Page 1

MODEL

MN4790A TEST SET FOR THE

ME7842B

TOWER MOUNTED AMPLIFIER TEST SYSTEM

MAINTENANCE MANUAL

490 JARVIS DRIVE l MORGAN HILL, CA 95037-2809

P/N: 10410-00245

REVISION: A

PRINTED: MARCH 2003

COPYRIGHT 2003 ANRITSU CO.

Page 2

WARRANTY

The Anritsu product(s) listed on the title page is (are) warranted against defects in materials and

workmanship for three years from the date of shipment.

Anritsu’s obligation covers repairing or replacing products which prove to be defective during the

warranty period. Buyersshall prepaytransportation chargesfor equipment returned to Anritsu for

warranty repairs. Obligation is limited to the original purchaser. Anritsu is not liable for

consequential damages.

LIMITATION OF WARRANTY

The foregoing warranty does not apply to Anritsu connectors that have failed due to normal wear.

Also,the warranty does not apply to defects resulting from improper or inadequate maintenance by

the Buyer, unauthorized modification or misuse, or operation outside of the environmental

specifications of the product.No otherwarranty isexpressed or implied, andthe remedies provided

herein are the Buyer’s sole and exclusive remedies.

TRADEMARK ACKNOWLEDGEMENTS

Scorpion and Scorpion Navigator are registered trademarks of Anritsu Company.

Windows is a registered trademark of Microsoft Corporation.

NOTICE

Anritsu Company has prepared this manual for use by Anritsu Company personnel and customers

as a guide for the proper installation, operation and maintenance of Anritsu Company equipment

and computer programs. The drawings, specifications, and information contained herein are the

property of Anritsu Company, and any unauthorized use or disclosure of these drawings,

specifications, and information is prohibited; they shall not be reproduced,copied, or used in whole

or in part as the basis for manufacture or sale of the equipment or software programs without the

prior written consent of Anritsu Company.

Page 3

Symbols used in manuals

Safety Symbols

To prevent the risk of personal injury or loss related to equipment

malfunction, ANRITSU Company uses the following symbols to indi

cate safety-related information. For your own safety, please read this

information carefully BEFORE operating the equipment.

-

DANGER

Indicates a very dangerous procedure that could result in serious in

jury or death if not performed properly.

WARNING Indicates a hazardous procedure that could result in serious injury or

death if not performed properly.

CAUTION Indicates a hazardous procedure or danger that could result in light-

to-severe injury, or loss related to equipment malfunction, if proper

precautions are not taken.

Safety Symbols Used on Equipment and in Manuals

Some or all of the following five symbols may or may not be used on all ANRITSU equipment. In addition,

there may be other labels attached to products that are not shown in the diagrams in this manual.

The following safety symbols are used inside or on the equipment near

operation locations to provide information about safety items and op

eration precautions. Ensure that you clearly understand the meanings

of the symbols and take the necessary precautions BEFORE operating

the equipment.

This symbol indicates a prohibited operation. The prohibited operation

is indicated symbolically in or near the barred circle.

-

-

This symbol indicates a compulsory safety precaution. The required

operation is indicated symbolically in or near the circle.

This symbol indicates warning or caution. The contents are indicated

symbolically in or near the triangle.

This symbol indicates a note. The contents are described in the box.

These symbols indicate that the marked part should be recycled.

MN4790A MM Safety-1

Page 4

For Safety

WARNING

Always refer to the operation manual when working near locations at

which the alert mark, shown on the left,is attached. If the operation, etc.,

is performed without heeding the advice in the operation manual, there is

a risk of personal injury. In addition, the equipment performance may be

reduced.

Repair

WARNING

Moreover, this alert mark is sometimes used with other marks and descrip

tions indicating other dangers.

WARNING

When supplying AC power to this equipment, connect the accessory 3-pin

power cord to a 3-pin grounded power outlet. If a grounded 3-pin outlet is

not available, use a conversion adapter and ground the green wire, or

connect the frame ground on the rear panelof the equipment to ground. If

power is supplied without grounding the equipment, there is a risk of receiving a severe or fatal electric shock.

WARNING

This equipment cannot be repaired by the operator. DO NOT attempt to re

move the equipment covers or to disassemble internal components. Only

qualified service technicians with a knowledge of electrical fire and shock

hazards should service this equipment. There are high-voltageparts in this

equipment presenting a risk of severe injury or fatal electric shock to un

trained personnel. In addition, there is a risk of damage to precision com

ponents.

-

-

-

-

WARNING

If this equipment is used in a manner not specified by the manufacturer,

the protection provided by the equipment may be impaired.

Safety-2 MN4790A MM

Page 5

Table of Contents

Chapter 1 General Information

1-1 SCOPE OF MANUAL .......................1-1

1-2 INTRODUCTION .........................1-1

1-3 IDENTIFICATION NUMBER ..................1-1

1-4 ONLINE MANUAL ........................1-1

1-5 TMATS SYSTEM OVERVIEW ..................1-2

1-6 HARDWARE DESCRIPTION...................1-2

1-7 SYSTEM DESCRIPTION .....................1-2

MS4623B VNMS ·······················1-2

MN4790A Test Set ······················1-3

1-8 RECOMMENDED TEST EQUIPMENT .............1-6

1-9 STATIC SENSITIVE

COMPONENT HANDLING PROCEDURES...........1-6

1-10 SERVICE CENTERS .......................1-8

Chapter 2 Replaceable Parts

2-1 INTRODUCTION .........................2-1

2-2 EXCHANGE ASSEMBLY PROGRAM ..............2-1

2-3 REPLACEABLE SUBASSEMBLIES AND PARTS .......2-2

2-4 PARTS ORDERING INFORMATION ..............2-2

Chapter 3 Performance Verification Procedure

3-1 INTRODUCTION .........................3-1

3-2 CONVENTIONS..........................3-1

3-3 PRELIMINARY ..........................3-1

MS4623B VNMS ·······················3-1

ME7842B TMATS ······················3-2

Required Equipment·····················3-2

Preliminary Setup ······················3-2

3-4 DIRECTIVITY AND TEST PORT MATCH............3-5

Test Procedure ························3-5

3-5 DYNAMIC RANGE........................3-11

Test Procedure ·······················3-11

MN4790A MM i

Page 6

3-6 IMD MEASUREMENT......................3-14

Test procedure ·······················3-14

Chapter 4 Troubleshooting

4-1 INTRODUCTION .........................4-1

4-2 OPERATIONAL CHECK .....................4-1

Required Equipment·····················4-1

4-3 INTERNAL SIGNAL PATH INSERTION LOSS CHECK....4-1

Test Setup ··························4-1

Test Procedure ························4-2

4-4 TEST CHANNEL STEP ATTENUATOR CHECK ........4-4

Test Setup ··························4-4

Test Procedure ························4-4

4-5 TROUBLESHOOTING ......................4-6

Test Set Fails to Power Up··················4-6

Line Source and Interface Checks··············4-6

Power Supply Voltage Check ················4-6

Chapter 5 Removal and Replacement Procedures

5-1 INTRODUCTION .........................5-1

5-2 EQUIPMENT REQUIRED ....................5-1

5-3 REMOVING THE COVERS....................5-1

Preliminary··························5-1

Procedure···························5-1

5-4 A1 GPIB PARALLEL INTERFACE PCB .............5-4

5-5 A2 COMBINER ..........................5-5

5-6 A3 STEP ATTENUATOR .....................5-6

5-7 A4 AND A5 BIAS TEES......................5-7

5-8 A6 POWER SUPPLY .......................5-8

5-9 A7 CONTROL PCB .......................5-10

5-10 FAN ASSEMBLY.........................5-11

5-11 SP3T AND SPDT SWITCHES..................5-12

ii MN4790A MM

Page 7

Appendix A Connector Maintenance Check Procedures

A-1 INTRODUCTION .........................A-1

A-2 PRECAUTIONS ..........................A-1

Pin Depth Problems ·····················A-1

Pin Depth Tolerance·····················A-2

Avoid Over Torquing Connectors ··············A-2

Teflon Tuning Washers ···················A-2

Avoid Mechanical Shock ··················A-2

Keep Connectors Clean ···················A-3

Visual Inspection ······················A-3

A-3 REPAIR AND MAINTENANCE .................A-3

Index

MN4790A MM iii/vi

Page 8

Page 9

Chapter 1 General Information

1-1 SCOPE OF MANUAL This manual provides general service and preventive maintenance

information for the Anritsu MN4790A test set for the ME7842B Tower

Mounted Amplifier Test System.It contains procedures for:

Testing the instrument for proper operation

q

Verifying measurement accuracy and traceability to National In

q

stitute of Standards and Technology (NIST)

-

Troubleshooting a failed instrument to the exchange subassem

q

bly level or to the subsystem requiring adjustment

Locating and replacing failed parts

q

Throughout this manual, the terms ME7842B and Tower Mounted

Amplifier Test System (or TMATS) will be used interchangeably to re-

fer to the entire ME7842B Tower Mounted Amplifier Test System;the

terms MS4623B, Vector Network Measurement System (or VNMS), and

Scorpion

Vector Network Measurement System; the terms MN4790A and test

set will be used interchangeably to refer to the model MN4790A test

set, unless otherwise noted.

®

will be used interchangeably to refer to the model MS4623B

1-2 INTRODUCTION This chapter provides a general description of the T owerMounted

Amplifier Test System’ sserial numbers ,frequency ranges, and related

manuals.It alsoincludes a service strategy,availableservice facilities ,

static-sensitive component handling precautions, and a list of recom

mended test equipment.

1-3 IDENTIFICATION

NUMBER

All Anritsu instruments are assigned a six-digit ID number, such as

“021001.”This number appears on a decal affixed to the rear panel.

Please use this identification number during any correspondence with

Anritsu Customer Service about this instrument.

-

-

1-4 ONLINE MANUAL This manual is available on CD ROM as an Adobe Acrobat™ (*.pdf)

file. The file can be viewed using Acrobat Reader™, a free program

that is also available on the CD ROM. This file is “linked” such that

the viewer can choose a topic to view from the displayed “bookmark”

list and “jump” to the manual page on which the topic resides.The text

can also be word-searched. A copy of this CD ROM can be ordered

from Anritsu.

MN4790A MM 1-1

Page 10

TMATS SYSTEM OVERVIEW GENERAL INFORMATION

1-5 TMATS SYSTEM

OVERVIEW

1-6 HARDWARE

DESCRIPTION

The Anritsu ME7842B Tower Mounted Amplifier Test System is in

tended for the measurement and real-time graphical displayof a tower

mounted amplifier in the frequency range from 10 MHz to 6 GHz of

the following parameters:

S-Parameters Including Hot S

q

K-Factor

q

Gain Compression and Phase Distortion

q

Intermodulation Distortion (500 MHz to 6 GHz)

q

Harmonics

q

Noise Figure

q

Drain Current and Power Added Efficiency (PAE)

q

Adjacent Channel Power Ratio (ACPR)

q

The ME7842B hardware (Figure 1-) consists of an MS4623B 3-port

Scorpion, an MN4790A test set, and a customer supplied personal

computer (PC).

22

1-7 SYSTEM DESCRIPTION An overall block diagram of the TMATS is shown in Figure 1-2 on

page 1-5.Brief descriptions of the MS4623B 3-port Scorpion and the

MN4790A test set are given below:

-

MS4623B VNMS The Scorpion Vector Network Measurement System functions under

GPIB control of the software residing in the PC. The software supports

tuning and alignment operations by generating real time graphical

displays of the measured data on the PC screen.

Under software control, 3

sured and displayed. Also, the Upper and Lower Side Band (USB &

LSB) components of the IMD products are measured and displayed

separately.

The 3-port Scorpion includes the following capabilities:

q

Two internal,independent RF sources. Each source has a range

of –15 dBm to +5 dBm. A 0 dB to 70 dB step attenuator

(10 dB-per-step) is provided for each source resulting in a power

output range of –85 dBm to +5 dBm from each source.

q

Complete built-in capability for IMD measurements (A combiner

is provided within the test set.)

q

Complete built-in reflectometer for S-parameter measurements

rd,5th

and 7thorder IMD products can be mea

-

1-2 MN4790A MM

Page 11

GENERAL INFORMATION SYSTEM DESCRIPTION

MN4790A Test Set The Series MN4790A test set contains two SPDT pin switches at Test

Port 1 and Test Port 3. One output of each switch is linked to a

Wilkinson type combiner that combines the two RF signals from Port 1

and Port 3 of the Scorpion.As an option to boost the input RF power to

the amplifier-under-test (AUT), external preamplifiers can be inserted

between:

Scorpion Port 1 and the test set Test Port 1

q

Scorpion Port 3 and the test set Test Port 3

q

The output of the combiner is fed to a SP3T source selection switch

that enables one of the following to be applied to the AUT:

The combined signal from the Scorpion sources

q

The signal from the Scorpion Source 1 via Port 1

q

(bypassing the combiner)

A modulated signal from an optional, external modulation

q

synthesizer

The second output of the switch at Test Port 1 is linked to the source

selection switch.The second output of the switch at Test Port 3 is

linked to the Bypass output port at the front panel.

The output of the source selection switch is fed to a SPDT switch that

enables the signal to be routed to the ANT A port or the ANT B port at

the front panel.

An SPDT switch multiplexes the signal to and from the RBS A and

RBS B ports at the front panel. The output of this switch is linked to a

SP3T selection switch that enables the signal to be routed to one of the

two AUX Out ports, or via the built-in step attenuator to Test Port 2 of

the test set.

The MN4790A front and rear panels are illustrated in Figure 1-1 on

the following page. Figure 1-2,on page 1-5, shows an overall block dia

gram of the test system.

-

MN4790A MM 1-3

Page 12

SYSTEM DESCRIPTION GENERAL INFORMATION

Front Panel

Rear Panel

Figure 1-1. MN4790A Test Set Front and Rear Panel

1-4 MN4790A MM

Page 13

GENERAL INFORMATION SYSTEM DESCRIPTION

®

SCORPION

MS4623B

PORT 3 PORT 1 PORT 2

OPTIONAL

EXTERNAL

PREAMPLIFIERS

PORT 3 PORT 1

S2

S6

MN4790A TYPICAL TEST SE T

NOISE SOURCE

SCORPION VNMS

COMBINER

S1

S4

PORT 2

NNN

NNN

STEP

ATTENUATOR

70 DB ,

10 DB /STEP

S7

GPIB

GPIB

AUX-OUT2

AUX-OUT1

SYSTEM

CONTROLLER

(PC )

OPTIONAL

SPECTRUM

ANALYZER

OR

MODULATIO N

ANALYZER

OPTIONAL

POWER

METER

RX/TX

RX/TX

S5

NNNNNNN

DC BIAS 1

DC BIAS 2

POWER

SUPPLY

AUX-IN 1 AUX-IN 2

OPTIONAL

MODULATIO N

SYNTHESIZER

S3

BYPASS ANT A ANT B RBS B RBS A

ANT

ANT

T YPICA L TM A D EVICE

BPF

BPF

BPF

BPF

LNA

LNA

BPF

BPF

B

A

Figure 1-2. Basic Functional Block Diagram of the Tower Mounted Amplifier Test System (TMATS) with the

MN4790A Test Set

MN4790A MM 1-5

Page 14

RECOMMENDED TEST EQUIPMENT GENERAL INFORMATION

1-8 RECOMMENDED TEST

EQUIPMENT

Table 1-1 lists the recommended test equipment to be used for all

maintenance activities for the MN4790A models. Note the “Use”codes

listed in the right hand column of the table. These codes list the appli

cable maintenance activities for the equipment listed.

Table 1-1. Recommended Test Equipment

INSTRUMENT

Power Meter Anritsu ML2437A or ML2438A

Power Sensor Anritsu MA2472A

GPIB Cable IEEE 488.2 compliant Anritsu 2100-2, or equivalent

Air Line Anritsu 18N50 or SC3833

Short Anritsu 22A50

Offset Termination 20 dB Return Loss Anritsu 29A50-20

Thru Line Return Loss 35 dB, DC to 3 GHz Anritsu 3670NN50-2 or 15NN50-0.6B

Calibration Kit Anritsu 3753R or 3753LF

Personal Computer Windows 98/2000/XP

GPIB Interface IEEE 488.2

* USE CODES:

A Adjustment/ Internal Hardware Calibration

O Operational Testing

P PerformanceVerification

T Troubleshooting

CRITICAL

SPECIFICATION

Any P, T

National Instruments PCI-GPIB (Desktop)

National Instruments PCMCIA-GPIB (Notebook)

RECOMMENDED

MANUFACTURER/MODEL

-

USE*

P

P

P

P

P

P

P, T

P, T

P

1-9 STATIC SENSITIVE

COMPONENT HANDLING

PROCEDURES

The MN4790A test set contains components that can be damaged by

static electricity. Figure 1-3,on the following page, illustrates the pre

cautions that should be followed when handling static-sensitive subas

-

semblies and components. If followed, these precautions will minimize

the possibilities of static-shock damage to these items.

1-6 MN4790A MM

-

Page 15

GENERAL INFORMATION STATIC SENSITIVE COMPONENT HANDLING

PROCEDURES

Do not touch exposed contacts on

1.

any static sensitive component.

Wear a static-discharge wristband

4.

when working with static sensitive

components.

Do not slide static sensitive com

2.

ponent across any surface.

Label all static sensitive devices.

5.

-

Do not handle static sensitive com

3.

ponents in areas where the floor or

work surface covering is capable of

generating a static charge.

Keep component leads shorted to-

6.

gether whenever possible.

-

Handle PCBs only by their edges.

7.

Do not handle by the edge connec

tors.

-

Lift & handle solid state devices by

8.

their bodies – never by their leads.

Transport and store PCBs and

9.

other static sensitive devices in

static-shielded containers.

10. ADDITIONAL PRECAUTIONS:

·

Keep work spaces clean and free of any objects capable of holdingor storing a static charge.

·

Connect soldering tools to an earth ground.

·

Use only special anti-static suction or wick-type desoldering tools.

Figure 1-3. Static Sensitive Component Handling Procedures

MN4790A MM 1-7

Page 16

SERVICE CENTERS GENERAL INFORMATION

1-10 SERVICE CENTERS Anritsu offers a full range of repair and calibration services at fully

staffed and equipped service centers throughout the world.Table 1-2

lists all of the Anritsu services centers.

Table 1-2. Anritsu Service Centers

UNITED STATES

ANRITSU COMPANY

490 Jarvis Drive

Morgan Hill, CA 95037-2809

Telephone: (408) 776-8300

1-800-ANRITSU

FAX: 408-776-1744

ANRITSU COMPANY

10 New Maple Ave., Unit 305

Pine Brook, NJ 07058

Telephone: (973) 227-8999

1-800-ANRITSU

FAX: 973-575-0092

ANRITSU COMPANY

1155 E. Collins Blvd

Richardson, TX 75081

Telephone: 1-800-ANRITSU

FAX: 972-671-1877

AUSTRALIA

ANRITSU PTY. LTD.

Unit 3, 170 Foster Road

Mt Waverley, VIC 3149

Australia

Telephone: 03-9558-8177

FAX: 03-9558-8255

BRAZIL

ANRITSU ELECTRONICA LTDA.

Praia de Botafogo, 440, Sala 2401

CEP22250-040, Rio de Janeiro, RJ, Brasil

Telephone: 021-527-6922

FAX: 021-53-71-456

FRANCE

ANRITSU S.A

9 Avenue du Quebec

Zone de Courtaboeuf

91951 Les Ulis Cedex

Telephone: 016-09-21-550

FAX: 016-44-61-065

GERMANY

ANRITSU GmbH

Grafenberger Allee 54-56

D-40237 Dusseldorf, Germany

Telephone: 0211-968550

FAX: 0211-9685555

INDIA

MEERA AGENCIES PVT. LTD.

23 Community Centre

Zamroodpur, Kailash Colony Extension,

New Delhi, India 110 048

Phone: 011-2-6442700/6442800

FAX : 011-2-644250023

ISRAEL

TECH-CENT, LTD.

4 Raul Valenberg St

Tel-Aviv 69719

Telephone: (03) 64-78-563

FAX: (03) 64-78-334

ITALY

ANRITSU Sp.A

Roma Office

Via E. Vittorini, 129

00144 Roma EUR

Telephone: (06) 50-99-711

FAX: (06) 50-22-4252

JAPAN

ANRITSU CUSTOMER SERVICE LTD.

1800 Onna Atsugi-shi

Kanagawa-Prf. 243 Japan

Telephone: 0462-96-6688

FAX: 0462-25-8379

SINGAPORE

ANRITSU (SINGAPORE) PTE LTD.

10, Hoe Chiang Road

#07-01/02 Keppel Towers

Singapore 089315

Telephone: 282-2400

FAX: 282-2533

SOUTH AFRICA

ETECSA

12 Surrey Square Office Park

330 Surrey Avenue

Ferndale, Randburt, 2194

South Africa

Telephone: 011-27-11-787-7200

FAX: 011-27-11-787-0446

SWEDEN

ANRITSU AB

Botivid Center

Fittja Backe 13A

145 84 Stockholmn

Telephone: (08) 534-707-00

FAX: (08) 534-707-30

TAIWAN

ANRITSU CO., INC.

7F, No. 316, Section 1

NeiHu Road

Taipei, Taiwan, R.O.C.

Telephone: 886-2-8751-1816

FAX: 886-2-8751-2126

1-8 MN4790A MM

Page 17

Chapter 2 Replaceable Parts

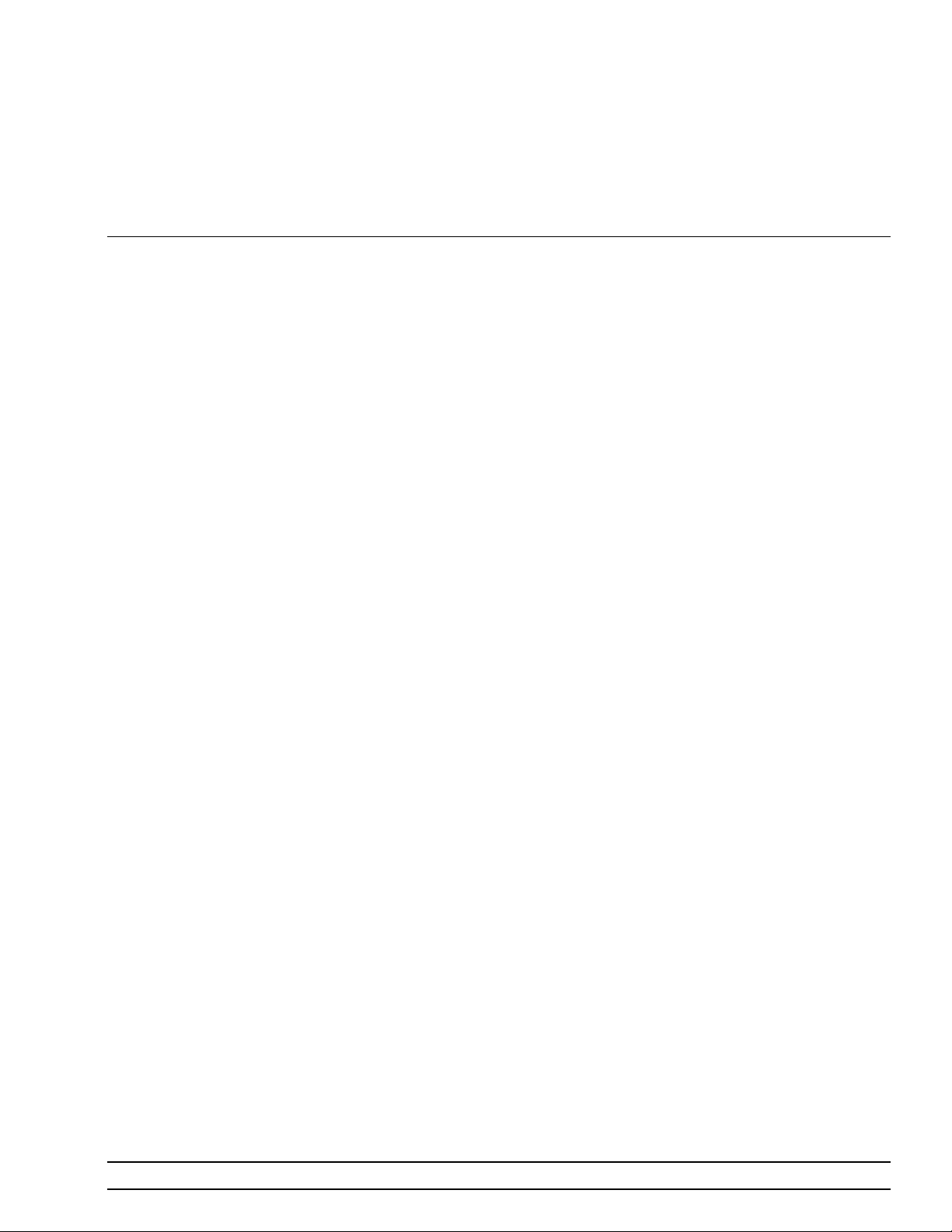

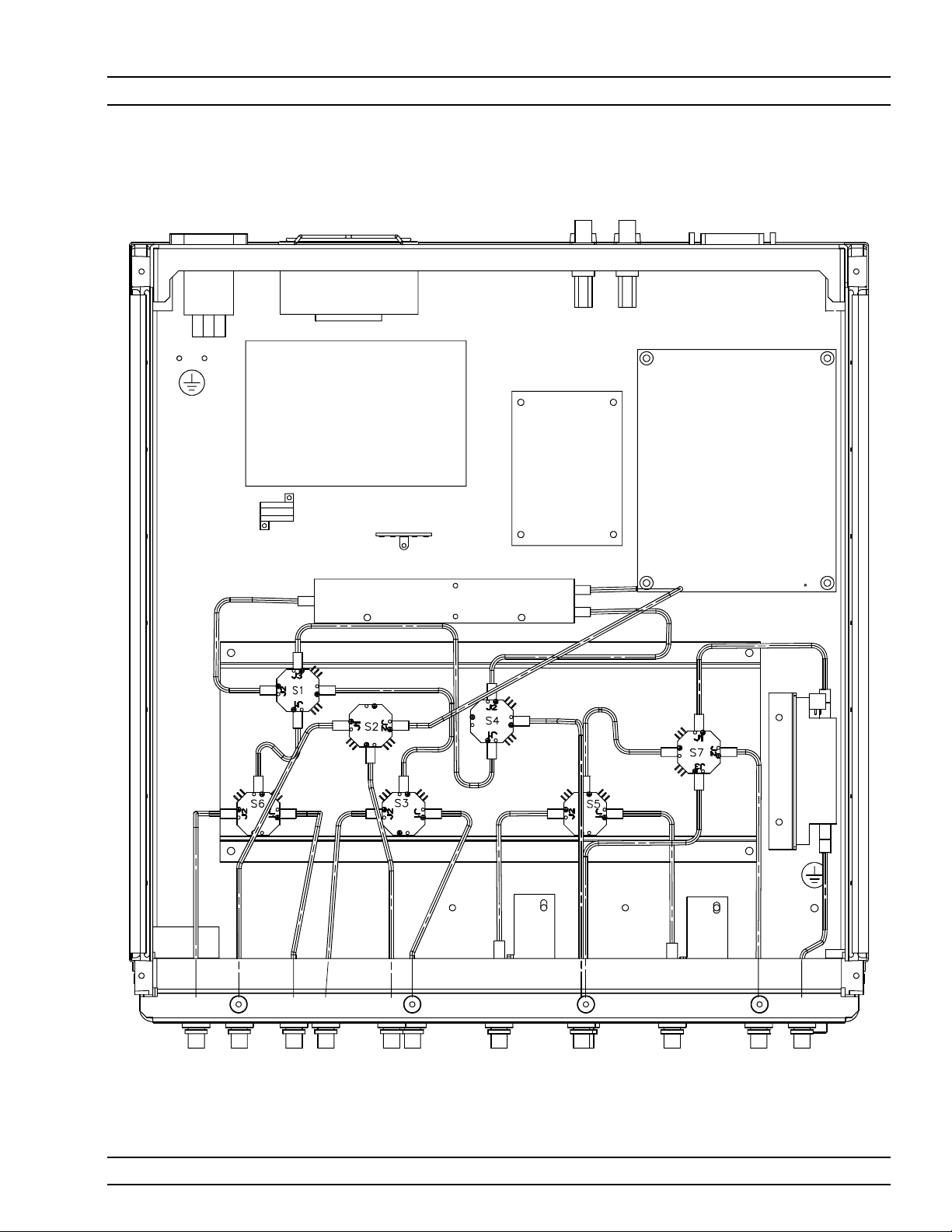

2-1 INTRODUCTION This chapter provides replaceable parts information for the model

MN4790A test set. The major replaceable test set assemblies and

parts are listed in Table 2-1, following page. The locations of these as

semblies/parts are shown in Figure 2-1 on page 2-3.

-

2-2 EXCHANGE ASSEMBLY

PROGRAM

Anritsu maintains a module exchange program for selected

subassemblies. If a malfunction occurs in one of these subassemblies,

the defective item can be exchanged. Upon receiving your request,

Anritsu will ship the exchange subassembly to you,typically within 24

hours. You then have 45 days in which to return the defective item. All

exchange subassemblies or RF assemblies are warranted for 90 days

from the date of shipment,or for the balance of the original equipment

warranty, whichever is longer.

NOTE

Please have the exact model number and serial number of

your unit available when requesting this service,as the

information about your unit is filed according to the

instrument’s model and serial number.For more

information about the program, contact your local sales

representative or call Anritsu Customer Service direct

(refer to Section 2-4).

MN4790A MM 2-1

Page 18

REPLACEABLE SUBASSEMBLIES AND PARTS REPLACEABLE PARTS

2-3 REPLACEABLE

SUBASSEMBLIES AND

PARTS

Table 2-1. Replaceable Subassemblies

Part Number Description Location (Figure 2-1)

1020-46 SP3T Switch S1 and S7

1020-47 SPDT Switch S2 to S6

1091-346 Combiner A2

2000-989 GPIB Interface Assembly A1

40-159 Power Supply A6

SC6737 Bias Tee Assembly A4 and A5

ND60327 Fan Assembly FAN

43045-3 Control PCB Assembly A7

339H40998A Step Attenuator A3

B45259 N Type Test Port Connector N-Connectors

2-4 PARTS ORDERING

INFORMATION

Table 2-1 lists the major replaceable subassemblies and parts for the

MN4790A. These assemblies and parts are presently covered by the

Anritsu exchange assembly program.

All parts listed in Table 2-1 may be ordered from your local Anritsu

service center (Table 1-2,page 1-8).Or, they may be ordered directly

from the factory at the following address:

Anritsu Company

ATTN: Customer Service

490 Jarvis Drive

Morgan Hill,CA 95037-2809

Telephone: (408)-778-2000

FAX: (408)-778-0239

2-2 MN4790A MM

Page 19

REPLACEABLE PARTS PARTS ORDERING INFORMATION

LINE

MODULE

POWER SUPPLY

POWER

SUPPLY

LOAD

SOLDER JUNCTION

J3

J2

S1

J1

COMM

J2

S6

RBS A/B DC BIAS

SOURCE/FUSE

FAN

A6

COMBINER

RF PIN SWITCHES (7)

COMM

COMM

S3

J2

J1

J1

J1

S2

J2

CONTROL

A2

J2

COMM

S4

J1

J2

GPIB

CONNECTOR

PCB

A7

ATTENUATOR

COMM

S5

J1

GPIB

PARALLEL

INTERFACE

PCB

A1

J1

S7

J2

J3

A3

RBS A

BIAS

TEE

A4

Figure 2-1. MN4790A Major Assemblies Location Diagram (Top View)

RBS B

BIAS

TEE

A5

MN4790A MM 2-3

Page 20

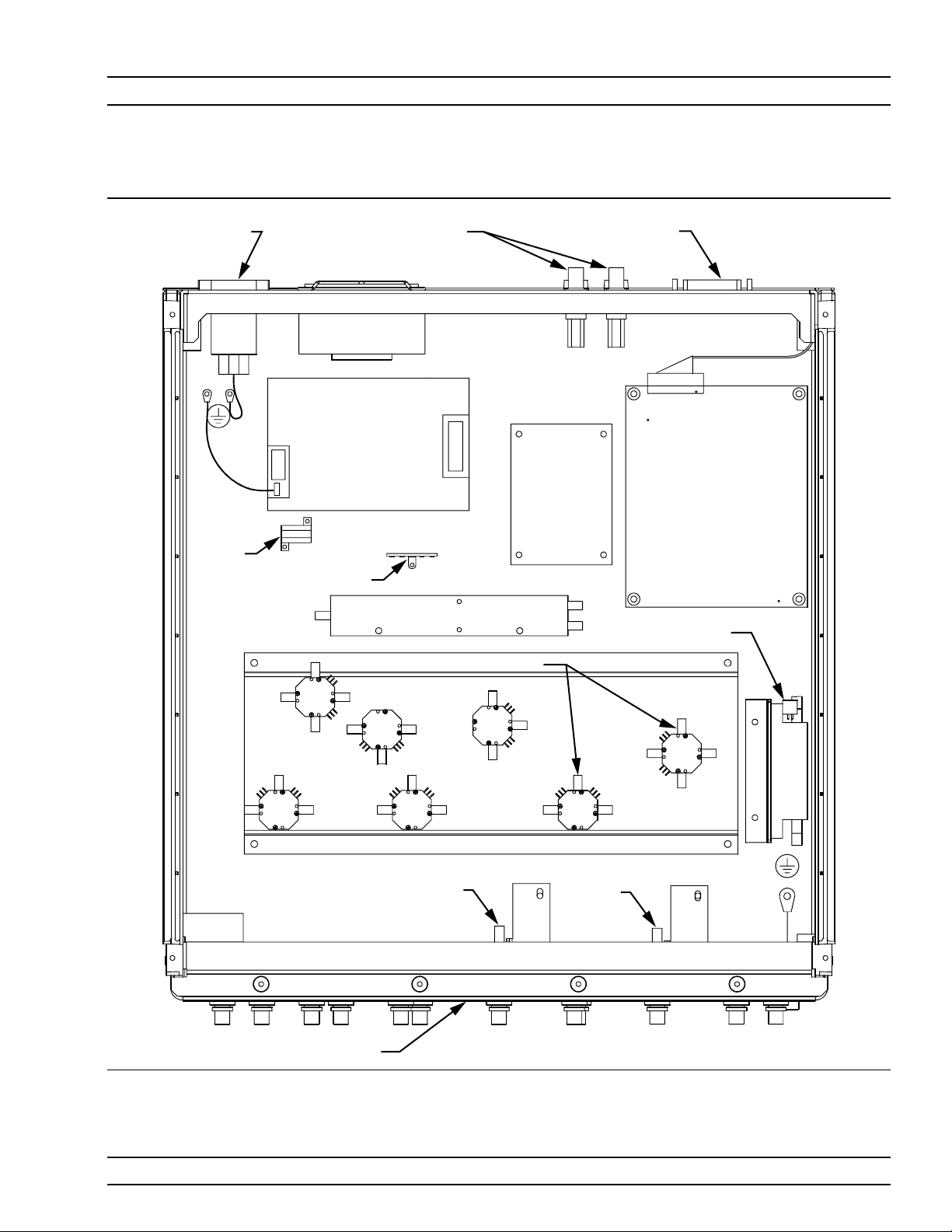

PARTS ORDERING INFORMATION REPLACEABLE PARTS

A6

A1

A7

A2

A3

A4

Figure 2-2. MN4790A Wiring Diagram (Top View)

2-4 MN4790A MM

A5

Page 21

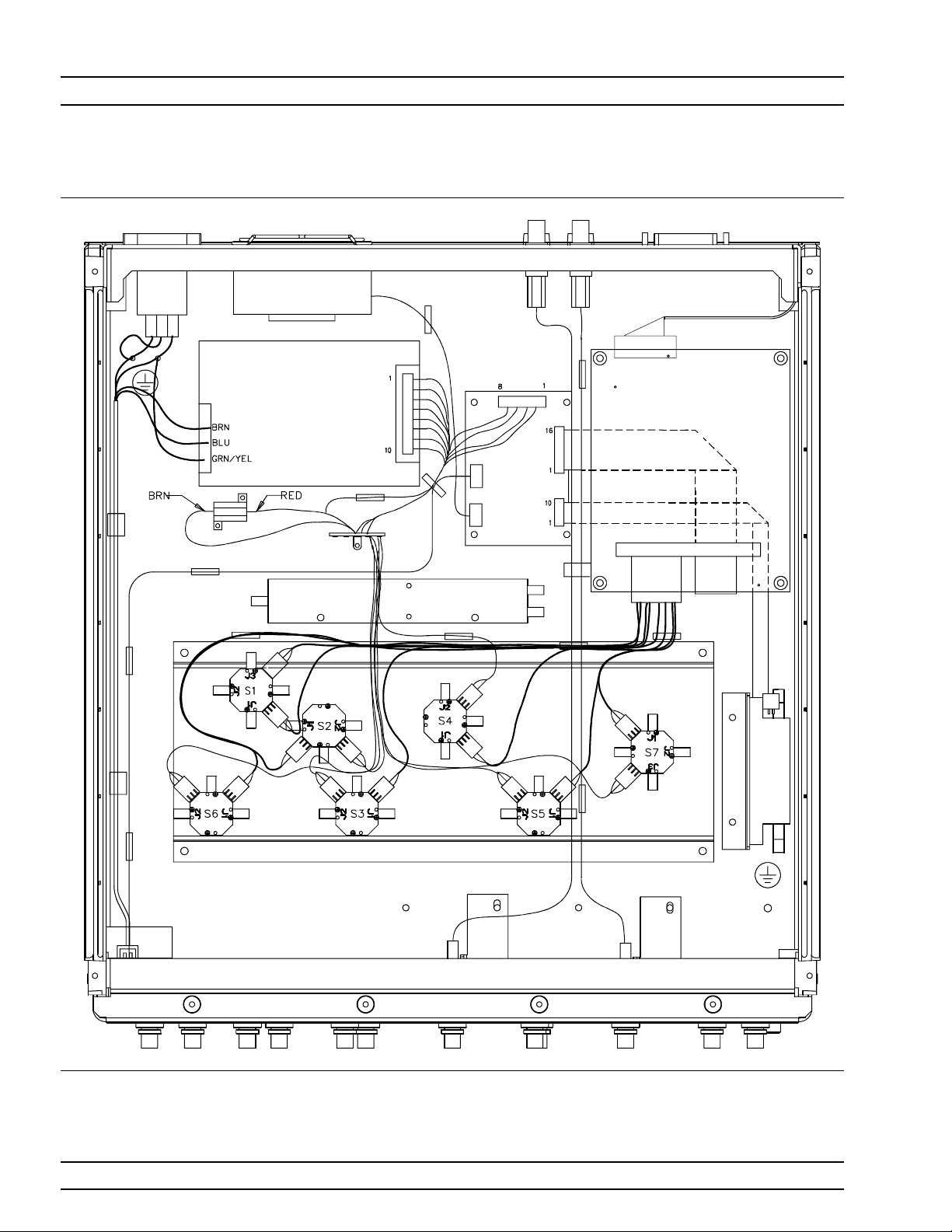

REPLACEABLE PARTS PARTS ORDERING INFORMATION

A6

A2

A7

A1

A3

A4

Figure 2-3. MN4790A RF Cabling Diagram (Top View)

MN4790A MM 2-5/2-6

A5

Page 22

Page 23

Chapter 3 Performance Verification Procedure

3-1 INTRODUCTION This chapter provides test procedures to verify the performance of the

Tower Mounted Amplifier Test System. The following tests should be

used to verify the performance of the equipment:

MS4623B VNMS Performance Verification

q

ME7842B (MS4623B and MN4790A) TMATS Performance Verifi

q

cation

3-2 CONVENTIONS The test instructions in this chapter will direct the use of the front

panel hard-keys and soft-keys of the MS4623B.These hard-keys and

soft-keys are distinguished by a different typeface. For example:

Step 1. Press the Utility key and select:

DIAGNOSTICS

TROUBLESHOOTING

MORE

VERIFY ALC CALIBRATION

The Utility key is a front panel hard-key and the DIAGNOSTICS,

TROUBLESHOOTING, MORE, and VERIFY ALC CALIBRATION keys

are all soft-keys.

3-3 PRELIMINARY The following information describes the preliminary setup and

indicates the general tests that verify the performance of your test

system. It is important to first verify the performance of the MS4623B

separate from TMATS.

-

MS4623B VNMS Prior to performing any of the MS4623B performance verification

tests, disconnect the RF cables linked between the front panels of the

MS4623B and the MN4790A test set.

Follow the procedures in Chapter 2 of the MS462XX Vector Network

Measurement Systems Maintenance Manual (part number

10410-00205) to verify that the MS4623B is working properly.

MN4790A MM 3-1

Page 24

PRELIMINARY PERFORMANCE VERIFICATION

ME7842B TMATS Prior to performing any of the ME7842B TMATSperformance

verification tests:

Install the Scorpion Navigator Software on the PC controller

q

Connect the RF cables between the MS4623B and the MN4790A

q

test set.

The ME7842B Performance Verification includes the following tests:

Directivity and Test Port Match Verification

q

Dynamic Range Verification

q

IMD Measurement Operational Checkout

q

Required Equipment The following equipment list is required for all test set verification

tests in this chapter:

Anritsu MS4623B Vector Network Measurement System

q

Anritsu 15NN50-0.6B or 3670NN50-2 Test Port Cable

q

Personal Computer with a Windows Operating System, Scorpion

q

Navigator, and a National Instruments GPIB Interface Installed

The following is an addition requirement for the dynamic range verification:

q

Anritsu 3753LF or 3753R N Connector Calibration Kit

The following are additional requirements for the directivity and test

port match verifications:

q

Anritsu 3753LF or 3753R N Connector Calibration Kit

q

Anritsu 18N50 or SC3833 Air Line

q

Anritsu 29A50-20 Offset Termination (2)

q

Anritsu 22A50 Open/Short

Preliminary Setup Turn on the MS4623B and the MN4790A test set and allow them to

warm up for 30 minutes.

Step 1. Connect a GPIB cable between the IEEE488.2 port of the MS4623B

and the GPIB port of the MN4790A test set.

Step 2. Connect a GPIB cable between the IEEE488.2 port of the MS4623B

and the GPIB interface of the PC controller.

3-2 MN4790A MM

Page 25

PERFORMANCE VERIFICATION PRELIMINARY

Step 3. On the PC, open the Windows Explorer program and locate the execut

able ‘MN4790A.exe’ in the ‘C:\Program Files\Navigator’ folder, as

shown in Figure 3-1.

-

Figure 3-1. Starting the MN4790A

Step 4. Move the mouse pointer to highlight MN4790A.exe and double click to

open the program. A GPIB configuration window, below, will be

displayed.

Step 5. If the GPIB address of the MN4790A test set is four,then click the OK

button. If not, move the slide to select a GPIB address that matches

the GPIB address of the MN4790A test set,then click the OK button.

NOTE

The GPIB address of the MN4790A test set is configured

via the dip switch jumper block located above the GPIB

MN4790A MM 3-3

Page 26

PRELIMINARY PERFORMANCE VERIFICATION

port connector on the rear panel. Figure 3-2 shows the dip

switch setting for a GPIB address of four.

Figure 3-2. GPIB Dip Switch Block for the MN4790A

After selecting the GPIB address, the MN4790A Switch Control win

dow, below,will be displayed.

-

Step 6. This window allows you to select different switched signal paths by

using pre-defined cases. Refer to Table A-1 in the ME7842B operation

manual for definitions of the switched signal path for each case.

NOTE

The scroll bar under the Step Attenuation reference allows

you to change the step attenuator in 10 dB increments.

3-4 MN4790A MM

Page 27

PERFORMANCE VERIFICATION DIRECTIVITY AND TEST PORT MATCH

3-4 DIRECTIVITY AND TEST

PORT MATCH

Test Procedure

Step 1. Follow the preliminary setup procedures on pages 3-2 through 3-4.

Step 2. Click on the Case3 button in MN4790A Switch Control window. This

Step 3. On the MS4623B, press the Default key, then the 0 key to reset the in-

Step 4. Insert the Calibration Component Coefficients diskette into the floppy

This procedure verifies the corrected directivity and test port match of

the:

ANT A Port

q

RBS A Port

q

ANT B Port

q

RBS B Port

q

will configure the switches in the MN4790A test set to allow the sig

-

nals to go through the following paths:

Test Port 1 to the ANT A Port (bypassing the internal combiner)

q

Test Port 2 to the RBS A Port

q

Test Port 3 to the Bypass Port

q

strument.

drive of the MS4623B.

Step 5. Press the Cal key and select:

MORE

COMPONENT UTILITIES

INSTALL KIT INFO FROM FLOPPY DISK

Step 6. Allow the instrument to completely load the data, then select:

RETURN

PERFORM CAL 2 PORT

NEXT CAL STEP

REFLECTION ONLY

BOTH PORTS (S11, S22)

NORMAL (1601 POINTS MAXIMUM)

DATAPOINTS

801 MAX PTS

NEXT CAL STEP

Step 7. Verify that the PORT 1 CONN and PORT2 CONN are TYPE N (F), (If

not, press the PORT 1 CONN or PORT 2 CONN soft-key to change the

connector type.) then select:

START CAL

MN4790A MM 3-5

Page 28

DIRECTIVITY AND TEST PORT MATCH PERFORMANCE VERIFICATION

Step 8. When prompted by the MS4623B, connect the associated calibration

components from the calibration kit to the ANT A port for Test Port 1

and to the RBS A port for Test Port 2. Select MEASURE BOTH PORTS

to continue.

Step 9. After the calibration is complete, press the Enter key to continue.

Step 10. Press the Display key and select:

DISPLAY MODE

SINGLE CHANNEL

RETURN

GRAPH TYPE

LOG MAGNITUDE

Step 11. Connect the N male connector end of the air line to the ANT A port

and terminate the GPC-7 end of the air line with the short.

Step 12. Press the Display key and select AUTO SCALE.

Step 13. Press the Marker key and select READOUT MARKERS.

Step 14. Turn on Marker 1, Marker 2, and Marker 3.

Step 15. Using the rotary knob,position Marker 1 and Marker 2 to adjacent

peaks of the ripple with the greatest negative trough (or to adjacent

troughs if the ripple has the greatest positive peak).

3-6 MN4790A MM

Page 29

PERFORMANCE VERIFICATION DIRECTIVITY AND TEST PORT MATCH

Step 16. Position Marker 3 to the bottom of the trough (or to the top of the peak

if the ripple has the greatest positive peak).Refer to Figure 3-3, below.

Figure 3-3. Log Magnitude Display Plot

Step 17. Sum the values of the two markers (Marker 1 and Marker 2) at the

peaks (or troughs) and divide the result by two. This is the average

value of the two peaks (or troughs). Refer to the example formula be

low:

-+-

23001 22958

MM

+

AverageValue

Record this average value.

Step 18. Record the Marker 3 value.

Step 19. Find the absolute difference of the values recorded in Steps 17 and 18

as follows:

|M3|–|AverageValue |= 23.279 – 22.980 = 0.299

This is the peak-to-peak ripple value. Use an RF measurement chart

(page 3-10) to find the corresponding return loss value. This is the

measured effective test port match.Verify that the test port match is

better than 35 dB.

12

=

2

(. )(. )

=

2

=-

22980

.

-

MN4790A MM 3-7

Page 30

DIRECTIVITY AND TEST PORT MATCH PERFORMANCE VERIFICATION

Step 20. Remove the short and connect the 29A50-20 offset termination to the

GPC-7 end of the air line.

Step 21. Press the Display key and select AUTO SCALE.

Step 22. Find the largest ripple between 10 MHz and 3 GHz.

Step 23. Repeat Steps 15 through 19.

Step 24. Find the corresponding 1+Xor 1–Xvalue from the RF measurement

chart. Use the following formula to calculate the effective directivity

value:

For ripple with a negative trough:

Effective Directivity =

Return Loss value + |(Marker 3 value)| - |(1 - X value)|

For ripple with a positive peak:

Effective Directivity =

Return Loss value + |(Marker 3 value)| + |(1 + X value)|

Step 25. Verify that the directivity is better than 40 dB from 10 MHz to 3 GHz.

Step 26. Find the largest ripple between 3 GHz and 6 GHz.

Step 27. Repeat Steps 23 through 24 and verify that the effective directivity is

better than 35 dB from 3 GHz to 6 GHz.

Step 28. Press the Ch 4 key,then the Display key.

Step 29. Select:

GRAPH TYPE

LOG MAGNITUDE

RETURN

Step 30. Remove the air line from the ANT A port and connect it to the RBS A

port. Terminate the GPC-7 end of the air line with the short.

Step 31. Repeat Steps 14 through 27.

Step 32. On the PC, click the Case4 button on the MN4790A Switch Control

window. This will configure the switches in the MN4790A test set to

allow signals to go through the following paths:

q

Test Port 1 to the ANT B Port (Bypassing the internal combiner)

q

Test Port 2 to the RBS B Port

q

Test Port 3 to the Bypass Port

Step 33. On the MS4623B, press the Cal key and select REPEAT PREVIOUS

CAL.

3-8 MN4790A MM

Page 31

PERFORMANCE VERIFICATION DIRECTIVITY AND TEST PORT MATCH

Step 34. When prompted by the MS4623B, connect the associated calibration

components from the calibration kit to the ANT B port for Test Port 1

and to the RBS B port for Test Port 2. Select MEASURE BOTH PORTS

to continue.

Step 35. After the calibration is complete, press the Enter key to continue.

Step 36. Press the Ch 1 key.

Step 37. Connect the N male connector end of the air line to the ANT B port

and terminate the GPC-7 end of the air line with the short.

Step 38. Repeat Steps 12 through 31.

Step 39. Press the Ch 4 key.

Step 40. Remove the air line from the ANT B port and connect it to the RBS B

port. Terminate the GPC-7 end of the air line with the short.

Step 41. Repeat Steps 12 through 31.

Table 3-1, below, shows the test port match and directivity specifications. Table 3-2, following page, shows the RF measurement chart.

Table 3-1. Test Port Match and Directivity Specifications

Specifications ANT A RBS A ANT B RBS B

Test Port Match

10 MHz to 6 GHz

Directivity

10 MHz to 3 GHz

Directivity

3 GHz to 6 GHz

35 dB

40 dB

35 dB

MN4790A MM 3-9

Page 32

DIRECTIVITY AND TEST PORT MATCH PERFORMANCE VERIFICATION

Table 3-2. RF Measurement Chart

The first three columns are conversion

tables for return loss, reflection coefficient,

and SWR.

The last four columns are values for

interactions of a small phasor X with a

large phasor (unity reference) expressed

in dB related to the reference.

The RF Measurement Chart can be used

to determine the uncertainty due to

bridge/autotester VNA directivity. The

“X dB Below Reference” column

represents the difference between the

directivity and the measured reflection

(return loss). The “Ref + X dB” and

“Ref – X dB” values are 360°. Therefore,

the peak-to-peak ripple (1 ± X) is the total

measurement uncertainty caused by the

error signal.

For example, if a 30 dB return loss is

measured with a 40 dB directivity

autotester, the X dB Below Reference

value is 10 dB. The Ref+XdBvalue is

2.3866 dB and the Ref–XdBvalue is

3.3018 dB.

The actual return loss is between

27.6134 dB (– 30 + 2.3866) and

33.3018 dB (– 30 – 3.3018). The

peak-to-peak ripple on a swept

measurement will be 5.6884 dB. If the

error and directivity signals are equal, the

Ref+XdBvalue equals 6 dB (voltage

doubling causesa6dBchange) and the

Ref–XdBvalue becomes infinite, since

the two signals are equal in amplitude and

180° out of phase (zero voltage).

(Ref + X)

X

(Ref - X)

(Ref)

Phasor Interaction

SWR

17.3910 0.8913 1 1 5.5350 -19.2715 24.8065

8.7242 0.7943 2 2 5.0780 -13.7365 18.8145

5.8480 0.7079 3 3 4.6495 -10.6907 15.3402

4.4194 0.6310 4 4 4.2489 -8.6585 12.9073

3.5698 0.5623 5 5 3.8755 -7.1773 11.0528

3.0095 0.5012 6 6 3.5287 -6.0412 9.5699

2.6146 0.4467 7 7 3.2075 -5.1405 8.3480

2.3229 0.3981 8 8 2.9108 -4.4096 7.3204

2.0999 0.3548 9 9 2.6376 -3.8063 6.4439

1.9250 0.3162 10 10 2.3866 -3.3018 5.6884

1.7849 0.2818 11 11 2.1567 -2.8756 5.0322

1.6709 0.2512 12 12 1.9465 -2.5126 4.4590

1.5769 0.2239 13 13 1.7547 -2.2013 3.9561

1.4985 0.1995 14 14 1.5802 -1.9331 3.5133

1.4326 0.1778 15 15 1.4216 -1.7007 3.1224

1.3767 0.1585 16 16 1.2778 -1.4988 2.7766

1.3290 0.1413 17 17 1.1476 -1.3227 2.4703

1.2880 0.1259 18 18 1.0299 -1.1687 2.1986

1.2528 0.1122 19 19 0.9237 -1.0337 1.9574

1.2222 0.1000 20 20 0.8279 -0.9151 1.7430

1.1957 0.0891 21 21 0.7416 -0.8108 1.5524

1.1726 0.0794 22 22 0.6639 -0.7189 1.3828

1.1524 0.0708 23 23 0.5941 -0.6378 1.2319

1.1347 0.0631 24 24 0.5314 -0.5661 1.0975

1.1192 0.0562 25 25 0.4752 -0.5027 0.9779

1.1055 0.0501 26 26 0.4248 -0.4466 0.8714

1.0935 0.0447 27 27 0.3796 -0.3969 0.7765

1.0829 0.0398 28 28 0.3391 -0.3529 0.6919

1.0736 0.0355 29 29 0.3028 -0.3138 0.6166

1.0653 0.0316 30 30 0.2704 -0.2791 0.5495

1.0580 0.0282 31 31 0.2414 -0.2483 0.4897

1.0515 0.0251 32 32 0.2155 -0.2210 0.4365

1.0458 0.0224 33 33 0.1923 -0.1967 0.3890

1.0407 0.0200 34 34 0.1716 -0.1751 0.3467

1.0362 0.0178 35 35 0.1531 -0.1558 0.3090

1.0322 0.0158 36 36 0.1366 -0.1388 0.2753

1.0287 0.0141 37 37 0.1218 -0.1236 0.2454

1.0255 0.0126 38 38 0.1087 -0.1100 0.2187

1.0227 0.0112 39 39 0.0969 -0.0980 0.1949

1.0202 0.0100 40 40 0.0864 -0.0873 0.1737

1.0180 0.0089 41 41 0.0771 -0.0778 0.1548

1.0160 0.0079 42 42 0.0687 -0.0693 0.1380

1.0143 0.0071 43 43 0.0613 -0.0617 0.1230

1.0127 0.0063 44 44 0.0546 -0.0550 0.1096

1.0113 0.0056 45 45 0.0487 -0.0490 0.0977

1.0101 0.0050 46 46 0.0434 -0.0436 0.0871

1.0090 0.0045 47 47 0.0387 -0.0389 0.0776

1.0080 0.0040 48 48 0.0345 -0.0346 0.0692

1.0071 0.0035 49 49 0.0308 -0.0309 0.0616

1.0063 0.0032 50 50 0.0274 -0.0275 0.0549

1.0057 0.0028 51 51 0.0244 -0.0245 0.0490

1.0050 0.0025 52 52 0.0218 -0.0218 0.0436

1.0045 0.0022 53 53 0.0194 -0.0195 0.0389

1.0040 0.0020 54 54 0.0173 -0.0173 0.0347

1.0036 0.0018 55 55 0.0154 -0.0155 0.0309

1.0032 0.0016 56 56 0.0138 -0.0138 0.0275

1.0028 0.0014 57 57 0.0123 -0.0123 0.0245

1.0025 0.0013 58 58 0.0109 -0.0109 0.0219

1.0022 0.0011 59 59 0.0097 -0.0098 0.0195

1.0020 0.0010 60 60 0.0087 -0.0087 0.0174

Reflection

Coefficient

Return

Loss

(dB)

XdB

Below

Reference

Relative to Unity Reference

Ref+X

(dB)

Ref-X

(dB)

Ref ± X

Pk to Pk Ripple

(dB)

3-10 MN4790A MM

Page 33

PERFORMANCE VERIFICATION DYNAMIC RANGE

3-5 DYNAMIC RANGE This procedure verifies the dynamic range of the:

ANT A Port to the RBS A Port

q

ANT B Port to the RBS B Port

q

Bypass Port to the RBS B Port

q

Test Procedure

Step 1. Follow the preliminary setup procedures on pages 3-2 through 3-4.

Step 2. Click on the Case3 button in MN4790A Switch Control window. This

will configure the switches in the MN4790A test set to allow the

signals to go through the following paths:

Test Port 1 to the ANT A Port (bypassing the internal combiner)

q

Test Port 2 to the RBS A Port

q

Test Port 3 to the Bypass Port

q

Step 3. On the MS4623B, press the Default key, then the 0 key to reset the in-

strument.

Step 4. Press the Ch 3 key,then the Display key.

Step 5. Select:

DISPLAY MODE

SINGLE CHANNEL

RETURN

GRAPH TYPE

LOG MAGNITUDE

Step 6. Press the Avg key and select:

SELECT I.F. BANDWIDTH

I.F.BW 10Hz

Step 7. Connect a test port cable between the ANT A port and the RBS A port.

Wait until one sweep has completed.

Step 8. Press the Display key and select:

TRACE MEMORY

STORE DATA TO MEMORY

VIEW DATA(/) MEMORY

RETURN

SCALE

Step 9. Change the REFERENCE VALUE to -80 dB.

Step 10. Disconnect the cable from the ANT A port.

MN4790A MM 3-11

Page 34

DYNAMIC RANGE PERFORMANCE VERIFICATION

Step 11. Connect the offset terminations to the ANT A port and to the open end

of the cable.

Step 12. Verify that the displayed trace is below -75 dB from 10 MHz to

50 MHz and below -80 dB from 50 MHz to 6 GHz.

Step 13. On the PC, click the Case4 button in the MN4790A Switch Control

window. This will configure the switches in the MN4790A test set to

allow the signals to go through the following paths:

Test Port 1 to the ANT B Port (bypassing the internal combiner)

q

Test Port 2 to the RBS B Port

q

Test Port 3 to the Bypass Port

q

Step 14. Connect the test port cable between the ANT B port and the RBS B

port. Wait until one sweep has completed.

Step 15. On the MS4623B, press the Display key and select:

TRACE MEMORY

STORE DATA TO MEMORY

VIEW DATA(/) MEMORY

Step 16. Disconnect the cable from the ANT B port.

Step 17. Connect the offset terminations to the ANT B port and to the open end

of the cable.

Step 18. Verify that the displayed trace is below -75 dB from 10 MHz to

50 MHz and below -80 dB from 50 MHz to 6 GHz.

Step 19. Press the Meas key and select:

MORE

S23, TRANS b1/a3

Step 20. Disconnect the terminations from the ANT B port and from the open

end of the cable. Connect the open end of the cable to the Bypass port.

Wait until one sweep has completed.

Step 21. Press the Display key and select:

TRACE MEMORY

STORE DATA TO MEMORY

VIEW DATA(/) MEMORY

Step 22. Disconnect the cable from the Bypass port.

Step 23. Connect the offset termination to the Bypass port and to the open end

of the cable.

3-12 MN4790A MM

Page 35

PERFORMANCE VERIFICATION DYNAMIC RANGE

Step 24. Verify that the displayed trace is below -80 dB.

Table 3-3. Dynamic Range Test Specifications

Dynamic Range Between Ports Specification Measured

ANT A and RBS A

10 MHz to 50 MHz

50 MHz to 6 GHz

ANT B and RBS B

10 MHz to 50 MHz

50 MHz to 6 GHz

Bypass and RBS B

10 MHz to 6 GHz 80 dB

75 dB

80 dB

75 dB

80 dB

MN4790A MM 3-13

Page 36

IMD MEASUREMENT PERFORMANCE VERIFICATION

3-6 IMD MEASUREMENT This procedure verifies that the IMD measurement signal path is op

erational.

Test procedure

Step 1. Follow the preliminary setup procedures on pages 3-2 through 3-4.

Step 2. Click on the Case1 button in the MN4790A Switch Control window.

This will configure the switches in the MN4790A test set to allow the

signals to go through the following paths:

Test Port 1 to the ANT A Port (through the combiner)

q

Test Port 3 to the ANT A Port (through the combiner)

q

Test Port 2 to the RBS A Port

q

Step 3. On the MS4623B, press the Default key, then the 0 key to reset the in

strument.

Step 4. Press the Appl key and select:

CHANGE APPLICATION SETUP

MEASUREMENT TYPE

IMD

Step 5. Press the Display key and select:

-

-

DISPLAY MODE

SINGLE CHANNEL

RETURN

GRAPH TYPE

LOG MAGNITUDE

Step 6. Connect a test port cable between the ANT A port and the RBS A port.

Step 7. Press the Appl key and select:

SWEEP MODE: CW RCVR

DISPLAY SELECTION: PRODUCT

RETURN

TONE 2 OFFSET: 301 kHz

Step 8. Press the Freq key and select:

CW MODE ON

Step 9. Change the CW frequency to 869 MHz.

Step 10. Press the Display key and select:

AUTO SCALE

3-14 MN4790A MM

Page 37

PERFORMANCE VERIFICATION IMD MEASUREMENT

Step 11. Press the Avg key and select:

SELECT I.F. BANDWIDTH

I.F.BW 10Hz

Step 12. Press the Marker key and select:

READOUT MARKERS

Step 13. Select the soft-key next to the 1:, 2:, 3:,and 4: markings to turn on

these markers. Use the rotary knob to move:

Marker 1 to the peak of Tone 1

q

Marker 2 to the peak of Tone 2

q

Marker 3 to the peak left of Tone 1

q

Marker 4 to the peak right of Tone 2

q

Step 14. Select the soft-key next to the 1: marking so that Marker 1 is now the

active marker (distinguished by a square surrounding the marker

number). See Figure 3-4.

Figure 3-4. Log Magnitude Display Plot

Step 15. Press the Marker key and select:

DREF MODE: ON

READOUT MARKERS

MN4790A MM 3-15

Page 38

IMD MEASUREMENT PERFORMANCE VERIFICATION

Step 16. Verify that the (1-2) reading is less than 2 dB and that the (1-3) and

(1-4) readings are less than 60 dB (see Figure 3-5).

Figure 3-5. Log Magnitude Display Plot

3-16 MN4790A MM

Page 39

Chapter 4 Troubleshooting

4-1 INTRODUCTION The tests in this section provide a method of testing the MN4790A test

set for proper operation. These tests are intended to be used as

troubleshooting tools for checking the operational functionality of the

components in the MN4790A.

4-2 OPERATIONAL CHECK Operational tests for the MN4790A consists of the following:

Internal Signal Path Insertion Loss Check

q

Test Channel Step Attenuator Check

q

NOTE

Prior to performing these tests, the MS4623B must be verified to be in good condition. Follow the procedures in

Chapter 2 of the MS462XX Vector Network Measurement

Systems Maintenance Manual (part number 10410-00205)

to verify that the MS4623B is working properly.

Required Equipment

q

Anritsu MS4623B Vector Network Measurement System

4-3 INTERNAL SIGNAL PATH

INSERTION LOSS CHECK

Test Setup

Step 1. Follow the preliminary setup procedures on pages 3-2 through 3-4.

Step 2. On the MS4623B, connect a through cable to Port 1 and a second

q

Anritsu 3753R or 3753LF N Connector Type Calibration Kit

q

Anritsu 33NN50B (from 3753R/1) or 34NN50A Adapter

q

Anritsu 3670NN50-2 Through Cable or Equivalent

q

Anritsu 3670N50-2 Through Cable or Equivalent

q

Anritsu 2100-2 GPIB Interface Cable

q

Personal Computer with a Windows Operating System, Scorpion

Navigator, and a National Instruments GPIB Interface Installed

This test checks the insertion loss of various switched signal paths. If

the measured insertion loss is improperly high, then a RF component

in that signal path may be defective.

through cable to Port 2.

MN4790A MM 4-1

Page 40

INTERNAL SIGNAL PATH INSERTION LOSS CHECK TROUBLESHOOTING

Step 3. Perform a Forward Path Transmission Frequency Response calibra

tion from 10 MHz to 6 GHz with 401 data points.

Step 4. Set up the MS4623B display to:

SINGLE CHANNEL

S21

LOG MAGNITUDE

Test Procedure This test procedure is illustrated in Table 4-1.

Step 1. For each test sequence, click on the appropriate “Case” button in the

Switch Control window

Step 2. Connect the through cables to the appropriate ports of the test system

and measure the insertion loss of the pre-set signal path per Table 4-1.

Table 4-1. Internal Signal Path Insertion Loss Test Sequences

Test

Sequence

A Case3 Test Port 1 of the

B Case3 Test Port 3 of the

C Case3 RBS A Port of the

D Case4 Test Port 1 of the

E Case4 RBS B Port of the

F* Case1 Test Port 1 of the

G* Case1 Test Port 3 of the

H Case20 Aux In 1 Port of the

I Case19 Aux In 2 Port of the

J Case21 RBS A Port of the

K Case8 RBS B Port of the

* Measure Insertion Loss from 500 MHz to 6 GHz only.

Case Button

Connect Port 1 of

the MS4623B to

MN4790A

MN4790A

MN4790A

MN4790A

MN4790A

MN4790A

MN4790A

MN4790A

MN4790A

MN4790A

MN4790A

Connect Port 2 of

the MS4623B to

ANT A Port of the

Bypass Port of the

Test Port 2 of the

ANT B Port of the

Test Port 2 of the

ANT A Port of the

ANT A Port of the

ANT B Port of the

ANT A Port of the

Aux Out 1 Port of the

Aux Out 2 Port of the

MN4790A

MN4790A

MN4790A

MN4790A

MN4790A

MN4790A

MN4790A

MN4790A

MN4790A

MN4790A

MN4790A

Measured

Insertion Loss

-

Maximum Allowable

Insertion Loss

15 dB

15 dB

15 dB

15 dB

15 dB

15 dB

15 dB

15 dB

15 dB

15 dB

15 dB

Step 3. Refer to Table 4-2,following page, for solutions to any of the insertion

loss tests failures

4-2 MN4790A MM

Page 41

TROUBLESHOOTING INTERNAL SIGNAL PATH INSERTION LOSS CHECK

Table 4-2. Internal Signal Path Insertion Loss Test Sequence Failure Solutions

Test Sequence Failure Solutions

A Replace Switches S3, S1 or S4

B Replace Switch S2

C Replace Switches S5, S7 or Step Attenuator

D Replace Switch S3

E Replace Switches S5, S7 or Step Attenuator

F Replace Switch S4 or Combiner

G Replace Switch S2 or Combiner

H Replace Switch S6

I Replace Switch S6

J Replace Switches S5 or S7

K Replace Switches S5 or S7

MN4790A MM 4-3

Page 42

TEST CHANNEL STEP ATTENUATOR CHECK TROUBLESHOOTING

4-4 TEST CHANNEL STEP

ATTENUATOR CHECK

Test Setup

Step 1. Follow the preliminary setup procedures on pages 3-2 through 3-4.

Step 2. On the MS4623B, press the Default key, then the 0 key to reset the

Step 3. Press the Display key.

Step 4. Select:

Step 5. Press the Ch 3 key, then the Display key.

Step 6. Select:

Step 7. Press the Avg key.

This test checks that the Test Channel Step Attenuator functions

properly.

instrument.

DISPLAY MODE

SINGLE CHANNEL

RETURN

GRAPH TYPE

LOG MAGNITUDE

RETURN

Step 8. Select:

Step 9. Connect a through cable between Port 1of the MS4623B and the

Test Procedure

Step 1. On the PC controller, select the Case3 button in the MN4790A Switch

Step 2. On the MS4623B, select:

Step 3. Allow the trace to sweep twice, then select:

SELECT I.F. BANDWIDTH

I. F. BW 10 Hz

RBS A port of the MN4790A. Connect a second through cable between

Port 2 of the MS4623B and Test Port 2 of the MN4790A.

Control window.

TRACE MEMORY

STORE DATA TO MEMORY

VIEW DATA(/) MEMORY

RETURN

4-4 MN4790A MM

Page 43

TROUBLESHOOTING TEST CHANNEL STEP ATTENUATOR CHECK

Step 4. Select:

SCALE

10 dB/DIV

Step 5. On the PC, position the mouse pointer to the scroll bar on the right

hand side of the MN4790A Switch Control window.Right-click to move

the pointer downward and change the attenuation setting to 10 dB.

Step 6. Verify that the displayed S21 trace is within the range specified in Ta

ble 4-3.

Step 7. Repeat Steps 5 and 6 for the other specified attenuation levels in Ta

ble 4-3.

Table 4-3. Step Attenuator Specifications

Step Attenuator Setting Attenuation Specification (dB)

10 10 ± 1

20 20 ± 1

30 30 ± 2

40 40 ± 2

50 50 ± 2

60 60 ± 3

70 70 ± 3

Step 8. If the test result is out of the expected range,replace the step attenu

ator.

-

-

-

MN4790A MM 4-5

Page 44

TROUBLESHOOTING TROUBLESHOOTING

4-5 TROUBLESHOOTING The following paragraphs provide suggestions for troubleshooting cer

tain test-set components.

Test Set Fails to

Power Up

WARNING

Line Source and

Interface Checks

Step 1. Verify that the ac power source is providing stable power at the correct

If the MN4790A test set fails to power up when connected to an ac

power source and the Power key is pressed,perform the power supply

checks described below.

WARNING

Hazardous voltages are present inside the instrument

when ac line power is connected. Turn off the instrument

and remove the line cord before removing any covers or

panels. Troubleshooting or repair procedures should only

be performed by qualified service personnel who are fully

aware of the potential hazards.

line voltage.

NOTE

The MN4790A is designed to automatically sense and operate with ac line voltages in the range of 85 to 264 VAC,

with a frequency of 47 to 63 Hz.

-

Step 2. Verify that the power input cord is in good condition.

Step 3. Verify that the power line fuse is installed,that it is not blown (open),

Power Supply Voltage

Check

Step 1. Turn off the test set and disconnect the power cord from the instru

Step 2. Remove the top cover.

Step 3. Reconnect the power cord to the test set and turn it on.

and that it is the correct value (1.6A,Slow Blow, part number 631-81).

ment. Ensure that all external cable connections to the test set’s front

and rear panel are also disconnected.

4-6 MN4790A MM

Page 45

TROUBLESHOOTING TROUBLESHOOTING

Step 4. Using a digital multi-meter or oscilloscope, measure the dc power sup

Table 4-1. Power Supply Voltages

Measured Pin Common Pin DC Supply Voltage (V)

TP2 TP1 +5 ± 0.25

TP4 TP1 +15 ± 0.9

ply voltages on the Controller PCB at the test points listed in Ta

ble 4-1 (see to Figure 4-2, below).

-

-

Figure 4-2. A6 Power Supply Test Point Location Diagram

Step 5. If any of the dc voltage tests fail,replace the A6 dc power supply. Refer

to the A6 power supply remove and replace procedures in Chapter 5.

MN4790A MM 4-7/4-8

Page 46

Page 47

Chapter 5 Removal and Replacement Procedures

5-1 INTRODUCTION This chapter provides procedures for removing and reinstalling the

replaceable subassemblies listed in Chapter 2, Table 2-1.

5-2 EQUIPMENT REQUIRED All procedures in this chapter require the use of either a #1 or #2 size

Phillips type screw driver. Most procedures require the use of a

5/16 inch wrench and the Anritsu 01-201 (8 inch-pounds) torque

wrench. Some procedures require the use of a small jewelers Phillips

screwdriver.

CAUTION

Always use a torque wrench calibrated to 8 inch-pounds

when tightening SMA connectors. Over-torquing will cause

damage to the RF connectors.

5-3 REMOVING THE COVERS Troubleshooting operations require removal of the top cover.

Replacement of some test set assemblies and parts require removal of

all covers. The following procedure describes this process.

Preliminary

Step 1. Switch the test set power off and remove the power cord.

Step 2. Remove the test set from the ME7842B test system by disconnecting

all cable connections and separating the test set from the MS4623B.

Procedure Refer to Figure 5-1, page 5-3, during this procedure.

NOTE

It is only necessary to loosen the test set’s front handle

assemblies to remove the top, bottom, or side covers.

However, if the front panel is to be removed, the handle

assemblies should also be removed.

MN4790A MM 5-1

Page 48

REMOVING THE COVERS REMOVE AND REPLACE

Step 3. Loosen (or remove) the right and left handle assemblies, as follows:

a. Place the test set on its top (bottom-side up).

b. Loosen (or remove) the screws at the sides of the handle

assemblies.

c. If removing the handles, pull them away from the unit and set

aside.

CAUTION

The green headed screws have metric

threads. Be sure to retain all of the screws

and replace them in their original location.

Step 4. To remove the top cover:

a. Place the test set in normal (top-side up) position.

b. Remove the feet from the two top corners at the rear of the test

set.

c. Remove the center screw from the rear of the top cover.

d. Lift and slide the top cover away from the test set.

Step 5. To remove the bottom cover:

a. Place the test set on its top (bottom-side up).

b. Remove the feet from the two bottom corners at the rear of the

test set.

c. Remove the center screw from rear of the bottom cover.

d. Lift and slide the bottom cover away from the test set.

Step 6. To remove the right cover:

a. Place the test set on its left side.

b. Remove the feet from the two right-side corners at the rear of

the test set.

c. Remove the center screw from the right cover.

d. Lift and slide the side cover away from the test set.

Step 7. To remove the left cover:

a. Place the test set its right side.

b. Remove the feet from the two left-side corners at the rear of the

test set.

c. Remove the center screw from rear of the left side cover.

d. Lift and slide the side cover away from the test set.

5-2 MN4790A MM

Page 49

Figure 5-1. MN4790A Test Set Cover Removal

To replace the instrument covers, perform the previous steps in the

reverse order.

MN4790A MM 5-3

Page 50

A1 GPIB PARALLEL INTERFACE PCB REMOVE AND REPLACE

5-4 A1 GPIB PARALLEL

INTERFACE PCB

This Section provides a procedure for removing and replacing the A1

GPIB Parallel Interface PCB in the test set.

Step 1. Remove the top cover from the test set (Section 5-3).

Step 2. Disconnect the two cables from connectors J2 and J3. (Figure 5-2).

Step 3. Remove the four mounting screws.

Step 4. Lift the A1 PCB assembly out from the test set chassis.

Remove

Mounting

Screws (4)

Remove

Cables

A6

J3

A1

A7

J2

A2

A3

Figure 5-2. A1 GPIB Parallel Interface PCB Removal

To replace A1 GPIB Parallel Interface PCB, reverse the order of the

removal procedure.

5-4 MN4790A MM

Page 51

REMOVE AND REPLACE A2 COMBINER

5-5 A2 COMBINER This Section provides a procedure for removing and replacing the A2

Combiner in the test set.

Step 1. Remove the top cover from the test set (Section 5-3).

Step 2. Disconnect the three RF cables from the Combiner using a 5/16-inch

wrench (Figure 5-3).

Step 3. Remove the two Combiner mounting screws with a Phillips

screwdriver.

Step 4. Lift the Combiner out from the test set chassis.

Remove RF

Cables (3)

Remove

Mounting

Screws (2)

Figure 5-3. A4 Combiner Removal

A6

A2

A7

A1

A3

To replace combiner, reverse the order in the removal procedure.

MN4790A MM 5-5

Page 52

A3 STEP ATTENUATOR REMOVE AND REPLACE

5-6 A3 STEPATTENUATOR This Section provides a procedure for removing and replacing the A3

Step Attenuator in the test set.

Step 1. Remove the right side cover from the test set (Section 5-3).

Step 2. Disconnect the Step Attenuator ribbon-cable from the Step Attenuator

(Figure 5-4).

Step 3. Disconnect the RF cables from the Step Attenuator using a 5/16-inch

wrench.

Step 4. Remove the two large Step Attenuator mounting screws with a Phil

Step 5. Slide the Step Attenuator out from the test set chassis.

Figure 5-4. A3 Step Attenuator Removal

-

lips screwdriver.

Remove RF Cables

Remove Ribbon Cable

A3

Remove Larger Mounting Screws

To replace the step attenuator, reverse the order of the removal

procedure.

5-6 MN4790A MM

Page 53

REMOVE AND REPLACE A4 AND A5 BIAS TEES

5-7 A4 AND A5 BIAS TEES This Section provides a procedure for removing and replacing the A4

and A5 Bias Tees in the test set.

Step 1. Remove the top cover from the test set (Section 5-3).

Step 2. Unscrew the RBS Bias connectors from the top of the Bias Tee using a

3/16-inch wrench (Figure 5-5).

Step 3. Remove the RF cables from the Bias Tee and the SP3T switch with a

5/16-inch wrench.

Step 4. Remove the Bias Tee mounting screws with a #1 Phillips screwdriver.

Step 5. Unscrew the Bias Tee from the front panel RF connector with a

5/16-inch wrench and remove the Bias Tee.

A6

A2

Remove the

RF Cable

Remove the Mounting Screws,

A7

A1

A3

Unscrew the

RBS Bias Cable

Unscrew the Bias Tee From

the Front Panel RF Connector

Figure 5-5. A4, A5 Bias Tee Removal

To replace the Bias Tee,reverse the order of the removal procedure.

MN4790A MM 5-7

Page 54

A6 POWER SUPPLY REMOVE AND REPLACE

5-8 A6 POWER SUPPLY This Section provides a procedure for removing and replacing the A6

Power Supply in the test set.

Step 1. Remove the top and bottom covers from the test set (Section 5-3).

Step 2. Disconnect all the cable connections from the Power Supply (Fig

ure 5-6).

Step 3. Turn the test set on its side.

Disconnect Power Supply

Input and Ground Connection

Disconnect Power Supply

Output Connection

A6

A7

A2

A1

-

A3

Figure 5-6. A6 Power Supply Removal (Bottom View)

5-8 MN4790A MM

Page 55

REMOVE AND REPLACE A6 POWER SUPPLY

Step 4. Hold the Power Supply and remove the four mounting screws with a

Phillips screwdriver (Figure 5-7).

Step 5. Lift the Power supply out from the test set chassis.

Remove the Power Supply

Mounting Screws

Figure 5-7. A6 Power Supply Removal (Bottom View)

To replace the Power Supply, reverse the order of the removal proce

dure.

-

MN4790A MM 5-9

Page 56

A7 CONTROL PCB REMOVE AND REPLACE

5-9 A7 CONTROL PCB This Section provides a procedure for removing and replacing the A7

Control PCB in test set.

Step 1. Remove the top cover from the test set (Section 5-3).

Step 2. Disconnect the cables on the Control PCB at P1, J1, J2, J3, J4,and J5

(Figure 5-8).

Step 3. Remove the four mounting screws.

Step 4. Lift the Control PCB out from the test set chassis.

Remove Calble

Connections

A6

A2

Remove Mounting

Screws (4)

P1

J4

J1

J5

A7

J3

J2

A1

A3

Figure 5-8. A7 Control PCB Removal

To replace the Control PCB, reverse the order of the removal proce

-

dure.

5-10 MN4790A MM

Page 57

REMOVE AND REPLACE FAN ASSEMBLY

5-10 FAN ASSEMBLY This Section provides a procedure for removing and replacing the rear

panel fan assembly.

Step 1. Remove the top cover from the test set (Section 5-3).

Step 2. Remove the four screws holding the fan guard in place (Figure 5-9).

Step 3. Remove the fan guard and lift out the fan.

Figure 5-9. Fan Removal

To replace the fan,reverse the order of the removal procedure.

MN4790A MM 5-11

Page 58

SP3T AND SPDT SWITCHES REMOVE AND REPLACE

5-11 SP3T AND SPDT

SWITCHES

A6

This Section provides a procedure for removing and replacing the

SP3T and SPDT RF switches.

Step 1. Remove the top cover from the test set (Section 5-3).

Step 2. Disconnect the RF cables from the SP3T or SPDT switch (Figure 5-10).

Step 3. Disconnect the wire connectors from the SP3T or SPDT switch.

Step 4. Remove the four Phillips screws from the SP3T or SPDT switch.

Step 5. Lift the SP3T or SPDT switch out from the test set chassis.

Disconnect

RF Cables

J1 J2

COMM

-5

+5

G

-5

+5

G

A7

A1

L1

L2

G

(Not Used)

Disconnect

Wire Connectors

SPDT

A2

S1

S4

S5

S6

S2

S3

Figure 5-10. SP3T and SPDT RF Switch Removal

To replace the SP3T or SPDT switch, reverse the order of the removal

procedure.

S7

A3

J3

COMM

J2

J1

L3

L2

SP3T

L1

Remove Phillips

Screws Only (4)

S4, S7 S1,S3, S5, S6 S2

5-12 MN4790A MM

Page 59

REMOVE AND REPLACE SP3T AND SPDT SWITCHES

Table 5-1 . SP3T and SPDT RF Switch Wiring Legend

SP3T or SPDT

Switch Number

S1

S2 Orange Red Brown Green Blue Not Used

S3 Orange Red Brown Purple Gray Not Used

S4 Orange Red Brown Black White Not Used

S5 Orange Red Brown Red Brown Not Used

S6 Orange Red Brown Orange Yellow Not Used

S7 Orange Red Brown Green Yellow Blue

Pin –5

Wire Color

Orange Red Brown

Pin +5

Wire Color

Wire Color

Pin G

Pin L1

Wire Color

Brown Red Orange

Pin L2

Wire Color

Pin L3

Wire Color

MN4790A MM 5-13/5-14

Page 60

Page 61

Appendix A

0

1

2

3

4

5

1

2

3

4

2

11

2

Connector Maintenance

Check Procedures

A-1 INTRODUCTION This appendix provides general, precautionary information and in

-

structions pertaining to precision connectors.

A-2 PRECAUTIONS The following paragraphs are precautionary notes relating to mainte

nance considerations for precision connectors

Pin Depth Problems Based on Anritsu precision components returned for repair,

destructive pin depth of mating connectors is the major cause of

REFERENCE

PLANE

PIN

DEPTH

(INCHES)

FEMALE

Figure A-1. N Connector Pin Depth

Definition

REFERENCE

PLANE

(INCHES)

PIN

DEPTH

MALE

failure in the field. When a precision component is mated with a

connector having a destructive pin depth, damage will likely occur to

the precision component’s connector. A connector is considered to have

destructive pin depth when the center pin is too long with respect to

the connector’s reference plane (Figure A-1).

Before mating an unknown or new device with your test set port

connectors or calibration devices, always measure the pin depth of the

device’s connectors. Use an Anritsu Pin Depth Gauge,or equivalent,for

these measurements (Figure A-2). Also, measure the connector pin

depth of a device when intermittent or degraded performance is

suspected.

Gauging sets for measuring the pin depth of precision connectors are

available from your nearest Anritsu service center, or from the factory.

Instructions for measuring connector pin depth are included with the

gauging set.

-

Figure A-2. Pin Depth Gauge

MN4790A MM A-1

Page 62

PRECAUTIONS APPENDIX A

Pin Depth Tolerance The center pin of a precision connector has a tolerances measured in

mils (one mil = 1/1000 inch). The connectors of test devices may not be

precision types and they may not have the proper pin depth. These

connectors should be measured before mating to ensure suitability.

When gauging pin depth, if the connector being measured indicates

out of tolerance in the “+” region of the gauge (Table A-1), the center

pin is too long. Mating under this condition will likely damage the mat

ing connector. On the other hand,if the test device connector indicates

out of tolerance in the “–” region,the center pin is too short. While this

will not cause any damage, it will result in a poor connection and a

consequent degradation in performance.

Table A-1. Connector Pin Depth Tolerance

-

Avoid Over Torquing

Connectors

Teflon Tuning

Washers

Port Connector Type Pin Depth (Mils)

GPC-7

N Male

N Female

3.5 mm Male, Female

K Male, Female

V Male

V Female

207

207

+0.000

–0.003

–0.000

+0.004

–0.004

+0.000

–0.000

+0.002

+0.0000

–0.0035

+0.000

to –0.001

+0.000

to –0.001

Gauge

Reading

Same As

Pin Depth

207

Same As

Pin Depth

+0.000

–0.004

Over torquing connectors is destructive;it may damage the connector

center pin.Finger tight is usually sufficient,especially on Type N con

nectors. Should it be necessary to use a wrench to tighten SMA or

WSMA connectors, use a torque wrench that breaks at 8 inch-pounds.

As a general rule, never use pliers to tighten connectors.

The center conductor on many precision connectors contains a small

Teflon tuning washer located near the point of mating (interface). This

washer compensates for minor impedance discontinuities at the inter

face. The washer’s location is critical to the connector’s performance.

Do not disturb the Teflon Tuning Washer.

-

-

Avoid Mechanical

Shock

Precision connectors are designed to withstand years of normal bench

handling. Do not drop or otherwise treat them roughly. They are labo

ratory-quality devices, and like other such devices, they require careful

handling.

A-2 MN4790A MM

Page 63

APPENDIX A REPAIR AND MAINTENANCE

Keep Connectors

Visual Inspection Precision connectors should be inspected periodically. Check for the

A-3 REPAIR AND

MAINTENANCE

Clean

The precise geometry that makes a precision connector’s high perfor

mance possible can be disturbed by dirt and other contamination ad

hering to connector interfaces. When not in use, keep the connectors

covered.

following:

Bent or broken center pin

q

Damaged threads

q

Other bent or damaged connector parts

q

Dirt or foreign material in connector cavity

q

Anritsu recommends that no maintenance other than cleaning be

attempted by the customer. Any device with a suspected defective

connector should be returned to Anritsu for repair and/or service when

needed.

-

-

MN4790A MM A-3/A-4

Page 64

INDEX A TO D

Index

A

A1 GPIB Parallel Interface PCB

Location····················2-2

Part Number ·················2-2

Replacement ·················5-4

A2 Combiner

Description ··················1-3

Part Number ·················2-2

Replacement ·················5-5

A3 Step Attenuator

Location····················2-2

Part Number ·················2-2

Replacement ·················5-6

A4 Bias Tee

Location····················2-2

Part Number ·················2-2

Replacement ·················5-7

A5 Bias Tee

Location····················2-2

Part Number ·················2-2

Replacement ·················5-7

A6 Power Supply

Location····················2-2

Part Number ·················2-2

Replacement··············5-8to5-9

A7 Control PCB

Location····················2-2

Part Number ·················2-2

Replacement·················5-10

Acrobat Reader ·················1-1

Adobe Acrobat··················1-1

Anritsu Service Centers·············1-8

B

Bias Tee

Location····················2-2

Part Number ·················2-2

Replacement ·················5-7

Block Diagram,TMATS·············1-5

C

CDROM·····················1-1

Cleaning Connectors ··············A-3

Combiner

Description ··················1-3

Location····················2-2

Replacement ·················5-5

Connector Maintenance

Cleaning ···················A-3

Introduction ·················A-1

Mechanical Shock ··············A-2

Pin Depth Problems ·············A-1

Pin Depth Tolerances ············A-2

Precautions··················A-1

Repair/Maintenance ·············A-3

Teflon Tuning Washer ············A-2

Torquing Connectors·············A-2

Visual Inspection···············A-3

Control PCB

Location····················2-2

Part Number ·················2-2

Replacement·················5-10

Conventions for

Front Panel Keys···············3-1

Instrument References············1-1

Menu Keys ··················3-1

Covers, Removing ············5-1to5-2

D

Description

Combiner ···················1-3

Hardware ···················1-2

ME7842B ···················1-2