Page 1

REFERENCE MANUAL

CNC LASER MACHINE

AMNC-F

AMNC-F-LASER-E02-200710

Page 2

PREFACE Read this manual carefully to obtain a thorough knowledge of the AMNC-F for the laser machine.

Be sure to follow the instructions to ensure proper procedures and prevent injuries and accidents. Do not operate

the AMNC-F by guesswork. Keep the manual at hand

and refer to it whenever you are not sure of how to

perform any of the procedures.

For the operation and maintenance of the laser machine,

refer to its own operator’s manual.

200709010504

Reference Manual:

AMNC-F

© 2007 by AMADA CO., LTD.

No part of this publication may be photocopied or otherwise reproduced without the prior written permission of AMADA CO., LTD.

ii

Printed in Japan

Page 3

CONTENTS

Part I Displays................................................................................ I-1

1. Description ............................................................................. I-4

1-1. Description of display operation...................................... I-4

1-1-1. Basic operation......................................................... I-4

1-1-2. Entering letters and numerals .................................. I-4

1-1-3. Scroll bars ................................................................ I-4

1-1-4. Cursor....................................................................... I-4

1-2. Composition of displays .................................................. I-5

2. Areas common to displays ..................................................... I-9

2-1. Processing status display area 1 .................................... I-9

2-2. Processing status display area 2 ................................... I-18

2-3. Data edit area................................................................. I-20

2-4. Status icons.................................................................... I-43

3. PRE-EDIT display (background)........................................... I-44

3-1. Creating program from PRE-EDIT display..................... I-44

3-2. Calling program from PRE-EDIT display ....................... I-45

3-3. Saving program from PRE-EDIT display ....................... I-47

3-4. Transferring job to PROGRAM display .......................... I-47

3-5. Transferring selected job................................................ I-48

3-6. Transferring schedule to SCHEDULE display................ I-48

4. SCHEDULE display .............................................................. I-49

4-1. Creating program from SCHEDULE display .................. I-50

4-2. Calling program from SCHEDULE display..................... I-50

4-3. Saving program from SCHEDULE display..................... I-52

4-4. Selecting start job........................................................... I-52

5. PROGRAM display ............................................................... I-53

5-1. Creating program from PROGRAM display................... I-54

5-2. Calling program from PROGRAM display...................... I-54

5-3. Saving program from PROGRAM display...................... I-55

6. RESULT display.................................................................... I-56

7. UTILITY display .................................................................... I-60

7-1. G50 ................................................................................ I-61

7-2. Return to 2nd

7-3. G00 ................................................................................ I-63

7-4. Nozzle/Head Exchange Position.................................... I-64

Machine Position ..................................... I-62

(Continued on next page.)

iii

Page 4

7-5. JOG Cutting ....................................................................I-66

7-6. Shuttle Exchange............................................................I-68

7-7. Adjust HS Sensor............................................................I-69

7-8. Check Assist Gas............................................................I-70

7-9. Adjust the Nozzle Unit Centering ....................................I-72

7-10. Adjust Focus .................................................................I-74

7-11. Adjust WACS.................................................................I-78

7-12. Adjust AIV......................................................................I-79

7-13. Adjust Offset..................................................................I-80

7-14. Internal electric discharge.............................................I-82

7-15. Beam-Out......................................................................I-83

7-16. Clean the Nozzle Unit ...................................................I-84

7-17. Skeleton Cut .................................................................I-85

7-18. Settings .........................................................................I-88

7-19. Input error .....................................................................I-89

8. Processing condition displays ...............................................I-90

8-1. Common areas of processing condition displays ...........I-91

8-1-1. Common area 1 .......................................................I-91

8-1-2. Common area 2 .......................................................I-93

8-1-3. Common area setting operations.............................I-95

8-2. CUT display................................................................... I-101

8-2-1. Output Check display ............................................. I-103

8-3. PIERCE display ............................................................ I-104

8-4. EDGE display................................................................ I-107

8-5. LIST display ...................................................................I-110

8-5-1. Calling processing conditions..................................I-111

8-5-2. Finding processing conditions.................................I-111

8-5-3. Copying processing conditions ...............................I-113

8-5-4. Changing material name.........................................I-113

8-5-5. Deleting processing conditions ...............................I-114

8-5-6. Exporting processing conditions .............................I-115

8-5-7. Importing processing conditions .............................I-115

8-5-8. Exporting all processing conditions at a time..........I-116

8-5-9. Importing all processing conditions at a time ..........I-117

8-6. SET LASER display .......................................................I-118

8-6-1. LASER PRM display ...............................................I-118

8-6-2. AIV display ............................................................. I-121

8-6-3. HS EDGE display................................................... I-124

8-6-4. PROBE display ...................................................... I-126

8-7. SET OPTION displays .................................................. I-128

8-8. DETAIL OFF display ..................................................... I-129

iv

Page 5

8-8-1. COND. display........................................................ I-130

8-8-2. LIST display............................................................ I-130

8-8-3. SET LASER display ............................................... I-130

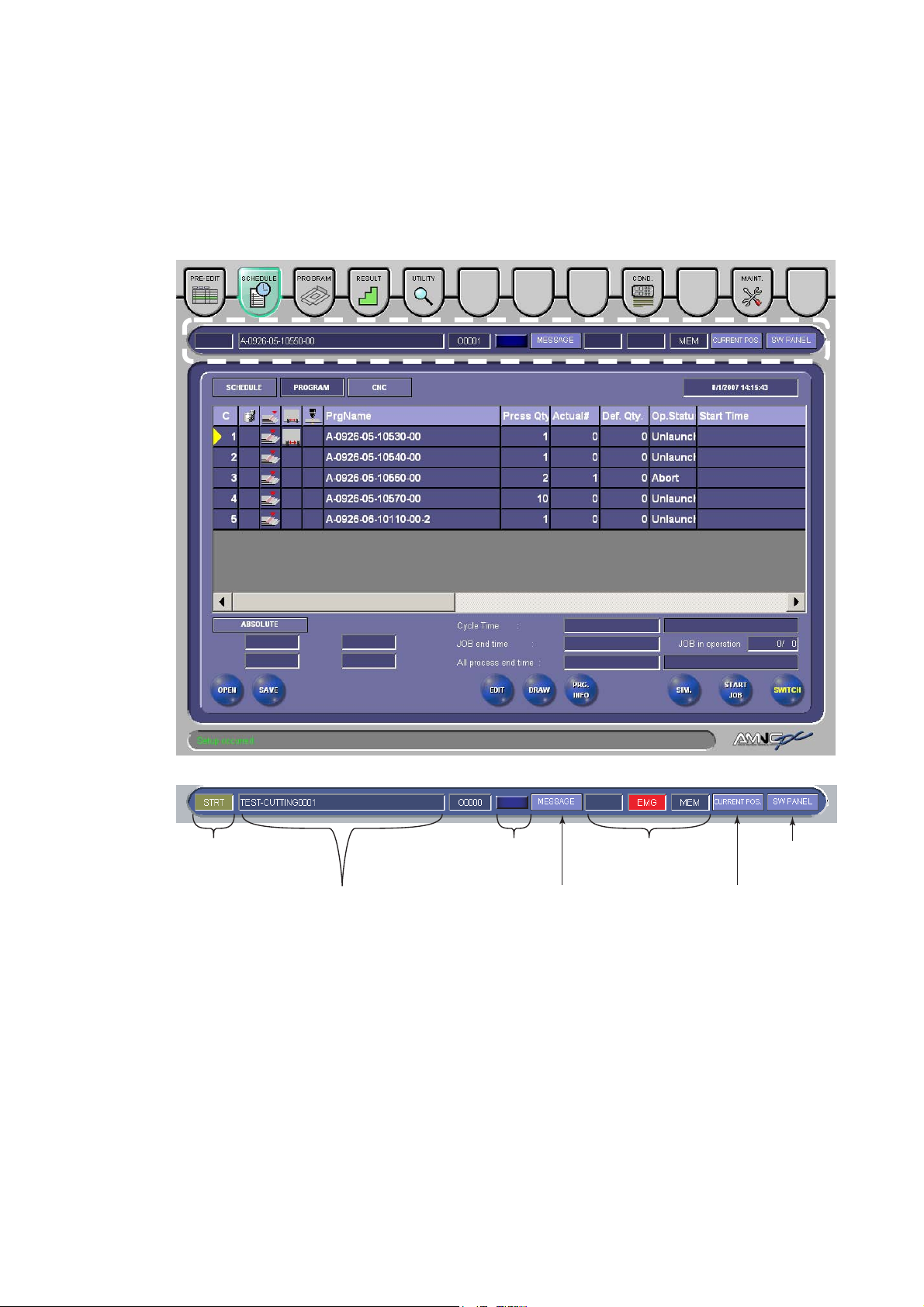

9. Maintenance display ............................................................ I-131

9-1. DATA INPUT AND OUTPUT ......................................... I-132

9-1-1. Copying data .......................................................... I-133

9-1-2. Moving data............................................................ I-134

9-2. CNC MAINTENANCE ................................................... I-135

9-2-1. Reading O number................................................. I-136

9-2-2. Writing O number ................................................... I-136

9-3. VERSION INFORMATION ............................................ I-142

9-4. EXTERNAL IO SETUP ................................................. I-143

9-5. SET ALL LASER DEFAULTS........................................ I-144

9-6. E-MAIL NOTICE FUNCTION........................................ I-145

9-6-1. Details of Setup of E-mail Notice display ............... I-146

9-6-2. Details of E-mail Notice Function display............... I-148

9-6-3. Details of E-mail Transmission display................... I-149

9-7. INSPECTION ................................................................ I-153

9-7-1. INSPECTION ......................................................... I-153

9-7-2. TASK ...................................................................... I-155

9-7-3. ADD ITEM .............................................................. I-156

9-7-4. NOTICE.................................................................. I-157

9-7-5. HOLIDAY................................................................ I-158

9-7-6. SETTING................................................................ I-159

9-7-7. CALENDAR............................................................ I-160

9-8. BACKUP SCHEDULER ................................................ I-161

9-9. USER SETTINGS ......................................................... I-164

9-10. APPLICATION SETTINGS.......................................... I-171

9-11. AF LASER MAINTENANCE ........................................ I-172

9-12. M LASER MAINTENANCE ......................................... I-179

Part II Program Management........................................................ II-1

1. Creating program................................................................... II-3

1-1. Creating program from PRE-EDIT or

SCHEDULE display ........................................................II-3

1-2. Creating program from PROGRAM display.................... II-6

2. Calling program......................................................................II-9

2-1. Calling program from PRE-EDIT or

SCHEDULE display ........................................................II-9

(Continued on next page.)

v

Page 6

2-2. Calling program from PRE-EDIT or

PROGRAM display ........................................................ II-12

3. Saving program ....................................................................II-14

3-1. Saving program from PRE-EDIT or

SCHEDULE display ....................................................... II-14

3-2. Saving program from PROGRAM display .....................II-17

4. Saving schedule ...................................................................II-20

5. Moving program.................................................................... II-22

6. Copying program .................................................................. II-25

7. Deleting program .................................................................. II-28

8. Editing program ....................................................................II-30

8-1. Searching for word......................................................... II-30

8-2. Replacing word .............................................................. II-32

8-3. Copying and pasting word ............................................. II-35

8-4. Setting multiple-part processing..................................... II-37

8-4-1. Calling program from PRE-EDIT or

SCHEDULE display ................................................II-39

8-4-2. Calling program from PROGRAM display............... II-41

8-4-3. Calling program from Edit display ........................... II-42

8-4-4. Example of use of Multi display............................... II-44

8-4-5. Coping inability to correct on Multi display.............. II-46

8-4-6. Changing program codes........................................ II-47

8-4-7. End position command R........................................ II-47

8-4-8. Examples of operation ............................................II-47

9. Searching for program.......................................................... II-54

9-1. Searching for program from Open display..................... II-54

9-2. Searching for program from Data input and

output display................................................................. II-56

10. Schedule Operation............................................................II-58

10-1. Creating schedule ........................................................II-58

10-2. Copying and pasting schedule..................................... II-61

10-3. Deleting schedule job................................................... II-63

10-4. Deleting all schedule jobs ............................................ II-64

11. Setting up............................................................................ II-66

11-1. Schedule operation ...................................................... II-66

11-2. Program operation .......................................................II-68

12. Editing processing conditions .............................................II-69

12-1. Calling processing conditions ...................................... II-69

12-2. Editing processing conditions ...................................... II-70

12-3. Saving processing conditions ...................................... II-71

13. Types of floppy disks ..........................................................II-72

vi

Page 7

Part III NC Codes ...........................................................................III-1

1. Description of program ......................................................... III-4

1-1. Block .............................................................................. III-4

1-2. Word............................................................................... III-4

1-3. Composition of program................................................. III-4

1-4. Main program and subprogram...................................... III-6

2. G-codes ................................................................................ III-7

2-1. Positioning (G00) ........................................................... III-9

2-2. Linear interpolation (G01) .............................................. III-9

2-3. Circular interpolation (G02, G03) .................................. III-10

2-4. Dwell (G04) ................................................................... III-11

2-5. Exact stop (G09, G61, G64) ......................................... III-11

2-6. Unloading (G10)............................................................ III-12

2-7. Piercing mode (G24)..................................................... III-12

2-8. Auto-repositioning (G25, G27) ...................................... III-12

2-9. Assist gas selection (G31) ............................................ III-14

2-10. Z-axis tracking (G32, G33).......................................... III-14

2-11. Laser beam path compensation (G40, G41, G42)...... III-15

2-12. Automatic zero return and operation end

(G50, G130) ................................................................ III-18

2-13. Regular-shaped hole macros...................................... III-19

2-13-1. Single-hole cutting (G111 to G116) ...................... III-20

2-13-2. Shape registration and continuous-hole cutting... III-25

2-13-3. Shape registration and pattern cutting

(G126, G128, G129, G136, G137)....................... III-26

2-14. Absolute and incremental programming (G90, G91).. III-30

2-15. Coordinate system setup (G92) .................................. III-31

2-16. Offset origin setup (G93)............................................. III-32

2-17. Multiple-part processing (G75, G76, G98).................. III-33

2-17-1. Multiple-part processing reference point and

part spacing setup................................................ III-34

2-17-2. Macro store .......................................................... III-34

2-17-3. Multiple-part processing commands

(G75, G76) ........................................................... III-35

2-17-4. Program examples ............................................... III-36

2-18. HS edge detection (G121, G122) ............................... III-37

2-18-1. HS edge detection calibration (G122) .................. III-38

2-18-2. Compensation by edge measurement

(G121 L1 to L5).................................................... III-41

2-18-3. Fine adjustment of measurement error ................ III-58

(Continued on next page.)

vii

Page 8

2-19. OVS (G140, G141, G149) ...........................................III-60

2-20. Scaling and coordinate rotation (G150) .......................III-79

2-21. Pipe cutting NC-codes (G08, G17, G18, G107) ..........III-80

2-21-1. NC-code restrictions and cautions ........................III-81

2-21-2. Program example..................................................III-82

3. M-codes ................................................................................III-83

3-1. Operation stop (M00, M01)............................................III-85

3-2. End processing (M02, M30)...........................................III-85

3-3. Repositioning (M10, M11) ..............................................III-85

3-4. Worksheet thickness detection range (M20 to M29) .....III-86

3-5. Loading (M33)................................................................III-86

3-6. Two-stack unloading (M65)............................................III-86

3-7. Workchute (M80, M81, M180) .......................................III-87

3-8. Subprogram call (M96) ..................................................III-87

3-9. Subprogram end (M97)..................................................III-87

3-10. Processing mode (M100, M101)..................................III-88

3-11. Worksheet designation (M102) ....................................III-88

3-12. Laser cutting (M103, M104).........................................III-89

3-13. Shuttle pallet change (M707).......................................III-90

3-14. Z-axis tracking sensor calibration

(M722, M723, M727)..................................................III-90

3-15. Beam on and off (M758) ..............................................III-90

3-16. Shuttle move to cleaning position (M788, M789).........III-91

3-17. Pallet set (M790, M791)...............................................III-91

3-18. Pallet pins (M792, M793).............................................III-91

4. Other codes ..........................................................................III-92

4-1. Cutting condition (E-code) .............................................III-92

4-2. Sequence number (N-code) ..........................................III-97

4-3. Skip command (GOTO-code) ........................................III-92

4-4. Workchute (M80, M81, M180) .......................................III-93

4-5. Macro store command (U- and V-codes).......................III-93

viii

Page 9

Part I

Displays

1. Description ...................................................................................I-4

1-1. Description of display operation............................................I-4

1-1-1. Basic operation...............................................................I-4

1-1-2. Entering letters and numerals ........................................I-4

1-1-3. Scroll bars ......................................................................I-4

1-1-4. Cursor.............................................................................I-4

1-2. Composition of displays ........................................................I-5

2. Areas common to displays ...........................................................I-9

2-1. Processing status display area 1 ..........................................I-9

2-2. Processing status display area 2 .........................................I-18

2-3. Data edit area.......................................................................I-20

2-4. Status icons..........................................................................I-43

3. PRE-EDIT display (background).................................................I-44

3-1. Creating program from PRE-EDIT display...........................I-44

3-2. Calling program from PRE-EDIT display..............................I-45

3-3. Saving program from PRE-EDIT display..............................I-47

3-4. Transferring job to PROGRAM display ................................I-47

3-5. Transferring selected job......................................................I-48

3-6. Transferring schedule to SCHEDULE display......................I-48

4. SCHEDULE display ....................................................................I-49

4-1. Creating program from SCHEDULE display ........................I-50

4-2. Calling program from SCHEDULE display...........................I-50

4-3. Saving program from SCHEDULE display...........................I-52

(Continued on next page.)

I-1

Page 10

4-4. Selecting start job ................................................................I-52

5. PROGRAM display .....................................................................I-53

5-1. Creating program from PROGRAM display.........................I-54

5-2. Calling program from PROGRAM display ...........................I-54

5-3. Saving program from PROGRAM display ...........................I-55

6. RESULT display.......................................................................... I-56

7. UTILITY display .......................................................................... I-60

7-1. G50 ......................................................................................I-61

7-2. Return to 2nd

Machine Position ...........................................I-62

7-3. G00 ......................................................................................I-63

7-4. Nozzle/Head Exchange Position..........................................I-64

7-5. JOG Cutting .........................................................................I-66

7-6. Shuttle Exchange.................................................................I-68

7-7. Adjust HS Sensor.................................................................I-69

7-8. Check Assist Gas.................................................................I-70

7-9. Adjust the Nozzle Unit Centering .........................................I-72

7-10. Adjust Focus ......................................................................I-74

7-11. Adjust WACS......................................................................I-78

7-12. Adjust AIV...........................................................................I-79

7-13. Adjust Offset.......................................................................I-80

7-14. Internal electric discharge ..................................................I-82

7-15. Beam-Out...........................................................................I-83

7-16. Clean the Nozzle Unit ........................................................I-84

7-17. Skeleton Cut ......................................................................I-85

7-18. Settings ..............................................................................I-88

7-19. Input error ..........................................................................I-89

8. Processing condition displays.....................................................I-90

8-1. Common areas of processing condition displays ................I-91

8-1-1. Common area 1 ............................................................I-91

8-1-2. Common area 2 ............................................................I-93

8-1-3. Common area setting operations.................................. I-95

8-2. CUT display.........................................................................I-101

8-2-1. Output Check display ...................................................I-103

8-3. PIERCE display ..................................................................I-104

8-4. EDGE display......................................................................I-107

8-5. LIST display ........................................................................I-110

8-5-1. Calling processing conditions....................................... I-111

8-5-2. Finding processing conditions...................................... I-111

8-5-3. Copying processing conditions ....................................I-113

8-5-4. Changing material name ..............................................I-113

8-5-5. Deleting processing conditions ....................................I-114

I-2

Page 11

8-5-6. Exporting processing conditions ..................................I-115

8-5-7. Importing processing conditions...................................I-115

8-5-8. Exporting all processing conditions at a time ...............I-116

8-5-9. Importing all processing conditions at a time ...............I-117

8-6. SET LASER display ............................................................I-118

8-6-1. LASER PRM display ....................................................I-118

8-6-2. AIV display....................................................................I-121

8-6-3. HS EDGE display .........................................................I-124

8-6-4. PROBE display.............................................................I-126

8-7. SET OPTION displays ........................................................I-128

8-8. DETAIL OFF display............................................................I-129

8-8-1. COND. display..............................................................I-130

8-8-2. LIST display..................................................................I-130

8-8-3. SET LASER display .....................................................I-130

9. Maintenance display ..................................................................I-131

9-1. DATA INPUT AND OUTPUT ...............................................I-132

9-1-1. Copying data ................................................................I-133

9-1-2. Moving data..................................................................I-134

9-2. CNC MAINTENANCE .........................................................I-135

9-2-1. Reading O number .......................................................I-136

9-2-2. Writing O number .........................................................I-136

9-3. VERSION INFORMATION ..................................................I-142

9-4. EXTERNAL IO SETUP........................................................I-143

9-5. SET ALL LASER DEFAULTS ..............................................I-144

9-6. E-MAIL NOTICE FUNCTION..............................................I-145

9-6-1. Details of Setup of E-mail Notice display .....................I-146

9-6-2. Details of E-mail Notice Function display.....................I-148

9-6-3. Details of E-mail Transmission display.........................I-149

9-7. INSPECTION ......................................................................I-153

9-7-1. INSPECTION ...............................................................I-153

9-7-2. TASK ............................................................................I-155

9-7-3. ADD ITEM ....................................................................I-156

9-7-4. NOTICE........................................................................I-157

9-7-5. HOLIDAY......................................................................I-158

9-7-6. SETTING......................................................................I-159

9-7-7. CALENDAR..................................................................I-160

9-8. BACKUP SCHEDULER ......................................................I-161

9-9. USER SETTINGS ...............................................................I-164

9-10. APPLICATION SETTINGS................................................I-171

9-11. AF LASER MAINTENANCE ..............................................I-172

9-12. M LASER MAINTENANCE ...............................................I-179

I-3

Page 12

1. DESCRIPTION

1-1. Description of display operation

1-1-1. BASIC OPERATION

The machine has various buttons arranged on each display. The

buttons function when the corresponding portions on the display are

pressed or touched. Some of the buttons illuminate to indicate that

they are pressed.

1-1-2. ENTERING LETTERS AND NUMERALS

Use the accessory keyboard to enter or edit the letters and numerals on

each display.

1-1-3. SCROLL BARS

One or two scroll bars appear when all data cannot be shown on one

display as is the case with a file list. The display can also be scrolled

by pressing the scroll bar up and down buttons or moving up and down

the scroll bar lever.

1-1-4. CURSOR

When you touch the display position to which you want to move the

cursor, the cursor moves to that position.

If the display has cursor buttons, press the cursor buttons to move the

cursor to your desired position on the display.

The cursor moves also when the display is scrolled with the scroll bar

or bars.

I-4

Page 13

1-2. Composition of displays

There are eight displays: PRE-EDIT, SCHEDULE, PROGRAM,

RESULT, UTILITY, COND. (processing condition), and MAINT.

(maintenance). Press the corresponding button to change to each

display.

PRE-EDIT (background) button

Pressed to open the PRE-EDIT display to create and edit the next

program or schedule while the machine is operating. You can also

check the setup of the next program and check the part by drawing it

while the machine is operating.

I-5

Page 14

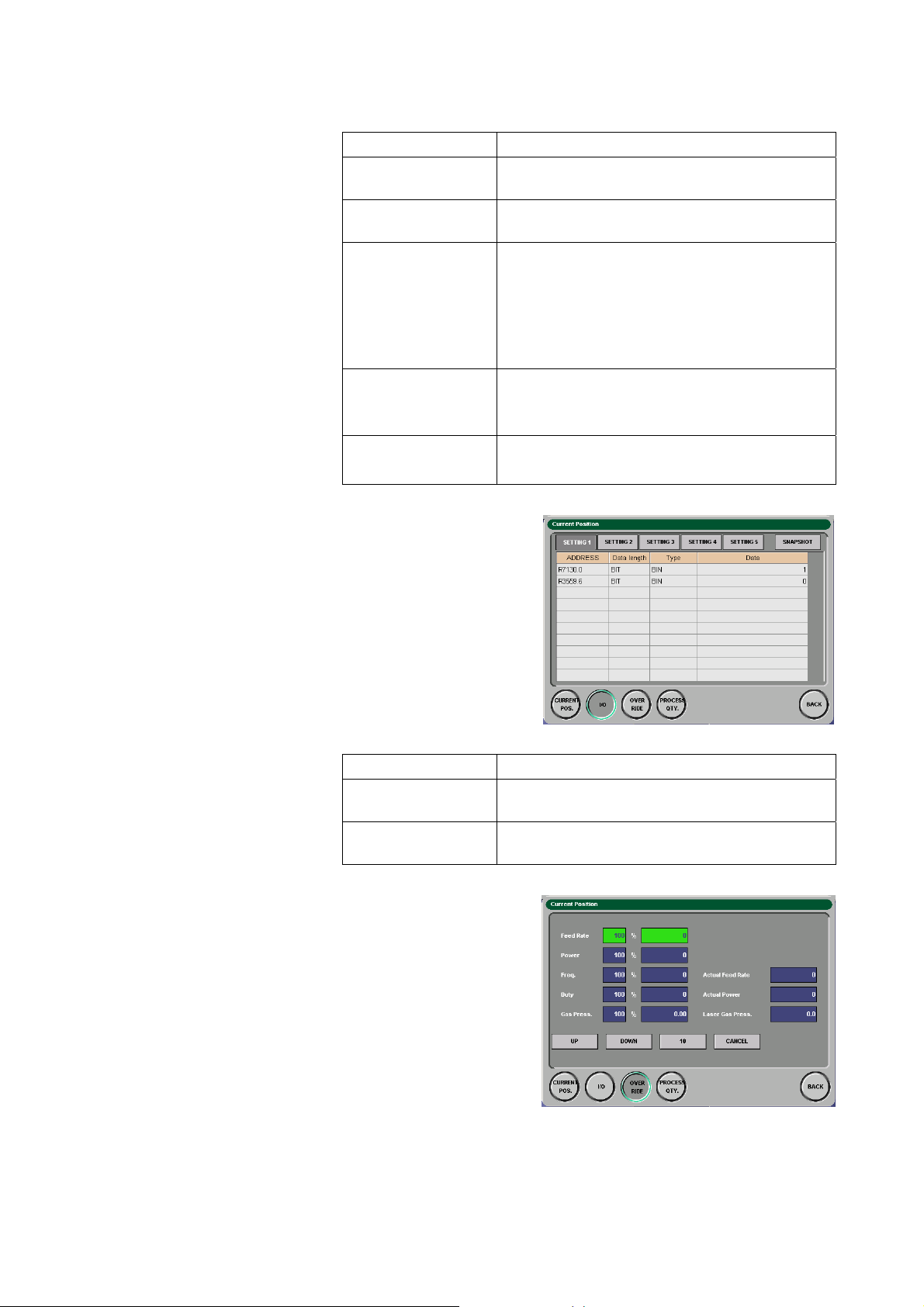

SCHEDULE button

Pressed to open the SCHEDULE display to read a schedule, create a

schedule, and set a start job or end job. You can also check the setup

and check the part by drawing it before operating the machine.

PROGRAM button

Pressed to open the PROGRAM display to show a program. You can

also check the setup and check the part by drawing it before operating

the machine.

I-6

Page 15

RESULT button

Pressed to open the RESULT display to show the actual processing

results.

UTILITY button

Pressed to open the UTILITY display to zero-return the machine’s axes

and make various adjustments.

I-7

Page 16

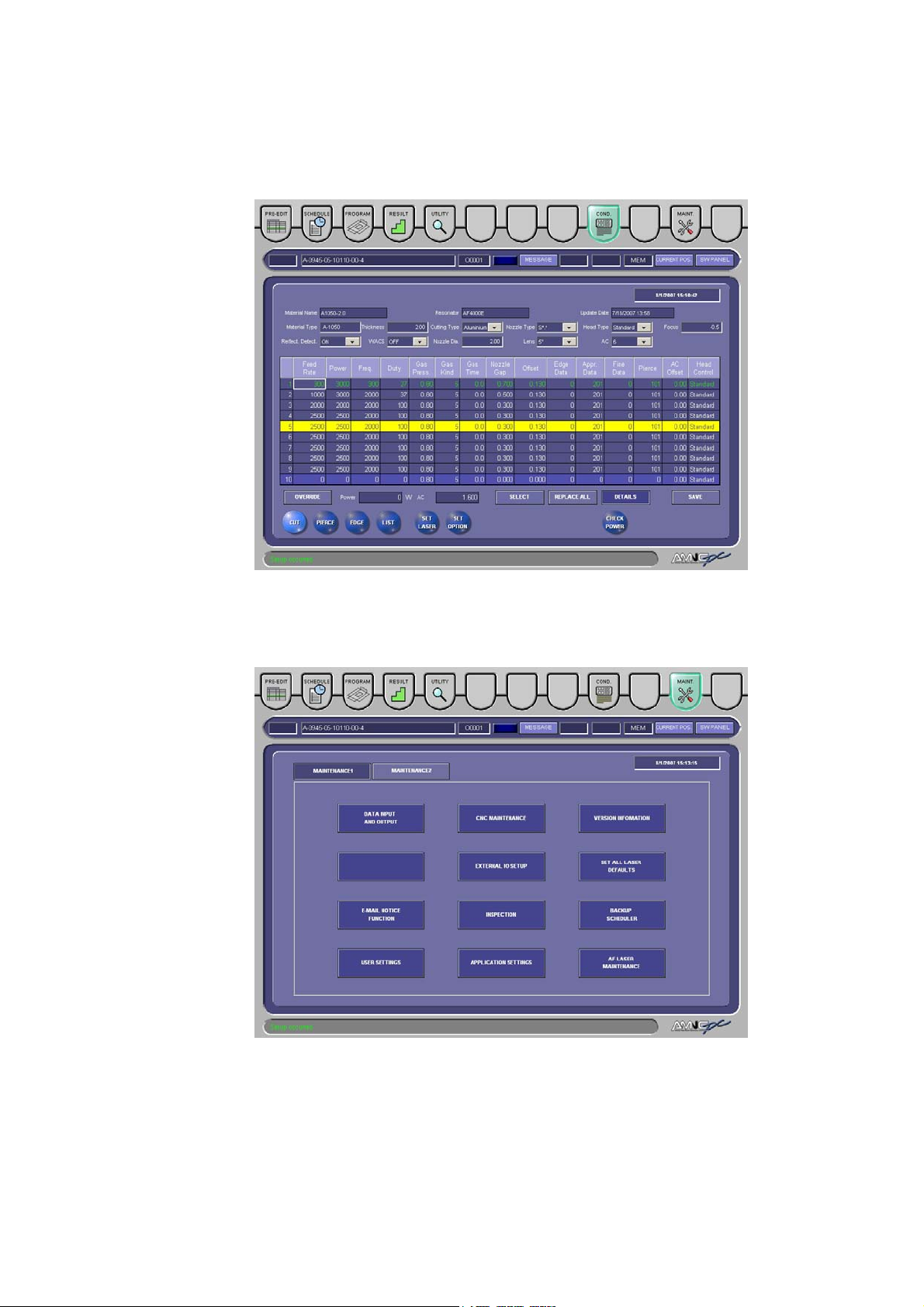

COND. button

Pressed to open the display to select and set the laser processing

conditions.

MAINT. button

Pressed to open the maintenance display to show maintenance items

and machine information.

I-8

Page 17

2. Areas common to displays

2-1. Processing status display area 1

Here are described the buttons and items on the common area of the

PRE-EDIT, SCHEDULE, and PROGRAM displays.

[4] PROCESSING

STATUS

DISPLAY FIELD

[5] RUNNING PROGRAM

DISPLAY FIELD

[6] OPERATION

STATUS

DISPLAY FIELD

[1] MESSAGE

BUTTON

[7] NC STATUS

DISPLAY FIELD

[2] CURRENT

POS. BUTTON

[3] SW. PANEL

BUTTON

I-9

Page 18

[1] MESSAGE button

Pressed to open the MESSAGE

display. When an alarm or warning

occurs, the MESSAGE display

automatically opens.

• Alarm display

Shows currently occurring

alarms or warnings.

• History display

Shows alarms or warnings

that have occurred to date.

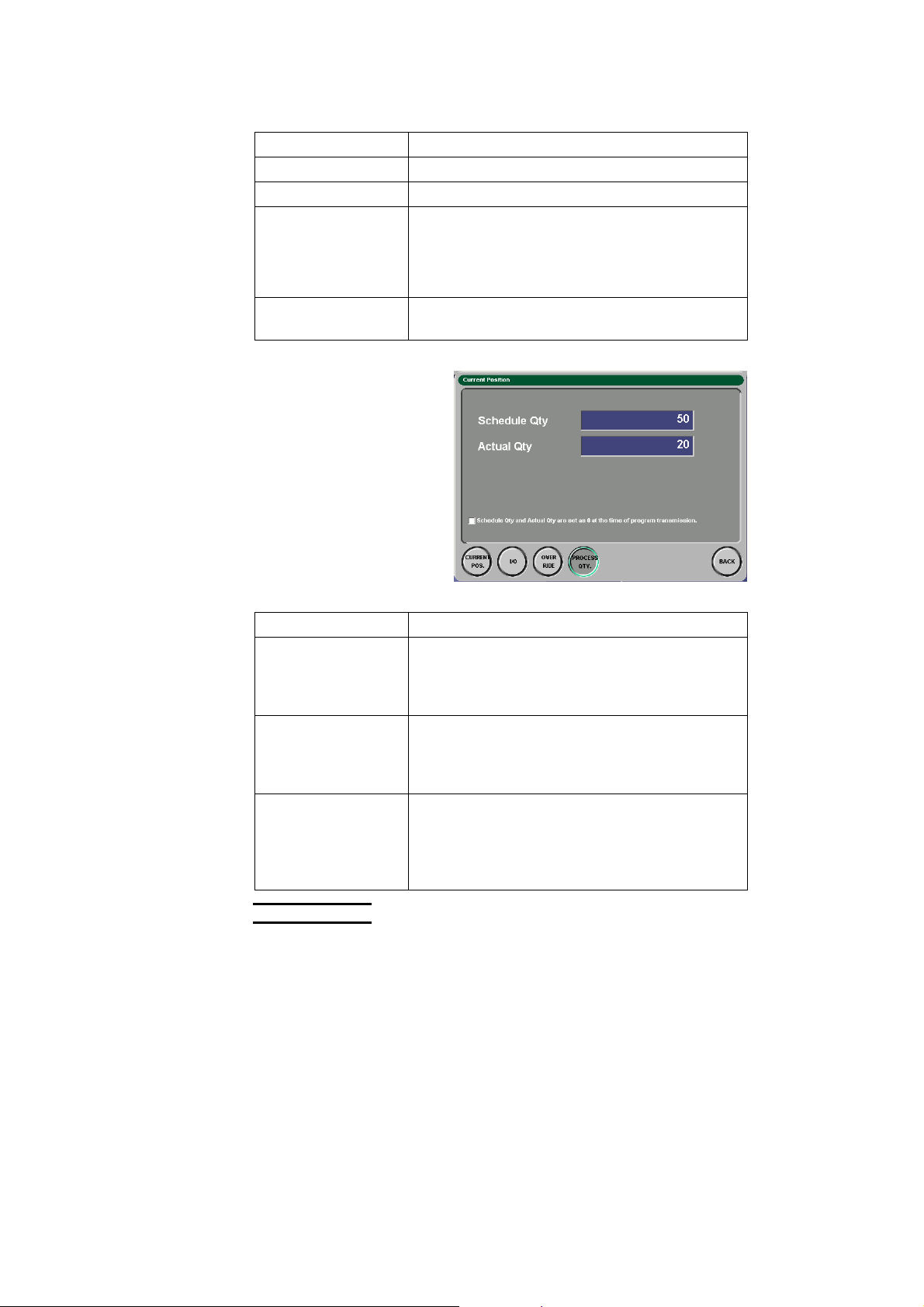

[2] CURRENT POS. button

Pressed to open the Current Position

display.

• Current Position display

I-10

Page 19

Item Description

ABS button Shows the current positions in the work

coordinate system.

MACHINE button Shows the current positions in the machine

coordinate system.

REL button Shows the current positions in the relative

coordinate system.

Preset: Sets the selected axis to the specified

position.

Origin: Sets the relative coordinate position of

the selected axis to 0.

REMAIN button

Shows the remainder of the movement

commanded for one block in the MEMORY

mode.

TOTAL button

• I/O display

Item Description

SETTING 1 to 5

buttons

SNAP SHOT button Saves the settings in the CSV format in a floppy

• Override display

Changes the override

(multiplication factor) to the

Feed Rate, Power, Freq.,

Duty, and Gas Press.

fields.

Shows the current position of each axis in all

coordinate systems.

Set 10 addresses per display or a total of 50

addresses.

disk.

I-11

Page 20

Item Description

UP button Increments the override by 10% (or 1%).

DOWN button Decrements the override by 10% (1%).

10 button

1 button

Changes the setting unit of the override

between 10% and 1%.

*The override is fixed at the unit of 10% for

duty.

CANCEL button Returns the override for the selected item to

100%.

• Process quantity display

Shows the number of

worksheets to be

processed and the number

of worksheets already

processed.

Item Description

Schedule Qty field Shows the number of worksheets to be

processed. Enter a value, and press the

ENTER key. (The setting range is 0 to 9999

worksheets).

Actual Qty field Shows the number of worksheets already

processed. Enter a value, and press the

ENTER key. (The setting range is 0 to 9999

worksheets).

“Schedule Qty and

Actual Qty are set as

Checked to zero the Schedule Qty and Actual

Qty fields when the program is transferred.

0 at the time of

program

transmission” box

I-12

NOTE

O When the automatic operating mode is other than PROGRAM, the

PROCESS QTY. button is not shown.

Page 21

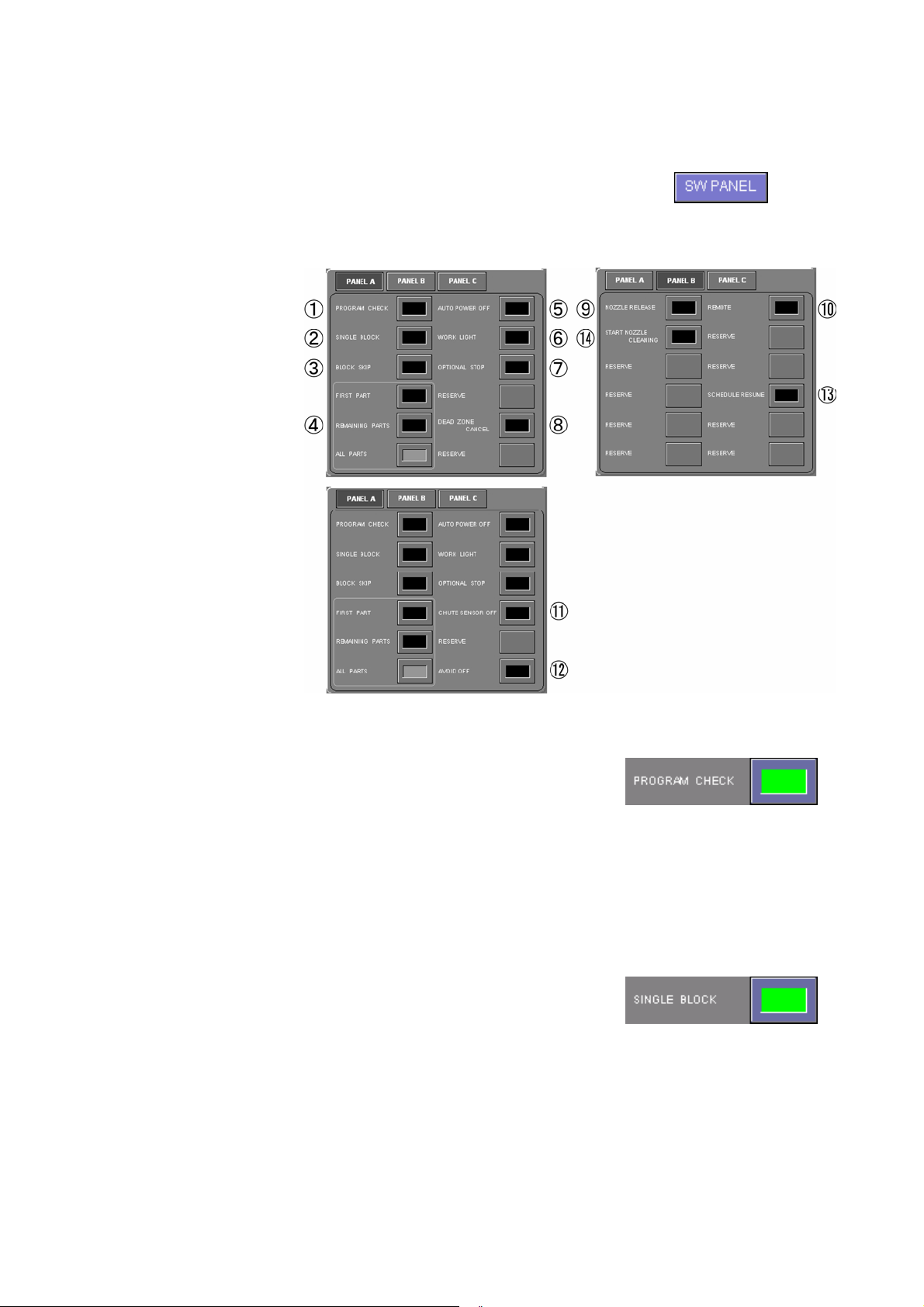

[3] SW PANEL button

Pressed to cycle through the

following panels with the buttons

required for the operation of the

machine.

◯1 PROGRAM CHECK button

Press the PROGRAM CHECK

button, and start the program. The

machine dry runs. During the dry

run, the coordinate values on the

display change, but the axes do not

move and the M-codes are not

executed. After the dry run, the

machine must be manually

zero-returned.

◯2 SINGLE BLOCK button

Press the SINGLE BLOCK button,

and then press the START button.

The machine executes one block of

the program and then stops.

I-13

Page 22

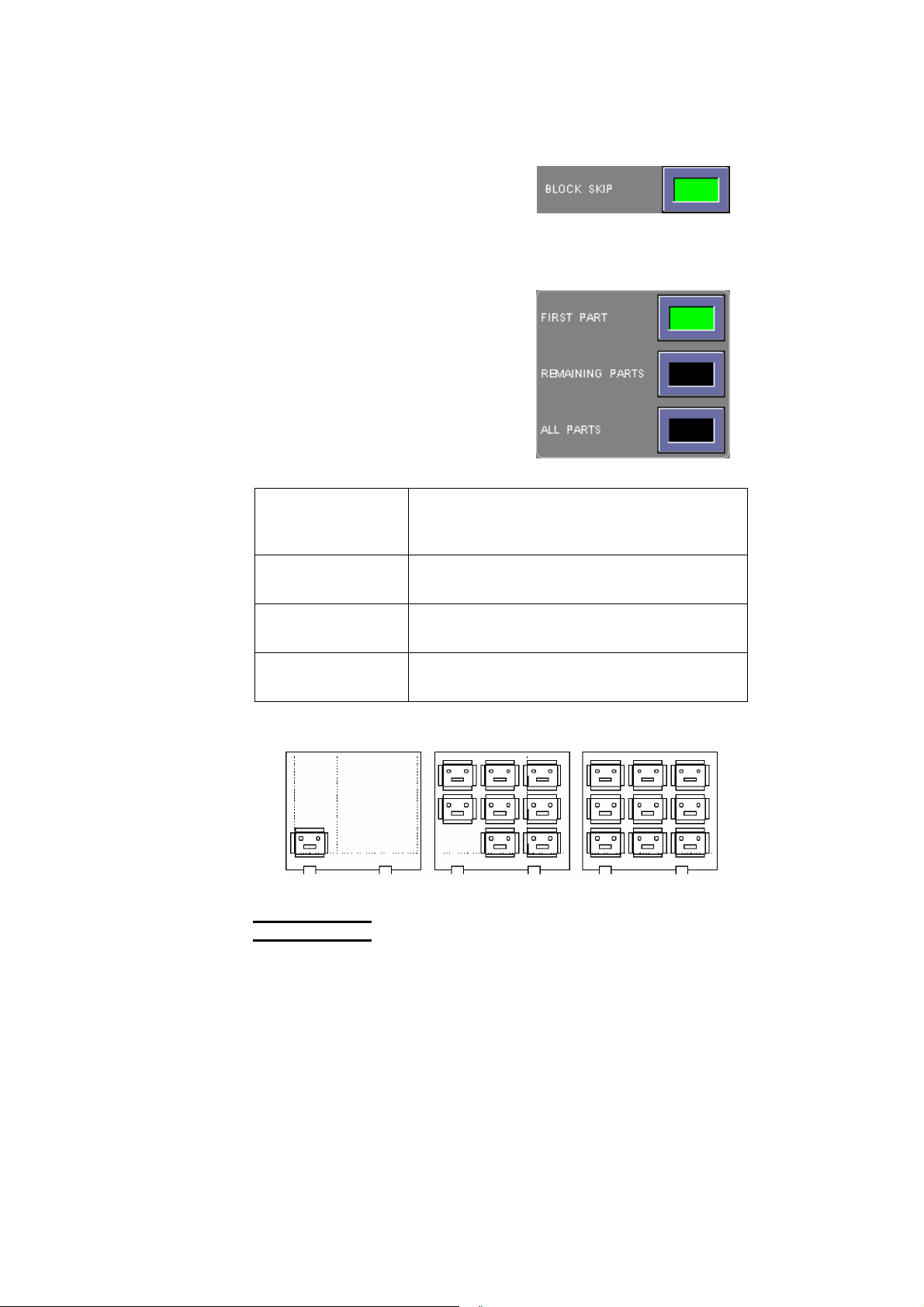

◯3 BLOCK SKIP button

Press the BLOCK SKIP button, and

then start the program. The

machine ignores each block with a

slash (/) at the beginning and goes

to the next block.

◯4 Multiple-part mode buttons

Press one of the multiple-part mode

buttons to select the multiple-part

processing function you want to

perform.

Do not use these buttons when the

program is not a multiple-part

processing program.

All extinguished All of these buttons are extinguished when the

program is not a multiple-part processing

program.

FIRST PART button

illuminated

REMAINING PARTS

The machine cuts only the first of multiple parts

programmed.

The machine cuts the remaining parts.

button illuminated

ALL PARTS button

The machine cuts all parts.

illuminated

First part Remaining parts All parts

NOTE

O Before starting a multiple-part processing program, be sure to press and

illuminate one of the multiple-part processing setup buttons. An alarm

occurs in the middle of the process if the buttons are all extinguished.

Before starting a non-multiple-part processing program, press and extinguish

all buttons. If one of the buttons is illuminated, the program cannot normally

run.

I-14

Page 23

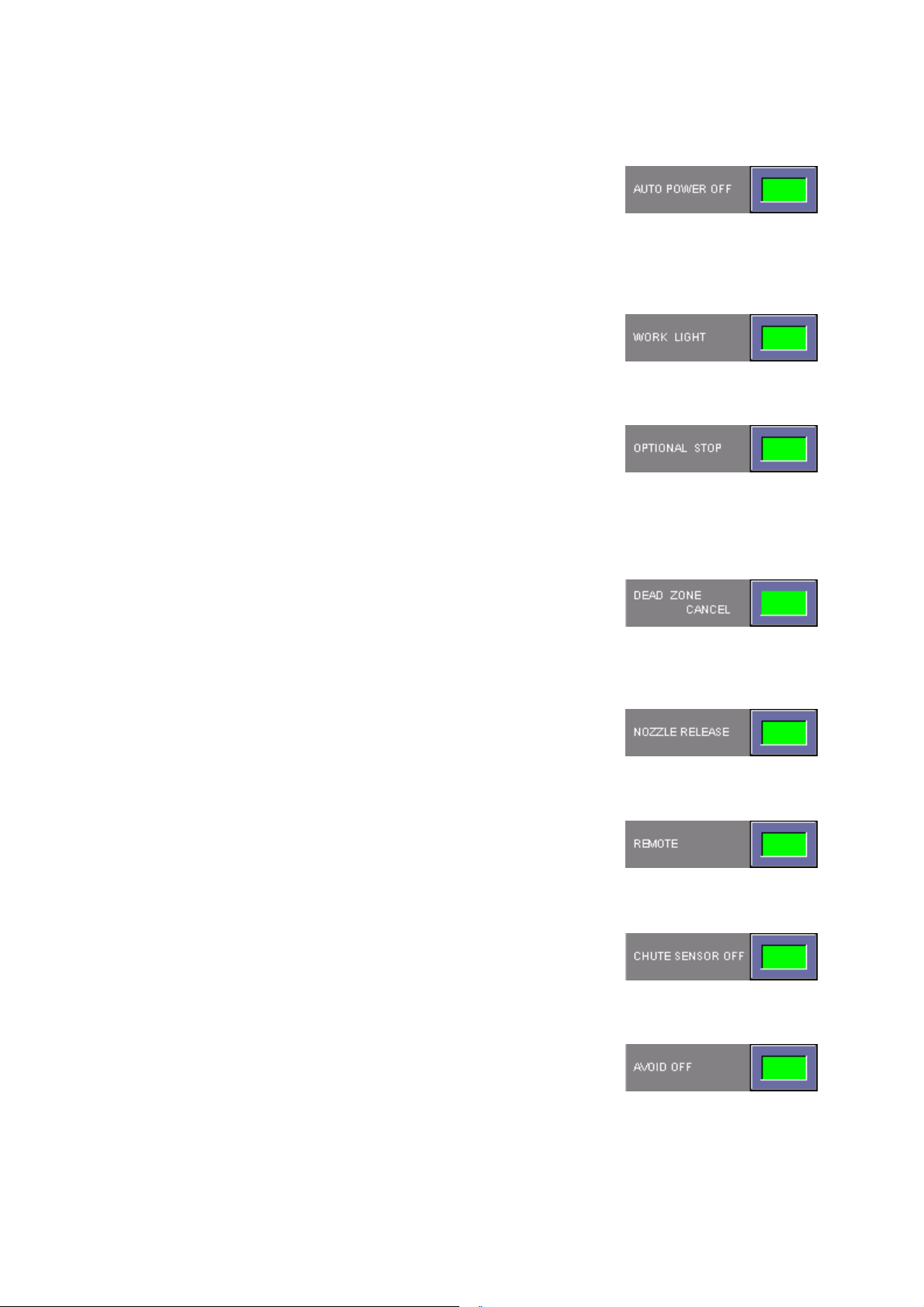

◯5 AUTO POWER OFF button

Press the AUTO POWER OFF

button. When the machine stops

after the end of its program operation

or after the occurrence of an alarm, it

can be automatically powered off.

◯6 WORK LIGHT button

Pressed to turn on the work light.

◯7 OPTIONAL STOP button

Pressed to pause the machine when

M01 (optional stop command) is

read.

Press the START button for the

machine to resume its operation.

◯8 DEAD ZONE CANCEL button

Pressed to disable the dead zone

detection function when the laser

head enters an area where it may

strike a workclamp.

◯9 NOZZLE RELEASE button

Pressed to release the nozzle for

nozzle change.

◯10 REMOTE button

Pressed to perform DNC operation

when the CNC operating mode is

selected.

◯11 CHUTE SENSOR OFF button

Pressed to disable the chute drop

detection function.

◯12 AVOID OFF button

Pressed to disable the workclamp

avoidance function when the

worksheet enters an area where it

may strike a workclamp.

I-15

Page 24

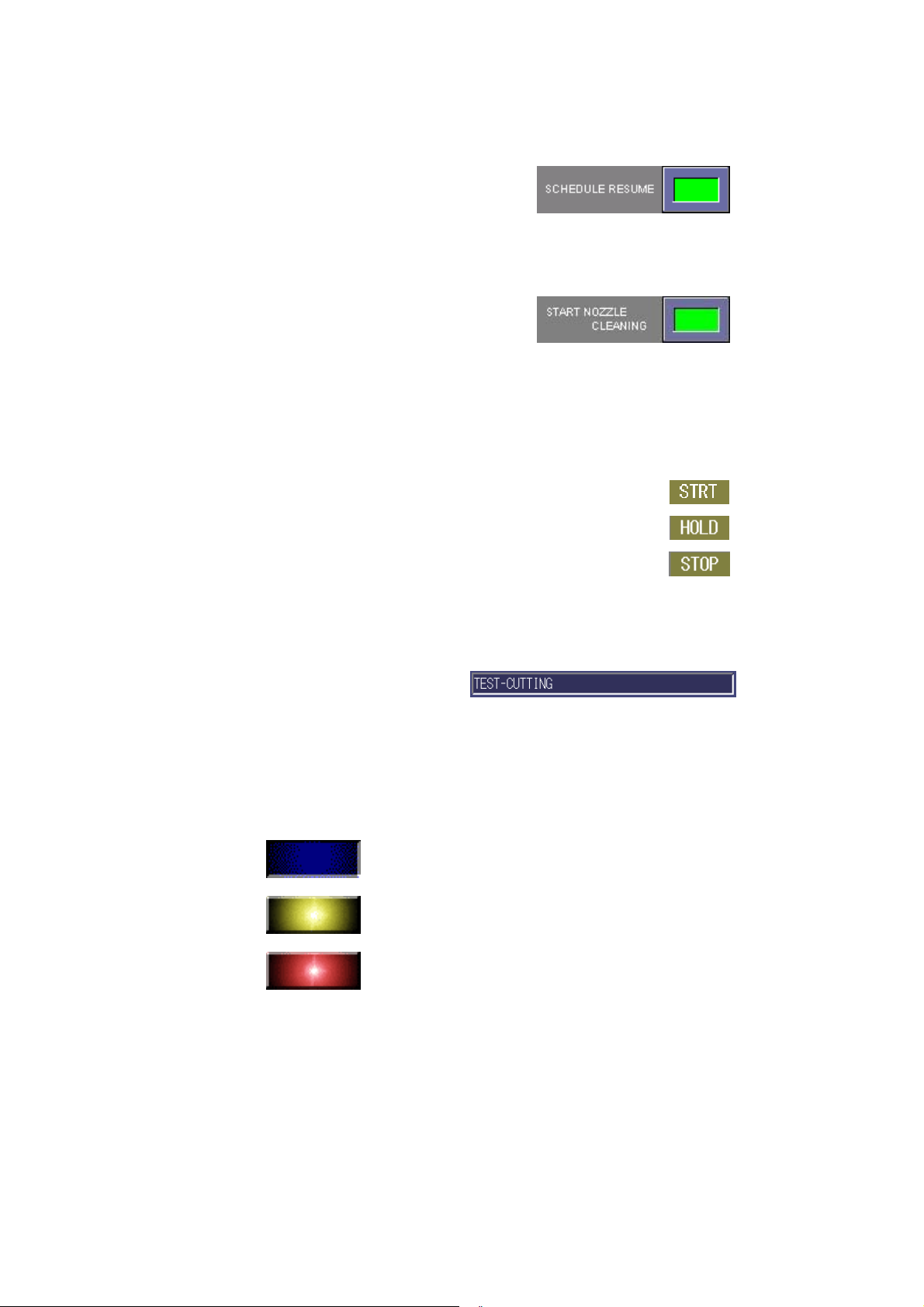

◯13 SCHEDULE RESUME button

Pressed to enable the machine to

resume its operation from where it is

stopped during its schedule

operation.

◯14 START NOZZLE CLEANING button

Pressed to enable the automatic

cleaning of the nozzle at the start of

the program.

[4] Processing status display field

Shows the processing status of the machine based on the NC status as

follows:

STRT: Shows the execution of a program.

HOLD: Shows the input of a stop signal.

STOP: Shows the input of a processing end signal.

[5] Running program display field

Shows the name of the

program being run or on

standby.

[6] Operating status display field

Shows the operating status of the machine.

Operation stopped (blue)

Warning occurred (flashing yellow)

I-16

Alarm occurred (steady red)

Page 25

[7] NC status display fields

◯1 ◯2 ◯3

1

◯

: Shows “Mcode” when an M-code is being run.

2

: Shows “EMG” when the machine is in an emergency stop condition.

◯

3

◯

: Displays the current NC mode.

REF: RETRACT mode MEM: MEMORY mode

JOG: MANUAL mode DNC: DNC mode

MDI: MDI mode EDIT: EDIT mode

I-17

Page 26

2-2. Processing status display area 2

(

)

Here are described the buttons and display items on the common area

of the SCHEDULE and PROGRAM displays.

COORDINATE

SYSTEM CHANGE

BUTTON

PROGRAM INDICATOR

GREEN

SCHEDULE INDICATOR (ORANGE)

Display items

Item Description

Coordinate system

change button

Cycle Time field Shows the processing time of the current

JOB end time field Shows the scheduled end time of the current

All process end time

field

Program indicator

(green)

JOB in operation

field

Schedule indicator

(orange)

Changes the current coordinate system

between the machine coordinate system and

absolute coordinate system.

program.

job.

Shows the scheduled end time of the current

schedule.

Shows the progress of the program relative to

the scheduled processing time. Appears

yellow when the program is stopped.

Shows the number of processed jobs relative to

the total number of jobs.

Shows the progress of the program relative to

the total number of worksheets scheduled.

I-18

Page 27

NOTE

O The all process end time (or scheduled end time of all processing operations)

is calculated from the time settings made on the User settings display as

described in 9-9. in this Part. This is also true of the job end time.

O If the program information does not include the scheduled processing time,

the progress of the program is not shown.

O The actual processing time may be different from the scheduled processing

time.

I-19

Page 28

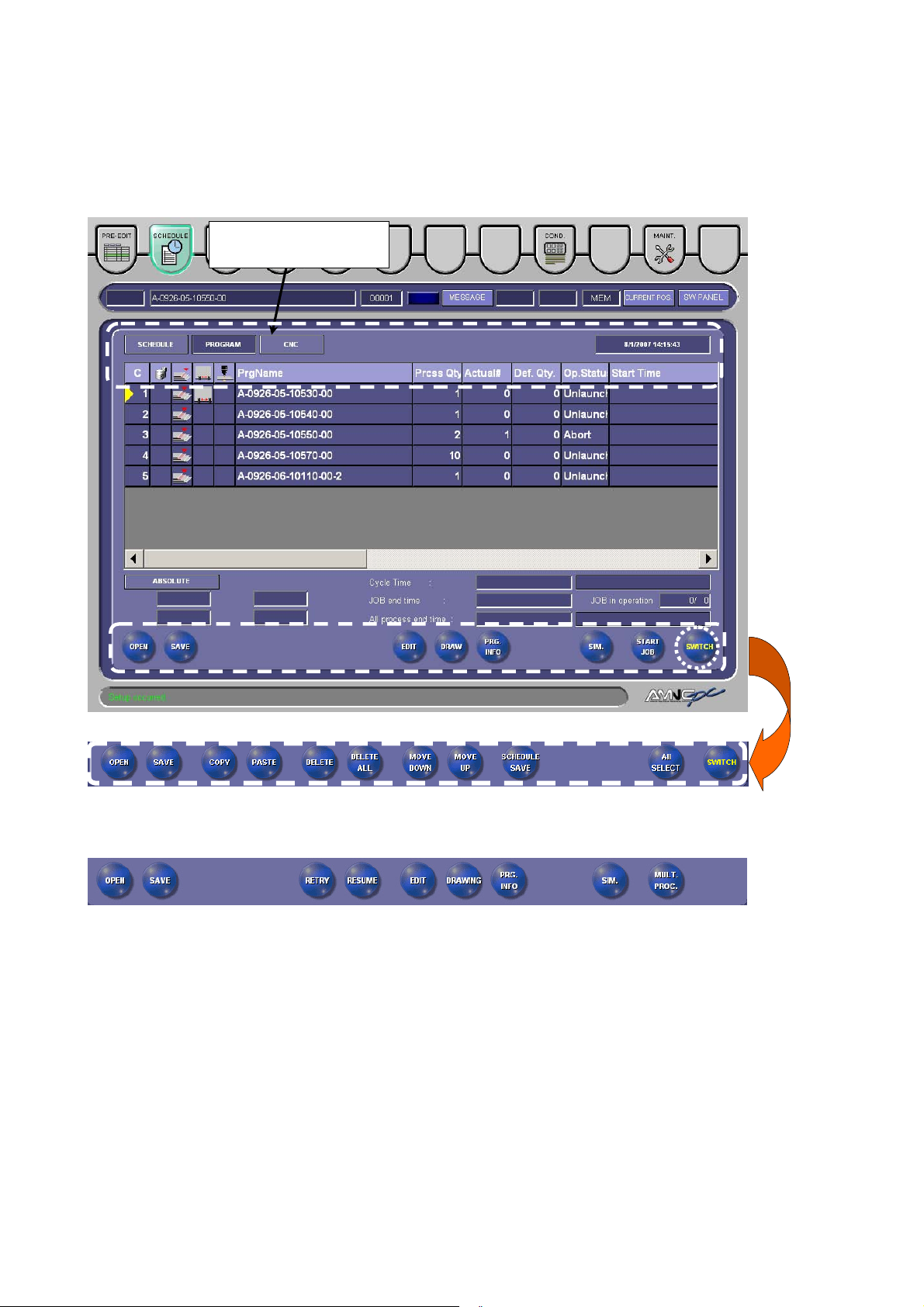

2-3. Data edit area

Here are described the display items and buttons on the common areas

of the PRE-EDIT, SCHEDULE, and PROGRAM displays.

OPERATING MODE

CHANGE BUTTONS

Press SWITCH button

to change menu

PROGRAM display has

no SWITCH button

I-20

Page 29

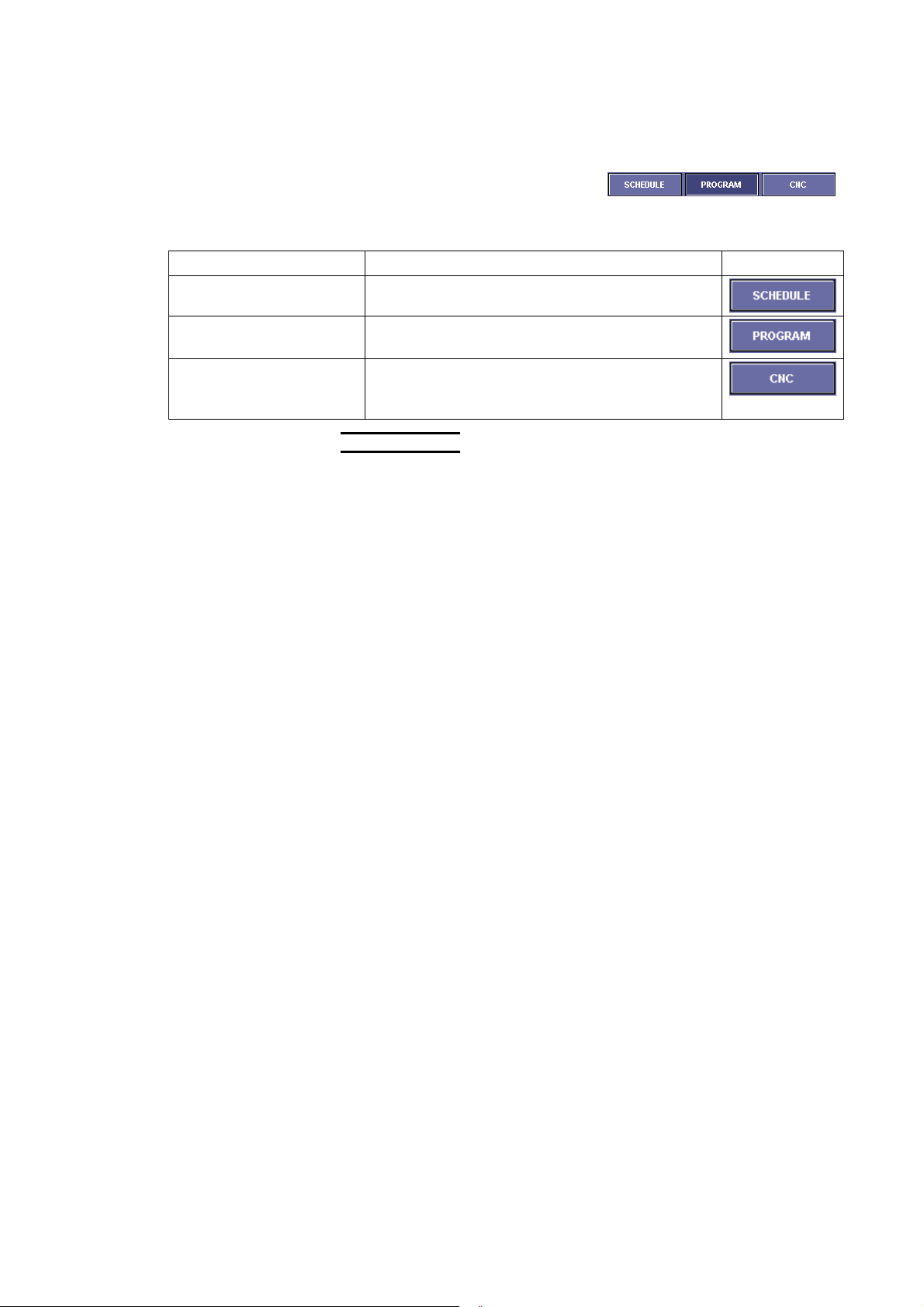

[1] Operating mode change buttons

Change the automatic operating

mode of the machine to suit a

particular operating procedure.

Item Description

SCHEDULE button Performs the schedule operation of the machine.

PROGRAM button Performs the single-program operation of the

machine.

CNC button Performs the CNC operation of the machine.

Press the REMOTE button on PANEL B to

perform the DNC operation.

NOTE

O The automatic operating mode of the machine cannot be changed while it is

operating.

O Change the automatic operating mode on the SCHEDULE or PROGRAM

display. It cannot be changed on the PRE-EDIT display.

I-21

Page 30

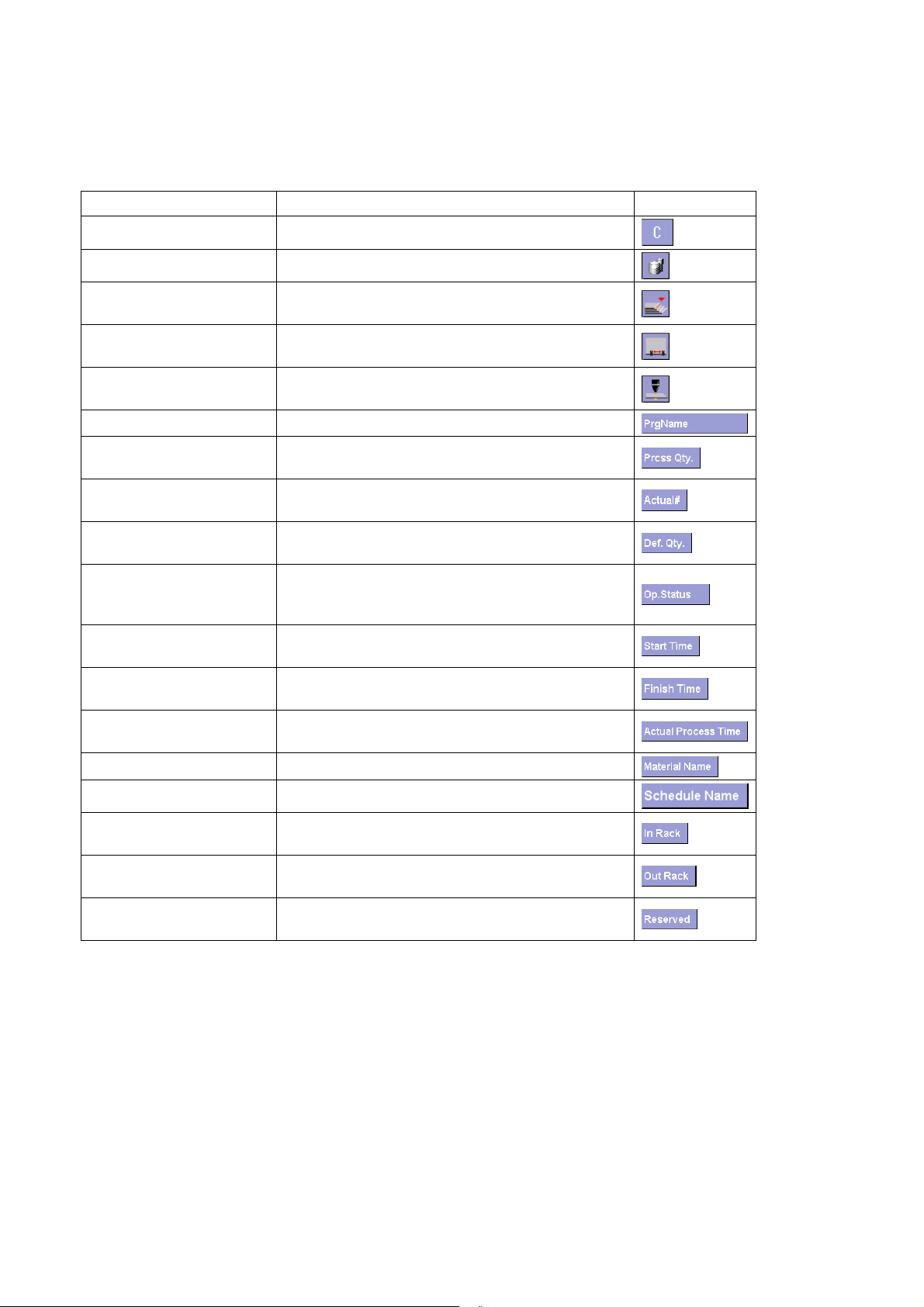

[2] List display items

The display items are as shown below.

Item Description Icon

C cell Deselects the data indicated by a green line.

Tool change and setup Not used on the laser cutting machine.

Material change and

setup

Workclamp position

change and setup

Laser setup Appears when it is necessary to change the

Prg Name Shows the program name.

Prcss Qty. Shows the number of worksheets to be

Actual # Shows the number of worksheets already

Def. Qty. Shows the number of defective worksheets. It

Op. Status Shows whether the job is not yet started, is being

Start Time Shows the job start time during the schedule

Finish Time Shows the job end time during the schedule

Actual Process Time Shows the time taken to process one worksheet

Material Name Shows the material name.

Schedule Name Shows the schedule name.

In Rack Sets the number of the shelf onto which to load

Out Rack Sets the number of the shelf from which to unload

Reserved Reserved for an optional unit like a loader or

Appears when it is necessary to change the

worksheet.

Appears when it is necessary to change the

workclamp position.

setup as the processing conditions change.

processed. It can be set on this display.

processed. It can be set on this display.

can be set on this display.

processed, or is normally completed. The job

skip function can also be selected.

operation.

operation.

during the schedule operation.

worksheets when an autostorage unit is installed.

parts when an autostorage unit is installed.

unloader.

I-22

*The display items depend on the search conditions.

Page 31

[3] OPEN button

Calls a program or schedule to the

data edit area.

1 Press the OPEN button to open the OPEN display.

2 Select the source

media, press the

SWITCH button to

SELECT MEDIA

SELECT WHETHER TO

CALL PROGRAM OR

SCHEDULE

show a list of

programs or

schedules, select the

program or schedule

you want to call from

the list, and press the

OK button.

Item Description

SDD button Lists the programs or schedules registered in

the SDD system.

FD button Lists the programs or schedules registered in

the floppy disk.

NC button Lists the programs or schedules saved in the

AMNC unit.

SHARED

HOLDER

Lists the programs or schedules saved in the

specified shared folder.

button

SWITCH button Changes the listed data between the programs

and schedules.

SEARCH

Searches the program or schedule list.

button

SCHEDULE

DETAILS

Shows the contents of each schedule. Select

the schedule, and press the button.

button

Enter key field Type the name of a program, and press the

ENTER key on the keyboard to search for the

program. When the name of the program is

read with a bar code reader, it is shown here.

“Quick search

is reflected on

Checked to reflect the typed search condition in

the program name on the search display.

condition” box

I-23

Page 32

NOTE

O The SDD system is Amada’s data management system composed of

the automatic programming unit AP100, AP60 or AP40 and the data

server ASIS100PCL.

O The specified shared holder is the holder that is set as shared holder on

the SPECIFY DRIVE display as described on 9-9. in this Part. If no

shared holder is specified, the SHARED HOLDER button is grayed out.

3 If there is a program

of the same name as

that of the selected

program, the Confirm

overwrite display

opens as shown right.

Item Description

SCHEDULE

REGIST button

Registers the called program with the same

contents as those of the registered program.

OK button Registers the called program by overwriting the

existing program of the same name with it.

CANCEL

Returns to the Open display.

button

4 Enter the number of

worksheets to be

processed, and press

the OK button to

register the program

on the Open display.

I-24

Item Description

OK button Registers the job with the entered number of

worksheets to be processed.

CANCEL

Returns to the Open display.

button

Page 33

NOTE

O Only one program can be called in the PROGRAM mode.

O The items shown on the Qty. input display vary with the “Enter Process

Qty screen” setting made on the SELECT VIEW display as described

on 9-9 in this Part.

O The display shown below opens when you press the PRE-EDIT or

SCHEDULE monitor CHANGE button and check the In rack and Out

rack fields on the SELECT VIEW display as described on 9-9 in this

Part.

Item Description

MULTI RACK

button

Specifies the number of worksheets for each

shelf, number of each shelf, etc.

I-25

Page 34

[4] SAVE button

Saves the selected program.

1 Select the program

you want to save, and

press the Save to

button to open the

Save data display.

Item Description

RENAME

button

DELETE button Removes the selected program from the

SDD button Saves the program in the SDD system.

NC button Saves the program in the NC unit. (Select the

NEW button Creates a new folder in the storage area of the

FD button Saves the program in the floppy disk.

SHARED

HOLDER

button

Overwrite

confirm box

NOTE

O Multiple programs can be selected for saving on the PRE-EDIT and

SCHEDULE displays.

2 Specify the

destination, and press

the OK button to open

the Confirm saved

data display.

Check the program

name and other

items, and press the

EXECUTE button.

Changes the name of the selected program.

programs to be saved.

(Select the folder to which to save the

program.)

folder in which to save the program.)

NC unit.

Saves the program in the specified shared

folder.

Asks whether or not to overwrite a program of

the same name with the new program when

saving the new program.

I-26

Page 35

Item Description

RENAME

button

DELETE button Removes the program from the programs to be

ABORT button Aborts the save.

BACK button Returns to the Save display.

EXECUTE

button

3 When the Saving data

display changes to

“Saved”, press the OK

button.

If the “Close

automatically when

process is complete”

box is checked, the

display shown right

will automatically

close from the next

time on.

Changes the name of the program.

saved.

Saves the selected data.

4 Press the EXIT button to close the window.

[5] COPY button

Copies the selected program.

Select the program you want to copy,

and press the button.

[6] PASTE button

Pastes the copied data on the data

edit area.

Select the destination list line, and

press the button.

[7] DELETE button

Deletes the selected program.

Select the program you want to

delete, and press this button.

I-27

Page 36

[8] DELETE ALL button

Deletes all programs registered on

the display.

[9] MOVE DOWN button

Moves down the program selected

on the display.

Select the program you want to

move down, and press the button.

[10] MOVE UP down

Moves up the program selected on

the data edit area.

Select the program you want to

move up, and press the button.

[11] SCHEDULE SAVE button

When a job is saved as schedule, it

can be simply called next time.

1 Select the job you want to save as schedule, and press the

SCHEDULE SAVE button.

2 Enter the name of the

schedule in the

Schedule name filed

on the Type Schedule

Name display, and

press the OK button.

3 Specify the

destination, and press

the OK button.

I-28

Page 37

4 Press the OK button.

5 Press the BACK

button to close the

display.

I-29

Page 38

[12] EDIT button

Changes the program placed on the

data edit area.

Select the program you want to

change, and press the button to

open the Edit display.

EDIT AREAS

SETUP AND G CODE BUTTONS

DRAW AREAS

* Shown above is the Edit display that opens when the G CODE button

is pressed

The buttons on the Edit display are described in detail below.

• SETUP display

Shows the setup

information of the selected

program.

Entry of accurate

information on the SETUP

display allows you to utilize

the setup function.

I-30

Page 39

• G CODE display

Shows the edit and draw areas.

Item Description

DRAWINGS button Draws the part in the draw area according to

the program shown in the edit area.

STEP DRAW button Draws the part in the draw area sequentially

according to the program lines selected in the

edit area.

Even when the down arrow key on the

keyboard is pressed, the part is sequentially

drawn.

When the STEP DRAW button is pressed, the

DRAWINGS button changes to the END DRAW

button. Press the END DRAW button to abort

the step draw.

When the draw process is completed, the END

DRAW button changes to the DRAWINGS

button.

G←DIAGRAM

button

FIRST LINE button Places the cursor at the first line of the program

LAST LINE button Places the cursor at the last line of the program

ENLARGE button Enlarges the selected portion of the figure

REDUCE button Reduces the selected portion of the figure

CENTER button Places the selected portion of the figure at the

AUTOSCALE button Shows the drawn figure to the size of the draw

STANDARD button Shows the position of the part in the worksheet

Highlights the G code for the selected portion of

the drawn figure.

Press the button, and select the portion of the

figure whose G code you want to check.

shown in the edit area.

shown in the edit area.

drawn in the draw area.

Press the button, and select the portion of the

figure you want to expand.

drawn in the draw area.

The reduction is referenced to the center of the

draw area.

center of the draw area.

area.

whose dimensions are set on the SETUP

display.

I-31

Page 40

Item Description Display

PARAM button Sets the drawing parameters.

Refresh during edit

Redraws a G code each time the cursor moves to the next or previous

line during the G code edit process.

Execute drawing on startup

Automatically draws the part in the draw area when the EDIT button is

pressed.

Display Scale

Shows the coordinates in the background of the draw area.

Display multiple process frame

Shows the multiple process frame in the draw area.

Scale

Sets the enlargement or reduction ratio when the ENLARGE or

REDUCE button is pressed, respectively.

Drawing color

Fixing:

Draws all paths in the default color (pink).

Cutting condition:

Draws the paths in different colors for different processing conditions.

E1: Blue, E2: Light blue, E3: Yellow, E4: White, E5 to E9: Red, E10

(marking line): Broken pink line, No condition: Pink

I-32

Page 41

Item Description Display

SEARCH button Opens the Search display.

Enter the character string to

find, select the search direction

(Up or Down), and press the

SEARCH NEXT button. To quit

the Search display, press the

BACK button.

REPLACE button Opens the Replace characters

display.

COPY button Opens the Specify the line that

you want to copy/cut display.

CUT: Cuts the specified range.

COPY: Copies the specified

range.

Item Description

PASTE button Pastes the data copied with the COPY button.

Select the destination line, and press the button

EXTRACT T button Not used on the laser cutting machine.

CHECK T button Not used on the laser cutting machine.

TOOLING button Not used on the laser cutting machine.

NEW button Creates a program.

MULT. PROC. button Opens the Multi display.

OK button Registers the edited data in the PRE-EDIT display.

BACK button Aborts the processing and returns to the PRE-EDIT display.

I-33

Page 42

[13] DRAWING button

Draws the part according to the data

of the program on the data edit area.

Select the program to use for

drawing the part, and press the

DRAWING button to open the

Confirm drawing display.

The buttons on the Confirm drawing display are described in detail

below.

Item Description

ENLARGE button Enlarges the figure drawn.

Press the button, and select the portion of the

figure you want to enlarge.

REDUCE button Reduces the figure shown enlarged.

Press the button to reduce the figure as

referenced to the center of the display.

CENTER button Changes the display position.

Press the button, and select the portion of the

figure you want to show as the center of the

display.

AUTOSCALE button Draws the figure on an automatic scale.

STANDARD button Shows the position of the part in the worksheet

whose dimensions are set on the SETUP

display.

PARAM button Sets the drawing parameters.

REFERENCE

O For details of the parameters, refer to “2-3. Data edit area, [12] EDIT button”

in this Part.

I-34

Page 43

[14] SIM button

Calculates the setup of all programs

shown on the data edit area, and

shows the setup results.

The SIM button is not enabled

unless the Laser setup and

Material/clamp setup boxes are

checked on the Application settings

display.

SETUP ICON

Material setup Shows that the material name

Workclamp position setup Shows that the workclamp position

Laser setup Shows that the setup items checked

Press the setup icon to

open the Setup Main

display for the setup.

changes with the processing

condition data.

changes with the setup made on the

Edit display.

on the display as described in “9-10.

Application settings” change.

I-35

Page 44

NOTE

O The setup status can be checked by the color of each button.

Red: Setup required, Yellow: Setup under way, Gray: No setup to make or

setup completed.

O When there is only one setup item, either setup display automatically opens.

• Laser setup display

Opens when the processing conditions of the program specified by

M102 change.

The current setup items are shown on the left side, and the new setup

items are shown in red on the right side.

When the setup in a lower row is completed, press the SETUP

COMPLETE button.

To complete all setups at a time, press the EXIT ALL button.

Shown in red

at setup

Current setup

I-36

Page 45

• Material/clamp setup display

Opens when the material or clamp setup icon is selected or the

MATERIAL/CLAMP button on the Setup Main display is pressed.

Make new material and workclamp setups.

The buttons on the Material/clamp setup display are described below.

SETUP COMPLETE

button

BACK button Returns to the Setup Main display.

[15] TRANS JOB button

Specifies the job you want to transfer

from the PRE-EDIT display to the

PROGRAM display.

Select the job, press the TRANS

JOB button, and press the

CONFIRM button. The job is

transferred to the PROGRAM

display.

Current setup

Item Description

Pressed when each setup is completed.

Shown in

red at setup

I-37

Page 46

[16] START JOB button

Specifies the job on the SCHEDULE

display from which you want to start

the schedule operation.

Select the job from which you want

to start the schedule operation, and

press the START JOB button. The

selected job is indicated by a yellow

arrow.

The schedule operation is started at

the specified job.

[17] PRG. INFO button

Shows the setup and other

information of the selected program.

I-38

Page 47

[18] RETRY button

Retry is a function of resuming the

operation by feeding or returning

from the middle or start position of

the program on a part basis (pierce

point) and on a block basis (single

block).

O Before using the retry function, the Z-axis must be raised to prevent it from

O The following functions and commands do not properly operate:

◯1 HS edge detection function (G121, G122)

◯

◯

◯

O Before using the retry function from the beginning of the program after reset,

NOTICE

striking an obstacle during its travel.

NOTE

2

OVS function (G140, G141, G149)

3

Measuring probe function (G120)

4

Repositioning function (G25, G27)

be sure to return each axis to the start position. Otherwise the axes do not

properly operate.

1

◯

2

◯

3

◯

4

◯

◯1 NEXT PART button

Press the NEXT PART button, turn

the SHUTTER OPEN keyswitch to

OFF, and press the START button to

move the axis to the start position

(pierce position) of the next path.

A multiple-part processing program moves the axis to the next part

reference point.

I-39

Page 48

◯2 PREV. PART button

Press the PREV. PART button, turn

the SHUTTER OPEN keyswitch to

OFF, and press the START button to

move the axis to the start position

(pierce position) of the previous path.

A multiple-part processing program moves the axis to the previous part

reference point.

◯3 NEXT BLOCK button

Press the NEXT BLOCK button, turn

the SHUTTER OPEN keyswitch to

OFF, and press the START button to

rapid the axis to the next block.

◯4 PREV. BLOCK button

Press the PREV. BLOCK button, turn

the SHUTTER OPEN keyswitch to

OFF, and press the START button to

rapid the axis to the previous block.

◯5 CLOSE button

Ends the retry function and closes

the Retry display.

After closing the Retry display, press the START button to cause the

machine to start processing from that position.

I-40

Page 49

[19] RESUME button

The resume function allows the axis

to rapid to the stopped position after

it is stopped by pressing the STOP

button, for example.

O Never perform the following operations until performing the resume function.

Otherwise the machine does not properly operate:

1

◯

2

◯

3

◯

4

◯

O The following functions and commands do not properly operate:

◯1 HS edge detection function (G121, G122)

2

◯

3

◯

4

◯

NOTE

Calling and using another program to operate the machine

Editing the resume program

Changing the processing conditions

Turning the TRACE OFF button to ON or OFF

OVS function (G140, G141, G149)

Measuring probe function (G120)

Repositioning function (G25, G27)

• RESUME button

Press the RESUME button, and then

press the START button to rapid the

axis to the position where it was

stopped last time.

• CLOSE button

Ends the retry function and closes

the Resume display.

After closing the Resume display, press the START button to cause the

machine to start processing from that position.

NOTE

O Depending on the resume position, the machine may be unable to resume its

operation properly due to a processing defect, for example. In such a case,

use the retry function to adjust the processing resume position.

I-41

Page 50

[20] MULT. PROC. button

The multiple-part processing function

allows the multiple-part processing

settings to be corrected simply by

changing the display settings of a

single-part or multiple-part

processing program.

REFERENCE

O For details of the multiple-part processing function, refer to “8-4. Setting

multiple-part processing” in Part II, Program management.

I-42

Page 51

2-4. Status icons

The current status is indicated by an icon at the lower right of the

screen. The meanings of the icons are as described in the table

below.

ICON

No. Icon Meaning Description

1

2

3

4

5

6

7

8

Event being

monitored

Dial-up connection

being made

Event being

monitored and

dial-up connection

being made

Mail transmission

failed and event

monitoring stopped

Inspection date

overdue

Backup date overdue The icon means that there is data past the backup

Automatic backup

failed

Recovery item set The icon means that a recovery item is set. The item

An event is being monitored. The icon means that

event monitoring is normally started.

The icon means that the dial-up connection specified

on the Setup of E-mail Notice display is being made.

The icon means that the machine is in both of the

status 1 and 2.

While an event was being monitored, another event

occurred, and mail transmission was attempted but

failed. The failure of mail transmission automatically

stops the event monitoring process.

The icon does not appear when the transmission of

mail from the E-mail Transmission display failed.

Check the message to see if the mail transmission

succeeded or failed.

If the icon is not shown during the event monitoring

process, the items may not be properly set on the

Setup of E-mail Notice display, or the network may not

be properly functioning. Remove the cause of the

problem.

The icon means that there is an overdue inspection

item. Inspect the overdue item.

date.

The icon means that automatic backup failed.

is recovered at the next startup.

I-43

Page 52

3. PRE-EDIT DISPLAY (BACKGROUND)

Press the PRE-EDIT button to open

the PRE-EDIT display to create or

edit the next program while the

machine is operating.

You can also check the setup of the

next program and check the next

part by drawing it while the machine

is operating.

OPERATING MODE

3-1. Creating program from PRE-EDIT

display

REFERENCE

O For details of the display, refer to “1-1. Creating program from PRE-EDIT or

SCHEDULE display” in Part II, Program management.

1 With no job selected, press the EDIT button.

2 Enter the program name, and press the G CODE button.

3 Enter the G code program in the left edit area.

I-44

Page 53

4 After creating the program, press the DRAWINGS button to draw

the part according to the program in the right draw area, and

check the program.

NOTE

O If the drawn figure overfills the draw area, press the AUTOSCALE

button.

5 After checking the program, press the OK button.

3-2. Calling program from PRE-EDIT display

REFERENCE

O For details of the display, refer to “2-1. Calling program from PRE-EDIT or

SCHEDULE display” in Part II, Program management.

1 Press the OPEN button to open the OPEN display.

2 Press the source media, and press the SWITCH button to select

whether to call a program from the program data list or schedule

data list. Select the necessary data from the list, and press the

OK button.

Two or more programs can be called at a time.

If the program you want to call cannot be found although you have

saved it, it may be saved in another folder. Press the SEARCH

button to open the Search display. Enter the folder name in the

Folder name field, and search for the folder.

REFERENCE

O For the searching procedure, refer to “9. Searching for program” in Part

II, Program management.

NOTE

O If the selected

program is present as

job, the Confirm

overwrite display

opens as shown right.

I-45

Page 54

SCHEDULE

REGIST button

Registers the called program without

overwriting a program of the same name with

it.

OK button Registers the called program by overwriting a

program of the same name with it.

O If the selected

program is registered

on the PROGRAM

display, the Confirm

overwrite display

opens as shown right.

3 Enter the number of worksheets to be processed, and press the

OK button. If you have called multiple programs, check their

names, and enter the number of worksheets to be processed for

each program.

NOTE

O The In rack, Out rack, and Reserve fields are for an autostorage unit.

If the machine is not equipped with an autostorage unit, it is not

necessary to enter any values in these fields.

O The MULTI RACK button is provided for using another autostorage. If

the machine is not equipped with another autostorage unit, the MULTI

RACK button is not necessary.

O The items shown on the Qty. input display vary with the settings made

on the Schedule monitor list item display opened by pressing the

CHANGE button on the Schedule monitor display as described on 9-9

in this Part.

4 The selected program is registered on the PRE-EDIT display.

I-46

Page 55

3-3. Saving program from PRE-EDIT display

REFERENCE

O For details of the display, refer to “3-1. Saving program from PRE-EDIT or

SCHEDULE display” in Part II, Program management.

1 Select the program you want to save, and press the SAVE button.

(You can select and save multiple programs at a time.)

2 Specify the destination, and press the OK button.

NOTE

O If the Confirm overwrite box is checked, the program to be overwritten

is shown in red characters on the next Confirm overwrite display.

3 Check the program to save, and press the EXECUTE button.

4 When the Saving data display changes to “Saved”, press the OK

button.

NOTE

O If the “Close automatically when process is complete” box is checked,

the display shown right will automatically close from the next time on.

5 After checking that the program is saved, press the OK button.

3-4. Transferring job to PROGRAM display

Select the job you want to transfer to the PROGRAM display.

Check that the automatic operating mode is PROGRAM, select the job

to be transferred to the PROGRAM display, and press the TRANS JOB

button.

NOTE

O If the automatic operating mode is PROGRAM, only one program can be

called.

O Change the automatic operating mode on the SCHEDULE or PROGRAM

display. It cannot be changed on the PRE-EDIT display.

I-47

Page 56

3-5. Transferring selected job

Press the TRANS JOB button to transfer the selected job to the

PROGRAM display.

NOTE

O If the CONFIRM button is pressed here, the data shown on the PROGRAM

display is deleted.

3-6. Transferring schedule to SCHEDULE

display

Transfer the schedule (all jobs) from the PRE-EDIT display to the

SCHEDULE display.

Check that the automatic operating mode is SCHEDULE.

To transfer a new schedule to the SCHEDULE display, press the

CONFIRM button.

To add another schedule to the schedule already transferred to the

SCHEDULE display, press the ADD button.

NOTE

O Change the automatic operating mode on the SCHEDULE or PROGRAM

display. It cannot be changed on the PRE-EDIT display.

O If the CONFIRM button is pressed here, the data shown on the SCHEDULE

display is deleted.

I-48

Page 57

4. SCHEDULE DISPLAY

Press the SCHEDULE button to

open the SCHEDULE display to read

a schedule, create a schedule, and

set the start and end jobs. You can

also check the setup of the machine

and check the part by drawing it

before operating the machine.

Operating mode change buttons

Change the automatic operating mode of the machine.

To perform the schedule operation of the machine, press the

SCHEDULE button.

Item Description

SCHEDULE button Performs the schedule operation of the

machine.

PROGRAM button Performs the single-program operation of the

machine.

CNC button Performs the CNC operation of the machine.

NOTE

O The automatic operating mode of the machine cannot be changed while it is

operating.

I-49

Page 58

4-1. Creating program from SCHEDULE

display

1 With no job selected, press the EDIT button.

REFERENCE

O For details of the display, refer to “1-1. Creating program from

PRE-EDIT or SCHEDULE display” in Part II, Program management.

2 Enter the program name, and press the G CODE button.

3 Enter the G code program in the left edit area.

4 After creating the program, press the DRAWINGS button to draw

the part according to the program in the right draw area, and

check the program.

NOTE

O If the drawn figure overfills the draw area, press the AUTOSCALE

button.

5 After checking the program, press the OK button.

4-2. Calling program from SCHEDULE

display

1 Press the OPEN button to open the OPEN display.

REFERENCE

O For details of the display, refer to “2-1. Calling program from PRE-EDIT

or SCHEDULE display” in Part II, Program management.

2 Press the source media, and press the SWITCH button to select

whether to call a program from the program data list or schedule

data list. Select the necessary data from the list, and press the

OK button.

Two or more programs can be called at a time.

If the program you want to call cannot be found although you have

saved it, it may be saved in another folder. Press the SEARCH

button to open the Search display. Enter the folder name in the

Folder name field, and search for the folder.

I-50

Page 59

NOTE

O If the selected

program is present as

job, the message

display appears as

shown right.

SCHEDULE

REGIST button

Registers the called program without

overwriting a program of the same name with

it.

OK button Registers the called program by overwriting a

program of the same name with it.

O If the selected

program is registered

on the PROGRAM

display, the message

display appears as

shown right.

3 Enter the number of worksheets to be processed, and press the

OK button. If you have called multiple programs, check their

names, and enter the number of worksheets to be processed for

each program.

NOTE

O The In rack, Out rack, and Reserve fields are for an autostorage unit.

If the machine is not equipped with an autostorage unit, it is not

necessary to enter any values in these fields.

O The MULTI RACK button is provided for using another autostorage. If

the machine is not equipped with another autostorage unit, the MULTI

RACK button is not necessary.

O The items shown on the Qty. input display vary with the settings made

on the Line setting display as described in this Part.

4 The selected program is registered on the SCHEDULE display.

I-51

Page 60

4-3. Saving program from SCHEDULE

display

1 Select the program you want to save, and press the SAVE button.

(You can select and save multiple programs at a time.)

REFERENCE

O For details of the display, refer to “3-1. Saving program from PRE-EDIT

or SCHEDULE display” in Part II, Program management.

2 Specify the destination, and press the OK button.

NOTE

O If the Confirm overwrite box is checked, the program to be overwritten

is shown in red characters on the next Confirm saved data display.

3 Check the program to save, and press the EXECUTE button.

4 When the Saving data display changes to “Saved”, press the OK

button.

NOTE

O If the “Close automatically when process is complete” box is checked,

the display shown right will automatically close from the next time on.

5 After checking that the program is saved, press the OK button.

4-4. Selecting start job

Specify the first job at which to perform the schedule operation of the

machine.

Select the start job, and press the START JOB button. The selected

job is indicated by a yellow arrow.

The schedule operation is started at the specified job and performed to

the last job.

I-52

Page 61

5. PROGRAM DISPLAY

Press the PROGRAM button to open

the PROGRAM display to show a

processing program. You can also

check the setup of the machine and

check the part by drawing it before

operating the machine.

OPERATING MODE

CHANGE

Operating mode change buttons

Change the automatic operating mode of the machine.

To perform the program operation of the machine, press the

PROGRAM button.

Item Description

SCHEDULE button Performs the schedule operation of the

machine.

PROGRAM button Performs the single-program operation of the

machine.

CNC button Performs the CNC operation of the machine.

NOTE

O The automatic operating mode of the machine cannot be changed while it is

operating.

I-53

Page 62

5-1. Creating program from PROGRAM

display

1 Change the automatic operating mode to PROGRAM, and press

the EDIT button.

REFERENCE

O For details of the display, refer to “1-2. Creating program from

PROGRAM display” in Part II, Program management.

2 Press the NEW button.

3 Enter the program name, and press the G CODE button.

4 Enter the G code program in the left edit area.

5 After creating the program, press the DRAWINGS button to draw