Page 1

PRESS BRAKE (ZII)

RG35S–100

OPERATOR'S MANUAL

RG25-125-

E02

-200510

Page 2

PREFACE Read this manual carefully to obtain a thorough knowledge of machine operation and maintenance.

Be sure to follow the instructions to ensure proper procedures and prevent injuries and accidents. Do not operate

the machine by guesswork. Keep the manual at hand

and refer to it whenever you are not sure of how to perform

any of the procedures.

Operator's Manual:

Press Brake (ZII) RG35S-100

© 2005 by AMADA CO., LTD.

No part of this publication may be photocopied or otherwise reproduced without the prior written permission of AMADA CO., LTD.

ii

Printed in Japan

Page 3

CONTENTS

Part I Safety.................................................................................... I-1

1. Safety rules ............................................................................ I-2

2. DANGER and WARNING plates........................................... I-10

Part II Description.......................................................................... II-1

1. Functions ...............................................................................II-2

2. General view ..........................................................................II-3

3. Specifications......................................................................... II-5

4. Dimensions ............................................................................ II-6

5. Standard accessories ............................................................II-9

6. Options..................................................................................II-10

Part III Installation.......................................................................... III-1

1. Summary............................................................................... III-2

1-1. Environmental conditions............................................... III-2

1-2. Input power source......................................................... III-2

1-3. Things to be supplied by customer ................................ III-3

2. Installation procedures.......................................................... III-4

2-1. Location.......................................................................... III-4

2-2. Lifting.............................................................................. III-5

2-3. Foundation ..................................................................... III-6

2-4. Placing ........................................................................... III-6

2-5. Leveling.......................................................................... III-6

2-6. Supplying hydraulic oil ................................................... III-8

2-7. Supplying electric power ................................................ III-8

Part IV Controls..............................................................................IV-1

1. Controls on electrical enclosure............................................ IV-2

2. Controls on upper beam ....................................................... IV-3

3. Hydraulic equipment controls ............................................... IV-4

4. Other controls .......................................................................IV-6

(Continued on next page.)

iii

Page 4

Part V Operation ............................................................................V-1

1. Inspection before start of day’s work .....................................V-3

2. Preparing for operation.......................................................... V-3

3. Turning on power...................................................................V-5

4. Removing tools ......................................................................V-6

4-1. Preparing for removing tools........................................... V-6

4-2. Removing punches .........................................................V-8

4-3. Removing dies ................................................................V-9

5. Installing tools .......................................................................V-11

5-1. Preparing for installing tools ..........................................V-11

5-2. Installing dies .................................................................V-12

5-3. Installing punches ..........................................................V-14

6. Preparing for special bending...............................................V-16

6-1. Installing and removing punch holders .......................... V-16

6-1-1. Removing punch holders ........................................V-16

6-1-2. Installing punch holders ..........................................V-17

6-2. Installing punches rearside front....................................V-18

6-3. Installing wide dies.........................................................V-19

7. Other uses ............................................................................ V-20

7-1. Adjusting punch holders.................................................V-20

7-2. Using one-touch punch holders (option)........................V-23

7-2-1. Installing and removing punches from front ............V-25

7-2-2. Installing and removing punches by sliding them

along groove of rear clamping plates .....................V-28

7-2-3. Installing and removing rear clamping plates..........V-29

8. Aligning tools ........................................................................V-32

8-1. RG35S ...........................................................................V-32

8-2. RG50, RG80, and RG100.............................................. V-34

9. Setting tool origin ..................................................................V-37

10. Bending operation...............................................................V-38

10-1. Setting rising speed change position ...........................V-38

10-2. Setting multiple opening limit .......................................V-39

10-3. Bending worksheet ......................................................V-40

10-3-1. Temporarily setting multiple closing limit...............V-40

10-3-2. Setting worksheet..................................................V-41

10-3-3. Setting bend angle ................................................V-42

11. Turning off power ................................................................V-44

12. Troubleshooting ..................................................................V-46

13. Clearing emergency stop condition .................................... V-48

iv

Page 5

Part VI Maintenance.......................................................................VI-1

1. Inspection before start of day’s work .................................... VI-2

2. Maintaining hydraulic system................................................ VI-4

2-1. Checking hydraulic oil level............................................ VI-4

2-2. Changing hydraulic oil.................................................... VI-5

2-3. Maintaining tools ............................................................ VI-6

3. Lubrication ............................................................................ VI-7

4. Hydraulic circuit diagrams..................................................... VI-8

4-1. RG35S ........................................................................... VI-8

4-2. RG50, RG80, and RG100............................................. VI-10

5. Electric circuit diagrams....................................................... VI-13

v

Page 6

vi

Page 7

Part

I

Safety

1. Safety rules ..................................................................................I-2

2. DANGER and WARNING plates.................................................I-10

I-1

Page 8

1. SAFETY RULES

Observe these safety rules to prevent injuries and accidents:

a) Never modify the machine. If the control circuit or other part of the machine

is modified, the ram may malfunction.

b) Whenever the machine is not in use, remove the key from the POWER

ON/OFF keyswitch, and hand it to the chief operator for custody.

c) Assign trained operators to the operation and maintenance of the machine.

d) Inspect the machine before the start of the day's work.

e) Install the machine with a rear clearance of at least 1000 mm {40 in.} where

it is not exposed to direct sunlight. If the electrical equipment of the

machine is overheated as a result, the machine may malfunction.

f) Before starting the operation of the machine, check that there are no

persons and obstacles around the machine. Pay particular attention to the

rear of the machine. Never place hand tools and parts on the installed dies

and the lower beam.

g) Never put your hand or hands between the punches and dies.

I-2

Page 9

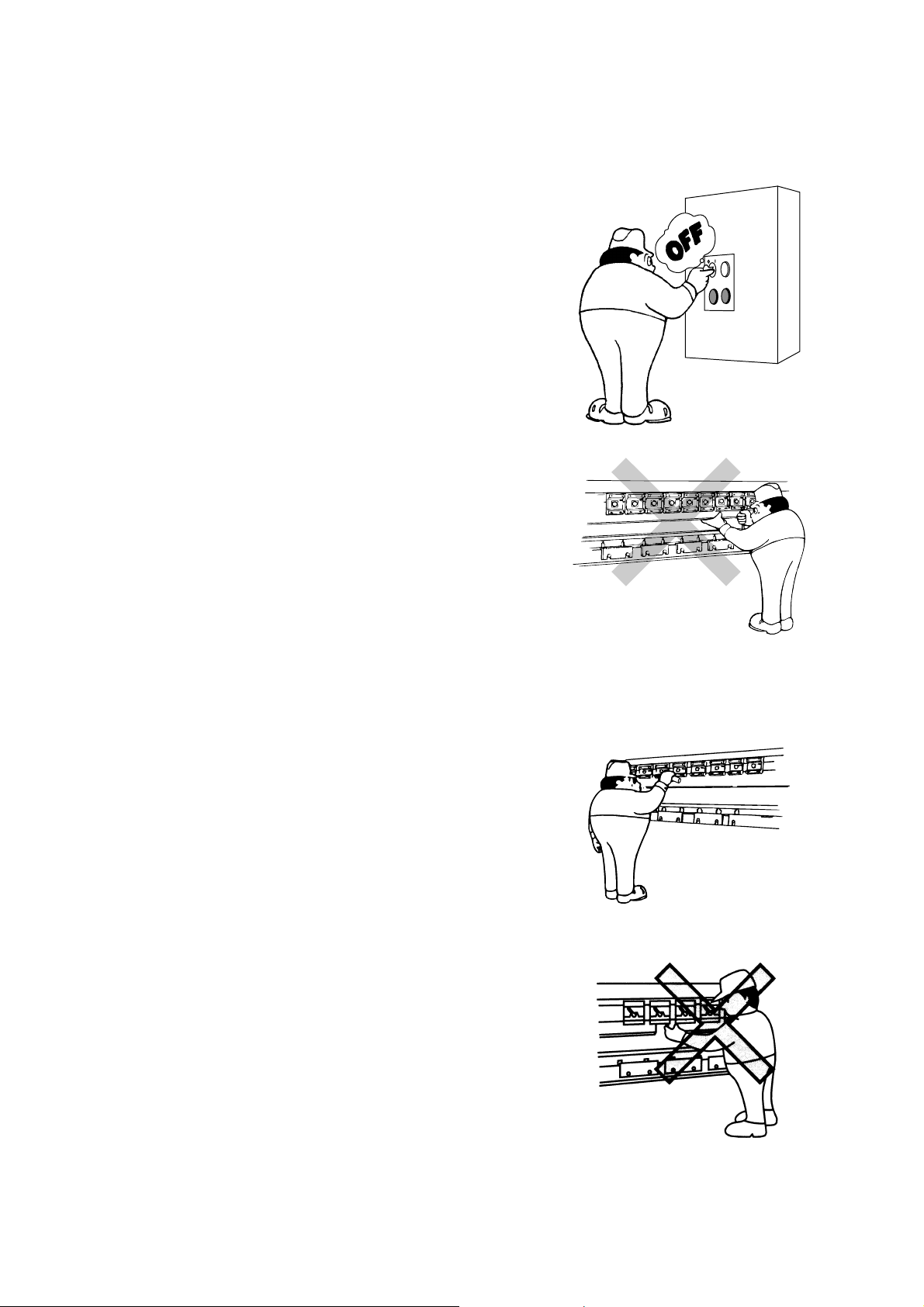

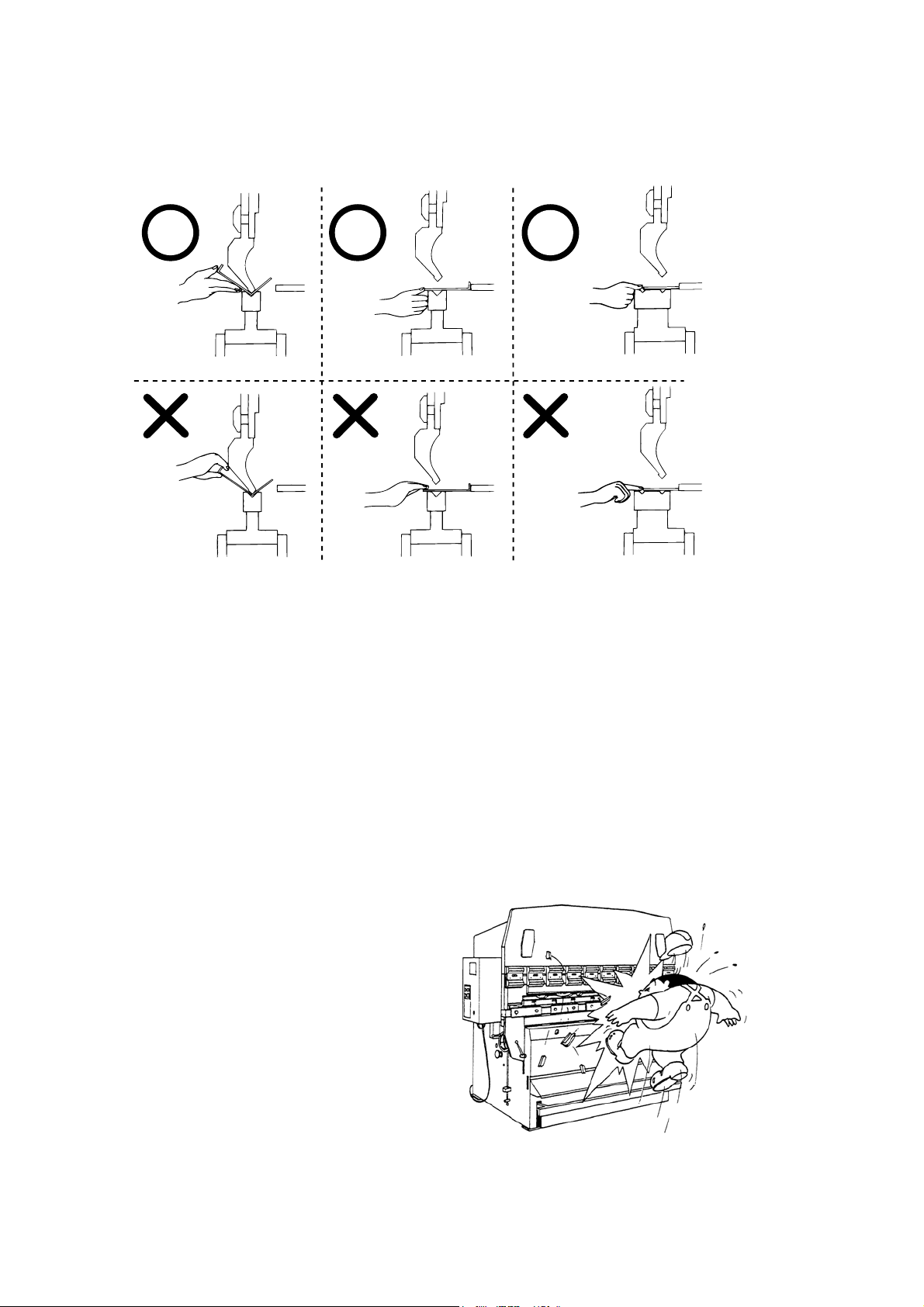

h) When changing the tools, strictly observe the following rules:

• Before installing and removing the

dies, turn the POWER ON/OFF

keyswitch to OFF, remove the key from

the keyswitch, and keep it by yourself.

(Install and remove the dies as

described in “4. Removing tools” and

“5. Installing tools” in Part V.)

• Before installing and removing the

punches, turn the multiple closing limit

setting handwheel to close the ram to

the desired position, turn the POWER

ON/OFF keyswitch to OFF, remove the

key from the keyswitch, and keep it by

yourself. Never put your hand or

hands between the punch and die to

support the punch. (Install and

remove the punches as described in

“4. Removing tools” and “5. Installing

tools” in Part V.)

• Securely fix the punches, dies, and die

holders before applying pressure to

them.

• When you install and remove the tools

with an assistant operator or

operators, be sure to coordinate your

work with them.

• Never put your hands between the

punches and dies to support a punch,

for example.

• When you install a tool by sliding it

sideways, take care not to get your

hand pinched between it and another

tool already installed.

I-3

Page 10

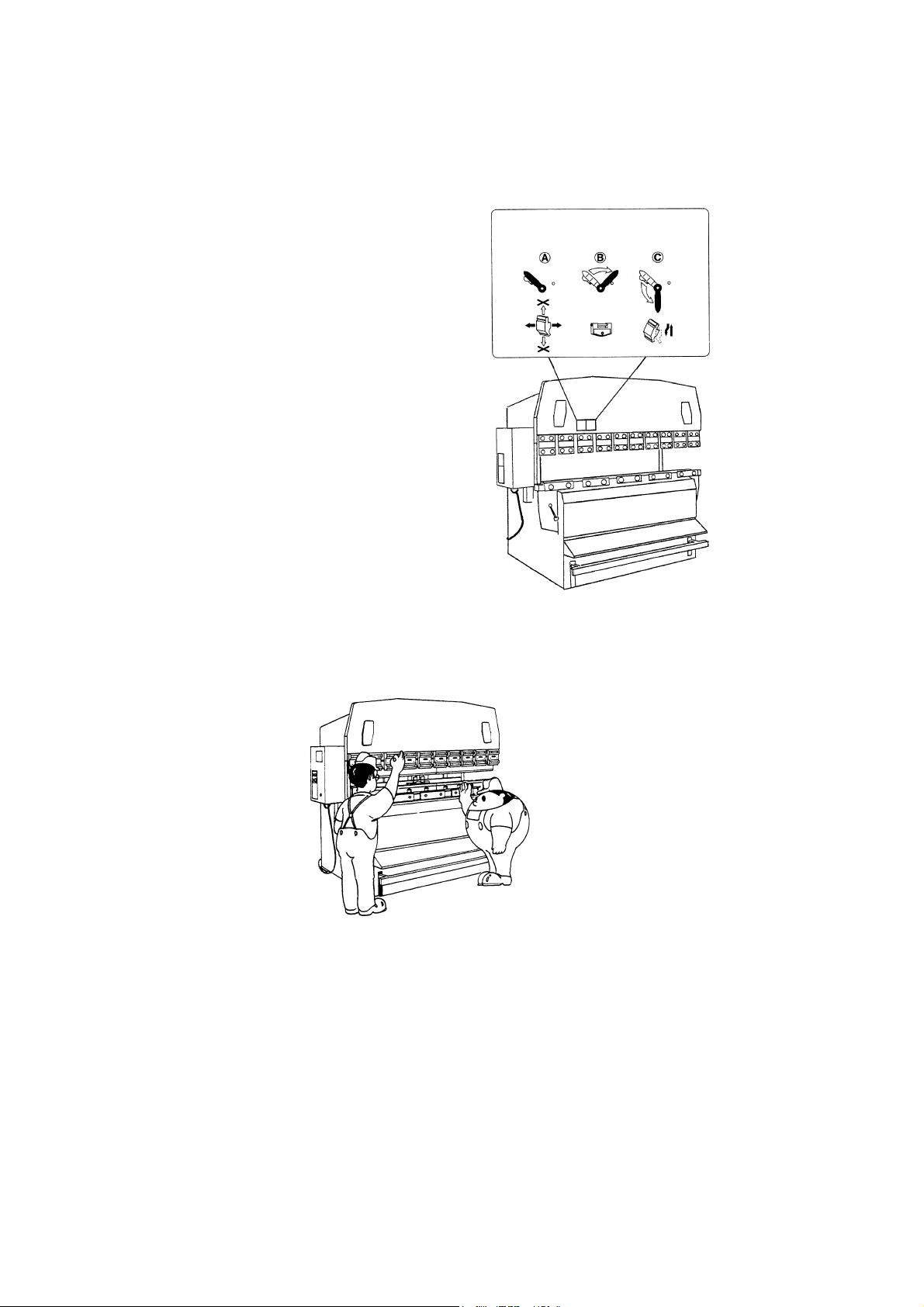

If your machine is equipped with optional one-touch punch holders, keep the

following rules:

• When applying pressure to the

punches or bending the worksheet,

ONE-TOUCH PUNCH HOLDER

LEVER POSITIONS

POSITION POSITION POSITION

turn the punch holder levers to the

position ◯B.

POSITIONS FOR OPERATING

LEVER AND INSTALLING AND

REMOVING PUNCHES

• Install or remove the punch holder

levers only in the position ◯B.

• Affix the punch holder lever position

sticker in an easy-to-see place to

prevent procedural mistakes.

i) When you bend worksheets with an assistant operator or operators, you

must press the bar pedal after fully ensuring the safety of all of them.

I-4

Page 11

j) Before adjusting the stoppers, turn the POWER ON/OFF keyswitch to OFF,

remove the key from the keyswitch, and keep it by yourself. Be sure to

adjust the stoppers from the rear of the machine.

k) Correctly set the position where the bending speed of the ram is to be

changed. If this position is not correctly set, the worksheet may start to

bend unexpectedly.

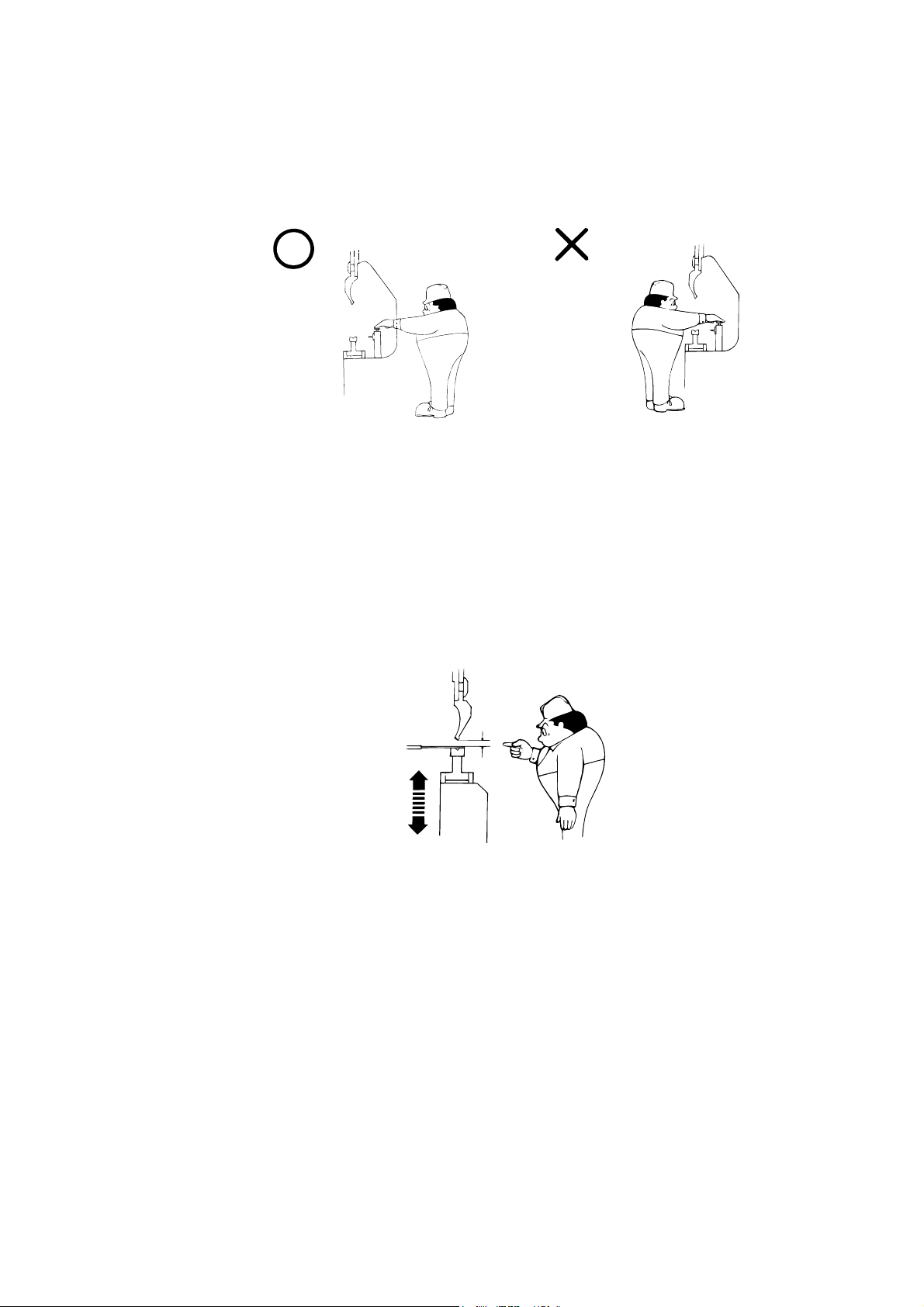

l) When bending a small worksheet, set the stroke length of the ram to 6 mm

{0.24 in.} or less, and hold the worksheet as shown on the next page. Take

care not to get your fingers pinched between the punches and dies or

between the punches and worksheet.

6 mm

{0.24 in.}

or less

I-5

Page 12

Hold the worksheet as shown below.

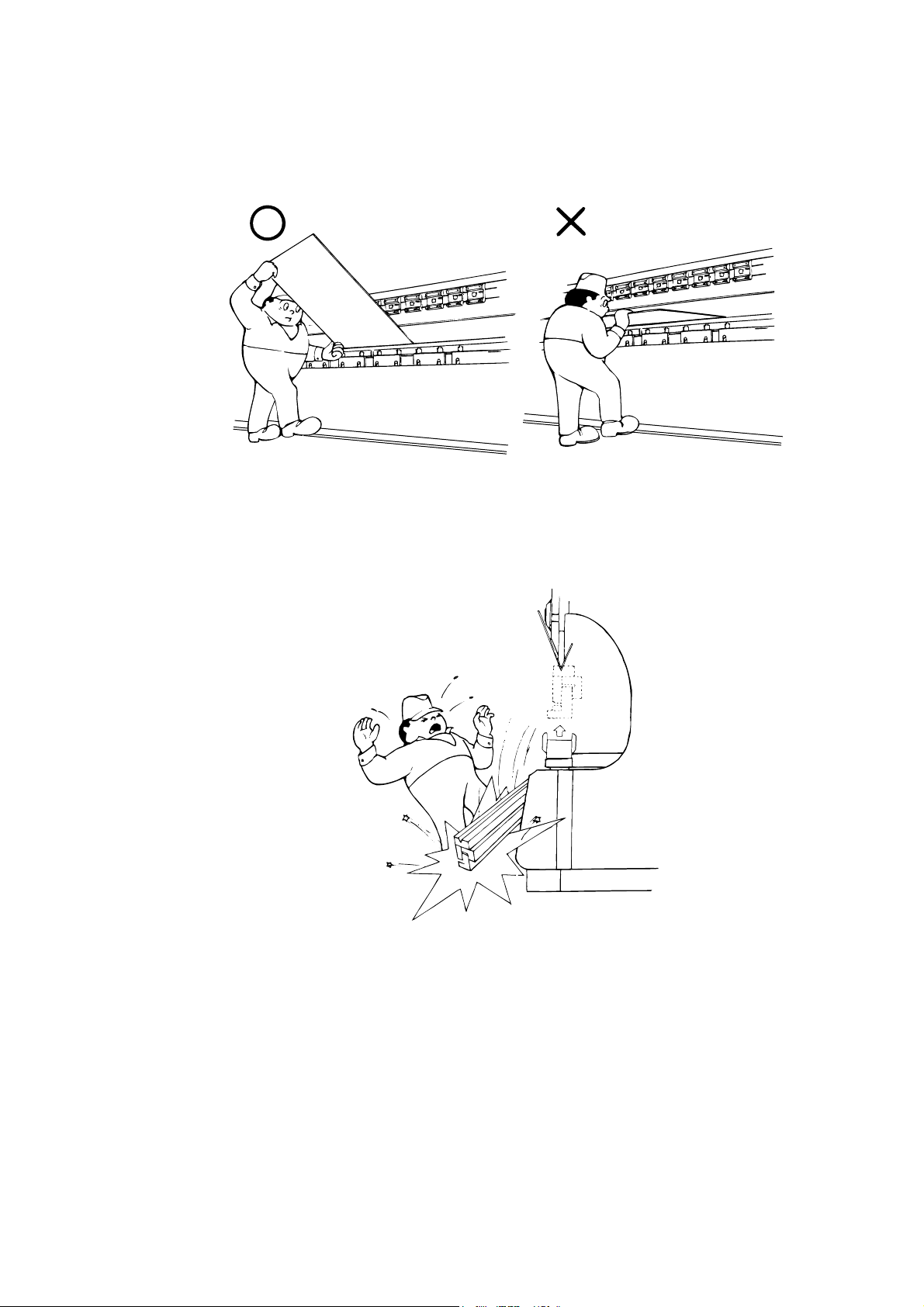

m) If your machine is equipped with an optional backgauge, push the

worksheet against the stoppers of the backgauge after the backgauge is

properly positioned. Otherwise the worksheet may be pushed forward

when the backgauge moves forward.

n) Use Amada genuine punches and dies on the machine. The machine

performs various controls by reference to the Amada genuine punches and

dies. Non-genuine punches and dies are different in brittleness and

allowable tonnage from the genuine punches and dies. Use of such nongenuine tools may cause various troubles and detract from safety of the

machine.

o) Apply to the installed tools a pressure

that is not higher than the allowable

tonnage marked on them. Unless a

proper pressure is applied to them, the

tools may break and scatter in a

dangerous manner.

When 2V-dies are used, use the Vgroove toward the rear of the machine

for additional safety from breakage.

I-6

Page 13

p) When bending a large worksheet, be careful of its springing upward. Hold

one side of the worksheet or otherwise be ready for its springing upward.

q) Before bending each worksheet, check that the tools are securely installed

and tightened. With a sharp bend or U-bend, the punches and dies may

eat into the worksheet and fall together with the worksheet.

I-7

Page 14

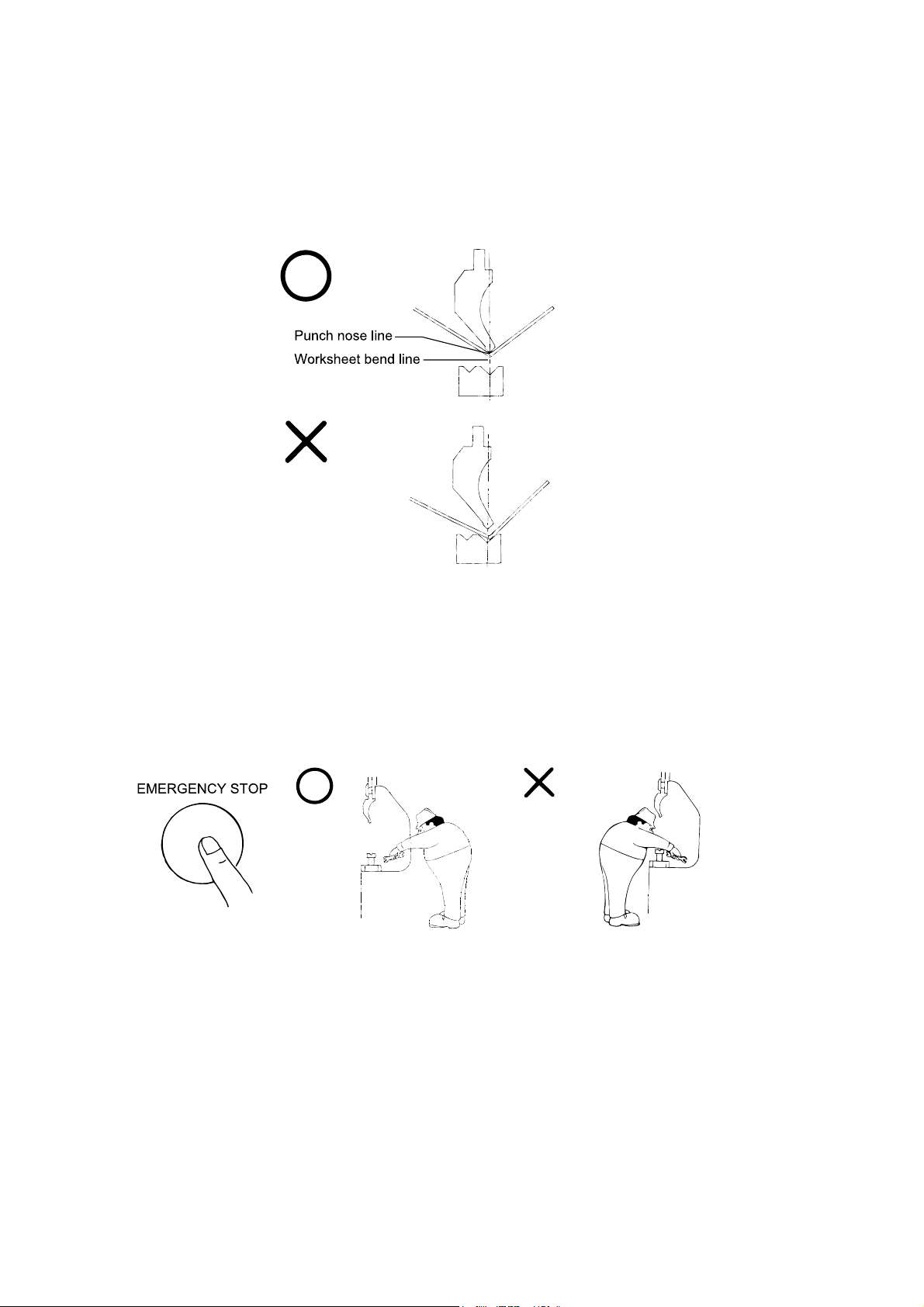

r) When rebending the same worksheet, align the nose line of the punches

with the bend line of the worksheet. If the worksheet is rebent without

aligning the lines, abnormal noise may be produced, and the tools may

break and scatter in a dangerous manner.

s) Whenever trouble occurs during the operation of the machine, press one of

the EMERGENCY STOP buttons, turn the POWER ON/OFF keyswitch to

OFF, remove the key from the keyswitch, keep it by yourself, and fix the

problem. When picking a worksheet that has fallen into the machine, be

sure to do so from the rear of the machine. As soon as the machine

develops trouble, report it to the chief operator.

I-8

Page 15

t) If the machine suddenly loses its power due to a power failure, the ram may

open to the maximum opening limit. In such a case, hold the worksheet

over the ram so that it does not fall.

u) Before walking away from the machine, turn the POWER ON/OFF

keyswitch to OFF, remove the key from the keyswitch, and keep it by

yourself.

v) Before opening the electrical enclosure, be sure to turn off the machine

circuit breaker. You may receive an electric shock if you touch any parts in

the electrical enclosure.

w) Be sure to perform periodic maintenance on the machine. For the items of

maintenance to be performed, refer to Part VI, Maintenance.

x) Before maintaining or cleaning the machine, turn off the shop circuit breaker,

relieve the residual hydraulic pressure in the machine, and post a sign to

inform other workers that the machine is under maintenance.

y) When relocating the machine, ask AMADA about how to move the machine.

If moved incorrectly, the machine may turn over.

I-9

Page 16

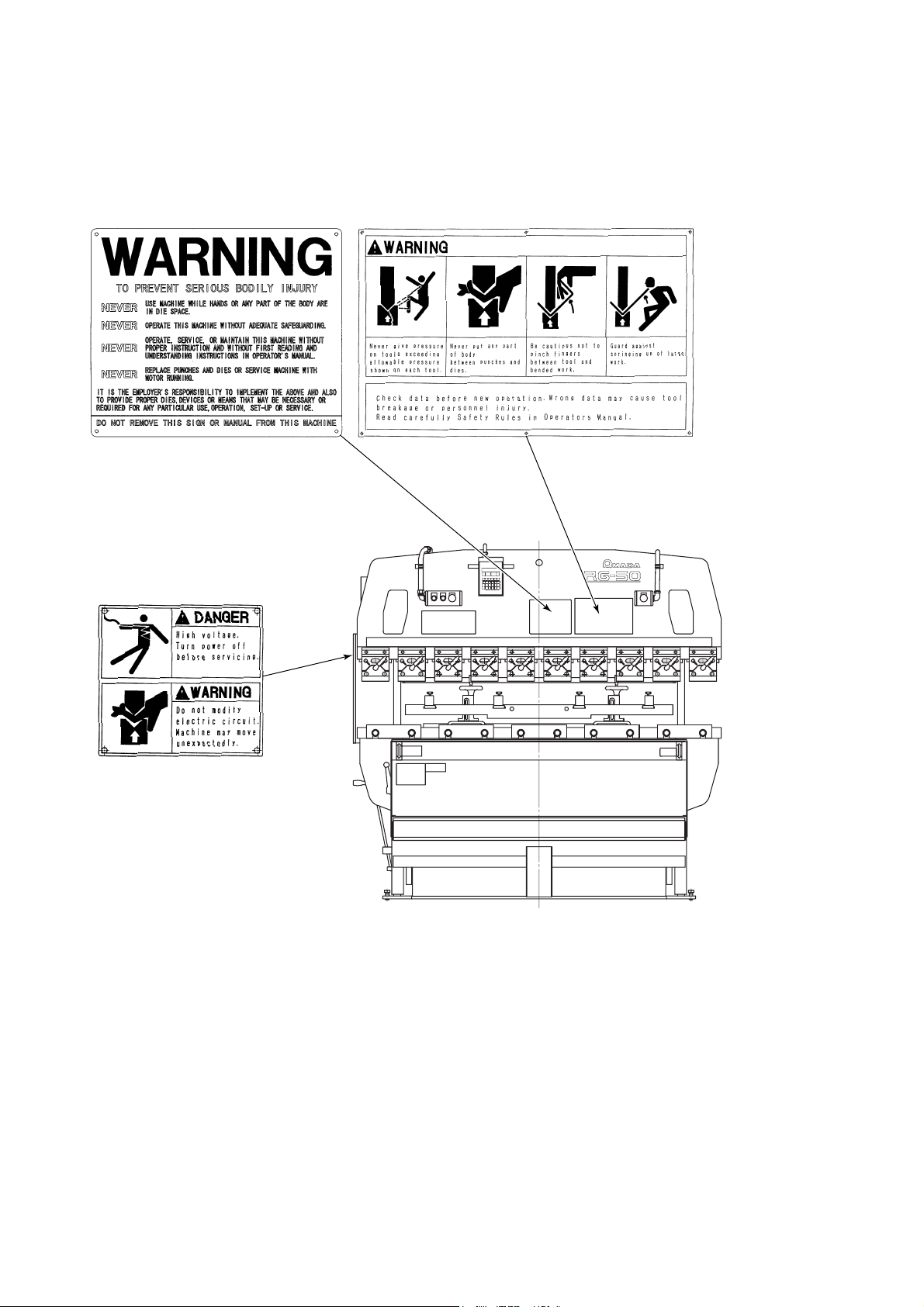

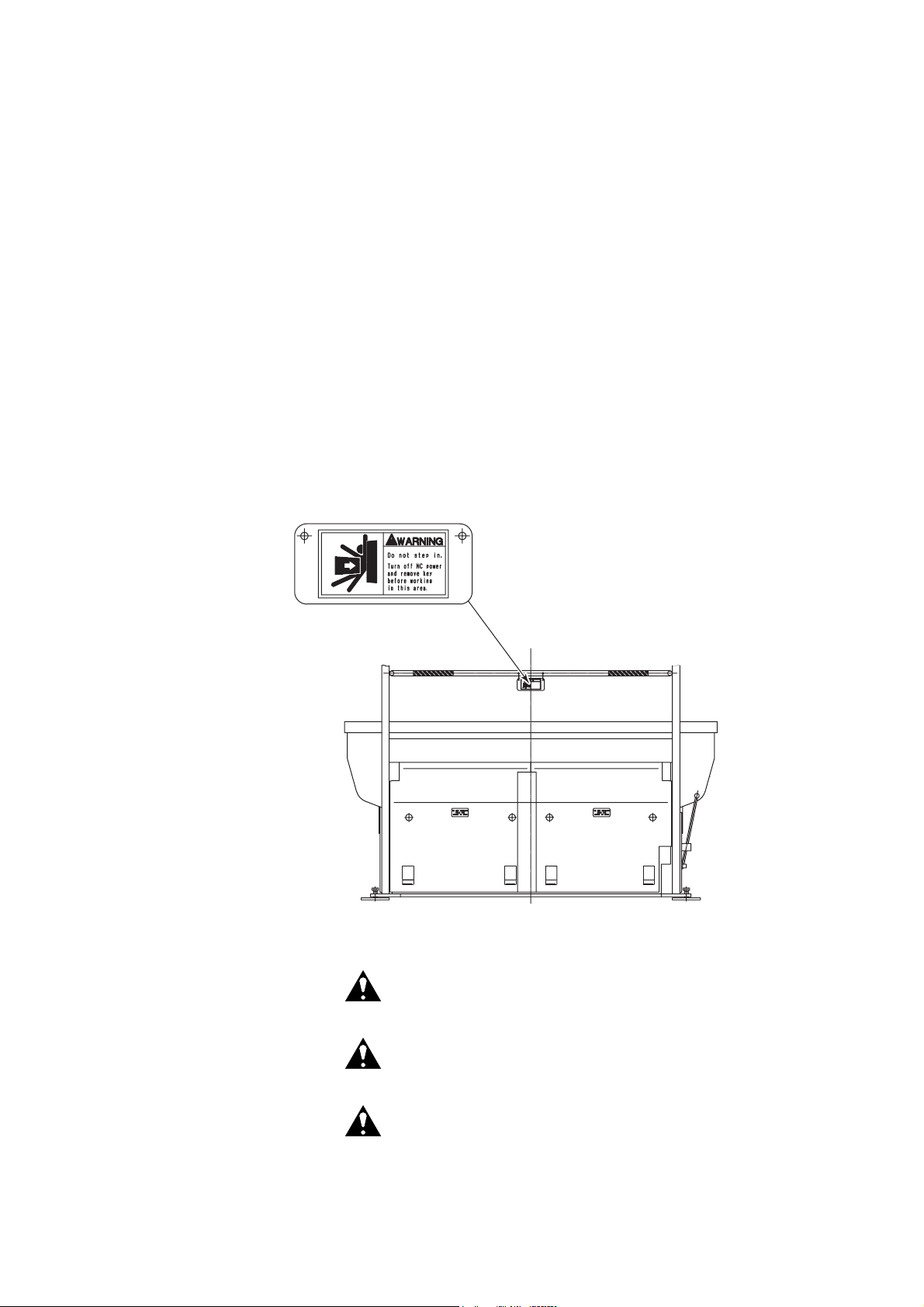

2. DANGER AND WARNING PLATES

Keep the DANGER and WARNING plates well noticeable and never remove

them.

I-10

Page 17

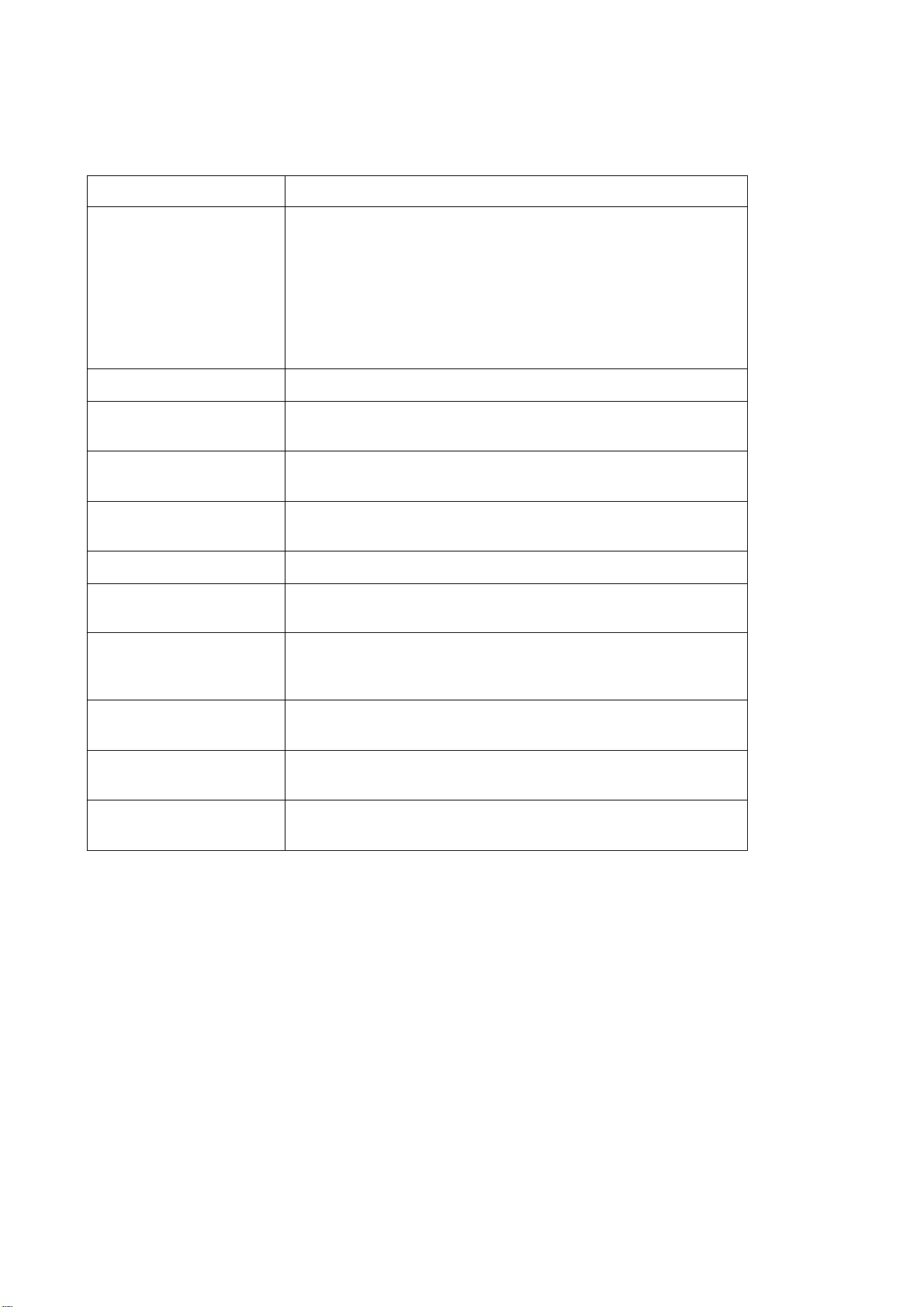

Hazard seriousness level

DANGER

WARNING

CAUTION

Indicates an imminently hazardous situation

which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation

which, if not avoided, may result in minor or

moderate injury.

I-11

Page 18

I-12

Page 19

Part

II

Description

1. Functions .................................................................................... II-2

2. General view ............................................................................... II-3

3. Specifications.............................................................................. II-5

4. Dimensions ................................................................................. II-6

5. Standard accessories .................................................................II-9

6. Options....................................................................................... II-10

II-1

Page 20

1. FUNCTIONS

This machine is a hydraulic press brake of the central pressure

application and parallel rising type. It has the following features:

• The hydraulic circuit is simplified to minimize oil leakage and facilitate

maintenance.

• A main cylinder is installed at the center of the ram to minimize the

distortion produced in the upper and lower beams during pressure

application.

• Installed at the center of the ram, a bearing guide unit slides up and

down along the main cylinder surface that doubles as sliding surface,

in order to keep the upper and lower beams accurately parallel.

• A punch-to-die clearance setting unit allows the ram stroke length to

be set to a required minimum and the working efficiency to be

enhanced as a result.

• The bar pedal can be pressed as required to adjust the ram approach

speed or stop the ram mid-stroke. This is ideal for bending

worksheets on which scribed lines must be aligned with the punch

nose line.

• Punch holders and die holders are installed in the upper and lower

beams and provide for easy installation of punches and dies,

respectively.

• Standard tools are light in mass, easy to carry, available in many

types, and adaptable to a variety of bending operations. (For the

tools, refer to their catalogs.)

II-2

Page 21

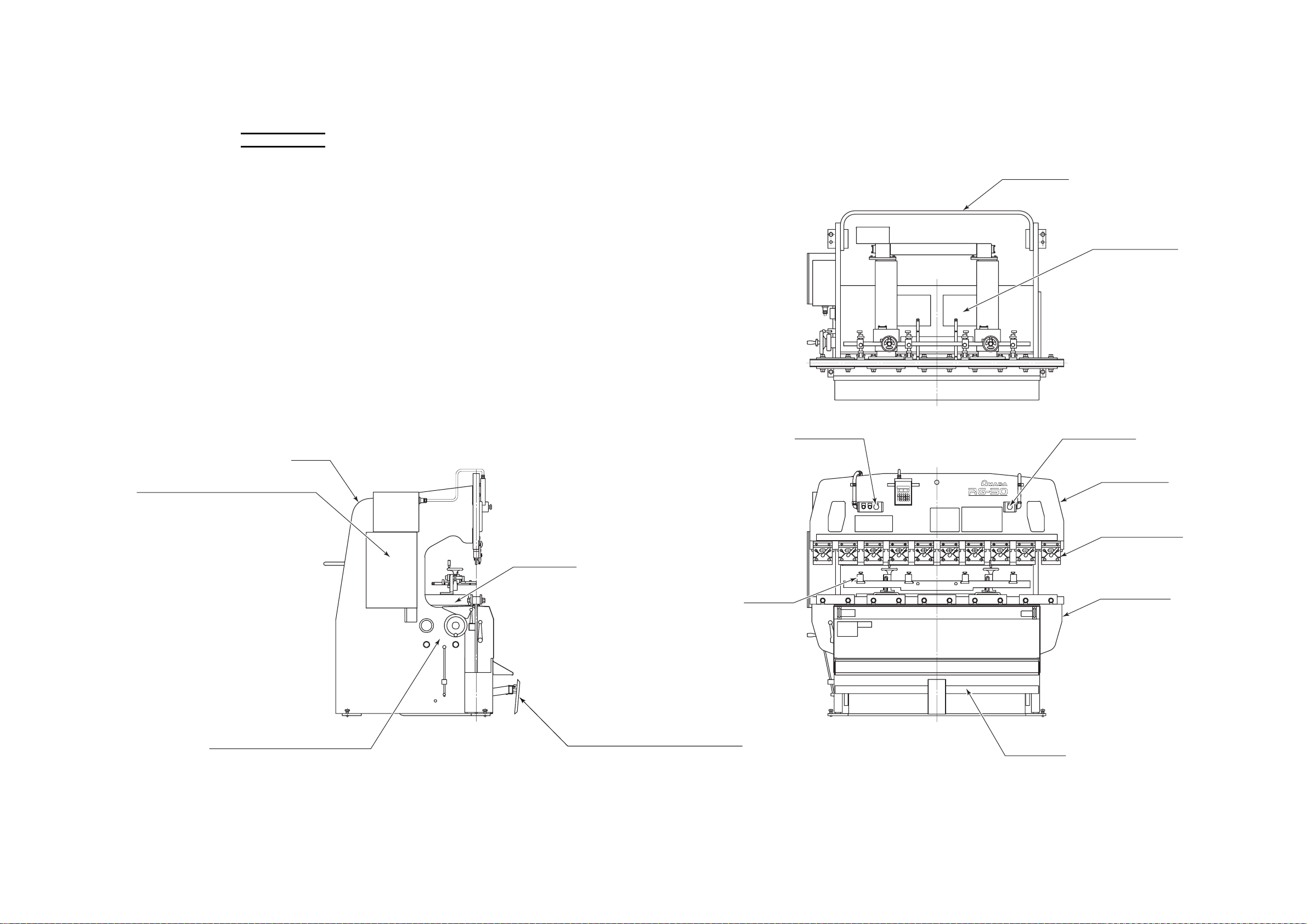

2. GENERAL VIEW

NOTE

O This drawing shows the general view of the RG50 machine.

REAR GUARD

HYDRAULIC UNIT

Hydraulic oil tank and hydraulic

drive unit are located at rear

of lower beam.

FRAME

ELECTRICAL ENCLOSURE

Power distribution and control circuits

are built in. Power and hydraulic pump

motor switches are located.

Shop's main power source is connected

to terminals in this enclosure.

HYDRAULIC

EQUIPMENT CONTROLS

Knobs and levers required for

operation of ram are located.

SUPPORTER

PEDAL STOPPER

Pressed to allow ram to be operated

only by single operator. Bar pedal can

be pressed only when foot is placed on

pedal stopper to disable pedal stopper.

STOPPER

EMERGENCY

STOP BUTTON

EMERGENCY

STOP BUTTON

UPPER BEAM

PUNCH HOLDER

LOWER BEAM

BAR PEDAL

Pressed as required to adjust ram approach

speed or stop ram mid-stroke.

II-3

Page 22

II-4

Page 23

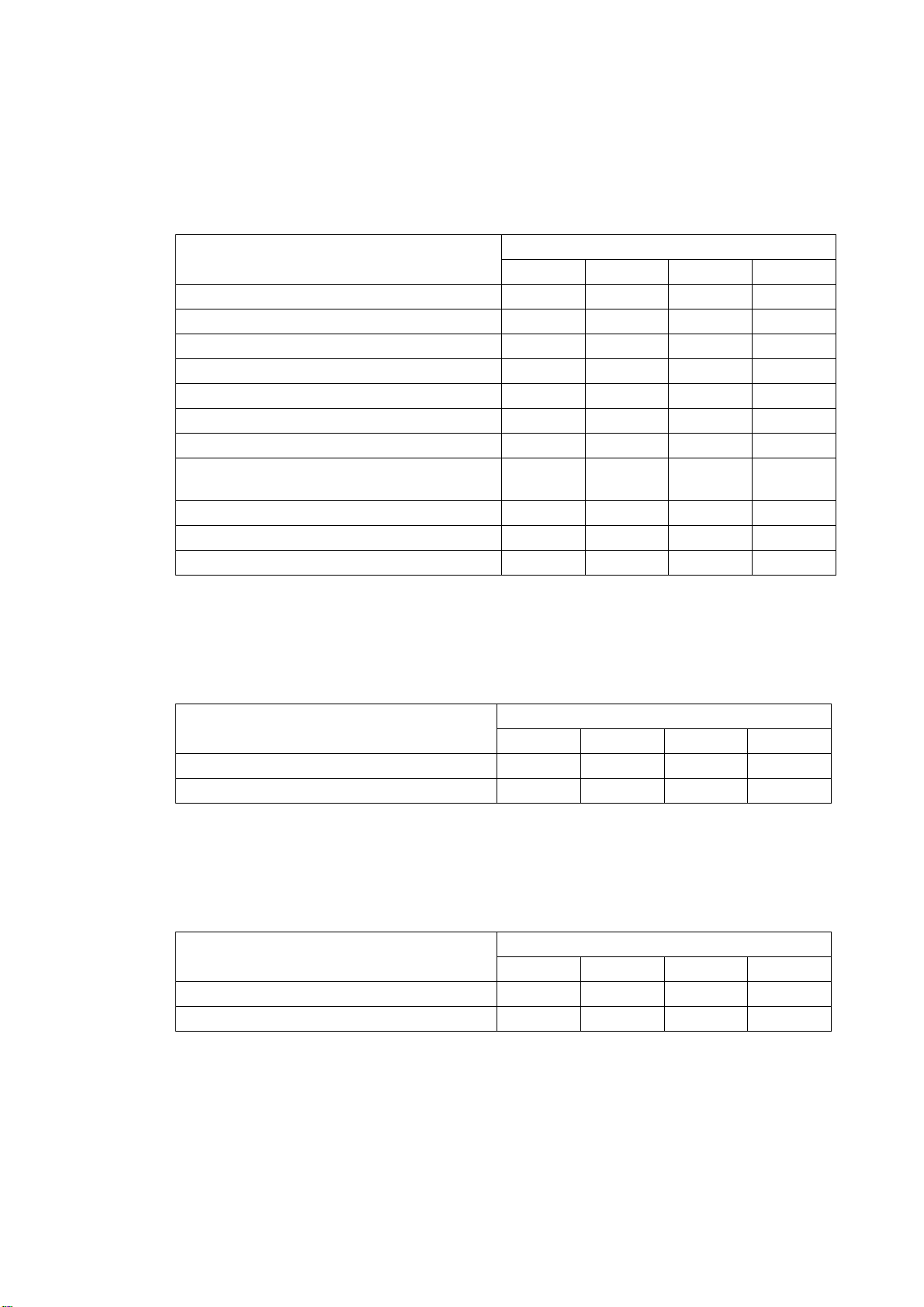

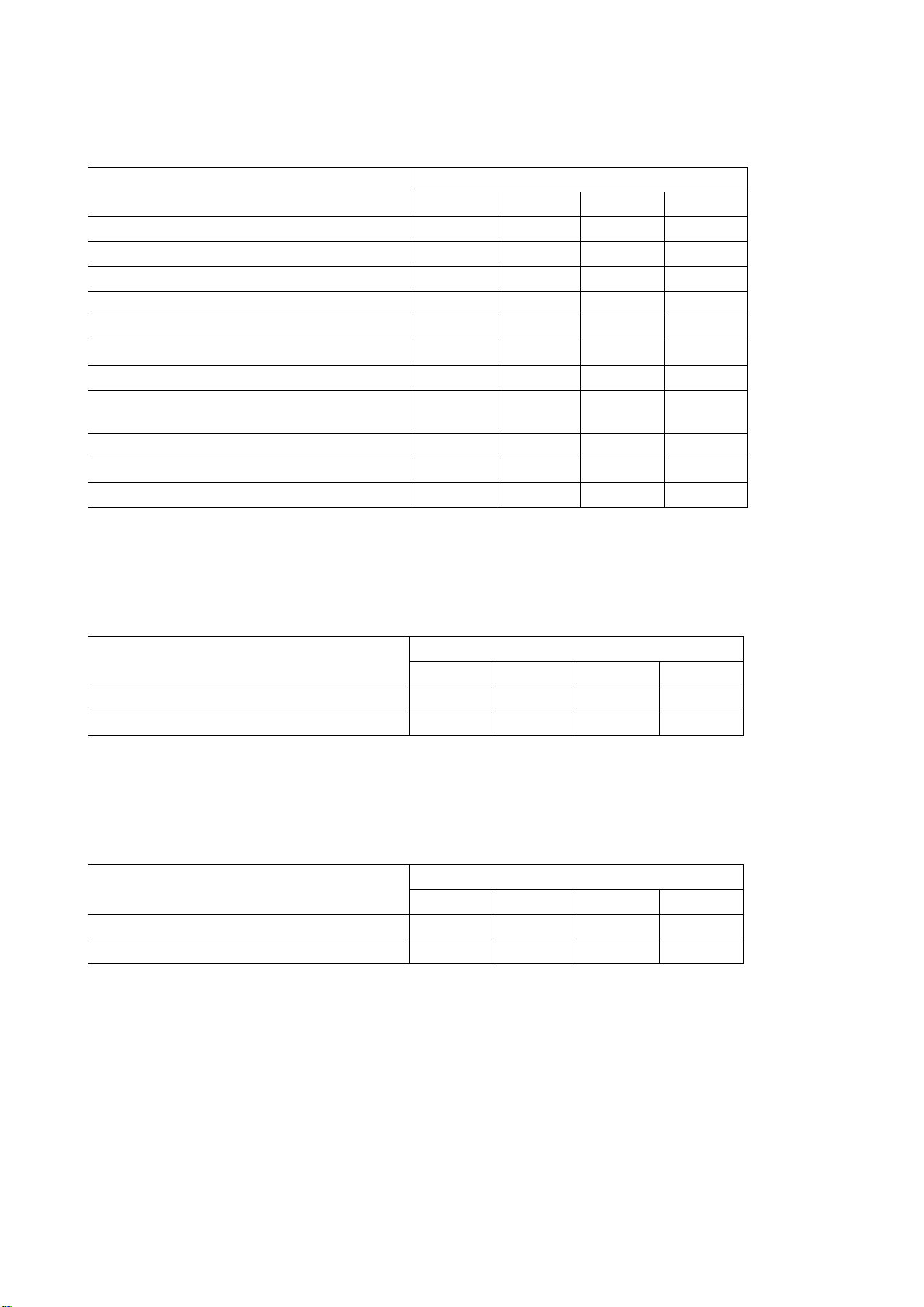

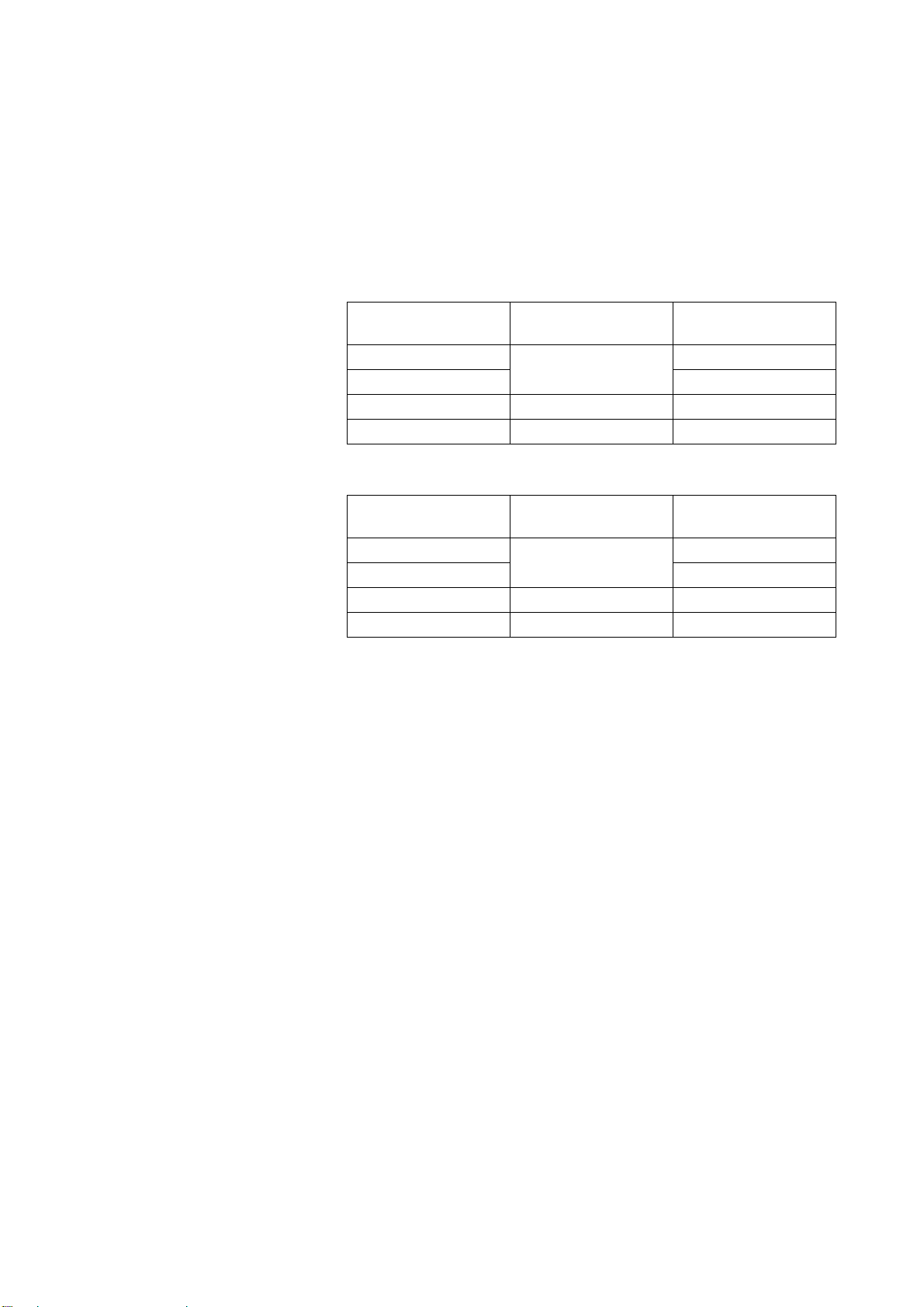

3. SPECIFICATIONS

Metric unit system (International system of units)

Item

Maximum bend length (mm) 1250 2085 2505 3100

Press capacity (kN) 343 490 784 980

Stroke length (mm) 100 100 100 100

Open height without punch holders (mm) 370 370 370 370

Approach speed at 50/60 Hz (mm/sec) 46/55 38/45 38/45 49/59

Bending speed at 50/60 Hz (mm/sec) 8/9.5 7/8.5 7/8.5 8.3/10.1

Moving-down speed (mm/sec) 40 35 52 52

Number of main cylinders

(number of auxiliary cylinders)

Hydraulic pump motor output (kW) 2.2 3.7 5.5 7.5

Hydraulic oil tank capacity (L) 26 51 51 65

Machine mass (kg) 1600 2900 5100 6400

RG35S RG50 RG80 RG100

1 1 (2) 1 (2) 1 (2)

Model

Power supply of 380/400/460 V

Item

RG35S RG50 RG80 RG100

Primary power cable (mm2)223.58

Load current (A) 9.1 13.2 23.0 30.0

Model

Power supply of 200/230 V

Item

Primary power cable (mm2) 3.5 3.5 8 14

Load current (A) 17.0 22.3 38.0 49.1

RG35S RG50 RG80 RG100

Model

II-5

Page 24

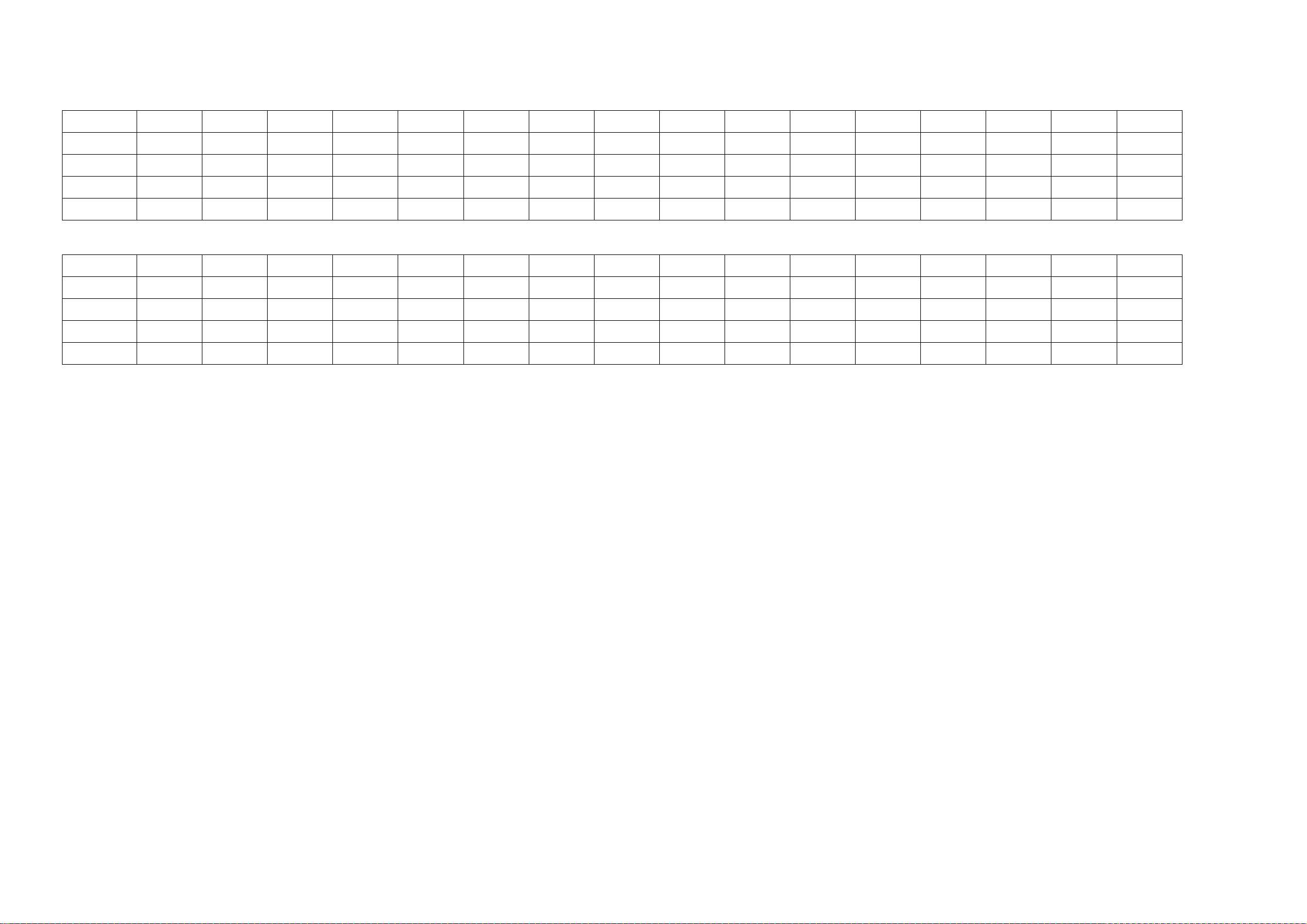

English unit system

Item

Maximum bend length (in.) 49.2 82.1 98.6 122.0

Press capacity (US tonf) 38.6 55.1 88.2 110.2

Stroke length (in.) 3.9 3.9 3.9 3.9

Open height without punch holders (in.) 14.6 14.6 14.6 14.6

Approach speed at 50/60 Hz (ips) 1.8/2.2 1.5/1.8 1.5/1.8 1.9/2.3

Bending speed at 50/60 Hz (ips) 0.31/0.37 0.28/0.33 0.28/0.33 0.33/0.40

Moving-down speed (ips) 1.6 1.4 2.0 2.0

Number of main cylinders

(number of auxiliary cylinders)

Hydraulic pump motor output (HP) 3.0 5.0 7.4 10.1

Hydraulic oil tank capacity (US gal) 6.9 13.5 13.5 17.2

Machine mass (lb) 3530 6390 11250 14110

RG35S RG50 RG80 RG100

1 1 (2) 1 (2) 1 (2)

Model

Power supply of 380/400/460 V

Item

RG35S RG50 RG80 RG100

Primary power cable (mm2)223.58

Load current (A) 9.1 13.2 23.0 30.0

Model

Power supply of 200/230 V

Item

Primary power cable (mm2) 3.5 3.5 8 14

Load current (A) 17.0 22.3 38.0 49.1

RG35S RG50 RG80 RG100

Model

II-6

Page 25

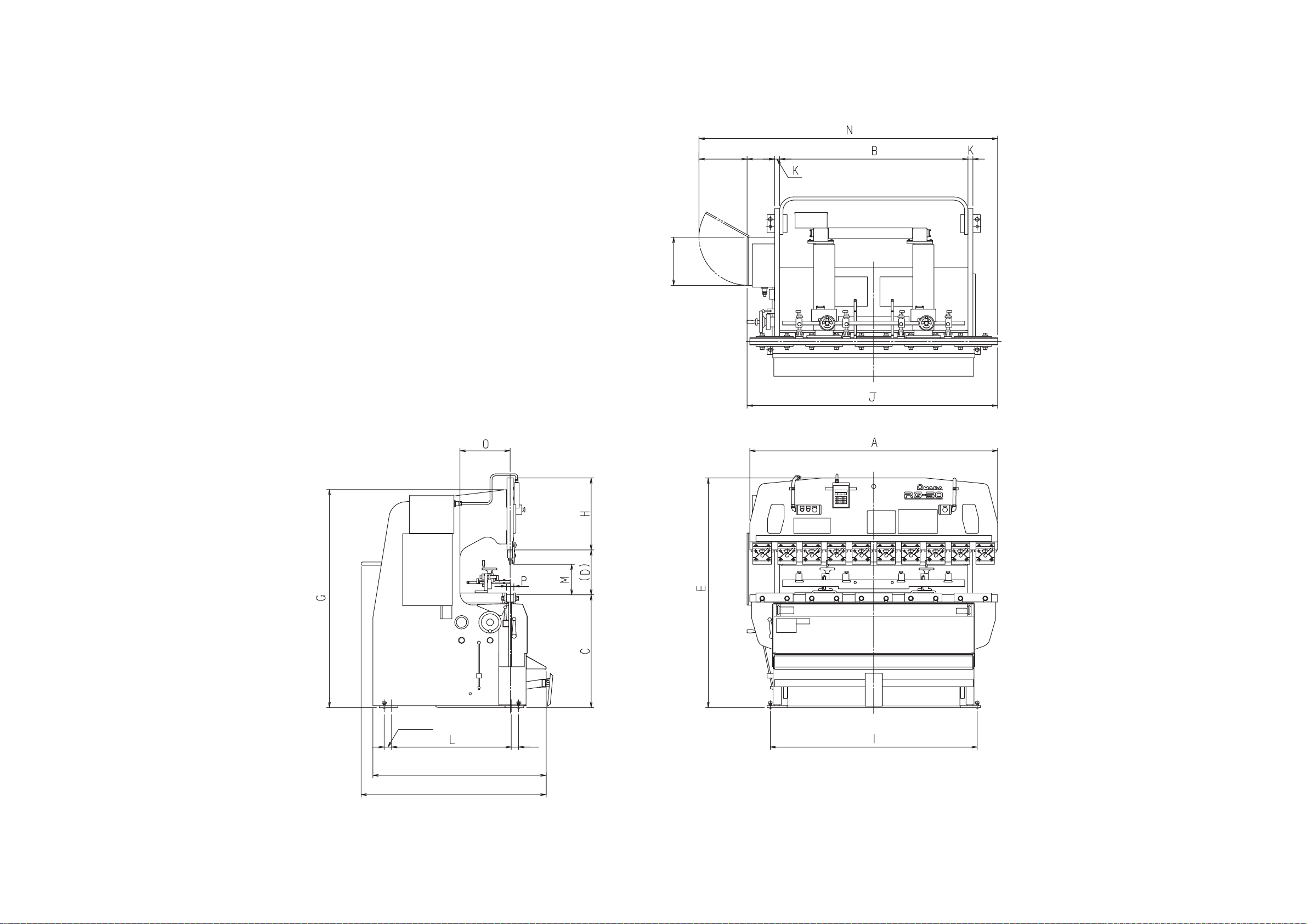

4. DIMENSIONS

400 mm

{15.7 in.}

390 mm

{15.4 in.}

225 mm

{8.9 in.}

F*

F**

60 mm

{2.4 in.}

60 mm

{2.4 in.}

*Depth of RG35S, RG50, RG80

**Depth of RG100

II-7

Page 26

Unit: mm

Model A B C (D) E F G H I J K L M N O P

RG35S 1200 1020 935 370 1955 1495 1800 650 920 1355 25 445 250 1745 200 60

RG50 2000 1520 940 370 1910 1495 1820 600 1670 2025 40 970 250 2410 400 60

RG80 2400 2050 945 370 2065 1495 1920 750 2240 2515 60 970 250 2895 400 60

RG100 3000 2550 1035 370 2305 1555 2110 900 2750 3065 60 1090 250 3445 400 90

Unit: in.

Model A B C (D) E F G H I J K L M N O P

RG35S 47.2 40.2 36.8 14.6 77 58.9 70.9 25.6 36.2 53.3 0.98 17.5 9.8 68.7 7.9 2.4

RG50 78.7 59.8 37.0 14.6 75.2 58.9 71.7 23.6 65.7 79.7 1.57 38.2 9.8 94.9 15.7 2.4

RG80 94.5 80.7 37.2 14.6 81.3 58.9 75.6 29.5 88.2 99.0 2.36 38.2 9.8 114.0 15.7 2.4

RG100 118.1 100.4 40.7 14.6 90.7 61.2 83.1 35.4 108.3 120.7 2.36 42.9 9.8 135.6 15.7 3.5

II-8

Page 27

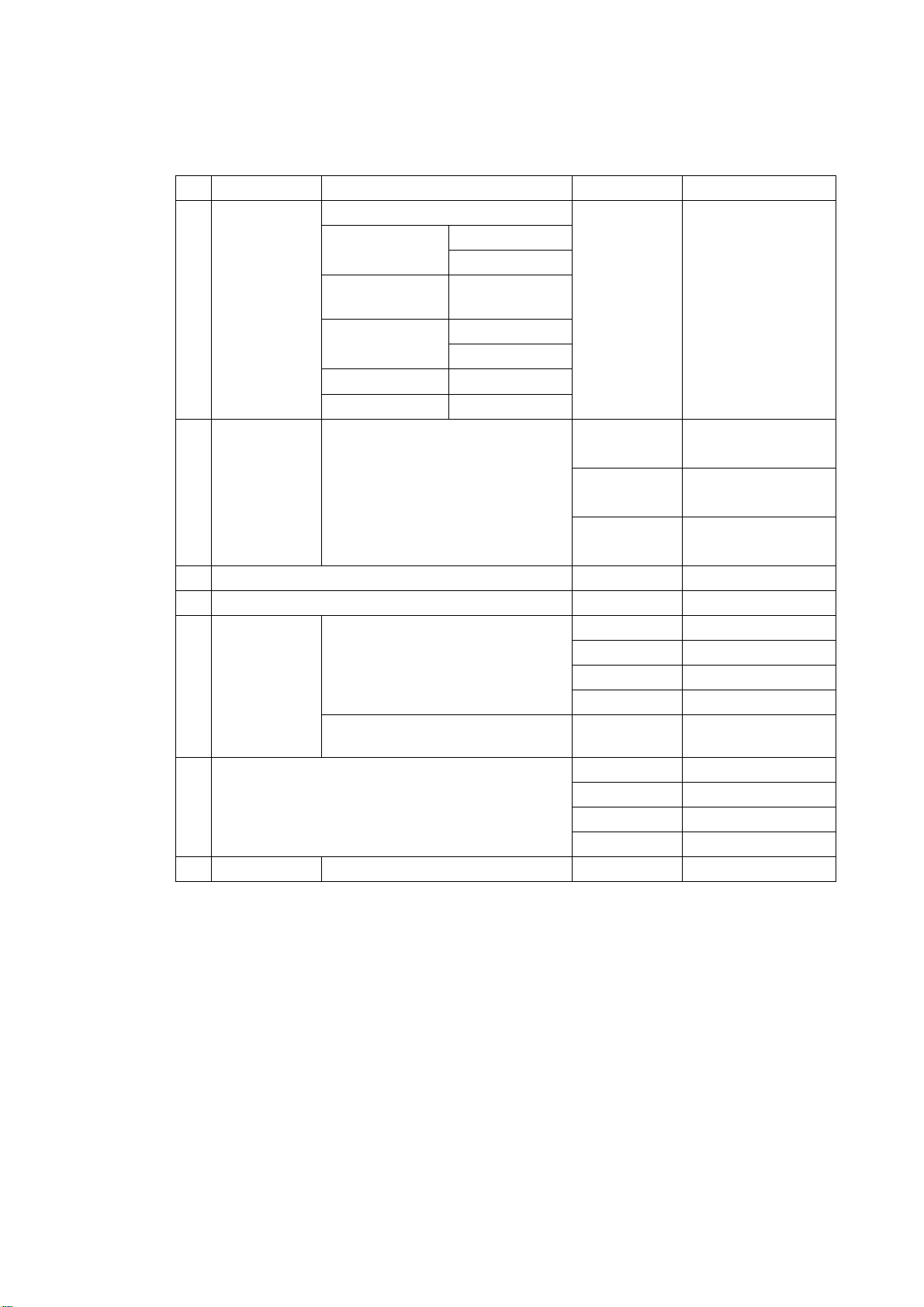

5. STANDARD ACCESSORIES

No. Item Description Qty Applicable model

Tool box

Single-ended

wrench

45° offset box

1 Tool set

2 Hydraulic oil Super Hydraulic oil 56 (Nippon oil)

3 Stopper 2 (0) ALL

4 Supporter 4 (2) ALL

5 2V-die holder

6 Punch holder

7 Bulb LS-6 2 ALL

Note: Quantity values enclosed in parentheses apply when machine is equipped with optional

backgauge.

wrench

Allen wrench

Brass bar

Hammer 1/2 pound

Size L: 830 mm {32.7 in.} long,

75 mm {3.0 in.} high

Size S: 412 mm {16.2 in.} long,

75 mm {3.0 in.} high

30 mm

13 mm

14 × 17 mm

8 mm, long type

5 mm

φ20 × 200 mm

1ALL

26 L

{6.9 US gal}

51 L

{13.5 US gal}

65 L

{17.2 US gal}

1RG35S

2RG50

3RG80

4RG100

1 RG35S, 50

6RG35S

10 RG50

12 RG80

15 RG100

RG35S

RG50, 80

RG100

II-9

Page 28

6. OPTIONS

Name Function

Auto-backgauge system

Remote foot pedals

RR-type front gauge

Worksheet follower

One-touch punch holders*

Dial-type punch holders*

Double-side punch

holders*

Optical safety device

• Can set worksheet contact positions (bending positions) for up

to 99 processes.

• Allows continuous bending by programmed operation.

• Displays set values and current position of backgauge by LEDs.

• Has such functions as elongation compensation, backlash

compensation, and timing.

• Like bar pedal, open and close ram.

• Installed at front of machine to support worksheet with stoppers

and used for positioning worksheet at front of machine.

• Supports large worksheet during bending while following bend

angle.

• Allow punches to be installed and removed by levers without

use of any other tool.

• Allow height of punches to be adjusted with dials.

• Allow punches to be installed on both of front and rear sides.

• Emits light beams at front of installed punches and dies and

automatically stops machine as soon as two or more light

beams are interrupted by operator’s body parts or other objects.

Side guards

Two-hand control buttons

Two-person foot pedals

*Standard option

• Close up gaps in left and right frames and prevent operator’s

body parts from entering machine.

• Simultaneously pressed to open and close ram in place of bar

pedal.

• Simultaneously pressed by two persons to open and close ram

in place of bar pedal.

II-10

Page 29

Part

III

Installation

1. Summary.....................................................................................III-2

1-1. Environmental conditions.....................................................III-2

1-2. Input power source...............................................................III-2

1-3. Things to be supplied by customer ......................................III-3

2. Installation procedures................................................................III-4

2-1. Location................................................................................III-4

2-2. Lifting....................................................................................III-5

2-3. Foundation ...........................................................................III-6

2-4. Placing .................................................................................III-6

2-5. Leveling................................................................................III-6

2-6. Supplying hydraulic oil .........................................................III-8

2-7. Supplying electric power ......................................................III-8

When the machine is delivered to you directly from AMADA, it is usually

transported by the specialized carrier. Instruct them where to install the

machine.

Select such a machine installation place where the space required for

worksheet loading, part unloading and machine maintenance can be

secured and where the machine can be installed on a flat surface

without ground subsidence. For details, refer to “2. Installation

procedures”.

WARNING

O Moving or carrying the machine may not only

damage the machine, but also is dangerous. Ask

a qualified contractor to perform this work.

III-1

Page 30

1. SUMMARY

1-1. Environmental conditions

• Keep the machine at least 10 m {33 ft} away from a welder or any

other equipment that may produce electrical noise and magnetic

fields.

• Where the ambient temperature is not higher than 5 °C {41 °F}, keep

the machine and hydraulic pump motor energized during the day's

work.

• The higher the humidity in the place where the machine is installed,

the lower the insulation performance of its electric parts becomes.

This results in the premature degradation of the electric parts. Do

not install the machine in such a humid place.

• Install the machine in a place where it is not subjected to dust, dirt,

and organic or corrosive gases.

1-2. Input power source

Power requirement: 200/230/380/400/460 VAC±10% (transformer tap

and motor wiring is required), 3 phases, 50/60 Hz±1 Hz

NOTICE

O Supply the machine from a power source independent of a welder or any

other equipment that may produce line voltage variations. Otherwise the

machine may misoperate.

III-2

Page 31

1-3. Things to be supplied by customer

Primary power cable

Four-conductor VCT cable (600V polyvinyl chloride insulated cabtyre

cable)

380/400/460 V specification

Model Each conductor size

RG35S 9.1 A

RG50

RG80 3.5 mm

RG100 8 mm

200/230 V specification

Model Each conductor size

RG35S 17.0 A

RG50

RG80 8 mm

RG100 14 mm

2 mm

3.5 mm

Current carrying

capacity

2

13.2 A

2

2

23.0 A

30.0 A

Current carrying

capacity

2

22.3 A

2

2

38.0 A

49.1 A

III-3

Page 32

2. INSTALLATION PROCEDURES

2-1. Location

Select a place where an ample space can be secured for the machine

by paying full attention to the required floor area and the following items:

• There must be no pillars and other obstacles where the tools are

installed and removed. (At least 835 mm {33 in.} long tools must be

able to be horizontally installed and removed through the left and right

frame gaps of the machine.)

• The ceiling must be at least 1000 mm {40 in.} from the top of the

machine. (Take the height of the base plates into account.)

• There must be an additional space to locate a tool storage case and

any other necessary items.

• Space must be available for worksheet loading, part unloading,

machine maintenance, and other tasks.

A space of 1000 mm {40 in.} or more must be available at the rear of

the machine.

An enough space must be available for the cover of the electrical

enclosure to be opened.

A space of 1000 mm {40 in.} or more must be available from the cover

edge at the right side of the ram.

NOTICE

O Do not install the machine in a place where it is exposed to dust from such

operations as sandblasting and to direct sunlight, rain and wind.

O It is ideal to install the machine on a concrete floor to prevent deflection due to

ground subsidence.

1000 mm

{40 in.}

700 mm

{28 in.}

300 mm

{12 in.}

1000 mm

{40 in.}

III-4

FRONT

Page 33

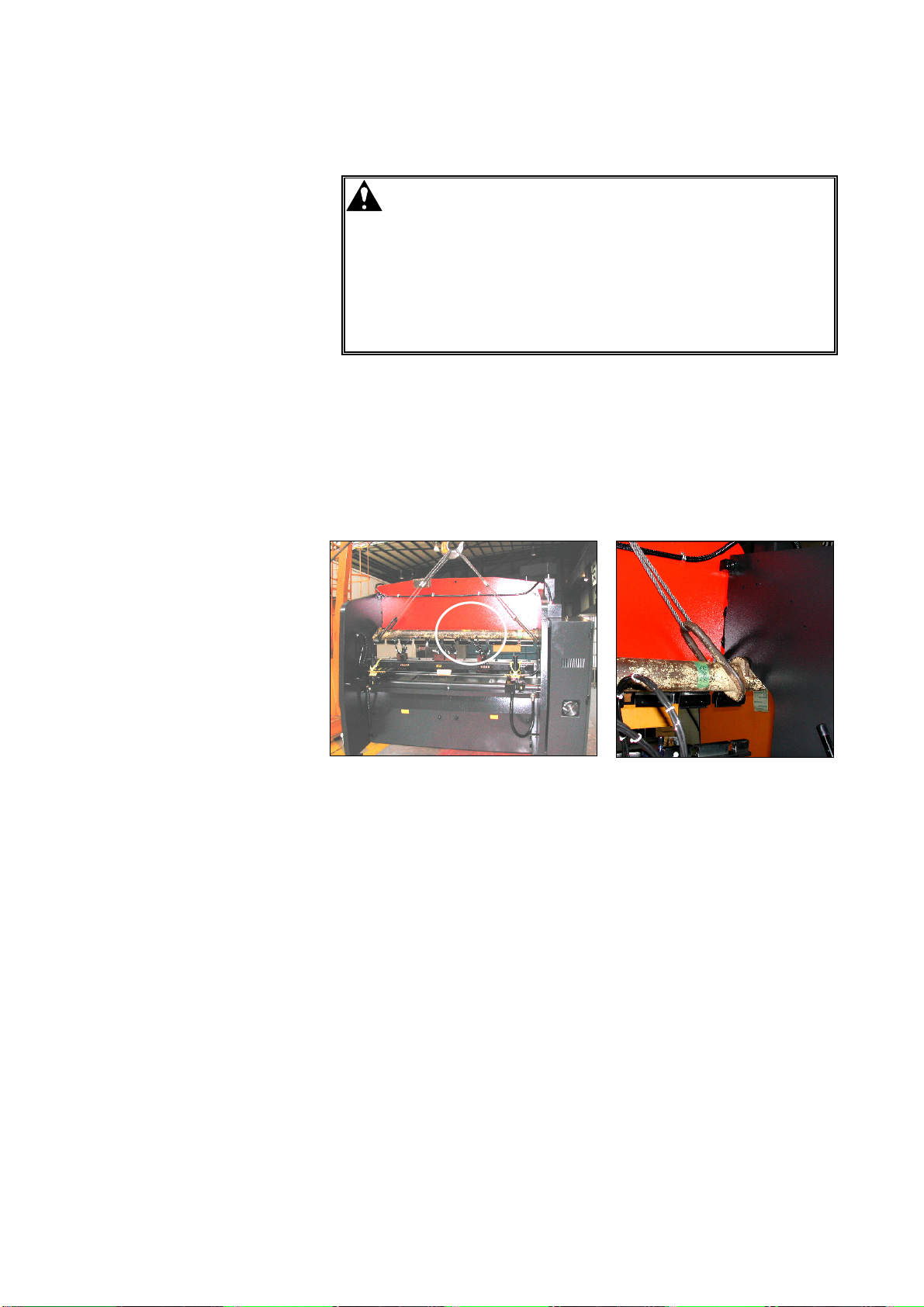

2-2. Lifting

WARNING

For the mass of the machine, refer to “Machine mass” in the

specifications on pages II-5 and II-6. This mass is that of a standard

specification machine and increases when the machine is fitted with

optional units.

When lifting the machine, pass special lifting devices through the frame

gaps as shown below, apply wire rope slings to the lifting devices, and

lift the machine with a crane.

O The machine requires special lifting

devices. Never use steel pipes or apply

wire rope slings directly to the frame of the

machine. Doing so is not only

dangerous, but also damages the

machine.

O If it is necessary to lift the machine for

layout change, for example, ask a qualified

contractor to perform the work.

III-5

Page 34

2-3. Foundation

To maintain its bending accuracy, install the machine on a flat concrete

floor constructed strong enough to carry its mass. Before carrying the

machine to the location, execute the foundation work by referring to the

foundation drawing supplied by AMADA. If the ground is soft with a

bearing capacity of 49 kN/m

foundation with steel bars or the like.

2-4. Placing

Usually, fixing the machine with anchor bolts is not necessary.

Place base plates (150 mm {6 in.} square and 9 to 16 mm {0.4 to 0.6 in.}

thick steel plates) on the foundation, and install the machine on the base

plates.

2-5. Leveling

2

{0.51 US tonf/ft

2

}

or less, reinforce the

After installing the machine, be sure to level it. Unless it is properly

leveled, it will not perform and last as originally designed. Leveling the

machine calls for the use of spirit levels accurate to 0.05 mm/m {0.0006

in./ft} or less, a thickness gauge, and stretch bars (or die holders).

Levelness in left-right direction

Place a spirit level at the center of the ram.

III-6

Page 35

Levelness in front-back direction

Place a stretch bar (or die holder) on the two leveling pins inside each of

the left and right frames of the machine.

Insert a thickness gauge between the front or rear leveling pin and the

stretch bar.

The thickness of the thickness gauge to be inserted is marked at the

front left or right of the ram.

The position where to insert the thickness gauge depends on the

position of the mark on the lower beam as shown below.

When the mark is placed at the upper front of the ram, insert the

thickness gauge between the front leveling pin and the stretch bar.

When the mark is placed at the lower front of the ram, insert the

thickness gauge between the rear leveling pin and the stretch bar.

Leveling machine

Place a spirit level on each stretch bar (or die holder).

Adjust the level of the machine to within 0.05 mm/m {0.0006 in./ft} in the

front-back and left-right directions by turning the leveling bolts at the four

corners of the machine.

III-7

Page 36

2-6. Supplying hydraulic oil

The hydraulic unit is located at the rear of the machine. Remove the

top cover or covers of the hydraulic oil tank, and pour the recommended

hydraulic oil into the hydraulic oil tank to the specified level of the oil

gauge. The specified level is near the middle mark of the oil gauge

when the ram is at the maximum opening limit. (Refer to “2.

Maintaining hydraulic system” in Part VI.)

Model Tank capacity

RG35S 26 L {6.9 US gal}

RG50, RG80 51 L {13.5 US gal}

RG100 65 L {17.2 US gal}

Recommended hydraulic oil: Amada Oil A-110

Esso Nuto H46

Mobil DTE 25

Shell Tellus Oil 46

(ISO VG46 equivalent)

The hydraulic oil Super Hyrando 56 of Nippon Oil Co., Ltd. is delivered

with the machine.

2-7. Supplying electric power

WARNING

Connecting power source

Connect the power source to the machine as described below.

1 Turn off the machine circuit breaker and the shop circuit breaker.

2 Pull the three-phase power cable through the power inlet at the

bottom of the electrical enclosure, and connect it to the L1, L2 and

L3 primary terminals of the terminal block.

3 Securely connect the grounding conductor to the ground terminal.

After wiring the power cable, check the voltage with a tester.

Primary power cable Four-conductor cable

Input power source 200/230/380/400/460 VAC±10%, 3 phases,

O Have a qualified electrician perform all

electric work to prevent accidents and

damage.

O Before making the electrical connections,

be sure to turn off the shop circuit breaker.

O Be sure to connect the grounding

conductor for safety.

50/60 Hz±1 Hz

III-8

Page 37

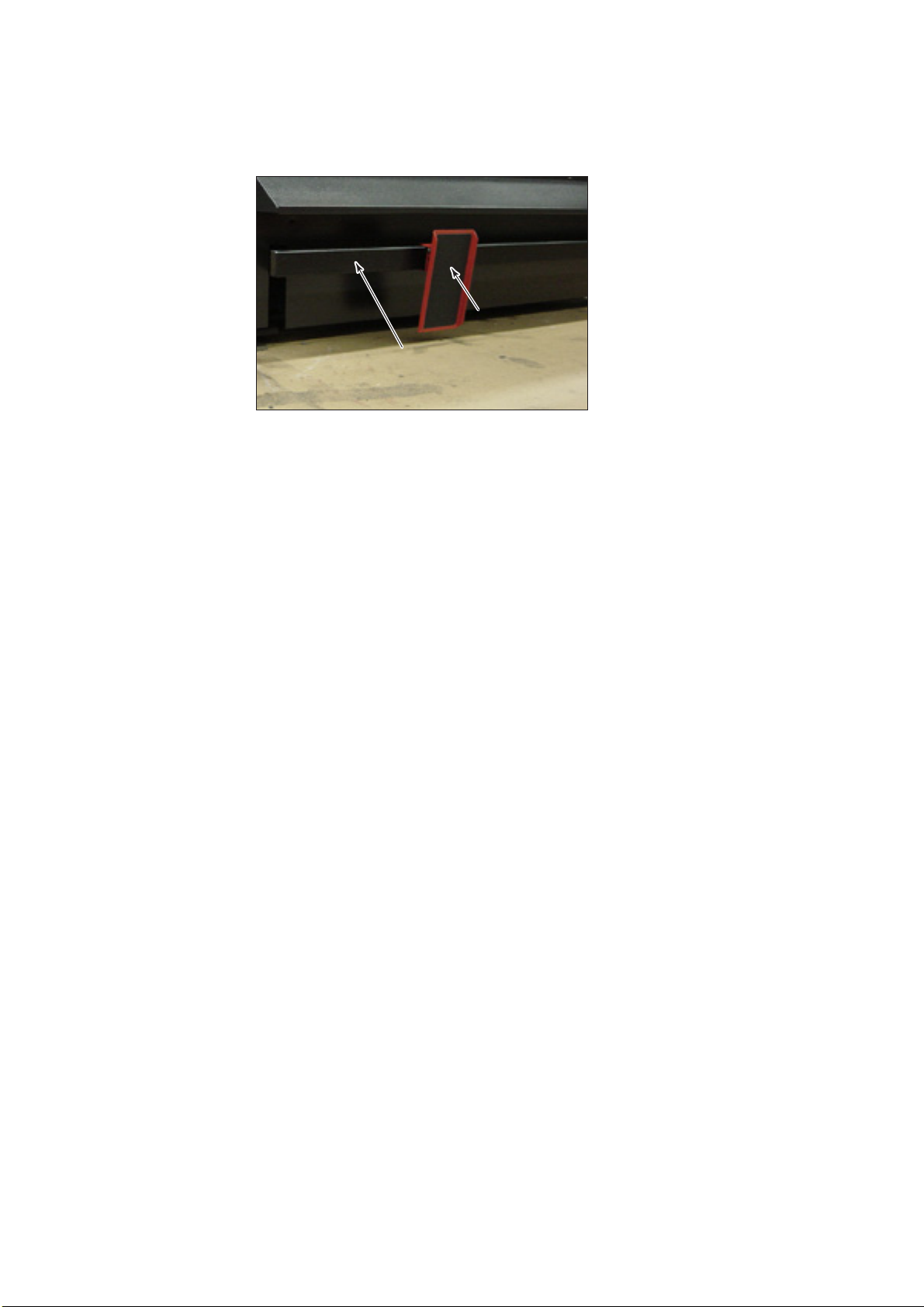

Checking rotation direction of hydraulic pump motor

WARNING

Check the rotation direction of the hydraulic pump motor as described

below.

1 Remove the cover of the rotating shaft of the hydraulic pump

motor.

2 Turn on the shop circuit breaker and the machine circuit breaker.

3 Turn the POWER ON/OFF keyswitch to ON.

4 Push back the bar pedal lock lever, if provided.

5 Press the HYD. ON button. The button illuminates, and the

hydraulic pump motor starts.

6 Check the rotation direction of the hydraulic pump motor, and

immediately press the HYD. OFF button. The hydraulic pump

motor stops, and the HYD. ON button extinguishes.

O To check the rotation direction of the

hydraulic pump motor, do not get any part

of your body or clothing too close to any

rotating parts (like the coupling of the

motor to the pump).

If you have any part of your body or

clothing caught in a rotating part, you may

get hurt.

CORRECT

DIRECTION

[RG50, RG80, RG100] [RG35S]

When the hydraulic pump motor runs in the correct direction, its

wiring is properly connected. Replace the cover of the rotating

shaft, and complete the connecting procedure.

When the hydraulic pump motor runs in the reverse direction, turn

the POWER ON/OFF keyswitch to OFF, turn off the machine circuit

breaker and the shop circuit breaker, and interchange two of the

three power conductors L1, L2 and L3 connected to the primary

terminals in the electrical enclosure. This makes correct wiring

connections. Replace the cover of the rotating shaft, and

complete the connecting procedure.

III-9

Page 38

NOTICE

O Supply electric power to the machine from a source different from that of a

welder or any other equipment that produces electrical noise. Use a welder,

electric drill, sander, or grinder at least 10 m {33 ft} away from the machine.

O The type of primary power cable varies with machine model. Maintain the

supply voltage variations to within ±10%.

O Use a grounding conductor of size not smaller than that of the L1, L2, and L3

power conductors.

III-10

Page 39

Part

IV

Controls

1. Controls on electrical enclosure.................................................... IV-2

2. Controls on upper beam ................................................................... IV-3

3. Hydraulic equipment controls .................................................... IV-4

4. Other controls ............................................................................ IV-6

IV-1

Page 40

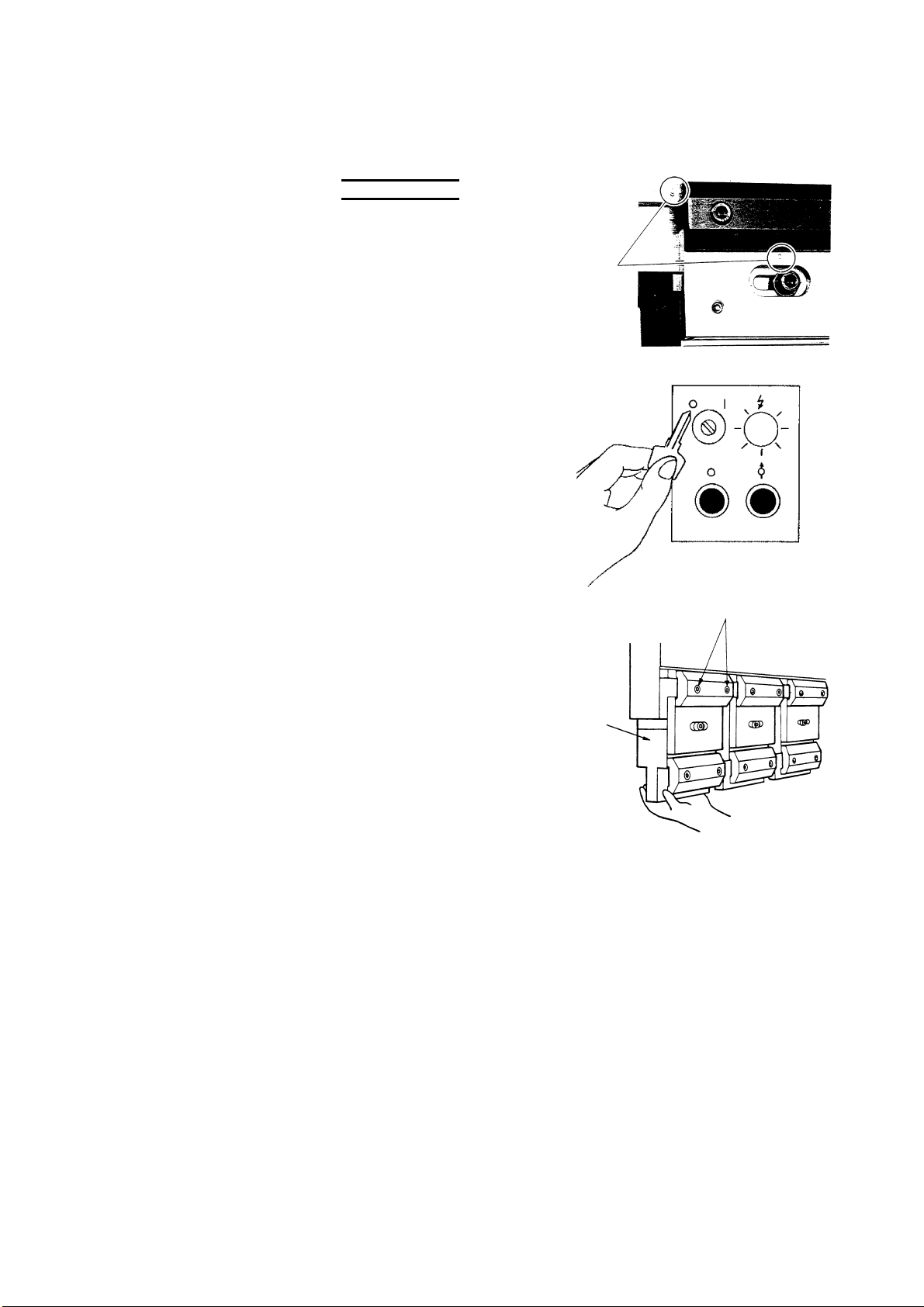

1. CONTROLS ON ELECTRICAL ENCLOSURE

[6] MACHINE

CIRCUIT

BREAKER

[2] POWER LAMP

[1] POWER ON/OFF

KEYSWITCH

[5] EMERGENCY

[4] HYD. OFF BUTTON

[3] HYD. ON BUTTON

STOP BUTTON

[1] POWER ON/OFF keyswitch

Used to turn on and off the power of the machine.

[2] POWER lamp

Illuminates to indicate that the machine circuit breaker is turned to ON to

supply electric power to the machine.

[3] HYD. ON button

Pressed to illuminate itself and start the hydraulic pump motor.

[4] HYD. OFF button

Pressed to extinguish the HYD. ON button and stop the hydraulic pump

motor.

[5] EMERGENCY STOP button

Pressed in an emergency to stop all motions of the machine. When

pressed and locked, the EMERGENCY lamp on the upper beam is

illuminated.

[6] Machine circuit breaker

Used to turn on and off the power to the electrical enclosure.

IV-2

Page 41

2. CONTROLS ON UPPER BEAM

[1][1] [2]

[2][2]

[3][3] [3]

(Not installed on RG35S)

[3][3]

[1] EMERGENCY lamp

Illuminates to indicate that the machine is under the emergency stop

condition.

[2] DOWN button

Pressed to force down the ram.

[3] EMERGENCY STOP button or buttons

Pressed in an emergency to stop all motions of the machine. When

pressed and locked, the EMERGENCY lamp is illuminated.

NOTE

O The RG35S have the one EMERGENCY STOP button on the upper beam.

The RG50, RG80, and RG100 have the two EMERGENCY STOP buttons.

IV-3

Page 42

3. HYDRAULIC EQUIPMENT CONTROLS

[1][1]

[4][4]

[6] [6]

[9] [9]

[8] [8]

[3] [3]

[7] [7]

[5] [5]

[2] [2]

[1] Pressure adjusting knob (Regulator)

Used to adjust the pressure applied between the punches and dies.

Turned counterclockwise (–) to decrease the pressure and clockwise (+)

to increase the pressure. To obtain the maximum press capacity,

usually keep the knob turned fully clockwise (+).

[2] Bar pedal lock lever (Not installed on RG35S)

Used to lock the bar pedal in the fully pressed state when the ram is

closed to the multiple closing limit. Lock and unlock the bar pedal while

it is pressed.

DANGER

O When the bar pedal lock lever is used, the

bar pedal is fixed in the fully pressed state,

and the applied pressure is maintained.

The ram may follow the multiple closing

limit setting made with its handwheel and

may produce an excessive pressure.

IV-4

Page 43

[3] Multiple opening limit setting lever

Used to set the multiple opening limit (stop position) of the ram. Open

the ram to the position where you want to stop the ram, and turn down

the lever to set the stop position. Turn up the lever to clear the stop

position and open the ram to the maximum opening limit.

[4] Pressure gauge

Indicates the pressure applied between the punches and dies when the

cut-off valve knob is turned fully counterclockwise.

[5] Cut-off valve knob

Used to stop the flow of hydraulic oil to the pressure gauge so that the

pressure gauge does not indicate the pressure. Turned fully clockwise

when there is no need to check the pressure.

[6] Multiple closing limit setting handwheel

Used to set the multiple closing limit of the ram. Turned clockwise to

raise the multiple closing limit and counterclockwise to lower the multiple

closing limit when the handwheel lock knob is turned fully

counterclockwise.

NOTICE

O Do not turn the multiple closing limit setting handwheel counterclockwise with

the bar pedal pressed and held. Doing so may break the multiple closing

limit setting mechanism and render the machine unusable.

[7] Handwheel lock knob

Used to lock the multiple closing limit setting handwheel after setting the

multiple closing limit of the ram with the handwheel. Turned fully

clockwise to lock the handwheel.

NOTICE

O When the handwheel lock knob is overloosened to unlock the multiple closing

limit setting handwheel, the handwheel may not be locked again. To loosen

the knob, turn it once to twice.

[8] Rising speed change position setting lever

Used to change the rising speed of the ram from the approach speed to

the bending speed (low speed).

[9] Digital multiple closing limit display (Digicollar)

Located behind the multiple closing limit setting handwheel and

indicates the current position of the ram set with the handwheel. Press

the reset button alongside the display to reset the display to “0”.

IV-5

Page 44

4. OTHER CONTROLS

[1] Bar pedal

Pressed to adjust the ram approach speed or stop the ram mid-stroke.

The ram closes to the multiple closing limit when the bar pedal is fully

pressed and opens to the multiple opening limit or maximum opening

limit when the bar pedal is released.

[2] Pedal stopper

Pressed to allow the ram to be operated only by a single operator. The

bar pedal can be pressed only when a foot is placed on the pedal

stopper to disable the pedal stopper. When the foot is released from

the pedal stopper, the pedal stopper opens under its own mass and

does not allow the bar pedal to be pressed. The pedal stopper can be

moved to any desired working position.

[2] PEDAL

[2] PEDAL

STOPPER

STOPPER

[1] BAR PEDAL[1] BAR PEDAL

IV-6

Page 45

Part

V

Operation

1. Inspection before start of day’s work .......................................... V-3

2. Preparing for operation ............................................................... V-3

3. Turning on power ........................................................................V-5

4. Removing tools ........................................................................... V-6

4-1. Preparing for removing tools................................................ V-6

4-2. Removing punches ..............................................................V-8

4-3. Removing dies .....................................................................V-9

5. Installing tools ............................................................................ V-11

5-1. Preparing for installing tools................................................ V-11

5-2. Installing dies ......................................................................V-12

5-3. Installing punches ...............................................................V-14

6. Preparing for special bending ....................................................V-16

6-1. Installing and removing punch holders ...............................V-16

6-1-1. Removing punch holders..............................................V-16

6-1-2. Installing punch holders................................................ V-17

6-2. Installing punches rearside front .........................................V-18

6-3. Installing wide dies ..............................................................V-19

7. Other uses .................................................................................V-20

7-1. Adjusting punch holders......................................................V-20

7-2. Using one-touch punch holders (option) .............................V-23

7-2-1. Installing and removing punches from front ................. V-25

7-2-2. Installing and removing punches by sliding them

along groove of rear clamping plates........................... V-28

(Continued on next page.)

V-1

Page 46

7-2-3. Installing and removing rear clamping plates............... V-29

8. Aligning tools .............................................................................V-32

8-1. RG35S ................................................................................V-32

8-2. RG50, RG80, and RG100................................................... V-34

9. Setting tool origin ....................................................................... V-37

10. Bending operation.................................................................... V-38

10-1. Setting rising speed change position ................................ V-38

10-2. Setting multiple opening limit ............................................ V-39

10-3. Bending worksheet ...........................................................V-40

10-3-1. Temporarily setting multiple closing limit.................... V-40

10-3-2. Setting worksheet....................................................... V-41

10-3-3. Setting bend angle ..................................................... V-42

11. Turning off power ..................................................................... V-44

12. Troubleshooting ....................................................................... V-46

13. Clearing emergency stop condition ......................................... V-48

V-2

Page 47

1. INSPECTION BEFORE START OF DAY’S WORK

Inspection before the start of the day's work is very important for the

safe and trouble-free operation of the machine. Before starting its

operation, inspect the machine as described in “1. Inspection before

start of day’s work” in Part VI.

2. PREPARING FOR OPERATION

Prepare the machine for operation as described below.

1 Turn up the multiple

opening limit setting

lever to open the ram

to the maximum

opening limit.

2 Pull forward the rising

speed change

position setting lever

to prevent the ram

from unexpectedly

closing.

3 Loosen the

handwheel lock knob,

and turn the multiple

closing limit setting

handwheel fully

counterclockwise.

V-3

Page 48

4 Turn the cut-off valve

knob fully

counterclockwise to

enable the pressure

gauge.

5 Turn the pressure

adjusting knob fully

clockwise (+).

V-4

Page 49

3. TURNING ON POWER

Start the machine as described below.

1 Turn on the shop circuit breaker.

2 Turn the machine circuit

breaker to ON.

The POWER lamp illuminates.

3 Insert the key in the POWER

ON/OFF keyswitch, and turn

the keyswitch to ON.

4 Push back the bar pedal lock

lever, except RG35S.

5 Press the HYD. ON button.

The button illuminates, and the

hydraulic pump motor starts.

V-5

Page 50

4. REMOVING TOOLS

DANGER

O Never put your hand or hands between the

punches and dies.

O When changing the tools, strictly observe

the following cautions:

{ Before removing the dies, turn the

POWER ON/OFF keyswitch to OFF,

remove the key from the keyswitch, and

keep it by yourself.

| Before removing the punches, turn the

multiple closing limit setting handwheel

to close the ram to the desired position,

turn the POWER ON/OFF keyswitch to

OFF, remove the key from the

keyswitch, and keep it by yourself.

Never put your hand or hands between

the punch and die to support the

punch.

} When you remove the tools with an

assistant operator or operators, be sure

to coordinate your work with them.

O Be sure to remove the punches first and

then the dies.

4-1. Preparing for removing tools

Before removing the tools, set the multiple opening limit of the ram as

described below.

NOTE

O The maximum opening limit refers to the bottom dead center of the ram, and

the multiple opening limit refers to the stop position of the ram set with the

multiple opening limit setting lever.

1 Check the punch-die

combination dimension H

shown right.

2 Loosen the handwheel lock knob to unlock the multiple closing limit

setting handwheel.

3 Turn the multiple closing limit setting handwheel fully

counterclockwise.

4 Clear the pedal stopper, and fully press the bar pedal.

The ram closes to the multiple closing limit and stops.

V-6

Page 51

5 With the bar pedal

fully pressed, turn the

multiple closing limit

setting handwheel

clockwise to set the

height between the

punch holders and die

holders to the

dimension H plus 2 to

H + 2 to 3 mm

{0.08 to 0.12 in.}

2 to 3mm

2 to 3 mm

2 to 3 mm

(0.08 to 0.12 in.)

{0.08 to 0.12 in.}

{0.08 to 0.12 in.}

3 mm {0.08 to 0.12

in.}.

NOTICE

O Do not turn the multiple closing limit setting handwheel

counterclockwise with the bar pedal pressed and held. Doing so may

break the multiple closing limit setting mechanism. Even when the

handwheel is turned counterclockwise, the ram does not open.

O To adjust the multiple closing limit of the ram to a lower position, release

the bar pedal to open the ram, turn the multiple closing limit setting

handwheel counterclockwise, and press the bar pedal again.

6 Release the bar

pedal, and turn up the

multiple closing limit

setting lever to clear

the multiple opening

limit of the ram.

The ram opens to the

maximum opening

limit.

7 Clear the pedal stopper, press the bar pedal again to close the ram

to the position you want to set as the multiple opening limit, and

hold the bar pedal in that state.

The ram stops in that position.

8 Turn down the

multiple opening limit

setting lever to set the

multiple opening limit

of the ram.

NOTE

O Positively turn down the multiple opening limit setting lever so that the

ram does not open.

9 Release the bar pedal.

The ram remains at the multiple opening limit.

V-7

Page 52

10 To perform the subsequent

tasks safely, press the HYD.

OFF button, turn the POWER

ON/OFF keyswitch to OFF, and

remove the key from the

keyswitch.

4-2. Removing punches

WARNING

Remove the punches from the punch holders as described below.

1 Loosen the fixing

bolts of the punch

clamping plate or

plates.

The punch drops onto

the V-groove of the

die.

O When removing the punch in step 1, do

not support it from below with your hand

as shown below. Otherwise you may get

your hand or fingers pinched.

FIXING

BOLT

V-8

2 Slide the punch

sideways to remove it.

LOOSEN

FIXING BOLTS

PUNCH DROPS ONTO

V-GROOVE OF DIE

Page 53

When optional one-touch punch holders (refer to page V-23)

are available:

1 Turn the punch holder lever or

levers counterclockwise as

shown right.

2 Slide the punch sideways to

remove it.

4-3. Removing dies

After removing the punches, remove the dies from the ram as described

below.

Removing 2V-dies

Loosen the die fixing bolts, and remove the die.

DIE

WASHER

BOLT

Removing 1V-dies for forming sashes

Remove the 1V-dies for forming sashes as described for the 2V-dies on

the above.

1V-DIE

(FOR FORMING SASHES)

DIE HOLDER

2V-DIE

DIE FIXING BOLT

DIE HOLDER

DIE FIXING BOLT

DIE HOLDER FIXING BOLT

V-9

Page 54

Removing 1V-dies

Loosen the front die-block fixing bolts, and remove the die together with

the die block.

NOTICE

O The rear clamping plates of the ram and die blocks establish the reference

surface for aligning the punches and dies. Never loosen them.

CLAMPING

PLATES

REAR FRONT

DIE BLOCK

DIE BLOCK

1V-DIE

REAR

RAM

FRONT

CLAMPING

PLATES

V-10

Page 55

5. INSTALLING TOOLS

WARNING

O Never put your hand or hands between the

punches and dies.

O When changing the tools, strictly observe

the following cautions:

{ Before installing the dies, turn the

POWER ON/OFF keyswitch to OFF,

remove the key from the keyswitch, and

keep it by yourself.

| Before installing the punches, turn the

multiple closing limit setting handwheel

to close the ram to the desired position,

turn the POWER ON/OFF keyswitch to

OFF, remove the key from the

keyswitch, and keep it by yourself.

Never put your hand or hands between

the punch and die to support the

punch.

} When you install the tools with an

assistant operator or operators, be sure

to coordinate your work with them.

O Be sure to install the dies first and then the

punches.

5-1. Preparing for installing tools

Before installing the tools, wipe off the upper beam and ram tool

installation surfaces and tools, refer to “4-1. Preparing for removing

tools” in this Part, and set the multiple opening limit of the ram.

V-11

Page 56

5-2. Installing dies

Install the dies on the ram as described below.

Installing 2V-dies

NOTICE

O Install 2V-dies so that the

V-groove to be used faces

the rear of the machine by

considering safety in the

event of die breakage.

When the die holders are

installed with the step facing

the rear as shown right, the

V-groove to be used comes

to the rear.

O When using two or more die

holders, install them with a

clearance of about 5 mm

{0.2 in.} between them.

NOTE

O When using two or more dies, install them so as to create no gap between

them.

STEP

REAR

REAR

FRONT

(OPERATOR SIDE)

ABOUT 5 mm

ABOUT 5 mm {0.2 in.}

FRONT

(OPERATOR SIDE)

{0.2 in.}

1 Place the die holder for the 2V-

die on the top of the ram.

2 Set the die fixing bolts

as shown right.

SPRING

WASHER

BOLT

3 Slide the 2V-die from

the front of the

machine onto the die

holder with the Vgroove to be used

facing the rear.

4 Fasten the die holder

with the die holder

fixing bolts.

DIE HOLDER

a + 2 mm {0.08 in.}

2V-DIE

DIE FIXING BOLT

DIE HOLDER FIXING BOLT

DIE HOLDER

V-12

Page 57

Installing 1V-dies for forming sashes

Install the 1V-dies for forming sashes as described for the 2V-dies on

the previous page.

1V-DIE

(FOR FORMING SASHES)

DIE HOLDER

Installing 1V-dies

NOTICE

O The rear clamping plates of the ram and die blocks establish the reference

surface for aligning the punches and dies. Never loosen them.

CLAMPING

PLATES

DIE FIXING BOLT

DIE HOLDER FIXING BOLT

1V-DIE

REAR

REAR FRONT

DIE BLOCK

DIE BLOCK

NOTE

O Depending on the type of 1V-die, the tool height and ram stroke length may

not be large enough for the punch and die to properly engage. In such a

case, use the optional die block on the ram. Install the die block by paying

attention to its orientation as shown below.

RAM

FRONT

CLAMPING

PLATES

1 Place the 1V-die together with the die block on the top of the ram.

2 Tighten the front die-block fixing bolts.

V-13

Page 58

5-3. Installing punches

WARNING

O When installing a punch, do not support it

from below with your hand as shown

below. Otherwise you may get your hand

or fingers pinched.

After installing the dies, install the punches to the punch holders as

described below.

NOTE

O When installing sectionalized punches

and dies, stagger them by about 5 mm

{0.2 in.} as shown right to prevent the

worksheet from being scratched.

PUNCH

1 Slide the punch into

the V-groove of the

die as shown right.

2 Determine the

installation position of

the punch by sliding it

left and right, and

lightly tighten the

fixing bolts of the

punch clamping plate

or plates.

UPPER

BEAM

PUNCH

HOLDER

CLAMPING

PLATE

2 to 3 mm {0.08 to 0.12 in.}

PUNCH

DIE

ABOUT 5 mm {0.2 in.}

V-14

Page 59

When optional one-touch punch holders (refer to page V-23)

are available:

1 Insert the fall prevention tongue of the punch into the fall

prevention groove of the clamping plate or plates as shown lower

left, and slide the punch into position.

2 Tighten the punch holder lever or levers clockwise to prevent the

punch from as shown lower right.

V-15

Page 60

6. PREPARING FOR SPECIAL BENDING

6-1. Installing and removing punch holders

When special-shaped punches are used or when a worksheet comes

into contact with punch holders during bending, the punch holders may

be removed from the upper beam for bending the worksheet. Install

and remove the punch holders as described below.

6-1-1. REMOVING PUNCH HOLDERS

1 Remove the punches from the punch holders. (Refer to “4.

Removing tools” in this Part.)

2 Turn the POWER

ON/OFF keyswitch to

OFF, and remove the

key from the

keyswitch.

3 Turn up the multiple

opening limit setting

lever to clear the

multiple opening limit

of the ram.

The ram opens to the

maximum opening

limit.

4 Loosen the clamping

bolts of each punch

holder while

supporting the punch

holder with the other

hand, and remove the

punch holder.

CLAMPING BOLTS

PUNCH

HOLDER

V-16

Page 61

6-1-2. INSTALLING PUNCH HOLDERS

NOTE

O The numbers that specify

their installation position of

the punch holders are

marked on the punch

holders and upper beam.

Install each punch holder in

the position that matches its

marked number.

1 Turn the POWER

ON/OFF keyswitch to

OFF, and remove the

key from the

keyswitch.

NUMBERS

2 While pushing each

punch holder against

CLAMPING BOLTS

the upper beam with

one hand, fingertighten its clamping

bolts with the other

hand.

PUNCH

HOLDER

3 Install the punches and dies along the entire length of the upper

beam and ram, respectively. (Refer to “5. Installing tools” in this

Part.)

4 Align the punches and dies. (Refer to “8. Aligning tools” in this

Part.)

V-17

Page 62

5 Place a worksheet

along the entire length

of the dies, clear the

pedal stopper, and

press the bar pedal to

apply a pressure

lower than the

allowable tonnage of

the tools and bring the

punch holders into

tight contact with the

upper beam.

6 With the upper beam and punch holders in tight contact, retighten

the clamping bolts of the punch holders.

PRESSURE GAUGE

6-2. Installing punches rearside front

WARNING

Depending on the bend shape of

parts, the punches may have to be

installed rearside front as shown

right. In such a case, install the

punches as described below.

1 Turn the POWER ON/OFF

keyswitch to OFF, and remove

the key from the keyswitch.

O If you reach between the upper beam and

ram to install the clamping plates at the

rear of the punch holders, you may get

your hands pinched. Never do so.

O When you install the clamping plates at

the rear of the punch holders, turn off the

power of the machine and optional

backgauge, and go to the rear of the

machine.

FRONT

V-18

Page 63

2 Remove the fixing

bolts of the clamping

plate of each punch

holder, and remove

the clamping plate.

3 Install the clamping

plates at the rear of

the punch holders,

and fasten them with

the fixing bolts.

4 Install the punches. (Refer to “5. Installing tools” in this Part.)

6-3. Installing wide dies

With the machine model RG100 having bar attached to the clamping

plate at the top of the ram, removing the bar allows 90 mm {3.5 in.} wide

dies to be installed.

FRONT

V-19

Page 64

7. OTHER USES

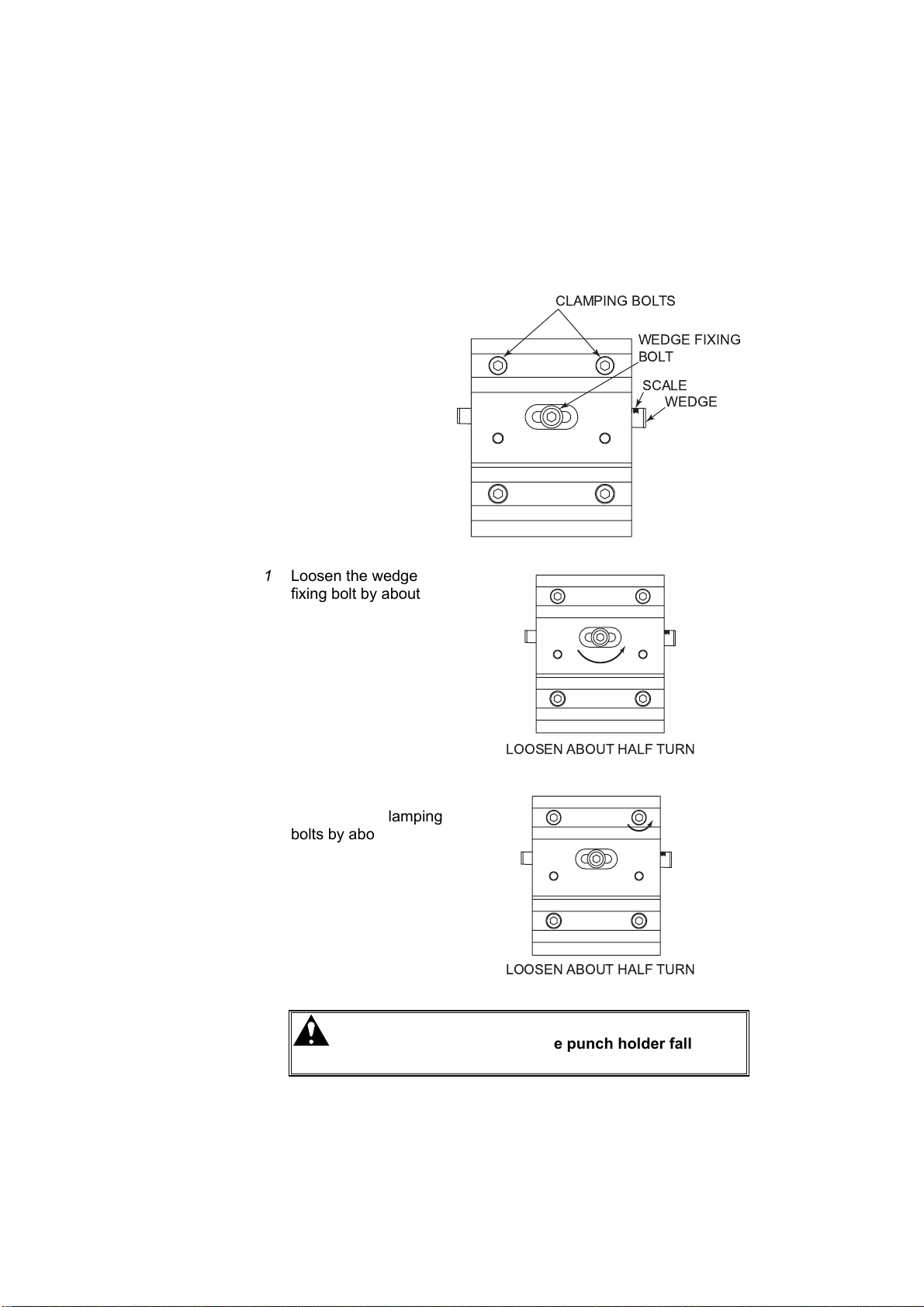

7-1. Adjusting punch holders

If the worksheet is not bent to a uniform angle along the entire bend

length, adjust the punch holders as described below.

Before adjusting the punch

holder, record the current

value of the scale marked

on the wedge. This value

serves as a guide when

returning the punch holder

to the original state.

1 Loosen the wedge

fixing bolt by about a

half turn with an Allen

wrench.

2 Loosen either of the

left and right clamping

bolts by about a half

turn with an Allen

wrench, and lightly

tighten it again.

CAUTION

O If both of the two clamping bolts are

loosened, the punch holder falls. Be

sure to loosen only either of them.

V-20

Page 65

3 Apply the accessory

brass bar to either of

the left and right sides

of the wedge, and

strike it with a

hammer.

NOTE

O To bend the

worksheet to an acute

angle, strike the brass

bar from right to left

facing the front of the

machine.

O To bend the

worksheet to an

obtuse angle, strike

the brass bar from left

to right facing the front

of the machine.

Guide for adjusting punch holders:

Consider bending a 1.6 mm {0.06 in.} thick worksheet of mild steel

to an angle of about 90° with a die V-groove opening width of 10

mm {0.4 in.}. In this example, moving the wedge by one

graduation of the scale changes the bend angle by 20 to 30’.

NOTICE

O When striking the wedge with a hammer, be sure to use the accessory

brass bar. Never strike the wedge directly with the hammer.

4 After completing the

adjustment, securely

tighten the wedge

fixing bolt.

5 While pressing and

holding the bar pedal

to apply pressure to

the punch and die,

securely tighten the

clamping bolts.

CAUTION

O The pressure to apply here should be

about one-third of the allowable

tonnage of the tools.

V-21

Page 66

6 Actually bend the worksheet to check that the bend angle is

uniform.

7 If the bend angle is not uniform, repeat the procedure from the

beginning.

V-22

Page 67

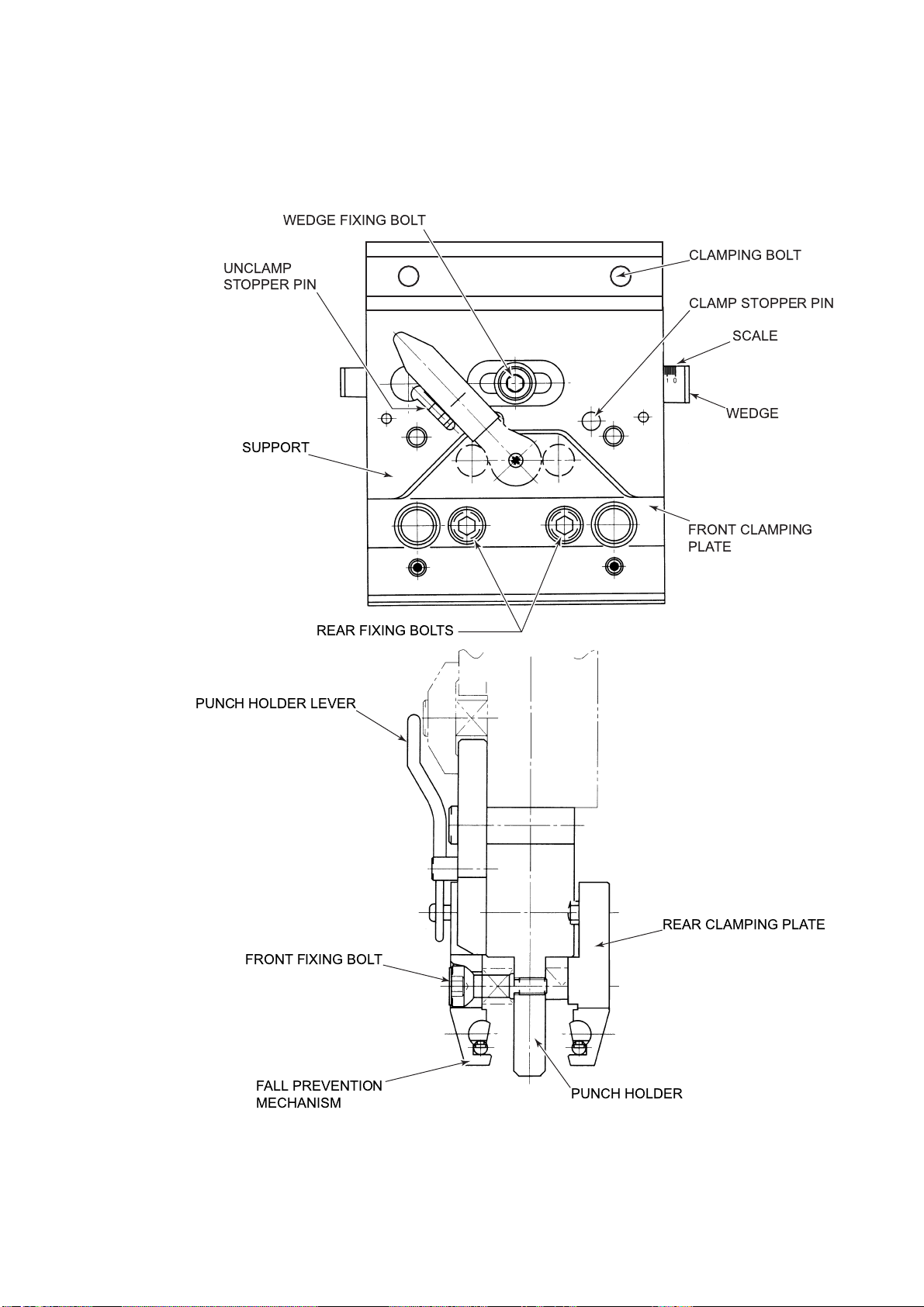

7-2. Using one-touch punch holders (option)

Names of parts

WEDGE FIXING BOLT

UNCLAMP

STOPPER PIN

SUPPORT

REAR FIXING BOLTS

PUNCH HOLDER LEVER

CLAMPING BOLT

CLAMP STOPPER PIN

SCALE

WEDGE

FRONT CLAMPING

PLATE

FRONT FIXING BOLT

FALL PREVENTION

MECHANISM

REAR CLAMPING PLATE

PUNCH HOLDER

V-23

Page 68

Punch holder lever positions

Position ◯

A

Turn the lever to this position to install and remove the punches by

sliding them sideways.

NOTE

O When the lever is turned to the position ◯A the punches cannot be installed

and removed from the front of the machine.

Position ◯B (Basic lever position)

Turn the lever to this position to clamp the punches and to install and

remove the lever itself.

Position ◯

Turn the lever to this position to install and remove 100 mm {4 in.} or

shorter sectionalized punches from the front of the machine.

C

V-24

Page 69

7-2-1. INSTALLING AND REMOVING PUNCHES FROM FRONT

WARNING

Installing punches from front

WARNING

CAUTION

O Before installing and removing the

punches, turn the POWER ON/OFF

keyswitch to OFF, remove the key from the

keyswitch, and keep it by yourself.

O If the punch is 100 mm {4 in.} or more in

length, do not install it from the front of the

machine. You cannot safely support it

with your hand or hands.

O When installing

a punch from the

front of the

machine, push it

straight up.

If the punch is

pushed up

inclined, the

clamping plate remains open and allows

the punch to fall.

Check that the punch does not fall when

pulled down, and then release it.

1 Turn down the

unclamp stopper pin,

and turn the punch

holder lever

counterclockwise to

the position ◯

2 Hold the sides of the

punch as shown right,

and push the punch

upward so that it

becomes parallel with

the punch holder.

C

.

V-25

Page 70

3 Turn the punch holder

lever clockwise to the

position ◯

A

, and turn

up the unclamp

stopper pin.

4 After positioning the punch, turn the punch holder lever clockwise

to the position ◯

B

to clamp the punch.

5 Install the punch as described in “5-3. Installing punches” in this

Part.

V-26

Page 71

Removing punches from front

WARNING

O If the punch is 100 mm {4 in.} or more in

1 Turn down the

unclamp stopper pin,

and turn the punch

holder lever to the

position ◯

C

.

2 Hold the sides of the

punch as shown right,

and remove the

punch from the front

of the machine.

length, do not remove it from the front of

the machine. You cannot safely support

it with your hand or hands.

3 Turn the punch holder

lever clockwise to the

position ◯

A

, and turn

up the unclamp

stopper pin.

V-27

Page 72

7-2-2. INSTALLING AND REMOVING PUNCHES BY SLIDING THEM

ALONG GROOVE OF REAR CLAMPING PLATES

WARNING

O Before installing and removing the

punches, turn the POWER ON/OFF

keyswitch to OFF, remove the key from the

keyswitch, and keep it by yourself.

Installing punches in rear clamping plates

1 Insert the fall

prevention tongue of

the punch into the fall

prevention groove of

the rear clamping

plate as shown right.

2 After positioning the

punch, turn the rear

fixing bolts clockwise

with an Allen wrench

to clamp the punch.

FALL PREVENTION

MECHANISM

3 Install the punch as

described in “5-3.

Installing punches” in

this Part.

NOTICE

O When turning the rear

fixing bolts with the

Allen wrench to clamp

the punch, be sure to

tighten the left and

right of the rear

clamping plate parallel

and with equal force.

If you overtighten the

clamping plate with

the leverage of a long

wrench or pipe, the

durability of the

belleville springs may

suffer.

REAR FIXING

BOLTS

V-28

Page 73

Removing punches from rear clamping plates

WARNING

1 Turn the rear fixing

bolts

counterclockwise by

one turn with an Allen

wrench as shown

right.

2 Remove the punch by

sliding it sideways.

O When loosening the rear fixing bolts, do

not turn them counterclockwise by more

than one and a half turns. If the bolts are

turned by more than one and a half turns,

the rear fall prevention mechanism does

not operate, allowing the punch to fall in a

dangerous manner.

TURN REAR FIXING BOLTS

COUNTERCLOCKWISE

REAR FIXING

BOLTS

7-2-3. INSTALLING AND REMOVING REAR CLAMPING PLATES

WARNING

Before installing and removing the rear clamping plates, be sure to

remove the punch holder units from the upper beam.

O Before installing and removing the rear

clamping plates, turn the POWER ON/OFF

keyswitch to OFF, remove the key from the

keyswitch, and keep it by yourself.

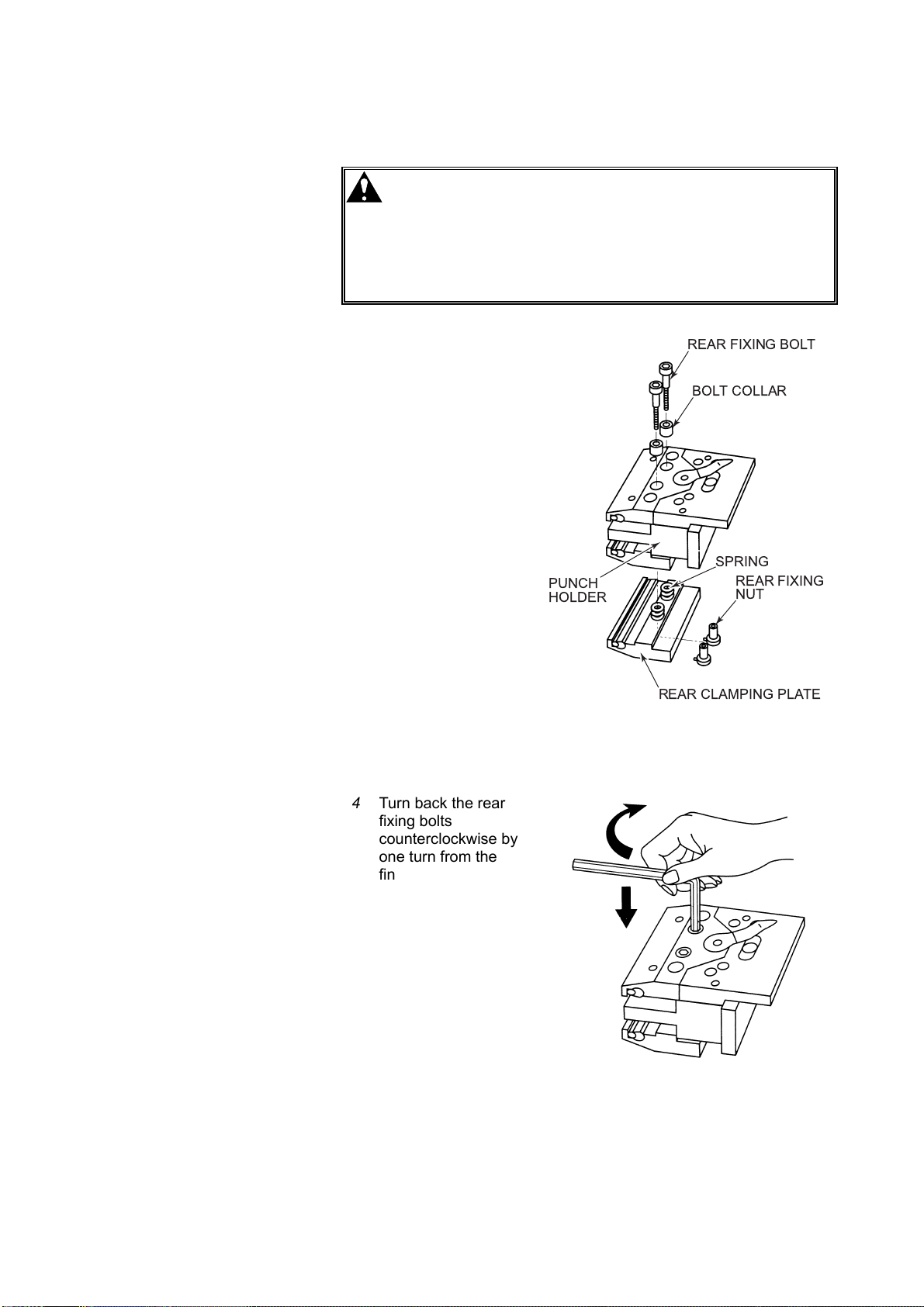

Removing rear clamping plates

1 Place the punch

holder unit so that the

rear clamping plate

faces down as shown

right.

REAR CLAMPING

PLATE

V-29

Page 74

2 Turn the rear fixing

bolts

counterclockwise with

an Allen wrench, and

remove them from the

rear fixing nuts.

REAR FIXING BOLT

BOLT COLLAR

3 Remove the bolt

collars from the front

clamping plate, lift the

punch holder, and

remove the rear

clamping plate.

Assemble the rear

clamping plate as

shown right, and store

it.

REAR FIXING BOLT

BOLT COLLAR

SPRING

REAR CLAMPING

PLATE

V-30

Page 75

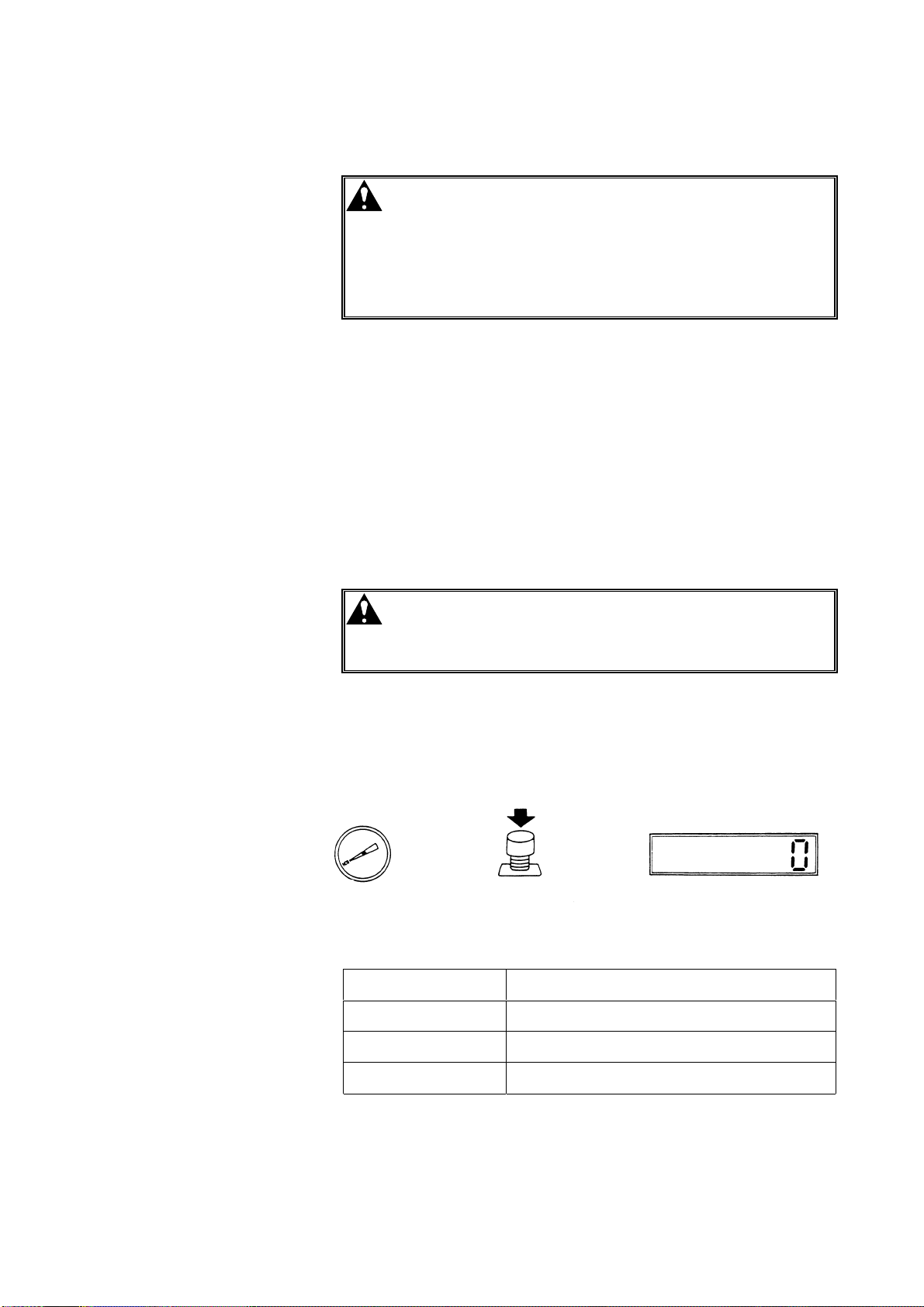

Installing rear clamping plates

WARNING

O Do not turn the rear fixing bolts

1 Place the punch

holder unit as shown

right with the keys of

the rear fixing nuts

aligned with the nut

anti-rotation keyways

of the rear clamping

plate.

2 Insert the springs in

the spring seats of the

rear clamping plate,

and position the

punch holder as

shown right.

3 Insert the bolt collars

into the rear fixing-bolt

installation holes of

the front clamping

plate, and fingertighten the rear fixing

bolts clockwise with

an Allen wrench while

pushing down the

front clamping plate.

counterclockwise by more than one turn

from the finger-tightened position. If the

bolts are turned by more than one turn, the

rear fall prevention mechanism may not

operate, allowing the punch to fall in a

dangerous manner.

REAR FIXING BOLT

BOLT COLLAR

SPRING

PUNCH

HOLDER

REAR CLAMPING PLATE

REAR FIXING

NUT

4 Turn back the rear

fixing bolts

counterclockwise by

one turn from the

finger-tightened

position, so that the

punch can be slid

sideways.

V-31

Page 76

8. ALIGNING TOOLS

8-1. RG35S

WARNING

After installing the tools, align them as described below.

When you reinstall the dies after removing them together with the die

holders, align them again.

1 Turn the POWER ON/OFF

keyswitch to ON.

O Never put your hand or hands between the

punches and dies.

O Apply to the installed tools a pressure that

is not higher than the allowable tonnage

marked on them. Unless a proper

pressure is applied to them, the tools may

break and scatter in a dangerous manner.

2 Press the HYD. ON button.

The button illuminates, and the

hydraulic pump motor starts.

3 Clear the pedal stopper, and

fully press the bar pedal.

The ram closes to the multiple

closing limit and stops.

CLEARANCE

V-32

Page 77

4 With the bar pedal fully pressed, slowly turn the multiple opening

limit setting handwheel clockwise.

The ram slowly closes. (Its multiple closing limit rises.)

5 When the clearance between

the punches and punch holders

is about to disappear, turn the

multiple closing limit setting

PRESSURE

GAUGE

handwheel further clockwise,

while checking the pressure

gauge, in order to apply the

pressure until the pointer of the

pressure gauge indicates the

NC9 value.

WARNING

O If the allowable tonnage of the installed

tools is smaller than the NC9 value, set

their origin with a pressure smaller than

the allowable tonnage.

6 Tighten the handwheel lock knob to lock the multiple closing limit

setting handwheel.

7 Press the bar pedal two to three times until the dies completely

engage with the punches.

8 With the bar pedal fully

pressed, retighten the fixing

bolts of the punch clamping

plates. (If the optional onetouch punch holders are used,

retightening their levers is not

necessary.)

9 When the dies are 2V-dies or

sash forming 1V-dies, with the

bar pedal fully pressed, tighten

the fixing bolts of the dies.

10 Release the bar pedal to complete the tool aligning procedure.

The ram opens to the multiple opening limit and stops.

V-33

Page 78

8-2. RG50, RG80, and RG100

CAUTION

1 Turn the POWER ON/OFF

keyswitch to ON.

2 Check that the bar pedal lock

lever is not pulled forward. If

pulled forward, push it back.

3 Press the HYD. ON button.

The button illuminates, and the

hydraulic pump motor starts.

O When you are aligning the tools with the

bar pedal locked, do not stop the hydraulic

pump motor by pressing the HYD. OFF

button or turning the POWER ON/OFF

keyswitch to OFF. Doing so will open the

ram.

UNLOCK BAR PEDAL

PUSH BACK

BAR PEDAL LOCK LEVER

V-34

4 Clear the pedal stopper, and

fully press the bar pedal.

The ram closes to the multiple

closing limit and stops.

CLEARANCE

Page 79

5 With the bar pedal fully pressed, slowly turn the multiple closing

limit setting handwheel clockwise.

The ram slowly closes. (Its multiple closing limit rises.)

6 When the clearance between

the punches and punch holders

is about to disappear, turn the

multiple closing limit setting

PRESSURE

GAUGE

handwheel further clockwise,

while checking the pressure

gauge, in order to apply the

pressure until the pointer of the

pressure gauge indicates the

NC9 value.

WARNING

O If the allowable tonnage of the installed

tools is smaller than the NC9 value, set

their origin with a pressure smaller than

the allowable tonnage.

7 Tighten the handwheel lock knob to lock the multiple closing limit

setting handwheel.

8 Press the bar pedal two to three times until the dies completely

engage with the punches.

9 Pull forward the bar pedal lock

lever, and release the bar

pedal.

PULL

FORWARD

The bar pedal is locked, and the

ram is fixed in that position.

BAR PEDAL LOCK LEVER

10 Retighten the fixing bolts of the

punch clamping plates. (If the

optional one-touch punch

holders are used, retightening

their levers is not necessary.)

11 When the dies are 2V-dies or

sash forming 1V-dies, tighten

their fixing bolts.

V-35

Page 80

12 Clear the pedal stopper, fully

press the bar pedal, and push

PUSH BACK

back the bar pedal lock lever.

The bar pedal is unlocked.

BAR PEDAL LOCK LEVER

13 Release the bar pedal to complete the tool aligning procedure.

The ram opens to the multiple opening limit and stops.

V-36

Page 81

9. SETTING TOOL ORIGIN

WARNING

After aligning the tools, set their origin as required. Once set, the tool