Page 1

Vipros 358 King User Pre-installation Guide Amada America Inc.

Vipros 358 King User Pre-installation Guide

Print Date 11/05/97 Page 1 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 2

Vipros 358 King User Pre-installation Guide Amada America Inc.

Warning

Qualified personnel must complete al l work.

Do not apply power to the Vipros 358 King until an A.E.S.I. (Amada

Engineering and Service Incorporated) Engineer is present and has

instructed you to do so.

Print Date 11/05/97 Page 2 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 3

Vipros 358 King User Pre-installation Guide Amada America Inc.

Contents

Contents....................................................................................................................................................3

Introduction ...............................................................................................................................................5

Motion Package Specifications.................................................................................................................6

Punching System Specifications...............................................................................................................7

58 Station - 4 Auto-Index Turret Configuration...................................................................................8

Fanuc O4PC CNC Controller....................................................................................................................9

Supply Requirem ent s ..............................................................................................................................10

Installing the Electrical Power Supply...............................................................................................11

Installing the Air Supply.....................................................................................................................12

Planning the Location of the Vipros 358 King.........................................................................................13

Lifting the Machine ............................................................................................................................14

Machine Dimensions - Plan View......................................................................................................15

Machine Dimensions - Elevation View..............................................................................................16

Machine Dimensions - End View ......................................................................................................17

Maintenance Areas ...........................................................................................................................18

The Chiller...............................................................................................................................................19

Chiller Placement..............................................................................................................................20

Connections.......................................................................................................................................21

Foundation Requirements.......................................................................................................................22

Machine Anchoring Requirements..........................................................................................................23

Print Date 11/05/97 Page 3 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 4

Vipros 358 King User Pre-installation Guide Amada America Inc.

Floor J-bolt Mounting Hole Detail (saw cut hole)..............................................................................23

Floor J-bolt Mounting Hole Plan View (saw cut hole).......................................................................24

Alternative Floor J-bolt Mounting Hole Detail (Core Drill).................................................................25

Alternative J-bolt Mounting Method Plan View (Core Drill)...............................................................26

Floor J-bolt Mounting Procedure.......................................................................................................27

Foundation Mo unti ng P roc edu re ............................................................................................................29

Foundation J-bolt Detail ....................................................................................................................29

Foundation Plan View .......................................................................................................................30

Foundation Elevation View................................................................................................................31

Removing the Protective Coating...........................................................................................................32

Machine Leveling....................................................................................................................................33

Rocking Test......................................................................................................................................34

Floor Condition: Crowning.................................................................................................................35

Floor Condition: Slope.......................................................................................................................36

Leveling Procedure ...........................................................................................................................37

Print Date 11/05/97 Page 4 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 5

Vipros 358 King User Pre-installation Guide Amada America Inc.

Introduction

This manual describes the tasks that the purchaser of a Vipros 358 King must complete before calling the service

organization to complete the installation and operator training.

An overview of the preparations is as follows:

Plan the location of the Vipros 358 King in the shop, taking into account all the maintenance areas indicated

on the floor plan.

Prepare the Vipros 358 King floor area as required.

Uncrate the Vipros 358 King and Fanuc O4PC control and place them on the floor.

Install the air supply.

Install the electri cal supply.

Remove the protective coating from the surface of the Vipros 358 King.

Anchor the Machine to the floor or foundation using the apropriate method described in this document

Note: It is the purchaser’s responsibility to install any safety devices to ensure the safety area.

Print Date 11/05/97 Page 5 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 6

Vipros 358 King User Pre-installation Guide Amada America Inc.

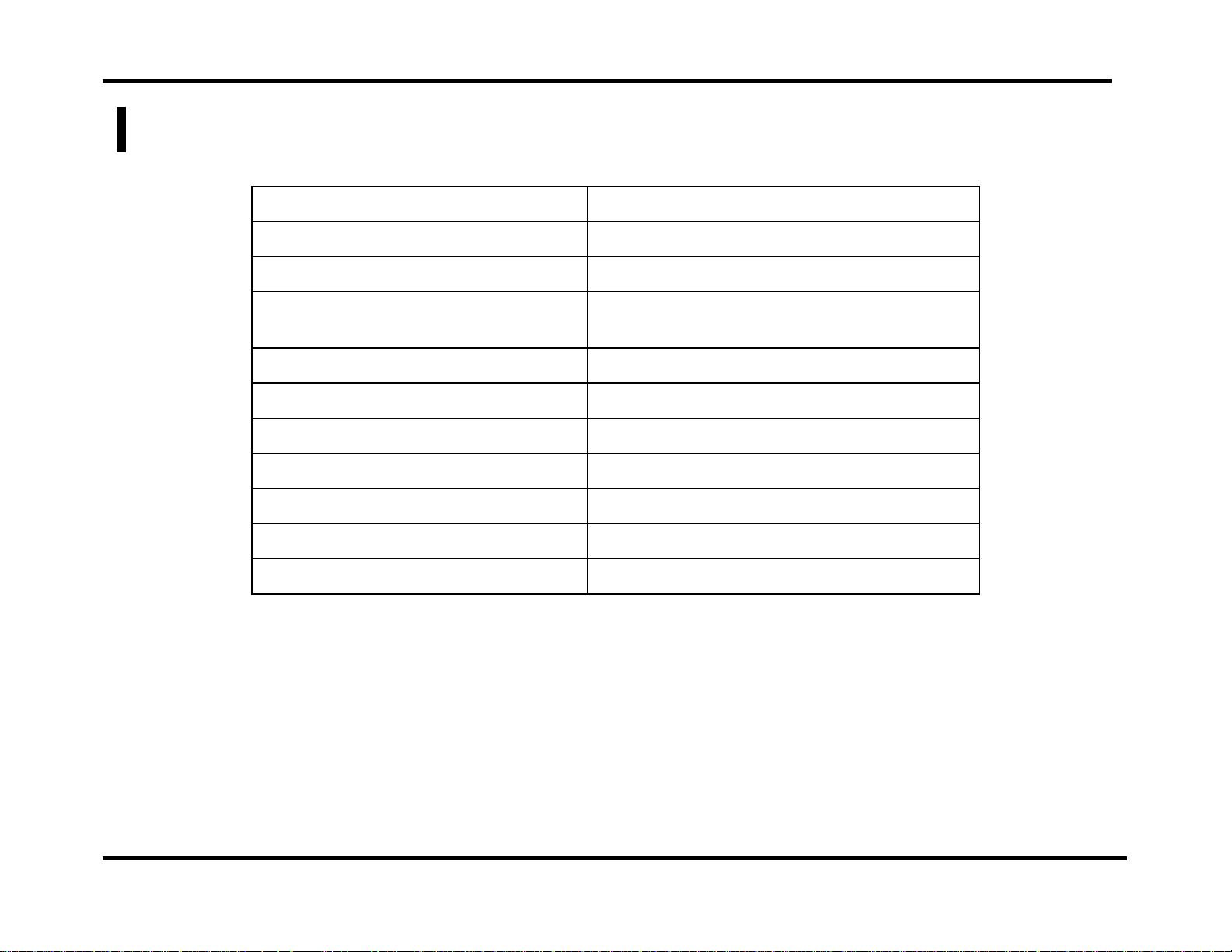

Motion Package Specifications

Travel Method X and Y axes work piece movement

Control Method X, Y, T & C

Drive Motors Fanuc AC Servo (X, Y, T, C)

Maximum Sheet Size 50.000" (Y) x 157.480" (X) with one

repositioning cycle

Maximum Sheet Thickness 0.125"

Maximum Material Weight 110 lb.

Maximum Axis Travel 78.740"(X) x 50.000"(Y)

Max. Linear Table Speed 3150 IPM

Punching Accuracy ±0.004"

Positioning Accuracy ±0.001"

Repeatability ±0.001"

Print Date 11/05/97 Page 6 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 7

Vipros 358 King User Pre-installation Guide Amada America Inc.

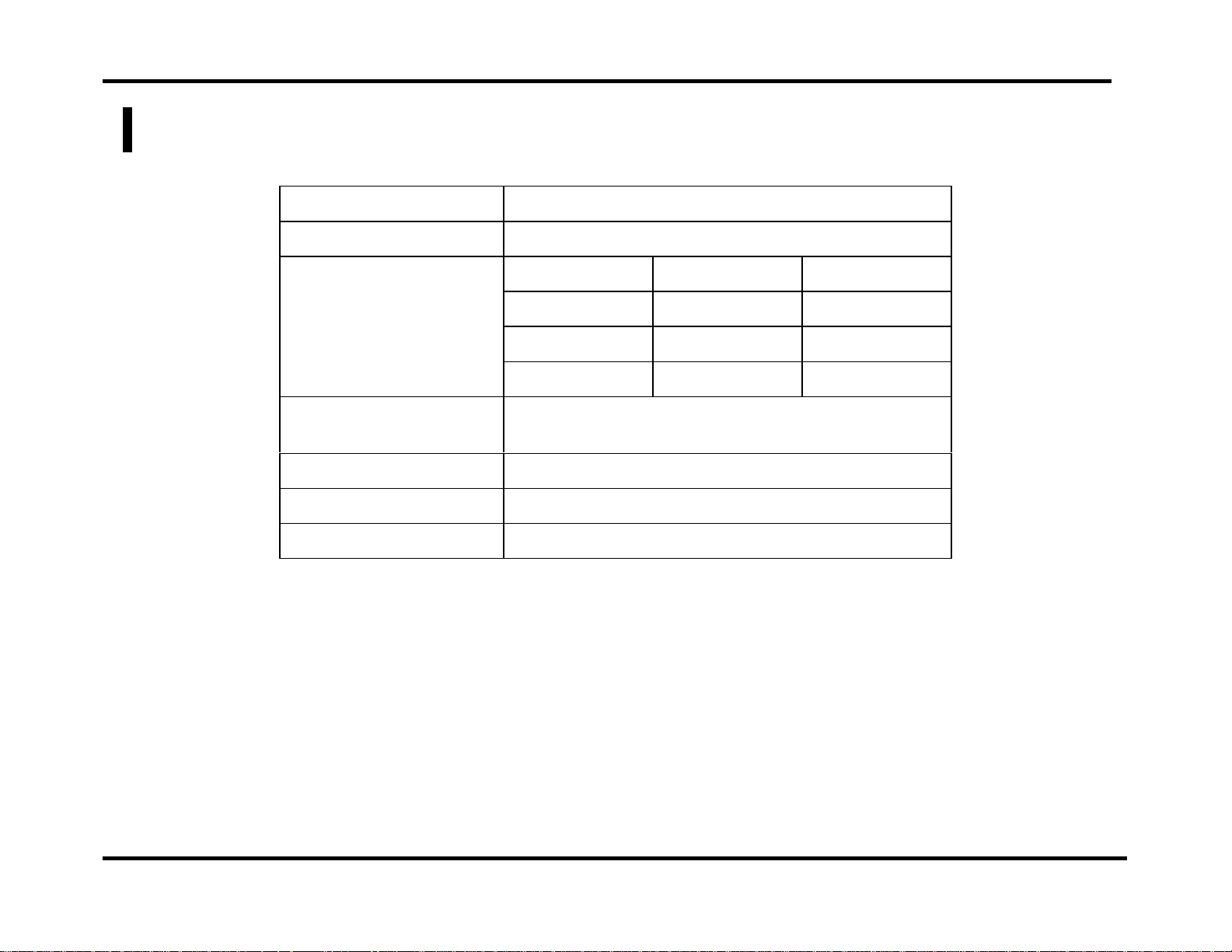

Punching System Specifications

Press Capacity 33 Tons

Press Stroke 1.256"

Stroke Rate (X/Y) Stroke Length Pitch Stroke Rate

0.315" 1.000" 300/375

0.178" 1.000" 375/375

0.178" 0.078" 600/600

Maximum Hole

Diameter

Tool Type Amada Thick Turret

Turret Rotation Speed 25 RPM

Turret Capacity 58 Stations (4 auto-index)

4.500"

Print Date 11/05/97 Page 7 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 8

Vipros 358 King User Pre-installation Guide Amada America Inc.

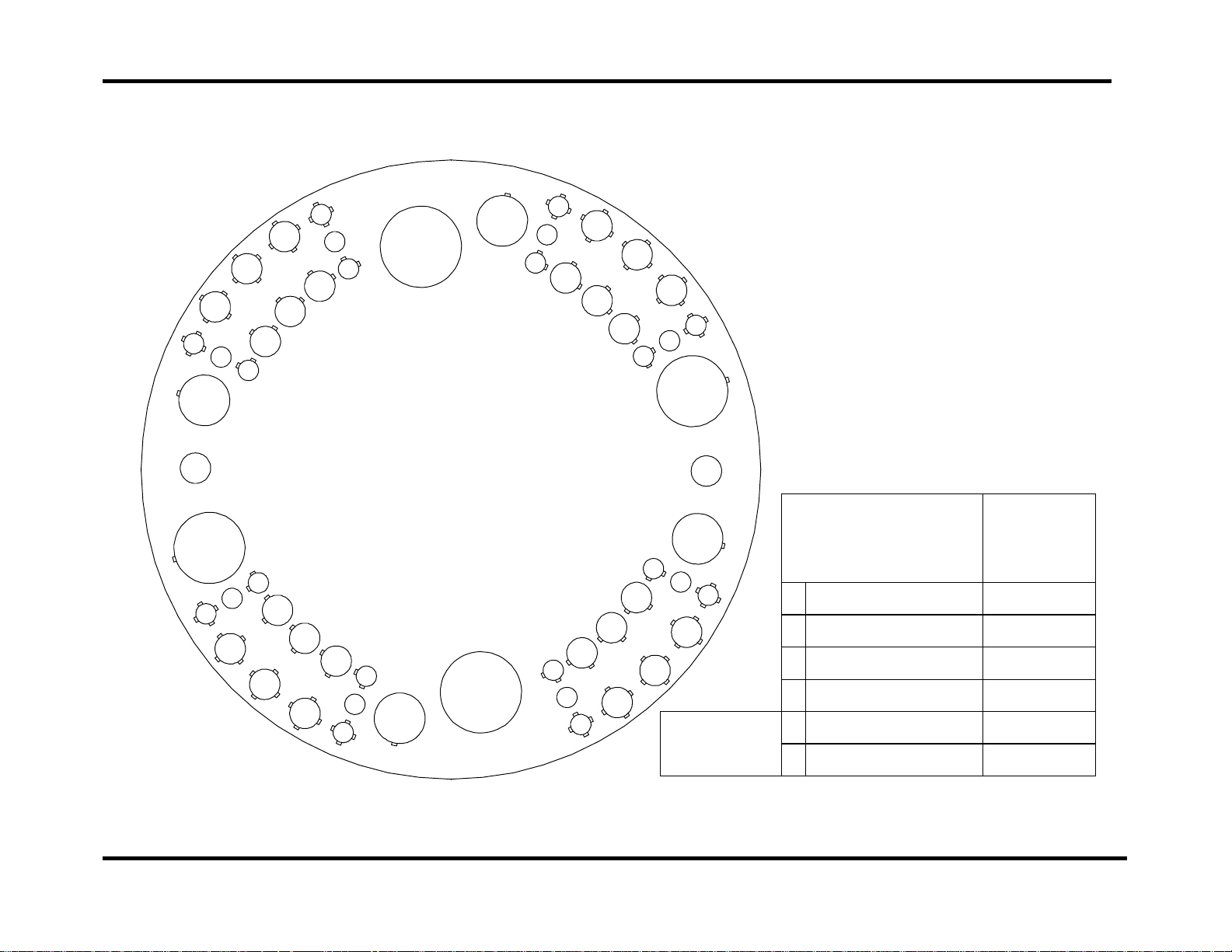

58 Station - 4 Auto-Index Turret Configuration

201

305

202

A/I

307

258

357

204

256

354

309

106

103

155

153

352

311

108

110

314

213

115

A/I

112

1200mm disk

216

117

58 STATION

4 AUTO INDEX

VIPROS 358 KING VIPROS 368 KING

VIPROS 558 VIPROS 568

PEGA 358S

151

350

149

146

247

245

348

144

A/I

141

242

218

120

343

319

139

321

122

137

124

126

132

340

323

135

325

227

229

231

233

336

338

Auto Index

328

A/I

334

230

A

B

C

D

B

E

Maximum

Size Round

½" (12.7mm)

1¼" (31.7mm)

2" (50.8mm )

3½" (88.9mm)

1¼" (31.7mm)

4½" (114.3mm)

Number of

Stations

(Keyed)

24 (16)

24 (24)

4 (4)

2 (2)

2 (2)

2 (2)

Print Date 11/05/97 Page 8 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 9

Vipros 358 King User Pre-installation Guide Amada America Inc.

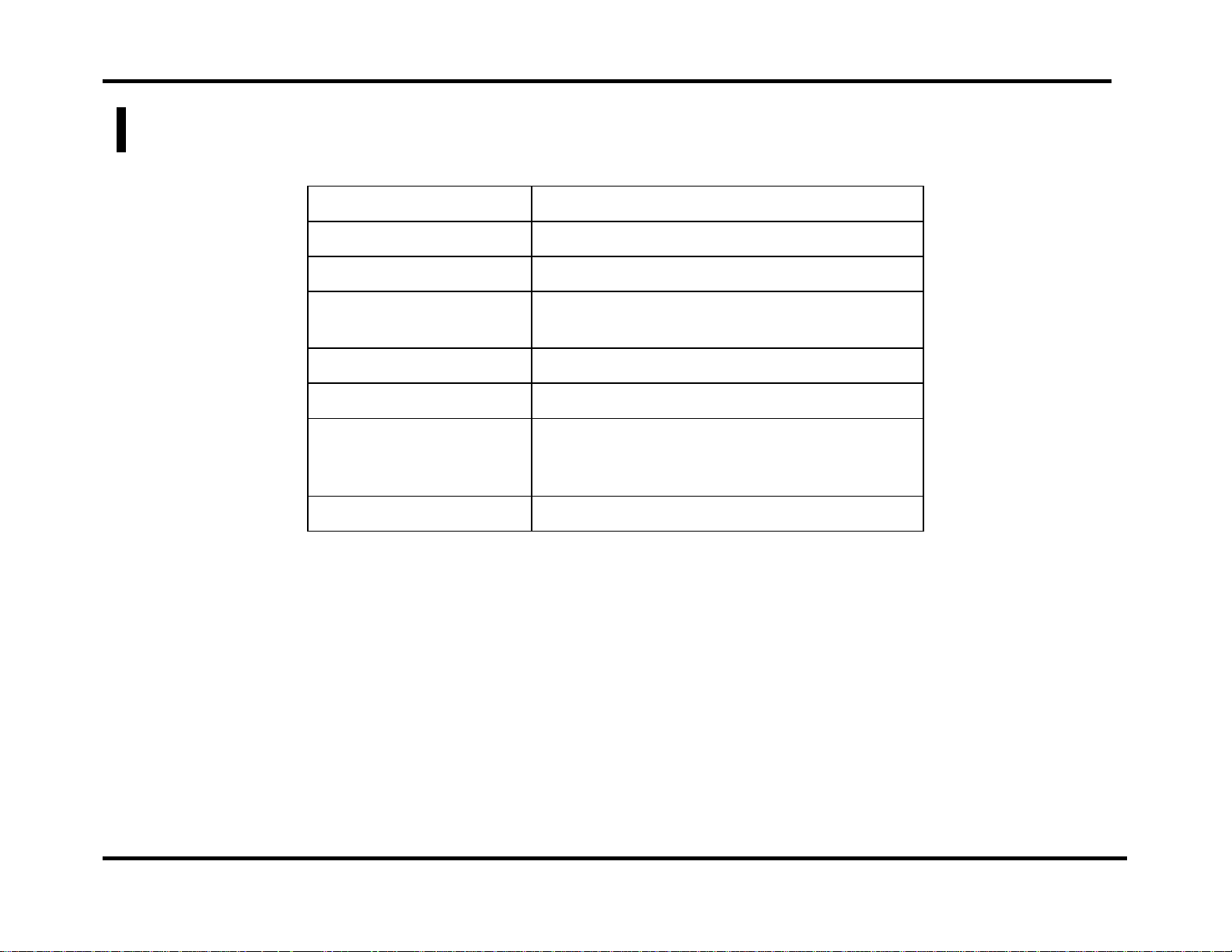

Fanuc O4PC CNC Controller

Model Fanuc O4PC

Control Function X, Y, T & C

Input Method MDI, Paper Tape, DNC

Minimum Command

Unit

Minimum Travel Unit 0.001" (X, Y) .010 (C)

Operating Modes Automatic, MDI & Manual

Display Modes

Interlock Displays Oil Temperature, Door Open

0.001" (X, Y) .010 (C)

Program Contents, Position Information,

Program Check, Parameters, Tool Hit

Counter, Self Diagnostics

Print Date 11/05/97 Page 9 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 10

Vipros 358 King User Pre-installation Guide Amada America Inc.

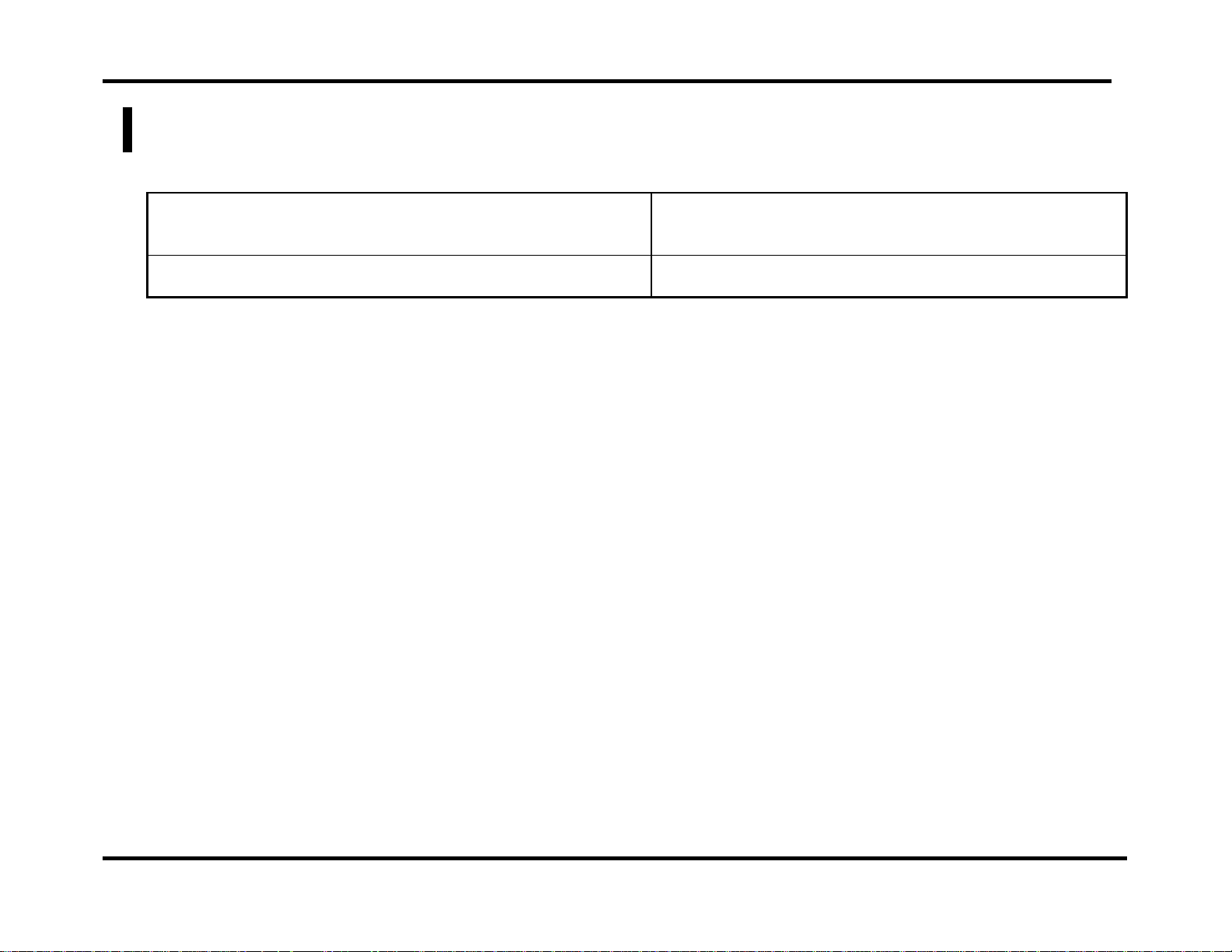

Supply Requirements

Electrical Power Supply Vipros 358 King

SBC-5.5 Chiller*

Air Supply 80 psi @ 8.8 ft³/min.

*Voltage must be specified when machine is ordered

230 / 460 3ph ±10%, 28 kVA

230 or 460 3ph ±10%, 15 kVA

Print Date 11/05/97 Page 10 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 11

Vipros 358 King User Pre-installation Guide Amada America Inc.

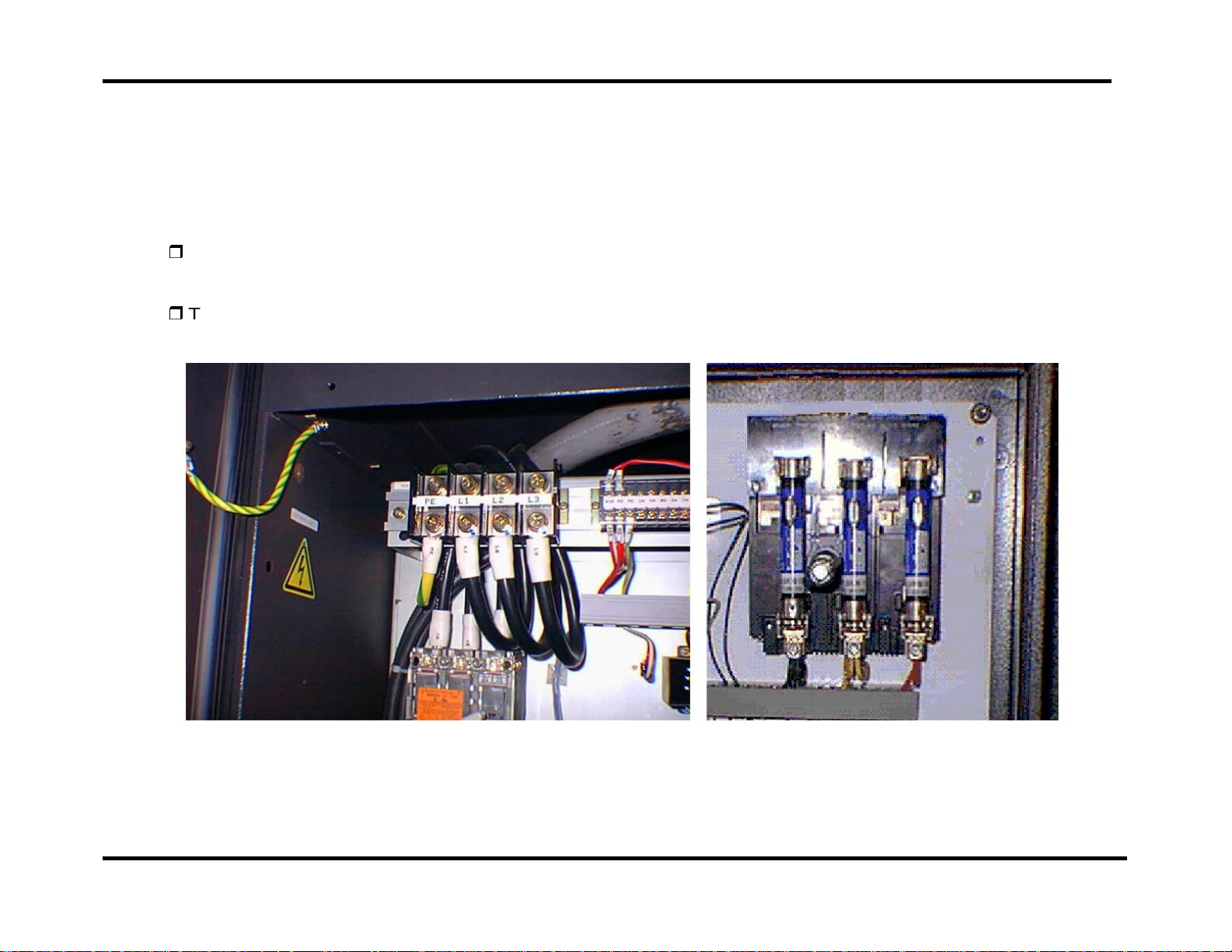

Installing the Electrical Power Supply

The Vipros 358 King requires two electrical power sources. The first power source is supplied to the Fanuc O4PC

control. The Fanuc O4PC control should be supplied from a power line separate from those used for welding machines

or other machines that produce electrical noise. The second source is connected to the SBC-5.5 chiller.

The Vipros 358 King electrical inlet is 60" above floor level inside the magnetic enclosure located to the rear of

the Fanuc O4PC control.

The SBC-5.5 chiller electrical inlet is 48" above floor level at the end of the chiller.

Vipros King SBC 5.5 Chiller

Print Date 11/05/97 Page 11 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 12

Vipros 358 King User Pre-installation Guide Amada America Inc.

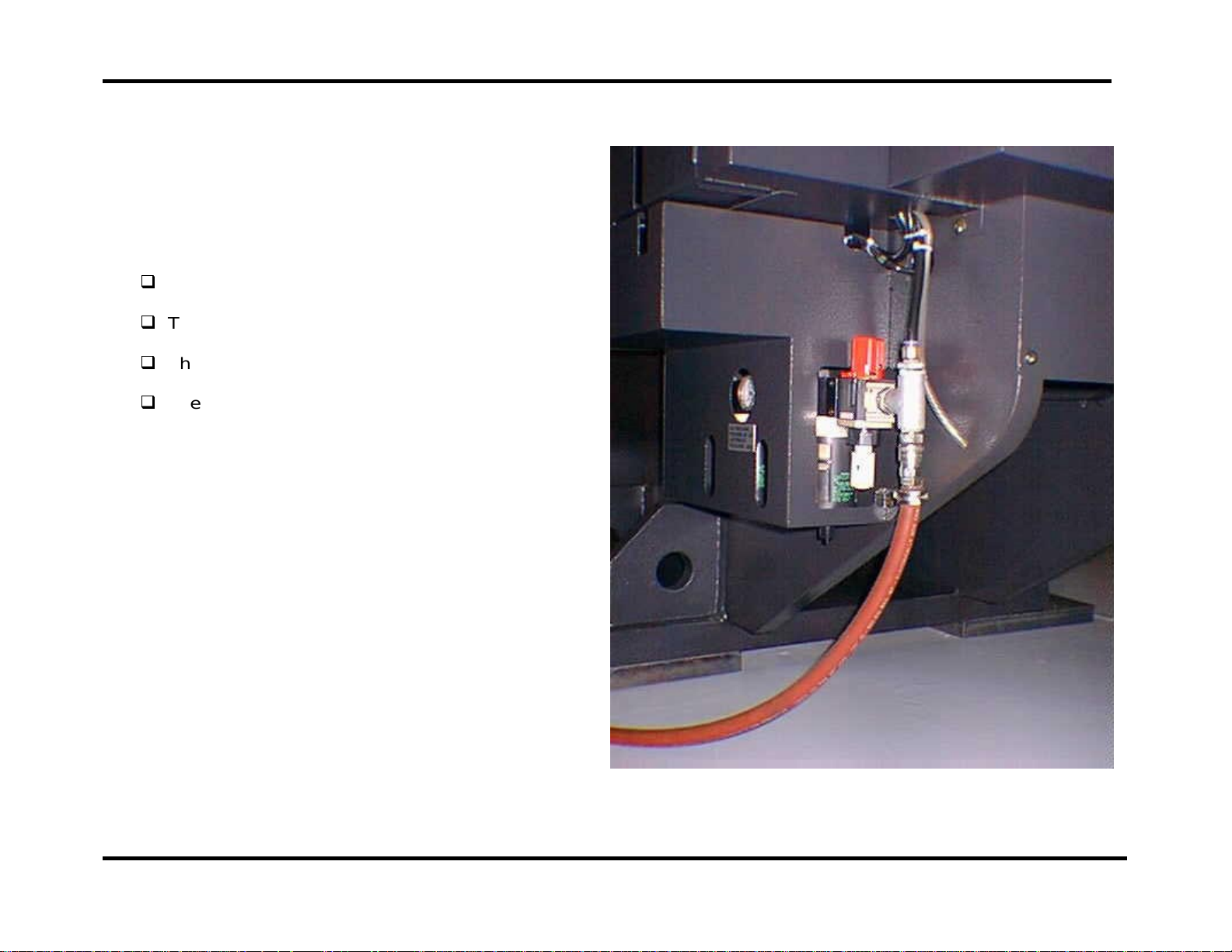

Installing the Air Supply

The Vipros 358 King must be connected to a

compressed air system by hose or pipe. The

compressed air must be clean and dry.

Please note the following:

The minimum inner pipe diameter is ½".

The air pressure required is 80 psi.

The air volume required is 8.8 ft³/min.

The air inlet is approximately 16" above the floor

level at the rear of the Vipros 358 King.

Print Date 11/05/97 Page 12 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 13

Vipros 358 King User Pre-installation Guide Amada America Inc.

Planning the Location of the Vipros 358 King

The following diagrams provide the details for positioning the Vipros 358 King.

No obstacles are allowed in the worksheet travel area and the ceiling must be at least 40" above the top of

the Vipros 358 King.

All of the maintenance areas recommended should be used, but at a minimum you must ensure that the

doors of the Fanuc O4PC CNC unit can be opened.

The Vipros 358 King, Fanuc O4PC control, and SBC-5.5 chiller must be protected from direct sunlight or

other heat sources.

The floor must be of sufficent quailty to addiquitly support the wieght of the machine. See

Procedure

for details.

Floor Mounting

Print Date 11/05/97 Page 13 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 14

Vipros 358 King User Pre-installation Guide Amada America Inc.

Lifting the Machine

Machine Weight 16 tons.

Lifting lugs front and rear of

Machine Frame.

This cover

may need to

be removed

121."

VIPROS

This cover

may need to

be removed

358

KING

Print Date 11/05/97 Page 14 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 15

Vipros 358 King User Pre-installation Guide Amada America Inc.

Machine Dimensions - Plan View

Print Date 11/05/97 Page 15 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 16

Vipros 358 King User Pre-installation Guide Amada America Inc.

Machine Dimensions - Elevation View

Material

Pass

Line

96.5"

39.6"

Floor Level

1.3"

11.4"

45.5"

38.3"

Turret Center

62.2"

55.1"

37.4"38.0"

19.7"

9.8"

103.1"

179.1"

Punch Center

7.1"

50.0"

8.3"

27.6"

Y Axis Zero

38.0"55.9"

19.7"

1.2"

Hydraulic

Unit

CNC Unit

55.2"

63.0"

Print Date 11/05/97 Page 16 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 17

Vipros 358 King User Pre-installation Guide Amada America Inc.

Machine Dimensions - End View

Print Date 11/05/97 Page 17 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 18

Vipros 358 King User Pre-installation Guide Amada America Inc.

Maintenance Areas

81.1"

Print Date 11/05/97 Page 18 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 19

Vipros 358 King User Pre-installation Guide Amada America Inc.

The Chiller

The Chiller Unit is very important to the reliable operation of the Vipros 358 King.

The Chiller must be placed so that an adequate flow of air is maintained.

The position of the Chiller is flexible. The Vipros 358 King is supplied with two (2) fifteen-foot lengths of

hose to connect the Chiller to the Hydraulic Unit. The customer may supply a longer length of hose if

required.

Under normal operating conditions the Chiller may be placed against walls as shown. However for

maintenance purposes access to all sides of the Chiller may be required.

The Chiller must have a minimum of 60" of clearance above the Chiller for proper airflow.

Print Date 11/05/97 Page 19 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 20

Vipros 358 King User Pre-installation Guide Amada America Inc.

,,

yy

{{

Chiller Placement

Print Date 11/05/97 Page 20 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 21

Vipros 358 King User Pre-installation Guide Amada America Inc.

Connections

Hydraulic Unit Chiller

Print Date 11/05/97 Page 21 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 22

Vipros 358 King User Pre-installation Guide Amada America Inc.

Foundation Requirements

The Vipros 358 King does not require a special foundation to perform as expected, however there are minimum

requirements that an existing floor must meet in order to assure machine reliability and tool life. If the existing floor

does not meet the following minimum requirements, plans for a recommended foundation are given in the section

Foundation Mounting Procedure

The minimum acceptable floor conditions to assure a successful installation are:

The area of the floor where the machine frame is to be located must be a single, homogeneous slab in good

condition. There must be no cracks or other signs of deterioration of the floor.

The floor must be 4" to 6" thick.

The floor must be capable of supporting 3.5 tons/ft².

The floor must be level to 0.032"/ft.

If the existing floor meets the minimum requirement list above, it must still be inspected carefully when the anchor

boltholes are cut. Voids under the floor, or wetness (not associated with the hole cutting procedure) should be

considered signs of an inadequate floor and a new machine location or new foundation must be considered.

It is the customer’s responsibility to determine that the floor meets these minimum requirements. Placing the machine

on an inadequate, cracked floor, or straddling seams in a floor may be grounds for voiding the machine warranty!

Amada America, Inc. does not recommend the use of vibration isolating mounts under the machine feet, as these

devices have been shown to increase the vibration within the machine frame, increasing the likelihood of vibration

related problems. Solid leveling devices are acceptable provided they incorporate a means of anchoring the machine

to the floor with the supplied J-bolts.

Print Date 11/05/97 Page 22 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 23

Vipros 358 King User Pre-installation Guide Amada America Inc.

Machine Anchoring Requirements

To maintain machine reliability, extend tool life, and remain level over an extended period the Vipros 358 King must be

anchored in place on an adequate floor or foundation.

At a minimum the floor must consist of a single, homogeneous slab, level to within 0.032"/ft², and capable of supporting

3.5 tons/ft². It is the purchaser’s responsibility to determine that the floor meets these minimum requirements.

Floor J-bolt Mounting Hole Detail

(saw cut hole)

This machine mounting method should be used only if the

floor is of such quality that it will support the weight of the

machine with the anchor J-bolts used only for maintaining

the location of the machine.

Machi ne Foot

Base Plate

Saw cut hole in foundation

Machine Foot

5.0"

Floor Line

Supplie d J -bolt

24.00"

7.0"

15.75"

5."

10.00"

Print Date 11/05/97 Page 23 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 24

Vipros 358 King User Pre-installation Guide Amada America Inc.

Floor J-bolt Mounting Hole Plan View (saw cut hole)

Print Date 11/05/97 Page 24 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 25

Vipros 358 King User Pre-installation Guide Amada America Inc.

Alternative Floor J-bolt Mounting Hole Detail

(Core Drill)

This machine mounting method should only be used if

the floor is of such quality that it will support the weight

of the machine with the anchor J-bolts used only for

maintaining the location of the machine.

10" Diameter Core Drill

hole in existing fl oor

A

Machine Foot

A

Floor Line

Supplied J-bol t

A

Print Date 11/05/97 Page 25 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 26

Vipros 358 King User Pre-installation Guide Amada America Inc.

Alternative J-bolt Mounting Method Plan View (Core Drill)

Print Date 11/05/97 Page 26 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 27

Vipros 358 King User Pre-installation Guide Amada America Inc.

Floor J-bolt Mounting Procedure

Step 1. Saw cut or Core drill a hole in the existing floor

and remove the underlying dirt to the required

24" depth.

See

Floor J-bolt Mounting Hole Plan View (saw

cut hole)

Plan View (Core Drill

dimensions of the four anchor holes required.

Step 2. Set base plate over the hole.

or

Alternative J-bolt Mounting Method

for correct layout

Step 3. Set the machine on the base plate.

Print Date 11/05/97 Page 27 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 28

Vipros 358 King User Pre-installation Guide Amada America Inc.

Step 4. Set the J-bolt through the hole in machine foot;

attach washer and nut to hold J-bolt in place.

Step 5 Pour the Concrete.

Ensure that the J-bolt remains correctly aligned

to the machine frame during the pouring and

hardening time of the concrete.

Ensure that the concrete level is equal to the

floor level

Step 6. To complete the mounting procedure, level the

machine frame by inserting leveling shims

between the machine foot and base plate.

See

Leveling the Machine

procedure.

Print Date 11/05/97 Page 28 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

section for correct

Page 29

Vipros 358 King User Pre-installation Guide Amada America Inc.

Foundation Mounting Procedure

An ideal foundation is given on the following pages. This foundation must be used if the existing floor cannot meet the

minimum requirements to support the machine.

The foundation must consist of a single, homogeneous slab. The foundation must be level to within 0.032" / ft.

Anchoring the Vipros 358 King to the floor using the anchor-bolts supplied is essential to ensure reliable performance.

Amada generally recommends that the foundation have a minimum load bearing capacity of 3.5 ton/ft2. It is the

purchaser’s responsibility to determine that the foundation meets these requirements.

Please note the following:

The base plates, shims, anchor bolts, nuts, and washers

are shipped with the Vipros 358 King.

The concrete J-bolt pads should be filled after the machine

is placed on the foundation.

Foundation J-bolt Detail

See

J-bolt Mounting Procedure

machine on foundation.

for proper method of mounting

Machine Foot

Foundation Line

Supplied J-bolt

Anchor hole in foundatio n

Machine

Fram e

5.0"

24.00"

7.0"

15.75"

Machine Foot

Base Plate

5."

10.00"

Print Date 11/05/97 Page 29 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 30

Vipros 358 King User Pre-installation Guide Amada America Inc.

Foundation Plan View

151.1"

96."

48."

48."

24."

103.1"

J-bolt Centerline

Machine Centerline

29.5" J-bolt Centerline

14.75"

Print Date 11/05/97 Page 30 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 31

Vipros 358 King User Pre-installation Guide Amada America Inc.

Foundation Elevation View

Print Date 11/05/97 Page 31 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 32

Vipros 358 King User Pre-installation Guide Amada America Inc.

(

)

)

Removing the Protective Coating

The Vipros 358 King must be thoroughly cleaned of protective coating. The sheet metal guards can be removed from

around the turret to allow cleaning of the upper and lower turrets, tool bores and die holders.

Please note the following:

Remove the wrapping paper from the

X and Y-axes ball screws then

remove the protective coating.

Remove the wrapping paper from the

X and Y LM guides then remove the

protective coating, make sure that you

remove the paper from both sides of

the carriage.

Clean die holders one at a time.

Remove a die holder, clean and

replace it before removing the next

die holder. If the die holders are

mixed up, serious turret alignment

problems may occur.

A suitable solvent should be used to

remove the protective coating.

Y AXIS BALL SCREW

UPPER AND LOWER TURRETS

Y AXIS LM GUIDES

X AXIS BALL SCREW

X AXIS LM GUIDES (TOP AND BOTTOM

1 EACH SIDE

Print Date 11/05/97 Page 32 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 33

Vipros 358 King User Pre-installation Guide Amada America Inc.

Machine Leveling

Proper Machine leveling is critical to the Vipros 358 King performing as designed.

Materials and tools required:

Supplied with the machine:

Assorted thickness machine leveling shim stock

Anchor bolts

Supplied by AESI servi ce:

Spirit level capable of reading 0.0005"/ft

One (1) 12 ton hydraulic bottle jack

Not supplied:

Additional shim stock of 0.005" thickness may be required to achieve a properly leveled machine.

Print Date 11/05/97 Page 33 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 34

Vipros 358 King User Pre-installation Guide Amada America Inc.

Rocking Test

After the machine frame has been leveled the use of the following G-code is necessary to determine that the machine

frame is properly leveled and balanced.

Should the machine frame vibrate or move excessively during the rocking test the machine frame must be re-leveled

using the procedure in this manual.

Should the proper leveling technique not eliminate the excessive frame motion, consideration must be given to

relocation of the machine or replacement of the existing floor with an adequate foundation.

G92 X78.740 Y50.000

G06 A.100B0

N1

G91 X-.250 T

X.250

M97 P1

G50

(Use any valid tool number)

TTT

Print Date 11/05/97 Page 34 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 35

Vipros 358 King User Pre-installation Guide Amada America Inc.

Floor Condition: Crowning

The flatness of the floor plays an important step in the

leveling procedure of the machine. To properly level the

machine the weight bearing points must be as far from the

centerline of the machine frame as possible.

Should a condition known as crowning exist the weight

bearing points of the machine may not be far enough from

the machine centerline to ensure a stable machine.

Under these conditions a procedure known as

Shimming

should be used.

Half-

To move the weight bearing points further from the

machine centerline the use of half-shims of .125" thick on

top of the base plate as shown is recommended.

After the half-shims are installed and the machine frame

is leveled use the rocking test to determine that the

machine frame is stable enough to allow production

without damaging the machine.

Under extreme conditions the use of half-shims may not

move the machine weight bearing points far enough from

the machine centerline to ensure the machine frame is

stable.

Base Plate

Crowned

Floor

Base Plate

Crowned

Floor

Machine

centerline

Machine Foot

Base Plate

Weight

Bearing Point

Machine

centerline

Machine Foot

Base Plate

Weight Bearing Point

Half-shim

Under these conditions a more suitable location must be

found for the machine, or a new foundation for the

machine will be necessary.

Print Date 11/05/97 Page 35 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 36

Vipros 358 King User Pre-installation Guide Amada America Inc.

Floor Condition: Slope

The slope of the floor plays an important step in the

leveling procedure of the machine. To properly level the

machine the weight bearing points must be as far from the

centerline of the machine frame as possible.

Should the floor slope excessively the weight bearing

points of the machine may not be far enough from the

machine centerline to ensure a stable machine.

Under these conditions a procedure known as

Shimming

should be used.

Half-

To move the weight bearing points further from the

machine centerline the use of half-shims of .125" thick on

top of the base plate and leveling shims as shown is

recommended.

After the half-shims are installed and the machine frame

is leveled, use the rocking test to determine that the

machine frame is stable enough to allow production

without damaging the machine.

Under extreme conditions the use of half-shims may not

move the machine weight bearing points far enough from

the machine centerline to ensure the machine frame is

stable.

Machine Foot

Base Plate

Weight Bearing Point

Sloped Floor

Machine Foot

Base Plate

Weight Bearing Point

Sloped Floor

Machine

centerline

Base Plate

Shim

Machine

centerline

Shim

Base Plate

Half-shim

Under these conditions a more suitable location must be

found for the machine, or a new foundation for the

machine will be necessary

.

Print Date 11/05/97 Page 36 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 37

Vipros 358 King User Pre-installation Guide Amada America Inc.

Leveling Procedure

1) Determine the high end of machine frame by placing the spirit

level on the turret to measure the level of the machine frame

in the y-axis.

.0005"/ft

2) Use the bottle jack to lift the low end of the machine frame.

Shim equally between both machine feet and the base plates

until the machine frame measures near level on the y-axis

with the turret end of the machine frame slightly higher than

the carriage end.

Shim Equaly Both Sides

Bottle

Jack

3) Center the bottle jack under the carriage end of the machine

frame.

Lift the machine frame until all weight is off of the machine

feet at the carriage end of the machine frame.

Lift the machine frame as little as possible to take the weight

Remove weight

of machine from

base plates

Bottle

Jack

off of the base plates.

Print Date 11/05/97 Page 37 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 38

Vipros 358 King User Pre-installation Guide Amada America Inc.

4) With the machine supported on the bottle jack at the carriage

end of the machine frame and the machine feet at the turret

end of the machine frame, place the spirit level on the turret.

.0005"/ft

Measure and record the level of the turret in the x-axis

direction.

Lower the machine frame to place all machine feet in contact

with the leveling shims and base plates.

5) Lift the turret end of the machine frame to allow shimming

between the machine feet and base plates to level the

machine frame in the x-axis direction.

Repeat steps 3 to 5 until the machine frame measures level to

0.0005"/ft in step 4, then continue.

Shim to

level X-axis

Bottle

Jack

6) With the bottle jack supporting the weight of the carriage end

of the machine monitor the level of the turret in the x-axis as

the bottle jack is slowly lowered to place the carriage end

machine feet in contact with the base plates.

Any change in the level indicates that the carriage end of the

machine needs to be leveled.

Remove weight

of machine from

base plates

Bottle

Jack

Print Date 11/05/97 Page 38 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 39

Vipros 358 King User Pre-installation Guide Amada America Inc.

7) Lift the carriage end of the machine frame to allow shimming

between the machine feet and base plates to level the

carriage end of the machine frame in the x-axis direction.

Repeat steps 6 and 7 until no difference in level is noted when

the machine weight is on or off of the base plates and shims,

then continue.

Shim to

level X-axis

Bottle

Jack

8) With all of the machine feet setting on the shims and base

plates place the spirit level on the turret to measure and note

the level of the machine frame in the y-axis.

.0005"/ft

9) Using the bottle jack lift the low end of the machine frame and

shim equally under both machine feet to level the machine

frame in the y-axis.

Repeat steps 8 to 9 until the machine frame measures level to

0.0005"/ft in the y-axis, then continue.

Shim Equaly Both Sides

Bottle

Jack

Print Date 11/05/97 Page 39 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 40

Vipros 358 King User Pre-installation Guide Amada America Inc.

10) Run the machine using the rocking test G-code to determine

that the machine frame is leveled adequately. Should

excessive movement of the machine frame be noticed check

for the conditions discussed in

Floor Condition Slope

11) Tighten the anchor bolt nuts to prevent the machine frame

from moving when in use. Monitor the machine level while

tightening the anchor bolts to assure the machine level is not

changed.

12) Lower and lock the outrigger weight support feet in place.

.

Floor Condition Crowning

and

Print Date 11/05/97 Page 40 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Page 41

Vipros 358 King User Pre-installation Guide Amada America Inc.

Amada America Inc.

7025 Firestone Blvd.

Buena Park CA. 90621

Phone: (714) 739 2111

Fax: (714) 739 4099

e-mail: info@amada.com

Print Date 11/05/97 Page 41 of 41

This document available on the World Wide Web at http://amada.com/support/pdf/v358kuig.pdf

Loading...

Loading...