Page 1

Agilent L4400 Series

LXI Class C Instruments

User’s Guide

Agilent Technologies

Page 2

i

Page 3

Notices

CAUTION

WARNING

© Agilent Technologies, Inc. 2011, 2012

No part of this manual may be reproduced

in any form or by any means (including

electronic storage and retrieval or transla

tion into a foreign language) without prior

agreement and written consent from Agi

lent Technologies, Inc. as governed by

United States and international copyright

laws.

Manual Part Number

34989-90000

Edition

Fourth Edition. Sept. 2012

Printed in Malaysia

Agilent Technologies, Inc.

5301 Stevens Creek Blvd.

Santa Clara, CA 95052 USA

Warranty

The material contained in this document is provided “as is,” and is

-

subject to being changed, without

notice, in future editions. Further,

-

to the maximum extent permitted

by applicable law, Agilent dis

claims all warranties, either

express or implied, with regard to

this manual and any information

contained herein, including but not

limited to the implied warranties

of merchantability and fitness for a

particular purpose. Agilent shall

not be liable for errors or for inci

dental or consequential damages

in connection with the furnishing,

use, or performance of this docu

ment or of any information contained herein. Should Agilent and

the user have a separate written

agreement with warranty terms

covering the material in this docu

ment that conflict with these

terms, the warranty terms in the

separate agreement shall control.

Technology Licenses

The hardware and/or software described

in this document are furnished under a

license and may be used or copied only

in accordance with the terms of such

license.

than Limited Rights as defined in F A R

52.227-14 (June 1987) or DFAR

252.227-7015 (b)(2) (November 1995),

as applicable in any technical data

Safety Notices

-

A CAUTION notice denotes a hazard.

It calls attention to an operating procedure or practice that, if not correctly

performed or adhered to, could result

in damage to the product or loss of

important data. Do not proceed

beyond a CAUTION notice until the

-

indicated conditions are fully understood and met.

-

A WARNING notice denotes a hazard. It calls attention to an operating

-

procedure or practice, that, if not

correctly performed or adhered to,

could result in personal injury or

death. Do not proceed beyond a

WARNING notice until the indicated

conditions are fully understood and

met.

i

Restricted Rights Legend

If software is for use in the performance

of a U.S. Government prime contract or

subcontract, Software is delivered and

licensed as “Commercial computer soft

ware” as defined in DFAR 252.227-7014

(June 1995), or as a “commercial item”

as defined in FAR 2.101(a) or as

“Restricted computer software” as

defined in F AR 52.227-19 (June 1987) or

any equivalent agency regulation or con

tract clause. Use, duplication or disclosure of Software is subject to Agilent

Technologies’ standard commercial

license terms, and non-DOD Depart

ments and Agencies of the U.S. Government will receive no greater than

Restricted Rights as defined in FAR

52.227-19(c)(1-2) (June 1987). U.S.

Government users will receive no greater

-

-

-

Page 4

Additional Safety Notices

Alternating current

Frame or chassis

terminal

Standby supply. Uni t is

not completely

disconnected from ac

mains when switch is off

Caution, risk of

electric shock

Caution, refer to

accompanying

If you have questions about your shipment, or if you need information

about warranty, service, or technical support, contact Agilent

Technologies:

In the United States: (800) 829-4444

In Europe: 31 20 547 2111

In Japan: 0120-421-345

Or go to ww.agilent.com/find/assist for information on contacting

Agilent in your country of specific location. You can also contact

your Agilent Technologies Representative.

The following general safety precautions

must be observed during all phases of

operation of this instrument. Failure to

comply with these precautions or with

specific warnings or instructions elsewhere in this manual violates safety standards of design, manufacture, and

intended use of the instrument.

Technologies assumes no liability of the

customer’s failure to comply with the

requirements.

Agilent

General

Do not use this products in any manner

not specified by the manufacturer. The

protective features of this product may be

impaired if it is used in a manner not

specified in the operation instructions.

Before Applying Power

Verify that all safety precautions are

taken. Make all connections to the unit

before applying power.

Ground the Instrument

Do Not Modify the

Instrument

Do not install substitute parts or perform

any unauthorized modification to the

product. Return the product to an Agilent

Sales and Service Office for service and

repair to ensure that safety features are

maintained.

In Case of Damage

Instruments that appear damaged or

defective should be made inoperative and

secured against unintended operation

until they can be repaired by qualified

service personnel.

Safety Symbols

This product is provided with protective

earth terminals. To minimize shock hazard, the instrument must be connected to

the ac power mains through a grounded

power cable, with the ground wire firmly

connected to an electrical ground (safety

ground) at the power outlet. Any interruption of the protective (grounding)

conductor or

tive earth terminal wi

shock hazard that could result in personal

injury.

disconnection of the protec-

ll cause a potential

Do Not Operate in an

Explosive Atmosphere

Do not operate the instrument in the presence of flammable gases or fumes.

Do Not Remove the

Instrument Cover

Only qualified, service-trained personal

who are aware of the hazards involved

should remove instrument covers.

Always disconnect the power cable and

any external circuits before removing the

instrument cover.

ii

Page 5

Declaration of Conformity

Declarations of Conformity for this product and for other Agilent products may be downloaded from the Internet. There

are two methods to obtain the Declaration of Conformity:

• Go to http://regulations.corporate.agilent.com/DoC/search.htm . You can then search by product number to

find the latest Declaration of Conformity.

• Alternately, you can go to the product web page (www.agilent.com/find/L4400), click on the Document

Library tab then scroll down until you find the Declaration of Conformity link.

iii

Page 6

iv

Page 7

Contents

1 Introduction to the L4400 Series LXI Instruments

2 Software Installation and Configuration

Instrument Considerations 2

Environmental Operating Conditions 2

Electrical Operating Conditions 3

Interconnection Solutions Overview 4

Bench-Top Operation and Instrument Rack Mounting 5

Bench-Top Operation 5

Rack Mounting 5

Procedure 6

Applying Power 11

Connecting the Power Cord and Turning On the Instrument 11

Installing the Agilent IO Libraries and L4400 Instrument Drivers 14

Installing the Agilent IO Libraries 14

Installing the L4400 Instrument Drivers 15

Configuring the L4400 Instruments 17

Selecting a LAN Network 17

Connecting the LAN Cables 18

IP Addresses and Host Names 20

Configuring the LAN Interface 21

Identifying the Instruments 27

Using the Instrument Web Interface 28

LAN Configuration Command Summary 32

GPIB Configuration 33

Firmware Updates 39

Downloading the Update Utility and Firmware 39

Instrument Power-On and Default LAN Configuration States 45

LAN Reset (Default) Configuration 45

L4400 User’s Guide v

Page 8

3 Operating and Programming

L4400 Instrument Front Panel Overview 48

The LAN Reset Button 48

The Front Panel LEDs 48

L4400 Instrument Rear Panel Overview 50

L4400 Series Channel Addressing Scheme 52

Introduction to the SCPI Command Language 52

Syntax Conventions 53

Command Separators 54

Using the MIN and MAX Parameters 54

Querying Parameter Settings 54

Specifying Channel Lists and Scan Lists 55

L4400 SCPI Command Summary 55

L4400 Series Programming Examples 59

Modifying IVI-COM Examples (.NET) 59

Modifying IVI-C Examples 61

Modifying VISA and VISA COM Examples 62

Using L4400 Instruments in Agilent 34980A Applications 64

Analog Bus Applications 65

Environmental Operating Conditions 66

Electrical Operating Conditions 66

Safety Interlock 67

User-Defined Channel Labels 68

Scanning Applications 69

Rules for Scanning 69

Creating the Scan List 71

Trigger Count 75

Sweep Count 76

Channel Delay 77

Reading Format 79

Non-Sequential Scanning 79

Monitor Mode 80

Scanning with External Instruments 81

Alarm Limits 84

Viewing Stored Alarm Data 87

Using the Alarm Output Lines 88

vi L4400 User’s Guide

Page 9

Using Sequences 89

Defining a Sequence 90

Querying the Sequence Definition 93

Executing a Sequence 93

Executing a Sequence on an Alarm Condition 94

Deleting Sequences 95

Reading the List of Stored Sequences 95

Instrument State Storage 96

Error Conditions 97

Relay Cycle Count 98

Calibration Overview 98

4 L4421A 40-Channel Armature Multiplexer

Low Frequency Multiplexer Switch Instrument 100

L4421A Measurement Functions 100

L4421A SCPI Command Summary 101

L4421A Example Program Segments 103

L4421A 40-Channel Armature Multiplexer Hardware Description 104

L4421A Simplified Schematic 106

L4421A D-Sub Connectors 107

34921T Terminal Block 108

5 L4433A Dual/Quad 4x8 Reed Matrix

Matrix Switch Instrument 112

L4433A SCPI Command Summary 113

L4433A Example Program Segments 114

Linking Multiple L4433A Instruments 116

L4433A Dual/Quad 4x8 Reed Matrix Hardware Description 118

L4433A Simplified Schematic for Two-Wire Mode 120

L4433A D-Sub Connectors for Two-Wire Mode 121

34933T-001 Terminal Block for Two-Wire Mode 122

L4433A Simplified Schematic for One-Wire Mode 124

L4433A D-Sub Connectors for One-Wire Mode 125

34933T-002 Terminal Block for One-Wire Mode 126

L4400 User’s Guide vii

Page 10

6 L4437A General Purpose Switch

General Purpose Switch Instrument 128

L4437A SCPI Command Summary 130

L4437A Example Program Segments 131

L4437A 32-Channel General Purpose Switch Hardware Description 132

L4437A Simplified Schematic 132

L4437A D-Sub Connectors 133

34937T Terminal Block 134

7 L4445A Microwave Switch/Attenuator Driver

L4445A SCPI Command Summary 136

L4445A Microwave Switch/Attenuator Driver 138

Recommended Switches and Attenuators 141

Power Supplies 142

Channel Numbering 143

Simple Switch Control 144

Remote Module Identifiers 145

Drive Modes 145

Using Single Drive Switches and Attenuators 146

Using Dual Drive Switches and Attenuators 147

Using Pulse Drive 148

Long Execution Times 149

Verifying Switch State 149

LED Drive 151

Default and Reset States 152

Y1150A 155

Y1151A 159

Y1152A 164

Y1153A 169

Y1154A 174

Y1155A 179

Mounting the Remote Modules 187

SCPI Programming Examples 188

viii L4400 User’s Guide

Page 11

8 L4450A 64-Bit Digital I/O with Memory and Counter

L4450A SCPI Command Summary 192

L4450A 64-Bit Digital I/O with Memory and Counter 199

Basic Digital I/O Operations 200

Handshaking 203

Buffered I/O Operations 210

Interrupt Lines 213

Byte Ordering 214

Pattern Matching 215

Counter 216

Initiated Measurement Mode 217

Clock 218

L4450A D-Sub Connectors 218

34950T Terminal Block 221

9 L4451A 4-Channel Isolated D/A Converter with Waveform Memory

L4451A 4-Channel Isolated D/A Converter with Waveform Memory 224

L4451A SCPI Command Summary 226

L4451A Example Program Segments 228

L4451A Simplified Block Diagrams 231

L4451A D-Sub Connector Pinout 232

34951T Terminal Block 233

10 L4452A Multifunction Module with DIO, D/A, and Totalizer

L4452A Multifunction Module 236

Digital Input/Output 236

Totalizer Input 236

Analog Output (DAC) 236

L4452A SCPI Command Summary 237

L4452A Example Program Segments 241

L4452A Simplified Block Diagram 243

L4452A D-Sub Connector 244

34952T Terminal Block 245

L4400 User’s Guide ix

Page 12

A L4451A and L4452A Calibration Procedures

Calibration Procedures 248

Agilent Technologies Calibration Services 248

Calibration Interval 248

Time Required for Calibration 249

Automating Calibration Procedures 249

Recommended Test Equipment 249

Calibration Security 250

Calibration Message 251

Calibration Count 251

Calibration Process 252

Aborting a Calibration in Progress 252

Performance Verification Tests 253

L4451A and L4452A Performance Test Considerations 253

L4451A 4-Channel Isolated DAC Module 253

L4452A Multifunction Module 261

x L4400 User’s Guide

Page 13

Agilent L4400 LXI Class C Instruments

User’s Guide

1

Introduction to the L4400 Series

LXI Instruments

Instrument Considerations 2

Interconnection Solutions Overview 4

Bench-Top Operation and Instrument Rack Mounting 5

Applying Power 11

Welcome. The products covered in this user’s guide represent the Agilent

L4400 Series of LXI Class C instruments. LXI, an acronym for LAN

eXtensions for Instrumentation, is an instrumentation standard for

devices that use the Ethernet (LAN) as their primary communications

interface.

The L4400 series family of instruments provide switching and

multifunction test capabilites for design verification, automated test, and

data acquisition applications. The instruments include:

• L4421A 40- Channel Armature Multiplexer Module

• L4433A Dual/Quad 4x8 Reed Matrix Module

• L4437A 32- Channel General Purpose Switch Module

• L4445A Microwave Switch/Attenuator Driver Module

• L4450A 64- Bit Digital I/O Module with Memory and Counter

• L4451A 4- Channel Isolated D/A Converter w/ Waveform Memory

Module

• L4452A Multifunction Module

This chapter contains general information on instrument environmental

and electrical operating conditions, instrument interconnections, and rack

mounting instructions. The chapter also contains information on applying

power.

Agilent Technologies

1

Page 14

1 Introduction to the L4400 Series LXI Instruments

Instrument Considerations

This section lists important items and actions that can affect the

operation of your modules.

Environmental Operating Conditions

The L4400 Series LXI modules are designed to operate in a temperature

range of 0 °C to +55 °C with non- condensing humidity. The maximum

hu

midity is 80% at 40 °C or higher. Do not use in locations where

conductive dust or electrolytic salt dust may be present.

The modules should be operated in an indoor environment where

emperature and humidity are controlled. Condensation can pose a

t

potential shock hazard. Condensation can occur when the modules are

moved from a cold to a warm environment, or if the temperature and/or

humidity of the environment changes quickly.

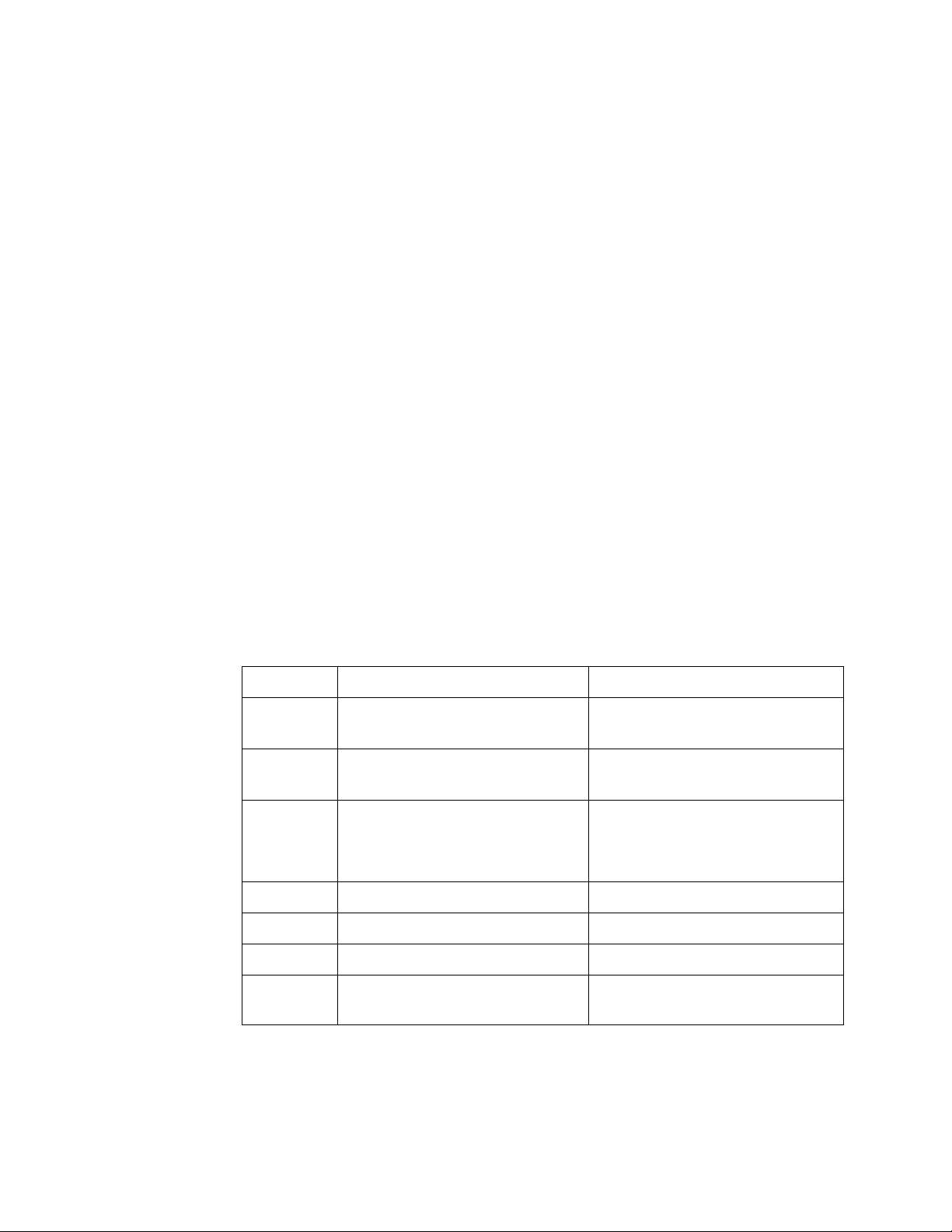

The following table shows maximum voltage ratings for each module.

If conditions change, ensure that condensation has evaporated and the

ument has thermally stabilized until pollution degree 1 conditions

instr

are restored before turning on power to the equipment.

Table 1-1. L4400 Series LXI Instrument Voltage Ratings.

Instrument

L4421A 40 channels, 300V rms or DC, 1A,

L4433A Dual/quad 4x8 matrix, 150 Vpeak,

L4437A

L4445A See Chapter 7 - L4445A See Chapter 7 - L4445A

L4450A 64 channels, 5V, 30 mA Max 64 channels, 5v, 30 mA Max

L4451A 4 channels 16V, 20 mA 4 channels, 16V, 20 mA

L4452A 32 DIO channels, 42V, 400 mA,

Pollution Degree 1 Specific ations Pollution Degree 2 Specifications

40 channels, 100V rms or DC, 1A,

60 VA/channel

0.5A, 10

28 channels, 300 V rms or DC, 1A,

60

4 channels, 250 V rms or 30 VDC,

5A, 150 VA per channel

2 channel DAC, 12V, 10 mA

VA/chann el

VA per channel

60 VA/channel

Dual/quad 4x8 matrix, 100 Vpeak,

.5 A, 10 VA per channel

0

28 channels, 100 V rms or DC, 1A,

60 VA per channel

4 channels, 100 V rms or 30 VDC,

5A, 150 VA per channel

32 DIO channels, 42V, 400 mA,

2 channel DAC, 12V, 10 mA

2 L4400 User’s Guide

Page 15

Pollution Degree 1: No pollution or only dry, non-conductive

NOTE

NOTE

WARNING

CAUTION

pollution occurs. The pollution has no influence (on insulation)

(IEC 61010-1 2nd Edition).

Pollution Degree 2: Normally only non-conductive pollution

occurs. Occasionally, a temporary conductivity (leakage current

between isolated conductors) caused by condensation can be

expected (IEC 61010-1 2nd Edition).

Electrical Operating Conditions

To avoid electric shock, turn off the L4400 instrument and

disconnect or de-energize all field wiring to the instrument

and to the analog bus connector (if present) before removing

any terminal block covers.

Introduction to the L4400 Series LXI Instruments 1

Transients

The L4421A, L4433A, and L4437A modules are designed to safely

withstand occasional transient overvoltages up to 1000 Vpeak. Typically,

these transient overvoltages result from switching inductive loads or from

nearby lightning strikes. The lightning- caused transient overvoltages that

may occasionally occur on mains power outlets may be as high as 2500

Vpeak.

The L4445A, L4450A, L4451A, and L4452A modules are intended for only

w- voltage applications, and should not be connected to circuits that

lo

may generate or conduct large transient voltages.

High Energy Sources

These instruments are designed to handle inputs up to their rated

currents or their rated powers, whichever is less. Under certain fault

conditions, high energy sources could provide substantially more current

or power than a module can handle. It is important to provide external

current limiting, such as fuses, if the instrument inputs are connected to

high- energy sources.

Install current limiting devices between high energy sources and

the module inputs.

L4400 User’s Guide 3

Page 16

1 Introduction to the L4400 Series LXI Instruments

Interconnection Solutions Overview

Depending on your specific requirements, you can connect your DUT

to the L4400 LXI instrument using the following optional interconnection

solutions. See the L4400 series Product Data Sheets for additional

information. The data sheets can be located on the Web at:

www.agilent.com/find/L4400

Ter mi na l B lo ck s Detachable terminal blocks are available for most of the

L4400 series instruments and offer a flexible method for connecting

external wiring (300V rated). Each terminal block is customized for a

specific module.

Ordering Information: 349xxT(e.g., 34921T, 34937T, etc.)

Shielded Cables Standard cables are available for 50- pin D- sub and

78- pin D- sub connectors. Depending on the module and your specific

requirements, one or two cables may be required per module.

Ordering Information:

Y1135A (1.5 meters, 50- pin D- sub, 300V)

Y1136A (3 meters, 50- pin D- sub, 300V)

Y1137A (1.5 meters, 78- pin D- sub, 300V)

Y1138A (3 meters, 78- pin D- sub, 300V)

Solder Cup Connector Kits These connector kits are available if you want to

build your own custom cables.

Ordering Information:

Y1139A (50- pin D- sub female, 125V, for L4421A/L4433A/L4437A)

Y1141A (50- pin D- sub male, 125V, for L4451A/L4452A)

Y1142A (78- pin D- sub male, 60V, for L4450A)

L4445A Remote (Extender) Modules and Distribution Boards These kits expand the

number of switches and attenuators controlled by the L4445A Microwave

Switch/Attenuator Driver instrument.

Ordering Information:

34945EXT (External Driver)

Distribution Boards:

Y1150A (Eight N181x SPDT switches)

Y1151A (Two 87104x/106x multiport or 87406B matrix switches)

Y1152A (One 87204x/206x or 87606B switch and two N181x switches)

Y1153A (Two 84904/5/6/7/8 or 8494/5/6 step attenuators)

Y1154A (Two 87222 transfer switches and six N181x SPDT switches)

Y1155A (Generic screw terminals for driving 16 switch coils

4 L4400 User’s Guide

Page 17

Introduction to the L4400 Series LXI Instruments 1

Bench-Top Operation and Instrument Rack Mounting

The L4400 series instruments can be located on a bench- top or rack

mounted in standard 19- inch EIA rack cabinets.

Bench-Top Operation

Cooling and ventilation of the L4400 series instruments are through the

sides of the instrument chassis. When placed on the bench- top, ensure

the sides of the instrument are not directly covered or blocked.

Rack Mounting

The L4400 instruments are mounted in EIA rack cabinets using the

Y1160A rack mount kit. The kit allows you to mount one or two L4400

instruments side- by- side on a sliding shelf, while occupying one EIA rack

unit of space.

Rackmounting instructions are provided with the kit and are also

ovided here.

pr

Rack Mounting Kit Contents

The contents of the Y1160A sliding shelf rack mount kit are listed in

Table 1- 2.

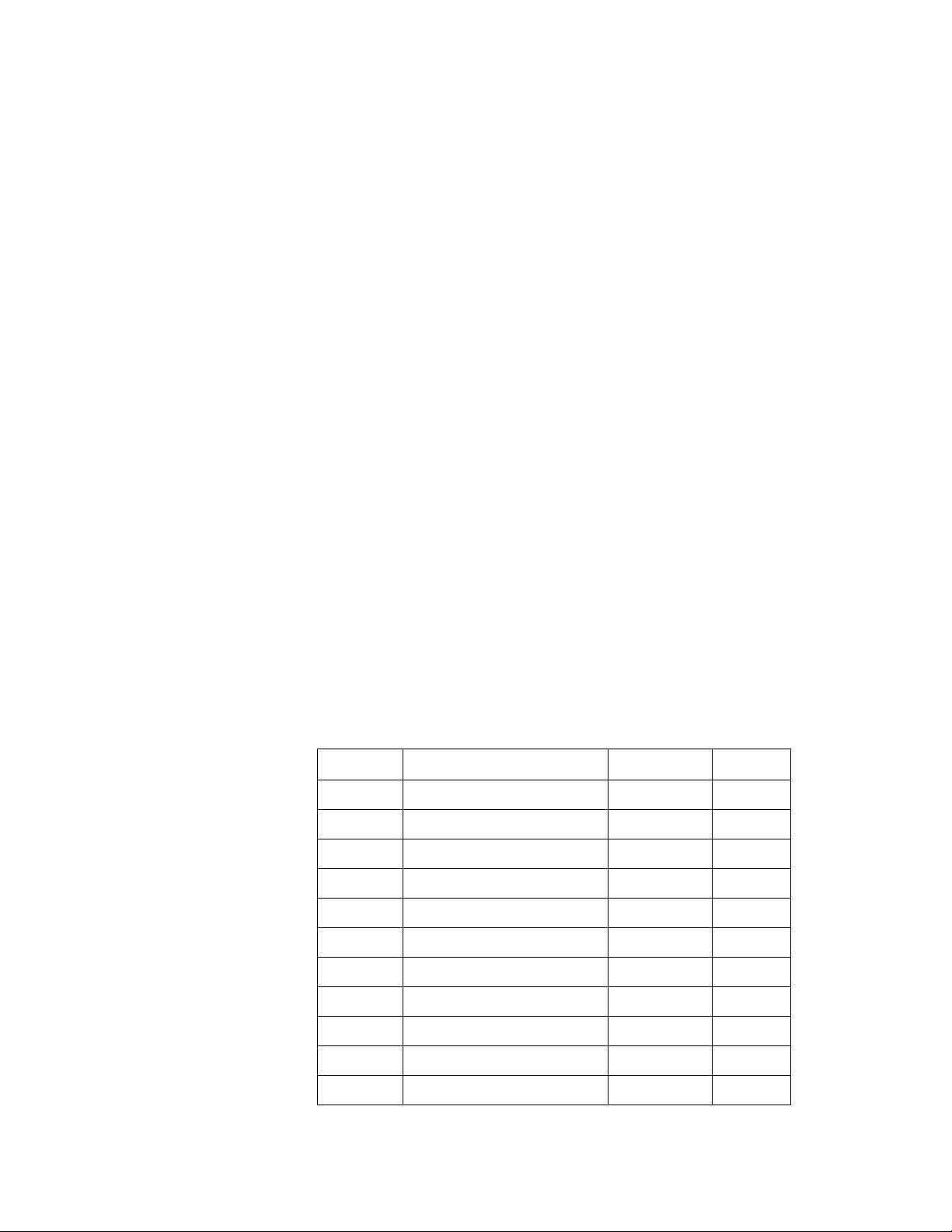

Table 1-2. L4400 (Y1160A) Rack Mount Kit Contents.

Item Description

1 M4x8 flat head screw 1515-1367 12

2 10-32 pan head dress screw 0570-1577 4

3 10-32 x 0.625 pan head screw 2680-0105 10

4 10-32 x 0.5 flat head screw 2510-0283 2

5 10-32 clip-on nut 0590-0804 12

6 10-32 nut w/lock washer 2740-0003 4

7 Sliding shelf 5180-0102 1

8 Shelf rails 5180-0103 2

Part Number Quantity

9 Filler panels 5180-0104 2

10 Rear (rail) brackets 5180-0105 2

--- Installation Instructions Y1160-90030 1

L4400 User’s Guide 5

Page 18

1 Introduction to the L4400 Series LXI Instruments

1

2

3

4

5

6

7

8

9

10

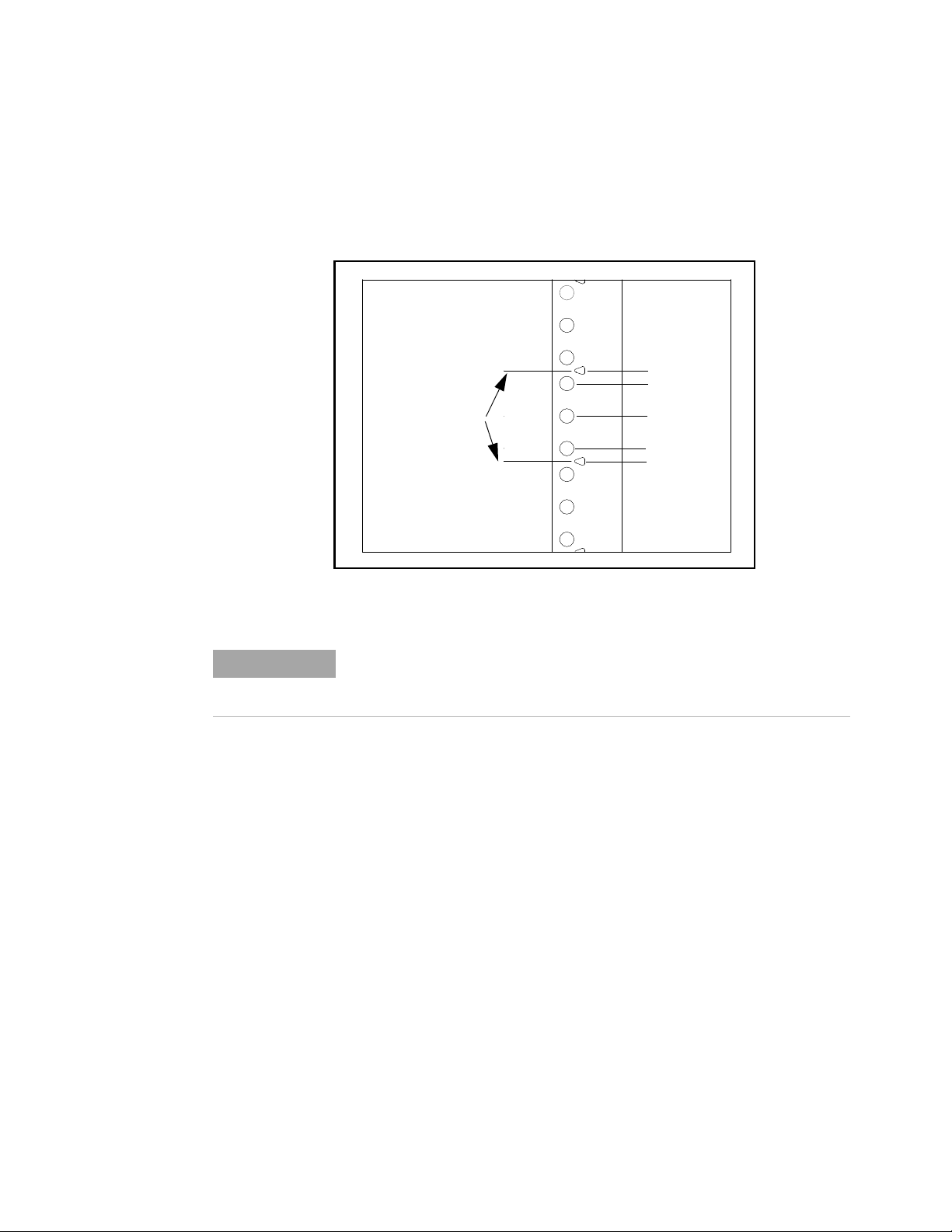

Procedure

Figure 1- 1 is a composite drawing of the Y1160A sliding shelf rack

mount kit. The drawing shows the location/usage of the hardware items

listed in Table 1- 2.

Figure 1-1. Y1160A Instrument Rack Mount Kit (L4400 Series).

6 L4400 User’s Guide

Page 19

Introduction to the L4400 Series LXI Instruments 1

EIA unit indicators

(1 EIA unit)

44.45 mm

(1.75 in)

6.35 mm

15.875 mm

15.875 mm

6.35 mm

NOTE

The L4400 instrument(s) can be mounted between any two adjacent EIA

unit indicators (Figure 1- 2). On Agilent racks, an EIA unit indicator is

represented by a triangle (

) on the rack’s front and rear-facing

columns. A single EIA unit extends from the triangle indicator to the

next indicator on the column (1 Unit = 44.45 mm = 1.75 in).

Figure 1-2. EIA Unit Indicators for Installing the Y1160A Rack Mount Kit.

It is not necessary to remove the cabinet side panels to rack mount the

L4400 instruments. The side panels can be removed, however, if

additional access to the cabinet’s vertical columns is desired.

Install the Shelf Rails

1. Select the vertical position in the rack between any two adjacent EIA

unit indicators where the L4400 instrument is to be installed. Insert

clip- on nuts (item 5) on the three holes between the unit indicators.

Place nuts on both the left and right front- facing columns (Figure 1- 3).

L4400 User’s Guide 7

Page 20

1 Introduction to the L4400 Series LXI Instruments

(center of rack)

front-facing columns

center-facing colums

back of rack

insert clip nuts

between rack unit

indicators

insert clip nut

if column present

insert clip nuts

on first and third

holes between indicators

rail “channel

If center-facing columns with holes are present on the frame, insert a

clip- on nut on the hole perpendicular to the center hole on the front

facing column. See Figure 1- 3.

2. With the rail “channel” facing the cent

to the front facing column using a 10- 32 flathead screw (item 4) and the

center clip- on nut on the front- facing column. Repeat for the rail on the

opposite column. Ensure the rail channel faces the center of the rack.

If the rack has center- facing columns (Figure 1- 3), insert a 10- 32 pan

head sc

front- facing column). Repeat for the rail on the opposite column.

3. On the rack’s rear-facing columns, insert clip-on nuts on the first and

hird holes between the EIA unit indicators that are at the same vertical

t

position as the indicators on the front- facing columns.

4. Attach the rear brackets to the rail ends using tw

screws (item 3) and two 10-32 nuts with lockwashers (item 6) per rail.

Adjust the bracket along the rail until the bracket end aligns with

(covers) the rack’s rear- facing columns. Tighten the 10- 32 pan head

screws to firmly connect the bracket to the rail and maintain the rail

length.

Connect the rail brackets to the rear-facing columns using two 10- 32 pan

ad screws per column.

he

Figure 1-3. Rack Column and Shelf Rail Orientation.

er of the rack, connect the rail

rew through the rail opening and clip nut (perpendicular to the

o 10- 32 pan head

8 L4400 User’s Guide

Page 21

Introduction to the L4400 Series LXI Instruments 1

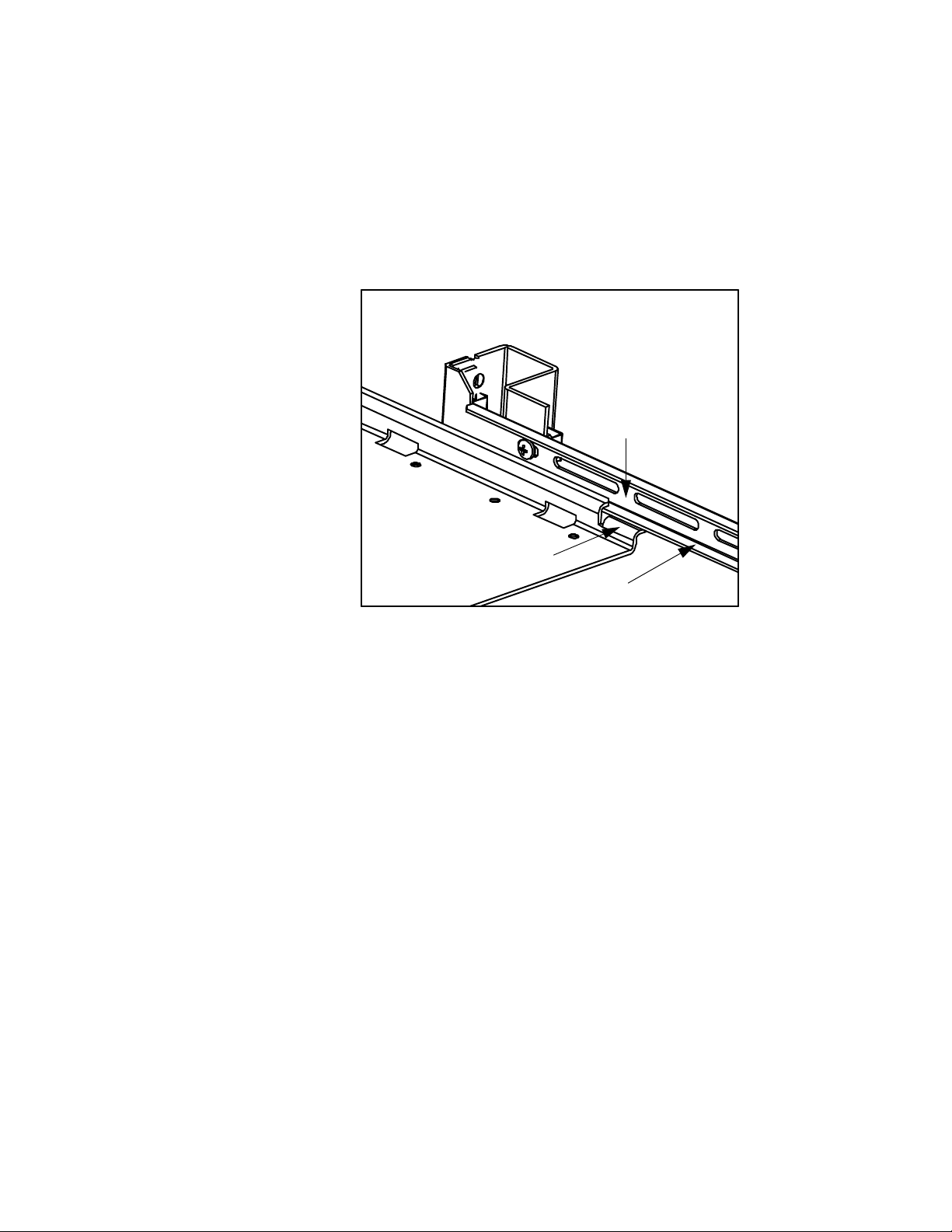

Rail channel

Shelf tab

Bottom surface

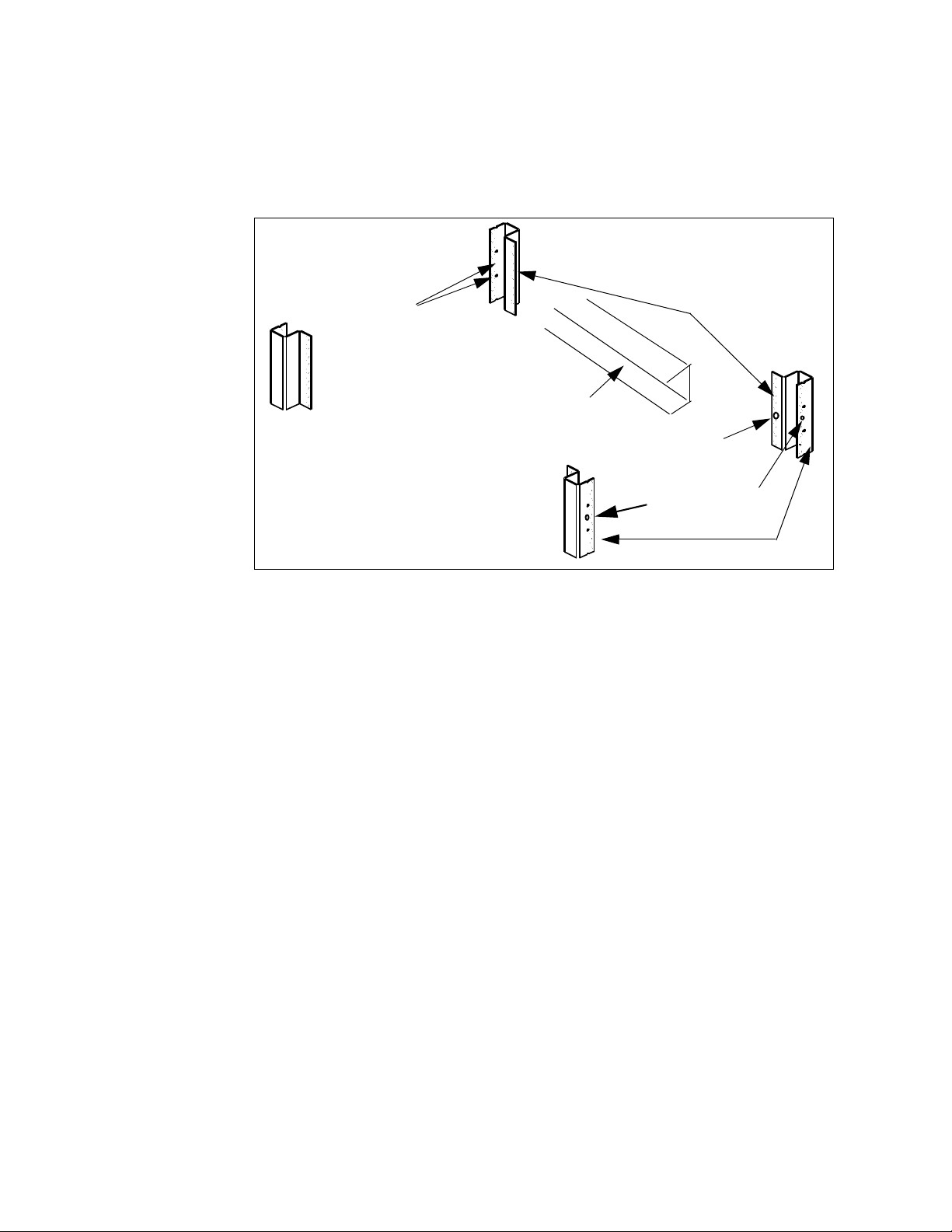

Install the Sliding Shelf

Facing the rack, slide the shelf (item 7) onto the bottom surfaces of the

rail channels. The tabs at the back of the shelf pass underneath the

channel surface. The tabs allow you to extend the shelf from the cabinet,

thus providing a working surface for mounting the instruments.

Figure 1-4. Installing the Shelf.

Install Instruments on the Shelf

The L4400 instruments can be installed flush (even) with front edge of

the shelf, recessed in 50 mm increments, or reverse-mounted with the

front of the instrument facing the back of the rack cabinet.

1. Extend the shelf from the rack such that approximately 50% - 75% of

he shelf surface is outside of the rack. (The tabs on the back of the

t

shelf that run underneath the rail channel prevent the shelf from

tipping.)

2. Determine the position of the instruments (flush, recessed, reversed).

o accommodate the terminal blocks (available with some of the L4400

T

instruments) and to simplify cable routing, it is recommended that the

instruments be mounted flush (even) with the front or back edge of the

shelf.

3. Note the location of the four mounting holes on the bottom of the

ument (Figure 1- 1). Set the carrier on the shelf, and align the

instr

mounting holes with the holes on the shelf. Insert four M4x8 flat head

screws (item 1) upward through the bottom of the shelf and into the

carrier mounting holes.

L4400 User’s Guide 9

Page 22

1 Introduction to the L4400 Series LXI Instruments

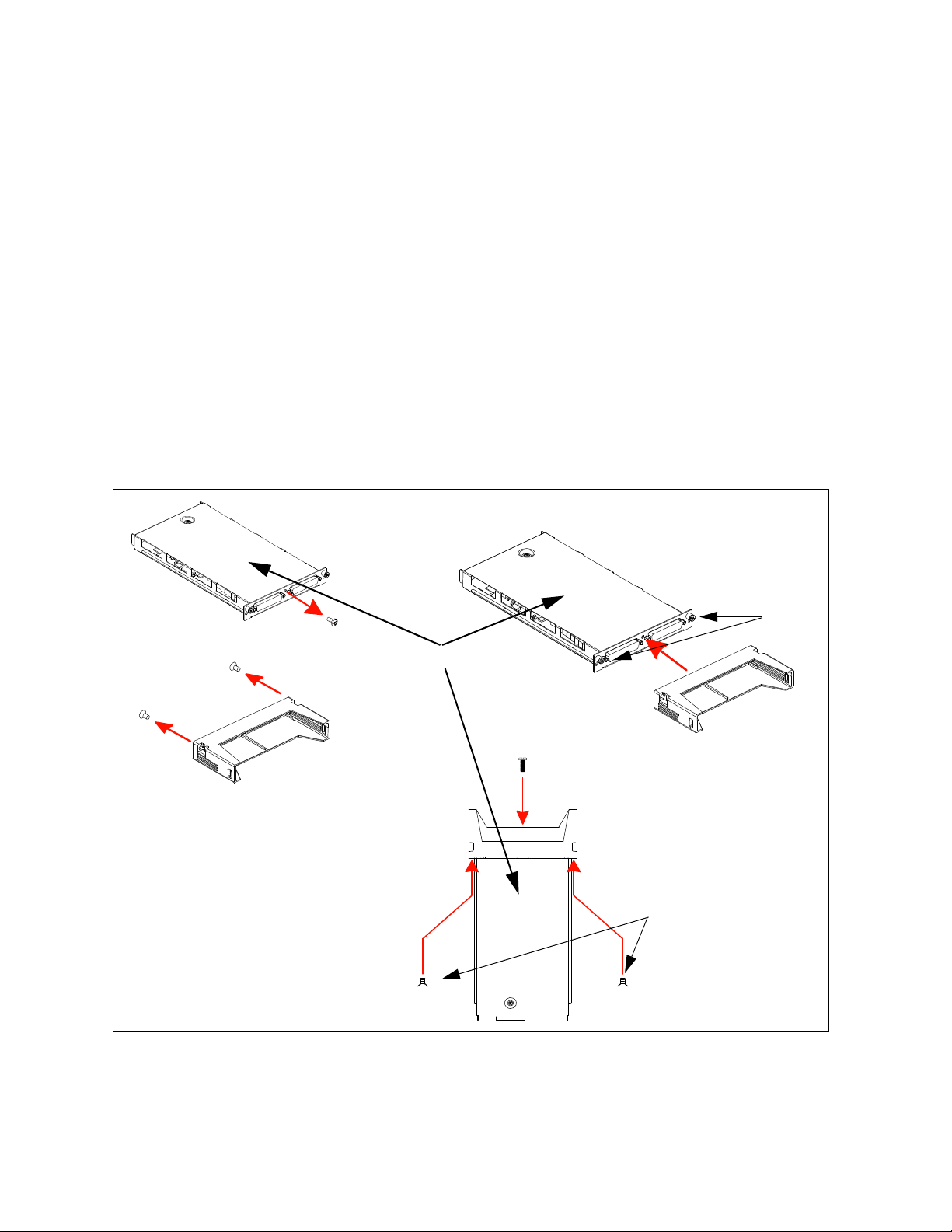

terminal block

flat head screws

support sleeve

pan head screw

pan head screw

flat head screws

spring-loaded

mounting screws

instrument sub-assembly

4. Install the second L4400 instrument (if present) in the shelf area

adjacent to the first instrument. If only one instrument is installed,

install a filler panel on the front edge of the unused area. Insert two

M4x8 flat head screws (item 1) upward through the bottom of the shelf

and into the panel.

5. Connect the instrument power cord, LAN cable, and GPIB cable if

esent.

pr

6. For instruments that have accompanying terminal blocks, partially

move the instrument sub- assembly from the instrument (carrier) by

re

loosening the spring- loaded mounting screws (Figure 1- 5). Remove the

support sleeve from the terminal block. Locate and remove the flat head

screws from the sleeve and remove the pan head screw from between the

instrument’s D- sub connectors (Figure 1- 5). Connect the sleeve to the

instrument using the flat head and pan head screws as shown. Reconnect

the sub- assembly.

10 L4400 User’s Guide

Figure 1-5. Connecting the Terminal Block Support Sleeve.

Page 23

Connect the Shelf to the Rack Frame

NOTE

Once the instruments are installed and all power cords and cables are

routed as intended, slide the shelf into the cabinet until the shelf handles

meet the front- facing columns of the rack frame. Using two10- 32 pan

head dress screws (item 2) per column, secure the shelf to the frame.

Applying Power

The input power, operating environment, and storage environment

specifications for the L4400 series instruments are listed in Table 1- 3.

Refer to the instrument data sheets for a complete listing of instrument

specifications. The data sheets can be found on the Web at:

Introduction to the L4400 Series LXI Instruments 1

Refer to Chapters 4-10 for information on Terminal Block wiring and

connecting the terminal block to the instrument.

www.agilent.com/find/L4400

Table 1-3. Agilent L4400 Series Instrument Input Power Specifications.

Instrument Description

L4421A

L4433A

L4437A

L4445A

L4450A

L4451A

L4452A

Power Supply:

Power Line Frequency:

Power Consumption: 50VA

Operating Environment:

Storage Environment:

Universal 100V to 240V

50Hz to 60Hz

Full accuracy for 0

Full accuracy to 80% R.H. at 40

C to 70C

-40

±10% auto sensing

C to 55C

Connecting the Power Cord and Turning On the Instrument

Connect the power cord supplied with the instrument or a power cord

rated for the conditions listed in Table 1- 3 to the electrical outlet and to

the instrument.

Turn the instrument on (and off) by pressing the power button shown in

igure 1- 6.

F

±10%

C

L4400 User’s Guide 11

Page 24

1 Introduction to the L4400 Series LXI Instruments

Power Button

Refer to Table 3- 1 (Chapter 3) for definitions of the LEDs (ATTN, LAN,

PWR) on the L4400 instrument front panel.

Figure 1-6. Location of the L4400 Series Instrument Power Button.

12 L4400 User’s Guide

Page 25

Agilent L4400 LXI Class C Instruments

User’s Guide

2

Software Installation and Configuration

Installing the Agilent IO Libraries and L4400 Instrument Drivers 14

Configuring the L4400 Instruments 17

GPIB Configuration 33

Firmware Updates 39

Instrument Power-On and Default LAN Configuration States 45

This chapter contains the software installation and configuration

procedures required for you to use the L4400 series instruments. Also

included are procedures for configuring the LAN and (optional) GPIB

interfaces, and for testing the communication (IO) paths to the

instruments.

Agilent Technologies

13

Page 26

2 Software Installation and Configuration

Installing the Agilent IO Libraries and L4400 Instrument Drivers

Communication and control of the L4400 series instruments from a

Microsoft® programming environment is provided through the following

software that is included with the L4400A instruments:

gilent E2094A IO Libraries Suite 14.1

• A

• A

gilent L4400A Product Reference CD-ROM (p/n 34989- 13601)

This section covers the sequence and procedures for installing the IO

raries and instrument drivers required to program the instruments.

lib

Installing the Agilent IO Libraries

The Agilent IO Libraries Suite must be installed first, followed by the

L4400 instrument drivers that are located on the Product Reference

CD- ROM (p/n 34989- 13601). The IO Libraries are contained on the Agilent

Automation- Ready CD included with the instrument, or may be downloaded from the Agilent website at h

ttp://www.agilent.com/find/iosuite.

Before installing the IO libraries, review table 2-1 to verify that your computer meets the specifications required by the software.

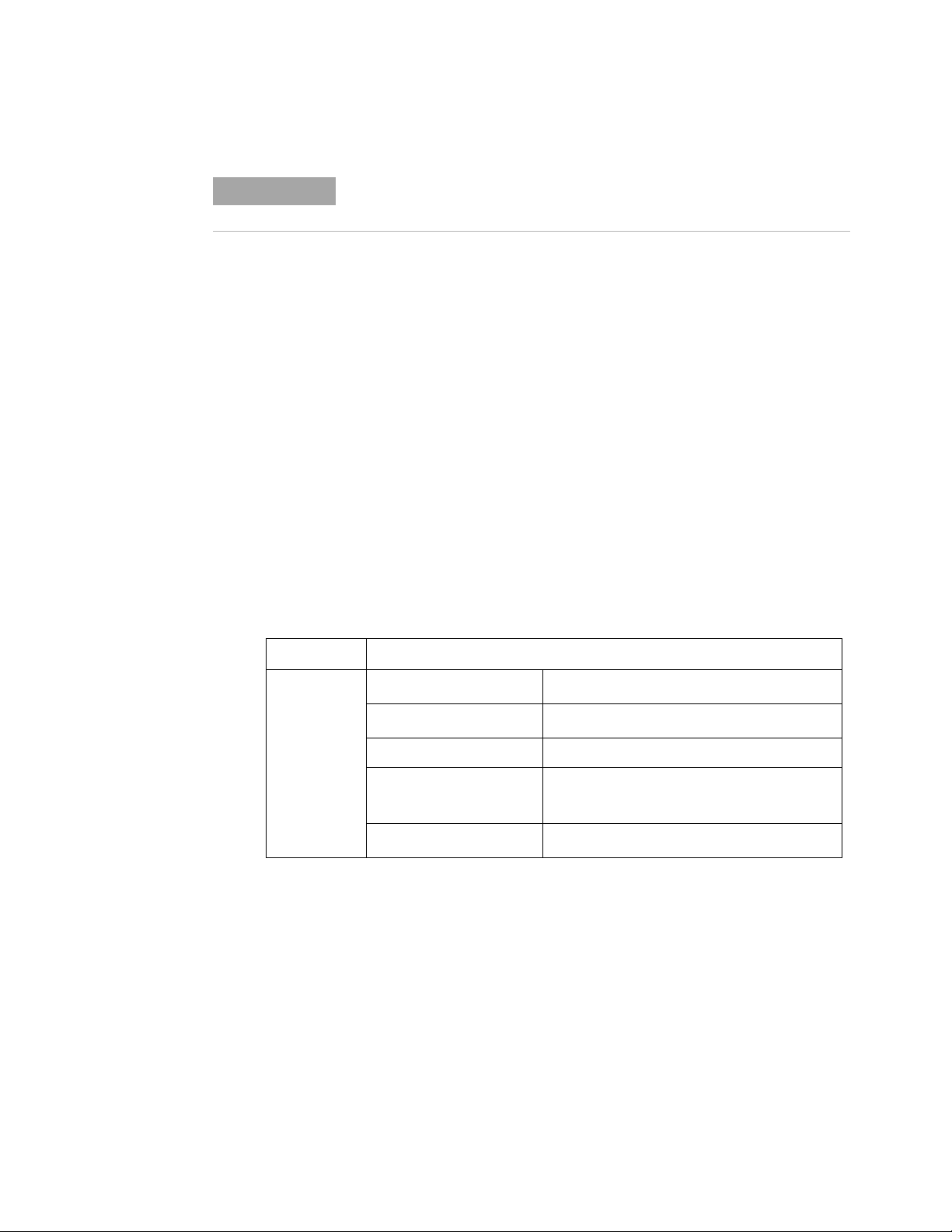

Table 2-1. Agilent IO Libraries Suite System Requirements.

Processor 450 MHz Intel Pentium® II or higher

Operating System Windows XP Professional or Home Edition (Service Pack 1 or

later

Windows 2000 Professional (Service Pack 4 or later)

Web Browser Microsoft Internet Explorer 5.01 or greater (recommended)

Available Memory 128 MB (256 MB or greater recommended)

Available Disk Space 225 MB required for installation:

- 160 MB for Microsoft .NET Framework

- 65 MB for Agilent IO Libraries Suite

175 MB required for operation:

- 110 MB for Microsoft .NET Framework

- 65 MB for Agilent IO Libraries Suite

Video Super VGA (800x600) with 256 colors

14 L4400 User’s Guide

Page 27

Software Installation and Configuration 2

NOTE

NOTE

Close all applications on your computer. Insert the Agilent

Automation- Ready CD into the CD-ROM drive. Follow the instructions as

prompted during the installation. Accept all default directories specified.

If the IO libraries installation does not start automatically, select St

Run from the Windows Start menu and type <drive>:\autorun\auto.exe

where <drive> is the designator of the CD- ROM drive.

If another vendor’s implementation of VISA (Virtual Instrument

Software Architecture) is currently installed on your computer, contin ue

installation of the Agilent IO Libraries by installing Agilent VISA in

side-by-side mode. More information on side-by-side operation can be

found in the Agilent IO Libraries Suite Help (available after installation

is complete) under “Using Agilent VISA with Another Vendor’s VISA.

Installing the Agilent IO Libraries also installs the Interchangeable

Virtual Instrument (IVI) Shared Components. The IVI Shared

Components are required before IVI drivers (e.g. IVI-COM, IVI-C) can

be installed (see “Installing the L4400 Instrument Drivers”).

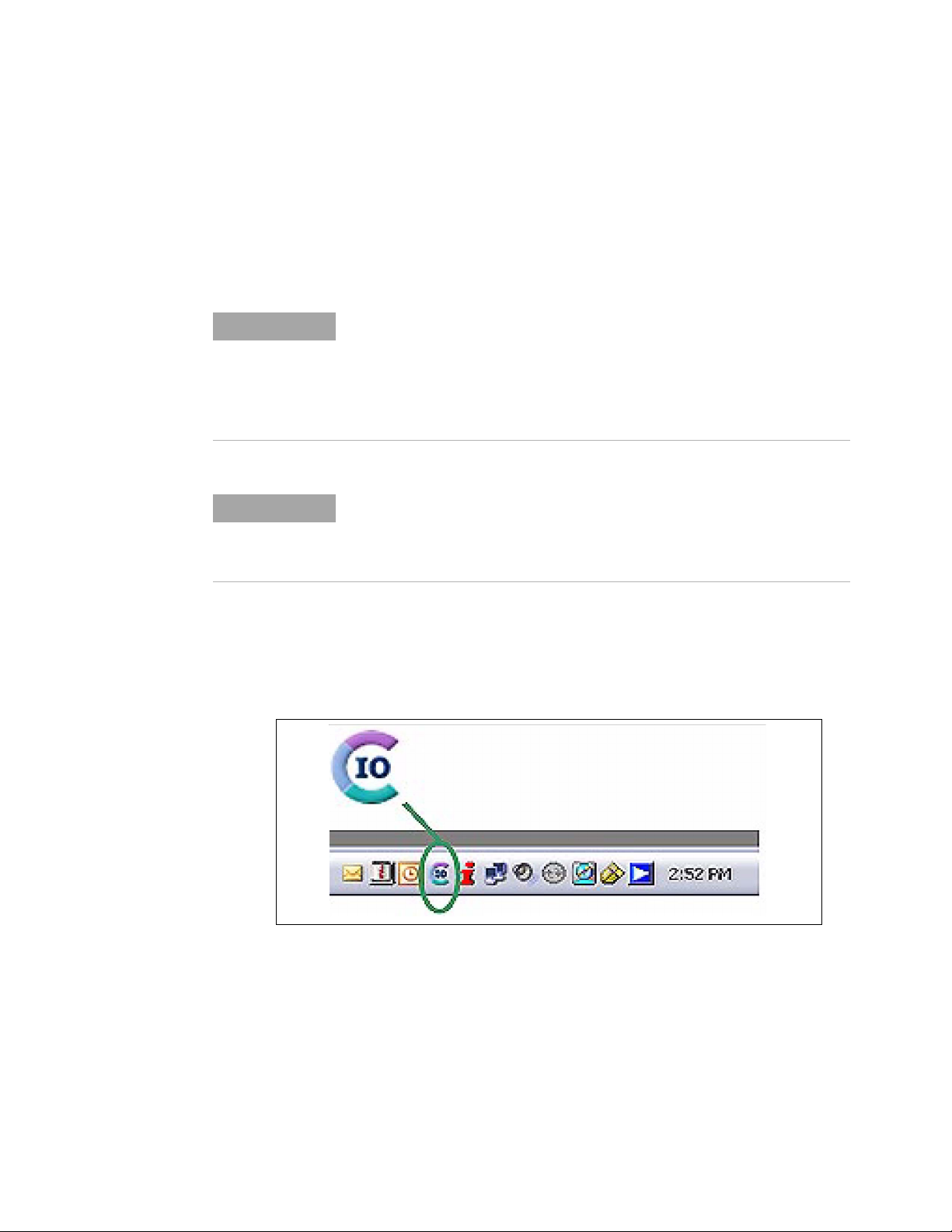

After the IO libraries have been successfully installed, you will see the

Agilent IO Control (IO icon) in the taskbar notification area of your

computer screen (Figure 2- 1).

art >

Figure 2-1. Agilent IO Control Icon.

Installing the L4400 Instrument Drivers

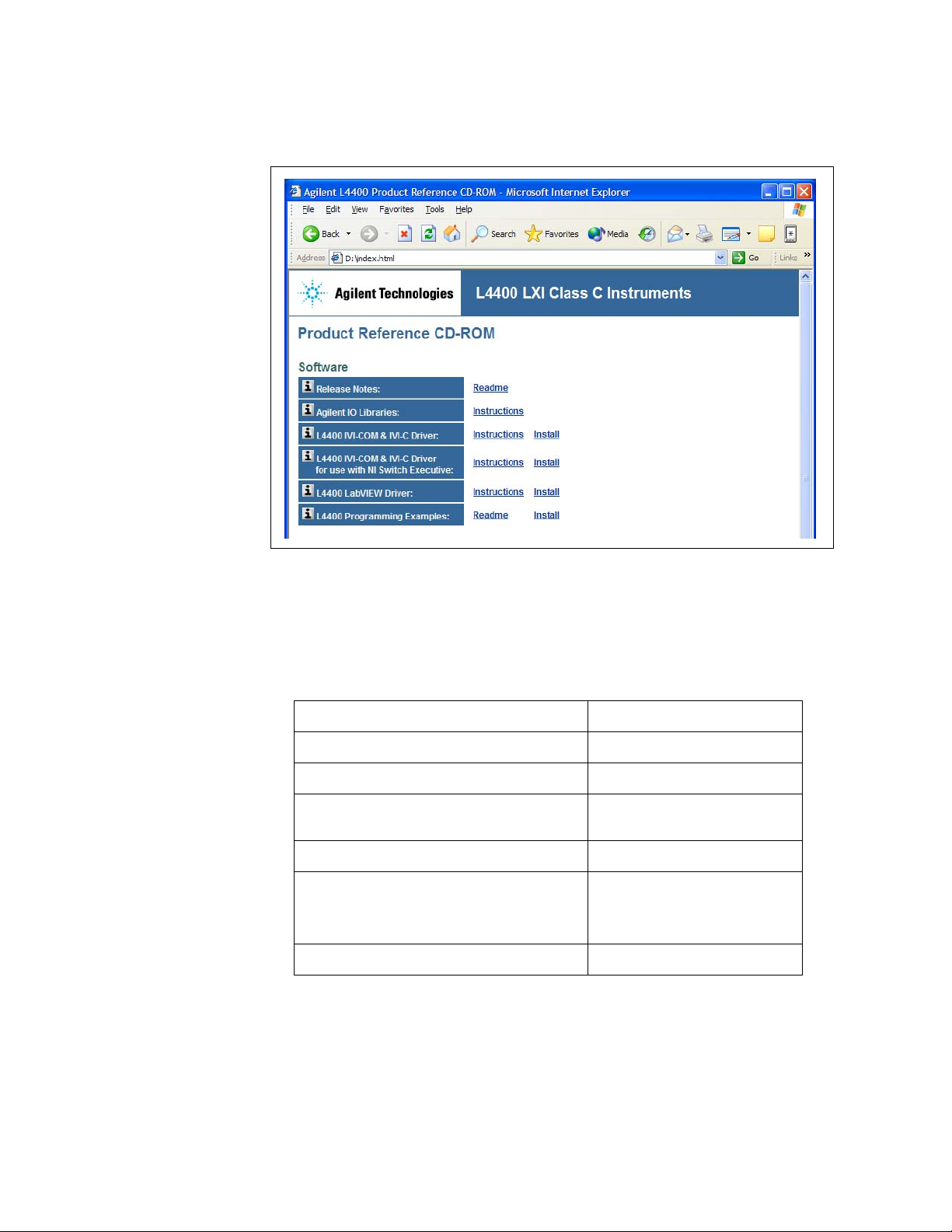

Insert the L4400 Product Reference CD-ROM into the computer. The installation program will open the menu window shown

automatically , select Start -> Run -> Open: <cd-rom drive>:\index.html.

L4400 User’s Guide 15

in Figure 2-2. If the program does not start

Page 28

2 Software Installation and Configuration

Figure 2-2. L4400 Product Reference CD-ROM Software (Driver) Menu

Install the appropriate driver from the menu based

on the environment you will use to

program the L4400 instruments. Table 2-2 contains a list of common environments and

corresponding drivers. Accept all default directories specified during installation.

Table 2-2. L4400 Programming Environments and Recommended Drivers

Programming Environment

Microsoft® Visual C 6.0 Visual C++, ANSI C

Microsoft® Visual Basic 6.0

Microsoft Visual Studio .NET for C#, C,

isual Basic

V

Agilent VEE

National Instruments LabVIEW

National Instruments LabWindows/CVI

Recommended Drivers

IVI-C, IVI COM, VISA

IVI-COM, VISA, VISA-COM

IVI-COM

IVI-COM

LabVIEW Plug&Play (with

44XX native mode driver),

L

IVI-C

IVI-C

For information on firmware updates that may be available after purchase,

refer to “Firmware Updates” at the end of this chapter.

16 L4400 User’s Guide

Page 29

Configuring the L4400 Instruments

Instrument configuration as applied to the L4400 series of LXI instruments involves the following:

• identifying the IP address and host name (LAN programming)

• (optional) setting the GPIB address

• testing the communication paths (LAN and/or GPIB) to the instrument

• opening the Web interface to the instrument

Each task listed above is accomplished using the Agilent Connection

Expert Feature of the Agilent IO Libraries Suite.

The information included this section of the chapter is:

Software Installation and Configuration 2

• Selecting a LAN Network

• Connecting the LAN Cables

• Configuring the LAN Interface

• GPIB Configuration

Selecting a LAN Network

This user’s guide defines a private (isolated) LAN as a network in which

instrument access is limited to a direct connection between the computer

and the instrument, or to multiple instruments connected via a dedicated

router or switch. A site (company- wide) LAN is defined as a network in

which instrument access is available to many users in on- site and remote

locations.

The instrument’s application and/or your company’s Information

Technology (IT) department may have guidelines that help decide the type

(private or site) of network used. If a network configuration has not been

determined, refer to the following considerations concerning each type.

Private LAN Considerations

Some of the basic parameters of a private LAN network to consider are:

security, performance, reliability, and IP address availability.

L4400 User’s Guide 17

Page 30

2 Software Installation and Configuration

Security: a private network generally involves direct connections between

the computer and the instruments, and may include switches and routers.

Access to the instrument is limited to users connected directly to the

private network, as opposed to users on a site network that could locate

and access the instrument from any location - possibly disrupting tests in

progress. Code generation for test systems on a private network is often

simplified as protection against unauthorized users may not be required.

Performance: test systems where large amounts of data are transferred

usually have faster throughput on a private network. On a site network,

heavy and unpredictable LAN traffic (lots of data) affects each instrument

(node) on the network. The impact on a test system is that repeatability is

difficult to achieve as latencies are difficult to account for.

Reliability: private networks are fundamentally more reliable than site

networks as they host fewer users and are less complex than site

networks. Private networks are isolated from conditions that could bring

down (crash) a site network.

IP Address Availability: Every instrument (node) on a LAN (private or

site) has an IP (Internet Protocol) address. Due to the expanding use of

the internet, the number of site network IP addresses available is limited.

By using a router with Dynamic Host Configuration Protocol (DHCP)

capability on a private network, the router can assign an IP address to

each instrument thus creating a sub- network (subnet) that does not

consume site IP addresses.

Site LAN Considerations

For applications requiring access by many users or by users at distributed

sites, a site LAN network is required. In addition to supporting multiple

users, site LANs often offer the advantage of being maintained by IT

departments.

When using a site LAN, consult your IT department regarding all LAN

configuration and security issues.

Connecting the LAN Cables

LAN cables are connected to the LAN terminal on the instrument, the

computer, and to the router or switch if they are part of your network.

18 L4400 User’s Guide

Page 31

Software Installation and Configuration 2

Router / Switch

Connection

Ethernet Hub / Switch / Router

Direct

Connection

CAT5 Crossover Cable

PC

Typical Private (isolated) LAN Networks

PC

L4400

L4400 L4400 L4400 L4400

Private Network Connections

Figure 2- 3 shows typical LAN cable connections for a private network.

When making a direct connection betw

PC, use the LAN crossover cable provided with the instrument. Note, if

your computer supports Auto- MDIX or contains a LAN card with gigabit

data transfer rates, the crossover cable is not required. A standard LAN

cable can be used instead. For private LAN networks that include a switch

or router, use standard LAN cables for network connections. Do not use

the crossover cable.

Once the LAN cables are connected, you can turn on the L4400

instr

Figure 2-3. Typical Private LAN Network Connections.

een the L4400 instrument and the

ument(s).

L4400 User’s Guide 19

Page 32

2 Software Installation and Configuration

Router / Switch

Connection

PC

Ethernet Hub / Switch / Router

standard LAN cable

PC

To Site LAN

To Site L AN

Typical Site LAN Networks

L4400

L4400

L4400 L4400

L4400

Site Network Connections

Figure 2- 4 shows typical LAN cable connections for a site network.

Figure 2-4. Typical Site LAN Network Connections.

On site networks, the L4400 instruments and the computer are connected

irectly to site LAN ports, or are connected to the site LAN through a

d

switch. In each site network configuration, standard LAN cables are used.

Once all LAN cables are connected, turn on the L4400A instrument.

IP Addresses and Host Names

Dynamic Host Configuration Protocol (DHCP) and Automatic IP are

enabled on each L4400 series instrument shipped from Agilent. This allows

the instrument to automatically obtain an address on the network. If there

is a DHCP server on the network, the server will assign the address to the

instrument.

If there is not a DHCP server on the network, the L4400 instrument will

utomatically determine an address to use. The address will be in the

a

range of 169.254.xxx.xxx. If available, the instrument will try to acquire its

default setting of 169.254.44.88.

20 L4400 User’s Guide

Page 33

Software Installation and Configuration 2

NOTE

Host Names Each L4400 instrument has a default host name. The format

of the host name is:

A- L44xxA- yyyyy

where ‘L44xxA’ is replaced b

‘yyyyy’ are the last five digits of the instrument serial number.

The instrument host name is reported b

network servers that support Dynamic Domain Name Service (DNS). For

network servers that do not support Dynamic DNS, only the IP address is

reported.

y the module number (e.g. L4421A) and

y Agilent Connection Expert for

Instrument Addressing

During programming, an L4400 series instrument is accessed through its

address string which consists of an IP address or host name. For example:

TCPIP0::19

The L4400 series instruments can also be accessed using

part of the address string. For example:

TCPIP0::A-L44

2:168:1.221::inst0::INSTR

a host name as

50A-12345.agilent.com::inst0::INSTR

The L4400 instruments can be restored to their default conf igurations by

pressing the ‘Reset’ pin on the instrument’s front or rear panels.

Computer Configuration

Most computers used for instrument/system control are configured for

LAN and Internet access. Before starting Agilent Connection Expert to

locate and configure the instruments, verify that your computer is able to

connect to the network that will include the instruments.

A Web browser is used to open web interfaces to the L4400 instruments

e “Using the Instrument Web Interface”). In some network

(Se

configurations, a proxy server cannot be used to access the instrument IP

addresses. In these situations, the browser must be set to disable the

proxy for the instrument’s address.

Configuring the LAN Interface

With the L4400 instrument(s) turned on and connected to a private or site

LAN network, start Agilent Connection Expert utility by clicking on the

Agilent IO Control icon and selecting “Agilent Connection Expert from the

pop- up menu (Figure 2- 5).

L4400 User’s Guide 21

Page 34

Clicking the icon opens the

pop-up menu

2 Software Installation and Configuration

NOTE

The procedure for using Agilent Connection Expert to locate and

configure L4400 instruments is independent of the type of netw ork you

are using (private or site) and the network devices present (switches or

routers).

For more information on Interactive IO, refer to the Agilent IO Libraries

Suite Getting Started Guide. The guide is available on-line by clicking

on the Agilent IO Control icon and then selecting Documentation

Libraries Suite Getting Started.

IO

22 L4400 User’s Guide

Figure 2-5. Starting Agilent Connection Expert.

Locating the Instruments

Agilent Connection Expert opens with a “welcome screen” and window

similar to that shown in Figure 2- 6. The computer interfaces configured

during installation of the Agilent IO Libraries are displayed in the left

column (Explorer pane) and the properties of the configured interface and

instrument are displayed in the right column (Properties pane).

Page 35

Explorer pane

Properties pane

Software Installation and Configuration 2

Figure 2-6. Agilent Connection Expert (ACE) Opening Window.

To search the network for instruments, click on “Add Instrument” located

he Connection Expert tool bar. From the “Add Instrument” window,

on t

select the LAN (TCPIP0) interface and click on ‘OK’. See Figure 2- 7.

L4400 User’s Guide 23

Figure 2-7. Agilent Connection Expert “Add Instrument Window”.

Page 36

2 Software Installation and Configuration

NOTE

Clicking on “Find Instruments” (Figure 2- 8) opens the search window.

Clicking on “Find Now” performs the search for instruments on the LAN

network. Instruments found (discovered) on the network (local subnet) are

indicated as shown. In the Figure 2- 8 example, two instruments were

located on the router subnet.

Figure 2-8. L4400 Instrument Private LAN Connection.

The “Find Instrument” function of Agilent Connection Expert is

supported only on computers that have a single LAN card installed. If

your computer has more than one LAN card, the L4400 instruments

must be entered “manually” using the IP addresses.

Adding and Configuring the Instruments

To add an instrument to the network configuration, select (highlight) the

instrument host name/IP address and click on ‘OK’ in the “Search for

Instruments on the LAN” window. This opens the “LAN Instrument” window shown in Figure 2- 9.

24 L4400 User’s Guide

Page 37

Click either to

test connection

Note serial number to identify

multiple instruments

Software Installation and Configuration 2

Figure 2-9. Verifying a Communication Path to the Instrument.

The LAN Instrument window identifies the instrument’s host name, its IP

address, its VIS

A address, and product number. Because the network

server used in this example does not support Dynamic DNS, the host

name is not registered for use by the server. Thus, the instrument is

accessed by its IP address.

Click on “Test Connection” or “Identify Instrument” to test the communication path to the instrument. Click on”OK” to add the configured instrument to your network.

Repeat the sequence of Figures 2- 7 t

instruments are added, they appear in the Agilent Connection Expert

hrough 2- 9 for each instrument. As

Explorer pane as shown in Figure 2- 10. Selecting the instrument in the

Explorer pane displays its proper

ties in the Properties pane.

L4400 User’s Guide 25

Page 38

2 Software Installation and Configuration

NOTE

Figure 2-10. Configured Instruments added to LAN Network.

Interactive IO

The Interactive IO feature of Agilent Connection Expert allows you to

interact with the instruments by sending commands and seeing the

instruments’ responses. Interactive IO can help you:

oubleshoot communication problems

• tr

• le

arn the instrument's command set

• pr

ototype commands and check the instrument's responses before

writing code

With Interactive IO, you can choose from a menu of common commands

(*IDN?, *RST

command set (see Chapters 4- 10 for the commands available with each

instrument).

Figure 2- 11 shows how Interactive IO is started from Agilent Connection

t.

Exper

, *TST?), or execute commands from the instrument’s

For more information on Interactive IO, refer to the Agilent IO Libraries

Suite Getting Started Guide. The guide is available on-line by clicking

on the Agilent IO Control icon and then selecting Documentation

Libraries Suite Getting Started.

IO

26 L4400 User’s Guide

Page 39

Software Installation and Configuration 2

Select (highlight) instrument

Select Interactive IO

Figure 2-11. Selecting an Instrument and Starting Interactive IO.

Identifying the Instruments

L4400 series instruments are comprised of the carrier, the instrument

sub- assembly, and on selected instruments, a wiring terminal block. The

carrier and instrument sub- assembly have separate serial numbers and

separate firmware revisions. The commands used to query these

parameters are:

• *ID

• SYS

• SYS

These commands can be executed from the Interactive IO window.

mples of the information returned by each command are as follows:

Exa

L4400 User’s Guide 27

N? (returns the carrier serial number and firmware revision)

Tem:CTYPe? 1 (returns the instrument sub- assembly serial

number and firmware revision)

Tem:CDEScription? 1 (returns the instrument description.)

Page 40

2 Software Installation and Configuration

*IDN?

Agilent Technologies, L4421A, MY00012345, 0.12-0.04-0.00-0.00

product

carrier serial number

SYST:CTYP? 1

Agilent Technologies,L4421A, MY44000237, 2.16

product

sub-assembly serial number

SYST:CDES? 1

“40-Channel Armature Multiplexer with Low Thermal Offset”

Using the Instrument Web Interface

Each L4400 series instrument can be programmed using its Web-based

interface. The Web interface functions as a virtual front panel which can

also be used for:

• interactive control

• familiarization with instrument capabilities

• determining / changing instrument configuration

• troubleshooting and debugging

carrier firmware revision

sub-assembly firmware revision

Comprehensive on-line help providing Web interface usage information is

available with each Web window.

The instrument Web interface can be opened from Agilent Connection

Expert as shown in Figure 2- 12. The Web interface can also be opened

directly from a Web browser by entering the instrument’s IP address or

host name in the browser’s ‘Address’ window.

28 L4400 User’s Guide

Page 41

Select the instrument /

open the Web interface

Software Installation and Configuration 2

Figure 2-12. Opening the Instrument Web Interface.

L4400 User’s Guide 29

Page 42

2 Software Installation and Configuration

NOTE

An example of the Web interface window is shown in Figure 2- 13.

Figure 2-13. L4450A Web Interface (Welcome Page).

Instruments on the network can be physically identified by selecting

Turn on Front Panel Identification Indicator

interface. This causes the instrument’s front panel LAN LED to flash

continually until Turn off Front Panel Identification Indicator is

selected.

within the Web

Editing the Instrument’s LAN Settings

Once a communication path to the instrument has been opened, the

instrument’s LAN configuration can be viewed and modified using the Web

interface.

30 L4400 User’s Guide

Page 43

Software Installation and Configuration 2

On the Web “welcome page”, click ‘View and Modify Configuration’. This

opens the configuration window shown in Figure 2-14.

Figure 2-14. Viewing LAN Configuration Settings from the Web Interface.

L4400 User’s Guide 31

Page 44

2 Software Installation and Configuration

NOTE

Clicking ‘Modify Configuration’ opens the window shown in Figure 2- 15

which allows you to edit the parameters shown.

Figure 2-15. Changing the Instrument LAN Interface Configuration.

Selecting “Help with this Page” on any Web interface window provides

information on the use of the current Web interface page. Selecting

“Help with this Page”on the “Browser Web Control” page provides a

listing of the help contents.

LAN Configuration Command Summary

In addition to using the Web interface, the instrument’s LAN configuration

can be set/changed changed programmatically. Chapter 3, Table 3-3

provides a listing of the LAN configuration commands implemented by the

L4400 series instruments.

Refer to the L4400 Programmers Reference on the Product Reference

ROM (p/n 34989- 13601) for detailed information on the commands.

CD-

32 L4400 User’s Guide

Page 45

GPIB Configuration

NOTE

The L4400 series instruments are available with an optional GPIB

interface. The steps required to configure L4400 instruments for use over

GPIB include:

Software Installation and Configuration 2

The following information assumes the GPIB interface card has been

installed in your computer. If necessary, install the card as instructed by

the documentation provided with the card.

• connecti

• adding t

Agilent Connection Expert)

• changing t

instruments)

• te

sting the IO path

Each L4400 series instrument is shipped fr

GPIB address of 9. Because instruments on the GPIB bus must have

unique addresses, the L4400 instruments must be turned on one at a time,

and the GPIB address changed before the next instrument is turned on

and added to the configuration.

ng the GPIB cables

he instrument to the GPIB interface configuration (using

he instrument GPIB address (systems with multiple L4400

om the factory with a default

Connecting the GPIB Cables

GPIB cables can be connected in a “star” (all cables connect directly to the

computer) or “linear” (instrument to instrument) configuration.

For systems with multiple L4400 series instruments, turn on only one

0 instrument at this time. If there is another instrument on the bus

L440

at GPIB address 9 (i.e. 34980A), turn off that instrument until the address

of the current L4400 instrument is changed.

Starting Agilent Connection Expert

Start Agilent Connection Expert by clicking the Agilent Control icon and

selecting “Agilent Connection Expert” from the pop- up menu (Figure 2- 5).

The computer interfaces configured during installation of the Agilent IO

libraries are displa

GPIB interface if a GPIB card is installed in your computer.

L4400 User’s Guide 33

yed in the left column (Explorer pane) including the

Page 46

2 Software Installation and Configuration

Adding Instruments to the GPIB Configuration

Highlight the GPIB interface (GPIB0) and select “Add Instrument” on the

tool bar. Select the GPIB interface in the “Add Instrument” window and

click ‘OK’.

Figure 2-16. Adding Instruments to the GPIB Interface.

In the ‘configurable properties’ window s

address 9 and click ‘OK’. This is the factory default address that will be

changed as necessary in the following steps.

Figure 2-17. Specifying the GPIB Address when Adding an Instrument.

hown in Figure 2- 17, select GPIB

34 L4400 User’s Guide

Page 47

Software Installation and Configuration 2

Verifying the GPIB Path

In the Agilent Connection Expert window, select and open ‘Interactive IO’.

Verify communication to the instrument by sending the *IDN? command

using Send & Read below the command line.

Figure 2-18. GPIB Communication Using the Default GPIB Address.

The GPIB Address String

When programming the L4400 instruments over GPIB, the instrument’s

GPIB address is included in the address string. For example:

GPIB0::9::INSTR

Changing the GPIB Address

If you have only one L4400 instrument on the GPIB interface and there are no other

instruments on the bus, the L4400 instrument address can remain set to 9. If you have

multiple L4400 instruments or there is another GPIB instrument at address 9, then one of

the addresses must be changed.

The command used to set the GPIB address on all L4400 instruments is:

SYSTem:COMMunication:GPIB:ADDRess < addre

The command can be abbreviated by including

only the upper-case letters in the com-

mand syntax. The Interactive IO window is used to set the

ss >

GPIB address as shown in

L4400 User’s Guide 35

Page 48

2 Software Installation and Configuration

Figure 2-19. In this example, the GPIB address is set to 10.

Figure 2-19. Setting the GPIB Address Using the Interactive IO Window.

Once the address is changed within the instrument, the address must also

anged in the Agilent Connection Expert’s “configuration tables.”

be ch

36 L4400 User’s Guide

Page 49

Software Installation and Configuration 2

Highlight instrument and

select, change address to

‘10’.

From the Agilent Connection Expert main window, highlight the instrument added and

then click ‘Change Properties ...”. Within the configurable properties window, change

the address of the instrument from ‘9’ to ‘10’ and click ‘OK’.

Figure 2-20. Changing the GPIB Address within Configuration Expert.

Verifying the new GPIB Path

To verify the GPIB address change, you can close the Interactive IO window, select the

instrument, and reopen Interactive IO. Or, with Interactive IO remaini ng op en , select

‘Connect’ and change the address from ‘9’ to ‘10’. Once connected to GPIB address

L4400 User’s Guide 37

Page 50

2 Software Installation and Configuration

‘10’, you can send the *IDN? command and verify the response from the instrument.

Figure 2-21. Connecting to GPIB Address 10 using Interactive IO.

Adding Additional Instruments

Additional instruments are added to the GPIB configuration using the process described

earlier. The steps are summarized as follows and assume the GPIB cable has been connected between the computer and the new instrument.

1. Turn on the “next” L4400 instrument. Do

addresses are still set to the default address of ‘9’.

2. Open the Agilent Configuration Expert “Add Instrument” window and select the

trument’s GPIB address in the “configurable properties” window (Figures 2-16 and

ins

2-17).

3. Open the Agilent Connection Expert “Interac

the instrument’s GPIB address using the command:

SYSTem:COMMunication:GPIB:ADDRess < address >

4. Change the address in the Agilent Connection

instrument address (Figure 2-20).

5. Verify the communication path to

the new address.

not turn on those instruments whose

tive IO” window (Figure 2-18). Change

Expert’s configuration table t o the new

38 L4400 User’s Guide

Page 51

Firmware Updates

Firmware updates for the L4400 series instruments consist of updates to

the instrument carrier firmware, and if necessary, an update of the instru

ment module firmware. The updates are made available via the Web. The

firmware is installed using the Agilent L4400 Firmware Update Utility,

also available on the web. This section contains information for locating

and downloading the update utility and firmware to your computer, and

then using the utility to install the firmware.

Downloading the Update Utility and Firmware

Firmware updates (if available) for the L4400 series instruments can be

found on the Web at:

www.agilent.com/find/L4400

Software Installation and Configuration 2

-

Once this page is displayed, click on ‘Library’ under the heading “More

Details.” From the ‘Library’ window select:

L4400 Firmware Update Revision <revision number>

Documents & Downloads

Agilent L4400 Firmware Update Utility

Save the utility application to a directory (e.g. Temp) on your PC. Note the

directory location as you will need to install the utility from this location.

Installing the Firmware Update Utility

Downloading the firmware update utility copies the application to your PC

but does not install the utility. From the directory where the application

was saved, double- click the firmware update utility application (.exe file).

For example:

FirmwareUpdateUtility_B_01_09_V3.exe

This starts the application’s installation “wizard”. Follow the instructions

as prompted. This will create and install the utility in the directory:

C:\Program Files\Agilent\Firmware Update Utility

L4400 User’s Guide 39

Page 52

2 Software Installation and Configuration

Downloading and Installing the Instrument Firmware

Once the utility is saved, return to the Web page and click on:

Agilent Firmware Revision <revision number>

Save the firmware file to a directory on your PC (e.g. Temp). Note the

directory location as you will need to specify the path to the firmware file

when you run the firmware update utility.

When updating from the LAN interface, the update utility requires you to

specify the instrument host name or IP address. Before running the utility,

test the communication path to the instrument(s) using Agilent Connection

Expert. Open Agilent Connection Expert and refresh the LAN and GPIB (if

present) interfaces by clicking ‘Refresh All’ (Figure 2- 10). A “

circle next to the instrument indicates communication with the instrument

on that interface. Note the host names or IP addresses (assuming an

update over the LAN interface) of the instruments to receive firmware

updates.

1. From the directory where the update utility was installed, start the utility by selecting

FirmwareUpdateUtility.exe.

” in a green

40 L4400 User’s Guide

Page 53

Software Installation and Configuration 2

NOTE

Click ‘Next’ until the window shown in Figure 2-22 appears.

Figure 2-22. Firmware Update Utility Firmware File Selection.

2. Using the ‘Browse’ button, specify the path to the firmware file and

t

hen click ‘Next’.

The ‘Applicable Model’ window lists the L4400 series instruments

which are updateable by the current firmware (.xs) image. The window

is NOTused to select the instrument receiving the firmware update.

Firmware updates are performed on one instrume

nt at a time. Once the

firmware update is complete, you must exit and re-start the utility to

update each instrument.

L4400 User’s Guide 41

Page 54

2 Software Installation and Configuration

3. Select the I/O interface to be used to upgrade the instrument firmware

and then select ‘Next’ (Figure 2- 23).

Figure 2-23. Selecting the Instrument Interface.

4. If the LAN interface is selected (Figure 2- 23), enter the instrument host

me or IP address and click ‘Update’. If the GPIB interface is used, select

na

the instrument’s GPIB address.

42 L4400 User’s Guide

Page 55

Software Installation and Configuration 2

enter host name

or IP address

NOTE

The firmware update process takes several minutes. The instrument’s front

panel ATTN indicator will flash green while the update is in progress.

Figure 2-23. Entering the Instrument Host Name or IP Address.

When the update to the instrument carrier firmware is complete, the

re

sults are indicated as shown in Figure 2- 24. Note that an update of the

instrument sub- assembly firmware may continue for a few moments after

the update results message appears.

Instrument sub-assembly firmware updates are performed automatically

if the current sub-assembly firmware revision is incompatible with the

updated carrier firmware.

L4400 User’s Guide 43

Page 56

2 Software Installation and Configuration

Figure 2-24. Instrument Firmware Update Complete.

5. Once the carrier update AND instr

occurs) complete and no instrument activity is indicated by the front

panel LEDs, cycle power on the instrument. Once the power-on sequence

completes, select ‘Refresh All’ in the Agilent Connection Expert (Figure

2- 10).

Agilent Connection Expert may report t

has changed. This is represented by a yellow triangle and an exclamation

point (!) next to the updated instrument. Select (highlight) the instrument

name. Select ‘Change Properties...’ and then click either ‘Test Connection’

or ‘Identify Instrument’ to update Agilent Connection Expert and then

click ‘OK’. Repeat for each updated instrument on the LAN and GPIB

interfaces.

ument sub- assembly update (if one

hat the instrument’s configuration

44 L4400 User’s Guide

Page 57

Software Installation and Configuration 2

Instrument Power-On and Default LAN Configuration States

The L4400 series instruments covered in this user’s guide are set to their

power on and preset states using any one the following commands:

*RST

SYSTem:CPON 1

SYSTem:PRESet

Table 2- 3 lists the power- on and preset states for each instrument.

Table 2-3. L4400 Instrument Power-on and Preset States

L4400 Series Instrument

L4421A 40-Channel Armature Multiplexer

L4433A Dual/Quad 4x8 Reed Matrix

L4437A 32-Channel Form A/ Form C

General Purpose Switch

L4445A Microwave Switch / Attenuator Driver

L4450A 64-Bit Digital I/O w/Memory and Counter

L4451A 4-Channel Isolated D/A Converter

w/Memory

L4452A Multifunction with Digital I/O, D/A,

Totalizer

LAN Reset (Default) Configuration

Power-on Preset States

All channels open

All channels open

2-wire/1-wire mode: no change

All channels open

Channel drives enabled =

userdefin

I/O ports = Input

Count = 0

Trace memory = cleared

DACs = 0Vdc

Trace wavforms = cleared

DIO Ports = Input

Count = 0

DACs = 0Vdc

ed defaults

Pressing the “LAN Reset” button (recessed) on the L4400 instrument front

or rear panel restores the instrument’s default LAN configuration. Table

2- 4 lists the default LAN configuration settings.

L4400 User’s Guide 45

Page 58

2 Software Installation and Configuration

Table 2-4. Default LAN Configuration Settings.

LAN Parameter

DHCP

Automatic IP Addressing

IP Settings if DHCP Server

U

navailable

DNS Server

Host Name (registered with

DNS if available)

D

LAN Keep Alive

Ethernet Connection Monitoring

Default (Reset) Setting

ON

ON

IP Address: 169.254

Subnet Mask: 255.255.0.0

Default Gateway: 0.0.0.0

0.0.0.0 (may be assigned by the DHCP server)

A-product number-last 5 digits of serial number

1800 (seconds)

ON - instrument monitors its LAN connection;

will attempt to automatically reconnect if disconnected from network.

.44.88 (default)

46 L4400 User’s Guide

Page 59

Agilent L4400 LXI Class C Instruments

User’s Guide

3

Operating and Programming

L4400 Instrument Front Panel Overview 48

L4400 Instrument Rear Panel Overview 50

L4400 Series Channel Addressing Scheme 52

Introduction to the SCPI Command Language 52

L4400 SCPI Command Summary 55

L4400 Series Programming Examples 59

Analog Bus Applications 65

User-Defined Channel Labels 68

Scanning Applications 69

Scanning with External Instruments 81

Alarm Limits 84

Using Sequences 89

Instrument State Storage 96

Error Conditions 97

Relay Cycle Count 98

Calibration Overview 98

This chapter contains general operating and programming information

applicable to multiple L4400 series instruments.

Agilent Technologies

47

Page 60

3 Operating and Programming

Instrument sub-assembly

Instrument carrier

Power

LAN Reset

L4400 Instrument Front Panel Overview

LXI instruments within the the L4400 family consist of the instrument

carrier, an instrument sub- assembly, and if applicable, a wiring terminal

block. The front panel of an L4400 instrument is shown in Figure 3- 1.

Figure 3-1. L4400 Instrument Front Panel (L4421A shown).

The only time it is necessary to remove the instrument sub-assembly

rom the carrier is to attach a support sleeve to those sub-assemblies

f

that use a wiring terminal block.

Chapter 1 contains information for removing the sub- assembly from the

rier and attaching the sleeve.

car

The LAN Reset Button

The LAN reset button allows you reset the instrument’s LAN

configuration to its default state. Refer to “LAN Reset (Default)

Configuration” in Chapter 2 for a listing of the default settings.

The Front Panel LEDs

The front panel LEDs:

ATTN

LAN

PWR

provide information on the status of the instrument. Table 3- 1 lists the

ument’s status conditions based on the color and functioning of the

instr

LEDs.

48 L4400 User’s Guide

Page 61

Operating and Programming 3

Table 3-1. L4400 LED Definitions and Instrument Status.

LED Color

ATTN

LAN

PWR

ATTN

LAN

PWR

ATTN

LAN

PWR

ATTN

LAN

PWR

ATTN

LAN

PWR

ATTN

LAN

PWR

Off

Off

Off

flashing

flashing

Green

Off

Green

Green

Off

Green (flashing)

Green

Off

Red

Green

Red (flashing)

Green

Green

Condition

Instrument is not turned on, and may or may

ot be connected to line power.

n

Power-on/boot-up. ATTN and LAN

red and then green during the power-on

self-test.

LAN connection

- instrument has an IP address

Instrument identificat

instrument Web interface:

ON:

Turn on Front Panel Interface Indicator

OFF: Turn off Front Panel Interface Indicator

No LAN connection due to:

- disconnected LAN cable

- failure to acquire an IP address

- waiting for DHCP-assigned address

Instrument programming error or self-test

e

rror. Error queue is read using

SYSTem:ERRor?

ion. Activated from

will flash

ATTN

LAN

PWR

L4400 User’s Guide 49

Green (flashing)

Green

Green

Instrument Busy State

- firmware download

- lengthy instrument operation in progress

Page 62

3 Operating and Programming

Analog Bus Port

External Trigger/Alarm DIO Port

GPIB Interface

(optional)

LAN Port

Power

LAN Reset

1

5

6

9

ABus1 LO (pin 4)

ABus2 LO (pin 3)

ABus3 LO (pin 2)

ABus4 LO (pin 1)

Current

ABus1 HI (pin 9)

ABus2 HI (pin 8)

ABus3 HI (pin 7)

ABus4 HI (pin 6)

(2A Max.)

(L4421A only)

L4400 Instrument Rear Panel Overview

The rear panel of an L4400 series instrument is shown in Figure 3- 2.

Note that the ports and connectors available are based on the

instrument’s options and functionality.

Figure 3-2. L4400 Instrument Rear Panel (L4421A shown).

Analog Bus Port

The Analog bus port, available on the rear panel of the L4421A

40- Channel Armature Multiplexer Module and the L4433A Dual/Quad 4x8

Reed Matrix Module, allows signals to be routed to external instruments

such as digital multimeters (DMMs). There are four busses (ABUS1 -

ABUS 4) on the port. Figure 3- 3 defines each bus and corresponding pin

numbers.

Figure 3-3. L4400 Analog Bus Port Pinouts.

50 L4400 User’s Guide

Page 63

Operating and Programming 3

Input

5 V

0 V

> 1 µs

Output

3.3 V

0 V

Approx. 2 µs

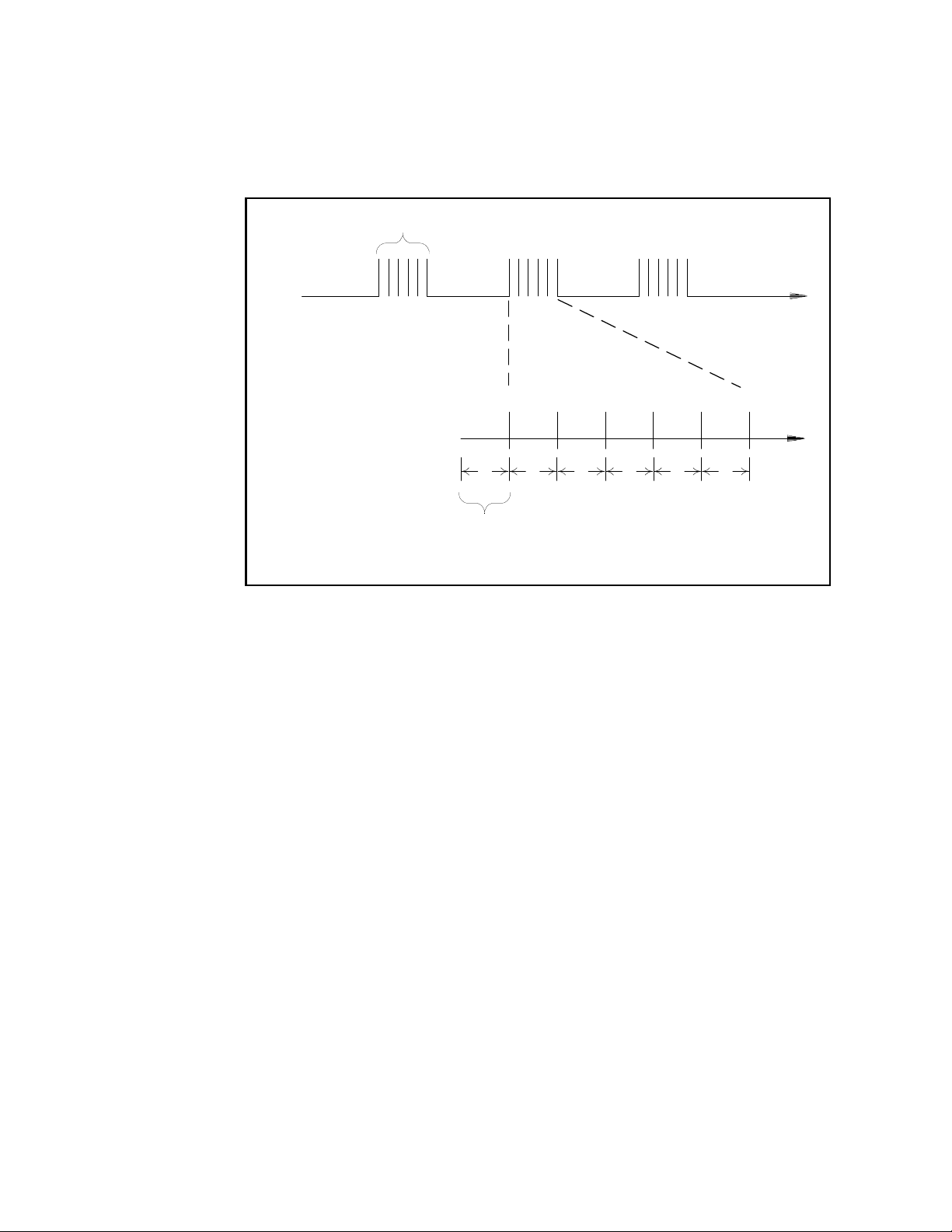

External Trigger Usage

Alarm Usage

5

1

9

6

Alarm 1 output (pin 1)

Alarm 2 output (pin 2)

Gnd (pin 9)

Channel closed output

(Trig Out - pin 5)

Gnd (pin 9)

Channel advance input

(Trig In - pin 6)

5

1

9

6

or

See “Scanning with External Instruments” later in this chapter for

information on how the analog bus is used for scanning a channel list

with an external DMM.

Ext Trig/Alarms/DIO Port

The external trigger, alarms, and DIO port enables you to synchronize

scanning between a switching instrument such as the L4421A and an

external DMM. The port also allows you to output alarm signals to an

external device or control system. Figure 3- 4 shows the pin out and

signal definitions for the port.

L4400 User’s Guide 51

Figure 3-4. External Trigger and Alarm Port Pin Definitions.

GPIB Connector

The GPIB interface is available on all L4400 series instruments as

Option- GPIB. This option must be purchased with the product. Products

not ordered with the GPIB interface cannot be reconfigured to add it later.

LAN Port

The LAN port on the L4400 series instruments supports 10 Mbps and

100 Mbps data transfer rates (10BaseT/100BaseTx). The port is Non

Auto- MDIX which means that the LAN crossover cable supplied with the

Page 64

3 Operating and Programming

instrument must be used when connecting the L4400 instrument directly

(without a switch or router) to the computer. See “Connecting the LAN

Cables” in Chapter 2 for more information.

L4400 Series Channel Addressing Scheme

The channel addressing scheme for the L4400 series LXI instuments uses

the form 1ccc where ccc is the three- digit channel number. Following are

examples of the scheme. Refer to the individual instrument chapters for

more information on channel numbering.

Table 3-2. L4400 Series Channel Addressing Examples.

Channel Number

1014 Channel 14 on Bank 1 of the L4421A multiplexer module.

1921 Channel 921 (analog bus relay for ABUS 1) on Bank 2 of the