Page 1

NC TURRET PUNCH PRESS

ARIES 222, 224

PROGRAMMING MANUAL

PRO-01198908

Copyright © 1998 by Amada Engineering & Service Co., Inc.

14921 East Northam Street, La Mirada, CA 90638

All rights reserved. No part of this book shall be reproduced, stored in a retrieval system, or transmitted by

any means, electronic, mechanical, photocopying, recording, or otherwise, without written permission from

the publisher. No patent liability is assumed with respect to the use of the information contained herein.

While every precaution has been taken in the preparation of this book, the publisher assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use

of the information contained herein.

Page 2

PROGRAMMING BASICS

CONTENTS

PROCESS FOR THE PRODUCTS

PROGRAMMING

CALCULATION OF COORDINATES

BASIC FUNCTION CODES

TAPE FORMAT ......................................................

G92 - ESTABLISHING COORDINATE SYSTEM

G90 -

ABSOLUTE PROGRAMMING

.G91 -

INCREMENTAL PROGRAMMING

G70 - PUNCH OFF (NO PUNCHING)

G27 - AUTO REPOSITIONING

G25 -

AUTO REPOSITIONING

G50 - HOME RETRACT

GO4 - DWELL .......................................................

MOO - PROGRAM STOP

MO1 -

OPTIONAL STOP

MO8 - PUNCH DELAY START, MO9 - PUNCH DELAY CANCEL..

Ml2 -

TOO - DESIGNATION OF TOOL NUMBER

No000 -

FO- DESIGNATION OF AXIS FEED SPEED

PROGRAM NAME

PROGRAMMING PROCEDURE

HINTS ON PROCESSING

CALCULATING LONG RECTANGULAR HOLE

CALCULATING LARGE RECTANGULAR. OPENING

CALCULATING RECTANGULAR OPENING WITH ROUNDED CORNERS

CALCULATING 45” NOTCH

HINTS ON PROGRAMMING

HINTS ON AUTO REPOSITIONING

illBBLlNG

SEQUENCE NUMBER

.......................................................

.............................................

..............................................

..............................................

..............................................

START, Ml3 - NIBBLING CANCEL

....................................................

..............................................

.......................................

..................................... l-3

...........................

....................................

...................................

.................

........................................

..........................................

.............................. l-9

......................................

............................

.........................................

.......................

:.

.........................................

.................

.....................................

.;.

.-.

................ l-5

........

.......

.......................

.......................

.:.

.........

:...l-15

..... 1-19

l-l

1-2

1-4

1-4

l-4

1-5

l-!!-

l-6

l-7

l-7

l-7

1-B

l-8

l-8

l-9

l-9

l-10

l-10

l-l

l-13

l-17

1-22

l-25

l-26

1.

Page 3

,.

I.:..

BASIC SOFTWARE

972 -

DESIGNATION OF PATTERN ORIGIN

G28 - LINE AT ANGLE 2-2

G29 - ARC ..

..~....................................................2-

G26 - BOLT HOLE CIRCLE

..............................................

...........................................

............................

2-l

4

2-6

G36 - GRID-X, G37 - GRID-Y ....................................... 2-8

G66 - SHEAR PROOF

G67 -

SQUARE ..................................................... 2-12

G68 - NIBBLING ARC ..

...................

.;.

.......................................... 2-14

............................

.:.

2-10

G69 - NIBBLING LINE ............................................... 2-16

G78 - PUNCHING ARC ................................................. 2-18._

G79 - PUNCHING LINE .............................

.-.

............... 2-20

PATTERN MEMORY AND PATTERN RECALL............................. 2-21

G93 - OFFSET ....................................................... 2-23

MACRO FUNCTION .................................................. 2-25

BLOCK DELETION ................................................... 2-29

INPUT OF DECIMAL POINT ........................................... 2-29

MULTIPLE PART PUNCHING

GENERAL DESCRIPTION.AND PROGRAMMING EXAMPLE . . . . . . . . . . . . . . . . 3-l

G98 - SETTING OF REFERENCE POINT AND LAYOUT FOR

MULTIPLE PART PUNCHING’ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

UOO TO

Voo -

STORING OF PART PROGRAM . . . . . . . . . . . . . . .

.,. _.

. . . . 3-8

G75, G76 Woo 00 -RECALLING AND EXECUTION OF

PART PROGRAM . . . . . . . . . _ . . . . _. . . . . . . . _ _. . . . . . . 3-10

TRIAL PUNCHING, POST-TRIAL PUNCHING, AND FULL PUNCHING . . . . . . . 3-14

.,

....

. .

.I I’

--:

I.,.,

:’

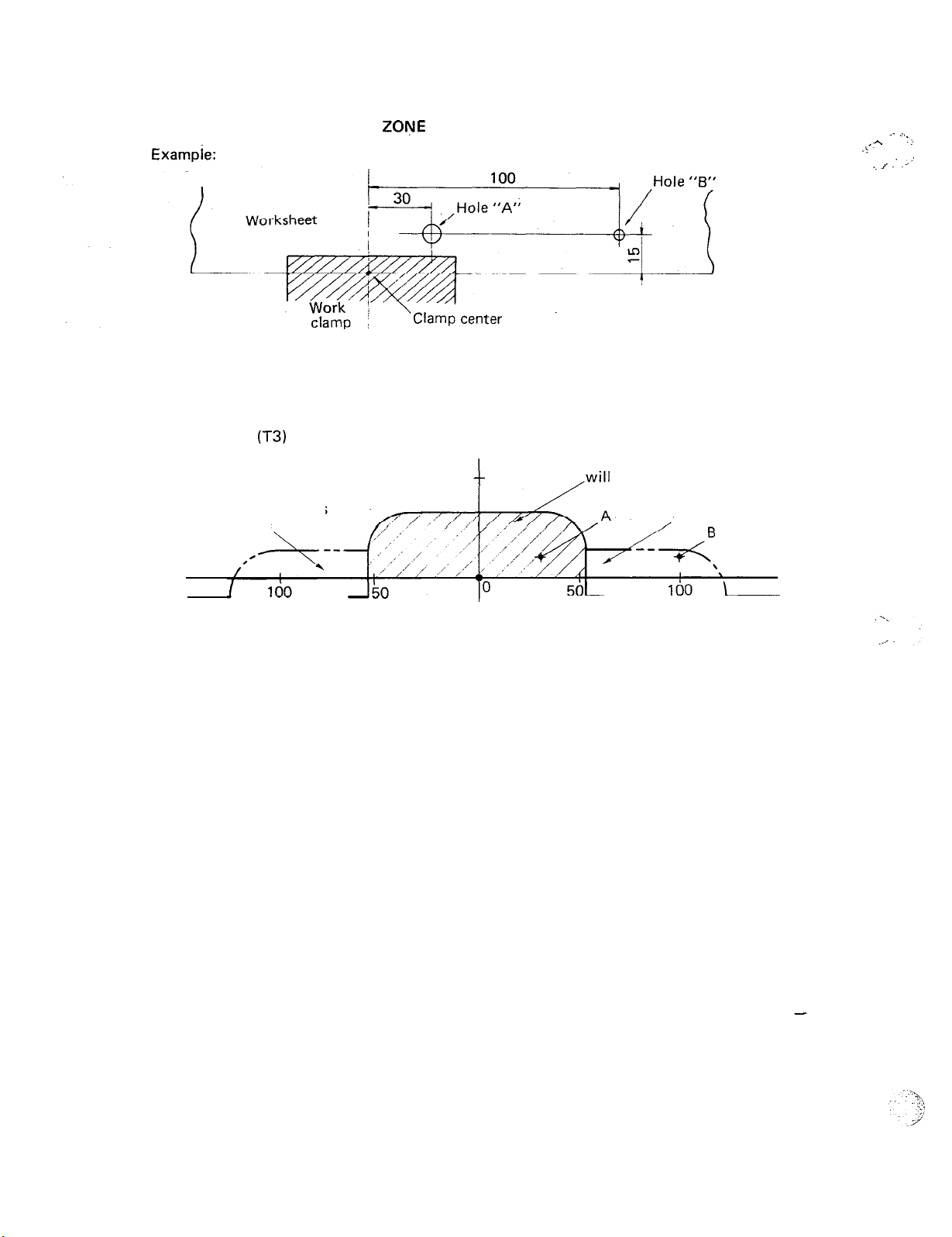

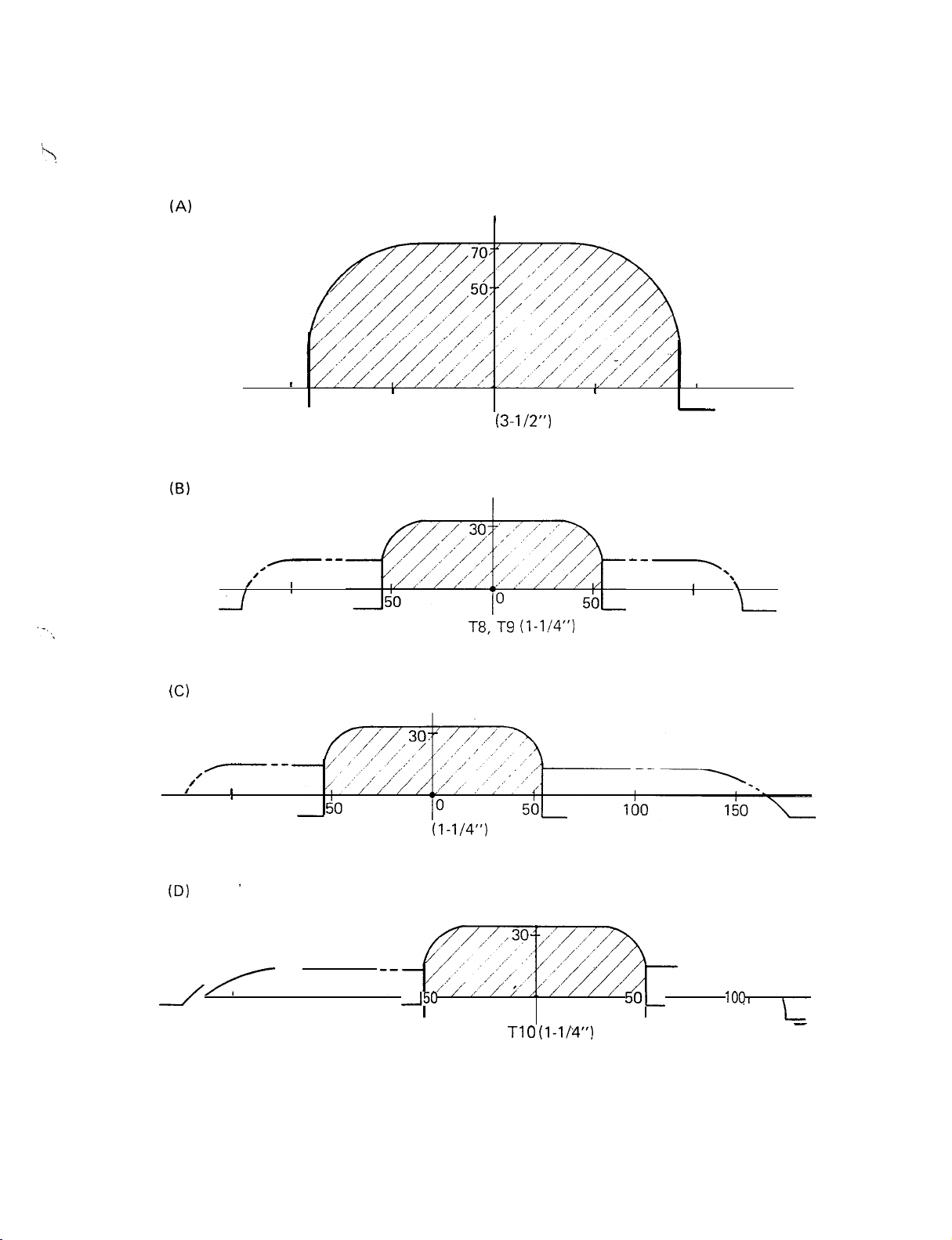

CLAMP DEAD ZONE DIAGRAM

CLAMP DEAD ZONE

HOW TO USE DEAD ZONE DIAGRAMS

DEAD ZONE DIAGRAMS

................................................. 4-l

................................ 4-2

.............................................. 4-3

(APPENDIX) ‘PROGRAMMING EXAMPLE

EX. 1 GENERAL PUNCHING ...........................................

5-1

EX. 2 PUNCHING WITH AUTO REPOSITIONING ......................... 5-5

EX. 3 MULTIPLE PART PUNCHING ....................................... 5-11

EX. 4 GENERAL PUNCHING (Example of plotting data entry) ................ 5-20

(APPENDIX) DISPLAYED FORMAT ON CRT.. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-l

-

Page 4

. . _1

. .

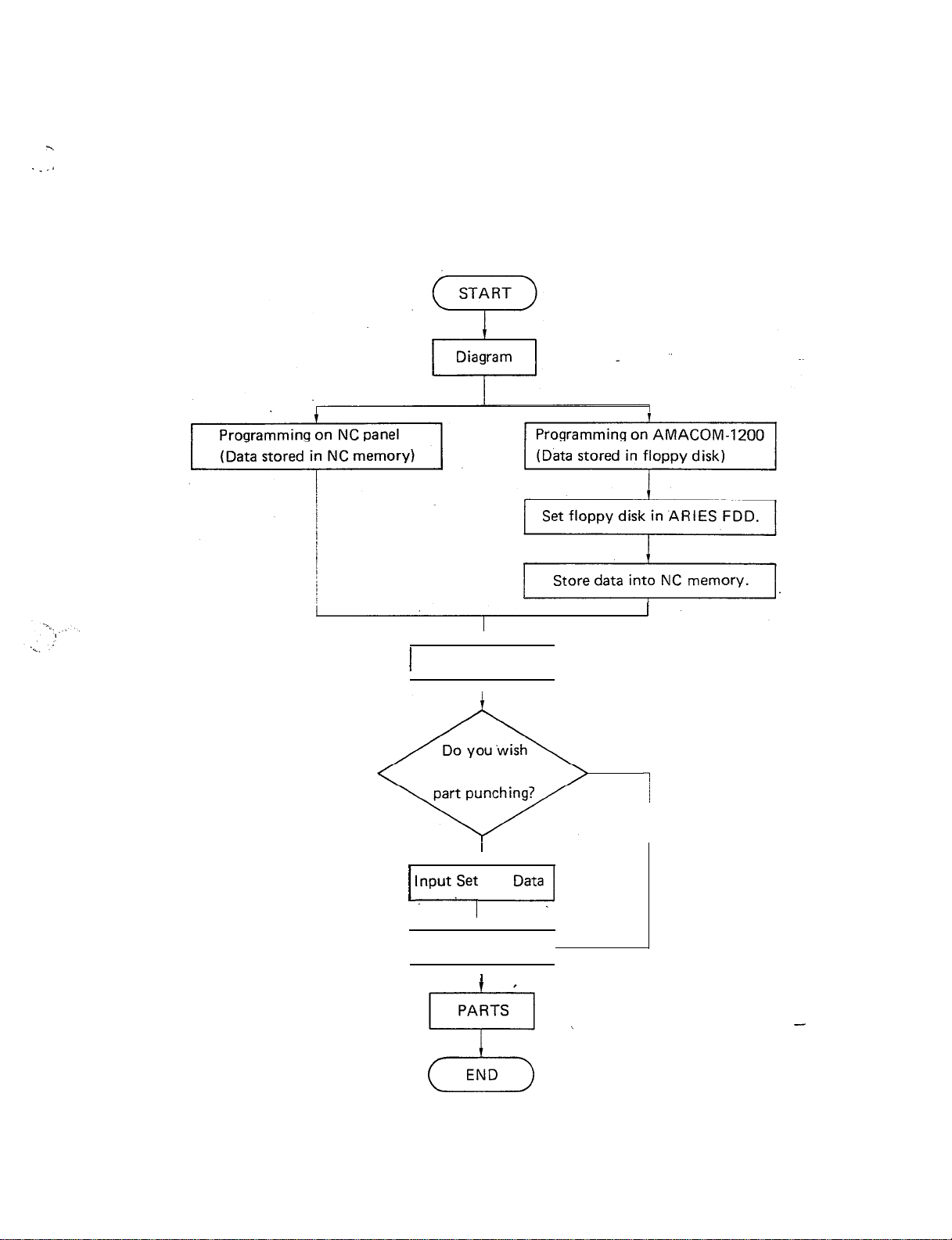

PROGRAMMING BASICS

PROCESS FROM DIAGRAM TO PARTS

Program Search

I

to perform multiple

/

YES

1 lyputse;

Push Start Button

Up

Data.1

I

NO

-

l-l

Page 5

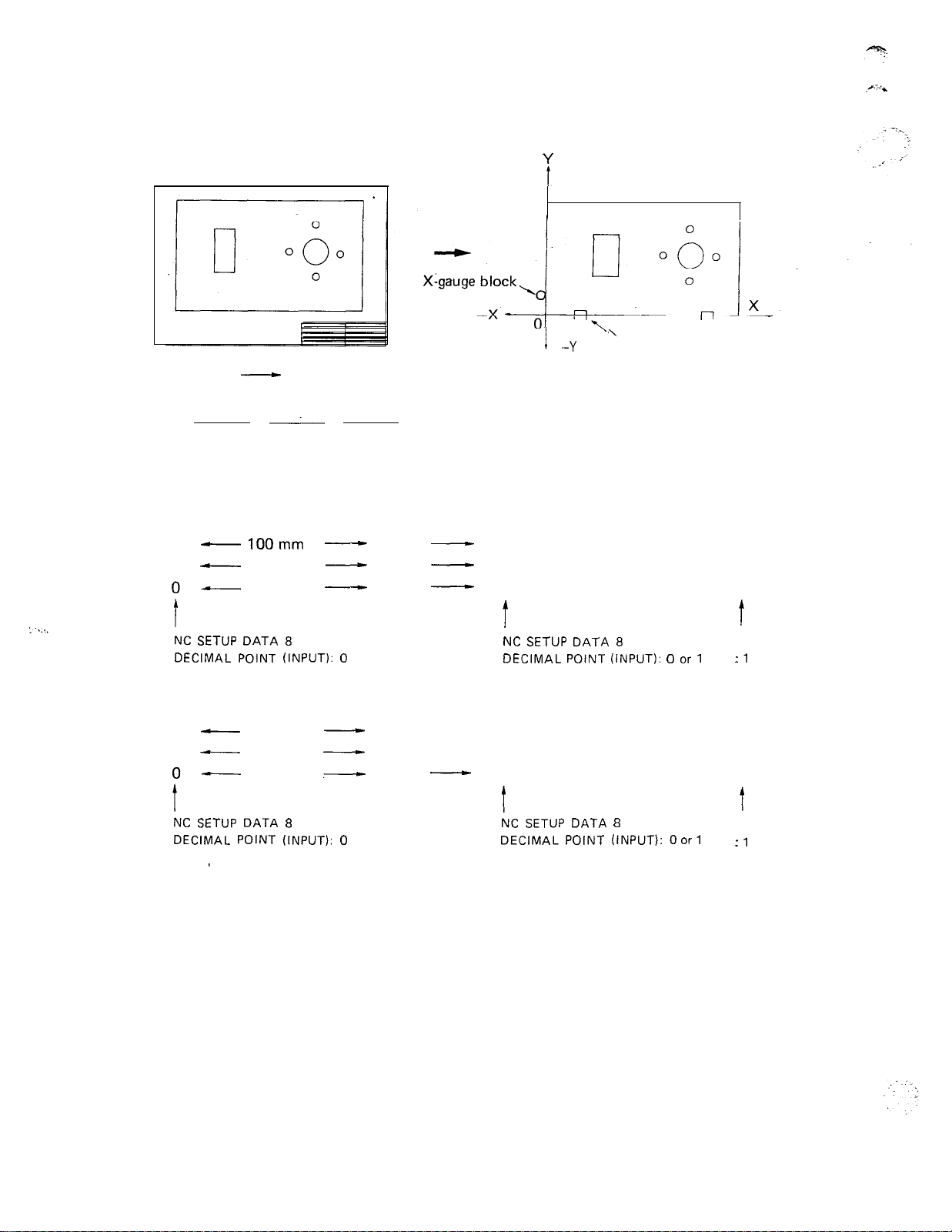

PROGRAMMING

First quadrant

Diagram

1.

Calculation of coordinates

2.

X

3.

-

First quadrant of X and Y coordinate system

Y

A

Diagram

T

i

i .-y

’

Work clamp

UNIT OF MEASUREMENT FOR PROGRAMS

All dimensions for programs are based on units of 0.01 mm (millimeters) or 0.001” (inches).

[millimeters]

100

35.5

o-

-

-

1OOmm

35.5 mm

Omm

-

-

-

100.00

35.50

-

-

0

-

100.

35.5

0

10000

3550

0

i

NC SETUP

DECIMAL

[inches]

20

2.7

o-

NC SETUP

DECIMAL

NOTE:

!

DATA

POINT

-

-

DATA

POINT

,

Refer to the “NC setup” in the OPERATOR’S MANUAL.

8

(INPUT):

20”

2.7”

0

8

(INPUT):

NC SETUP

0

-

.-

20.000-

2.700-

0

-

DECIMAL

.20.

2.7

0

t

NC SETUP

0

DECIMAL

DATA

POINT

DATA

POINT

8

(INPUT): 0 or

8

(INPUT):0or

1

1

t

: 1

20000

2700

:

1

0

l-2

Page 6

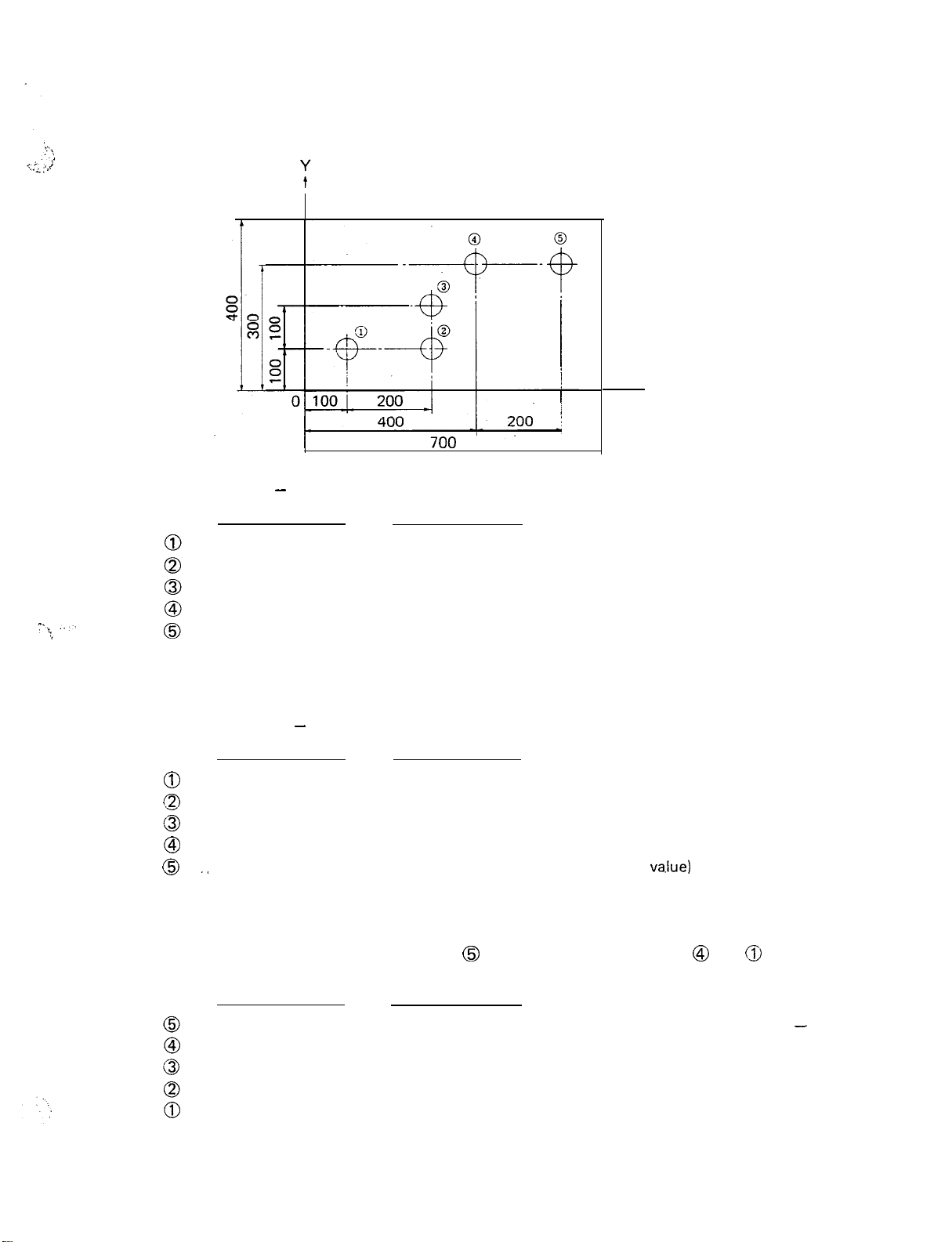

CALCULATION OF COORDINATES

Absolute value - Distance from origin

X

X coordinate value

Incremental

X coordinate value

a

QJ

c3

co

0 ./

100.

300.

300.

400.

600.

value - Distance from previous position

100.

200.

0

100.

200.

Y coordinate value

100.

100.

200.

300.

300.

Y coordinate value

ioo.

0

100.

100.

0

(Absolute value)

(Incremental value)

(Incremental value)

(Incremental value)

(Incremental

va.lue)

(In the case of zero, no decimals are needed.)

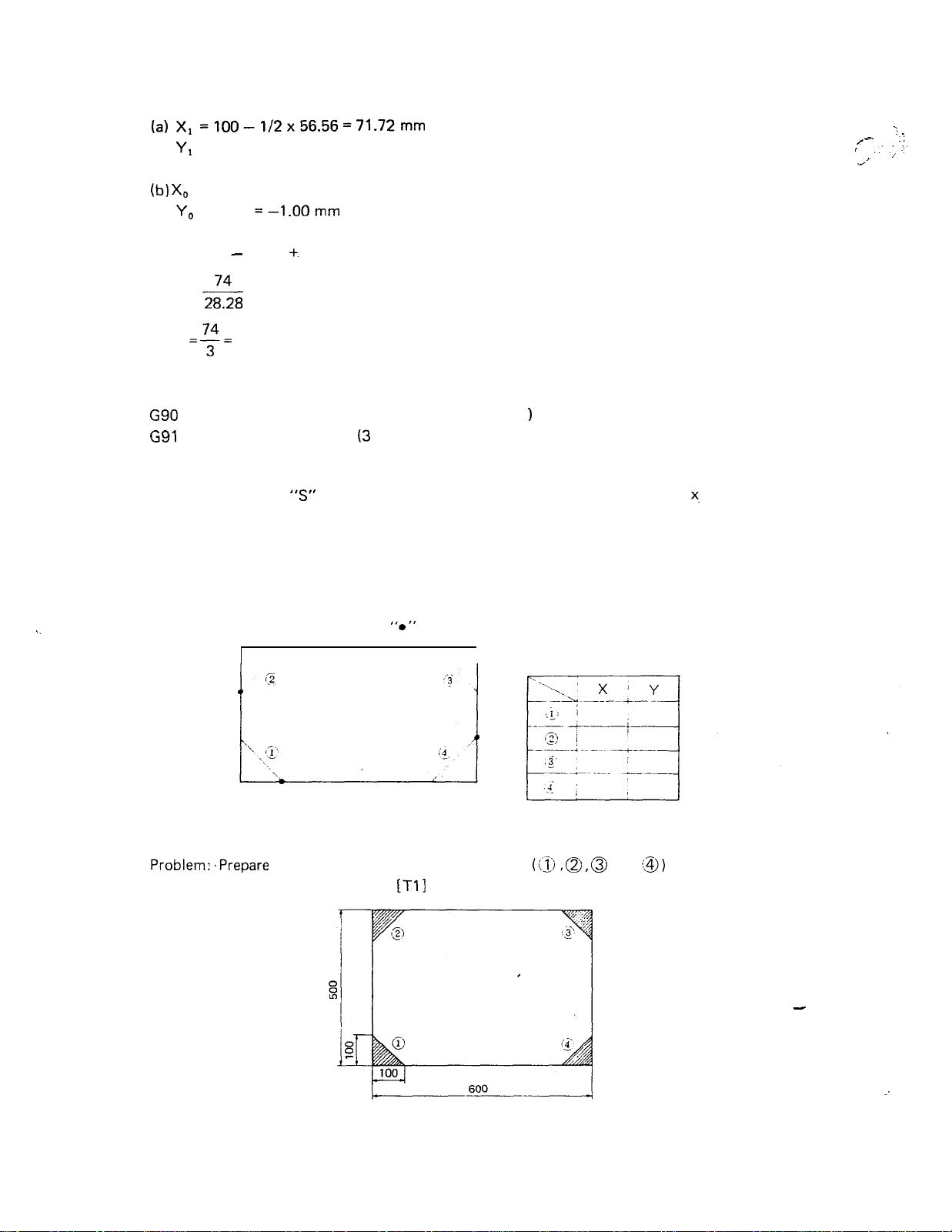

Problem: Calculate the absolute value of @ and the incremental value of @ thru @ .

X coordinate value

Y coordinate value

l-3

(Absolute value)

(Incremental value)

(Incremental value)

(Incremental value)

(Incremental value)

-

Page 7

BASIC FUNCTION CODES

GO0

MOO

TOO

NO000

“G” function (Preparatory function)

“M” function (Miscellaneous function)

‘7”

function (Tool function)

Sequence number

FORMAT

Arrange the function codes as follows:

NO000

GO0 Go0 X*00000

Y+OOOOO TOO MOO

NOTE: a) Unnecessary codes need not be entered.

b)

Enter only necessary digits of X, Y and N.

c)

The plus sign (+I of X and Y can be omitted.

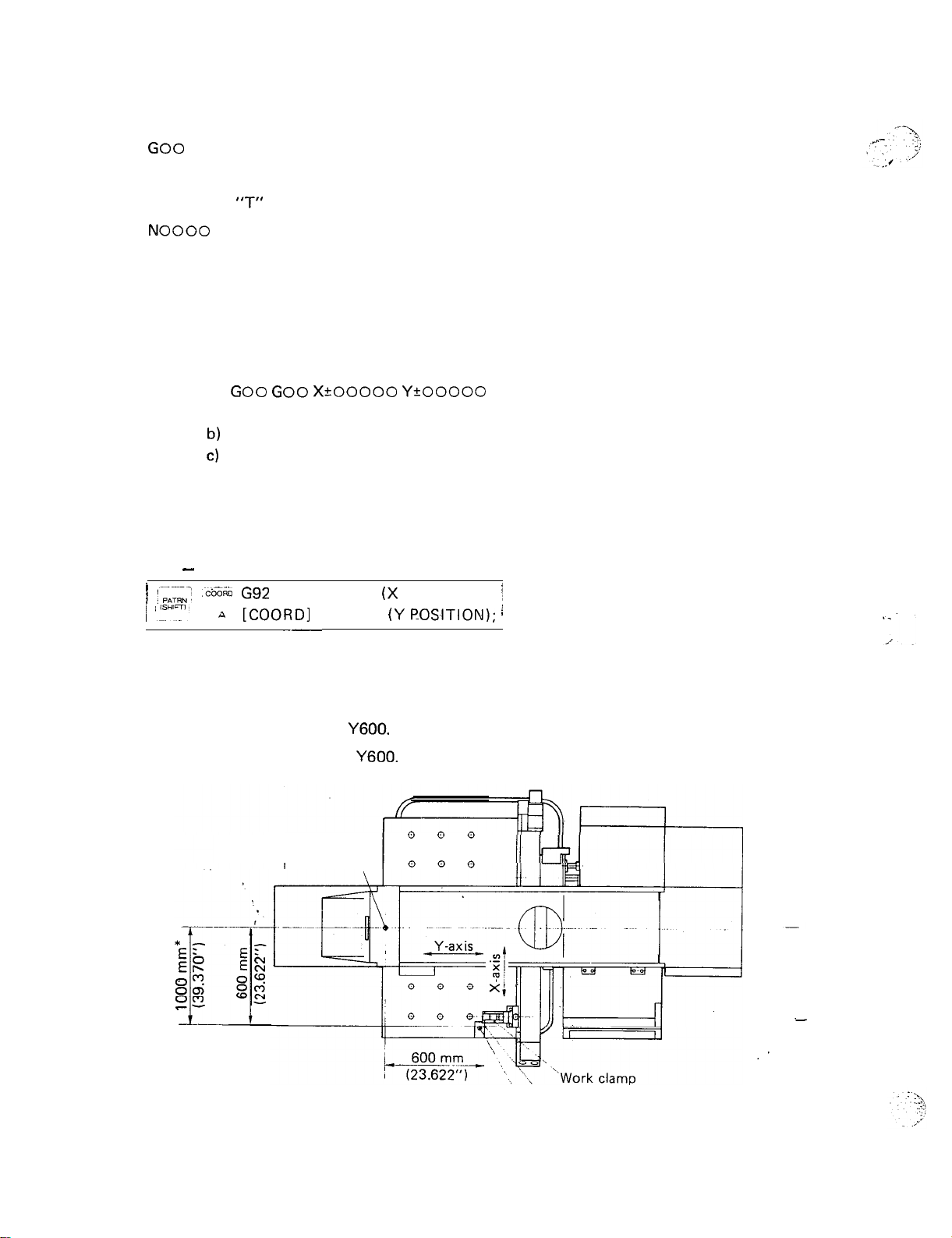

G92

-

ESTABLISHING COORDINATE SYSTEM

) ;;z .c&Gb Gg2

A

I’““‘?

[COORDI

-__

X (X POSITION)

Y (Y

F!OSITION); 1

/

This code is used to designate the distance from the worksheet origin to the punch center.

Enter “G92” and the distances in the X- and Y-axis direction.

ARIES-222

AR I ES-224

ARIES

Metric-specification machine

G92 X600. Y600.

G92 X1000. Y600.

center

Punch

-224”

0 0

0 0 8

Inch-specification machine

G92 X23.622 Y23.622

G92 X39.370 Y23.622

0

\ “Worksheet origin

‘X-gauge block

l-4

Page 8

-?.

.!

\.. _.,:

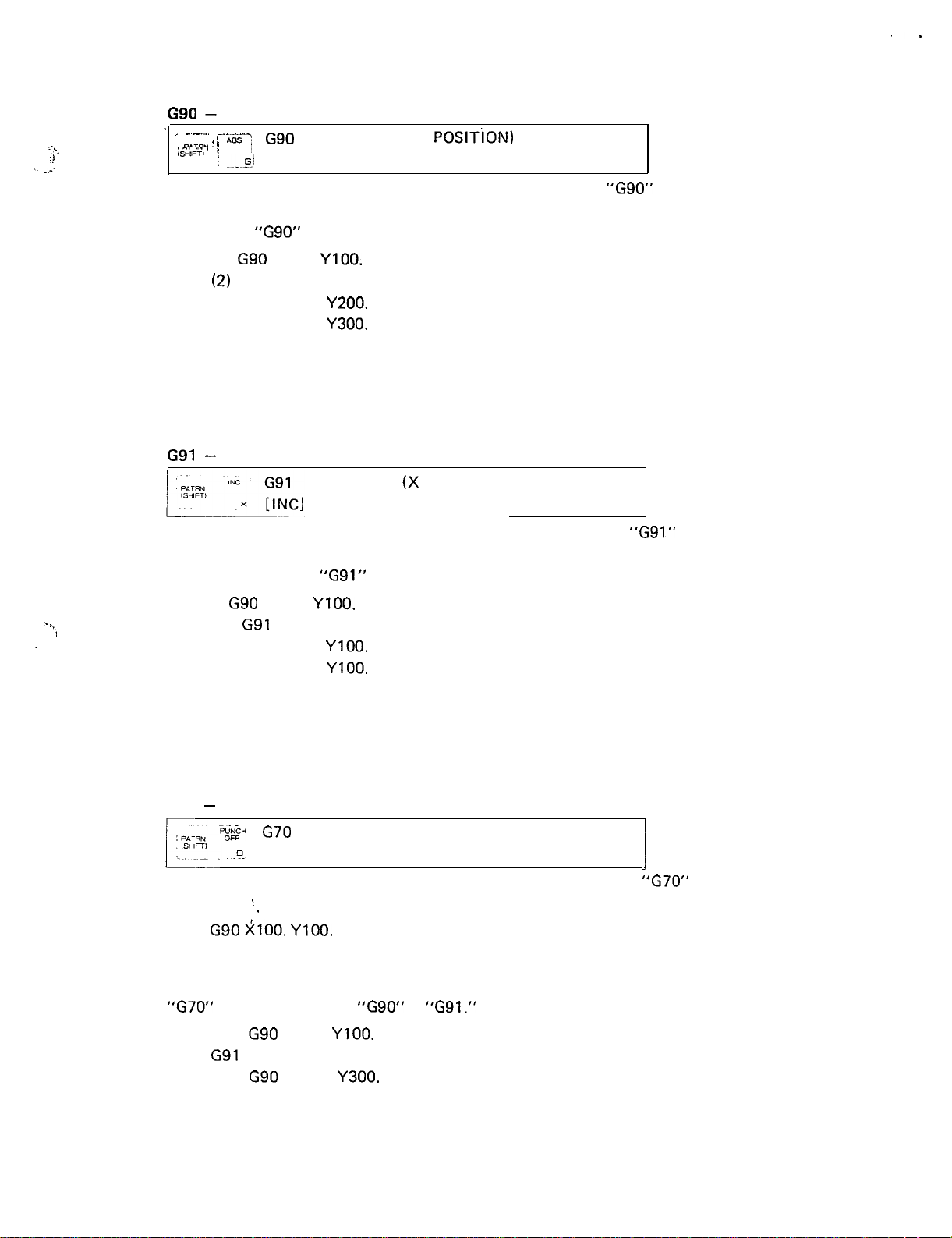

G90

’ : ---.. t-is/

i mmr4 ! ’

,SHlFT,/

When the absolute values are used for coordinate values, enter

ABSOLUTE PROGRAMMING

-

GgO

I

: .--~_G_l

[ABSI

X (X POSITiON)

Y (Y POSITION) T (TOOL NO.);

“G90”

prior to the coordinate

values. If the absolute values are used at the subsequent blocks of the program, it is not necessary to enter

“G90”

again until incremental values are used.

‘Ex.: (1)

(2)

(3)

(4)

G90

X100.

x300. Y 100.

x300. Y200.

x400. Y300.

YlOO.

T2 (Absolute value)

(Absolute value)

(Absolute value)

(Absolute value)

The value of the X- or Y-axis which does not move can be omitted..,

-

G91

INCREMENTAL PROGRAMMING

X (X POSITION)

Y (Y POSITION) T (TOOL NO.);

When the incremental values are used for coordinate values, enter

___

“G91“

prior to the coordinate values. If the incremental values are used at the subsequent blocks of the program, it is

not necessary to enter

Ex.: (1)

.-

i,_

I

”

(2)

(3)

G90

X100.

G91

X200. Y 0

(4)

YlOO.

x 0

x100.

“G91”

again until absolute values are used.

T2 (Absolute value)

(Incremental value)

YlOO.

YIOO.

(Incremental value)

(Incremental value)

The value of the X- or Y-axis which does not move can be omitted.

G70 - PUNCH OFF

‘$$I- G70

.

..e’

[PUNCH OFF1 Y (Y POSITION) T (TOOL NO.);

X (X POSITION)

This code is used to move the worksheet without punching. Enter

X-Y-.

Ex.:

“G70”

Ex.:

I,

G90 >i;lOO. YlOO.

T2

G70 X300.

can be entered with

G90

G91

G70 X200.

G90

X100.

YlOO.

Y300.

(The axes move at a position of “X300. Y 100.” without

punching.)

“G90”

or

“G91.”

,

T2 (Punching)

(No punching)

(Punching)

1-5

j

“G70”

prior to entering’

Page 9

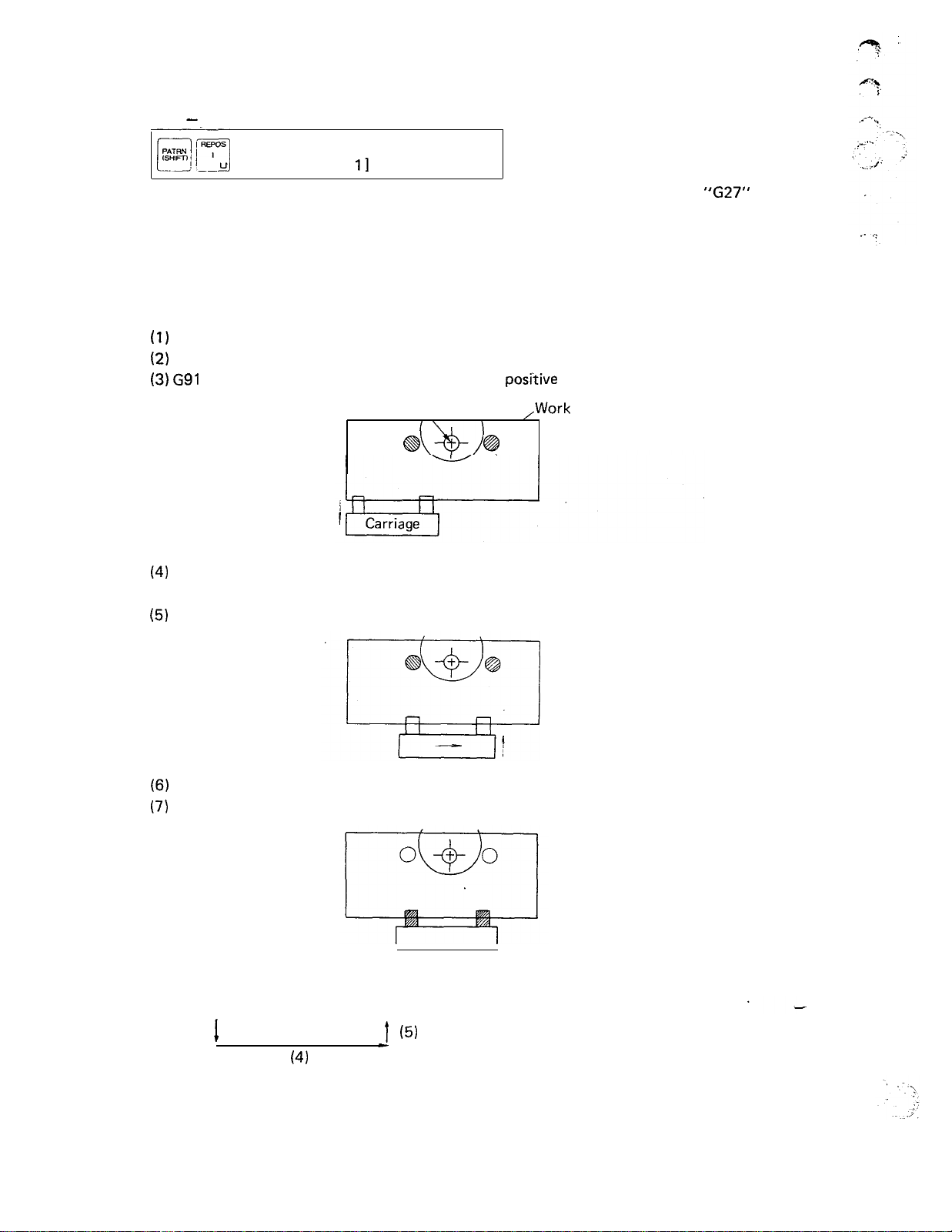

G27 -AUTO REPOSITIONING

G27

[Z/‘--=y

I

--u

[REPOSITION

11

X (DISTANCE);

This code is used to extend the punching range in the X-axis direction. Enter

the X-axis value.

Ex.:

G27 X500.

The X-axis value must be designated by an incremental value.

The following shows the repositioning cycle for a G27 X500. command.

(I)

Work hold:

(2)

Unclamp:

(3) G91

(41

Y2.4:

x-500.:

The work holders hold the worksheet.

The clamps open.

The table moves 2.4 mm in the

tion.

Punch center

-8

@?

posi‘tive

,Work

direction from the current posi-

holder

The carriage moves 500 mm in the negative direction from the current

position,

(5)

Y-2.4:

The table moves 2.4 mm in the negative direction.

“G27”

and

(6)

Clamp:

(7)

Work release:

The clamps close.

The work holders release the worksheet,

Table and Carriage movement

2.4: ’

(41

500 mm

1 (5)

-

2.4 mm

,

l-6

Page 10

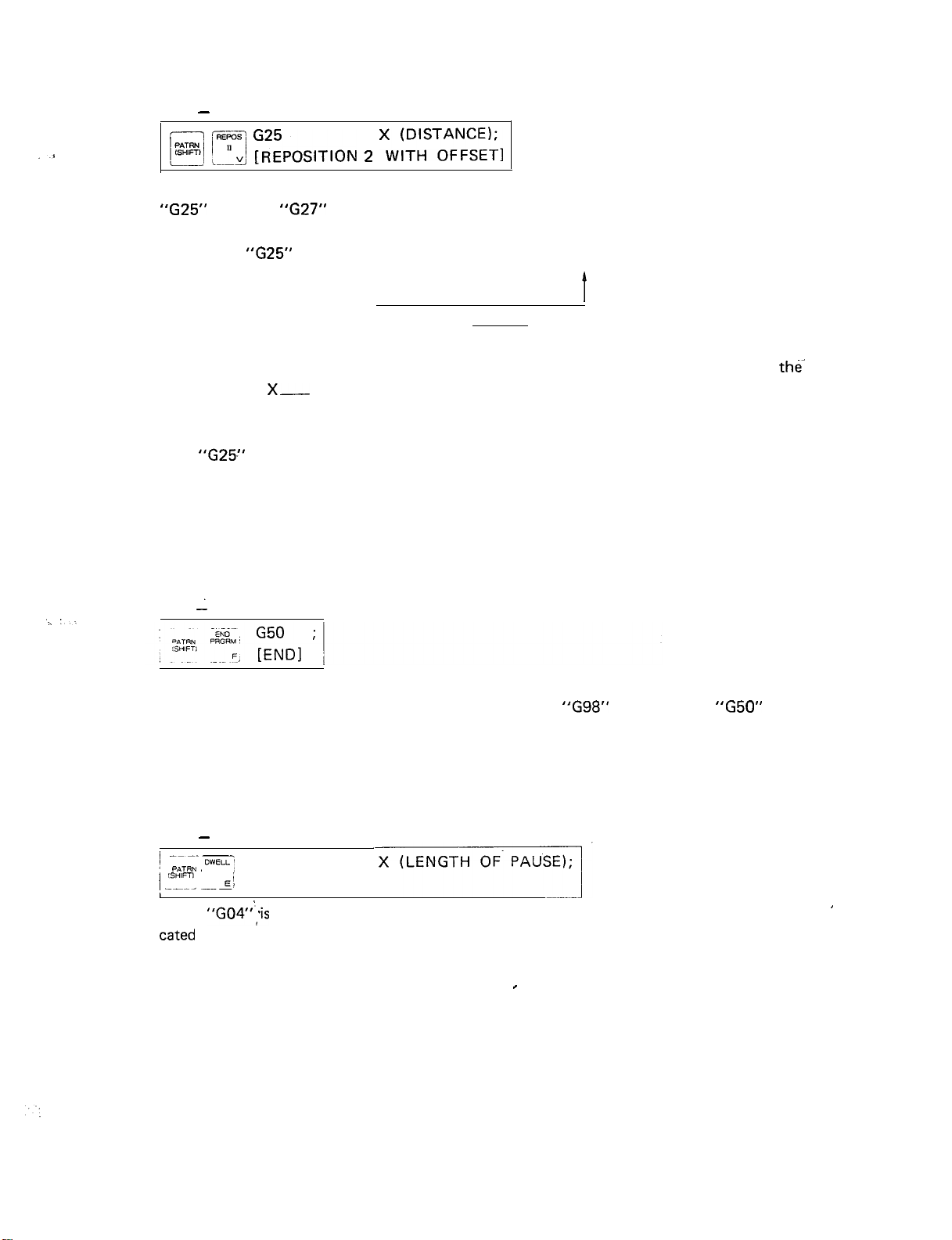

G25

AUTO REPOSITIONING

-

IF] 13

~~~PoSITICIN 2

xW!TD~~~EE~I

When the worksheet edge which is clamped has a bend, curves or excessive burrs, enter

“G25”

instead of

“G27”

to ensure accurate repositioning. These factors can cause inaccurate

worksheet positioning when automatic repositioning is performed, unless the G25 code is

used. When

“G25”

is read, the same movement will be-obtained as in the following:

2.4 mm

I

1.2 mm

t

G25 X

First the table moves 2.4 mm in the positive direction from the current position. Then

carriage moves

from the current position and the table moves 1.2 mm in the negative

X--

the-

direction. Next, the X and Y coordinate system is offset by Y1.2 to compensate for the

difference between the table positions before and after the automatic repositioning.

After

“G25”

is read, the punching range along the Y-axis is moved 1.2 mm in the negative

direction from the standard,,punching range.

-11.4 to 609.0 mm (-0.448” to 23.976”)

G50 i HOME RETRACT

When “G50” is read, the carriage and table return to their origins. No punching occurs during

the retraction. The offset values designated by “G93” and

“G98”

are cancelled.

“G50”

must

be entered as a single block; however, the sequence number can be entered along with it.

GO4 - DWELL

1 -~--

pAT+yp., ,Dw”u-:

1 ““i. -E[

1

GO4

[DWELL]

When “G04”‘,!s entered with “X” value, the punching operation stops during the time indi-

cated

by the value of “X.”

The minimum programmable increment of the value following

“X” is 0.01 sec. The maximum value is 63.5 sec.

GO4 X10. . . . . .

Operation stops during 10 sec.

I

’

l-7

Page 11

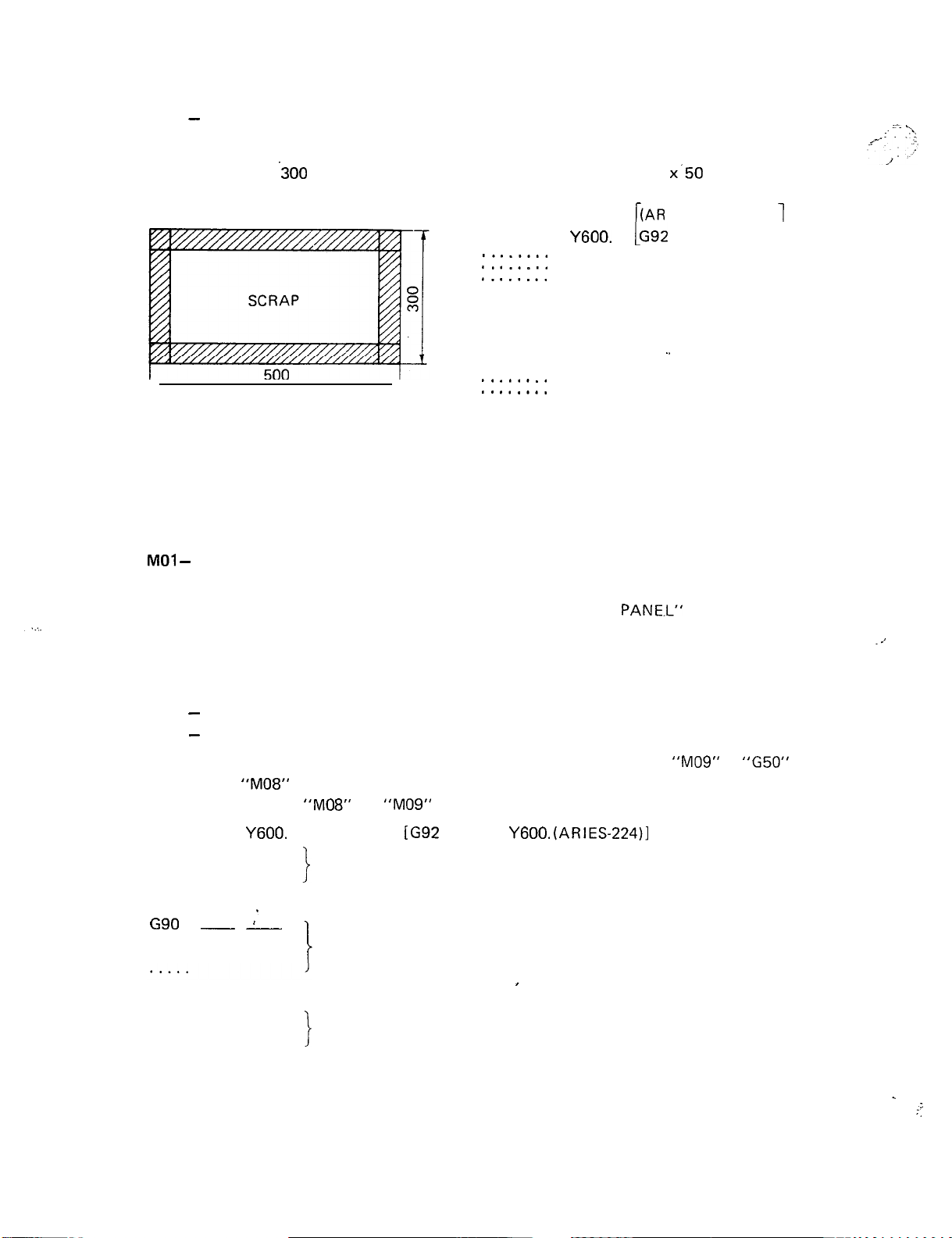

MOO -PROGRAM STOP

Enter “MOO” if a program stop is desired.

Ex.:

Punching a

-300

mm x 500 mm rectangular opening with a 50 mm

x.50

mm square

punch.

(ARIES-222)

G92 X600. Y600.

........

........

........

[(AR I ES-224)

LG92

X1000. Y6OO.j

Y42.

Y42.

Y42.

MOO (Machine stops here)

I-

-l

........

........

.’

When “MOO” is read, the machine stops. When the START button is pressed after the scrap

has been removed, the machine will continue the punching operation. “MOO” must be en-

tered as a single block; however, the sequence number can be entered with it.

MO1 -

OPTIONAL STOP

: ;-- \

1

This code has the same function as “MOO”; however, the machine will stop only when the

OPTNAL STOP button is lighted. (Refer to the

“NC CONTROL PANE.L” in the OPER-

ATOR’S MANUAL.) .

MO8

MO9

When “M08” is read, the hit rate is changed from standard to low until

is read. Use

than 3.2 mm (0.125”).

G92 X600. Y600. (ARIES-222)

. . . . .

. . . . .

PUNCH DELAY START

-

PUNCH DELAY CANCEL

-

“M08”

when the sum of worksheet thickness and the formed height is more

“M08”

,

Standard hit rate

and

“M09”

must be entered as a single block, respectively.

[G92

X1000. Y600. (ARIES-224)]

“M09”

or

“G50”

MO8

-

G90

X Y

. . . . .

-

)’

Low hit rate

MO9

. . . . .

. . . . .

Standard hit rate

G50

.,

l-8

.

.:

‘.

Page 12

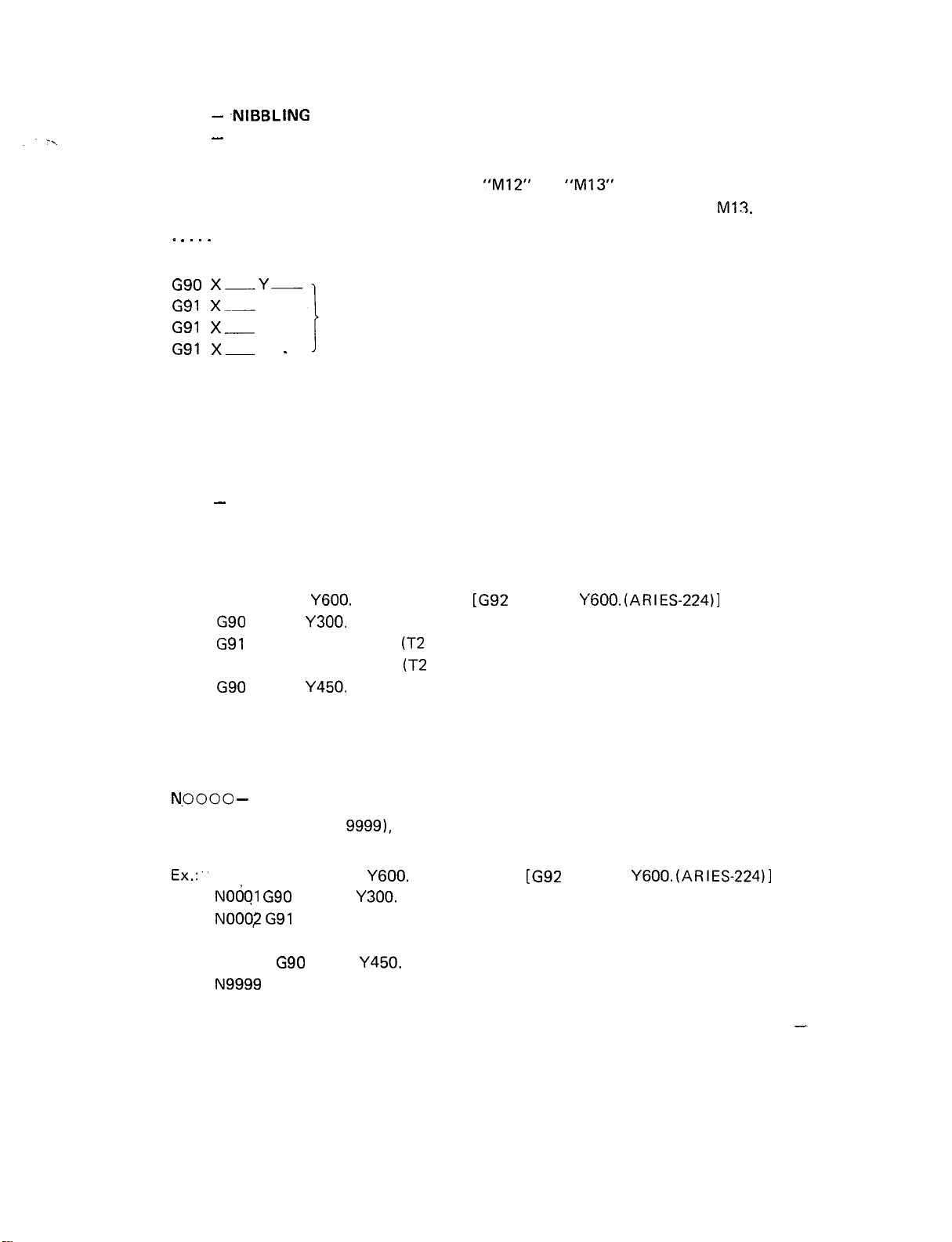

Ml2 -.NIBBLING

START

Ml3 -NIBBLING CANCEL

When “Ml 2” is read, nibbling is performed until “Ml 3” is read. In nibbling, the press clutch

“M12”

and

is always engaged with the brake released.

“M13”

block, respectively. Pattern punching cannot be commanded between Ml2 and

must be entered as a single

Ml3

. . . . .

Ml2

G90 X-Y

G91 X-..e

G91

X.-m.-

Nibbling [Hole intervals should be 6 mm (0.236”) or less.]

G91 X-

Ml3

. . . . .

. . . . .

TOO - DESIGNATION OF TOOL NUMBER

This code is used. to designate the tool station number in order to select the tool to be used.

If the same tool is to be used continuously, it is not necessary to enter this code again until a

different tool is needed.

Ex.: G92 X600.

G90

X450. Y300. T2

G91

X50.00

x50.00

G90

X500. Y450. T3

N.0000 -

SEQUENCE NUMBER

Y600.

(ARIES-222)

(T2

not required)

.

(T2

not required)

[G92

X1000.

Y600.

(ARIES-224)]

Any numeral (from 1 to 9999), with four or less digits, beginning with “N” can be entered

at the beginning of each block. This code is used for indexing each block.

Ex.:”

NOdql G90

NO002 G91

NO003

NO004

N9999

The sequence number need not be entered if it is not necessary. Entry at key points

instead of all blocks will be useful.

G92 X600.

X450. Y300. T2

X50.

x50.

G90

X500. Y450. T3

G50

Y600.

(ARIES-222) [G92 X1000. Y600. (ARIES-224)]

.

,

-

Zeros which directly follow “N” may be omitted.

1-9

Page 13

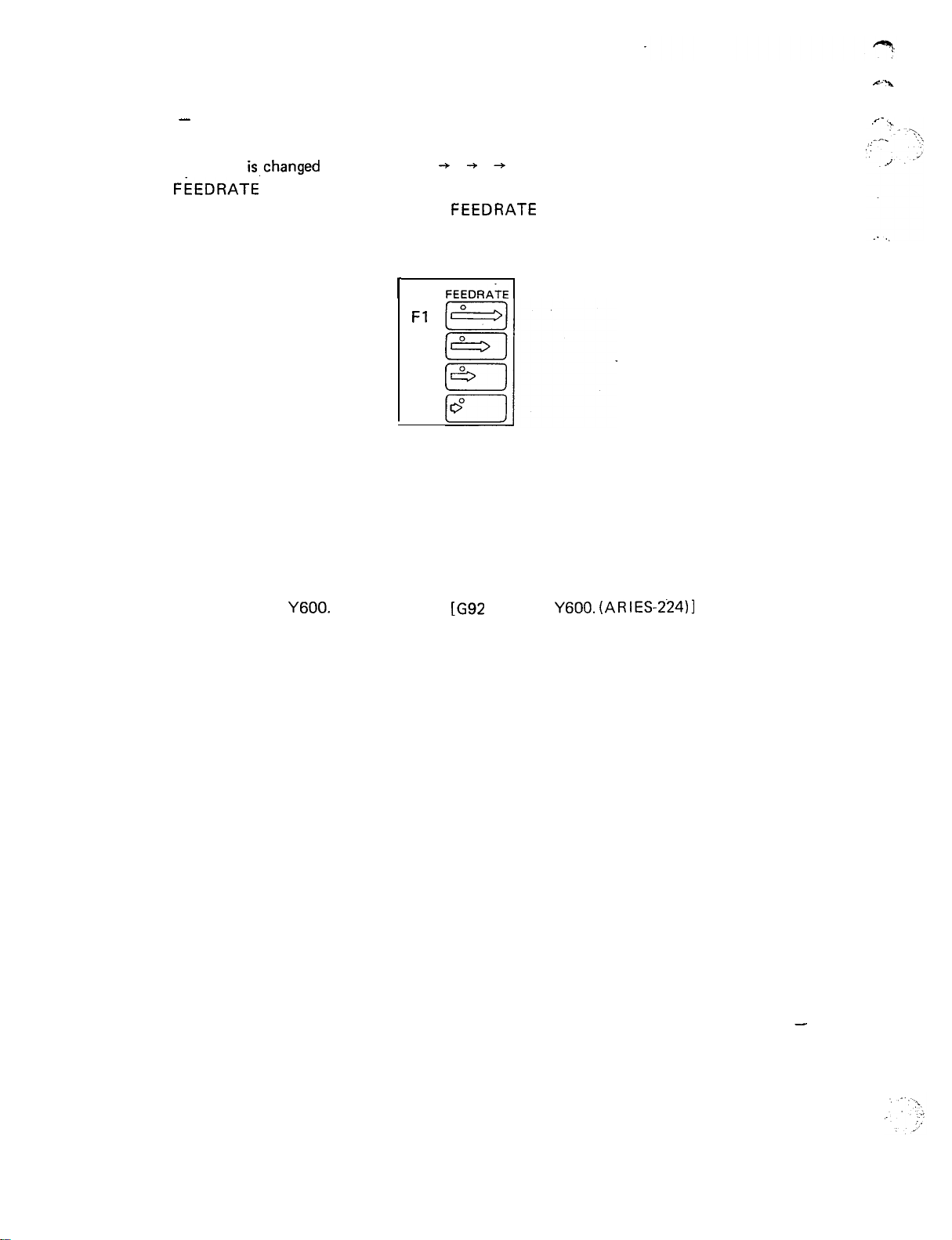

FO- DESIGNATION OF AXIS FEED SPEED

The axis feed speed can be changed by this code. The axis feed speed is decreased as the value

+

following “F”

the FEEDRATE buttons located on the NC control panel. When there is the difference

between instructions by this code and the FEEDRATE buttons, the priority will be given to

the slower axis feed speed. The instruction of the “F” code is held until a new “F” code is

read or the RESET key is pressed.

is,changed

from 1 to 4 (1

2 + 3 + 4). This code has the same function as

I

PROGRAM NAME

Enter the program name at the top of the program for the identification of individual ones.

The name must be within 8 alphabets or numeral characters and only the alphabet letter can

be used for the first character of the name.

Ex.:

ARIES 1

G92 X600. Y600. (ARIES-2221

G50

This program name can also be input and changed from the NC control panel.

Fl

F2

F3

F4

FEEDRATE

[G92

X1000. Y600.

(ARIES224)l

I-IO

-

Page 14

PROGRAMMING

PROCEDURE

1. Determining the processing method

2. Determining the clamp

posZtion

Position the clamps as far apart as possible and check the “dead zone” (see the DEAD

ZONE DIAGRAMS).

3.

Checking the tool and station number

(a) Check to ensure the proper tool is used for the cut-out required.

Ex.:

150 mm dia. round hole

300 mm x 400 mm square opening

-nibbling with a 20 mm dia. punch

Ushear-proof

punching with a 50 mm x

50 mm square punch

(b) Check to ensure desired tools can be loaded into the turret.

Problem: Is the combined use of the following tools for one program possible?

50 mm dia., 35 mm dia., 80 mm dia., 20 mm x 20 mm sq., and 30 mm dia.

(2” dia., 1.4” dia., 3” dia., 0.8” x 0.8” sq., and 1.25” dia.)

4.

Determining the punching sequence

This must be determined by taking into consideration both the processing time and

accuracy.

General precaution

(a) Begin and finish with the upper right corner of the diagram.

(b) Begin with small holes, then square openings, and notching.

(c) The tools should not be selected more than twice.

(d) In multiple part punching, shearing of the worksheet should be done last.

.-

5. Calculating the coordinates

Calculate the coordinate values in units of 0.01 mm (millimeters) or 0.001” (inches).

6. Checking

Check the clamp positions, punching sequence-and coordinate values.

,

I-II

Page 15

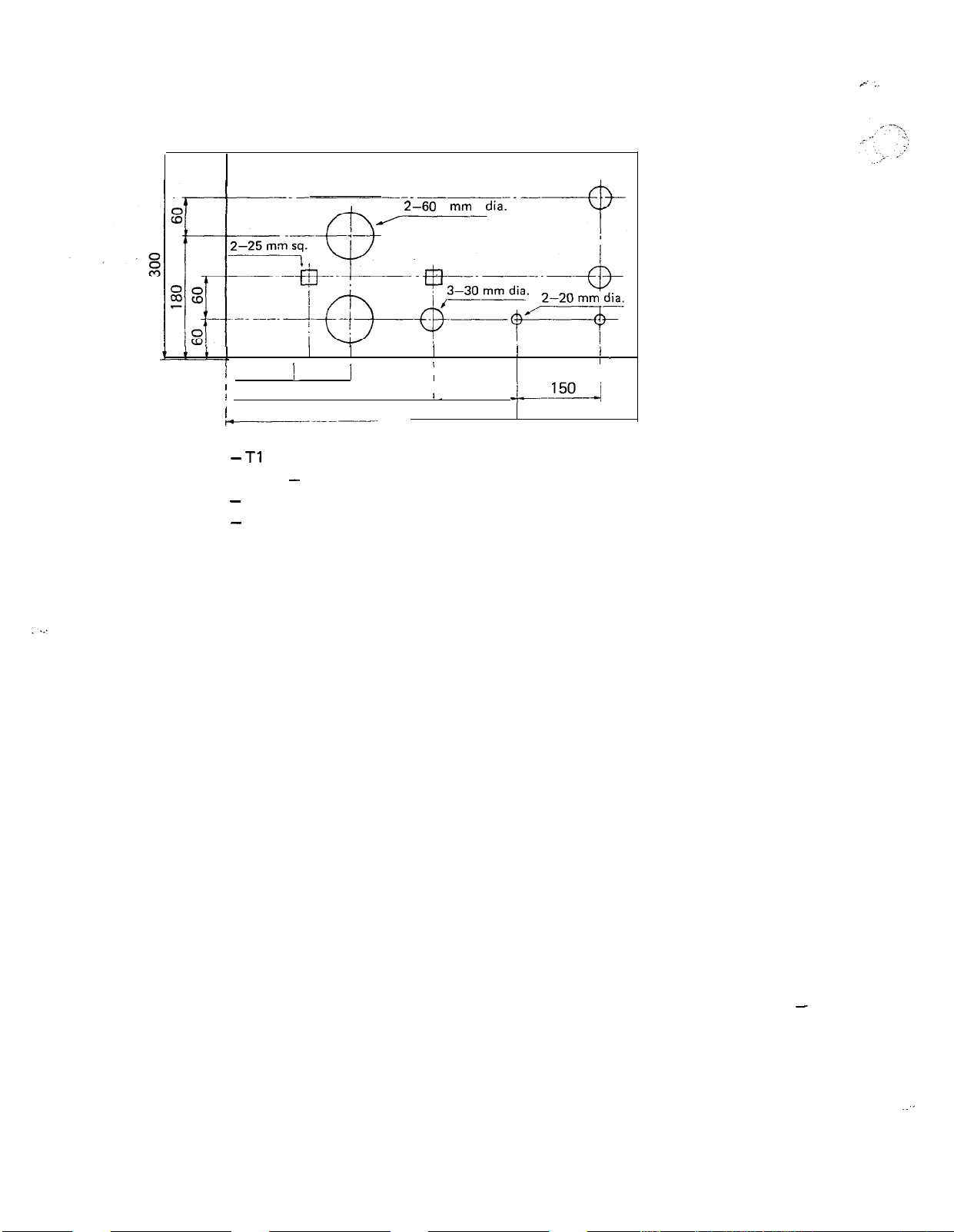

Problem: Program the following diagram. (Enter the sequence No.)

2-60

mm dia.

I

150 I. 50

I

/

/

/

r------

60 mm dia. -

Tl

25 mm x 25 mm sq. - T6

30 mm dia. - T2

20 mm dia. - T4

300

I

/

I

,. 150

700

-----

,

l-.-~

I

I -

,

1-12

-

..”

Page 16

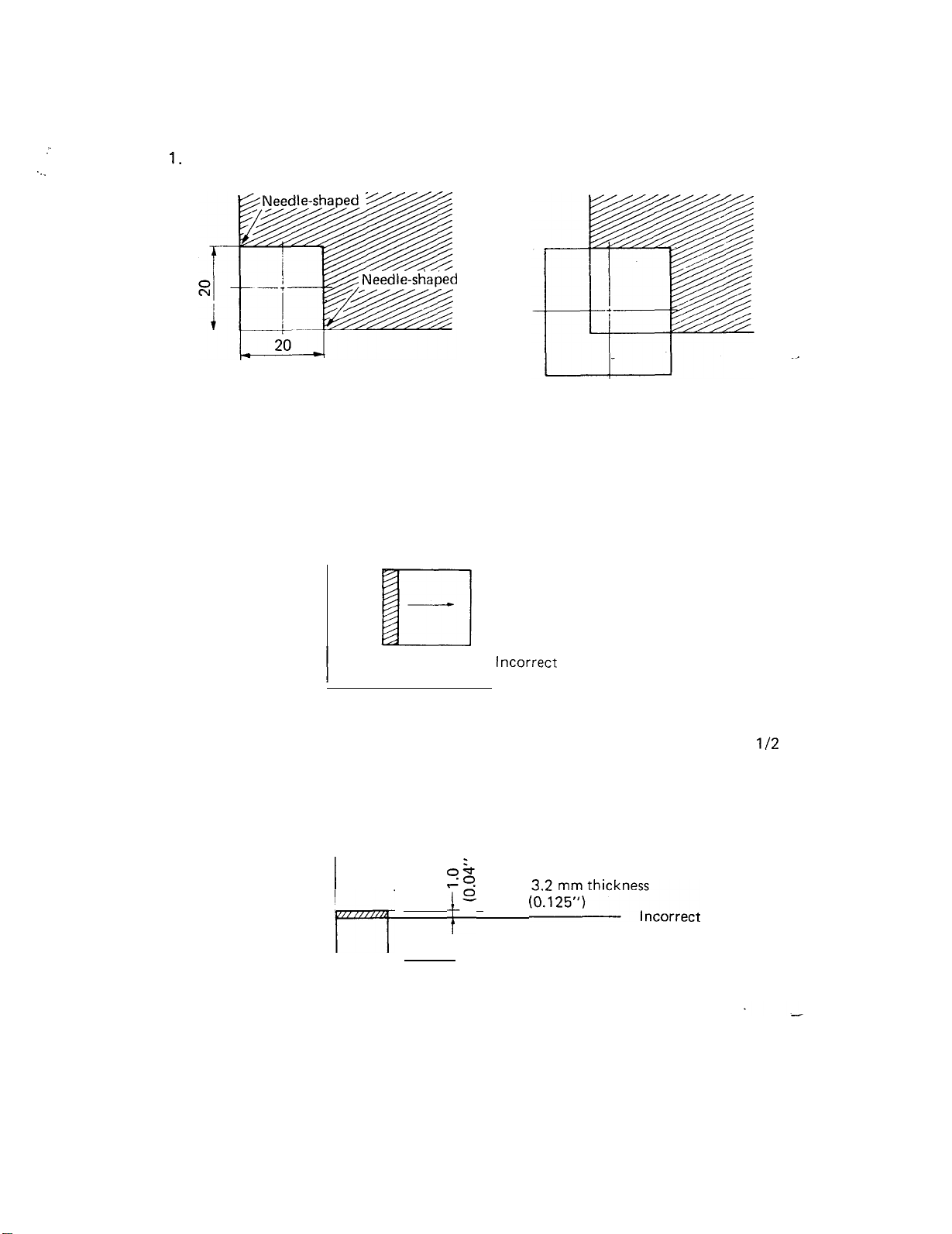

HINTS ON PROCESSING

:

1.

Notching should not be performed with a punch of the same size as the notch.

. . .

Incorrect

(20 mm x 20 mm square punch is used.)

(30 mm’x 30 mm square punch is used.)

Correct

Problem: Prepare a program to punch out a 20 mm x 20 mm sq. notch with a 15 mm x 15

mm sq. punch.

2.

Do not punch along the shorter punch side when using a long rectangular punch.

incorrect

3. When shear-proof punching is performed, the feed pitch should be larger than

punch width, but smaller than the entire punch width minus 0.5 mm (0.02”).

4.

The depth of notching should not be less than the plate thickness.

I

/

il.,~

p

(30:;y,thickrm:correct

l/2

the

1-13

Page 17

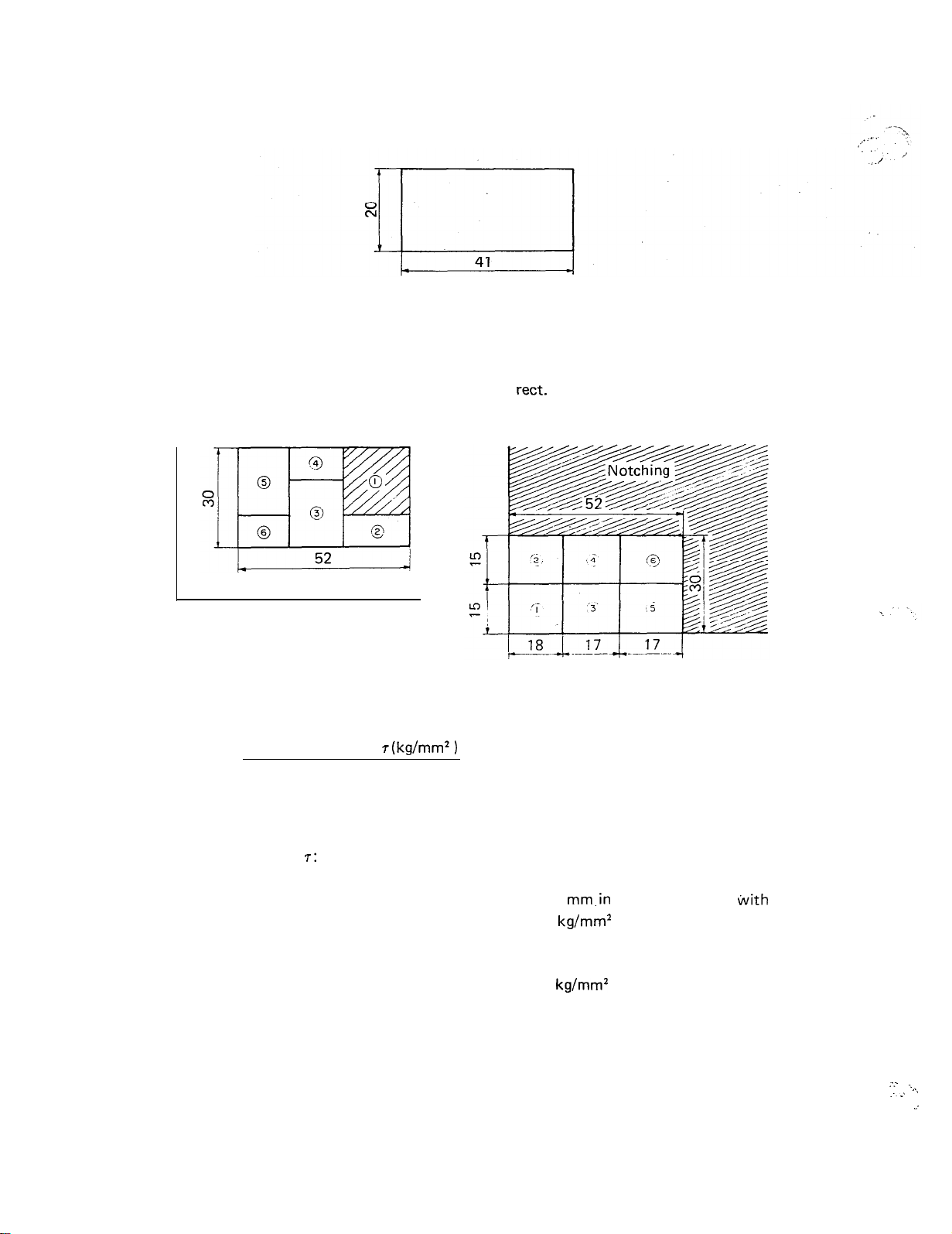

Problem: Determine the method for punching a 20 mm x 41 mm rectangular hole with a

20 mm x 20 mm sq. punch.

5.

Determine the punching method so that the stripper plate holds the worksheet as much

as possible.

Method for punching a 30 mm x 52 mm

Ex.:

rect.

hole with a 20 mm x 20 mm sq.

punch.

6.

The force required to punch the worksheet must not exceed the machine capacity.

The required punching force is obtained by the following formula:

P (ton) =

A (mm) x t (mm) x r (kg/mm*)

1000

where, P: Force required

A: Length of cut edge

t: Thickness of worksheet

7:

Shearing strength of worksheet

Problem: Is it possible to punch holes with a’diameter of 40

thickness of 4.5 mm and a shearing strength of’40

mm.in

kg/mm2

a mild steel plate

?

tiith

a

Problem: Is it possible to punch a 20 mm x 20 mm square hole in a stainless steel plate with

a thickness of 3 mm and a shearing strength’of 60

kg/mm2

?

1-14

:: :

.._I

I\

./

Page 18

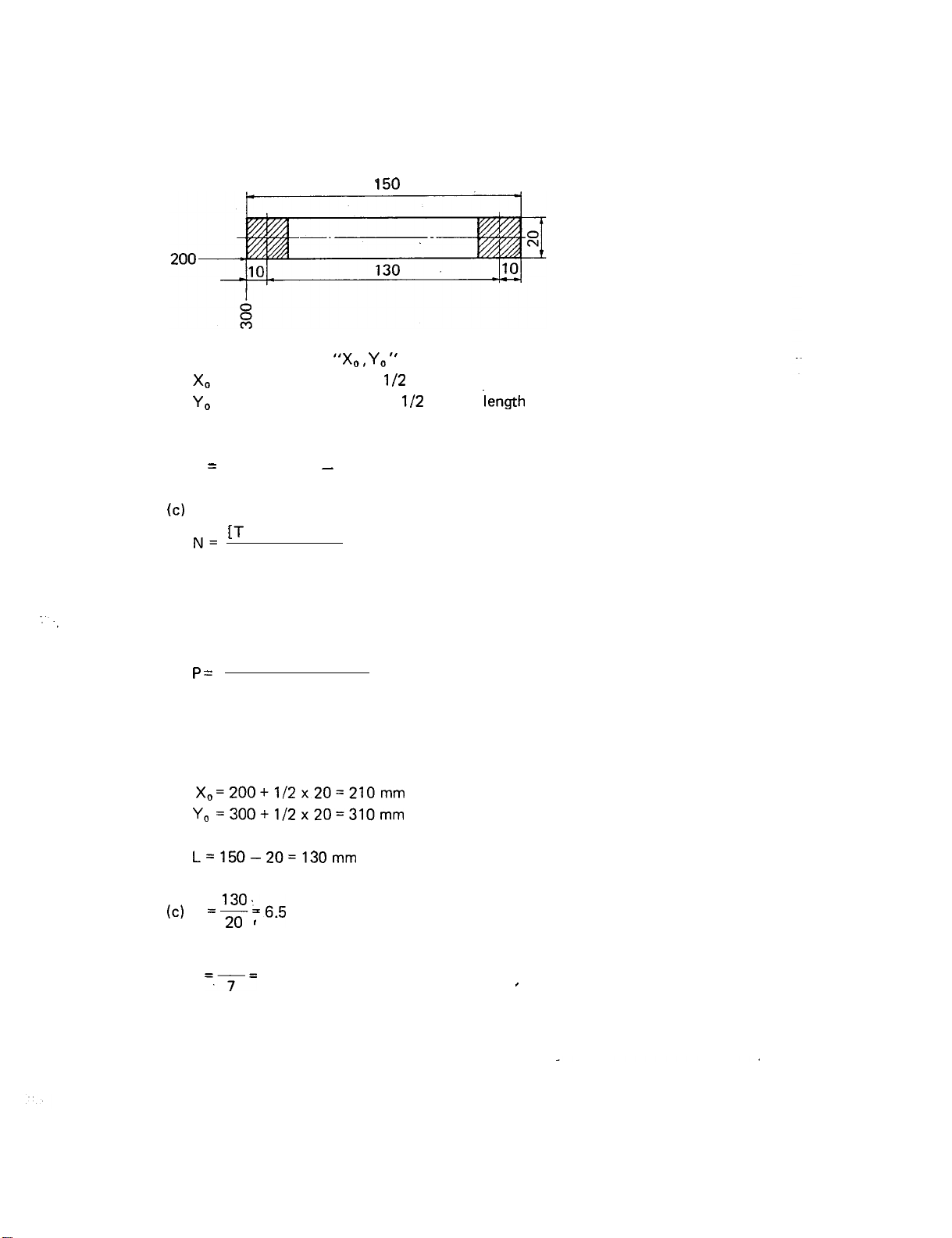

CALCULATING LONG RECTANGULAR HOLE

When punching a 20 mm x 150 mm rectangular hole with a 20 mm x 20 mm sq. punch

Ex.:

(Punching begins with the left side of the hole)

150

(a) First punch position

X,

= [X value at left end] +

Y,

= [Y value at lower end] +

“X0, Y,,”

(Absolute value)

l/2

[Punch length along X-axis]

l/2

[Punch

length

along Y-axis]

(b) Travel distance “L”

L = [Total length] - [Punch width]

.

(c)

Punching frequency “N”

NC [T

ravel distance]

[Punch width]

When decimal numbers are obtained

Ex.: 6.2 -7

When integral numbers are obtained

Ex.: 9-10

(d) Feed pitch “P”

[Travel d istancel

’ =

[Punching frequency]

NOTE: The value- of “P” should be larger than l/2 the punch width, but smaller than

the entire punch width minus 0.5 mm.

(a) X,

=200+1/2x20=210mm

Y, =300+1/2x20=310mm

(b)

L=l50-20=130mm

(c)

N

=g;6.5

(d) P

130

=,7=

-7 times

I

18.57 mm

I

I-15

Page 19

Therefore the program is:

G90

X210. Y310. T3

G91

X 18.57

X

18.57

(20mmx20mmsq.)

X 18.57

X 18.57

X

18.57

X 18.57

-

X

18.57

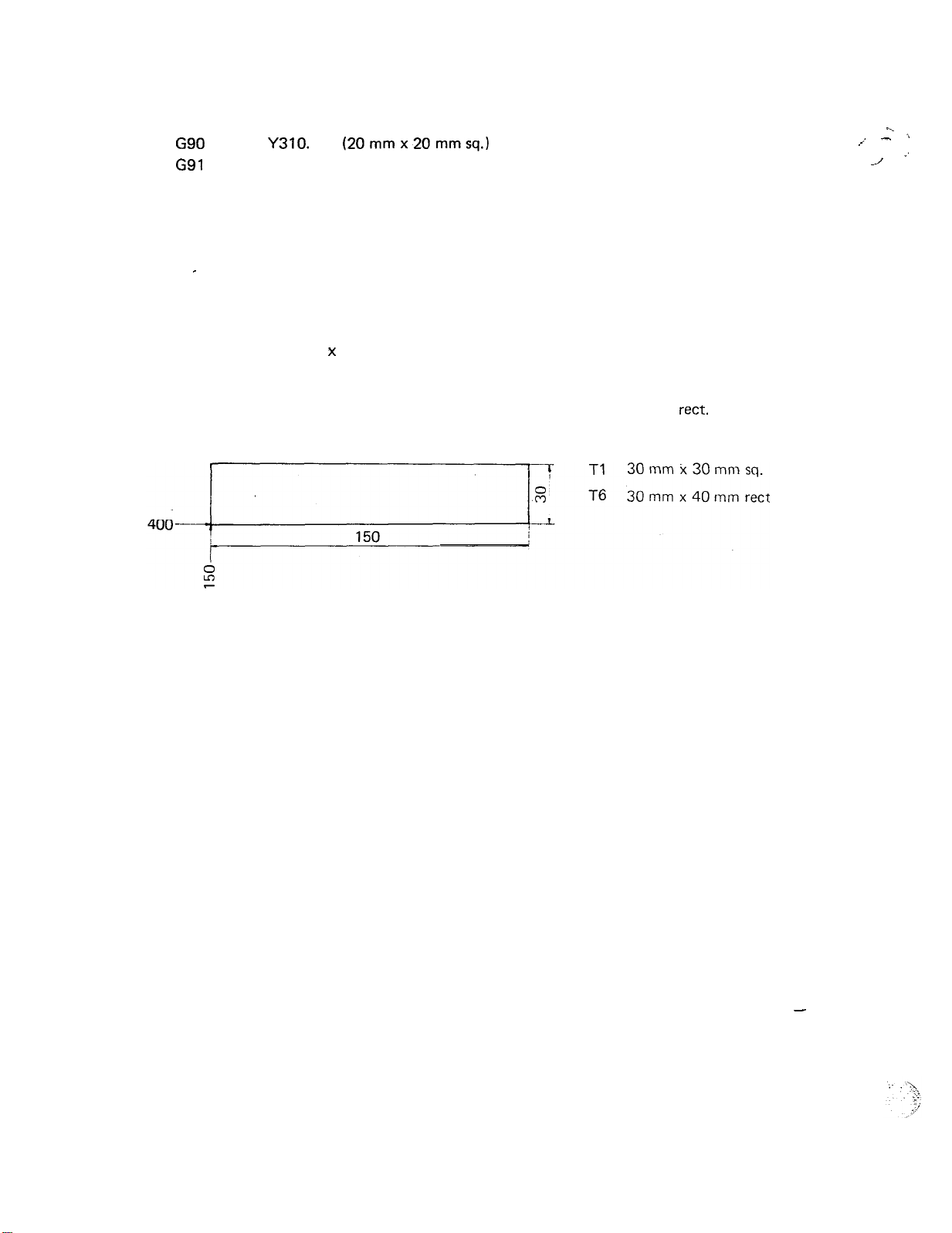

Problem: Punch a 30 mm x 150 mm rectangular hole with a 30 mm-x 30 mm sq. punch.

-.

,,. - ’

J -’

Problem: Punch a 30 mm x 150 mm rectangular hole with a 30 mm x 40 mm

rect.

punch.

1-16

-

Page 20

CALCULATING LARGE RECTANGULAR OPENING

Ex.: When punching a 200 mm x 300 mm rectangular opening with a 30 mm x 30 mm sq.

punch

30 mm x 30 mm sq.

Tl

(a) Punching procedure

Finish punching at the upper right corner in order to remove the scrap easily.

(b) First punch position

X,

= [X value at right end] -

Y,

= [Y value at upper end] -

(c) Punching frequency and feed pitch of

(d) Punching frequency and feed pitch of

(e) Prepare the program in accordance with the punching sequence.

NOTE:

(f) Enter “MOO” or

(b) X0 =

Y, =[250+1/2x200]

(cl

L = 300 - 30 = 270 mm

Do not punch the final punch position because the last punch fails- on the first

punch position,

[400 + I/2 x

“X,,

,

Y,”

(Absolute value)

l/2

[Punch length along X-axis]

l/2

[Punch length along Y-axis]

“MOI”

in order to remove the scrap.

3001 -

[I/2 x

-[1/2x30]

301 =

535 mm

-1,’

,a

=335mm

N =g=g.() -+

P=+=27

mm

10 times

1-17

Page 21

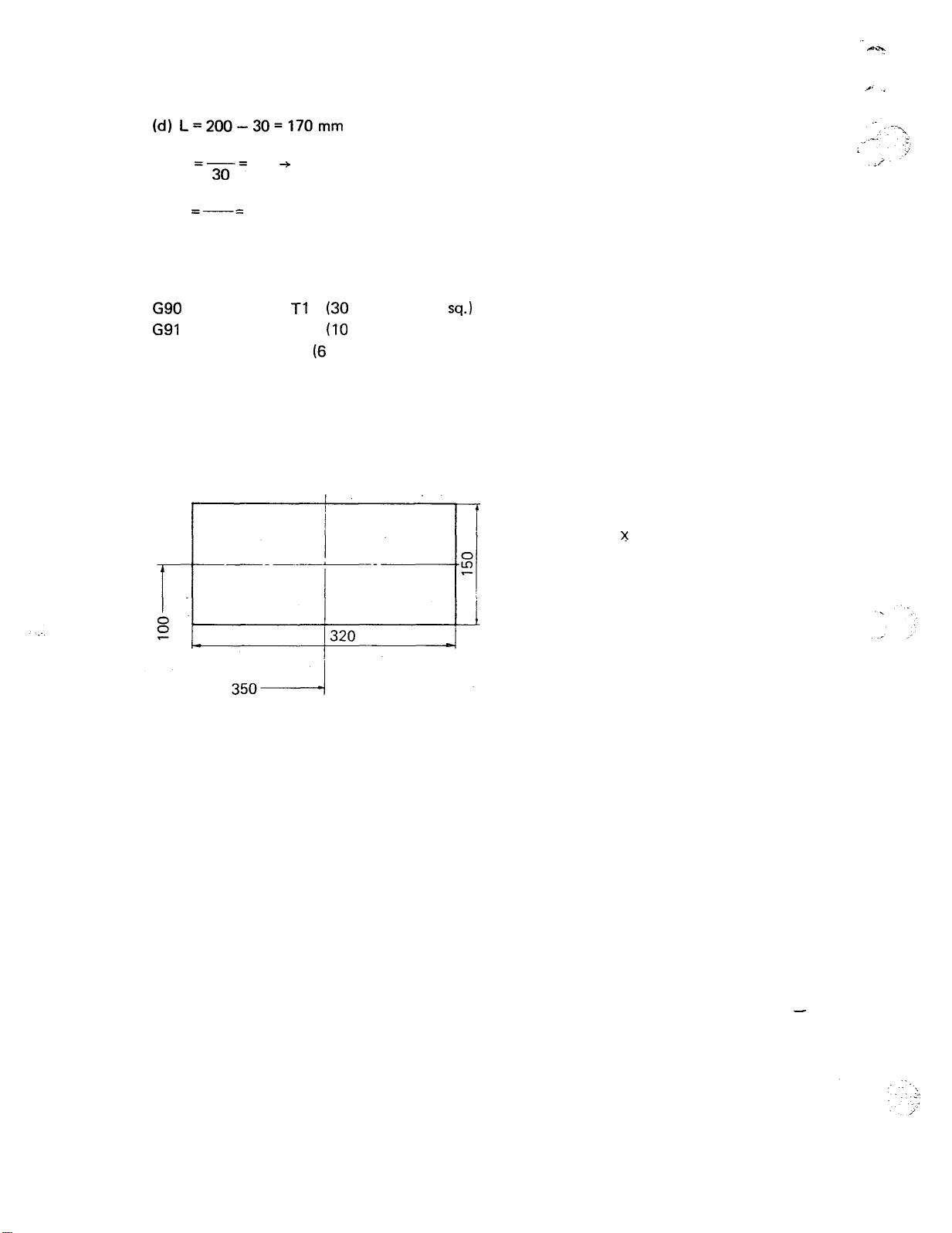

(d) L=200-30=170mm

170

170

6

5.6 + 6 times

mm

28.33

N

p

=x=

z---z

Therefore the program is:

G90

X535. Y335.

G91

X-27.

Tl

mm x 30 mm

(IO times)

sq.)

(30

Y-28.33 (6 times)

X27.

Y28.33

(IO times)

(5 times)

MOO

Problem: Punch a 150 mm x 320 mm rectangular opening with a 20 mm x 20 mm sq. punch.

T3

20 mm x 20 mm sq.

1-18

-

Page 22

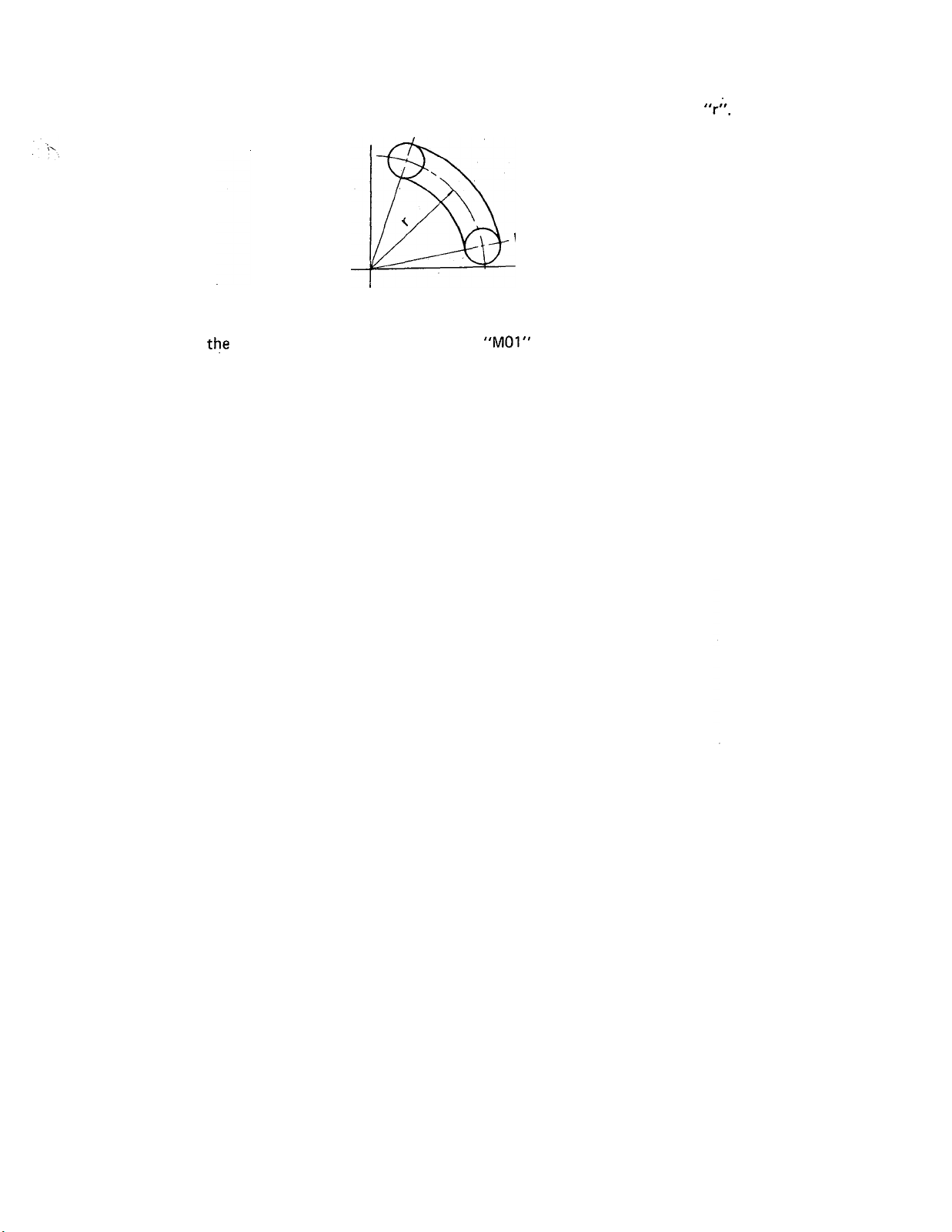

CALCULATING RECTANGULAR OPENING WITH ROUNDED CORNERS

-. .,

When punching a 150 mm x 250 mm opening with rounded corners of

/.

Ex.:

8R,

using a

16 mm dia. round punch and a 20 mm x 20 mm square punch

h

+

o--.

;-

--t

0

a

400

250

0

(ij

_--

-I

tf ‘

s

a--

-I7 i

T2 16 mm dia.

T3

20 mm x 20 mm sq.

’

8

y--+8+-

( Starting point

I

t

(a) Punching procedure

First, punch 4 corners of 8R with 16 mm dia. round punch.

Finish punching at the upper right corner.

(b) Punching positions for 4 corners.

Punching position for one corner

Punching positions for other corners

-Absolute value

Incremental value (Opening length - 2 x R)

-

(c) First punch position with a square punch (X,,

-Absolute value

Y,

)

(d) Punching frequency and feed pitch of @

(e) Punching frequency and feed pitch of

0

(f) Travel distance from the finishing point on one side to the starting point on another side

-Incremental value

X value: Radius

Y value: Radius

(g) Prepare the program in accordance with. punching procedures.

(h) Enter

“dO0”

or “MO1 “ in order to remove the scrap.

1-19

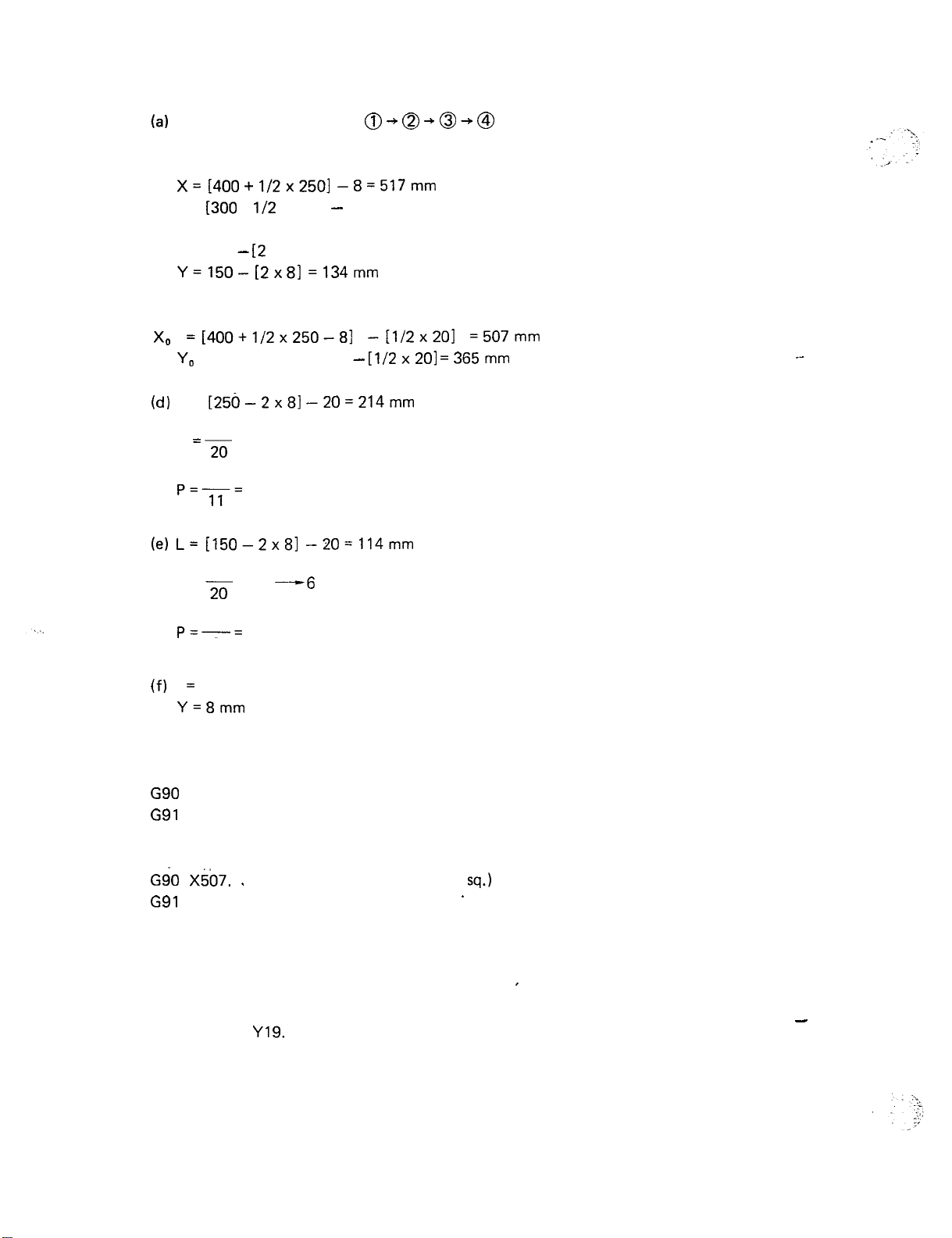

Page 23

(a)

4 corners and then @

--f

@ + @ + @

(b) Absolute value (upper right corner)

X=[400+1/2x250]

Y = [300 +

l/2

x 1501 - 8 = 367 mm

-8=517mm

Incremental value

X = 250 - [2 x 81 = 234 mm

Y=150- [2x81 =134mm

(c) Position of the first square punching

X0 =[400+1/2x250-81

Y,

= [300+1/2x 1501 -

(d)

L=

[256-2xX]

-[1/2x20]

[1/2x201 =365mm

-20=214mm

=507mm

214

N

=x

= 10.7

214

P=y=

(e) L= [150-2x8]

114

N = 20 = 5.7

114

p=-=

6

(f)

X = 8 mm

-11 times

19.45 mm

---6

19 mm

-20=114mm

times

Y=8mm

Therefore the program is:

G90

G91

X-234.

X517.

Y367. T2

Y-l 34.

X234.

GiO

X567. 3

G91

X-19.45.

Y365. T3

X-8. Y-8.

Y-l 9.

X8.

Y-8.

x19.45

X8. Y8.

Y19.

MOO

(16 mm dia.1

(20 mm x 20 mm

(11 times)

(6 times)

(11 times)

(6 times)

sq.)

’

-

I-20

Page 24

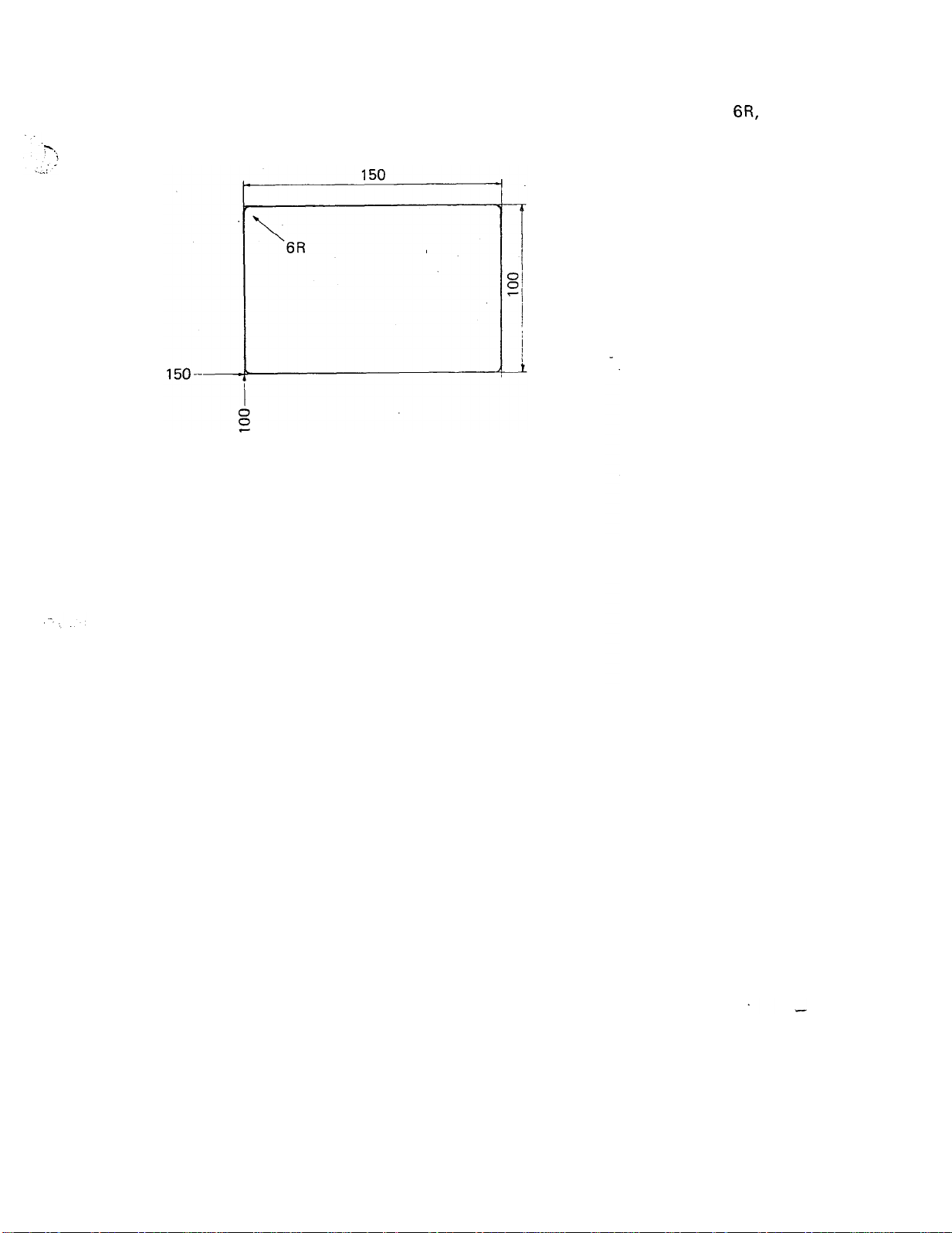

Pioblem: Punch a 100 mm x 150 mm rectangular opening with rounded corners of 6R, using

a 12 mm dia. round punch and a 20 mm x 20 mm square punch.

T2 12 mm dia.

T3

20 mm x 20 mm sq.

1-21

Page 25

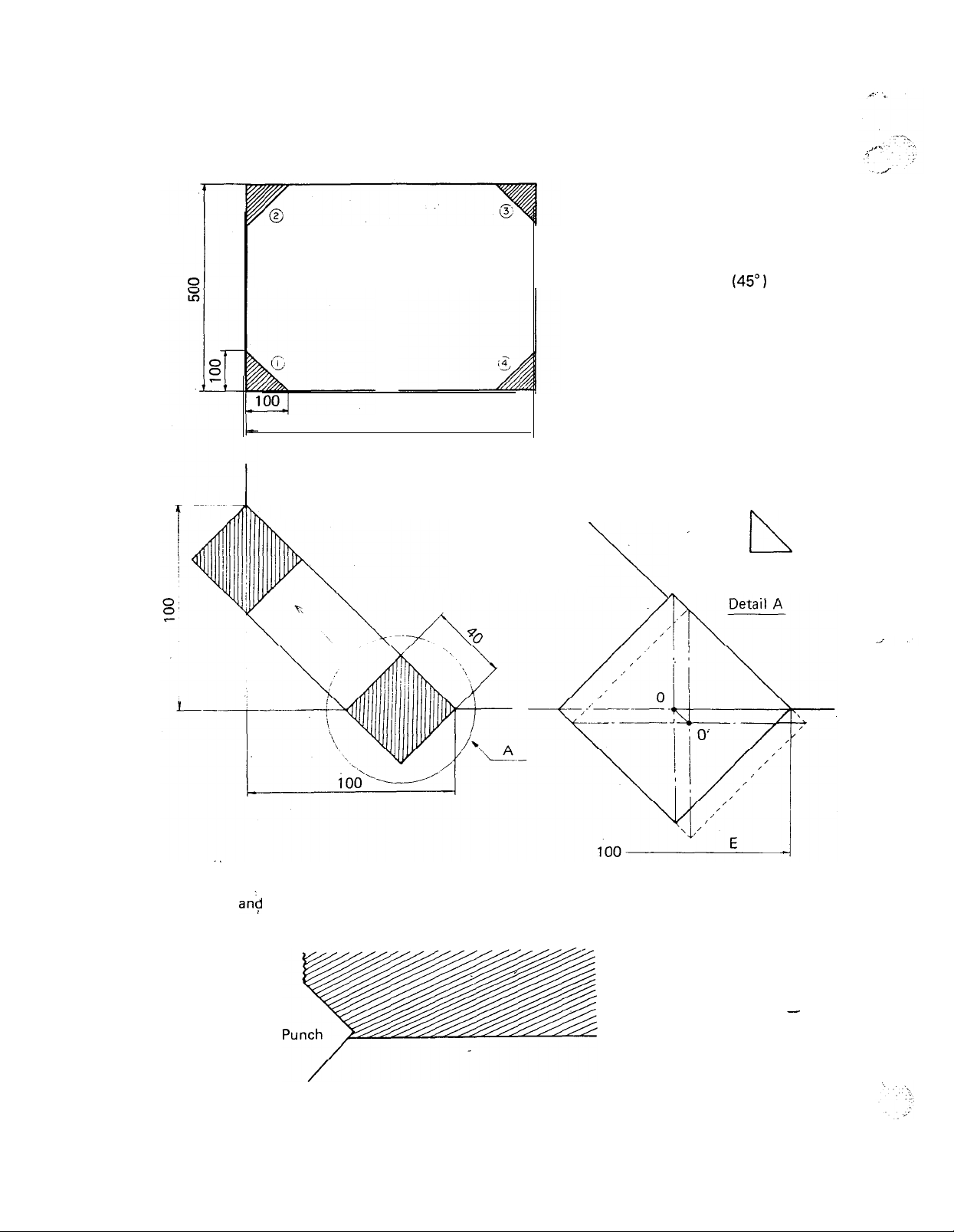

CALCULATING 45” NOTCH

When punching 45” notches in 4 corners of a 500 mm x 600 mm plate

Ex.:

T6

600

40 mm x 40 mm sq. (45”)

Corner detail

The starting

an?

finishing points of notching should be shifted about 1 mm in order to en-

sure accurate notching.

0

I

Imm

n

1 mm

0’

\,

1-22

-

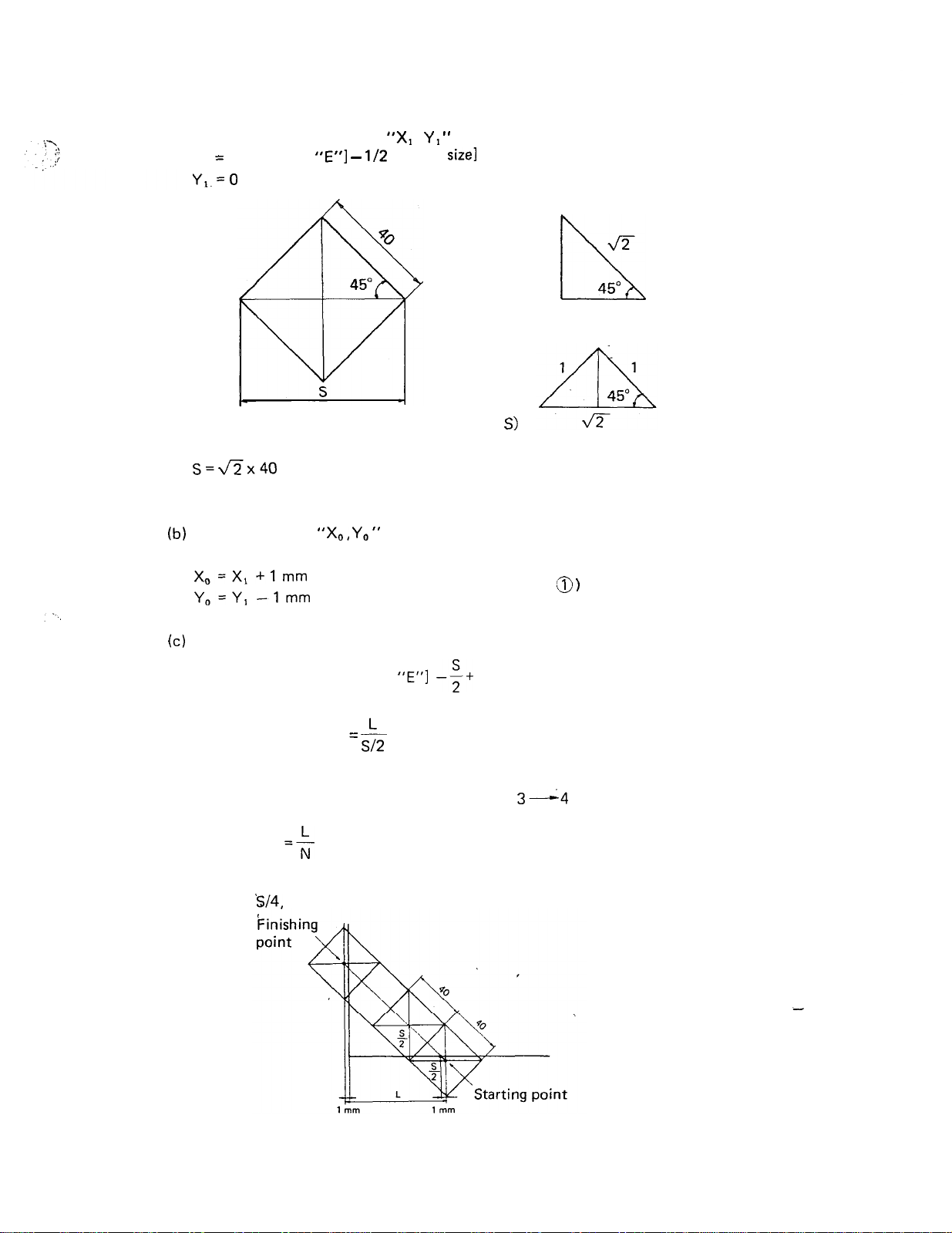

Page 26

Notching the lower left corner

(a) Provisional starting point (0)

=

[Notch size

Xl

Y,.=O

s=fix40

= 1.414 x 40 = 56.56 mm

Starting point (0’)

(b)

Shift both X and Y axes about 1 mm from (0).

X,=X,-+lmm

Y,=Y,-lmm

“E”] - l/2

“X0, Y,,”

(In case of the lower left corner \B

“Xl

, Y, ” (Absolute value)

[Punch

(Diagonal punch size:

(Absolute value)

Size]

S>

1

L

&T

45”

1

)

Punching frequency and feed pitch

(cl

Travel distance L = [Notch size

Punching frequency N =

Feed pitch P

NOTE:,

=k

The feed pitches of the X- and Y-axes should be

S/4, but smaller than S/2 minus 0.5 mm (0.02”).

$2

","I -G+

2 x

1 mm

When decimal numbers are obtained

Ex.: 2.3 -3

When integral numbers are obtained

Ex.:

3-4

equal

and

should

be larger

than

l-23

Page 27

(a) X1

(b) X,

=lOO-1/2x56.56=71.72mm

=Omm

Y1

= 71.72 + 1 = 72.72 mm

Y,

=0- 1

=-l.OOmm

(c) L = 100 - 28.28 +. 2 = 73.72

&

N=

P

=$=

= 2.62 -3 times

24.67 mm

Therefore the program is:

G90 X72.72 Y-l. T6

G91

X-24.67 Y24.67

(40 mm x 40 mm sq. 45”

(3

times)

-.

/n, ‘.I

i

,..‘.,.’

’

.,’

1

Problem: Calculate

“5”

of a 30 mm x 30 mm sq. 45” punch, and of a 50 mm x. 50 mm sq.

45” punch.

Problem: What will the sign of 1 mm be when calculating the starting point (0’) for each

corner?

“0”

I.

Problem:,Prepare

the program for notching all corners

x 35.4 mm sq. (45”) punch

mark means starting points.

I

(ix), a, 0

.

.

[Tll

and @) with a 35.4 mm

. .

1-24

-

:

Page 28

HINTS ON PROGRAMMING

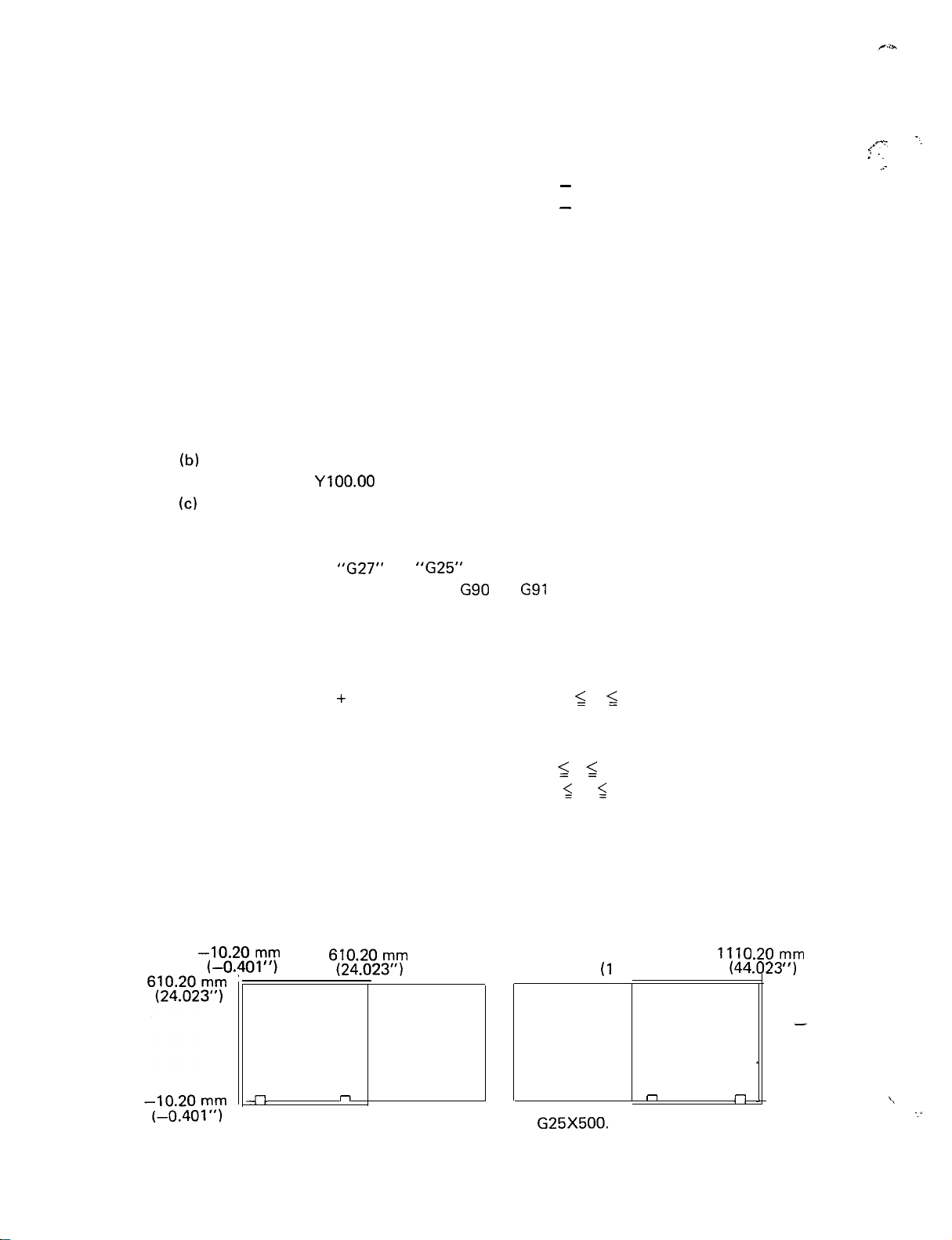

1. PUNCHING RANGE

Punching range common to all stations

AR I ES-222

X-axis:

Y-axis:

-lo:2

mm to 610.2 mm (metric), -0.401” to 24.023” (imperial)

-10.2 mm to 610.2 mm (metric), -0.401” to 24.023” (imperial)

AR I ES-224

X-axis:

-10.2 mm to 1010.2 mm (metric), -0.401” to 39.772“ (imperial)

Y-axis: -10.2 mm to 610.2 mm (metric), -0.401” to 24.023” (imperial)

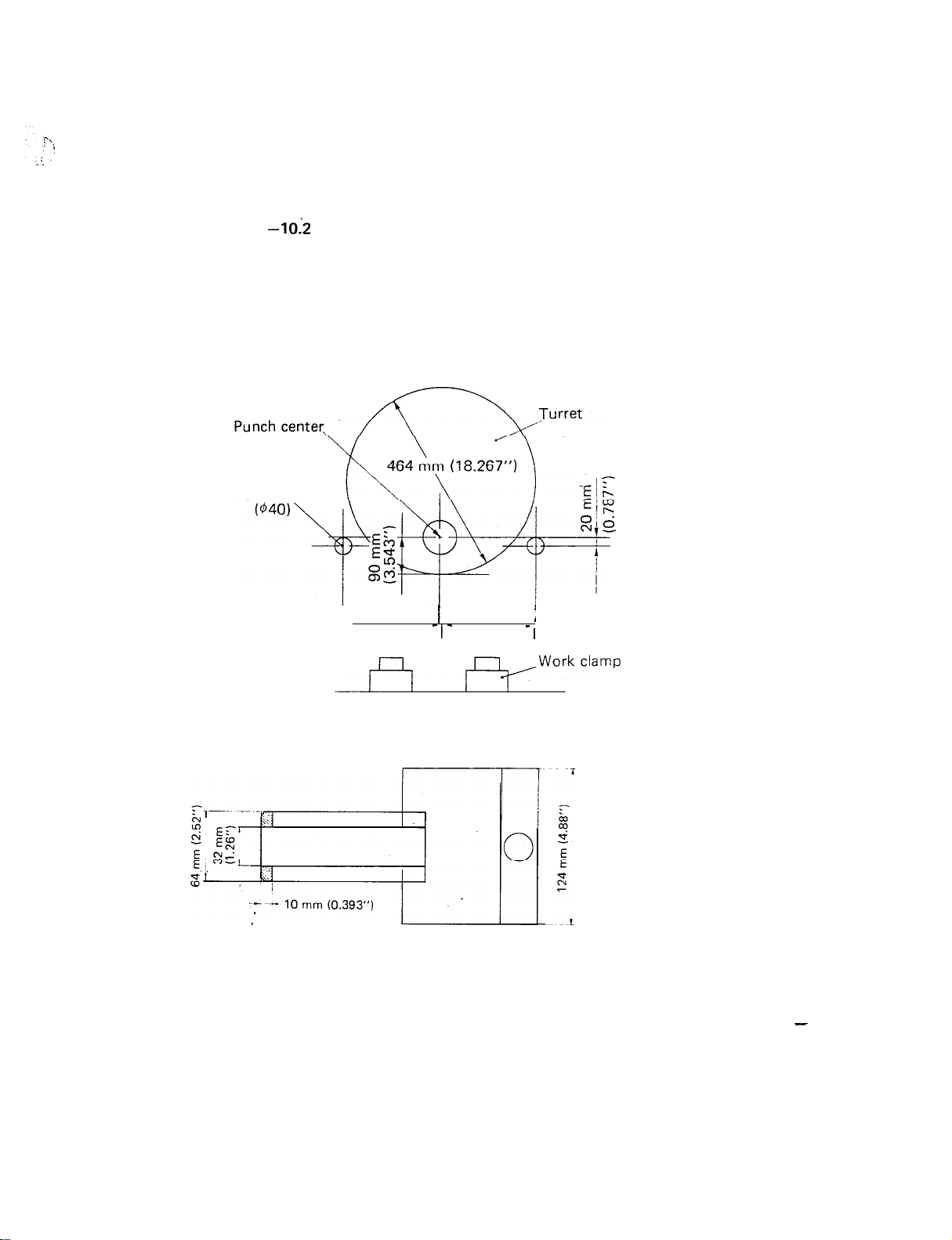

2. POSITION OF WORKHOLDERS

Work holder

200 mm

(7.874”) - 1 - (7.874”) -

3. WORK CLAMP DIMENSIONS

200 mm

/

j

I

-

1-25

Page 29

HINTS ON AUTO REPOSITIONING .

1.

Repositioning travel distance ---as small as possible

ARIES-222 [Maximum processing position (X value)] - 610 mm (24.015”)

ARIES-224 [Maximum processing position (X value)] - 1010 mm (39.764”)

,.c

-.

:

I

‘.

.i

2. Clamp position

---as far apart as possible

Consider the following:

l Dead zone

l Worksheet size

l Notches

3. First processing area

----as large as possible

4. Reposition

(a) Ensure the worksheet is under the work holders.

(b)

Ensure the clamps do not pass between the upper and lower turrets when the reposi-

tioning is done.

(c)

Ensure the X-axis absolute value is greater than the repositioning travel distance. If

it is not greater than the repositioning travel distance, over-travel will

5.

Coordinate value after

Use dimensions as per diagram. Mode of

6.

Avoid changing tools immediately after repositioning to save processing time.

7.

Processing area after auto repositioning (AR I ES-222)

YlOO.00

“G27”

mm (min.)

and

“G25”

G90

and

G91

does not change.

occur.

-10.2 mm (-0.401”) + repositioning travel distance 5 X 5 610.2 mm (24.023”) +

repositioning travel distance.

Ex.:

G27 X500. (X20.000)

Processing area after auto repositioning = 489.8 5 X 5 1110.2 mm

(19.283”

5

X 2 44.023")

NOTE: When the repositioning detector switch has been turned to ON, the repositioning

light will be lighted and a pause is made for confirmation before auto repositioning

provided the programmed Y-axis value is less than 95 mm (3.74”). In this case be

“sure, to check to ensure that there is no interference between the work holders

and work clamps before pressing start button.

11_0d2$gT

,I

*,

y2;;g?!7

Travel area

489.80 mm

(I

9.283”)

Travel area

ll;:

.2c

13m;l

.0;

1

4-l

rl

Before repositioning

After G25X500. (X20.000) repositioning

m

fy _

l-26

,I

\

\

‘..

Page 30

-

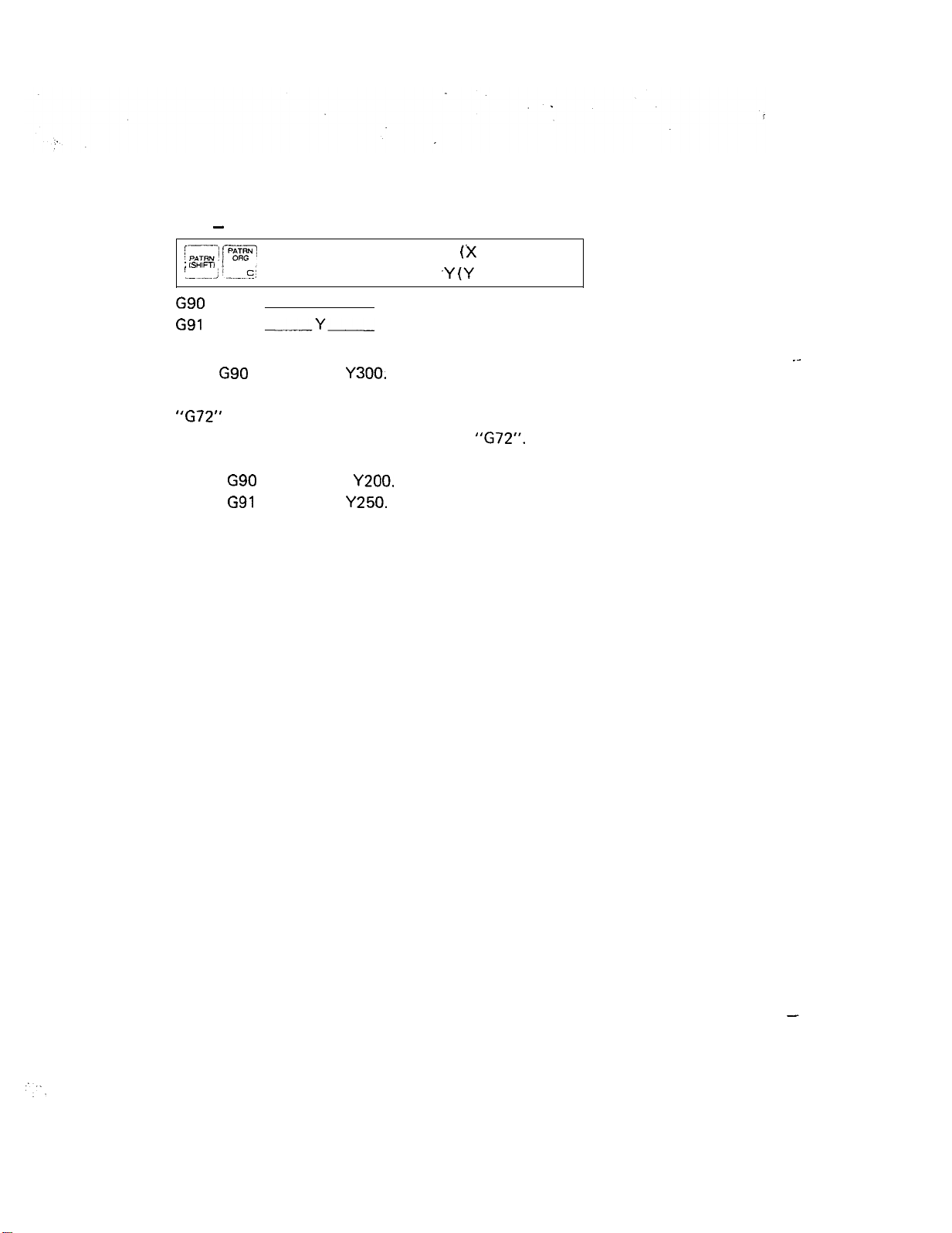

G72

DESIGNATION OF PATTERN ORIGIN

!cRN-! pR3

i

lSHlFTl /

.-.-j ‘._--..G

G72

,

[PATTRN ORIGIN]

BASIC SOFTWARE

X (X POSITION)

.Y

(Y POSITION);

G90

G72 X

G91

G72 X

This code is used to designate the pattern origin.

Ex.:

G90

The pattern origin can be entered both as an absolute value and as an incremental value.

“G72”

Never enter the M or T code in a block with

For example, never enter:

If an incremental value of X and Y is given after a pattern command, the value must refer

to the final pattern point.

-Y-

G72 X500. Y300.

merely selects a coordinate; neither positioning nor punching is performed.

G90

G72 X300. Y200. T2

G91

G72 X150. Y250. MOO

Y

“G72”.

.-

2-l

-

Page 31

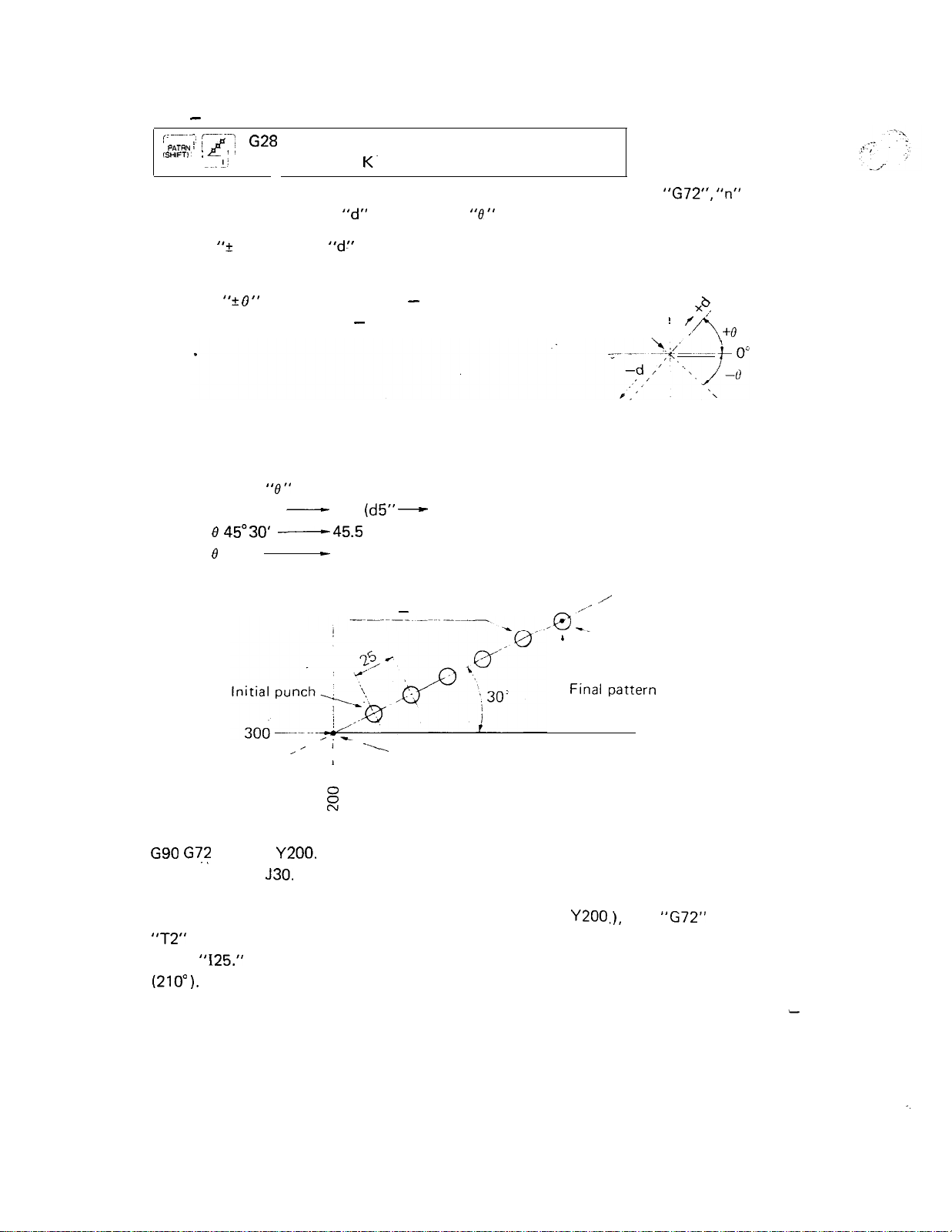

G28

-

(‘-..-.---; r&y

PAATRN

: !

ISHIFT)’ ;

LINE AT ANGLE

G2*

~.. ‘j

[LINE ANGLE1 K. (NO. HOLE) T (TOOL NO.);

I (PITCH)

J (ANGLE)

Starting from either the current position or from a point designated by

are punched with a pitch of

I: Pitch “+ d”

When

“d”

at an angle of

“d:’

is negative, the punching is performed in the opposite direc-

“0“

to the X-axis.

tion from that of positive “d”.

J :

Angle

‘9. 0 ”

Counterclockwise - positive

Clockwise - negative

Pattern origin

\ :

K: Number of holes “n” (excluding the point of the pattern origin)

NOTE:

Example:

“d” and

d 200 mm

e 45”30’

e

45”

“0”

are given as follows:

-

200. (d5”

-------45.5

-

45.

6 holes - 10 mm dia

-

5.)

/

.B I:

L

Final

“G72”, “n”

I

3

!

f

?’

‘i,

punch

holes

+o

I

G90

G!?

X300.

G28 125. J30. K6 T2

,

Y200.

/’

L

E

“

Pattern origin

10 mm dia: T2

When punching the same hole at the pattern origin (X300.,

“T2”

in the upper instruction block.

When

(210”

“125.”

1.

becomes “I-25.“,

punching is performed in the direction of 180” symmetry

,

Y200.

,),

omit

point

“G72”

and enter

. .

2-2

Page 32

Problem:

Problem:

4 holes - 10 mm dia.

7 holes - 5 mm dia.

10 mm dia.: T2

b ij’ -a.

5 mm dia.: T8

2-3

Page 33

G29 - ARC

I (RADIUS) J (START ANGLE)

-\

,^

I.

On the circumference of a circle having a radius

point designated by

punched, starting from a point at an angle of

“G72”

as the center,

+‘n”

“0”

I: Radius “r” - positive

J: Start angle “? 0”

Counterclockwise - positive

Clockwise - negative

K: Number of holes

P: Angle increment “+

“n”

Atl”

Counterclockwise - positive

Clockwise - negative

Example:

Final punch

“r” with either the current position or a

holes with an angle increment of

“AO”

to the X-axis.

are

Final pattern point

380-

I.1

Pattern origin

2

G90

G72 X380. Y120.

Gi!iI 1180.

J30.

K6 P15.

When punching the same hole at the pattern origin (X380..

“T2”

in the upper instruction block.

When

“P15.”

becomes “P-l

with the starting point.

l-9

,,z

5.“,

punching is performed in a clockwise direction beginning

Y120.1,

omit

“G72”

and enter

-

2-4

Page 34

Problem:

1

2

5

5 holes - 20 mm dia.

20 mm dia.: T3

Problem:

5 holes - 20 mm dia.

20 mm dia.: T3

2-5

Page 35

G26 -BOLT HOLE CIRCLE

i,;; @’

! ,SrnFTl

G26

!

-.H_!

[BOLT HOLE] K (NO. HOLE) T, (TOO!. NO.); ,

---

On the circumference of a circle having a radius

point designated by “G72” as the center,

I (RADIUS) J (START ANGLE)

“r” with either the current position

“n”

holes dividing the circumference into

equal parts are punched, beginning with a point at an angle of

I: Radius “r” - positive

“0”

to the X-axis.

or‘s

“n”

.

‘.

.’

.’

2’

J: Start angle

“+_

0”

K: Number of holes “f n”

Example:

\

G90

G72 X300. Y250.

G26 180. J45. K6 T2

Counterclockwise - positive

Clockwise - negative

Counterclockwise - positive

Clockwise - negative

i

\.h,

’> \ Pattern

/ \

A ’

-

2

origi‘bn

%\

Finai

pattern point

/

‘Final

punch

When punching the same hole at the pattern origin

“T2”

in the upper instruction block.

The final pattern point coincides with the pattern origin.

2-6

(X300., Y250.1,

omit

“G72”

and enter

-

”

,:

._

Page 36

Problem: Punch four 20 mm dia. holes using code G26, then punch two 20 mm

using an incremental instruction.

,,,

4 holes - 20 mm dia.

mm dia. bolt hole circle

/

20 mm dia.

dia.

holes

I

I

i

20 mm dia.: T3

2-7

-

Page 37

G36 -GRID-X

G37 -GRID-Y

I (PITCH X) P

J (PITCH Y) K

T (TOOL NO.);

I (PITCH X) P

J

(PITCH

T (TOOL NO.);

Y) K

(#X

(#Y

SPACES)

(#Y

SPACES)

(#X

SPACES)

SPACES)

ir’--

.-’

--\

-,

..“’

Starting from either the current position or from a point designated by

of “n,

“d2 ”

G36: Punching starts from the X-axis side.

G37: Punching starts from the Y-axis side.

I: Pitch X “+ d,

P: #X spaces “n,

J: Pitch Y “+ d,

K: #Y spaces

Example:

spaces with a pitch of

”

parallel to the

Y-axisis

”

”

”

“n2 “

+X direction - positive

-‘X

+Y direction - positive

-.Y

“dl ”

parallel to the X-axis and

punched.

direction - negative

direction - negative

23

.holes -

“n2 “

10 mm dia.

“G72”,

spaces with a pitch of

IO mm dia.: T2

a grid pattern

Initial

punch,_ _

I

_-i

L---

_

---_I

Initial punch

--s

I

i

1

7

Final punch

\

Final pattern point

G90

G72 X350. Y410.

G36 150. P3 J-20. K5 T2

When punching the same hole at the pattern origin (X350.,

“T2”

in the upper instruction block.

(G36l

G90

2-8

,

G72 X350. Y410.

G37 150. P3 J-20. K5 T2

Final pattern point

Final punch

--

T

f-!

r

I

i

(G37)

Y410.1,

omit

“G72”

,,/

//

f

L

,

;

and enter

-

-.

Page 38

Problem: Program the following using codes G36 and G37. Indicate their respective final

punches.

24 holes - 14 mm dia.

14 mm dia.: T3

Problem:

210

1

50

mm x 50 mm sq.:

T1

2-9

Page 39

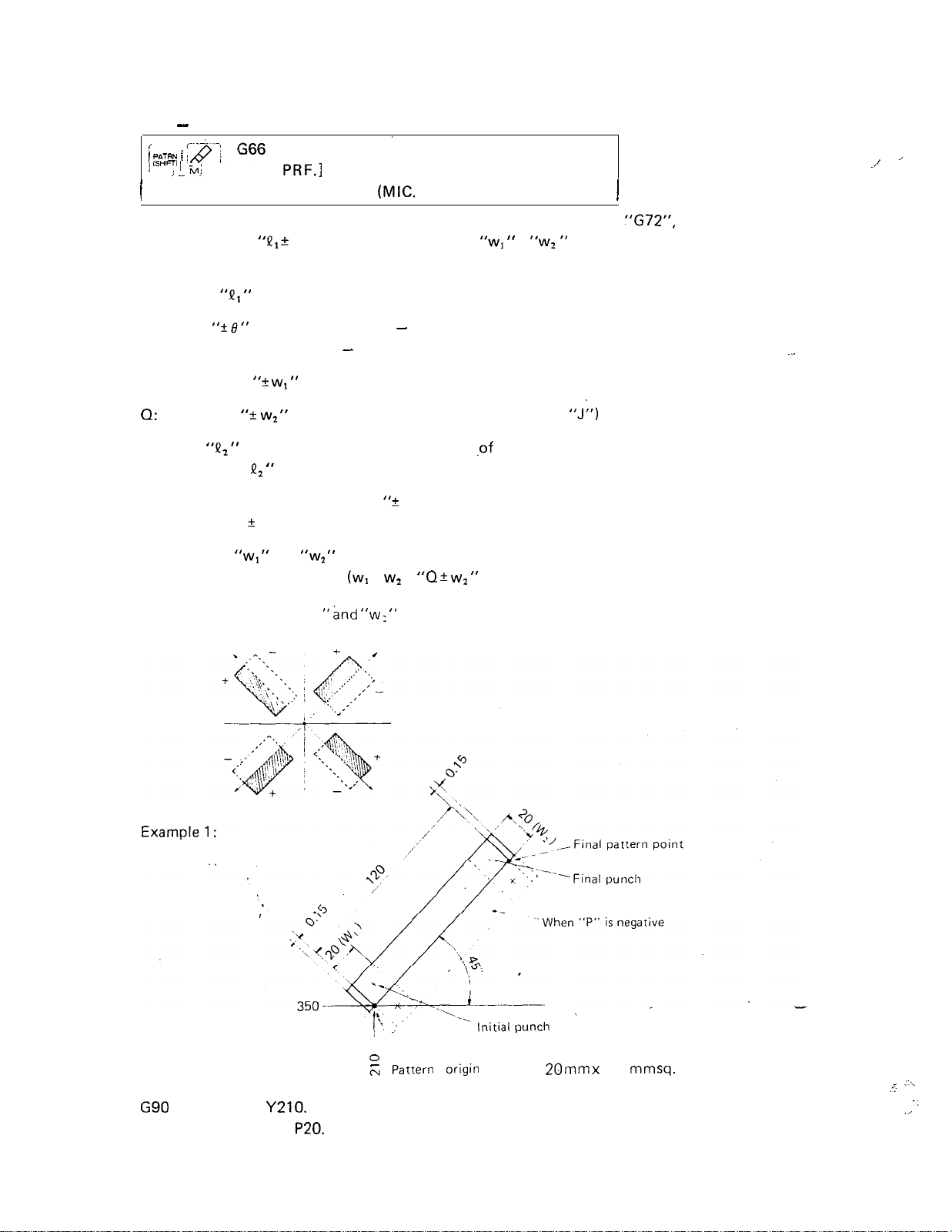

G66

<

----,

/ PAWN

/ (S~IFTI i

I

I

SHEAR PROOF

j

i .~ M;

[SHEAR

K (WIDTH)

I (LENGTH) J (ANGLE)

PRF.]

P (TOOL LTH.) Q (TOOL WTH.)

D (MIC. JOINT) T (TOOL NO.);

Starting from either the current position or from a point designated by

with a length of

‘VI 2

2d” and a punch width of

“wl ”

x

“w2”

is performed at an angle of

“0” to the X-axis.

1

“G72”,

a shear proof

..I

-- ’

I: Length

J: Angle “+

“J1, ”

8”

Counterclockwise - positive

Clockwise - negative

P:

Tool length “k w1 ” (punch width in the “J” direction)

0:

Tool width “? w2 ” (punch width in the direction of 90” to

K: Width

“P1 ”

(Punching length in the direction

.of

90” to “J”)

“J”)

If K = Q, “K P, “ can be omitted.

D: Micro joint compensation value “? d” (in relation to punching length)

If d = 0, “D + d” can be omitted.

The values of

When a square punch is used

“wl “

and “w2 ” must have the same sign.

The sign of “w, ”

(w,

= w2 ), “0 f wz ” can be omitted.

and “w: ”

.-

G90

G72 X350. Y210.

G66 1120. J45.

P20.

DO.1 5 T3

0

- Pattern

N

origin

2-10

20

mm

x

20

mm

sq. (45”): T3

.

:\

:‘

I,

.,

Page 40

When “G72” is omitted and

origin (X350., Y210.) is also punched.

When

“P20.”

line.

I (length

The final pattern point does not coincide with the final punch-center.

When “D0.15” becomes

determined by 0.15 x 2 = 0.3.

Example 2:

becomes

“Q1 “)

must be at least 1.5 times as large as P (tool length “* w1 ‘I).

“P-20.“,

“D-0.15”,

“T3”

is entered in the upper instruction block, the pattern

a shear proof is performed in the direction of the dotted

the overall punching length

Final pattern point

“I”

is 0.3 mm shorter as

2-&

:o,

\

\

\

\

. .

G90

G72 X200. Y150.

G66 180.

When

“G72”

origin (X200., Y150.) is also punched.

When

line.

I (length “VI “) must be at least 1.5 times as large as P (tool length “lw,

K (width

The final pattern point does not coincide with the final punch center.

Square,punch

“P20.”

“P2 “)

Problem:

J30. P20.

is omitted and

becomes “P-20.“,

must be at least 1.5 times as large as P (tool length “Iw, ‘I).

= w2 ) must be used when K (width

(w,

’

200

K50. T2

“T2”

’ /’

‘_ ’

is entered in the upper instruction block, the pattern

a shear proof is performed in the direction of the dotted

/

400

<yyWh’”

Y’

/

/

/

,

20 mm x 20 mm sq. (30” ): T2

“P2 “)

is entered.

IW

“p“

is

“).

negative

6 mm x 60 mm

2-11

Rect.:

T6

Page 41

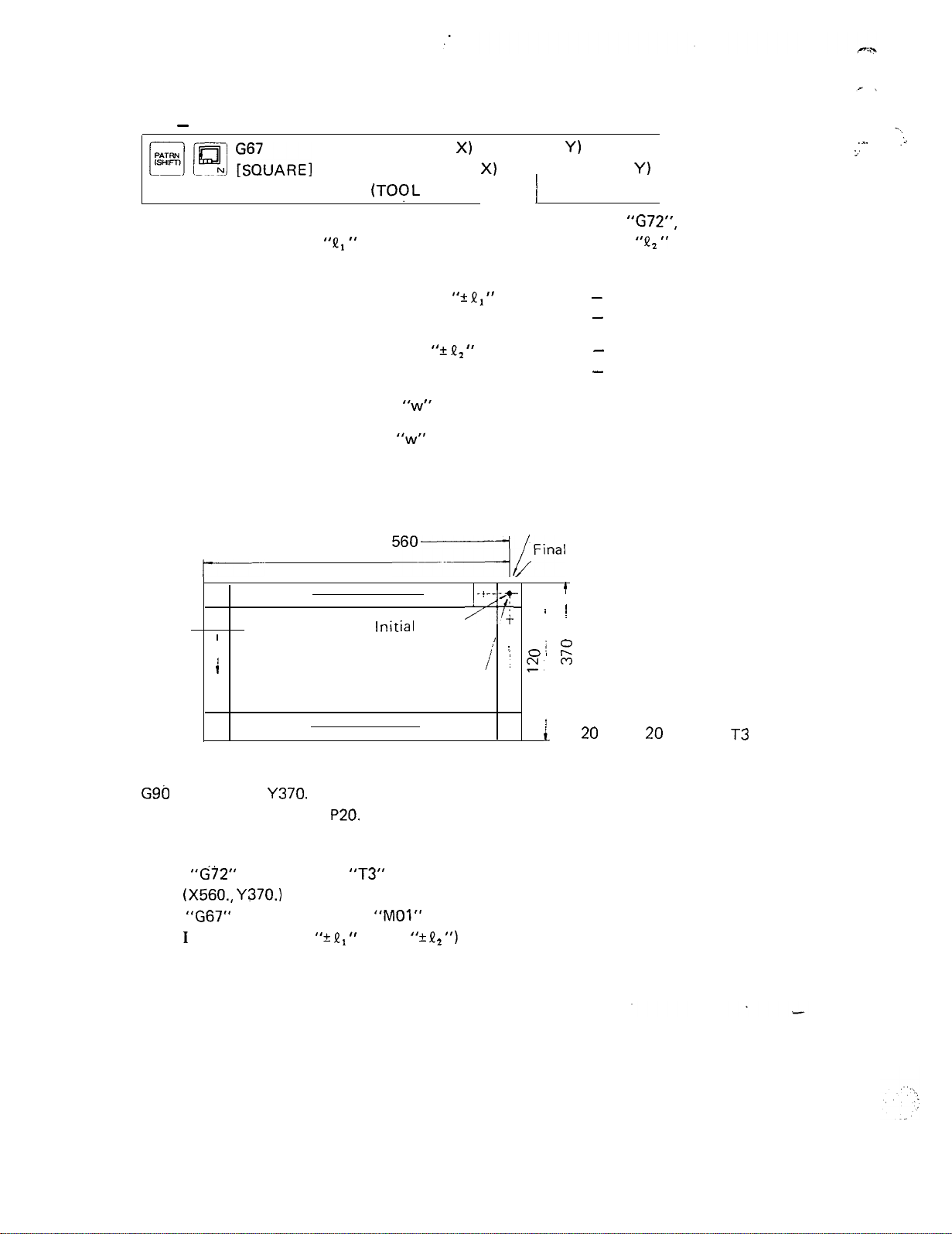

G67 - SQUARE

I (LENGTH Xl J (WIDTH Y)

H

F!! I;ZJAREI

Starting from either the current position or from a point designated by

opening with a length of

P (TOOL LTH. X) Q (TOOL WTH. Yl ,

T (TOOL NO.); MOO (STOP);

parallel to the X-axis and a length of

“Ql”

--

j

“G72”,

“!&I

Y-axis is punched, using a square punch with a width of “w”.

I: Opening length in the-X-axis direction “? Q, ” +X direction - positive

-Y direction - negative

a rectangular

parallel to the

L.’

‘-.-

-,

.:.

J:

Opening length in the Y-axis direction “+ P,

+Y direction - positive.

”

-Y direction - negative

P:

Tool length in the X-axis direction

Q: Tool width in the Y-axis direction

“w”

(positive value only)

“w”

(positive value only)

NOTE: As a square punch is normally used on programming G67 function, “Q” is often

omitted.

Example:

240

560~i~Final

Pattern origin

pattern point

P-

20

I

I

i

G9tI

G72 X560.

G67 I-240. J-120.

Y370.

P20.

T3

Initial

Final punch

punch

-+---+

,q+

1,

8’ :

/

j c, c-9

i I

oi e

!

c

f

20

mm x 20 mm sq.:

T3

MOO

When

“G72”

is omitted and

“T3”

is entered in the upper instruction block, the pattern

origin (X560., Y370.) is also punched.

When

“G67”

is fused,

“MOO” or

Both I and J (length X “?

“MOl”

III “

and Y ‘9 Q,

length “w”).

should be entered in order to remove the scrap.

must be at least three times as large as P (tool

“1

2-12

Page 42

Problem:

350

200

I

1

z

30 mm x 30 mm sq.: T6

.y,

.

.’

2-13

Page 43

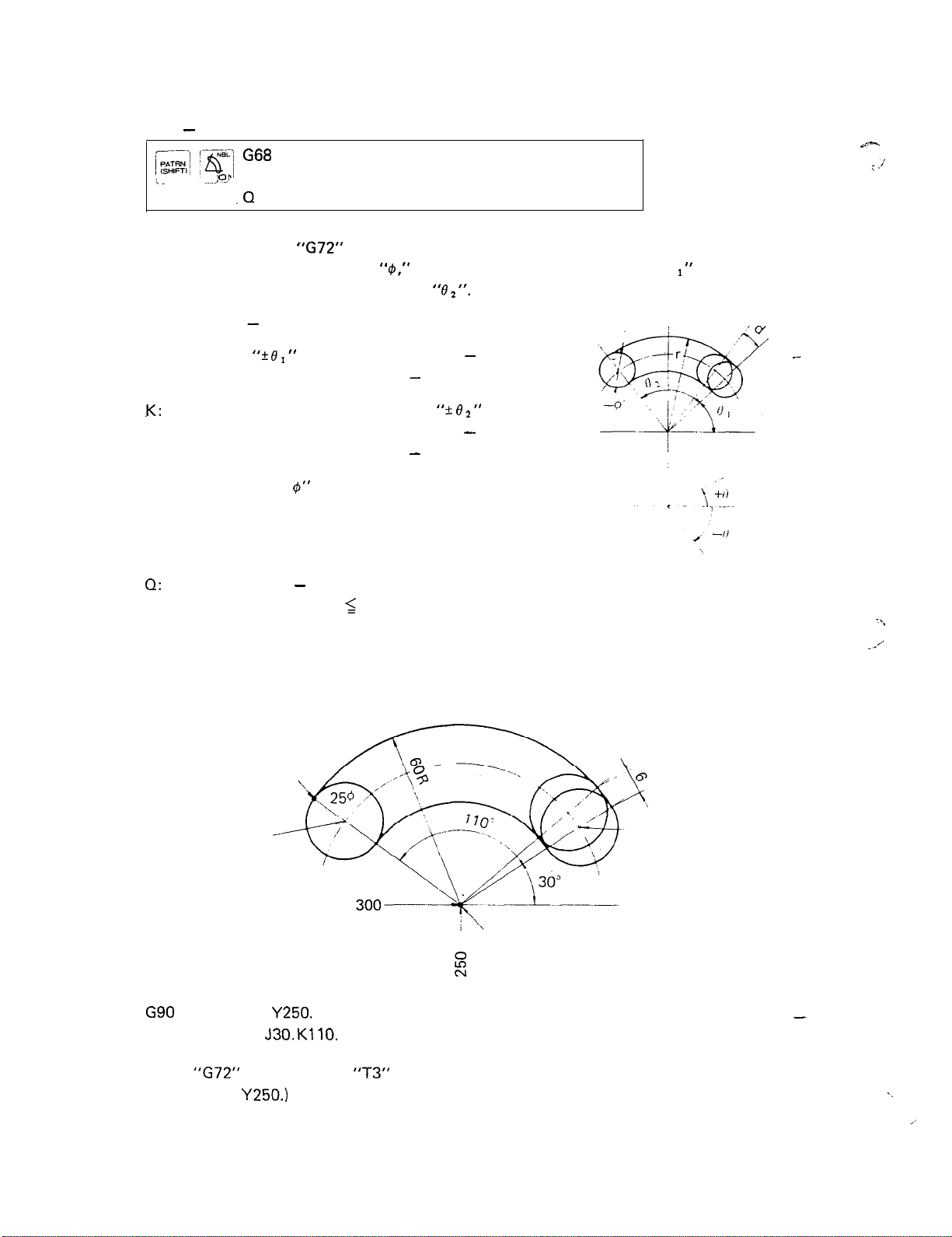

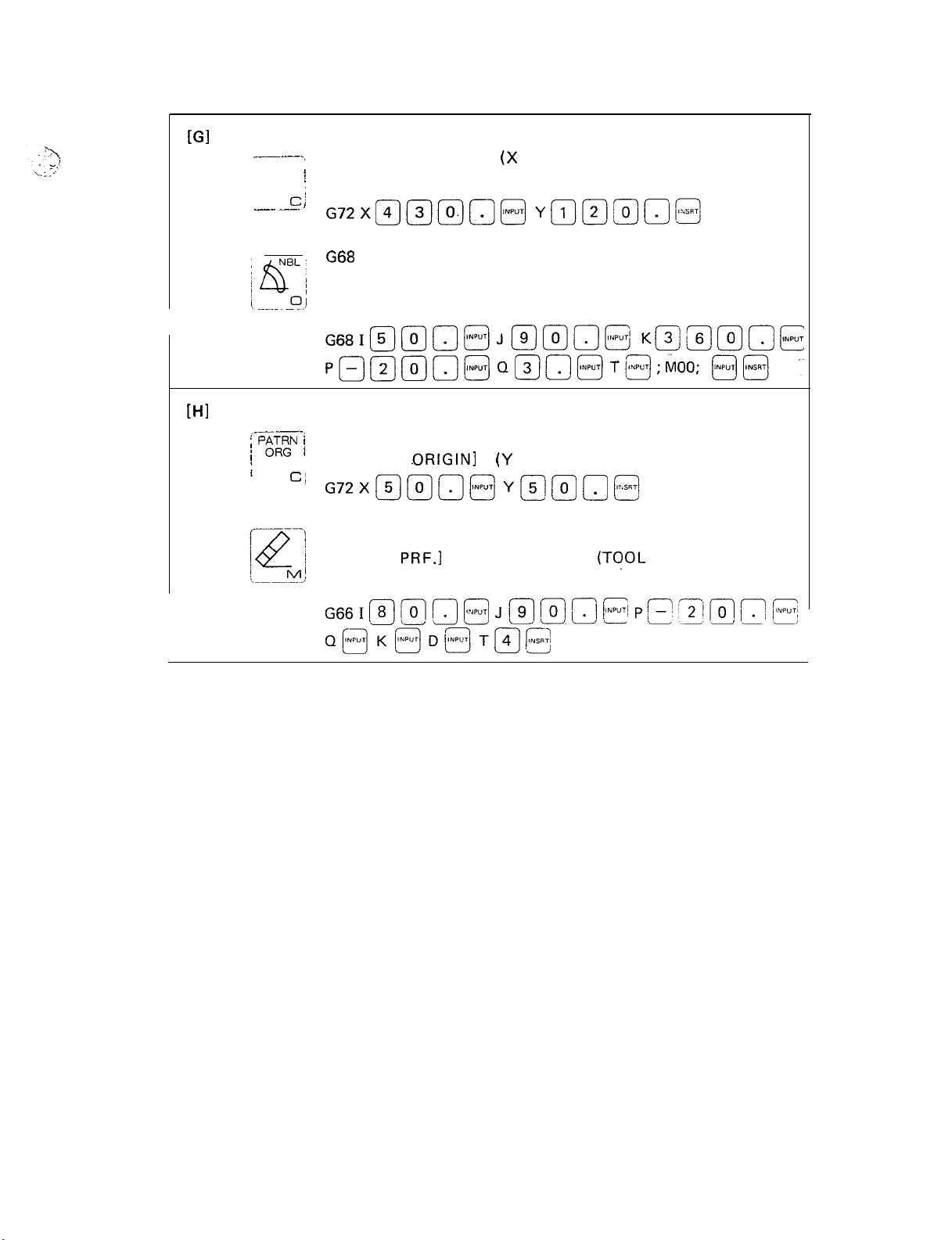

G68

NIBBLING ARC

-

~zi-~ i”] G68

i.

-.;

4,

.Q

I (RADIUS) J (START ANGLE)

[NIBBLE ARC] K (MOV. ANGLE) P (TOOL DIA.)

(NIB. PITCH) T (TOOL NO.): MOO (STOP);

u-

: ,I’

On the circumference of a circle having a radius

point designated by

using a punch with a diameter of

and moving up to an incremental angle of

“G72”

as the center, a nibbling with a pitch of “d” is performed by

starting from a point at an angle of “0 1 ” to the X-axis

“4,”

“eZ “.

“r” with either the current position or a

I: Radius “r” - positive value

J:

Start angle “k 0,

”

Counterclockwise - positive

Clockwise - negative

K:

Moving angle in which nibbling occurs “2 0 2

”

Counterclockwise - positive

Clockwise - negative

P: Tool diameter “f

4”

Enter the positive value when nibbling the outer side

of the circle and the negative value when nibbling the

inner side.

0:

Nibbling pitch “d” - positive value only

Worksheet thickness < d 2 6 mm (0.236”)

NOTE: Maximum worksheet thickness for nibbling: 3.2 mm (0.125”)

.-

“.

__”

Example:

Final pattern point

Final punch

,

G90

G72 X300.

G68 160.

When

“G72”

Y250.

J30. KllO.

P-25. Q6. T3

is omitted and

“T3”

is entered in the upper instruction block, the pattern

origin (X300., Y250.) is also punched.

, \

i

Pattern origin

25 mm dia.:

----- Initial

T3

punch

-

-.

,’

2-14

Page 44

When the value of “P” is zero, nibbling is performed on the arc with the radius “r”.

Example:

When nibbling a worksheet with a thickness of more than 3.2 mm

(ARC) or G78 (PUNCHING ARC).

“I

When the scrap remains inside, make “J” (start angle “k

or

“MO1 ”

in order to remove the scrap.

Problem: Program the following using NBL-A

(G68)

and SHP

90” or 45” and enter “MOO”

‘0,

(G66).

(0.125”),

use code G29

.-

20 mm dia.: T3

-

50 mm sq.: T6

8

e

A

,

400

>

600

2-15

Page 45

G69

L&~

..-J

NIBBLING LINE

-

;;yBBLE LINEl I (LENGTH) J (ANGLE)

PJ

P (TOOL DIA.) Q (NIB. PITCH)

T (TOOL NO.);

.J_ -

,/

,._e’

::

.-I

Starting from either the current position or from a point designated by

with a pitch of “d” and a length

a punch with a diameter of

Length “R” (from the initial punch center to the final punch center)

I:

Angle

J:

P:

0:

Worksheet thickness < d 2 6 mm (0.236”)

NOTE: Maximum worksheet thickness for nibbling: 3.2 mm

Example:

‘*? e ”

Tool diameter “k

When the value is positive, nibbling is performed on the left

side of the straight line (on the hatched side in the figure);

when it is negative, nibbling is performed on the right side

of the straight line.

Nibbling pitch “d” - positive value only

(0.125”)

Counterclockwise - positive

Clockwise - negative

4”

“4”.

.of

“I?” at an angle of

. . ’

to the X-axis is performed using

“0”

renal punch

“G72”,

a nibbling

Final pattern point

Initial

\

‘Pattern origin

E

G90

G72 X300.

G69 1180.

If

“G72”

is omitted and

(X300.,

If P = 0, the initial punch center coincides with the pattern origin.

When nibbling a worksheet with a thickness of more than 3.2 mm

(LINE AT ANGLE) or G79 (PUNCHING LINE).

Yl20.)

Yl20.

J30.

P25. Q6. T3

“T3”

is also punched.

is entered in the upper instruction block, the pattern origin

25 mm dia.: T3

(0.125”),

use code

G28

2-16

Page 46

Problem:

‘23>/

Problem:

ii2

I

225.3

25 mm dia.: T3

Pitch: 4 mm

25 mm dia.: T3

Pitch: 5 mm

r

2-l 7

-

Page 47

G78 -PUNCHING ARC

/ ;p;%.%,‘~rg cm

!

1:

0;

[PUNCH ARC] K (MOV. ANGLE) P (TOOL DIA.)

.-

0

(NIB. PITCH) D (THICKNESS) T (TOOL NO.);

On the circumference of a circle having a radius

point designated by “G72” as the center, a punching which is the same as the NIBBLING

ARC

(G68)

is performed by turning the clutch on and off at a pitch of “d”, using a tool

with a diameter of

to an incremental angle of “0 2

“@“,

starting from a point at an angle of “0 1 ” to the X-axis and moving up

I (RADIUS) J (START ANGLE)

I

“r” with either the current position or a

“.

I: Radius “r” - positive value

J:

Start angle

K: Angle in which punching occurs ‘9 e2

P: Tool diameter “A

Enter the positive value when punching the outer side of the circle and the negative value

when punching the inner side.

0:

Nibbling pitch “d” - positive value only

Worksheet thickness < d

D: Worksheet thickness “t”

NOTE:

Example:

pattern point

Final

“+_ 6’, “

When the value of “t” is larger than the value of “d” (t > d), it is regarded as a program error.

Counterclockwise - positive

Clockwise - negative

”

4”

Counterclockwise - positive

Clockwise - negative

.-

Final punch

,

I

G90

G72 X300. Y350.

G78 1100. J25.

When

origin (X300., Y350.) is also punched.

“G72”

is omitted and “T6” is entered in the upper instruction block, the pattern

KllO.

P-30. Q6. D4.5 T6

5:

c-9

I’

dia.: T6

punch

Pattern origin

-

2-18

Page 48

When the value of “P” is zero, punching is performed on the arc with the radius

Example:

\

i

PO

:

B

7”.

When

the

scrap remains inside, enter “MOO” or

“MOl”

in order to remove the scrap.

2-19

Page 49

G79

. 1

PUNCHING LINE

-

HFJ

YZNCH LINE] g ((Lrj$TT~.,‘T~~~;l~));

1

Starting from either the current position or from a point designated by

which is the same as the NIBBLING LINE (G69) is performed by turning the clutch on and

off at a pitch of “d”,

of “0 ” to the X-axis.

I: Length “Q” (from the initial punch center to the final punch center)

J: Angle “+

P: Tool diameter “?

When the value is positive, punching is performed on the left side of the straight line (on

the hatched side in the figure); when it is negative, punching is performed on the right

side of the straight line. Refer to the NIBBLING LINE (G69) on page 2-16.

Q: Nibbling pitch “d” - positive value only

Worksheet thickness < d

D: Worksheet thickness “t”

NOTE:

Example:

0”

When “t” is larger than “d” (t > d), it is regarded as a program error.

using a punch with a diameter of

Counterclockwise - positive

Clockwise - negative

4”

“@“,

in the length of

“G72”,

“e”

a punching

at an angle

.-

/

?

.

$

_( 1

G90

G72

If

“G72”

(X300., Y120.) is also punched.

If P = 0, the initial punch center coincides with the pattern origin.

X306.

Y120.

G79 1210. J25.

is omitted and

P40.

Q6. D4.5 T6

“T6”

Pattern origin

is entered in the

2-20

upper

instruction block, the pattern origin

Final pattern po-int

30 mm dia.: T6

-

:..\

: I

.

.

-.;

Page 50

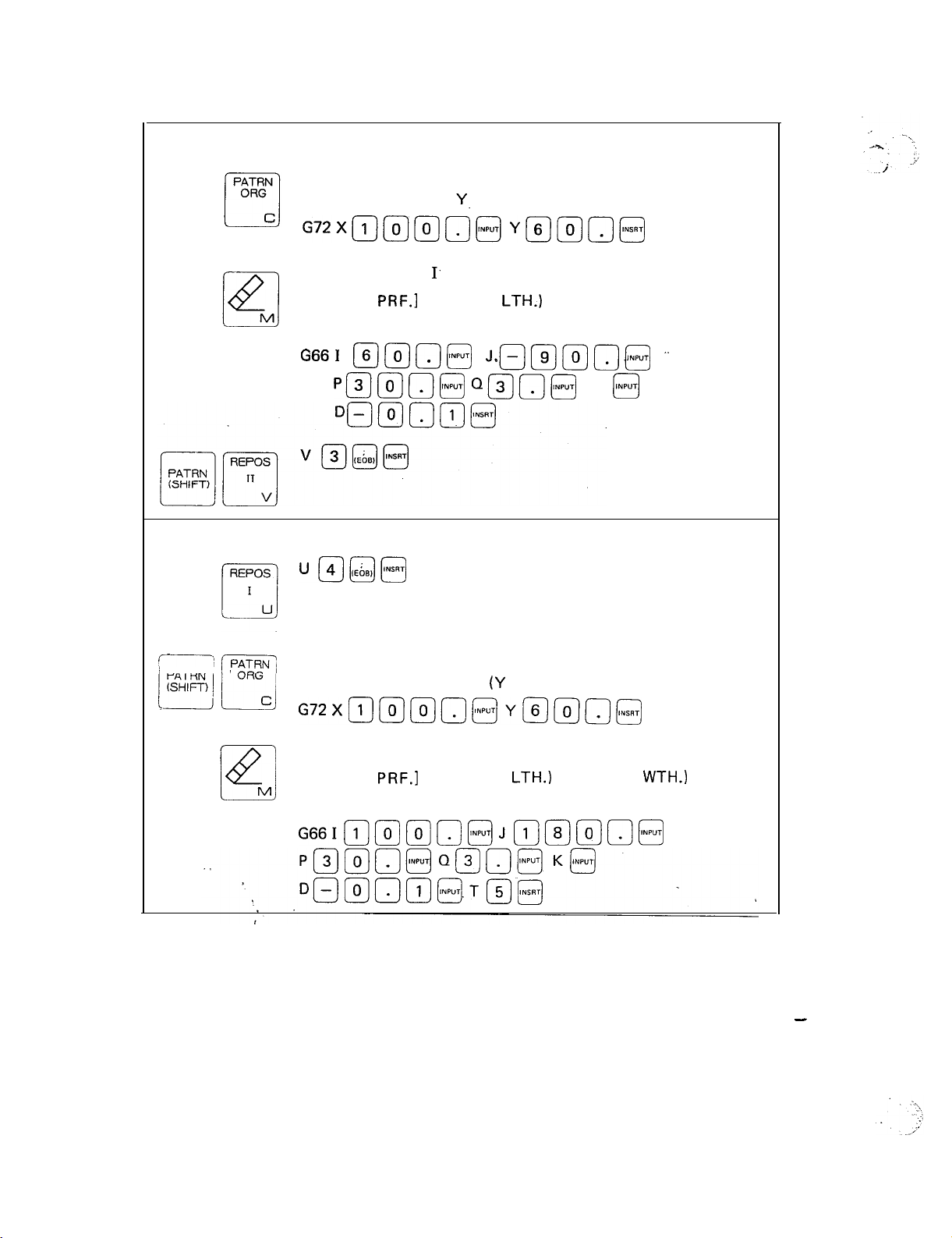

PATTERN MEMORY AND PATTERN’ RECALL

When a pattern instructed by the codes G26, G28, G29, G36, G37, G66, G67, G68, G69,

G78

or G79 is used repeatedly, the pattern can be memorized and recalled whenever re-

quired. To memorize a pattern, enter the address letter “A” along with a one-digit numeral

(from 1 to 5). To recall the pattern, enter the address letter “B” and the same one-digit

numeral as that was used by “A”.

Example:

r

G90

G72 X300.

Al G26 1125.

Y250.

J60.

300

K6 T2

-I

750

[Pattern memory]

IO

mm dia.: T2

G70 X400.

G25 X350.

_

G72 X750.

Bl

[Pattern recall]

“AO” should always be entered at the front of the pattern command block; “BO” must be

entered as a single block by itself.

“AO” and “BO” are only used for the pattern memory

and recall. Memorization and recalling of a coordinate value are impossible with these.

2-21

Page 51

Problem: Program the following with “AO”, “BO” and “G28”.

,.*

,’

-..

-.

:

i

200’~

’ T

34holesy

lam,Ydia

10mm dia.: T2

’

v--tps

2-22 ,

Page 52

-

---

-

PATRN

SHlFTi

G90

G93 X

G93

OFFSET

_.-. -.

j OFFST Gg3

.P

[OFFSET]

X-

-.

G93

,-

.~

-__-___

G91

------------------------1

Y

Y-----I

X (OFFSET

X)

Y (OFFSET Y);

3

I

1

I

This.code

X and Y coordinate system:

X’ and Y’ coordinate system:

designates the origin of the local coordinate system.

Basic coordinate system (Global coordinate system)

Local coordinate system

X” and Y” coordinate system: Local coordinate system

When designating the X’ and Y’ coordinate system

G90

G93 X50. Y75.

When designating the X” and Y” coordinate system

G90

G93 X200. Yl25. or,

G91

G93 X150. Y50.

Method of designating point A

(I 1 G90

(2) G90

(3) G90

X300.

Y205.

T2

G93 X50. Y75.

X250.

Y130.

G93 X50. Y75.

”

G93 X200. Y125. (or

X100. Y80. T2

When

changin$

G90

G93 X0 YO

from the local coordinate system to the global coordinate system

T2

G91

G93 X150.

Y50.1

-

2-23

Page 53

The G93 code is merely for establishing a coordinate system; it is not to be used for positioning or punching. Do not enter “T” or “M” with “G93”.

Example:

G90

G93 X50.

YlOO.

T2

Program error

Basic format of a program using “G93”

G92

G90

G93 X

x-

----Y-

X

-..-.--Y-

Y

-

T

~

G50

. . i.,

2-24

:;

::

Page 54

MACRO FUNCTION

1. Macro storing

Using the macro function, the contents of multiple blocks of data can be stored within the

memory of NC as a single macro data; and this stored data can be recalled whenever required.

To store multiple blocks of data, enter the address letter “U” along with a two-digit numeral

from “01 to 99” as a single block, preceding the multiple blocks which-.you wish to memo:

rize, and enter the address letter

address letter “U” as a single block, after the

“V”

using the same two-digit numeral as was used for the

mu‘ltiple

blocks which you wish to memorize.

The

twodigit

numeral following

“U” or

“V”

is called the “macro number”. This macro

number comes in the following three types:

01 - 59: The blocks of data between “U” and

“V”

remain stored while they are simul-

taneously being executed.

60 - 89: The blocks of data between “U” and

“V”

are only stored into the memory.

90 - 99: Storing of multiple macros is accomplished.

2. Macro recalling

.

The multiple blocks of data which were stored by “U” and

“V”

can be recalled by the ad-

dress letter “W” with the same two-digit numeral that was used at “U” and “V”.

2-25

Page 55

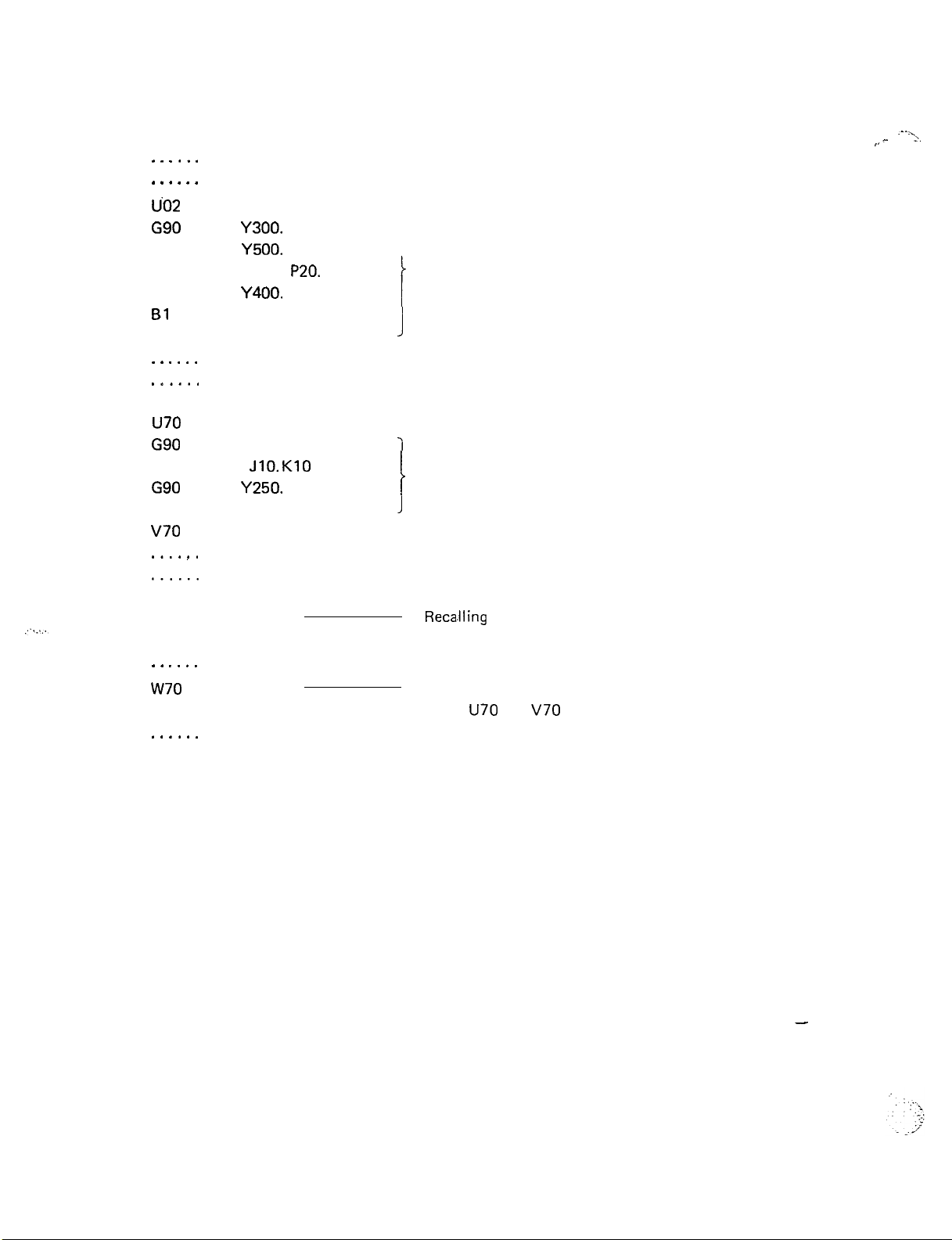

3. Example

. . . . . .

. . . . . .

u.02

G90

X100. Y300. T8

G72 X150. Y500.

Al G66 1100. JO

G72 X450. Y400.

Bl

vo2

. . . . . .

.-....

u70

G90

X200. Y 100. T3

G37 18. P3 JIO. KIO

G90

X550. Y250.

G28 125. J-90. K6

v70

......

......

P20.

1

These instructions remain stored while they are

simultaneously being executed.

t

J

i

These instructions are merely stored.

I

J

.--:

>.

r,-

wo2

. . . . . .

. . . . . .

w70

. . . . . .

. . . . . .

Reca-Iling

tween U02 and V02

Recalling and processing of instructions stored be-

tween

and processing of instructions stored be-

U70

and V70

-

2-26

Page 56

4. Multiple recalling of macro

The data which was stored as macro data can be recalled, and the recalled data can also

be stored and then be recalled again.

‘Example: U05

. . . . . . . . . .

. . . . . . . . . .

gl

@

vo5

u20

. . . . . . . . . .

3

wo5

. . . . . . . . . .

@

v20

u70

. . . . . . . . . .

@

w20

. . . . . . . . . .

@

v70

w70

In the above example, the execution is carried out in the following manner.

This multiple recalling is possible up to triple level.

5.

Memory capacity for macro (Macro numbers 01 to

Th,e

maximum memory capacity for macro is 3100 characters. One character equals:

(1)

OneSletter

(2)

One numeral

(G, X, Y, T, M, etc.)

(1,

2, 3, . . . . . .

0)

.

89)

(3) One symbol (EOB, -, /, etc.)

The delete, space, and other codes which are ignored by the NC are not considered as

characters.

,

-

2-27

Page 57

6.

Storing and recalling of multiple macros

Multiple macros can be stored and recalled by using the macro numbers 90 to 99. These

macro numbers are only capable of defining a group of multiple macros as one macro,

and they are unable to store execution instructions.

Example: iJ90

UOI

. . . .

. . . .

VOl

UIO

. . . .

. . . .

VI0

u15

. . . .

. . . .

VI5

G90

‘X100. Y200. ----This block is not stored.

uo2

. . . .

. . . .

. . . .

The maximum number of macros that can be stored by each of the macro numbers 90 to

99 is 15.

,

2-28

Page 58

BLOCK DELETION

If a slash character is entered at the beginning of a block and if

th.e

LED of BLOCK SKIP

button on the NC control panel is lighted, the block command following the slash character

is disregarded. If the LED is not lighted, the command is not disregarded but is executed.

Exampie: G90

X320. Y210. T2

G91

X50.

I

X100.

G90

X570. Y310. T4

YlOO.

T3

Basic format of BLOCK DELETION

I

G90

x-.-

X

Y

Y

T

INPUT OF DECIMAL POINT

Such data as the length, angle and time which are contained in the program can be input with

the decimal pojnt values as follows:

-

510 mm

123.4 mm

45.3”

5 sec.

x510. (= X51000)

-

-

-

X123.4 (= Xl

J45.3 (=

x5. (= X500)

2340)

J45301

The decimal point is available as an input for the addresses X, Y, C, I, J, K, P, Q and D.

2-29

Page 59

.*.

il..,

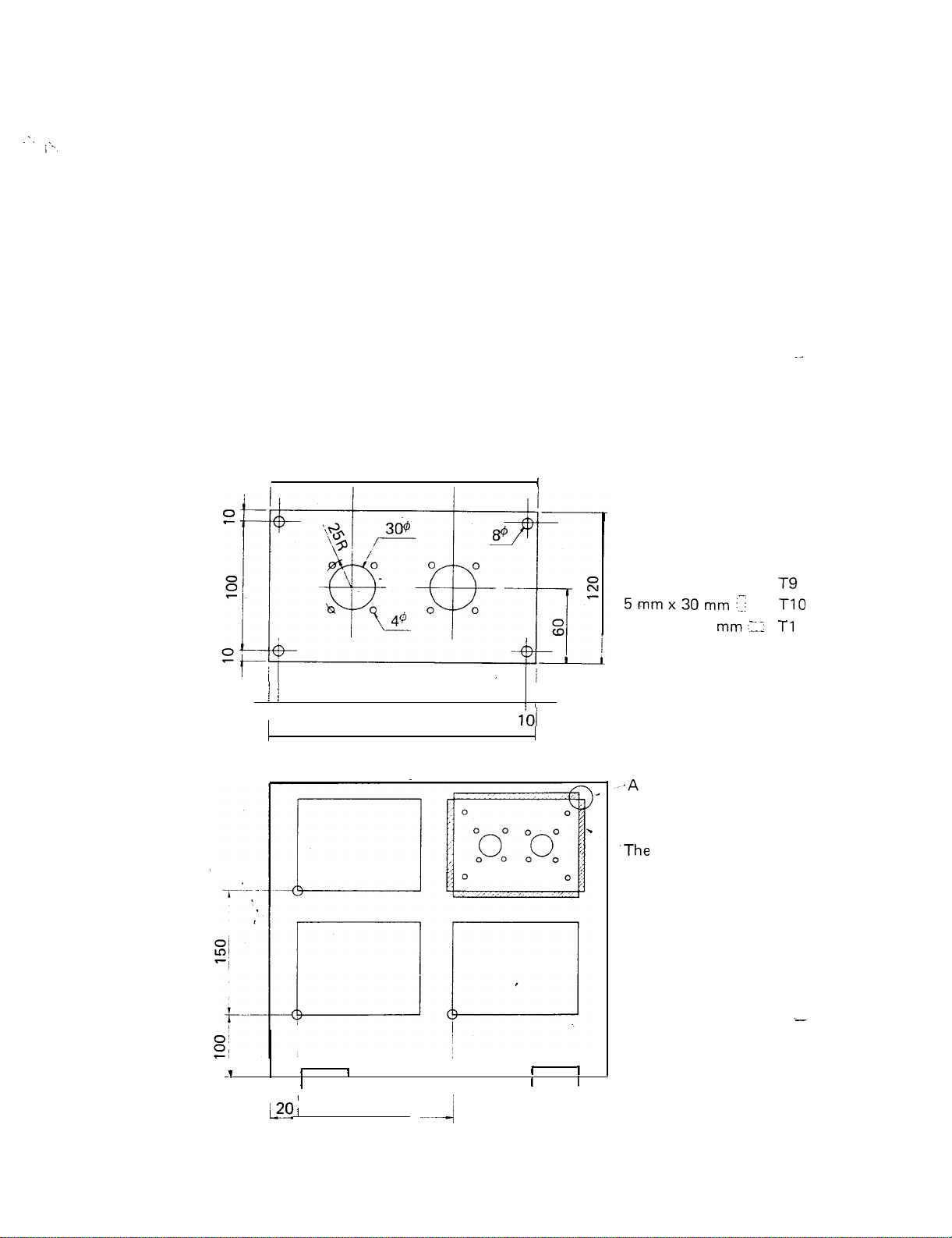

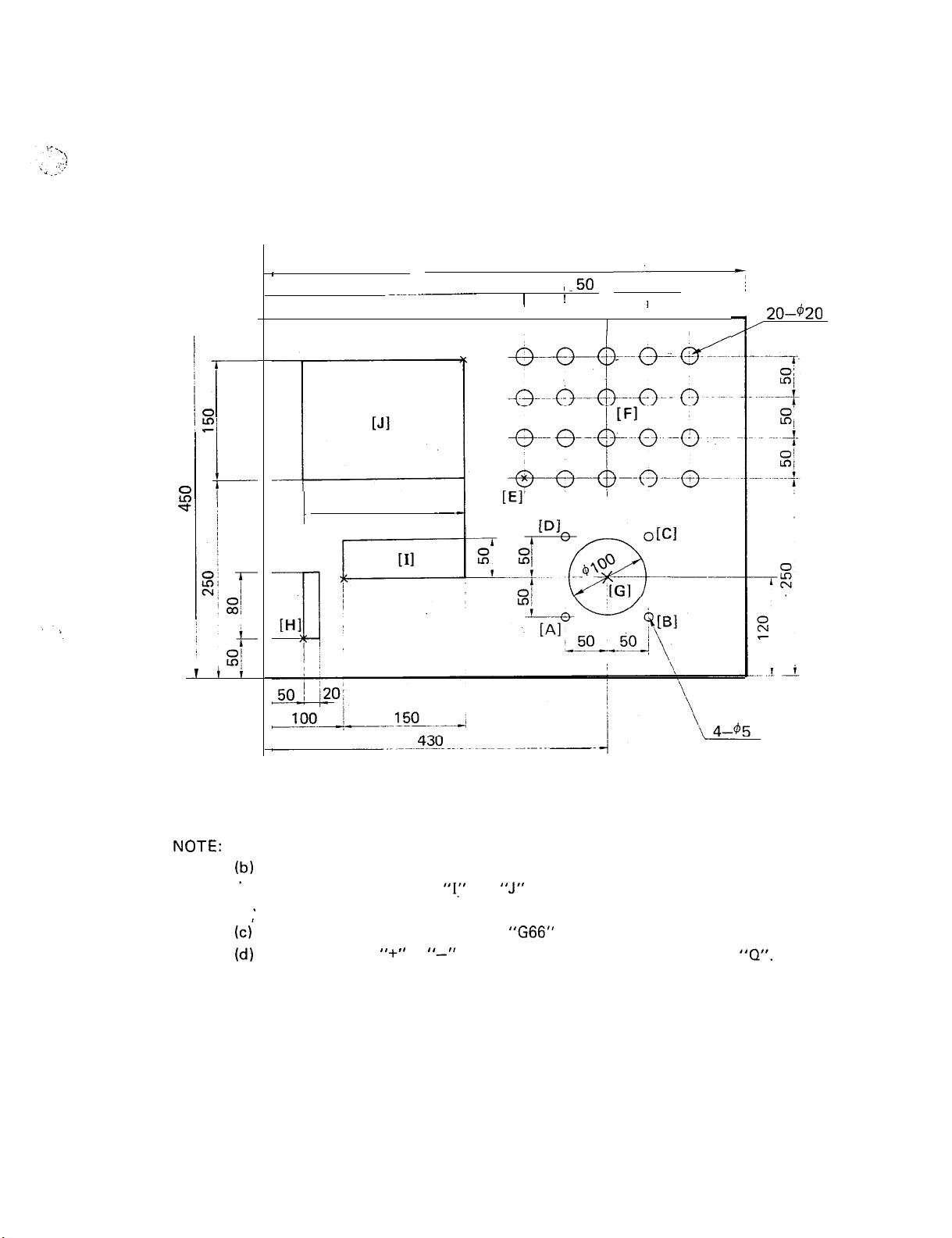

MULTIPLE PART PUNCHING

GENERAL DESCRIPTION AND PROGRAMMING EXAMPLE

1. Multiple part punching function

This function is used to punch multiple products which have the same punching pattern

from one worksheet. Once the punching of only one product is programmed, the punching

of multiple products with any desired layout on the worksheet can be performed by using

simple commands.

2. Removal of each product after multiple part punching

When punching four products from one worksheet, such as the one depicted in the figure

below, the following two removal methods can be used:

.-

‘10

a.

Micro-joint method

j /

I I

60

I

80

180

200

60

/

1’0’

I

8 mm dia.

4 mm dia.

30 mm dia.

5mmx30mm::

5 mm x 50

.The

hatched portions

mm:::

: T3

: T2

:

T9

: TlO

:

Tl

are punched out in

the “Micro-joint

method”.

Punching 4 products

from one worksheet

I

I

k20 /

I

I

Work1

1

clamp

250

d~mmA

I

I

1

Work

1

clamp

3-l

Page 60

As shown in the figure, the hatched portions are punched out by rectangular punches in

such a manner that the four corners of each product remain unpunched. The four corners

are connected to the worksheet by means of an approx. 0.15 mm joint. After completing

the entire punching process, the worksheet with punched products is removed from the

machine, and each product is then separated from the worksheet.

r-r -\

x

)I

0.15

I

I

Punch out

I -

Micro joint;’

(four corners)

Product

,

@

1

Detail; of portion A

/

-Lnf--

‘I

Oi

-

Worksheet

-’

b. Separation method

Each product is separated from the worksheet after punching. Each time one product

is cut out, the operator stops the machine and removes the product using a magnet or

by other means.

. .

I

1

t

Work clamp-

I

I

A

:.

.:

3-2

Page 61

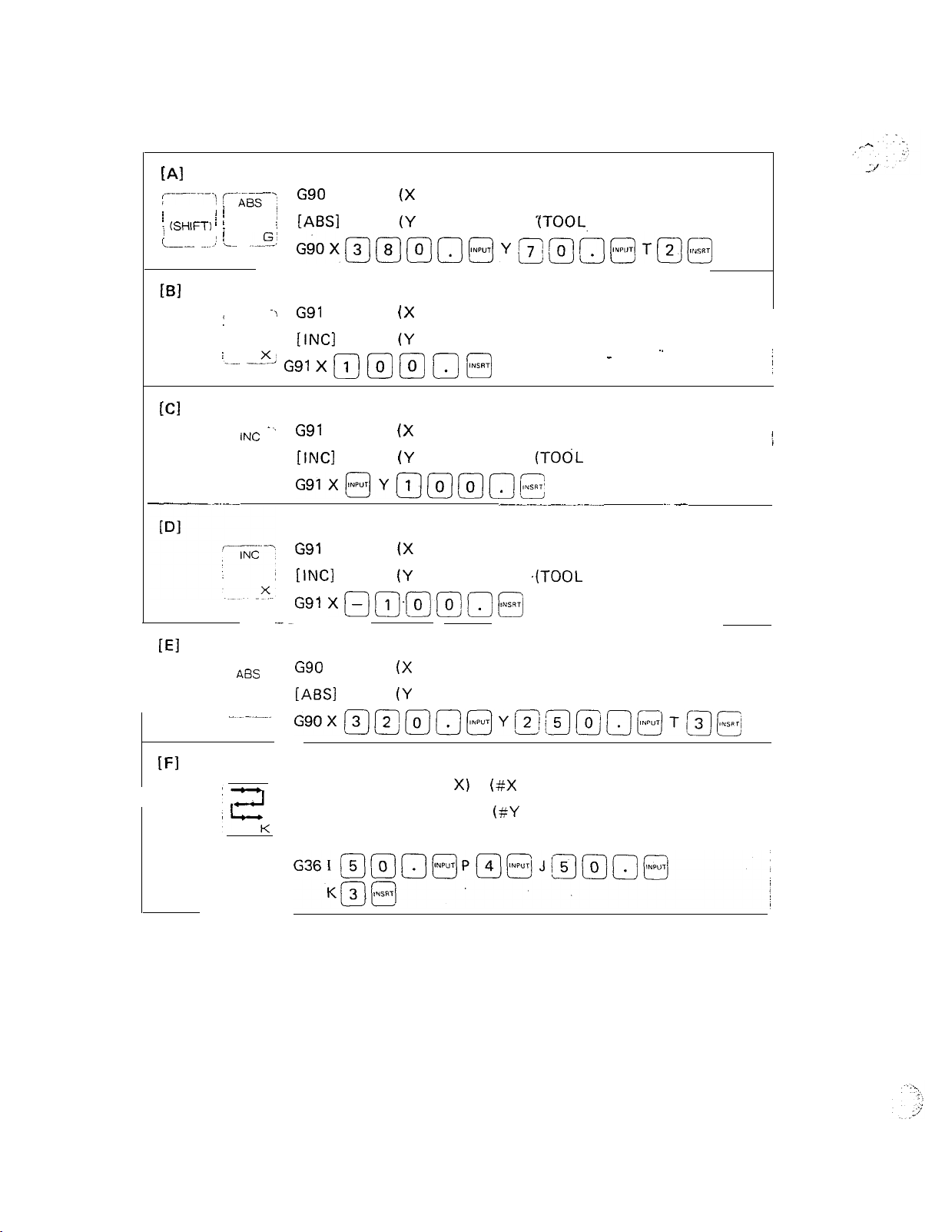

3.

Program example using multiple part punching function

*\

:..

The program for punching the product depicted in the figure on Page 3-1 using the “micro-

joint” method is as follows:

[G92

G92

G98

X600.

X20.

Y600.

(ARIES-2221

YlOO.

1250.

X1000.

J150. Pl Kl

Y600. (ARIES-22411

w

(1)

The.reference

point for multi-

ple part punching is set.

Ul

G90

X190.

YlO.

x10.

YllO.

G72 X60.

Al G26 125. J45. K4 T2

G72 X140.

Bl

Vl

u2

X140.

X60.

v2

u3

G72

G66

G72

G66

v3

u4

G72

G66

G72

G66

v4

YllO.

T3

Y60.

Y60.

Y60.

T9 (30%

x200.

Y120.

1120. J-90.

x0 YO

1120.

x0 Y120.

1200. JO

x200.

1200. JlBO. P50. 05.

J90. P30.

P50. 05.

YO

P30. 05.

Q5. D-0.15

(89)

(44)

D-0.15

D-0.15 Tl (5 x 50

D-O.15

TlO (5

x 30 g

FZZ )

.-

*

(2) Program (part program) for

punching one product. This

part program is stored.

)

j

Program (part program) for

punching the exterior shape

of one product. This part

program is stored.

J

G76

G76

G76

G75

G50

Wl 04 Ul -Vl

W2

Q3, U2-V2

W3 Q2

W4 Q3 . .

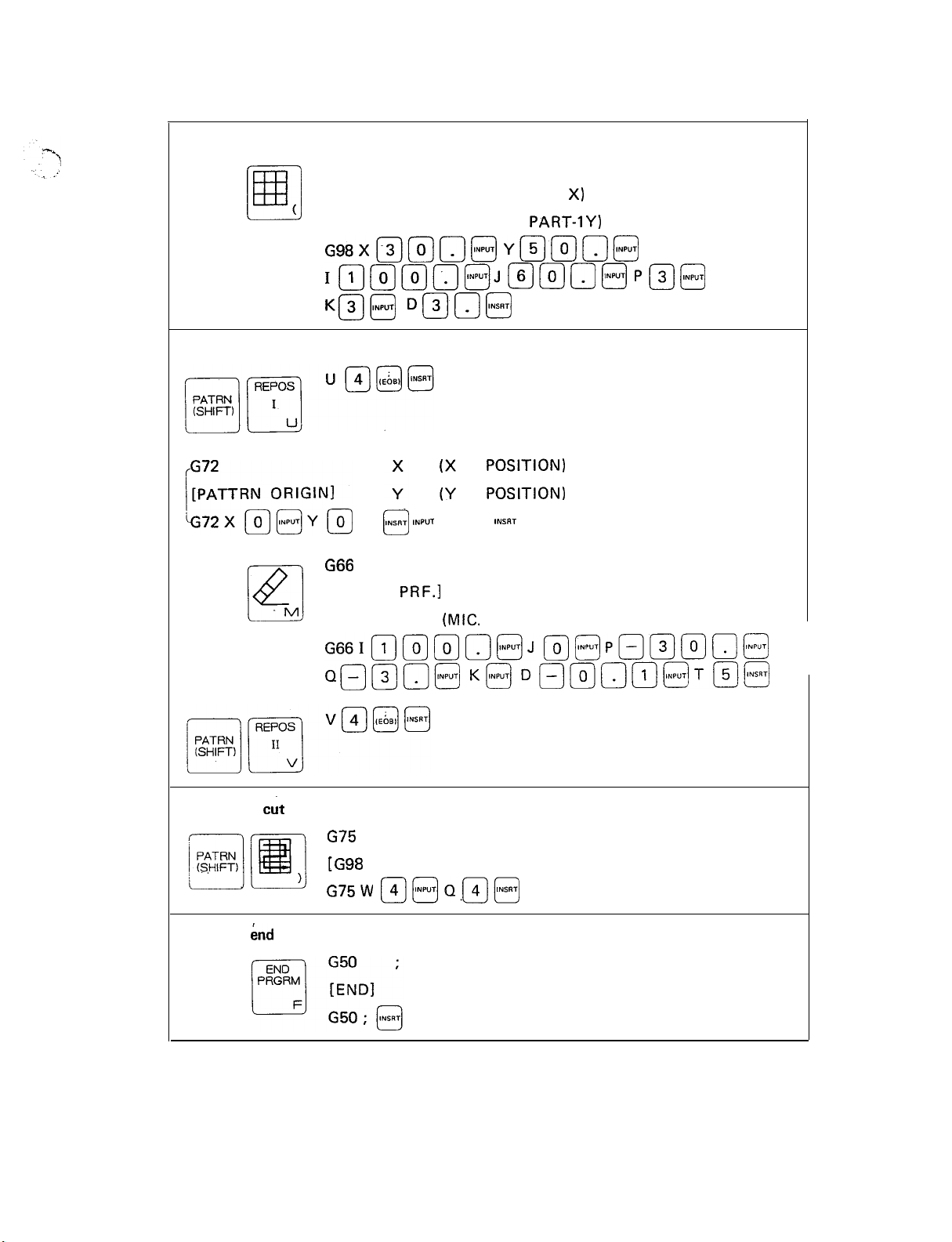

execution instruction

execution instruction

U3-V3

execution instruction

U4-V4

execution instruction

’

__--

-

Recalling and execution of

(4)

each part program for the

specified punching layout.

After preparing the above program, one product in the lower left, corner in the figure on

Page 3-l can be trial-punched by key operation’on the NC control panel. After checking

the dimensions of the product, the punching of multiple products over the entire surface

of the worksheet can then be performed.

3-3

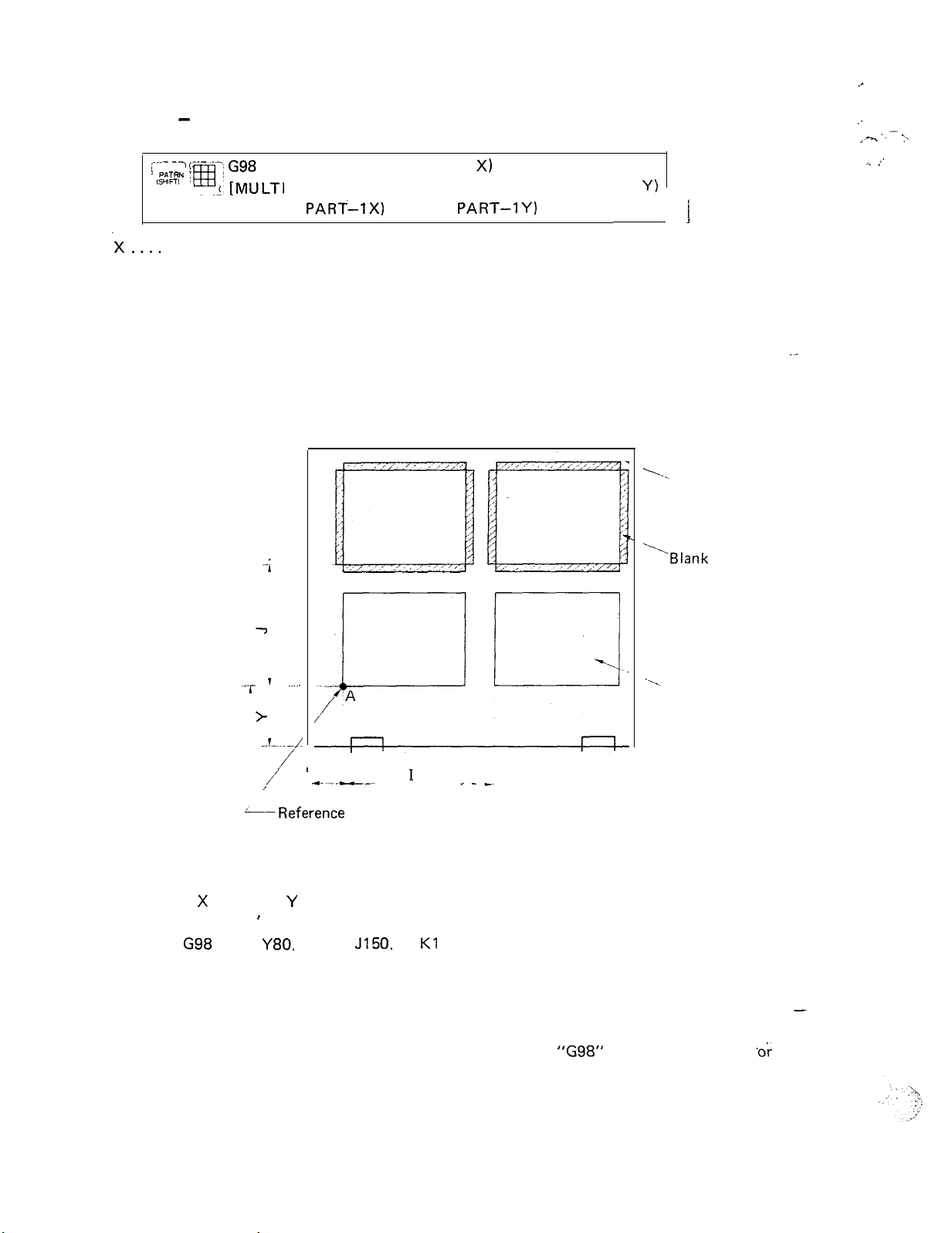

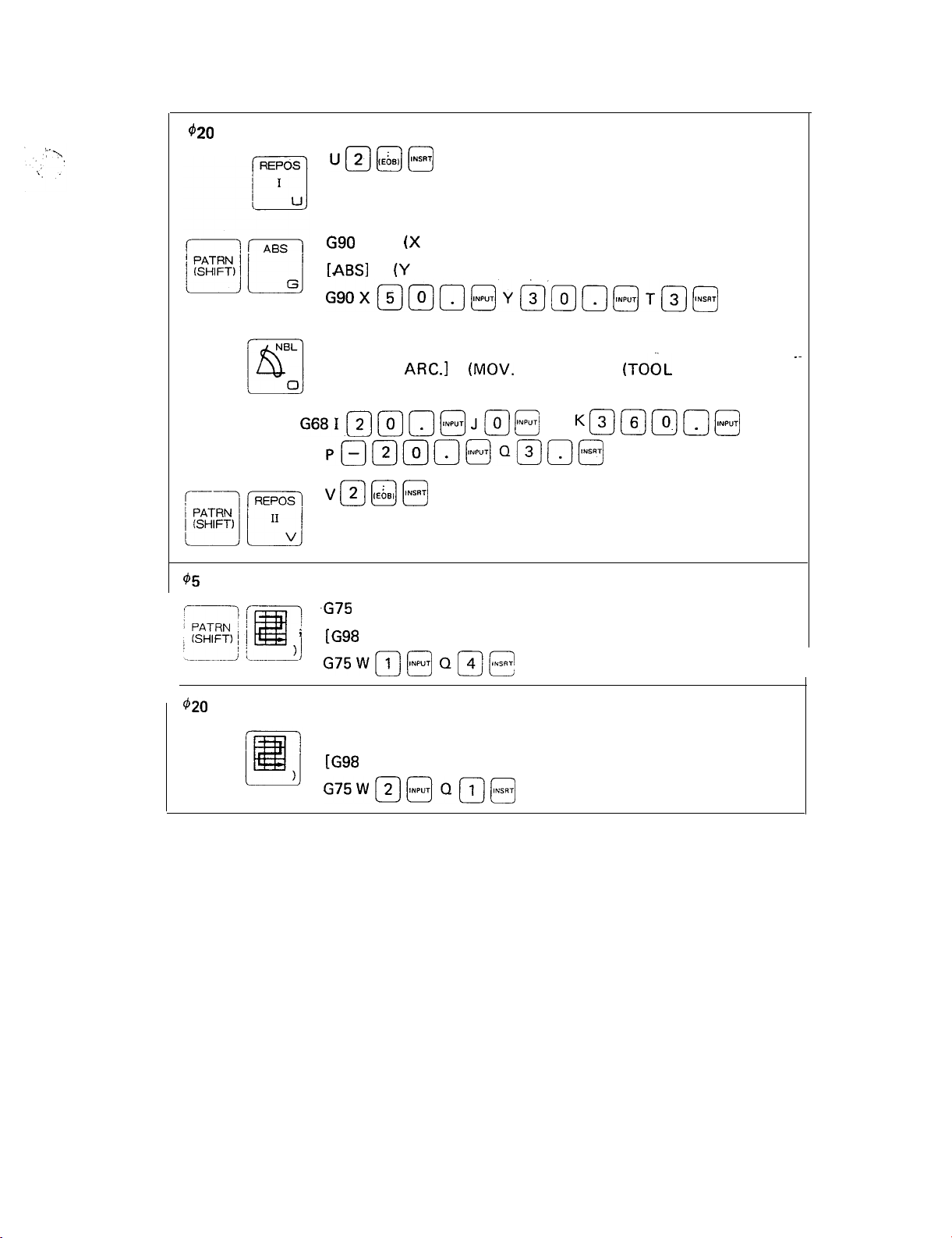

Page 62

G98

SETTING OF REFERENCE POINT AND LAYOUT FOR MULTIPLE

-

PART PUNCHING

~.._ -~ r...-~.’ PATeN :

ISHIFT,

,

i

PA’ ;::LTl

PART]

P (NO.

PART-lx)

X (OFFSET X) Y (OFFSET Y)

I (PART LTH. X) J (PART.WTH. Y) ,

K (NO.

PART-1Y)

D (SPACING) ;

:

-.

:,

;-. ‘.

I. ,I’

j

.x....

Y

. . . .

I

. . . .

J

. . . .

P

. . . .

K

. . . .

D

. . . .

Offset X (X-coordinate value of reference point)

Offset Y (Y-coordinate value of reference point)

Part length X (Pitch along X-axis)

Part length Y (Pitch along Y-axis)

No. Part-l X (Number of products in X-axis direction, excluding product at reference

point)

No. Part-l Y (Number of products in Y-axis direction, excluding product at reference

point)

Spacing (Space between products when I and J are product dimensions)

‘...

Worksheet

I.

\Blank

.L..

Product

.--r

-;

7

,

>

-!-.. >/!

i

/

--..

/

‘Work clamp Work clamp

’

x

-.~-_--

1

_ _ _,

.-

L__Reference point for punching

multiple products

Ex.: If X = 30 ‘mm, Y = 80 mm, I = 200 mm and J = 150 mm in the figure above, the pro-

NOTE:

gram is:

G98

X30. Y80. 1200.

a)

’

J150.

PI

Kl

The reference point for punching multiple products must be located in the lower

left corner of the product which is located at the lower left portion of ‘the

worksheet.

b) The values “I”, “J”,

“P” and “K” specified by

“G98”

must be either zero

,o;

positive values.

c)

The value “D” can be omitted if unnecessary.

3-4

-

Page 63

Inclusion and priority relations between G98 and G93

1.

The X- and Y-coordinates specified by “G98” are determined by the coordinate system

which is set by “G92”.

2.

The coordinate system set by

the subsequent commands of

“G98”,

“G98”

once specified, cannot be cancelled except by using

or “G50”.

3. The X- and Y-coordinates specified by “G93” are determined by the coordinate system

which is set by

“G93”

.4.

“G98”.

values of

which is specified prior to the setting of

’

The values obtained by adding the X and Y values of

“G93”,

“G98”.

“G98”

respectively, will determine the origin of

will remain effective even after

“G98”

and the X and Y

this.program.

Example 1. When there is no cutting area between products and the outer edges of each

product are cut eithef by shearing or other procedures after punching (Trimming will be necessary).

If X

=20

mm, Y = 60 mm, I = 100 mm and J = 80 mm in the above figure, the program is:

G98

X20. Y60. 1100.

J80.

P3 K2

‘l.

Worksheet

_\

‘\

Product

I

-

3-5

Page 64

Example 2. This is an example of a situation where there is neither a cutting area between

products nor a clamping area and trimming is not performed.

If X

=.200

mm and Y = 150 mm, the program is:

G98

X0 YO 1200.

Example 3. This depicts the punching of products only in the X-axis direction.

JI50.

PI KI

/-.,

_

‘Worksheet

b-..

‘*_

Product

i

Y

II

If X = 30 mm, Y = 80 mm and I= 1 IO mm in the above figure, the program is:

G98

X30.

,

As shown’above, J = 0 and K = 0.

Y80. I1

A

L

-

I

C

IO. JO P4 KO

.

3-6

Page 65

Example 4.

This shows the punching of products only in the Y-axis direction.

1’

X

If X = 30

G98

As’shown above, I = 0 and P = 0.

mm,

X30.

Y = 80 mm and J = 150 mm, the program is:

Y80.

IO

JI50.

PO K3

\

\

Worksheet

‘\

Product

3-7

Page 66

UOo

TO VOO

uoo

......

......

......

1

Part program

i

I

STORING OF PART

-

PKOC;RAM

voo I

To store the pat-t program for one product, “U” and a two-digit numeral (macro number)

must be entered at the beginning of the part program to be stored, and

two-digit numeral that was used by “U” must also be entered at the end of the part program. The part program thus positioned between “UOO”

memory.

ind “VOO”~‘is

“V”

and the same

stored in the

&, -.--.-

-

--

NOTE: a) The same macro numbers must be attached to “U” and

one part program.

b)

Three types of macro numbers are available; one type ranges from 01 to 59,

another type from 60 to 89 and the other type from 90 to 99.

c)

The macro numbers 01 through 05 can be specified as one digit by omitting the

zero.

d)

On the macro numbers 01 through 89, the maximum limit of the part program

allowed to be stored is 3100 characters on one processing tape.

“V”

in order to store

3-8

Page 67

UI

X190. YIIO. T3

(84)

YlO.

x10.

YI 10.

VI

* *a

UZ

G72 X60. Y60.

AI G26 125. J45. K4 T2

G72 X140. Y60.

81

v2

u3

X140. Y60. T9

(304)

X60.

v3

u4

G72 X200.

G66 1120. J-90.

YI20.

P30. 05.

G72 X0 YO

G66 1120.

J90. P30. 05.

D-0.15

v4

u5

G72 X0

G66 1200. JO

YI20.

P50.

05. D-0.15 Tl (5 x 50 :g

G72 X200. YO

G66 1200.

J180. P50.

05. D-0.15

v5

Program example (I

In this example, the processing by one type of

tool is stored as a part program.

In this program, the processing by one type of

tool is performed on the whole surface of the

worksheet. Then, ‘the next type of tool is

selected and the processing by it also is made

(44)

on the whole surface of the worksheet. The

time required for selection of tool can thus be

redu ted.

D-0.15 TIO (5 x 30

1

.-

B,

1

u50

X190. YIIO. T3

YIO.

‘x10.

YllO.

G72 X60. Y60.

AI G26 125. J45. K4 T2

G72

,X1

40. Y60.

Bl

Xl 40. Y60:;

’

T9

X60.

G72 X200.

G66 1120. J-90.

YI20.

P30.

05. D-O. 15 TIO

G72 X0 YO

G66 1120.

G72 X0

G66 1200. JO

J90. P30.

YI20.

Q5. D-0.15

P50.

05. D-O.1 5 TI

G72 X200. YO

G66 1200.

JI80. P50.

Q5. D-0.1 5

v50

Program example

(2)

In this example, the processing for one product

by five types of tools is stored as a part

pro-

gram.

All processing of one product is performed by

using five types of tools. Then, all processing

of the next product is also performed by using

the same five types of tools. The time for

’

tion of tools increases. Although the program

selec-

is simple, the processing time is greater than in

example (I ) above.

,

3-9

Page 68

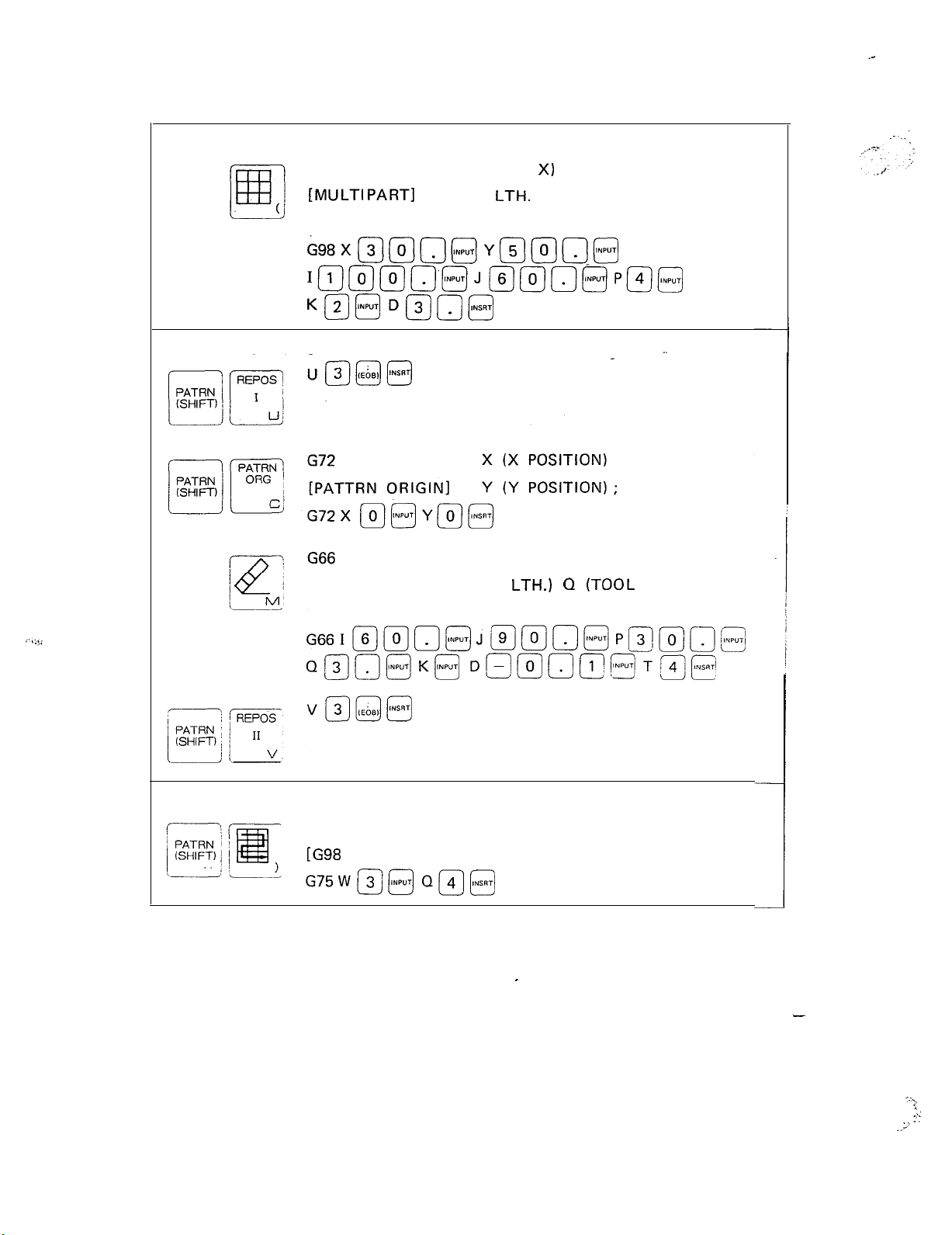

G75, G76 WOO 00

[G98

RECALL X DIR.] Q (QUADRANT);

RECALLING AND EXECUTION OF PART PROGRAM

-

The part program for punching one product entered between “UOO” and “VOO” is recalled

by “WOO”, and the program is executed to process all products according to the punching

layout designated by

“Gg8”.

..% -. ‘.

.,. .:

_ ,. .,’

I.

G75...

The part program entered between