38

6-13 ML2419A 50 MHz, 0 dBm Reference Calibration Procedure Chapter 6 — Maintenance

Trigger Output

Refer to Section 6-7 “Microcontroller Operation” for information on the Range Calibrator using the on-board

push-button switches.

1. Using a general-purpose oscilloscope and BNC lead, verify that every time the level is changed by

pressing the STEP button, a 300 µs duration positive going TTL pulse is generated at the TRIGGER BNC

output.

2. Set the oscilloscope vertical scale to 2 V/Div, horizontal scale to 100 µs/Div, and trigger on the rising edge.

The trace should appear as below:

Figure 6-3. ML2419A Trigger BNC Output Trace

6-13 ML2419A 50 MHz, 0 dBm Reference Calibration Procedure

Scope

This document details how to calibrate and adjust the ML2419A 50 MHz, 0 dBm Reference.

Equipment Required

• Anritsu MF2412B Frequency Counter

• RF Cable with BNC male connection at one end and an N-type male connection at other end

• Agilent 432A Analog Power Meter

• Agilent 34420A Nano Volt / Micro Ohm Meter or equivalent

• Agilent 8478B Power Sensor

6-10 PN: 10585-00007 Rev. B ML2419A OMM

Page 39

Chapter 6 — Maintenance 6-13 ML2419A 50 MHz, 0 dBm Reference Calibration Procedure

Frequency Calibration for the 50 MHz, 0 dBm Reference

Procedure

1. Power on the ML2419A and MF2412B. Allow both units to warm up for 30 minutes before taking any

measurements.

2. On the MF2412B, press the Preset Key.

Figure 6-4. MF2412B Preset Key

3. On the MF2412B, press the Input key (also the number 0 key).

Figure 6-5. MF2412B Input Key

ML2419A OMM PN: 10585-00007 Rev. B 6-11

Page 40

6-13 ML2419A 50 MHz, 0 dBm Reference Calibration Procedure Chapter 6 — Maintenance

4. On the MF2412B, press the Left Arrow key to highlight Input CH area.

Figure 6-6. MF2412B Input CH

5. On the MF2412B, press the enter key until “Input 2” is selected.

Figure 6-7. MF2412B Input 2

6-12 PN: 10585-00007 Rev. B ML2419A OMM

Page 41

Chapter 6 — Maintenance 6-13 ML2419A 50 MHz, 0 dBm Reference Calibration Procedure

6. On the MF2412B, press the right arrow key to highlight the Impd2 area.

Figure 6-8. MF2412B Impd2

7. On the MF2412B, press the enter key until 50 Ω is selected.

Figure 6-9. MF2412B 50 Ω

ML2419A OMM PN: 10585-00007 Rev. B 6-13

Page 42

6-13 ML2419A 50 MHz, 0 dBm Reference Calibration Procedure Chapter 6 — Maintenance

Inductor core for frequency

adjustment

8. On the MF2412B, press the “Return to Meas” key

Figure 6-10. MF2412B Return to Measure

9. Connect an RF cable from Input 2 of the MF2412B to the 50 MHz 0 dBm output connector on the

ML2419A.

10. Adjust the inductor core through the access hole in the module cover, using a non-metallic tool, so that

the frequency counter reads 50 MHz, +/- 10 kHz.

Figure 6-11. ML2419A Inductor Core

6-14 PN: 10585-00007 Rev. B ML2419A OMM

Page 43

Chapter 6 — Maintenance 6-13 ML2419A 50 MHz, 0 dBm Reference Calibration Procedure

Output Power Level Calibration for the 50 MHz, 0 dBm Reference

Procedure

1. Connect the Agilent 34420A to the Agilent 432A using the 4-wire cable provided with the Agilent 34420A.

4-wire cable provided with the Agilent 34420A,

along with two BNC to binding-posts adapters

needed to connect the four wires to the rear of

the 432A power meter.

Connection shown to the Agilent 34420A.

Connection shown to the rear of the 432A

power meter.

Green = V

White = GND of V

Red = V

Black = GND of V

rf

rf

comp

comp

ML2419A OMM PN: 10585-00007 Rev. B 6-15

Page 44

6-13 ML2419A 50 MHz, 0 dBm Reference Calibration Procedure Chapter 6 — Maintenance

2. Connect the Agilent Power Sensor 8478B to the Agilent Power Meter 432A.

432A Power meter shown connected to the

8478B power sensor.

Figure 6-12. 432A Power Meter and 8487B Power Sensor

3. Power on the 432A power meter and the 34420A voltmeter. Allow the units to warm up for 30 minutes

before taking any measurements.

6-16 PN: 10585-00007 Rev. B ML2419A OMM

Page 45

Chapter 6 — Maintenance 6-13 ML2419A 50 MHz, 0 dBm Reference Calibration Procedure

4. On the front panel of the 432A power meter, set the mount resistance to 200 Ω.

Figure 6-13. 432A Mount Resistance

5. On the front panel of the 432A power meter, set the calibration factor to 100.

Figure 6-14. Set 432A Calibrator

ML2419A OMM PN: 10585-00007 Rev. B 6-17

Page 46

6-13 ML2419A 50 MHz, 0 dBm Reference Calibration Procedure Chapter 6 — Maintenance

6. After the 432A and 34420A have warmed up for 15 minutes, perform a zero of the 432A power meter

according to the instructions listed in the 432A user manual.

7. On the front panel of the 432A power meter, set the Range to 0 dBm.

Figure 6-15. Set 432A Range

8. Unplug the ML2419A so there is no output from the 50 MHz, 0 dBm Reference.

9. Connect the 8478B power sensor to the ML2419A 50 MHz, 0 dBm Reference.

10. Select DCV 1-2 on the Agilent 34420A. Record the number shown in the display of the 34420A as V0.

(This will be a number near 20 micro-volts.)

V

= ____________ V

0

6-18 PN: 10585-00007 Rev. B ML2419A OMM

Page 47

Chapter 6 — Maintenance 6-13 ML2419A 50 MHz, 0 dBm Reference Calibration Procedure

Figure 6-16. 34420A DCV 1-2 Key

11. Plug in the ML2419A so the 50 MHz, 0 dBm Reference is active.

12. Record the new number on the Agilent 34420A as V1. (This will be a number near 80 milli-volts.)

V

= ____________ V

1

13. 10.While the Reference is still ON, press the DCV key on the 34420A and record this number as V

(This will be a number near 5 volts.)

V

= ____________ V

comp

comp

.

Figure 6-17. 34420A DCV Key

ML2419A OMM PN: 10585-00007 Rev. B 6-19

Page 48

6-13 ML2419A 50 MHz, 0 dBm Reference Calibration Procedure Chapter 6 — Maintenance

14. Use the below equation to determine P

(the 50 MHz, 0 dBm Reference output power in Watts). Start

meas

by finding the Mismatch (M), then using this number along with V

P

.

meas

, V1, V

0

, R, and EE to solve for

comp

15. If P

is between 0.000998 and 0.001002 W then calibration is complete. If outside of these limits,

meas

adjust the power level through the access hole in the module cover, using a non-metallic tool, and

re-calculate P

until it’s within the 1.0000 +/- 0.002 mW limit.

meas

Figure 6-18. Level Adjustment Access

6-20 PN: 10585-00007 Rev. B ML2419A OMM

Page 49

Chapter 6 — Maintenance 6-14 Post test

Tested By:_______________________________________ Date: _______________________________

6-14 Post test

Upon Completion of the tests:

• Remove the AC power.

• Remove all test leads and cables.

• Secure the range Calibrator top cover by tightening the six captive screws (Figure 6-1 on page 6-3). Take

care to not overtighten the screws.

ML2419A OMM PN: 10585-00007 Rev. B 6-21

Page 50

6-14 Post test Chapter 6 — Maintenance

6-22 PN: 10585-00007 Rev. B ML2419A OMM

Page 51

Appendix A — ML2419A Range Calibrator Specifications

Specifications

Signal Channel Ranges

RANGE 1

RANGE 2

RANGE 3

RANGE 4

RANGE 5

The top two ranges (Range 1 and Range 2) operate using DC voltage levels, while Range 3, Range 4, and Range 5 operate with voltages chopped

at 250 Hz to reduce offset and drift errors. The power meter expects an additional gain of 309.5 from the external voltage source (sensor or

Range Calibrator) when operating in the chopped mode. During operation in the three lower ranges, the Chop reference is provided by the meter.

The voltages provided by the Range Calibrator are such that each range will be tested close to the maximum and minimum power levels for that

range (with the exception of Range 5, which is tested at maximum and at 30 % of maximum only). Where possible, a single voltage is used to

measure the dB level at the overlap between two adjacent ranges.

Output Levels

Range 1 Upper Level

Range 1 Lower Level

Range 2 Upper Level

Range 2 Lower Level

Range 3 Upper Level

Range 3 Lower Level

Range 4 Upper Level

Range 4 Lower Level

Range 5 Upper Level

Range 5 Lower Level

Range 7 Upper Level

Range 7 Lower Level

Range 8 Upper Level

Range 8 Lower Level

Range 9 Upper Level

Range 9 Lower Level

This section provides range, mechanical, power supply, and environmental specifications.

The power meter Signal Channel incorporates five voltage measurement ranges spanning "power" levels

from +7 dB to –70 dB relative to 1.0 V. These ranges are divided as follows:

+7 to –12 dB

–11 to –28 dB

–25 to –44 dB

–41 to –58 dB

–56 to –70 dB

(dB relative to 1.0000 V)

ML2430A Series

Power Meter

+6.990 dB

–11.834 dB

–11.834 dB

–25.774 dB

–25.861 dB

–41.803 dB

–41.803 dB

–57.814 dB

–57.814 dB

–61.726 dB

–

–

–

–

–

–

ML248xx / ML249xB Series

Power Meter

–0.954 dB

–11.834 dB

–11.834 dB

–25.774 dB

–25.861 dB

–41.803 dB

–41.803 dB

–57.814 dB

–57.814 dB

–61.726 dB

–0.954

–11.834

–11.834

–16.897

–16.897

–25.774

Range 1 Upper Level Accuracy

Set point Accuracy

Temperature Stability

Long-Term Drift

±0.002 dB

± 10.612 PPM per °C (± 9.217 x 10-4 dB over ± 10 °C)

± 5.003 PPM per month (± 5.214 x 10-4 dB over 12 months)

All Other Levels

Set point Accuracy

Temperature Stability

Long-Term Drift

Noise

Range 1 Upper Level

Range 1 Lower Level

Range 2 Upper Level

Range 2 Lower Level

Range 3 Upper Level

Range 3 Lower Level

Range 4 Upper Level

Range 4 Lower Level

Range 5 Upper Level

Range 5 Lower Level

(worst case accuracy)

±0.003 dB

± 14.617 PPM per °C = ± 0.001 dB over 10 °C

± 9.928 PPM per month = ± 0.001 dB over 12 months

(1 kHz bandwidth)

1.02 x 10-5 Vrms

1.75 x 10-7 Vrms

1.75 x 10-7 Vrms

1.03 x 10-7 Vrms

1.64 x 10-6 Vrms

1.17 x 10-7 Vrms

1.17 x 10-7 Vrms

1.03 x 10-7 Vrms

1.03 x 10-7 Vrms

1.03 x 10-7 Vrms

ML2419A OMM PN: 10585-00007 Rev. B A-1

Page 52

Appendix A — ML2419A Range Calibrator Specifications

50 MHz, 0.0 dBm Reference1

Reference Power

Power Accu racy

Frequency

Frequency Accuracy

RF Output Connector

Mechanical

Dimensions

Weig ht

These specifications are valid when the output is terminated with a matched 50 ohm load.

0 dBm / 1.000 mW

+/- 1.2 % per year

50 MHz (nominal)

<1%

Front Panel, 50 ohm precision N-Type (female)

All equipment markings meet the requirements of EN 61010-1:1993.

Width: 213 mm (8.39 in)

Height: 88 mm (3.46 in)

Depth: 250 mm (9.84 in)

2.2 Kg (4.84 lb)

Power Supply Requirements

AC Line Power (selectable)

Fuse Rating

Environmental

Operating Temperature Range

Storage Temperature Range

Maximum Relative Humidity

230 V / 50 Hz 115 V / 60 Hz 6 VA maximum

0.1 A, 250 V, antisurge (T)

Full accuracy specified at 25 °C (77 °F) ± 10 °C, maximum relative humidity of 75 % at 40 °C (104 °F),

non-condensing

0°C to 50°C (32°F to 122°F)

–40 to +70 °C (–40 °F to +156 °F)

95 % at 40 °C (104 °F), non-condensing

General Options and Accessories

760–209

D41310

Hardside Transit Case

Soft Carry Case with Shoulder Strap

1.This precision output provides a nominal 50 MHz, 0.0 dBm reference signal to approximate a sensor calibration.

For a traceable calibration, use the 50 MHz source on the ML24xxx series power meter.

A-2 PN: 10585-00007 Rev. B ML2419A OMM

Page 53

Appendix B — Range Calibrator Verification Spreadsheet Information

B-1 Introduction

The Range Calibrator Verification Spreadsheet is a form that can be used to enter range data during a power

meter calibration. There are two versions of this form, one for the ML243xA power meters and one for the

ML248xx/ML249xA power meters. This form can be obtained from the Anritsu public website:

http://www.anritsu.com, under the Library tab of the power meter model being calibrated. The advantage of

using these forms is it will provide pass/fail indications automatically when entering the range data.

B-2 Using the Spreadsheet Form

The following procedure can be used to enter data into the spreadsheet from the Range Calibrator Report (see

Figure 4-4, “Example Range Calibrator Report” on page 4-3). The Range Calibrator Report can be printed

using the PRINT selection (see “PRINT” on page 4-2) on the ML2430A Series Power Meter.

1. Open the appropriate Excel spreadsheet file for your series of power meter:

ML2430A Series Power Meter: 49424.xls

ML248xx / ML249xA: 63153.xls