Page 1

50 High Frequency Electronics

High Frequency Design

HIGH-Q RESONATORS

C

eramic coaxial resonators have

become an everyday sight in

engineering development laboratories and manufacturing production lines. These components use the

size-reducing effects of high diectric

constant ceramic materials to make

the smallest possible resonators for

VCOs and filters operating from VHF

to microwave frequencies.

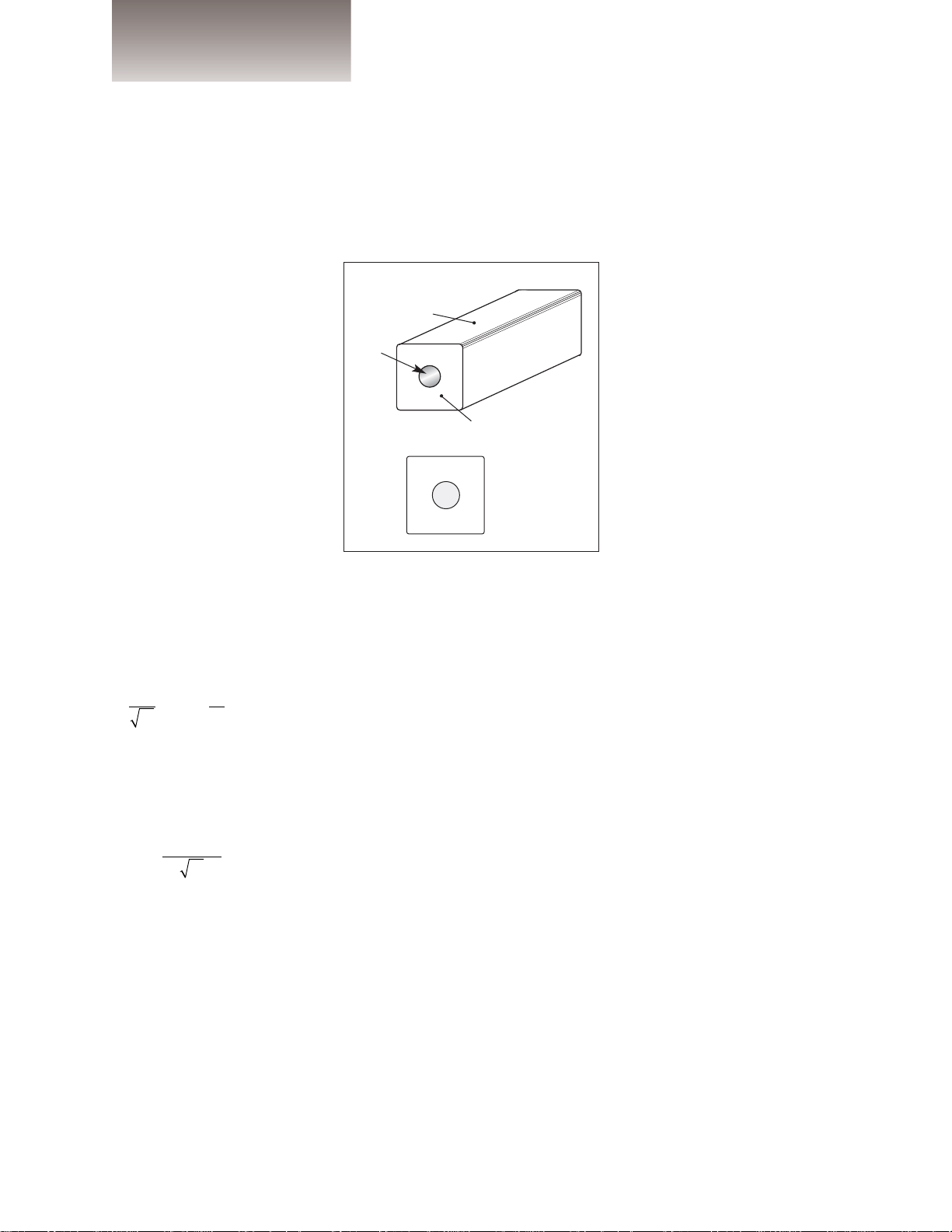

Figure 1 shows the typical construction of a commercially available

ceramic resonator. The configuration

is coaxial, with an approximately

square cross-section outer conductor

and a round (cylindrical) center conductor. Physical dimensions for a particular coaxial element are W, d and

l. Together with the dielectric constant of the ceramic material, ε

r

, the

approximate coaxial line characteristic impedance can be calculated by:

Commonly-used products typically

have Z

0

in the range of 5 to 15 ohms.

The electrical length of a coaxial

line is affected by ε

r

as follows:

Since the ceramics used in these

coaxial elements have ε

r

from 10 to

more than 100, so we can see from

the above equation that the electrical

length can be reduced by a factor of

ten or more from the free space

length. For example, a 300 MHz 1/4wavelength line section with ε

r

of 90

has a length of 1.037 in. (26.3 mm),

compared to a free space length of

9.84 in. (250 mm).

The typical resonator consists of a

shorted λ/4 line section, although an

open-circuit λ/2 line may be used for

some applications. Typically, a ceramic coaxial element can be obtained in

a specified length, with one end plated to “short-circuit” the center conductor to the outer conductor.

Resonator Q can vary significantly with different materials, frequencies and size, but will have a value in

the hundreds (~150 to 500).

Tuning the Resonator

For VCO applications the resonator must be tuned over a significant frequency range. The simplest

method for doing this is to select a

coaxial element with a self-resonant

frequency (SRF) that is 20 to 30 percent higher than the operating frequency, where it will present an

inductive reactance. Parallel capacitance (e.g. a varactor tuning diode)

can then be added to obtain resonance at the desired frequency.

The inductive reactance of a coaxial line can be approximated using:

where Z

0

is the characteristic

impedance of the line, and Θ is its

electrical length in radians. (Θ =

2πl/λ

eff

, where λ

eff

is the wavelength

in the dielectric at the operating frequency.)

This value of inductance (actually,

a range of values, since it varies with

frequency), can be used to design the

desired VCO circuit.

Tuning of resonators for filters

does not necessarily mean production

line tweaking. Often, resonators are

tuned with fixed capacitors to compensate for the shift in resonance due

to different coupling coefficients

between filter sections. This enables

a single resonator type to be used in

a typical “stagger-tuned” filter.

Cautions and Caveats

There are physical limitations in

the ceramic resonator manufacturing

processes. Each manufacturer will

have a recommended range of SRF

for each product, which is governed

by practical lengths for each crosssection profile. Consult with the supplier if you want a resonator at the

limits of the recommended sizes.

High reactance values can be

obtained close to resonance. If such

use is considered, examine such factors as temperature stability (of the

resonator and the surrounding circuitry) and manufacturing tolerances

from piece-to-piece and lot-to-lot.

Finally, remember all the stray

and parasitic reactances and resistances: the effect of plating on the

shorted end, the inductance of the

inner conductor connecting tab, and

the effects due to the PC board

mounting method and proximity to

adjacent components.

()

Basic Data on High-Q

Ceramic Coaxial Resonators

Conductors silver-plated on

ceramic body:

Outer

Inner

(hollow)

Ceramic dielectric

Figure 1 · Construction of a ceramic coaxial resonator and its physical dimensions.

W d l = length

From November 2002 High Frequency Electronics

Copyright © 2002, Summit Technical Media, LLC

108=

λ

freespace

ε

W

d

r

60

Z

0

λ

effective

ln .

ε

r

=

XZ

=

tan Θ

L

0

Loading...

Loading...