查询AD7142供应商

Programmable Capacitance-to-Digital

Converter with Environmental

Preliminary Technical Data

FEATURES

Programmable capacitance-to-digital converter

30 Hz update rate (@ maximum sequence length)

Better than one femto Farad resolution

14 capacitance sensor input channels

No external RC tuning components required

Automatic conversion sequencer

On-chip automatic calibration logic

Automatic compensation for environmental changes

Automatic adaptive threshold and sensitivity levels

On-chip RAM to store calibration data

SPI®- or I

Separate V

Interrupt output and GPIO

32-lead, 5 mm x 5 mm LFCSP

2.7 V to 3.3 V supply voltage

Low operating current

APPLICATIONS

Personal music and multimedia players

Cell phones

Digital still cameras

Smart hand-held devices

Television, A/V and remote controls

Gaming consoles

2

C®- (AD7142-1) compatible serial interface

level for serial interface

DRIVE

Full power mode: less than1 mA

Low power mode: 50 μA

C

SHIELD

V

CIN0

CIN1

CIN2

CIN3

CIN4

CIN5

CIN6

CIN7

CIN8

CIN9

CIN10

CIN11

CIN12

CIN13

SRC

SRC

DRIVE

Compensation

AD7142/AD7142-1

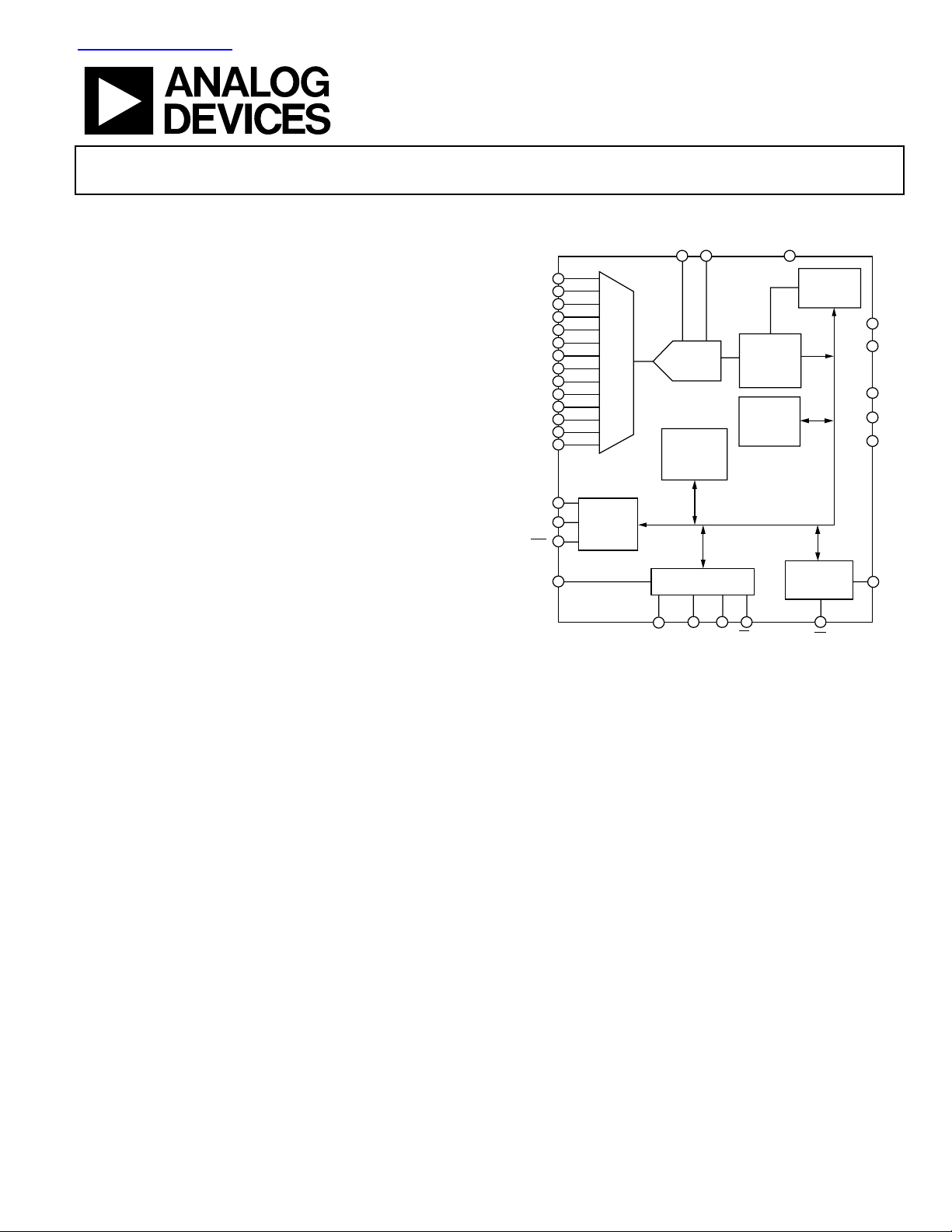

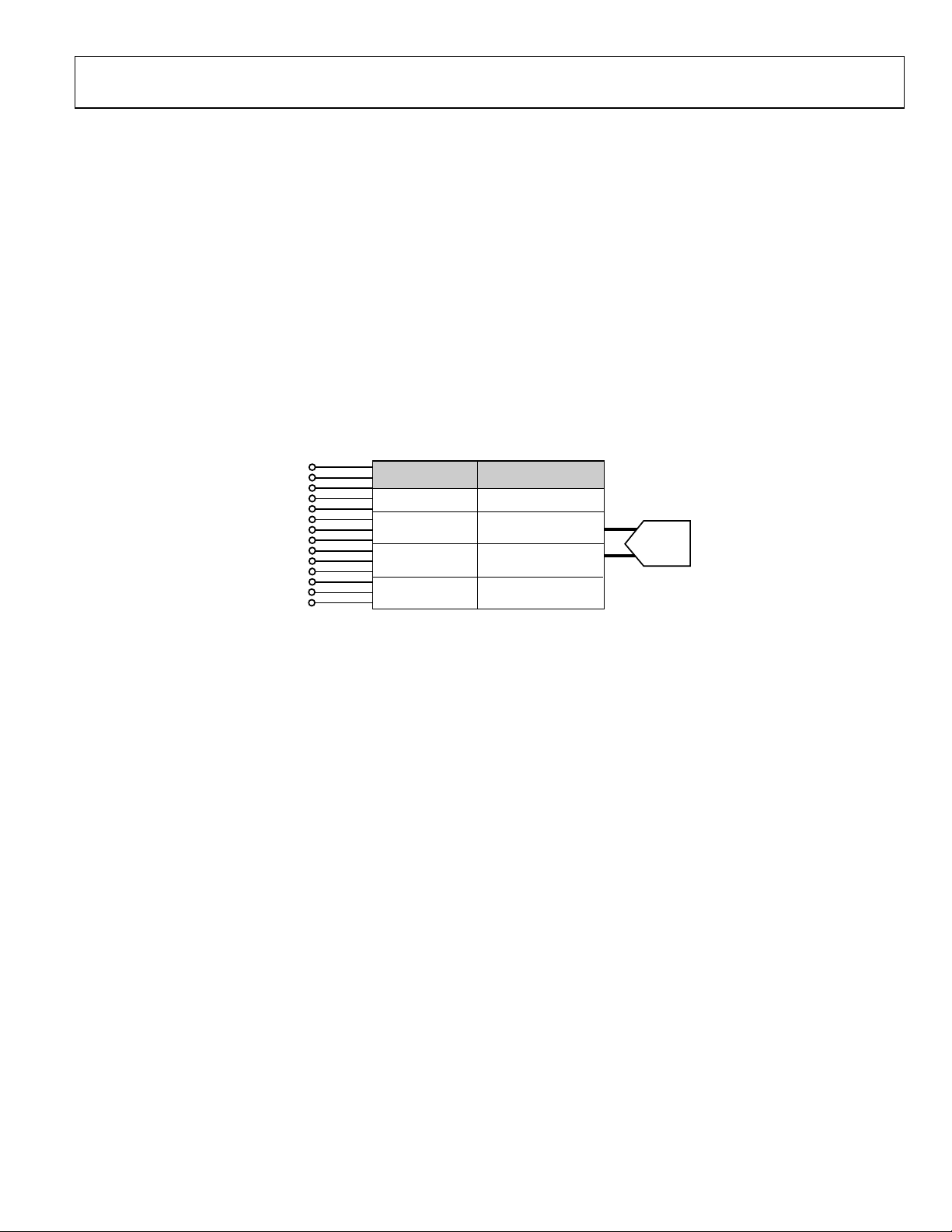

FUNCTIONAL BLOCK DIAGRAM

V

V

REF+

REF–

30

31

32

1

2

3

4

5

6

7

8

9

10

11

12

15

16

20

SWITCH

240kHz

EXCITATION

SOURCE

MATRIX

16-BIT

Σ-Δ

CDC

AD7142

CONTROL

AND

DATA

REGISTERS

SERIAL INTERFACE

AND CONTROL LOGIC

22 23 24 25

21

SDO/

SDI/

ADD0

SCLK

SDA

Figure 1.

CALIBRATION

CALIBRATION

CS/

ADD1

ENGINE

RAM

TEST

272829

POWER-ON

RESET

LOGIC

INTERRUPT

AND GPIO

LOGIC

INT

13

14

17

18

19

26

AV

CC

AGND

DV

CC

DGND1

DGND2

GPIO

05702-001

GENERAL DESCRIPTION

The AD7142 and AD7142-1 are integrated capacitance-todigital converters (CDCs) with on-chip environmental

calibration for use in systems requiring a novel user input

method. The AD7142 and AD7142-1 can interface to external

capacitance sensors implementing functions such as capacitive

buttons, scroll bars, or joypads.

The CDC has 14 inputs, channeled through a switch matrix to a

16-bit, 240 kHz sigma-delta (∑-∆) capacitance-to-digital

converter. The CDC is capable of sensing changes in the

capacitance of the external sensors and uses this information to

register a sensor activation. The external sensors can be

arranged as a series of buttons, as a scroll bar or wheel, or as a

combination of sensor types. By programming the registers, the

user has full control over the CDC setup. High resolution scroll

bar sensors require software to run on the host processor.

Rev. PrD

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

The AD7142 and AD7142-1 have on-chip calibration logic to

account for

changes in the ambient environment. The calibration

sequence is performed automatically and at continuous intervals,

while the sensors are not touched. This ensures that there are no

false or nonregistering touches on the external sensors due to a

changing environment.

The AD7142 has an SPI-compatible serial interface, and the

2

AD7142-1 has an I

C-compatible serial interface. Both versions

of AD7142 have an interrupt output, as well as a general-purpose

input output (GPIO).

The AD7142 and AD7142-1 are available in a 32-lead, 5 mm ×

5 mm LFCSP package and operate from a 2.7 V to 3.3 V supply.

The operating current consumption is less than 1 mA, falling

to 50 µA in low power mode (conversion interval of 400 ms).

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 © 2005 Analog Devices, Inc. All rights reserved.

AD7142/AD7142-1 Preliminary Technical Data

TABLE OF CONTENTS

Features .............................................................................................. 1

Adaptive Threshold and Sensitivity............................................. 20

Applications....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description......................................................................... 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

SPI Timing Specifications AD7142............................................ 4

2

I

C Timing Specifications AD7142-1 ........................................ 5

Absolute Maximum Ratings............................................................ 6

ESD Caution.................................................................................. 6

Pin Configuration and Functional Descriptions......................... 7

Typical Performance Characteristics ............................................. 8

Theory of Operation ........................................................................ 9

Capacitance Sensing Theory ....................................................... 9

Operating Modes........................................................................ 10

Capacitance Sensor Input Configuration.................................... 11

Interrupt Output............................................................................. 21

CDC Conversion Complete Interrupt..................................... 21

Sensor Threshold Interrupt ...................................................... 21

INT

GPIO

Output Control ....................................................... 22

Outputs ............................................................................................ 24

Excitation Source........................................................................ 24

C

Output ............................................................................. 24

SHIELD

GPIO ............................................................................................ 24

Serial Interface................................................................................ 25

SPI Interface ................................................................................ 25

2

I

C Interface ................................................................................ 27

V

Input ................................................................................. 29

DRIVE

PCB Design Guidelines ................................................................. 30

Capacitive Sensor Board Mechanical Specifications............. 30

Chip Scale Packages ................................................................... 30

CIN Input Multiplexer Setup.................................................... 11

Capacitiance-to-Digital Converter............................................... 12

Oversampling the CDC Output ............................................... 12

Capacitance Sensor Offset Control .......................................... 12

Conversion Sequencer ............................................................... 12

CDC Conversion Time.............................................................. 13

CDC Conversion Results........................................................... 14

Non-Contact Proximity Detection............................................... 15

Environmental Calibration ........................................................... 19

REVISION HISTORY

12/05—Preliminary Version D

7/05—Preliminary Version C

2/05—Preliminary Version B

Power-Up Sequence ....................................................................... 31

Typical Applicat i o n C i rc uits ......................................................... 32

Register Map ................................................................................... 33

Detailed Register Descriptions..................................................... 34

Bank 1 Registers ......................................................................... 34

Bank 2 Registers ......................................................................... 44

Bank 3 Registers ......................................................................... 47

Outline Dimensions ....................................................................... 62

Ordering Guide .......................................................................... 62

1/05—Preliminary Version A

Rev. PrD | Page 2 of 64

Preliminary Technical Data AD7142/AD7142-1

SPECIFICATIONS

VCC = 2.7 V to 3.3 V, TA = −40oC to +85°C, unless otherwise noted.

Table 1.

Parameter Min Typ Max Unit Test Conditions/Comments

CAPACITANCE-TO-DIGITAL CONVERTER

Update Rate 30 Hz Maximum programmed sequence length

Resolution 16 Bit

Range ±2 pF

No Missing Codes 16 Bit

Total Unadjusted Error TBD fF

Power Supply Rejection 500 aF/V

Output Noise (Peak-to-Peak) 10 aF/√Hz

Parasitic Capacitance 60 pF

EXCITATION SOURCE

Frequency TBD 240 TBD kHz

Output Voltage AV

CC

V

Short-Circuit Current 10 mA

Maximum Output Load 500 pF Capacitance load on source to ground

C

Output Drive 10 μA

SHIELD

C

Bias Level AVCC/2 V

SHIELD

LOGIC INPUTS (SDI, SCLK, CS, SDA, GPI, TEST)

V

Input High Voltage 0.7 x V

IH

VIL Input Low Voltage 0.3 x V

I

Input High Voltage −1 μA

IH

V

DRIVE

V

DRIVE

IIL Input Low Voltage 1 μA

Hysteresis 150 mV

OPEN-DRAIN OUTPUTS (SDO, SDA, INT)

VOL Output Low Voltage 0.4 V I

IOH Output High Leakage Current 0.1 1 μA V

LOGIC OUTPUTS

VOL Output Low Voltage 0.4 V I

VOH Output High Voltage V

− 0.6 V I

DRIVE

Floating State Leakage Current ±10 μA Pin tri-stated

POWER

AV

V

I

DRIVE

CC

DV

CC,

CC

2.7 3.6 V

1.65 DVCC + 0.3 V Serial interface operating voltage

1 TBD mA Full power mode

50 TBD μA Low power mode (conversion delay = 400 ms)

2 TBD μA Full shutdown

Guaranteed by design, but not production

tested

Parasitic capacitance to ground, guaranteed

by characterization

= −1 mA

SINK

= V

OUT

DRIVE

= 1 mA, V

SINK

SOURCE

= 1 mA

= 1.6 V to DVCC + 0.3 V

DRIVE

Rev. PrD | Page 3 of 64

AD7142/AD7142-1 Preliminary Technical Data

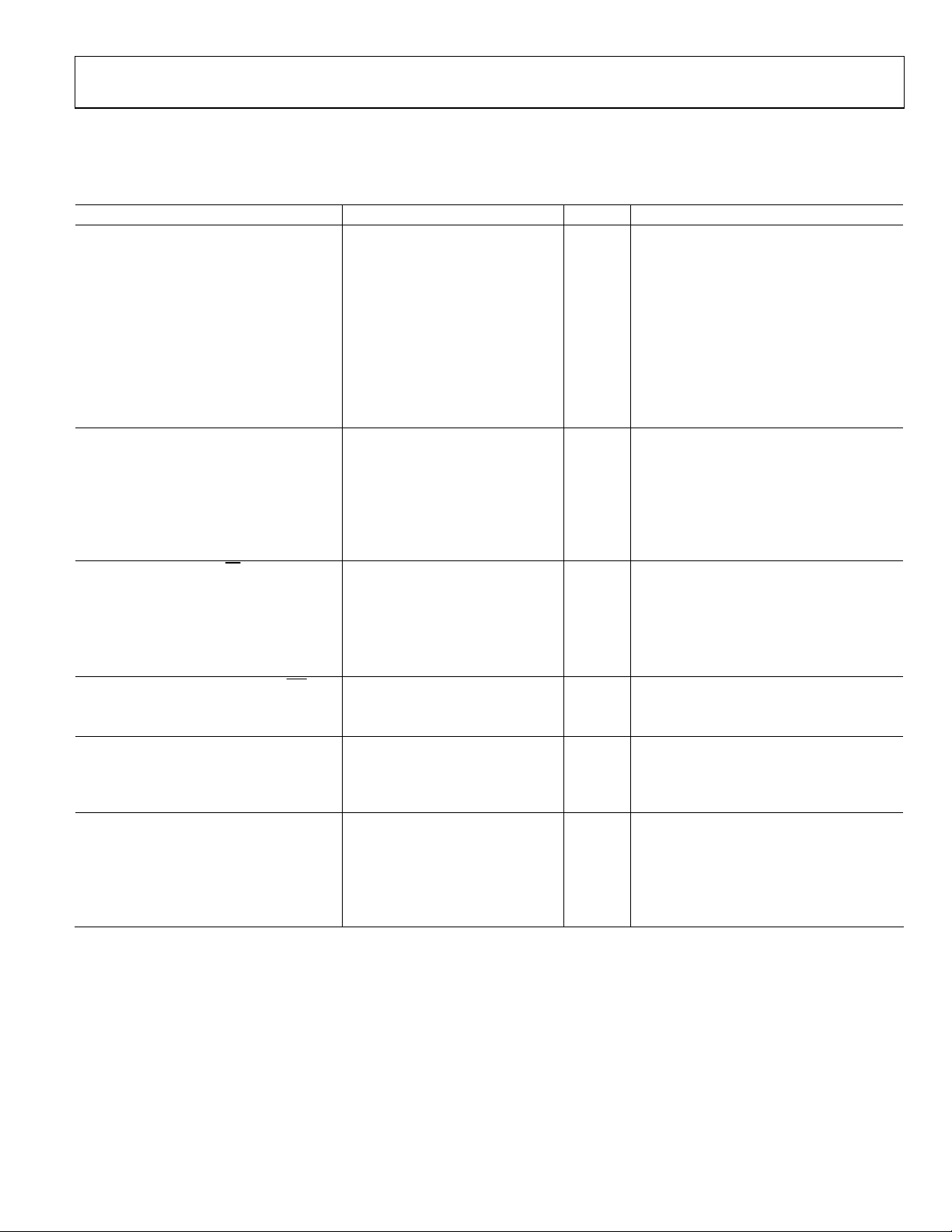

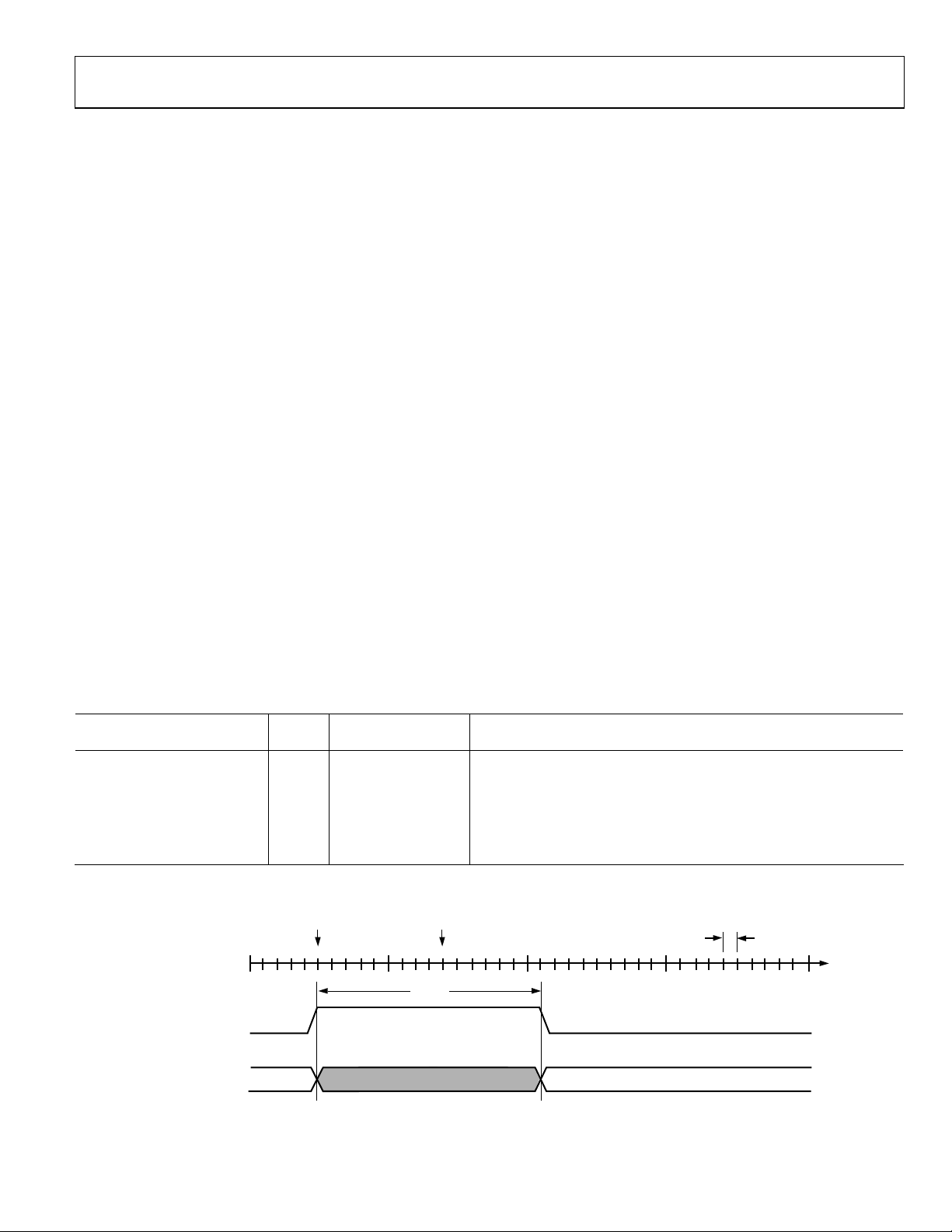

SPI TIMING SPECIFICATIONS AD7142

TA = −40°C to +105°C; V

compliance. All input signals are specified with t

Table 2. SPI Timing Specifications

Parameter Limit at T

1

f

SCLK

10 kHz min

10 MHz max

t

1

t

2

5 ns min

20 ns min SCLK high pulse width

t3 20 ns min SCLK low pulse width

t4 15 ns min SDI set-up time

t5 15 ns min SDI hold time

t

6

20 ns max SDO access time after SCLK falling edge

t7 16 ns max

t

8

1

Mark/space ratio (duty cycle) for the DCLK input is 40/60 to 60/40.

TBD ns

CS

SCLK

SDI

= 1.8 V to 3.6 V; AVCC, DVCC = 2.7 V to 3.6 V, unless otherwise noted. Sample tested at 25°C to ensure

DRIVE

= tF = 5 ns (10% to 90% of VCC) and timed from a voltage level of 1.6 V.

R

MIN

, T

MAX

Unit Description

CS falling edge to first SCLK falling edge

CS rising edge to SDO high impedance

SCLK rising edge to

t

1

t

t

4

MSB

2

1

t

5

t

3

23

15

16

LSB

CS high

12

t

8

15

16

t

SDO

6

MSB

Figure 2. SPI Detailed Timing Diagram

LSB

t

7

05702-002

Rev. PrD | Page 4 of 64

Preliminary Technical Data AD7142/AD7142-1

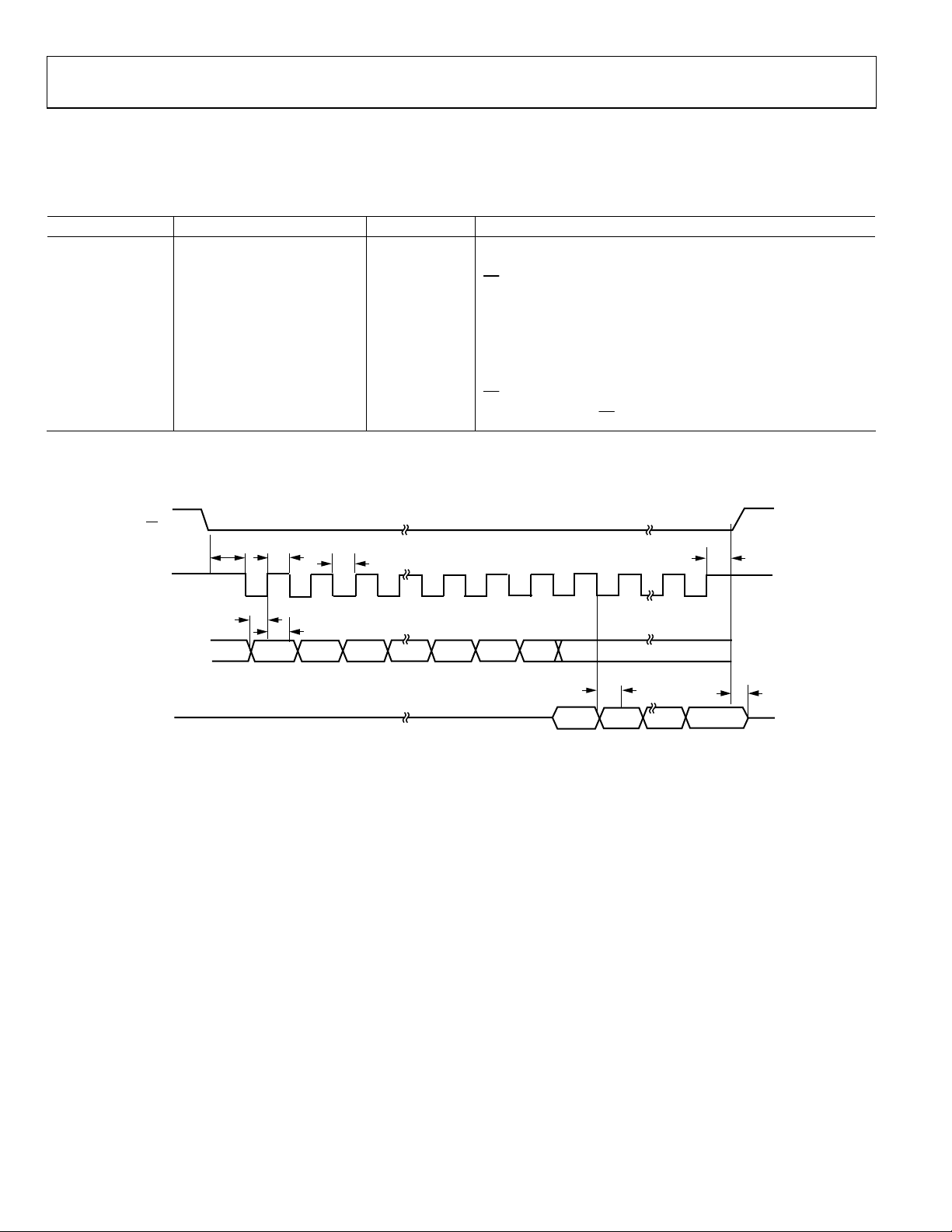

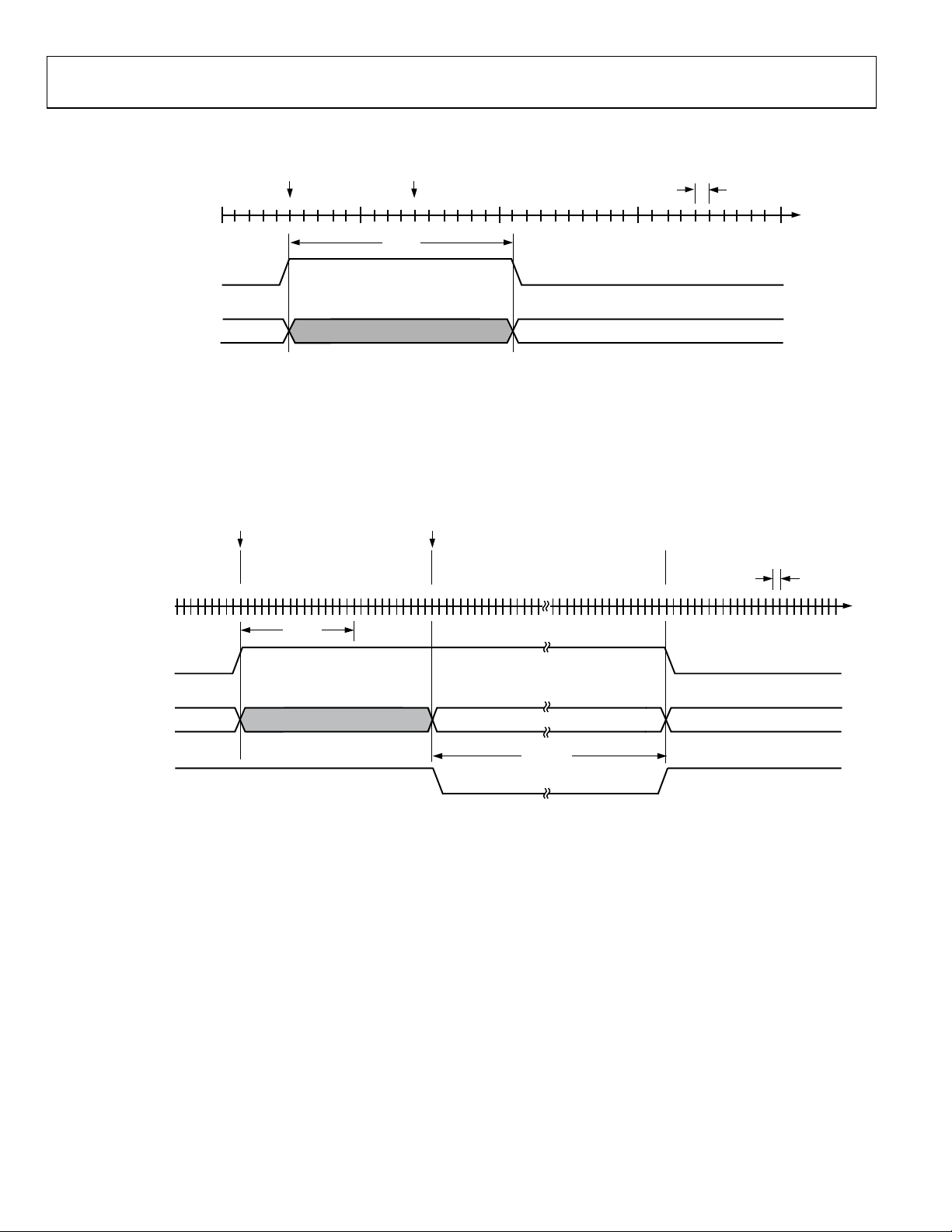

S

A

I2C TIMING SPECIFICATIONS AD7142-1

TA = −40°C to +105°C; V

Sample tested at 25°C to ensure compliance. All input signals timed from a voltage level of 1.6 V.

2

Table 3. I

C Timing Specifications

Parameter Limit Unit Description

f

t

t

t

t

t

t

t

t

SCLK

1

2

3

4

5

6

7

8

400 kHz max

0.6 μs min Start condition hold time, t

1.3 μs min Clock low period, between 10% points, t

0.6 μs min Clock high period, between 90% points, t

100 ns min Data setup time , t

50 ns min Data hold time, t

0.6 μs min Stop condition setup time, t

0.6 μs min Start condition setup time, t

1.3 μs min Bus free time between stop and start conditions, t

tR 300 ns max Clock/data rise time

tF 300 ns max Clock/data fall time

1

Guaranteed by design, but not production tested.

= 1.8 V to 3.6 V; AVCC, DVCC = 2.7 V to 3.6 V, unless otherwise noted.

DRIVE

1

SU; DAT

HD; DAT

HD; STA

SU; STO

SU; STA

LOW

HIGH

BUF

t

t

2

SCLK

t

1

DAT

t

8

STOP START STOPSTART

R

t

5

t

F

t

3

Figure 3. I

t

4

2

C Detailed Timing Diagram

t

1

t

7

t

6

05702-003

Rev. PrD | Page 5 of 64

AD7142/AD7142-1 Preliminary Technical Data

ABSOLUTE MAXIMUM RATINGS

Table 4.

Parameter Rating

AVCC to AGND, DVCC to DGND −0.3 V to +3.6 V

Analog Input Voltage to AGND −0.3 V to AVCC + 0.3 V

Digital Input Voltage to DGND −0.3 V to V

Digital Output Voltage to DGND −0.3 V to V

Input Current to Any Pin Except

Supplies

1

10 mA

DRIVE

DRIVE

+ 0.3 V

+ 0.3 V

ESD Rating 2.5 kV

Operating Temperature Range −40°C to +105°C

Storage Temperature Range −65°C to +150°C

Junction Temperature 150°C

LFCSP Package

Power Dissipation 450 mW

θJA Thermal Impedance 135.7°C/W

IR Reflow Peak Temperature 260°C (±0.5°C)

Lead Temperature (Soldering 10 sec) 300°C

1

Transient currents of up to 100 mA do not cause SCR latch-up.

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

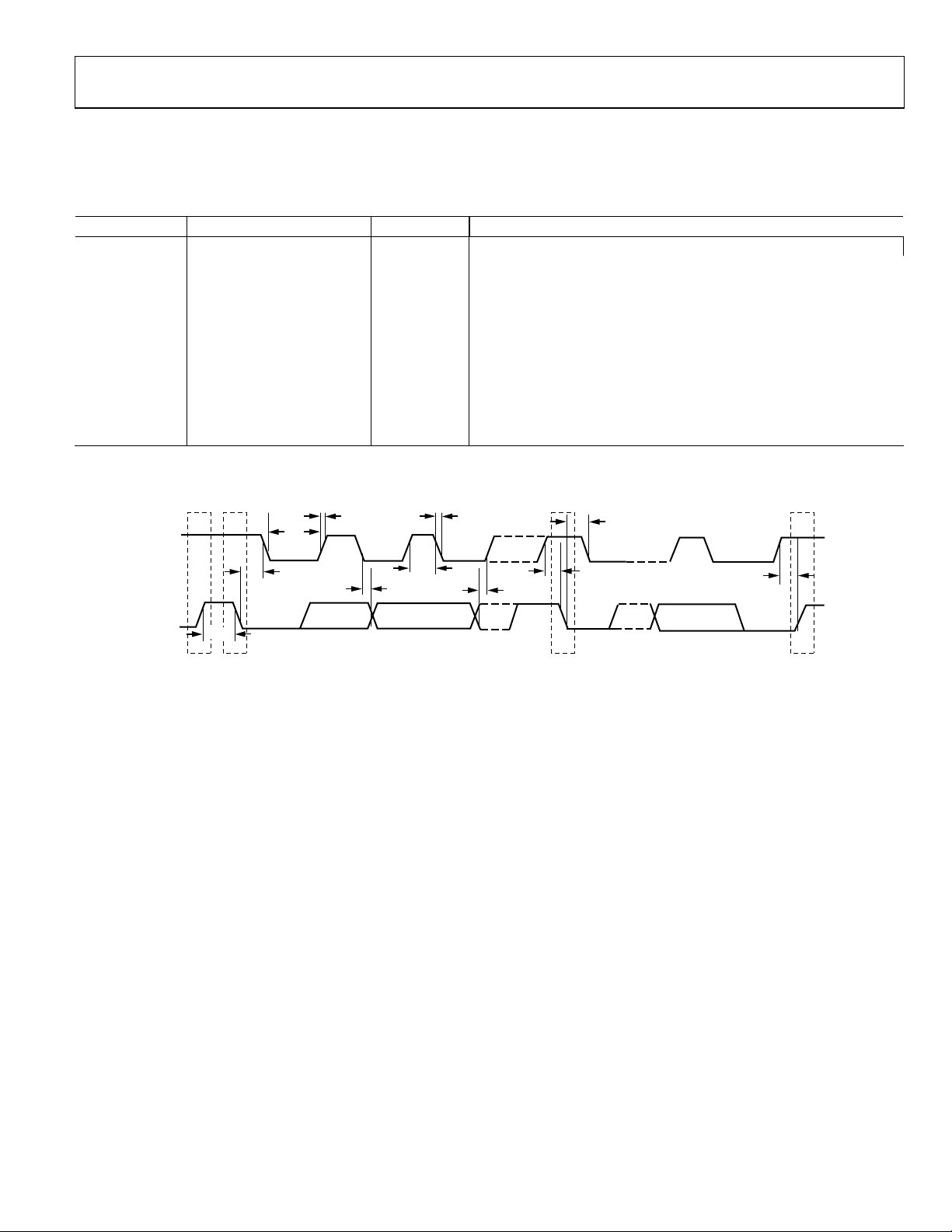

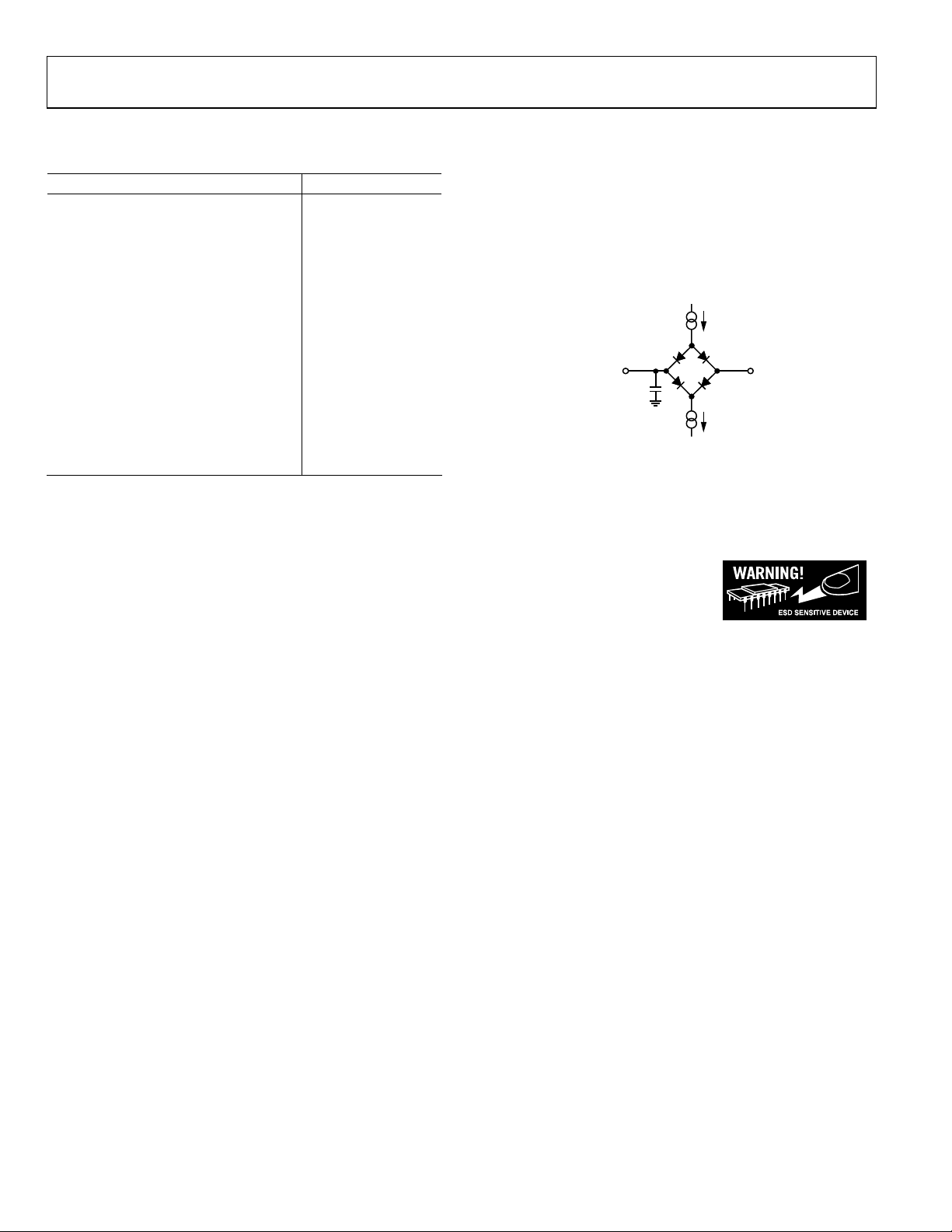

200μAI

TO OUTPUT

PIN

C

L

50pF

200μAI

Figure 4. Load Circuit for Digital Output Timing Specifications

OL

1.6V

OH

05702-004

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Rev. PrD | Page 6 of 64

Preliminary Technical Data AD7142/AD7142-1

+

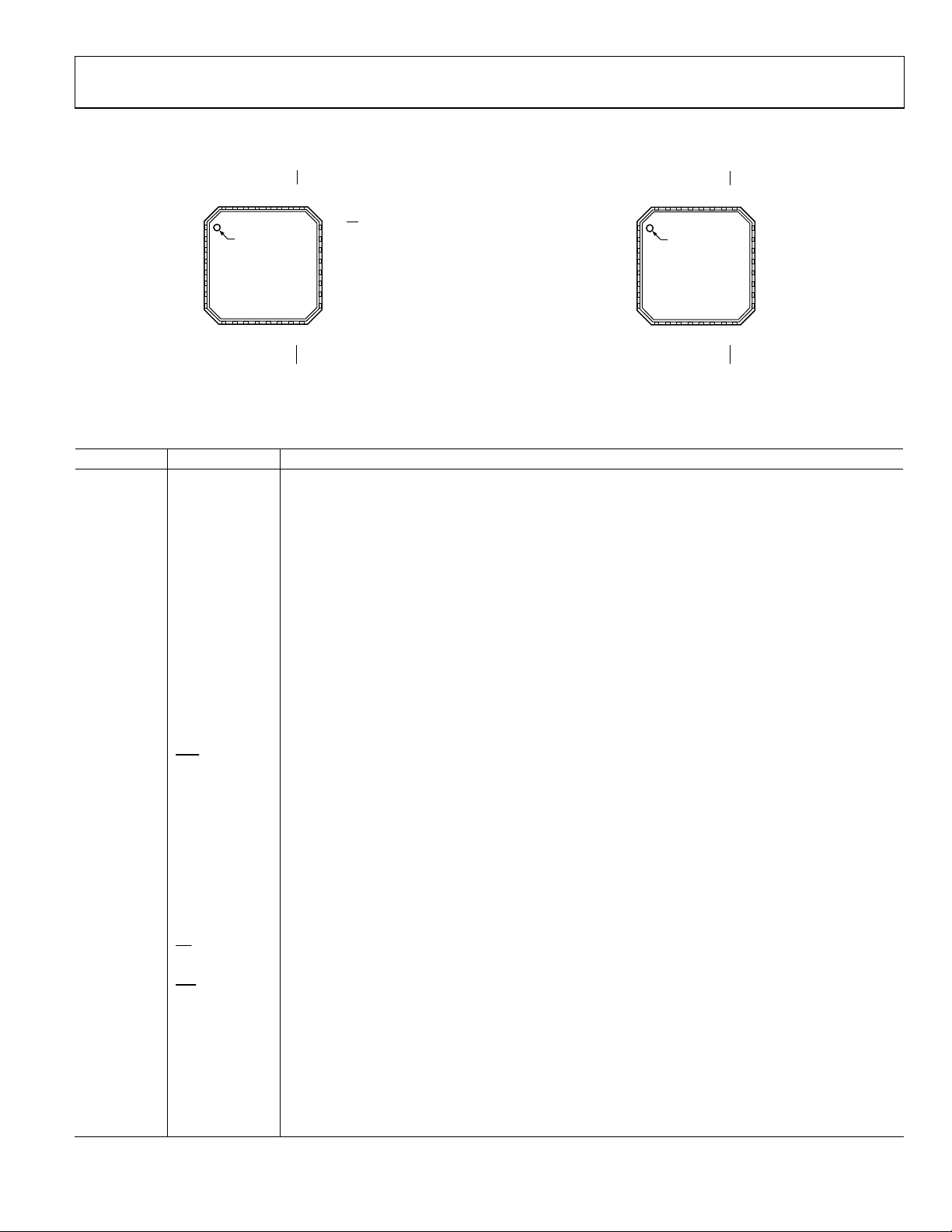

PIN CONFIGURATION AND FUNCTIONAL DESCRIPTIONS

T

REF

REF–

V

CIN2

32

TEST

CIN0

V

GPIO

CIN1

31

30

IN

29

28

27

26

25

CIN2

32

REF+

REF–

V

TEST

GPIO

CIN1

CIN0

31

30

INT

V

26

25

29

28

27

1CIN3

PIN 1

2CIN4

INDICATOR

3CIN5

4CIN6

AD7142

5CIN7

TOP VIEW

6CIN8

(Not to Scale)

7CIN9

8CIN10

9

11

13

10

12

3

CC

AV

CIN11

CIN12

CIN1

SHIELD

C

Figure 5. AD7142, 32-Lead LFCSP Pin Configuration

24 CS

23 SCLK

22 SDI

21 SDO

20 V

DRIVE

19 DGND2

18 DGND1

17 DV

CC

15

14

16

SRC

SRC

AGND

05702-005

1CIN3

2CIN4

3CIN5

4CIN6

5CIN7

6CIN8

7CIN9

8CIN10

PIN 1

INDICATOR

AD7142-1

TOP VIEW

(Not to Scale)

9

11

12

10

CIN13

CIN11

CIN12

SHIELD

C

16

15

13

14

CC

SRC

SRC

AV

AGND

Figure 6. AD7142-1, 32-Lead LFCSP Pin Configuration

Table 5. Pin Function Descriptions

Pin No. Name Description

1 CIN3 Capacitance Sensor Input.

2 CIN4 Capacitance Sensor Input.

3 CIN5 Capacitance Sensor Input.

4 CIN6 Capacitance Sensor Input.

5 CIN7 Capacitance Sensor Input.

6 CIN8 Capacitance Sensor Input.

7 CIN9 Capacitance Sensor Input.

8 CIN10 Capacitance Sensor Input.

9 CIN11 Capacitance Sensor Input.

10 CIN12 Capacitance Sensor Input.

11 CIN13 Capacitance Sensor Input.

12 C

13 AV

SHIELD

CC

CDC Shield Potential Output. Requires 10 nF capacitor to ground. Connect to external shield.

CDC Supply Voltage.

14 AGND Analog Ground Reference Point for All CDC Circuitry. Tie to analog ground plane.

15 SRC CDC Excitation Source Output.

16

SRC

17 DV

CC

Inverted Excitation Source Output.

Digital Core Supply Voltage.

18 DGND1 Digital Ground.

19 DGND2 Digital Ground.

20 V

DRIVE

Serial Interface Operating Voltage Supply.

21 SDO AD7142 SPI Serial Data Output.

SDA AD7142-1 I2C Serial Data Input/Output. SDA requires pull-up resistor.

22 SDI AD7142 SPI Serial Data Input.

ADD0 AD7142-1 I2C Address Bit 0.

23 SCLK Clock Input for Serial Interface.

24

CS

AD7142 SPI Chip Select Signal.

ADD1 AD7142-1 I2C Address Bit 1.

25

INT

General Purpose Interrupt Output. Programmable polarity. Requires pull-up resistor.

26 GPIO Programmable GPIO.

27 TEST Factory Test Pin. Tie to ground.

28 V

29 V

REF+

REF−

CDC Positive Reference Input. Normally tied to analog power.

CDC Negative Reference Input. Tie to analog ground.

30 CIN0 Capacitance Sensor Input.

31 CIN1 Capacitance Sensor Input.

32 CIN2 Capacitance Sensor Input.

24 ADD1

23 SCLK

22 ADD0

21 SDA

20 V

DRIVE

19 DGND2

18 DGND1

17 DV

CC

05702-044

Rev. PrD | Page 7 of 64

AD7142/AD7142-1 Preliminary Technical Data

TYPICAL PERFORMANCE CHARACTERISTICS

Figure 7. Supply Current vs. AV

DD

Rev. PrD | Page 8 of 64

Preliminary Technical Data AD7142/AD7142-1

THEORY OF OPERATION

The AD7142 and AD7142-1 are capacitance-to-digital

converters (CDCs) with on-chip environmental compensation,

intended for use in portable systems requiring high resolution

user input. The internal circuitry consists of a 16-bit, ∑-∆ converter that converts a capacitive input signal into a digital value.

There are 14 input pins on the AD7142 and AD7142-1, CIN0 to

CIN13. A switch matrix routes the input signals to the CDC.

The result of each capacitance-to-digital conversion is stored in

on-chip registers. The host subsequently reads the results over

the serial interface. The AD7142 contains an SPI interface and

the AD7142-1 has an I

2

C interface ensuring that the parts are

compatible with a wide range of host processors. Because the

AD7142 and AD7142-1 are identical parts, with the exception of

the serial interface, AD7142 refers to both the AD7142 and

AD7142-1 throughout this data sheet.

The AD7142 interfaces with to up to 14 external capacitance

sensors. These sensors can be arranged as buttons, scroll bars,

joypads, or as a combination of sensor types. The external

sensors consist of electrodes on a 2- or 4-layer PCB that

interfaces directly to the AD7142.

The AD7142 has a general interrupt output,

when new data has been placed into the registers.

to interrupt the host on sensor activation. The AD7142 operates from a 2.7 V to 3.6 V supply, and is available in a 32-lead,

5 mm × 5 mm LFCSP.

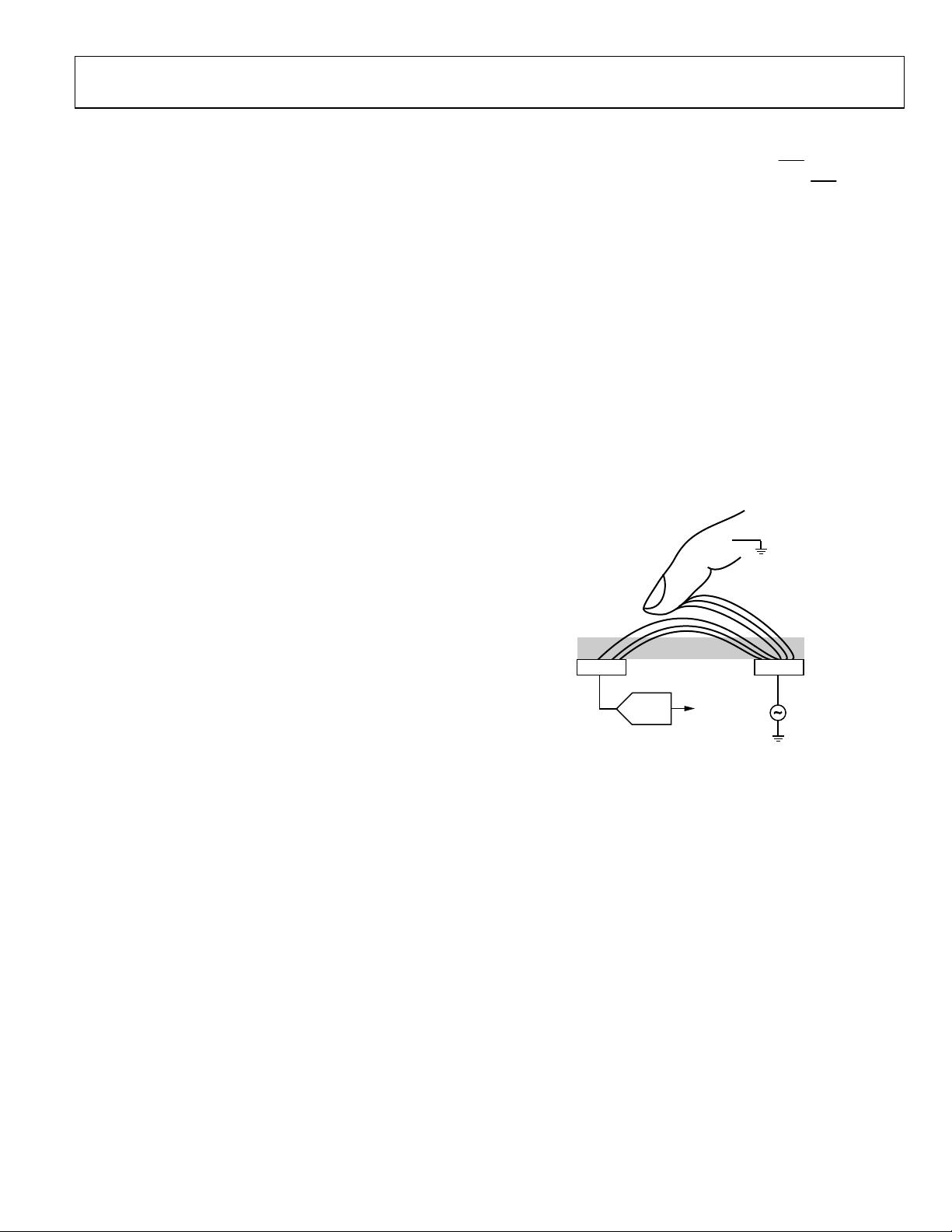

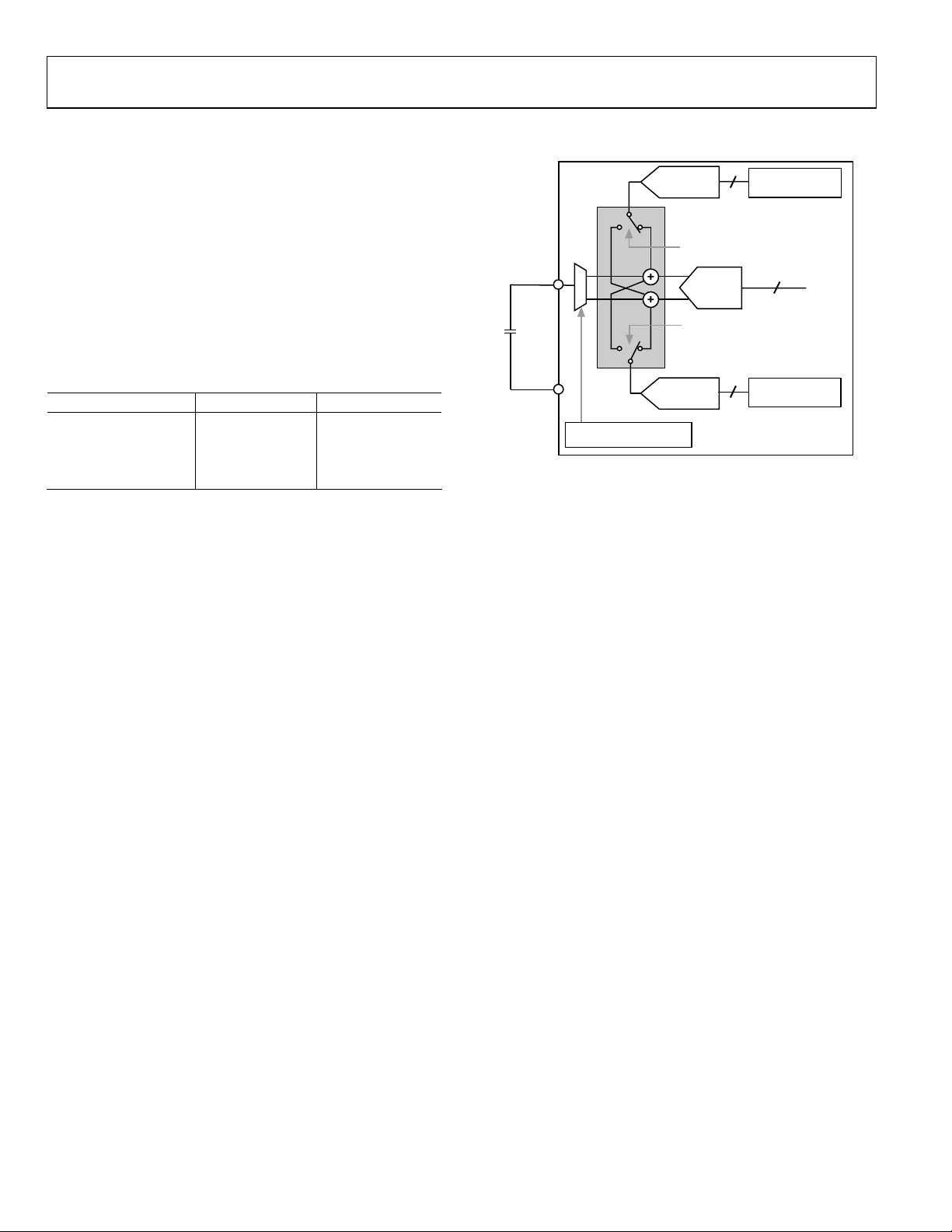

CAPACITANCE SENSING THEORY

The AD7142 uses a method of sensing capacitance known as

the shunt method. Using this method, an excitation source is

connected to a transmitter generating an electric field to a

receiver. The field lines measured at the receiver are translated

into the digital domain by a ∑-∆ converter. When a finger, or

other grounded object, interferes with the electric field, some of

the field lines are shunted to ground and do not reach the

receiver (see

measured at the receiver decreases when an object comes close

to the induced field.

Figure 8). Therefore, the total capacitance

INT

, to indicate

INT

is used

The AD7142 can be set up to implement any set of input

sensors by programming the on-chip registers. The registers

can also be programmed to control features such as averaging,

offsets, and gains for each of the external sensors. There is a

sequencer on-chip to control how each of the capacitance

inputs is polled.

The AD7142 has on-chip digital logic and 528 words of RAM

that are used for environmental compensation. The effects of

humidity, temperature, and other environmental factors can

effect the operation of capacitance sensors. Transparent to the

user, the AD7142 performs continuous calibration to

compensate for these effects, allowing the AD7142 to give

error-free results at all times.

The AD7142 requires some minor companion software that

runs on the host or other microcontroller to implement sensor

functions such as a scroll bar or joypad. However, no companion

software is required to implement buttons, including 8-way

button functionality. The algorithms required for button

sensors are implemented in digital logic on-chip.

The AD7142 can be programmed to operate in either always

powered mode, or in an automatic wake-up mode. The auto

wake-up mode is particularly suited for portable devices that

require low power operation giving the user significant power

savings coupled with full functionality.

RX

16-BIT

DATA

Σ-Δ

ADC

Figure 8. Sensing Capacitance Method

TX

EXCITATION

SIGNAL

240KHz

05702-007

In practice, the excitation source and ∑-∆ ADC are implemented

on the AD7142, while the transmitter and receiver are constructed

on a PCB that makes up the external sensor.

Registering a Sensor Activation

When a sensor is approached, the total capacitance associated

with that sensor, measured by the AD7142, changes. When the

capacitance changes to such an extent that a set threshold is

exceeded, the AD7142 registers this as a sensor touch.

For example, consider the case of two button sensors that are

connected to the AD7142 in a differential manner. When one

button is activated, the AD7142 registers an increase in capacitance;

if the other button is activated, the AD7142 registers a decrease

in capacitance. If neither of the buttons are activated, the AD7142

measures the background or ambient capacitance level.

Rev. PrD | Page 9 of 64

AD7142/AD7142-1 Preliminary Technical Data

Preprogrammed threshold levels are used to determine if a

change in capacitance is due to a button being activated. If the

capacitance exceeds one of the threshold limits, the AD7142

registers this as a true button activation.

The same thresholds principle is used to determine if other

types of sensors, such as sliders or joypads, are activated.

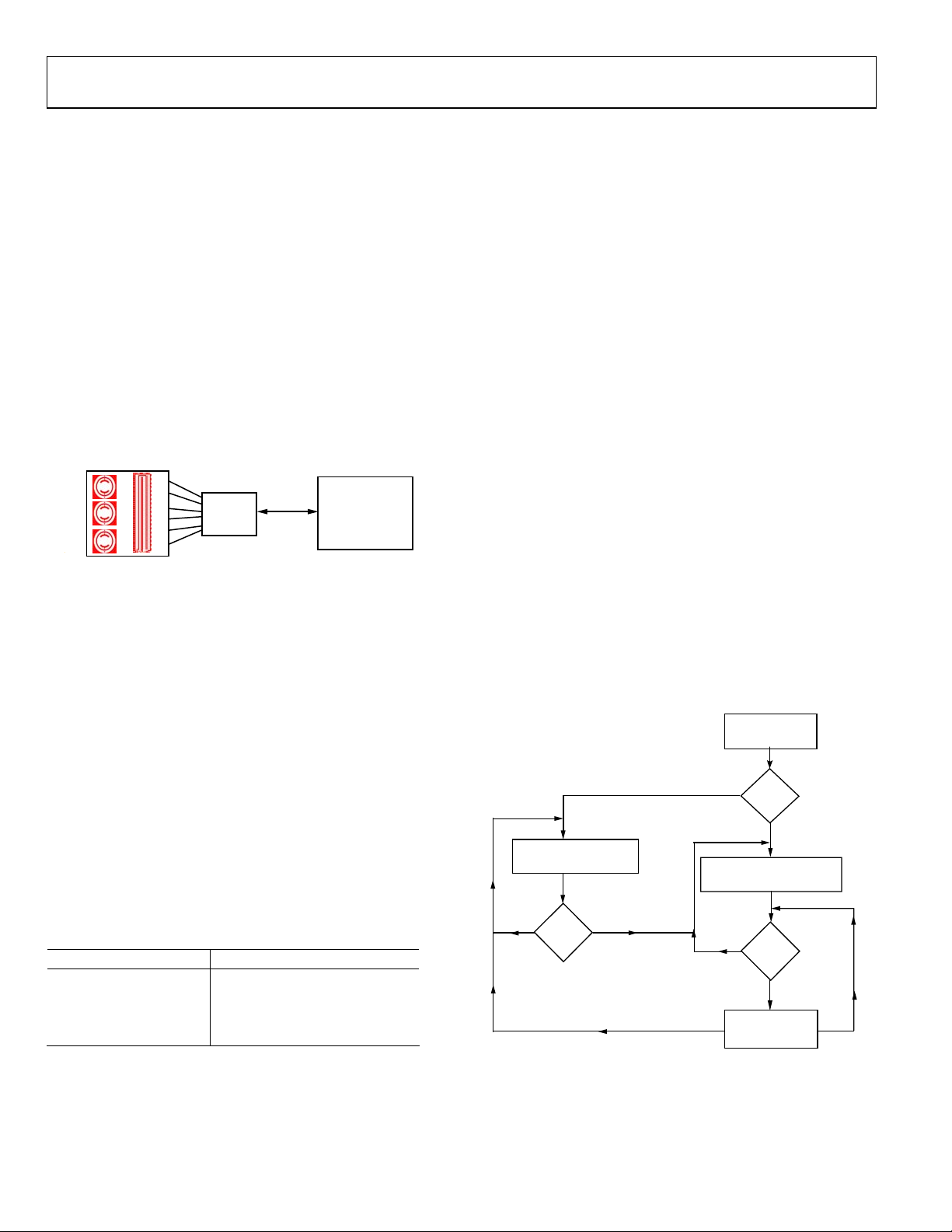

Complete Solution for Capacitance Sensing

Analog Devices provides a complete solution for capacitance

sensing. The two main elements to the solution are the sensor

PCB and the AD7142.

If the application requires sensors in the shape of a slider or

joypad, software is required that runs on the host processor.

(No software is required for button sensors.) The software

typically requires 3 kB of code and 500 bytes of data memory

for a slider sensor.

SENSOR PCB

AD7142

Figure 9. 3-Part Capacitance Sensing Solution

SPI or I2C

HOST PROCESSOR

1 MIPS

3kB ROM

500BYTES RAM

Analog Devices supplies the sensor PCB design to the customer

based on the customer’s specifications, and supplies any necessary

software on an open-source basis. Standard sensor designs are

also available as PCB library components.

OPERATING MODES

The AD7142 has three operating modes. Full power mode,

where the device is always fully powered, is suited for applications

where power is not a concern, for example game consoles that

have an ac power supply. Low power mode, where the part

automatically powers down, is tailored to give significant power

savings over full power mode, and is suited for mobile applications

where power must be conserved. The AD7142 also has a complete shutdown mode.

The POWER_MODE bits (Bit 0 and Bit 1) of the control

register set the operating mode on the AD7142. The control

register is at Address 0x000.

Table 6. POWER_MODE Settings

POWER_MODE Bits Operating Mode

00 Full power mode

01 Full shutdown mode

10 Low power mode

11 Full shutdown mode

Tabl e 6 shows the POWER_MODE settings for each operating

mode. To put the AD7142 into shutdown mode, set the

POWER_MODE bits to either 01 or 11.

05702-008

The power-on default setting of the POWER_MODE bits is 00,

full power mode.

Full Power Mode

In full power mode, all sections of the AD7142 remain fully

powered at all times. While a sensor is being touched, the

AD7142 processes the sensor data. If no sensor is touched, the

AD7142 measures the ambient capacitance level and uses this

data for the on-chip compensation routines. In full power

mode, the AD7142 converts at a constant rate. See the

Conversion Time

section for more information.

CDC

Low Power Mode

When in low power mode, the AD7142 POWER_MODE bits

are set to 10 upon device initialization. If the external sensors

are not touched, the AD7142 reduces its conversion frequency,

thereby greatly reducing its power consumption. The part

remains in a low power state while the sensors are not touched.

Every 400 ms, the AD7142 performs a conversion and uses this

data to update the compensation logic. When an external

sensor is touched, the AD7142 begins a conversion sequence

every 40 ms to read back data from the sensors. In low power

mode, the total current consumption of the AD7142 is an

average of the current used during a conversion, and the

current used while the AD7142 is waiting for the next

conversion to begin. For example, when the low power mode

conversion interval is 400 ms, the AD7142 uses typically 0.9 mA

current for 40 ms, and 15 A for 360 ms of the conversion

interval. (Note that these conversion timings can be altered

through the register settings. See the

CDC Conversion Time

section for more information.)

AD7142 SETUP

AND INITIALIZATION

POWER_MODE = 10

ANY

NO

SENSOR

TOUCHED?

YES

CONVERSIONS EVERY 400ms

UPDATE COMPENSATION

LOGIC DATA PATH

ANY

SENSOR

NO

TOUCHED?

YES

Figure 10. Low Power Mode Operation

SEQUENCER-CONTROLLED

CONVERSIONS ON ALL SENSORS

EVERY 40ms

ANY

SENSOR

YES

TOUCHED?

NO

TIMEOUT

PROXIMITY

TIMER

COUNT DOWN

05702-009

Rev. PrD | Page 10 of 64

Preliminary Technical Data AD7142/AD7142-1

CAPACITANCE SENSOR INPUT CONFIGURATION

Each stage of the AD7142 capacitance sensors can be uniquely

configured by using the registers in

Tabl e 53 and Tabl e 54 . These

registers are used to configure input pin connection set ups,

sensor offsets, sensor sensitivities, and sensor limits for each

stage. Apply this feature to optimize the function of each sensor

to the application. For example, a button sensor connected to

STAGE0 may require a different sensitivity and offset values

than a button with a different function that is connected to a

different stage.

CIN INPUT MULTIPLEXER SETUP

The CIN_CONNECTION_SETUP registers in Tab l e 5 3 list the

different options that are provided for connecting the sensor

input pin to the CDC converter.

The AD7142 has an on-chip multiplexer to route the input

signals from each pin to the input of the converter. Each input

pin can be tied to either the negative or the positive input of the

CDC, or it can be left floating. Each input can also be internally

connected to the C

an input is not used, always connect it to C

signal to help prevent cross coupling. If

SHIELD

SHIELD.

For each input pin, CIN0 to CIN13, the multiplexer settings can

be set on a per sequencer stage basis. For example, CIN0 is

connected to the negative CDC input for conversion STAGE1,

left floating for sequencer STAGE1, and so on for all twelve

conversion stages.

Two bits in each register control the mux setting for the input pin.

CIN0

CIN1

CIN2

CIN3

CIN4

CIN5

CIN6

CIN7

CIN8

CIN9

CIN10

CIN11

CIN12

CIN13

CIN_CONNECTION

_SETUP BITS

00

01 CINX CONNECTED TO

10

11

Figure 11. Input Mux Configuration Options

CIN SETTING

CINX FLOATING

NEGATIVE CDC INPUT

CINX CONNECTED TO

POSITIVE CDC INPUT

CINX CONNECTED TO

C

SHIELD

+

–

CDC

05702-010

Rev. PrD | Page 11 of 64

AD7142/AD7142-1 Preliminary Technical Data

CAPACITIANCE-TO-DIGITAL CONVERTER

The capacitance-to-digital converter on the AD7142 has a

sigma-delta (Σ-) architecture with 16-bit resolution. There are

14 possible inputs to the CDC that are connected to the input of

the converter through a switch matrix. The sampling frequency

of the CDC is 240 kHz.

OVERSAMPLING THE CDC OUTPUT

It is possible to sample the result of any CDC conversion at a

rate less than 240 kHz. The decimation rate, or over–sampling

ratio, is determined by Bits[9:8] of the control register, as listed

in

Tabl e 7.

Table 7. CDC Decimation Rate

Decimation Bit Value Decimation Rate CDC Sample Rate

00 256 312.5 Hz

01 128 625 Hz

10 64 1.25 kHz

11 64 1.25 kHz

The decimation process on the AD7142 is an averaging process

where a number of samples are taken and the averaged result is

output. The amount of samples taken is set equal to the

decimation rate, so 256, 128, or 64 samples are averaged to

obtain the CDC output.

The decimation process reduces the amount of noise present in

the final CDC result. However, the higher the decimation rate,

the lower the sampling frequency, thus, a tradeoff is required

between a noise-free signal and speed of sampling.

CAPACITANCE SENSOR OFFSET CONTROL

Apply the STAGE_OFFSET registers to null any capacitance

sensor offsets associated with printed circuit board parasitic

capacitance, or capacitance due to any other source, such as

connectors. This is only required once during the initial

capacitance sensor characterization.

A simplified block diagram in

STAGE_OFFSET registers to null the offsets. The 7-bit

POS_AFE_OFFSET and NEG_AFE_OFFSET registers provide

0.16 pF resolution offset adjustment over a range of 20 pF. Apply

the positive and negative offsets to either the positive or the

negative CDC input using the NEG_AFE_OFFSET and

POS_AFE_OFFSET registers.

Figure 12 shows how to apply the

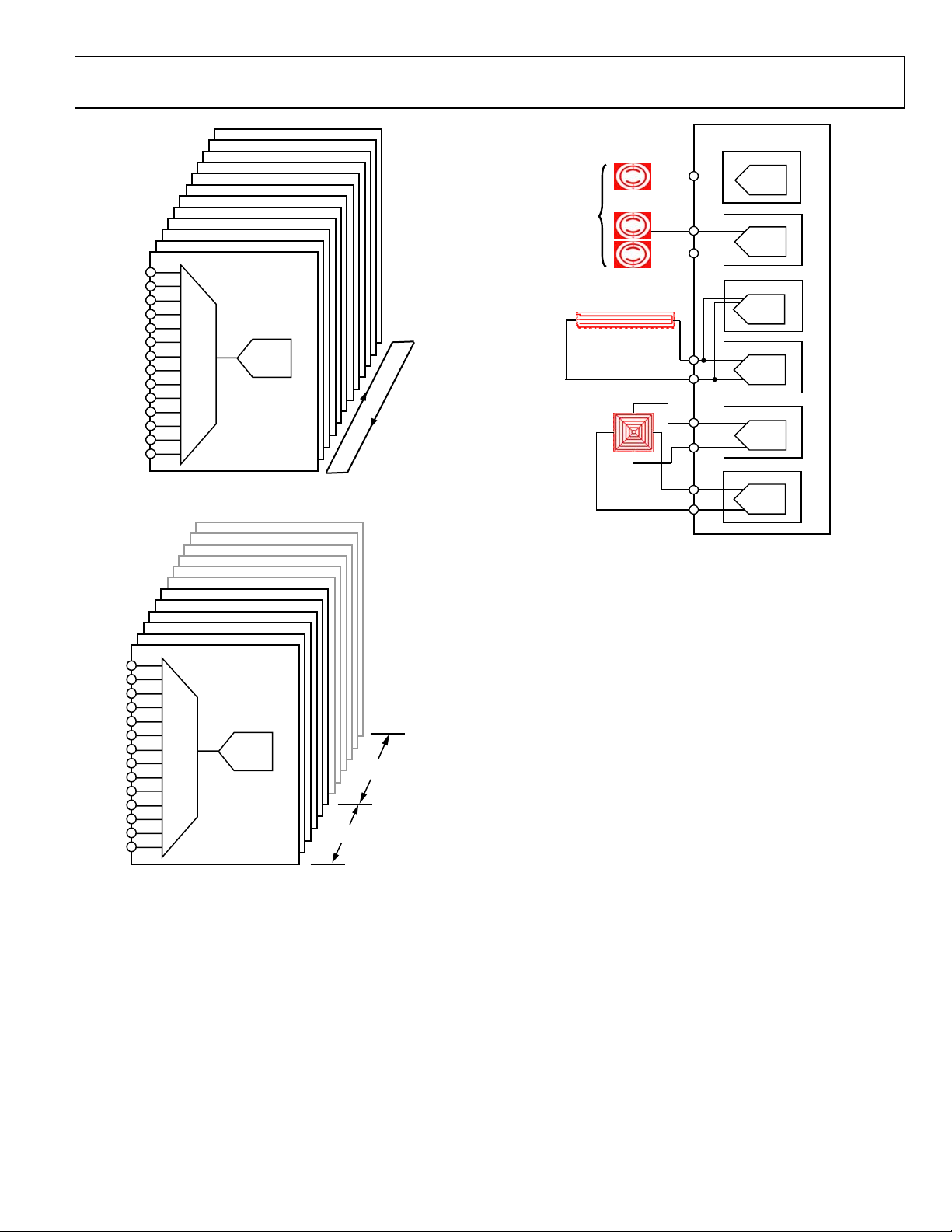

CONVERSION SEQUENCER

The AD7142 has an on-chip sequencer to implement

conversion control for the input channels. Up to 12 conversion

stages can be performed in sequence. By using the Bank 2

registers, each stage can be uniquely configured to support

multiple capacitance sensor interface requirements. For

example, a slider sensor can be assigned to STAGE1 with a

button sensor assigned to STAGE2.

The AD7142 on-chip sequencer controller provides conversion

control beginning with STAGE0.

of the CDC conversion stages and CIN inputs. A conversion

sequence is defined as a sequence of CDC conversion starting at

STAGE0 and ending at the stage determined by the value programmed in the SEQUENCE_STAGE_NUM register. In

the conversion sequence is from STAGE0 through STAGE5.

Depending on the number and type of capacitance sensors that are

used, not all conversion stages are required. Use the

SEQUENCE_STAGE_NUM register to set the number of

conversions in one sequence, depending on the sensor interface

requirements. For example, this register would be set to 5 if the

CIN inputs were mapped to only six stages as shown in

In addition, set the STAGE_CAL_EN registers according to the

number of stages that are used.

SENSOR

+DAC

(20pF RANGE)

CIN

EXT

CIN_CONNECTION_SETUP

REGISTER

Figure 12. Analog Front End Offset Control

–DAC

(20pF RANGE)

Figure 13 shows a block diagram

7

POS_AFE_OFFSET

REGISTER

POS_AFE_OFFSET_SWAP

REGISTER

+

16-BIT

CDC

_

NEG_AFE_OFFSET_SWAP

16

REGISTER

7

NEG_AFE_OFFSET

REGISTER

Figure 14,

Figure 14.

05702-011

Rev. PrD | Page 12 of 64

Preliminary Technical Data AD7142/AD7142-1

C

C

C

C

C

C

C

C

STAGE 11

STAGE 10

STAGE 9

STAGE 8

STAGE 7

STAGE 6

STAGE 5

STAGE 4

STAGE 3

STAGE 2

STAGE 1

CIN0

CIN1

CIN2

CIN3

CIN4

CIN5

CIN6

CIN7

CIN8

CIN9

IN10

IN11

IN12

IN13

STAGE 0

Σ-Δ

16-BIT

ADC

SWITCH MATRIX

CON

E

ENC

U

EQ

S

N

O

ERSI

V

05702-012

Figure 13. AD7142 CDC Conversion Stages

STAGE 11

STAGE 10

STAGE 9

STAGE 8

STAGE 7

STAGE 6

STAGE 5

STAGE 4

STAGE 3

STAGE 2

STAGE 1

CIN0

CIN1

CIN2

CIN3

CIN4

CIN5

CIN6

CIN7

CIN8

CIN9

IN10

IN11

IN12

IN13

NOTES

1. SEQUENCE_STAGE_NUM = 5.

2. FF_SKIP_CNT = 3 (VALUE SELECTED FROM TABLE 8

FOR DECIMATION = 128).

STAGE 0

Σ-Δ

16-BIT

ADC

SWITCH MATRIX

FF_SKIP_CNT

SEQUENCE_CONV_NUM

Figure 14. Example Using SEQUENCE_CON_NUM and

FF_SKIP_CNT Registers

The number of required conversion stages depends wholly on

the number of sensors attached to the AD7142.

Figure 15 shows

how many conversion stages are required for each sensor, and

how many inputs to the AD7142 each sensor requires.

05702-013

BUTTONS

SLIDER

8-WAY SWITCH

Figure 15. Sequencer Setup for Sensors

A button sensor generally requires one sequencer stage;

however, it is possible to configure two button sensors to

operate differentially. Only one button from the pair can be

activated at a time; pressing both buttons together results in

neither button being activated. This configuration requires one

conversion stage.

A slider sensor requires two stages: one stage for sensor

activation; the other stage for measuring positional data from

the slider. In

Figure 15, the slider activation uses STAGE2, while

the positional data uses STAGE3.

The 8-way switch is made from two pairs of differential buttons.

It, therefore, requires two conversion stages, one for each of the

differential button pairs. The buttons are orientated so that one

pair makes up the top and bottom portions of the 8-way switch;

the other pair makes up the left and right portions of the 8-way

switch.

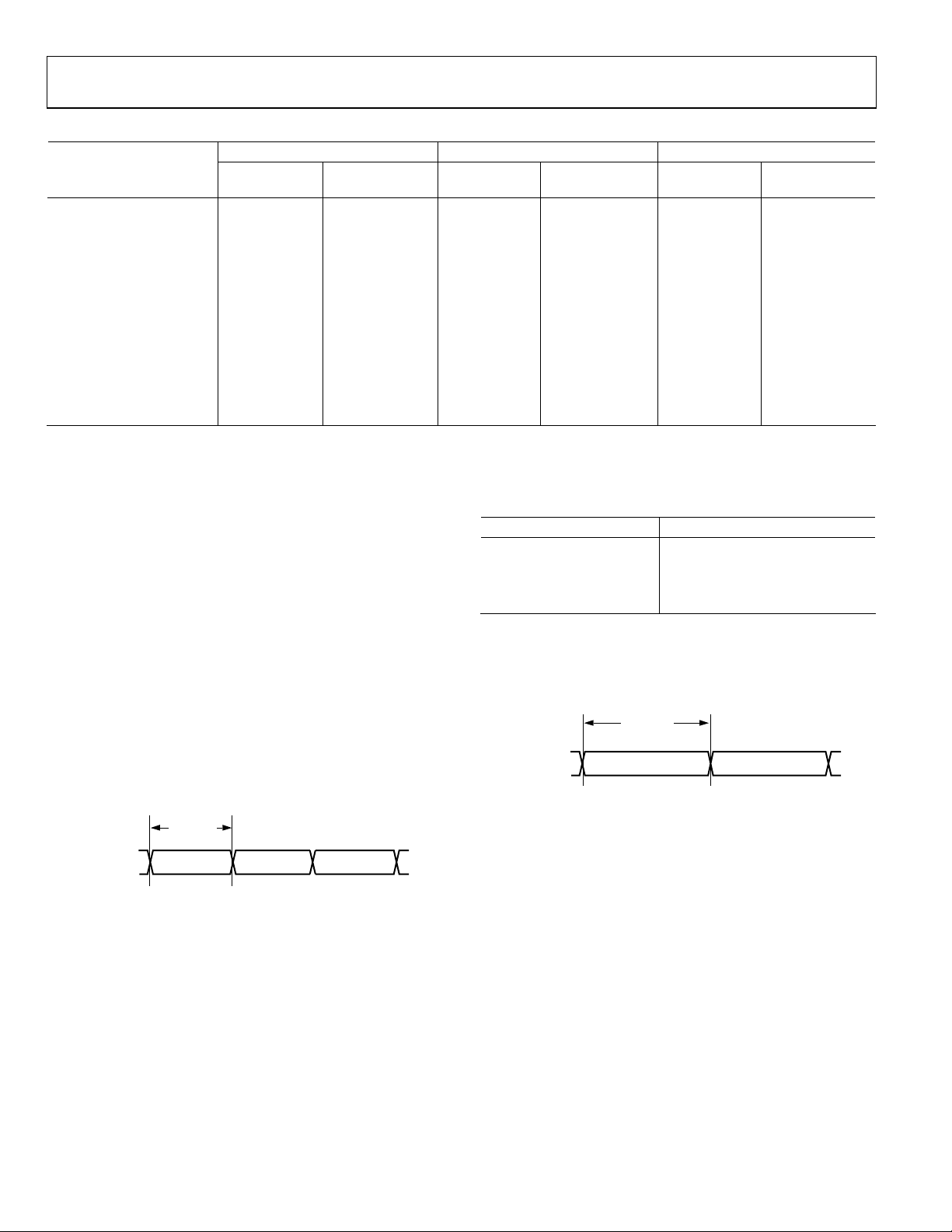

CDC CONVERSION TIME

The time required for one complete measurement by the CDC

is defined as the CDC conversion time. For optimal system performance, configure the AD7142 CDC conversion time within a

range of 35 ms to 40 ms. The SEQUENCE_STAGE_NUM,

FF_SKIP_CNT, and DECIMATION registers determine the

conversion time as listed in

AD7142 SEQUENCER

CIN1

CIN2

CIN3

CIN4

CIN5

CIN6

CIN7

CIN8

Tabl e 8.

STAGE 0

+

CDC

–

STAGE 1

+

CDC

–

STAGE 2

+

CDC

–

STAGE 3

+

CDC

–

STAGE 4

+

CDC

–

STAGE 5

+

CDC

–

05702-014

Rev. PrD | Page 13 of 64

AD7142/AD7142-1 Preliminary Technical Data

C

C

Table 8. CDC Conversion Times for Full Power Mode

DECIMATION = 64 DECIMATION = 128 DECIMATION = 256

SEQUENCE_STAGE_NUM

FF_SKIP_CNT

Time (ms)

FF_SKIP_CNT

0 11 9.2 11 18.4 11 36.5

1 11 18.4 11 36.8 5 36.5

2 11 27.6 7 36.8 3 36.5

3 11 36.8 5 36.8 2 36.5

4 9 38.4 4 38.4 2 46.0

5 7 36.8 3 36.8 1 36.8

6 6 37.6 2 32.2 1 43.0

7 5 36.8 2 36.8 1 49.1

8 4 34.5 2 41.4 0 27.6

9 4 38.4 1 30.7 0 30.7

10 3 33.8 1 33.8 0 33.7

11 3 36.8 1 36.8 0 36.8

CDC Conversion

For example, while operating with a decimation rate of 128,

if the SEQUENCE_STAGE_NUM register is set to 5 for the

conversion of six stages in a sequence, the FF_SKIP_CNT

register should be set to 3 resulting in a conversion time of

36.8 ms. This example is shown in

Figure 14.

Determining the FF_SKIP_CNT value is only required one time

during the initial setup of the capacitance sensor interface. This

value determines which CDC samples are not used (skipped) in

the proximity detection fast FIFO.

Full Power Mode CDC Conversion Time

The full power mode CDC conversion time is set by

LP_CONV_DELAY is set to 3. With a setting of 3, the AD7142

automatically wakes up, performing a conversion every 400 ms.

Table 9. LP_CONV_DELAY Settings

LP_CONV_DELAY BITS Delay Between Conversions

00 100 ms

01 200 ms

10 300 ms

11 400 ms

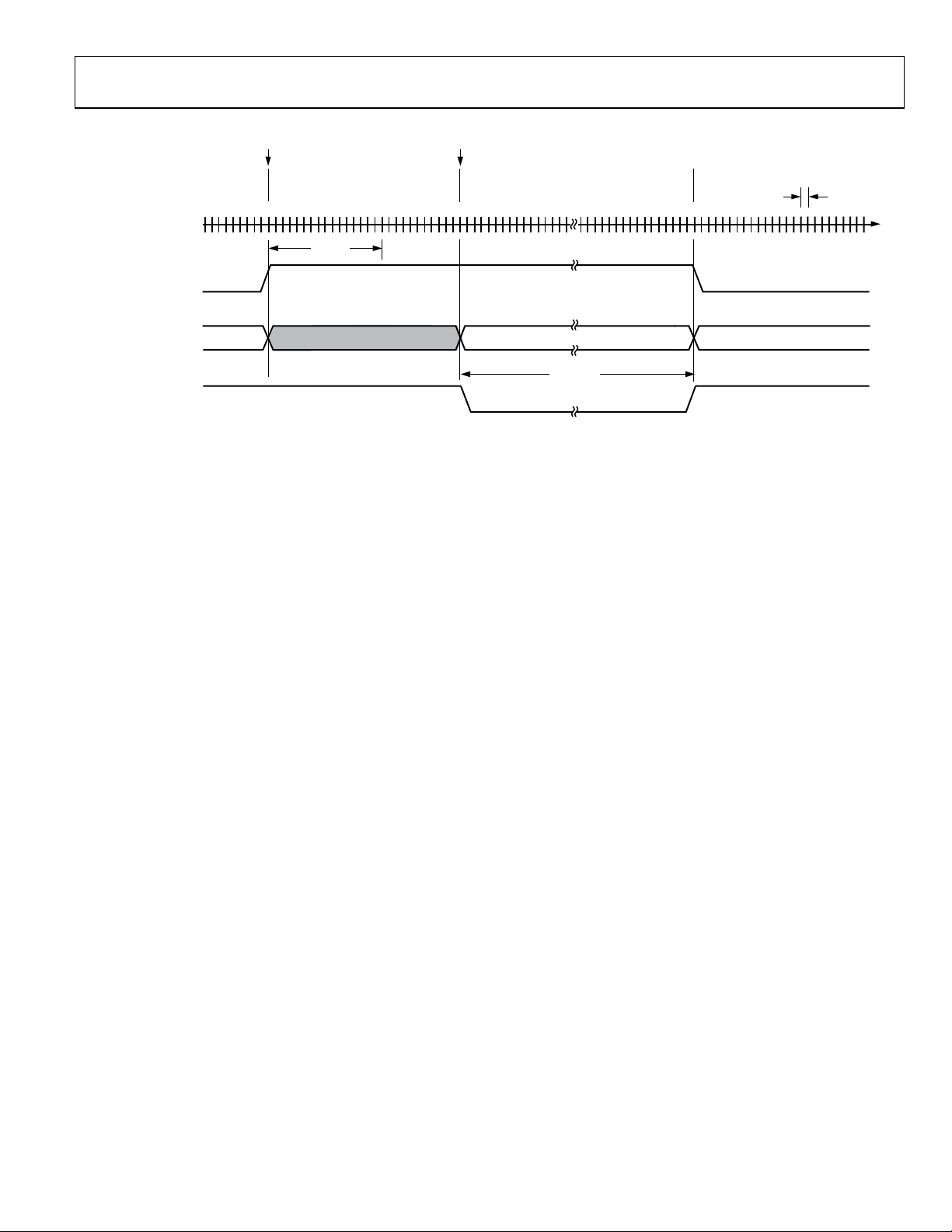

Figure 17 shows a simplified timing example of the low power

CDC conversion time. As shown, the low power CDC

conversion time is set by t

register.

configuring the SEQUENCE_STAGE_NUM, FF_SKIP_CNT

and DECIMATION registers as outlined in

Tabl e 8.

CDC Conversion

Time (ms)

t

CONV_LP

FF_SKIP_CNT

and the LP_CONV_DELAY

CONV_FP

CDC Conversion

Time (ms)

Figure 16 shows a simplified timing diagram of the full power

CDC conversion time. The full power mode CDC conversion

time t

ONVERSION

is set using Tabl e 8.

CONV_FP

t

CONV_FP

CDC

CONVERSIONNCONVERSION

NOTES

1.

t

= VALUE SET FROM TABLE 8.

CONV_FP

Figure 16. Full Power Mode CDC Conversion Time

N + 1

CONVERSION

N + 2

05702-015

Low Power Mode CDC Conversion Time with Delay

The frequency of each CDC conversion while operating in the

low power automatic wake up mode is controlled by using the

LP_CONV_DELAY register bits (Bits[3:2] in Register 0x00), in

addition to the registers listed in

Tabl e 8. This feature provides

some flexibility for optimizing the conversion time to meet

system requirements vs. AD7142 power consumption. For

example, maximum power savings is achieved when the

Rev. PrD | Page 14 of 64

CDC

ONVERSION

Figure 17. Low Power Mode CDC Conversion Time CDC Conversion Results

CONVERSION N CONVERSION N + 1

NOTES

t

1.

CONV_LP

=t

+ LP_CONV_DELAY

CONV_FP

05702-016

CDC CONVERSION RESULTS

Certain applications, such as a slider function, require reading

back the CDC conversion results for host processing. The

registers required for host processing are located in Register

Bank 3. The host processes the data read back from these

registers to determine relative position information.

In addition to the results registers in Bank 3, the AD7142

provides the 16-bit CDC output data directly starting at

Address 0x00B of Register Bank 1. Reading back the CDC

16-bit conversion data register allows for customer specific

application data processing.

Preliminary Technical Data AD7142/AD7142-1

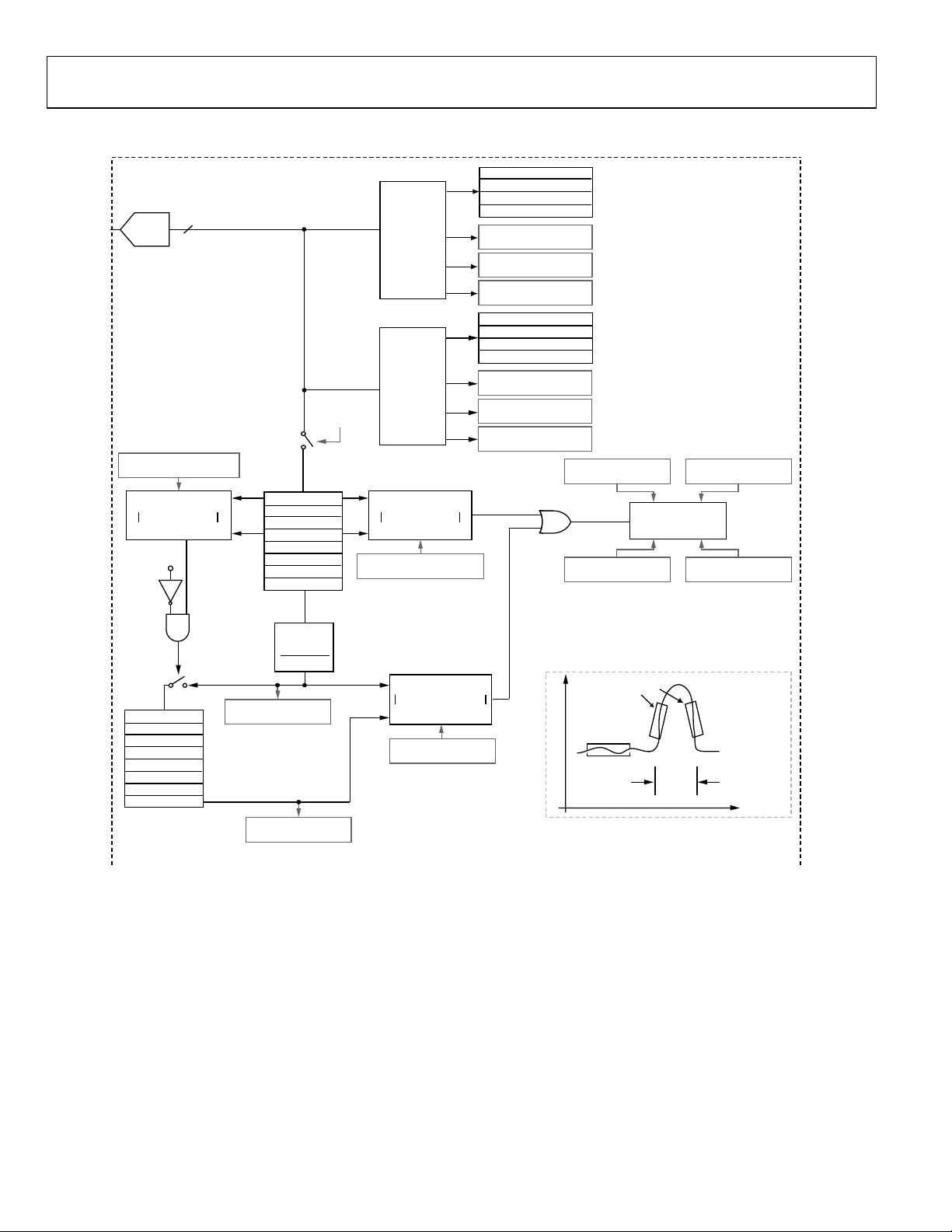

NON-CONTACT PROXIMITY DETECTION

The AD7142 internal signal processing continuously monitors

all capacitance sensors for non-contact proximity detection.

This feature provides the ability to detect when a user is

approaching a sensor, at which time all internal calibration is

immediately disabled while the AD7142 is automatically

configured to detect a valid contact.

The proximity control register bits are described in

Tabl e 10 .

The FP_PROXIMITY_CNT and LP_PROXIMITY_CNT register

bits control how long the calibration disable period is after

proximity is detected. The calibration is disabled during this

time and enabled again at the end of this period provided that

the user is no longer approaching, or in contact with, the sensor.

Figure 18 and Figure 19 show examples of how these registers

are used to set the full and low power mode calibration disable

periods.

Recalibration

In the event of a very long proximity detection event, such as a

user hovering over a sensor for a long period of time, the

FP_PROXIMITY_RECAL and LP_PROXIMITY_RECAL bits

in register 0x004 can be applied to force a recalibration. This

feature ensures that the ambient values are recalibrated

regardless of how long the user may be hovering over a sensor.

A recalibration ensures maximum AD7142 sensor performance.

Figure 20 and Figure 21 show examples of using the

FP_PROXIMITY_RECAL and LP_PROXIMITY_RECAL

register bits to force a recalibration while operating in the full

and low power modes. These figures show a user approaching a

sensor followed by the user leaving the sensor while the

proximity detection remained active after the user left the

sensor. This situation could occur if the user interaction created

some moisture on the sensor for example thus causing the new

sensor value to be different from the expected value. In this

case, the internal recalibration would be applied to

automatically recalibrate the sensor. The force calibration event

takes two interrupt cycles: nothing should be read from or

written to the AD7142 during the recalibration period.

Proximity Sensitivity

There are two conditions that set the internal proximity

detection signal as described in

Figure 22 with Comparator 1

and Comparator 2. Comparator 1 detects when a user is

approaching a sensor. The sensitivity of Comparator 1 is

controlled by PROXIMITY_DETECTION_RATE. For example,

if PROXIMITY_DETECTION_RATE is set to 4, the Proximity

1 signal is set when the absolute difference between WORD1

and WORD3 exceed four LSB codes. Comparator 2 detects

when a user is hovering over a sensor or approaches a sensor

very slowly. The sensitivity of Comparator 2 is controlled by the

PROXIMITY_RECAL_LVL in

Register 0x003. For example, if

PROXIMITY_RECAL_LVL is set to 75, the Proximity 2 signal

is set when the absolute difference between the fast filter

average value and the ambient value exceeds 75 LSB codes.

Table 10. Proximity Control Registers (Refer to

Figure 22)

Length

Register

(Bits)

Register Address Description

FP_PROXIMITY_CNT 4 0x002 Full power mode proximity control

LP_PROXIMITY_CNT 4 0x002 Low power mode proximity control

FP_PROXIMITY_RECAL 8 0x004 Full power mode proximity recalibration control

LP_PROXIMITY_RECAL 6 0x004 Low power mode proximity recalibration control

PROXIMITY_RECAL_LVL 8 0x003 Proximity recalibration level

PROXIMITY_DETECTION_RATE 6 0x003 Proximity detection rate

CDC CONVERSIONS

(INTERNAL)

PROXIMITY DETECTION

(INTERNAL)

CALIBRATION

(INTERNAL)

USER APPROCHES

SENSOR HERE

12345678910111213141516

Figure 18. Full Power Mode Proximity Detection Example with FP_PROXIMITY = 1

USER LEAVES SENSOR

AREA HERE

t

CALDIS

CALIBRATION DISABLED

CALIBRATION ENABLED

t

CONV_FP

05702-017

Rev. PrD | Page 15 of 64

AD7142/AD7142-1 Preliminary Technical Data

CDC CONVERSIONS

(INTERNAL)

USER APPROCHES

SENSOR HERE

12345678910111213141516

USER LEAVES SENSOR

AREA HERE

t

CALDIS

t

CONV_FP

PROXIMITY DETECTION

CALIBRATION

CDC CONVERSIONS

(INTERNAL)

PROXIMITY DETECTION

(INTERNAL)

CALIBRATION

(INTERNAL)

(INTERNAL)

(INTERNAL)

USER A PPROCHES

CALIBRATION DISABLED

NOTES

1. CONVERSION TIME

2. PROXIMITY IS SET WHEN USER APPROACHES THE SENSOR AT WHICH TIME THE INTERNAL CALIBRATION IS DISABLED.

3.

t

= (

CALDIS

t

= (

t

CONV_LP

t

× LP_PROXIMITY_CNT × 4) + LP_CONV_DELAY.

CONV_LP

+ LP_CONV_DELAY).

CONV_FP

CALIBRATION ENABLED

Figure 19. Low Power Mode Proximity Detection with LP_PROXIMITY = 4 and LP_CONV_DELAY = 0

SENSOR HERE

USER IN CONTACT WITH SENSOR

t

DISCAL

USER LEAVES SENSOR

AREA HERE

CDC CONVERSION VALUES EXCEED

PROXIMITY_RECALIBRATION _LVL

16 30 70

RECALIBRATION PERIOD

CALIBRATION ENABLEDCALIBRATION DISABLED

05702-018

t

CONV_FP

t

RECALIBRATION

(INTERNAL)

NOTES

1. CONVERSION TIME

2.

t

t

DISCAL

=

= (

CONV_FP

t

CONV_FP

3.

t

RECAL

t

DETERMINED FROM TABLE 8

CONV_FP

× FP_PROXIMITY_CNT)

× FP_PROXIMITY_RECAL)

RECAL

Figure 20. Full Power Mode Proximity Detection with Forced Recalibration Example with FP_PROXIMITY = 1 and FP_PROXIMITY_RECAL = 40

Rev. PrD | Page 16 of 64

05702-019

Preliminary Technical Data AD7142/AD7142-1

CDC CONVERSIONS

(INTERNAL)

PROXIMITY DETECTION

(INTERNAL)

CALIBRATION

(INTERNAL)

RECALIBRATION

(INTERNAL)

Figure 21. Low Power Mode Proximity Detection with Forced Recalibration Example with LP_PROXIMITY = 4 and LP_PROXIMITY_RECAL = 10

USER APPROCHES

SENSOR HERE

NOTES

CONVERSION TIME

1.

2.

t

=

t

DISCAL

RECAL

= (

CONV_LP

t

CONV_LP

3.

t

USER LEAVES SENSOR

USER IN CONTACT WITH SENSOR

16 30 70

t

DISCAL

t

=

t

CONV_LP

× (16 × LP_PROXIMITY_CNT)

× LP_PROXIMITY_RECAL × 4)

+ LP_CONV_DELAY.

CONV_HP

AREA HERE

CDC CONVERSION VALUES EXCEED

PROXIMITY_RECALIBRATION _LVL

RECALIBRATION PERIOD

t

RECAL

t

CONV_FP

CALIBRATION ENABLEDCALIBRATION DISABLED

05702-020

Rev. PrD | Page 17 of 64

AD7142/AD7142-1 Preliminary Technical Data

STAGE_MAX_WORD0

Σ-Δ

16

16-BIT

CDC

SLOW_FILTER_UPDATE_LVL

REGISTER 0x003

COMPARATOR 3

WORD 0 – WORD 3

PROXIMITY

SLOW FILTER EN

SW1

STAGE_SF_WORD0

STAGE_SF_WORD1

STAGE_SF_WORD2

STAGE_SF_WORD3

STAGE_SF_WORD4

STAGE_SF_WORD5

STAGE_SF_WORD6

STAGE_SF_WORD7

BANK 3 REGISTERS

SW

STAGE_FF_WORD0

STAGE_FF_WORD1

STAGE_FF_WORD2

STAGE_FF_WORD3

STAGE_FF_WORD4

STAGE_FF_WORD5

STAGE_FF_WORD6

STAGE_FF_WORD7

7

WORD(N)

Σ

N = 0

8

STAGE_FF_AVG

BANK 3 REGISTERS

STAGE_SF_AMBIENT

BANK 3 REGISTERS

CONTROL

LOGIC

PROXIMITY_DETECTION_RATE

BANK 3 REGISTERS

MAX LEVEL

DETECTION

LOGIC

MIN LEVEL

DETECTION

LOGIC

COMPARATOR 1

WORD 0 – WORD 3

REGISTER 0x003

COMPARATOR 2

AVERAGE – AMBIENT

PROXIMITY_RECAL_LVL

REGISTER 0x003

STAGE_MAX_WORD1

STAGE_MAX_WORD2

STAGE_MAX_WORD3

STAGE_MAX_AVG

BANK 3 REGISTERS

STAGE_MAX_TEMP

BANK 3 REGISTERS

STAGE_HIGH_THRESHOLD

BANK 3 REGISTERS

STAGE_MIN_WORD0

STAGE_MIN_WORD1

STAGE_MIN_WORD2

STAGE_MIN_WORD3

STAGE_MIN_AVG

BANK 3 REGISTER3

STAGE_MIN_TEMP

BANK 3 REGISTERS

STAGE_LOW_THRESHOLD

BANK 3 REGISTERS

PROXIMITY 1

PROXIMITY 2

BANK 3 REGISTERS

BANK 3 REGISTERS

FP_PROXIMITY_CNT

REGISTER 0x004

PROXIMITY

FP_PROXIMITY_RECAL

REGISTER 0x004

STAGE_FF_WORDX

STAGE_SF_WORDX

CDC OUTPUT CODE

LP_PROXIMITY_CNT

REGISTER 0X004

PROXIMITY TIMING

CONTROL LOGIC

LP_PROXIMITY_RECAL

SENSOR

CONTACT

REGISTER 0X004

AMBIENT VALUE

TIME

NOTES

1. SLOW FILTER EN IS SET AND SW1 IS CLOSED WHEN /WORD 0–WORD 3/ EXCEEDS THE VALUE PROGRAMMED IN THE SLOW_FILTER_UPDATE REGISTER PROVIDING

PROXIMITY IS NOT SET.

2. PROXIMITY 1 IS SET WHEN /WORD 0–WORD 3/ EXCEEDS THE VALUE PROGRAMMED IN THE PROXIMITY_DETECTION_RATE REGISTER.

3. PROXIMITY 2 IS SET WHEN /AVERAGE–AMBIENT/ EXCEEDS THE VALUE PROGRAMMED IN THE PROXIMITY_RECAL_LVL REGISTER.

4. DESCRIPTION OF COMPARATOR FUNCTIONS:

COMPARATOR 1: USED TO DETECT WHEN A USER IS APPROACHING OR LEAVING A SENSOR.

COMPARATOR 2: USED TO DETECT WHEN A USER IS HOVERING OVER A SENSOR, OR APPROACHING A SENSOR VERY SLOWLY.

ALSO USED TO DETECT IF THE SENSOR AMBIENT LEVEL HAS CHANGED AS A RESULT OF THE USER INTERACTION.

FOR EXAMPLE, HUMIDITY OR DIRT LEFT BEHIND ON SENSOR.

COMPARATOR 3: USED TO ENABLE THE SLOW FILTER UPDATE RATE. THE SLOW FILTER IS UPDATED WHEN SLOW FILTER EN IS SET AND PROXIMITY IS NOT SET.

05702-021

Figure 22. AD7142 Proximity Detection and Environmental Calibration

Rev. PrD | Page 18 of 64

Preliminary Technical Data AD7142/AD7142-1

ENVIRONMENTAL CALIBRATION

The AD7142 provides on-chip capacitance sensor calibration to

automatically adjust for environmental conditions that have an

effect on the capacitance sensor ambient levels. Capacitance

sensor output levels are sensitive to temperature, humidity, and

in some cases, dirt. The AD7142 achieves optimal and reliable

sensor performance by continuously monitoring the CDC

ambient levels and correcting for any changes by adjusting the

initial STAGE_OFFSET_HIGH and STAGE_OFFSET_LOW

register values. The CDC ambient level is defined as the

capacitance sensor output level during periods when the user is

not approaching or in contact with the sensor.

The compensation logic runs automatically on every conversion

after configuration when the AD7142 is not being touched. This

allows the AD7142 to account for rapidly changing environmental conditions.

calibration algorithm prevents errors such as this from

occurring.

SENSOR 1 INT

ASSERTED

CDC OUTPUT CODES

SENSOR 2 INT

NOT ASSERTED

CHANGING ENVIRONMENTALCONDITIONS

Figure 24. Typical Sensor Behavior without Calibration Applied

STAGE_OFFSET_HIGH

(INITIAL REGISTER VALUE)

CDC AMBIENT

VALUE DRIFTING

STAGE_OFFSET_LOW

(INITIAL REGISTER VALUE)

t

05702-023

The ambient compensation control registers give the host access

to general setup and controls for the compensation algorithm.

The RAM stores the compensation data for each conversion

stage, as well as setup information specific to each stage.

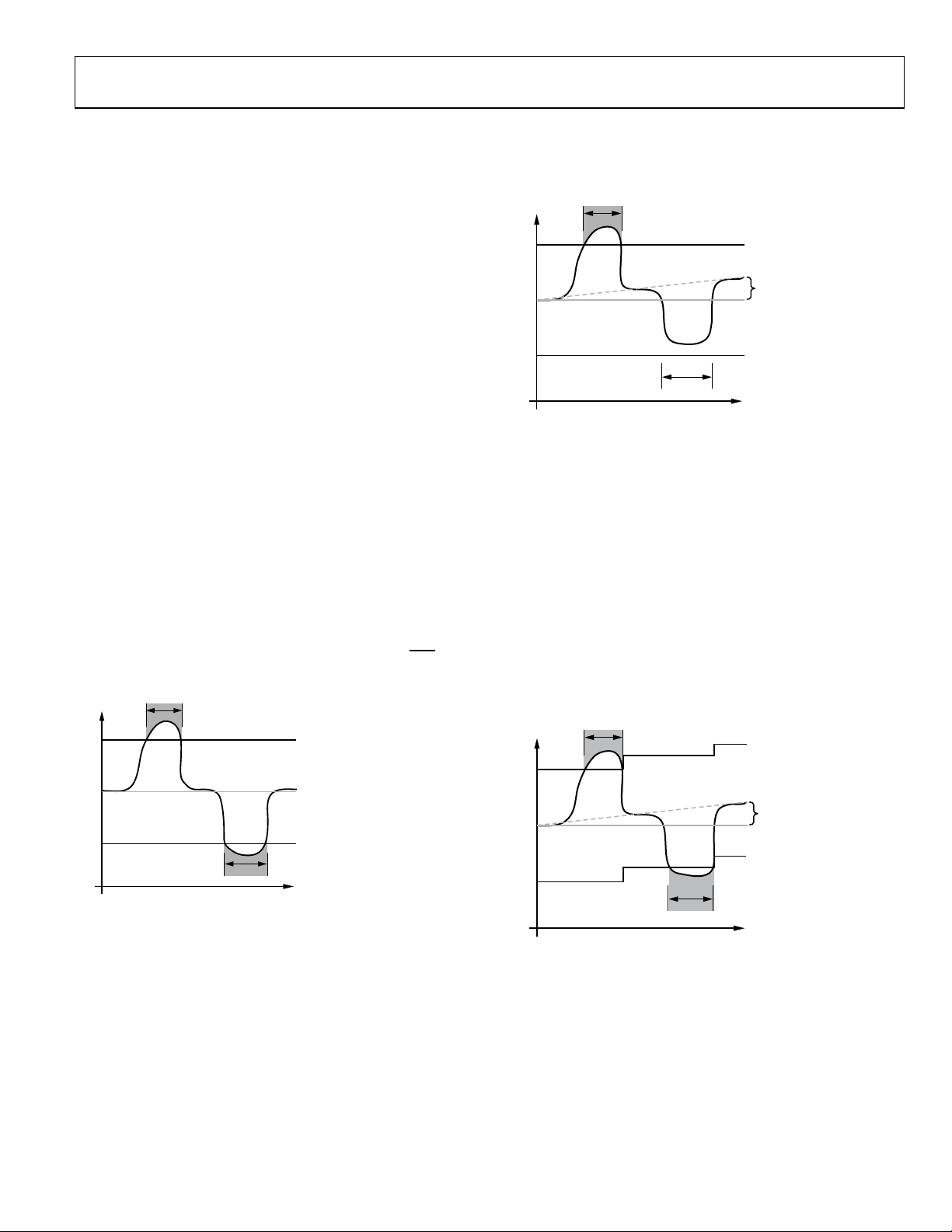

Figure 23 shows an example of an ideal capacitance sensor

behavior where the CDC ambient level remains constant

regardless of the environmental conditions. In this example, the

initial settings programmed in the STAGE_OFFSET_HIGH and

STAGE_OFFSET_LOW registers are sufficient to detect a

sensor contact resulting with the AD7142 asserting the

INT

output when the offset levels are exceeded.

SENSOR 1 INT

ASSERTED

CDC OUTPUT CODES

SENSOR 2 INT

ASSERTED

CHANGING ENVIRONMENTALCONDITIONS

STAGE_OFFSET_HIGH

(INITIAL REGISTER VALUE)

CDC AMBIENT VALUE

STAGE_OFFSET_LOW

(INITIAL REGISTER VALUE)

t

Figure 23. Ideal Sensor Behavior with a Constant Ambient Level

Capacitance Sensor Behavior Without Calibration

Figure 24 shows the typical behavior of a capacitance sensor

with no applied calibration. This figure shows ambient levels

drifting over time as environmental conditions change. The

ambient level drift has resulted in the detection of a missed user

contact on Sensor 2. This is a result of the initial low offset level

remaining constant while the ambient levels drifted upward

beyond the detection range. The

with Calibration

section describes how the AD7142 adaptive

Capacitance Sensor Behavior

Capacitance Sensor Behavior with Calibration

The AD7142 on-chip adaptive calibration algorithm prevents

sensor detection errors such the one shown in

Figure 24. This is

achieved by monitoring the CDC ambient levels and internally

adjusting the initial offset level register values according to the

amount of ambient drift measured on each sensor. This closed

loop routine ensures the reliability and repeatability operation

of every sensor connected to the AD7142 under dynamic

environmental conditions.

Figure 25 shows a simplified

example of how the AD7142 applies the adaptive calibration

process resulting in no interrupt errors under changing CDC

ambient levels due to environmental conditions.

SENSOR 1 INT

ASSERTED

1

CDC OUTPUT CODES

4

05702-022

CHANGING ENVIRONMENTALCONDITIONS

NOTES

1. INITIAL STAGE_OFFSET_HIGH REGISTER VALUE

2. POST CALIBRATED REGISTER STAGE_OFFSET_HIGH VALUE

3. POST CALIBRATED REGISTER STAGE_OFFSET_HIGH VALUE

4. INITIAL STAGE_OFFSET_LOW REGISTER VALUE

5. POST CALIBRATED REGISTER STAGE_OFFSET_LOW VALUE

6. POST CALIBRATED REGISTER STAGE_OFFSET_LOW VALUE

2

5

SENSOR 2 INT

ASSERTED

Figure 25. Typical Sensor Behavior with

Calibration Applied on the Data Path

3

6

STAGE_OFFSET_HIGH

(POST CALIBRATED

REGISTER VALUE)

CDC AMBIENT

VALUE DRIFTING

STAGE_OFFSET_LOW

(POST CALIBRATED

REGISTER VALUE)

t

05702-024

Rev. PrD | Page 19 of 64

AD7142/AD7142-1 Preliminary Technical Data

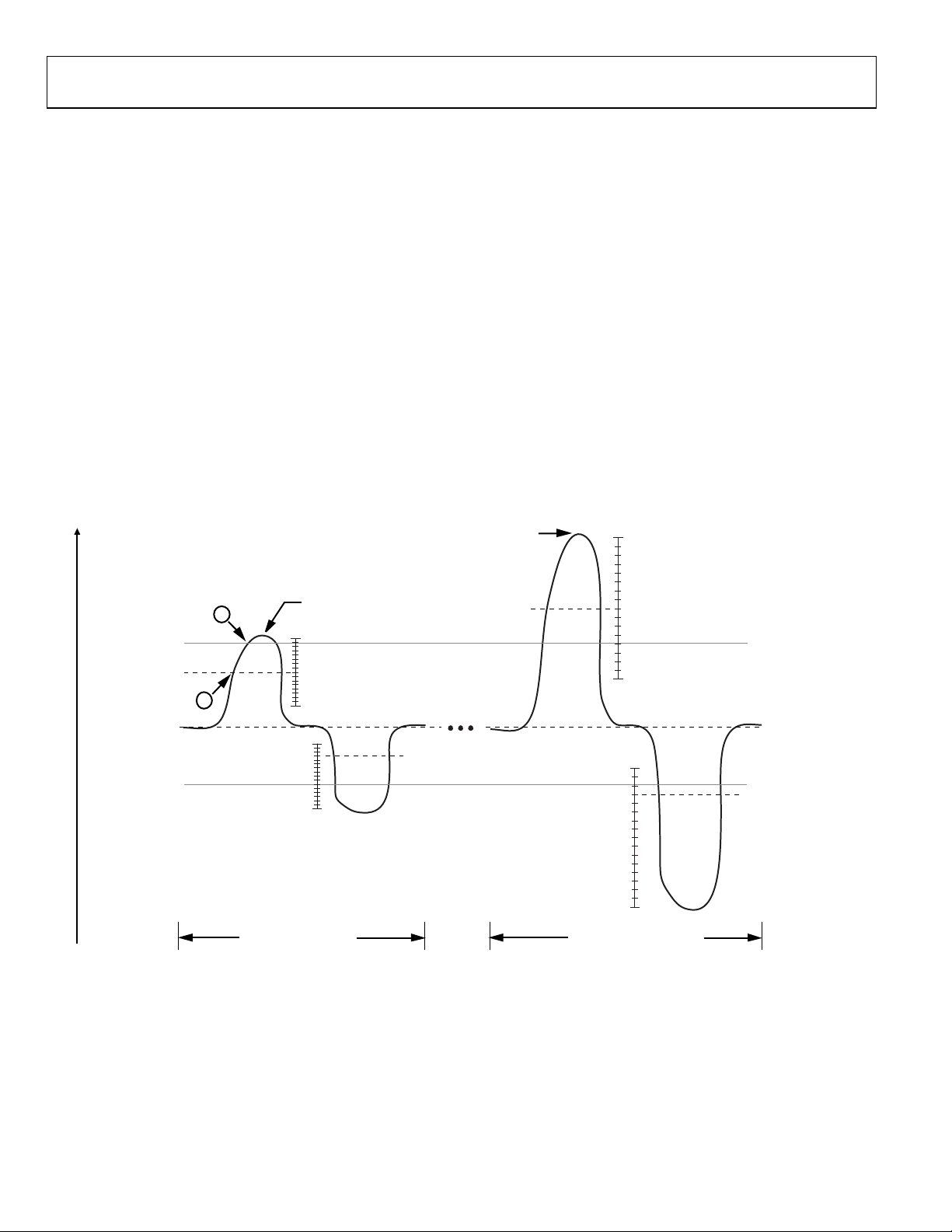

ADAPTIVE THRESHOLD AND SENSITIVITY

The AD7142 provides an on-chip self-learning adaptive

threshold and sensitivity algorithm. This algorithm continuously monitors the output levels of each sensor and automatically

rescales the threshold levels proportionally to the sensor area

covered by the user. As a result, the AD7142 maintains optimal

threshold and sensitivity levels for all types of users regardless

of their finger sizes.

The threshold level is always referenced from the ambient level

and is defined as the CDC converter output level that must be

exceeded for a valid sensor contact. The sensitivity level is

defined as how sensitive the sensor is before a valid contact is

registered.

Figure 26 provides an example of how the adaptive threshold

and sensitivity algorithm works. In a case where the adaptive

threshold and sensitivity algorithm are disabled, the positive

and negative sensor threshold levels are set by the

STAGE_OFFSET_HIGH and STAGE_OFFSET_LOW initial

values. Reference A in

Figure 26 shows that this results in an under

sensitive threshold level for a small finger user, demonstrating the

disadvantages of a fixed threshold level. By enabling the adaptive

threshold and sensitivity algorithm, the positive and negative

threshold levels are determined by the POS_THRESHOLD_SENSI

TIVITY and NEG_THRESHOLD_SENSITIVITY register values

and the most recent average maximum sensor output value.

These registers can be used to select 16 different positive and

negative sensitivity levels ranging between 25% and 95.32% of

the most recent average maximum output level referenced from

the ambient value. Reference B shows that the positive adaptive

threshold level is set at almost mid sensitivity with a 62.51%

threshold level by setting POS_THRESHOLD_SENSITIVITY =

1000.

Figure 26 also provides a similar example for the negative

threshold level with NEG_THRESHOLD_SENSITIVITY = 0001.

CDC OUTPUT CODES

AMBIENT LEVEL

NEG ADAPTIVE THRESHOLD LEVEL = 39.08%

Figure 26. Threshold Sensitivity Example with POS_THRESHOLD_SENSITIVITY = 1000 and NEG_THRESHOLD_SENSITIVITY = 0011

A

B

AVERAGE MAX VALUE

95.32%

62.51% = POS ADAPTIVE THRESHOLD LEVEL

25%

25%

95.32%

SENSOR CONTACTED

BY SMALL FINGER

AVERAGE MAX VALUE

25%

NEG ADAPTIVE THRESHOLD LEVEL = 39.08%

95.32%

SENSOR CONTACTED

BY LARGE FINGER

95.32%

62.51% = POS ADAPTIVE THRESHOLD LEVEL

STAGE_OFFSET_HIGH

(INITIAL VALUE)

25%

STAGE_OFFSET_LOW

(INITIAL VALUE)

05702-025

Rev. PrD | Page 20 of 64

Loading...

Loading...