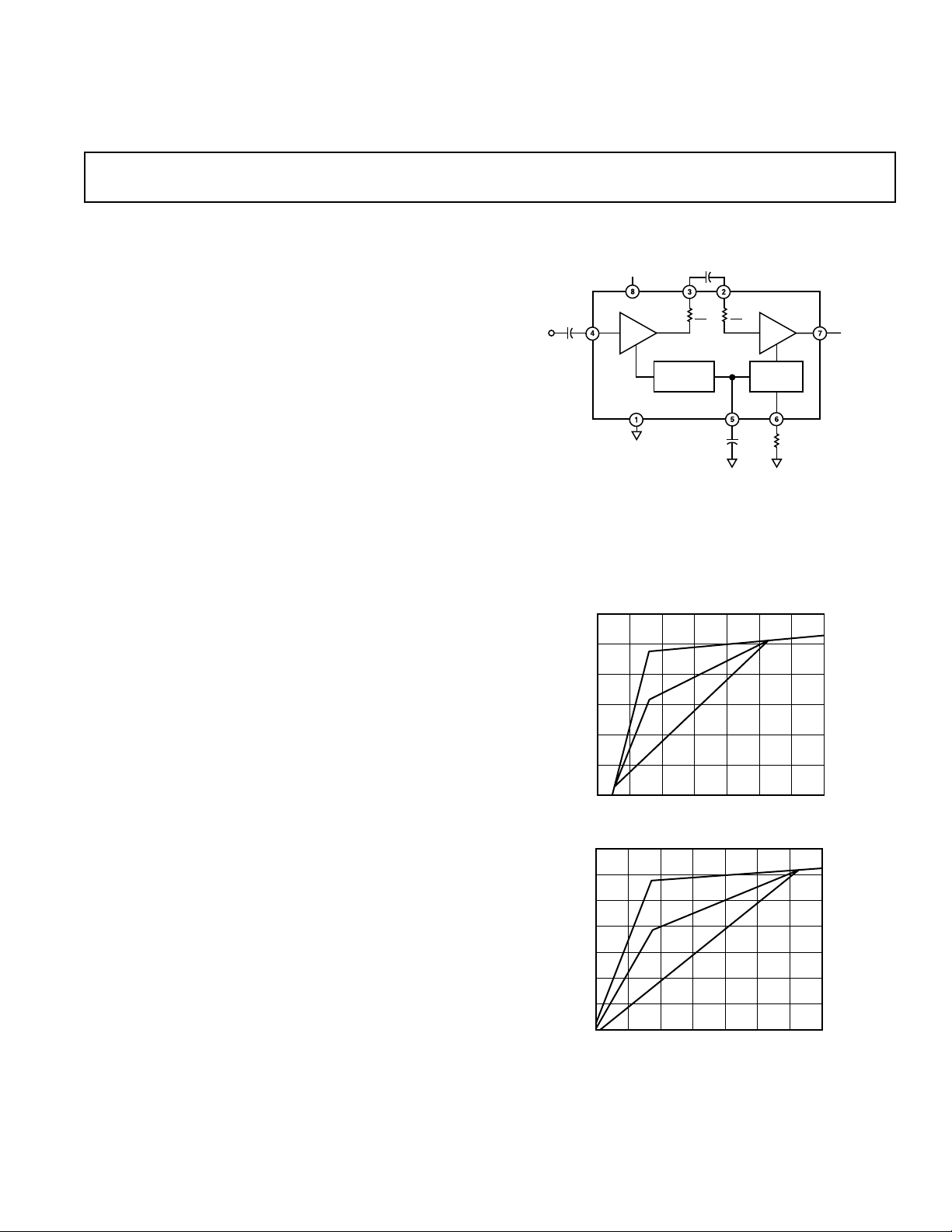

VCA

+1

VCA

IN

BUF

OUT

V+

V+

+

C2

10mF

BUFFER

LEVEL

DETECTOR

CONTROL

SSM2165

C1

0.1mF

AUDIO

IN+

V

OUT

R1

25kV

C3

22mF

AVG CAP

COMPRESSION

RATIO SET

GND

R

A

2

R

A

2

+

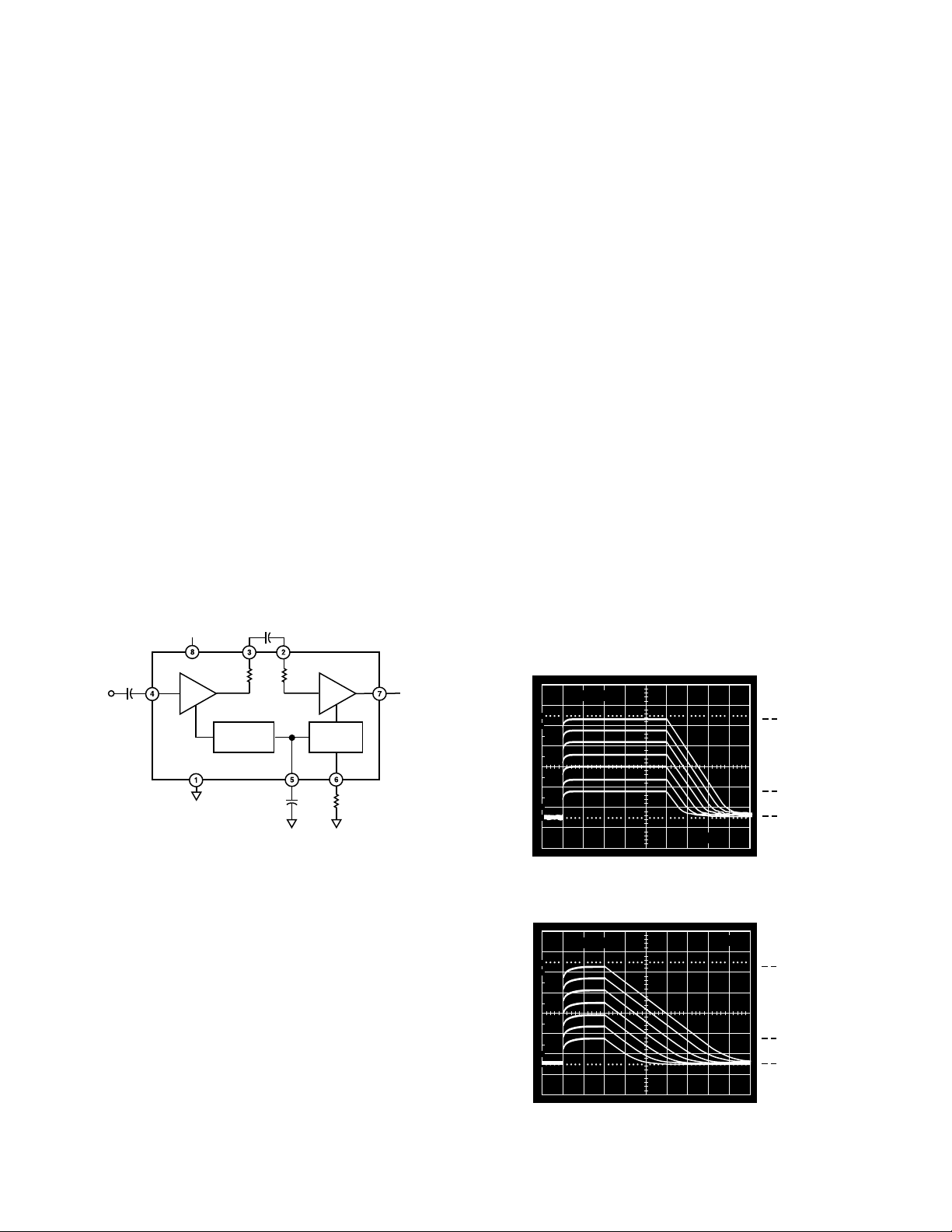

Microphone Preamplifier with

a

Variable Compression and Noise Gating

FEATURES

Complete Microphone Conditioner in an 8-Lead Package

Single +5 V Operation

Preset Noise Gate Threshold

Compression Ratio Set by External Resistor

Automatic Limiting Feature Prevents ADC Overload

Adjustable Release Time

Low Noise and Distortion

20 kHz Bandwidth (ⴞ1 dB)

Low Cost

APPLICATIONS

Microphone Preamplifier/Processor

Computer Sound Cards

Public Address/Paging Systems

Communication Headsets

Telephone Conferencing

Guitar Sustain Effects Generator

Computerized Voice Recognition

Surveillance Systems

Karaoke and DJ Mixers

GENERAL DESCRIPTION

The SSM2165 is a complete and flexible solution for conditioning microphone inputs in computer audio systems. It is also

excellent for improving vocal clarity in communications and

public address systems. A low noise voltage controlled amplifier

(VCA) provides a gain that is dynamically adjusted by a control

loop to maintain a set compression characteristic. The compression ratio is set by a single resistor and can be varied from 1:1 to

over 15:1 relative to the fixed rotation point. Signals above the

rotation point are limited to prevent overload and to eliminate

“popping.” A downward expander (noise gate) prevents amplification of noise or hum. This results in optimized signal levels

prior to digitization, thereby eliminating the need for additional

gain or attenuation in the digital domain that could add noise or

impair accuracy of speech recognition algorithms. The flexibility

of setting the compression ratio and the time constant of the

level detector, coupled with two values of rotation point, make

the SSM2165 easy to integrate in a wide variety of microphone

conditioning applications.

The SSM2165 is an ideal companion product for audio codecs

used in computer systems, such as the AD1845 and AD1847.

The device is available in 8-lead SOIC and P-DIP packages, and

guaranteed for operation over the extended industrial temperature

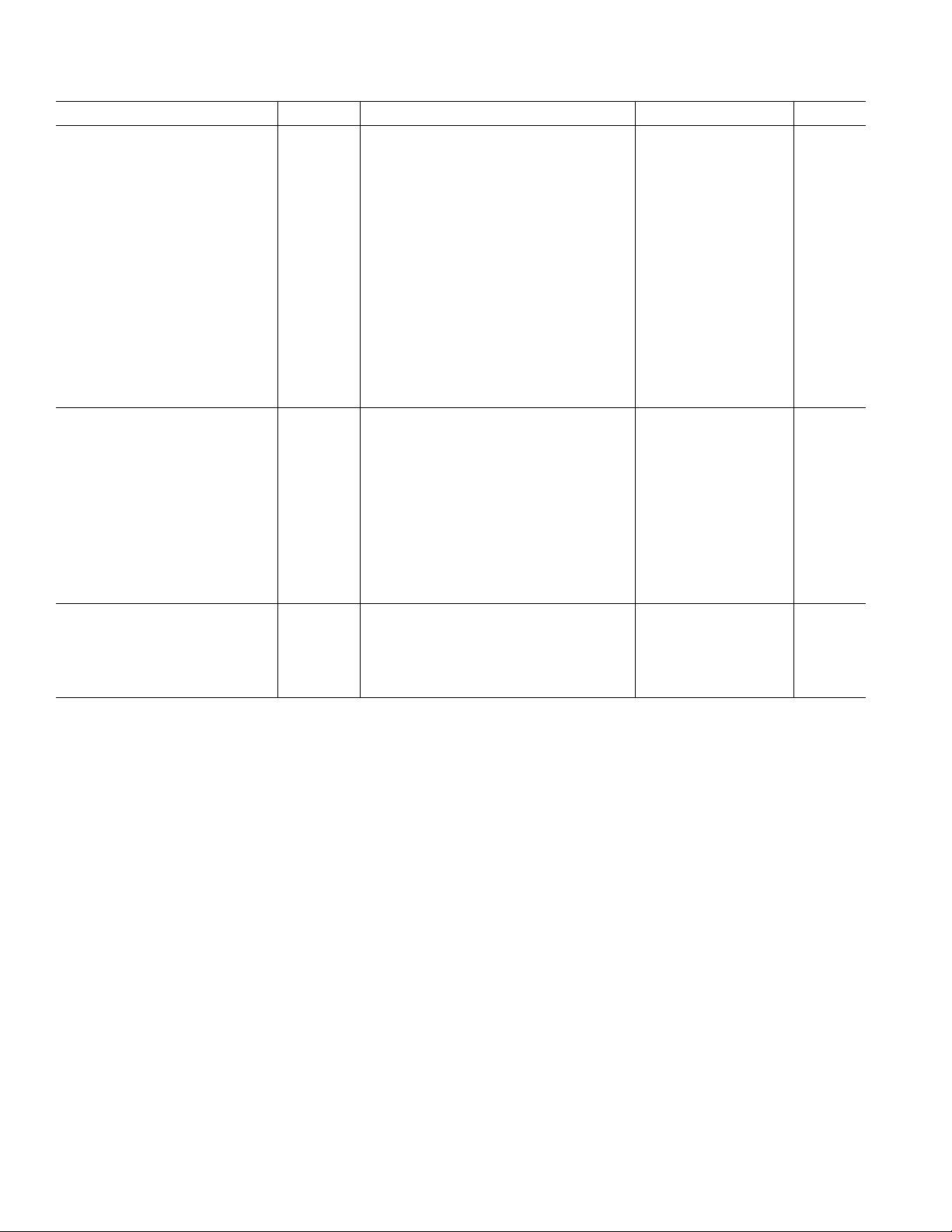

range of –40°C to +85°C. As shown in Figure 1a, the SSM2165-1

has a rotation point of –25.7 dBu (40 mV)

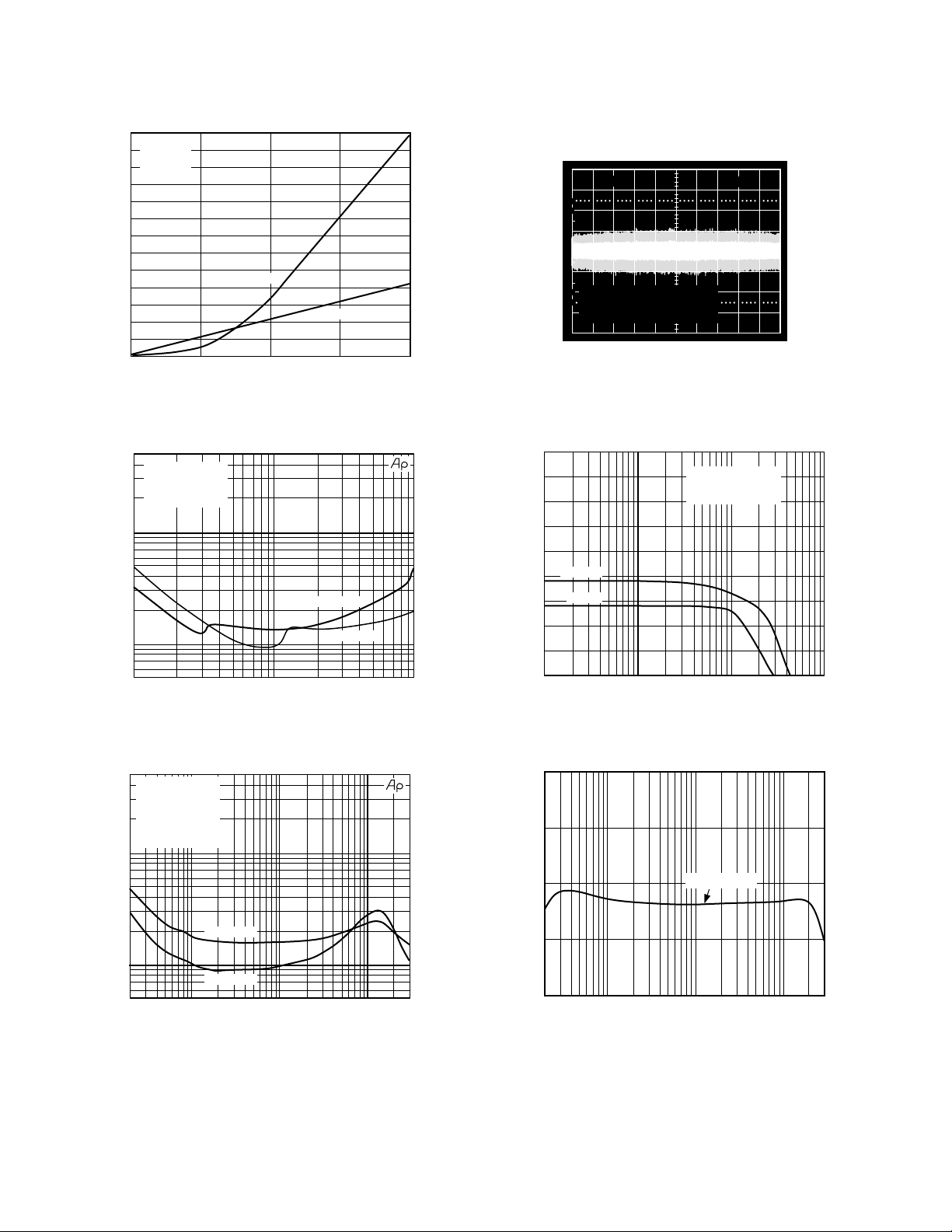

and gives –7.7 dBu (320 mV) before limiting. As shown in Figure

1b, the SSM2165-2 has a rotation point of –17.8 dBu (100 mV),

*

Patents pending.

1

All signals are in rms volts or dBu (0 dBu = 0.775 V rms).

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

1

, a VCA gain of 18 dB,

SSM2165*

FUNCTIONAL BLOCK DIAGRAM

a VCA gain of 8 dB and gives –9.8 dBu (250 mV) before limiting.

Both have a noise gate threshold of –64 dBu (500 µV), below

which downward expansion reduces the gain with a ratio of

approximately 1:3. That is, a –3 dB reduction of output signal

occurs with a –1 dB reduction of input signal. For applications

requiring adjustable noise gate threshold, VCA gain up to 18 dB,

and adjustable rotation point, please refer to the SSM2166.

0

–10

–20

–30

–40

OUTPUT – dBu

–50

–60

INPUT – dBu

Figure 1a. SSM2165-1 Compression and Gating Characteristics

0

–10

–20

–30

–40

OUTPUT – dBu

–50

–60

–70

INPUT – dBu

Figure 1b. SSM2165-2 Compression and Gating Characteristics

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1999

–10–80 –70 –60 –50 –40 –30 –20

–10–80 –70 –60 –50 –40 –30 –20

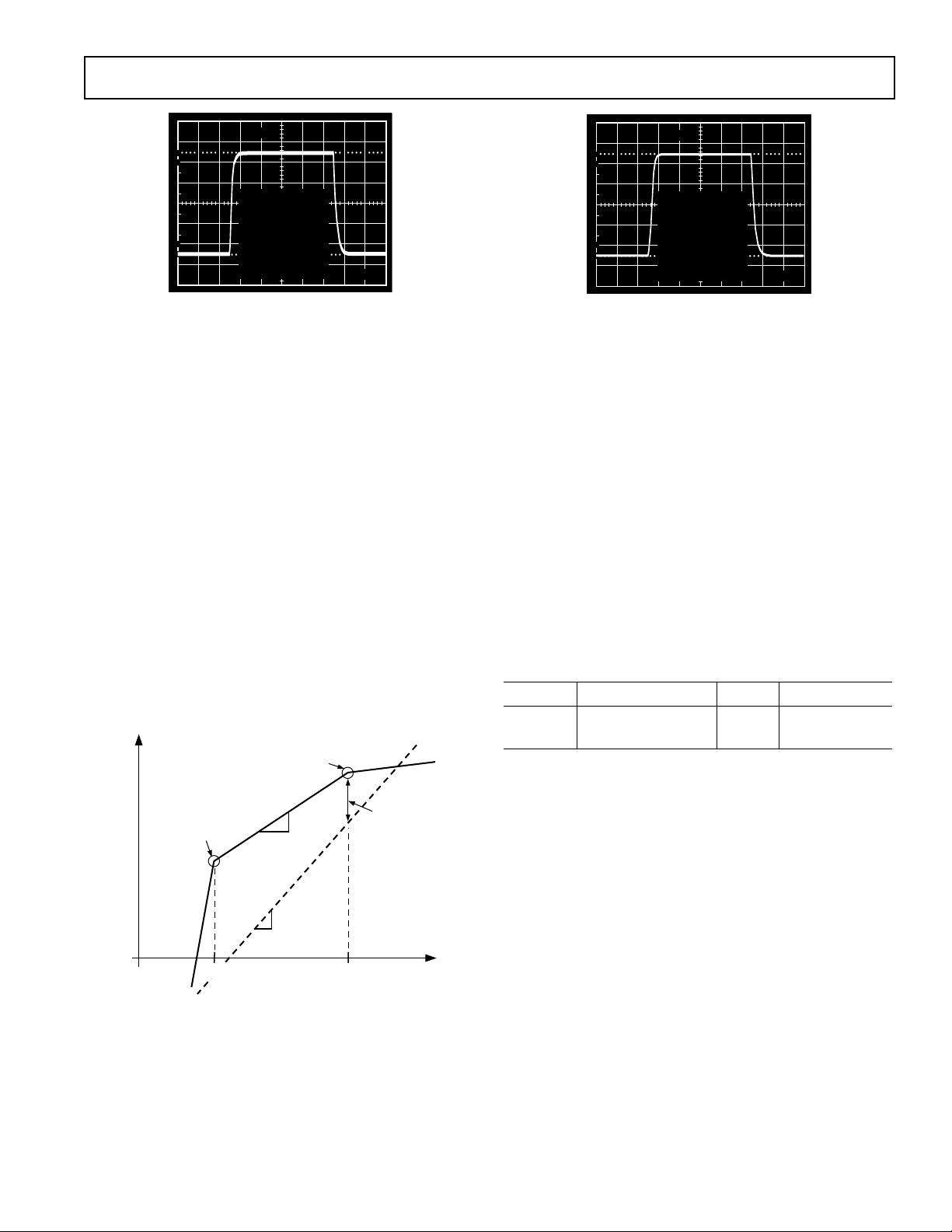

SSM2165–SPECIFICATIONS

(V+ = +5 V, f = 1 kHz, RL = 100 k⍀, R

= 0 ⍀, TA = +25ⴗC, unless otherwise noted)

COMP

Parameter Symbol Conditions Min Typ Max Units

AUDIO SIGNAL PATH

Voltage Noise Density

e

n

15:1 Compression, V

= GND 17 nV/√Hz

IN

Noise 20 kHz Bandwidth, VIN = GND –109 dBu

2

1

Total Harmonic Distortion THD+N

SSM2165-1 2nd and 3rd Harmonics, V

SSM2165-2 2nd and 3rd Harmonics, V

= –30 dBu 0.2 0.5 %

IN

= –20 dBu 0.2 0.5 %

IN

22 kHz Low-Pass Filter

Input Impedance Z

Output Impedance Z

IN

OUT

180 kΩ

75 Ω

Load Drive Resistive 5 kΩ

Capacitive 2 nF

Input Voltage Range 1% THD 1 V rms

Output Voltage Range 1% THD 1.4 V rms

Gain Bandwidth Product 1:1 Compression

SSM2165-1 VCA G = 18 dB 300 kHz

SSM2165-2 VCA G = 8 dB 100 kHz

CONTROL SECTION

VCA Dynamic Gain Range 40 dB

VCA Fixed Gain

SSM2165-1 18 dB

SSM2165-2 8dB

Rotation Point

SSM2165-1 40 mV rms

SSM2165-2 100 mV rms

Compression Ratio, Min 1:1

Compression Ratio, Max 15:1

Control Feedthrough 15:1 Compression ±5mV

POWER SUPPLY

Supply Voltage Range V

Supply Current I

S

SY

4.5 5.5 V

7.5 10 mA

Quiescent Output Voltage Level 2.2 V

Power Supply Rejection Ratio2PSRR 50 dB

NOTES

1

0 dBu = 0.775 V rms.

2

Referred to input.

Specifications subject to change without notice.

–2–

REV. A

SSM2165

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +10 V

Audio Input Voltage . . . . . . . . . . . . . . . . . . . . . Supply Voltage

Operating Temperature Range . . . . . . . . . . . . –40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . . –65°C to +150°C

Junction Temperature (T

) . . . . . . . . . . . . . . . . . . . . . .+150°C

J

Lead Temperature (Soldering, 60 sec) . . . . . . . . . . . . .+300°C

ESD RATINGS

883 (Human Body) Model . . . . . . . . . . . . . . . . . . . . . . . 2.0 kV

THERMAL CHARACTERISTICS

Thermal Resistance

8-Lead Plastic DIP

θ

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103°C/W

JA

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43°C/W

θ

JC

8-Lead SOIC

θ

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158°C/W

JA

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43°C/W

θ

JC

ORDERING GUIDE

Temperature Package Package

Model Range Description Options

SSM2165-1P –40°C to +85°C Plastic DIP N-8

SSM2165-2P –40°C to +85°C Plastic DIP N-8

SSM2165-1S –40°C to +85°C Narrow SOIC SO-8

SSM2165-2S –40°C to +85°C Narrow SOIC SO-8

PIN CONFIGURATION

GND

VCA

BUF

OUT

AUDIO +IN

1

2

IN

3

4

SSM2165

TOP VIEW

(Not to Scale)

8

V+

7

OUTPUT

6

COMP RATIO SET

5

AVG CAP

PIN FUNCTION DESCRIPTIONS

Pin # Mnemonic Function

1 GND Ground

2 VCA

IN

VCA Input Pin. A typical

connection is a 1 µF–10 µF

capacitor from the buffer output

pin (Pin 3) to this pin.

3 BUF

OUT

Input Buffer Amplifier Output

Pin. Must not be loaded by

capacitance to ground.

4 AUDIO +IN Input Audio Signal. The input

signal should be ac-coupled

(0.1 µF typical) into this pin.

5 AVG CAP Detector Averaging Capacitor.

A capacitor, 2.2 µF–22 µF, to

ground from this pin is the

averaging capacitor for the

detector circuit.

6 COMP RATIO SET Compression Ratio Set Pin. A

resistor to ground from this pin

sets the compression ratio as

shown in Figure 1.

7 OUTPUT Output Signal.

8 V+ Positive Supply, +5 V Nominal.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the SSM2165 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

REV. A

–3–

WARNING!

ESD SENSITIVE DEVICE

SSM2165

260

240

220

200

180

160

140

– kV

120

COMP

R

100

80

60

40

20

0

1:1 15:12:1 5:1 10:1

–Typical Performance Characteristics

TA = +258C

= +5V

V

S

= 100kV

R

L

SSM2165–1

SSM2165–2

COMPRESSION RATIO

Figure 2. Compression Ratio vs. R

COMP

5mV

100

90

10

TA = +258C

0%

COMPRESSION RATIO = 15:1

NOISE BW = 20kHz

1s

Figure 5. Wideband Output Noise

5

TA = +258C

COMP RATIO = 1:1

= 100kV/10kV

R

L

= +5V

V

S

1

THD+N – %

SSM2165–1

0.1

0.050

0.01 1

0.1

INPUT – V rms

SSM2165–2

Figure 3. THD + N (%) vs. Input (V rms)

5

TA = +258C

V

= +5V

S

COMP RATIO = 1:1

V

= –20dBu (–1)

IN

= –30dBu (–2)

V

IN

R

= 100kV

L

1

THD+N – %

70

60

50

40

30

G = 18dB

20

GAIN – dB

G = 8dB

10

0

–10

–20

1k 1M10k 100k

COMP RATIO = 15:1

R

COMP

= 40mV rms

V

IN

FREQUENCY – Hz

= 0

Figure 6. GBW Curves vs. VCA Gain

–30

–40

–50

PSRR – dB

V+ = 561V p-p

SSM2165–1

0.1

0.050

20 30k100

SSM2165–2

1k 10k

FREQUENCY – Hz

Figure 4. THD + N (%) vs. Frequency (Hz)

–4–

–60

–70

20 30k100 1k

FREQUENCY – Hz

10k

Figure 7. PSRR vs. Frequency, Referred to Input

REV. A

SSM2165

20mV

100

90

TA = +258C

C

= 2.2mF

AVG

= 10kV

R

L

10

0%

COMP RATIO = 1:1

= 12.5mV (–1)

V

IN

= 40mV (–2)

V

IN

10ms

Figure 8. Small Signal Transient Response

APPLICATIONS INFORMATION

The SSM2165 is a complete microphone signal conditioning

system in a single integrated circuit. Designed primarily for

voiceband applications, this integrated circuit provides amplification, rms detection, limiting, variable compression, and downward expansion. The internal rms detector has a time constant

set by an external capacitor. An integral voltage-controlled

amplifier (VCA) provides up to 40 dB of gain in the signal path

with approximately 30 kHz bandwidth. The device operates on

a single +5 V supply, accepts input signals up to 1 V

1

, and pro-

duces output signal levels at limiting of 320 mV and 250 mV for

the SSM2165-1 and SSM2165-2 respectively, into loads > 5 kΩ.

The SSM2165 contains an input buffer and automatic gain

control (AGC) circuit for audio and voice band signals. Circuit

operation is optimized by providing user-adjustable compression

ratio and time constant. A downward expansion (noise gating)

feature reduces background and circuit noise below 500 µV.

The rotation point determines the output signal levels before

limiting (referred to the input), and is 40 mV for the SSM2165-1

and 100 mV for the SSM2165-2.

V

rp

LIMITING

REGION

VCA GAIN

DOWNWARD

EXPANSION

THRESHOLD

(NOISE GATE)

OUTPUT – dB

DOWNWARD

EXPANSION

REGION

INPUT – dB

LIMITING

THRESHOLD

(ROTATION POINT)

COMPRESSION

REGION

V

DE

1

r

1

1

Figure 10. General Input/Output Characteristics of the

SSM2165

1

All signals are in rms volts or dBu (0 dBu = 0.775 V rms).

200mV

100

90

TA = +258C

C

= 2.2mF

AVG

= 10kV

R

L

10

0%

COMP RATIO = 1:1

V

= 125mV (–1)

IN

= 400mV (–2)

V

IN

10ms

Figure 9. Large Signal Transient Response

THEORY OF OPERATION

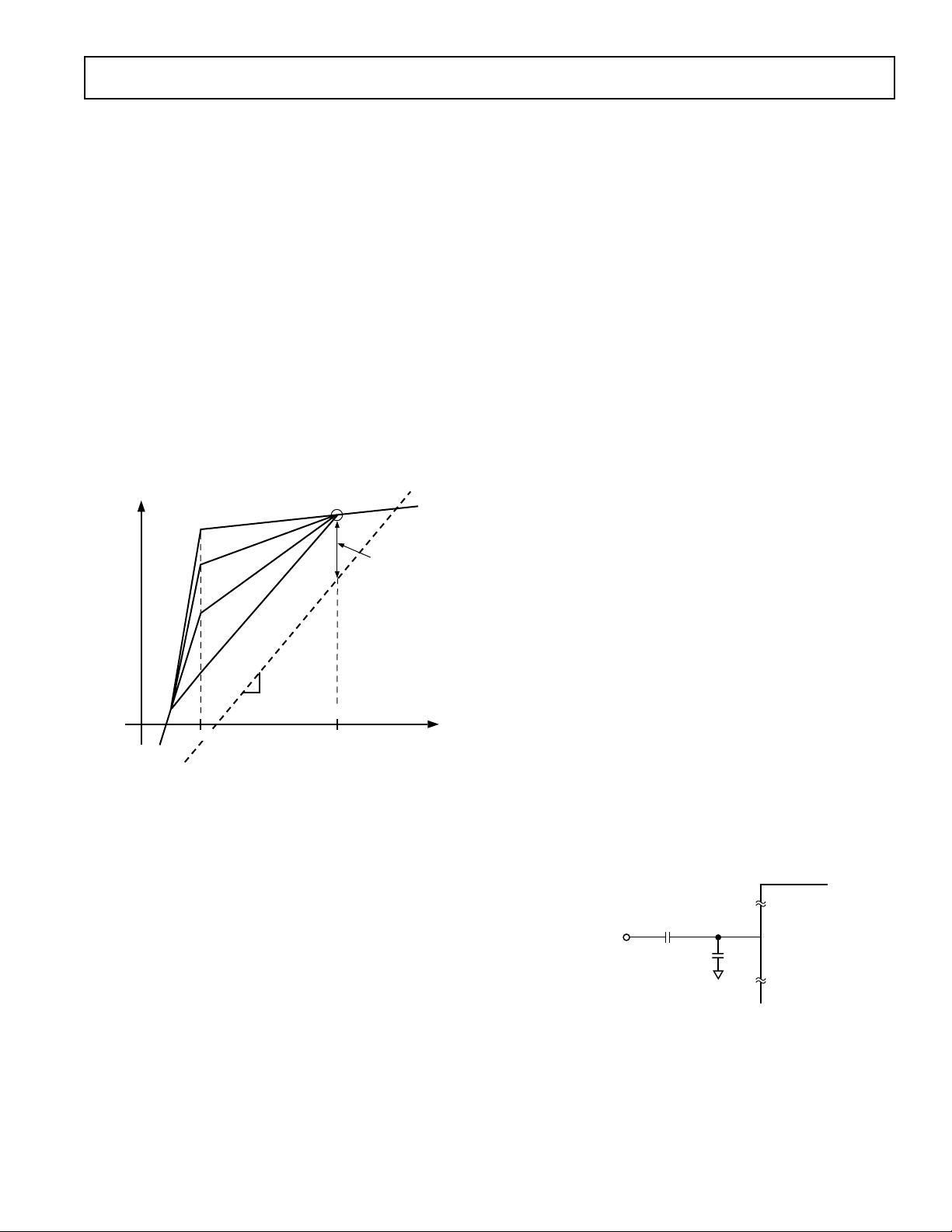

Figure 10 illustrates the general transfer characteristic for the

SSM2165 where the output level in dBu is plotted as a function

of the input level in dBu (0 dBu = 0.775 V rms). For input

signals in the range of V

(Downward Expansion) to V

DE

RP

(Rotation Point) an “r” dB change in the input level causes a

1 dB change in the output level. Here, “r” is defined as the

“compression ratio.” The compression ratio may be varied

from 1:1 (no compression) to over 15:1 via a single resistor,

. Input signals above V

R

COMP

are compressed with a fixed

RP

compression ratio of approximately 10:1. This region of operation is the “limiting region.” Varying the compression ratio has

no effect on the limiting region. The breakpoint between the

compression region and the limiting region is referred to as the

“limiting threshold” or “rotation point,” and is different for the

SSM2165-1 and SSM2165-2, see Table I.

Table I. Characteristics vs. Dash Number

SSM2165 Rotation Point Gain Output*

–1 40 mV (–25.7 dBu) 18 dB 320 mV (–6 dBu)

–2 100 mV (–17.7 dBu) 8 dB 250 mV (–8 dBu)

*At limiting.

The term “rotation point” derives from the observation that the

straight line in the compression region “rotates” about this point

on the input/output characteristic as the compression ratio is

changed.

When the compression is set to 2:1, a –2 dB change of the

input signal level in the compression region causes –1 dB

change of the output level. Likewise, at 10:1 compression, a

–10 dB change of the input signal level in the compression

region causes a –1 dB change in the output level. The gain of

the system with an input signal level of V

is fixed regardless of

RP

the compression ratio, and is different for the SSM2165-1 and

SSM2165-2 (see Figures 1a and 1b). The “nominal gain” of

the system is 18 dB for the SSM2165-1, and 8 dB for the

SSM2165-2. System gain is measured at V

RP

and is (V

OUT

– VIN)

in dB.

Input signals below V

are downward expanded at a ratio of

DE

approximately 1:3. As a result, the gain of the system is small

for very small input signal levels below V

be quite large for input signals above V

expansion threshold, V

, is fixed at 500 µV (–64 dBu) for both

DE

, even though it may

DE

. The downward

DE

dash versions.

REV. A

–5–

SSM2165

The SSM2165 Signal Path

Figure 11 illustrates the block diagram of the SSM2165. The

audio input signal is processed by the unity gain input buffer

and then by the VCA. The buffer presents an input impedance

of approximately 180 kΩ to the source. A dc voltage of approxi-

mately 1.5 V is present at AUDIO +IN (Pin 4), requiring the

use of a blocking capacitor (C1) for ground-referenced sources.

A 0.1 µF capacitor is a good choice for most audio applications.

The buffer is designed to drive only the low impedance input of

the VCA, and must not be loaded by capacitance to ground.

The VCA is a low distortion, variable-gain amplifier whose gain

is set by the internal control circuitry. The input to the VCA is

a virtual ground in series with 500 Ω. An external blocking

capacitor (C2) must be used between the buffer’s output and

the VCA input. The desired low frequency response and the

total of 1 kΩ impedance between amplifiers determines the

value of this capacitor. For music applications, 10 µF will give

high pass f

1 µF will give f

= 16 Hz. For voice/communications applications,

C

= 160 Hz. An aluminum electrolytic capacitor

C

is an economical choice. The VCA amplifies the input signal

current flowing through C6 and converts this current to a

voltage at the SSM2165’s output (Pin 7). The net gain from

input to output can be as high as 40 dB for high compression

ratios and depending on the gain set by the control circuitry.

The output impedance of the SSM2165 is typically less than

75 Ω, and the external load on Pin 7 should be >5 kΩ. The

nominal output dc voltage of the device is approximately 2.2 V.

Use a dc blocking capacitor for grounded loads.

C2

10mF

OUT

500V500V

LEVEL

DETECTOR

AVG CAP

22mF

+

VCA

IN

VCA

CONTROL

+

R1

25kV

COMPRESSION

RATIO SET

C3

V

OUT

AUDIO

IN+

C1

0.1mF

V+

V+

+1

SSM2165

GND

BUF

BUFFER

Figure 11. Functional Block Diagram and Typical Voice

Application

The bandwidth of the SSM2165 is quite wide at all gain settings. The upper –3 dB point is approximately 300 kHz. The

GBW plots are shown in Figure 6. While the noise of the input

buffer is fixed, the input referred noise of the VCA is a function

of gain. The VCA input noise is designed to be a minimum

when the gain is at a maximum, thereby optimizing the usable

dynamic range of the part. A photograph of the SSM2165’s

wideband peak-to-peak output noise is illustrated in Figure 5.

The Level Detector

The SSM2165 incorporates a full-wave rectifier and a patentpending, true rms level detector circuit whose averaging time

constant is set by an external capacitor connected to the AVG

CAP pin (Pin 5). Capacitor values from 18 µF to 22 µF have

been found to be more appropriate in voiceband applications,

where capacitors on the low end of the range seem more appropriate for music program material. For optimal low frequency

operation of the level detector down to 10 Hz, the value of the

capacitor should be around 22 µF. Some experimentation with

larger values for the AVG CAP may be necessary to reduce the

effects of excessive low frequency ambient background noise.

The value of the averaging capacitor affects sound quality: too

small a value for this capacitor may cause a “pumping effect”

for some signals, while too large a value can result in slow response times to signal dynamics. Electrolytic capacitors are

recommended here for lowest cost.

The rms detector filter time constant is approximately given by

10 × C

milliseconds where C

AVG

is in µF. This time con-

AVG

stant controls both the steady-state averaging in the rms detector as well as the release time for compression, that is, the time

it takes for the system gain to react when a large input is followed by a small signal. The attack time, the time it takes for

the gain to be reduced when a small signal is followed by a large

signal, is mainly controlled by internal circuitry that speeds up

the attack for large level changes, and controlled partly by the

AVG CAP value. This limits overload time to under 1 ms in

most cases.

The performance of the rms level detector is illustrated in Figure 12 for C

= 2.2 µF and Figure 13 for C

AVG

= 22 µF. In

AVG

each of these photographs, the input signal to the SSM2165

(not shown) is a series of tone bursts in 6 successive 10 dB

steps. The tone bursts range from –66 dBu (0.5 mV rms) to

–6 dBu (0.5 V rms). As illustrated in the photographs, the

attack time of the rms level detector is dependent only on C

AVG

,

but the release times are linear ramps whose decay times are

dependent on both for C

rate of release is approximately 240 dB/s for a C

and 12 dB/s for a C

100

90

10

0%

AVG

100mV

and the input signal step size. The

AVG

= 2.2 µF,

AVG

of 22 µF.

6dBV

66dBV

85dBV

100ms

Figure 12. RMS Level Detector Performance with

C

= 2.2 µF

AVG

100mV

100

90

10

0%

1s

6dBV

66dBV

85dBV

Figure 13. RMS Level Detector Performance with

C

= 22 µF

AVG

–6–

REV. A

SSM2165

Control Circuitry

The output of the rms level detector is a signal proportional to

the log of the true rms value of the buffer output with an added

dc offset. The control circuitry subtracts a dc voltage from this

signal, scales it, and sends the result to the VCA to control the

gain. The VCA’s gain control is logarithmic: a linear change in

control signal causes a dB change in gain. It is this control law

that allows linear processing of the log rms signal to provide the

flat compression characteristic on the input/output characteristic shown in Figure 10.

Compression Ratio

Changing the scaling of the control signal fed to the VCA

causes a change in the circuit’s compression ratio, “r.” This

effect is shown in Figure 14. The compression ratio can be set

by connecting a resistor between the COMP RATIO pin (Pin

6) and GND. Lowering RCOMP gives smaller compression

ratios as indicated in Figure 2, with values of about 5 kΩ or less

resulting in a compression ratio of 1:1. AGC performance is

achieved with compression ratios between 2:1 and 15:1, and is

dependent on the application. A 200 kΩ potentiometer may be

used to allow this parameter to be adjusted.

15:1

5:1

VCA GAIN

V

RP

OUTPUT – dB

2:1

1:1

1

1

V

DE

INPUT – dB

Figure 14. Effect of Varying the Compression Ratio

Rotation Point

An internal dc reference voltage in the control circuitry sets the

rotation point. The rotation point determines the output level

above which limiting occurs. That is, in the limiting region, a

10 dB change of input results in a 1 dB change of output. The

rotation point is set to 40 mV (–26 dBu) for the SSM2165-1

and 100 mV (–18 dBu) for the SSM2165-2. In the SSM2165,

limiting is compression at a fixed compression ratio of approximately 15:1. The fixed gain in the VCA is 18 dB for the

SSM2165-1 and 8 dB for the SSM2165-2. The output signals

at limiting are, therefore, 320 mV and 250 mV respectively.

These are summarized in Table I.

Maximum Output

Since limiting occurs for signals larger than the rotation point

(V

> VRP), the rotation point effectively sets the maximum

IN

output signal level. The application will determine which version of the SSM2165 should be selected. The output level

should match the maximum input allowed by the following

stage. Occasional larger signal transients will then be attenuated

by the action of the limiter.

Downward Expansion Threshold

The downward expansion threshold, or noise gate, is determined by a reference voltage internal to the control circuitry.

The noise gate threshold is 500 µV for both versions of the

SSM2165. Users requiring some other noise gate should consider using the SSM2166. High volume users may wish to consider a custom version of the SSM2165 with other noise gate

thresholds or rotation points.

Power-On/Power-Off Settling Time

Cycling the power supply to the SSM2165 will result in quick

settling times: the off-on settling time of the SSM2165 is less

than 200 ms, while the on-off settling time is less than 1 ms.

Note that transients may appear at the output of the device

during power up and power down. A clickless mute function is

available on the SSM2166 only.

PC Board Layout Considerations

Since the SSM2165 is capable of wide bandwidth operation at

high gain, special care must be exercised in the layout of the PC

board which contains the IC and its associated components.

The following applications hints should be considered and/or

followed:

1. In some high system gain applications, the shielding of input

wires to minimize possible feedback from the output of the

SSM2165 back to the input circuit may be necessary.

2. A single-point (“star”) ground implementation is recommended in addition to maintaining short lead lengths and

PC board runs. In systems where an analog ground and a

digital ground are available, the SSM2165 and its surrounding circuitry should be connected to the analog ground.

Wire-wrap board connections and grounding implementations are to be explicitly avoided.

3. The internal buffer of the SSM2165 was designed to drive

only the input of the internal VCA and its own feedback

network. Stray capacitive loading to ground from either Pin

3 or Pin 2 in excess of 5 pF to 10 pF can cause excessive

phase shift and can lead to circuit instability.

4. When using high impedance sources, it can be advantageous

to shunt the source with a capacitor to ground at the input

pin of the IC (Pin 4) to lower the source impedance at high

frequencies, as shown in Figure 15. A capacitor with a value

of 1000 pF is a good starting value and sets a low pass corner

at 31 kHz for 5 kΩ sources.

C1

AUDIO IN

> 5kV)

(R

S

NOTE: ADDITIONAL CIRCUIT DETAILS

OMITTED FOR CLARITY.

0.1mF

C

1000pF

X

4

+IN

SSM2165

Figure 15. Circuit Configuration for Use with High

Impedance Signal Sources

REV. A

–7–

SSM2165

+5V

C2

10mF

+

BUF

OUT

V+

+1

BUFFER

DETECTOR

SSM2165-1

GND

LEVEL

AVG CAP

22mF

+

C3

GENERATOR

AND AC

VOLTMETER

+2V

2kV

+

C1

0.1mF

MICROPHONE

(ELECTRET)

Figure 16. Electret Microphone Preamp Example

Compression Adjustment—A Practical Example

To illustrate how to set the compression ratio of the SSM2165,

we will take a practical example. The SSM2165 will be used

interface an electret-type microphone to a post-amplifier, as

shown in Figure 16. The signal from the microphone was measured under actual conditions to vary from 2 mV to 30 mV.

The post-amplifier requires no more than 350 mV at its input.

We will therefore choose the SSM2165-1, whose “rotation”

point is 40 mV and whose VCA fixed gain is 18 dB (×8), thus

giving 320 mV at limiting. From prior listening experience, we

will use a 2:1 compression ratio. The noise gate threshold of the

SSM2165-1 will operate when the input signal falls below 500 µV.

These objectives are summarized in Table II. The transfer characteristic we will implement is illustrated in Figure 18.

Table II. Objective Specification of Example

Input Range 2 mV–30 mV

Output Range To 350 mV

Limiting Level 320 mV

Compression 2:1

Gain 18 dB

Noise Gate 500 µV

Test Equipment Setup

The recommended equipment and configuration is shown in

Figure 17. A low noise audio generator with a smooth output

adjustment range of 100 µV to 25 mV is a suitable signal

source. The output voltmeter should go up to 2 volts. The

oscilloscope is used to verify that the output is sinusoidal, that

no clipping is occurring in the buffer, and to observe the limiting and noise gating “knees.”

Breadboard Considerations

When building your breadboard, keep the leads to Pins 2 and 3

as short as possible. Use a central analog ground and decouple

power supply connections adequately.

SIGNAL

GENERATOR

AC

VOLTMETER

SSM2165-1

AC

VOLTMETER

OSCILLOSCOPE

Figure 17. Test Equipment Setup

–8–

VCA

IN

VCA

CONTROL

200kV

1:1

R1 – COMPRESSION

15:1 RATIO SET

CW

AC VOLTMETER

AND OSCILLOSCOPE

HEADPHONES

STEP 1. Initialize Potentiometer

With power off, preset R1—Compression Ratio potentiometer

to zero ohms.

STEP 2. Check Setup

With power on, adjust the generator for an input level of

50 mV (–24 dBu), 1 kHz. The output meter should indicate

approximately 350 mV (–6.9 dBu). If not, check your setup.

STEP 3. Find the Rotation Point

Set the input level to 50 mV (–24 dBu), and observe the output

on the oscilloscope. The output will be in the limiting range of

operation. Slowly reduce the input signal level until the output

level just begins to stop limiting and follows the input down.

Increase the input so that the output is 320 mV (–7.7 dBu). You

have located the knee of the rotation point.

STEP 4. Adjust the Compression Ratio

With the input set as in Step 3, note the exact value of the input

signal level just below the knee (around 40 mV (–26 dBu)).

Next, reduce the input to 1/4 the value noted, (around 10 mV

(–38 dBu)), for a change of –12 dB. Next, increase the R

COMP

potentiometer resistance so the output is 160 mV (–13.7 dBu)

for an output change of –6 dB. You have now set the compression, which is the ratio of input change to output change, in dB,

to 2:1.

STEP 5. Confirm the Noise Gate Threshold

Set the input to 1 mV, and observe the output on the oscilloscope. A 20 dB pad between generator and input may facilitate

this measurement. Reduce the input gradually until the output

falls off more rapidly. This point is the noise gate threshold, and

should be approximately 500 µV (–64 dBu). The noise gate

threshold on the SSM2165 is fixed at 500 µV, a practical value

for many microphones. Should you require a different noise gate

threshold, consider using the SSM2166.

STEP 6. Listen

At this time, you may replace the signal generator with a

properly powered electret microphone and listen to the results

through a set of headphones. The microphone’s internal FET

usually requires around +2 V through a 2 kΩ resistor; this varies

with the manufacturer. Experiment with the compression ratio

value and averaging capacitor size. More compression will keep

the output steady over a wider range of microphone-to-source

distance. Varying the averaging capacitor, C

, changes the

AVG

REV. A

SSM2165

rms detector averaging time, and the decay time of the gate.

Both compression ratio and decay time are usually determined

by critical listening to the intended audio input.

STEP 7. Record Values

With the power removed from the test fixture, measure and

record the values of the

300

45

OUTPUT – mV

COMPRESSION

REGION

NOISE GATING REGION

0.5 2 30 40

RCOMP

and C

AVG.

INPUT – mV

LIMITING REGION

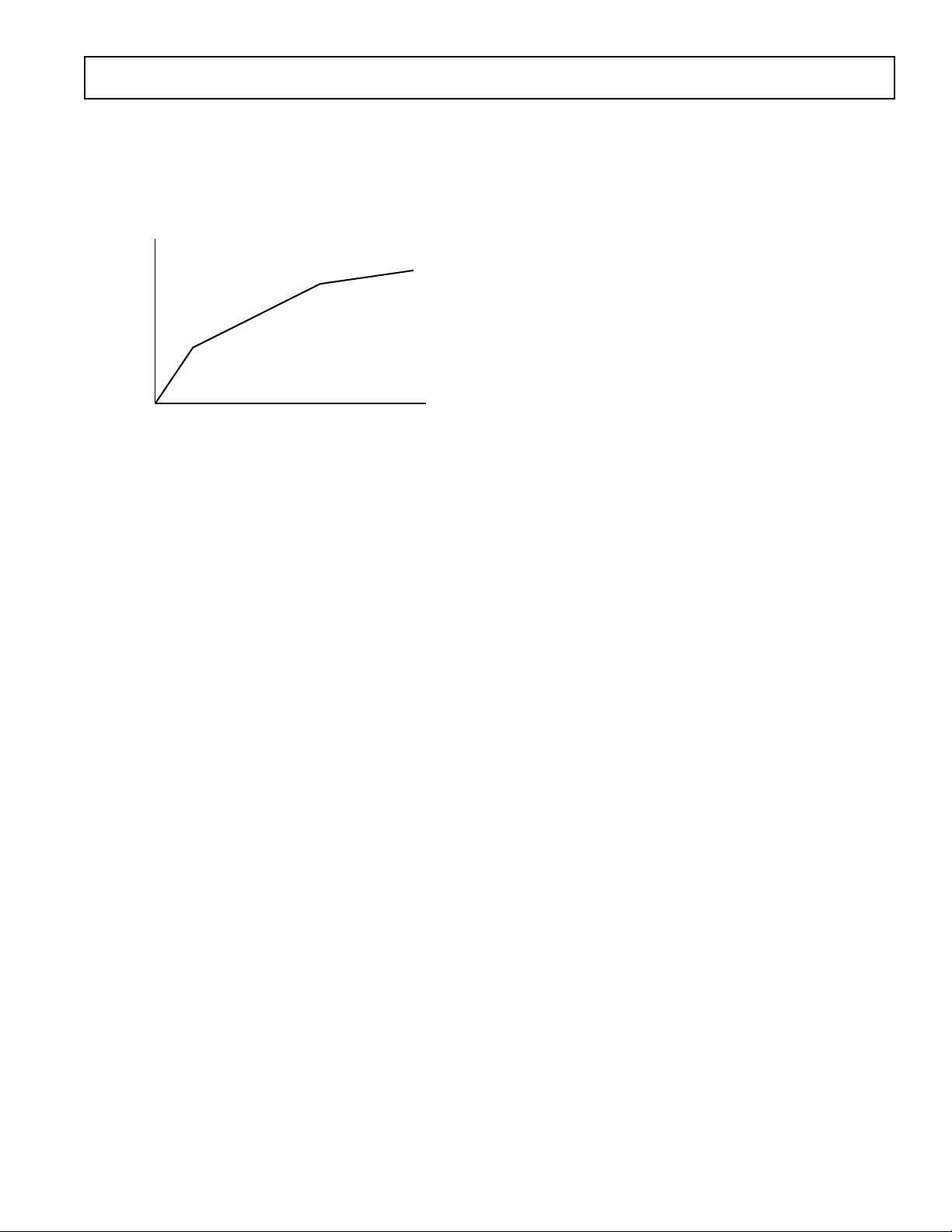

Figure 18. Transfer Characteristic

SUMMARY

We have implemented the transfer characteristic of Figure 18.

For inputs below the 500 µV noise gate threshold, circuit and

background noise will be downward expanded (gain-reduced) at

a ratio of approximately 1:3. That is, a –1 dB change in the

noise will result in –3 dB decrease at the output. Above threshold, the signal will increase at a rate of 1 dB for each 2 dB input

increase, until the rotation point is reached at an input of

approximately 40 mV. In the limiting region, the compression

ratio increases to approximately 15:1. That is, a 15 dB increase

in input will produce a 1 dB increase at the output, so there will

be little further increase for higher level inputs.

Other Versions

The SSM2165 is an 8-lead version of the 14-lead SSM2166

which is recommended for applications requiring more versatility. The SSM2166 allows selection of noise gate threshold and

rotation point, and allows the buffer to provide up to 20 dB of

gain. Power-down and mute functions are also built in. Customized versions of the SSM2165 are available for large volume

users. The wide dynamic range of the SSM2165 makes it useful

in many applications other than microphone signal conditioning

such as a sustain generator for guitars. For further information,

contact your Analog Devices representative.

REV. A

–9–

SSM2165

PIN 1

0.210

(5.33)

MAX

0.160 (4.06)

0.115 (2.93)

0.022 (0.558)

0.014 (0.356)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

8-Lead Plastic DIP

(N-8)

0.430 (10.92)

0.348 (8.84)

8

0.100 (2.54)

5

0.280 (7.11)

14

BSC

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.070 (1.77)

0.045 (1.15)

0.130

(3.30)

MIN

SEATING

PLANE

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.195 ( 4.95)

0.115 (2.93)

C2178a–0–6/99

0.1574 (4.00)

0.1497 (3.80)

PIN 1

0.0098 (0.25)

0.0040 (0.10)

SEATING

8-Lead Narrow-Body SOIC

(SO-8)

0.1 968 (5.00)

0.1 890 (4.80)

85

0.0500 (1.27)

PLANE

0.2440 (6.20)

0.2284 (5.80)

41

BSC

0.0192 (0.49)

0.0138 (0.35)

0.0688 (1.75)

0.0532 (1.35)

0.0098 (0.25)

0.0075 (0.19)

0.0196 (0.50)

0.0099 (0.25)

88

0.0500 (1.27)

08

0.0160 (0.41)

3 458

–10–

PRINTED IN U.S.A.

REV. A

Loading...

Loading...