Page 1

Agilent 6800 Series

AC Power Source/Analyzer

Product Note

Using the Agilent Technologies 6800 Series

AC Power Source/Analyzers for Generation

and Measurement

Applications:

• Simulating AC Line Sub-Cycle Dropouts

• Generating MIL-STD-704D Waveforms

• Performing IEC 555-2 Measurements

• Performing Inrush Current Measurements

• Generating User-Defined Waveforms

• Operating the Agilent 6812A and 6813A

at Low Frequencies

Page 2

2

3

4

6

8

11

14

18

21

24

28

Introduction

This note provides information on how you can

use the features of the Agilent Technologies 6800

series ac power source/analyzers to address a

variety of applications. Although your exact application may not be listed here, the capabilities

described can be generalized and applied to your

specific needs. The programming examples are

given in QBASIC.

These are the capabilities that are discussed and

a description of how they can be applied:

Table of Contents

Introduction to the Agilent 6800 AC Power Source/Analyzer

Agilent 6800 Series Output Transients

Agilent 6800 Series Triggering

Agilent 6800 Series Measurements

Application 1: Simulating AC Line Sub-Cycle Dropouts

Application 2: Generating MIL-STD-704D Waveforms

Application 3: Performing IEC 555-2 Measurements

Application 4: Performing Inrush Current Measurements

Application 5: Generating User-Defined Waveforms

Application 6: Operating the Agilent 6812A and 6813A

at Low Frequencies

Page 3

3

The 6800 series ac power source/analyzers are

members of the Agilent Technologies “One-Box”

Solution power products family. These products

offer an integrated solution for ac power testing

applications.

The 6800 series combines the functionality of the

following instruments in one box:

• power amplifier

• arbitrary waveform generator

• power analyzer

• harmonic analyzer

• waveform digitizer

The power amplifier and arbitrary waveform

generator capabilities produce waveforms with

programmable amplitude, frequency, and waveshape. Each model has pre-programmed sine,

square, and clipped sine waveshapes. For added

flexibility, twelve user-defined waveforms can

be created and stored in non-volatile memory.

Waveforms can be programmed using the 6800

series transient generation system to simulate

sophisticated and repeatable ac line disturbances

or output sequences.

The power analyzer and harmonic analyzer capabilities provide high precision measurements

including:

• rms, dc, ac+dc voltage and current

• peak voltage and current

• real, apparent, and reactive power

• harmonic analysis of voltage and current waveforms providing amplitude and phase up to the

50th harmonic

• total harmonic distortion

• triggered acquisition of digitized voltage and

current

The 6800 series can be used in bench or ATE applications. The fully featured front panel and built-in

GPIB and RS-232 interfaces allow you to program

waveforms, measure parameters, and monitor the

status of the ac power source/analyzer.

Each model features a SCPI (Standard Commands

for Programmable Instruments) command set. This

industry standard command set simplifies test system development by offering command set commonality between all types of instrumentation. Instruments performing the same function use the same

self-documenting SCPI instructions. For example,

the same commands are used to program a waveshape on the 6800 series ac power source/analyzers

as on a function generator. Because you spend less

time learning device commands, you can get your

application up and running faster.

The following sections of this product note explain

how to optimize your usage of the features of the

6800 series products. At the end of this product

note there are practical examples that show how

these features can be applied.

Introduction to the Agilent 6800 AC Power Source/Analyzer

Page 4

4

A programmable output value of the ac power

source/analyzer can operate in one of four modes:

FIXED, Step, Pulse, or List. The default setting is

FIXED mode, where the output will stay “fixed” at

the programmed value until another command is

sent to change it. The remaining three operating

modes constitute the Transient Subsystem. Output

transients are used to:

• synchronize output changes with a particular

phase of the voltage waveform

• synchronize output changes with trigger signals

• simulate ac line disturbances with precise duration and phase control

• create sequences of output changes

Output transients are triggered actions and will

cause the output of the ac power source/analyzer

to react in a manner defined by the selected mode.

What Programmable Functions can be

Controlled by the Transient Subsystem?

The 6800 series provides control of many output

parameters. Most of these can be programmed as

an output transient. The following output parameters are subject to transient control:

• ac output voltage

• dc output voltage (Agilent 6812A and 6813A only)

• frequency

• phase (Agilent 6834A only)

• waveform shape

• ac voltage slew rate

• dc voltage slew rate (6812A and 6813A only)

• frequency slew rate

• peak current limit (6812A and 6813A only)

• rms current limit

• dwell time (List mode only)

Upon receipt of a trigger, an output parameter set

to Step, Pulse, or List mode will transition from an

immediate level (its initial output setting) to one or

more levels (successive output settings). The number of successive output settings is, in part, what

differentiates one transient mode from another.

What is a STEP Transient?

A Step transient generates a single triggered output change (from an immediate output level to

ONE successive output level) of one or more of the

output parameters subject to transient control.

Only output parameters programmed to Step mode

will be part of the triggered action. The output

will remain at the final output level once the Step

transient is complete.

What is a PULSE Transient?

A Pulse transient generates a triggered output

change that returns to its immediate output level

after a programmed time period. A Pulse transient

can also be programmed to repeat the output

change more than once or continuously.

What is a LIST Transient?

A List transient generates a sequence of output

changes. Each output change of the sequence is

called a List point. All parameters subject to transient control can be programmed at each List point.

A List can contain up to one hundred points. The

list of points can be programmed to execute once

or to repeat from one to an infinite number of times.

Agilent’s 6800 series List points can be paced by

external triggers. When paced by triggers, the output will remain at a particular List point until a

trigger is received. Only then will it proceed to the

next programmed point.

List points can also be paced by individual programmable dwell time parameters associated with

every point. Only when the dwell time for a particular List point expires will it proceed to the next

List point.

Once the List is completed, the output returns to

the immediate levels.

Agilent 6800 Series Output Transients

Page 5

5

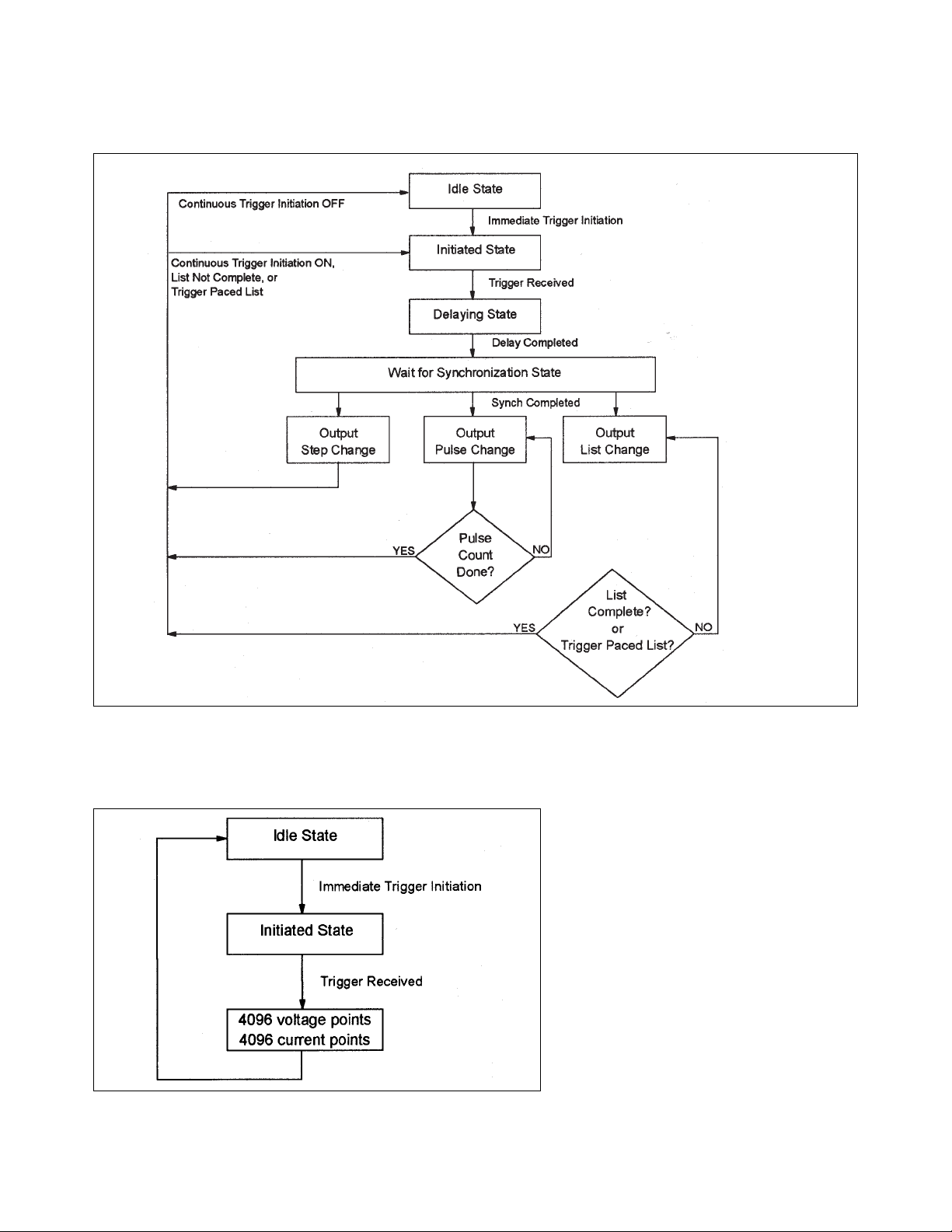

Model of the Transient System

Page 6

6

In ATE applications, triggers are often a convenient way of synchronizing test system events and

increasing test throughput. These benefits also

apply to the triggering subsystems in the 6800

series products since these products combine the

capabilities of many test instruments. Each model

is equipped with the ability to send and receive

triggers, and to perform or initiate a multitude of

synchronized functions upon receiving a trigger.

Triggers can be used to change the output, synchronize a change to a phase of a waveform cycle,

and synchronize a measurement to an output

change. The effectiveness of the triggering capability

can be shown when measuring worst case inrush

current of a switching power supply. Using the

6800 series triggering subsystem, the output can

be triggered to turn on at a phase near the peak

of the ac cycle for simulating a worst case ac line

condition. Simultaneously, the ac source can be

triggered to take current measurements to characterize the behavior of the power supply under test.

In addition, triggering can be extended to external

test equipment via the Trigger Out connection.

The 6800 series has two main triggering subsystems,

one for generating transients and one for making

measurements. These two subsystems have common

trigger sources that can synchronize transient and

measurement events.

What Actions Can be Triggered?

The following actions of the 6800 series can be

triggered:

• a change in output setting

• the start of a Step, Pulse, or List transient

• the pace of a List sequence

• the acquisition of digitized voltage and current

• the synchronization of an output change to

a phase of the cycle

A programmable time delay can be specified for

triggers that generate output changes. This allows

the insertion of a specified time delay between

the receipt of the trigger and the action of the

ac power source/analyzer output.

What Can Serve as the Source of the Trigger?

The 6800 series can receive triggers from the

following sources:

The GPIB. The computer can send trigger commands

to the ac power source/analyzer. There is a short

command processing time associated with this

source.

External Trigger In. This is the 6800 series TRIGGER

IN connector. It accepts TTL levels, with the falling

edge detected as the trigger.

TTL Trigger. The TTL trigger is an internal trigger

that causes the acquisition of digitized voltage and

current data.

This internal trigger can be generated when an

output transient begins or ends, or as the result

of List step execution.

How Can Triggers be Generated?

The 6800 series can generate a trigger on the

TRIGGER OUT connector as a result of the following actions:

• the beginning of a Step, Pulse, or List output

transient

• the completion of a Step or Pulse output

transient

• the completion of a List sequence

• the beginning of a List step

The TRIGGER OUT signal is a nominal

10-microsecond low-true pulse.

How Can the Agilent 6800 Series be Enabled

to Respond to a Trigger?

The default state of the ac power source/analyzer

is the idle state where trigger detection is disabled.

To respond to a trigger, it must be placed in the

“initiated state.” This can be done via the front

panel or over the bus. Once initiated, the ac power

source/analyzer can detect a trigger from the

selected source.

When the trigger is detected, the ac power source/

analyzer will perform the trigger action after waiting any programmed trigger delay time. Upon completion of the trigger action, the ac power source/

analyzer will return to the idle state.

Agilent 6800 Series Triggering

Page 7

7

Output Transient Trigger Model

Measurement Trigger Model

Page 8

8

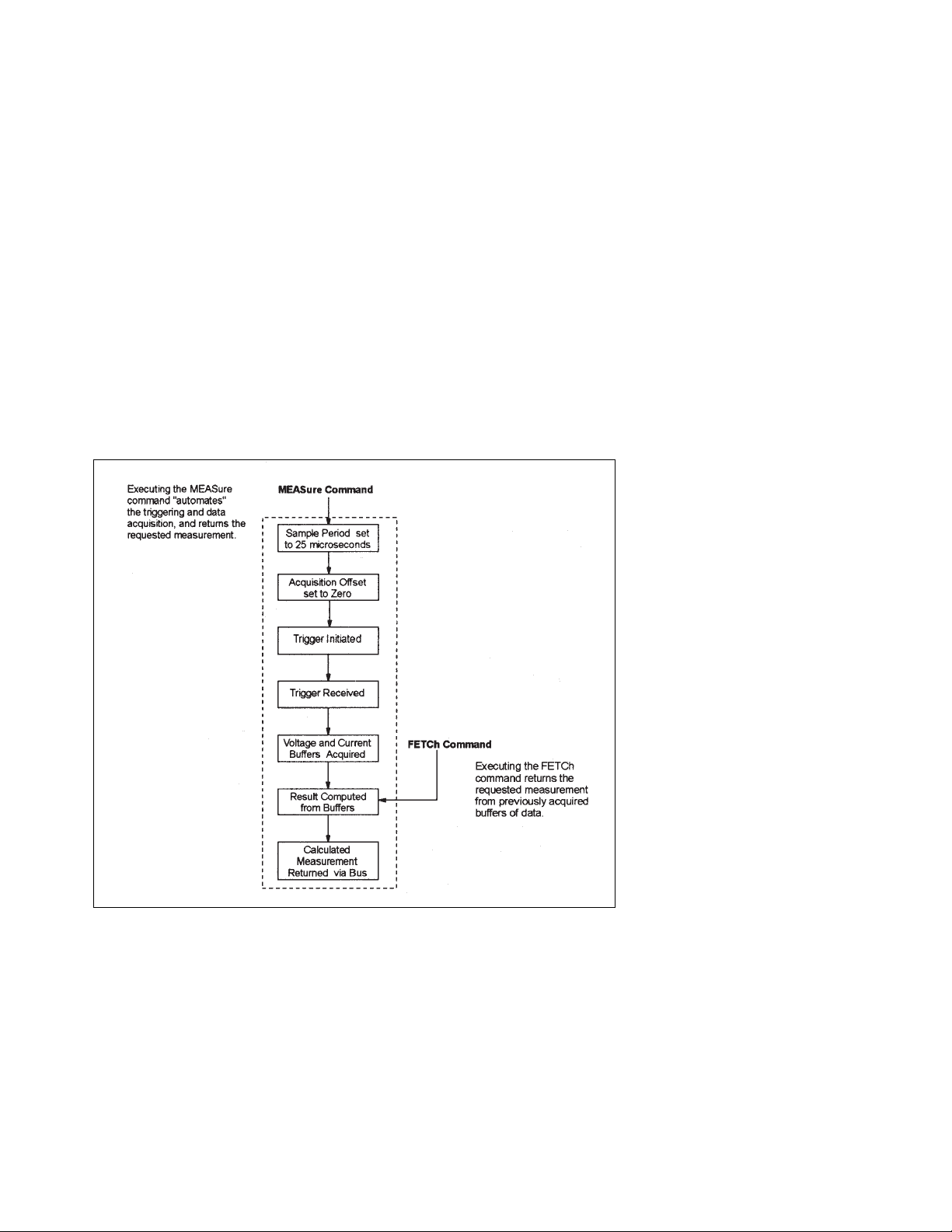

The built-in power analyzer capability offers many

voltage, current, and power measurements to the

user. While on, the ac power source/analyzers are

continuously sampling instantaneous output voltage and current for several output cycles and writing the data to buffers. Each buffer, one for voltage

and one for current, holds 4096 data points. The

voltage and current data is used to calculate the

requested measurement parameter. There are two

basic methods to obtain a measurement: using the

MEASure command or the FETCh command. These

commands can return a single measured parameter,

an array of voltage and current harmonic data, or

an array of the 4096 voltage or current data values.

What is a MEASure Command?

When this command is sent to the 6800 series

ac power source/analyzer, the unit begins acquiring new voltage and current data into its data

buffers. Upon completing the acquisition of 4096

data points for voltage and current, the unit then

performs the required calculation to return the

requested measurement parameter. When a new

acquisition of instantaneous output voltage and

current data is desired, this command should be

used to return the requested measurement.

What is a FETCh Command?

This command allows the user to retrieve measured parameters from previously acquired voltage

and current data. For example, the FETCh command can be used after a MEASure command to

return calculated parameters from the same 4096

data points that were acquired by the MEASure

command. In addition, the FETCh command can

be used to retrieve measurement information after

triggering an acquisition of digitized voltage and

current data. This method provides the flexibility

to synchronize the data acquisition with a triggered

event, and then return many calculations from

the existing voltage and current data buffers.

Agilent 6800 Series Measurements

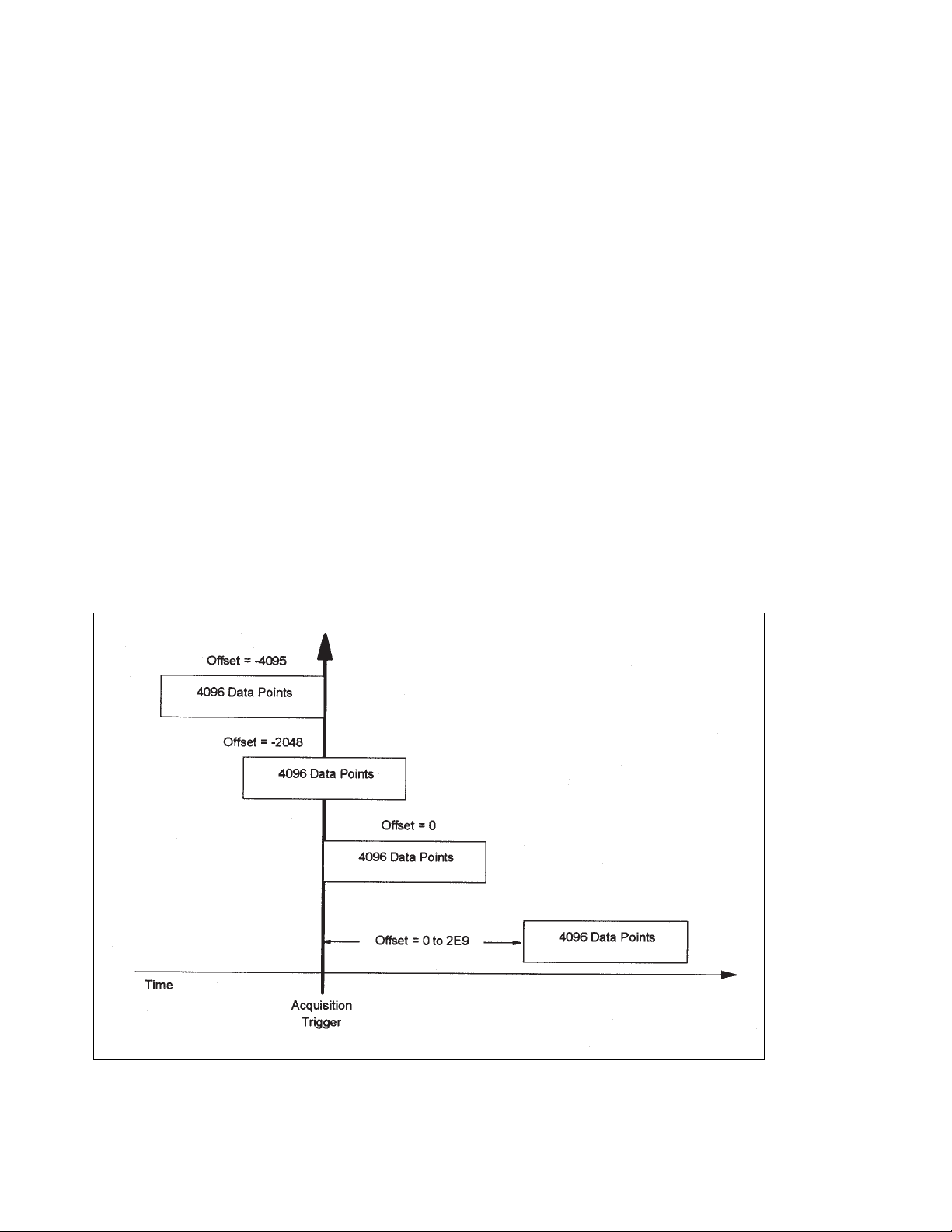

Pre-event and Post-event Acquisition Triggering

Page 9

9

How Can the Acquisition of Voltage and Current

Data be Controlled?

Two characteristics of the voltage and current

acquisition can be controlled: the sample rate,

and the beginning of acquisition relative to the

trigger. The ac power source/analyzer has a sample

rate of approximately 40 kHz (a sample every 25

microseconds) as the default setting. This means

it takes approximately 100 milliseconds for the

data buffers to fill with voltage and current data

points. The sample period can be programmed

from a minimum of 25 microseconds to a maximum of 250 microseconds (at 25-microsecond

increments).

The acquisition of voltage and current data can

also be initiated relative to the acquisition trigger,

thereby enabling the capture of pre-event and

post-event data. To capture pre-event or post-event

voltage and current data, the offset of data points

relative to the trigger is programmed. The range

of offset that can be programmed is from -4096 to

2xl0

9

points. If the offset is negative, the values at

the beginning of the data buffer represent samples

taken prior to the trigger. If the offset value is zero

(the default setting), all data is acquired directly

after the trigger. If the offset value is positive, the

acquisition of valid buffer data will be delayed

from the receipt of the trigger.

MEASure and FETCh Command Execution Diagram

Page 10

10

The following section contains six application

examples. For each application, there is:

• An overview of the application

• A description of the Agilent 6800 series features

used to implement the application

• The advantages and benefits of the 6800 series

solution

• The details of the implementation of the solution

• A sample program in QBASIC using the National

GPIB interface card

• A description of variations on the application

(if applicable)

The following table lists the 6800 series features

used in each of the applications.

Applications

Application

1 2 3 4 5 6

Transient Generation

Step mode

•

Pulse mode

•

List mode

• •

Transient generation with a trigger delay

•

Synchronization with output phase

• •

User-defined waveform generation

•

Voltage slew control

•

Frequency slew control

Measurement and Analysis

Synchronization with transients

Harmonic analysis

•

Measurement window control

•

High resolution current range

•

measurements

Digitized data acquisition

•

Event-referenced data acquisition

•

Data acquisition sample rate control

•

Page 11

11

Overview of application

The ability of a switching power supply to maintain its output voltage setting in the presence of

typical ac line disturbances is critical to its enduse. If the end-use of the power supply is installation into a computer, for example, sensitivity to

ac line variations can result in unexpected loss of

critical data and system downtime. To simulate

these common ac line voltage variations, an amplitude controlled ac voltage can be applied to the

ac input of the power supply.

For this example, the power supply requires a

single phase ac source set to a nominal line voltage

of 120 Vrms and frequency of 60 Hz. To test the

power supply under worst case conditions, a voltage dropout to 0 Vrms should occur between 80°

and 110° (i.e. a duration of 0.001389 seconds) on

the voltage waveform. This is a steadystate test,

which means that the dropout occurs after the

ac input of the power supply under test has settled

from all non-repetitive inrush conditions that

typically occur at power-up.

Agilent 6800 series features used

• RMS voltage in Pulse mode

• Trigger synchronization to the output voltage

phase

• Trigger delay

Advantages/benefits of the Agilent 6800 series

solution

• By using the trigger phase synchronization

capability, the timing of the dropout is accurate

and repeatable.

• By using the transient capability, the computer

is not devoted to sequencing the output.

• By using the trigger delay, it is assured that the

power supply is in steadystate operation.

• One command initiates the test.

Implementation details

How the 6800 series implements the dropout

The computer sends a trigger to the ac power

source/analyzer with a programmable delay of

5 seconds to ensure that the ac input to the power

supply under test is in a steadystate condition.

The ac source outputs a low distortion 120 Vrms

sinewave during the trigger delay and allows the

power supply to stabilize into steadystate operation. After 5 seconds, the ac power source/analyzer

responds to the trigger and drops the output voltage to 0 Vrms starting at 80° of one output voltage

cycle and lasting for 0.001389 seconds.

Agilent 6800 series setup

• Connect the ac source output to the ac input

of the power supply under test.

• Set the output waveform to sine.

• Set the rms voltage to Pulse mode.

• Set the initial (immediate) voltage to 120 Vrms.

• Set the triggered voltage level to 0 Vrms.

• Set the frequency to 60 Hz.

• Set the Pulse count to 1.

• Set the Pulse width to 0.001389 seconds

(the width of 30° of phase dropout for a 60 Hz

sinewave).

• Set the transient trigger source to BUS.

• Set the transient trigger source synchronization

to PHASE.

• Set the phase synchronization to 80°.

• Set the trigger delay to 5 seconds.

• Initiate the transient trigger system.

• Enable the output of the ac power source/

analyzer.

• Send a bus trigger.

Application 1:

Simulating AC Line Sub-Cycle Dropouts

Page 12

12

Upon the receipt of the trigger, the ac source

continues to output a 120 Vrms, 60 Hz sinewave

for 5 seconds. After the 5-second trigger delay,

the rms voltage drops to 0 Vrms at 80° of the

cycle and then rises back to 120 Vrms (0.001389

seconds later) at 110° of the cycle.

Variations on this implementation

1. The Pulse width can be increased to simulate

full cycle dropouts.

2. The Pulse count can be set to a value >1 and

the Pulse period can be programmed to 0.01667

seconds (the period of a 60 Hz sinewave) to

create multiple dropouts.

3. The triggered level of the rms voltage can be set

higher than the initial setting of 120 Vrms to

simulate a voltage surge.

4. The rms voltage slew rate can be programmed

in Pulse mode to simulate a gradual brown out

(sag) condition versus an abrupt dropout. The

Pulse width can be increased to simulate a sag

over multiple ac line cycles.

Timing Diagram of Application 1

Page 13

13

Page 14

14

Overview of application

U.S. Military Standard 704D (September 30, 1980)

establishes the requirements of electrical power

transfer between the aircraft or ground support

electrical system, and the electronic equipment

utilizing this power on board the aircraft. When

testing to this standard, electrical aircraft equipment must be subjected to voltage and frequency

transients that can occur under normal operation,

emergency power operation, and during power

source transfers.

The “pass” criteria for aircraft equipment is dependent upon the specification of the equipment under

test. In general, the intent of the test is that:

• the equipment is permitted a degradation or

loss of function unless required otherwise by

its specifications

• the equipment is not permitted to produce a

damaging or unsafe condition

• the equipment must automatically recover full

specified performance when normal ac power

characteristics are restored

For this example, the equipment under test has

a single phase ac input with 115 Vrms and 400 Hz

requirements. The device is tested under ac voltage

transients initially, and then under frequency transient conditions. These transients are as follows:

At 400 Hz:

Voltage Test 1: 180 Vpk (127 Vrms) for 10 ms, and

then slew to 124 Vpk (88 Vrms) at 800 Vpk

(566 Vrms) per second.

Voltage Test 2: 80 Vpk (57 Vrms) for 10 ms, and

then slew to 108 Vpk (76 Vrms) at 400 Vpk

(283 Vrms) per second.

At 115 Vrms:

Frequency Test 1: 425 Hz for 1 s, 420 Hz for 4 s,

410 Hz for 5 s, and 407 Hz for 4 s.

Frequency Test 2: 375 Hz for 1 s, 380 Hz for 4 s,

390 Hz for 5 s, and 393 Hz for 4 s.

In this example, the voltage and frequency transients will be executed as an integrated test

sequence.

Agilent 6800 series features used

• RMS voltage and frequency control in List mode

• RMS voltage slew control

• List dwell time control

• Triggering system to execute the List

Advantages/benefits of the Agilent 6800 series

solution

• The List capability allows the ac power

source/analyzer outputs to sequence through

each RMS voltage and frequency setting with

accurate timing according to the standard and

without controller intervention.

• By using the programmable RMS voltage slew

control, the RMS voltage level excursions can

be faithfully reproduced as per the standard.

• The List settings for MIL-STD-704D are stored

in non-volatile memory, so the test need only

be set up once and then executed as needed.

Implementation details

How the 6800 series implements MIL-STD-704D RMS

voltage and frequency transients

The computer sets up List sequence, then ac power

source/analyzer is sent a bus trigger. Upon receipt

of the trigger, the ac power source/analyzer’s output is set according to the voltage, voltage slew,

and frequency values of the first List point. The

output will remain at the first List point setting

until the dwell time for that List point expires. The

unit will then sequence through each successive

List point paced by the respective dwell times until

the List is completed. Upon completion of the List,

the output will return to the immediate settings.

Agilent 6800 series setup

• Connect the ac source output to the ac input

of the equipment under test.

• Set the rms voltage to 115 Vrms.

• Set the frequency to 400 Hz.

• Set the rms voltage to List mode.

• Set the rms voltage slew to List mode.

• Set the frequency to List mode.

• Set the List to sequence automatically.

Application 2:

Generating MIL-STD-704D Waveforms

Page 15

15

Agilent 6800 series setup (continued)

• Set the List points as follows:

List Vrms Dwell

Point Vrms frequency Slew Time

1 115 V 400 Hz INF *60 s

2 127 V 400 Hz INF 0.01 s

3 88 V 400 Hz 566 V/s 0.07 s

4 115 V 400 Hz INF *60 s

5 57 V 400 Hz INF 0.01 s

6 76 V 400 Hz 283 V/s 0.07 s

7 115 V 400 Hz INF *60 s

8 115 V 425 Hz INF 1 s

9 115 V 420 Hz INF 4 s

10 115 V 410 Hz INF 5 s

11 115 V 407 Hz INF 4 s

12 115 V 400 Hz INF *60 s

13 115 V 375 Hz INF 1 s

14 115 V 380 Hz INF 4 s

15 115 V 390 Hz INF 5 s

16 115 V 393 Hz INF 4 s

17 115 V 400 Hz INF *60 s

*

List points 1, 4, 7, 12, and 17 represent periods of time when the ac input to

the equipment under test is set to the nominal levels prior to the onset of the

next transient. The length of time the output of the ac power source/analyzer

is set to the nominal level can be determined by user-convenience (60 seconds

for this example).

• Set the transient trigger source to BUS.

• Initiate the transient trigger.

• Enable the output of the ac power source/

analyzer.

• Send a bus trigger.

Upon receipt of the trigger, the List sequence will

begin and the ac power source/analyzer output will

go to the setting represented in the first List step.

Each List step will be executed at the expiration

of the programmed dwell time of the previous step.

After the last List step is executed, the output of

the ac source will change to the immediate output

settings (Fixed mode settings).

Page 16

16

List Timing Diagram for Application 2

Page 17

17

Page 18

18

Overview of application

IEC 555-2 (1982) is a regulatory standard that

pertains to ac line disturbances, namely current

harmonics. These current harmonics are caused by

connecting household appliances and similar electrical equipment to a 230 V, 50 Hz ac mains. This

standard establishes limits on the amount of harmonic energy electrical equipment can inject on the

ac line to ensure that other devices connected to

the ac power distribution system are not adversely

affected. The generated current harmonics can vary

or fluctuate with time (due to electronic products

that cycle the ac line), or can have steadystate

(quasi-stationary) characteristics.

When testing electronic equipment with a single

phase ac input for compliance to the quasi-stationary

part of this standard, it is necessary to have an ac

source with low distortion and low output impedance to avoid introducing unacceptable measurement errors. The measurement instrument must

use the required Rectangular (or Hanning) measurement window and must have the capability to

return measured current amplitude data up to

the 40th harmonic of the fundamental.

Agilent 6800 series features used

• RMS Voltage and frequency control

• Measurement window control

• Harmonic current measurement

Advantages/benefits of the Agilent 6800 series

• The 6800 series provides a “One-Box” Solution,

so a separate power analyzer is not required for

quasi-stationary harmonic measurements.

• The 6800 series provides an IEC 555 compliant

Rectangular measurement window built into the

standard unit.

• The low distortion, low output impedance and

16-bit measurement accuracy of the 6800 series

provide full compliance to the measurement

requirements.

Implementation details

How the 6800 series implements IEC 555 quasi-stationary

harmonic current measurements

The output of the ac power source/analyzer is

set to 230 V and 50 Hz. The measurement window

is changed from the default value (KBessel) to

the Rectangular window. To perform the harmonic

analysis, the ac power source/analyzer is sent a

command to measure an array of harmonic current

amplitudes. This array of current harmonics can

be transferred to the computer for PASS/FAIL

analysis versus the limits of the standard.

Application 3:

Performing IEC 555-2 Measurements

Page 19

19

Agilent 6800 series setup

• The ac source output is connected to the ac

input of the equipment under test.

• Set the output waveform to sine.

• Set the rms voltage to Fixed mode.

• Set the frequency to Fixed mode.

• Set the voltage to 230 Vrms.

• Set the frequency to 50 Hz.

• Set the measurement window to Rectangular.

• Enable the output of the ac power source/

analyzer.

• Wait until the ac input to the equipment is in

a steadystate condition.

• Send the harmonic current array measurement

command to return 50 harmonic current

amplitudes.

Using the computer:

• Read the harmonic current array into the

computer.

• Compare the measured harmonic current amplitudes of harmonic numbers 2 through 40 to the

IEC 555-2 quasi-stationary standard limits.

Page 20

20

Page 21

21

Overview of application

Switch mode power supplies are commonly used

in many electronic products. These power supplies

typically have input capacitors that cause high

levels of peak inrush current to be drawn as they

charge from the rectified line at turn-on. The peak

amplitude of the inrush current varies with the

turn-on phase of the ac voltage cycle. Usually, the

highest peak inrush currents occur near the peak

(90°) of the voltage cycle. Characterization of

inrush current versus turn-on phase allows for

determination of worst case inrush current conditions, which must be determined to properly select

fuses and circuit breakers, to uncover component

stresses, and to determine if a product will produce ac line disturbances that interact with other

equipment connected to the branch circuit.

For this example, the equipment under test

requires an ac line voltage of 120 Vrms at 60 Hz.

Agilent 6800 series features used

• RMS voltage and frequency control

• Peak current measurement

• Pre-event current data capture

• Trigger synchronization to the output voltage

phase

• Measurement and waveform generation

synchronization

• High crest factor

Advantages/benefits of the Agilent 6800 series

solution

The 6800 series provides a “One-Box” Solution for

measurement and waveform generation and eliminates the worry of synchronizing separate instruments. The ability to turn-on relative to the output

voltage phase allows worst case inrush characterization, which results in a more reliable product.

Implementation details

How the 6800 series implements peak inrush current

measurements

The RMS voltage is programmed to Step mode

to generate a turn-on condition from 0 Vrms to

120 Vrms. The turn-on is synchronized to the

phase of the output voltage. The current measurement is programmed to occur at turn-on with

10 milliseconds of pre-event data to ensure that

the full inrush event is captured. To characterize

the inrush current of the unit under test, the turnon phase is initially set to 40° for the first peak

inrush current measurement and is then increased

at 10° increments up to 90° for succeeding peak

inrush current measurements. Between tests, the

input capacitors of the unit under test are allowed

to fully discharge for proper characterization.

Application 4:

Performing Inrush Current Measurements

Page 22

22

Agilent 6800 series setup

• Set the initial (immediate) voltage to 0 Vrms.

• Set the triggered voltage level to 120 Vrms.

• Set the frequency to 60 Hz.

• Set the peak current limit to maximum.

• Set the transient trigger source to BUS.

• Set the trigger synchronization source to Phase.

• Set the initial synchronization Phase to 40°

(re-program to 50°, 60°, 70°, 80°, and 90°).

• Set the acquisition trigger source to TTLTrg.

• Set the data acquisition offset to -409 points.

• Enable the output of the ac power source/

analyzer.

• Initiate the transient trigger.

• Initiate the acquisition trigger.

• Send a Bus trigger.

• Fetch the peak current measurement.

Upon receipt of the trigger, the ac power source/

analyzer output goes to 120 Vrms when the phase

voltage waveform reaches 40°. The data buffer

acquires 409 instantaneous current data points

before the turn-on event and 3687 instantaneous

current data points beginning at the onset of the

turn-on event (for a total buffer of 4096 current

data points) to generate the peak current measurement. To continue the peak inrush current characterization, change the synchronization phase (from

40° to 50°, 60°, 70°, 80°, and 90°) and repeat the

same procedure.

Timing Diagram for Application 4

Page 23

23

Page 24

24

Overview of application

The creation of user-defined waveforms is useful

for simulating ac line disturbances that are unique

to the operational environment of the device being

tested, and then measuring that device’s susceptibility to the disturbance. This is the fundamental

objective of environmental test standards that pertain to the ac line. A specific example is the draft

for IEC 77A (Secretariat) 101 draft (dated 10/15/93),

which defines the test and measurement methods

for evaluating electronic and electrical equipment

immunity to voltage harmonics and inter-harmonics on the ac line. Upon subjecting the equipment

to the voltage harmonics, it must recover to its full

operative capabilities to meet the “pass” criteria

of this draft.

For this example, a waveform with harmonic voltage content as defined by the IEC 77A (Secretariat)

101 draft (dated 10/15/93) will be created, stored,

and generated by the ac power source/analyzer.

Harmonic Voltage Levels (for 120 Vrms)

Harmonic Number Class 1 Class 2

3 9.6 V 7.2 V

5 10.8 V 9.6 V

7 6 V 8.4 V

11 2.4 V 8.4 V

13 2.4 V 7.2 V

The equipment under test used for this example

has an ac input rating of 120 Vrms, 60 Hz, and

5 Arms. The waveform generated will comply with

the Class 1 harmonic combination (as currently

proposed) shown above. This draft specifies that

the equipment under test must be subjected to

the harmonic waveform of either Class for 2 minutes, succeeded by 2 minutes of the fundamental

(120 Vrms sinewave) waveform.

Agilent 6800 series features used

• Non-volatile, user-defined (arbitrary) waveform

creation/storage

• rms voltage programming

• Frequency programming

• Waveform shape transient generation

• List transient mode

Advantages/benefits of the Agilent 6800 series

solution

The user-defined waveform is stored in nonvolatile memory, eliminating the need for constant re-creation and making it easy to recall

the waveform as the test is needed. A List of output waveforms can be generated by combining

built-in and user-defined waveforms, simplifying

complex test sequences. The user-defined waveform can be recalled as if it was one of the standard output shapes (such as sine and square

waveforms) and can be used in all modes where

the FUNCtion:SHAPe command is valid.

Implementation details

How the 6800 series implements user-defined waveforms

The computer is used to generate an array of

1024 voltage amplitude points that represent one

cycle of the 77A (Secretariat) 101 Class 1 waveform. This data is sent to the ac source as a named

(CLASS 1) user-defined waveform and is stored in

a non-volatile memory location. The List mode of

the ac power source/analyzer is used to sequence

through the appropriate output settings at 2-minute

intervals as per the draft. The programmed parameters for each List point are shape (waveform) and

dwell time. The rms voltage and frequency output

settings remain in Fixed mode. The first List point

is the fundamental waveform (120 Vrms sinewave

at 60 Hz) and will be output upon receipt of a transient trigger for 2 minutes. The CLASS 1 waveform

will be output for 2 minutes as part of the second

List point. After this 2-minute test, the fundamental waveform will be output again as part of the

final List point.

Application 5:

Generating User-Defined Waveforms

Page 25

25

Agilent 6800 series setup

• Connect the ac source output to the ac input of

the equipment under test.

• Use the computer to develop a 1024 point array

representing a cycle of voltage amplitude data.

• Use the TRACe:DEFine command to name the

waveform CLASS 1 and allocate non-volatile

storage space.

• Use the TRACe:DATa command to send the 1024

point array to the ac power source/analyzer.

• Set the Shape to List mode.

• Set the List points as follows:

List Point Shape Dwell Time

1 Sine 120 s

2 CLASS1 120 s

3 Sine 120 s

• Set the List to sequence automatically.

• Set the transient trigger source to BUS.

• Initiate the transient trigger.

• Enable the output.

• Send a Bus trigger.

Upon receipt of the trigger, the first List step is

executed and the output is set to a 120 Vrms, 60 Hz

sinewave. After 120 seconds, the ac power source/

analyzer automatically executes the second List

step. The output will remain at the CLASS 1 test

level for 120 seconds and then will execute the

third List step. After the entire List is executed,

the output of the ac power source/analyzer will

return to the Fixed mode levels.

Timing Diagram for Application #5

Page 26

262728

Page 27

Page 28

Overview of application

For some applications, such as the simulation of

European railway power systems, a low frequency

(16.6 Hz) ac waveform is required. Generating low

frequency waveforms with ac sources can present

testing challenges due to output power derating

and programming inaccuracies, depending on the

regulation technique used. If the ac source has

measurement capability, control of the measurement sample period is necessary to capture sufficient cycles of the output waveform to ensure

measurement accuracy.

The 6812A and 6813A can meet the above challenges at frequencies below 45 Hz. These two

models provide precise control of the waveform

generation and measurement system for optimal

operation at low frequencies. For this example,

the equipment under test will require an ac input

at 230 Vrms and 16.6 Hz. Real power, apparent

power, and power factor will be accurately measured using the high resolution current measurement range.

Agilent 6812A and 6813A features used

• Programmable Vrms and frequency

• Realtime regulation mode

• Sinewave generation

• Programmable voltage and current sample rate

• Power measurement (power factor, VA, and Watts)

• x10 current measurement range

Advantages/benefits of the Agilent 6812A and

6813A solutions

• Programmable regulation mode allows for accurate output voltage and current limit control.

• Programmable measurement sample rate provides high accuracy measurements for low

frequency signals.

• Use of the FETCh command provides fast

measurements from the same data buffers.

• x10 current measurement range increases

the accuracy for low current and low power

measurements.

Implementation details

How the 6812A and 6813A generate low frequency ac

waveforms and perform low frequency ac measurements

A 230 Vrms sinewave is programmed at a frequency

of 16.6 Hz. To perform measurements at this output frequency, the programmable sample period is

increased from 25 microseconds to 75 microseconds. A triggered acquisition of voltage and current

provide the data from which the power measurements are calculated. This method of acquisition is

necessary since the MEASure command will reset

the sample period back to the default value of 25

microseconds. A FETCh command is sent to return

the real power (Watts), power factor, and apparent

power measurements from the same voltage and

current data buffer.

Agilent 6800 series setup

• Connect the ac source output to the ac input

of the equipment under test.

• Set the regulation mode to Realtime.

• Set the rms voltage to Fixed mode.

• Set the frequency to Fixed mode.

• Set the shape to sine.

• Set the rms voltage to 230 V.

• Set the frequency to 16.6 Hz.

• Enable the output.

• Set the measurement sample period to

75 microseconds.

• Trigger the acquisition of voltage and

current data.

• Fetch the real power.

• Fetch the power factor.

• Fetch the apparent power.

Application 6:

Operating the Agilent 6812A and 6813A at Low Frequencies

Page 29

29

Page 30

Agilent Technologies’ Test and Measurement

Support, Services, and Assistance

Agilent Technologies aims to maximize the value you receive,

while minimizing your risk and problems. We strive to ensure

that you get the test and measurement capabilities you paid

for and obtain the support you need. Our extensive support

resources and services can help you choose the right Agilent

products for your applications and apply them successfully.

Every instrument and system we sell has a global warranty.

Support is available for at least five years beyond the production life of the product. Two concepts underlie Agilent’s

overall support policy: “Our Promise” and “Your Advantage.”

Our Promise

“Our Promise” means your Agilent test and measurement equipment will meet its advertised performance and functionality.

When you are choosing new equipment, we will help you with

product information, including realistic performance specifications and practical recommendations from experienced test

engineers. When you use Agilent equipment, we can verify that

it works properly, help with product operation, and provide

basic measurement assistance for the use of specified capabilities, at no extra cost upon request. Many self-help tools are

available.

Your Advantage

“Your Advantage” means that Agilent offers a wide range of

additional expert test and measurement services, which you

can purchase according to your unique technical and business

needs. Solve problems efficiently and gain a competitive edge

by contracting with us for calibration, extra-cost upgrades, outof-warranty repairs, and on-site education and training, as well

as design, system integration, project management, and other

professional services. Experienced Agilent engineers and technicians worldwide can help you maximize your productivity,

optimize the return on investment of your Agilent instruments

and systems, and obtain dependable measurement accuracy

for the life of those products.

By internet, phone, or fax, get assistance with all your

test and measurement needs.

Online Assistance

www.agilent.com/find/assist

Phone or Fax

United States:

(tel) 1 800 452 4844

Canada:

(tel) 1 877 894 4414

(fax) (905) 206 4120

Europe:

(tel) (31 20) 547 2323

(fax) (31 20) 547 2390

Japan:

(tel) (81) 426 56 7832

(fax) (81) 426 56 7840

Latin America:

(tel) (305) 269 7500

(fax) (305) 269 7599

Australia:

(tel) 1 800 629 485

(fax) (61 3) 9210 5947

New Zealand:

(tel) 0 800 738 378

(fax) (64 4) 495 8950

Asia Pacific:

(tel) (852) 3197 7777

(fax) (852) 2506 9284

Product specifications and descriptions in this

document subject to change without notice.

Copyright © 1995, 2000 Agilent Technologies

Printed in U.S.A. 10/00

5963-7044E

Loading...

Loading...