CII51002-3.1

2. CycloneII Architecture

Functional Description

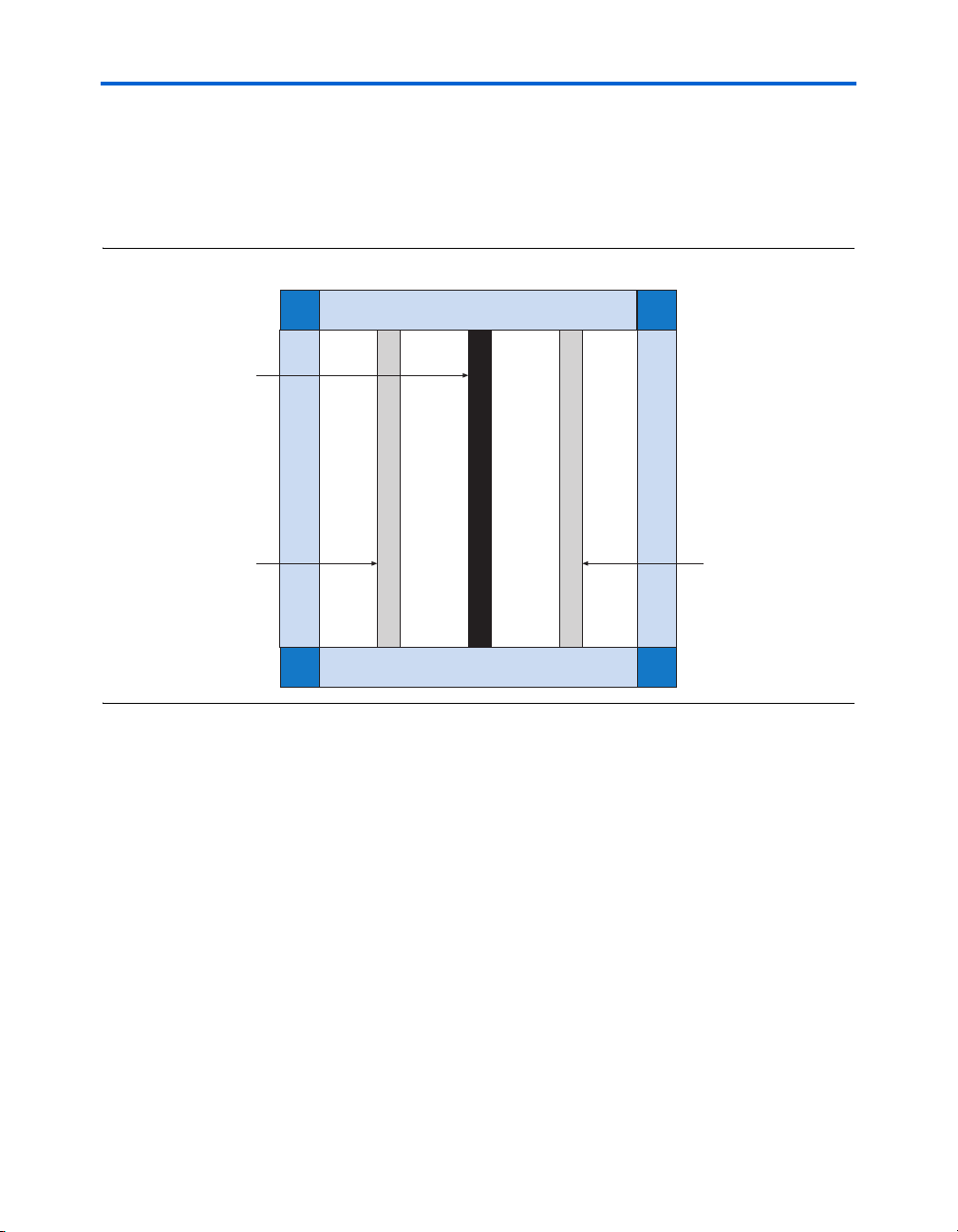

Cyclone®II devices contain a two-dimensional row- and column-based

architecture to implement custom logic. Column and row interconnects

of varying speeds provide signal interconnects between logic array

blocks (LABs), embedded memory blocks, and embedded multipliers.

The logic array consists of LABs, with 16 logic elements (LEs) in each

LAB. An LE is a small unit of logic providing efficient implementation of

user logic functions. LABs are grouped into rows and columns across the

device. Cyclone II devices range in density from 4,608 to 68,416 LEs.

Cyclone II devices provide a global clock network and up to four

phase-locked loops (PLLs). The global clock network consists of up to 16

global clock lines that drive throughout the entire device. The global clock

network can provide clocks for all resources within the device, such as

input/output elements (IOEs), LEs, embedded multipliers, and

embedded memory blocks. The global clock lines can also be used for

other high fan-out signals. Cyclone II PLLs provide general-purpose

clocking with clock synthesis and phase shifting as well as external

outputs for high-speed differential I/O support.

M4K memory blocks are true dual-port memory blocks with 4K bits of

memory plus parity (4,608 bits). These blocks provide dedicated true

dual-port, simple dual-port, or single-port memory up to 36-bits wide at

up to 260 MHz. These blocks are arranged in columns across the device

in between certain LABs. Cyclone II devices offer between 119 to

1,152 Kbits of embedded memory.

Each embedded multiplier block can implement up to either two 9 × 9-bit

multipliers, or one 18 × 18-bit multiplier with up to 250-MHz

performance. Embedded multipliers are arranged in columns across the

device.

Each Cyclone II device I/O pin is fed by an IOE located at the ends of LAB

rows and columns around the periphery of the device. I/O pins support

various single-ended and differential I/O standards, such as the 66- and

33-MHz, 64- and 32-bit PCI standard, PCI-X, and the LVDS I/O standard

at a maximum data rate of 805 megabits per second (Mbps) for inputs and

640 Mbps for outputs. Each IOE contains a bidirectional I/O buffer and

three registers for registering input, output, and output-enable signals.

Dual-purpose DQS, DQ, and DM pins along with delay chains (used to

Altera Corporation 2–1

February 2007

Logic Elements

s

phase-align double data rate (DDR) signals) provide interface support for

external memory devices such as DDR, DDR2, and single data rate (SDR)

SDRAM, and QDRII SRAM devices at up to 167 MHz.

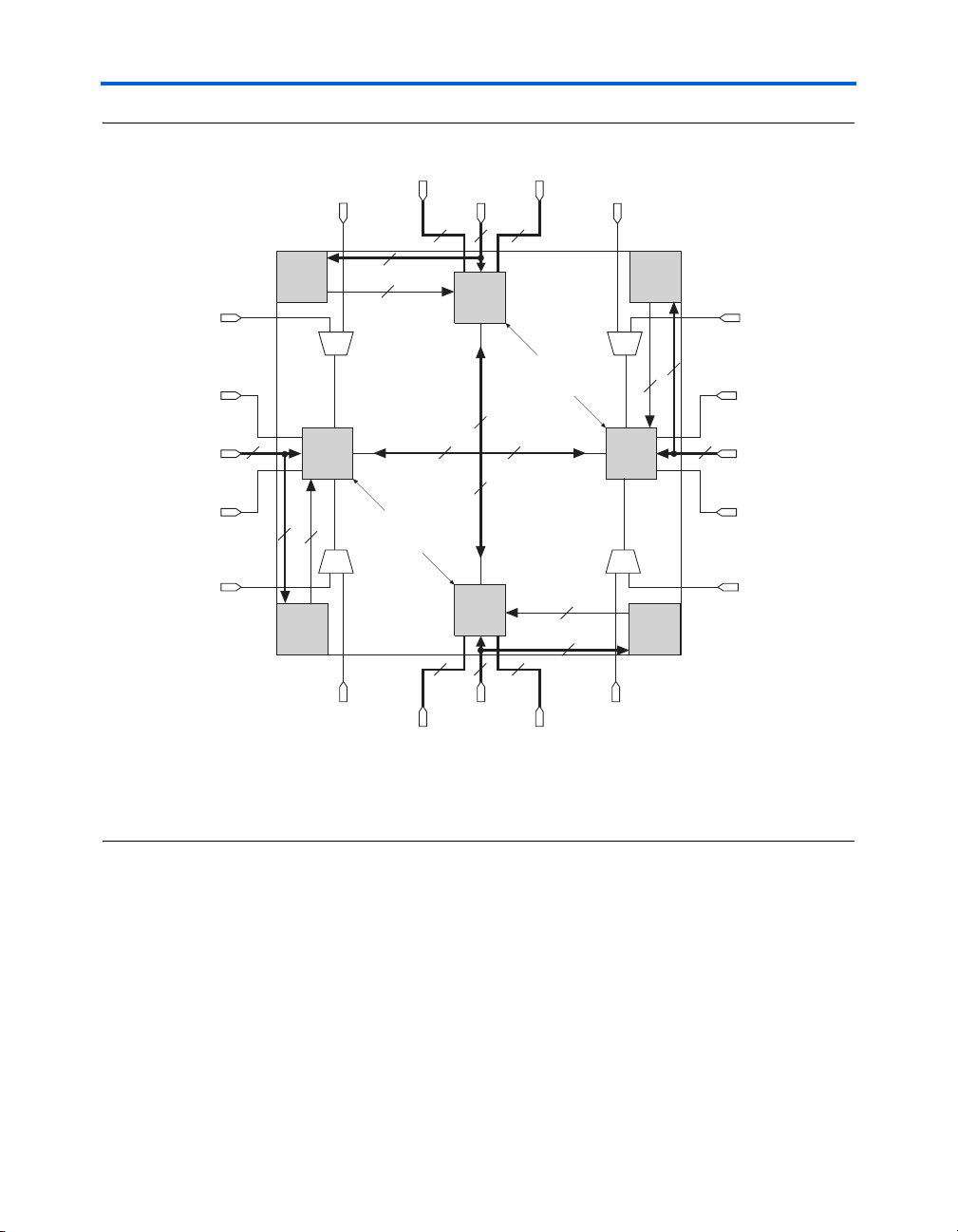

Figure 2–1 shows a diagram of the Cyclone II EP2C20 device.

Figure 2–1. Cyclone II EP2C20 Device Block Diagram

PLL PLLIOEs

Embedded

Multipliers

M4K Blocks

Logic Elements

Logic

IOEs

Array

PLL PLLIOEs

Logic

Array

Logic

Array

Logic

Array

IOEs

M4K Block

The number of M4K memory blocks, embedded multiplier blocks, PLLs,

rows, and columns vary per device.

The smallest unit of logic in the Cyclone II architecture, the LE, is compact

and provides advanced features with efficient logic utilization. Each LE

features:

■ A four-input look-up table (LUT), which is a function generator that

can implement any function of four variables

■ A programmable register

■ A carry chain connection

■ A register chain connection

■ The ability to drive all types of interconnects: local, row, column,

register chain, and direct link interconnects

■ Support for register packing

■ Support for register feedback

2–2 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

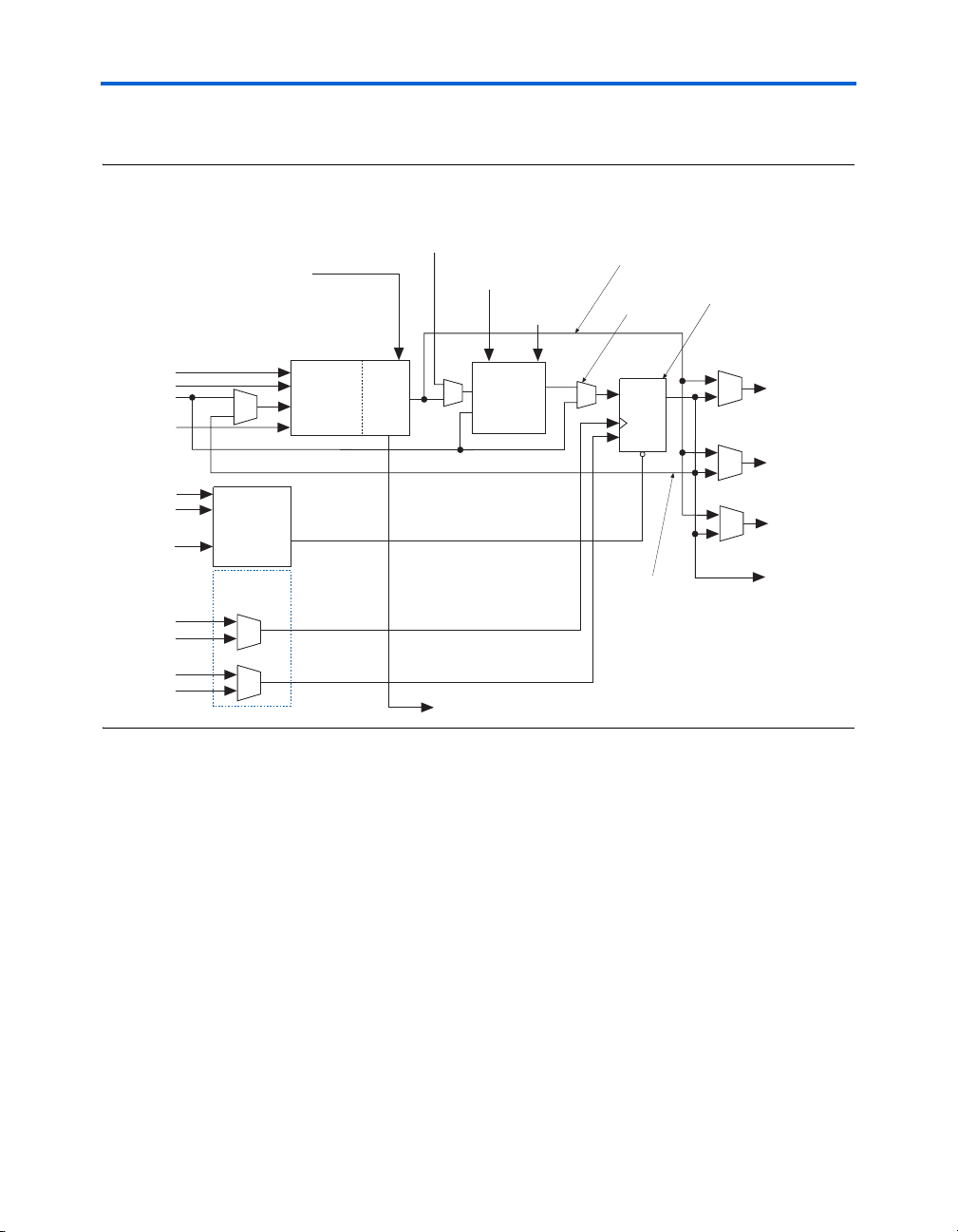

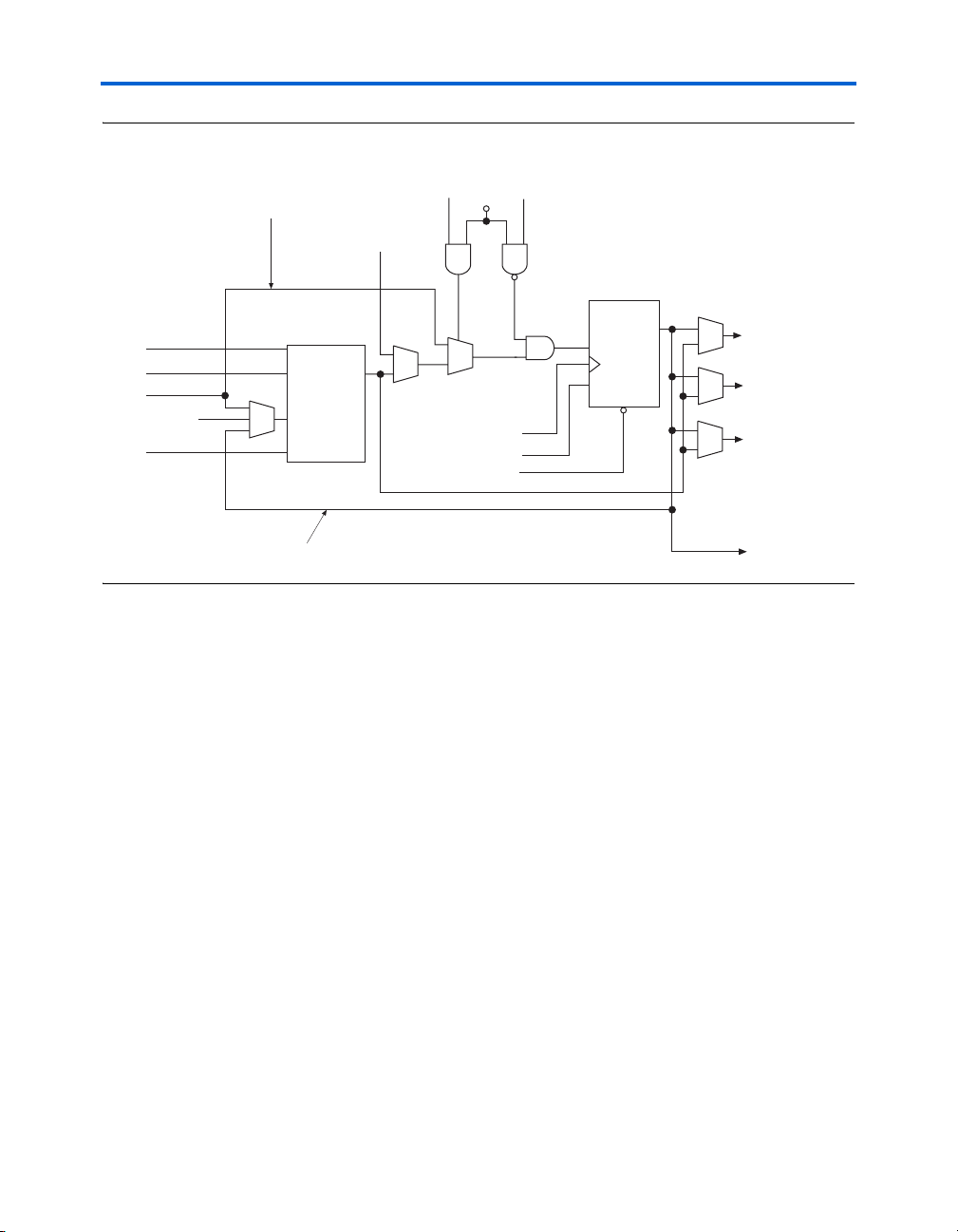

Figure 2–2. Cyclone II LE

y

LAB Carry-In

Figure 2–2 shows a Cyclone II LE.

Register Chain

Routing From

Previous LE

LAB-Wide

Synchronous

Load

Synchronous

LAB-Wide

Clear

Register Bypass

Packed

Register Select

Cyclone II Architecture

Programmable

Register

data1

data2

data3

data4

labclr1

labclr2

Chip-Wide

Reset

(DEV_CLRn)

labclk1

labclk2

labclkena1

labclkena2

Asynchronous

Clear Logic

Clock &

Clock Enable

Select

Look-Up

Ta bl e

(LUT)

Carry

Chain

LAB Carr

Synchronous

Load and

Clear Logic

-Out

D

ENA

CLRN

Register

Feedback

Q

Row, Column,

And Direct Link

Routing

Row, Column,

And Direct Link

Routing

Local Routing

Register Chain

Output

Each LE’s programmable register can be configured for D, T, JK, or SR

operation. Each register has data, clock, clock enable, and clear inputs.

Signals that use the global clock network, general-purpose I/O pins, or

any internal logic can drive the register’s clock and clear control signals.

Either general-purpose I/O pins or internal logic can drive the clock

enable. For combinational functions, the LUT output bypasses the

register and drives directly to the LE outputs.

Each LE has three outputs that drive the local, row, and column routing

resources. The LUT or register output can drive these three outputs

independently. Two LE outputs drive column or row and direct link

routing connections and one drives local interconnect resources, allowing

the LUT to drive one output while the register drives another output. This

feature, register packing, improves device utilization because the device

can use the register and the LUT for unrelated functions. When using

register packing, the LAB-wide synchronous load control signal is not

available. See “LAB Control Signals” on page 2–8 for more information.

Altera Corporation 2–3

February 2007 Cyclone II Device Handbook, Volume 1

Logic Elements

Another special packing mode allows the register output to feed back into

the LUT of the same LE so that the register is packed with its own fan-out

LUT, providing another mechanism for improved fitting. The LE can also

drive out registered and unregistered versions of the LUT output.

In addition to the three general routing outputs, the LEs within an LAB

have register chain outputs. Register chain outputs allow registers within

the same LAB to cascade together. The register chain output allows an

LAB to use LUTs for a single combinational function and the registers to

be used for an unrelated shift register implementation. These resources

speed up connections between LABs while saving local interconnect

resources. See “MultiTrack Interconnect” on page 2–10 for more

information on register chain connections.

LE Operating Modes

The Cyclone II LE operates in one of the following modes:

■ Normal mode

■ Arithmetic mode

Each mode uses LE resources differently. In each mode, six available

inputs to the LE—the four data inputs from the LAB local interconnect,

the LAB carry-in from the previous carry-chain LAB, and the register

chain connection—are directed to different destinations to implement the

desired logic function. LAB-wide signals provide clock, asynchronous

clear, synchronous clear, synchronous load, and clock enable control for

the register. These LAB-wide signals are available in all LE modes.

®

The Quartus

II software, in conjunction with parameterized functions

such as library of parameterized modules (LPM) functions, automatically

chooses the appropriate mode for common functions such as counters,

adders, subtractors, and arithmetic functions. If required, you can also

create special-purpose functions that specify which LE operating mode to

use for optimal performance.

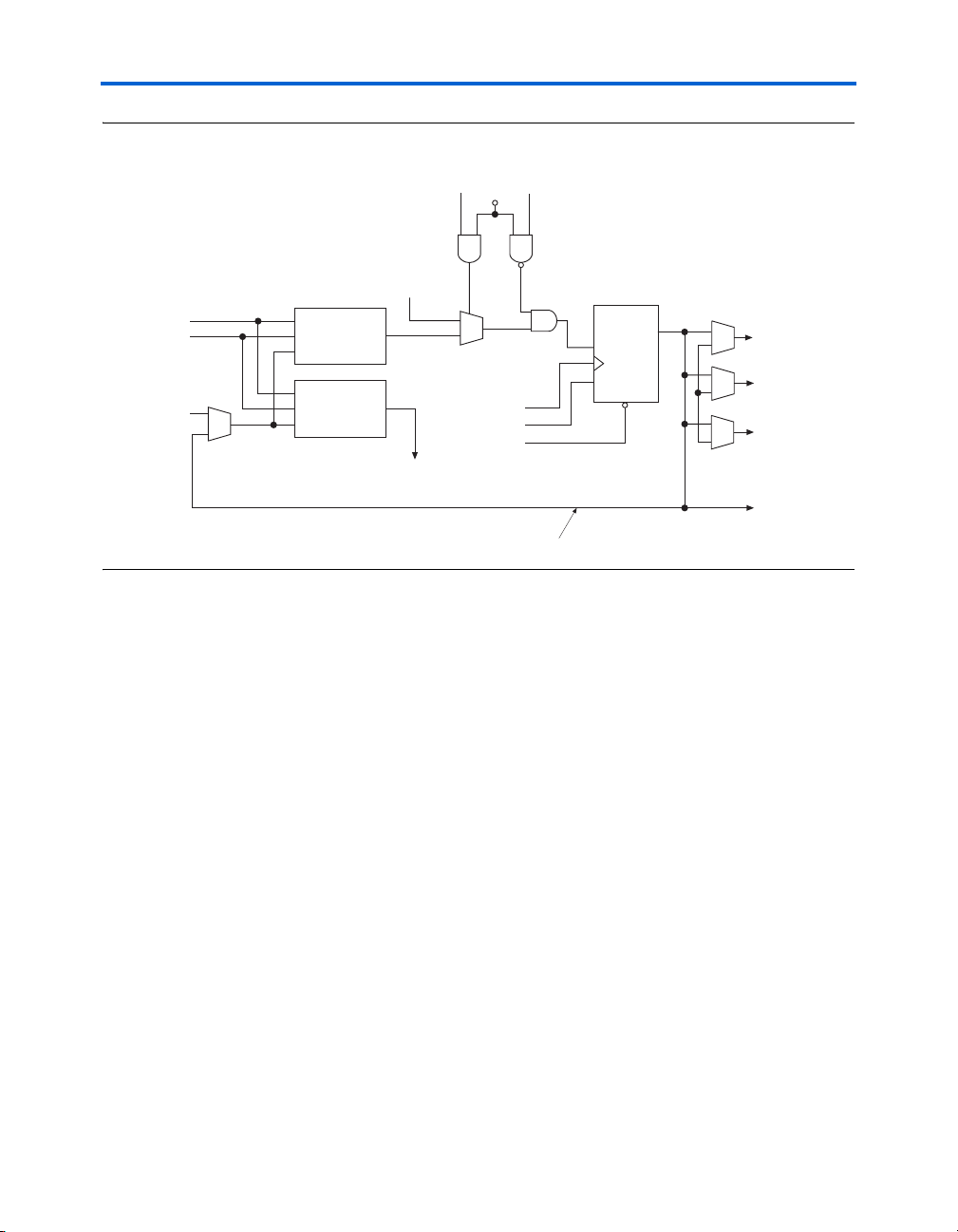

Normal Mode

The normal mode is suitable for general logic applications and

combinational functions. In normal mode, four data inputs from the LAB

local interconnect are inputs to a four-input LUT (see Figure 2–3). The

Quartus II Compiler automatically selects the carry-in or the data3

signal as one of the inputs to the LUT. LEs in normal mode support

packed registers and register feedback.

2–4 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

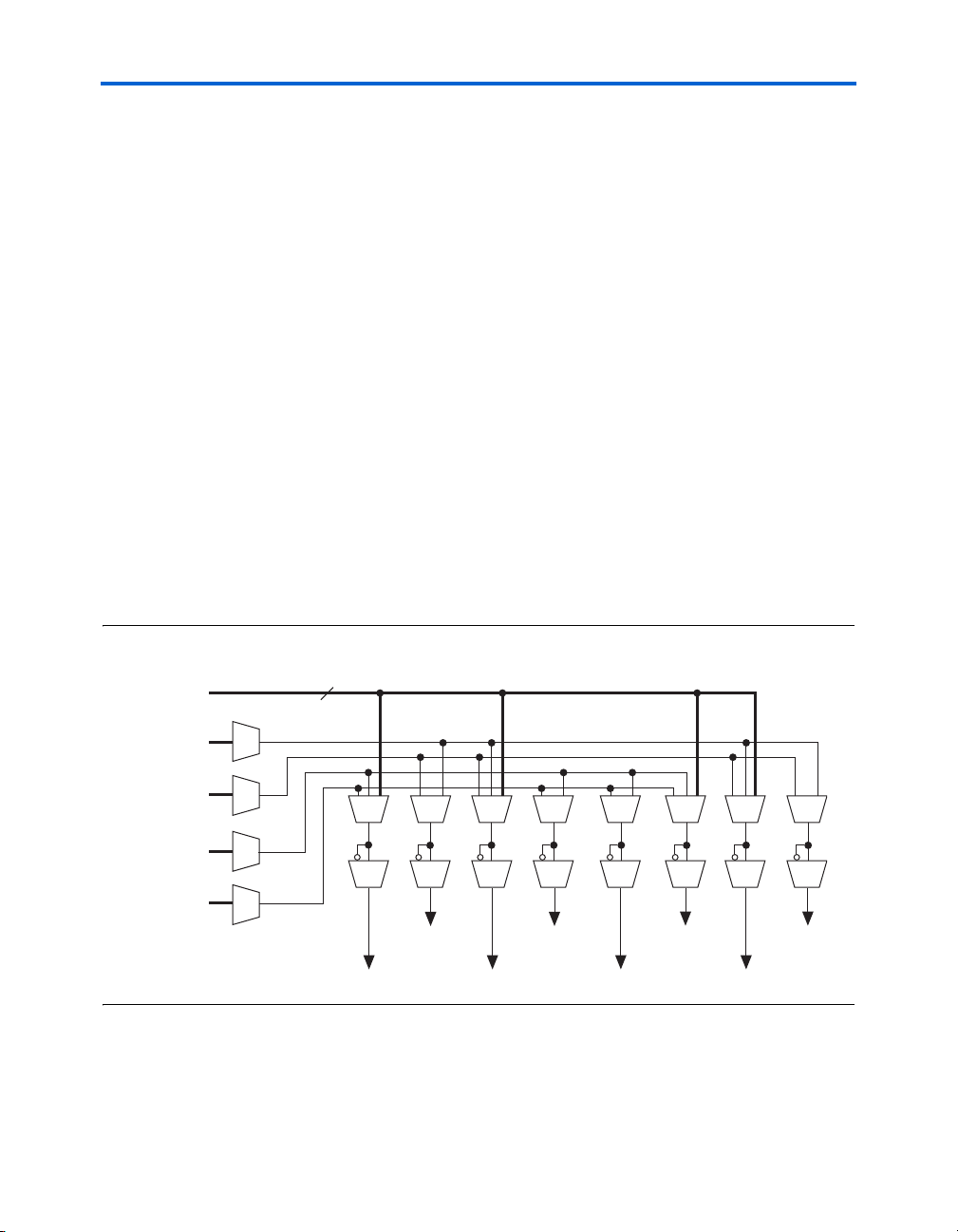

Figure 2–3. LE in Normal Mode

Cyclone II Architecture

data1

data2

data3

cin (from cout

of previous LE)

data4

Packed Register Input

Four-Input

Register Feedback

Arithmetic Mode

The arithmetic mode is ideal for implementing adders, counters,

accumulators, and comparators. An LE in arithmetic mode implements a

2-bit full adder and basic carry chain (see Figure 2–4). LEs in arithmetic

mode can drive out registered and unregistered versions of the LUT

output. Register feedback and register packing are supported when LEs

are used in arithmetic mode.

Register chain

connection

LUT

sload

(LAB Wide)

clock (LAB Wide)

ena (LAB Wide)

aclr (LAB Wide)

(LAB Wide)

sclear

D

ENA

CLRN

Q

Row, Column, and

Direct Link Routing

Row, Column, and

Direct Link Routing

Local routing

Register

chain output

Altera Corporation 2–5

February 2007 Cyclone II Device Handbook, Volume 1

Logic Elements

Figure 2–4. LE in Arithmetic Mode

(LAB Wide)

Register chain

connection

sload

sclear

(LAB Wide)

data1

data2

cin (from cout

of previous LE)

Three-Input

LUT

Three-Input

LUT

clock (LAB Wide)

ena (LAB Wide)

aclr (LAB Wide)

cout

Register Feedback

D

ENA

Q

CLRN

Row, column, and

direct link routing

Row, column, and

direct link routing

Local routing

Register

chain output

The Quartus II Compiler automatically creates carry chain logic during

design processing, or you can create it manually during design entry.

Parameterized functions such as LPM functions automatically take

advantage of carry chains for the appropriate functions.

The Quartus II Compiler creates carry chains longer than 16 LEs by

automatically linking LABs in the same column. For enhanced fitting, a

long carry chain runs vertically, which allows fast horizontal connections

to M4K memory blocks or embedded multipliers through direct link

interconnects. For example, if a design has a long carry chain in a LAB

column next to a column of M4K memory blocks, any LE output can feed

an adjacent M4K memory block through the direct link interconnect.

Whereas if the carry chains ran horizontally, any LAB not next to the

column of M4K memory blocks would use other row or column

interconnects to drive a M4K memory block. A carry chain continues as

far as a full column.

2–6 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

Cyclone II Architecture

t

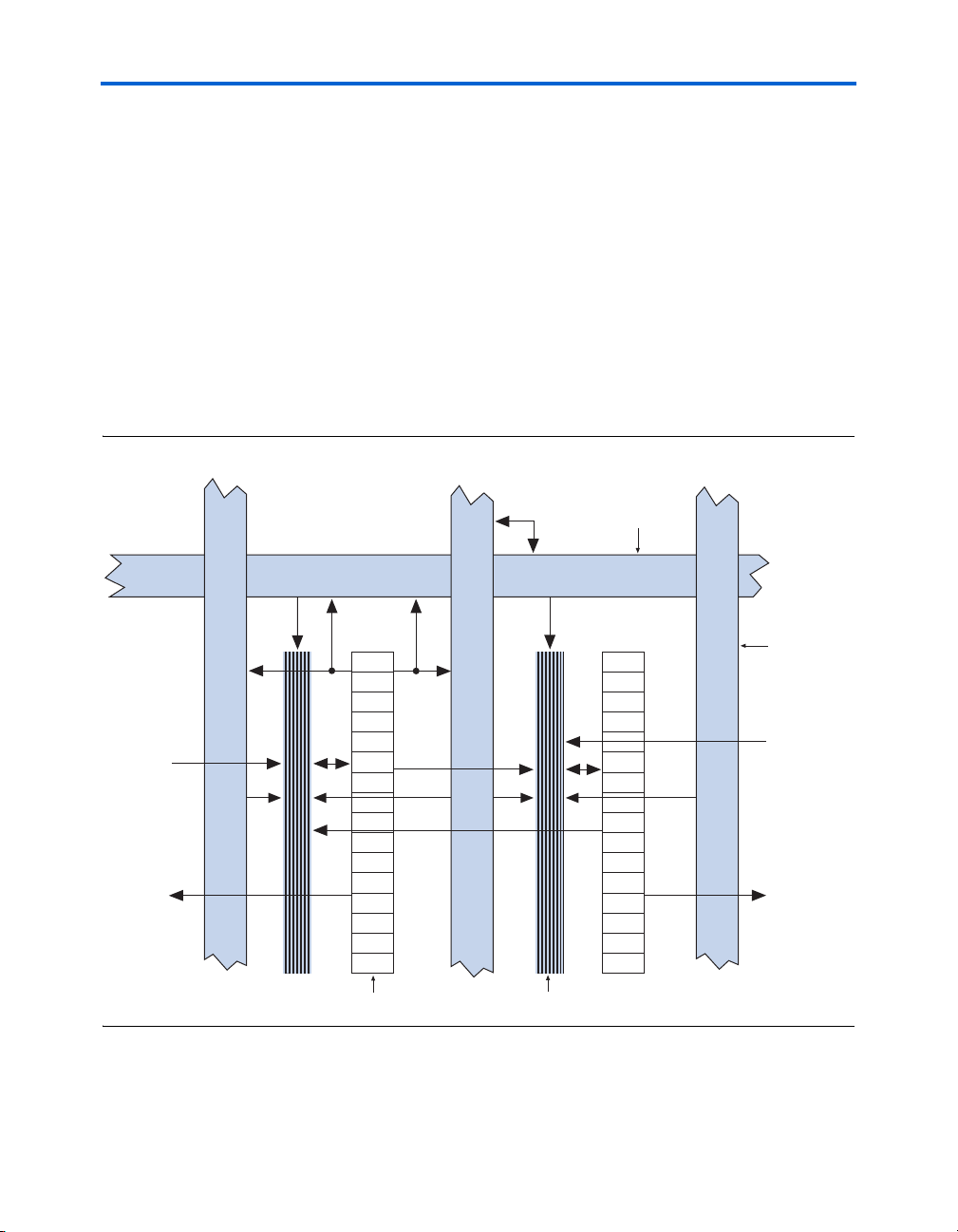

Logic Array Blocks

Each LAB consists of the following:

■ 16 LEs

■ LAB control signals

■ LE carry chains

■ Register chains

■ Local interconnect

The local interconnect transfers signals between LEs in the same LAB.

Register chain connections transfer the output of one LE’s register to the

adjacent LE’s register within an LAB. The Quartus II Compiler places

associated logic within an LAB or adjacent LABs, allowing the use of

local, and register chain connections for performance and area efficiency.

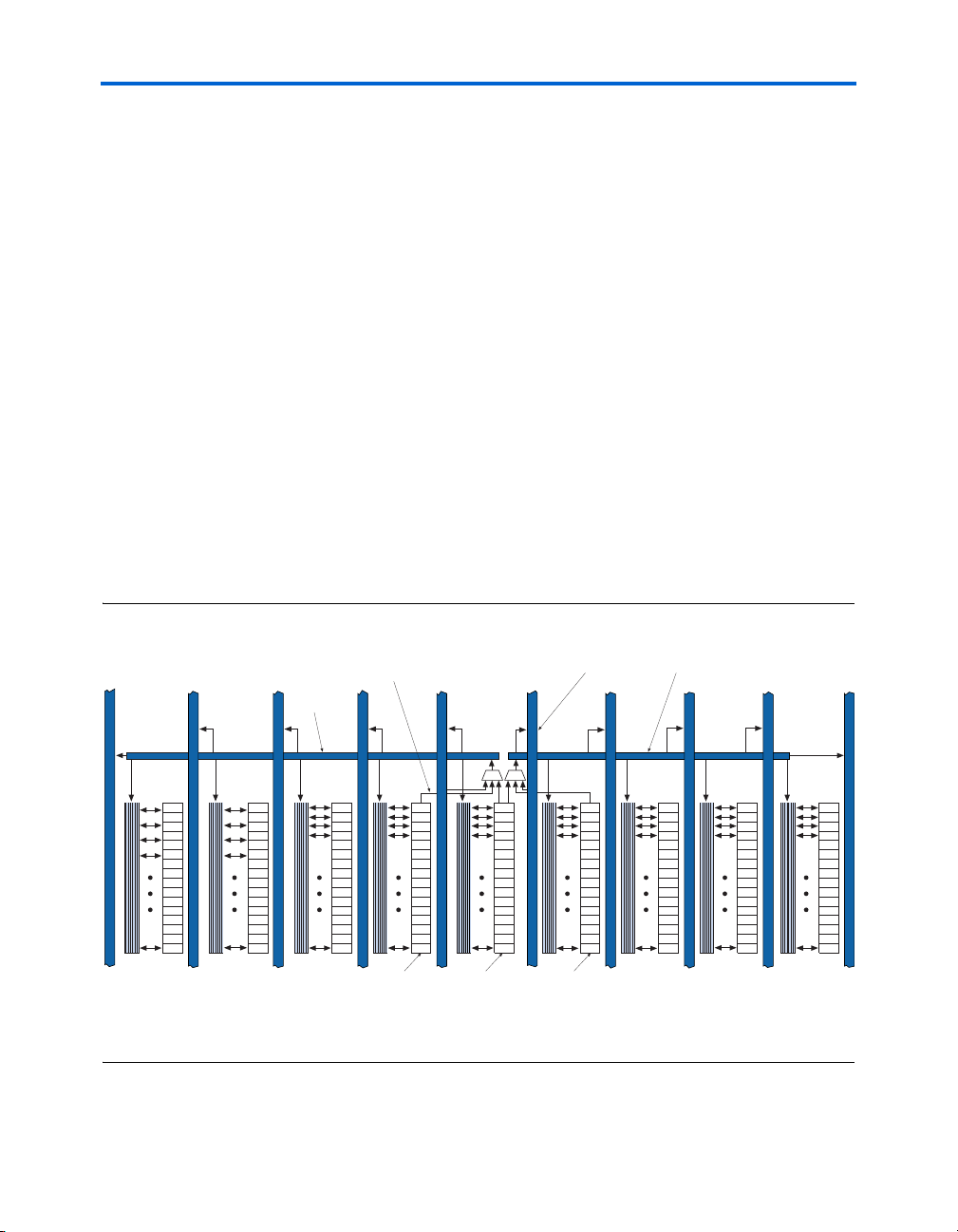

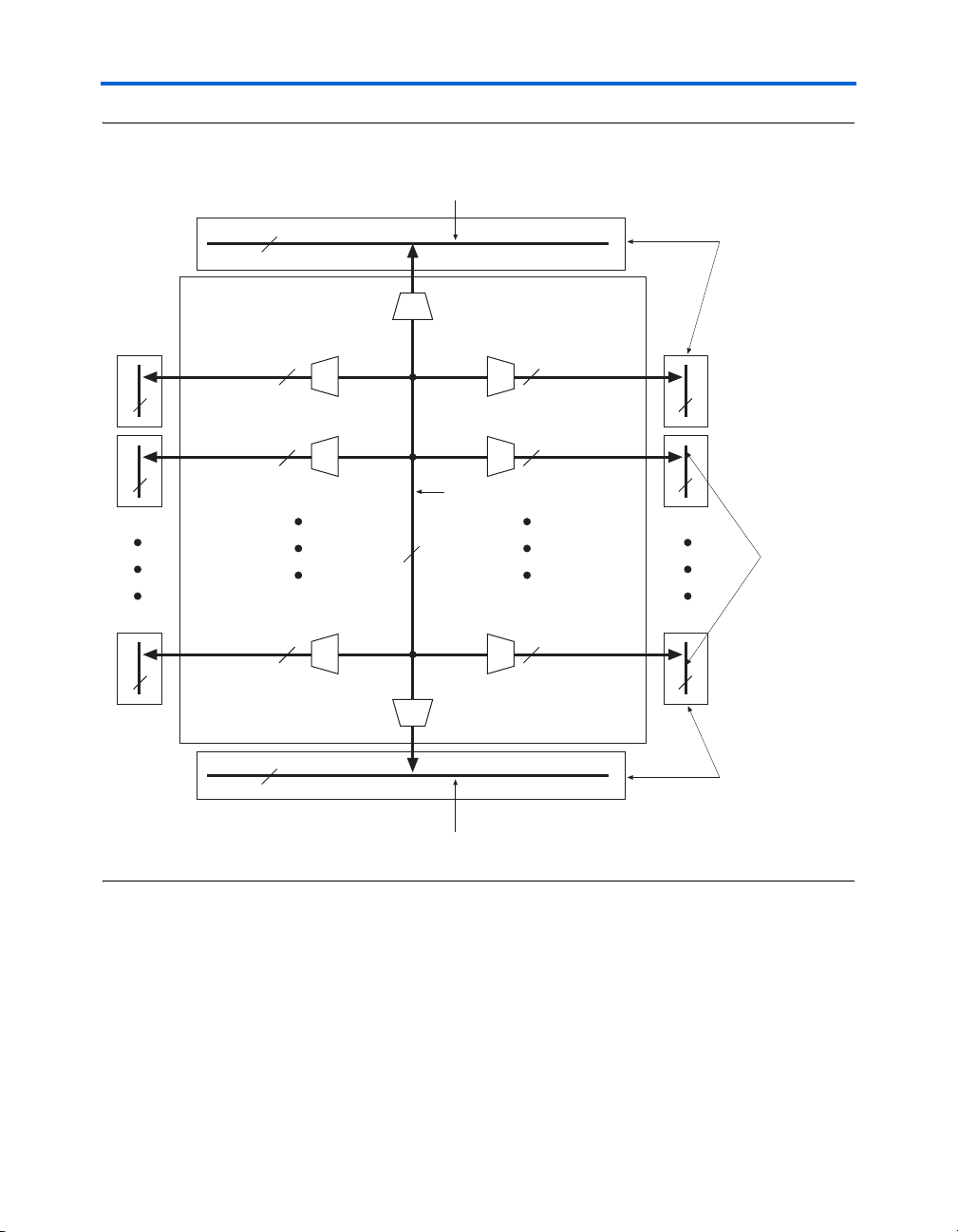

Figure 2–5 shows the Cyclone II LAB.

Figure 2–5. Cyclone II LAB Structure

Row Interconnect

Column

Interconnect

Direct link

Direct link

interconnect

from adjacent

block

Direct link

interconnect

to adjacent

block

LAB

Local Interconnect

interconnect

from adjacen

block

Direct link

interconnect

to adjacent

block

Altera Corporation 2–7

February 2007 Cyclone II Device Handbook, Volume 1

Logic Array Blocks

LAB Interconnects

The LAB local interconnect can drive LEs within the same LAB. The LAB

local interconnect is driven by column and row interconnects and LE

outputs within the same LAB. Neighboring LABs, PLLs, M4K RAM

blocks, and embedded multipliers from the left and right can also drive

an LAB’s local interconnect through the direct link connection. The direct

link connection feature minimizes the use of row and column

interconnects, providing higher performance and flexibility. Each LE can

drive 48 LEs through fast local and direct link interconnects. Figure 2–6

shows the direct link connection.

Figure 2–6. Direct Link Connection

Direct link interconnect from

left LAB, M4K memory

block, embedded multiplier,

PLL, or IOE output

Direct link

interconnect

to left

Interconnect

Direct link interconnect from

right LAB, M4K memory

block, embedded multiplier,

PLL, or IOE output

Direct link

interconnect

to right

Local

LAB

LAB Control Signals

Each LAB contains dedicated logic for driving control signals to its LEs.

The control signals include:

■ Two clocks

■ Two clock enables

■ Two asynchronous clears

■ One synchronous clear

■ One synchronous load

2–8 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

Cyclone II Architecture

This gives a maximum of seven control signals at a time. When using the

LAB-wide synchronous load, the clkena of labclk1 is not available.

Additionally, register packing and synchronous load cannot be used

simultaneously.

Each LAB can have up to four non-global control signals. Additional LAB

control signals can be used as long as they are global signals.

Synchronous clear and load signals are useful for implementing counters

and other functions. The synchronous clear and synchronous load signals

are LAB-wide signals that affect all registers in the LAB.

Each LAB can use two clocks and two clock enable signals. Each LAB’s

clock and clock enable signals are linked. For example, any LE in a

particular LAB using the labclk1 signal also uses labclkena1. If the

LAB uses both the rising and falling edges of a clock, it also uses both

LAB-wide clock signals. De-asserting the clock enable signal turns off the

LAB-wide clock.

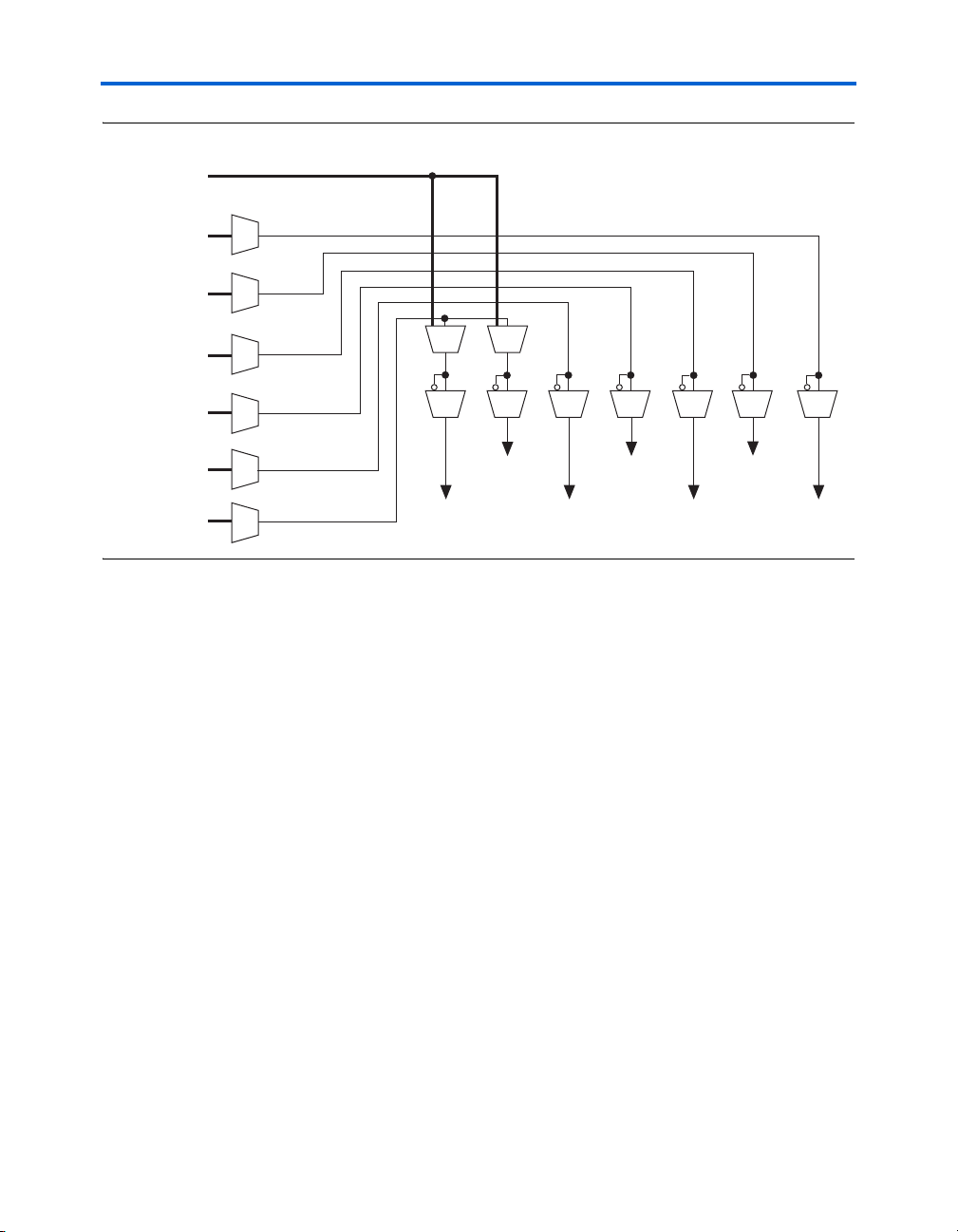

The LAB row clocks [5..0] and LAB local interconnect generate the LABwide control signals. The MultiTrack

allows clock and control signal distribution in addition to data. Figure 2–7

shows the LAB control signal generation circuit.

Figure 2–7. LAB-Wide Control Signals

Dedicated

LAB Row

Clocks

Local

Interconnect

Local

Interconnect

Local

Interconnect

Local

Interconnect

6

LAB-wide signals control the logic for the register’s clear signal. The LE

directly supports an asynchronous clear function. Each LAB supports up

to two asynchronous clear signals (labclr1 and labclr2).

labclkena1

™

interconnect’s inherent low skew

labclkena2

labclk2labclk1

syncload

labclr1

labclr2

synclr

Altera Corporation 2–9

February 2007 Cyclone II Device Handbook, Volume 1

MultiTrack Interconnect

A LAB-wide asynchronous load signal to control the logic for the

register’s preset signal is not available. The register preset is achieved by

using a NOT gate push-back technique. Cyclone II devices can only

support either a preset or asynchronous clear signal.

In addition to the clear port, Cyclone II devices provide a chip-wide reset

pin (DEV_CLRn) that resets all registers in the device. An option set before

compilation in the Quartus II software controls this pin. This chip-wide

reset overrides all other control signals.

MultiTrack

Interconnect

In the Cyclone II architecture, connections between LEs, M4K memory

blocks, embedded multipliers, and device I/O pins are provided by the

MultiTrack interconnect structure with DirectDrive™ technology. The

MultiTrack interconnect consists of continuous, performance-optimized

routing lines of different speeds used for inter- and intra-design block

connectivity. The Quartus II Compiler automatically places critical paths

on faster interconnects to improve design performance.

DirectDrive technology is a deterministic routing technology that ensures

identical routing resource usage for any function regardless of placement

within the device. The MultiTrack interconnect and DirectDrive

technology simplify the integration stage of block-based designing by

eliminating the re-optimization cycles that typically follow design

changes and additions.

The MultiTrack interconnect consists of row (direct link, R4, and R24) and

column (register chain, C4, and C16) interconnects that span fixed

distances. A routing structure with fixed-length resources for all devices

allows predictable and repeatable performance when migrating through

different device densities.

Row Interconnects

Dedicated row interconnects route signals to and from LABs, PLLs, M4K

memory blocks, and embedded multipliers within the same row. These

row resources include:

■ Direct link interconnects between LABs and adjacent blocks

■ R4 interconnects traversing four blocks to the right or left

■ R24 interconnects for high-speed access across the length of the

device

2–10 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

Cyclone II Architecture

The direct link interconnect allows an LAB, M4K memory block, or

embedded multiplier block to drive into the local interconnect of its left

and right neighbors. Only one side of a PLL block interfaces with direct

link and row interconnects. The direct link interconnect provides fast

communication between adjacent LABs and/or blocks without using

row interconnect resources.

The R4 interconnects span four LABs, three LABs and one M4K memory

block, or three LABs and one embedded multiplier to the right or left of a

source LAB. These resources are used for fast row connections in a fourLAB region. Every LAB has its own set of R4 interconnects to drive either

left or right. Figure 2–8 shows R4 interconnect connections from an LAB.

R4 interconnects can drive and be driven by LABs, M4K memory blocks,

embedded multipliers, PLLs, and row IOEs. For LAB interfacing, a

primary LAB or LAB neighbor (see Figure 2–8) can drive a given R4

interconnect. For R4 interconnects that drive to the right, the primary

LAB and right neighbor can drive on to the interconnect. For R4

interconnects that drive to the left, the primary LAB and its left neighbor

can drive on to the interconnect. R4 interconnects can drive other R4

interconnects to extend the range of LABs they can drive. Additionally,

R4 interconnects can drive R24 interconnects, C4, and C16 interconnects

for connections from one row to another.

Figure 2–8. R4 Interconnect Connections

Adjacent LAB can

R4 Interconnect

Driving Left

Drive onto Another

LAB's R4 Interconnect

LAB

Neighbor

Primary

LAB (2)

C4 Column Interconnects (1)

LAB

Neighbor

Notes to Figure 2–8:

(1) C4 interconnects can drive R4 interconnects.

(2) This pattern is repeated for every LAB in the LAB row.

Altera Corporation 2–11

February 2007 Cyclone II Device Handbook, Volume 1

R4 Interconnect

Driving Right

MultiTrack Interconnect

R24 row interconnects span 24 LABs and provide the fastest resource for

long row connections between non-adjacent LABs, M4K memory blocks,

dedicated multipliers, and row IOEs. R24 row interconnects drive to

other row or column interconnects at every fourth LAB. R24 row

interconnects drive LAB local interconnects via R4 and C4 interconnects

and do not drive directly to LAB local interconnects. R24 interconnects

can drive R24, R4, C16, and C4 interconnects.

Column Interconnects

The column interconnect operates similar to the row interconnect. Each

column of LABs is served by a dedicated column interconnect, which

vertically routes signals to and from LABs, M4K memory blocks,

embedded multipliers, and row and column IOEs. These column

resources include:

■ Register chain interconnects within an LAB

■ C4 interconnects traversing a distance of four blocks in an up and

down direction

■ C16 interconnects for high-speed vertical routing through the device

Cyclone II devices include an enhanced interconnect structure within

LABs for routing LE output to LE input connections faster using register

chain connections. The register chain connection allows the register

output of one LE to connect directly to the register input of the next LE in

the LAB for fast shift registers. The Quartus II Compiler automatically

takes advantage of these resources to improve utilization and

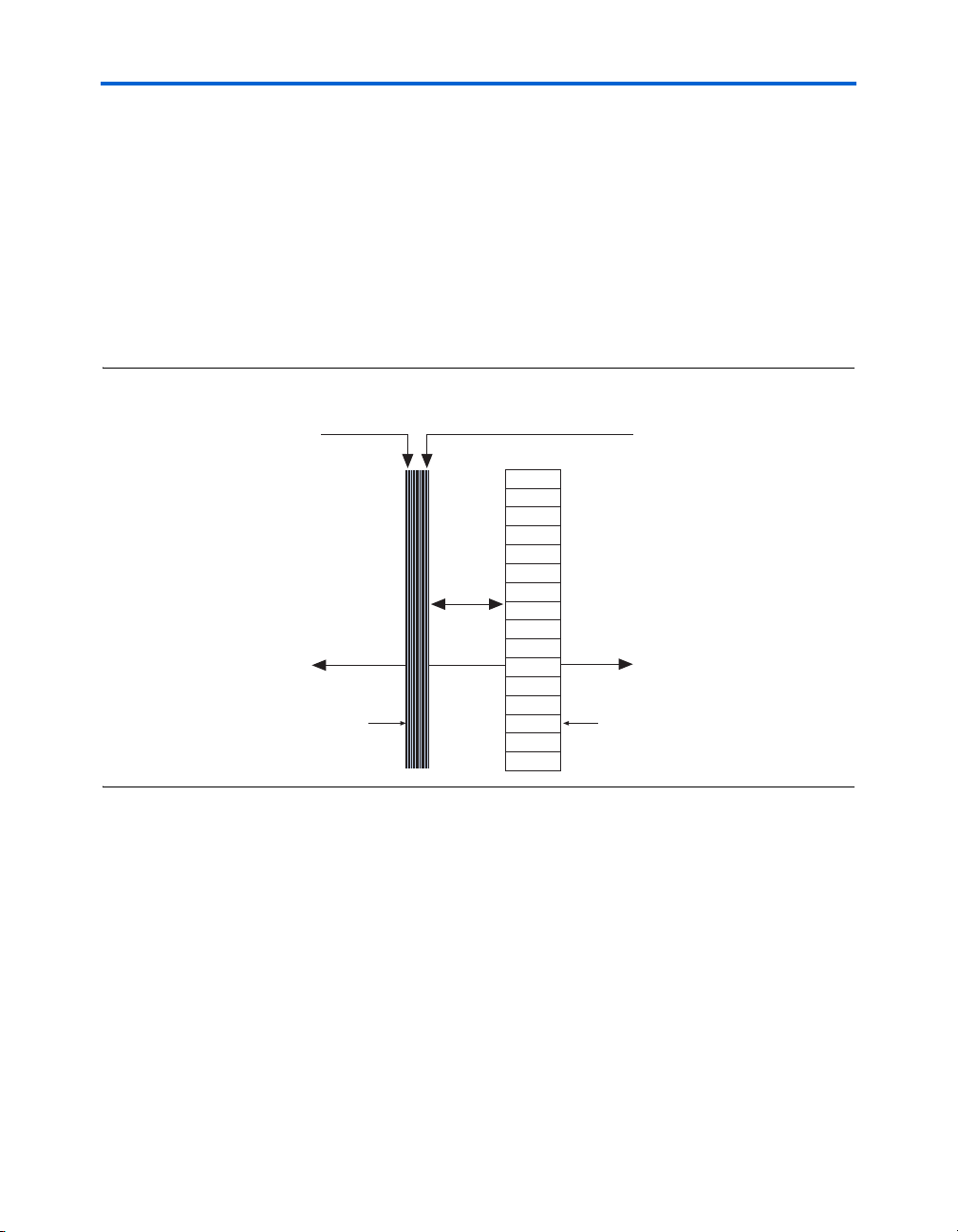

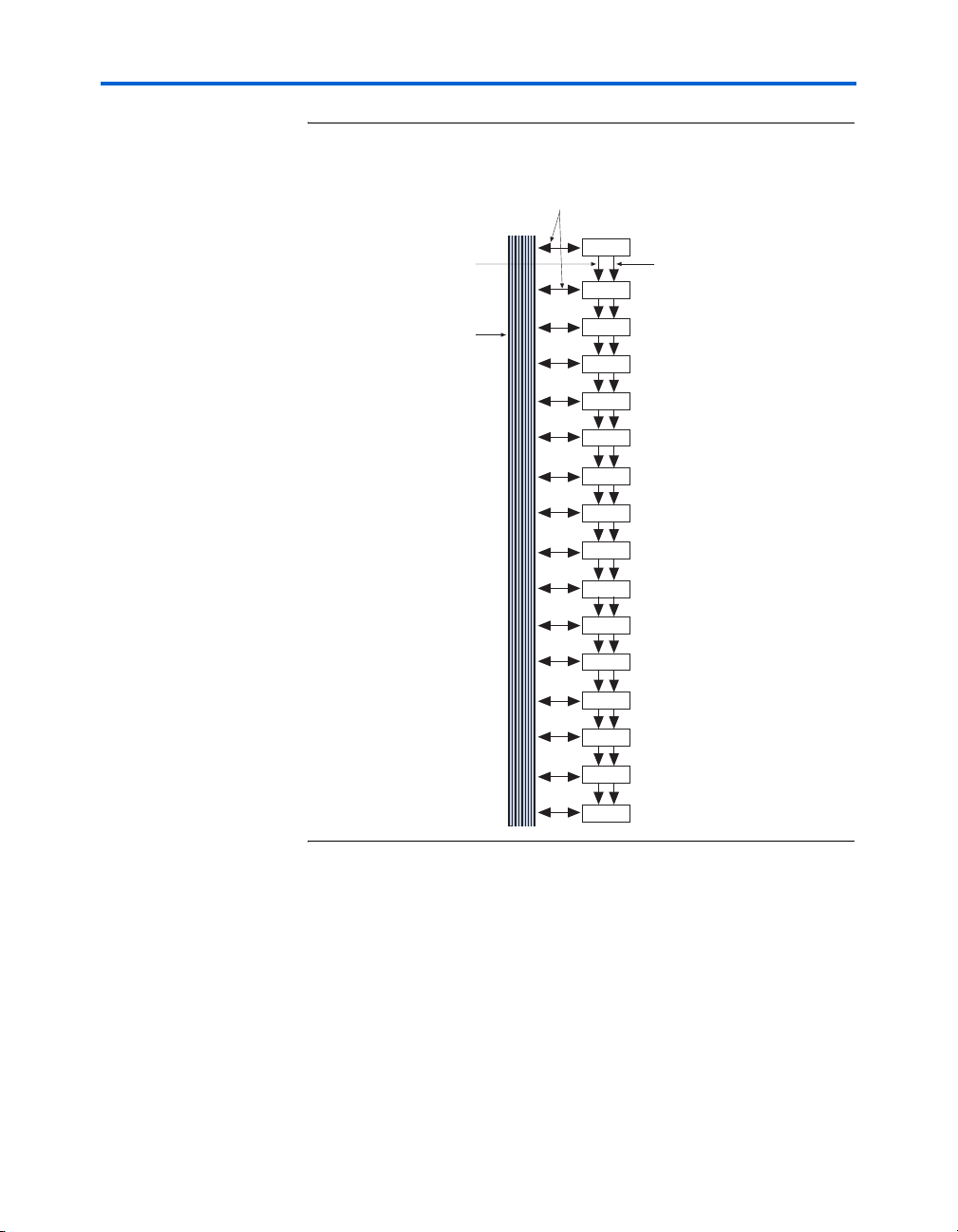

performance. Figure 2–9 shows the register chain interconnects.

2–12 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

Figure 2–9. Register Chain Interconnects

t

Local Interconnect

Routing Among LEs

in the LAB

Cyclone II Architecture

Carry Chain

Routing to

Adjacent LE

Local

Interconnect

LE 1

LE 2

LE 3

LE 4

LE 5

LE 6

LE 7

LE 8

LE 9

LE 10

LE 11

LE 12

LE13

LE 14

LE 15

Register Chain

Routing to Adjacen

LE's Register Input

LE 16

The C4 interconnects span four LABs, M4K blocks, or embedded

multipliers up or down from a source LAB. Every LAB has its own set of

C4 interconnects to drive either up or down. Figure 2–10 shows the C4

interconnect connections from an LAB in a column. The C4 interconnects

can drive and be driven by all types of architecture blocks, including

PLLs, M4K memory blocks, embedded multiplier blocks, and column

and row IOEs. For LAB interconnection, a primary LAB or its LAB

neighbor (see Figure 2–10) can drive a given C4 interconnect. C4

interconnects can drive each other to extend their range as well as drive

row interconnects for column-to-column connections.

Altera Corporation 2–13

February 2007 Cyclone II Device Handbook, Volume 1

MultiTrack Interconnect

4

Figure 2–10. C4 Interconnect Connections Note (1)

C4 Interconnect

Drives Local and R

Interconnects

Up to Four Rows

C4 Interconnect

Driving Up

LAB

Row

Interconnect

Adjacent LAB can

drive onto neighboring

LAB's C4 interconnect

Local

Interconnect

Primary

LAB

LAB

Neighbor

C4 Interconnect

Driving Down

Note to Figure 2–10:

(1) Each C4 interconnect can drive either up or down four rows.

2–14 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

C16 column interconnects span a length of 16 LABs and provide the

fastest resource for long column connections between LABs, M4K

memory blocks, embedded multipliers, and IOEs. C16 column

interconnects drive to other row and column interconnects at every

fourth LAB. C16 column interconnects drive LAB local interconnects via

C4 and R4 interconnects and do not drive LAB local interconnects

directly. C16 interconnects can drive R24, R4, C16, and C4 interconnects.

Device Routing

All embedded blocks communicate with the logic array similar to

LAB-to-LAB interfaces. Each block (for example, M4K memory,

embedded multiplier, or PLL) connects to row and column interconnects

and has local interconnect regions driven by row and column

interconnects. These blocks also have direct link interconnects for fast

connections to and from a neighboring LAB.

Table 2–1 shows the Cyclone II device’s routing scheme.

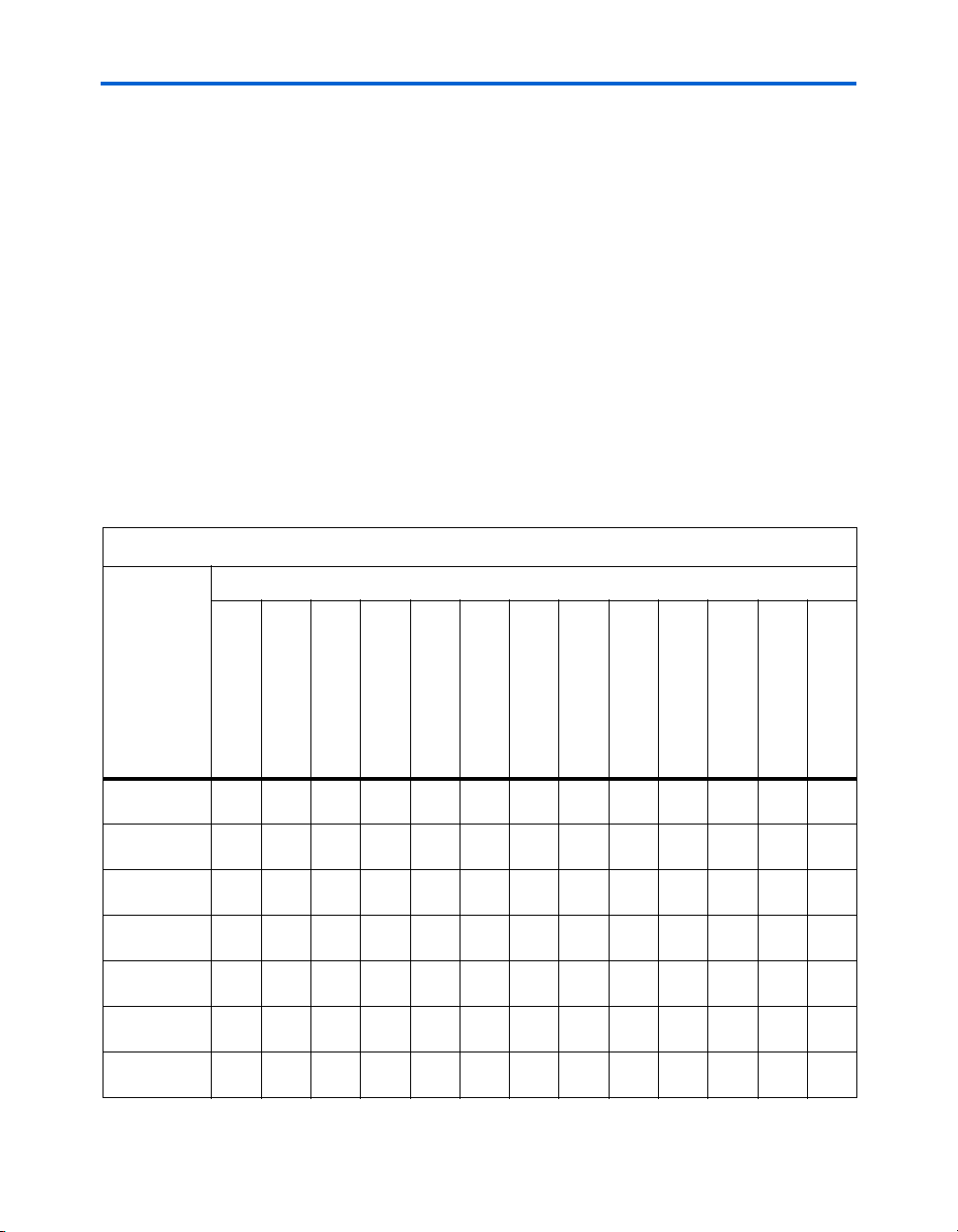

Table 2–1. Cyclone II Device Routing Scheme (Part 1 of 2)

Destination

Cyclone II Architecture

Source

LE

Register Chain

Local Interconnect

R4 Interconnect

C4 Interconnect

R24 Interconnect

C16 Interconnect

M4K RAM Block

Direct Link Interconnect

Register

Chain

Local

Interconnect

Direct Link

Interconnect

R4

Interconnect

R24

Interconnect

C4

Interconnect

C16

Interconnect

Altera Corporation 2–15

February 2007 Cyclone II Device Handbook, Volume 1

v

v vvvv

vvvv

v vvvv

vvvv

v

vvvvvv

PLL

Column IOE

Embedded Multiplier

Row IOE

Global Clock Network & Phase-Locked Loops

Table 2–1. Cyclone II Device Routing Scheme (Part 2 of 2)

Destination

Source

Register Chain

Local Interconnect

LE vvvv v

M4K memory

Block

Embedded

Multipliers

PLL vv v

Column IOE vv

Row IOE vvvv

vvv v

vvv v

R4 Interconnect

Direct Link Interconnect

C4 Interconnect

R24 Interconnect

C16 Interconnect

LE

M4K RAM Block

Embedded Multiplier

PLL

Row IOE

Column IOE

Global Clock

Network &

Phase-Locked

Loops

2–16 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

Cyclone II devices provide global clock networks and up to four PLLs for

a complete clock management solution. Cyclone II clock network features

include:

■ Up to 16 global clock networks

■ Up to four PLLs

■ Global clock network dynamic clock source selection

■ Global clock network dynamic enable and disable

Cyclone II Architecture

Each global clock network has a clock control block to select from a

number of input clock sources (PLL clock outputs, CLK[] pins, DPCLK[]

pins, and internal logic) to drive onto the global clock network. Tab le 2 –2

lists how many PLLs, CLK[] pins, DPCLK[] pins, and global clock

networks are available in each Cyclone II device. CLK[] pins are

dedicated clock pins and DPCLK[] pins are dual-purpose clock pins.

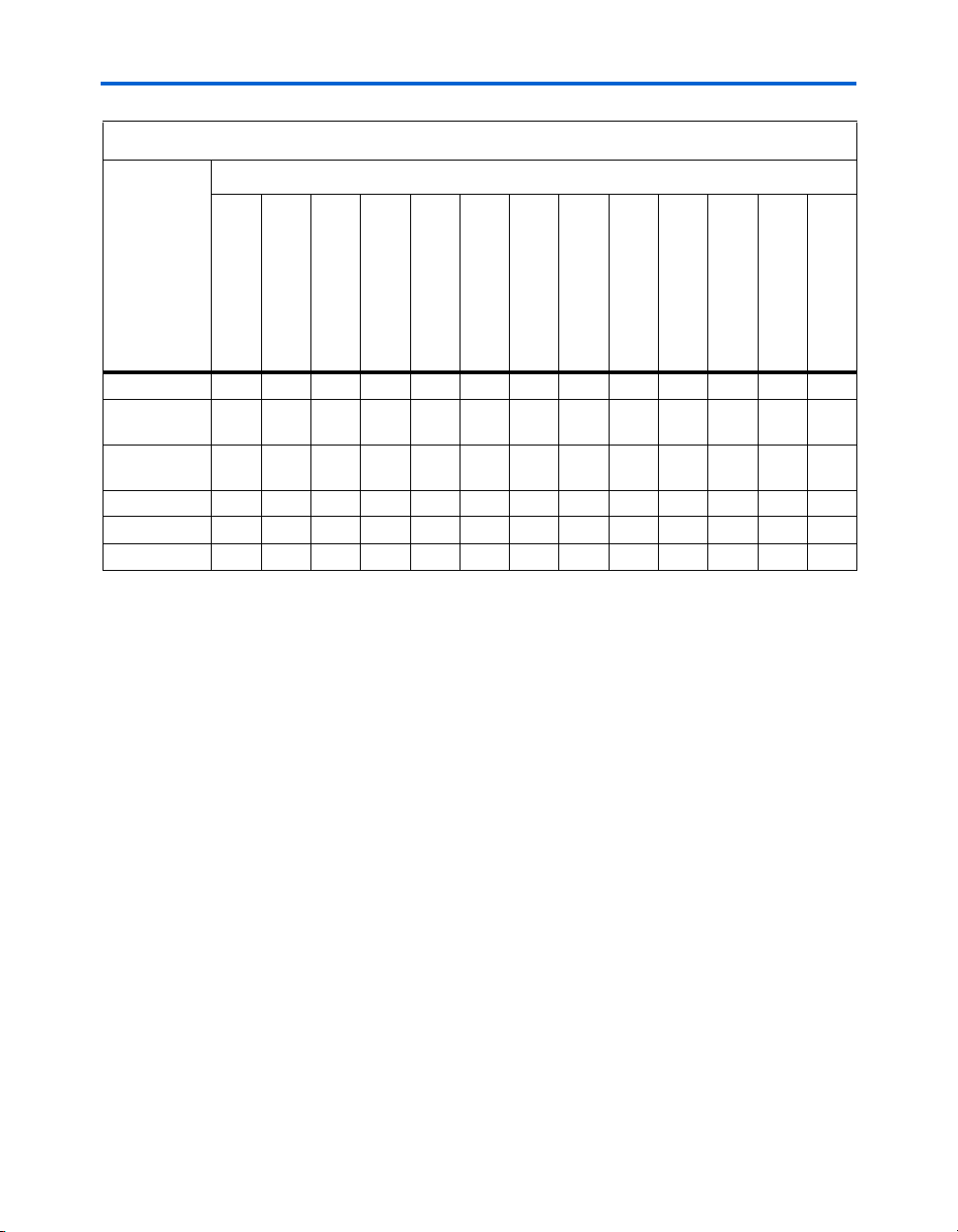

Table 2–2. Cyclone II Device Clock Resources

Device

EP2C5 2 8 8 8

EP2C8 2 8 8 8

EP2C15 4 16 20 16

EP2C20 4 16 20 16

EP2C35 4 16 20 16

EP2C50 4 16 20 16

EP2C70 4 16 20 16

Number of

PLLs

Number of

CLK Pins

Number of

DPCLK Pins

Number of

Global Clock

Networks

Figures 2–11 and 2–12 show the location of the Cyclone II PLLs, CLK[]

inputs, DPCLK[] pins, and clock control blocks.

Altera Corporation 2–17

February 2007 Cyclone II Device Handbook, Volume 1

Global Clock Network & Phase-Locked Loops

Figure 2–11. EP2C5 & EP2C8 PLL, CLK[], DPCLK[] & Clock Control Block Locations

DPCLK10 DPCLK8

Clock Control

Block (1)

PLL 2

DPCLK0

CLK[3..0]

DPCLK1

4

4

PLL 1

DPCLK2

GCLK[7..0]

Note to Figure 2–11:

(1) There are four clock control blocks on each side.

4

8

8

8

4

8

GCLK[7..0]

Clock Control

DPCLK4

DPCLK7

CLK[7..4]

DPCLK6

Block (1)

2–18 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

Figure 2–12. EP2C15 & Larger PLL, CLK[], DPCLK[] & Clock Control Block Locations

DPCLK[9..8]DPCLK[11..10]

CDPCLK7

CLK[11..8]

4

CDPCLK6

22

Cyclone II Architecture

4

3

GCLK[15..0]

Clock Control

Block (1)

Clock Control

Block (1)

16

16 16

16

GCLK[15..0]

3

4

4

22

CLK[15..12] CDPCLK3

DPCLK[5..4]DPCLK[3..2]

3

PLL 4

CDPCLK5

4

DPCLK7

CLK[7..4]

4

DPCLK6

CDPCLK4

CDPCLK0

DPCLK0

CLK[3..0]

DPCLK1

CDPCLK1

PLL 3 PLL 2

(2) (2)

4

4

3

(2) (2)

PLL 1

CDPCLK2

Notes to Figure 2–12:

(1) There are four clock control blocks on each side.

(2) Only one of the corner CDPCLK pins in each corner can feed the clock control block at a time. The other CDPCLK pins

can be used as general-purpose I/O pins.

Altera Corporation 2–19

February 2007 Cyclone II Device Handbook, Volume 1

Global Clock Network & Phase-Locked Loops

Dedicated Clock Pins

Larger Cyclone II devices (EP2C15 and larger devices) have 16 dedicated

clock pins (CLK[15..0], four pins on each side of the device). Smaller

Cyclone II devices (EP2C5 and EP2C8 devices) have eight dedicated clock

pins (CLK[7..0], four pins on left and right sides of the device). These

CLK pins drive the global clock network (GCLK), as shown in

Figures 2–11 and 2–12.

If the dedicated clock pins are not used to feed the global clock networks,

they can be used as general-purpose input pins to feed the logic array

using the MultiTrack interconnect. However, if they are used as generalpurpose input pins, they do not have support for an I/O register and

must use LE-based registers in place of an I/O register.

Dual-Purpose Clock Pins

Cyclone II devices have either 20 dual-purpose clock pins,

DPCLK[19..0] or 8 dual-purpose clock pins, DPCLK[7..0]. In the

larger Cyclone II devices (EP2C15 devices and higher), there are

20 DPCLK pins; four on the left and right sides and six on the top and

bottom of the device. The corner CDPCLK pins are first multiplexed before

they drive into the clock control block. Since the signals pass through a

multiplexer before feeding the clock control block, these signals incur

more delay to the clock control block than other DPCLK pins that directly

feed the clock control block. In the smaller Cyclone II devices (EP2C5 and

EP2C8 devices), there are eight DPCLK pins; two on each side of the device

(see Figures 2–11 and 2–12).

A programmable delay chain is available from the DPCLK pin to its fanout destinations. To set the propagation delay from the DPCLK pin to its

fan-out destinations, use the Input Delay from Dual-Purpose Clock Pin

to Fan-Out Destinations assignment in the Quartus II software.

These dual-purpose pins can connect to the global clock network for

high-fanout control signals such as clocks, asynchronous clears, presets,

and clock enables, or protocol control signals such as TRDY and IRDY for

PCI, or DQS signals for external memory interfaces.

2–20 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

Cyclone II Architecture

Global Clock Network

The 16 or 8 global clock networks drive throughout the entire device.

Dedicated clock pins (CLK[]), PLL outputs, the logic array, and

dual-purpose clock (DPCLK[]) pins can also drive the global clock

network.

The global clock network can provide clocks for all resources within the

device, such as IOEs, LEs, memory blocks, and embedded multipliers.

The global clock lines can also be used for control signals, such as clock

enables and synchronous or asynchronous clears fed from the external

pin, or DQS signals for DDR SDRAM or QDRII SRAM interfaces. Internal

logic can also drive the global clock network for internally generated

global clocks and asynchronous clears, clock enables, or other control

signals with large fan-out.

Clock Control Block

There is a clock control block for each global clock network available in

Cyclone II devices. The clock control blocks are arranged on the device

periphery and there are a maximum of 16 clock control blocks available

per Cyclone II device. The larger Cyclone II devices (EP2C15 devices and

larger) have 16 clock control blocks, four on each side of the device. The

smaller Cyclone II devices (EP2C5 and EP2C8 devices) have eight clock

control blocks, four on the left and right sides of the device.

The control block has these functions:

■ Dynamic global clock network clock source selection

■ Dynamic enable/disable of the global clock network

In Cyclone II devices, the dedicated CLK[] pins, PLL counter outputs,

DPCLK[] pins, and internal logic can all feed the clock control block. The

output from the clock control block in turn feeds the corresponding

global clock network.

The following sources can be inputs to a given clock control block:

■ Four clock pins on the same side as the clock control block

■ Three PLL clock outputs from a PLL

■ Four DPCLK pins (including CDPCLK pins) on the same side as the

clock control block

■ Four internally-generated signals

Altera Corporation 2–21

February 2007 Cyclone II Device Handbook, Volume 1

Global Clock Network & Phase-Locked Loops

Of the sources listed, only two clock pins, two PLL clock outputs, one

DPCLK pin, and one internally-generated signal are chosen to drive into a

clock control block. Figure 2–13 shows a more detailed diagram of the

clock control block. Out of these six inputs, the two clock input pins and

two PLL outputs can be dynamic selected to feed a global clock network.

The clock control block supports static selection of DPCLK and the signal

from internal logic.

Figure 2–13. Clock Control Block

Internal Logic

Static Clock Select (3)

DPCLK or

CDPCLK

Clock Control Block

Enable/

Disable

Global

Clock

Static Clock

Select (3)

CLK[n + 3]

CLK[n + 2]

CLK[n + 1]

CLK[n]

inclk1

inclk0

CLKSWITCH (1)

(3)

PLL

C0

C1

C2

CLKSELECT[1..0] (2) CLKENA (4)

f

IN

Notes to Figure 2–13:

(1) The CLKSWITCH signal can either be set through the configuration file or it can be dynamically set when using the

manual PLL switchover feature. The output of the multiplexer is the input reference clock (fIN) for the PLL.

(2) The CLKSELECT[1..0] signals are fed by internal logic and can be used to dynamically select the clock source for

the global clock network when the device is in user mode.

(3) The static clock select signals are set in the configuration file and cannot be dynamically controlled when the device

is in user mode.

(4) Internal logic can be used to enabled or disabled the global clock network in user mode.

2–22 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

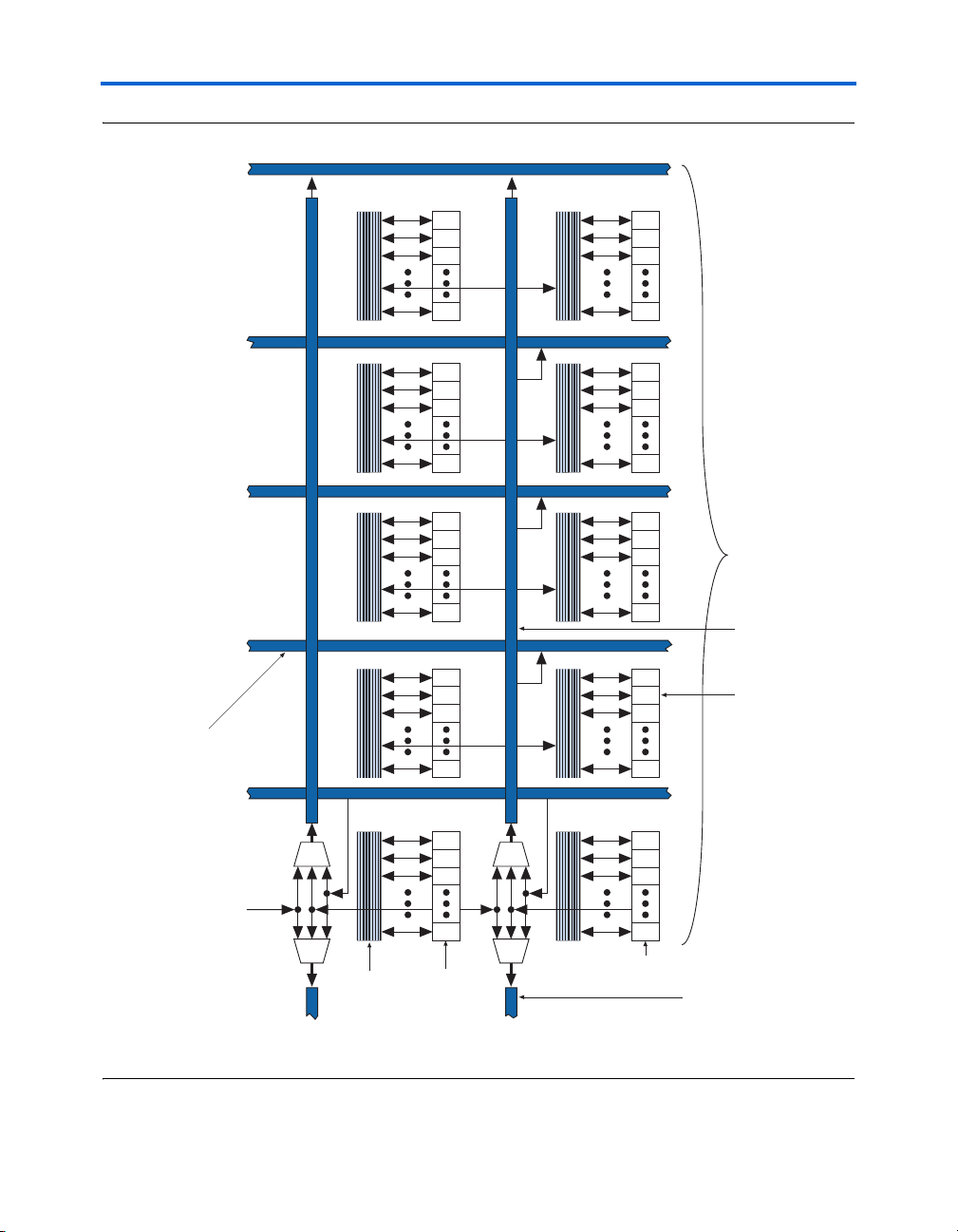

Global Clock Network Distribution

Cyclone II devices contains 16 global clock networks. The device uses

multiplexers with these clocks to form six-bit buses to drive column IOE

clocks, LAB row clocks, or row IOE clocks (see Figure 2–14). Another

multiplexer at the LAB level selects two of the six LAB row clocks to feed

the LE registers within the LAB.

Figure 2–14. Global Clock Network Multiplexers

Global Clock

Network

Cyclone II Architecture

Column I/O Region

IO_CLK [5..0]

Clock [15 or 7..0]

LAB Row Clock

LABCLK[5..0]

Row I/O Region

IO_CLK [5..0]

LAB row clocks can feed LEs, M4K memory blocks, and embedded

multipliers. The LAB row clocks also extend to the row I/O clock regions.

IOE clocks are associated with row or column block regions. Only six

global clock resources feed to these row and column regions. Figure 2–15

shows the I/O clock regions.

Altera Corporation 2–23

February 2007 Cyclone II Device Handbook, Volume 1

Global Clock Network & Phase-Locked Loops

k

Figure 2–15. LAB & I/O Clock Regions

Column I/O Clock Region

IO_CLK[5..0]

6

Cyclone Logic Array

LAB Row Clocks

labclk[5..0]

6

LAB Row Clocks

labclk[5..0]

6

LAB Row Clocks

labclk[5..0]

6

6 6

6

Global Clock

Network

8 or 16

6

6

LAB Row Clocks

labclk[5..0]

LAB Row Clocks

labclk[5..0]

6

LAB Row Clocks

labclk[5..0]

6

I/O Clock Regions

6

6

Row I/O Cloc

Region

IO_CLK[5..0]

6

I/O Clock Regions

Column I/O Clock Region

IO_CLK[5..0]

f For more information on the global clock network and the clock control

block, see the PLLs in Cyclone II Devices chapter in Volume 1 of the

Cyclone II Device Handbook.

2–24 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

Cyclone II Architecture

PLLs

Cyclone II PLLs provide general-purpose clocking as well as support for

the following features:

■ Clock multiplication and division

■ Phase shifting

■ Programmable duty cycle

■ Up to three internal clock outputs

■ One dedicated external clock output

■ Clock outputs for differential I/O support

■ Manual clock switchover

■ Gated lock signal

■ Three different clock feedback modes

■ Control signals

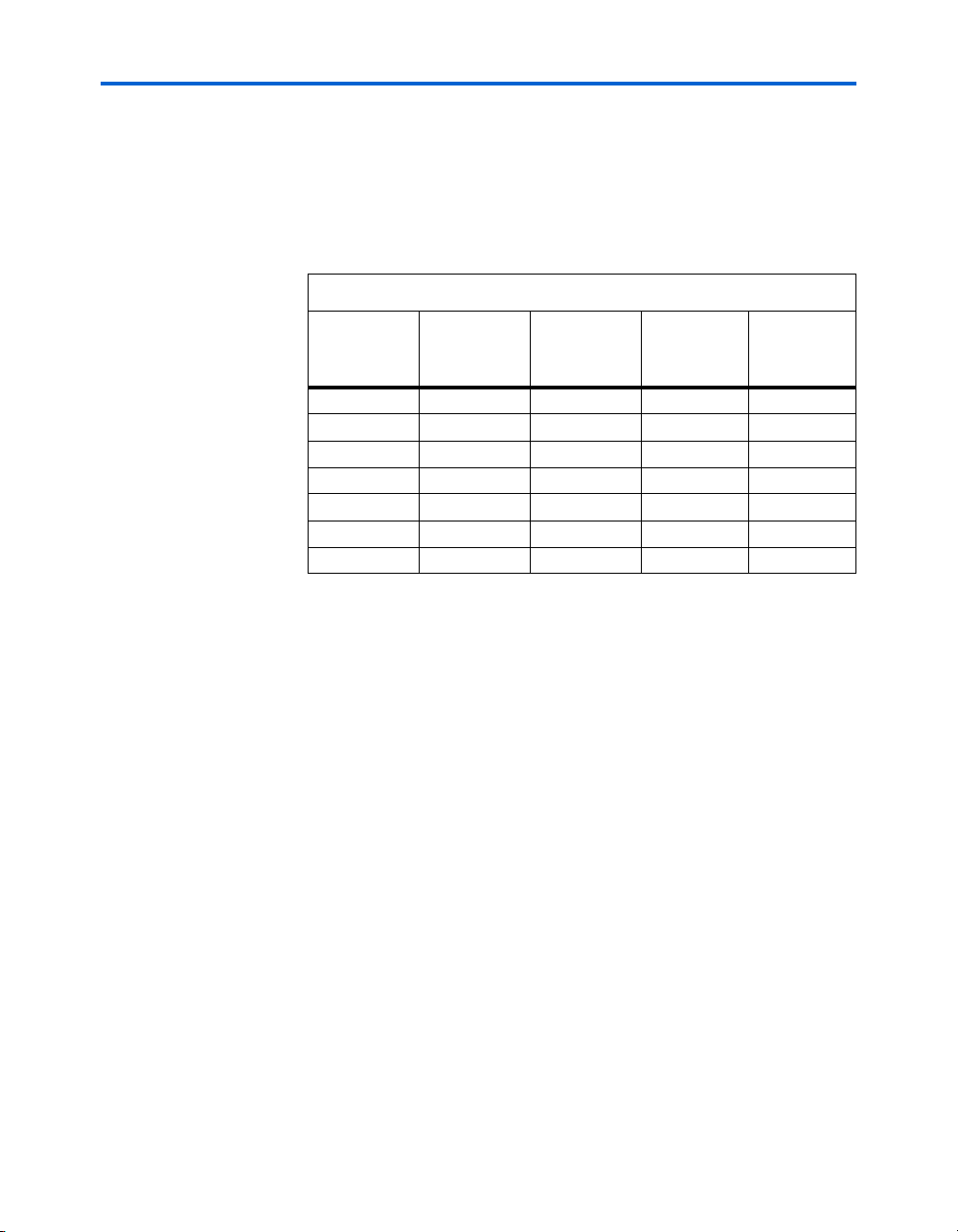

Cyclone II devices contain either two or four PLLs. Table 2–3 shows the

PLLs available for each Cyclone II device.

Table 2–3. Cyclone II Device PLL Availability

Device PLL1 PLL2 PLL3 PLL4

EP2C5 vv

EP2C8 vv

EP2C15 vvvv

EP2C20 vvvv

EP2C35 vvvv

EP2C50 vvvv

EP2C70 vvvv

Altera Corporation 2–25

February 2007 Cyclone II Device Handbook, Volume 1

Global Clock Network & Phase-Locked Loops

Table 2–4 describes the PLL features in Cyclone II devices.

Table 2–4. Cyclone II PLL Features

Feature Description

Clock multiplication and division m / (n × post-scale counter)

m and post-scale counter values (C0 to C2) range from 1 to 32. n ranges

from 1 to 4.

Phase shift Cyclone II PLLs have an advanced clock shift capability that enables

Programmable duty cycle The programmable duty cycle allows PLLs to generate clock outputs with

Number of internal clock outputs The Cyclone II PLL has three outputs which can drive the global clock

programmable phase shifts in increments of at least 45°. The finest

resolution of phase shifting is determined by the voltage control oscillator

(VCO) period divided by 8 (for example, 1/1000 MHz/8 = down to 125-ps

increments).

a variable duty cycle. This feature is supported on each PLL post-scale

counter (C0-C2).

network. One of these outputs (C2) can also drive a dedicated

PLL<#>_OUT pin (single ended or differential).

Number of external clock outputs

Manual clock switchover The Cyclone II PLLs support manual switchover of the reference clock

Gated lock signal The lock output indicates that there is a stable clock output signal in phase

Clock feedback modes In zero delay buffer mode, the external clock output pin is phase-aligned

Control signals

The C2 output drives a dedicated

used to drive an external clock output, it can be used to drive the internal

global clock network. The C2 output can concurrently drive the external

clock output and internal global clock network.

through internal logic. This enables you to switch between two reference

input clocks during user mode for applications that may require clock

redundancy or support for clocks with two different frequencies.

with the reference clock. Cyclone II PLLs include a programmable counter

that holds the lock signal low for a user-selected number of input clock

transitions, allowing the PLL to lock before enabling the locked signal.

Either a gated locked signal or an ungated locked signal from the locked

port can drive internal logic or an output pin.

with the clock input pin for zero delay.

In normal mode, the PLL compensates for the internal global clock network

delay from the input clock pin to the clock port of the IOE output registers

or registers in the logic array.

In no compensation mode, the PLL does not compensate for any clock

networks.

The

pllenable signal enables and disables the PLLs.

The areset signal resets/resynchronizes the inputs for each PLL.

The pfdena signal controls the phase frequency detector (PFD) output

with a programmable gate.

PLL<#>_OUT pin. If the C2 output is not

2–26 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

Figure 2–16 shows a block diagram of the Cyclone II PLL.

Figure 2–16. Cyclone II PLL Note (1)

Cyclone II Architecture

VCO Phase Selection

Selectable at Each

PLL Output Port

Post-Scale

Counters

CLK0 (1)

CLK1

CLK2 (1)

CLK3

Manual Clock

Switchover

Select Signal

inclk0

inclk1

Reference

Input Clock

= f

/n

f

REF

IN

f

IN

÷n

f

FB

PFD

up

down

Charge

Pump

Loop

Filter

÷m

Lock Detect

& Filter

VCO

8

f

VCO

8

÷k

(3)

8

÷c0

÷c1

÷c2

Global

Clock

Global

Clock

Global

(2)

Clock

PLL<#>_OUT

To I/O or

general routing

Notes to Figure 2–16:

(1) This input can be single-ended or differential. If you are using a differential I/O standard, then two CLK pins are

used. LVDS input is supported via the secondary function of the dedicated CLK pins. For example, the CLK0 pin’s

secondary function is LVDSCLK1p and the CLK1 pin’s secondary function is LVDSCLK1n. If a differential I/O

standard is assigned to the PLL clock input pin, the corresponding CLK(n) pin is also completely used. The

Figure 2–16 shows the possible clock input connections (CLK0/CLK1) to PLL1.

(2) This counter output is shared between a dedicated external clock output I/O and the global clock network.

f For more information on Cyclone II PLLs, see the PLLs in the Cyclone II

Devices chapter in Volume 1 of the Cyclone II Device Handbook.

Embedded Memory

The Cyclone II embedded memory consists of columns of M4K memory

blocks. The M4K memory blocks include input registers that synchronize

writes and output registers to pipeline designs and improve system

performance. The output registers can be bypassed, but input registers

cannot.

Altera Corporation 2–27

February 2007 Cyclone II Device Handbook, Volume 1

Embedded Memory

Each M4K block can implement various types of memory with or without

parity, including true dual-port, simple dual-port, and single-port RAM,

ROM, and first-in first-out (FIFO) buffers. The M4K blocks support the

following features:

■ 4,608 RAM bits

■ 250-MHz performance

■ True dual-port memory

■ Simple dual-port memory

■ Single-port memory

■ Byte enable

■ Parity bits

■ Shift register

■ FIFO buffer

■ ROM

■ Various clock modes

■ Address clock enable

1 Violating the setup or hold time on the memory block address

registers could corrupt memory contents. This applies to both

read and write operations.

Table 2–5 shows the capacity and distribution of the M4K memory blocks

in each Cyclone II device.

Table 2–5. M4K Memory Capacity & Distribution in Cyclone II Devices

Device M4K Columns M4K Blocks Total RAM Bits

EP2C5 2 26 119,808

EP2C8 2 36 165,888

EP2C15 2 52 239,616

EP2C20 2 52 239,616

EP2C35 3 105 483,840

EP2C50 3 129 594,432

EP2C70 5 250 1,152,000

2–28 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

Cyclone II Architecture

Table 2–6 summarizes the features supported by the M4K memory.

Table 2–6. M4K Memory Features

Feature Description

Maximum performance (1) 250 MHz

Total RAM bits per M4K block (including parity bits) 4,608

Configurations supported 4K × 1

Parity bits One parity bit for each byte. The parity bit, along with

Byte enable M4K blocks support byte writes when the write port has

Packed mode Two single-port memory blocks can be packed into a

Address clock enable M4K blocks support address clock enable, which is

Memory initialization file (.mif) When configured as RAM or ROM, you can use an

Power-up condition Outputs cleared

Register clears Output registers only

Same-port read-during-write New data available at positive clock edge

Mixed-port read-during-write Old data available at positive clock edge

2K × 2

1K × 4

512 × 8

512 × 9

256 × 16

256 × 18

128 × 32 (not available in true dual-port mode)

128 × 36 (not available in true dual-port mode)

internal user logic, can implement parity checking for

error detection to ensure data integrity.

a data width of 1, 2, 4, 8, 9, 16, 18, 32, or 36 bits. The

byte enables allow the input data to be masked so the

device can write to specific bytes. The unwritten bytes

retain the previous written value.

single M4K block if each of the two independent block

sizes are equal to or less than half of the M4K block

size, and each of the single-port memory blocks is

configured in single-clock mode.

used to hold the previous address value for as long as

the signal is enabled. This feature is useful in handling

misses in cache applications.

initialization file to pre-load the memory contents.

Note to Ta b le 2– 6 :

(1) Maximum performance information is preliminary until device characterization.

Altera Corporation 2–29

February 2007 Cyclone II Device Handbook, Volume 1

Embedded Memory

Memory Modes

Table 2–7 summarizes the different memory modes supported by the

M4K memory blocks.

Table 2–7. M4K Memory Modes

Memory Mode Description

Single-port memory M4K blocks support single-port mode, used when

simultaneous reads and writes are not required.

Single-port memory supports non-simultaneous

reads and writes.

Simple dual-port memory Simple dual-port memory supports a

simultaneous read and write.

Simple dual-port with mixed

width

True dual-port memory True dual-port mode supports any combination of

True dual-port with mixed

width

Embedded shift register M4K memory blocks are used to implement shift

ROM The M4K memory blocks support ROM mode. A

FIFO buffers A single clock or dual clock FIFO may be

Simple dual-port memory mode with different

read and write port widths.

two-port operations: two reads, two writes, or one

read and one write at two different clock

frequencies.

True dual-port mode with different read and write

port widths.

registers. Data is written into each address

location at the falling edge of the clock and read

from the address at the rising edge of the clock.

MIF initializes the ROM contents of these blocks.

implemented in the M4K blocks. Simultaneous

read and write from an empty FIFO buffer is not

supported.

1 Embedded Memory can be inferred in your HDL code or

directly instantiated in the Quartus II software using the

®

MegaWizard

2–30 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

Plug-in Manager Memory Compiler feature.

Cyclone II Architecture

Clock Modes

Table 2–8 summarizes the different clock modes supported by the M4K

memory.

Table 2–8. M4K Clock Modes

Clock Mode Description

Independent In this mode, a separate clock is available for each port (ports A

and B). Clock A controls all registers on the port A side, while

clock B controls all registers on the port B side.

Input/output On each of the two ports, A or B, one clock controls all registers

Read/write Up to two clocks are available in this mode. The write clock

Single In this mode, a single clock, together with clock enable, is used to

Table 2–9 shows which clock modes are supported by all M4K blocks

when configured in the different memory modes.

for inputs into the memory block: data input, wren, and address.

The other clock controls the block’s data output registers.

controls the block’s data inputs, wraddress, and wren. The

read clock controls the data output, rdaddress, and rden.

control all registers of the memory block. Asynchronous clear

signals for the registers are not supported.

Table 2–9. Cyclone II M4K Memory Clock Modes

Clocking Modes

Independent v

Input/output vvv

Read/write v

Single clock vvv

True Dual-Port

Mode

Simple Dual-Port

Mode

Single-Port Mode

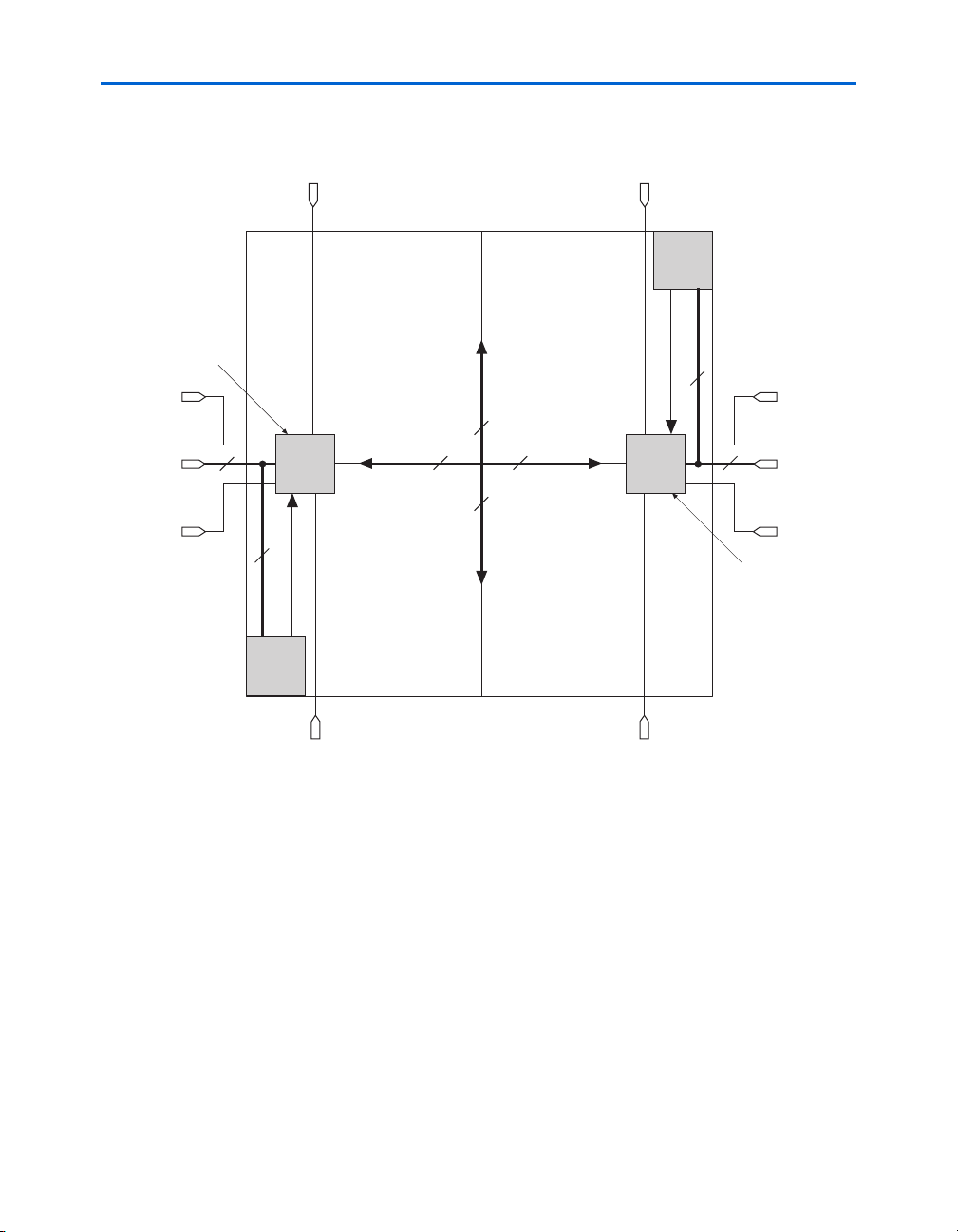

M4K Routing Interface

The R4, C4, and direct link interconnects from adjacent LABs drive the

M4K block local interconnect. The M4K blocks can communicate with

LABs on either the left or right side through these row resources or with

LAB columns on either the right or left with the column resources. Up to

16 direct link input connections to the M4K block are possible from the

left adjacent LAB and another 16 possible from the right adjacent LAB.

M4K block outputs can also connect to left and right LABs through each

16 direct link interconnects. Figure 2–17 shows the M4K block to logic

array interface.

Altera Corporation 2–31

February 2007 Cyclone II Device Handbook, Volume 1

Embedded Multipliers

Figure 2–17. M4K RAM Block LAB Row Interface

C4 Interconnects

Direct link

interconnect

to adjacent LAB

Direct link

interconnect

from adjacent LAB

16

dataout

M4K RAM

16 16

M4K RAM Block Local

Interconnect Region

Block

Byte enable

Control

Signals

Clocks

datainaddress

6

LAB Row Clocks

R4 Interconnects

Direct link

interconnect

to adjacent LAB

Direct link

interconnect

from adjacent LAB

f For more information on Cyclone II embedded memory, see the

Cyclone II Memory Blocks chapter in Volume 1 of the Cyclone II Device

Handbook.

Embedded

Multipliers

2–32 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

Cyclone II devices have embedded multiplier blocks optimized for

multiplier-intensive digital signal processing (DSP) functions, such as

finite impulse response (FIR) filters, fast Fourier transform (FFT)

functions, and discrete cosine transform (DCT) functions. You can use the

embedded multiplier in one of two basic operational modes, depending

on the application needs:

■ One 18-bit multiplier

■ Up to two independent 9-bit multipliers

Embedded multipliers can operate at up to 250 MHz (for the fastest speed

grade) for 18 × 18 and 9 × 9 multiplications when using both input and

output registers.

Each Cyclone II device has one to three columns of embedded multipliers

that efficiently implement multiplication functions. An embedded

multiplier spans the height of one LAB row. Table 2–10 shows the number

of embedded multipliers in each Cyclone II device and the multipliers

that can be implemented.

Table 2–10. Number of Embedded Multipliers in Cyclone II Devices Note (1)

Cyclone II Architecture

Device

EP2C5 1 13 26 13

EP2C8 1 18 36 18

EP2C15 1 26 52 26

EP2C20 1 26 52 26

EP2C35 1 35 70 35

EP2C50 2 86 172 86

EP2C70 3 150 300 150

Note to Table 2–10:

(1) Each device has either the number of 9 × 9-, or 18 × 18-bit multipliers shown. The total number of multipliers for

each device is not the sum of all the multipliers.

Embedded

Multiplier Columns

Embedded

Multipliers

9 × 9 Multipliers 18 × 18 Multipliers

The embedded multiplier consists of the following elements:

■ Multiplier block

■ Input and output registers

■ Input and output interfaces

Figure 2–18 shows the multiplier block architecture.

Altera Corporation 2–33

February 2007 Cyclone II Device Handbook, Volume 1

Embedded Multipliers

Figure 2–18. Multiplier Block Architecture

signa

signb

aclr

clock

ena

(1)

(1)

Data A

Data B

DQ

ENA

CLRN

DQ

ENA

CLRN

Input

Register

Embedded Multiplier Block

DQ

ENA

CLRN

Output

Register

Note to Figure 2–18:

(1) If necessary, these signals can be registered once to match the data signal path.

Each multiplier operand can be a unique signed or unsigned number.

Two signals, signa and signb, control the representation of each

operand respectively. A logic 1 value on the signa signal indicates that

data A is a signed number while a logic 0 value indicates an unsigned

number. Table 2–11 shows the sign of the multiplication result for the

various operand sign representations. The result of the multiplication is

signed if any one of the operands is a signed value.

Table 2–11. Multiplier Sign Representation

Data A (signa Value) Data B (signb Value) Result

Unsigned Unsigned Unsigned

Unsigned Signed Signed

Signed Unsigned Signed

Signed Signed Signed

Data Out

2–34 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

Cyclone II Architecture

There is only one signa and one signb signal for each dedicated

multiplier. Therefore, all of the data A inputs feeding the same dedicated

multiplier must have the same sign representation. Similarly, all of the

data B inputs feeding the same dedicated multiplier must have the same

sign representation. The signa and signb signals can be changed

dynamically to modify the sign representation of the input operands at

run time. The multiplier offers full precision regardless of the sign

representation and can be registered using dedicated registers located at

the input register stage.

Multiplier Modes

Table 2–12 summarizes the different modes that the embedded

multipliers can operate in.

Table 2–12. Embedded Multiplier Modes

Multiplier Mode Description

18-bit Multiplier An embedded multiplier can be configured to support a

single 18 × 18 multiplier for operand widths up to 18 bits.

All 18-bit multiplier inputs and results can be registered

independently. The multiplier operands can accept

signed integers, unsigned integers, or a combination of

both.

9-bit Multiplier An embedded multiplier can be configured to support

two 9 × 9 independent multipliers for operand widths up

to 9-bits. Both 9-bit multiplier inputs and results can be

registered independently. The multiplier operands can

accept signed integers, unsigned integers or a

combination of both.

There is only one signa signal to control the sign

representation of both data A inputs and one signb

signal to control the sign representation of both data B

inputs of the 9-bit multipliers within the same dedicated

multiplier.

Altera Corporation 2–35

February 2007 Cyclone II Device Handbook, Volume 1

Embedded Multipliers

Embedded Multiplier Routing Interface

The R4, C4, and direct link interconnects from adjacent LABs drive the

embedded multiplier row interface interconnect. The embedded

multipliers can communicate with LABs on either the left or right side

through these row resources or with LAB columns on either the right or

left with the column resources. Up to 16 direct link input connections to

the embedded multiplier are possible from the left adjacent LABs and

another 16 possible from the right adjacent LAB. Embedded multiplier

outputs can also connect to left and right LABs through 18 direct link

interconnects each. Figure 2–19 shows the embedded multiplier to logic

array interface.

Figure 2–19. Embedded Multiplier LAB Row Interface

Direct Link Interconnect

from Adjacent LAB

R4 InterconnectsC4 Interconnects

18 Direct Link Outputs

to Adjacent LABs

36

Direct Link Interconnect

from Adjacent LAB

LAB Block

Interconect Region

LAB LAB

16

5

36

Row Interface

Block

Embedded Multiplier

to LAB Row Interface

Block Interconnect Region

36 Inputs per Row 36 Outputs per Row

Embedded Multiplier

18

16

Control

[35..0][35..0]

18 18

C4 Interconnects

18

LAB Block

Interconect Region

2–36 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

Cyclone II Architecture

There are five dynamic control input signals that feed the embedded

multiplier: signa, signb, clk, clkena, and aclr. signa and signb

can be registered to match the data signal input path. The same clk,

clkena, and aclr signals feed all registers within a single embedded

multiplier.

f For more information on Cyclone II embedded multipliers, see the

Embedded Multipliers in Cyclone II Devices chapter.

I/O Structure & Features

IOEs support many features, including:

■ Differential and single-ended I/O standards

■ 3.3-V, 64- and 32-bit, 66- and 33-MHz PCI compliance

■ Joint Test Action Group (JTAG) boundary-scan test (BST) support

■ Output drive strength control

■ Weak pull-up resistors during configuration

■ Tri-state buffers

■ Bus-hold circuitry

■ Programmable pull-up resistors in user mode

■ Programmable input and output delays

■ Open-drain outputs

■ DQ and DQS I/O pins

■ V

REF

pins

Cyclone II device IOEs contain a bidirectional I/O buffer and three

registers for complete embedded bidirectional single data rate transfer.

Figure 2–20 shows the Cyclone II IOE structure. The IOE contains one

input register, one output register, and one output enable register. You can

use the input registers for fast setup times and output registers for fast

clock-to-output times. Additionally, you can use the output enable (OE)

register for fast clock-to-output enable timing. The Quartus II software

automatically duplicates a single OE register that controls multiple

output or bidirectional pins. You can use IOEs as input, output, or

bidirectional pins.

Altera Corporation 2–37

February 2007 Cyclone II Device Handbook, Volume 1

I/O Structure & Features

Figure 2–20. Cyclone II IOE Structure

Logic Array

OE Register

OE

Output Register

Output

Input (1)

Input Register

Note to Figure 2–20:

(1) There are two paths available for combinational or registered inputs to the logic

array. Each path contains a unique programmable delay chain.

The IOEs are located in I/O blocks around the periphery of the Cyclone II

device. There are up to five IOEs per row I/O block and up to four IOEs

per column I/O block (column I/O blocks span two columns). The row

I/O blocks drive row, column (only C4 interconnects), or direct link

interconnects. The column I/O blocks drive column interconnects.

Figure 2–21 shows how a row I/O block connects to the logic array.

Figure 2–22 shows how a column I/O block connects to the logic array.

2–38 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

Figure 2–21. Row I/O Block Connection to the Interconnect

)

Cyclone II Architecture

R4 & R24 Interconnects

Direct Link

Interconnect

to Adjacent LAB

LAB Local

Interconnect

LAB

C4 Interconnects

io_datain0[4..0]

io_datain1[4..0] (2)

Direct Link

Interconnect

from Adjacent LAB

I/O Block Local

Interconnect

35

io_clk[5..0]

35 Data and

Control Signals

from Logic Array (1

Row

I/O Block

Row I/O Block

Contains up to

Five IOEs

Notes to Figure 2–21:

(1) The 35 data and control signals consist of five data out lines, io_dataout[4..0], five output enables,

io_coe[4..0], five input clock enables, io_cce_in[4..0], five output clock enables, io_cce_out[4..0],

five clocks, io_cclk[4..0], five asynchronous clear signals, io_caclr[4..0], and five synchronous clear

signals, io_csclr[4..0].

(2) Each of the five IOEs in the row I/O block can have two io_datain (combinational or registered) inputs.

Altera Corporation 2–39

February 2007 Cyclone II Device Handbook, Volume 1

I/O Structure & Features

s

Figure 2–22. Column I/O Block Connection to the Interconnect

28 Data &

Control Signals

from Logic Array (1)

28

I/O Block

Local Interconnect

R4 & R24 Interconnects

Column I/O Block

io_datain0[3..0]

io_datain1[3..0] (2)

Column I/O

Block Contains

up to Four IOE

io_clk[5..0]

LAB LAB LAB

LAB Local

Interconnect

C4 & C24 Interconnects

Notes to Figure 2–22:

(1) The 28 data and control signals consist of four data out lines, io_dataout[3..0], four output enables,

io_coe[3..0], four input clock enables, io_cce_in[3..0], four output clock enables, io_cce_out[3..0],

four clocks, io_cclk[3..0], four asynchronous clear signals, io_caclr[3..0], and four synchronous clear

signals, io_csclr[3..0].

(2) Each of the four IOEs in the column I/O block can have two io_datain (combinational or registered) inputs.

2–40 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

The pin’s datain signals can drive the logic array. The logic array drives

the control and data signals, providing a flexible routing resource. The

row or column IOE clocks, io_clk[5..0], provide a dedicated routing

resource for low-skew, high-speed clocks. The global clock network

generates the IOE clocks that feed the row or column I/O regions (see

“Global Clock Network & Phase-Locked Loops” on page 2–16).

Figure 2–23 illustrates the signal paths through the I/O block.

Figure 2–23. Signal Path Through the I/O Block

Row or Column

io_clk[5..0]

Cyclone II Architecture

To Other

IOEs

To Logic

Array

From Logic

Array

io_datain0

io_datain1

io_csclr

io_coe

io_cce_in

io_cce_out

io_caclr

io_cclk

io_dataout

oe

ce_in

ce_out

Data and

Control

Signal

Selection

aclr/preset

sclr/preset

clk_in

clk_out

dataout

IOE

Each IOE contains its own control signal selection for the following

control signals: oe, ce_in, ce_out, aclr/preset, sclr/preset,

clk_in, and clk_out. Figure 2–24 illustrates the control signal

selection.

Altera Corporation 2–41

February 2007 Cyclone II Device Handbook, Volume 1

I/O Structure & Features

Figure 2–24. Control Signal Selection per IOE

Dedicated I/O

Clock [5..0]

Local

Interconnect

Local

Interconnect

Local

Interconnect

Local

Interconnect

Local

Interconnect

Local

Interconnect

io_coe

io_csclr

io_caclr

io_cce_out

io_cce_in

io_cclk

clk_out

ce_inclk_in

ce_out

sclr/preset

aclr/preset

In normal bidirectional operation, you can use the input register for input

data requiring fast setup times. The input register can have its own clock

input and clock enable separate from the OE and output registers. You can

use the output register for data requiring fast clock-to-output

performance. The OE register is available for fast clock-to-output enable

timing. The OE and output register share the same clock source and the

same clock enable source from the local interconnect in the associated

LAB, dedicated I/O clocks, or the column and row interconnects. All

registers share sclr and aclr, but each register can individually disable

sclr and aclr. Figure 2–25 shows the IOE in bidirectional

configuration.

oe

2–42 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

Figure 2–25. Cyclone II IOE in Bidirectional I/O Configuration

io_clk[5..0]

Column

or Row

Interconect

OE

OE Register

PRN

clkout

ce_out

aclr/prn

Chip-Wide Reset

sclr/preset

DQ

ENA

CLRN

Output Register

PRN

DQ

ENA

CLRN

Output

Pin Delay

Open-Drain Output

Cyclone II Architecture

V

CCIO

Optional

PCI Clamp

V

CCIO

Programmable

Pull-Up

Resistor

data_in1

Bus Hold

data_in0

Input Pin to

Input Register Delay

or Input Pin to

Logic Array Delay

clkin

ce_in

Input Register

PRN

DQ

ENA

CLRN

The Cyclone II device IOE includes programmable delays to ensure zero

hold times, minimize setup times, or increase clock to output times.

A path in which a pin directly drives a register may require a

programmable delay to ensure zero hold time, whereas a path in which a

pin drives a register through combinational logic may not require the

delay. Programmable delays decrease input-pin-to-logic-array and IOE

input register delays. The Quartus II Compiler can program these delays

to automatically minimize setup time while providing a zero hold time.

Altera Corporation 2–43

February 2007 Cyclone II Device Handbook, Volume 1

I/O Structure & Features

Programmable delays can increase the register-to-pin delays for output

registers. Table 2–13 shows the programmable delays for Cyclone II

devices.

Table 2–13. Cyclone II Programmable Delay Chain

Programmable Delays Quartus II Logic Option

Input pin to logic array delay Input delay from pin to internal cells

Input pin to input register delay Input delay from pin to input register

Output pin delay Delay from output register to output pin

There are two paths in the IOE for an input to reach the logic array. Each

of the two paths can have a different delay. This allows you to adjust

delays from the pin to internal LE registers that reside in two different

areas of the device. You set the two combinational input delays by

selecting different delays for two different paths under the Input delay

from pin to internal cells logic option in the Quartus II software.

However, if the pin uses the input register, one of delays is disregarded

because the IOE only has two paths to internal logic. If the input register

is used, the IOE uses one input path. The other input path is then

available for the combinational path, and only one input delay

assignment is applied.

The IOE registers in each I/O block share the same source for clear or

preset. You can program preset or clear for each individual IOE, but both

features cannot be used simultaneously. You can also program the

registers to power up high or low after configuration is complete. If

programmed to power up low, an asynchronous clear can control the

registers. If programmed to power up high, an asynchronous preset can

control the registers. This feature prevents the inadvertent activation of

another device’s active-low input upon power up. If one register in an

IOE uses a preset or clear signal then all registers in the IOE must use that

same signal if they require preset or clear. Additionally a synchronous

reset signal is available for the IOE registers.

External Memory Interfacing

Cyclone II devices support a broad range of external memory interfaces

such as SDR SDRAM, DDR SDRAM, DDR2 SDRAM, and QDRII SRAM

external memories. Cyclone II devices feature dedicated high-speed

interfaces that transfer data between external memory devices at up to

167 MHz/333 Mbps for DDR and DDR2 SDRAM devices and

167 MHz/667 Mbps for QDRII SRAM devices. The programmable DQS

delay chain allows you to fine tune the phase shift for the input clocks or

strobes to properly align clock edges as needed to capture data.

2–44 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

In Cyclone II devices, all the I/O banks support SDR and DDR SDRAM

memory up to 167 MHz/333 Mbps. All I/O banks support DQS signals

with the DQ bus modes of ×8/×9, or ×16/×18. Table 2–14 shows the

external memory interfaces supported in Cyclone II devices.

Table 2–14. External Memory Support in Cyclone II Devices Note (1)

Cyclone II Architecture

Memory Standard I/O Standard

SDR SDRAM LVTTL (2) 72 167 167

DDR SDRAM SSTL-2 class I (2) 72 167 333 (1)

SSTL-2 class II (2) 72 133 267 (1)

DDR2 SDRAM SSTL-18 class I (2) 72 167 333 (1)

SSTL-18 class II (3) 72 125 250 (1)

QDRII SRAM (4) 1.8-V HSTL class I

(2)

1.8-V HSTL class II

(3)

Notes to Table 2–14:

(1) The data rate is for designs using the Clock Delay Control circuitry.

(2) The I/O standards are supported on all the I/O banks of the Cyclone II device.

(3) The I/O standards are supported only on the I/O banks on the top and bottom of the Cyclone II device.

(4) For maximum performance, Altera recommends using the 1.8-V HSTL I/O standard because of higher I/O drive

strength. QDRII SRAM devices also support the 1.5-V HSTL I/O standard.

Maximum Bus

Width

36 167 668 (1)

36 100 400 (1)

Maximum Clock

Rate Supported

(MHz)

Maximum Data

Rate Supported

(Mbps)

Cyclone II devices use data (DQ), data strobe (DQS), and clock pins to

interface with external memory. Figure 2–26 shows the DQ and DQS pins

in the ×8/×9 mode.

Altera Corporation 2–45

February 2007 Cyclone II Device Handbook, Volume 1

I/O Structure & Features

Figure 2–26. Cyclone II Device DQ & DQS Groups in ×8/×9 Mode Notes (1), (2)

DQ Pins DQS Pin DM PinDQ Pins

Notes to Figure 2–26:

(1) Each DQ group consists of a DQS pin, DM pin, and up to nine DQ pins.

(2) This is an idealized pin layout. For actual pin layout, refer to the pin table.

(2)

Cyclone II devices support the data strobe or read clock signal (DQS)

used in DDR and DDR2 SDRAM. Cyclone II devices can use either

bidirectional data strobes or unidirectional read clocks. The dedicated

external memory interface in Cyclone II devices also includes

programmable delay circuitry that can shift the incoming DQS signals to

center align the DQS signals within the data window.

The DQS signal is usually associated with a group of data (DQ) pins. The

phase-shifted DQS signals drive the global clock network, which is used

to clock the DQ signals on internal LE registers.

Table 2–15 shows the number of DQ pin groups per device.

Table 2–15. Cyclone II DQS & DQ Bus Mode Support (Part 1 of 2) Note (1)

Device Package

EP2C5 144-pin TQFP (2) 3 300

208-pin PQFP 7 (3) 433

EP2C8 144-pin TQFP (2) 3 300

208-pin PQFP 7 (3) 433

256-pin FineLine BGA

EP2C15 256-pin FineLine BGA 8 4 4 4

484-pin FineLine BGA 16 (4) 888

EP2C20 256-pin FineLine BGA 8 4 4 4

484-pin FineLine BGA 16 (4) 888

Number of ×8

Groups

®

8 (3) 444

Number of ×9

Groups (5), (6)

Number of ×16

Groups

Number of ×18

Groups (5), (6)

2–46 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

Table 2–15. Cyclone II DQS & DQ Bus Mode Support (Part 2 of 2) Note (1)

Cyclone II Architecture

Device Package

EP2C35 484-pin FineLine BGA 16 (4) 888

672-pin FineLine BGA 20 (4) 888

EP2C50 484-pin FineLine BGA 16 (4) 888

672-pin FineLine BGA 20 (4) 888

EP2C70 672-pin FineLine BGA 20 (4) 888

896-pin FineLine BGA 20 (4) 888

Notes to Table 2–15:

(1) Numbers are preliminary.

(2) EP2C5 and EP2C8 devices in the 144-pin TQFP package do not have any DQ pin groups in I/O bank 1.

(3) Because of available clock resources, only a total of 6 DQ/DQS groups can be implemented.

(4) Because of available clock resources, only a total of 14 DQ/DQS groups can be implemented.

(5) The ×9 DQS/DQ groups are also used as ×8 DQS/DQ groups. The ×18 DQS/DQ groups are also used as ×16

DQS/DQ groups.

(6) For QDRI implementation, if you connect the D ports (write data) to the Cyclone II DQ pins, the total available ×9

DQS /DQ and ×18 DQS/DQ groups are half of that shown in Table 2–15.

Number of ×8

Groups

Number of ×9

Groups (5), (6)

Number of ×16

Groups

Number of ×18

Groups (5), (6)

You can use any of the DQ pins for the parity pins in Cyclone II devices.

The Cyclone II device family supports parity in the ×8/×9, and ×16/×18

mode. There is one parity bit available per eight bits of data pins.

The data mask, DM, pins are required when writing to DDR SDRAM and

DDR2 SDRAM devices. A low signal on the DM pin indicates that the

write is valid. If the DM signal is high, the memory masks the DQ signals.

In Cyclone II devices, the DM pins are assigned and are the preferred

pins. Each group of DQS and DQ signals requires a DM pin.

When using the Cyclone II I/O banks to interface with the DDR memory,

at least one PLL with two clock outputs is needed to generate the system

and write clock. The system clock is used to clock the DQS write signals,

commands, and addresses. The write clock is shifted by –90° from the

system clock and is used to clock the DQ signals during writes.

Figure 2–27 illustrates DDR SDRAM interfacing from the I/O through

the dedicated circuitry to the logic array.

Altera Corporation 2–47

February 2007 Cyclone II Device Handbook, Volume 1

I/O Structure & Features

Figure 2–27. DDR SDRAM Interfacing

DQS

DQ

PLL

OE

-90˚ Shifted clk

LE

Register

Register

t

LE

LE

V

CC

Register

LE

GND

Register

clk

Clock Delay

Control Circuitry

Clock Control

Block

LE

OE

Register

LE

Register

en/dis

ENOUT ena_register_mode

LE

DataA

Register

LE

DataB

Register

Global Clock

Dynamic Enable/Disable

Circuitry

LE

Register

LE

RegisterLERegisterLERegister

f For more information on Cyclone II external memory interfaces, see the

External Memory Interfaces chapter in Volume 1 of the Cyclone II Device

Handbook.

Adjacent LAB LEs

LE

Register

Resynchronizing

to System Clock

2–48 Altera Corporation

Cyclone II Device Handbook, Volume 1 February 2007

Cyclone II Architecture

Programmable Drive Strength

The output buffer for each Cyclone II device I/O pin has a programmable

drive strength control for certain I/O standards. The LVTTL, LVCMOS,

SSTL-2 class I and II, SSTL-18 class I and II, HSTL-18 class I and II, and

HSTL-1.5 class I and II standards have several levels of drive strength that

you can control. Using minimum settings provides signal slew rate

control to reduce system noise and signal overshoot. Table 2–16 shows

the possible settings for the I/O standards with drive strength control.

Table 2–16. Programmable Drive Strength (Part 1 of 2) Note (1)