Page 1

User’s Guide

Part Number: E3632-90001

October 2007.

For Safety information, Warranties, and Regulatory information,

see the pages behind the Index.

© Copyright Agilent Technologies, Inc. 2000-2007

All Rights Reserved.

Agilent E3632A

DC Power Supply

Page 2

The Agilent E3632A is a high performance 120 watt-dual range DC power

supply with GPIB and RS- 232 interfaces. The combinatio n of bench-top and

system features in this power supply provides versatile solutions for your

design and test requirements.

Convenient bench-top features

• Dual range

• Easy-to-us e knob control settings

• Highly visible vacuum-fluorescent display meters

• High accuracy and high resolution

• Remote voltage sensing

• Overvoltage and overcurrent protection

• Output on/off

• Excellent load and line regulation and low rip ple and noise

• Operating states storage

• Portable, ruggedized case with non-sk id feet

Flexible system features

• GPIB (IEEE-488) and RS-232 interfaces are standard

• SCPI (Standard Commands for Programmable Instruments) compatibility

• I/O setup easily done from front-panel

• Software calibration, no internal adjustments required

Agilent E3632A

DC Power Supply

Page 3

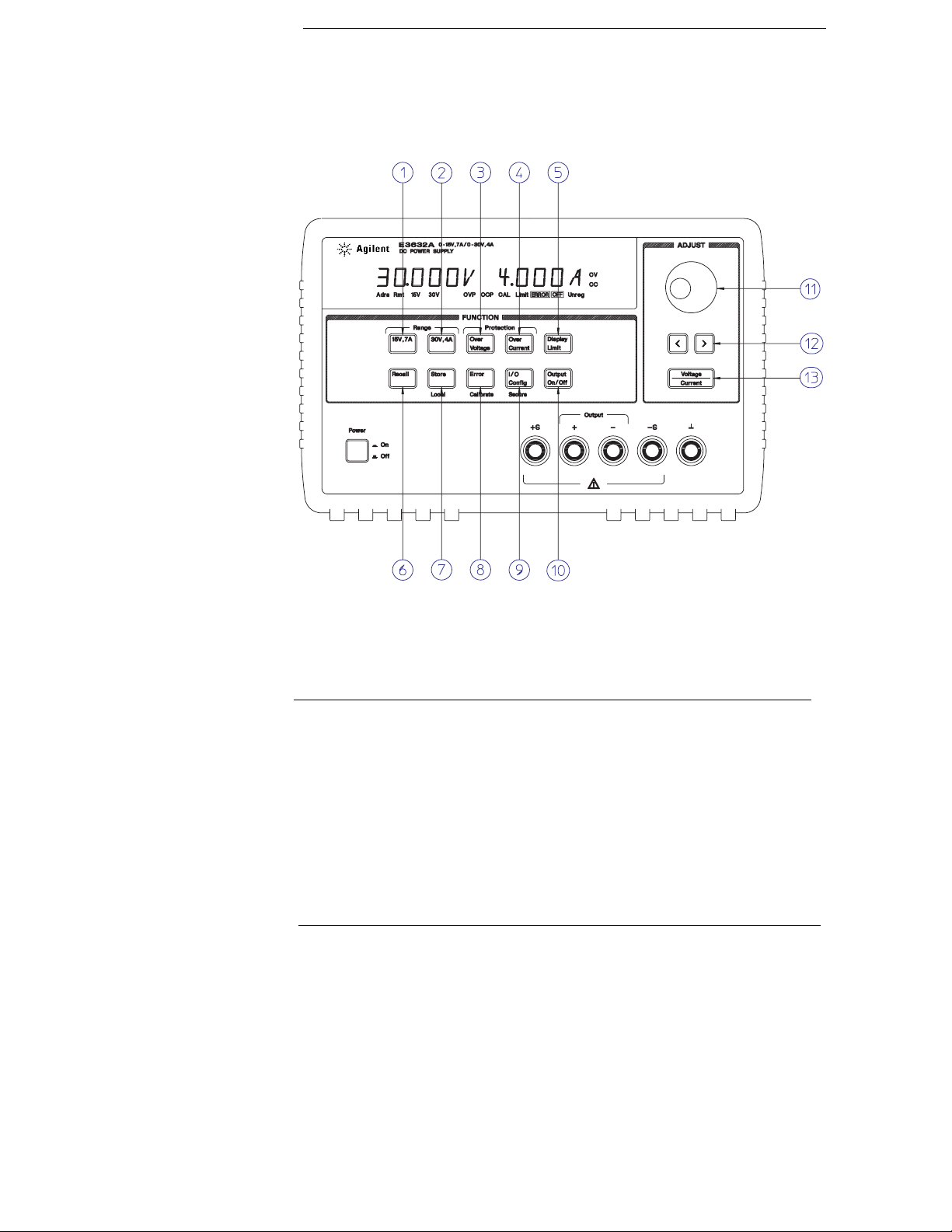

The Front Panel at a Glance

1 15V/7A range selection key

2 30V/4A range selection key

3 Overvoltage protection key

4 Overcurrent protection key

5 Display limit key

6 Recall operating state key

7 Store operating state/Local key

8 Error/Calibrate key

9 I/O Configuration/Secure key

10 Output On/Off key

11 Control knob

12 Resolution selection keys

13 Voltage/current adjust selection key

2

Page 4

1 15V/7A range selection key Selects the 15V/7A range and allows the full rated output

to 15V/7A.

2 30V/4A range selection key Selects the 30V/4A range and allows the full rated output

to 30V/4A.

3 Overvoltage protection key Enables or disables the overvoltage protection function,

sets trip voltage level, and clears the overvoltage condition.

4 Overcurrent protection key Enables or disables the overcurrent protection function,

sets trip current level, and clears the overcurrent condition.

5 Display limit key Shows voltage and current limit values on the display and allows

knob adjustment for setting limit values.

6 Recall operating state key Recalls a previously stored operating state from location

‘‘1’’, ‘‘2’’, or ‘‘3’’.

7 Store operating state / Local key1 Stores an operating state in location ‘‘1’’, ‘‘2’’, or

‘‘3’’ / or returns the power supply to local mode from remote interface mode.

8 Error / Calibrate key2 Displays error codes generated during operation, self-test and

calibration / or enables calibration mode (the power supply must be unsecured before

performing calibration). See Service Guide for more details on calibration.

9 I/O Configuration / Secure key3 Configures the power supply for remote interfaces

/ or secure or unsecure the power supply for calibration. See Service Guide for more

details on how to secure or unsecure the power supply.

10 Output On/Off key Enables or disables the power supply output. This key toggles

between on and off.

11 Control knob Increases or decreases the value of the blinking digit by turning

clockwise or counter clockwise.

12 Resolution selection keys Move the blinking digit to the right or left.

13 Voltage/current adjust selection key Selects the knob control function for voltage

or current adjustment.

1

The key can be used as the ‘‘Local’’ key when the power supply is in the remote

interfac e mode.

2

You can enable the ‘‘calibration mode’’ by holding down this key when you turn on

the power supply.

3

You can use it as the ‘‘Secure’’ or ‘‘Unsecure’’ key when the power supply is in the

calibration mode.

3

Page 5

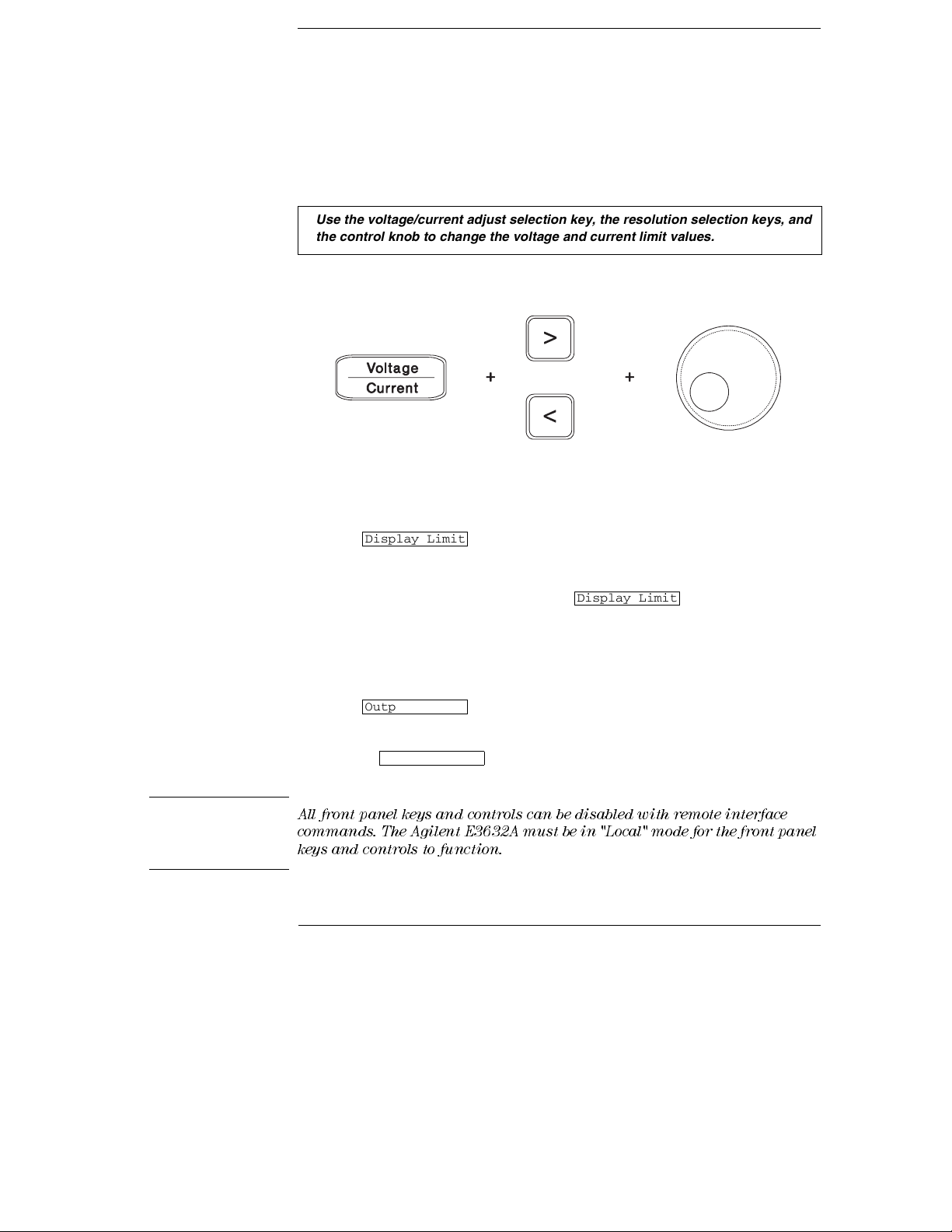

Front-Panel Voltage and Current Limit Settings

You can set the voltage and current limit values from the front panel using the

following method.

Use the voltage/current adjust selection key, the resolution selection keys, and

the control knob to change the voltage and current limit values.

1 Select the desired range using the range selection keys after turning on the power

supply.

2 Press the key to show the limit values on the display.

3 Move the blinking digit to the appropriate position using the resolution selection keys

and change the blinking digit value to the desired voltage limit by turning the control

knob. If the display limit times out, press the

4 Set the knob to current control mode using the voltage/current adjust selection key.

5 Move the blinking digit to the appropriate position using the resolution selection keys

and change the blinking digit value to the desired current limit by turning the control

knob.

6 Press the key to enable the output. After about 5 seconds, the

display will go to output monitoring mode automatically to display the voltage and

current at the output or the display will go to output monitoring mode immediately by

pressing the

Display Limit

Output On/Off

Output On/Off

key again.

Display Limit

key again.

Note

All front panel keys and controls can be disabled with remote interface

commands. The Agilent E3632A must be in "Local" mode for the front panel

keys and controls to function.

4

Page 6

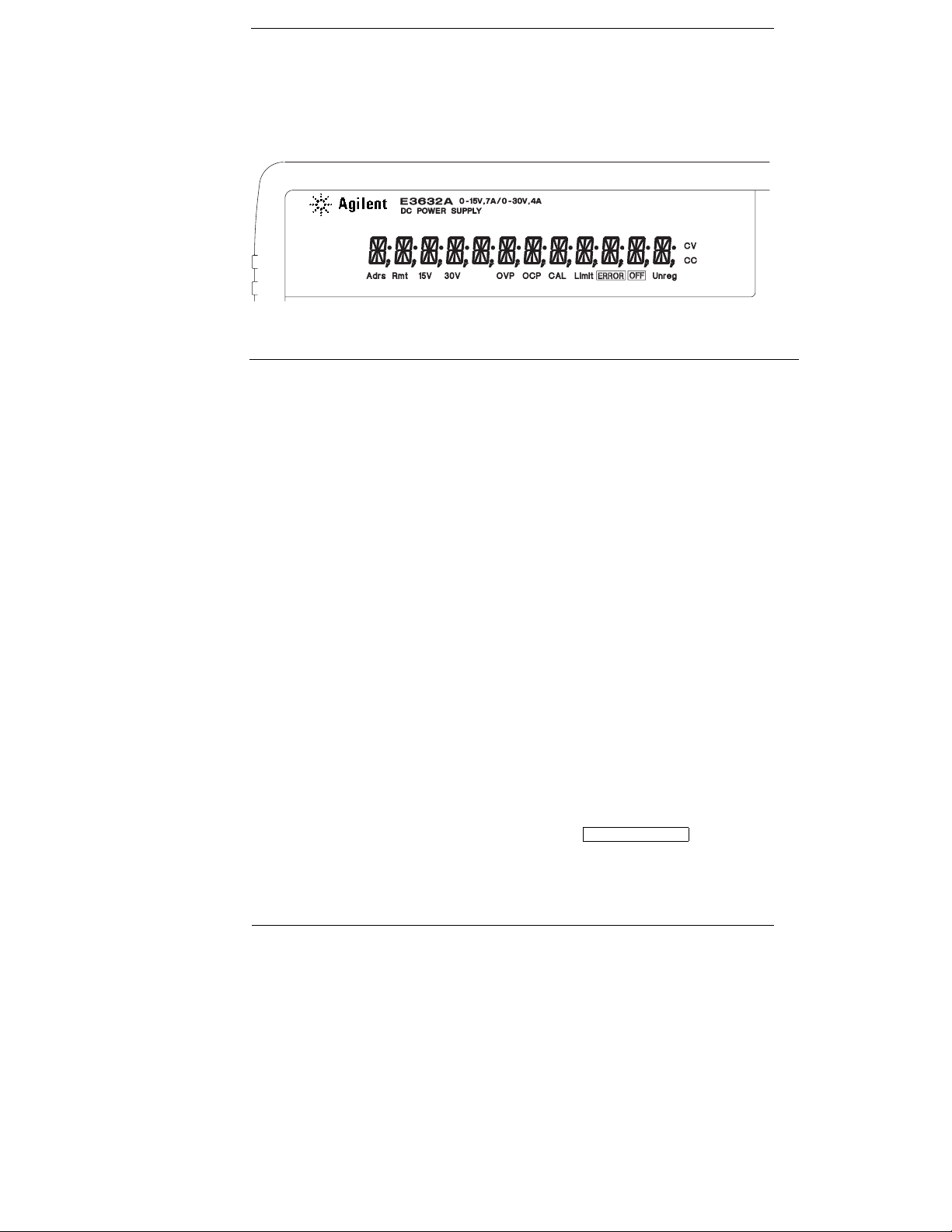

Display Annunciators

Adrs Power supply is addressed to listen or talk over a remote interface.

Rmt Power supply is in remote interface mode.

15V Shows the 15V/7A range is selected.

30V Shows the 30V/4A range is selected.

OVP The overvoltage protection function is enabled when the annunciator

OCP The overcurrent protection function is enabled when the annunciator

CAL The power supply is in calibration mode.

Limit The display shows the limit values of voltage and current.

ERROR Hardware or remote interface command errors are detected and the error

OFF The output of the power supply is disabled (See page 52 for more

Unreg The output of the power supply is unregulated (output is neither CV

CV The power supply is in constant voltage mode.

CC The power supply is in constant current mode.

turns on or the overvoltage protection circuit has caused the power

supply to shutdown when the annunciator blinks.

turns on or the overcurrent protection circuit has caused the power

supply to shutdown when the annunciator blinks.

bit has not been cleared.

information).

nor CC).

To review the display annunciators, hold down key as you

Display Limit

turn on the power supply.

5

Page 7

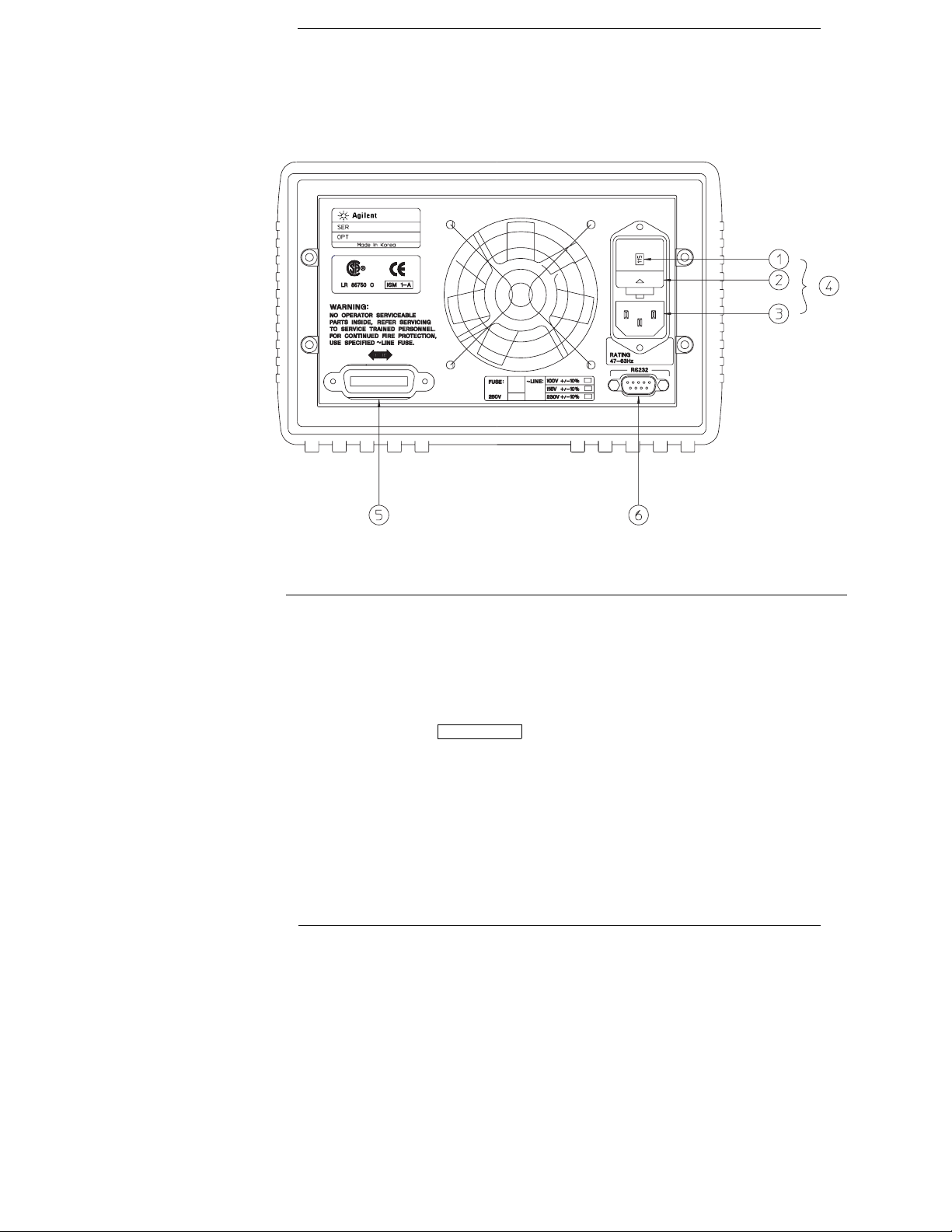

The Rear Panel at a Glance

1 Power-line voltage setting

2 Power-line fuse-holder assembly

3 AC inlet

Use the front-panel key to:

• Select the GPIB or RS-232 interface (see chapter 3).

• Set the GPIB bus address (see chapter 3).

• Set the RS-232 baud rate and parity (see chapter 3).

I/O Config

4 Power-line module

5 GPIB (IEEE-488) interface connector

6 RS-232 interface connector

6

Page 8

In This Book

General Information

supply. This chapter also provides instructions for checking your power

supply, connecting to ac power, and selecting power-line voltage.

Initial Operation

outputs and properly responds to operation from the front panel.

Front-Panel Operation

keys and how they are used to operate the power supply from the front panel.

This chapter also shows how to configure the power supply for the remote

interface and gives a brief introduction to the calibration features.

Remote Interface Reference

you program the power supply over the remote interface. This chapter also

explains how to program for status reporting.

Error Messages

working with the power supply. Each listing contains information to help you

diagnose and solve the problem.

Application Programs

to help you develop programs for your application.

Tut or ia l

gives specific details on the operation and use of the A gilent E3632A power

supply.

Specifications

Chapter 7 describes basic operation of linear power supplies and

Chapter 1 contains a general description of your power

Chapter 2 ensures that the power supply develops its rated

Chapter 3 describes in detail the use of front-panel

Chapter 4 contains reference information to help

Chapter 5 lists the error messages that may appear as you are

Chapter 6 contains some remote interface applications

Chapter 8 lists the power supply’s specifications.

If you have questions re la ting to the operation of the power suppl y, call

1-800-829-4444

Technologies Sales Office.

If your Agilen t E3632 A fail s withi n one ye ar of purc has e, A gilen t will

repair or re pl ace it free of charge . C all 1 -800-258-5165 ("Ex press

Exchan ge") in the United States , or con tact your near es t Agil ent

Technologies Sales Office.

in the United States, or contac t your ne are st A gile nt

7

Page 9

8

Page 10

Contents

Chapter 1 Gen e ral In form a tio n

Safety Considerations 14

Safety and EMC Requirements 14

Options and Accessories 15

Options 15

Accessories 15

Description 16

Installation 19

Initial Inspection 19

Cooling and Location 19

Input Power Requirements 22

Power-Line Cord 22

Power-Line Voltage Selection 22

Chapter 2 Initial Operation

Preliminary Checkout 27

Power-On Checkout 28

Output Checkout 29

Voltage Output Checkout 29

Current Output Checkout 30

Chapter 3 Fron t- Pa n el Ope rat ion

Front-Panel Operation Overview 35

Constant Voltage Operation 36

Constant Current Operation 38

Storing and Recalling Operating States 40

Programming Overvoltage Protection 42

Setting the OVP Level and Enable the OVP Circuit 42

Checking OVP Operation 43

Clearing the Overvoltage Condition 43

Programming Overcurrent Protection 45

Setting the OCP Level and Enable the OCP Circuit 45

Checking OCP Operation 46

Clearing the Overcurrent Condition 46

Remote Voltage Sensing 48

CV Regulation 48

Output Rating 48

Output Noise 48

Stability 49

Remote Voltage Sensing Connections 49

Contents

9

Page 11

Contents

Contents

Chapter 3 Front-Panel Operation (continued)

Disabling the Output 50

Disablin g the Output Using an External Relay 51

Knob Locking 51

System-Rel ated Operations 52

Self-Test 52

Error Conditions 53

Display Control 54

Firmw are Revisi on Query 55

SCPI Language Version 55

Remote Interface Configuration 56

Remote Interface Selection 56

GPIB Address 57

Baud Rate Selection (RS-232) 57

Parity Selection (RS-232) 57

To Set the GPIB Address 58

To Set the Baud Rate and Parity (RS-232) 59

GPIB Interface Configuration 61

RS-232 Interface Configuration 62

RS-232 Configurati on Overview 62

RS-232 Data Frame Format 62

Connection to a Computer or Terminal 63

DTR / DSR Handshake Protocol 64

RS-232 Troubles hooti ng 65

Calibration Overview 66

Calibration Security 66

Calibration Count 70

Calibration Message 70

10

Page 12

Contents

Chapter 4 Remote Interface Reference

SCPI Command Summary 73

Simplified Programming Overview 78

Using the APPLy Command 78

Using the Low-Level Commands 78

Reading a Query Response 79

Selecting a Trigger Source 79

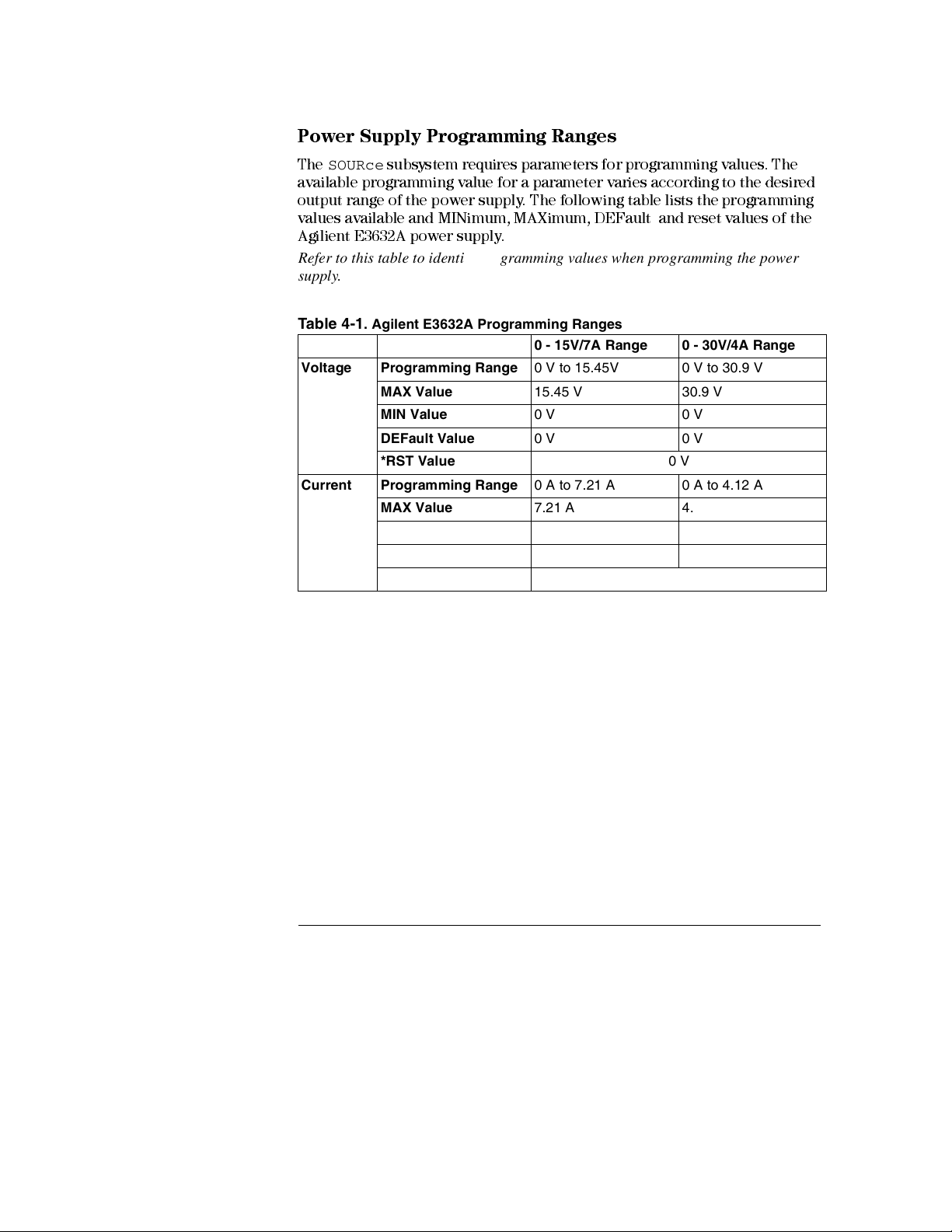

Power Supply Programm ing Ranges 80

Using the APPLy Command 81

Output Setting and Operation Commands 82

Triggering Comm ands 89

Trigger Source Choices 89

Triggering Comm ands 91

System-Related Commands 92

Calibration Commands 96

RS-232 Interface Commands 99

The SCPI Status Registers 100

What is an

What is an

SCPI Status System 101

The Questionable Status Register 102

The Standard Event Register 103

The Status Byte Register 104

Using Service Request (SRQ) and Serial POLL 105

Using *STB? to Read the Status Byte 106

Using the Message Available Bit (MAV) 106

To Interrupt Your Bus Controll er Usi ng SRQ 106

To Determine When a Command Sequence is Com pl eted 107

Using *OPC to Signal When Data is in the Output Buffer 107

Status Reporting Commands 108

An Introduction to the SCPI Language 111

Command Format Used in This Manual 112

Command Separators 113

Using the

Querying Parameter Settings 114

SCPI Command Terminators 114

IEEE-488.2 Co mm on Co mm ands 114

SCPI Parameter Types 115

Halting an Output in Progress 116

SCPI Conformance Information 117

IEEE-488 Conformance Information 120

Event

Register? 100

Enable

MIN

and

Register? 100

MAX

Parameters 113

Contents

11

Page 13

Contents

Contents

Chapter 5 Error Messages

Execution Errors 123

Self-Test Errors 128

Calibration Errors 129

Chapte r 6 Applic a tio n Pro gra m s

C++ Example for GPIB(IEEE 488) 133

Excel 5.0 Example for Windows 3.1 and GPIB 135

Chapter 7 Tutorial

Overview of Agilent E3632A Operation 141

Output Characteristics 143

Unregulated State 145

Unwanted Signals 145

Connecting the Load 147

Output Isolation 147

Multiple Loads 147

Remote Voltage Sensing 148

Load Consideration 149

Extending the Voltage and Current Range 151

Series Connections 151

Parallel Connections 151

Remote Programming 152

Reliability 154

12

Chapter 8 Specifications

Performance Specifications 157

Supplemental Ch aracteristi cs 159

Index

163

Page 14

1

General Information

Page 15

General Information

This chapter provides a general description of your power supply . This chapter

also contains instructions for initial inspection, location and cooling for bench

and rack operation, selecting the power-line voltage, and connecting your

power supply to ac power.

Safety Considerations

This power supply is a Safety Class I instrument, which means that it has a

protective earth terminal. That terminal must be connected to earth ground

through a power source with a 3-wire ground receptacle.

Before installation or operation , check the power supply and review this

manual for safety markings and instructions. Safety information for specific

procedures is located at the appropriate places in this manual. See also

‘‘

Safety

’’ at the beginning of this manual for general safety information.

Safety and EMC Requirements

This power supply is designed to comply with the following safety and EMC

(Electromagnetic Compatibility) requirements:

• IEC 1010-1(1990)/EN 61010-1(1993) + A2 (1995): Safety Requirements for

Electrical Equipment for Measurement, Control, and Laboratory Use

• CSA C22.2 No.1010.1-92: Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use

• UL 1244: Electrical and Electric Measuring and Testing Equipment

• EMC Directive 89/336/EEC

• Low Voltage Directive: 73/23/EEC

• EN 55011(1991) Group I, Class A/CISPR II(1990): Limits and Methods of

Radio Interface Characteristics of Industrial, Scientific, and Medical(ISM)

Radio-Frequency Equipment.

• EN50082-1(1992):

IEC 801-2(1991): Electrostatic Discharge Requirements

IEC 801-3(1984): Radiated Electromagnetic Fi eld Requi rements

IEC 801-4(1988): Electrical Fast Transient/Burst Requirements

• ICES/NMB-001

This ISM device complies with Canadian ICES-001.

Cet appareil ISM est conforme à la norme NMB-001 du Canada.

14

Page 16

Chapter 1 General Information

Options and Accessories

Options and Accessories

Options

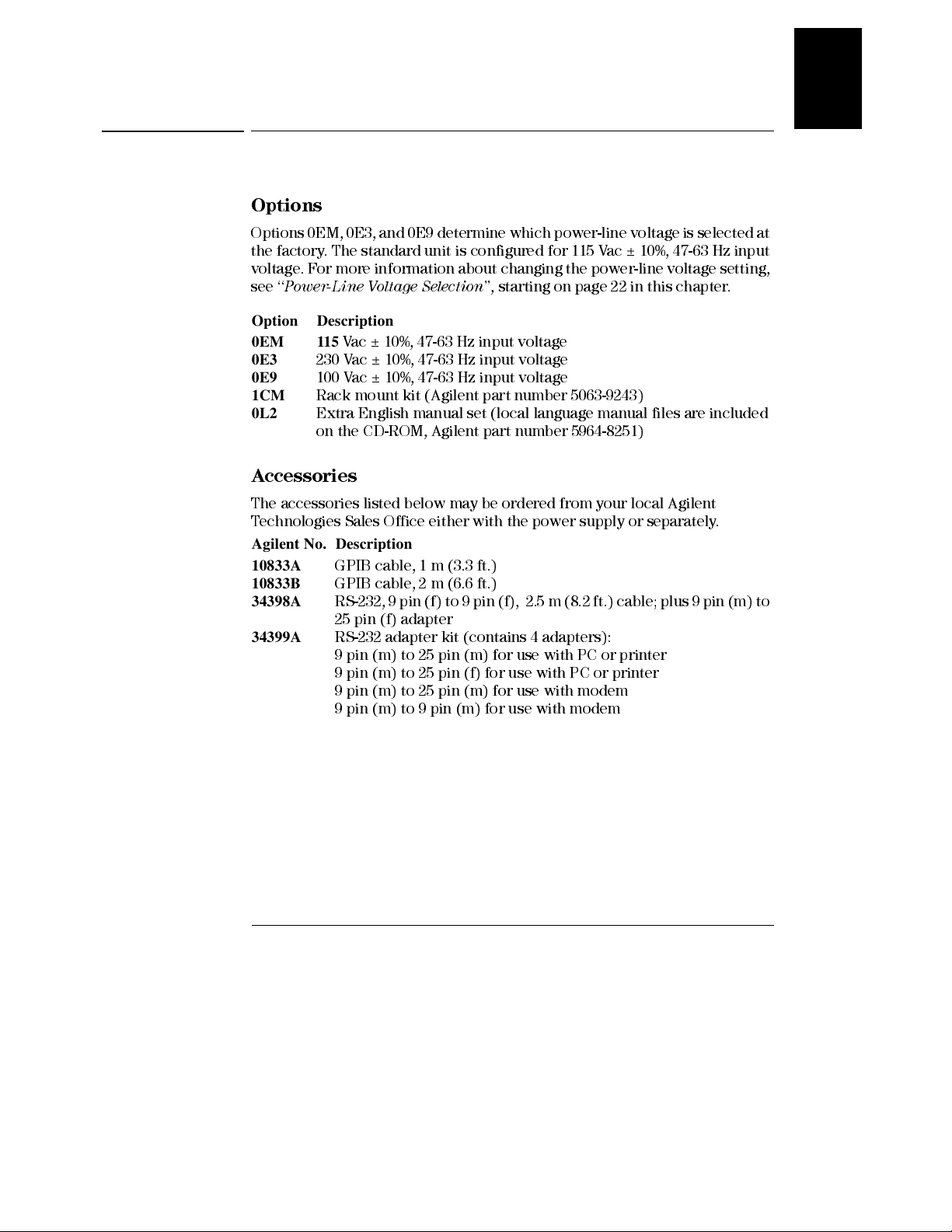

Options 0EM, 0E3, and 0E9 determine which power-line voltage is selected at

the factory. The standard unit is configured for 115 Vac ± 10%, 47-63 Hz input

voltage. For more information about changing the power-line voltage setting,

see ‘‘

Power-Line Voltage Selection

Option Description

0EM 115

0E3

0E9

1CM

0L2

Vac ± 10%, 47-63 Hz input voltage

230 Vac ± 10%, 47-63 Hz input voltage

100 Vac ± 10%, 47-63 Hz input voltage

Rack mount kit (Agilent part number 5063-9243)

Extra English manual set (local language manual fil es are included

on the CD-ROM, Agi lent part number 5964-8251)

Accessories

’’, starting on page 22 in this chapter.

1

The accessories listed below may be ordered from your local Agilent

Technologies Sales Office either with the power supply or separately.

Agilent No. Description

10833A

10833B

34398A

34399A

GPIB cable, 1 m (3.3 ft.)

GPIB cable, 2 m (6.6 ft.)

RS-232, 9 pin (f) to 9 pin (f), 2.5 m (8.2 ft.) cable; plus 9 pin (m) to

25 pin (f) adapter

RS-232 adapter kit (contains 4 adapters):

9 pin (m) to 25 pin (m) for use with PC or printer

9 pin (m) to 25 pin (f) for use with PC or printer

9 pin (m) to 25 pin (m) for use with modem

9 pin (m) to 9 pin (m) for use with modem

15

Page 17

Chapter 1 General Information

Description

Description

The Agilent E3632A DC power supply feature a combination of programming

capabilities and linear power supply performance that makes it ideal for power

systems applications. The power supply is programmable locally from the front

panel or remotely over the GPIB and RS-232 interfaces. This power supply has

two ranges, allowing more voltage at a lower current. The desired output range

is selected from the front panel or over the remote interfaces.

Operational features include:

• Dual range of 15V/7A or 30V/4A

• Constant voltage (CV) or constant current (CC) operation

• Overvoltage protection (OVP) and overcurrent protection (OCP)

• Three storage locations (1 to 3) for user-defined operating states

• Automatic turn-on self-test

• Remote sensing for load voltage

• User calibration from the front panel or over the remote interfaces

The front panel operation permits:

• Easy-to-use of knob control

• Output range selection

• Enabling or disabling OVP and OCP features

• Setting the OVP and OCP trip levels

• Clearing OVP and OCP conditions

• Setting and displaying the voltage and current limit values

• Saving and recalling operating states

• Returning the power supply to local mode from remote interface mode

• Displaying remote interface error message

• Calibrating the power supply, includ ing changing the calibration secure

code

• Configuring the power supply for remote interfaces

• Enabling or disabling the output

16

Page 18

Chapter 1 General Information

Description

When operated over the remote interface, the power supply can be both a

listener and a talker. Using an external controller, you can instruct the power

supply to set the output and to send the status data back over the GPIB or RS-

232. Capabilities include the following features:

• Voltage and current programming

• Voltage and current readback

• Present and stored status readback

• Programming syntax error detection

• Complete self-test

The front-panel VFD (Vacuum-Fluorescent Display) incl udes :

1

• Displaying actual values of output voltage and current (

• Or displaying the limit values of voltage and current (

• Checking the operating status from the annunciators

• Checking the type of error from the error codes (messages)

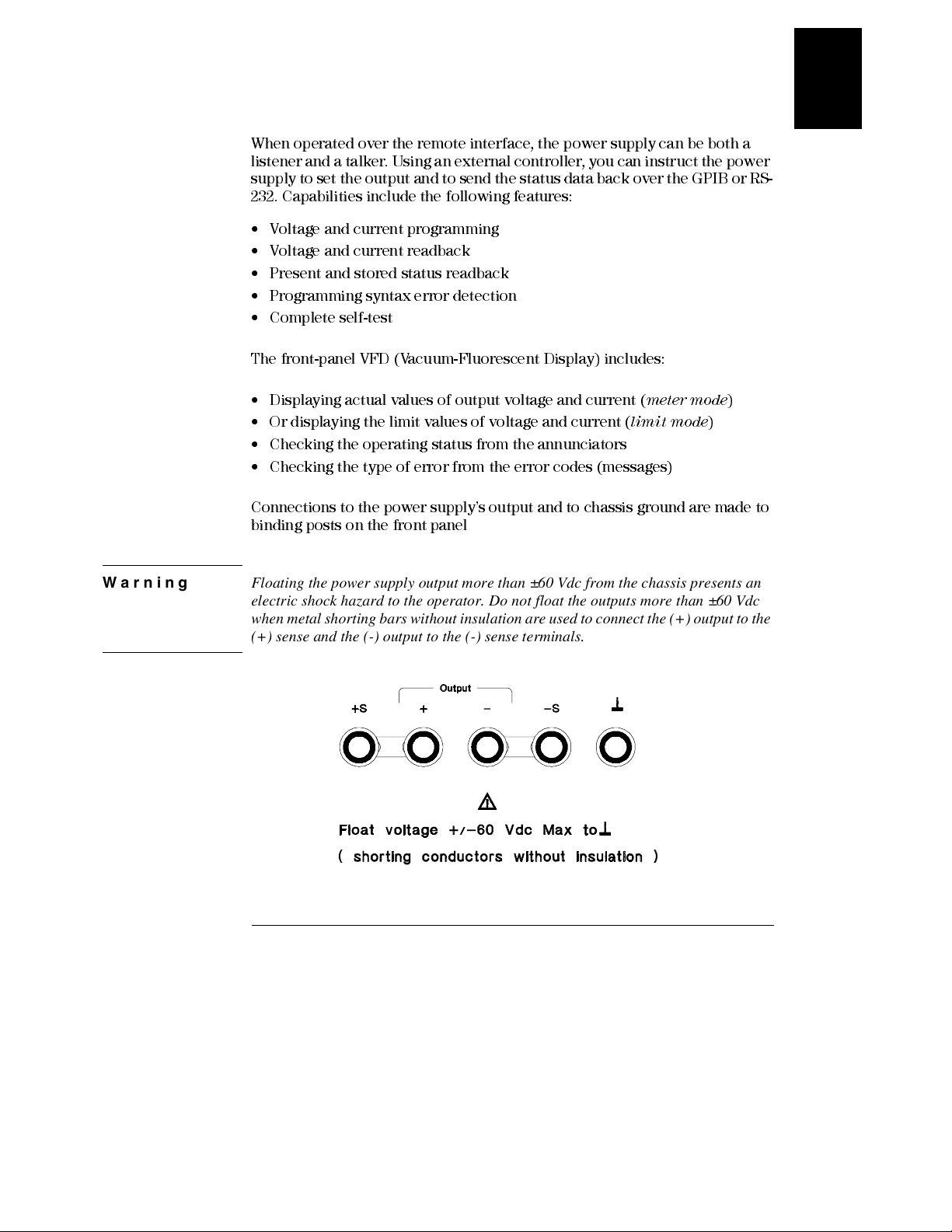

Connections to the power supply’s output and to chassis ground are made to

binding posts on the front panel

Warning Floating the power supply output more than ±60 Vdc from the chassis presents an

electric shock hazard to the operator. Do not float the outputs more than ±60 Vdc

when metal shorting bars without insulation are used to connect the (+) output to the

(+) sense and the (-) output to the (-) sense terminals.

meter mode

limit mode

)

)

17

Page 19

Chapter 1 General Information

Description

Warning Outputs can be floated to maximum of ±240 Vdc provided that the metal shorting bars

without insulation are either replaced with insulated conductors or they are removed

from the terminals so there is no operator access to the output conductors without

insulation. All field wiring insulation must be adequate for the voltage present.

The power supply is shipped with a detachable, 3-wire grounding type power

cord. The ac line fuse is an extractor type on the rear panel. The power supply

can be calibrated from the front panel directly or with a controller over the

GPIB or RS-232 interface using calibration commands. Correction factors are

stored in

Calibration from the front panel or a controller eliminate the need to remove

the top cover or even the need to remove the power supply from your system

cabinet. Y ou can guard against unauthorized calibration by using the “Secured”

calibration protection function.

non-volatile

memory and are used during output programming.

18

Page 20

Chapter 1 General Information

Installation

Installation

Initial Inspection

When you receive your power supply, inspect it for any obvious damage that

may have occurred during shipment. If any damage is found, notify the carrier

and the nearest Agilent Sales Office immediately. Warranty information is

shown in the front of this manual.

Keep the original packing materials in case the power supply has to be returned

to Agilent Technologies in the future. If you return the power supply for service,

attach a tag identifying the owner and model number. Also include a brief

description of the problem.

Mechanical Check

This check confirms that there are no broken keys or knob, that the cabinet

and panel surfaces are free of dents and scratches, and that the display is not

scratched or cracked.

1

Electrical Check

Chapter 2 describes an initial operation procedure which, when successfully

completed, verifies to a high level of confidence that the power supply is

operating in accordance with its specifications. Detailed electrical verification

procedures are included in the

Service Guide

.

Cooling and Location

Cooling

The power supply can operate without loss of performance within the

temperature range of 0 °C to 40 °C, and with derated output current from

40 °C to 55 °C. A fan cools the power supply by drawing air through the rear

panel and exhausting it out the sides. Using an Agilent rack mount will not

impede the flow of air.

Bench Operation

Y our power supply must be installed in a location that allows sufficient space

at the sides and rear of the power supply for adequate air circulation. The

rubber bumpers must be removed for rack mounting.

19

Page 21

Chapter 1 General Information

Installation

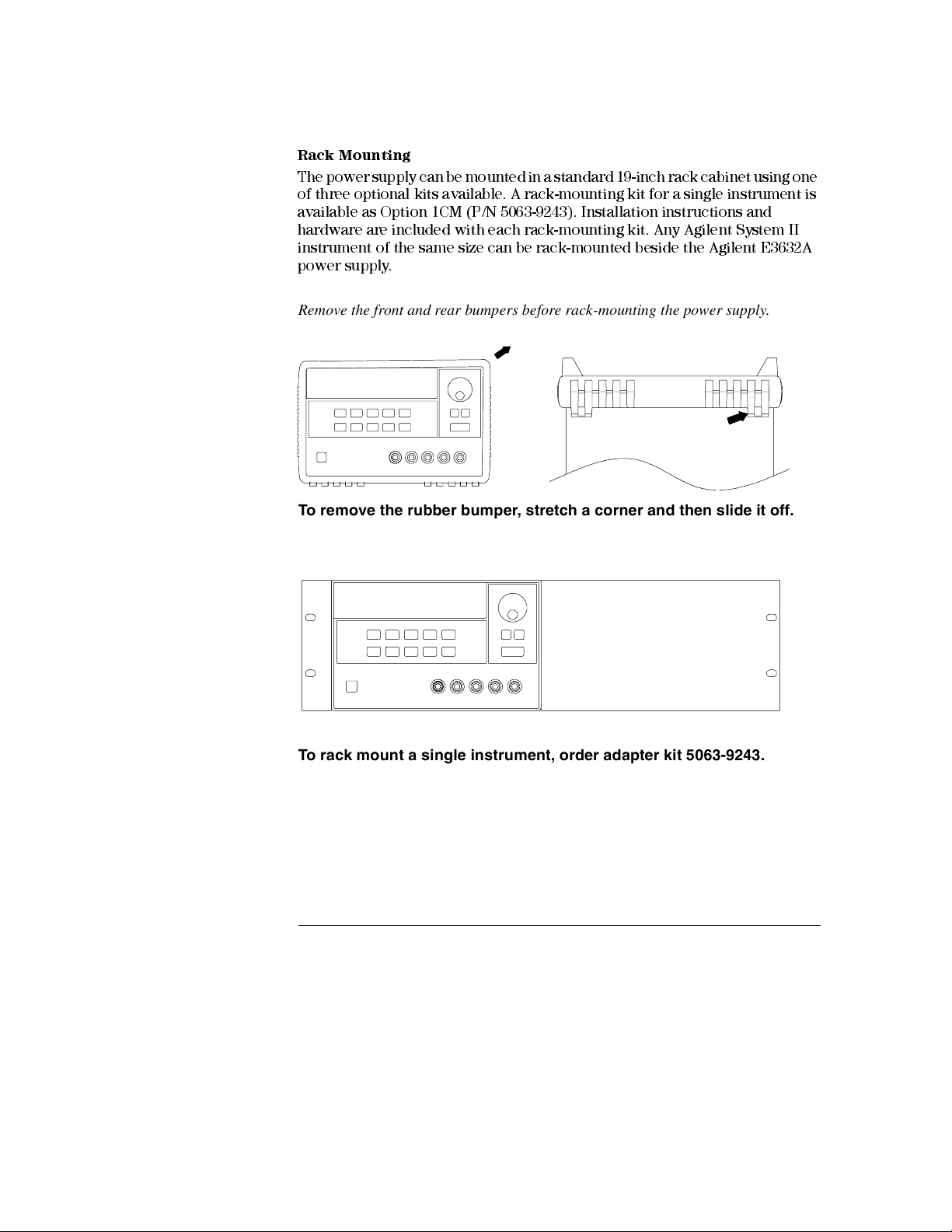

Rack Mounting

The power supply can be mounted in a standard 19-inch rack cabinet using one

of three optional kits available. A rack-mounting kit for a single instrument is

available as Option 1CM (P/N 5063-9243). Installation instructions and

hardware are included with each rack-mounting kit. Any Agilent System II

instrument of the same size can be rack-mounted beside the Agilent E3632A

power supply.

Remove the front and rear bumpers before rack-mounting the power supply.

To remove the rubber bumper, stretch a corner and then slide it off.

To rack mount a single instrument, order adapter kit 5063-9243.

20

Page 22

Chapter 1 General Information

Installation

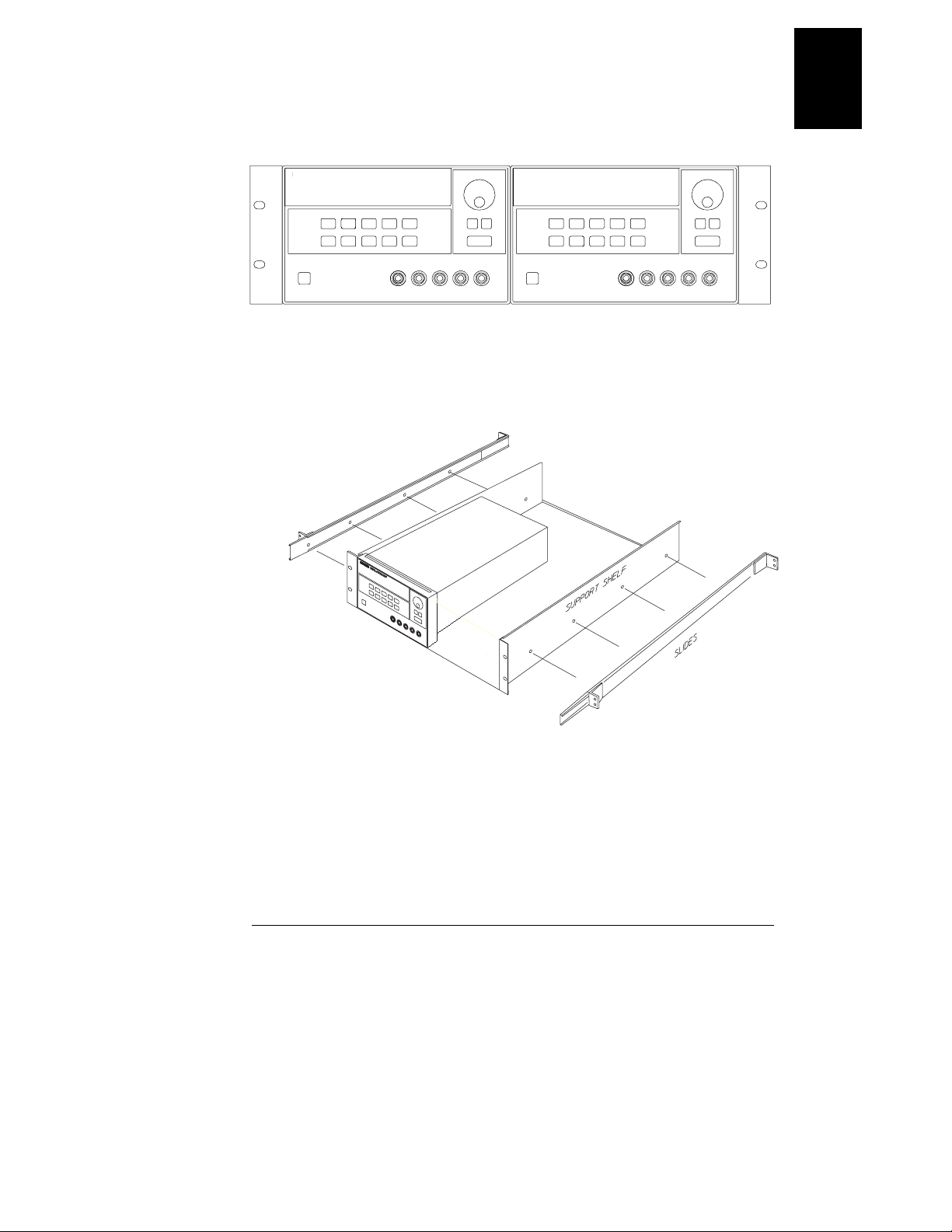

To rack mount two instrument of the same depth side-by-side, order

lock-link kit 5061-9694 and flange kit 5063-9214.

1

To install two instruments in a sliding support shelf, order support shelf

5063-9256, and slide kit 1494-0015.

21

Page 23

Chapter 1 General Information

Input Power Requirements

Input Power Requirements

Y ou can operate your power supply from a nominal 100 V, 115 V , or 230 V single

phase ac power source at 47 to 63 Hz. An indication on the rear panel shows

the nominal input voltage set for the power supply at the factory . If necessary ,

you can change the power-line voltage setting according to the instructions on

the next page.

Power-Line Cord

The power supply is shipped from the factory with a power-line cord that has

a plug appropriate for your location. Contact the nearest Agilent Technologies

Sales and Service Office if the wrong power-line cord is included with your

power supply. Your power supply is equipped with a 3-wire grounding type

power cord; the third conductor being the ground. The power supply is

grounded only when the power-line cord is plugged into an appropriate

receptacle. Do not operate your power supply without adequate cabinet

ground connection.

Power-Line Voltage Selection

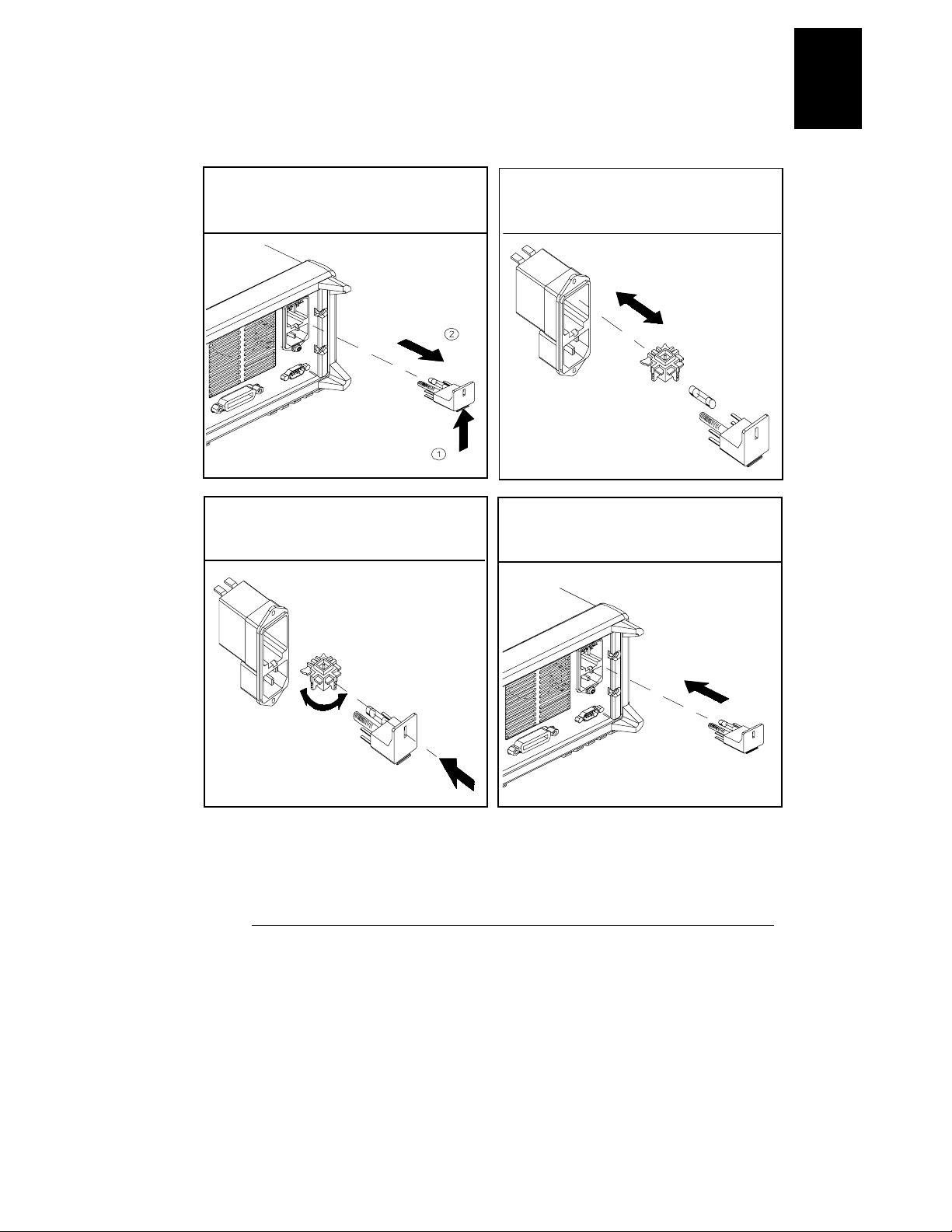

Power-line voltage selection is accomplished by adjusting two components:

power-line voltage selector and power-line fuse on the power-line module of

the rear panel. To change the power-line voltage, proceed as follows:

22

Page 24

Chapter 1 General Information

Input Power Requirements

1

1 Remove the power cord. Remove the

fuse-holder assembly with a flat-blad

screwdriver from the rear panel.

3 Rotate the power-line voltage selector

until the correct voltage appears.

2 Install the correct line fuse. Remove

the power-line voltage selector from the

power-line module.

100 or 115 Vac, 4 AT fuse

230 Vac, 2.5 AT fuse

4 Replace the power-line voltage selector

and the fuse-holder assembly in the rear

panel.

100, 115, or 230 Vac

23

Page 25

Chapter 1 General Information

Input Power Requirements

24

Page 26

Chapter 1 General Information

Input Power Requirements

1

25

Page 27

2

Initial Operation

Page 28

Initial Operation

There are three basic tests in this chapter. The automatic power-on test

includes a self-test that checks the internal microprocessors and allows the

user visually to check the display. The output check ensures that the power

supply develops its rated outputs and properly responds to operation from the

front panel. For complete performance and/or verification tests, refer to the

Service Guide

This chapter is intended for both the experienced and the inexperienced user

because it calls attention to certain checks that should be made prior to

operation.

Throughout this chapter the key to be pressed is shown in the left margin.

.

26

Page 29

Chapter 2 Initial Operation

Preliminary Checkout

Preliminary Checkout

The following steps help you verify that the power supply is ready for use.

1

Verify the power-line voltage setting on the rear panel.

The power-line voltage is set to the proper value for your country when the

power supply is shipped from the factory. Change the voltage setting if it is not

correct. The settings are: 100, 115, or 230 Vac.

2

Verify that the correct power-line fuse is installed.

The correct fuse is installed for your country when the power supply is shipped

from the factory. For 100 or 115 Vac operation, you must use a 4 AT fuse. For

230 Vac operation, you must use a 2.5 AT fuse.

3

Connect the power-line cord and turn on your power supply.

The front-panel display will light up and a power-on self-test occurs

automatically when you turn on the power supply.

See "Power-Line Voltage Selection", starting on page 22 in chapter 1 if you

need to change the power-line voltage or the powe r-line fuse .

To replace the 4 AT fuse, order Agilent part number 2110-0996.

To replace the 2.5 AT fuse, order A gile nt part nu m ber 2110-0999.

2

27

Page 30

Chapter 2 Initial Operation

Power-On Checkout

Power-On Checkout

The power-on test includes an automatic self-test that checks the internal

microprocesso rs and allow s the user visuall y to check the display. You will

observe the following sequence on the display after pressing the front panel

power switch to on.

1 All segments of the display including all annunciators will turn on for about one

second.

To review the annunciators, hold down key as you turn on

the power suppl y

.

2 The GPIB address or RS-232 message will then be displayed for about one

second.

ADDR 05 (or RS-232)

The GPIB address is set to ‘‘5’’ when the power supply is shipped from the

factory for remote interface configuration. If this is not the first time the power

supply is turned on, a different interface (RS-232) or a different GPIB address

may appear.

See "Remote Interface Configuration" in chapter 3 starting on page 56 if you

need to change the remote interface configuration.

Display Limit

Output On/Off

Note

3The “15V”, “OVP”, “OCP” and “OFF” annunciators are on. All others are off.

The power supply will go into the

(the

OFF

annunciator turns on); the 15V/7A range is selected (the

annunciator turns on); and the knob is selected for

OVP

and

OCP

the

annunciator also turn on.

power-on / reset

state; the output is disabled

15V

voltage

control. Notice that

4 Enable the outputs.

Press the key to enable the output. The

off and the

Output On/Off

15V, OVP, OCP

OFF

, and CV annunciators are lit. The

annunciator turns

blinking

digit can

be adjusted by turning the knob. Notice that the display is in the meter mode.

‘‘Meter mode’’ means that the display shows the actual output voltage and

current.

If the power supply detects an error during power-on self-test, the

annunciator will turn on.

See "Error Messages" for more information

ERROR

starting on page 121 in chapter 5

28

Page 31

Power

Output On/Off

Chapter 2 Initial Operation

Output Checkout

Output Checkout

The following procedures check to ensure that the power supply develops its

rated outputs and properly responds to operation from the front panel. For

complete performance and verification tests, refer to the

For each step, use the keys shown on the left margins.

Voltage Output Checkout

The following steps verify basic voltage functions with no load.

1 Turn on the power supply.

The power supply will go into the

OFF

(the

annunciator turns on); and the knob is selected for

2 Enable the outputs.

The

lit. The

display is in the meter mode. ‘‘Meter mode’’ means that the display shows the

actual output voltage and current.

annunciator turns on); the 15V/7A range is selected (the

OFF

annunciator turns off and the

blinking

digit can be adjusted by turning the knob. Notice that the

power-on / reset

15V, OVP, OCP

state; the output is disabled

Service Guide

15V

voltage

control.

, and CV annunciators are

.

2

3

Check that the front-panel voltmeter properly responds to knob control for the 15V/7A range.

Turn the knob clockwise or counter clockwise to check that the voltmeter

responds to knob control and the ammeter indicates nearly zero.

4

Ensure that the voltage can be adjusted from zero to the full rated

value.

Adjust the knob until the voltmeter indicates 0 volts and then adjust the knob

until the voltmeter indicates ‘‘

1

You can use the resolution selection keys to move the blinking digit to the

right or left when settin g the voltage.

1

15.0

volts’’.

29

Page 32

Power

Chapter 2 Initial Operation

Output Checkout

Current Output Checkout

The following steps check basic current functions with a short across the

power supply’s output.

1

Turn on the power supply.

The power supply will go into the

OFF

(the

annunciator turns on); the 15V/7A range is selected (the

annunciator turns on); and the knob is selected for

2

Conne c t a s hor t a c r os s (+) and ( - ) o utp ut te r mi n a ls wi th an in s ulated test lead.

power-on / reset

state; the output is disabled

15V

voltage

control.

Output On/Off

Display Limit

Volt/Curr

3

Enable the output.

The

OFF

The

CV

or CC annunciator turns on depending on the resistance of the test

lead. The

annunciator turns off and the

blinking

digit can be adjusted by turning the knob. Notice that the

15V, OVP

, and

OCP

annunciators are lit.

display is in the meter mode. ‘‘Meter mode’’ means that the display shows the

actual output voltage and current.

4

Adjust the voltage limit value to 1.0 volt.

Set the display to the

Adjust the voltage limit to 1.0 volt to assure CC operation. The

limit

mode (the

Limit

annunciator will be

blinking

CC

annunciator

will turn on.

5

Check that the front-panel ammeter properly responds to knob control for the 15V/7A range.

Set the knob to the

clockwise when the display is in the meter mode (the

current

control, and turn the knob clockwise or counter

Limit

annunciator is off).

Check that the ammeter responds to knob control and the voltmeter indicates

nearly zero (the voltmeter will show the voltage drop caused by the test lead).

).

30

Page 33

Chapter 2 Initial Operation

Output Checkout

6

Ensure that the current can be adjusted from zero to the full rated value.

Note

Adjust the knob until the ammeter indicates 0 amps and then until the ammeter

indicates 7.0 amps.

If an error has been detec ted dur ing the outpu t chec kout proce dur es , the

ERROR

starting on page 121 in chapter 5.

annu nciat or will turn o n. See "Error Messages" for more information

1

2

1

You can use the resolution selection keys to move the blinking digit the right

or left when setting the cu rr en t.

31

Page 34

Chapter 2 Initial Operation

Output Checkout

32

Page 35

3

Front-Panel Operation

Page 36

Front-Panel Operation

So far you have learned how to install your power supply and perform initial

operation. During the initial operation , you were briefly introduced to

operating from the front panel as you learned how to check basic voltage and

current functions. This chapter will describe in detail the use of these front-

panel keys and show how they are used to accomplish power supply operation.

• Front-Panel Operation Overview, page 35

• Constant Voltage Operation, page 36

• Constant Current Operation, page 38

• Storing and Recalling Operating States, page 40

• Programmin g Overvoltage Protection, page 42

• Programming Overcurrent Protection, page 45

• Remote Voltage Sensing, page 48

• Disabling the Output, page 50

• Disabling the Output Using an External Relay, page 51

• Knob Locking, page 51

• System-Related Operations , page 52

• Remote Interface Configuration, page 56

• GPIB Interface Configuration, page 61

• RS-232 Interface Configuration, page 62

• Calibration Overview, page 66

Note

Throughout this chapter the key to be pressed is shown in the left margin.

See "Error Messages", starting on page 121 in chapter 5 if you encounter any

errors dur ing front-pan el opera tion.

34

Page 37

Chapter 3 Front-Panel Operation

Front-Panel Operation Overview

Front-Panel Operation Overview

The following section describes an overview of the front-panel keys before

operating your power supply.

• The power supply is shipped from the factory configured in the

operation mode. At power-on, the power supply is autom aticall y set to

operate in the front-panel operation mode. When in this mode, the front-

panel keys can be used. When the power supply is in

remote

you can return to front-panel operation mode at any time by pressing the

Local

key if you did not previously send the front-panel lockout command.

A change between front-panel and remote operation modes will

in a change in the output parameters.

• The power supply has two output ranges of 15V/7A or 30V/4A. This feature

allows more voltage at a lower current or more current at a lower voltage.

The desired output range is selected from the front panel or over the remote

15V

or

30V

interfaces. The

annunciator indicates the presently selected

range.

• When you press key (the

display of the power supply goes to the

Display Limit

Limit

annunciator blinks), the

limit

mode and the present limit

values will be displayed. In this mode, you can also observe the change of

the limit values when adjusting the knob. If you press the

key again or let the display time-out after several seconds, the power supply

Limit

will return the display to the

meter

mode (the

annunciator turns off).

In this mode, the actual output voltage and current will be displayed.

• The output of the power supply can be enabled or disabled from the front

panel using the

Output On/Off

key. When the output is off, the

annunciator turns on and the output is disabled.

• The display provides the present operating status of the power supply with

annunciators and also informs the user of error codes. For example, the

power supply is operating in CV mode in the 15V/7A range and controlled

CV

and

15V

from the front panel, then the

however, the power supply is remotely controlled, the

annunciators will turn on. If,

Rmt

also turn on, and when the power supply is being addressed over GPIB

interface, the

Adrs

annunciator will turn on. See "

Display A nnu nc iators

on page 5 for more information.

front-panel

operation mode,

not

result

Display Limit

OFF

annunciator will

"

3

35

Page 38

Power

Chapter 3 Front-Panel Operation

Constant Voltage Operation

Constant Voltage Operation

To set up the power supply for constant voltage (CV) operation, proceed as

follows.

• Front-panel operation:

1

Connect a load to the output terminals.

With power-off, connect a load to the (+) and (-) output terminals.

2

Turn on the power supply.

Display Limit

Volt/Curr

The power supply will go into the

OFF

(the

annunciator turns on); the 15V/7A range is selected (the

annunciator turns on); and the knob is selected for

T o operate the power supply in the 30V/4A range, press the key bef ore

proceeding to the next step. The

3

Set the display to the limit mode.

Not i c e that the

Limit

annunciator blinks, indicating that the display is in the

limit mod e. Wh en the dis pla y is in t he

power-on / reset

30V

annunciator turns on.

limit

state; the output is disabled

mode, you can see the voltage and

voltage

control.

30V,4A

15V

current limit values of the power supply.

In constant voltage mode, the voltage values between the meter and limit

modes ar e the sam e , but the cu rr en t value s are not. Mor eover, if the

display is in the meter mode, you cannot see the change of current limit

value when adjusting the knob. We recommend that you should set the

display to “lim it” m ode to see the chan ge of curr en t lim it valu e in the

constant voltage mode whenever adjusting the knob.

4

Adjust the knob for the desired current limit.

Check that the

The second digit of the ammeter will be

Limit

annunciator still blinks. Set the knob for

blinking

1

current

control.

. The blinking digit can be

changed using the resolution selection keys and the blinking digit can be

adjusted by turning the knob. Adjust the knob to the desired current limit.

1

You can use the resolution selection keys to move the blinking digit to the

right or left when settin g curr en t.

36

Page 39

Chapter 3 Front-Panel Operation

Constant Voltage Operation

Volt/Curr

Display Limit

Output On/Off

5

Adjust the knob for the desired output voltage.

Check that the

The second digit of the voltmeter will be

Limit

annunciator still blinks. Set the knob for

blinking

1

voltage

control.

. Change the blinking digit

using the resolution selection keys and adjust the knob to the desired output

voltage.

6

Return to the meter mode.

Display Limit

Press key or let the display time-out after several seconds to

return to the meter mode. Notice that the

Limit

annunciator turns off and the

display shows “OUT PUT OFF” mes sage.

7

Enable the output.

The

OFF

annunciator turns off and the

15V

or

30V, OVP, OCP

and CV

annunciators are lit. Notice that the display is in the meter mode. In the

mode, the display shows the actual output voltage and current.

Refer to “Programming Overvoltage Protection” and “Programming

Overcurrent Protection” sections, starting on

information on

8

Verify that the power supply is in the constant voltage mode.

OVP

and

OCP

annunciators.

page 42 and page 45 for more

If you operate t he power supply in the constant v oltage (CV) mode, verify that

the

CV

annunciator is lit. If the CC annunciator is lit, choose a

higher

current

limit.

meter

3

Note

During actual CV operation, if a load change causes the current limit to be

exceeded, the power supply will automatically crossover to the constant

curren t mode at the prese t cur re nt lim i t and the output voltage wil l drop

proportionately.

• Remote inte rfac e oper ation:

CURRent {<current>|MIN|MAX} Set the current

VOLTage {<voltage>|MIN|MAX Set the voltage

OUTPut ON Enable the output

1

You can use the resolution selection keys to move the blinking digit to the

right or left when settin g voltage.

37

Page 40

Power

Chapter 3 Front-Panel Operation

Constant Current Operation

Constant Current Operation

To set up the power supply for constant current (CC) operation, proceed as

follows.

• Front-panel operation:

1

Connect a load to the output terminals.

With power-off, connect a load to the (+) and (-) output terminals.

2

Turn on the power supply.

Display Limit

The power supply will go into the

OFF

(the

annunciator turns on); the 15V/7A range is selected (the

annunciator turns on); and the knob is selected for

To operate the power supply in the 30V/4A range, press key before

proceeding to the next step. The

3

Set the display to the limit mode.

Not i c e that the

Limit

annunciator blinks, indicating that the display is in the

limit mod e. Wh en the dis pla y is in t he

power-on / reset

30V

annunciator turns on.

limit

state; the output is disabled

mode, you can see the voltage and

voltage

30V,4A

control.

15V

current limit values of the selected supply.

In constant current mode, the current values between the meter mode and

limit mode are the same, but the voltage values are not. Moreover, if the

display is in the meter mode, you cannot see the change of voltage limit

value when adjusting the knob. We recommend that you should set the

display to “limit” mode to see the change of voltage limit value in the

constant current mode whenever adjusting the knob.

4

Adjust the knob for the desired voltage limit.

Check that the

blinks

to indicate the knob is selected for voltage control. The blinkin g digit

Limit

annunciator still blinks and the second digit of voltmeter

1

can be changed using the resolution keys and the blinking digit can be adjusted

by turning the knob. Adjust the knob for the desired voltage limit.

1

You can use the resolution selection keys to move the blinking digit to the

right or left when settin g the voltage.

38

Page 41

Chapter 3 Front-Panel Operation

Constant Current Operation

Volt/Curr

Display Limit

Output On/Off

5

Adjust the knob for the desired output current.

Check that the

The second digit of the ammeter will be

Limit

annunciator still blinks. Set the knob for

blinking

. Change the blinking digit

1

current

control.

using the resolution selection keys and adjust the knob to the desired output

current.

6

Return to the meter mode.

Display Limit

Press key or let the display time-out after several seconds to

return the meter mode. Notice that the

Limit

annunciator turns off and the

display shows “OUT PUT OFF” mes sage.

7

Enable the output.

The

OFF

annunciator turns off and the

15V

or

30V, OVP, OCP

and CC

annunciators are lit. Notice that the display is in the meter mode. In the

mode, the display shows the actual output voltage and current.

Refer to “Programming Overvoltage Protection” and “Programming

Overcurrent Protection” sections, starting on

information on

8

Verify that the power supply is in the constant current mode.

OVP

and

OCP

annunciators.

page 42 and page 45 for more

If you operate the power supply in the constant current (CC) mode, verify that

the

CC

annunciator is lit. If the CV annunciator is lit, choose a

higher

voltage

limit.

meter

3

Note

During actual CC operation , if a load chan ge cau se s the voltage l im it to be

exce ed ed , t he power supply wi ll au t o ma t i ca lly crossov er to constant v o l t a g e

mode at the preset voltage limit and the output current will drop

proportionately.

• Remote inte rfac e oper ation:

VOLTage {<voltage>|MIN|MAX} Set the voltage

CURRent {<current>|MIN|MAX} Set the current

OUTPut ON Enable the output

1

You can use the resolution selection keys to move the blinking digit to the

right or left when settin g the cur ren t.

39

Page 42

Chapter 3 Front-Panel Operation

Storing and Recalling Operating States

Storing and Recalling Operating States

Store

You can store up to three different operating states in

This also enables you to recall the entire instrument configuration with just a

few key presses from the front panel.

The memory locations are suppli ed with the reset states from the factory for

front-panel operation. Refer to the description of

page 94 in chapter 4 for more information. The following steps show you how

to store and recall an operating state.

• Front-panel operation:

1

Set up the power supply for the desired operating state.

The storage feature “remembers” output range selection, the limit value

settings of voltage and current, output on/off state, OVP and OCP on/off state,

and OVP and OCP trip levels.

2

Turn on the storage mode.

Three memory locations (numbered 1, 2 and 3) are available to store the

operating states. The operating states are stored in

are remembered when being recalled.

non-volatile

*RST

command, starting on

non-volatile

memory and

memory.

STORE 1

This mes sage appear s on the dis pla y for approxim ate ly 3 se cond s.

3

Store the operating state in memory location “3”.

Turn the knob to the right to specify the memory location 3.

STORE 3

To cancel the store operation, let the display time-out after about 3 seconds

Store

or press any other function key except the

returns to the normal operating mode and to the function pressed.

40

key. The power suppl y

Page 43

Chapter 3 Front-Panel Operation

Storing and Recalling Operating States

Store

Recall

4

Save the operating state.

The operating state is now stored. To recall the stored state, go to the following

steps.

DONE

This mes sage appear s on the dis pla y for approxim ate ly 1 se cond .

5

Turn on the recall mode.

Memory location “1” will be displ ayed in the recall mode.

RECALL 1

This mes sage appear s on the dis pla y for approxim ate ly 3 se cond s.

6

Recall the stored operating state.

Turn the knob to the right to change the displayed storage location to 3.

RECALL 3

3

Recall

If this setting is not followed within 3 seconds with key stroke, the

power suppl y retu rns to norm al oper atin g mode an d wil l not rec all the

instrument state 3 from memory.

7

Restore the operating state.

The power supply should now be configured in the same state as when you

stored the state on the previous steps.

Recall

DONE

This mes sage appear s on the dis pla y for approxim ate ly 1 se cond .

• Remote inte rfac e oper ation:

*SAV {1|2|3} Store an operating state to a specified location

*RCL {1|2|3} Recall a previously stored state from a specified location

41

Page 44

Chapter 3 Front-Panel Operation

Programming Overvoltage Protection

Programming Overvoltage Protection

Overvoltage protection guards the load against output voltages that reach a

specified value greater than the programmed protection level. It is

accomplished by shorting the output via an internal SCR when the trip level is

set to equal or greater than 3 volts, or by progamming the output to 1 volt when

the trip level is set to less than 3 volts.

The following steps show how to set the OVP trip level, how to check OVP

operation, and how to clear overvoltage condition.

• Front-panel operation:

Setting the OVP Level and Enable the OVP Circuit

Power

Output On/Off

Over Voltage

Note

Over Voltage

1

Turn on the power supply.

The power supply will go into the

OFF

(the

annunciator turns on); and the knob is selected for

2

Enable the output.

The

3

Enter the OVP menu and set the trip level.

annunciator turns on); the 15V/7A range is selected (the

OFF

annunciator turns off and the display will go to the meter mode.

power-on / reset

state; the output is disabled

15V

voltage

control.

LEVEL 32.0 V

Y ou will see the above message on the display when you enter the OVP menu.

Adjust the control knob for the desired OVP trip level.

Note that you cannot set the trip level s to lower than 1.0 volt.

4

Enable the OVP circuit.

OVP ON

You will see the above message after pressing key.

Over Voltage

42

Page 45

Chapter 3 Front-Panel Operation

Programming Overvoltage Protection

Over Voltage

5

Exit the OVP menu.

CHANGED

The “CHANGED” mess age is highli ghted for a second to show that the new

OVP trip level is now in effect. If the OVP settings are not changed, “NO

CHANGE” will be displayed. The power supply will exit the OVP menu and the

OVP

display will return to the meter mode. Check that the

on.

annunciator turns

Checking OVP Operation

To check OVP operation, raise the output voltage to near the trip point. Then

very gradually increase the output by turning the knob until the OVP circuit

trips. This will cause the power supply output to drop to near zero, the

CC

annunciator to

message also appears on the display.

blink

, and the

annunciator to turn on. The “OVP TRIPPED”

Clearing the Overvoltage Condition

When the OVP condition occurs (the “OVP TRIPPED” message is shown on

the display), the

voltage source such as a battery, disconnect it first. The following steps show

how to clear the overvoltage conditions and get back to normal mode

operation. In the following steps, the display will go back to "OVP TRIPPED"

if you let the display time out after about several seconds.

OVP

annunciator

blinks

. When it was caused by external

OVP

3

Over Voltage

Display Limit

Over Voltage

or

1

Readjust the OVP trip level or the output voltage level.

Lower the output voltage level below the OVP trip point after pressing the

Display Limit

Over Voltage

the key.

2

Move to the clear mode.

ovp on

You will see the above message after pressing the key. If you

changed the output voltage level, press the key twice. Turn the

knob to the right until the "OVP CLEAR" appears on the display.

or raise the OVP trip level by using the knob after pressing

Over Voltage

Over Voltage

43

Page 46

Chapter 3 Front-Panel Operation

Programming Overvoltage Protection

Over Voltage

Note

3

Clear the overvoltage condition and exit this menu.

Now, when you press key again, the “DONE” message is

displayed for a second and the

Over Voltage

OVP

annunciator will not blink any more. The

output will return to meter mode.

• Remote inte rfac e oper ation:

VOLT:PROT {<voltage>|MIN|MAX} Set the OVP level

VOLT:PROT:STAT {OFF|ON) Disable or enable the OVP circuit

VOLT:PROT:CLE Clear the tripped OVP circuit

The power supply’s OVP circuit contains a crowbar SCR, which effectively

shorts the output of the power supply whenever the overvoltage condition

occurs. If external voltage source such as a battery is connected across the

output, and the overvoltage cond ition ina dver tentl y occu rs, the SC R w ill

continuousl y sin k a large cu rr en t from the sourc e; possi bly dam agin g the

power suppl y. To avoid this a diode m us t be conne cte d in se rie s with the

output as shown below.

Figure 3-1. Recommended Protection Circuit for Battery Charging

44

Page 47

Chapter 3 Front-Panel Operation

Programming Overcurrent Protection

Programming Overcurrent Protection

Overcurrent protection guards the load against output currents that reach a

specified value greater than the programmed protection level. It is

accomplished by programm ing the output current to zero.

The following steps show how to set the overcurrent protection trip level, how

to check OCP operation and how to clear overcurrent condition.

• Front-panel operation:

Power

Output On/Off

Over Current

Over Current

Setting the OCP Level and Enable the OCP Circuit

1

Turn on the power supply.

The power supply will go into the

OFF

(the

annunciator turns on); and the knob is selected for

2

Enable the output.

The

3

Enter the OCP menu and set the trip level.

Y ou will see the above message on the display when you enter the OCP menu.

Adjust the knob for the desired OCP trip level.

4

Enable the OCP circuit.

annunciator turns on); the 15V/7A range is selected (the

OFF

annunciator turns off and the display will go to the meter mode.

LEVEL 7.5 A

power-on / reset

state; the output is disabled

15V

voltage

control.

OCP ON

You will see the above message after pressing the key.

Over Current

3

45

Page 48

Chapter 3 Front-Panel Operation

Programming Overcurrent Protection

Over Current

5

Exit the OCP menu.

CHANGED

The “CHANGED” message is displayed for a second to show that the new OCP

trip level is now in effect. If the OCP settings are not changed, “NO CHANGE”

will be displayed. The power supply will exit the OCP menu and the display

OCP

will return to the meter mode. Check that the

annunciator turns on.

Checking OCP Operation

To check OCP operation, raise the output current to near the trip point. Then

very gradually increase the output by turning the knob until the OCP circuit

trips. This will cause the power supply’s output current to drop to zero and the

OCP

annunciator to

blink

. The “OCP TRIPPED” message also appears on the

display.

Clearing the Overcurrent Condition

When the OCP condition occurs (the “OCP TRIPPED” message is shown on

the display), the

voltage source such as a battery, disconnect it first. The following steps show

how to clear the overcurrent conditions and get back to normal mode

operation. In the following steps, the display will go back to "OCP TRIPPED"

if you let the display time out after about several seconds.

OCP

annunciator blinks. When it was caused by external

Over Current

Display Limit

or

1

Readjust the OCP trip level or the output current level.

Lower the output current level below the OCP trip point after pressing the

Display Limit

Over Current

the key.

2

Move to the clear mode.

or raise the OCP trip level by using the knob after pressing

ocp on

You will see the above message after pressing the key. If you

changed the output current level, press the key twice. Turn the

Over Current

Over Current

knob to the right until the "OCP CLEAR" appears on the display.

46

Page 49

Chapter 3 Front-Panel Operation

Programming Overcurrent Protection

Over Current

3

Clear the overcurrent condition and exit this menu.

Now, when you press key again, the “DONE’’ message is

displayed for a second and the

output will return to meter mode.

• Remote inte rfac e oper ation:

CURR:PROT {<current>|MIN|MAX} Set the OCP level

CURR:PROT:STAT {OFF|ON} Disable or enable the OCP circuit

CURR:PROT:CLE Clear the tripped OCP circuit

Over Current

OCP

annunciator will not blink any more. The

3

47

Page 50

Chapter 3 Front-Panel Operation

Remote Voltage Sensing

Remote Voltage Sensing

Remote voltage sensing is used to maintain regulation at the load and reduce

the degradation of regulation that would occur due to the voltage drop in the

leads between the power supply and the load.

By connecting the power supply for remote voltage sensing, voltage is sensed

at the load rather than at the power supply’s output terminals. This will allow

the power supply to automatically compensate for the voltage drop in

applications with lo ng lead lengths as well as to accurately read back the

voltage directly across the load.

When the power supply is connected for remote sensing, the OVP circuit senses

the voltage at the

CV Regulation

The voltage load regulation specification in chapter 8 applies at the output

terminals of the power supply. When remote sensing, add 5 mV to this

specification for each 1 V drop between the positive sensi ng point and (+)

output terminal due to the change in load current. Because the sense leads are

part of the power supply’s feedback path, keep the resistance of the sense leads

at or below 0.5

sensing

Ω

per lead to maintain the above specified performance.

points (load) and not the output terminals.

Output Rating

The rated output voltage and current specifications in chapter 8 apply at the

output terminals of the power supply. With remote sensing, any voltage

dropped in the load leads must be added to the load voltage to calculate

maximum output voltage. The performance specifications are not guaranteed

when the maximum output voltage is exceeded. If the excessive demand on

Unreg

the power supply forces the power supply to lose regulation, the

annunciator will turn on to indicate that the output is unregulated.

Output Noise

Any noise picked up on the sense leads also appears at the output of the power

supply and may adversely affect the voltage load regulation. Twist the sense

leads to minimize external noise pickup and run them parallel and close to the

load leads. In noisy environments it may be necessary to shield the sense leads.

Ground the shield at the power supply end only.

of the sense conductors

48

.

Do not use the shield as one

Page 51

Chapter 3 Front-Panel Operation

Remote Voltage Sensing

Stability

Using remote sensing under certain combinations of load lead lengths and

large load capacitances may cause your application to form a filter, which

becomes part of the voltage feedback loop. The extra phase shift created by

this filter can degrade the power supply’s stability, resulting in poor transient

response or loop instability. In severe cases, it may cause oscillations. To

minimize this possibility, keep the load leads as short as possible and twist

them together. As the sense leads are part of the power supply’s programming

feedback loop, accidental open-connections of sense or load leads during

remote sensing operation have various unwanted effects. Provide secure and

permanent connections.

Remote Voltage Sensing Connections

Remote voltage sensing requires connecting the load leads from output

terminals to the load and connecting the sense leads from sense terminals to

the load as shown below. Observe polarity when connecting the sensing leads

to the load.

Notice that the metal shor ting bars shoul d be rem oved from the outpu t and

sense ter m inal s for rem ote voltage se ns ing conn ections .

3

Note

Note

For local voltage sensing connections, the sense leads must be connected to

the output termin als .

During remote sensing setup, it is strongly recommended to power off (by

presssi ng power ON/OF F button) the powe r su ppl y to avoid

damage to the load or the power su ppl y.

Figure 3-2. Remote Voltage Sensing Connections

undesirable

49

Page 52

Chapter 3 Front-Panel Operation

Disabling the Output

Disabling the Output

The output of the power supply can be disabled or enabled from the front panel.

• When the power supply is in the “Off” state, the

OFF

the output is disabled. The

returns to the “On” state. When the output is disabled, the voltage value is 0

volts and the current value is 0.02 amps.

• The output state is stored in

when power has been off or after a remote interface reset.

While the output is disa bled , the ra nge se le ction keys, the control knob,

resol utio n sele ctio n key s, and ad just select io n key a re sti ll wor king . If the

display is in the me ter mode , you ca nn ot see the ch anges of output

voltage and current settings on the display when turning the knob. To see

or ch eck th e cha ng es wh en t he out pu ts a re d isa bl ed, t he dis pla y sh ou ld b e

in the limit mode.

• Front-panel operation:

You can disable the output by pressing key. This key toggles

between output “Off” and “On” states.

• Remote inte rfac e oper ation:

OUTP {OFF|ON} Disable or enable the output

annunciator turns off when the power supply

volatile

memory; the output is always disabled

Output On/Off

OFF

annunciator turns on and

50

Page 53

Chapter 3 Front-Panel Operation

Disabling the Output Using an External Relay

Disabling the Output Using an External Relay

When the output of the E3632A is turned off, it is implemented by setting the

output to 0 volts and 0.02 amps. This gives a zero output voltage without

actually disconnecting the output. To disconnect the output an external relay

must be connected between the output and the load. A TTL signal of either low

true or high true is provided to control an external relay. This signal can only

be controlled with the remote command

output is available on the RS-232 connection pin 1 and pin 0.

When the

(4.5 V) and pin 9 is low (0.5 V). The levels are reversed when the

OUTPut:RELay

OUTPut:RELay

state is “OFF”.

state is “ON”, the TTL output of pin 1 is high

OUTPut:RELay {OFF|ON}

. The TTL

3

Note

Note

TTL output of pin 1 or pin 9 of the RS-232 connector is available only after

installin g two jumpe rs insi de the powe r su ppl y. See the Se rvic e Guide for

more information.

Do not use the RS-232 interface if you have configured the power supply to

output relay control signals. Internal components on the RS-232 circuitry

may be damaged .

Knob Locking

The knob locking function can be used to disable the knob, thereby preventing

any unwanted changes during an experiment, or when you leave the power

supply unattended. To disable the knob, press the resolution selection key until

the blinking digit disappears.

Notice that the knob and front panel keys are disabled when in the remote

interface mode.

51

Page 54

Chapter 3 Front-Panel Operation

System-Related Operations

System-Related Operations

This section gives information on topics such as self-test, error conditions, and

front-panel display control. This information is not directly related to setting

up the power supply but is an important part of operating the power supply.

Self-Test

A

power-on

This test assures you that the power supply is operational. This test does not

perform the extensive set of tests that are included as part of the complete self-

test described below. If the power-on self-test fails, the

turns on.

•A

complete

seconds to execute. If all tests pass, you can have a high confidence that the

power supply is operational.

self-test occurs automatically when you turn on the power supply.

ERROR

self-test performs a series of tests and takes approximately 2

annunciator

• If the

• Front-panel operation:

• Remote inte rfac e oper ation:

complete

If the self-test fails, “FAIL” is displayed and the

See the

Technologies for service.

The

panel keys except the key) and the power-line switch simultaneously

and then continuing to press the key for 5 seconds. The complete self-

test will be finished in 2 seconds.

Service Guide

complete

self-test is successful, “PASS” is displayed on the front panel.

ERROR

for instructions on returning the power supply to Agilent

self-test is enabled by pressing the the(actually any front

Error

Recall

annunciator turns on.

Recall

*TST?

Returns “0” if the complete self-test passes or “1” if it fails.

52

Page 55

Chapter 3 Front-Panel Operation

System-Related Operations

Error Conditions

When the front-panel

syntax or hardware errors have been detected. A record of up to 2 0 errors can

be stored in the power supply’s error queue.

starting on

• Errors are retrieved in first-in-first-out (FIFO) order. The first error returned

is the first error that was stored. When you have read all errors from the queue,

ERROR

the

error is generated.

• If more than 20 errors have occurred when you operate the power supply over

the remote interface, the last error stored in the queue (the most recent error)

is replaced with -350, “

you remove errors from the queue. If no errors have occurred when you read

the error queue, the power supply responds with +0, “

interface or “NO ERRORS” from the front panel.

• The error queue is cleared when power has been off or after a

status) command has been executed. The

clear the error queue.

• Front-panel operation:

If the

errors stored in the queue. All errors are cleared when you read all errors.

page 121 for a complete listing of the errors.

annunciator turns off. The power supply beeps once each time an

ERROR

annunciator is on, press the key repeatedly to read the

ERROR

annunciator turns on, one or more command

Too many erro rs

See chapter 5 “Error Messages”,

”. No additional errors are stored until

No error

*RST

(reset) command does not

Error

” over the remote

*CLS

(clear

ERR -113

3

• Remote inte rfac e oper ation:

SYST:ERR? Reads and error from the error queue

Errors have the following format (the error string may contain up to 80

characters).

-113, "Undefined header"

53

Page 56

Chapter 3 Front-Panel Operation

System-Related Operations

Display Control

For security reasons, you may want to turn off the front-panel display. From

the remote interface, you can display a 12-character message on the front

panel.

The display ca n be e na bled / disabl ed from the re m ote inte rface onl y.

• When the display is turned off, outputs are not sent to the display and all

annunciators are disabled except the

operation is otherwise unaffected by turning off the display.

ERROR

annunciator. Front-panel

• The display state is stored in

when power has been off, after a remote interface reset, or after returning to

local from remote.

• You can display a message on the front panel by sending a command from the

remote interface. The power supply can display up to 12 characters of the

message on the front panel; any additional characters are truncated. Commas,

periods, and semicolons share a display space with the preceding character,

and

are not

outputs are not sent to the display.

• Sending a message to the display from the remote interface overrides the

display state; this means that you can display a message even if the display is

turned off.

The display state is automatically turned on when you return to the local (front

panel) operation. Press

interface.

• Remote inte rfac e oper ation:

DISP {OFF|ON} Disable / enable the display

DISP:TEXT <quoted string> Display the string enclosed in quotes

DISP:TEXT:CLE Clear the displayed message

The following statement shows how to display a message on the front panel

from a Agilent Technologies controller.

"DISP:TEXT ‘HELLO’ "

considered individual characters. When a message is displayed,

volatile

Local

memory; the display is always enabled

key to return to the local state from the remote

54

Page 57

Chapter 3 Front-Panel Operation

System-Related Operations

Firmware Revision Query

The power supply has three microprocessor s for control of various internal

systems. You can query the power supply to determine which revision of

firmware is installed for each microprocessor.

You can query the firm w ar e re vision from the re m ote inte rfac e onl y.

• The power supply returns four fields separated by commas and the fourth field

is a revision code which contains three numbers. The first number is the

firmware revision number for the main processor; the second is for the input/

output processor; and the third is for the front-panel processor.

• Remote inte rfac e oper ation:

*IDN? Returns "HEWLETT-PACKARD,E3632A,0,X.X-X.X-X.X"

Be sure to dimension a string variable with at least 40 characters.

SCPI Language Version

The power supply compli es with the rules and regulations of the present

version of SCPI (Standard Commands for Programmable Instruments). You

can determine the SCPI version with which the power supply is in compliance

by sending a command from the remote interface.

You can query the SCPI version from the remote interface only.

• Remote inte rfac e oper ation:

SYST:VERS? Query the SCPI version

Returns a string in the form “YYYY .V” where the “Y’s” represent the year of the

version, and the “V” represents a version number for that year (for example,

1995.0).

3

55

Page 58

Chapter 3 Front-Panel Operation

Remote Interface Configuration

Remote Interface Configuration

Before you can operate the power supply over the remote interface, you must

configure the power supply for the remote interface. This section gives

information on configuring the remote interface. For additional information

on programming the power supply over the remote interface,

Interface Reference", starting on page 71 in chapter 4.

Remote Interface Selection

The power supply is shipped with both an GPIB (IEEE-488) interface and an

RS-232 interface on the rear panel. Only one interface can be enabled at a time.

The

GPIB interfac e

factory.

The remote interface can be selected from the front-panel only.

• The interface selection is stored in

change when power has been off or after a remote interface reset.

• If you select the GPIB interface, you must select a unique address for the

power supply. The current address is displayed momentarily on the front

panel when you turn on the power supply.

• Your GPIB bus controller has its own address. Be sure to avoid using the

bus controller’s address for any instrument on the interface bus. Agilent

Technologies controll ers generally use address “21”.

• If you enable the RS-232 interface, you must select the baud rate and parity

to be used. “RS-232” is displayed momentarily on the front panel when you

turn on the power supply if you have selected this interface.

is selected when the power supply is shipped from the

non-volatile

memory, and

1

See "Remote

does not

2

1

Refer to "GPIB Interface Configuration" starting on page 61 for more information

on connecting the power supply to a computer over the GPIB interface.

2

Refer to "RS-232 Interface Configuration" starting on page 62 for more information

on connecting the power supply to a computer over the RS-232 interface.

56

Page 59

Chapter 3 Front-Panel Operation

Remote Interface Configuration

GPIB Address

Each device on the GPIB (IEEE-488) interface must have a unique address.

You can set the power supply’s address to any value between 0 and 30. The

current address is displayed momentarily on the front panel when you turn on

the power supply . The address is set to “05” when the power supply is shipped

from the factory.