Page 1

Quick Start Guide

™

VectorStar

ME7838D4

Multiport Broadband/Banded

Millimeter-Wave System

High Performance Modular Broadband/Banded Millimeter-Wave

Vector Network Analyzer (VNA) Multiport Measurement System

ME7838D4, 70 kHz to 145 (150) GHz

Anritsu Company

490 Jarvis Drive

Morgan Hill, CA 95037-2809

USA

http://www.anritsu.com

Part Number: 10410-00770

Copyright 2019 Anritsu Company, USA. All Rights Reserved.

Published: December 2019

Revision: B

Page 2

1. ME7838D4 Main Components

High Performance Modular Broadband/Banded Millimeter-Wave

Vector Network Analyzer (VNA) Measurement System, 70 kHz to 150 GHz

This guide provides quick setup instructions for the ME7838D4 Multiport Broadband/Banded mm-Wave VNA

System assembly. For additional safety and compliance information, and for more details about the assembly,

configuration, setup, and initial testing of the equipment, refer to the VectorStar™ ME7838x4 Series Multiport

Broadband Vector Network Analyzers Installation Guide – 10410-00734.

This and all other documentation that supports the ME7838D4 is available on the VectorStar product web

page:

http://www.anritsu.com/en-us/products-solutions/products/ms4640b-series.aspx

On this web page, you can select various tabs for more information about your instrument. Included is a

“Library” tab which contains links to all the latest technical documentation related to this instrument.

1. ME7838D4 Main Components

ME7838D4 Broadband Systems

The ME7838D4 Multiport Broadband system consists of the following components:

• MS4647A or MS4647B VNA with Option 007 (Receiver Offset) and Option 08x (Modular Broadband

Connection Capability)

• MN4697C Multiport Test Set

• 3736B Broadband Test Set

• 3739C Broadband Test Set

• Four MA25300A Millimeter-Wave Modules

• Front and rear panel cables

ME7838D4 Banded Systems

The ME7838D4 Multiport Banded system consists of the following components:

• MS464xA/B VNA with Option 08x

• MN4694C Multiport Test Set

• 3736B Broadband Test Set

• 3739C Broadband Test Set

• Four 3744A-EE, 3744A-EW, or four OML/VDI Millimeter-Wave Modules

• Front and rear panel cables

A MS464xA/B VNA unit is heavy. To avoid personal injury, it must be lifted and

maneuvered by at least two people during installation.

Caution

If mounting on a workbench surface, first position the 3739C Broadband Test Set

with access to its front and rear panels. Stack the remaining test sets on top of one

another, then finally the VNA.

If mounting into rack or console, make sure the Test Sets have been installed, and

that the rack/console is carefully positioned on a flat and level surface. If equipped,

make sure any casters are locked. Use two people to lift the VNA unit and two to

guide it into its shelf rails.

The test loops on the front and rear panels of the VNA are delicate. Be careful not to

bump or bend the test loops.

QSG-2 PN: 10410-00770 Rev. B VectorStar ME7838D4 QSG

Page 3

2. Rear Panel Connections Between System Components (MS464xA VNA)

WARNING

No operator serviceable parts inside.

Refer servicing to

qualified personnel.

Ext

Alc

Out

Ext

Analog

In

a

1

b a

2

b

2

IF Outputs

External I/O

~ LINE INPUT

47-63 Hz

85-240 VAC

150 VA Max

Fuse 250V 2A T

CAUTION

Do not operate with

power cord ungrounded.

CAUTION

For continued fire protection

replace only with specified

type and rated fuse.

Cable Length

Standard

Extended

Module Interface

MN469xC

Test Set

3736B

Test Set

3739C

Test Set

MS464xA

VNA

1

1

2

2

3

4

11 151617

18121314

19

20

21

22

5

6

6

6

6

7 7 7 7

7 7 7 7

8

8

9

9

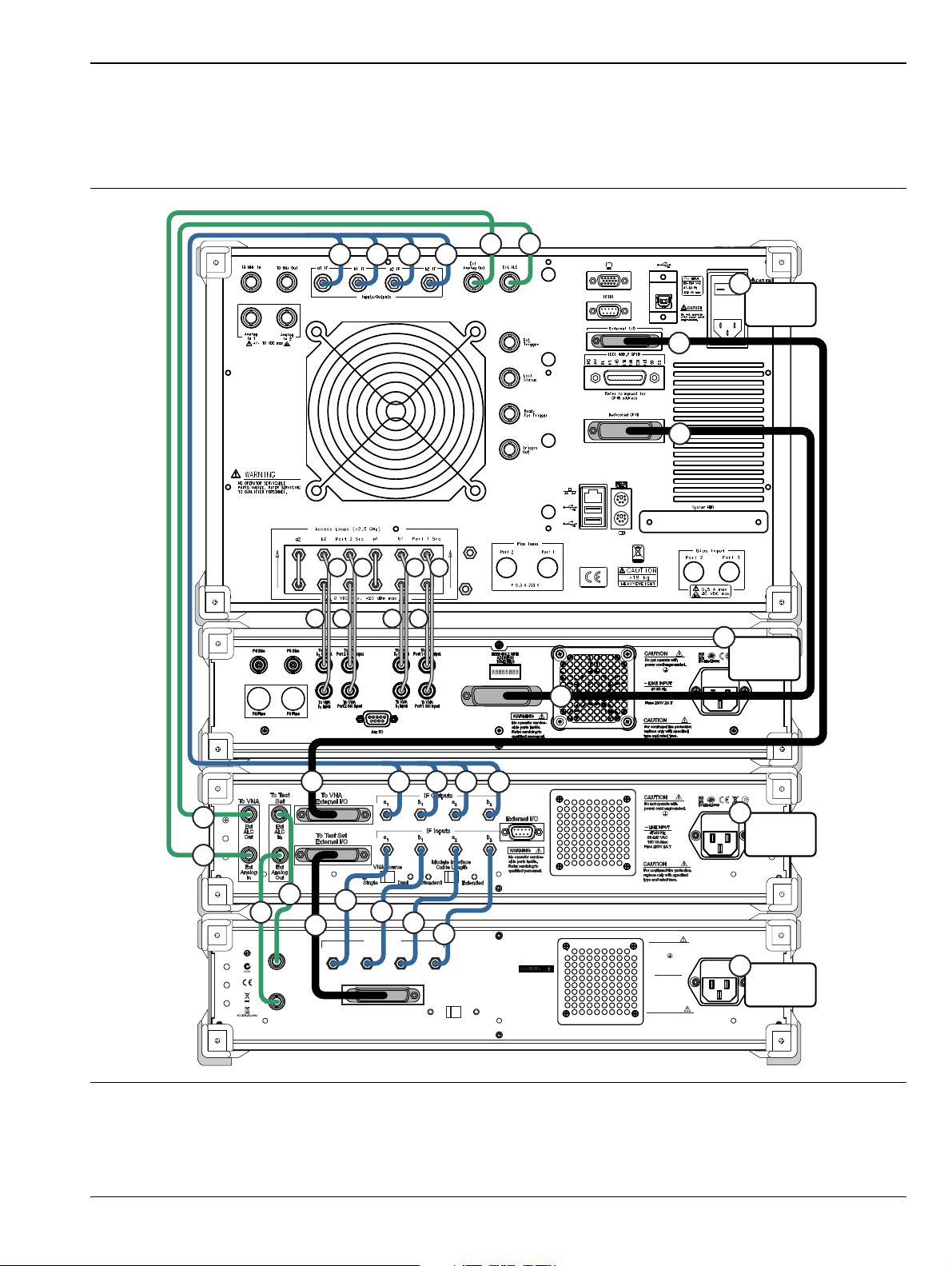

2. Rear Panel Connections Between System Components

(MS464xA VNA)

In this section, connect the cables between the VNA and the Test Sets as shown in Figure 1 and Table 1.

Figure 1 ME7838D4 – Rear Panel Cable Connections (MS464xA VNA)

VectorStar ME7838D4 QSG PN: 10410-00770 Rev. B QSG-3

Page 4

2. Rear Panel Connections Between System Components (MS464xA VNA)

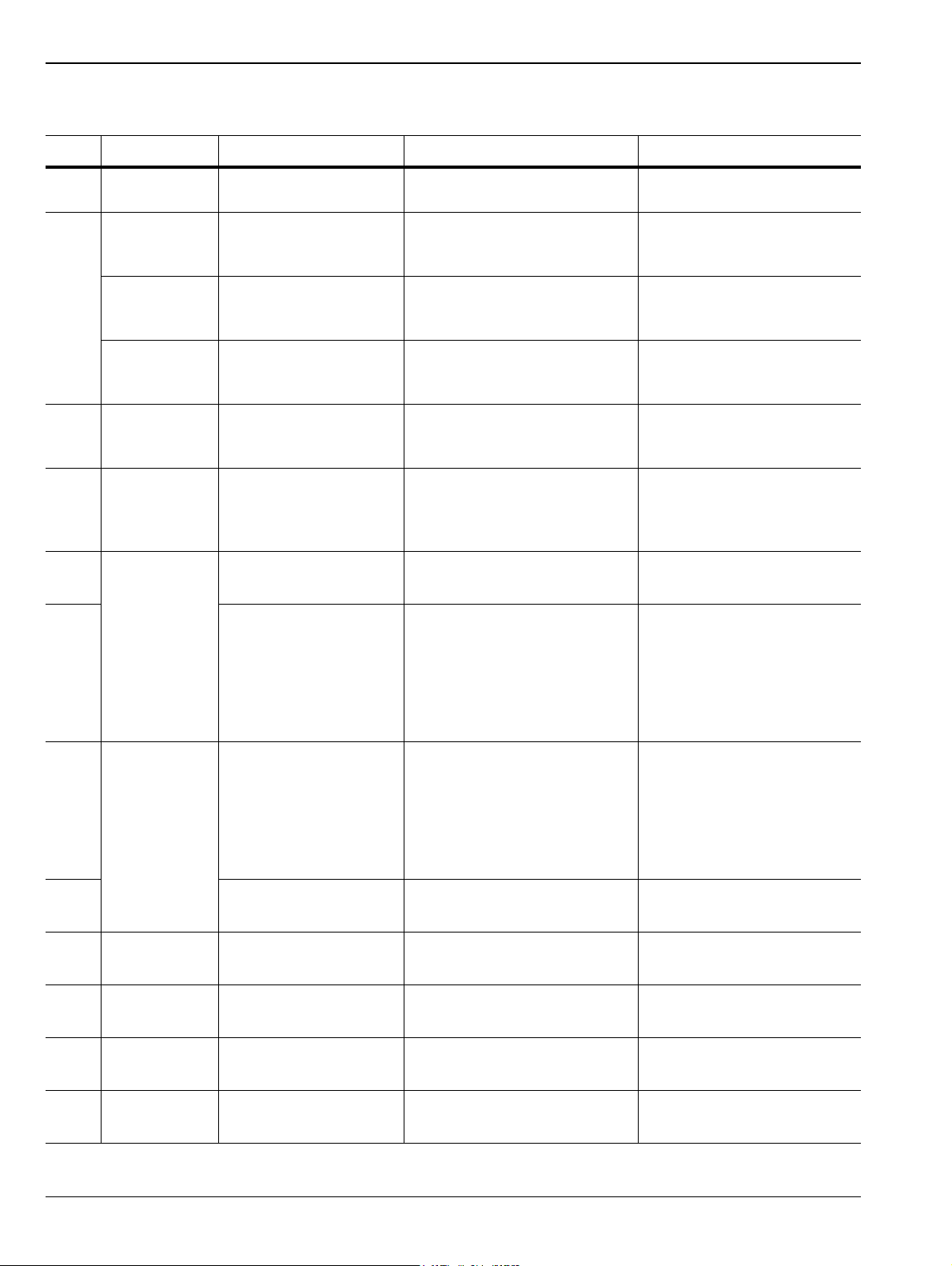

Tab le 1. ME7838D4 Multiport Rear Panel Cable Connections (1 of 2)

Index Part Number Cable Description Connection From Connection To

1 3-806-225 BNC (male-male), 24 in

2 3-806-225 BNC (male-male), 24 in

3 3-806-225 BNC (male-male), 24 in

4 3-806-225 BNC (male-male), 24 in

5

73598-1

(5 cable

6

bundle)

DB-25

SMA male-male flexible:

a

3-72243-1

3-72243-2

3-72243-3

3-72243-4

SMA male-male flexible:

3-72243-21

7

3-80734

(5 cable

bundle)

a

3-72243-22

3-72243-23

3-72243-24

8DB-25

9 2100-1 GPIB, 1 m

SMA male-male

11 62112-81

12 62112-80

13 62112-81

14 62112-80

15 62112-81

16 62112-80

17 62112-81

a

semi-rigid

SMA male-male

a

semi-rigid

SMA male-male

a

semi-rigid

SMA male-male

a

semi-rigid

SMA male-male

a

semi-rigid

SMA male-male

a

semi-rigid

SMA male-male

a

semi-rigid

MS464xA port labeled:

Ext Analog Out

MS464xA port labeled:

Ext ALC

3736B port labeled:

(To Test Set) EXT ANALOG

OUT

3736B port labeled:

(To Test Set) EXT ALC IN

3736B port labeled:

TO TEST SET EXTERNAL I/O

3736B ports labeled:

(IF INPUTS)

a1

b1

a2

b2

MS464xA ports labeled:

(Inputs/Outputs)

a1 IF

b1 IF

a2 IF

b2 IF

MS464xA port labeled:

External I/O

MS464xA port labeled:

Dedicated GPIB

MS464xA port labeled:

b2 loop out

MS464xA port labeled:

b2 loop in

MS464xA port labeled:

P2 source loop out

MS464xA port labeled:

P2 source loop in

MS464xA port labeled:

b1 loop out

MS464xA port labeled:

b1 loop in

MS464xA port labeled:

P1 source loop out

3736B port labeled:

EXT ANALOG IN

3736B port labeled:

EXT ALC OUT

3739C port labeled:

EXT ANALOG IN

3739C port labeled:

EXT ALC OUT

3739C port labeled:

EXTERNAL I/O

3739C ports labeled:

(IF OUTPUTS)

a1

b1

a2

b2

3736B ports labeled:

(IF OUTPUTS)

a1 IF

b1 IF

a2 IF

b2 IF

3736B port labeled:

TO VNA EXTERNAL I/O

MN469xC port labeled:

IEEE 488.2 GPIB

MN469xC port labeled:

TO VNA b2 OUTPUT

MN469xC port labeled:

TO VNA b2 INPUT

MN469xC port labeled:

TO VNA Port 2 Src OUTPUT

MN469xC port labeled:

TO VNA Port 2 Src INPUT

MN469xC port labeled:

TO VNA b1 OUTPUT

MN469xC port labeled:

TO VNA b1 INPUT

MN469xC port labeled:

TO VNA Port 1 Src OUTPUT

QSG-4 PN: 10410-00770 Rev. B VectorStar ME7838D4 QSG

Page 5

2. Rear Panel Connections Between System Components (MS464xA VNA)

Table 1. ME7838D4 Multiport Rear Panel Cable Connections (2 of 2)

Index Part Number Cable Description Connection From Connection To

18 62112-80

SMA male-male

a

semi-rigid

MS464xA port labeled:

P1 source loop in

MN469xC port labeled:

TO VNA Port 1 Src INPUT

19 MS464xA VNA

20 MN469xC Test Set

21 3736B Test Set

22 3739C Test Set

a. Tighten each cable in this group using an 8 mm (5/16 in) torque end wrench set to 0.9 N·m (8 lbf·in).

VectorStar ME7838D4 QSG PN: 10410-00770 Rev. B QSG-5

Page 6

3. Rear Panel Connections Between Components (MS464xB VNA)

WARNING

No operator serviceable parts inside.

Refer servicing to

qualified personnel.

Ext

Alc

Out

Ext

Analog

In

a

1

b a

2

b

2

IF Outputs

External I/O

~ LINE INPUT

47-63 Hz

85-240 VAC

150 VA Max

Fuse 250V 2A T

CAUTION

Do not operate with

power cord ungrounded.

CAUTION

For continued fire protection

replace only with specified

type and rated fuse.

Cable Length

Standard

Extended

Module Interface

MN469xC

Test Set

3736B

Test Set

3739C

Test Set

MS464xB

VNA

3

11 151617

18

121314

19

20

21

22

5

6

6

6

6

7 7 7 7

7 7 7 7

8

8

9

9

Ext In ALC 1

and

Ext In ALC 2

(With Option 031)

Ext ALC 1

(With

Option 031)

1

1

2

2

2

2

4

Ext ALC 2

(With

Option 031)

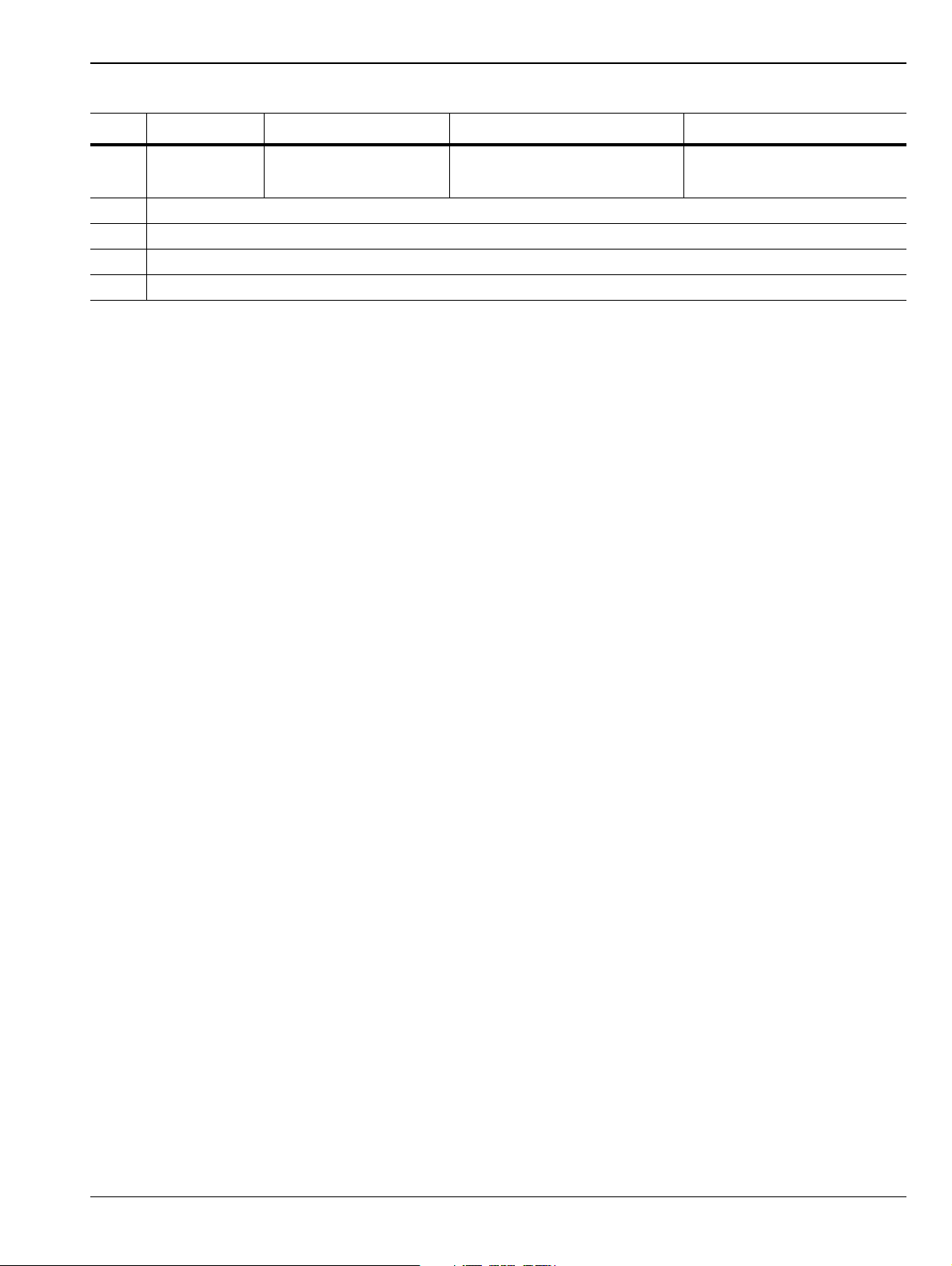

3. Rear Panel Connections Between Components (MS464xB VNA)

In this section, connect the cables between the VNA and the Test Sets as shown in Figure 2 or Figure 3, and

Table 2.

Cable Connections (Systems with Option 031 Dual Source Architecture)

Figure 2 ME7838D4 Multiport BB/mmW VNA System – Rear Panel Cables (With Option 031)

QSG-6 PN: 10410-00770 Rev. B VectorStar ME7838D4 QSG

Page 7

3. Rear Panel Connections Between Components (MS464xB VNA)

WARNING

No operator serviceable parts inside.

Refer servicing to

qualified personnel.

Ext

Alc

Out

Ext

Analog

In

a

1

b a

2

b

2

IF Outputs

External I/O

~ LINE INPUT

47-63 Hz

85-240 VAC

150 VA Max

Fuse 250V 2A T

CAUTION

Do not operate with

power cord ungrounded.

CAUTION

For continued fire protection

replace only with specified

type and rated fuse.

Cable Length

Standard

Extended

Module Interface

MN469xC

Test Set

3736B

Test Set

3739C

Test Set

MS464xB

VNA

3

11 151617

18

121314

19

20

21

22

5

6

6

6

6

7 7 7 7

7 7 7 7

8

8

9

9

1

1

2

2

4

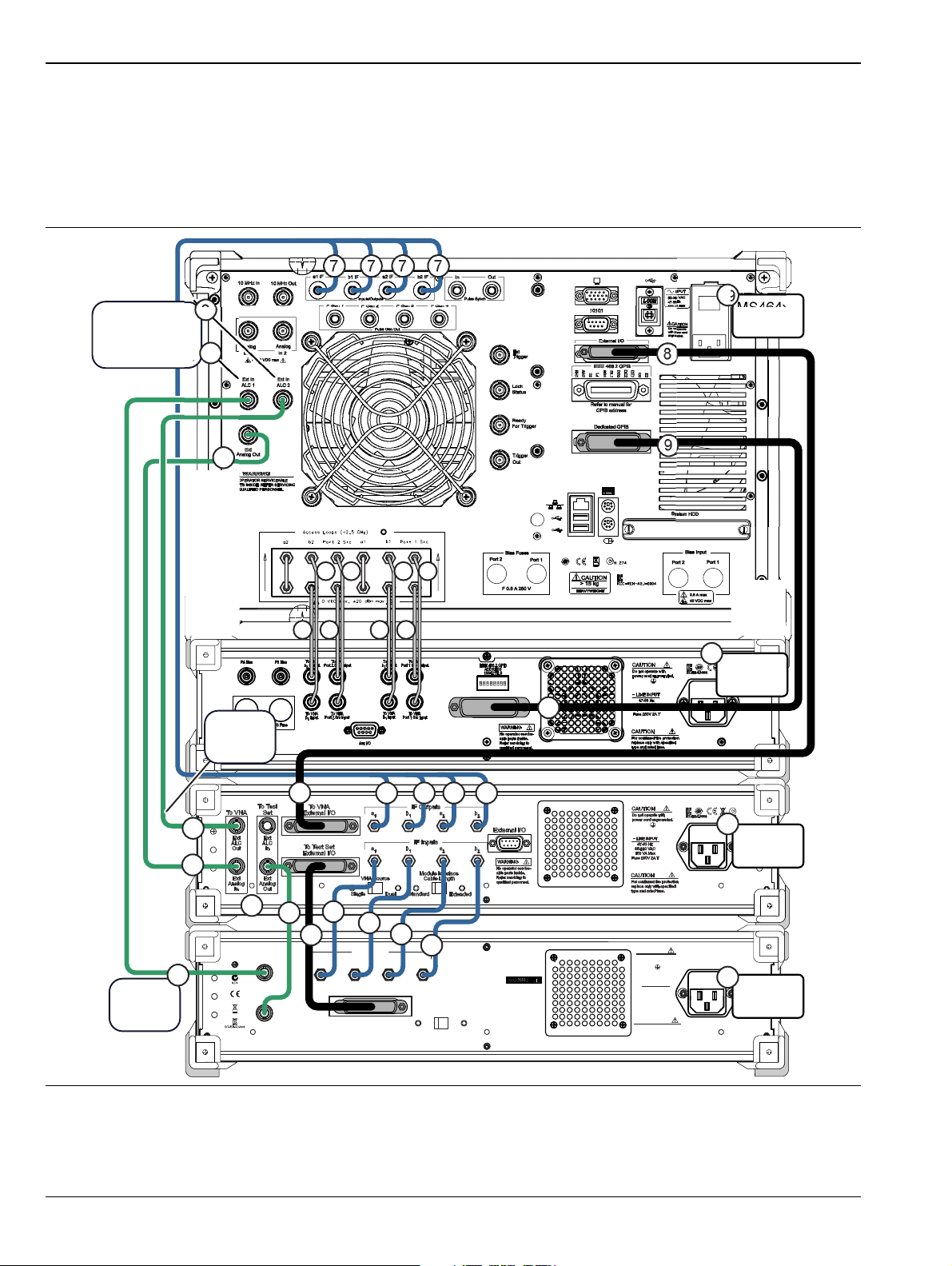

Cable Connections (Systems without Option 031)

Figure 3 ME7838D4 Multiport BB/mmW VNA System – Rear Panel Cables (No Option 031)

VectorStar ME7838D4 QSG PN: 10410-00770 Rev. B QSG-7

Page 8

3. Rear Panel Connections Between Components (MS464xB VNA)

Tab le 2. ME7838D4 Multiport Rear Panel Cable Connections (MS464xB) (1 of 2)

Index Part Number Cable Description Connection From Connection To

1

3-806-225 BNC (male-male), 24 in

3-806-225 BNC (male-male), 24 in

2

3-806-225 BNC (male-male), 24 in

3-806-225 BNC (male-male), 24 in

3

4

5

3-806-225 BNC (male-male), 24 in

3-806-225 BNC (male-male), 24 in

73598-1

(5 cable

6

7

bundle)

3-80734

(5 cable

bundle)

8

9

2100-1 GPIB, 1 m

11 62112-81

12 62112-80

13 62112-81

DB-25

SMA male-male flexible:

a

3-72243-1

3-72243-2

3-72243-3

3-72243-4

SMA male-male flexible:

3-72243-21

3-72243-22

a

3-72243-23

3-72243-24

DB-25

SMA male-male

a

semi-rigid

SMA male-male

a

semi-rigid

SMA male-male

a

semi-rigid

MS464xB port labeled:

Ext Analog Out

VNA port labeled:

Ext In ALC 1

(No Option 031) (Figure 3)

VNA port labeled:

Ext In ALC 1

(With Option 031) (Figure 2)

VNA port labeled:

Ext In ALC 2

(With Option 031) (Figure 2)

3736B port labeled:

(To Test Set) EXT ANALOG

OUT

3736B port labeled:

(To Test Set) EXT ALC IN

(Figure 3)

(Not used with Option 031)

3736B port labeled:

TO TEST SET EXTERNAL I/O

3736B ports labeled:

(IF INPUTS)

a1

b1

a2

b2

MS464xB ports labeled:

(Inputs/Outputs)

a1 IF

b1 IF

a2 IF

b2 IF

MS464xB port labeled:

External I/O

MS464xB port labeled:

Dedicated GPIB

MS464xB port labeled:

b2 loop out

MS464xB port labeled:

b2 loop in

MS464xB port labeled:

P2 source loop out

3736B port labeled:

EXT ANALOG IN

3736B port labeled:

EXT ALC OUT

3739C port labeled:

EXT ALC OUT

3736B port labeled:

EXT ALC OUT

3739C port labeled:

EXT ANALOG IN

3739C port labeled:

EXT ALC OUT

3739C port labeled:

EXTERNAL I/O

3739C ports labeled:

(IF OUTPUTS)

a1

b1

a2

b2

3736B ports labeled:

(IF OUTPUTS)

a1 IF

b1 IF

a2 IF

b2 IF

3736B port labeled:

TO VNA EXTERNAL I/O

MN469xC port labeled:

IEEE 488.2 GPIB

MN469xC port labeled:

TO VNA b2 OUTPUT

MN469xC port labeled:

TO VNA b2 INPUT

MN469xC port labeled:

TO VNA Port 2 Src OUTPUT

QSG-8 PN: 10410-00770 Rev. B VectorStar ME7838D4 QSG

Page 9

3. Rear Panel Connections Between Components (MS464xB VNA)

Table 2. ME7838D4 Multiport Rear Panel Cable Connections (MS464xB) (2 of 2)

Index Part Number Cable Description Connection From Connection To

14 62112-80

15 62112-81

16 62112-80

17 62112-81

18 62112-80

SMA male-male

a

semi-rigid

SMA male-male

a

semi-rigid

SMA male-male

a

semi-rigid

SMA male-male

a

semi-rigid

SMA male-male

a

semi-rigid

MS464xB port labeled:

P2 source loop in

MS464xB port labeled:

b1 loop out

MS464xB port labeled:

b1 loop in

MS464xB port labeled:

P1 source loop out

MS464xB port labeled:

P1 source loop in

MN469xC port labeled:

TO VNA Port 2 Src INPUT

MN469xC port labeled:

TO VNA b1 OUTPUT

MN469xC port labeled:

TO VNA b1 INPUT

MN469xC port labeled:

TO VNA Port 1 Src OUTPUT

MN469xC port labeled:

TO VNA Port 1 Src INPUT

19 MS464xB VNA

20 MN469xC Test Set

21 3736B Test Set

22 3739C Test Set

a. Tighten each cable in this group using an 8 mm (5/16 in) torque end wrench set to 0.9 N·m (8 lbf·in).

VectorStar ME7838D4 QSG PN: 10410-00770 Rev. B QSG-9

Page 10

4. Semi-rigid Cable Connections Between System Components

+27 dBm MAX AVOID STATIC DISCHARGE

ALL PORTS: CAUTION

Standby Operate

Frequency

Power

Sweep

Avg

Response

Display

Scale

Marker

Channel

Trace

Measurement

Calibration

Application

File

System

Help

Preset

RF

LO 2

Out

Out

In

In

1 1 1 1 1 1 1

7

8

9

10

2

3

4

5 5

3

1

Install Termination

Removed from

VNA RF1 or RF2

6

4. Semi-rigid Cable Connections Between System Components

Make the semi-rigid cable connections as shown in Figure 4 or Figure 5, and in Table 3.

If your system has Option 031 Dual Source Architecture (MS464xB only), use Figure 4. If your system does not

have Option 031, use Figure 5.

Figure 4 ME7838D4 Multiport Semi-rigid Cable Connections (with Option 031 Dual Source Architecture)

QSG-10 PN: 10410-00770 Rev. B VectorStar ME7838D4 QSG

Page 11

4. Semi-rigid Cable Connections Between System Components

+27 dBm MAX AVOID STATIC DISCHARGE

ALL PORTS: CAUTION

Standby Operate

Frequency

Power

Sweep

Avg

Response

Display

Scale

Marker

Channel

Trace

Measurement

Calibration

Application

File

System

Help

Preset

RF

LO 2

Out

Out

In

In

1 1 1 1 1 1 1

7

8

9

10

2

3

4

5 5

3

1

Figure 5 ME78383D4 Multiport Semi-rigid Cable Connections (No Option 031)

VectorStar ME7838D4 QSG PN: 10410-00770 Rev. B QSG-11

Page 12

4. Semi-rigid Cable Connections Between System Components

Tab le 3. ME7838D4 Multiport Semi-rigid Cable Interconnect Part Numbers and Locations (1 of 2)

Index Part Numbers Description/Torque Connection From Connection To

3-62109-42

V (m-m)

(MN4697C)

1

3-67357-38

K (m-m)

(MN4694C)

2

3

67357-230

67357-231

67357-232

(With Option

031)

4

67357-18

(No Option

031)

5 67357-19

6 V210

Front Panel RF Cable (4 each)

V or K male-male semi-rigid

Tighten using an 8 mm (5/16 in)

torque end wrench set to 0.9 N·m

(8 lbf·in).

Front Panel RF Cable

K male-male semi-rigid

Tighten using an 8 mm (5/16 in)

torque end wrench set to 0.9 N·m

(8 lbf·in).

Front Panel LO Cable (2 each)

K male-male semi-rigid

Tighten using an 8 mm (5/16 in)

torque end wrench set to 0.9 N·m

(8 lbf·in).

Front Panel RF Cable

K male-male semi-rigid

Tighten using an 8 mm (5/16 in)

torque end wrench set to 0.9 N·m

(8 lbf·in).

Front Panel LO Cable (2 each)

K male-male semi-rigid

Tighten using an 8 mm (5/16 in)

torque end wrench set to 0.9 N·m

(8 lbf·in).

Termination (With Option 031)

Tighten using an 8 mm (5/16 in)

torque end wrench set to 0.9 N·m

(8 lbf·in).

VNA port labeled:

b1 (In)

VNA port labeled:

b1 (Out)

VNA port labeled:

Port 1 Source (In)

VNA port labeled:

Port 1 Source (Out)

VNA port labeled:

Port 2 Source (In)

VNA port labeled:

Port 2 Source (Out)

VNA port labeled:

b2 (In)

VNA port labeled:

b2 (Out)

VNA port labeled:

RF 2 (Figure 4)

(With Option 031)

VNA port labeled:

RF (Figure 5)

(No Option 031)

VNA port labeled:

LO 1

VNA port labeled:

LO 2

VNA port labeled:

RF 1 (Figure 4)

(With Option 031)

3736B Test Set port

labeled:

RF Out (Figure 5)

(No Option 031)

3736B Test Set port

labeled:

LO 1 Out

3736B Test Set port

labeled:

LO 2 Out

Remove from VNA port

labeled:

RF 1 or RF 2

(With Option 031)

MN469xC port labeled:

b1 (In)

MN469xC port labeled:

b1 (Out)

MN469xC port labeled:

Port 1 Source (In)

MN469xC port labeled:

Port 1 Source (Out)

MN469xC port labeled:

Port 2 Source (In)

MN469xC port labeled:

Port 2 Source (Out)

MN469xC port labeled:

b2 (In)

MN469xC port labeled:

b2 (Out)

3736B Test Set port

labeled:

RF In

3736B Test Set port

labeled:

RF In

3736B Test Set port

labeled:

LO 1 In

3736B Test Set port

labeled:

LO 2 In

3739C Test Set port

labeled:

RF

3739C Test Set port

labeled:

RF

3739C Test Set port

labeled:

LO 1

3739C Test Set port

labeled:

LO 2

Add to 3736B Test Set

port labeled:

RF Out

QSG-12 PN: 10410-00770 Rev. B VectorStar ME7838D4 QSG

Page 13

4. Semi-rigid Cable Connections Between System Components

Table 3. ME7838D4 Multiport Semi-rigid Cable Interconnect Part Numbers and Locations (2 of 2)

Index Part Numbers Description/Torque Connection From Connection To

MS464xA VNA Option 051, 061, or 062, and 08x (Banded)

MS464xB VNA Option 051, 061, or 062, and 08x (Banded)

7

MS4647A VNA Option 051, 061, or 062, and 08x (Broadband)

MS4647B VNA Option 051, 061, or 062, and 08x (Broadband)

MN4694C

8

Test Set

MN4697C

Test Set

(Banded)

(Broadband)

9 3736B Test Set

10 3739C Test Set

VectorStar ME7838D4 QSG PN: 10410-00770 Rev. B QSG-13

Page 14

5. Front Panel Cable Connections

+27 dBm MAX AVOID STATIC DISCHARGE

ALL PORTS: CAUTION

RF

LO 2

Out

Out

In

In

Test Port 2

to Module SRC

(MA25300A only)

Test Port 4

to Module SRC

(MA25300A only)

Test Port 1

to Module SRC

(MA25300A only)

Test Port 3

to Module SRC

(MA25300A only)

Port 3

Module

Port 1

Module

Port 2

Module

Port 4

Module

Port 1

Port 4Port 3

Port 2

1

1

6

6

7

7

8

8

9

2

2

3

3

4

4

5

5

10

11

12

5. Front Panel Cable Connections

Make the cable connections as shown in Figure 6 and in Table 4.

Figure 6 Front Panel to mm-Wave Module Connections

QSG-14 PN: 10410-00770 Rev. B VectorStar ME7838D4 QSG

Page 15

5. Front Panel Cable Connections

Note

The cables for Test Port 1 through Test Port 4 to Module SRC are not used with mm-Wave modules

3744A-EE, 3744A-EW, or 3744A-Rx.

Table 4. ME7838D4 Cable Interconnect Part Numbers and Locations (1 of 2)

Index Part Number Description Connection From Connection To

Coaxial Cable (4 each)

1

2

3

4

5

6

7

8

5

6

7

8

5

6

7

8

806-209-R

75685-1

75685-2

75685-3

V male-female flexible, 36 in

Used with MA25300A Broadband Modules

a,b

only

Tighten at Test Set using an 8 mm (5/16 in)

torque end wrench set to 0.9 N·m

(8 lbf·in).

mm-Wave Module Interface Cables

(for MA25300A, 3743A, 3744A-EE,

3744A-EW modules)

a

Group of 5 cables for each port

Tighten at Test Set using an 8 mm

(5/16 in) torque end wrench set to 0.9 N·m

(8 lbf·in).

OML Module Interface Cables

Group of 4 cables for each port

Tighten at Test Set using an 8 mm

(5/16 in) torque end wrench set to 0.9 N·m

(8 lbf·in).

a

VDI Module Interface Cables

Group of 4 cables for each port

Tighten at Test Set using an 8 mm (5/16 in)

torque end wrench set to 0.9 N·m

(8 lbf·in).

mm-Wave Module Interface Cables

(for 3744A-Rx modules) Group of 3

cables for each port

a

Tighten at Test Set using an 8 mm

(5/16 in) torque end wrench set to 0.9 N·m

(8 lbf·in).

MN469xC port

labeled:

Port 1

Port 2

Port 3

Port 4

3739C Test Set:

Port 1, Port 2

RF, LO, Test, Ref,

Power/Signal

3736B Test Set

Port1, Port 2

(Port 3, Port 4)

RF, LO, Test, Ref,

Power/Signal

3739C Test Set

Port 1, Port 2

RF, LO, Test, Ref

3736B Test Set

Port1, Port 2

(Port 3, Port 4)

RF, LO, Test, Ref

3739C Test Set

Port 1, Port 2

RF, LO, Test, Ref

3736B Test Set

Port1, Port 2

(Port 3, Port 4)

RF, LO, Test, Ref

3739C Test Set

Port 1, Port 2

LO, Test,

Power/Signal

3736B Test Set

Port1, Port 2

(Port 3, Port 4)

LO, Test,

Power/Signal

MA25300A port

labeled:

(Port 1 Module) SRC

(Port 2 Module) SRC

(Port 3 Module) SRC

(Port 4 Module) SRC

mm-Wave Modules:

Port 1, Port 2 Modules

RF, LO, Test, Ref,

Power/Signal

mm-Wave Modules

Port 3, Port 4 Modules

RF, LO, Test, Ref,

Power/Signal

OML Modules

Port 1, Port 2 Modules

RF, LO, Test IF, Ref IF

OML Modules

Port 3, Port 4 Modules

RF, LO, Test IF, Ref IF

VDI Modules

Port 1, Port 2 Modules

RF Input, LO Input,

Meas. IF, Ref IF

VDI Modules

Port 3, Port 4 Modules

RF Input, LO Input,

Meas. IF, Ref IF

Rx Modules

Port 1, Port 2 Modules

LO, Test,

Power/Signal

Rx Modules

Port 3, Port 4 Modules

LO, Test,

Power/Signal

VectorStar ME7838D4 QSG PN: 10410-00770 Rev. B QSG-15

Page 16

5. Front Panel Cable Connections

Tab le 4. ME7838D4 Cable Interconnect Part Numbers and Locations (2 of 2)

Index Part Number Description Connection From Connection To

MS464xA VNA – Option 051, 061, or 062, and 08x (Banded)

MS464xB VNA – Option 051, 061, or 062, and 08x (Banded)

9

MS4647A VNA – Option 051, 061, or 062, and 08x (Broadband)

MS4647B VNA – Option 051, 061, or 062, and 08x (Broadband)

MN4694C Test Set (Banded)

10

MN4697C Test Set (Broadband)

11 3736B Test Set

12 3739C Test Set

a. Do not yet connect the cable ends to the Millimeter-Wave modules. Module connection instructions follow this section.

b. The 806-209-R Coaxial Cable is not included or required when using the 3744A-EE, 3744A-EW mm-Wave modules, or the

3744A-Rx Receiver Module.

QSG-16 PN: 10410-00770 Rev. B VectorStar ME7838D4 QSG

Page 17

6. Front Panel to Millimeter-Wave Module Connections

TEST

LO

Power/Signal

RF

REF

SRC

(Not used)

6

5

3744A-EE

3744A-EW

4

9

3

2

3743A

TEST

REF

SRC

RF

Power/Signal

1

3

LO

6

5

9

7

8

3743A

4

2

TEST

REF

SRC

LO

Power/Signal

RF

(Not used)

(Not used)

(Not used)

5

3743A-Rx

3

6

2

MA25300A

REF

4

2

RF

9

SRC

8

LO

6

TEST

3

Power/Signal

5

S/N

11

Port Assignment

10

6. Front Panel to Millimeter-Wave Module Connections

Connect the 3739C Broadband Test Set Port-1 and Port-2 cables to the MA25300A, 3743A, 3744A-EE,

3744A-EW, or 3744A-Rx Modules as shown below, observing the correct torque limits for each connector. See

Figure 7 and Table 5. Route the cable assemblies through the cable restraint.

For ease of connection, the module can be removed from the bracket, then reinstalled after cables

are secured. Observe torque instructions where indicated.

Each module (except the 3744A-Rx) is characterized for absolute power for a specific VNA Serial

Number and VNA Test Port as designated on the module port assignment label. Ensure the module

Note

matches the correct VNA and Test Set port.

If an alternative MA25300A or 3743 series mm-Wave module is used there will be approximately 1

dB of absolute power inaccuracy, which can be corrected by performing a power calibration.

For more detailed information on the modules including DUT Waveguide (WG) connection alignment

and custom bracket mounting, refer to 10410-00311-VectorStar

®

Broadband/Banded

Millimeter-Wave Modules Reference Manual.

Figure 7. Millimeter-Wave Module Connections

VectorStar ME7838D4 QSG PN: 10410-00770 Rev. B QSG-17

Page 18

6. Front Panel to Millimeter-Wave Module Connections

Tab le 5. Millimeter-Wave Module Connections

Cable P/N Index Description

N/A 1 Millimeter-Wave Module in bracket

0.8 mm Connector (MA25300A module)

• Tighten using a torque end wrench and a plain end wrench

• 6 mm Torque End Wrench set to 0.45 N·m (4 lbf·in). Recommended is Anritsu 01-524.

• 6 mm / 7 mm Open End Wrench. Recommended is Anritsu 01-525.

W1 - 1 mm Connector (3743A, 3744A-Rx modules)

DUT

Connector

• Tighten using a torque end wrench and a plain end wrench

• 6 mm Torque End Wrench set to 0.45 N·m (4 lbf·in). Recommended is Anritsu 01-504.

2

• 6 mm / 7 mm Open End Wrench. Recommended is Anritsu 01-505.

WR-10 or WR-12 to 1 mm connector (3744A-EE, 3744A-EW modules)

• Use Waveguide Adapter Toolkits (74394-2, 74394-3, or 74394-4).

• Tighten using a torque end wrench and a plain end wrench.

• 6 mm Torque End Wrench set to 0.45 N·m (4 lbf·in). Recommended is Anritsu 01-504.

• 6 mm / 7 mm Open End Wrench. Recommended is Anritsu 01-505.

TEST – SSMC Connector (Connected on all Modules)

3

• Tighten using a 4 mm (5/32 in) torque end wrench set to less than 0.17 N·m (1.5 lbf·in).

• Recommended is Anritsu 01-529-R torque wrench.

75685-1

or

75685-3

a

b,c

REF – SSMC Connector (Connected on all Modules except 3744A-Rx)

4

• Tighten using a 4 mm (5/32 in) torque end wrench set to less than 0.17 N·m (1.5 lbf·in).

• Recommended is Anritsu 01-529-R torque wrench.

5 Power/Signal Latching Bi-Lobe™ Connector (Connected on all modules)

LO – K Connector (Connected on all Modules)

6

• Tighten using an 8 mm (5/16 in) torque end wrench set to 0.9 N·m (8 lbf·in).

• Recommended is Anritsu 01-201.

7 Module Power and I/O Cable Restraint

SRC – V Connector (Connected on MA25300A and 3743A only)

8

• Tighten using an 8 mm (5/16 in) torque end wrench set to 0.9 N·m (8 lbf·in).

806-209-R

d

• Recommended is Anritsu 01-201.

RF – V Connector (Connected on all Modules except 3744A-Rx)

75685-1

a

9

• Tighten using an 8 mm (5/16 in) torque end wrench set to 0.9 N·m (8 lbf·in).

• Recommended is Anritsu 01-201.

N/A 10 Factory Calibrated Port Assignment Label

N/A 11 Module Serial Number Label

a. Cable assembly 75685-1 is used on MA25300A, 3743A, 3744A-EE, and 3744A-EW modules.

b. The REF cable is not used in the 75685-3 cable assembly.

c. Cable assembly 75685-3 is used on the 3744A-Rx module.

d. The 806-209-R Coaxial Cables are used only with the MA25300A and 3743A modules.

Inverting a Module

If necessary, a module can be turned over in the bracket to change the height of the DUT connector. To turn

the module over:

1. Remove the six Knurled Head Thumbscrews M2 × 8 mm (four M3 x 8 mm on the MA25300A).

2. Turn the module over

3. Install the cable assembly then install the module into the bracket.

4. Install the thumbscrews.

QSG-18 PN: 10410-00770 Rev. B VectorStar ME7838D4 QSG

Page 19

6. Front Panel to Millimeter-Wave Module Connections

Millimeter-Wave Module Operating Environment

The modules require use of heatsink with adequate air circulation. The following notes should be considered

before operating the MA25300A, 3743x, 3744x-xx, and 3743x-Rx Millimeter-Wave Modules:

• Thermal heat sinking similar to the supplied mounting brackets of the Millimeter-Wave Module should

be considered in custom mounting applications.

• Each MA25300A Module consumes a maximum of 12 watts.

• Each 3743x Module consumes a maximum of 12 watts.

• Each 3744x-EE and 3744x-EW Module consumes a maximum of 12 watts.

• Each 3744x-Rx Module consumes a maximum of 7 watts.

• The primary heat sinking path for the module is on the two external side surfaces used to mount to the

support brackets.

• With the attached cable mounting brackets, the case temperature rise is approximately 15 °C to 20 °C

above ambient.

VectorStar ME7838D4 QSG PN: 10410-00770 Rev. B QSG-19

Page 20

7. Front Panel to OML/VDI Module Connections

+27 dBm MAX AVOID STATIC DISCHARGE

ALL PORTS: CAUTION

RF

LO 2

Out

Out

In

In

Port 3

Module

Port 1

Module

Port 2

Module

Port 4

Module

Port 1

Port 4Port 3

Port 2

Port 2 RF, LO, Test, Ref

to OML/VDI Module

Port 1 RF, LO, Test, Ref

to OML/VDI Module

Port 3 RF, LO, Test, Ref

to OML/VDI Module

Port 4 RF, LO, Test, Ref

to OML/VDI Module

1

2

3 4

5

6

7

7. Front Panel to OML/VDI Module Connections

Connect the front panel cables between the 3736B and 3739C Test Sets, and the OML or VDI frequency

extension modules as shown in Figure 8, Figure 9, and Figure 10, and as described in Table 6, Table 7, and

Table 8.

Caution To avoid connector damage, observe torque requirements where indicated.

Figure 8 Cable Connections between 3736B, 3739C Test Sets, and OML or VDI Frequency Extension Modules

QSG-20 PN: 10410-00770 Rev. B VectorStar ME7838D4 QSG

Page 21

7. Front Panel to OML/VDI Module Connections

Table 6. ME7838D4 OML/VDI Cable Interconnect Part Numbers and Locations

Index Part Number Description Connection From Connection To

3739C Test Set

Port 1, Port 2

1

OML Module Interface Cable Assembly

Group of 4 cables for each port

Ref

RF

LO

75685-2

(2 each)

Tes t

3736B Test Set

Port 1, Port 2

OML Modules:

Port 1, Port 2 Modules

Ref IF

RF Input

LO Input

Tes t IF

OML Modules:

Port 3, Port 4 Modules

(Port 3, Port 4)

2

OML Module Interface Cable Assembly

Group of 4 cables for each port

Ref

RF

LO

Tes t

3739C Test Set

Port 1, Port 2

3

VDI Module Interface Cables Assembly

Group of 4 cables for each port

RF

Ref

Tes t

75685-2

(2 each)

LO

3736B Test Set

Port 1, Port 2

Ref IF

RF Input

LO Input

Tes t IF

VDI Modules:

Port 1, Port 2 Modules

RF Input

Ref. IF

Meas. IF

LO Input

VDI Modules:

Port 3, Port 4 Modules

(Port 3, Port 4)

4

VDI Module Interface Cables Assembly

Group of 4 cables for each port

RF

Ref

RF Input

Ref. IF

Tes t

LO

Meas. IF

LO Input

5 MN469xC Test Set

6 3736B Test Set

7 3739C Test Set

VectorStar ME7838D4 QSG PN: 10410-00770 Rev. B QSG-21

Page 22

7. Front Panel to OML/VDI Module Connections

Ref IF RF Input DC Power LO Input Test IF Ref IF RF Input DC Power LO Input Test IF

From ME7838 - 3739C

Test Set Port 1, Port 2

LO

OML Power Supply

TestRef RF

From ME7838 - 3736B

Test Set Port 3, Port 4

LO TestRef RF

OML

Frequency Extension

Modules

(Typical)

1

2

3

4

6

5

OML Power Supply

Figure 9 VNA/ Test Set Cable Connections to OML Modules

Tab le 7. OML Module Connections

Index Cable P/N Description

1 N/A OML Module

Ref IF – SMA Connector

2

• Tighten using an 8 mm (5/16 in) torque end wrench set to 0.9 N·m (8 lbf·in).

• Recommended is Anritsu 01-201.

RF Input – SMA Connector

3

4

75685-2

5

6 N/A OML Module Power Supply Connector

• Tighten using an 8 mm (5/16 in) torque end wrench set to 0.9 N·m (8 lbf·in).

• Recommended is Anritsu 01-201.

LO Input – SMA Connector

• Tighten using an 8 mm (5/16 in) torque end wrench set to 0.9 N·m (8 lbf·in).

• Recommended is Anritsu 01-201.

Tes t IF – SMA Connector

• Tighten using an 8 mm (5/16 in) torque end wrench set to 0.9 N·m (8 lbf·in).

• Recommended is Anritsu 01-201.

QSG-22 PN: 10410-00770 Rev. B VectorStar ME7838D4 QSG

Page 23

7. Front Panel to OML/VDI Module Connections

Ref. IFRF Input LO InputPower Meas. IF Ref. IFRF Input LO InputPower Meas. IF

From ME7838 - 3739C

Test Set Port 1, Port 2

LO

VDI Power Supply

Test

RefRF

From ME7838 - 3736B

Test Set Port 3, Port 4

VDI

VNA Extender

Modules

(Typical)

LO

VDI Power Supply

Test

RefRF

1

2

3

4

6

5

Figure 10 VNA/ Test Set Cable Connections to VDI Modules

Table 8. VDI Module Connections

Index Cable P/N Description

1 N/A VDI Module

RF Input – K (2.92 mm) Connector

2

• Tighten using an 8 mm (5/16 in) torque end wrench set to 0.9 N·m (8 lbf·in).

• Recommended is Anritsu 01-201.

Ref. IF – SMA Connector

3

75685-2

• Tighten using an 8 mm (5/16 in) torque end wrench set to 0.9 N·m (8 lbf·in).

• Recommended is Anritsu 01-201.

Meas. IF – SMA Connector

4

5

a

6

a.The VDI module connectors may differ slightly than on the illustration shown above. For example, depending on the model and

date built, the power supply connector may be round instead of rectangular.

• Tighten using an 8 mm (5/16 in) torque end wrench set to 0.9 N·m (8 lbf·in).

• Recommended is Anritsu 01-201.

LO Input- K (2.92 mm) Connector

• Tighten using an 8 mm (5/16 in) torque end wrench set to 0.9 N·m (8 lbf·in).

• Recommended is Anritsu 01-201.

VDI Module Power Supply Connector

VectorStar ME7838D4 QSG PN: 10410-00770 Rev. B QSG-23

Page 24

7. Front Panel to OML/VDI Module Connections

QSG-24 PN: 10410-00770 Rev. B VectorStar ME7838D4 QSG

Page 25

Page 26

Anritsu utilizes recycled paper and environmentally conscious inks and toner.

Anritsu Company

Morgan Hill, CA 95037-2809

490 Jarvis Drive

USA

Loading...

Loading...