Page 1

Dynamic Calibrated On-Chip Termination (ALTOCT)

Megafunction

User Guide

101 Innovation Drive

San Jose, CA 95134

www.altera.com

UG-01003-3.0

Subscribe

Page 2

© 2012 Altera Corporation. All rights reserved. ALTERA, ARRIA, CYCLONE, HARDCOPY, MAX, MEGACORE, NIOS, QUARTUS and STRATIX words and logos

are trademarks of Altera Corporation and registered in the U.S. Patent and Trademark Office and in other countries. All other words and logos identified as

trademarks or service marks are the property of their respective holders as described at www.altera.com/common/legal.html. Altera warrants performance of its

semiconductor products to current specifications in accordance with Altera's standard warranty, but reserves the right to make changes to any products and

services at any time without notice. Altera assumes no responsibility or liability arising out of the application or use of any information, product, or service

described herein except as expressly agreed to in writing by Altera. Altera customers are advised to obtain the latest version of device specifications before relying

on any published information and before placing orders for products or services.

ISO

9001:2008

Registered

February 2012 Altera Corporation Dynamic Calibrated On-Chip Termination (ALTOCT) Megafunction

User Guide

Page 3

Contents

Chapter 1. About this Megafunction

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Device Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Chapter 2. Parameter Settings

MegaWizard Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

Command Line Interface Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

Chapter 3. Functional Description

OCT Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

Power-Up Mode Calibration and On-Demand Calibration in Quartus II Software . . . . . . . . . . . . . 3–2

Design Example: Series Calibration for Four Calibration Blocks Using Stratix III Device . . . . . . . . . . 3–3

Generate the Dynamic On-Chip Termination Calibration Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

Verify Termination or Calibration Assignments of the Design Example . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

Functional Simulation in the ModelSim-Altera Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

ALTOCT Megafunction Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

Input Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

Output Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–9

Additional Information

Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Info–1

How to Contact Altera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Info–2

Typographic Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Info–3

February 2012 Altera Corporation Dynamic Calibrated On-Chip Termination (ALTOCT) Megafunction

User Guide

Page 4

Features

1. About this Megafunction

The Dynamic Calibrated On-Chip Termination (ALTOCT) megafunction is used in

double-data rate (DDR) external memory interfaces. This megafunction is closely

associated with the External DDR Memory PHY Interface (ALTMEMPHY)

megafunction. On-chip termination (OCT) improves signal quality over external

termination through reduced parasitic, board space, and external component costs.

The ALTOCT megafunction provides the following features:

■ Support for up to 10 OCT blocks

■ Support for calibrated on-chip series termination (RS) and calibrated on-chip

parallel termination (RT) on all I/O pins

■ Calibrated termination values of 25 and 50 ohm

Device Support

TheALTOCT megafunction supports the following Altera® devices:

■ Arria

■ Arria II GZ

■ Arria V

■ Cyclone

■ HardCopy

■ HardCopy IV

■ Stratix

■ Stratix IV

■ Stratix V

®

II GX

®

®

III

V

®

III

February 2012 Altera Corporation Dynamic Calibrated On-Chip Termination (ALTOCT) Megafunction

User Guide

Page 5

2. Parameter Settings

This section describes the parameter settings for the ALTOCT megafunction.You can

parameterize the megafunction using the MegaWizard

command-line interface (CLI). Altera recommends that you configure the

megafunctions using the MegaWizard Plug-In Manager.

™

Plug-In Manager or the

f This user guide assumes that you are familiar with megafunctions and how to create

them. If you are unfamiliar with Altera

®

megafunctions, refer to the Introduction to

Megafunctions User Guide.

MegaWizard Parameter Settings

Tab le 2– 1 provides descriptions of the options available on the individual pages of the

ALTOCT MegaWizard Plug-In Manager.

Table 2–1. ALTOCT MegaWizard Plug-In Manager Page Options and Description (Part 1 of 2)

MegaWizard

Plug-in

Manager

Page

1 Which action do you want to perform?

Select a megafunction from the list below Select ALTOCT from the I/O category.

Which device family will you be using? Specify the device family that you want to use.

2a

Which type of output file do you want to create?

What name do you want for the output file? Specify the name of the output file.

Return to this page for another create operation

Configuration Setting Description

You can select from the following options: Create a new

custom megafunction variation, Edit an existing custom

megafunction variation, or Copy an existing custom

megafunction variation.

You can choose AHDL(.tdf), VHDL(.vhd), or Verilog HDL

(.v) as the output file type.

Turn on this option if you want to return to this page to

create multiple megafunctions.

February 2012 Altera Corporation Dynamic Calibrated On-Chip Termination (ALTOCT) Megafunction

User Guide

Page 6

2–2 Chapter 2: Parameter Settings

MegaWizard Parameter Settings

Table 2–1. ALTOCT MegaWizard Plug-In Manager Page Options and Description (Part 2 of 2)

MegaWizard

Plug-in

Manager

Configuration Setting Description

Page

Currently selected device family Specifies the device family you chose on page 2a.

Turn on this option to ensure that the device selected

Match project/default

matches the device family that is chosen in the previous

page.

Calibrate OCT on power-up

Turn on this option if you want to calibrate OCT on

power-up.

How many OCT blocks should be used? Specify the number of OCT blocks for your design.

Turn on this option if you want to enable parallel

3

Enable parallel termination

Create ‘calibration_wait’ input port to prevent

calibration

Create ‘clken’ input port

termination instead of series termination. Observe the

changes in resource usage when this option is enabled.

calibration_wait

The

input port can be used to halt

calibration operation. This option is for advanced users

only. Typical users should not enable this option.

clken

The

input port is used as the clock enable signal.

This option is for advanced users only. Typical users

should not enable this option.

Enable independent calibration/shift

Turn on this option to enable independent

calibration/shift.

Turn on this option if you want to generate a netlist for

your third-party EDA synthesis tool to estimate the timing

and resource usage of the megafunction. If you turn on

4 Generate netlist

this option, a netlist file (_syn.v) is generated. This file is

a representation of the customized logic used in the

®

Quartus

II software and provides the connectivity of the

architectural elements in the megafunction but may not

represent true functionality.

Specify the types of files to be generated. The Variation

file (<function name>.v) contains wrapper code in the

language you specified on page 2a and is automatically

generated. Choose from the following types of files:

■ AHDL Include file (<function name>.inc)

■ VHDL component declaration file

(<function name>.cmp)

5 Summary Page

■ Quartus II symbol file (<function name>.bsf)

■ Instantiation template file (<function name>_inst.v)

■ Verilog HDL black box file (<function name>_bb.v)

For more information about the wizard-generated files,

refer to the Quartus II Help or to the Recommended HDL

Coding Styles chapter in volume 1 of the Quartus II

Handbook.

Dynamic Calibrated On-Chip Termination (ALTOCT) Megafunction February 2012 Altera Corporation

User Guide

Page 7

Chapter 2: Parameter Settings 2–3

Command Line Interface Parameters

Command Line Interface Parameters

Expert users can choose to instantiate and parameterize the megafunction through the

command-line interface using the clear box generator command. This method

requires you to have command-line scripting knowledge.

f For more information about using the clear box generator, refer to the Introduction to

Megafunctions User Guide.

Tab le 2– 2 lists the parameters for the ALTOCT megafunction.

Table 2–2. ALTOCT Megafunction Parameters

Parameter Name Type Required Description

ENABLE_PARALLEL_TERMINATION

OCT_BLOCK_NUMBER

LPM_HINT

LPM_TYPE

INTENDED_DEVICE_FAMILY

String Yes

Integer Yes

String No

String No

String No

Enables the RT State Machine. Values are TRUE and

FALSE. If omitted, value is FALSE.

The number of OCT blocks in the design. Values are

integer 1 to 10.

Allows you to specify Altera-specific parameters in

VHDL Design Files (.vhd). The default value is UNUSED.

Identifies the library of parameterized modules (LPM)

entity name in VHDL Design Files (.vhd).

This parameter is used for modeling and behavioral

simulation purposes. Create the ALTOCT megafunction

with the MegaWizard Plug-In Manager to get the value

for this parameter.

February 2012 Altera Corporation Dynamic Calibrated On-Chip Termination (ALTOCT) Megafunction

User Guide

Page 8

This chapter describes the functional description and the design examples of the

ALTOCT megafunction. This section also includes the ports descriptions of the

ALTOCT megafunction. You can use the ports to customize the ALTOCT

megafunction according to your application.

OCT Architecture

The OCT calibration architecture provides dynamic series and parallel on-chip

termination to improve I/O impedance matching and termination capabilities. OCT

improves signal quality over external termination through reduction of parasitic,

board space, and external component costs. The OCT architecture support RS with

and without calibration, RT with calibration, dynamic series and parallel termination

for single-ended I/O standards, and on-chip differential termination (RD) for

differential LVDS I/O standards. OCT is supported in all I/O banks by selecting one

of the OCT I/O standards.

3. Functional Description

Figure 3–1 shows the OCT calibration architecture in Stratix III devices. The

OCTUSRCLK

OCT calibration block to any I/O. To serially shift the 14-bit OCT RS calibration code

and the 14-bit OCT RT calibration code into the registers located in the I/O buffer, 28

clock cycles using

OCT calibration code (14-bit OCT RS code and 14-bit OCT RT) must be serially shifted

out from each OCT calibration block to the corresponding I/O buffer.

, and

ENASER

OCTUSRCLK

signals are used to serially transfer calibrated codes from each

are required. When calibration is complete, the 28-bit

SDATA

,

February 2012 Altera Corporation Dynamic Calibrated On-Chip Termination (ALTOCT) Megafunction

User Guide

Page 9

3–2 Chapter 3: Functional Description

OCT Architecture

After calibrated codes are shifted in serially to each I/O bank, the calibrated codes

must be converted from serial format to parallel format before the codes are used in

the I/O buffers. Use the

Figure 3–1. Signals for Shift-Out Codes from the OCT Calibration Block to I/O Buffers

S2PENA

signals to complete the serial-to-parallel shifting.

Power-Up Mode Calibration and On-Demand Calibration in Quartus II Software

Stratix III and Stratix IV have two termination related assignments:

INPUT_TERMINATION

output buffers, and sometimes simultaneously.

When calibrated termination uses only the Quartus

the power-up mode of the calibration scheme is used, and on-demand calibration

updates are unavailable.

To use on-demand calibration, the ALTOCT megafunction must be instantiated into

the design. If more than one group of pins needs to be calibrated on-demand, more

than one calibration block must be instantiated.

There are two methods to associate pin groups with a calibration block:

■ Instantiate the I/O buffer primitives at the top level and connect them to the

appropriate calibration blocks.

1 All I/O banks with the same V

particular I/O bank has its own calibration block. You can connect any

number of I/O pins that support calibrated termination to a calibration

block, unless the specific I/O pins on the device are not usable with a

particular calibration block. The Quartus II software produces warning

messages if there is no pin connected to the block.

and

OUTPUT_TERMINATION

. Termination can exist on input and

®

Settings File (QSF) assignments,

can share a calibration block, even if that

CCIO

Dynamic Calibrated On-Chip Termination (ALTOCT) Megafunction February 2012 Altera Corporation

User Guide

Page 10

Chapter 3: Functional Description 3–3

Design Example: Series Calibration for Four Calibration Blocks Using Stratix III Device

■ Use a QSF assignment to indicate which pin (bus) is associated with which

calibration block.

f For more information about the OCT architecture and the calibration modes for other

device families, refer to the respective device handbooks.

Design Example: Series Calibration for Four Calibration Blocks Using

Stratix III Device

This design example uses the ALTOCT megafunction to calibrate four calibration

blocks using series termination for the Stratix III device. This example uses the

MegaWizard Plug-In Manager in the Quartus II software.

In this example, you perform the following tasks:

■ Generate the dynamic on-chip termination calibration blocks using the ALTOCT

megafunction in the MegaWizard Plug-In Manager

■ Ensure that correct termination assignments are used in the design by using the

Assignment Editor

■ Simulate the design in the ModelSim-Altera software

The design examples are available for download from the following locations:

■ On the Documentation: Quartus II Development Software page, expand the Using

Megafunctions section and then expand the I/O section.

■ On the Documentation: User Guides section of the Altera website.

Generate the Dynamic On-Chip Termination Calibration Blocks

Perform the following steps to generate the dynamic on-chip termination calibration

blocks:

1. Open altoct_DesignExample.zip and extract altoct_ex.qar.

2. In the Quartus II software, open altoct_ex.qar and restore the archive file into your

working directory.

3. Open the top-level file, altoct_ex.bdf.

4. Double-click on a blank area in the schematic.

5. In the Symbol window, click MegaWizard Plug-In Manager. Page 1 of the

MegaWizard Plug-In Manager appears.

6. Select Create a new custom megafunction variation.

7. Click Next. Page 2a of the MegaWizard Plug-In Manager appears.

February 2012 Altera Corporation Dynamic Calibrated On-Chip Termination (ALTOCT) Megafunction

User Guide

Page 11

3–4 Chapter 3: Functional Description

Design Example: Series Calibration for Four Calibration Blocks Using Stratix III Device

8. In the MegaWizard Plug-In Manager pages, select or verify the configuration

settings shown in Tab le 3– 1. Click Next to advance from one page to the next.

Table 3–1. Configuration Settings for ALTOCT Design Example

MegaWizard

Plug-in

Configuration Setting Value

Manager Page

Select a megafunction ALTOCT

2a

Which device family will you be using? Stratix III

Which type of output file do you want to create? Verilog HDL

What name do you want for the output file? cal_out

Currently selected device family Stratix III

Match project/default Turned on

Calibrate OCT on power-up Turned off

3

How many OCT blocks should be used? 4

Enable parallel termination Turned off

Create ‘calibration_wait’ input port to prevent calibration Turned off

Create ‘clken’ input port Turned off

Enable independent calibration/shift Turned off

4 Generate netlist Turned off

Variation file Turned on

Quartus II symbol file Turned on

5

Instantiation template file Turned on

Verilog HDL black-box file Turned on

AHDL Include file Turned on

VHDL component declaration file Turned on

9. Click Finish. The

cal_out

module is now built.

10. In the Symbol window, click OK.

11. Move the mouse to align the cal_out symbol with the existing ports in the

altoct_ex.bdf file. Click to place the symbol. You have now completed the design

file.

12. On the File menu, click Save.

Dynamic Calibrated On-Chip Termination (ALTOCT) Megafunction February 2012 Altera Corporation

User Guide

Page 12

Chapter 3: Functional Description 3–5

Verify Termination or Calibration Assignments of the Design Example

Verify Termination or Calibration Assignments of the Design Example

This section describes the necessary assignments for the design example. Perform the

following steps to verify the assignments.

1. In the Quartus II software, on the Assignments menu, click Assignment Editor.

The Assignment Editor appears.

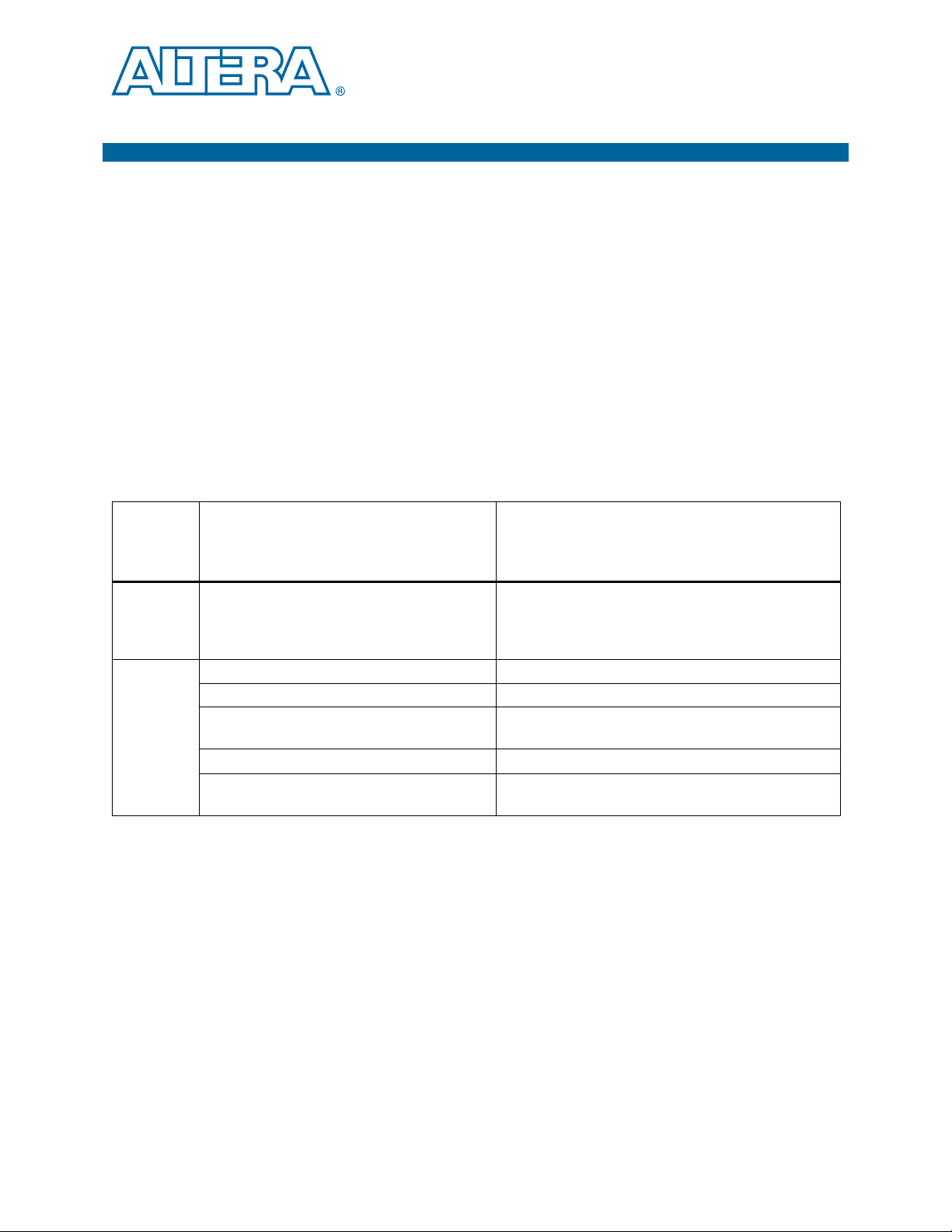

Figure 3–2 shows the assignments used in the design example.

Figure 3–2. Assignments Used in the altoct_ex Design

The first set of assignments are I/O Standard assignments that are used on the

pins of the design. This selection depends on which I/O standards are valid for a

particular application. In this design example, the functional output pins are

test_output[3..0]

, which are all assigned the SSTL-18 Class 1 standard.

The second set of assignments are Output Termination assignments that are

assigned to pins that have termination. You can specify the assignments as

non-calibrated termination or calibrated termination. In this design example, the

functional output pins are

test_output[3..0]

, which are all assigned the Output

Termination assignments with the value of Series 50 Ohm with Calibration. In

this assignment, these pins function as outputs for the FPGA chip only.

The third set of assignments are Termination Control Block assignments that are

used to indicate which calibration block is used to calibrate a particular I/O pin or

group. In this design example, the functional output pins are

test_output[3..0]

which are assigned with the value of

cal_out:inst|cal_out_alt_oct_q8n:cal_out_alt_oct_q8n_component|sd1a_x

where

x

indicates the termination calibration block that is used. Becausethe output

pins,

test_output[3..0]

, are four bits, each bit of the pin is assigned to one

calibration block.

2. Verify that all the assignments in the Assignment Editor match what is shown in

Figure 3–2.

,

,

February 2012 Altera Corporation Dynamic Calibrated On-Chip Termination (ALTOCT) Megafunction

User Guide

Page 13

3–6 Chapter 3: Functional Description

Functional Simulation in the ModelSim-Altera Software

Functional Simulation in the ModelSim-Altera Software

The design is simulated in the ModelSim®-Altera software to generate a waveform

display of the device behavior. You should be familiar with the ModelSim-Altera

software before using the design examples. To get started with the ModelSim-Altera

software, refer to the ModelSim-Altera Software Support page on the Altera website.

The support page includes links to such topics as installation, usage, and

troubleshooting.

Set up and simulate the design in the ModelSim-Altera software by performing the

following steps:

1. Unzip the altoct_ex_msim.zip file to any working directory on your PC.

2. Start the ModelSim-Altera software.

3. On the File menu, click Change Directory.

4. Select the folder in which you unzipped the files.

5. Click OK.

6. On the Tools menu, select TCL, then click Execute Macro.

7. Select the altoct_ex_msim.do file and click Open. The altoct_ex_msim.do file is a

script file used by the ModelSim-Altera software to automate all the necessary

settings for the simulation.

8. Verify the results shown in the Waveform Viewer window.

You can rearrange signals, remove signals, add signals, and change the radix by

modifying the script in altoct_ex_msim.do accordingly.

Dynamic Calibrated On-Chip Termination (ALTOCT) Megafunction February 2012 Altera Corporation

User Guide

Page 14

Chapter 3: Functional Description 3–7

Functional Simulation in the ModelSim-Altera Software

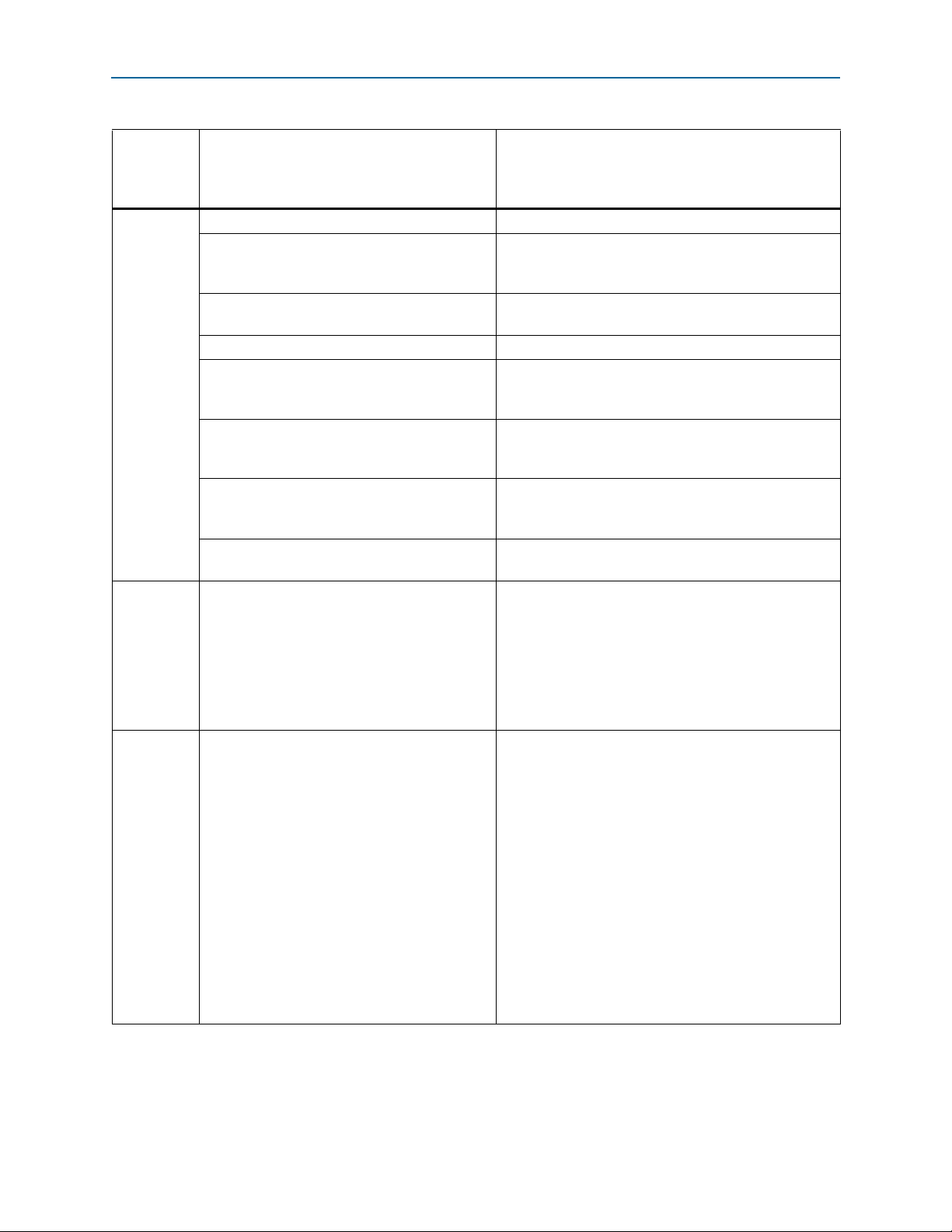

Figure 3–3 shows the expected simulation results in the ModelSim-Altera software.

Figure 3–3. ModelSim-Altera Simulation Waveforms

For these functional results, the primary objective is to highlight the dynamic

calibration process. The design example uses four calibration blocks named

calibration block [x], with x=0, 1, 2, 3.

Each calibration block has its own set of control and data signals. For example,

calibration block[3]

cal_shift_busy[3]

To req u es t c al ib r ati o n o n

has

calibration_request[3], calibration_busy[3]

signals.

calibration block[x]

, the

calibration_request[x]

, and

signal

must be asserted for at least 1 clock cycle to initiate the calibration. Multiple

calibration block requests are allowed.

The

calibration_busy[x]

performed in

calibration block[x]

Calibration is complete when the

The

cal_shift_busy[x]

calibration_busy[x]

calibration and the serial shifting of termination codes from

signal indicates the calibration process that is being

. Calibration typically takes 200 clock cycles.

calibration_busy[x]

signal is deasserted.

signal is asserted at the same time as the

signal. This signal actually indicates both the duration of the

calibration block[x]

to

the particular I/O buffers. Serial shifting of series termination codes typically takes 14

clock cycles.

After calibrated codes are shifted in serially to the particular I/O bank, the calibrated

codes must be converted from serial format to parallel format before being used in the

I/O buffers. To perform the conversion, the

s2pload[x]

signal is asserted at any time

for 1 clock cycle after the shifting process.

February 2012 Altera Corporation Dynamic Calibrated On-Chip Termination (ALTOCT) Megafunction

User Guide

Page 15

3–8 Chapter 3: Functional Description

ALTOCT Megafunction Ports

In the simulation waveform shown in Figure 3–3, all of the calibration blocks have

their

calibration_request

signals asserted at a particular time. Initially, requests for

calibration are done simultaneously for calibration block[0] and

calibration_request[3]

calibration_request[3]

. This can be observed in the behavior of the

and

calibration_request[0]

signals. Both signals are

asserted and deasserted at the same time.

Observe the behavior of the

calibration_busy[3]

and

calibration_busy[0]

signals.

Notice that both are also asserted and deasserted at the same time. This is because

multiple OCT calibration blocks can be calibrated at the same time. When these

signals get deasserted, calibration is complete.

Next, observe the

asserted at the same time as the

cal_shift_busy[3]

calibration_busy[3]

and

cal_shift_busy[0]

signals. They are both

and

calibration_busy[0]

signals, and both signals get deasserted after a number of clock cycles. These signals

indicate the status of calibration and serial shifting of the termination codes.

Notice that the

different time—

cal_shift_busy[3]

cal_shift_busy[3]

cal_shift_busy[0]

and

cal_shift_busy[0]

signals get deasserted at

gets deasserted first and followed by

. This is because the shifting process is serial, and only one

calibration block can be active at a time. In the event of multiple calibration block

requests, the priority calibration block[x] is based on this order. x=0, 1, 2, 3, 4, 5, 6, 7, 8,

9, which means calibration block[0] shift codes first and then followed by the other

blocks in the order. Observe Figure 3–3, the

and then followed by

cal_shift_busy[3]

cal_shift_busy[0]

gets deasserted first

. This is because calibration block[0] has

higher priority than calibration block[3].

Finally, the calibrated codes must be converted from serial format to parallel format

before being used in the I/O buffers. This is done by asserting and deasserting the

s2pload[0]

and

cal_shift_busy[0]

and

s2pload[3]

signals for 1 clock cycle only after

cal_shift_busy[3]

signals have been deasserted. See Figure 3–3.

Similar calibration process as described on 3–7 applies to the remaining portion of the

waveform. However, it applies to calibration block[2] and calibration block[1].

ALTOCT Megafunction Ports

Tab le 3– 2 and Ta bl e 3– 3 lists the input and output ports for the ALTOCT

megafunction.

Input Ports

Table 3–2. ALTOCT Megafunction Input Ports

Port Name Required Description Comments

aclr

calibration_request

calibration_wait

clock

rdn

Dynamic Calibrated On-Chip Termination (ALTOCT) Megafunction February 2012 Altera Corporation

User Guide

No Asynchronous clear If omitted, value is GND

Yes User request for calibration Input port

Clock cycles to wait before

No

Yes System clock –—

Yes

starting calibration after

calibration request

Pull-down reference

resistor

Input port

wide. If omitted, value is GND

Input port

[OCT_BLOCK_NUMBER - 1..0]

[OCT_BLOCK_NUMBER - 1..0]

[OCT_BLOCK_NUMBER - 1..0]

wide

wide

Page 16

Chapter 3: Functional Description 3–9

ALTOCT Megafunction Ports

Table 3–2. ALTOCT Megafunction Input Ports

Port Name Required Description Comments

rup

Yes Pull-up reference resistor Input port

[OCT_BLOCK_NUMBER - 1..0]

wide

Signal used to enable serial

s2pload

Yes

to parallel shifting of

calibrated codes to I/O

Input port

[OCT_BLOCK_NUMBER - 1..0]

wide

buffers

clken

No Clock enable If omitted, value is V

CC

Output Ports

Table 3–3. ALTOCT Megafunction Output Ports

Port Name Required Description Comments

Specifies the status of

cal_shift_busy

calibration_busy

paralleltermination

control

seriesterminationco

ntrol

Yes

Yes

Yes

Yes

calibration or shifting

operation. This signal is

asserted until the

calibration or shifting

operation is completed.

Specifies the status of the

calibration operation. This

signal is asserted until the

calibration operation is

completed.

Specifies parallel

termination

Specifies the serial

termination

Output port

Output port

[OCT_BLOCK_NUMBER - 1..0]

[OCT_BLOCK_NUMBER - 1..0]

wide

wide

Receives the current state of the pull-up and

pull-down transmitter control buses from a

termination logic block.

Output port

[OCT_BLOCK_NUMBER * 13..0]

wide

Receives the current state of the pull-up and

pull-down receiver control buses from a termination

logic block.

Output port

[OCT_BLOCK_NUMBER * 13..0]

wide

February 2012 Altera Corporation Dynamic Calibrated On-Chip Termination (ALTOCT) Megafunction

User Guide

Page 17

This chapter provides additional information about the document and Altera.

Document Revision History

The following table lists the revision history for this document.

Date Version Changes

Updated the following sections:

February 2012 3.0

November 2008 2.0

December 2006 1.0 Initial release

■ “Device Support” section

■ “MegaWizard Parameter Settings” section.

■ Updated the following sections:

■ “Device Support” section

■ “Features” section

■ “Functional Description” chapter

■ “Design Example: Series Calibration for Four Calibration Blocks Using Stratix III

Device” section

■ “Functional Simulation in the ModelSim-Altera Software” section

■ “This chapter describes the functional description and the design examples of the

ALTOCT megafunction. This section also includes the ports descriptions of the ALTOCT

megafunction. You can use the ports to customize the ALTOCT megafunction

according to your application.” section

■ “How to Contact Altera” section

■ Removed the following sections:

■ “Resource Utilization & Performance” section

■ “Software and System Requirements” section

■ “Instantiating Megafunctions in HDL Code” section

■ “Identifying a Megafunction after Compilation” section

■ “SignalTap II Embedded Logic Analyzer” section

■ Removed all screenshots in the “This section describes the parameter settings for the

ALTOCT megafunction.You can parameterize the megafunction using the MegaWizard

Plug-In Manager or the command-line interface (CLI). Altera recommends that you

configure the megafunctions using the MegaWizard Plug-In Manager.” section

■ Reorganized the “This section describes the parameter settings for the ALTOCT

megafunction.You can parameterize the megafunction using the MegaWizard

Manager or the command-line interface (CLI). Altera recommends that you configure the

megafunctions using the MegaWizard Plug-In Manager.” section into table format.

■ Renamed “About this User Guide” section to “Additional Information” and moved the

section to the end of the user guide.

Additional Information

™

™

Plug-In

February 2012 Altera Corporation Dynamic Calibrated On-Chip Termination (ALTOCT) Megafunction

User Guide

Page 18

Info–2 Additional Information

How to Contact Altera

How to Contact Altera

To locate the most up-to-date information about Altera products, refer to the

following table.

Contact

(1)

Contact Method Address

Technical support Website www.altera.com/support

Technical training

Website www.altera.com/training

Email custrain@altera.com

Product literature Website www.altera.com/literature

Nontechnical support (general) Email nacomp@altera.com

(software licensing) Email authorization@altera.com

Note to Table:

(1) You can also contact your local Altera sales office or sales representative.

Dynamic Calibrated On-Chip Termination (ALTOCT) Megafunction February 2012 Altera Corporation

User Guide

Page 19

Additional Information Info–3

Typographic Conventions

Typographic Conventions

The following table shows the typographic conventions this document uses.

Visual Cue Meaning

Bold Type with Initial Capital

Letters

bold type

Italic Type with Initial Capital Letters Indicate document titles. For example, Stratix IV Design Guidelines.

italic type

Initial Capital Letters

“Subheading Title”

Courier type

r An angled arrow instructs you to press the Enter key.

1., 2., 3., and

a., b., c., and so on

■ ■ ■ Bullets indicate a list of items when the sequence of the items is not important.

1 The hand points to information that requires special attention.

h The question mark directs you to a software help system with related information.

f The feet direct you to another document or website with related information.

? The multimedia icon directs you to a related multimedia presentation.

c

w

Indicate command names, dialog box titles, dialog box options, and other GUI

labels. For example, Save As dialog box. For GUI elements, capitalization matches

the GUI.

Indicates directory names, project names, disk drive names, file names, file name

extensions, software utility names, and GUI labels. For example, \qdesigns

directory, D: drive, and chiptrip.gdf file.

Indicates variables. For example, n + 1.

Variable names are enclosed in angle brackets (< >). For example, <file name> and

<project name>.pof file.

Indicate keyboard keys and menu names. For example, the Delete key and the

Options menu.

Quotation marks indicate references to sections in a document and titles of

Quartus II Help topics. For example, “Typographic Conventions.”

Indicates signal, port, register, bit, block, and primitive names. For example,

tdi

, and

input

. The suffix n denotes an active-low signal. For example,

data1

resetn

.

Indicates command line commands and anything that must be typed exactly as it

appears. For example,

c:\qdesigns\tutorial\chiptrip.gdf

.

Also indicates sections of an actual file, such as a Report File, references to parts of

files (for example, the AHDL keyword

TRI

example,

).

SUBDESIGN

), and logic function names (for

Numbered steps indicate a list of items when the sequence of the items is important,

such as the steps listed in a procedure.

A caution calls attention to a condition or possible situation that can damage or

destroy the product or your work.

A warning calls attention to a condition or possible situation that can cause you

injury.

The envelope links to the Email Subscription Management Center page of the Altera

website, where you can sign up to receive update notifications for Altera documents.

,

February 2012 Altera Corporation Dynamic Calibrated On-Chip Termination (ALTOCT) Megafunction

User Guide

Loading...

Loading...