Angelantoni Industrie POLAR 180 SH, POLAR 370 H, POLAR 550 SH, POLAR 110 H, POLAR 110 SH Service manual [en, it]

...

Angelantoni Industrie S.p.A.

06056 Massa Martana (Pg) Italy

Tel. (++39) 075

.

8955.1 (a.r.)

Fax (++39) 075

.

8955200

Internet: www.angelantoni.it

E-Mail:info@angelantoni.it

Installation, use and maintenance handbook

FREEZERS

Cod. 513005 - Rel. 080503

POLAR 110 H / POLAR 110 SH

POLAR 180 H / POLAR 180 SH

POLAR 370 H / POLAR 370 SH

POLAR 340 V / POLAR 340 SV

POLAR 530 V / POLAR 530 SV

POLAR 550 H / POLAR 550 SH

PO1207-F01

PO1207-F17

nato aqap110

iso 9001

iso 14001

AVVERTENZA IMPORTANTE

I prodotti realizzati dal costruttore sono caratterizzati da un elevato contenuto tecnologico che talvolta richiede

un adattamento tecnico di parti o componenti altrimenti reperibili sul mercato nella loro versione standard

commerciale. Pertanto, la sostituzione di parti o componenti con altri non originali, ossia non forniti e garantiti

direttamente dal COSTRUTTORE, nonché l’accertamento di interventi tecnici effettuati da personale non autorizzato,

comporteranno l’immediata cessazione della garanzia, se in essere, e comunque di qualsiasi responsabilità nei

confronti dell’acquirente e di terzi, da parte del COSTRUTTORE stesso.

IMPORTANT WARNING

The high level of technology of the products made by the manufacturer occasionally requires components to be

adapted from parts normally found on the market in their standard commercial version. Therefore, if it should be

ascertained that any parts have been replaced with other components that are not original, i.e. that have not

been supplied and guaranteed directly by the MANUFACTURER, or that any unauthorised technical interventions

have been carried out, the guarantee, if any is in force, shall be considered no longer valid and the MANUFACTURER

himself shall no longer be held responsible towards the purchaser and towards third parties.

AVVERTISSEMENT IMPORTANT

Les produits réalisés par le constructeur sont caractérisés par un haut niveau technologique qui demande parfois

une adaptation technique de parties ou de composants autrement disponibles sur le marché dans leur version

commerciale standard. Pour cette raison, la substitution de parties ou composants par d’autres non originaux,

c’est à dire non fournis et garantis directement par le CONSTRUCTEUR, ou bien la constatation que du personnel

non autorisé a effectué des interventions techniques; auront pour conséquence l’immédiate cessation de la garantie

en cours et de toute façon de toutes responsabilités du CONSTRUCTEUR vis à vis de l’acheteur ou de tierces

parties.

WICHTIGE WARNUNG

Das hohe technische Niveau der Produkte des Herstellers erfordert teilweise Komponenten, die verändert

werden müssen gegenüber handelsüblichen Produkten␣ ; wie sie am Markt zu finden sind.

Beim Austausch von Teilen oder Komponenten; die nicht dem Orginal entsprechen, das heißt nicht direkt vom

HERSTELLER geliefert und garantiert wurden, bzw. daß technische Veränderungen durch nicht autorisiertes

Personal vorgenommen wurde, gilt die Garantie, falls noch in Kraft, als erloschen und der HERSTELLER kann

nicht mehr länger haftbar gemacht werden gegenüber dem Käufer und Dritten.

AVISO IMPORTANTE

Los productos elaborados por el fabricante se caracterizan por un alto nivel tecnológico y ocasionalmente

requieren adaptaciones técnicas de partes o componentes que normalmente se encuentran en el mercado en

su versión comercial estándar.

Por tanto, la sustitución de partes o componentes, por otros que no sean originales, es decir no suministrados

y garantizados por el FABRICANTE, o bien se constata la intervención técnica por de personal no autorizado,

supondrá el cese inmediato de la garantía, si está en vigor, así como de cualquier otra responsabilidad del

FABRICANTE de cara tanto al comprador como a terceras personas.

464 Località Cimacolle

06056 Massa Martana (Pg) Italy

DICHIARAZIONE DI CONFORMITÀ

DECLARATION OF CONFORMITY

L’amministratore delegato

Managing Director

Gianluigi Angelantoni

La macchina è conforme ai dettami delle seguenti

Direttive CEE:

• Direttiva Macchine n° 98/37, successive modifiche

e DPR 459/96.

• Direttiva Bassa Tensione n° 73/23 e successive

modifiche.

• Direttiva Compatibilità Elettromagnetica n° 89/336

e successive modifiche.

In particolare soddisfa le seguenti Norme

Armonizzate:

• EN 292-1 Sicurezza del macchinario - Concetti

fondamentali, principi generali di progettazione -

Parte 1: Terminologia, metodologia di base. 1991.

• EN 292-2 Sicurezza del macchinario - Concetti

fondamentali, principi generali di progettazione -

Parte 2: Specifiche e principi tecnici. 1991.

• EN 294 Sicurezza del macchinario - Distanza di

sicurezza per impedire il raggiungimento di zone

pericolose con gli arti superiori. 1992

• EN 61326-1 Apparecchi elettrici di misura, control-

lo e laboratori. Prescrizioni di compatibilità elettro-

magnetica. - Parte 1: Prescrizioni generali e suc-

cessive modifiche.

• EN 61010-1 Prescrizioni di sicurezza per apparec-

chi elettrici di misura, controllo e per utilizzo in

laboratorio - Parte 1: Prescrizioni generali.

Denominazione prodotto:POLAR

Product Name

Ordine / Serie N.

Order/series N

°

Data

Date

Costruttore

Manufacturer

Mandatario

Agent

The machine complies with the regulations in the

following EEC Directives:

• Machinery Directive n

°

98/37, subsequent modi-

fications and DPR 459/96.

• Low Voltage Directive n

°

73/23 and subsequent

modifications.

• Electromagnetic Compatibility Directive n

°

89/336

and subsequent modifications.

In particular it complies with the following

Standardized Norms:

• EN292-1 Safety of machinery - Fundamental con-

cepts, general principles for design - Part 1: Termi-

nology, basic methodology, 1991.

• EN292-2 Safety of machinery - Fundamental con-

cepts, general principles for design - Part 2: Tech-

nical specifications and principles. 1991.

• EN294 Safety of machinery - Safety distance to

prevent upper limbs coming into contact with dan-

gerous areas. 1992.

• EN61326-1 - Electrical equipment for measure-

ment, control and laboratory use EMC requirements

- Part. 1 - General requirements.

• EN61010-1 Safety instructions for electrical appa-

ratus to measure, and control and for laboratory

use - Part 1: General instructions.

464 Località Cimacolle

06056 Massa Martana (Pg) Italy

DICHIARAZIONE DI CONFORMITÀ

DECLARATION OF CONFORMITY

ANGELANTONI INDUSTRIE S.p.A.

Nome (Stampatello) -

Printed name

Il Responsabile Qualità -

Quality Manager

Dott.ssa -

Miss

Gabriella Parodi

Si certifica che la totalità delle forniture sopraelencate

è conforme in ogni parte alle specifiche, ai disegni e

all’ordine cui si riferiscono e che le forniture sono state

verificate e provate in conformità con le condizioni ed

i requisiti dell’ordine e in particolare alla Direttiva 93/

42.

Modello:POLAR

Type

Matricola

Serial number

Data

Date

Da (Fornitore)

From (Supplier)

We certify that all the supplies mentioned in this do-

cument comply in any detail with the specifications, with

the drawings and with the purchase order refer to.

We also certify that the supplies have been checked and

tested according to the order conditions and requirements

and particularly to 93/42 law.

ANGELANTONI INDUSTRIE S.p.A.

Loc. Cimacolle

06056 Massa Martana (Pg) - Italia

Firma (Fornitore)

Signature (Supplier)

3

513005 POLAR

SUMMARY

1SUMMARY OF RATING PLATE DATA ....................................................................................................................................................... 4

2WARNINGS................................................................................................................................................................................................. 4

2.1 GENERAL WARNINGS ...................................................................................................................................................................... 4

2.2 WARNINGS FOR TRANSPORT AND HANDLING ............................................................................................................................ 5

2.3 WARNINGS FOR INSTALLATION ...................................................................................................................................................... 5

2.4 WARNINGS FOR PERSONNEL IN CHARGE OF THE MACHINE .................................................................................................... 5

2.5 WARNINGS FOR MAINTENANCE .................................................................................................................................................... 5

2.6 EXPLANATION OF SYMBOLS........................................................................................................................................................... 5

3 TECHNICAL SPECIFICATIONS................................................................................................................................................................. 6

3.1 TECHNICAL DATA.............................................................................................................................................................................. 6

3.2 FUSES................................................................................................................................................................................................ 7

3.3 ENVIRONMENTAL CONDITIONS...................................................................................................................................................... 7

3.4 TECHNICAL LAY-OUT DIAGRAMS.................................................................................................................................................... 8

4 HANDLING AND REMOVAL OF PACKAGING .......................................................................................................................................... 9

4.1 PERSONNEL REQUISITES............................................................................................................................................................... 9

4.2 MACHINE CONDITIONS.................................................................................................................................................................... 9

4.3 EQUIPMENT NEEDED FOR HANDLING .......................................................................................................................................... 9

4.4 REMOVAL OF PACKAGING............................................................................................................................................................. 11

4.4.1 How to remove the outer straps.............................................................................................................................................. 11

4.4.2 How to remove the cardboard casing..................................................................................................................................... 11

4.4.3 Removal of plastic materials................................................................................................................................................... 11

4.4.4 How to remove the wooden side blocks ................................................................................................................................. 11

4.4.5 How to remove the pallet........................................................................................................................................................ 12

4.5 HOW TO BLOCK THE MACHINE..................................................................................................................................................... 12

5DESCRIPTION OF THE SYSTEM ............................................................................................................................................................ 13

5.1 GENERAL VIEW ................................................................................................................................................................................. 13

5.2 INTERNAL VIEW .............................................................................................................................................................................. 14

5.3 DESCRIPTION OF EXTERNAL CONNECTIONS............................................................................................................................ 15

5.4 CONTROL SYSTEM ........................................................................................................................................................................ 17

5.5 COOLING SYSTEM ......................................................................................................................................................................... 18

5.5.1 CONTROL PANEL - description of the keys........................................................................................................................... 17

5.6 FUNCTIONING OF THE COOLING SYSTEM ................................................................................................................................. 18

5.7 FUNCTIONING OF THE auxiliary CO2 COOLING SYSTEM........................................................................................................... 18

5.8 INSULATION..................................................................................................................................................................................... 18

6INSTALLATION ......................................................................................................................................................................................... 19

6.1 POSITIONING OF THE MACHINE ................................................................................................................................................... 19

6.2 HOW TO CONNECT THE CO2 CYLINDERS................................................................................................................................... 19

6.2.1 HOW TO REPLACE THE CYLINDER .................................................................................................................................... 20

6.3 ELECTRICAL WIRING ..................................................................................................................................................................... 21

6.3.1 How to connect to the electrical mains supply........................................................................................................................ 21

6.3.2 Replacement of the supply cable ........................................................................................................................................... 21

6.3.3 Remote alarm ......................................................................................................................................................................... 22

6.4 Water condenser connection ............................................................................................................................................................ 22

7USE FORESEEN BY THE MANUFACTURER.......................................................................................................................................... 23

7.1 AIM OF THE MACHINES ................................................................................................................................................................. 23

7.2 INTENDED USE OF THE MACHINES ............................................................................................................................................. 23

7.3 OPERATOR ...................................................................................................................................................................................... 23

7.4 USE LIMITS...................................................................................................................................................................................... 23

7.5 USE OF PROTECTIVE CLOTHING ................................................................................................................................................. 23

7.6 DANGEROUS AREAS AND WASTE RISKS.................................................................................................................................... 23

8START-UP ................................................................................................................................................................................................ 24

8.1 DESCRIPTION OF THE CONTROL PANEL .................................................................................................................................... 24

8.2 START UP ........................................................................................................................................................................................ 25

8.3 REGULATION OF THE OPERATING TEMPERATURE ................................................................................................................... 25

8.4 CO2 ALARM SYSTEM ON/OFF....................................................................................................................................................... 26

8.5 REGULATION OF THE ALARM/CO2 SYSTEM TEMPERATURE LIMIT ......................................................................................... 26

8.6 OTHER FUNCTIONS OF CONTROL PANEL .................................................................................................................................. 26

8.6.1 Alarm signals .......................................................................................................................................................................... 26

9 USE ................................................................................................................................................................................................ 27

9.1 HOW TO INSTALL THE DRAWERS (only for vertical models)........................................................................................................ 27

9.2 HOW TO INSTALL THE SHELVES (only for vertical models) ........................................................................................................... 28

9.3 PRODUCT LOADING....................................................................................................................................................................... 28

9.4 TEMPERATURE CHART RECORDER ............................................................................................................................................ 29

9.4.1 Use of the recorder................................................................................................................................................................. 29

10 SAFETY DEVICES - CHECK AND SET-UP ............................................................................................................................................. 31

11 MAINTENANCE ........................................................................................................................................................................................ 31

11.1 ALARM SYSTEM AND AUXILIARY CO2 COOLING SYSTEM CONTROL ..................................................................................... 31

11.2 DEFROSTING AND CLEANING OF THE STRUCTURE ................................................................................................................. 31

11.3 CLEANING OF GASKETS ............................................................................................................................................................... 31

11.4 CLEANING OF THE CONDENSER ................................................................................................................................................. 32

11.4.1 Cleaning of the water condenser .......................................................................................................................................... 32

11.5 SERVICING OF THE COOLING SYSTEM....................................................................................................................................... 32

11.6 SERVICING OF THE ELECTRIC-ELECTRONIC SECTION............................................................................................................ 32

12 TROUBLESHOOTING .............................................................................................................................................................................. 33

13 REMOVAL FROM INSTALLATION SITE .................................................................................................................................................. 34

13.1 DISASSEMBLY ................................................................................................................................................................................. 34

13.2 SCRAPPING..................................................................................................................................................................................... 34

14 DIAGRAMS ............................................................................................................................................................................................... 35

14.1 REFRIGERATOR DRAWING............................................................................................................................................................ 35

14.2 ELECTRIC DRAWING...................................................................................................................................................................... 37

4

513005 POLAR

MASSA MARTANA - PG -

BIOMEDICAL

DIVISION

TYPE

SERIAL N. GAS

POWER SUPPLY

VHzPH

TYPE

CLASS

V

OUTPUT SERVICE POWER SUPPLY

Hz PH

A

IP

A

°C

Phase

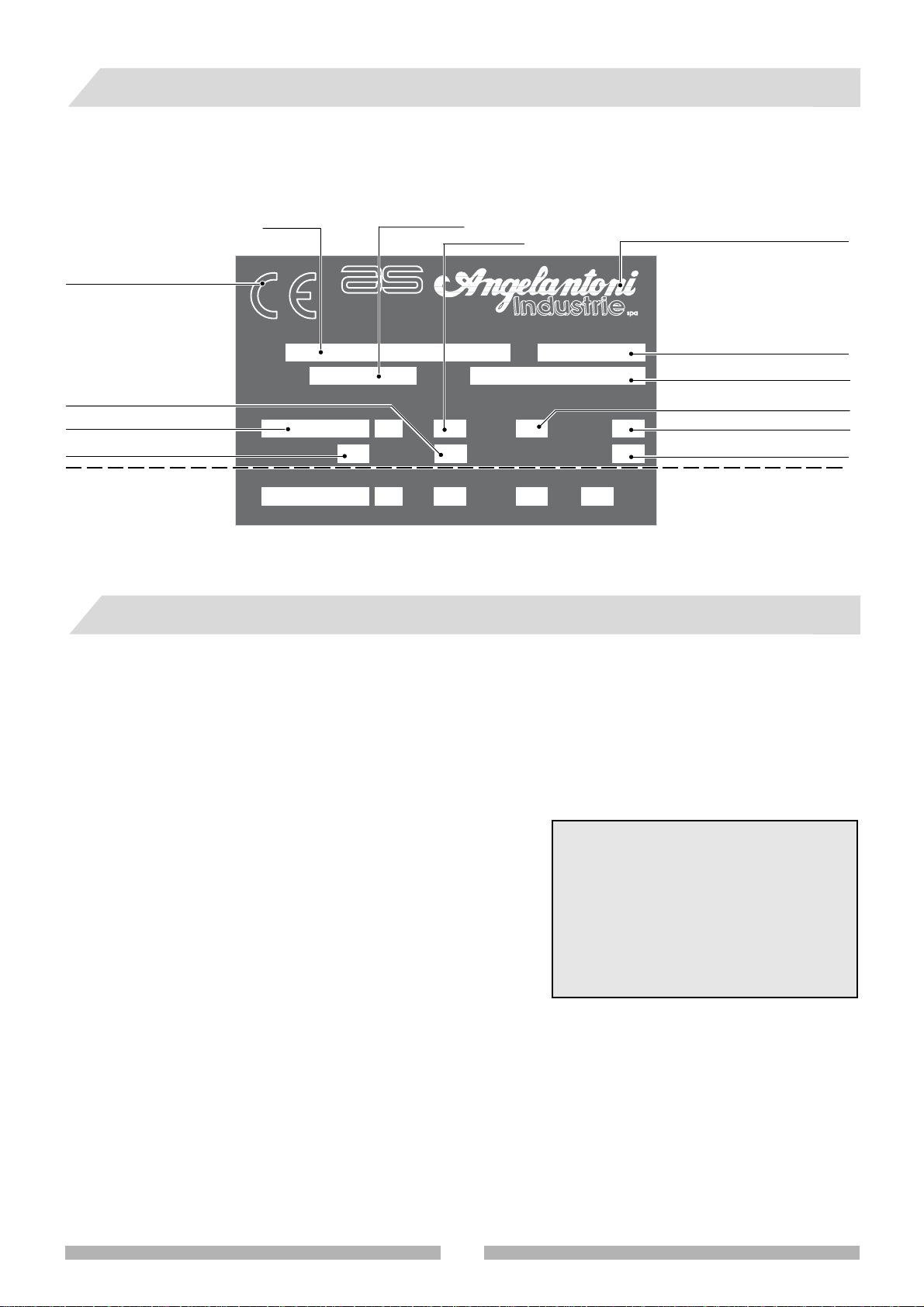

•Find the special rating plate on the machine in order to check the technical data.

• Check the machine model and supply voltage before carrying out any operation whatsoever.

• If you find any discrepancies, contact the manufacturer or your supplier immediately.

EC compliancy mark

Supply voltage

Model

Electrical absorption

Manufacturer’s address

Frequency

Refrigerant type

1 SUMMARY OF RATING PLATE DATA

2.1 GENERAL WARNINGS

• Do not carry out any operations or manoeuvres unless you are absolutely certain of their effect; if in doubt, contact

your nearest technical assistance service or the manufacturer himself.

• The manufacturer will not be held responsible for damage to the machine or to objects in the following cases:

-improper use of the machine

- use of unsuitable personnel

-incorrect assembly and installation

- defects in the plant systems

- unauthorized modifications or operations to the machine

- use of spare parts that are not original pieces

-failure to comply with the norms given in this handbook

- exceptional events

• This instruction handbook has been designed for the following

personnel:

- Personnel in charge of transport, handling and removal of pack-

aging

- Personnel in charge of the preparation of the plant systems and

installation site

-Installers

- Personnel in charge of using the machine

- Personnel in charge of maintenance

• The instruction handbook indicates the use foreseen by the manufacturer and cannot ever replace adequate

experience of the operator. It can only be used as a reminder of the main operations to be carried out.

• The instruction handbook should be kept carefully and should also be within easy reach for reference. If necessary,

photocopy the pages concerned directly with machine use. The handbook should last at least the life-time of the

machine itself.

• The instruction handbook gives technical information on how the machine is manufactured at the present time; the

manufacturer reserves the right to carry out any modifications he deems necessary to the machines and to the

instruction handbooks, without prior notice or replacement.

2WARNINGS

This machine is not referred to in enclosure IV of the

community norm on machines, and therefore the proce-

dure in article 8, paragraph 2, letter A in the Community

norms for machines 89/392/CEE and 91/368/EEC has

been applied. Article 8, paragraph 2, letter A of the

Community norms for machines 89/392/CEE and 91/

368/EEC obliges the manufacturer to provide the file

foreseen by the enclosure of the afore-mentioned laws,

and to store it in the technical archives of the company

Angelantoni Industrie spa, località Cimacolle, Massa

Martana, Perugia.

Temperature

Electrical protection grade

Series N°

Isolation class

Type (not used)

Data present only if the

appliance is equipped with

internal sockets.

5

513005 POLAR

Kg

This handbook should last at least as long as the machine itself. It is, therefore, a good idea to always keep it in its holder.

If you lose or destroy the handbook, you may ask for a copy. Please give the rating plate data (see chap. 1) in your

request.

2.2 WARNINGS FOR TRANSPORT AND HANDLING

• This symbol, placed on each packaging, indicates the weight of each package.

Always check that the tools and machines to handle and transport the machine are adequate.

•Always keep the machine in an upright position. If the machine should accidentally turn upside-down or

on its side, do not switch it on. Put it in the correct position and contact the manufacturer.

2.3 WARNINGS FOR INSTALLATION

•Installation should always be carried out by specialized personnel.

• Carefully follow the instructions on how to prepare the plant systems before installing the machine.

• When the installation site is being prepared, bear in mind the space and work conditions of the personnel in charge

of the machine so as to reduce to a minimum noise, fatigue, discomfort and anything else which may have a negative

influence on the staff.

• When designing the installation site, remember to leave sufficient space for control, maintenance, cleaning, and

removal of production waste material.

• Make sure there are clear notices near the machine to warn personnel who are not in charge of the dangers withing

the work range of the machine during the work cycle.

• Make sure that the work site is adequately lit so that personnel can work in optimum conditions.

• When designing the installation site, please refer to the norms in force and in particular:

- set up all the firefighting and safety devices.

2.4 WARNINGS FOR PERSONNEL IN CHARGE OF THE MACHINE

• The machine may only be used by personnel who have read the rules described in this handbook.

• If the chamber is opened in temperatures that differ greatly from ambient temperatures, problems could be created:

if the internal temperature is high, it will be very difficult to close the door because of expansion; if the internal

temperature is very low, phenomena of condensate and frosting due to ambient humidity could occur. If the door is

opened frequently in these conditions, it is not only dangerous but could cause damage to the gaskets of the door

and could obstruct the thermal exchangers.

2.5 WARNINGS FOR MAINTENANCE

•Always disconnect the machine from electrical mains supply (models supplied with electrical equipment) and release

pressure before carrying out any maintenance operation whatsoever.

•Always close all the stop valves above the machine.

• Do not use solvents or alcohol to clean the varnished parts as these products could damage the surface.

2.6 EXPLANATION OF SYMBOLS

• The symbols shown below may be found on the machine or in this instruction handbook.

• Pay attention to their meaning before going any further.

Operations that must be

carried out by at least

two people.

GENERAL DANGER

This symbol is always

accompanied by an

explanation of the danger

WARNING!

Important note

USE GLOVES

6

513005 POLAR

3 TECHNICAL SPECIFICATIONS

3.1 TECHNICAL DATA

Model

730x960x1080

450x560x450

113

-40

-85

±3

±2

0,66

3

560

R404A/

MIXTURE

52

220

730x960x1080

450x560x450

113

-20

-45

±2

±1

0,33

1,5

280

R404A

52

200

850x980x1080

570x700x450

180

-40

-85

±3

±2

0,66

3

560

R404A /

MIXTURE

52

250

850x980x1080

570x700x450

180

-20

-45

±2

±1

0,33

1,5

280

R404A

52

230

POLAR

370 SH

POLAR

370 H

POLAR

180 SH

POLAR

180 H

POLAR

110 SH

POLAR

110 H

1780x910x1020

1050x520x670

366

-40

-85

±3

±2

0,66

3

560

R404A /

MIXTURE

52

280

1780x910x1020

1050x520x670

366

-20

-45

±2

±1

0,33

1,5

280

R404A

52

260

External dimensions (LxDxH) (mm)

Internal dimensions (LxDxH) (mm)

Useful volume (l)

Temperature range (°C)

Temperature variations

inside the space (1) (°C)

Temperature fluctuations

over time (1) (°C)

Supply voltage

Rated output (kW)

Absorbed current (A)

Thermal dissipation (kcal/h)

Refrigerant

Noise level (dB(A))

Overall weight with

packaging (kg)

230 V (+ 6 / - 10%) / 50 / 1 + G

Model

External dimensions (LxDxH) (mm)

Internal dimensions (LxDxH) (mm)

Useful volume (l)

Temperature range (°C)

Temperature variations

inside the space (1) (°C)

Temperature fluctuations

over time (1) (°C)

Supply voltage

Rated output (kW)

Absorbed current (A)

Thermal dissipation (kcal/h)

Refrigerant

Noise level (dB(A))

Overall weight with

packaging (kg)

2320x910x1020

1590x520x670

550

-40

-85

±3

±2

0,66

3

560

R404A /

MIXTURE

55

390

1000x920x2000

700x530x1350

500

-20

-45

±2

±1

0,33

1,5

280

R404A

55

270

750x920x2000

450x530x1350

322

-40

-85

±3

±2

0,66

3

560

R404A /

MIXTURE

52

260

1000x920x2000

700x530x1350

500

-40

-85

±3

±2

0,8

4,8

650

R404A /

MIXTURE

55

290

POLAR

550 H

POLAR

530 SV

POLAR

530 V

POLAR

340 SV

POLAR

340 V

750x920x2000

450x530x1350

322

-20

-45

±2

±1

0,33

1,5

280

R404A

52

240

2320x910x1020

1590x520x670

550

-20

-45

±2

±1

0,33

1,5

280

R404A

55

370

POLAR

550 SH

(1) The values shown refer to tests carried out at a temperature of -40°C for the SH - SV models and of -80°C for the H –

V models.

230 V (+ 6 / - 10%) / 50 / 1 + G

7

513005 POLAR

3.2 FUSES

POLAR 110 SH

POLAR 180 SH

POLAR 370 SH

POLAR 340 SV

POLAR 530 SV

POLAR 550 SH

POLAR 110 H

POLAR 180 H

POLAR 370 H

POLAR 340 V

POLAR 530 V

POLAR 550 H

FU

FU

FU

FU

FU

FU

FU

FU

FU

FU

FU

FU

Model

6 A

6 A

6 A

6 A

6 A

6 A

10 A

10 A

10 A

10 A

10 A

10 A

TT

TT

TT

TT

TT

TT

TT

TT

TT

TT

TT

TT

Symbol Value Code

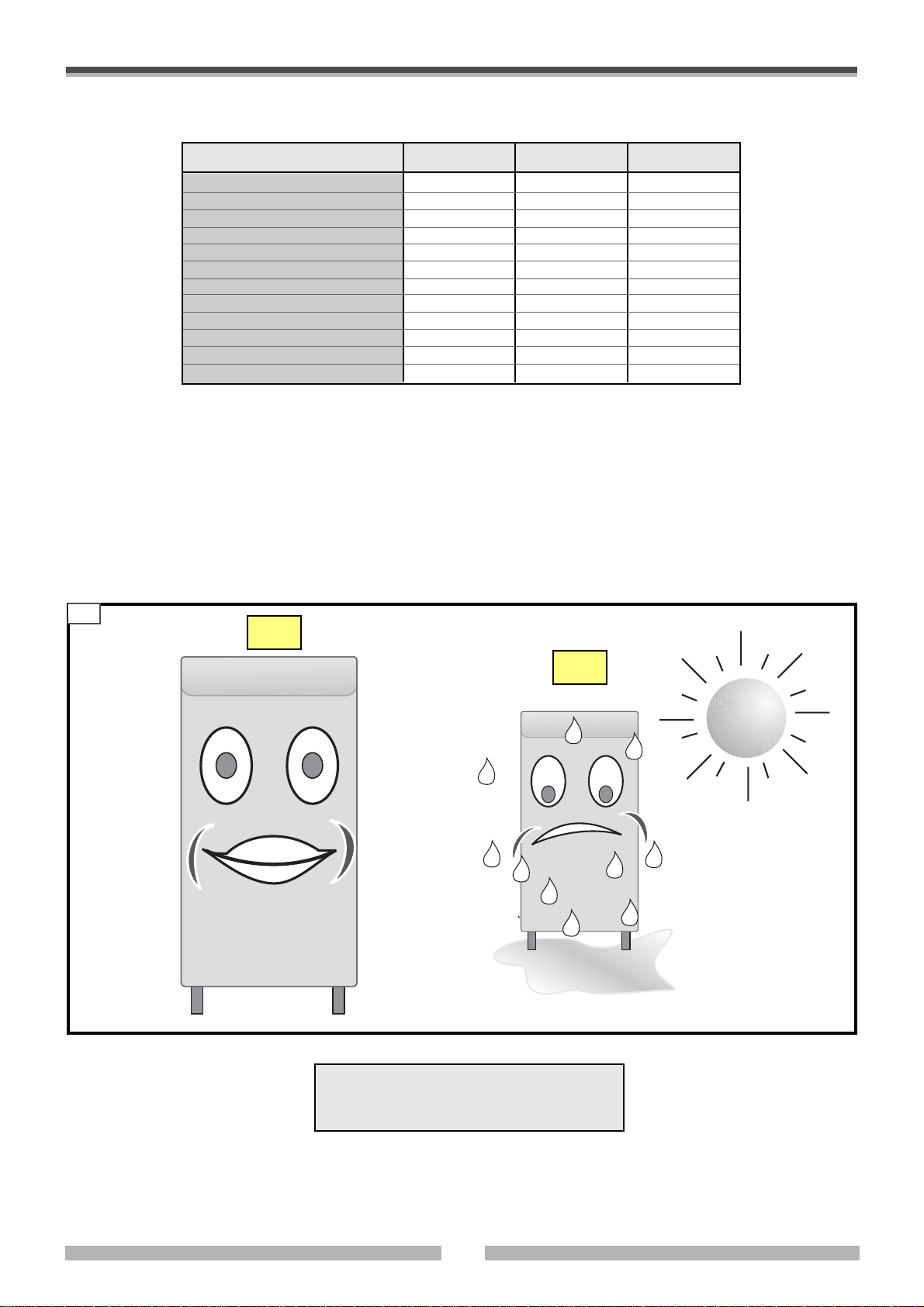

3.3 ENVIRONMENTAL CONDITIONS

In order for the appliance to operate correctly, it should be placed in a site with the following requisites:

•

far from heat sources,

•far from direct sunlight,

•far from air conditioning systems,

•in a dust-free ambient.

PO1207-130

Ambient temperature min: +10°C

max + 30°C

Relative humidity UR max 80%

20°C

40°C

PO1207-140

3.1

8

513005 POLAR

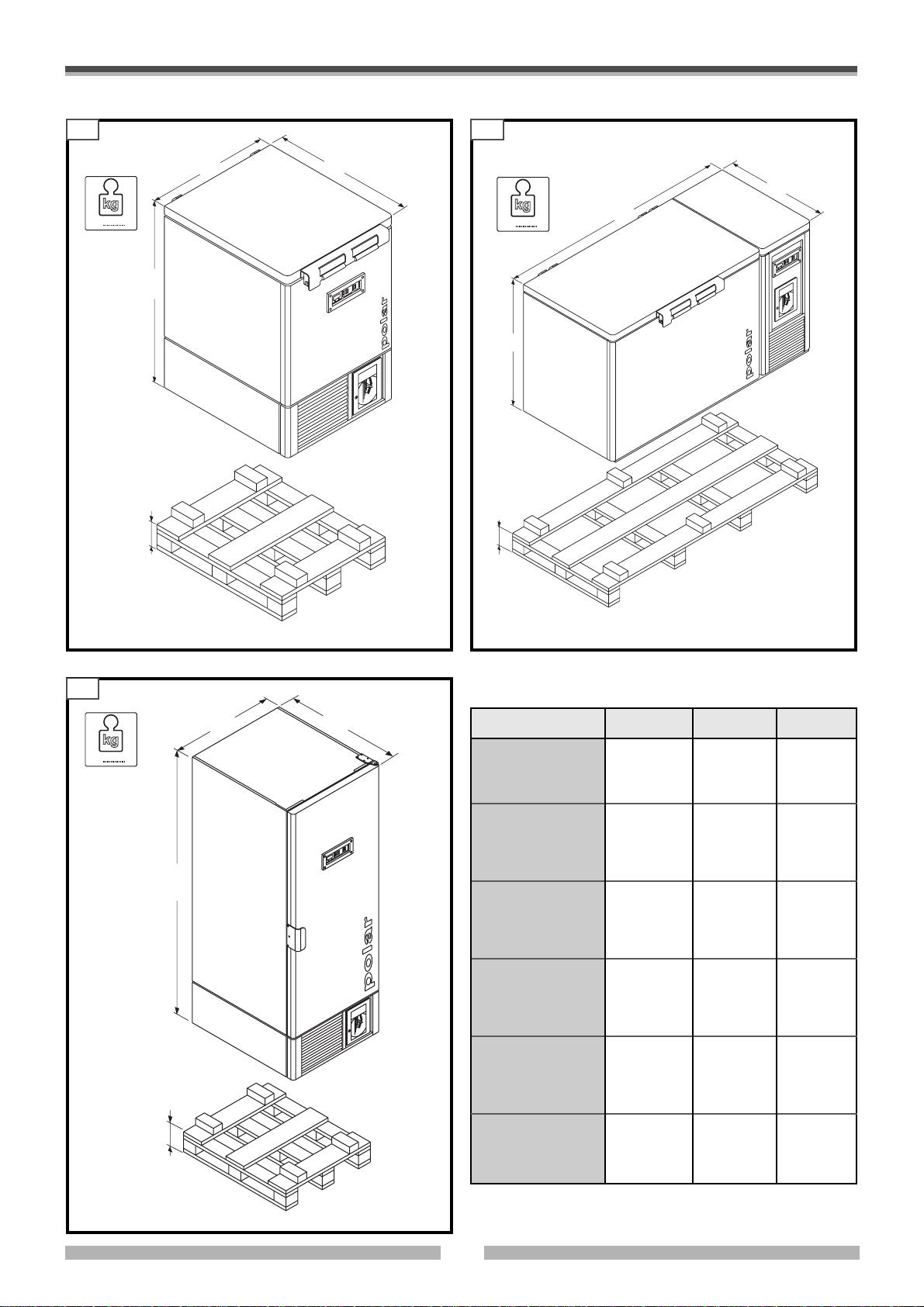

3.4 TECHNICAL LAY-OUT DIAGRAMS

C

B

A

145

PO1207-020

PO1207-030

3.33.2

1

4

5

C

B

A

PO1207-010

3.4

145

C

B

A

Kg

Kg

Kg

A

Polar 110 H

Polar 110 SH

Polar 180 H

Polar 180 SH

Polar 370 H

Polar 370 SH

Polar 340 V

Polar 340 SV

Polar 530 V

Polar 530 SV

Polar 550 H

Polar 550 SH

BC

MODEL

1080

1145

980

2000

1985

1145

730

980

1780

730

980

950

850

1145

800

850

850

2315

F

O

R

K

L

IF

T

T

R

U

C

K

S

ID

E

T

R

A

N

S

P

A

L

L

E

T

S

ID

E

F

O

R

K

L

IF

T

T

R

U

C

K

S

ID

E

T

R

A

N

S

P

A

L

L

E

T

S

ID

E

F

O

R

K

L

IF

T

T

R

U

C

K

S

ID

E

T

R

A

N

S

P

A

L

L

E

T

S

ID

E

9

513005 POLAR

DS1710-010

DS1710-050

DS1710-060

40° C

0°C

4.1

4.2

4.3

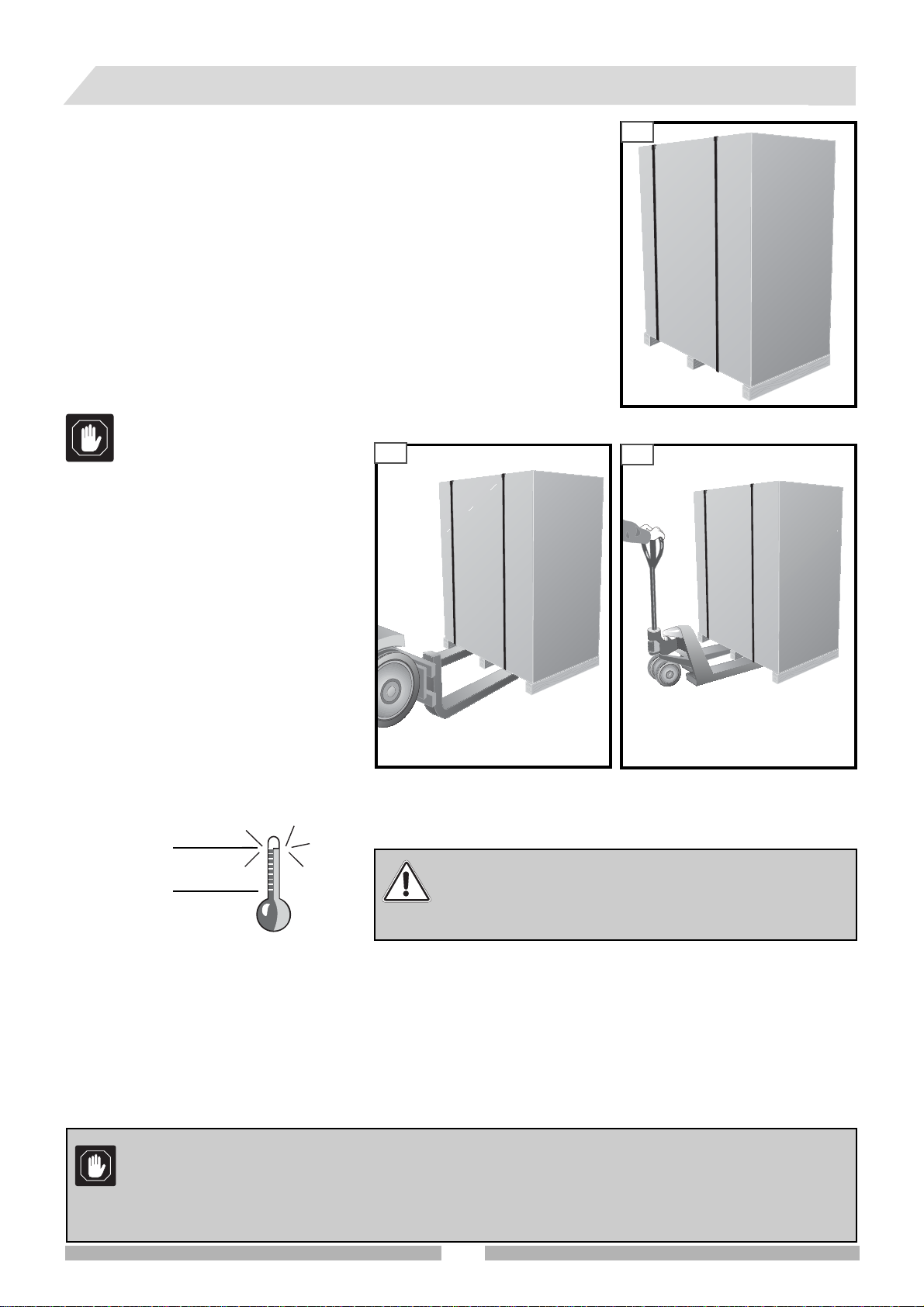

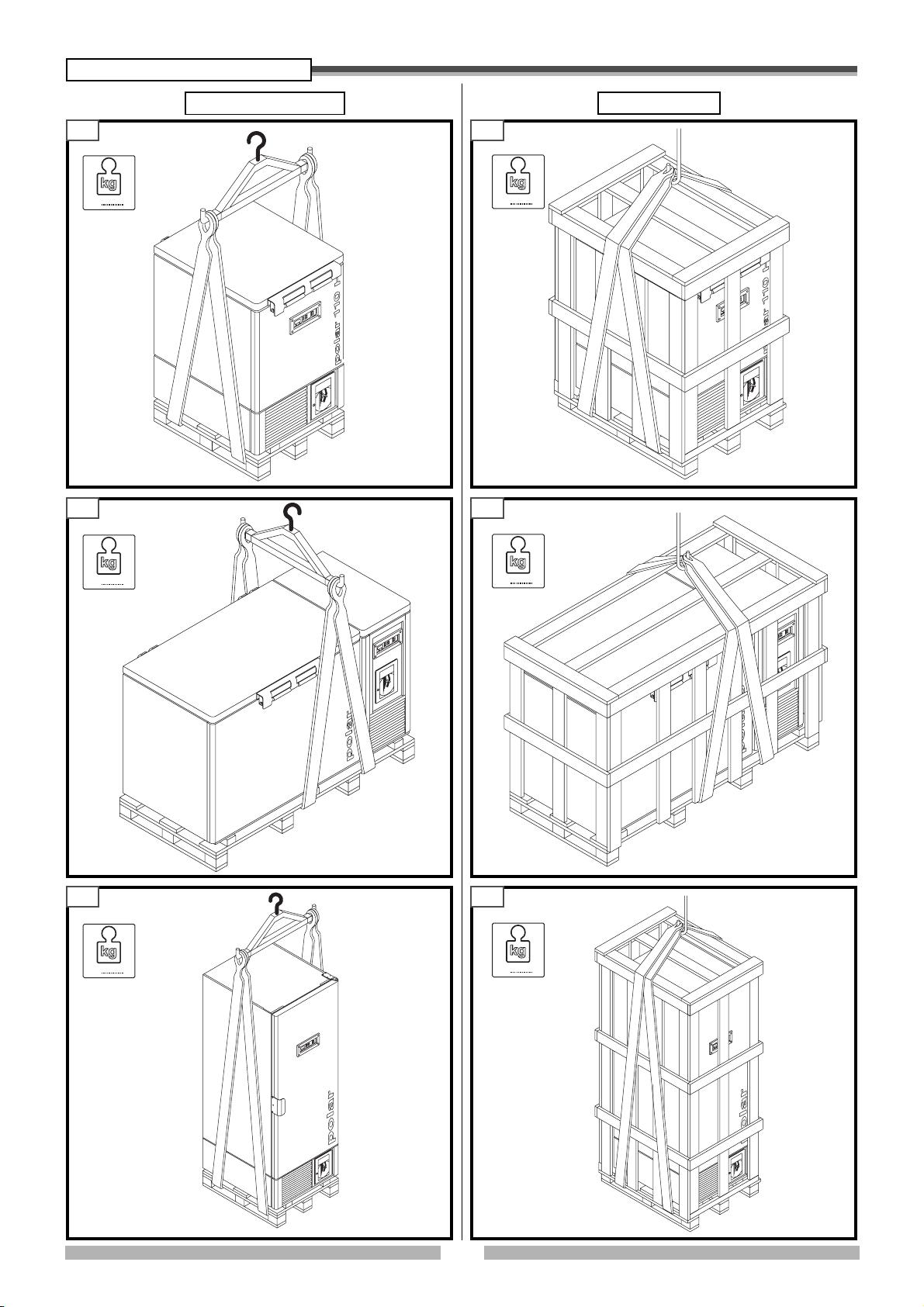

HOW TO RAISE AND MOVE WITH A BRIDGE CRANE

Accessories: textile fibre belts and PVC angle bars.

Weight: see technical specifications

4.1 PERSONNEL REQUISITES

Personnel in charge of handling the machine need no special requisites (just

remember the type of packaging).

However, we suggest that this is done by someone who is accustomed to using

machines for lifting and transport operations.

4.2 MACHINE CONDITIONS

The machine is normally supplied packed and on a pallet. If the machine is

delivered by our staff, it may be without packaging. Other types of packaging may

be supplied according to the destination and/or customer’s needs.

4.3 EQUIPMENT NEEDED FOR HANDLING

The machine can be raised and moved by a lift truck, bridge crane, crane or other

suitable means with an adequate capacity.

Make sure that the forks do not hit the machine frame.

If it is hit accidentally, check immediately for any damage

and if necessary, contact the manufacturer.

Check that the forks are level and

the load is stable before moving

the machine.

In order to handle the machine, the fol-

lowing rules should be observed:

• Move the machine slowly

• Do not tilt the machine, always keep it in

an upright position

•Always make sure you can control the

machine during handling

Warning:

• Do not turn the machine upside-down

• Do not drag the machine

• Do not shake the machine

How to store the machine

It should be kept in a dry environment with

an ambient temperature ranging from 0° ÷

40° C.

Do not use place the machine in a sling of metal cables or chains as these could damage it.

Never put a sling around a machine without its pallet.

In order to prevent the oil in the compressor from flowing into the refrigerating circuit, only transport, stock

and handle the equipment in an upright position according to the instructions on the packaging. If the

machine is placed on its side, leave it in an upright position for at least 24 hours before switching on.

Do not place packaged machines one on top of the other and always keep

them in an upright position as indicated by the special arrows marked on

the packaging itself.

4 HANDLING AND REMOVAL OF PACKAGING

HOW TO USE A LIFT TRUCK TO RAISE AND TRANSPORT PALLETIZED MACHINE

Take care to position the lift truck forks correctly so as not to damage the machine. The person in charge of handling

will be responsible for avoiding damage to the external structure during this operation.

10

513005 POLAR

PO1207-050

PO1207-090

Kg

Kg

Diagram of slings

With packagingWithout packaging

PO1207-060

PO1207-100

Kg

Kg

4.4 4.5

4.6 4.7

Kg

Kg

4.8 4.9

PO1207-070

PO1207-110

11

513005 POLAR

DS1710-010

DS1710-040

DS1710-030

DS1710-070

DS1710-090

4.10 4.11

4.12 4.13

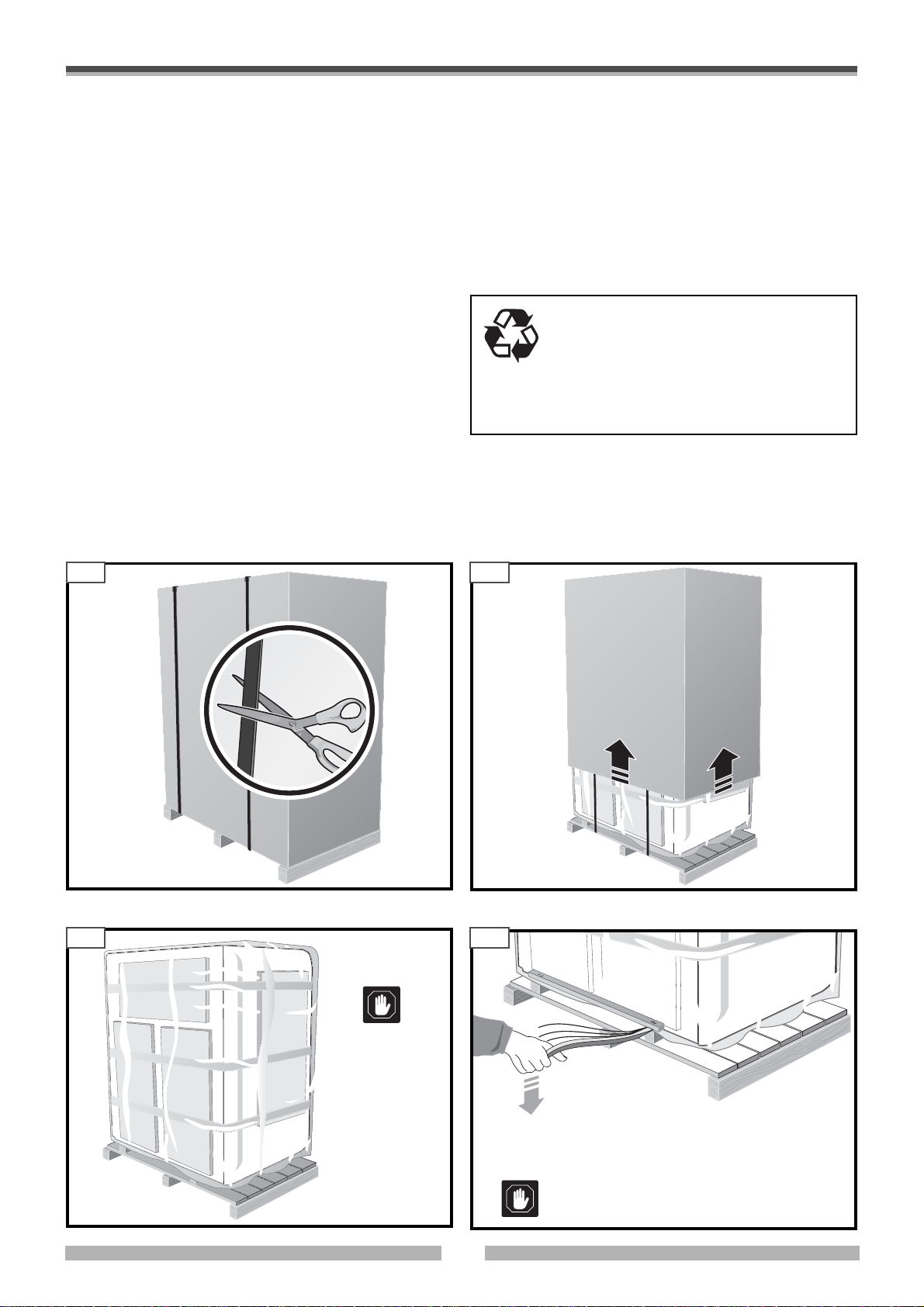

4.4.1 How to remove the outer straps 4.4.2 How to remove the cardboard casing

4.4.4 How to remove the wooden side blocks

All the packaging materials can be recycled

and can be disposed of according to the

regulations in force. Take care to eliminate

the packaging so that it does not become a

danger and throw away the plastic bags, as

they could cause children to suffocate.

• Remove the screws that block the ledges on the

cabinet.

•

Use a special lever to remove the two wooden blocks.

4.4 REMOVAL OF PACKAGING

MANUAL HANDLING

The machine is equipped with four wheels so that it can be moved manually.

If the floor of the installation site is flat, no special precautions are required.

Take all the necessary precautions, however, before moving the machine:

• Bear in mind the mass which has to be moved and calculate the number of people needed to control the mass during

movement.

• check that the floor is smooth and completely flat.

4.4.3 Removal of plastic materials

When removing

the plastic mate-

rials, make sure

that you don’t

scratch the sur-

face of the appli-

ance.

The machine is delivered ready-to-go.

Before removing the machine from its packaging, check

that it has not been damaged during transport.

If so:

a) Contact your area representative

b) Make a written report and if possible attach photographs

showing the damage

c) Send a copy of the report to:

Shipping agent insurance company

Shipping agent

Manufacturer or area representative

• Remove all the packaging and destroy according to the

laws in force.

•Eliminate the parts with nails and eliminate plastic bags

and plastic sheeting.

Take care not to scratch the surface of the

machine.

Loading...

Loading...