Precision, Low Power

a

FEATURES

Enhanced Replacement for LF441 and TL061

DC Performance:

200 A max Quiescent Current

10 pA max Bias Current, Warmed Up (AD548C)

250 V max Offset Voltage (AD548C)

2 V/C max Drift (AD548C)

2 V p-p Noise, 0.1 Hz to 10 Hz

AC Performance:

1.8 V/s Slew Rate

1 MHz Unity Gain Bandwidth

Available in Plastic and Hermetic Metal Can Packages

and in Chip Form

Available in Tape and Reel in Accordance with

EIA-481A Standard

MIL-STD-883B Parts Available

Dual Version Available: AD648

Surface-Mount (SOIC) Package Available

PRODUCT DESCRIPTION

The AD548 is a low power, precision monolithic operational

amplifier. It offers both low bias current (10 pA max, warmed

up) and low quiescent current (200 µA max) and is fabricated

with ion-implanted FET and laser wafer trimming technologies.

Input bias current is guaranteed over the AD548’s entire

common-mode voltage range.

The economical J grade has a maximum guaranteed input offset

voltage of less than 2 mV and an input offset voltage drift of less

than 20 µV/°C. This level of dc precision is achieved utilizing

Analog’s laser wafer drift trimming process. The combination of

low quiescent current and low offset voltage drift minimizes

changes in input offset voltage due to self-heating effects.

The AD548 is recommended for any dual supply op amp application requiring low power and excellent dc and ac performance.

In applications such as battery-powered, precision instrument

front ends and CMOS DAC buffers, the AD548’s excellent combination of low input offset voltage and drift, low bias current,

and low 1/f noise reduces output errors. High common-mode

rejection (82 dB, min on the “B” grade) and high open-loop

gain ensures better than 12-bit linearity in high impedance,

buffer applications.

The AD548 is pinned out in a standard op amp configuration

and is available in three performance grades. The AD548J and

AD548K are rated over the commercial temperature range of

0°C to 70°C. The AD548B is rated over the industrial temperature range of –40°C to +85°C.

The AD548 is available in an 8-lead plastic mini-DIP and

surface-mount (SOIC) packages.

BiFET Op Amp

AD548

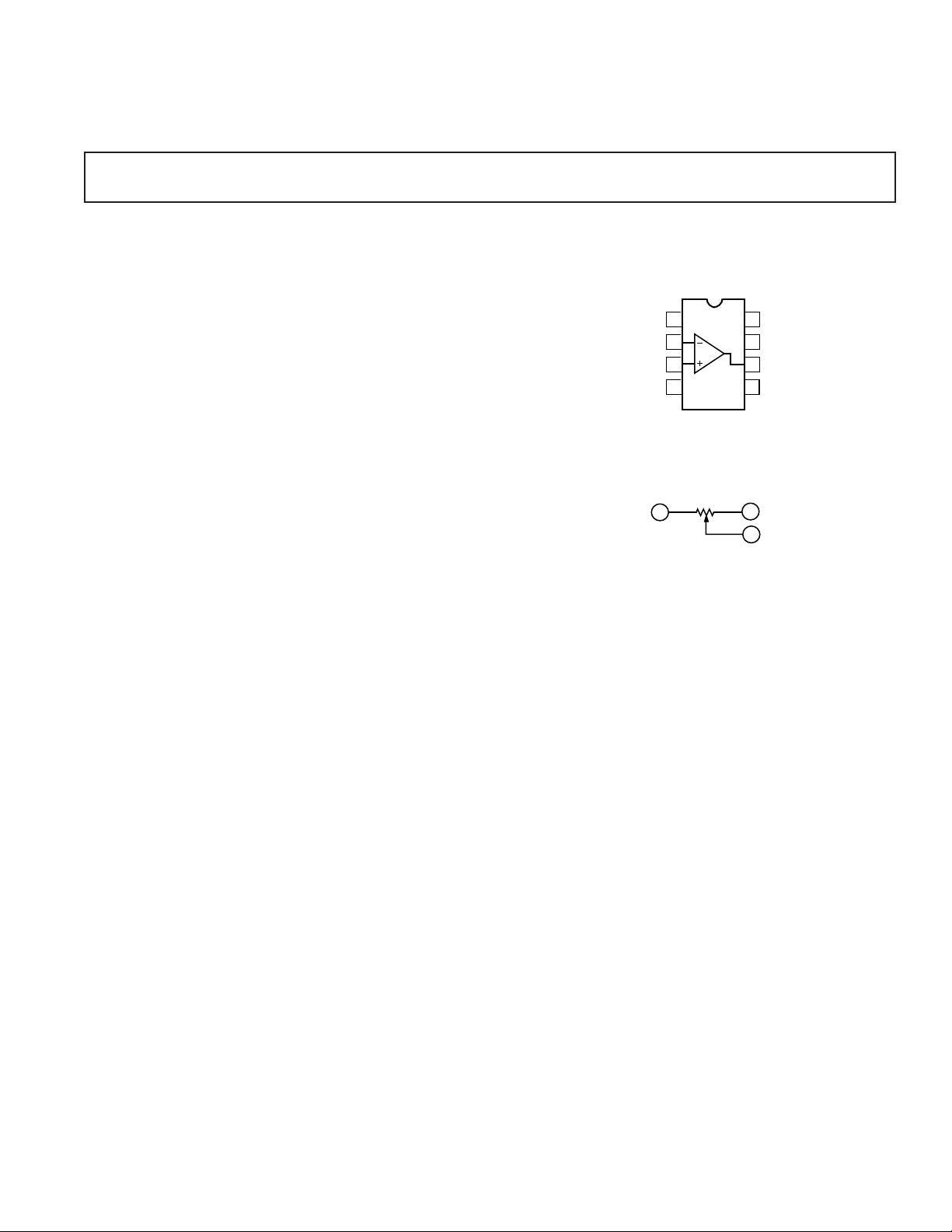

CONNECTION DIAGRAMS

Plastic Mini-DIP (N) Package

and

SOIC (R)Package

OFFSET NULL

INVERTING

NONINVERTING

NOTE: PIN 4 CONNECTED TO CASE

NC = NO CONNECT

PRODUCT HIGHLIGHTS

INPUT

INPUT

V–

1

2

3

4

1

AD548

TOP VIEW

10k

VOS TRIM

TOP VIEW

1. A combination of low supply current, excellent dc and ac

performance and low drift makes the AD548 the ideal op

amp for high performance, low power applications.

2. The AD548 is pin compatible with industry standard op

amps such as the LF441, TL061, and AD542, enabling

designers to improve performance while achieving a reduction

in power dissipation of up to 85%.

3. Guaranteed low input offset voltage (2 mV max) and drift

(20 µV/°C max) for the AD548J are achieved utilizing

Analog Devices’ laser drift trimming technology, eliminating

the need for external trimming.

4. Analog Devices specifies each device in the warmed-up

condition, insuring that the device will meet its published

specifications in actual use.

5. A dual version, the AD648, is also available.

6. Enhanced replacement for LF441 and TL061.

8

7

6

5

5

–15V

4

NC

V+

OUTPUT

OFFSET

NULL

REV. C

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

AD548–SPECIFICATIONS

(@ 25C and VS = 15 V dc unless otherwise noted.)

AD548J AD548K/B

Parameter Min Typ Max Min Typ Max Unit

INPUT OFFSET VOLTAGE

1

Initial Offset 0.75 2.0 0.3 0.5 mV

T

MIN

to T

MAX

3.0/3.0/3.0 0.7/0.8 mV

vs. Temperature 20 5 µV/°C

vs. Supply 80 86 dB

vs. Supply, T

MIN

to T

MAX

76/76/76 80 dB

Long-Term Offset Stability 15 15 µV/Month

INPUT BIAS CURRENT

Either Input2, VCM = 0 5 20 3 10 pA

Either Input

2

at T

, VCM = 0 0.45/1.3/20 0.25/0.65 nA

MAX

Max Input Bias Current Over

Common-Mode Voltage Range 30 15 pA

Offset Current, V

Offset Current at T

INPUT IMPEDANCE

Differential 1 × 10

= 0 5 10 2 5 pA

CM

MAX

0.25/0.65/10 0.15/0.35 nA

12

储31 × 1012储3 Ω储pF

Common Mode 3 × 1012储33 × 1012储3 Ω储pF

INPUT VOLTAGE RANGE

Differential

3

±20 ±20 V

Common Mode ±11 ±12 ±11 ±12 V

Common-Mode Rejection

= ±10 V 76 90 82 92 dB

V

CM

to T

T

MIN

V

= ±11 V 70 84 76 86 dB

CM

T

MIN

to T

MAX

MAX

76/76/76 90 82 92 dB

70/70/70 84 76 86 dB

INPUT VOLTAGE NOISE

Voltage 0.1 Hz to 10 Hz 2 2 µV p-p

f = 10 Hz 80 80 nV/√Hz

f = 100 Hz 40 40 nV/√Hz

f = 1 kHz 30 30 nV/√Hz

f = 10 kHz 30 30 nV/√Hz

INPUT CURRENT NOISE

f = 1 kHz 1.8 1.8 fA/√Hz

FREQUENCY RESPONSE

Unity Gain, Small Signal 0.8 1.0 0.8 1.0 MHz

Full Power Response 30 30 kHz

Slew Rate, Unity Gain 1.0 1.8 1.0 1.8 V/µs

Settling Time to ±0.01% 8 8 µs

OPEN LOOP GAIN

VO = ±10 V, RL ≥ 10 kΩ 300 1000 300 1000 3V/mV

to T

T

MIN

V

= ±10 V, RL ≥ 5 kΩ 150 500 150 500 V/mV

O

T

to T

MIN

, RL ≥ 10 kΩ 300/300/300 700 300 700 V/mV

MAX

, RL ≥ 5 kΩ 150/150/150 300 150 300 V/mV

MAX

OUTPUT CHARACTERISTICS

Voltage @ R

T

MIN

Voltage @ R

T

MIN

≥ 10 kΩ, ±12 ±13 ±12 ±13 V

L

to T

MAX

≥ 5 kΩ, ±11 ±12.3 ± 11 ± 12.3 V

L

to T

MAX

±12/± 12/±12 ±12

±11/± 11/±11 ±11

Short Circuit Current 15 15 mA

–2–

REV. C

SPECIFICATIONS (continued)

AD548J AD548K/B

Min Typ Max Min Typ Max Unit

POWER SUPPLY

Rated Performance ±15 ±15 V

Operating Range ±4.5 ±18 ±4.5 ± 18 V

Quiescent Current 170 200 170 200 µA

TEMPERATURE RANGE

Operating, Rated Performance

Commercial (0°C to 70°C) AD548J AD548K

Industrial (–40°C to +85°C) AD548A AD548B

Military (–55°C to +125°C) AD548S

PACKAGE OPTIONS

SOIC (R-8) AD548JR AD548KR

Plastic (N-8) AD548JN

4

AD548KN

Tape and Reel AD548JR-REEL AD548KR-REEL

NOTES

1

Input Offset Voltage specifications are guaranteed after five minutes of operation at TA = 25°C.

2

Bias Current specifications are guaranteed maximum at either input after five minutes of operation at TA = 25°C. For higher temperature, the current doubles every 10°C.

3

Defined as voltages between inputs, such that neither exceeds ±10 V from ground.

4

Not recommended for new designs; obsolete April 2002.

Specifications subject to change without notice.

4

4

AD548

REV. C

–3–

AD548

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .± 18 V

Internal Power Dissipation

Input Voltage

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± 18 V

2

. . . . . . . . . . . . . . . . . . . . 500 mW

l

Output Short Circuit Duration . . . . . . . . . . . . . . . . . Indefinite

Differential Input Voltage . . . . . . . . . . . . . . . . . . +V

and –V

S

Storage Temperature Range (Q, H) . . . . . . . –65°C to +150°C

(N, R) . . . . . . . . –65°C to +125°C

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause

permanent damage to the device. This is a stress rating only; functional operation

of the device at these or any other conditions above those indicated in the

operational sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

2

Thermal Characteristics: 8-Pin SOIC Package: θJA = 160°C/W, θ

S

8-Lead Plastic Package: θJA = 90°C/W.

3

For supply voltages less than ± 18 V, the absolute maximum input voltage is equal

to the supply voltage.

Operating Temperature Range

AD548J/K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0°C to 70°C

AD548B . . . . . . . . . . . . . . . . . . . . . . . . . . . . –40°C to +85°C

Lead Temperature Range (Soldering 60 sec) . . . . . . . . . 300°C

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD548 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high-energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

= 42°C/W;

JC

–4–

REV. C

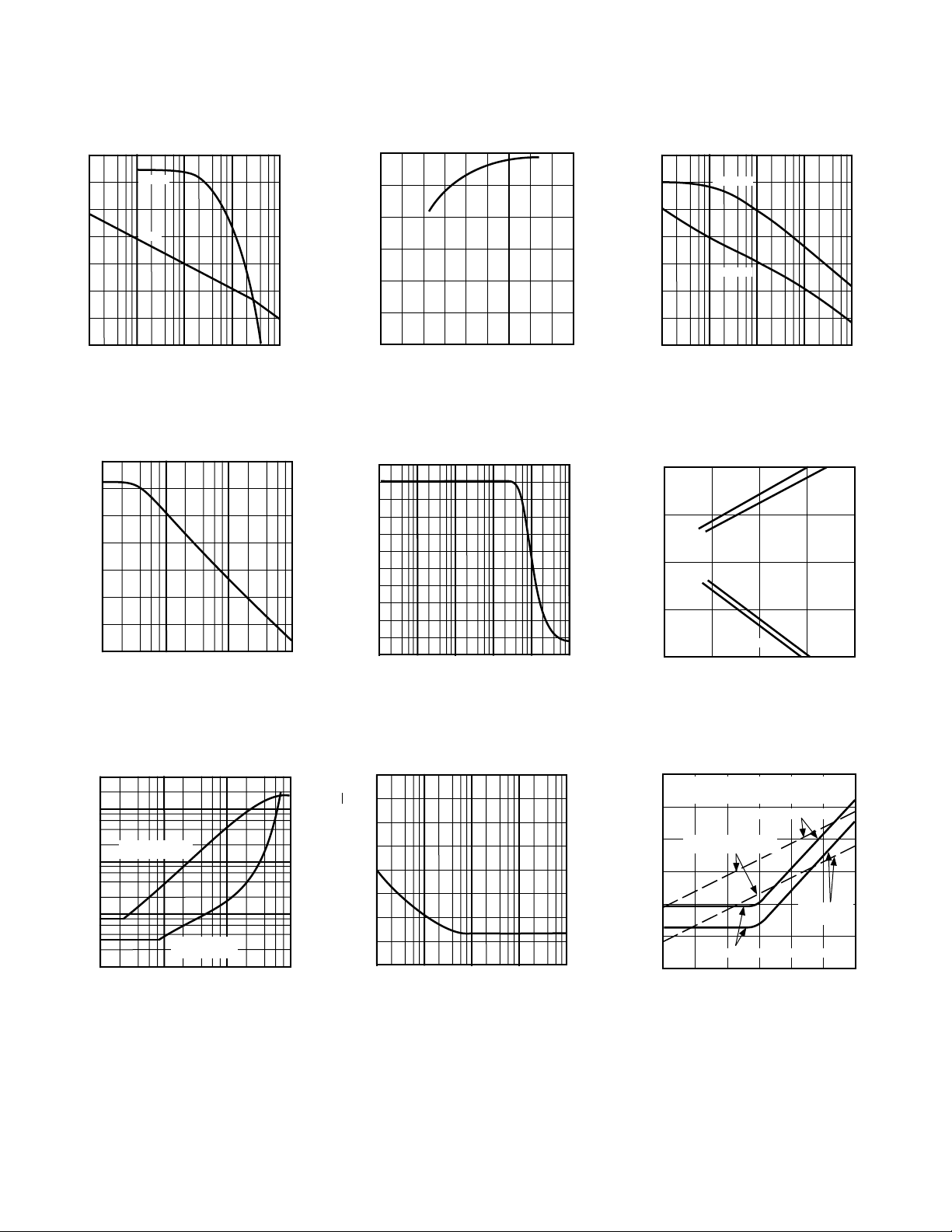

Typical Performance Characteristics–

AD548

20

15

+V

IN

10

–V

IN

INPUT VOLTAGE – ±V

5

0

0 5 10 15 20

SUPPLY VOLTAGE – V

TPC 1. Input Voltage Range

vs. Supply Voltage

200

180

160

140

QUIESCENT CURRENT – µA

20

15

10

5

OUTPUT VOLTAGE SWING – ±V

0

0 5 10 15 20

SUPPLY VOLTAGE – V

TPC 2. Output Voltage Swing

vs. Supply Voltage

10

8

6

4

INPUT BIAS CURRENT – pA

2

+V

OUT

–V

OUT

25°C

RL = 10k

30

25

20

15

10

5

OUTPUT VOLTAGE SWING – V p-p

0

10 100 1k 10k

LOAD RESISTANCE –

TPC 3. Output Voltage Swing

vs. Load Resistance

100nA

10nA

1nA

100pA

10pA

1pA

INPUT BIAS CURRENT

100fA

120

0 5 10 15 20

SUPPLY VOLTAGE – V

TPC 4. Quiescent Current vs.

Supply Voltage

10

8

6

4

INPUT BIAS CURRENT – pA

2

0

–10 –6 –2 2 6 10

COMMON-MODE VOLTAGE – V

TPC 7. Input Bias Current vs.

Common-Mode Voltage

0

0 4 8 12 16 20

SUPPLY VOLTAGE – V

TPC 5. Input Bias Current

vs. Supply Voltage

30

25

20

I – V

15

OS

I∆V

10

5

0

0 10 20 30 40 50 60 70

WARM-UP TIME – Sec

TPC 8. Change in Offset Voltage

vs. Warm-Up Time

10fA

–55 –25 5 35 65 95 125

TEMPERATURE – °C

TPC 6. Input Bias Current vs.

Temperature

1500

1250

1000

750

500

OPEN LOOP GAIN – V/mV

250

0

–55 –25 5 35 65 95 125

TEMPERATURE – °C

RL = 10k

TPC 9. Open-Loop Gain vs.

Temperature

REV. C

–5–

AD548

100

80

60

40

20

0

OPEN LOOP GAIN – dB

–20

–40

1k 10k 100k 1M 10M

PHASE

GAIN

FREQUENCY – Hz

TPC 10. Open-Loop Frequency

Response

90

80

70

60

50

CMRR – dB

40

30

20

1k 10k 100k 1M

FREQUENCY – Hz

TPC 13. CMRR vs. Frequency

100

80

60

40

20

PHASE IN DEGREES

0

–20

–40

120

110

100

90

80

70

OPEN LOOP VOLTAGE GAIN – dB

60

0 2 4 6 8 10 12 14 16 18

SUPPLY VOLTAGE – V

TPC 11. Open-Loop Voltage Gain

vs. Supply Voltage

22

20

18

16

14

12

10

8

6

OUTPUT VOLTAGE – V p-p

4

2

0

10 100 1k 10k 100k 1M

FREQUENCY – Hz

TPC 14. Large Signal Frequency

Response

120

100

80

60

40

20

0

POWER SUPPLY REJECTION – dB

–20

100 1k 10k 100k 1M

+SUPPLY

–SUPPLY

FREQUENCY – Hz

TPC 12. PSRR vs. Frequency

10

5

0

–5

OUTPUT VOLTAGE SWING – V

–10

0 2 4 6 8

10mV

1mV

1mV

10mV

SETTLING TIME – µs

TPC 15. Output Swing and Error

Voltage vs. Output Settling Time

4

1

FOLLOWER

WITH GAIN = 10

0.1

0.01

TOTAL HARMONIC DISTORTION – %

0.001

100 1k 10k

UNITY GAIN

FOLLOWER

FREQUENCY – Hz

TPC 16. Total Harmonic

Distortion vs. Frequency

100k

160

140

120

100

80

60

40

INPUT NOISE VOLTAGE – nV/√Hz

20

0

10 100 1k 10k 100k

FREQUENCY – Hz

TPC 17. Input Noise Voltage

Spectral Density

–6–

WHENEVER JOHNSON NOISE IS GREATER THAN

AMPLIFIER NOISE, AMPLIFIER NOISE CAN BE

CONSIDERED NEGLIGIBLE FOR APPLICATION

10,000

1,000

INPUT NOISE VOLTAGE – µV p-p

RESISTOR JOHNSON

100

10

1

0

100k 1M 10M 100M 1G 10G 100G

1kHz BANDWIDTH

NOISE

10Hz

BANDWIDTH

AMPLIFIER GENERATED NOISE

SOURCE IMPEDANCE –

TPC 18. Total Noise vs. Source

Impedance

REV. C

AD548

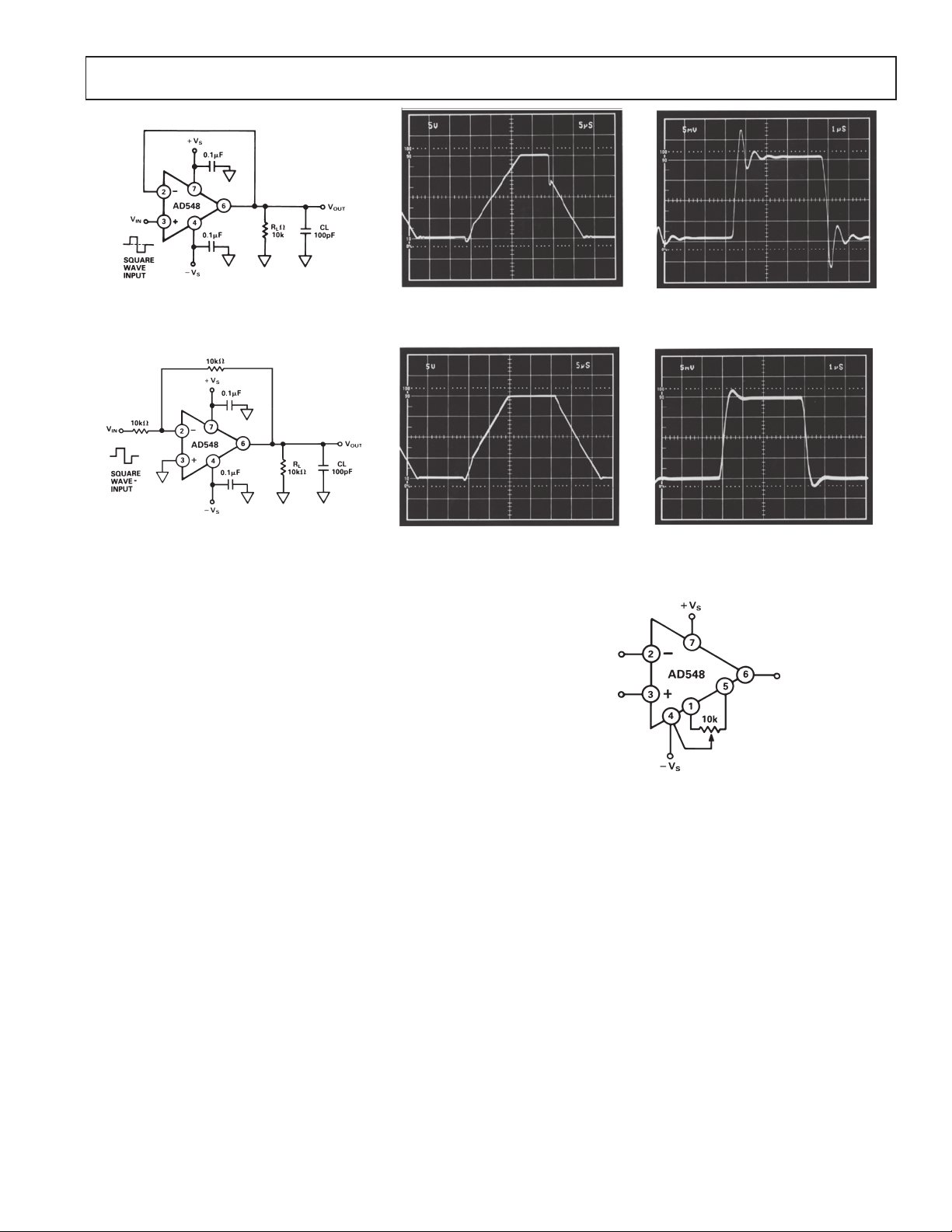

TPC 19a. Unity Gain Follower

TPC 20a. Utility Gain Inverter

APPLICATION NOTES

TPC 19b. Unity Gain Follower

Pulse Response (Large Signal)

TPC 20b. Utility Gain Inverter

Pulse Response (Large Signal)

The AD548 is a JFET-input op amp with a guaranteed maximum I

of less than 10 pA, and offset and drift laser-trimmed to

B

0.5 mV and 5 µV/°C, respectively (AD548B). AC specs include

1 MHz bandwidth, 1.8 V/µs typical slew rate and 8 µs settling time

for a 20 V step to ±0.01%—all at a supply current less than

200 µA. To capitalize on the device’s performance, a number of

error sources should be considered.

The minimal power drain and low offset drift of the AD548

reduce self-heating or “warm-up” effects on input offset voltage,

making the AD548 ideal for on/off battery-powered applications. The power dissipation due to the AD548’s 200 µA supply

current has a negligible effect on input current, but heavy output loading will raise the chip temperature. Since a JFET’s

input current doubles for every 10°C rise in chip temperature,

this can be a noticeable effect.

The amplifier is designed to be functional with power supply

voltages as low as ±4.5 V. It will exhibit a higher input offset

voltage than at the rated supply voltage of ±15 V, due to power

supply rejection effects. The common-mode range of the AD548

extends from 3 V more positive than the negative supply to 1 V

more negative than the positive supply. Designed to cleanly

drive up to 10 kΩ and 100 pF loads, the AD548 will drive a 2

kΩ load with reduced open-loop gain.

OFFSET NULLING

Unlike bipolar input amplifiers, zeroing the input offset voltage

of a BiFET op amp will not minimize offset drift. Using balance

Pins 1 and 5 to adjust the input offset voltage as shown in

Figure 1 will induce an added drift of 0.24 µV/°C per 100 µV of

nulled offset. The low initial offset (0.5 mV) of the AD548B

results in only 0.6 µV/°C of additional drift.

TPC 19c. Unity Gain Follower

Pulse Response (Small Signal)

TPC 20c. Unity Gain Inverter

Pulse Response (Small Signal)

Figure 1. Offset Null Configuration

LAYOUT

To take full advantage of the AD548’s 10 pA max input current,

parasitic leakages must be kept below an acceptable level. The

practical limit of the resistance of epoxy or phenolic circuit

board material is between 1 × 10

result in an additional leakage of 5 pA between an input of 0 V

and a –15 V supply line. Teflon

rial (with a resistance exceeding 10

12

Ω and 3 × 10

®

or a similar low leakage mate-

17

Ω) should be used to

12

Ω. This can

isolate high impedance input lines from adjacent lines carrying

high voltages. The insulator should be kept clean, since contaminants will degrade the surface resistance.

A metal guard completely surrounding the high impedance nodes

and driven by a voltage near the common-mode input potential

can also be used to reduce some parasitic leakages. The guarding

pattern in Figure 2 will reduce parasitic leakage due to finite

board surface resistance; but it will not compensate for a low

volume resistivity board.

Teflon is a registered trademark of DuPont.

REV. C

–7–

AD548

Figure 2. Board Layout for Guarding Inputs

INPUT PROTECTION

The AD548 is guaranteed to withstand input voltages equal to

the power supply potential. Exceeding the negative supply voltage on either input will forward bias the substrate junction of

the chip. The induced current may destroy the amplifier due to

excess heat.

Input protection is required in applications such as a flame

detector in a gas chromatograph, where a very high potential

may be applied to the input terminals during a sensor fault

condition. Figure 3 shows a simple current limiting scheme that

can be used. R

PROTECT

mum overload current is 1.0 mA (l00 kΩ for a 100 V overload,

for example).

Exceeding the negative common-mode range on either input

terminal causes a phase reversal at the output, forcing the

amplifier output to the corresponding high or low state. Exceeding the negative common-mode on both inputs simultaneously

forces the output high. Exceeding the positive common-mode

range on a single input does not cause a phase reversal, but if

both inputs exceed the limit the output will be forced high. In

all cases, normal amplifier operation is resumed when input

voltages are brought back within the common-mode range.

should be chosen such that the maxi-

Figure 4. AD548 Used as DAC Output Amplifier

That is:

VOSOutput =VOSInput 1+

R

FB

R

O

RFB is the feedback resistor for the op amp, which is internal to

the DAC. R

value of R

is the DAC’s R-2R ladder output resistance. The

O

is code dependent. This has the effect of changing

O

the offset error voltage at the amplifier’s output. An output

amplifier with a sub millivolt input offset voltage is needed to

preserve the linearity of the DAC’s transfer function.

The AD548 in this configuration provides a 700 kHz small

signal bandwidth and 1.8 V/µs typical slew rate. The 33 pF

capacitor across the feedback resistor optimizes the circuit’s

response. The oscilloscope charts in Figures 5 and 6 show small

and large signal outputs of the circuit in Figure 4. Upper traces

show the input signal V

. Lower traces are the resulting output

IN

voltage with the DAC’s digital input set to all 1s. The AD548

settles to ±0.01% for a 20 V input step in 14 µs.

5V 5µS 20V

100

90

Figure 3. Input Protection of IV Converter

D/A CONVERTER OUTPUT BUFFER

The circuit in Figure 4 shows the AD548 and AD7545 12-bit

CMOS D/A converter in a unipolar binary configuration. V

will be equal to V

digital word. V

adjusting R

IN

attenuated by a factor depending on the

REF

sets the full scale. Overall gain is trimmed by

REF

. The AD548’s low input offset voltage, low drift,

OUT

and clean dynamics make it an attractive low power output buffer.

The input offset voltage of the AD548 output amplifier results

in an output error voltage. This error voltage equals the input

offset voltage of the op amp times the noise gain of the amplifier.

–8–

10

0%

Figure 5. Response to ±20 V p-p Reference Square Wave

50mV

100

90

10

0%

2µS 200mV

Figure 6. Response to ±100 mV p-p Reference Square Wave

REV. C

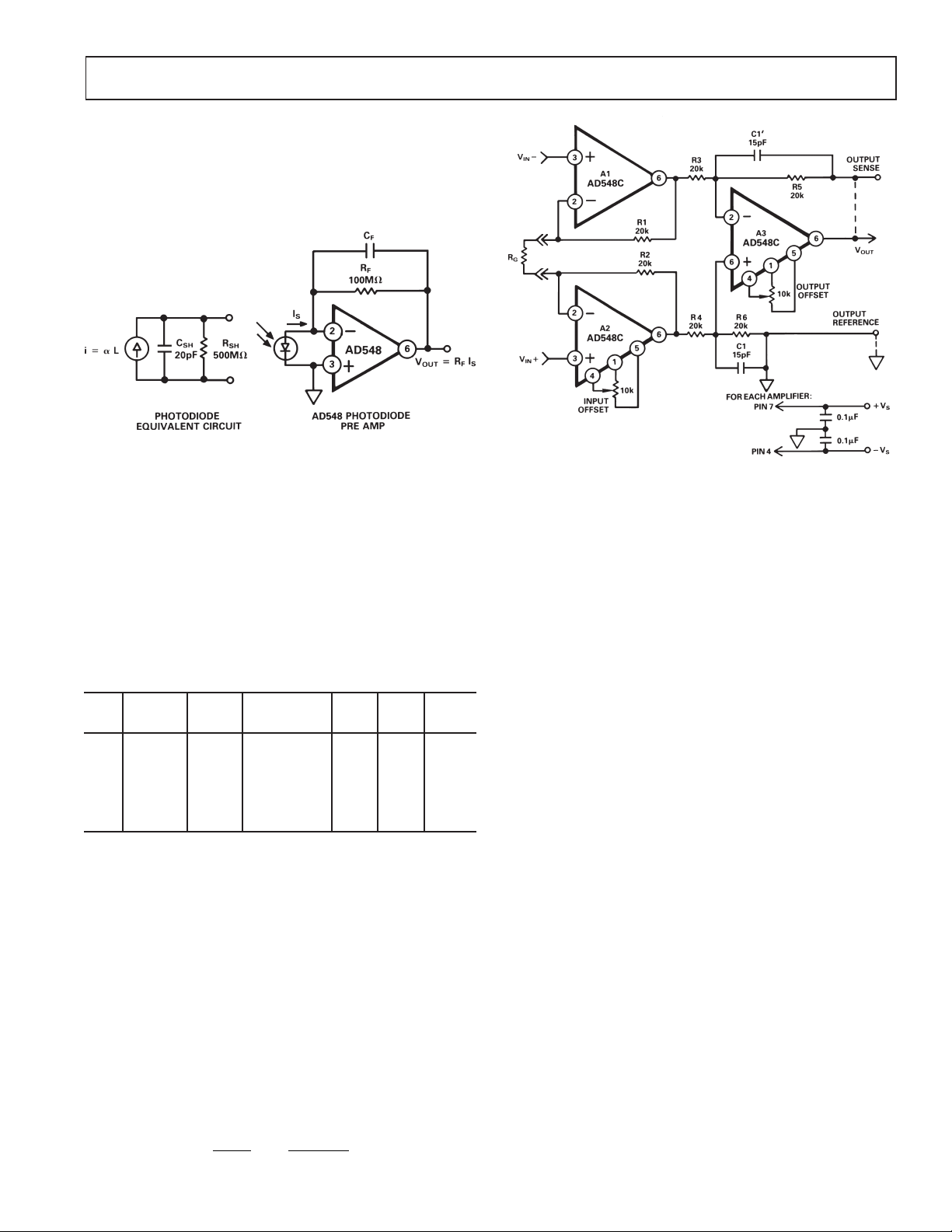

PHOTODIODE PREAMP

The performance of the photodiode preamp shown in Figure 7

is enhanced by the AD548’s low input current, input voltage

offset, and offset voltage drift. The photodiode sources a current

proportional to the incident light power on its surface. R

the photodiode current to an output voltage equal to R

converts

F

× IS.

F

Figure 7.

An error budget illustrating the importance of low amplifier

input current, voltage offset, and offset voltage drift to minimize

output voltage errors can be developed by considering the equivalent circuit for the small (0.2 mm

2

area) photodiode shown in

Figure 7. The input current results in an error proportional to

the feedback resistance used. The amplifier’s offset will produce

an error proportional to the preamp’s noise gain (I + R

where R

is the photodiode shunt resistance. The amplifier’s

SH

F/RSH

),

input current will double with every 10°C rise in temperature,

and the photodiode’s shunt resistance halves with every 10°C

rise. The error budget in Figure 8 assumes a room temperature

photodiode R

of 500 MΩ, and the maximum input current

SH

and input offset voltage specs of an AD548C.

TEMP

CRSH (M)VOS (V) (1+ RF/RSH) VOSIB (pA) IBRFTOTAL

–

25 15,970 150 151 µV 0.30 30 µV 181 µV

0 2,830 200 207 µV 2.26 262 µV 469 µV

25 500 250 300 µV 10.00 1.0 mV 1.30 mV

50 88.5 300 640 µV 56.6 5.6 mV 6.24 mV

75 15.6 350 2.6 mV 320 32 mV 34.6 mV

85 7.8 370 5.1 mV 640 64 mV 69.1 mV

Figure 8. Photodiode Preamp Errors Over Temperature

The capacitance at the amplifier’s negative input (the sum of the

photodiode’s shunt capacitance, the op amp’s differential input

capacitance, stray capacitance due to wiring, etc.) will cause a

rise in the preamp’s noise gain over frequency. This can result in

excess noise over the bandwidth of interest. C

reduces the

F

noise gain “peaking” at the expense of bandwidth.

INSTRUMENTATION AMPLIFIER

The AD548C’s maximum input current of 10 pA makes it an

excellent building block for the high input impedance instrumentation amplifier shown in Figure 9. Total current drain for

this circuit is under 600 µA. This configuration is optimal for

conditioning differential voltages from high impedance sources.

The overall gain of the circuit is controlled by R

, resulting in

G

the following transfer function:

V

OUT

= 1 +

V

IN

(R

+ R2)

1

R

G

Application Hints–AD548

Figure 9. Low Power Instrumentation Amplifier

Gains of 1 to 100 can be accommodated with gain nonlinearities

of less than 0.01%. Input errors, which contribute an output

error proportional to in amp gain, include a maximum untrimmed

input offset voltage of 0.5 mV and an input offset voltage drift

over temperature of 4 µV/°C. Output errors, which are indepen-

dent of gain, will contribute an additional 0.5 mV offset and

4 µV/°C drift. The maximum input current is 15 pA over the

common-mode range, with a common-mode impedance of over

12

1 × 10

matched to 0.01% to take full advantage of the AD548’s high

common-mode rejection. Capacitors C1 and C1′ compensate for

peaking in the gain over frequency caused by input capacitance

when gains of 1 to 3 are used.

The –3 dB small signal bandwidth for this low power instrumentation amplifier is 700 kHz for a gain of 1 and 10 kHz for a gain of

100. The typical output slew rate is 1.8 V/µs.

LOG RATIO AMPLIFIER

Log ratio amplifiers are useful for a variety of signal conditioning

applications, such as linearizing exponential transducer outputs

and compressing analog signals having a wide dynamic range.

The AD548’s picoamp level input current and low input offset

voltage make it a good choice for the front-end amplifier of the

log ratio circuit shown in Figure 10. This circuit produces an

output voltage equal to the log base 10 of the ratio of the input

currents I

voltage inputs.

Input currents I

a matched pair of logging transistors. Voltages at points A and

B are developed according to the following familiar diode

equation:

In this equation, k is Boltzmann’s constant, T is absolute temperature, q is an electron charge, and I

current of the logging transistors. The difference of these two

voltages is taken by the subtractor section and scaled by a factor

of approximately 16 by resistors R9, R10, and R8. Temperature

Ω. Resistor pairs R3/R5 and R4/R6 should be ratio

and I2. Resistive inputs R1 and R2 are provided for

1

and I2 set the collector currents of Q1 and Q2,

1

VBE= (kT/q)ln(IC/IES)

is the reverse saturation

ES

REV. C

–9–

AD548

compensation is provided by resistors R8 and R15 that have a

positive 3500 ppm/°C temperature coefficient. The transfer

function for the output voltage is:

V

= 1V log10(I

OUT

Frequency compensation is provided by R11, R12, C1, and C2.

Small signal bandwidth is approximately 300 kHz at input currents above 100 µA and will proportionally decrease with lower

signal levels. D1, D2, R13, and R14 compensate for the effects

of the two logging transistors’ ohmic emitter resistance.

To trim this circuit, set the two input currents to 10 µA and adjust

V

to zero by adjusting the potentiometer on A3. Then set I

OUT

to 1 µA and adjust the scale factor such that the output voltage is

1 V by trimming potentiometer R10. Offset adjustment for A1 and

A2 is provided to increase the accuracy of the voltage inputs.

This circuit ensures a 1% log conformance error over an input

current range of 300 pA to 1 mA, with low level accuracy

limited by the AD548’s input current. The low level input voltage

accuracy of this circuit is limited by the input offset voltage and

drift of the AD548.

)

I

/

2

1

2

Figure 10. Log Ratio Amplifier

–10–

REV. C

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

Plastic Mini-DIP (N) Package SOIC (R) Package

AD548

Revision History

Location Page

Data Sheet changed from REV. B to REV. C.

Edits to FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Deleted TO-99 CONNECTION DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Deleted AD548C from SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Edits to ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Deleted Metal Can from Figure 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Deleted TO-99 (H) and Cerdip (Q) Packages from OUTLINE DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

REV. C

–11–

C00510–0–2/02(C)

–12–

PRINTED IN U.S.A.

Loading...

Loading...