Page 1

Part No. 060181-10, Rev. G

September 2006

OmniSwitch 6600 Family

Hardware Users Guide

www.alcatel.com

Page 2

This user guide documents OmniSwitch 6600 Family hardware, including

chassis and associated components.

The specifications described in this guide are subject to change without notice.

Copyright © 2006 by Alcatel Internetworking, Inc. All rights reserved. This document may not be reproduced in whole or in part without the express written permission of Alcatel Internetworking, Inc.

®

Alcatel

and Alcatel OmniVista

and the Alcatel logo are registered trademarks of Alcatel. Xylan®, OmniSwitch®, OmniStack®,

®

are registered trademarks of Alcatel Internetworking, Inc.

OmniAccess™, Omni Switch/Router™, PolicyView™, RouterView™, SwitchManager™, VoiceView™,

WebView™, X-Cell™, X-Vision™, and the Xylan logo are trademarks of Alcatel Internetworking, Inc.

This OmniSwitch product contains components which may be covered by one or more of the following

U.S. Patents:

•U.S. Patent No. 6,339,830

•U.S. Patent No. 6,070,243

•U.S. Patent No. 6,061,368

•U.S. Patent No. 5,394,402

•U.S. Patent No. 6,047,024

•U.S. Patent No. 6,314,106

•U.S. Patent No. 6,542,507

•U.S. Patent No. 6,874,090

26801 West Agoura Road

Calabasas, CA 91301

(818) 880-3500 FAX (818) 880-3505

info@ind.alcatel.com

US Customer Support—(800) 995-2696

International Customer Support—(818) 878-4507

Internet—http://eservice.ind.alcatel.com

ii OmniSwitch 6600 Family Hardware Users Guide September 2006

Page 3

Contents

About This Guide .......................................................................................................... ix

Supported Platforms .......................................................................................................... ix

Who Should Read this Manual? ........................................................................................xi

When Should I Read this Manual? ....................................................................................xi

What is in this Manual? ..................................................................................................... xi

What is Not in this Manual? ..............................................................................................xi

How is the Information Organized? .................................................................................xii

Documentation Roadmap .................................................................................................xii

Related Documentation ...................................................................................................xiv

User Manual CD ..............................................................................................................xv

Technical Support ............................................................................................................ xv

Chapter 1 OmniSwitch 6600 Family ..........................................................................................1-1

Stand-Alone and Stacked Configurations .......................................................................1-2

Stand-Alone ..............................................................................................................1-2

Stacked Configurations ............................................................................................1-2

Availability Features .......................................................................................................1-3

Smart Continuous Switching ....................................................................................1-3

Software Rollback ....................................................................................................1-4

Hot Swapping ...........................................................................................................1-4

Hardware Monitoring ...............................................................................................1-5

Application Examples .....................................................................................................1-6

Single Office Building with 1000 Users ...........................................................1- 6

Medium Campus with 1500 Users ....................................................................1- 7

Chapter 2 OmniSwitch 6600 Family Chassis and Hardware Components ....................2-1

OmniSwitch 6624 ............................................................................................................2-2

OmniSwitch 6600-U24 ...................................................................................................2-4

OmniSwitch 6600-P24 ....................................................................................................2-8

OmniSwitch 6648 ..........................................................................................................2-12

OmniSwitch 6602-24 ....................................................................................................2-14

OmniSwitch 6602-48 ....................................................................................................2-16

Status LEDs ...................................................................................................................2-18

Rear Panel .....................................................................................................................2-20

OmniSwitch 6600 Family Hardware Users Guide September 2006 iii

Page 4

Contents

Mounting the Switch .....................................................................................................2-21

Airflow Considerations ..........................................................................................2-21

Installation Options ................................................................................................2-22

Installing the Switch on a Tabletop or Bench .................................................2- 22

Rack-Mounting the Switch..............................................................................2- 22

Rack Mounting Stacked Configurations .........................................................2- 24

Power Cords ..................................................................................................................2-25

Grounding the Chassis ..................................................................................................2-25

Backup Power Supply ...................................................................................................2-26

Power Supply Specifications ..................................................................................2-28

Power Supply Redundancy ....................................................................................2-29

Redundant AC Circuit Recommendation........................................................2- 30

Installing a Backup Power Supply .........................................................................2-31

Removing a Backup Power Supply ........................................................................2-33

Blank Cover Panel Requirement ............................................................................2-34

Viewing Primary and Backup Power Supply Status ..............................................2-34

Viewing Power Supply Status for Stacked Configurations ...................................2-35

A Slot Number is Specified.............................................................................2- 35

No Slot Number is Specified...........................................................................2- 35

Gigabit Ethernet Uplink Modules .................................................................................2-36

OS6600-GNI-U2 ....................................................................................................2-36

OS6600-GNI-C2 ....................................................................................................2-38

Stacking Module ....................................................................................................2-39

Installing Uplink and Stacking Modules .......................................................................2-40

Removing Uplink and Stacking Modules .....................................................................2-42

Blank Cover Panel Requirement ............................................................................2-43

Mini Gigabit Interface Converters (MiniGBICs) ..........................................................2-44

MiniGBIC Specifications .......................................................................................2-45

Installing MiniGBICs ....................................................................................................2-46

Removing MiniGBICs ..................................................................................................2-47

100 Mbps SFPs (OS6600-U24) ....................................................................................2-48

100 Mbps SFP Specifications ............................................................................2-49

Installing SFPs (OS6600-U24) .....................................................................................2-51

Removing SFPs (OS6600-U24) ....................................................................................2-52

Temperature Management ............................................................................................2-53

Viewing Chassis Temperature Status .....................................................................2-53

Viewing Temperature Status for Stacked Configurations ......................................2-54

A Slot Number is Specified.............................................................................2- 54

No Slot Number is Specified...........................................................................2- 54

Temperature Errors ................................................................................................2-55

Warning Threshold..........................................................................................2- 55

Danger Threshold............................................................................................2- 55

Viewing Fan Status ................................................................................................2-56

iv OmniSwitch 6600 Family Hardware Users Guide September 2006

Page 5

Contents

Viewing Fan Status for Stacked Configurations ....................................................2-56

A Slot Number is Specified.............................................................................2- 56

No Slot Number is Specified...........................................................................2- 57

Chassis Airflow ......................................................................................................2-58

Blank Cover Panels .........................................................................................2- 59

Pinouts ...........................................................................................................................2-60

Console Port ..................................................................................................................2-62

Serial Connection Default Settings ........................................................................2-62

Modifying the Serial Connection Settings .............................................................2-62

Configuring X-ON/X-OFF Protocol ......................................................................2-64

Viewing Basic Chassis Information ..............................................................................2-65

Hardware Information ............................................................................................2-65

Slot and Component Information ...........................................................................2-66

Detailed Slot and Component Information ............................................................2-66

Basic Primary Slot and Component Information ...................................................2-69

Basic Chassis Information ......................................................................................2-70

X-ON/X-OFF Protocol Status ................................................................................2-70

Managing MAC Addresses on the Switch ....................................................................2-71

MAC Range Guidelines .........................................................................................2-71

OmniSwitch 6600 Family MAC Range Specifications .........................................2-71

Base Chassis MAC Address as Unique Identifier ..................................................2-72

Determining Current MAC Address Allocation on the Switch .............................2-72

Base Chassis MAC Address in Stacked Configurations ........................................2-72

Chapter 3 Installing and Managing Power over Ethernet (PoE) ......................................3-1

In This Chapter ................................................................................................................3-2

Power over Ethernet Specifications ................................................................................3-3

Viewing OS6600-BPS-P Status ......................................................................................3-4

Configuring Power over Ethernet Parameters .................................................................3-5

Power over Ethernet Defaults ..................................................................................3-5

Understanding and Modifying the Default Settings .................................................3-5

Setting the PoE Operational Status....................................................................3- 5

Configuring the Total Power Allocated to a Port..............................................3- 6

Configuring the Total Power Allocated to a Switch .........................................3- 6

Setting Port Priority Levels ...............................................................................3- 7

Setting the Capacitor Detection Method ...........................................................3- 8

Understanding Priority Disconnect .................................................................................3-9

Setting Priority Disconnect Status ............................................................................3-9

Disabling Priority Disconnect ...........................................................................3- 9

Enabling Priority Disconnect ............................................................................3- 9

Priority Disconnect is Enabled; Same Priority Level on All PD Ports ...........3- 10

Priority Disconnect is Enabled; Incoming PD Port has Highest

Priority Level..................................................................................................3- 10

Priority Disconnect is Enabled; Incoming PD Port has Lowest

Priority Level..................................................................................................3- 10

Priority Disconnect is Disabled.......................................................................3- 11

Monitoring Power over Ethernet via the CLI ...............................................................3-11

OmniSwitch 6600 Family Hardware Users Guide September 2006 v

Page 6

Contents

Chapter 4 Managing OmniSwitch 6600 Family Stacks .......................................................4-1

In This Chapter ................................................................................................................4-1

Specifications and Default Values ..................................................................................4-2

Stack Overview ...............................................................................................................4-3

Stacking Resiliency and Redundancy ......................................................................4-4

Slot Numbers within a Stack ....................................................................................4-4

CMM Roles in a Stack .............................................................................................4-5

CMM Role Redundancy....................................................................................4- 5

CLI Commands Supported on Both the Primary and Secondary

Role Switches...................................................................................................4- 6

Setting Up a Stacked Configuration ................................................................................4-8

Assigning Slot Numbers ...........................................................................................4-8

Slot Numbering Example ................................................................................4- 10

Connecting Cables to Stacking Ports .....................................................................4-11

Redundant Stack Connection ..........................................................................4- 13

Booting the Stack ...................................................................................................4-14

Verifying Slot Number Assignments ..............................................................4- 14

Verifying Primary and Secondary Status for the Stack...................................4- 14

Managing Switches in a Stack ......................................................................................4-16

Reloading a Switch with a Primary or Secondary CMM Role ..............................4-16

Synchronizing Switches in a Stack ........................................................................4-17

Changing the Secondary CMM Role to Primary ...................................................4-17

Stack Behavior During Takeover....................................................................4- 18

Resetting All Switches in a Stack ..........................................................................4-18

Monitoring Stacks .........................................................................................................4-19

Monitoring Stack Topology ...................................................................................4-19

Appendix A Regulatory Compliance and Safety Information ..............................................A-1

Declaration of Conformity: CE Mark ............................................................................A-1

Waste Electrical and Electronic Equipment (WEEE) Statement ............................A-1

Standards Compliance ....................................................................................................A-2

FCC Class A, Part 15 ..............................................................................................A-3

Canada Class A Statement ......................................................................................A-3

JATE ........................................................................................................................A-3

CISPR22 Class A warning ......................................................................................A-3

VCCI .......................................................................................................................A-4

Class A Warning for Taiwan and Other Chinese Markets ......................................A-4

Translated Safety Warnings ...........................................................................................A-5

Chassis Lifting Warning...................................................................................A- 5

Blank Panels Warning ......................................................................................A- 5

Electrical Storm Warning.................................................................................A- 5

Installation Warning .........................................................................................A- 6

Invisible Laser Radiation Warning...................................................................A- 6

Lithium Battery Warning .................................................................................A- 7

Operating Voltage Warning .............................................................................A- 7

Power Disconnection Warning.........................................................................A- 8

Proper Earthing Requirement Warning............................................................A- 8

vi OmniSwitch 6600 Family Hardware Users Guide September 2006

Page 7

Contents

Read Important Safety Information Warning...................................................A- 9

Restricted Access Location Warning ...............................................................A- 9

Wrist Strap Warning.......................................................................................A- 10

Instrucciones de seguridad en español .........................................................................A-11

Advertencia sobre el levantamiento del chasis...............................................A- 11

Advertencia de las tapaderas en blanco..........................................................A- 11

Advertencia en caso de tormenta eléctrica.....................................................A- 11

Advertencia de instalación .............................................................................A- 11

Advertencia de radiación láser invisible.........................................................A- 11

Advertencia de la batería de litio....................................................................A- 11

Advertencia sobre la tensión de operación.....................................................A- 11

Advertencia sobre la desconexión de la fuente ..............................................A- 11

Advertencia sobre una apropiada conexión a tierra .......................................A- 12

Leer “información importante de seguridad”.................................................A- 12

Advertencia de acceso restringido..................................................................A- 12

Advertencia de pulsera antiestática ................................................................A- 12

Clase de seguridad..........................................................................................A- 12

Index ...................................................................................................................... Index-1

OmniSwitch 6600 Family Hardware Users Guide September 2006 vii

Page 8

Contents

viii OmniSwitch 6600 Family Hardware Users Guide September 2006

Page 9

About This Guide

This OmniSwitch 6600 Family Hardware Users Guide describes your switch hardware components and

basic switch hardware procedures.

Supported Platforms

This information in this guide applies to the following products:

• OmniSwitch 6624

• OmniSwitch 6600-U24

• OmniSwitch 6600-P24

• OmniSwitch 6648

• OmniSwitch 6602-24

• OmniSwitch 6602-48

OmniSwitch 6600 Family switches are next generation enterprise edge/workgroup switches. The

OmniSwitch 6624 and 6602-24 offer 24 copper 10/100 ports, the 6600-P24 offers 24 copper 10/100 Power

over Ethernet (PoE) ports, the 6648 and 6602-48 offer 48 copper 10/100 ports, and the 6600-U24 offers 24

fiber 100 ports.

In addition, OmniSwitch 6624/6600-U24/6648 switches have one expansion port that can be used for a

Gigabit Ethernet uplink module and another expansion port that can be used for a Gigabit Ethernet uplink

or a stacking module while the 6602-24/6602-48 switches offer fixed Gigabit Ethernet uplinks and fixed

stacking ports. The stacking ports on all OmniSwitch 6600 Family switches allow two to eight

OmniSwitch 6600 Family switches to be configured as one virtual chassis known as a stack.

OmniSwitch 6600 Family Hardware Users Guide September 2006 page ix

Page 10

Supported Platforms About This Guide

Unsupported Platforms

The information in this guide does not apply to the following products:

• OmniSwitch (original version with no numeric model name)

• OmniSwitch 6800 Series

• OmniSwitch 7700

• OmniSwitch 7800

• OmniSwitch 8800

• Omni Switch/Router

• OmniStack

• OmniAccess

page x OmniSwitch 6600 Family Hardware Users Guide September 2006

Page 11

About This Guide Who Should Read this Manual?

Who Should Read this Manual?

The audience for this users guide is network administrators and IT support personnel who need to configure, maintain, and monitor switches and routers in a live network. However, anyone wishing to gain

knowledge on the OmniSwitch 6600 Family hardware will benefit from the material in this guide.

When Should I Read this Manual?

Read this guide as soon as you are ready to familiarize yourself with your switch hardware components.

You should have already stepped through the first login procedures and read the brief hardware overviews

in the OmniSwitch 6600 Family Getting Started Guide.

You should already be familiar with the very basics of the switch hardware, such as module LEDs and

module installation procedures. This manual will help you understand your switch hardware components

(chassis, cooling fans, power supplies, Gigabit uplink modules, stacking modules, backup power supplies)

in greater depth.

What is in this Manual?

This users guide includes the following hardware-related information:

• Descriptions of stand-alone and stacked configurations.

• Descriptions of “Availability” features.

• Descriptions of chassis types (OS6624, OS6600-U24, OS6600-P24, OS6648, 6602-24, and OS6602-

48).

• Instructions for mounting chassis.

• Descriptions of hardware components (status LEDs, Gigabit uplink modules, stacking modules, backup

power supplies, MiniGBICs)

• Managing stand-alone chassis.

• Setting up stacks.

• Managing stacks.

• Hardware-related Command Line Interface (CLI) commands

What is Not in this Manual?

The descriptive and procedural information in this manual focuses on switch hardware. It includes information on some CLI commands that pertain directly to hardware configuration, but it is not intended as a

software users guide. There are several OmniSwitch 6600 Family users guides that focus on switch software configuration. Consult those guides for detailed information and examples for configuring your

switch software to operate in a live network environment. See “Documentation Roadmap” on page -xii

and “Related Documentation” on page -xiv for further information on software configuration guides available for your switch.

OmniSwitch 6600 Family Hardware Users Guide September 2006 page xi

Page 12

How is the Information Organized? About This Guide

How is the Information Organized?

This users guide provides an overview of OmniSwitch 6600 Family switches in the first chapter, an overview and procedures for setting up and managing OmniSwitch 6600 Family switches in the second chapter, and an overview and procedures for setting up and managing stacks in the third chapter.

Documentation Roadmap

The OmniSwitch user documentation suite was designed to supply you with information at several critical

junctures of the configuration process.The following section outlines a roadmap of the manuals that will

help you at each stage of the configuration process. Under each stage, we point you to the manual or

manuals that will be most helpful to you.

Stage 1: Using the Switch for the First Time

Pertinent Documentation: OmniSwitch 6600 Family Getting Started Guide

Release Notes

A hard-copy OmniSwitch 6600 Family Getting Started Guide is included with your switch; this guide

provides all the information you need to get your switch up and running the first time. This guide provides

information on unpacking the switch, rack mounting the switch, installing uplink and stacking modules,

unlocking access control, setting the switch’s IP address, setting up a password, and setting up stacks. It

also includes succinct overview information on fundamental aspects of the switch, such as hardware

LEDs, the software directory structure, stacking, CLI conventions, and web-based management.

At this time you should also familiarize yourself with the Release Notes that accompanied your switch.

This document includes important information on feature limitations that are not included in other user

guides.

Stage 2: Gaining Familiarity with Basic Switch Functions

Pertinent Documentation: OmniSwitch 6600 Family Hardware Users Guide

OmniSwitch 6600 Family Switch Management Guide

Once you have your switch up and running, you will want to begin investigating basic aspects of its hard

ware and software. Information about switch hardware is provided in the OmniSwitch 6600 Family Hard-

ware Users Guide. This guide provide specifications, illustrations, and descriptions of all hardware

components–chassis, power supplies, uplink and stacking modules, and cooling fans. It also includes steps

for common procedures, such as removing and installing switch modules.

The OmniSwitch 6600 Family Switch Management Guide is the primary user guide for the basic software

features on a single switch. This guide contains information on the switch directory structure, basic file

and directory utilities, switch access security, SNMP, and web-based management. It is recommended that

you read this guide before connecting your switch to the network.

Note. The OmniSwitch 6600 Family Switch Management Guide was originally known as the “OmniSwitch

6624/6648 Switch Management Guide.”

page xii OmniSwitch 6600 Family Hardware Users Guide September 2006

Page 13

About This Guide Documentation Roadmap

Stage 3: Integrating the Switch Into a Network

Pertinent Documentation: OmniSwitch 6600 Family Network Configuration Guide

OmniSwitch 6600 Family Advanced Routing Configuration Guide

When you are ready to connect your switch to the network, you will need to learn how the OmniSwitch

implements fundamental software features, such as 802.1Q, VLANs, and Spanning Tree. The OmniSwitch

6600 Family Network Configuration Guide contains overview information, procedures and examples on

how standard networking technologies are configured in the OmniSwitch 6600 Family.

Note. The OmniSwitch 6600 Family Network Configuration Guide was originally known as the

“OmniSwitch 6624/6648 Network Configuration Guide.”

The OmniSwitch 6600 Family Advanced Routing Configuration Guide includes configuration information

for networks using Open Shortest Path First (OSPF).

Note. The OmniSwitch 6600 Family Advanced Routing Configuration Guide was originally known as the

“OmniSwitch 66/24/6648 Advanced Routing Configuration Guide”

Anytime

The OmniSwitch CLI Reference Guide contains comprehensive information on all CLI commands

supported by the switch. This guide includes syntax, default, usage, example, related CLI command, and

CLI-to-MIB variable mapping information for all CLI commands supported by the switch. This guide can

be consulted anytime during the configuration process to find detailed and specific information on each

CLI command.

OmniSwitch 6600 Family Hardware Users Guide September 2006 page xiii

Page 14

Related Documentation About This Guide

Related Documentation

The following are the titles and descriptions of all the OmniSwitch 6600 Family user manuals:

• OmniSwitch 6600 Family Getting Started Guide

Describes the hardware and software procedures for getting an OmniSwitch 6600 Family switch up and

running. Also provides information on fundamental aspects of OmniSwitch software and stacking

architecture.

• OmniSwitch 6600 Family Hardware Users Guide

Complete technical specifications and procedures for all OmniSwitch 6600 Family chassis, power

supplies, fans, and uplink and stacking modules.

• OmniSwitch CLI Reference Guide

Complete reference to all CLI commands supported on the OmniSwitch 6624, 6600-U24, 6600-P24,

6648, 6602-24, 6602-48, 7700, 7800, and 8800. Includes syntax definitions, default values, examples,

usage guidelines and CLI-to-MIB variable mappings.

• OmniSwitch 6600 Family Switch Management Guide

Includes procedures for readying an individual switch for integration into a network. Topics include the

software directory architecture, image rollback protections, authenticated switch access, managing

switch files, system configuration, using SNMP, and using web management software (WebView).

• OmniSwitch 6600 Family Network Configuration Guide

Includes network configuration procedures and descriptive information on all the major software

features and protocols included in the base software package. Chapters cover Layer 2 information

(Ethernet and VLAN configuration), Layer 3 information, security options (authenticated VLANs),

Quality of Service (QoS), and link aggregation.

• OmniSwitch 6600 Family Advanced Routing Configuration Guide

Includes network configuration procedures and descriptive information on all the software features and

protocols included in the advanced routing software package. Chapters cover the Open Shortest Path

First (OSPF) Protocol.

• Technical Tips, Field Notices

Includes information published by Alcatel’s Customer Support group.

• Release Notes

Includes critical Open Problem Reports, feature exceptions, and other important information on the

features supported in the current release and any limitations to their support.

page xiv OmniSwitch 6600 Family Hardware Users Guide September 2006

Page 15

About This Guide User Manual CD

User Manual CD

All user guides for the OmniSwitch 6600 Family are included on the User Manual CD that accompanied

your switch. This CD also includes user guides for other Alcatel data enterprise products. In addition, it

contains a stand-alone version of the on-line help system that is embedded in the OmniVista network

management application.

Besides the OmniVista documentation, all documentation on the User Manual CD is in

requires the Adobe Acrobat Reader program for viewing. Acrobat Reader freeware is available at

www.adobe.com.

Note. In order to take advantage of the documentation CD’s global search feature, it is recommended that

you select the option for searching PDF files before downloading Acrobat Reader freeware.

To verify that you are using Acrobat Reader with the global search option, look for the following button in

the toolbar:

Note. When printing pages from the documentation PDFs, de-select Fit to Page if it is selected in your

print dialog. Otherwise pages may print with slightly smaller margins.

PDF format and

Technical Support

An Alcatel service agreement brings your company the assurance of 7x24 no-excuses technical support.

You’ll also receive regular software updates to maintain and maximize your Alcatel product’s features and

functionality and on-site hardware replacement through our global network of highly qualified service

delivery partners. Additionally, with 24-hour-a-day access to Alcatel’s Service and Support web page,

you’ll be able to view and update any case (open or closed) that you have reported to Alcatel’s technical

support, open a new case or access helpful release notes, technical bulletins, and manuals. For more information on Alcatel’s Service Programs, see our web page at www.ind.alcatel.com, call us at 1-800-9952696, or email us at support@ind.alcatel.com.

OmniSwitch 6600 Family Hardware Users Guide September 2006 page xv

Page 16

Technical Support About This Guide

page xvi OmniSwitch 6600 Family Hardware Users Guide September 2006

Page 17

1 OmniSwitch 6600 Family

The OmniSwitch 6600 Family switches consist of the OmniSwitch 6624 (OS6624), OmniSwitch 6600U24 (OS6600-U24), OmniSwitch 6600-P24 (OS6600-P24), OmniSwitch 6648 (OS6648), OmniSwitch

6602-24 (OS6602-24), and the OmniSwitch 6602-48 (OS6602-48). The OmniSwitch 6600 Family

switches are next generation enterprise edge/workgroup switches. These switches are based on the same

software architecture as OmniSwitch 7000 and 8000 Family switches (i.e., OS7700, OS7800, and

OS8800) and are designed to meet the most stringent network requirements for mission-critical networks.

OmniSwitch 6600 Family switches are optimized for voice and data integration and provide non-blocking

multi-Gigabit Ethernet capacity. Additional features include Carrier-class intelligence, best of breed QoS,

Carrier-class resiliency, network management, and advanced policy-based VLANs and security.

OmniSwitch 6600 Family switches also support wirespeed Layer 2 and Layer 3 switching, industry-based

standards, and a full array of reliability, redundancy and resiliency capabilities.

OmniSwitch 6600 Family Hardware Users Guide September 2006 page 1-1

Page 18

Stand-Alone and Stacked Configurations OmniSwitch 6600 Family

Stand-Alone and Stacked Configurations

Stand-Alone

A stand-alone OmniSwitch 6600 Family switch is ideal for small and medium-sized network edge applications, offering 24 10/100 copper ports, 24 100 fiber ports, or 48 10/100 copper Power over Ethernet (PoE)

ports. These switches provide support for enterprise-based devices, such as computer workstations or IP

telephones.

A single OmniSwitch 6600 Family switch also supports two Gigabit Ethernet uplinks for high-bandwidth

connections to a backbone or server.

Stacked Configurations

In addition to working as individual, stand-alone switches, OmniSwitch 6600 Family switches can also be

linked together to form a single, high-density virtual chassis known as a stack.

Stacking switches provides scalability by allowing users to quickly and easily expand 10/100 port density.

Twenty-four 10/100 ports are added for each OS6624 or OS6602-24 brought into the stack; twenty-four

10/100 Power over Ethernet (PoE) ports are added for each OS6600-P24 brought into the stack; twentyfour 100 ports are added for each OS6600-U24 brought into the stack; forty-eight 10/100 ports are added

for each OS6648 or OS6602-48.

Up to eight switches can be stacked. OmniSwitch 6600 Family switches can be mixed and matched in any

combination within the stack. This provides a virtual chassis with a 10/100 or 100 capacity of up to 384

ports.

As with the stand-alone configuration, a stacked virtual chassis configuration provides Gigabit Ethernet

uplinks to a backbone or server.

Note. For detailed information on stacking OmniSwitch 6600 Family switches into a virtual chassis, refer

to Chapter 4, “Managing OmniSwitch 6600 Family Stacks.”

Note on Terminology. In the user manuals provided with your switch, the terms switch, slot and NI

(Network Interface) refer to individual OmniSwitch 6600 Family units in standalone mode or within a

stacked configuration. The term CMM (Chassis Management Module) refers to stacked OmniSwitch 6600

Family units operating in primary or secondary CMM roles. (An OmniSwitch 6600 Family switch operating in an idle CMM role would normally be referred to as a switch, slot, or, NI.)

page 1-2 OmniSwitch 6600 Family Hardware Users Guide September 2006

Page 19

OmniSwitch 6600 Family Availability Features

Availability Features

The switch provides a broad variety of Availability features. Availability features are hardware- and

software-based safeguards that help prevent the loss of data flow in the unlikely event of a subsystem failure. In addition, some Availability features allow you to maintain or replace hardware components without powering off your switch or interrupting switch operations. Combined, these features provide added

resiliency and help ensure that your switch is consistently available for your day-to-day network operations.

Hardware-related Availability features include:

• Smart Continuous Switching

• Software Rollback

• Hot Swapping

• Hardware Monitoring

Smart Continuous Switching

In stacked configurations, one OmniSwitch 6600 Family switch is designated as the primary “management module” for the stack. Because the stack can be thought of as a virtual chassis, the role of this

primary management switch is to monitor and manage the functions of the stack.

Similar to chassis-based switches such as the OmniSwitch 7700 and Omniswitch 7800, the stack also

allows users to assign an additional switch as a secondary management module. As with the OS7700 and

OS7800, the stack’s secondary switch immediately takes over management functions in the event of a

primary switch failure.

All other switches in the stack are considered idle, and act very much like Ethernet Network Interface

(ENI) modules in OS7700 and OS7800 switches, in that they provide Ethernet ports for 10/100 traffic.

The stack provides support for all idle switches during primary-to-secondary failover. In other words, if

the stack’s primary switch fails or goes offline for any reason, all idle switches will continue data transmission during the secondary switch’s takeover process. This Availability feature is referred to as Smart

Continuous Switching.

Incoming Layer 2 packets will continue to be sent to the appropriate egress port during failover. Spanning

Tree will continue handling BPDUs received on the switch ports, as well as port link up and down states.

The Spanning Tree topology will not be disrupted.

Note. Smart Continuous Switching is designed to maintain data flow only during primary/secondary

switch failover and is not intended to support long-term data flow. If both the primary and secondary

switches in the stack go offline, switch operations (including all 10/100 support) will be disabled.

For more information on primary, secondary, and idle switches, as well as the failover process, refer to

Chapter 4, “Managing OmniSwitch 6600 Family Stacks.”

OmniSwitch 6600 Family Hardware Users Guide September 2006 page 1-3

Page 20

Availability Features OmniSwitch 6600 Family

Software Rollback

Software rollback (also referred to as image rollback) essentially allows the OmniSwitch 6600 Family

switches (in both standalone and stacked configurations) to return to a prior “last known good” version of

software in the event of a system software problem. The switch controls software rollback through its

resilient directory structure design (i.e., /flash/working and /flash/certified).

For detailed information on the software rollback feature, as well as the switch’s /flash/working and

/flash/certified directories, refer to the “Managing CMM Directory Content” chapter in the OmniSwitch

6600 Family Switch Management Guide.

Hot Swapping

Hot swapping refers to the action of adding, removing, or replacing back up power supplies, as well as

uplink modules and MiniGBICs, without powering off your switch and disrupting other components in the

switch or stack. This feature greatly facilitates hardware upgrades and maintenance and also allows you to

easily replace components in the unlikely event of hardware failure. The following hardware components

can be hot swapped:

• OS6600-BPS Back Up Power Supply

• OS6600-GNI-C2 Gigabit Ethernet Uplink Submodule

• OS6600-GNI-U2 Gigabit Ethernet Uplink Submodule

• MiniGBICs installed in the OS6600-GNI-U2 Gigabit Ethernet Uplink Submodule on OS6624, OS660-

U24, OS6600-P24, and OS6648 switches or the built-in MiniGBIC slots on OS6602-24 and OS660248 switches; MiniGBICs include:

- MiniGBIC-SX

- MiniGBIC-LX

- MiniGBIC-LH-70

• 100 Mbps SFPs installed in the OS6600-U24; SFPs include:

- SFP-100-LC-MM

- SFP-100-LC-SM15

- SFP-100-LC-SM40

- SFP-100-MTRJ-MM

Note. Stacking modules cannot be hot swapped at any time. For information on stacking modules, refer to

Chapter 2, “OmniSwitch 6600 Family Chassis and Hardware Components.”

For instructions on hot swapping back up power supplies, uplink modules, and MiniGBICs, refer to

Chapter 2, “OmniSwitch 6600 Family Chassis and Hardware Components.”

page 1-4 OmniSwitch 6600 Family Hardware Users Guide September 2006

Page 21

OmniSwitch 6600 Family Availability Features

Hardware Monitoring

Automatic Monitoring

Automatic monitoring refers to the switch’s built-in sensors that automatically monitor operations. If an

error is detected (e.g., over-threshold temperature), the switch immediately sends a trap to the user. The

trap is displayed on the console in the form of a text error message. (In the case of an over-threshold

temperature condition, the chassis displays an amber TEMP LED in addition to sending a trap.)

LEDs

LEDs, which provide visual status information, are provided on the chassis front panel. LEDs are used to

indicate conditions such as hardware and software status, temperature errors, link integrity, data flow, etc.

For detailed LED descriptions, refer to Chapter 2, “OmniSwitch 6600 Family Chassis and Hardware

Components.”

User-Driven Monitoring

User-driven hardware monitoring refers to CLI commands that are entered by the user in order to access

the current status of hardware components. The user enters “show” commands that output information to

the console. Monitoring information for chassis components such as the optional back up power supply,

chassis temperature sensor, and chassis fans is provided in Chapter 2, “OmniSwitch 6600 Family Chassis

and Hardware Components.” Show commands for all features are described in detail in the OmniSwitch

CLI Reference Guide.

OmniSwitch 6600 Family Hardware Users Guide September 2006 page 1-5

Page 22

Application Examples OmniSwitch 6600 Family

Application Examples

The following application examples show two of the many ways OmniSwitch 6600 Family switches can

be used in an enterprise network setting.

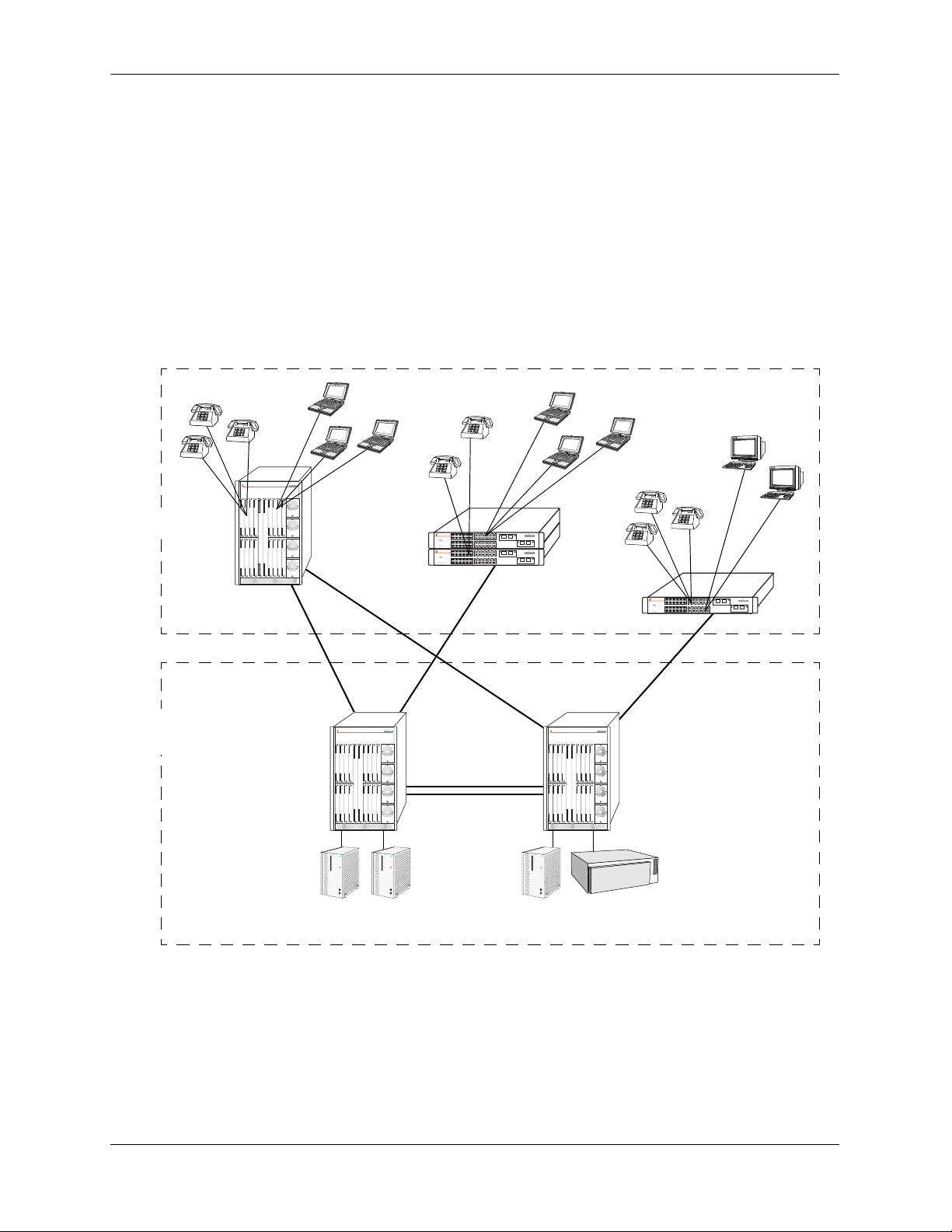

Single Office Building with 1000 Users

The following diagram shows converged voice and data applications, with 1000 users, in a single building

enterprise environment. Edge devices consist of a mixture of PCs and IP telephones. In this example, a

single OmniPCX 4400 in the core supports IP voice initiations and terminations. An OmniSwitch 7800

switch provides a port density of 1000 10/100 ports. The stackable OmniSwitch 6600 Family configurations provide redundant and dual connectivity from the edge to the redundant backbone/core, in which the

OmniSwitch 7800 core switches are used.

Edge

Backbone

Data Center

IP Phones

OmniSwitch 7800

IP Phones

Gigabit Gigabit

OmniSwitch 6648

OmniSwitch 6648

Gigabit

OmniSwitch 7800 OmniSwitch 7800

Gigabit

IP Phones

Gigabit

OmniSwitch 6648

Server Farm Server

OmniPCX

page 1-6 OmniSwitch 6600 Family Hardware Users Guide September 2006

Page 23

OmniSwitch 6600 Family Application Examples

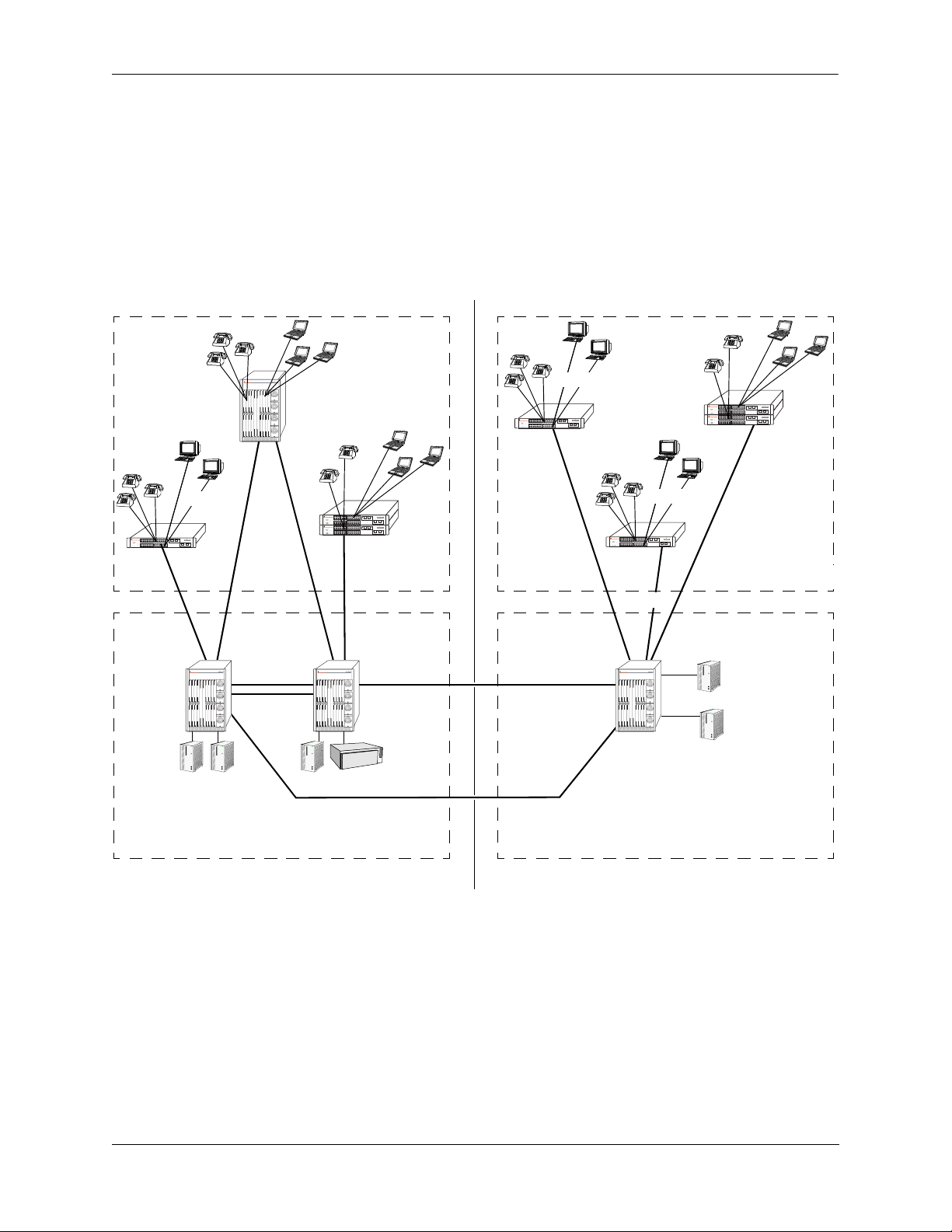

Medium Campus with 1500 Users

This example illustrates converged voice and data applications with 1500 users spread across two buildings in an enterprise campus. Edge devices consist of a mixture of PCs and IP telephones. And, like the

previous example, a single OmniPCX 4400 in the core supports IP voice initiations and terminations.

In building number one, an OmniSwitch 7800 switch provides a port density of 1000 10/100 ports, and the

stackable OmniSwitch 6600 Family configurations provide redundant and dual connectivity from the edge

to the redundant backbone/core. In building number two, the stackable OmniSwitch 6600 Family configurations provide 500 ports for connectivity from the edge to the backbone/core.

IP Phones

IP Phones

OmniSwitch 6648

10/10010/100

OmniSwitch 7800

Server Farm

OmniSwitch 7800

Gigabit

10/100

IP Phones

OmniSwitch 6648

OmniSwitch 6648

OmniSwitch 7800

10/100

Edge

OmniPCX

Backbone

Data Center

OmniSwitch 6648

Gigabit

10/100

OmniSwitch 6648

Gigabit

OmniSwitch 7800

10/100

OmniSwitch 6648

OmniSwitch 6648

Server Farm

Backbone

Data Center

10/100

Edge

Building Number One Building Number Two

OmniSwitch 6600 Family Hardware Users Guide September 2006 page 1-7

Page 24

Application Examples OmniSwitch 6600 Family

page 1-8 OmniSwitch 6600 Family Hardware Users Guide September 2006

Page 25

2 OmniSwitch 6600 Family

Chassis and Hardware

Components

OmniSwitch 6600 Family switches are available in six stackable chassis configurations—the 24-port

OmniSwitch 6624 (OS6624), OmniSwitch 6600-U24 (OS6600-U24), OmniSwitch 6600-P24 (OS6600P24), and OmniSwitch 6602-24 (OS6602-24) and the 48-port OmniSwitch 6648 (OS6648) and

OmniSwitch 6602-48 (OS6602-48). This chapter includes detailed information on each of these chassis

types. Topics include:

• OmniSwitch 6600 Family chassis descriptions

• Technical specifications

• Switch mounting

• Backup power supply

• Gigabit Ethernet uplink and stacking modules

• MiniGBICs

• 100 Mbps SFPs

• Temperature management

• Pinouts and console port specifications

• Monitoring switch status

• Base chassis MAC address

OmniSwitch 6600 Family Hardware Users Guide September 2006 page 2-1

Page 26

OmniSwitch 6600 Family Chassis and Hardware Components OmniSwitch 6624

OmniSwitch 6624

The OS6624 is a stackable edge/workgroup switch offering 24 10/100 Ethernet ports. The OS6624 can

also be equipped with upto four Gigabit Ethernet ports for connections to a high speed backbone or server.

The front panel of the OS6624 chassis contains the following major components:

• Console (DB-9) port

• Stack indicator LED

• 24 10/100 Ethernet ports

• One slot for OS6600-GNI-U2 (fiber) or OS6600-GNI-C2 (copper) Gigabit Ethernet uplink module

• One slot for Gigabit Ethernet uplink module as described above or stacking module

Note. The OmniSwitch 6624 is also known as the OmniSwitch 6602-24.

Refer to the illustration below for more front panel information. For detailed LED descriptions, refer to

page 2-18. For information on the chassis rear panel, refer to page 2-20.

Console Port

The OS6624 front panel provides one RS232

port for console connections. Serial console

connections are used by network administrators

for switch management. This female DB-9 connector provides a DCE console connection.

Gigabit Ethernet Uplink Module Slot

The OS6624 provides a dedicated slot for Gigabit Ethernet uplink

modules. This slot supports the following module types:

• OS6600-GNI-C2—Provides two fixed 1000BaseT copper

connections (uses two RJ-45 connectors). Supports distances

up to 100 meters.

• OS6600-GNI-U2—Provides two MiniGBIC bays that

support hot-swappable 1000BASE-X MiniGBIC transceivers.

OmniSwitch 6624

TM

CONSOLE

34567891011

1

OK1

PS1

PRI

TEMP

OK2

PS2

SEC

FAN SEL

2

Status and Slot Indicator LEDs

For information on the OS6624’s

status and slot indicator LEDs,

refer to page 2-18.

Slot Selector Button

The slot selector button, located

directly beneath the slot indicator

LED, is used to manually assign

slot numbers to switches in stacked

configurations. Refer to Chapter 4,

“Managing OmniSwitch 6600

Family Stacks,” for detailed infor-

mation.

1314151617181920212223

12

24

10/100 Ethernet Ports

The OS6624 provides 24 10/100

Ethernet ports. These ports are

twisted-pair and are individually

configurable as 10BaseT or

100BaseTX. The ports use RJ-45

connectors.

25 26 27 28

LINK/ACT

LINK/ACT

Stacking or Uplink Module Slot

The OS6624 provides an additional slot that

can accommodate either a stacking module or

a Gigabit Ethernet uplink module.

If you use a Gigabit Ethernet uplink module

in this slot, the OS6624 must be used as a

stand-alone switch.

A stacking module must be installed in this

slot if the switch is to be used in a stack. For

detailed information on stacking switches,

refer to Chapter 4, “Managing OmniSwitch

6600 Family Stacks.”

EXPANSION/STACKINGEXPANSION

LINK/ACT

LINK/ACT

OmniSwitch 6624 Front Panel

OmniSwitch 6600 Family Hardware Users Guide September 2006 page 2-2

Page 27

OmniSwitch 6600 Family Chassis and Hardware Components OmniSwitch 6624

OS6624 Specifications

Total number of 10/100 Mbps

24

ports per switch

Total number of Gigabit

4 (for stand-alone switches); 2 (for stacked configurations)

Ethernet ports per switch

Total number of 10/100 Mbps

192 (stack of eight switches)

ports per stack

Total number of Gigabit

16 (stack of eight switches)

Ethernet ports per stack

Fabric capacity 7.0 Gbps full duplex; 14 Gbps aggregate

Current draw Approximately 2.3 Amps

Power Approximately 55 Watts

Total available power supplies 2 (one factory-installed power supply and one optional backup power

supply)

Flash memory size 64 MB

RAM memory size 128 MB

Overall Width (rack-mount

19.125 inches

flanges included)

Chassis Width (rack-mount

17.2 inches

flanges not included)

Height 2.65 inches

Height (rack units) 1.5 RU

Chassis Depth 14 inches

Chassis Weight Approximately 12 lbs (13.5 lbs with optional backup power supply

installed)

Humidity 5% to 90% Relative Humidity (Operating)

0% to 95% Relative Humidity (Storage)

Altitude Sea level to 10,000 feet (3 km)

10/100 Ethernet Port Specifications

Connector type RJ-45

Standards supported IEEE 802.3u, IAB RFCs 826, 894

Data rate 10 or 100 Mbps (full or half duplex)

Maximum frame size 1518 Bytes; 1522 Bytes with IEEE 802.1Q tags

Connections supported 10BaseT hub or device; 100BaseTX hub or device

Cable supported 10BaseT: unshielded twisted-pair (UTP)

100BaseTX: unshielded twisted-pair (UTP), Category 5, EIA/TIA 568

or shielded twisted-pair (STP), Category 5, 100 ohm

Maximum cable distance 100 meters

OmniSwitch 6600 Family Hardware Users Guide September 2006 page 2-3

Page 28

OmniSwitch 6600 Family Chassis and Hardware Components OmniSwitch 6600-U24

OmniSwitch 6600-U24

The OS6600-U24 is a stackable edge/workgroup switch offering 24 fiber 100 Mbps Ethernet SFP ports.

The OS6600-U24 can also be equipped with up to four Gigabit Ethernet ports for connections to a high

speed backbone or server.

The front panel of the OS6600-U24 chassis contains the following major components:

• Console (RJ-45) port

• Stack indicator LED

• 24 fiber 100 Ethernet SFP ports

• One slot for OS6600-GNI-U2 (fiber) or OS6600-GNI-C2 (copper) Gigabit Ethernet uplink module

• One slot for Gigabit Ethernet uplink module as described above or stacking module

The following SFP transceivers are available for the OS6600-U24:

• SFP-100-LC-MM—100Base FX multimode 62.5/125 and 50/125 micron fiber, supports distances up

to 2 km; uses LC connectors.

• SFP-100-LC-SM15—100Base FX single mode 9/125 micron fiber, supports distances up to 15 km;

uses LC connectors.

• SFP-100-LC-SM40—100Base FX single mode 9/125 micron fiber, supports distances up to 40 km;

uses LC connectors.

• SFP-100-MTRJ-MM—100Base FX multimode 62.5/125 and 50/125 micron fiber, supports distances

up to 2 km; uses MTRJ connectors.

Note. See “Installing SFPs (OS6600-U24)” on page 2-51 for information on installing SFP transceivers.

Refer to the illustration on the following page for more front panel information. For detailed LED descriptions, refer to page 2-18. For information on the chassis rear panel, refer to page 2-20.

OmniSwitch 6600 Family Hardware Users Guide September 2006 page 2-4

Page 29

OmniSwitch 6600 Family Chassis and Hardware Components OmniSwitch 6600-U24

Console Port

The OS6600-U24 front panel provides one RJ-45

port for console connections. Serial console connections are used by network administrators for

switch management. This female RJ-45connector

provides a DCE console connection.

OmniSwitch 6600-U24

TM

357 911

CONSOLE

OK1

OK2

SEL

PS1

PS2 PRI SEC TEMPFAN

Status and Slot Indicator LEDs

For information on the OS6600-U24’s

status and slot indicator LEDs, refer to

page 2-18.

1

2 24

2143658710912111413

100 Fiber Ethernet SFP Ports

The OS6600-U24 provides 24

fiber 100 Ethernet SFP ports.

These ports can use the SFP-100LC-MM, SFP-100-LC-SM, and

Slot Selector Button

The slot selector button, located

SFP-100-MTRJ-MM transceivers

in any combination.

directly beneath the slot indicator

LED, is used to manually assign

slot numbers to switches in stacked

configurations. Refer to Chapter 4,

“Managing OmniSwitch 6600

Family Stacks,” for detailed infor-

mation.

Gigabit Ethernet Uplink Module Slot

The OS6600-U24 provides a dedicated slot for Gigabit Ethernet

uplink modules. This slot supports the following module types:

• OS6600-GNI-C2—Provides two fixed 1000BaseT copper

connections (uses two RJ-45 connectors). Supports distances

up to 100 meters.

• OS6600-GNI-U2—Provides two MiniGBIC bays that

support hot-swappable 1000BASE-X MiniGBIC transceivers.

13 15 17 19 21

1615 1817 2019 2221 2423

23

25 26 27 28

EXPANSION/STACKINGEXPANSION

LINK/ACT

LINK/ACT

Stacking or Uplink Module Slot

The OS6600-U24 provides an additional slot

that can accommodate either a stacking module or a Gigabit Ethernet uplink module.

If you use a Gigabit Ethernet uplink module

in this slot, the OS66600-U24 must be used

as a stand-alone switch.

A stacking module must be installed in this

slot if the switch is to be used in a stack. For

detailed information on stacking switches,

refer to Chapter 4, “Managing OmniSwitch

6600 Family Stacks.”

OmniSwitch 6600-U24 Front Panel

OmniSwitch 6600 Family Hardware Users Guide September 2006 page 2-5

Page 30

OmniSwitch 6600 Family Chassis and Hardware Components OmniSwitch 6600-U24

OS6600-U24 Specifications

Total number of 100 Mbps SFP

24

ports per switch

Total number of Gigabit

4 (for stand-alone switches); 2 (for stacked configurations)

Ethernet ports per switch

Total number of 100 Mbps SFP

192 (stack of eight switches)

ports per stack

Total number of Gigabit

16 (stack of eight switches)

Ethernet ports per stack

Fabric capacity 7.0 Gbps full duplex; 14 Gbps aggregate

Power The OS6600-U24 power supply provides 100 W

Total available power supplies 2 (one factory-installed power supply and one optional backup power

supply)

Flash memory size 64 MB

RAM memory size 128 MB

Overall Width (rack-mount

19.125 inches

flanges included)

Chassis Width (rack-mount

17.2 inches

flanges not included)

Height 2.65 inches

Height (rack units) 1.5 RU

Chassis Depth 14 inches

Chassis Weight Approximately 11.56 lbs not including uplink/stacking modules or

SFPs (13.06 lbs with optional backup power supply installed)

Humidity 5% to 90% Relative Humidity (Operating)

0% to 95% Relative Humidity (Storage)

Altitude Sea level to 10,000 feet (3 km)

OmniSwitch 6600 Family Hardware Users Guide September 2006 page 2-6

Page 31

OmniSwitch 6600 Family Chassis and Hardware Components OmniSwitch 6600-U24

100 Mbps Ethernet SFP Port Specifications

Connector type SFP

Standards supported IEEE 802.3u, IAB RFCs 826, 894 (see data sheet for more information)

Data rate 100 Mbps (full or half duplex)

Maximum frame size 1518 Bytes; 1522 Bytes with IEEE 802.1Q tags

Connections supported 100BaseFX

Cable supported SFP-100-LC-MM: 62.5/125 and 50/125 micron multimode fiber

SFP-100-LC-SM: 9/125 micron single mode

SFP-100-MTRJ-MM: 62.5/125 and 50/125 micron multimode fiber

Optical output power SFP-100-LC-MM: -19 to -14 dBm (62.5/125 micron);

-22.5 to -14 dBm (50/125 micron)

SFP-100-LC-SM15: -15 to -8 dBm

SFP-100-LC-SM40: -5 to 0 dBm

SFP-100-MTRJ-MM: -20 to -14 dBm

Input optical power

(Receiver sensitivity)

SFP-100-LC-MM: -31 to -14 dBm

SFP-100-LC-SM15: -31 to 0dBm

SFP-100-LC-SM40: -34 to 0 dBm

SFP-100-MTRJ-MM: -31 to -14 dBm

Maximum cable distance SFP-100-LC-MM: 2 km

SFP-100-LC-SM15: 15 km

SFP-100-LC-SM40: 40 km

SFP-100-MTRJ-MM: 2 km

OmniSwitch 6600 Family Hardware Users Guide September 2006 page 2-7

Page 32

OmniSwitch 6600 Family Chassis and Hardware Components OmniSwitch 6600-P24

OmniSwitch 6600-P24

The OS6600-P24 is a stackable edge/workgroup switch offering 24 Power over Ethernet (PoE) 10/100

Ethernet ports. The OS6600-P24 can also be equipped with up to four Gigabit Ethernet ports for connections to a high speed backbone or server.

The front panel of the OS6600-P24 chassis contains the following major components:

• Console (RJ-45) port

• Stack indicator LED

• 24 10/100 PoE ports

• One slot for OS6600-GNI-U2 (fiber) or OS6600-GNI-C2 (copper) Gigabit Ethernet uplink module

• One slot for Gigabit Ethernet uplink module as described above or stacking module

OmniSwitch 6600 Family Hardware Users Guide September 2006 page 2-8

Page 33

OmniSwitch 6600 Family Chassis and Hardware Components OmniSwitch 6600-P24

Refer to the illustration below for more front panel information. For detailed LED descriptions, refer to

page 2-18. For information on the chassis rear panel, refer to page 2-20.

Console Port

The OS6600-P24 front panel provides one RJ45 port for console connections. Serial console

connections are used by network administrators

for switch management. This female RJ-45 connector provides a DCE console connection.

OmniSwitch 6600-P24

TM

34567891011

CONSOLE

OK1

PS1

OK2

PS2

SEC

PRI

Status and Slot Indicator LEDs

For information on the OS6600-P24’s

status and slot indicator LEDs, refer

to page 2-18.

1

SEL

TEMP

FAN

2

12

10/100 Ethernet Ports

The OS6600-P24 provides 24

Power over Ethernet (PoE) 10/100

Ethernet ports. These ports are

twisted-pair and are individually

Slot Selector Button

The slot selector button, located

directly beneath the slot indicator

LED, is used to manually assign

configurable as 10BaseT or

100BaseTX. The ports use RJ-45

connectors. For information more

information, refer to page 2-18.

slot numbers to switches in stacked

configurations.

Gigabit Ethernet Uplink Module Slot

The OS6600-P24 provides a dedicated slot for Gigabit Ethernet

uplink modules. This slot supports the following module types:

• OS6600-GNI-C2—Provides two fixed 1000BaseT copper

connections (uses two RJ-45 connectors). Supports distances

up to 100 meters.

• OS6600-GNI-U2—Provides two MiniGBIC bays that

support hot-swappable 1000BASE-X MiniGBIC transceivers.

1314151617181920212223

25 26 27 28

LINK/ACT

LINK/ACT

24

EXPANSION/STACKINGEXPANSION

LINK/ACT

LINK/ACT

Stacking or Uplink Module Slot

The OS6600-P24 provides an additional slot

that can accommodate either a stacking module or a Gigabit Ethernet uplink module.

If you use a Gigabit Ethernet uplink module

in this slot, the OS6600-P24 must be used as

a stand-alone switch.

A stacking module must be installed in this

slot if the switch is to be used in a stack. For

detailed information on stacking switches,

refer to Chapter 4, “Managing OmniSwitch

6600 Family Stacks.”

OmniSwitch 6600-P24 Front Panel

OmniSwitch 6600 Family Hardware Users Guide September 2006 page 2-9

Page 34

OmniSwitch 6600 Family Chassis and Hardware Components OmniSwitch 6600-P24

OS6600-P24 Specifications

Total number of PoE 10/100

24

Mbps ports per switch

Total number of Gigabit

4 (for stand-alone switches); 2 (for stacked configurations)

Ethernet ports per switch

Total number of PoE 10/100

192 (stack of eight switches)

Mbps ports per stack

Total number of Gigabit

16 (stack of eight switches)

Ethernet ports per stack

Fabric capacity 7.0 Gbps full duplex; 14 Gbps aggregate

Current draw Switch functions (24 Volts max.): 2.3 Amps

PoE (49 Volts max.): 4.3 Amps

Power Switch functions (24 Volts max.): 55 Watts (100 Watts available)

PoE (49 Volts max.): 210 Watts

Total available power supplies

(OS6600-P24)

Total available power supplies

(OS6600-BPS-P)

2: Two built-in factory-installed power supplies (one powering switch

functions and the other powering PoE)

2: Two built-in factory-installed power supplies (one powering switch

functions and the other powering PoE)

Flash memory size 64 MB

RAM memory size 128 MB

Overall Width (rack-mount

19.025 inches

flanges included)

Chassis Width (rack-mount

17.1 inches

flanges not included)

Height 2.65 inches

Height (rack units) 1.5 RU

Chassis Depth 14.5 inches (without an OS6600-BPS-P)

19.3 inches (with an OS6600-BPS-P)

Chassis Weight Approximately 12 lbs

Humidity 5% to 90% Relative Humidity (Operating)

0% to 95% Relative Humidity (Storage)

Altitude Sea level to 10,000 feet (3 km)

OmniSwitch 6600 Family Hardware Users Guide September 2006 page 2-10

Page 35

OmniSwitch 6600 Family Chassis and Hardware Components OmniSwitch 6600-P24

10/100 Power over Ethernet (PoE) Port Specifications

Connector type RJ-45

Standards supported IEEE 802.3u, 802.3af (DTE Power via MDI MIB); IAB RFCs 826, 894

Data rate 10 or 100 Mbps (full or half duplex)

Maximum frame size 1518 Bytes; 1522 Bytes with IEEE 802.1Q tags

Connections supported 10BaseT or 100BaseTX IP phones, Bluetooth Access Points, Internet

cameras, and other devices requiring power over Ethernet

Cable supported 10BaseT: unshielded twisted-pair (UTP)

100BaseTX: unshielded twisted-pair (UTP), Category 5, EIA/TIA 568

or shielded twisted-pair (STP), Category 5, 100 ohm

Power supplied to port 15.4 watts per port

Maximum cable distance 100 meters

OmniSwitch 6600 Family Hardware Users Guide September 2006 page 2-11

Page 36

OmniSwitch 6600 Family Chassis and Hardware Components OmniSwitch 6648

OmniSwitch 6648

The OS6648 is a stackable edge/workgroup switch offering 48 10/100 Ethernet ports. The OS6648 can

also be equipped with up to four Gigabit Ethernet ports for connections to a high speed backbone or

server.

The front panel of the OS6648 chassis contains the following major components:

• Console (DB-9) port

• Stack indicator LED

• 48 10/100 Ethernet ports

• One slot for OS6600-GNI-U2 (fiber) or OS6600-GNI-C2 (copper) Gigabit Ethernet uplink module

• One slot for Gigabit Ethernet uplink module as described above or stacking module

Note. The OmniSwitch 6648 is also known as the OmniSwitch 6600-48.

Refer to the illustration below for more front panel information. For detailed LED descriptions, refer to

page 2-18. For information on the chassis rear panel, refer to page 2-20.

Console Port

The OS6648 front panel provides one RS232

port for console connections. Serial console

connections are used by network administrators

for switch management. This female DB-9 connector provides a DCE console connection.

272829303132333435

OmniSwitch 6648

TM

CONSOLE

OK1

PS1

PRI

TEMP

OK2

PS2

SEC

FAN

Status and Slot Indicator LEDs

For information on the OS6648’s

status and slot indicator LEDs,

refer to page 2-18.

Slot Selector Button

The slot selector button, located

directly beneath the slot indicator

25

26

34567891011

1

SEL

2

36

12

10/100 Ethernet Ports

The OS6648 provides 48 10/100

Ethernet ports. These ports are

twisted-pair and are individually

configurable as 10BaseT or

100BaseTX. The ports use RJ-45

connectors.

LED, is used to manually assign

slot numbers to switches in stacked

configurations. Refer to Chapter 4,

“Managing OmniSwitch 6600

Family Stacks,” for detailed infor-

mation.

OmniSwitch 6648 Front Panel

Gigabit Ethernet Uplink Module Slot

The OS6648 provides a dedicated slot for Gigabit Ethernet uplink

modules. This slot supports the following module types:

• OS6600-GNI-C2—Provides two fixed 1000BaseT copper

connections (uses two RJ-45 connectors). Supports distances

up to 100 meters.

• OS6600-GNI-U2—Provides two MiniGBIC bays that

support hot-swappable 1000BASE-X MiniGBIC transceivers.

3738394041424344454647

1314151617181920212223

EXPANSION

LINK/ACT

EXPANSION/STACKING

LINK/ACT

LINK/ACT

LINK/ACT

48

24

49 50 51 52

Stacking or Uplink Module Slot

The OS6648 provides an additional slot that

can accommodate either a stacking module or

a Gigabit Ethernet uplink module.

If you use a Gigabit Ethernet uplink module

in this slot, the OS6648 must be used as a

stand-alone switch.

A stacking module must be installed in this

slot if the switch is to be used in a stack. For

detailed information on stacking switches,

refer to Chapter 4, “Managing OmniSwitch

6600 Family Stacks.”

OmniSwitch 6600 Family Hardware Users Guide September 2006 page 2-12

Page 37

OmniSwitch 6600 Family Chassis and Hardware Components OmniSwitch 6648

OS6648 Specifications

Total number of 10/100 Mbps

48

ports per switch

Total number of Gigabit Ether-

net ports per switch

Total number of 10/100 Mbps

4 (for stand-alone switches);

2 (for stacked configurations)

384 (stack of eight switches)

ports per stack

Total number of Gigabit Ether-

16 (stack of eight switches)

net ports per stack

Fabric capacity 10.0 Gbps full duplex; 20.0 Gbps aggregate

Current draw Approximately 2.3 Amps

Power Approximately 55 Watts

Total power supplies 2 (one factory-installed power supply and

one optional backup power supply)

Flash memory size 64 MB

RAM memory size 128 MB

Overall Width (rack-mount

19.125 inches

flanges included)

Chassis Width (rack-mount

17.2 inches

flanges not included)

Height 2.65 inches

Height (rack units) 1.5 RU

Chassis Depth 14 inches

Chassis Weight Approximately 14 lbs (15.5 lbs with optional

backup power supply installed)

Humidity 5% to 90% Relative Humidity (Operating)

0% to 95% Relative Humidity (Storage)

Altitude Sea level to 10,000 feet (3 km)

10/100 Ethernet Port Specifications

Connector type RJ-45

Standards supported IEEE 802.3u, IAB RFCs 826, 894

Data rate 10 or 100 Mbps (full or half duplex)

Maximum frame size 1518 Bytes; 1522 Bytes with IEEE 802.1Q tags

Connections supported 10BaseT hub or device; 100BaseTX hub or device

Cable supported 10BaseT: unshielded twisted-pair (UTP)

100BaseTX: unshielded twisted-pair (UTP), Category 5, EIA/TIA 568

or shielded twisted-pair (STP), Category 5, 100 ohm

Maximum cable distance 100 meters

OmniSwitch 6600 Family Hardware Users Guide September 2006 page 2-13

Page 38

OmniSwitch 6600 Family Chassis and Hardware Components OmniSwitch 6602-24

35698

10

1

1

1

20

2

SEC

28

CLASS

UCT

252

S

C

1

S2

Sel

OK2

OmniSwitch 6602-24

The OS6602-24 is a stackable edge/workgroup switch offering 24 10/100 Ethernet ports. The OS6602-24

has Gigabit Ethernet ports for connections to a high speed backbone or server and two ports for stacking

switches.

The front panel of the OS6602-24 chassis contains the following major components:

• Console (RJ-45) port

• Stack indicator LED

• 24 10/100 Ethernet ports

• Two MiniGBIC Gigabit Ethernet uplink ports

• Two stacking ports

Refer to the illustration below for more front panel information. For detailed LED descriptions, refer to

page 2-18. For information on the chassis rear panel, refer to page 2-20.

10/100 Ethernet Ports

The OS6602-24 provides 24 10/100

Ethernet ports. These ports are

twisted-pair and are individually

configurable as 10BaseT or

100BaseTX. The ports use RJ-45

connectors.

Console Port

The OS6602-24 front panel provides one serial port for console

connections. Serial console connections are used by network

administrators for switch management. This female RJ-45 connector provides a DCE console

connection.

Status and Slot Indicator LEDs

For information on the OS6602-24’s

status and slot indicator LEDs, refer

to page 2-18.

Slot Selector Button

The slot selector button, located to

the right of the slot indicator LED,

is used to manually assign slot

numbers to switches in stacked

configurations. Refer to Chapter 4,

“Managing OmniSwitch 6600

Family Stacks,” for detailed infor-

mation.

3

7161514 211918

Gigabit Ethernet Uplink Ports

The OS6602-24 provides two MiniGBIC

Gigabit Ethernet slots. Refer to page 2-45 for

information on MiniGBIC types.

2 2324

Stacking Ports

The OS6602-24 provides two built-in stacking

ports. Refer to Chapter 4, “Managing

OmniSwitch 6600 Family Stacks,” for detailed

OmniSwitch 6602-24

TM

o

n

s

o

l

1 LASER PROD

PS1OK

P

6

27

tack

information on using these ports to stack switches

in a stack.

OmniSwitch 6602-24 Front Panel

OmniSwitch 6600 Family Hardware Users Guide September 2006 page 2-14

Page 39

OmniSwitch 6600 Family Chassis and Hardware Components OmniSwitch 6602-24

OS6602-24 Specifications

Total number of 10/100 Mbps

24

ports per switch

Total number of Gigabit

2

Ethernet ports per switch

Total number of 10/100 Mbps

192 (stack of eight switches)

ports per stack

Total number of Gigabit

16 (stack of eight switches)

Ethernet ports per stack

Fabric capacity 7.0 Gbps full duplex; 14 Gbps aggregate

Current draw Approximately 0.3 Amps @ 115VAC

Power Approximately 34 Watts @ 25C

Total available power supplies 2 (one factory-installed power supply and one optional backup power

supply)

Flash memory size 64 MB

RAM memory size 128 MB

Overall Width (rack-mount

18.95 inches

flanges included)

Chassis Width (rack-mount

17.25 inches

flanges not included)

Height 1.75 inches

Height (rack units) 1 RU

Chassis Depth 16.95 inches

Chassis Weight Approximately 11.9 lbs

Humidity 5% to 90% Relative Humidity (Operating)

0% to 95% Relative Humidity (Storage)

Altitude Sea level to 10,000 feet (3 km)