Page 1

Supplemental Operator’s Guide

for the Agilent 35670A Dynamic Signal Analyzer

By: David Forrest

Seattle Sound and Vibration, inc.

Print Date: December, 2000

ãSeattle Sound and Vibration, inc. 1996, 2000.

All rights reserved.

Agilent Part number 35670-90059

Special Permission Amoco Corporation and Agilent Technologies, Inc are granted

full editing, duplication and distribution privileges.

Page 2

AGILENT 35670A

Supplemental Operator’s Guide

SECTION 1 : TURNING ON THE AGILENT 35670A .......................................................................................... 1

SECTION 2 : MEASUREMENT STATE AFTER TURN-ON............................................................................... 2

SECTION 3 : MEASURING WITH TRANSDUCERS ...........................................................................................3

U

SING ICP-TYPE TRANSDUCERS WITH THE AGILENT 35670A .............................................................................. 3

U

SING TRANSDUCERS WITH EXTERNAL PREAMPLIFIERS .......................................................................................... 3

S

PECIFYING TRANSDUCER SENSITIVITY AND UNITS ................................................................................................. 4

SECTION 4 : MEASURING A SINGLE CHANNEL POWER SPECTRUM - DISPLACEMENT................... 5

S

ELECTING SINGLE CHANNEL OPERATION ............................................................................................................... 5

ETTING UP TRANSDUCER UNITS FOR DISPLACEMENT............................................................................................. 5

S

S

ELECTING FREQUENCY SPAN .................................................................................................................................. 5

Q

UANTIFYING POWER SPECTRUM RESULTS.............................................................................................................. 7

SECTION 5 : IMPROVING MEASUREMENT RESULTS................................................................................... 8

F

REQUENCY ZOOMING TO INCREASE RESOLUTION................................................................................................... 8

M

AXIMIZING DYNAMIC RANGE ................................................................................................................................8

VERAGING TO REDUCE MEASUREMENT VARIANCE................................................................................................ 9

A

SECTION 6 : MEASURING A SINGLE CHANNEL TIME WAVEFORM ...................................................... 11

S

ELECTING SINGLE CHANNEL OPERATION ............................................................................................................. 11

S

ELECTING TIME RECORD LENGTH......................................................................................................................... 12

D

ISPLAYING TIME WAVEFORMS ............................................................................................................................. 12

U

SING MANUAL ARM TO CAPTURE A SINGLE TIME WAVEFORM............................................................................ 12

VENT TRIGGERING................................................................................................................................................ 13

E

Q

UANTIFYING TIME TRACE RESULTS ..................................................................................................................... 14

SECTION 7 : MEASURING DUAL CHANNEL SPECTRA ............................................................................... 15

P

RESETTING THE ANALYZER................................................................................................................................... 15

S

ELECTING DUAL CHANNEL OPERATION................................................................................................................ 15

ELECTING FREQUENCY SPAN ................................................................................................................................15

S

D

ISPLAYING DUAL-CHANNEL POWER SPECTRUM MEASUREMENTS....................................................................... 15

U

SING MARKERS WITH DUAL CHANNEL MEASUREMENTS ..................................................................................... 16

C

OUPLED MARKERS ............................................................................................................................................... 17

C

OUPLED MARKERS WITH PEAK TRACKING ........................................................................................................... 17

SECTION 8 : IMPROVING DUAL CHANNEL MEASUREMENT RESULTS................................................ 18

M

AXIMIZING DYNAMIC RANGE .............................................................................................................................. 18

D

UAL CHANNEL AVERAGING ................................................................................................................................. 18

SECTION 9 : MEASURING DUAL CHANNEL TIME WAVEFORMS............................................................ 20

S

ELECTING DUAL CHANNEL OPERATION................................................................................................................ 20

S

ELECTING TIME RECORD LENGTH......................................................................................................................... 20

D

ISPLAYING DUAL TIME WAVEFORMS ................................................................................................................... 20

RMING DUAL CHANNEL TIME MEASUREMENTS ................................................................................................... 21

A

T

RIGGER ING A DUAL-CHANNEL TIME MEASUREMENT........................................................................................... 21

T

RIGGER DELAY ..................................................................................................................................................... 22

U

SING MARKERS WITH DUAL CHANNEL TIME MEASUREMENTS ............................................................................ 23

SECTION 10 : MEASURING DUAL CHANNEL SPECTRA AND TIME WAVEFORMS.......................... 23

Page 3

AGILENT 35670A

Supplemental Operator’s Guide

SECTION 11 : MODAL TESTING USING A HAMMER AND ACCELEROMETER ................................. 25

S

ETTING UP THE TRANSDUCER PARAMETERS ......................................................................................................... 25

ETTING UP INPUT RANGE ...................................................................................................................................... 26

S

C

HOOSING A PRELIMINARY FREQUENCY SPAN....................................................................................................... 26

S

PECIFYING TRIGGER PARAMETERS ....................................................................................................................... 26

S

ETTING UP TIME DISPLAYS ................................................................................................................................... 27

U

SING FORCE/RESPONSE WINDOWS ....................................................................................................................... 28

D

ISPLAYING HAMMER TEST RESULTS .................................................................................................................... 29

VERAGING ............................................................................................................................................................ 29

A

C

HANGING FREQUENCY SPAN ................................................................................................................................31

SECTION 12 : HAMMER TEST SETUP WITHOUT A FORCE TRANSDUCER........................................ 32

S

ETTING UP THE HAMMER TEST WITHOUT A FORCE TRANSDUCER ....................................................................... 32

SECTION 13 : ORDER DOMAIN RESULTS IN LIST MODE........................................................................ 33

SECTION 14 : COMPARING TWO-CHANNEL REAL-TIME SPECTRA WITH RECALLED DATA.... 35

S

ELECTING MEASUREMENT PARAMETERS .............................................................................................................. 35

D

ISPLAYING DUAL-CHANNEL SPECTRA COMPARED WITH RECALLED DATA ......................................................... 35

R

ECALLING THE SPECTRA FROM DISK .................................................................................................................... 36

R

ECALLING THE SPECTRA FROM NON-VOLATILE RAM ......................................................................................... 36

S

CALING THE DISPLAYS .......................................................................................................................................... 37

U

SING MARKERS TO COMPARE............................................................................................................................... 38

SECTION 15 : WATERFALL SPECTRA AT TIME INTERVALS ................................................................ 39

S

ELECTING SINGLE CHANNEL OPERATION ............................................................................................................. 39

S

ELECTING MEASUREMENT PARAMETERS .............................................................................................................. 39

S

ETTING UP THE WATERFALL DISPLAY.................................................................................................................. 39

S

ETTING UP TIME STEP ARM .................................................................................................................................. 40

SING SLICE MARKERS WITH WATERFALL DATA .................................................................................................. 40

U

C

OLLECTING A SPECIFIED NUMBER OF SPECTRA DURING A TIME INTERVAL ......................................................... 41

SECTION 16 : WATERFALL SPECTRA AT RPM INTERVALS .................................................................. 42

S

ETTING UP THE TACHOMETER .............................................................................................................................. 42

S

PECIFYING THE START RPM ................................................................................................................................. 42

C

OLLECTING A SPECIFIED NUMBER OF SPECTRA DURING AN RPM INTERVAL....................................................... 42

TARTING AND PAUS ING A MEASUREMENT ............................................................................................................ 43

S

S

CALING THE DISPLAY............................................................................................................................................ 43

SECTION 17 : 2-CHANNEL ABSOLUTE AND DIFFERENTIAL AMPLITUDE MEASUREMENT ....... 45

A

CCELEROMETER POLARITY................................................................................................................................... 45

M

EASURING AMPLITUDES, DIFFERENTIAL AMPLITUDE, AND PHASE...................................................................... 46

U

SING A MATH FUNCTION TO MEASURE DIFFERENTIAL MOTION .......................................................................... 47

SECTION 18 : MEASURING FREQUENCY RESPONSE WITH THE AGILENT 35670A ........................ 50

M

EASURING FREQUENCY RESPONSE USING IMPACT EXCITATION.......................................................................... 50

M

EASURING FREQUENCY RESPONSE USING BROADBAND EXCITATION ................................................................. 50

V

IEWING FREQUENCY RESPONSE RESULTS WITH A NYQUIST DIAGRAM ................................................................ 53

V

IEWING RESULTS USING REAL AND IMAGINARY TRACES .................................................................................... 54

SSESSING MEASUREMENT QUALITY ..................................................................................................................... 55

A

SECTION 19 : TWO SPECTRAL TRACES SHOWING MILS AND IPS WHILE EU IS G........................ 56

SECTION 20 : PEAK HOLD DURING A MACHINE RUN-UP AND COAST-DOWN ................................ 58

Page 4

AGILENT 35670A

Supplemental Operator’s Guide

SECTION 21 : USING AN EXTERNAL TRIGGER FOR TIME AVERAGING ........................................... 60

S

PECIFY USER LEVELS FOR TRIGGERING ................................................................................................................ 60

HARACTERIZING THE EXTERNAL TRIGGER ........................................................................................................... 60

C

S

ETTING UP EXTERNAL TRIGGER ........................................................................................................................... 61

M

EASURING TIME AVERAGED SPECTRUMS WITH EXTERNAL TRIGGERING............................................................. 62

SECTION 22 : SAVING TRACE DATA TO A 3.5” DISK OR NON-VOLATILE RAM .............................. 63

S

AVING TRACE TO 3.5” DISK .................................................................................................................................. 63

C

ONFIRMING CONTENTS OF 3.5” DISK FILE ............................................................................................................ 63

AVING TRACE TO NON-VOLATILE RAM (NV-RAM)........................................................................................... 64

S

C

ONFIRMING CONTENTS OF NV-RAM ................................................................................................................... 64

SECTION 23 : RECALLING TRACE DATA FROM 3.5” DISK OR NON-VOLATILE MEMORY.......... 65

R

ECALL TRACE FROM 3.5” DISK ............................................................................................................................ 65

R

ECALL TRACE DATA FROM NON-VOLATILE RAM (NV-RAM)............................................................................ 65

SECTION 24 : PLOTTING AND PRINTING TRACE DATA ......................................................................... 67

G

ENERATING OUTPUT WITH THE AGILENT 35670A............................................................................................. 67

P

LOTTING THE DISPLAY .......................................................................................................................................... 67

P

RINTING THE DISPLAY........................................................................................................................................... 68

SECTION 25 : IMPORTING PLOTS INTO MICROSOFT WORD................................................................ 69

D

ETERMINING IF MS WORD HAS HP-GL GRAPHICS IMPORT FILTER..................................................................... 69

I

NSTALLING THE MS WORD HP-GL GRAPHICS IMPORT FILTER............................................................................. 69

LOT TO A FILE USING THE AGILENT 35670A ..................................................................................................... 70

P

I

NSERTING PICTURE OF AN HP-GL PLOT FILE INTO A MS WORD DOCUMENT. ...................................................... 70

SECTION 26 : RUNNING A SINGLE CALIBRATION TEST ON COMMAND .......................................... 71

SECTION 27 : RETURNING THE AGILENT 35670A TO A PRESET CONDITION.................................. 71

SECTION 28 : PRECAUTIONS TO PREVENT LOSS OF DATA .................................................................. 71

SECTION 29 : TRANSDUCER UNIT CONVERSION WITH THE AGILENT 35670A............................... 72

M

EASURING ACCELERATION, DISPLAYING DISPLACEMENT................................................................................... 72

M

ATH FUNCTIONS AND XDCR UNIT CONVERT................................................................................................. 73

C

ONVERTING FREQUENCY RESPONSE UNITS TO COMPLIANCE ............................................................................... 73

SECTION 30 : USING THE AGILENT DEMO UNIT WITH THE AGILENT 35670A................................ 75

Page 5

Section 1 : Turning On the AGILENT 35670A

A

The entire turn-on procedure for the AGILENT 35670A takes 40 seconds. In

that time the analyzer completes a hardware self-test, boots its operating system,

completes a front end self-calibration and autoranges all input channels. The

default measurement state of the analyzer is a two-channel FFT measurement

with a span of 51.2 kHz, front ends autoranging, input low floating, and DC

coupled, averaging OFF and with a power spectrum display.

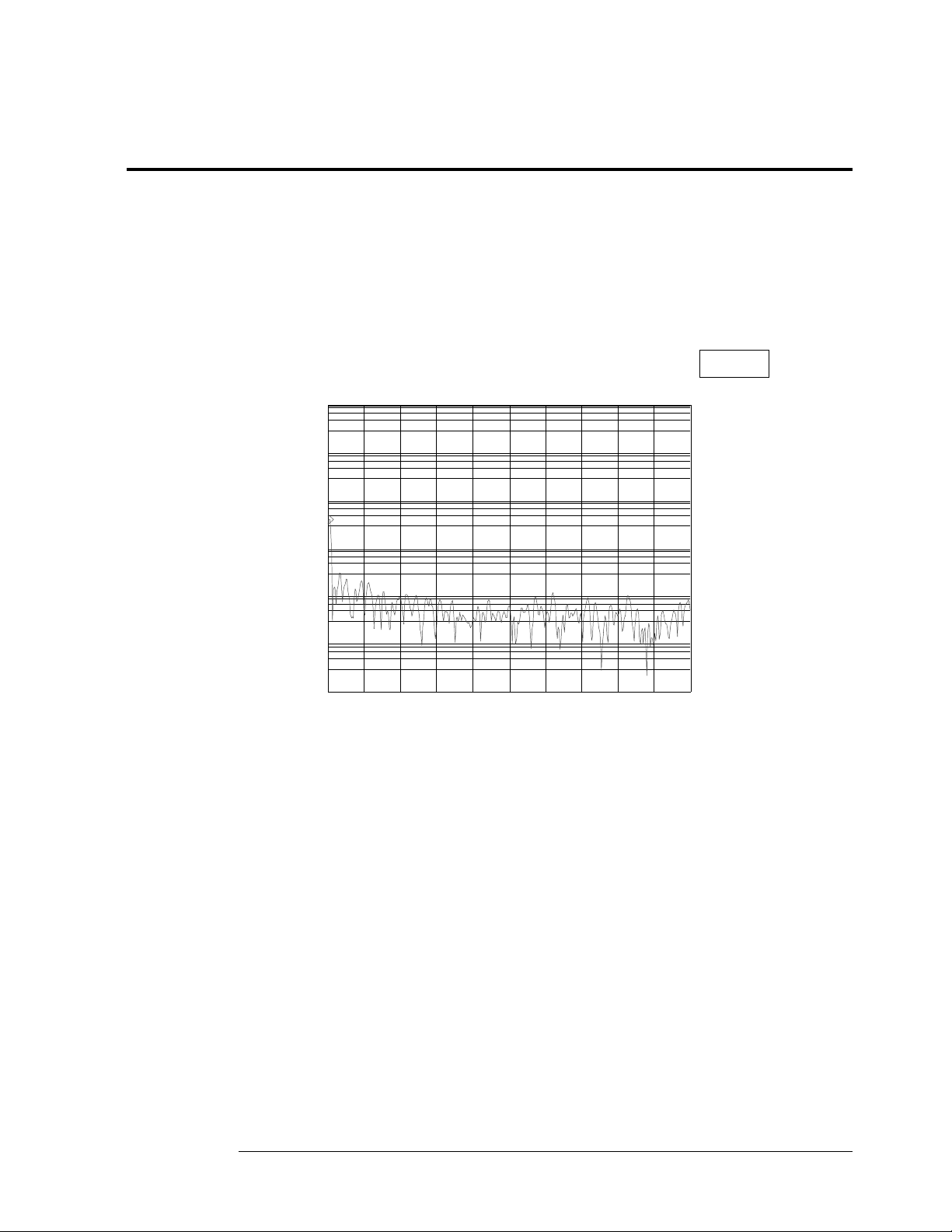

: CH1 Pwr Spec X:0 Hz Y:40.9385 uVrms

10

mVrms

LogMag

decades

nVrms

6

10

0Hz 51.2kHz

AGILENT 35670A

Supplemental Operator’s Guide

FFT

ANALYSIS

OCTAVE

ANALYSIS

ORDER

ANALYSIS

SWEPT

SINE

CORRELATN

ANALYSIS

HISTOGRAM

/ TIME

CHANNELS

1

4

2

REF CHANS

1,3

1

TIME

CAPTURE

Typical Display After Turn-on Sequence

1

Page 6

AGILENT 35670A

Supplemental Operator’s Guide

Section 2 : Measurement State After Turn-on

Inst Mode FFT Channels 2

Meas Data Data A PWR SPEC1 Data B PWR SPEC2

Trac Coord Coord A MAG-LOG Coord B MAG-LOG

Freq Start 0 Hz Stop 51.2 kHz

Window CH1 Type FLATTOP BW 488.88 Hz

Avg Status OFF Type RMS

Trigger Type FREE-RUN Level 0 V

Measurement Source INPUT

Data C TIME1 Data D TIME2

Coord C REAL Coord D REAL

Center 25.6 kHz Span 51.2 kHz

Rec Len 7.8125 ms Resoltn 400

CH2 Type FLATTOP BW 488.88 Hz

CH3 Type FLATTOP BW 488.88 Hz

CH4 Type FLATTOP BW 488.88 Hz

Number 10 Overlap 0 %

Fast Avg OFF Update 5

Rept Avg FREEZE Ovld Rej OFF

Slope POSITIVE

Ext Lvl 1.48 V

Ext Fltr OFF

CH1 Dlay 0 s CH2 Dlay 0 s

CH3 Dlay 0 s CH4 Dlay 0 s

Arm IMMEDIATE Strt RPM 600 rpm

RPM Step 60 rpm Time Stp 500 ms

Wtrfall 15 RPM Dir UP

Source Status OFF

Input CHANNEL 1 CHANNEL 2 CHANNEL 3 CHANNEL 4

Status ON ON OFF OFF

Range 3.9858 mVp 3.9858 mVp 3.9858 mVp 3.9858 mVp

Auto Rng OFF OFF OFF OFF

Coupling DC DC DC DC

InputLow FLOAT FLOAT FLOAT FLOAT

AliasFlt ON ON ON ON

A WtFltr OFF OFF OFF OFF

ICP OFF OFF OFF OFF

EngrUnit OFF OFF OFF OFF

EU Label USER USER USER USER

EU Mult 1 V/EU 1 V/EU 1 V/EU 1 V/EU

--- TACHOMETER ---

Puls/Rev 1

Level 0 V

Range LOW

Slope POSITIVE

Holdoff 0 s

Level 0 Vpk DC Offst 0 V

Type SINUSOID Sine Frq 10.24 kHz

Arb Fltr OFF Arb Reg D1

Arb Rept ON

2

Page 7

Section 3 : Measuring with Transducers

The AGILENT 35670A can be used with a broad range of transducers. Transducers

can use an external preamplifier to convert the raw signal into a voltage that is

compatible with the AGILENT 35670A. Some transducers have internal circuitry

which provides preamplification, however these internal circuits must be powered

externally. The AGILENT 35670A can provide the necessary constant-current

supply for transducers that are of type ICP, Isotron, Piezotron, DelaTron, Low

Impedance, etc.

Using ICP-Type Transducers with the AGILENT 35670A

To set up Channel 1 for an ICP-type transducer:

• Press the [Input] hardkey

• Press [FRONT END CH1 SETUP] softkey (F7).

• Press [ICP SUPLY ON OFF] softkey (F8) until ON is highlighted.

Note that the analyzer automatically switches the front end to AC Coupling in order

to reject the large DC signal that is generated by the constant-current supply.

To set up Channel 2 for an ICP transducer:

• Press the [Input] hardkey

• Press [CHANNEL 1 2 34] softkey (F1) until 2 is highlighted.

• Press [FRONT END CH2 SETUP] softkey (F7).

• Press [ICP SUPLY ON OFF] softkey (F8) until ON is highlighted.

AGILENT 35670A

Supplemental Operator’s Guide

For AGILENT 35670A analyzers with four channels, these same procedures can be

repeated for Channels 3 and 4.

Using Transducers with External Preamplifiers

No special front end setup is required to use transducers with external preamplifiers

except if the preamplifier’s DC component is too high, resulting in a loss of dynamic

range. This can be easily minimized by switching to AC coupling as follows:

• Press the [Input] hardkey

• Press [CHANNEL 1 234] softkey (F1) until 1 is highlighted.

• Press [FRONT END CH1 SETUP] softkey (F7).

• Press [COUPLING AC DC] softkey (F5) until AC is highlighted.

A transducer with an external preamplifier will convert mechanical units (EU) to

volts. Care must be taken to observe gain settings on the external preamplifier,

because these gain settings directly affect the resulting transducer sensitivity.

3

Page 8

AGILENT 35670A

Supplemental Operator’s Guide

For example, if an accelerometer has am internal sensitivity of 25 pC/g, and a charge

amplifier has a gain setting of 10 mV/pC, then the resulting transducer sensitivity is

250 mV/g. However is the gain setting on the charge amplifier is changed to 1

mV/pC, then the resulting sensitivity would then be 25 mV/g.

Specifying Transducer Sensitivity and Units

The AGILENT 35670A provides the ability to convert electrical signals into

Engineering Units. Units can be specified as either conventional units or User units.

Conventional units of motion available are:

acceleration: g, m/s^2, inch/s^2

velocity: m/s, inch/s

displacement: m, inch, mil

force: N, lb., dyne

To set up transducer properties for an accelerometer attached to Channel 2 with a

sensitivity of 9.7 pC/g, follow these steps:

• Press [Input] hardkey.

• Press [CHANNEL 1 2 34] softkey (F1) until 2 is highlighted.

• Press [XDCR UNIT CH2 SETUP] softkey (F8)

• Press the [XDCR SENSITVTY] softkey (F6).

• Enter 9.7, then press the [mV/EU] softkey (F2).

• Toggle the [XDCR UNIT ON OFF] softkey (F4) until ON is highlighted.

• Press the [XDCR UNIT LABEL] softkey (F7).

• Select the [g] softkey (F2).

Likewise if a force transducer is attached to Channel 1 with a sensitivity of 12.2

mV/lb., do the following:

• Press [Input] hardkey.

• Press [CHANNEL 1 234] softkey (F1) until 1 is highlighted.

• Press [XDCR UNIT CH1 SETUP] softkey (F8)

• Press the [XDCR SENSITVTY] softkey (F6).

• Enter 12.2, then press the [mV/EU] softkey (F2).

• Toggle the [XDCR UNIT ON OFF] softkey (F4) until ON is highlighted.

• Press the [XDCR UNIT LABEL] softkey (F7).

• Press the [MORE CHOICES] softkey (F9).

• Select the [lb] softkey (F6).

4

Page 9

AGILENT 35670A

Supplemental Operator’s Guide

Section 4 : Measuring a Single Channel Power Spectrum - Displacement

This section contains procedures for setting up and measuring a single channel

power spectrum of displacement using an AGILENT 35670A Dynamic Signal

Analyzer. Included are steps to select single channel operation, set up transducer

parameters, frequency span, choose input range, select windowing, and turn on

averaging in order to improve measurement accuracy. Instructions will also be

presented to set up trace coordinates and trace scaling.

Selecting Single Channel Operation

Specify the single-channel instrument mode to measure one signal. However it

should be noted that it is acceptable to measure a single channel in the default two-

channel instrument mode and simply ignore the second channel. Nevertheless

instructions will be given here to measure in single channel mode.

To measure a single-channel spectrum, turn on the AGILENT 35670A and then:

• Press the [Inst Mode] hardkey

• Press [CHANNELS 1 24 ] softkey (F7) until 1 is highlighted.

Setting Up Transducer Units for Displacement

To measure power spectrums using a displacement transducer with a sensitivity of

200 mV/mil, follow these steps:

• Press the [Input] hardkey.

• Enter 800 and then press the [Hz] softkey (F2).

Any frequency below 51.2 kHz may of course be entered, however the analyzer will

select the lowest span that contains the desired frequency. For example, if 1200 Hz

is entered, the analyzer is switched to a span of 1600 Hz.

Selecting Frequency Span

The default frequency span after turn-on is 51.2 kHz, which is usually too high for

most transducer measurements. To reduce the span to 800 Hz, perform the following

steps:

• Press the [Freq] hardkey.

• Enter 800 and then press the [Hz] softkey (F2).

5

Page 10

AGILENT 35670A

Supplemental Operator’s Guide

Any frequency below 51.2 kHz may of course be entered, however the analyzer will

select the lowest span that contains the desired frequency. For example, if 1200 Hz

is entered, the analyzer is switched to a span of 1600 Hz.

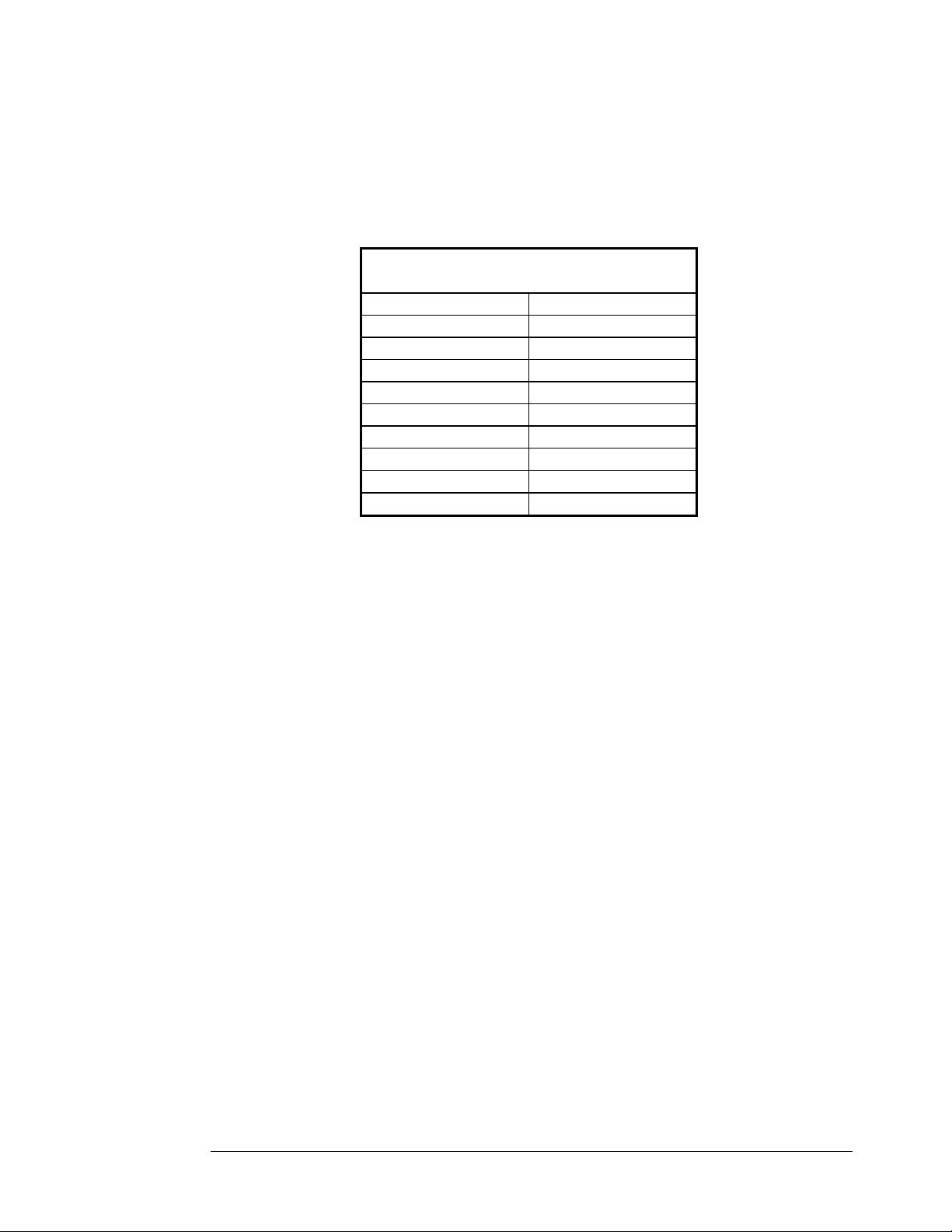

Frequency Spans Available

for the AGILENT 35670A

102.4 kHz * 100 Hz

51.2 kHz 50 Hz

25.6 kHz 25 Hz

12.8 kHz 12.5 Hz

6.4 kHz 6.25 Hz

3.2 kHz 3.125 Hz

1.6 kHz 1.5625 Hz

800 Hz 0.78125 Hz

400 Hz 0.390625

200 Hz 0.1953125 Hz

* Available in single-channel mode when anti-alias filter is turned off.

To begin data acquisition,

• Press the [Start] hardkey.

To automatically scale the display to fit the data,

• Press the [Scale] hardkey.

• Toggle the [AUTOSCALE ON OFF] softkey (F1) until ON is highlighted.

6

Page 11

AGILENT 35670A

Supplemental Operator’s Guide

Input CH1 Rng: 501.7819 mVpk CH2 Rng: 631.706 mVpk

Date: 10-02-96 Time: 08:42:00 PM

A: CH1 Pwr Spec X:160 Hz Y:169.558 mVrms

Vrms

LogMag

decades

uVrms

CH3 Rng: 2.5149 Vpk CH4 Rng: 2.5149 Vpk

1

6

1

0Hz 800Hz

Quantifying Power Spectrum Results

Use the marker knob to read the amplitude at any measured frequency. Rotate the

knob on the AGILENT 35670A front panel until the marker indicator (the small

diamond following the spectral trace) is placed at the frequency of interest. The

frequency and amplitude at this bin is presented as X and Y values at the top of the

trace. Units of [Hz] and [Vrms] or [grms] identify the results.

Special marker features such as peak tracking can speed analysis. To always track

the peak amplitude and frequency, follow these steps:

• Press the [Marker] hardkey.

• Press [PEAK TRK ON OFF] softkey (F6) until ON is highlighted.

The frequency and amplitude of the peak bin in every trace will be determined and

displayed.

7

Page 12

AGILENT 35670A

Supplemental Operator’s Guide

Section 5 : Improving Measurement Results

Frequency Zooming to Increase Resolution

The AGILENT 35670A has the ability to zoom in on a signal to show detail with

very fine resolution. After choosing a center frequency, it is possible to decrease the

span and therefore increase the resolution all the way down to 61 µHz. To zoom in

on a signal, move the marker to the desired center frequency, then:

• Press the [Freq] hardkey.

• Press the [CENTER] softkey (F2).

• Press the [Mkr Value] hardkey.

To set a new, lower span,

• Press the [Freq] hardkey.

• Press the [Down Arrow] hardkey

• Press the yellow [Start] hardkey to begin the zoomed measurement.

To return to baseband measurements,

• Press the [Freq] hardkey.

• Press the [ZERO START] softkey (F5).

Maximizing Dynamic Range

The default setting for input range is CH1 AUTO RANGE. For steady-state signals

this works well because the front end will find the input range that just exceeds the

signal level, and therefore maximize the dynamic range of the measurement. When a

front end is set up to autorange and the signal either overloads or becomes too faint

for the current range setting, the analyzer automatically searches for a new range and

then re-starts the measurement. To select CH1 AUTO RANGE:

• Select the [CH1 AUTO RANGE] softkey (F6)

If a signal is not steady, but has periods of high and low levels, then CH1 AUTO

RANGE may not set the front end at the most useful range. Instead, try CH1 AUTO

UP ONLY. This causes the input range to ratchet up when an overload is detected,

however when the signal is quiet, the front end range is not reduced. This prevents

an overload if another high level signal is expected. CH1 AUTO UP ONLY works

well with transient signals such as those expected during impact testing. To set up

this condition:

• Press the [Input] hardkey.

• Select the [CH1 AUTO UP ONLY] softkey (F5).

8

Page 13

AGILENT 35670A

Supplemental Operator’s Guide

If continuous real-time measurements over a long duration are required, and

absolutely no overload conditions are desired, then a fixed input range can be set that

is greater than any signal expected. During periods of low signal level, dynamic

range will not be optimal, however the entire measurement can be completed without

overloads. To set up a fixed range of 1 volt:

• Press the [Input] hardkey.

• Select the [CHANNEL 1 RANGE] softkey (F3), enter 1, then press the

[Vpk] softkey (F1).

If engineering units are turned on ([XDCR UNIT ON OFF]) then the range can be

specified in EU. For example, if an accelerometer is connected to channel 1 with

XDCR UNIT turned on and XDCR UNIT LABEL specified as [g], then the input

range can be specified as 4 “g” as per the following:

• Press the [Input] hardkey.

• Select the [CHANNEL 1 RANGE] softkey (F3)

• Enter 4, then press the [EU] softkey (F8).

Averaging to Reduce Measurement Variance

Spectral measurements of steady signals give results which have a statistical

variation over time. Averaging several results will help reduce this variation. The

AGILENT 35670A has several averaging techniques available. For general

spectrum measurements, RMS or power averaging is commonly used. To average a

series of ten spectrum measurements using RMS averaging, follow these steps:

• Press the [Avg] hardkey.

• Press the [NUMBER AVERAGES] softkey (F2), enter 10, then press the

[ENTER] softkey (F1).

• Press the [AVERAGE TYPE] softkey (F3)

• Press the [RMS] softkey (F1)

• Press the [Avg] hardkey.

• Turn on averaging by pressing the [AVERAGE ON OFF] softkey (F1)

until ON is highlighted.

9

Page 14

AGILENT 35670A

Supplemental Operator’s Guide

•

Systm Util Date: 10-02-96

Time: 08:40 PM

Date: 01-02-04 Time: 12:44:00 PM

A: CH1 Pwr Spec X:160 Hz Y:174.015 mVrms

1

Vrms

LogMag

6

decades

1

uVrms

0Hz 800HzAVG: 5

10

Page 15

Section 6 : Measuring a Single Channel Time Waveform

This section contains procedures for setting up and measuring a single channel time

waveform using an AGILENT 35670A Dynamic Signal Analyzer. Included are

steps to select single channel operation, set up the trace time length, and set up

triggering to capture a transient event. Instructions will also be presented to scale the

time trace.

Selecting Single Channel Operation

To measure a single-channel time waveform, turn on the AGILENT 35670A and

then:

• Press the [Inst Mode] hardkey

• Press [CHANNELS 1 2 4 ] softkey (F7) until 1 is highlighted.

Note: if the AGILENT 35670A was already turned on and in an unknown

state, then preset the analyzer by doing the following:

• Press the green [Preset] hardkey

• Press [DO PRESET] softkey (F1).

AGILENT 35670A

Supplemental Operator’s Guide

Then set the instrument mode to single channel as above.

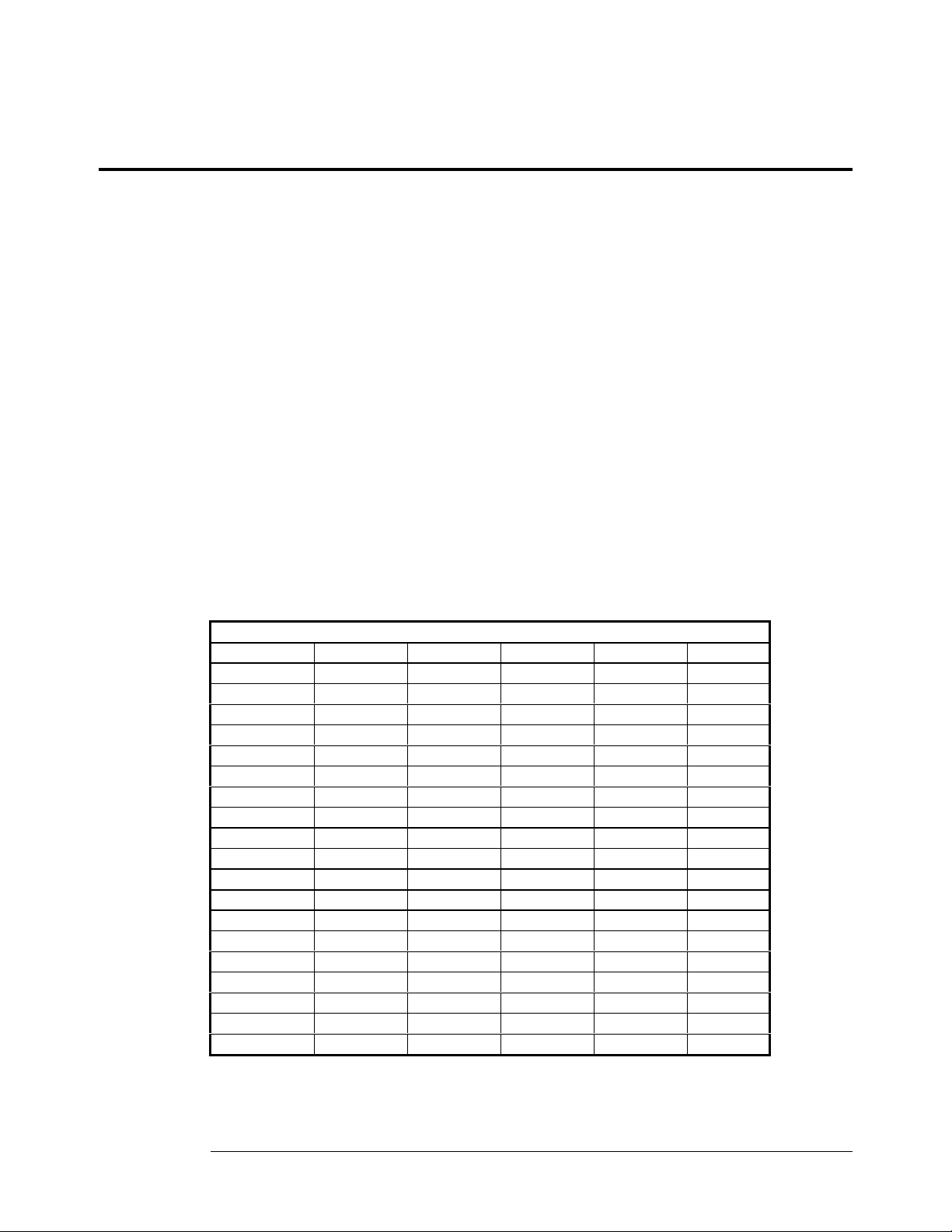

Time Record Length in Seconds vs. Resolution

Span - Hz 100 lines 200 lines 400 lines 800 lines 1600 lines

51200 Hz

25600 Hz

12800 Hz

6400 Hz

3200 Hz

1600 Hz

800 Hz

400 Hz

200 Hz

100 Hz

50 Hz

25 Hz

12.5 Hz

6.25 Hz

3.125 Hz

1.5625 Hz

0.78125 Hz

0.390625 Hz

0.1953125 Hz

0.001953 s 0.003906 s 0.007813 s 0.015625 s 0.03125 s

0.003906 s 0.007813 s 0.015625 s 0.03125 s 0.0625 s

0.007813 s 0.015625 s 0.03125 s 0.0625 s 0.125 s

0.015625 s 0.03125 s 0.0625 s 0.125 s 0.25 s

0.03125 s 0.0625 s 0.125 s 0.25 s 0.5 s

0.0625 s 0.125 s 0.25 s 0.5 s 1 s

0.125 s 0.25 s 0.5 s 1 s 2 s

0.25 s 0.5 s 1 s 2 s 4 s

0.5 s1 s2 s4 s8 s

1 s2 s4 s8 s16 s

2 s 4 s 8 s 16 s 32 s

4 s 8 s 16 s 32 s 64 s

8 s 16 s 32 s 64 s 128 s

16 s 32 s 64 s 128 s 256 s

32 s 64 s 128 s 256 s 512 s

64 s 128 s 256 s 512 s 1024 s

128 s 256 s 512 s 1024 s 2048 s

256 s 512 s 1024 s 2048 s 4096 s

512 s 1024 s 2048 s 4096 s 8192 s

11

Page 16

AGILENT 35670A

Supplemental Operator’s Guide

Selecting Time Record Length

The default time record length at a frequency span of 51.2 kHz is only 7.8 ms, which

is usually not enough time to capture a mechanical event or observe a transducer’s

time domain signal. To increase the time record length to 0.25 s, perform the

following steps:

• Press the [Freq] hardkey

• Press the [RECORD LENGTH] softkey (F8)

• Enter 0.25 and then press the [S] softkey (F1)

The analyzer selects a new frequency span of 1.6 kHz, which at the default

resolution of 400 lines, takes 0.25 seconds to capture. The following table outlines

the time record lengths for all possible frequency spans and resolutions:

Displaying Time Waveforms

Time waveforms are displayed in a time trace. To set up the analyzer to display a

single time trace of channel 1, follow these steps:

• Press the [Disp Format] hardkey.

• Press the [SINGLE] softkey (F1)

• Press the [Active Trace] hardkey.

• Press the [A] softkey (F1)

• Press the [Meas Data] hardkey.

• Press the [CHANNEL 1 234] softkey (F1) until 1 is highlighted.

• Press the [TIME CHANNEL 1] softkey (F5)

• Press the [Scale] hardkey.

• Toggle the [AUTOSCALE ON OFF] softkey (F1) until ON is highlighted.

Using Manual Arm to Capture a Single Time Waveform

Often it is desirable to observe just one time waveform in detail. To acquire just one

record length at a time, follow these instructions:

• Press the [Trigger] hardkey.

• Select the [ARM SETUP] softkey (F7)

• Select the [MANUAL ARM] softkey (F2)

• Press the yellow [Start] hardkey to begin the measurement.

• Press the [Trigger] hardkey again.

Then to arm a single time record,

• Press the [ARM] softkey (F9)

One time record will be captured and displayed. To capture another time record,

12

Page 17

AGILENT 35670A

Supplemental Operator’s Guide

• Press the [ARM] softkey (F9) again.

Event Triggering

The AGILENT 35670A has the ability to trigger the acquisition of a time waveform

based on the slope and level of the measured signal. To set up triggering properly,

the polarity of the measured pulse must be known in advance: will the event start

with a negative slope or positive slope? Will the event be mostly positive or mostly

negative? Use trial measurements to determine polarity if unknown.

Proper triggering is also affected by the input range. Fortunately the AGILENT

35670A has the ability to set the trigger point to be a percentage of the input range,

so even with CH1 AUTO UP ONLY, successful triggering should be possible

automatically.

To specify trigger parameters for a “positive” event on channel 1 where the trigger

point should have a positive slope, follow these steps:

• Press the [Trigger] hardkey.

• Press the [CHANNEL 1 234] softkey (F3) until 1 is highlighted.

• Press the [TRIGGER SETUP] softkey (F6)

• Press the [CHANNEL LEVEL] softkey (F1)

• Enter 5 then press the [PERCENT (%)] softkey (F4)

• Press the [SLOPE POS NEG] softkey (F5) until POS is highlighted.

Use pre-triggering to acquire some data before the trigger point. To set up a 0.01s

pre-trigger condition, follow these steps:

• Press the [Trigger] hardkey.

• Press the [TRIGGER SETUP] softkey (F6)

• Press the [ALL CHANNELS] softkey (F8)

• Press the [CHANNEL * DELAY] softkey (F9)

• Enter -.01 then press the [S] softkey (F1)

To start the data acquisition,

• Press the yellow [Start] hardkey.

The analyzer should show in highlighted text above the trace:

WAITING FOR CH 1 TRIGGER

13

Page 18

AGILENT 35670A

Supplemental Operator’s Guide

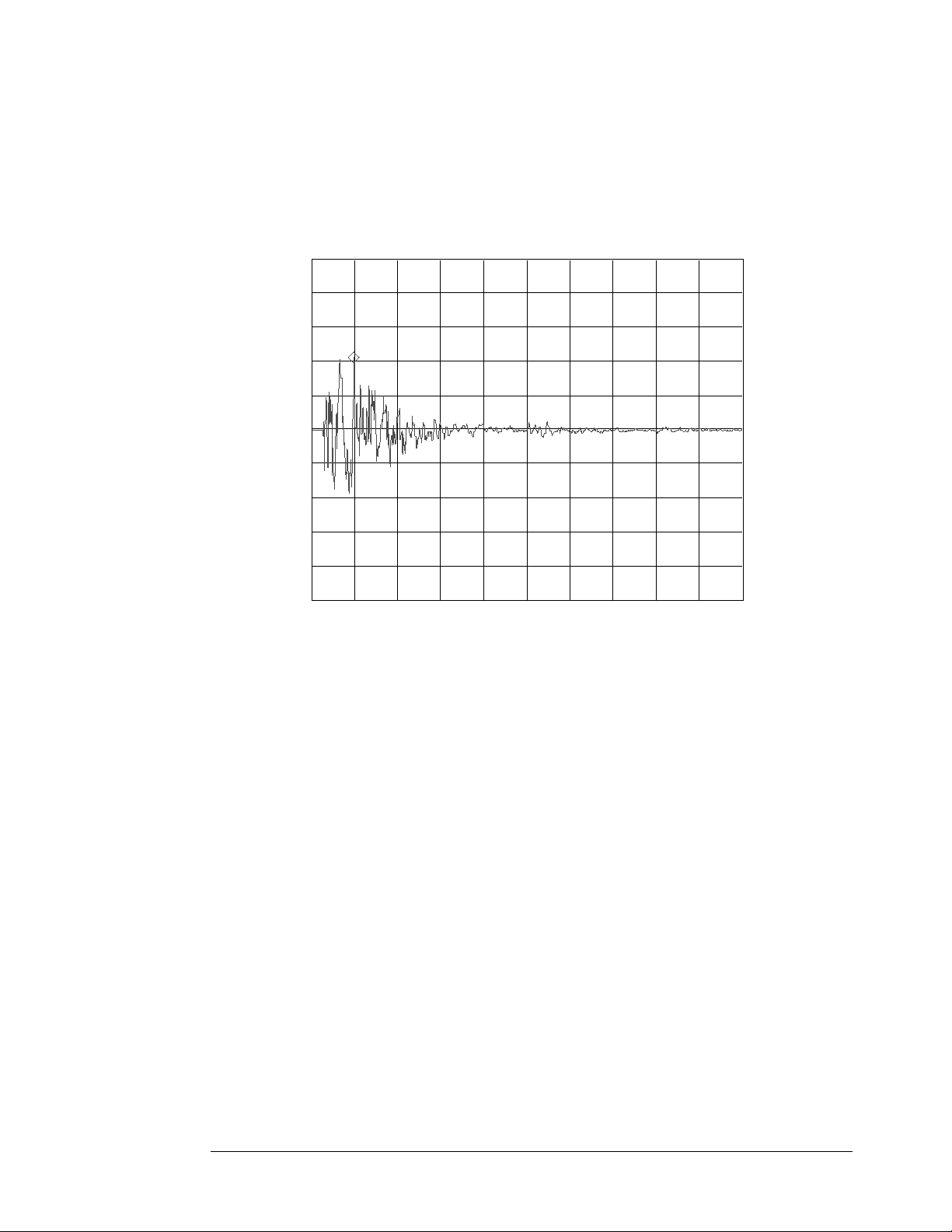

Input CH1 Rng: 1.0012 Vpk CH2 Rng: 631.706 mVpk

Date: 10-02-96 Time: 08:47:00 PM

A: CH1 Time X:38.0859 ms Y:1.06837 V

Real

/div

-2.5

CH3 Rng: 2.5149 Vpk CH4 Rng: 2.5149 Vpk

2.5

V

500

mV

V

-9.7656ms 489.7461ms

Quantifying Time Trace Results

Use the marker knob to read the amplitude at any time during the trace. Rotate the

knob on the AGILENT 35670A front panel until the marker indicator (the small

diamond following the spectral trace) is placed at the desired time. The time and

amplitude at this bin is presented as X and Y values at the top of the trace. Units of

[s] and [Vrms] or [grms] identify the results.

Peak tracking is very useful for determining maximum amplitude of positive peaks

in the time domain:

• Press the [Marker] hardkey.

• Press [PEAK TRK ON OFF] softkey (F6) until ON is highlighted.

Care must be taken with negative peaks, however, because PEAK TRK ON only

looks for the maximum value, and large negative peaks will be ignored.

14

Page 19

Section 7 : Measuring Dual Channel Spectra

This section contains procedures for setting up and measuring a dual channel

spectrum using an AGILENT 35670A Dynamic Signal Analyzer. Procedures are

similar to those in the section “Measuring Single Channel Spectrum,” however

display setup and results are different and will be described here.

To set up the analyzer for a dual channel spectrum measurement, proceed as follows:

Presetting the Analyzer

• Press the green [Preset] hardkey

• Press [DO PRESET] softkey (F1).

• Press the [Pause/Cont] hardkey if desired.

Selecting Dual Channel Operation

Measure two signals with the default two-channel instrument mode. If the analyzer

has been changed to 1 or 4 channel operation, then follow these steps:

• Press the [Inst Mode] hardkey

• Press [CHANNELS 1 2 4 ] softkey (F7) until 2 is highlighted.

AGILENT 35670A

Supplemental Operator’s Guide

Selecting Frequency Span

Reduce the span to 800 Hz as follows:

• Press the [Freq] hardkey

• Enter 800 and then press the [Hz] softkey (F2)

Displaying Dual-Channel Power Spectrum Measurements

To see the results of a dual-channel measurement, the analyzer’s display format must

be changed to display two traces. Proceed as follows:

• Press the [Disp Format] hardkey.

• Press the [UPPER/LOWER] softkey (F3)

• Press the [Active Trace] hardkey.

• Press the [A] softkey (F1).

• Press the [Meas Data] hardkey.

• Press the [CHANNEL 1 234] softkey (F1) until 1 is highlighted.

• Press the [PWR SPEC CHANNEL 1] softkey (F3)

• Press the [Scale] hardkey.

• Toggle the [AUTOSCALE ON OFF] softkey (F1) until ON is highlighted.

• Press the [Active Trace] hardkey again.

• Press the [B] softkey (F2).

15

Page 20

AGILENT 35670A

Supplemental Operator’s Guide

• Press the [Meas Data] hardkey.

• Press the [CHANNEL 1 2 34] softkey (F1) until 2 is highlighted.

• Press the [Scale] hardkey.

• Toggle the [AUTOSCALE ON OFF] softkey (F1) until ON is highlighted.

Note: many of these keystrokes are not necessary if performed in the given order

because the analyzer defaults to many of these settings.

To acquire dual channel spectra,

• Press the yellow [Start] hardkey.

Meas Data

[FFT]

Date: 10-02-96 Time: 08:49:00 PM

A: CH1 Pwr Spec X:60 Hz Y:147.382 mVrms

Vrms

LogMag

decades

uVrms

B: CH2 Pwr Spec

Vrms

LogMag

decades

uVrms

A: CH1 Pwr Spec B: CH2 Pwr Spec

C: CH1 Time D: CH2 Time

1

6

1

0Hz 800Hz

X:60 Hz Y:80.4887 mVrms

1

4

100

0Hz 800Hz

Using Markers with Dual Channel Measurements

Each trace has independent marker control. All functions available for a single

marker are possible with both markers. To set up individual, independent markers

on each channel, follow these steps:

• Press the [Active Trace] hardkey.

• Press the [A] softkey (F1).

• Press the [Marker] hardkey.

• Toggle the [MARKER ON OFF] softkey (F1) until ON is highlighted.

16

Page 21

AGILENT 35670A

Supplemental Operator’s Guide

Use the marker knob to read the amplitude at any measured frequency for Channel 1

in Trace A.

To set up the marker for Channel 2 in Trace B,

• Press the [Active Trace] hardkey.

• Press the [B] softkey (F2).

• Press the [Marker] hardkey.

• Toggle the [MARKER ON OFF] softkey (F1) until ON is highlighted.

The marker knob is now active for Trace B, which is Channel 2. To gain control of

the marker on Trace A again, make it the active trace as follows:

• Press the [Active Trace] hardkey.

• Press the [A] softkey (F1).

Coupled Markers

Markers on multiple traces can be coupled so that one marker will always track the

frequency specified in another trace. This makes comparisons of level differences

across channels simple. To set up coupled markers so that Trace B will follow the

marker frequency specified in Trace A, do the following:

• Press the [Active Trace] hardkey.

• Press the [A] softkey (F1).

• Press the [Marker] hardkey.

• Toggle the [COUPLED ON OFF] softkey (F1) until ON is highlighted.

Move the knob to move the marker in Trace A. Notice that the marker in Trace B

moves to the same frequency.

Coupled Markers with Peak Tracking

Coupled markers can be further used to track a peak frequency in Trace A and

determine the response amplitude at the peak frequency in Trace B. To do this, leave

coupled markers on, as above, then set up peak tracking in Trace A as follows:

• Press the [Active Trace] hardkey.

• Press the [A] softkey (F1).

• Press the [Marker] hardkey.

• Toggle the [PEAK TRK ON OFF] softkey (F1) until ON is highlighted.

• Press the yellow [Start] hardkey.

Notice that the marker in Trace A moves to the peak value, whereas the marker in

Trace B moves to the same frequency as determined in Trace A.

17

Page 22

AGILENT 35670A

Supplemental Operator’s Guide

Section 8 : Improving Dual Channel Measurement Results

Maximizing Dynamic Range

Autoranging to maximize the dynamic range of measurements in the AGILENT

35670A can function on all channels simultaneously. Therefore all capability

previously mentioned for single-channel front-end ranging is available for dualchannel operation.

To set up autorange on all channels, follow these steps:

• Press the [Input] hardkey.

• Press [ALL CHANNELS] softkey (F2).

• Select the [CH* AUTO RANGE] softkey (F6)

For signals that are not steady, use CH* AUTO UP ONLY. CH1 AUTO UP ONLY

can be used for all channels to set up modal impact testing. To set up this condition:

• Press the [Input] hardkey.

• Select the [CH* AUTO UP ONLY] softkey (F5).

To set up the same fixed range on all channels:

• Press the [Input] hardkey.

• Select the [CHANNEL * RANGE] softkey (F3)

• Enter the range, either in units of g or Volts.

Dual Channel Averaging

Averaging to reduce measurement variance applies to all channels being measured.

Dual channel averaging is set up the same as single channel averaging:

• Press the [Avg] hardkey.

• Press the [NUMBER AVERAGES] softkey (F2), enter 10, then press the

[ENTER] softkey (F1).

• Press the [AVERAGE TYPE] softkey (F3)

• Press the [RMS] softkey (F1)

• Press the [Avg] hardkey.

• Turn on averaging by pressing the [AVERAGE ON OFF] softkey (F1)

until ON is highlighted.

18

Page 23

AGILENT 35670A

Supplemental Operator’s Guide

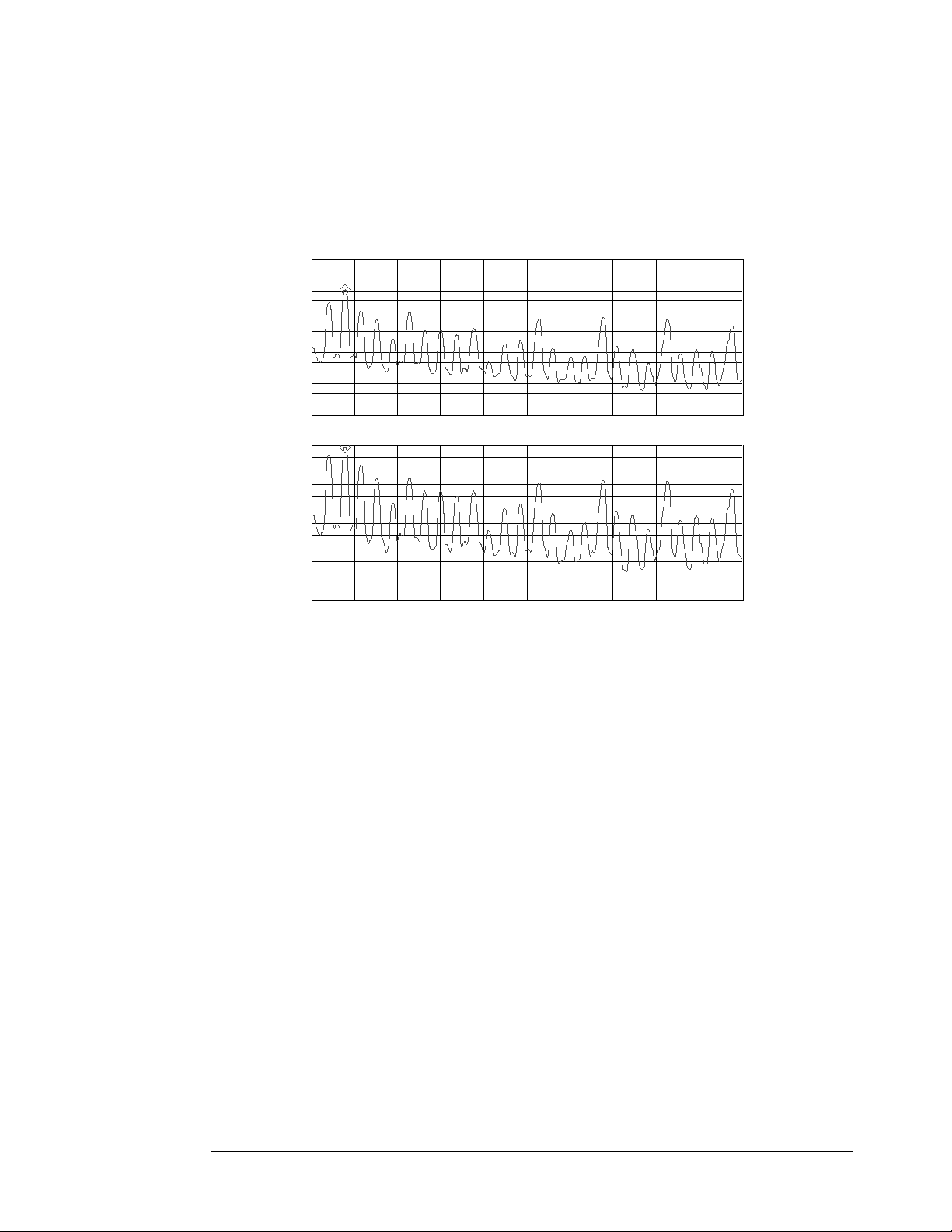

Avg

[FFT]

Date: 10-02-96 Time: 08:51:00 PM

A: CH1 Pwr Spec X:60 Hz Y:112.185 mVrms

Vrms

LogMag

decades

uVrms

B: CH2 Pwr Spec

mVrms

LogMag

decades

uVrms

Type: RMS Number: 10

Update Rt: 5 Overlap: 0 %

1

5

10

0Hz 800HzAVG: 10

X:60 Hz Y:95.0385 mVrms

100

4

10

0Hz 800HzAVG: 10

19

Page 24

AGILENT 35670A

Supplemental Operator’s Guide

Section 9 : Measuring Dual Channel Time Waveforms

This section contains procedures for setting up and measuring a single channel time

waveform using an AGILENT 35670A Dynamic Signal Analyzer. Included are

steps to select single channel operation, set up the trace time length, and set up

triggering to capture a transient event. Instructions will also be presented to scale the

time trace.

Selecting Dual Channel Operation

To measure a single-channel spectrum, turn on the AGILENT 35670A. The default

instrument mode is dual-channel operation.

Note: if the AGILENT 35670A was already turned on and in an unknown

state, then preset the analyzer by doing the following:

• Press the green [Preset] hardkey.

• Press [DO PRESET] softkey (F1).

This always returns the analyzer to dual-channel operation.

Selecting Time Record Length

Time record length can be entered directly or indirectly. It is entered directly under

the [Freq] hardkey as follows (this example sets up a 0.25 second time record):

• Press the [Freq] hardkey

• Press the [RECORD LENGTH] softkey (F8)

• Enter 0.25 and then press the [S] softkey (F1)

Time record length can also be specified indirectly by entering frequency and

resolution in lines. The relationship between time record length (T), lines of

resolution (N), and frequency (F) is:

N

=

T

()

F

1024.

For 400 lines of resolution (default) and 1600 Hz span, the time record length should

be 400/(1.024*1600) ≈ 0.25 seconds. The table showing the relationship between

lines, span, and time record length can be found in the section on Single Channel

Time Waveforms.

Displaying Dual Time Waveforms

Dual time waveforms can be shown in the UPPER/LOWER display format, with

AUTO SCALE turned ON, as follows:

• Press the [Disp Format] hardkey.

• Press the [UPPER/LOWER] softkey (F3).

• Press the [Active Trace] hardkey.

• Press the [A] softkey (F1)

• Press the [Meas Data] hardkey.

20

Page 25

AGILENT 35670A

Supplemental Operator’s Guide

• Press the [CHANNEL 1 234] softkey (F1) until 1 is highlighted.

• Press the [TIME CHANNEL 1] softkey (F5)

• Press the [Scale] hardkey.

• Toggle the [AUTOSCALE ON OFF] softkey (F1) until ON is highlighted..

• Press the [Active Trace] hardkey.

• Press the [B] softkey (F1)

• Press the [Meas Data] hardkey.

• Press the [CHANNEL 1 2 34] softkey (F1) until 2 is highlighted.

• Press the [TIME CHANNEL 2] softkey (F5)

• Press the [Scale] hardkey.

• Toggle the [AUTOSCALE ON OFF] softkey (F1) until ON is highlighted.

Arming Dual Channel Time Measurements

To manually arm a dual channel time measurement, proceed the same as for the

single channel case:

• Press the [Trigger] hardkey.

• Select the [ARM SETUP] softkey (F7)

• Select the [MANUAL ARM] softkey (F2)

• Press the yellow [Start] hardkey to begin the measurement.

• Press the [Trigger] hardkey.

Then to arm a single time record,

• Press the [ARM] softkey (F9)

One time record will be captured and displayed. To capture another time record,

• Press the [ARM] softkey (F9) again.

Triggering a Dual-Channel Time Measurement

Either channel may be monitored to initiate a trigger for a measurement. Setting up

the trigger event is the same as for single channel time waveforms, except that

channel 1 or channel 2 must be selected as the trigger. To specify the trigger

channel, proceed as follows:

• Press the [Trigger] hardkey.

• Press the [CHANNEL 1 234] softkey (F3) until 1 is highlighted.

This sets up the analyzer to trigger off an event on channel 1. To set up channel 2 as

the trigger channel, do the following:

• Press the [Trigger] hardkey.

• Press the [CHANNEL 1 2 34] softkey (F3) until 2 is highlighted.

21

Page 26

AGILENT 35670A

Supplemental Operator’s Guide

Then set up trigger parameters (for a positive event, positive slope) as follows:

• Press the [TRIGGER SETUP] softkey (F6)

• Press the [CHANNEL LEVEL] softkey (F1)

• Enter 5 then press the [PERCENT (%)] softkey (F4)

• Press the [SLOPE POS NEG] softkey (F5) until POS is highlighted.

Trigger Delay

Both channels should acquire data using the same pre-trigger delay. To set up a

0.01s pre-trigger condition, follow these steps:

• Press the [Trigger] hardkey.

• Press the [TRIGGER SETUP] softkey (F6)

• Press the [ALL CHANNELS] softkey (F8)

• Press the [CHANNEL * DELAY] softkey (F9)

• Enter -.01 then press the [S] softkey (F1)

To start the data acquisition,

• Press the yellow [Start] hardkey.

The analyzer should show in highlighted text above the trace:

WAITING FOR CH 1 TRIGGER

Trigger

[FFT]

Date: 10-03-96 Time: 05:23:00 PM

A: CH1 Time X:472.168 ms Y:371.577 mV

Real

/div

-500

B: CH2 Time

Real

/div

-500

Arm: Automatic Waterfall Steps: 15

Chn Level: 5 % Slope: Positive

500

mV

100

mV

mV

-9.7656ms 489.7461ms

500

100

mV

mV

mV

X:472.168 ms Y:-241.753 mV

-9.7656ms 489.7461ms

22

Page 27

AGILENT 35670A

Supplemental Operator’s Guide

Using Markers with Dual Channel Time Measurements

Compare the time trace of Channel 1 with Channel 2 using two techniques: peak

tracking and coupled markers. With peak tracking active on both channels, it is

possible to measure an event with two channels and easily compare peak amplitudes.

Set set up peak tracking for both channels, do the following:

• Press the [Active Trace] hardkey.

• Press the [A] softkey (F1).

• Press the [Marker] hardkey.

• Toggle the [PEAK TRK ON OFF] softkey (F6) until ON is highlighted.

• Press the [Active Trace] hardkey.

• Press the [B] softkey (F2).

• Press the [Marker] hardkey.

• Toggle the [PEAK TRK ON OFF] softkey (F6) until ON is highlighted.

Coupled markers can provide a quick comparison of relative levels during a transient

event at a specific time. To set up peak tracking on Channel 1 and force the marker

on Channel 2 to the time of Channel 1 peak, do the follow:

• Press the [Active Trace] hardkey.

• Press the [A] softkey (F1).

• Press the [Marker] hardkey.

• Toggle the [PEAK TRK ON OFF] softkey (F6) until ON is highlighted.

• Toggle the [COUPLED ON OFF] softkey (F1) until ON is highlighted.

Peak tracking looks for the maximum positive level in a trace. Therefore do not use

peak tracking to determine the maximum absolute amplitude of negative pulses in a

time trace.

Section 10 : Measuring Dual Channel Spectra and Time Waveforms

Two signals can be measured and examined in the time and frequency domains

simultaneously. To accomplish this, a quad display format must be set up as

follows:

First, preset the analyzer:

• Press the green [Preset] hardkey

• Press [DO PRESET] softkey (F1).

This places the analyzer into the default two channel mode. Set up the transducer

parameters as described previously, if desired. Then, set up the display for four

traces:

• Press the [Disp Format] hardkey.

• Press the [QUAD] softkey (F6).

23

Page 28

AGILENT 35670A

Supplemental Operator’s Guide

• Press the [Active Trace] hardkey.

• Press the [ABCD] softkey (F7).

• Press the [Scale] hardkey.

• Toggle the [AUTOSCALE ON OFF] softkey (F1) until ON is highlighted..

• Press the [Active Trace] hardkey.

• Press the [A] softkey (F1).

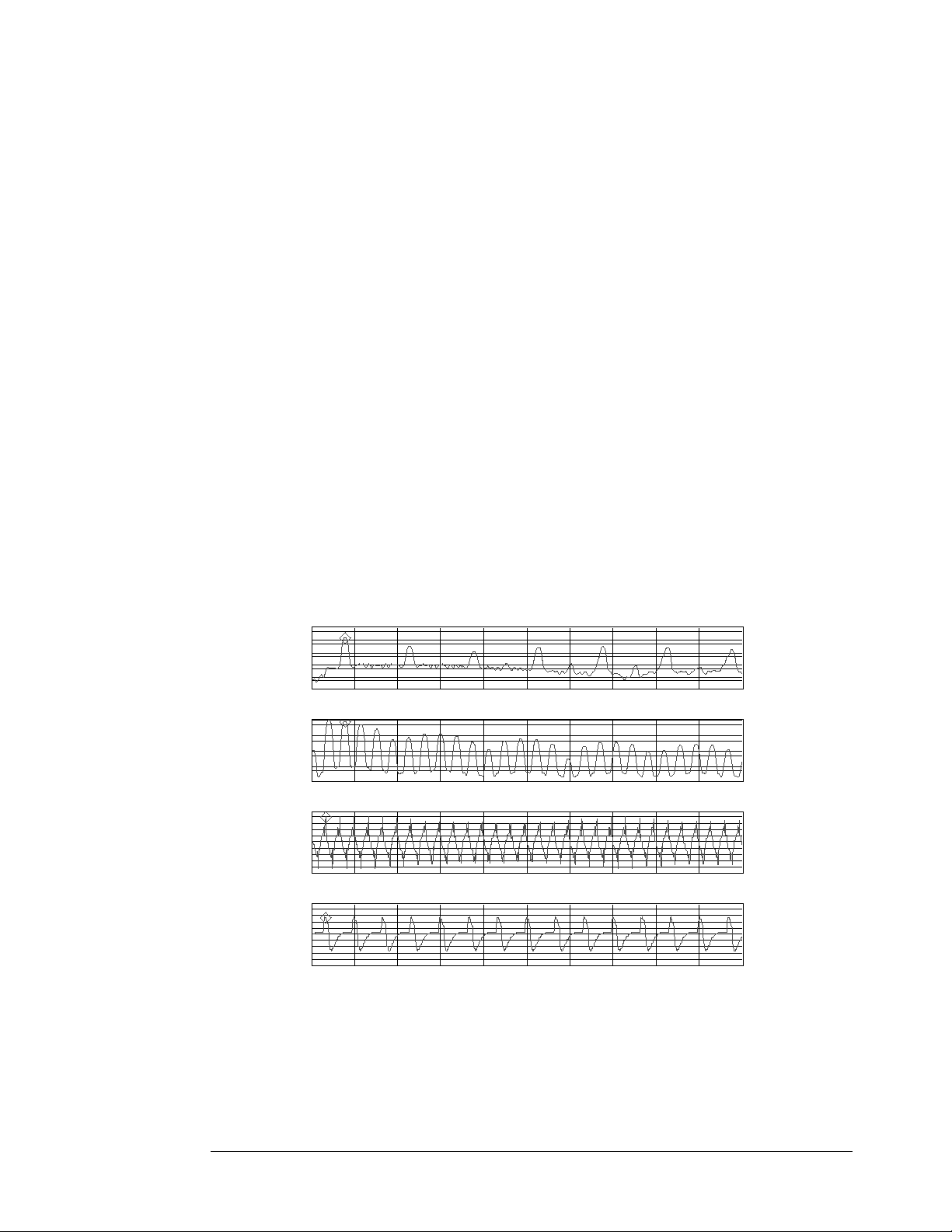

The default QUAD display shows Channel 1 power spectrum in Trace A, Channel 2

power spectrum in Trace B, Channel 1 time in Trace C, and Channel 2 time in Trace

D.

Individual markers can be used on each trace, or peak tracking and coupled markers

can be used as described for dual traces.

If averaging is applied to the power spectrum measurements, then the QUAD display

will show the averaged power spectra in Trace A and B, and the previously acquired

time traces in Trace C and D.

Scale Trace: A Ref Lvl: 1

Date: 10-02-96 Time: 08:54:00 PM

A: CH1 Pwr Spec

Vrms

LogMag

uVrms

B: CH2 Pwr Spec

mVrms

LogMag

uVrms

C: CH1 Time

Real

-500

D: CH2 Time

Real

-500

Per Div: 5 Ref Pos: Top

X:60 Hz Y:172.071 mVrms

1

10

0Hz 800HzAVG: 10

X:60 Hz Y:88.5405 mVrms

100

10

0Hz 800HzAVG: 10

X:14.6484 ms Y:427.266 mV

500

mV

mV

0s 499.5117ms

X:14.6484 ms Y:279.515 mV

500

mV

mV

0s 499.5117ms

24

Page 29

Supplemental Operator’s Guide

Section 11 : Modal Testing Using a Hammer and Accelerometer

Hammer testing is often the easiest and quickest technique for measuring frequency

response functions used in modal analysis. Instructions for using a hammer with a

force transducer and an accelerometer to measure frequency response functions are

presented.

Setting Up the Transducer Parameters

Connect the force transducer on the hammer to Channel 1. Mount the response

accelerometer to the desired location on the structure, and connect it (or its

preamplifier) to Channel 2. Preset the analyzer and set up transducer parameters as

follows, assuming an ICP accelerometer with a sensitivity of 11 mV/g and an ICP

force transducer on the hammer with a sensitivity of 5 mV/lb:

• Press the green [Preset] hardkey

• Press [DO PRESET] softkey (F1).

Wait for the analyzer to finish its preset routine.

• Press the [Pause/Cont] hardkey to pause the current measurement.

Set up the force transducer parameters as follows:

• Press the [Input] hardkey

• Press [CHANNEL 1 234] softkey (F1) until 1 is highlighted.

• Press [FRONT END CH1 SETUP] softkey (F7).

• Press [ICP SUPLY ON OFF] softkey (F8) until ON is highlighted.

• Press the [Input] hardkey.

• Press the [XDCR SENSITVTY] softkey (F6).

• Enter 5, then press the [mV/EU] softkey (F2).

• Toggle the [XDCR UNIT ON OFF] softkey (F4) until ON is highlighted.

• Press the [XDCR UNIT LABEL] softkey (F7).

• Press the [MORE CHOICES] softkey (F9).

• Select the [lb] softkey (F6).

• [XDCR UNIT CH1 SETUP] softkey (F8)

Set up the accelerometer parameters as follows:

• Press the [Input] hardkey.

• Press [CHANNEL 1 2 34] softkey (F1) until 2 is highlighted.

• Press [FRONT END CH2 SETUP] softkey (F7).

• Press [ICP SUPLY ON OFF] softkey (F8) until ON is highlighted.

• Press the [Input] hardkey.

• Press [XDCR UNIT CH2 SETUP] softkey (F8)

• Press the [XDCR SENSITVTY] softkey (F6).

• Enter 11, then press the [mV/EU] softkey (F2).

AGILENT 35670A

25

Page 30

AGILENT 35670A

Supplemental Operator’s Guide

• Toggle the [XDCR UNIT ON OFF] softkey (F4) until ON is highlighted.

• Press the [XDCR UNIT LABEL] softkey (F7).

• Select the [g] softkey (F2).

Setting Up Input Range

Use CH* AUTO UP ONLY as the autorange routine as follows:

• Press the [Input] hardkey.

• Press [ALL CHANNELS] softkey (F2).

• Select the [CH* AUTO UP ONLY] softkey (F5).

Then tap the structure with the hammer once. A yellow overload light by the input

BNC connectors will indicate an overload, and the range will increase one step.

Continue tapping on the structure, one tap at a time, allowing time for the input range

to increase, until an overload is no longer indicated. This may take many hammer

strikes. When an overload on either channel is no longer indicated, then the ranges

are set correctly.

Choosing a Preliminary Frequency Span

Setting up a frequency response measurement is an interative process. A span is

selected, a measurement is made, and the results are examined to determine if a

narrower or wider span is required. To start measuring frequency response, you

must select an initial span:

• Press the [Freq] hardkey.

• Enter 1600 and then press the [Hz] softkey (F2).

Note: span should be any frequency that encompasses all modes of interest. If in

doubt, start with a wider span.

Specifying Trigger Parameters

Hammer testing is triggered by the signal from the hammer. Without a force

transducer, the trigger must come from the accelerometer that is attached to the

hammer and connected to Channel 1. To set up a Channel 1 trigger, follow these

steps:

• Press the [Trigger] hardkey.

• Press the [CHANNEL 1 234] softkey (F3) until 1 is highlighted.

• Press the [TRIGGER SETUP] softkey (F6)

• Press the [CHANNEL LEVEL] softkey (F1)

• Enter 5 then press the [PERCENT (%)] softkey (F4)

• Press the [SLOPE POS NEG] softkey (F5) until POS is highlighted.

• Press the [Trigger] hardkey.

26

Page 31

AGILENT 35670A

Supplemental Operator’s Guide

• Press the [TRIGGER SETUP] softkey (F6)

• Press the [ALL CHANNELS] softkey (F8)

• Press the [CHANNEL * DELAY] softkey (F9)

• Enter -.01 then press the [S] softkey (F1)

Now to check that the trigger parameters are correct,

• Press the yellow [Start] hardkey.

The analyzer should show in highlighted text above the trace:

WAITING FOR CH 1 TRIGGER

Tap the hammer on the test structure to see if the measurement will trigger. If it will

not, adjust the trigger level and slope until successful.

Setting Up Time Displays

View both the time trace and the windowed time trace for both channels using the

QUAD display format as follows:

• Press the [Disp Format] hardkey.

• Press the [QUAD] softkey (F6).

• Press the [Active Trace] hardkey.

• Press the [A] softkey (F1)

• Press the [Meas Data] hardkey.

• Press the [CHANNEL 1 234] softkey (F1) until 1 is highlighted.

• Press the [TIME CHANNEL 1] softkey (F5)

• Press the [Active Trace] hardkey.

• Press the [B] softkey (F1)

• Press the [TIME CHANNEL 2] softkey (F5)

• Press the [Active Trace] hardkey.

• Press the [C] softkey (F1)

• Press the [CHANNEL 1 234] softkey (F1) until 1 is highlighted.

• Press the [MORE CHOICES] softkey (F9)

• Press the [WINDOWED TIME CH 1] softkey (F5)

• Press the [Active Trace] hardkey.

• Press the [D] softkey (F1)

• Press the [WINDOWED TIME CH 2] softkey (F5)

• Press the [Active Trace] hardkey.

• Press the [ABCD] softkey (F7).

• Press the [Scale] hardkey.

• Toggle the [AUTOSCALE ON OFF] softkey (F1) until ON is highlighted.

27

Page 32

AGILENT 35670A

Supplemental Operator’s Guide

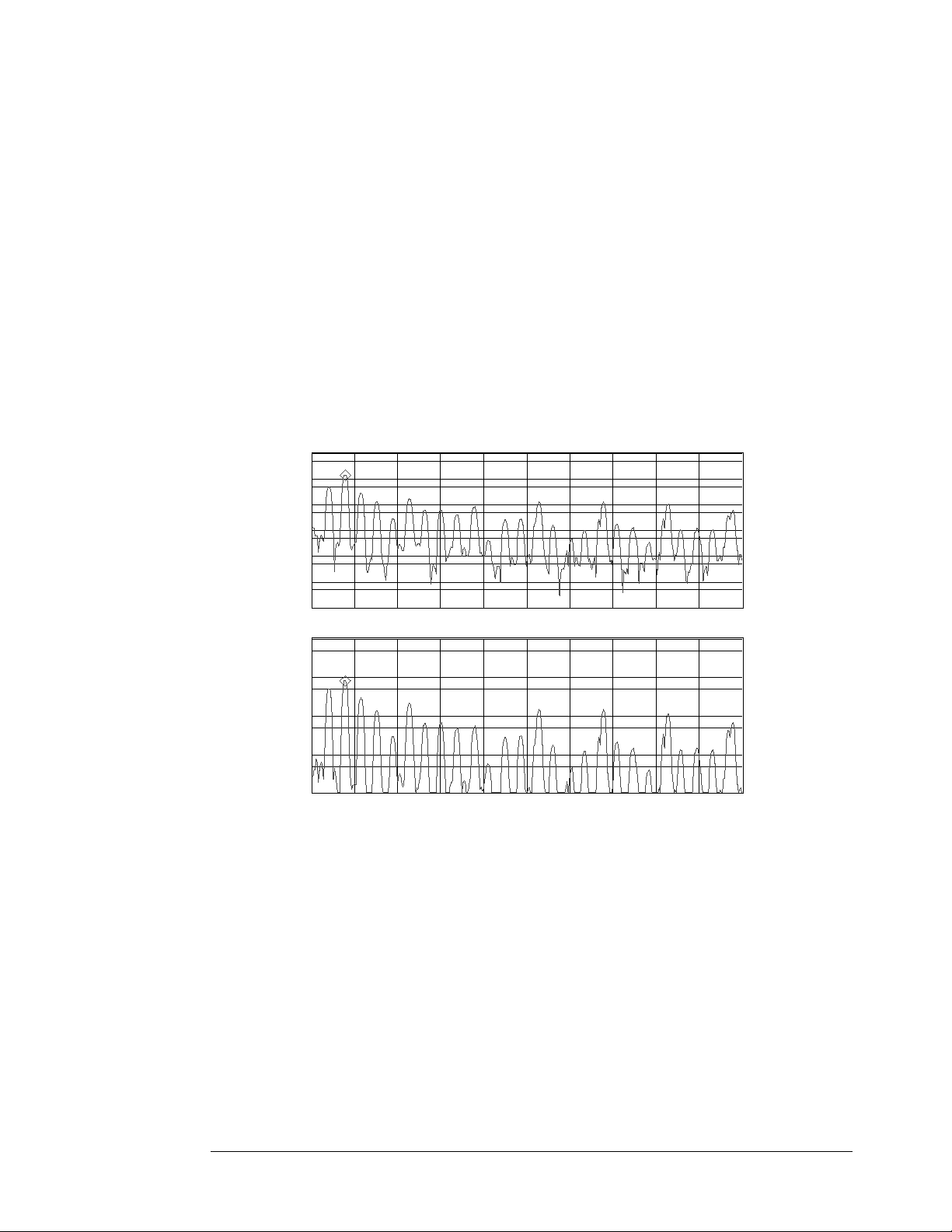

Window

[FFT]

Date: 10-02-96 Time: 09:02:00 PM

A: CH1 Time

Real

B: CH2 Time

Real

-200

C: CH1 Win Time

Real

D: CH2 Win Time

Real

-250

Type: Force/Expo Width: 15 ms

X:488.281 us Y:67.1154 mV

80

mV

-20

mV

-9.766ms 115.112ms

X:488.281 us Y:-74.925 mV

300

mV

mV

-9.766ms 115.112ms

X:488.281 us Y:48.1237 mV

70

mV

-30

mV

-9.766ms 115.112ms

X:488.281 us Y:-53.234 mV

250

mV

mV

-9.766ms 115.112ms

Decay: 30 ms

Using Force/Response Windows

Hammer measurements for modal analysis typically require special windows, named

Force/Response windows, to maximize measurement quality. The force window

merely zeros out the trace after a fixed time interval, so that noise or bumps from the

hammer after the desired impact do not get interpreted as excitation applied to the

structure. The fixed interval must be long enough to capture the whole pulse, so that

measurement of the impact does not get zeroed out. A typical value for the length of

a force window is T/7, where T is the record duration in seconds. For a 1600 Hz

span and resolution of 400 lines, the record length is 250 ms, so a “conservative”

force window might have a duration of 36 ms. Experience may show that a much

shorter duration may work better.

Response windows prevent leakage by artificially decaying the response so that by

the end of the record the signal is less than 5% of the peak. The artificial decay is

specified by a time constant, with shorter time constants providing higher decay

rates. A time constant that is guaranteed to decay a signal to less than 5% is T/4.

For a span of 1600 Hz and resolution of 400 lines, this translates into a response

28

Page 33

AGILENT 35670A

Supplemental Operator’s Guide

window time constant of 62.5 ms. To set up these Force/Response windows, follow

these steps:

• Press the [Window] hardkey.

• Press the [FORCE EXPO] softkey (F4).

• Press the [FORCE EXPO SETUP] softkey (F6).

• Press the [FORCE WIDTH] softkey (F6).

• Enter 36 and then press the [mS] softkey (F2).

• Press the [EXPO DECAY] softkey (F7).

• Enter 62.5 and then press the [mS] softkey (F2).

To view the effects of theForce/Response window,

• Press the yellow [Start] hardkey.

• Tap the structure with the hammer.

Observe the time trcaes. Compare them to their windowed time records. Determine

if the Force/Response windows met their object. Adjust windows if necessary. If it

appears that no window would be required, then it is possible to test with a

“UNIFORM” (meaning factor of 1) window instead of a force/response window. To

select a UNIFORM window,

• Press the [Window] hardkey.

• Press the [UNIFORM] softkey (F3).

Displaying Hammer Test Results

The results of hammer testing are frequency response functions, and the indicator of

measurement quality is coherence. These traces can be set up as follows:

• Press the [Disp Format] hardkey.

• Press the [UPPER/LOWER] softkey (F3).

• Press the [Active Trace] hardkey.

• Press the [A] softkey (F1)

• Press the [Meas Data] hardkey.

• Press the [FREQ RESP 2 / 1] softkey (F6)

• Press the [Scale] hardkey.

• Toggle the [AUTOSCALE ON OFF] softkey (F1) until ON is highlighted..

• Press the [Active Trace] hardkey.

• Press the [B] softkey (F1)

• Press the [Meas Data] hardkey.

• Press the [COHERENCE 2 / 1] softkey (F7)

Averaging

Averaging is a very effective technique for improving the quality of frequency

response measurements. A minimum of four averages reduces noise and variance

29

Page 34

AGILENT 35670A

Supplemental Operator’s Guide

significantly. Ten averages may take longer, but may be necessary when testing

difficult, non-linear structures. To set up five averages, follow these steps:

• Press the [Avg] hardkey.

• Toggle the [AVERAGE ON OFF] softkey (F1) until ON is highlighted.

• Press the [NUMBER AVERAGES] softkey (F2).

• Enter 5 and press the [ENTER] softkey (F1).

To avoid averaging overloaded data, turn on overload reject as follows:

• Press the [Avg] hardkey.

• Toggle the [OVLD REJ ON OFF] softkey (F1) until ON is highlighted.

To start taking measurements,

• Press the yellow [Start] hardkey.

•

Hammer the structure at one measurement point. After the data is acquired and

displayed, hammer the structure again, and repeat 5 times until the average is

complete.

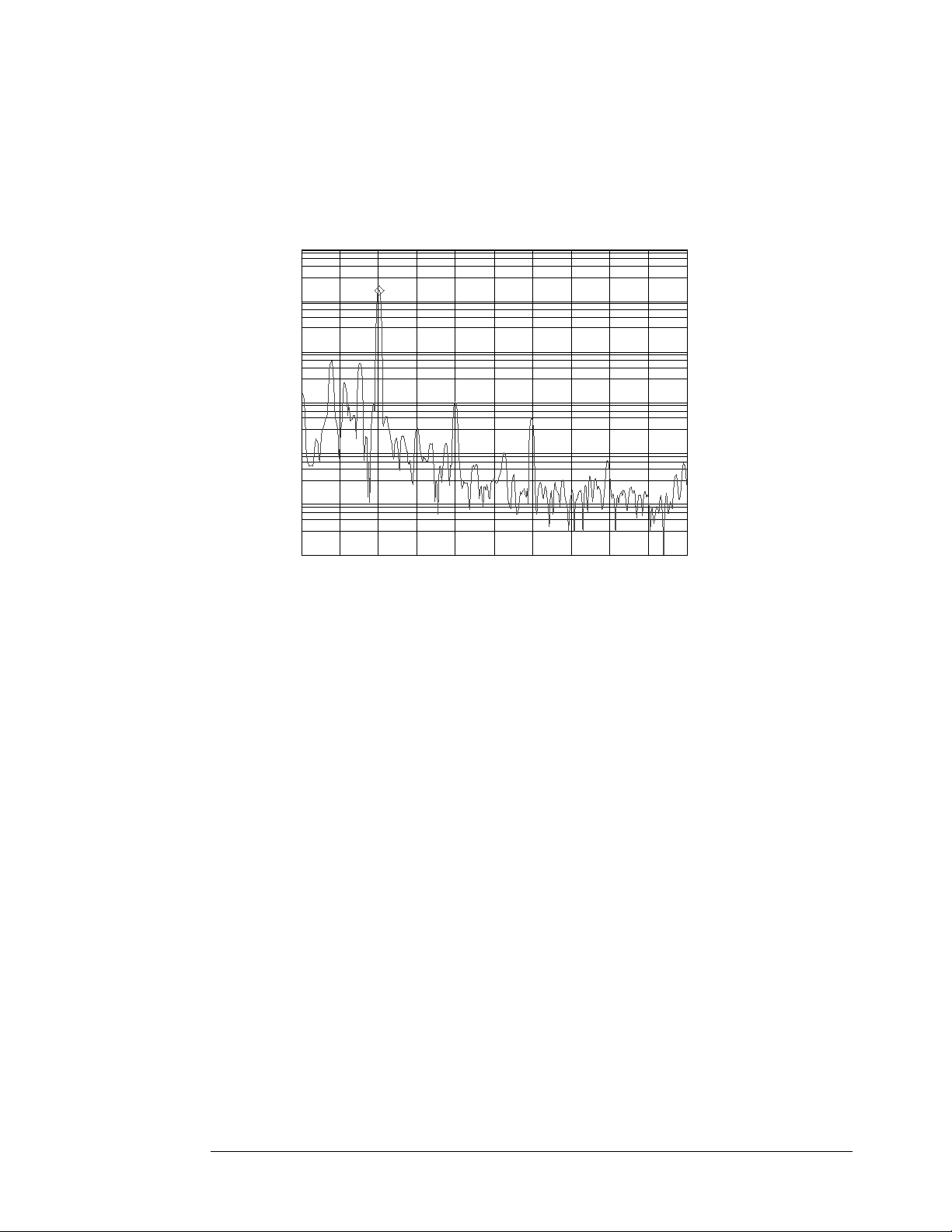

Avg

[FFT]

Date: 10-02-96 Time: 09:06:00 PM

A: Freq Resp2/1 X:2.96 kHz Y:98.678

LogMag

decades

B: Coherence2/1

Real

Type: RMS Number: 5

Update Rt: 5 Overlap: 0 %

100

4

10

e-3

0Hz 3.2kHzAVG: 5

X:2.96 kHz Y:963.738 e-3

0Hz 3.2kHzAVG: 5

/div

100

e-3

1

0

30

Page 35

AGILENT 35670A

Supplemental Operator’s Guide

Changing Frequency Span

Changing frequency span or resolution affects three important parameters in hammer

testing which must be changed to correspond to the new time record length: Trigger

Delay, Force Window Width, and Response Window Decay Time. The following

relationship between the parameters can be used as a guideline:

N

=

T

Where T is the time record length in seconds, N is the resolution in lines, and F is the

frequency span in Hz.

Delay T= 01.( )

()

F

1024.

ForceWidthT=

ExponentialDecayT=

When the frequency span is halved, the Time Record length doubles, as does the

Delay time, Force Width, and Exponential Decay. All three parameters should

change with the inverse of the change in frequency span.

7

4

31

Page 36

AGILENT 35670A

Supplemental Operator’s Guide

Section 12 : Hammer Test Setup Without a Force Transducer

Hammer testing for modal analysis without a force transducer can yield usable

results if an accelerometer is placed on the hammer and used to trigger the

measurement. Although frequency response functions acquired with this technique

will be affected by the dynamic characteristics of the hammer assembly and also its

mass-loading effects, approximate mode frequencies and mode shapes can still be

computed using modal analysis software.

On the other hand, power spectra obtained by measuring the single-channel response

to a non-instrumented hammer strike may also provide information regarding modal

frequencies and shapes, but success is too dependent on the consistency of the

hammer strike, and therefore this technique is not recommended.

Setting Up the Hammer Test Without a Force Transducer

Attach an accelerometer to the hammer using cement or wax, and connect this

transducer to Channel 1. Attach the response accelerometer to the desired location

on the structure, and connect it to Channel 2. Preset the analyzer and set up

transducer parameters as described in the section “Measuring with Transducers.”

Then proceed with the test in accordance with the proceeding section on “Modal

Testing with a Hammer and Accelerometer.”

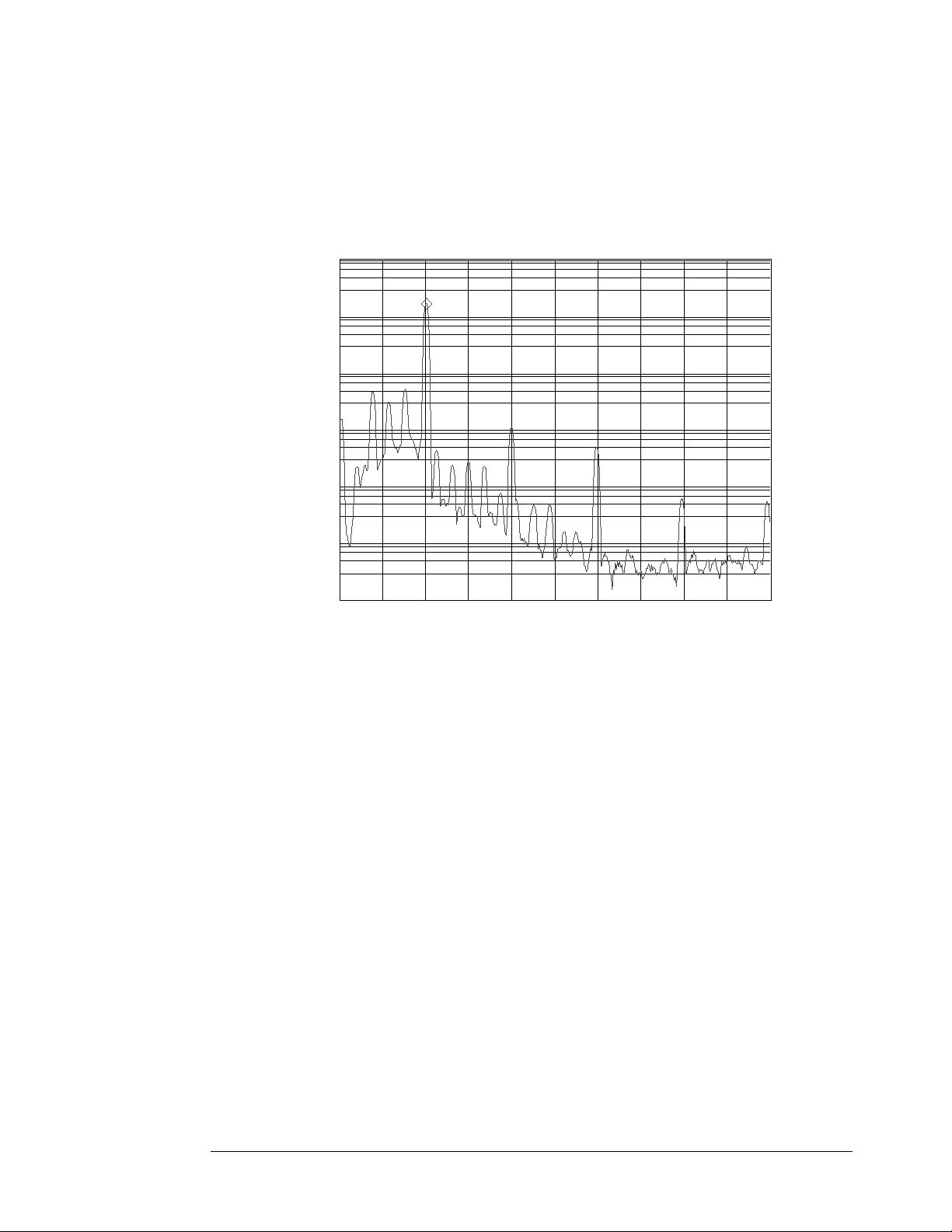

Avg

[FFT]

Date: 10-02-96 Time: 09:24:00 PM

A: Freq Resp2/1 X:656 Hz Y:444.409

LogMag

decades

B: Coherence2/1

Real

Type: RMS Number: 5

Update Rt: 5 Overlap: 0 %

1

e+3

5

10

e-3

0Hz 3.2kHzAVG: 5

X:656 Hz Y:939.573 e-3

0Hz 3.2kHzAVG: 5

/div

100

e-3

1

0

32

Page 37

Section 13 : Order Domain Results in List Mode

Machinery run-ups and run-downs can be analyzed with order analysis, which is

spectral analysis normalized to RPM. Results can be simplified by examining only a

list of amplitude versus order, so that only desired results are examined.

To set up and measure a list of 10 orders for a machinery run-up, follow these steps:

• Press the green [Preset] hardkey

• Press [DO PRESET] softkey (F1).

• Press the [Pause/Cont] hardkey if desired.

• Press the [ORDER ANALYSIS] softkey (F3).

• Press [CHANNELS 1 24 ] softkey (F7) until 1 is highlighted.

• Press the [Input] hardkey

• Press the [CH1 AUTO UP ONLY] software (F5).

Order analysis requires a tachometer signal connected to the TACH BNC at

the back of the analyzer. To set up the AGILENT 35670A for the tachometer

signal, follow these steps:

• Press the [TACHOMETR SETUP] softkey (F9).

• Toggle the [TACH DISP ON OFF] softkey (F6) until ON is highlighted.

• Press the [TACH PULS PER REV] softkey (F1).

• Enter the number of tachometer pulses per shaft revolution

and press the [ENTER] softkey (F1).

• Press the [LEVEL] softkey (F3).

• Enter the tachometer level and press the [ENTER] softkey (F1).

If in doubt about the tachometer level, enter 0.5 V and experiment with

level, slope, and trigger range until a tachometer display is shown.

Prepare the order display as follows:

• Press the [Disp Format] hardkey.

• Press the [UPPER/LOWER] softkey (F3).

• Press the [Active Trace] hardkey.

• Press the [B] softkey (F1)

Prepare the order results list as follows:

• Press the [Analys] hardkey.

• Press the [DATA TABLE] softkey (F5).

• Toggle the [TABLE ON OFF] softkey (F1) until ON is highlighted.

• Press the [INSERT X VALUE] softkey (F4).

• Enter 1 and press the [ORDERS] softkey (F1).

• Enter 2 and press the [ORDERS] softkey (F1).

• Enter 3 and press the [ORDERS] softkey (F1).

AGILENT 35670A

Supplemental Operator’s Guide

33

Page 38

AGILENT 35670A

Supplemental Operator’s Guide

• Enter 4 and press the [ORDERS] softkey (F1).

• Enter 5 and press the [ORDERS] softkey (F1).

• Enter 6 and press the [ORDERS] softkey (F1).

• Enter 7 and press the [ORDERS] softkey (F1).

• Enter 8 and press the [ORDERS] softkey (F1).

• Enter 9 and press the [ORDERS] softkey (F1).

• Enter 10 and press the [ORDERS] softkey (F1).

After the data table is built, it can be saved to disk with the following steps:

• Insert a 3.5” diskette into the AGILENT 35670A

• Press the [Save/Recall] hardkey.

• Press the [SAVE MORE] softkey (F3).

• Press the [SAVE DATA TABL] softkey (F4).

• Press the [ENTER] softkey (F1) to save the data table to the default

filename “DATA1.TBL”

• “DATA1.TBL” can be recalled later to set up the structure of the data

table.

To start taking measurements,

• Press the yellow [Start] hardkey.

Marker Trace: A X Ref: 0

Date: 10-02-96 Time: 09:36:00 PM

A: CH1 Pwr Spec X:2 Order Y:837.946 uVrms

Entry Label Order Vrms

LogMag

1 4.797 u

2 837.946 u

3 21.182 u

4 96.302 u

5 21.047 u

6 59.76 u

7 21.843 u

8 154.291 u

9 58.746 u

10 360.559 u

Y Ref: 100 u

34

Page 39

AGILENT 35670A

Supplemental Operator’s Guide

Section 14 : Comparing Two-Channel Real-Time Spectra with Recalled Data

Compare two channels of real-time data with spectra stored in registers using the

UPPR/LOWR FRNT/BACK display format of the AGILENT 35670A. Note that the

real-time data should be measured with the same frequency and resolution as the

stored data if valid, direct comparisons are desired.

Preset the analyzer as follows:

• Press the green [Preset] hardkey

• Press [DO PRESET] softkey (F1).

• Press the yellow [Pause/Cont] hardkey if desired.

Selecting Measurement Parameters

Refer to the section entitled “Measuring Dual Channel Spectra” to set up span,

ranges, coupling, averaging, and windowing. Transducer parameters set up is

described in the section “Measuring with Transducers.”

Displaying Dual-Channel Spectra Compared with Recalled Data

The results of a dual-channel measurement are compared to recalled spectra in data

registers via the following steps:

• Press the [Disp Format] hardkey.

• Press the [UPPR/LOWR FRNT/BACK] softkey (F5).

• Press the [Active Trace] hardkey.

• Press the [A] softkey (F1).

• Press the [Meas Data] hardkey.

• Press the [CHANNEL 1 234] softkey (F1) until 1 is highlighted.

• Press the [PWR SPEC CHANNEL 1] softkey (F3)

• Press the [Active Trace] hardkey again.

• Press the [B] softkey (F2).

• Press the [Meas Data] hardkey.

• Press the [MORE CHOICES] softkey (F9).

• Press the [DATA REGISTER] softkey (F8).

• Press the [D1] softkey (F1).

• Press the [Active Trace] hardkey.

• Press the [C] softkey (F1).

• Press the [Meas Data] hardkey.

• Press the [CHANNEL 1 2 34] softkey (F1) until 2 is highlighted.

• Press the [PWR SPEC CHANNEL 2] softkey (F3).

• Press the [Active Trace] hardkey again.

• Press the [D] softkey (F2).

• Press the [Meas Data] hardkey.

35

Page 40

AGILENT 35670A

Supplemental Operator’s Guide

• Press the [MORE CHOICES] softkey (F9).

• Press the [DATA REGISTER] softkey (F8).

• Press the [D2] softkey (F2).

Recalling the Spectra from Disk

Use data registers D1 and D2 to contain the spectra used for comparison. D1 is

compared to Channel 1 real-time data, and D2 is compared to Channel 2 real-time

data. Comparison data must either be measured, then stored into data registers D1

and D2, or recalled into registers D1 and D2 from disk or non-volatile RAM. For

instructions on how to store spectra to disk, see the section “Storing Data to a Disk

File.” For instructions on how to store spectra to data registers, see the section

“Storing Data in Data Registers.”

For this section, the comparison data is assumed to be stored in the disk file

“

COMPARE1.DAT” and “COMPARE2.DAT.” To recall these spectra into D1 and

D2, respectively, follow these steps:

• Insert the 3.5” disk containing the files “COMPARE1.DAT” and

“COMPARE2.DAT.”

• Press the [Save/Recall] hardkey.

• Press the [RECALL DATA] softkey (F4).

• Press the [RCL TRACE AND SCALE] softkey (F1).

• Press the [FROM FILE INTO D1] softkey (F1).

• Press the [CLEAR ENTRY] softkey (F9).

• Enter COMPARE1.DAT and press the [ENTER] softkey (F1).

Data from the file “COMPARE1.DAT” now appears in data register D1. Next, recall

COMPARE2.DAT” into dataregister D2 as follows:

“

• Press the [Save/Recall] hardkey.

• Press the [RECALL DATA] softkey (F4).

• Press the [RCL TRACE AND SCALE] softkey (F1).

• Press the [FROM FILE INTO D2] softkey (F2).

• Press the [CLEAR ENTRY] softkey (F9).

• Enter COMPARE2.DAT and press the [ENTER] softkey (F1).

Recalling the Spectra from Non-Volatile RAM

The comparison data files “COMPARE1.DAT” and “COMPARE2.DAT” are stored in

the non-volatile RAM. To recall these spectra into D1 and D2, respectively, follow

these steps:

• Press the [Save/Recall] hardkey.

• Press the [DEFAULT DISK] softkey (F9).

• Press the [NON VOL RAM DISK] softkey (F1).

36

Page 41

AGILENT 35670A

Supplemental Operator’s Guide