Page 1

User’s Guide

Publication Number 34970-90003 (order as 34970-90101 manual set)

Edition 3, March 2003

© Copyright Agilent Technologies, Inc. 1997-2003

For Safety information, Warranties, and Regulatory information,

see the pages following the Index.

Agilent 34970A

Data Acquistion / S witch Unit

Page 2

Page 3

Note: Unless otherwise indicated, this manual applies to all serial numbers.

The Agilent Technologies 34970A combines precision measurement

capability with flexible signal connections for your production and

development test systems. Three module slots are built into the rear

of the instrument to accept any combination of data acquisition or

switching modules. The combination of data logging and data

acquisition features makes this instrument a versatile solution for your

testing requirements now and in the future.

Convenient Data Logging Features

• Direct measurement of thermocouples, RTDs, thermistors, dc voltage,

ac voltage, resistance, dc current, ac current, frequency, and period

• Interval scanning with storage of up to 50,000 time-stamped readings

• Independent channel configuration with function, Mx+B scaling,

and alarm limits available on a per-channel basis

• Intuitive user interface with knob for quick channel selection,

menu navigation, and data entry from the front panel

• Portable, ruggedized case with non-skid feet

• BenchLink Data Logger Software for Microsoft

®

Windows

®

included

Flexible Data Acquisition / Switching Features

1

• 6

⁄

-digit multimeter accuracy, stability, and noise rejection

2

• Up to 60 channels per instrument (120 single-ended channels)

• Reading rates up to 600 readings per second on a single channel and

scan rates up to 250 channels per second

• Choice of multiplexing, matrix, general-purpose Form C switching,

RF switching, digital I/O, totalize, and 16-bit analog output functions

• GPIB (IEEE-488) interface and RS-232 interface are standard

• SCPI (Standard Commands for Programmable Instruments) compatibilit y

Agilent 34970A

Data Acquisition / S witch Unit

Page 4

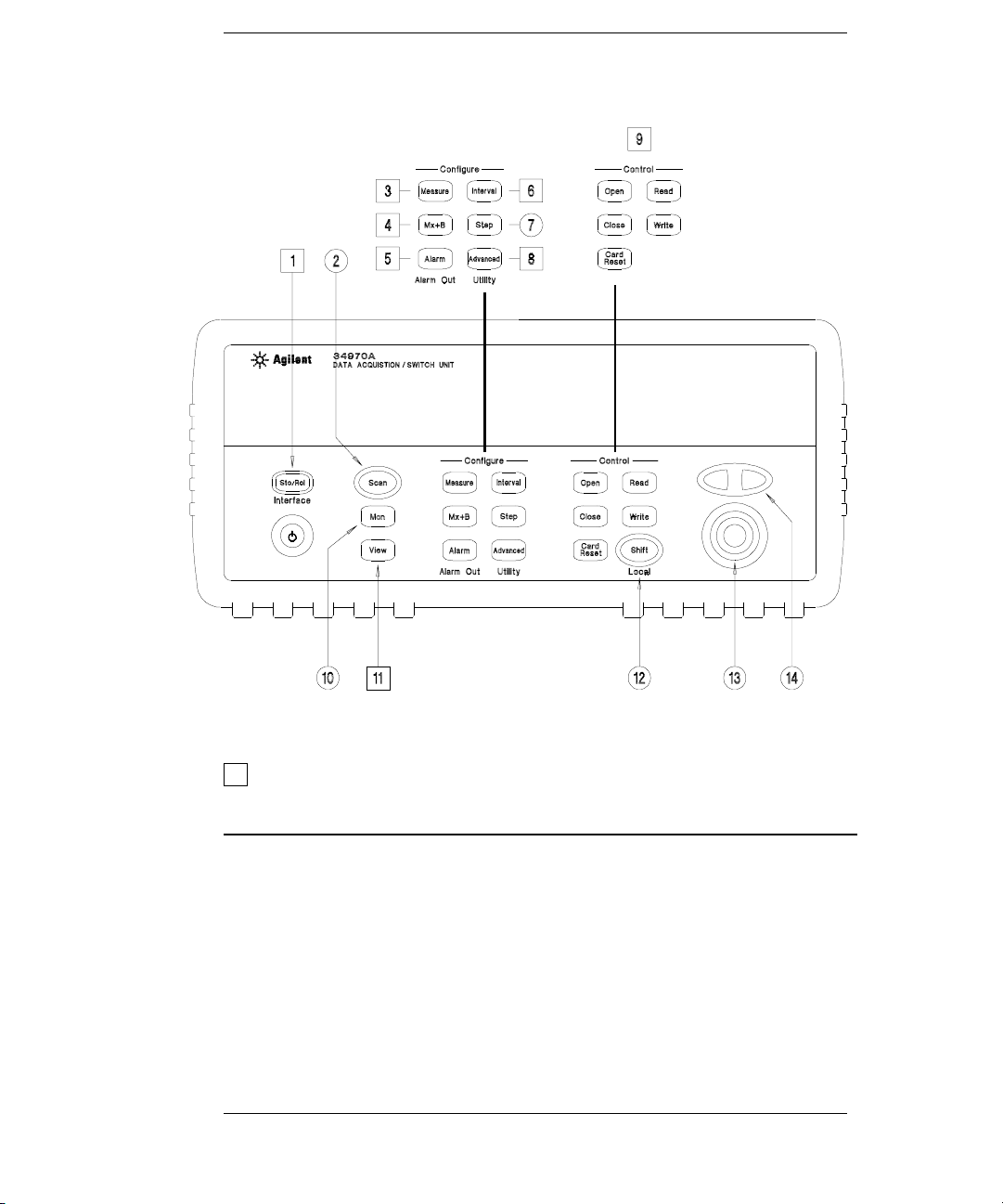

The Front Panel at a Glance

Denotes a menu key. See the next page for details on menu operation.

1 State Storage / Remote Interface Menus

2 Scan Start / Stop Key

3 Measurement Configuration Menu

4 Scaling Configuration Menu

5 Alarm / Alarm Output Configuration Menu

6 Scan-to-Scan Interval Menu

7 Scan List Single Step / Read Key

8 Advanced Measurement / Utility Menus

9 Low-Level Module Control Keys

10 Single-Channel Monitor On / Off Key

11 View Scanned Data, Alarms, Errors Menu

12 Shift / Local Key

13 Knob

14 Navigation Arrow Keys

2

Page 5

The Front-Panel Menus at a Glance

Several of the front-panel keys guide you through menus to configu re

various parameters of the instrument (see previous page). The following

steps demonstrate the menu structure using the key.

1 Press the menu key. You are automaticall y

guided to the first level of the menu.

Rotate the knob to view the other choices

on the first level of the menu.

The menu will automatically timeout after

about 20 seconds of inactivity. You will be

returned to the operation in progress prior

to entering the menu.

2 Press the same menu key again to move

to the next item of the menu. Typically,

this is where you choose parameter values

for the selected operation.

3 Rotate the knob to view the choices on this

level of the menu. When you reach the end

of the list, rotate the knob in the opposite

direction to view all of the other choices.

The current selection is highlighted for emphasis.

All other choices are dimmed.

4 Press the same menu key again to accept the

change and exit the menu. A brief confirmation

message is displayed.

Tip: To review the current configuration of a specific menu, press the menu key several times.

A message

NO CHANGES is displayed when you exit the menu.

3

Page 6

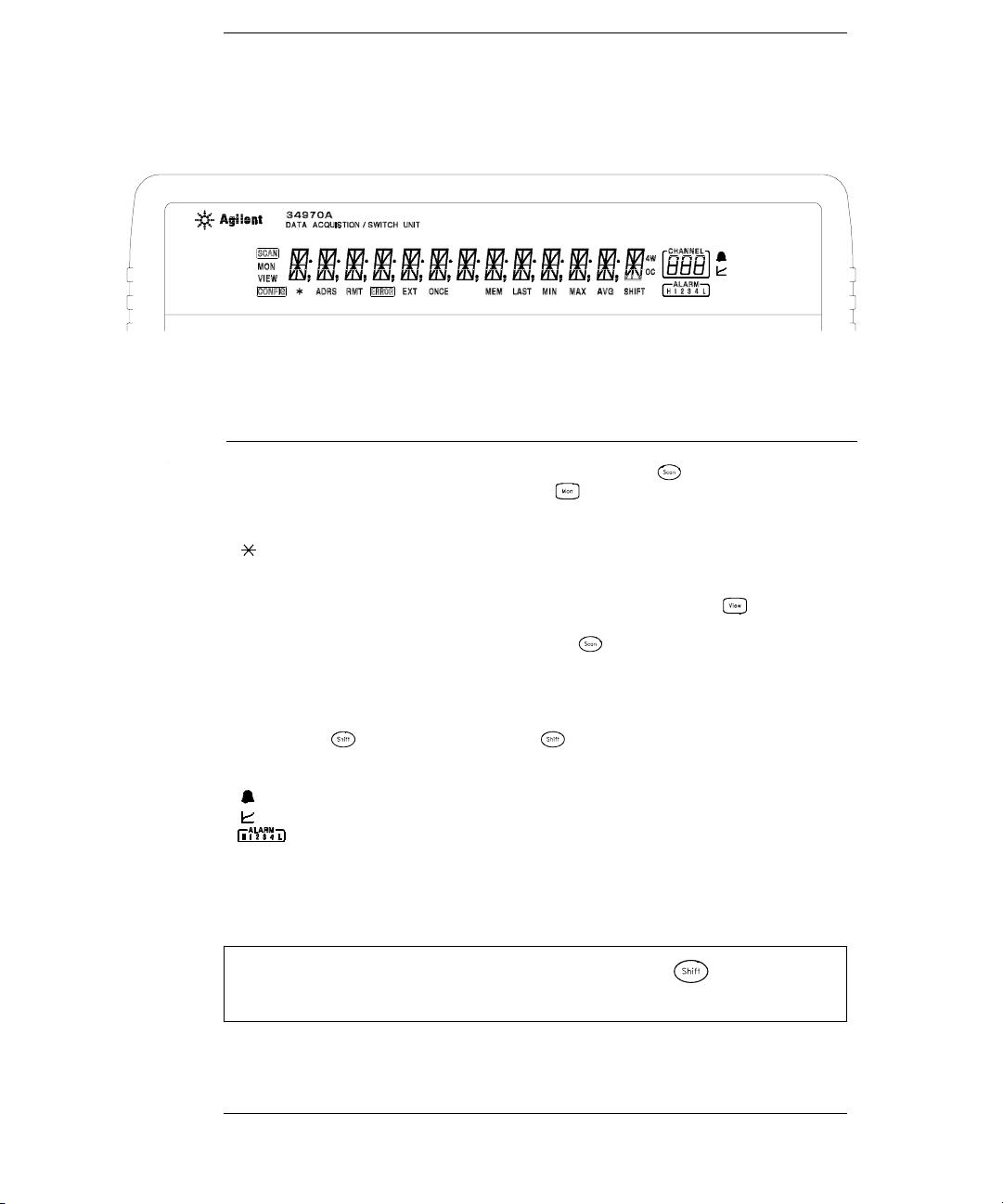

Display Annunciators

SCAN

MON

VIEW

CONFIG

ADRS

RMT

ERROR

EXT

ONCE

MEM

LAST

MIN

MAX

SHIFT

4W

OC

Scan is in progress or enabled. Press and hold again to turn off.

Monitor mode is enabled. Press again to turn off.

Scanned readings, alarms, errors, or relay cycles are being viewed.

Channel configuration is in progress on displayed channel.

Measurement is in progress.

Instrument is addressed to listen or talk over the remote interface.

Instrument is in remote mode (remote interface).

Hardware or remote interface errors are detected. Press to read errors.

Instrument is configured for an external scan interval.

Scan Once mode is enabled. Press to initiate and hold key to disable.

Reading memory overflow; new readings will overwrite the oldest readings.

Viewed data is the last reading stored during most recent scan.

Viewed data is the minimum reading stored during most recent scan.

Viewed data is the maximum reading stored during most recent scan.

has been pressed. Press again to turn off.

4-wire function is in use on displayed channel.

Offset compensation is enabled on displayed channel.

Alarms are enabled on displayed channel.

Mx+B scaling is enabled on displayed channel.

HI or LO alarm condition has occurred on indicated alarms.

To review the display annun ciators, hold down the key as you

turn on the instrument.

4

Page 7

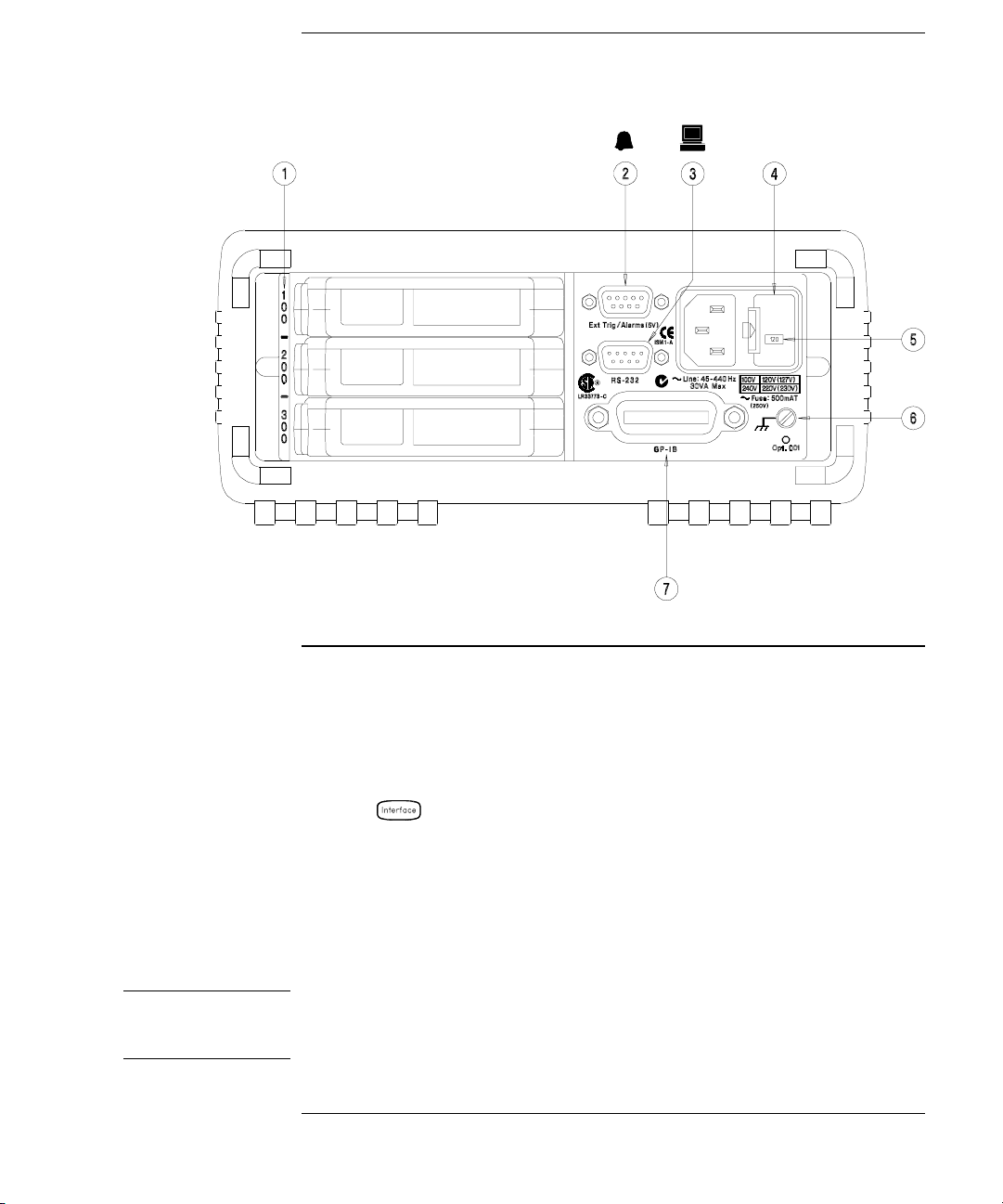

The Rear Panel at a Glance

WARNING

1 Slot Identifier (100, 200, 300)

2 Ext Trig Input / Alarm Outputs / Channel

Advance Input / Channel Closed Output

(for pinouts, see pages 83 and 128)

3 RS-232 Interface Connector

Use the Menu to:

• Select the GP-IB or RS-232 interface (see chapter 2).

• Set the GP-IB address (see chapter 2).

• Set the RS-232 baud rate, parity, and flow control mode (see chapter 2).

4 Power-Line Fuse-Holder Assembly

5 Power-Line Voltage Setting

6 Chassis Ground Screw

7 GP-IB (IEEE-488) Interface Connector

For protection from electrical shock, the power cord ground must not be

defeated. If only a two-contact electrical outlet is available, connect the

instrument’s chassis ground screw (see above) to a good earth ground.

5

Page 8

BenchLink Data Logger Software at a Glance

Agilent BenchLink Data Logger is a Windows-based application

designed to make it easy to use the 34970A with your

and analyzing measurements. Use the software to set up your test,

acquire and archive measurement data, and perform real-time display

and analysis of your incoming measurements.

BenchLink Data Logger’s key functions include the following:

• Configure measurements on the spreadsheet-like Scan Setup page.

• Display measurements graphically using the real-time Data Grid,

Strip Chart, Readout, Bar Meter, XY Plot, and Histogram wind ows.

• Add or configure graphics at any time.

• Use graphical controls to set output voltages, close channels, output

digital values, or view alarms.

• Copy measurement data and graphics to a file or to the Clipboard for

use in other applications.

• Add textual annotation and explanations to measurement results and

test reports.

• Track readings on a single channel through the Monitor toolbar.

• Enter information into the Event Log automatically or manually

while acquiring measurement data or during post-scan analysis.

• Print scan setups, event logs, and graphics.

• Communicate with the instrument using GPIB, RS-232, modem,

or LAN (using a LAN-to-GPIB gateway).

PC for gathering

To install the software, refer to “Installing BenchLink Data Logger

Software” on page 18.

To learn more about the software and its capabilities, refer to the

On-Line Help System for BenchL ink Data Logger.

6

Page 9

The Plug-In Modules at a Glance

For complete s pecifications on each plug-in module, refer to the module

sections in chapter 9.

34901A 20-Channel Armature Mu ltip le xer

• 20 channels of 300 V switching

• Two channels for DC or AC current measurements (100 nA to 1A)

• Built-in thermocouple reference junction

• Switching speed of up to 60 channels per second

• Connects to the internal multimeter

• For detailed information and a module diagram, see page 164.

Each of the 20 channels switches both

fully isolated inputs to the internal multimeter. The module is divided

into two banks of 10 two-wire channels each. When making four-wire

resistance measurements, channels from Bank A are automatically

paired with channels from Bank B. Two additional fused channels are

included on the module (22 channels total) for making calibrated

AC current measurements with the internal multimeter (external shunt

resistors are not required). You can close multiple channels on this

module only if you have not configured any channels to be part of the

scan list. Otherwise, all channels on the module are break-before-make.

HI and LO inputs, thus providing

DC or

34902A 16-Channel Reed Mult iple xer

• 16 channels of 300 V switching

• Built-in thermocouple reference junction

• Switching speed of up to 250 channels per second

• Connects to the internal multimeter

• For detailed information and a module diagram, see page 166.

Use this module for high-speed scanning and high-throughput

automated test applications. Each of the 16 channels switches both

HI and LO inputs, thus providing fully isolated inputs to the internal

multimeter. The module is divided into two banks of eight two-wire

channels each. When making four-wire resistance measurements,

channels from Bank A are automatically paired with channels from

Bank B. You ca n cl ose mu lt ipl e c ha nn els on t h is modul e only if you have

not configured any channels to be part of the scan list. Otherwi se, all

channels on the module are break-before-make.

7

Page 10

34903A 20-Channel Actuator / G eneral-Purpose Switch

• 300 V, 1 A actuation and switching

• SPDT (Form C) latching relays

• Breadboard area for custom circuits

• For detailed information and a module diagram, see page 168.

Use this module for those applications that require high-integrity

contacts or quality connections of non-multiplexed signals. This module

can switch 300 V, 1 A (50 W maximum switch power) to your device

under test or to actuate external devices. Screw terminals on the module

provide access to the Normally-Open, Normally-Closed, and Common

contacts for each of the 20 switches. A breadboard area is provided near

the screw terminals to implement custom circuitry, such as simple

filters, snubbers, or voltage dividers.

34904A 4x8 Two-Wire Matri x S witch

• 32 two-wire crosspoints

• Any combination of inputs and outputs can be connected at a time

• 300 V, 1 A switching

• For detailed information and a module diagram, see page 170.

Use this module to connect multiple instruments to multiple points on

your device under test at the same time. You can connect rows and

columns between multiple modules to build larger matrices such as

8x8 and 4x16, with up to 96 crosspoints in a single mainframe.

34905/6A Dual 4-Channel RF Multiplexers

• 34905A (50Ω) / 34906A (75Ω)

• 2 GHz bandwidth with on-board SMB connections

• 1 GHz bandwidth with SMB-to-BNC adapter cables provided

• For detailed information and a module diagram, see page 172.

These modules offer wideband switching capabilities for high frequency

and pulsed signals. Each module is organized in two independent banks

of 4-to-1 multiplexers. Both modules offer low crosstalk and excellent

insertion loss performance. To create larger

cascade multiple banks together. Only one channel in each bank may be

closed at a time.

8

RF multiplexers, you can

Page 11

34907A Multifunction Module

• Two 8-bit Digital Input/Output ports, 400 mA sink, 42 V open collector

• 100 kHz Totalize input with 1 Vpp sensitivity

• Two ±12 V Calibrated Analog Outputs

• For detailed information and module block diagrams, see page 174.

Use this module to sense status and control external devices such as

solenoids, power relays, and microwave switches. For greater flexibility,

you can read digital inputs and the count on the totalizer during a scan.

34908A 40-Channel Single- End ed Mu ltip le xer

• 40 channels of 300 V single-ended (common LO) switching

• Built-in thermocouple reference junction

• Switching speed of up to 60 channels per second

• Connects to the internal multimeter

• For detailed information and a module diagram, see page 176.

Use this module for high-density switching applications which require

single-wire inputs with a common

to ensure that only one relay is connected at any time.

LO. All relays are break-before-make

9

Page 12

In This Book

Quick Start Chapter 1 helps you get familiar with a few of the

instrument’s front-panel features. This chapter also shows how to

install the BenchLink Data Logger software.

Front-Panel Overview Chapter 2 introduces you to the front-panel

menus and describes some of the instrument’s menu features.

System Overview Chapter 3 gives an overview of a data acquisition

system and describes how parts of a sy stem work together.

Features and Functions Chapter 4 gives a detailed description of the

instrument’s capabilities and operation. You will find this chapter

useful whether you are operating the instrument from the front panel or

over the remote interface.

Remote Interface Reference Chapter 5 contains reference

information to help you program the instrument over the remote

interface using the

Error Messages Chapter 6 lists the error messages that may appear

as you are working with the instrument. Each listing contains enough

information to help you diagnose and solve the problem.

SCPI language.

Application Programs Chapter 7 contains several remote interface

program examples to help you develop programs for your application.

Tutorial Chapter 8 discusses measurement considerations and

techniques to help you obtain the best accuracies and reduce sources of

measurement noise.

Specifications Chapter 9 lists the technical specifications for the

mainframe and plug-in modules.

If you have questions relating to the operation of the 34970A,

call 1-800-452-4844 in the United States, or contact your nearest

Agilent Technologies Sales Office.

If your 34970A fails within three year s of original purchase, Agile nt will

either repair or replac e it free of charge. C all 1-877-447-7278 and ask

for “Express Exchange” or contact your local Agilent office.

10

Page 13

Contents

Chapter 1 Quick Start

To Prepare the Instrument for Use 17

Installing BenchLink Data Logger Software 18

To Connect Wiring to a Module 20

To Set the Time and Date 22

To Configure a Channel for Scanning 23

To Copy a Channel Configuration 25

To Close a Channel 26

If the Instrument Does Not Turn On 27

To Adjust the Carrying Handle 29

To Rack Mount the Instrument 30

Chapter 2 Front-Panel Overview

Front-Pa nel Menu Reference 35

To Monitor a Single Ch an ne l 37

To Set a Scan Interval 38

To Apply Mx+B Scaling to Measurements 39

To Configure Alarm Limits 40

To Read a Digital Input Port 42

To Write to a Digital Output Port 43

To Read the Totalizer Count 44

To Output a DC Voltage 45

To Configure the Remote Interface 46

To Store the Instr u me nt S tat e 48

Chapter 3 System Overv iew

Data Acquisition System Overview 50

Signal Routing and Switching 57

Measurement Input 60

Control Output 67

Contents

11

Page 14

Contents

Contents

Chapter 4 Features and Functions

SCPI Language Conventions 73

Scanning 74

Single-Channel Monit oring 93

Scanning With Extern al Ins tr um ent s 95

General Measurement Configuration 98

Temperature Measurement Configuration 106

Voltage Measurement Configuration 113

Resistance Meas ure me nt Con f iguration 115

Current Measurement Configuration 116

Frequency Measure ment Configuration 118

Mx+B Scaling 119

Alarm Limits 122

Digital Input Operations 133

Totalizer Operations 135

Digital Output Operations 138

DAC Output Operations 139

System-Related Operations 140

Remote Interface Configuration 150

Calibration Overview 155

Factory Reset State 160

Instrument Pr es et S tat e 161

Multiplexer Module Default Settings 162

Module Overvi ew 163

34901A 20-Channe l Mu lti p le xer 164

34902A 16-Channe l Mu lti p le xer 166

34903A 20-Channe l Ac tuator 168

34904A 4x8 Matrix Sw it ch 170

34905A/6A Dual 4-Channel RF Multiplexers 172

34907A Multifunction Module 174

34908A 40-Channel Sin g le -Ende d Mul t ipl exe r 176

12

Page 15

Contents

Chapter 5 Remote Interface Reference

SCPI Command Summary 181

Simplified Programming Overview 201

The MEASure? and CONFigure Commands 207

Setting the Function, Range, and Resolution 214

Temperature Configuration Commands 219

Voltage Configuration Commands 223

Resistance Configuration Commands 224

Current Configuration Commands 224

Frequency Configuration Commands 225

Scanning Over v i ew 226

Single-Channel Monitori ng Overview 237

Scanning With an Externa l In str u me nt 239

Mx+B Scaling Overview 244

Alarm System O v er v i ew 247

Digital Input Commands 255

Totalizer Commands 256

Digital Output Commands 258

DAC Output Commands 2 58

Switch Control Commands 259

State Storage Commands 261

System-Related Commands 264

Interface Configuration Commands 269

RS-232 Interface Configuration 270

Modem Communications 274

The SCPI Status System 275

Status System Comma nds 286

Calibration Commands 292

Service-Related Commands 294

An Introduction to the SCPI Language 296

Using Device Clear 302

Contents

Chapter 6 Error Messages

Execution Errors 305

Instrument Errors 309

Self-Test Errors 314

Calibration Errors 315

Plug-In Module Errors 317

13

Page 16

Contents

Contents

Chapter 7 A ppl ic ation Programs

Example Programs for Excel 7.0 321

Example Programs for C and C++ 328

Chapter 8 Tuto rial

System Cabling and Connections 335

Measurement Fundamentals 343

Low-Level Signal Multiplexing 378

Actuators and G en er a l-P u r p os e S w it ching 384

Matrix Switch ing 388

RF Signal Multiplexing 390

Multifunction Mo d ul e 392

Relay Life and Preventative Maintenance 399

Chapter 9 Specifi cations

DC, Resistance, and Temperature Accuracy Specifications 404

DC Measurement and Operating Charact eristics 405

AC Accuracy Specifications 406

AC Measurement and Operating Cha racteristics 407

Measurement Rate s an d Sys t em Char a c ter i sti c s 408

Module Specifications 409

BenchLink Data Logger Software Specifications 412

Product and Module Dimensions 413

To Calculate Total Measurement Error 414

Interpreting Internal DMM Specifications 416

Configuring for Highest Accuracy Measurements 419

Index

14

Page 17

1

1

Quick Start

Page 18

Quick Start

One of the first things you will want to do with your instrument is to

become acquainted with the front panel. We have written the exercises

in this chapter to prepare the instrument for use and help you get

familiar with some of its front-panel operations.

The front panel has several groups of keys to select various functions

and operations. A few keys have a shifted function printed in blue below

the key. To perform a shifted function, press (the

will turn on). Then, press the key that has the desired label below it.

For example, to select the Utility Menu, press .

SHIFT annunciator

If you accidentally press , just press it again to turn off the

annunciator.

This chapter is divided into the following sections:

• To Prepare the Instrume nt for Use, on page 17

• Installing BenchLink Data Logger Software, on page 18

• To Connect Wiring to a Module, on page 20

• To Set the Time and Date, on page 22

• To Configure a Channel for Scanning, on page 23

• To Copy a Channel Configuration, on page 25

• To Close a Ch annel, on page 26

• If the Instrument Does Not Turn On, on page 27

• To Adjust the Carrying Handle, on page 29

• To Rack Mount the Instrument, on page 30

SHIFT

16

Page 19

Chapter 1 Quick Start

To Prepare the Instrument for Use

To Prepare the Instrument for Use

1 Check the list of supplied items.

Verify that you have received the following items with your instrument.

If anything is missing, contact your nearest Agilent Technologies Sales Office.

One power cord.

This User’s Guide.

One Service Guide.

One Quick Reference Guide.

Certificate of Calibration (if you ordered the internal DMM).

Quick Start Package (if you ordered the internal DMM):

• One RS-232 cable.

• BenchLink Data Logger Software CD-ROM.

To install the software, see page 18.

• One J-type thermocouple and a flatblade screwdriver.

Any plug-in modules that you ordered are delivered in a separate

shipping container.

1

On/Standby

Switch

WARNING

Note that this switch

Standby only.

is

To disconnect t he

mains from the

instrumen t, remove

the power cord.

2 Connect the power cord and turn on the instrument.

The front-panel display will light up briefly while the instrument

performs its power-on self-test. The

GPIB address is also displayed.

The instrument initially powers up with all measurement channels

turned off. To review the power-on display with all annunciators

turned on, hold down as you turn on the instrument. If the

instrument does not turn on properly, see p age 27.

3Perform a complete self-test.

The complete self-test performs a more extensive set of tests than those

performed at power-on. Hold down as you turn on the instrument

and hold down the ke y until you hear a long beep. The self-test will begin

when you release the key following the beep.

If the self-test fails, see the 34970A Se rvice Guide for instructions on

returning the instrument to Agilent for service.

17

Page 20

Chapter 1 Quick Start

Installing BenchLink Data Logger Software

Installing BenchLink Data Logger Software

If you ordered the 34970A with the internal DMM, then the BenchLink

Data Logger software is included. The software is shipped on one

CD-ROM, but includes a utility to build installation floppy disks.

To install the software on your

of free disk space.

For system requirements and additional details on the features of the

software, refer to the specifications in chapter 9.

Installation Procedure

PC, you will need a minimum of 12 MB

If you are running Windows 95 or Windows NT 4.0

®

1. Insert the CD-ROM into your drive.

2. Select

the

3. Select the

sheet. Click on

If you are running Windows

1. Insert the

2. Select

3. Type <drive>

CD-ROM drive. Click OK to continue and follow the on-screen

Settings | Control Panel from the Start menu. Double-click on

Add/Remove Programs icon.

Install/Uninstall tab on the Add/Remove Programs property

Install and follow the on-screen instructions.

®

3.1

CD-ROM into your drive.

File | Run from the Program Manager menu bar.

:\setup, where drive is the letter representing your

instructions.

18

Page 21

Chapter 1 Quick Start

Installing BenchLink Data Logger Software

Creating Installation Floppy Disks

You have the option to create an installation on floppy disks from the

CD-ROM installation utility. This utility is provided so that you can

install BenchLink Data Logger on a computer that does not have a

CD-ROM drive.

Note: You will need a total of five (5) formatted floppy disks to create

an installation.

1

1. Go to a computer that is equipped with a

2. Start the installation procedur e as described on the previous page.

3. Select

procedures and follow the on-screen instructions.

Create disks... on the initial display of the installation

CD-ROM drive.

On-Line Help System

The software is shipped with an extensive on-line Help system to help

you learn the features of the software as well as troubleshoot any

problems that might arise as you are using t he software. As you are

installing the software, you will notice that the on-line Help system is

available in several languages.

19

Page 22

Chapter 1 Quick Start

To Connect Wiring to a Module

To Connect Wiring to a Module

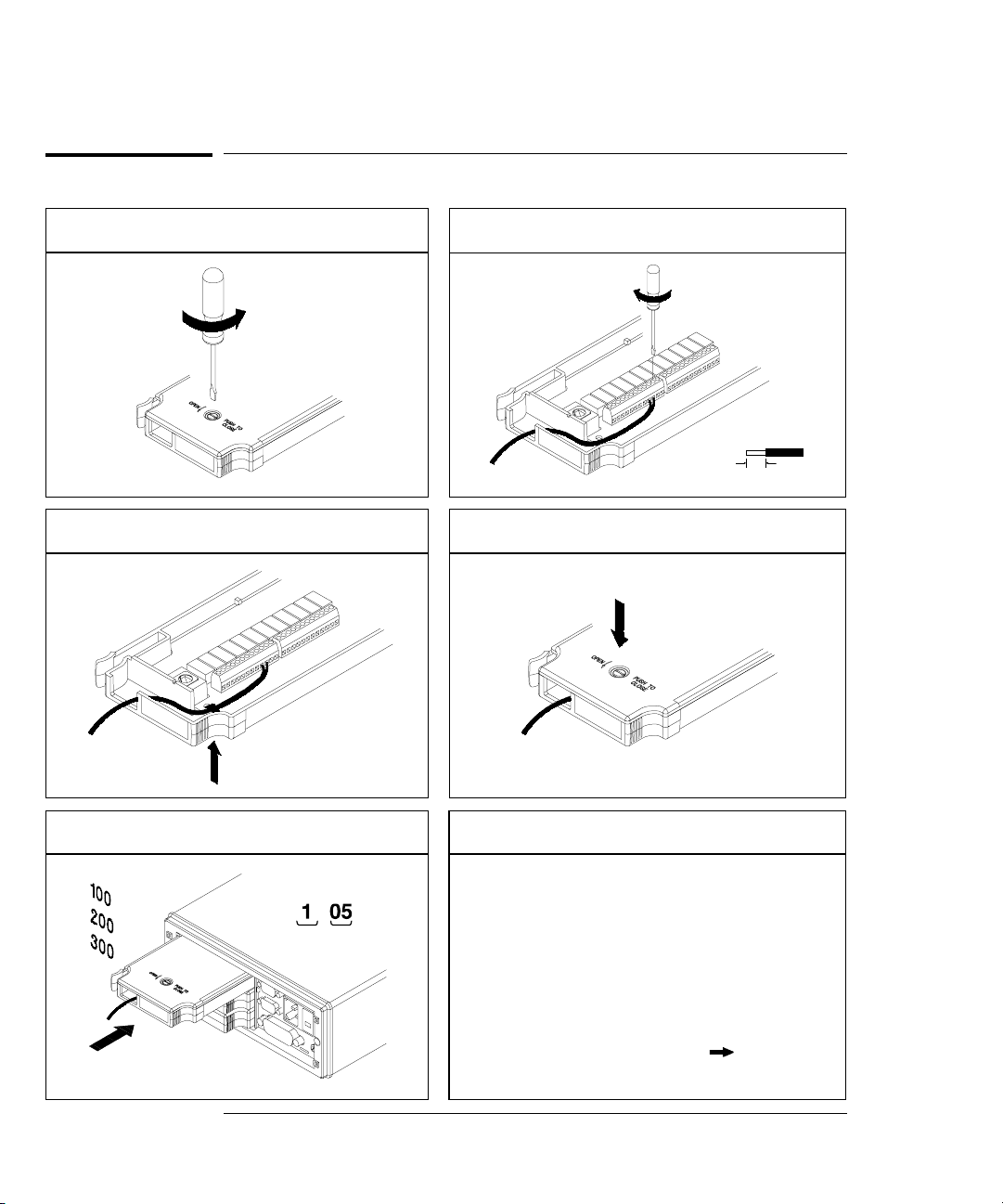

1 Remove the module cover.

3 Route wiring through strain relief.

2 Connect wiring to the screw terminals.

20 AWG

Typical

6 mm

4 Replace the module cover.

Cable Tie Wrap

(optional)

5 Install the module into mainframe.

Channel Number:

Slot Channel

20

Wiring Hints...

• For detailed informat io n on eac h mo du le ,

refer to the section starting on page 16 3.

• To reduce wear on the internal DMM relays,

wire like functions on adjacent chan ne ls .

• For information on grounding and shielding,

see page 335.

• The diagrams on the next page show how to

connect wiring to a mult ip le xe r mod ul e fo r

each measurement function.

Page 23

Chapter 1 Quick Start

To Connect Wiring to a Module

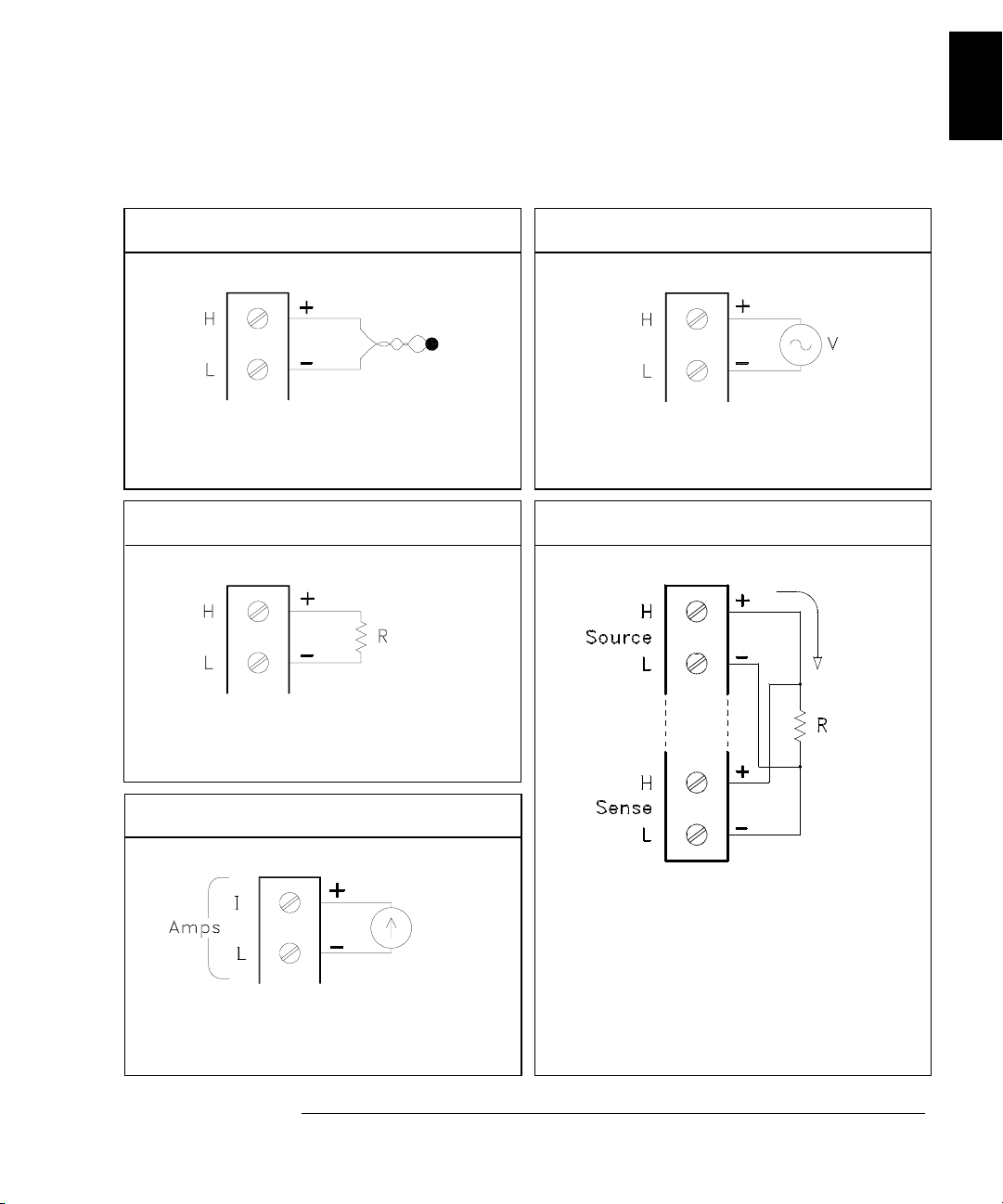

DC Voltage / AC Voltage / Frequency Thermocouple

1

Thermocouple Types: B, E, J, K, N, R, S, T

See page 351 for thermocouple color codes.

Ranges: 100, 1 k, 10 k, 100 k, 1 M, 10 M, 100 MΩ

RTD Types: 0.00385, 0.00391

Thermistor Types: 2.2 k, 5 k, 10 k

DC Current / AC Current

Ranges: 100 mV, 1 V, 10 V, 100 V, 300 V

4-Wire Ohms / RTD 2-Wire Ohms / RTD / Thermistor

Channel n (source) is automatically paired with

Channel n+10 (sense) on the 34901A or

Channel n+8 (sense) on the 34902A.

Valid only on channels 21 and 22 on the 34901A.

Ranges: 10 mA, 100 mA, 1A

Ranges: 100, 1 k, 10 k, 100 k, 1 M, 10 M, 100 MΩ

RTD Types: 0.00385, 0.00391

21

Page 24

Chapter 1 Quick Start

To Set the Time and Date

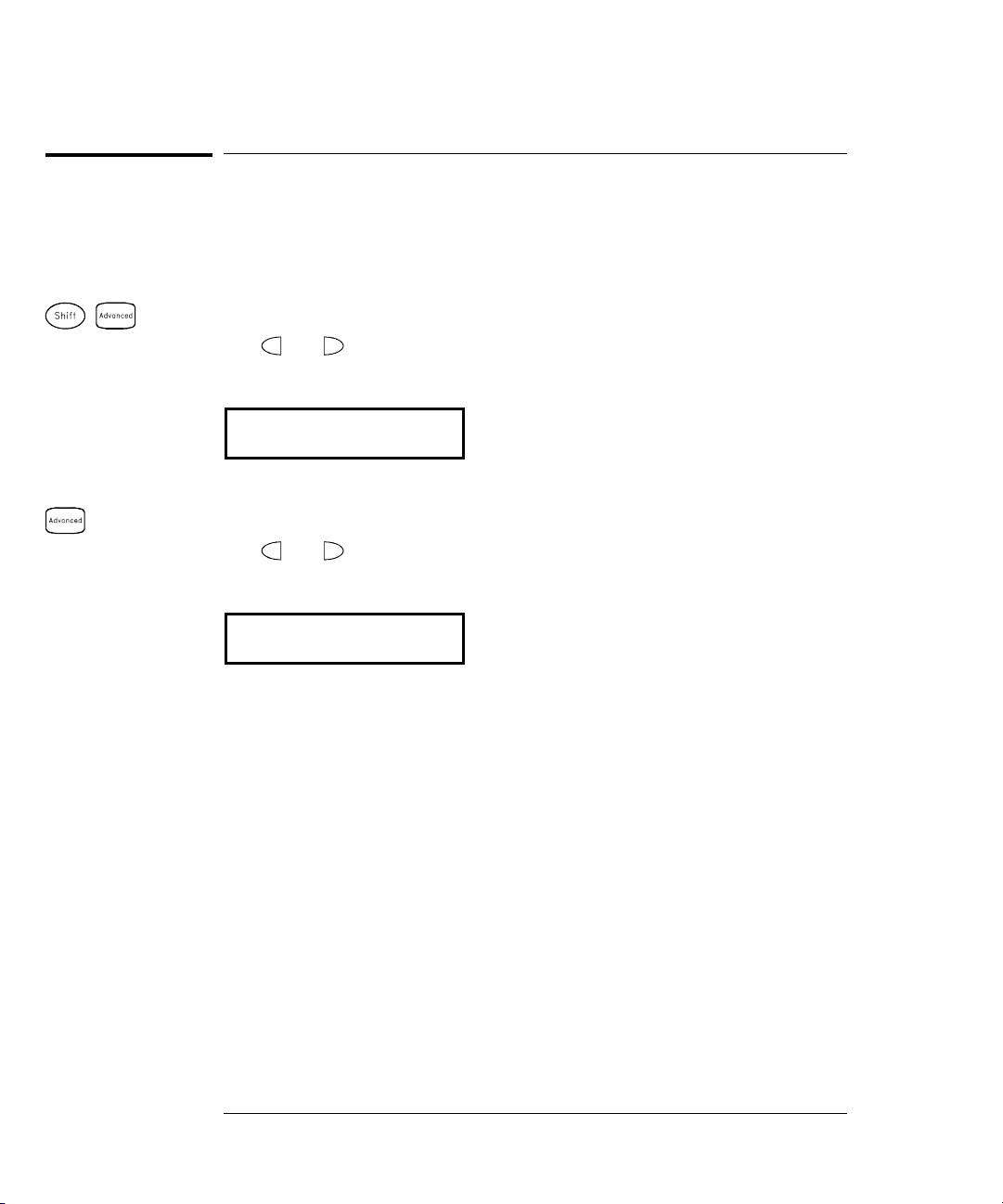

To Set the Time and Date

All readings during a scan are automatically time stamped and stored

in non-volatile memory. In addition, alarm data is time stamped and

stored in a separate non-volatile memory queue.

Utility

Utility

1 Set the time of day.

Use and to select the field to modify and turn the knob to change

the value. You can also edit the

AM/PM field.

7,0(30

2 Set the date.

Use and to select the field to modify and turn the knob to change

the value.

-81

22

Page 25

Chapter 1 Quick Start

To Configure a Channel for Scanning

To Configure a Channel for Scanning

Any channel that can be “read” by the instrument can also be included

in a scan. This includes readings on multiplexer channels, a read of a

digital port, or a read of the count on a totalizer channel. Automated

scanning is not allowed with the

digital output, or voltage output (

1 Select the channel to be added to the sc an list.

Turn the knob until the desired channel is shown on the right side of

front-panel display. The channel number is a three-digit number;

the left-most digit represents the slot number (100, 200, or 300) and the

two digits on the right indicate the channel number (102, 110, etc.).

Note: You can use and to skip to the beginning of the previous

or next slot.

For this example, assume that you have the 34901A multiplexer

installed in slot 100 and select channel 103.

RF multiplexer, matrix, actuator,

DAC) modules.

1

2 Select the measurement parameters for the selected channel.

Use the knob to scroll through the measurement choices on each level

of the menu. When you press to make your selection, the menu

automatically guides you through all relevant choices to configure a

measurement on the selected function. When you have finished

configuring the parameters, you are automatically exited from the menu.

The current selection (or default) is displayed in full bright for easy

identification. When you make a different selection, the new choice is

shown in full bright and it becomes the default selection. The order of

the choices always remains the same; however, you always enter the

menu at the current (full bright) setting for each parameter.

Note: The menu will timeout after about 20 seconds of inactivity and

any changes made previously will take effect.

For this example, con fi gur e ch a nne l 103 to mea sur e a J -type therm oc ouple

with 0.1

°C of display resolution.

23

Page 26

Chapter 1 Quick Start

To Configure a Channel for Scanning

Note: Press to sequentially step through the scan list and take a

measurement on each channel (readings are not stored in memory).

This is an easy way to verify your wiring connections before initiating

the scan.

3 Run the scan and stor e the re ad ing s i n non- vo l at ile memo ry.

The instrument automatically scans the configured channels in

consecutive order from slot 100 through slot 300 (the

SCAN annunciator

turns on). Channels that are not configured are skipped during the scan.

In the default configuration, the instrument continuously scans the

configured channels at a 10-second interval.

Press and hold to stop the scan.

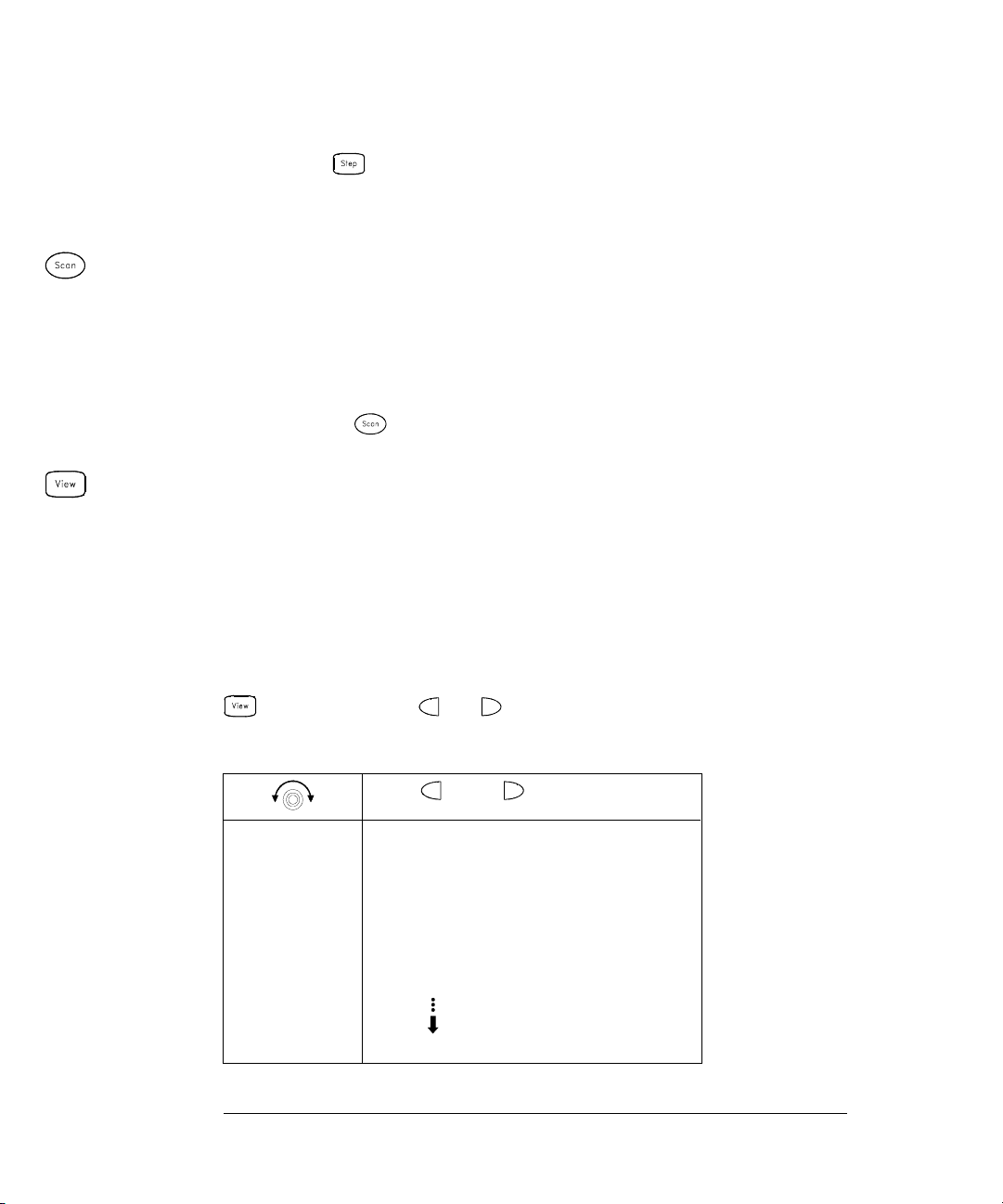

4 View the data f rom t he scan.

All readings taken during a scan are automatically time stamped and

stored in non-volatile memory. During the scan, the instrument

calculates and stores the minimum, maximum, and average on all

channels in the scan list. You can read the contents of memory at any

time, even during a scan.

From the front panel, data is available for the last 100 readings on each

channel readings taken during a scan (all of the data is available from

the remote interface). From the View menu, select

READINGS and press

again. Then press and to choose the data you want to view

for the selected channel as shown in the table below.

and

Select Channel Last Reading on Channel

Time of Last Reading

Minimum Reading on Channel

Time of Minimum Reading

Maximum Reading on Channel

Time of Maximum Reading

Average of Readings on Channel

Second Most Recent Reading on Channel

Third Most Recent Reading on Channel

99th Most Recent Reading on Channel

24

Page 27

Chapter 1 Quick Start

To Copy a Channel Configuration

To Copy a Channel Configuration

After configuring a channel to be included in the scan list, you can

copy that same configuration to other channels in the instrument

(including digital channels on the multifunction module). This feature

makes it easy to configure several channels for the same measurement.

When you copy the configuration from one channel to another, the

following parameters are automatically copied to the new channel:

• Measurement configuration

• Mx+B scaling configuration

• Alarm configuration

• Advanced measurement configuration

1 Select the channel to copy the conf ig uratio n from.

Turn the knob until the desired channel is shown on the right side of

front-panel display. For this example, let’s copy the configuration from

channel 103.

1

2 Select the copy function.

Use the knob to scroll through the measurement choices until you see

COPY CONFIG. When you press to make your selection, the menu

automatically guides you to the next step.

3 Select the channel to copy the conf ig uratio n to.

Turn the knob until the desired channel is shown on the right side of

front-panel display. For this example, let’s copy the configuration to

channel 105.

3$67(72

4 Copy the channel configuration to the selected cha nnel.

Note: To copy the same configuration to other channels, repeat this procedure.

25

Page 28

Chapter 1 Quick Start

To Close a Channel

To Close a Channel

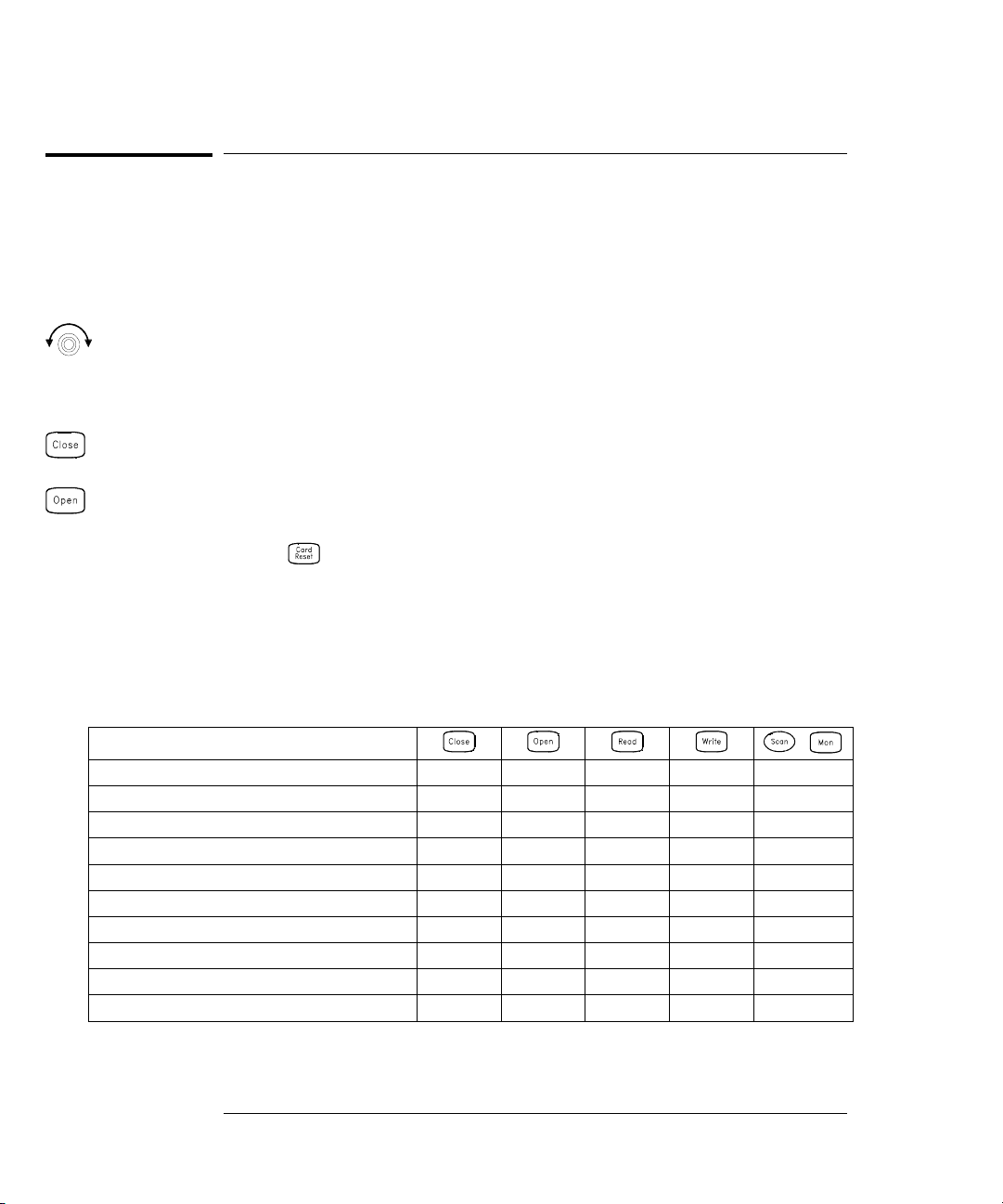

On the multiplexer and switch modules, you can close and open individual

relays on the module. However, note that if you have already configured

any multiplexer channels for scanning, you cannot independently close

and open individual relays on that module.

1 Select the channel.

Turn the knob until the desired channel is shown on the right side of

front-panel display. For this example, select channel 213.

2 Close the selected channel.

3 Open the selected channel.

Note: will sequentially open all channels on the module in the

selected slot.

The table below shows the low-level control operations available for

each of the plug-in modules.

Plug-In Module

34901A 20-Channel Mux

34902A 16-Channel Mux

34908A 40-Channel Single-Ended Mux

34903A 20-Channel Actuator

34904A 4x8 Matrix

34905A Dual 4-Channel RF Mux (50Ω)

34906A Dual 4-Channel RF Mux (75

34907A Multifun ction Module (DIO)

34907A Multifunction Module (Totalizer)

34907A Multifunction Module (DAC)

[1] Only one channel can be closed at a time on this module.

[2] Only one channel in each bank can be closed at a time on this module.

Ω)

26

,

•••

[1]

[2]

[2]

•••

••• •

••

••

•

•

•• •

••

•

•

•

Page 29

Chapter 1 Quick Start

If the Instrument Does Not Turn On

If the Instrument Does Not Turn On

Use the following steps to help solve problems you might encounter

when turning on the instrument. If you need more help, refer to the

34970A Service Guide for instructions on returning the instrument to

Agilent for service.

1 Verify that there is ac power to the instrument.

First, verify that the power cord is firmly plugged into the power

receptacle on the rear panel of the instrument. You should also make

sure that the power source you plugged the instrument into is

energized. Then, verify that the instrument is turned on.

The On/Standby switch is located on the lower left side of the front panel.

2 Verify the powe r -li ne voltage setting.

The line voltage is set to the proper value for your country when the

instrument is shipped from the factory. Change the voltage setting if

it is not correct. The settings are: 100, 120, 220, or 240 Vac.

1

Note: For 127 Vac operation, use the 120 Vac setting.

For 230 Vac operation, use the 220 Vac setting.

See the next page if you need to change the line voltage setting.

3 Verify that the po wer-line fuse is good .

The instrument is shipped fr om the fact ory with a 50 0 mA fuse inst alled.

This is the correct fuse for all line voltages.

See the next page if you need to replace the power-line fuse.

To replace the 500 mAT, 250 V fuse, order Agilent part number 2110-0458.

27

Page 30

Chapter 1 Quick Start

If the Instrument Does Not Turn On

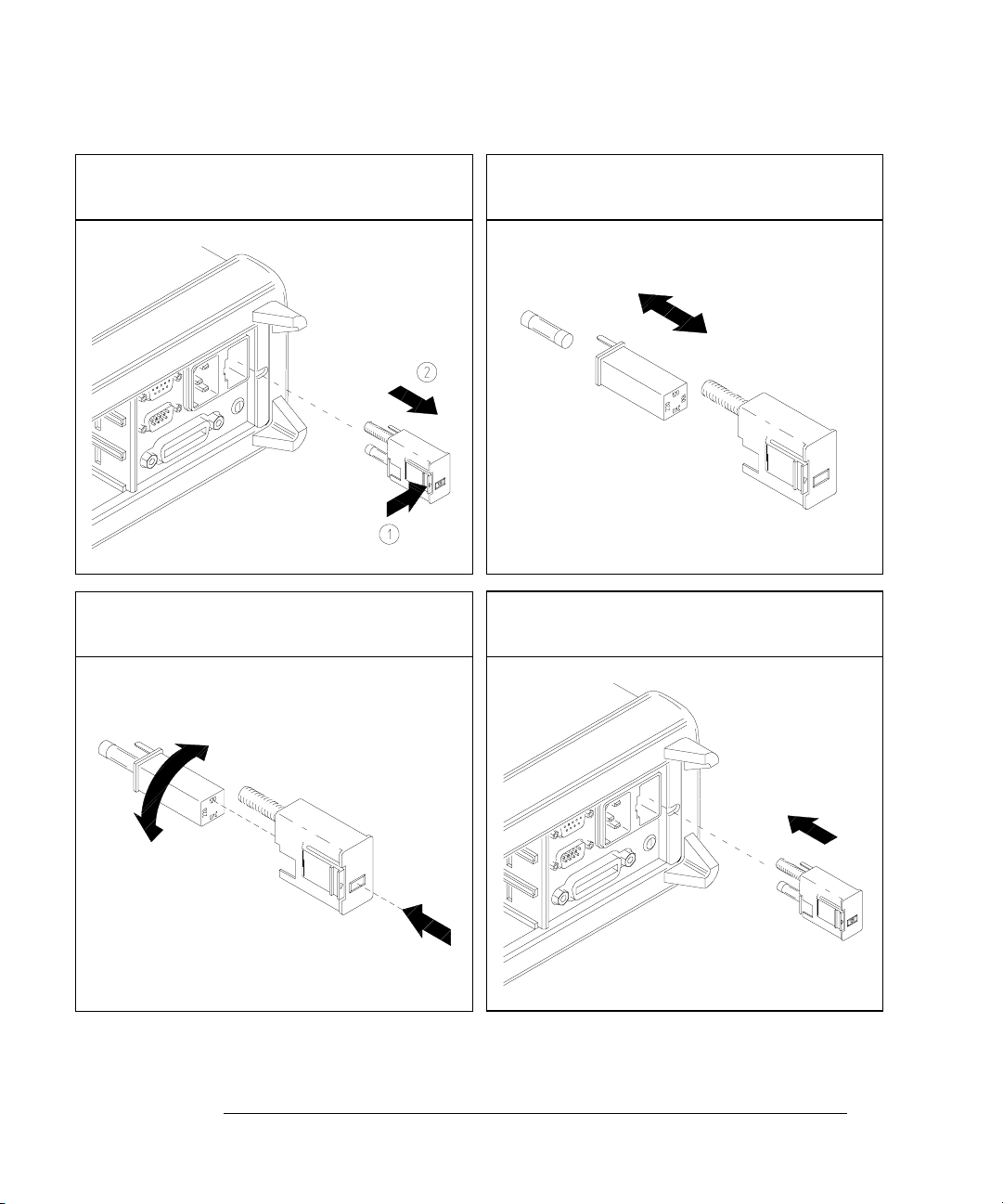

1 Remove the power cord. Remove the

fuse-holder assembly from the rear panel.

3 Rotate the line-voltage selector until the

correct voltage appears in the window.

2 Remove the line-voltage selector from

the assembly.

Fuse: 500 mAT (for all line voltages)

Agilent Part Number: 2110-0458

4 Replace the fuse-holder assembly in

the rear panel.

100, 120 (127), 220 (230) or 240 Vac

Verify that the correct line voltage is selected and the power-line fuse is good.

28

Page 31

Chapter 1 Quick Start

To Adjust the Carrying Handle

To Adjust the Carrying Handle

To adjust the position, grasp the handle by the sides and pull outward.

Then, rotate the handle to the desired position.

1

Bench-top viewing positions Carrying position

29

Page 32

Chapter 1 Quick Start

To Rack Mount the Instrument

To Rack Mount the Instrument

You can mount the instrument in a standard 19-inch rack cabinet using

one of three optional kits available. Instructions and mounting

hardware are included with each rack-mounting kit. Any Agilent System II

instrument of the same size can be rack-mounted beside the 34970A.

Note: Remove the carrying handle, and the front and rear rubber bumpers,

before rack-mounting the instrument.

To remove the handle, rotate it to the vertical position and pull the ends outward.

Front Rear (bottom view)

To remove the rubber bumper, stretch a corner and then slide it off.

30

Page 33

Chapter 1 Quick Start

To Rack Mount the Instrument

To rack mou n t a s in gl e in strument, o r de r a da p t er ki t 5063 -9 24 0.

To rack mount two instruments side-by-side, order lock-link kit 5061-9694 and

flange kit 5063-9212. Be sure to use the support rails inside the rack cabinet.

1

To install one or two instruments in a sliding support shelf, order shelf 5063-9255,

and slide kit 1494-0015 (for a single instrument, also order filler panel 5002-3999).

31

Page 34

32

Page 35

2

2

Front-Panel

Overview

Page 36

Front-Panel Overview

This chapter introduces you to the front-panel keys and menu operation.

This chapter does not give a detailed description of every front-panel

key or menu operation. It does, however, give you a good overview of the

front-panel menu and many front-panel operations. See chapter 4

“Features and Functions,” starting on page 71, for a complete discussion

of the instrument’s capabilities and operation.

This chapter is divided into the following sections:

• Front-Panel Menu Reference, on page 35

• To Monitor a Single Channel, on page 37

• To Set a Scan Interval, on page 38

• To Apply Mx+B Scaling to Measurements, on page 39

• To Configure Alarm Limits, on page 40

• To Read a Digital Input Port, on page 42

• To Write to a Digital Output Port, on page 43

• To Read the Totalizer Count, on page 44

• To Output a DC Vo ltage, on page 45

• To Configure the Remote Interface, on page 46

• To Store the Instrument State, on page 48

34

Page 37

Chapter 2 Front-Panel Overview

Front-Panel Menu Reference

Front-Panel Menu Reference

This section gives an overview of the front-panel menus. The menus are

designed to automatically guide you through all parameters required to

configure a particular function or operation. The remainder of this

chapter shows examples of using the front-panel menus.

Configure th e measurement parameters on th e displayed channel.

• Select measure me nt function (dc volts, oh ms , et c.) on the displayed channel.

• Select transducer type for temperature measurements.

• Select units (°C, °F, or K) for temperature measurements.

• Select measureme nt rang e or au to ran ge .

• Select measureme nt resolution.

• Copy and paste measurement confi gu r at io n to other channels.

Configure the scaling parameters for the displayed channel.

• Set the gain (“M”) and offset (“B”) value for the displayed channel.

• Make a null measurement and store i t as the offset value.

• Specify a custom la be l (RPM, PSI, etc.) for the disp la ye d ch an ne l.

2

Configure al arms on the displayed channel.

• Select one of fou r ala rms to report alarm condit io ns on th e displayed channe l.

• Configure a hi gh lim it , lo w lim it , or bo th for the displayed chan ne l.

• Configure a bit pa ttern which will gene rat e an ala rm (di gi t a l in pu t on ly ).

Configure the four Alarm Outp ut ha rdw a re li ne s.

• Clear the state of the four alarm outp ut lin es .

• Select the “Latch” or “Track” mode for the four alarm output lines.

• Select the slope (ris in g or fa ll ing edge) for the four alarm out pu t li ne s.

Configure the event or action that controls the scan interval.

• Select the scan int erv al mod e (in te rva l, manual, external, or al arm ).

• Select the scan cou nt.

35

Page 38

Chapter 2 Front-Panel Overview

Front-Panel Menu Reference

Configure the advanced measurement features on displayed channel.

• Set the integration time for measurements on the displayed channel.

• Set the channel-to-channel del ay for scanning.

• Enable/disabl e th e th erm oc ou pl e ch ec k fe ature (T/C measurement s on ly ).

• Select the refere nce ju nc ti on source (T/C measureme nt s on ly ).

• Set the low frequency limit (ac measurements only).

• Enable/disable offset compensation (resistance measurements only).

• Select the binary or decimal mode for digital operations (digital input/output only).

• Configure the to ta lizer reset mode (total iz er on ly ).

• Select which edge is detected (rising or falling) for totalizer operations.

Configure system-related instrument parameters.

• Set the real-time system clock and calendar.

• Query the firmware revisions for the mainframe and installed modules.

• Select the inst rumen t ’ s pow er-o n co nf ig uration (last or factory reset).

• Enable/disable the internal DMM.

• Secure/unsecure the instrument for calibration.

View readings, alarms, and errors.

• View the last 100 sc anned readings from me mo ry (la st , min, max, and average ).

• View the first 20 alarms in the alar m queue (reading and time alarm occ urred).

• View up to 10 errors in the error queue.

• Read the number of cycles for the displayed relay (relay maintenance feature).

Store and recall in stru me nt sta tes.

• Store up to five inst rument states in non-volatile memory.

• Assign a name to ea ch storage location .

• Recall stored st ates, power-down sta te , fa ct ory rese t state, or preset sta te .

Configure the remote interface.

• Select the GPIB addre ss.

• Configure the RS -23 2 in te rfa ce (bau d rat e, pari ty , an d fl ow co ntrol).

36

Page 39

Chapter 2 Front-Panel Overview

To Monitor a Single Channel

To Monitor a Single Channel

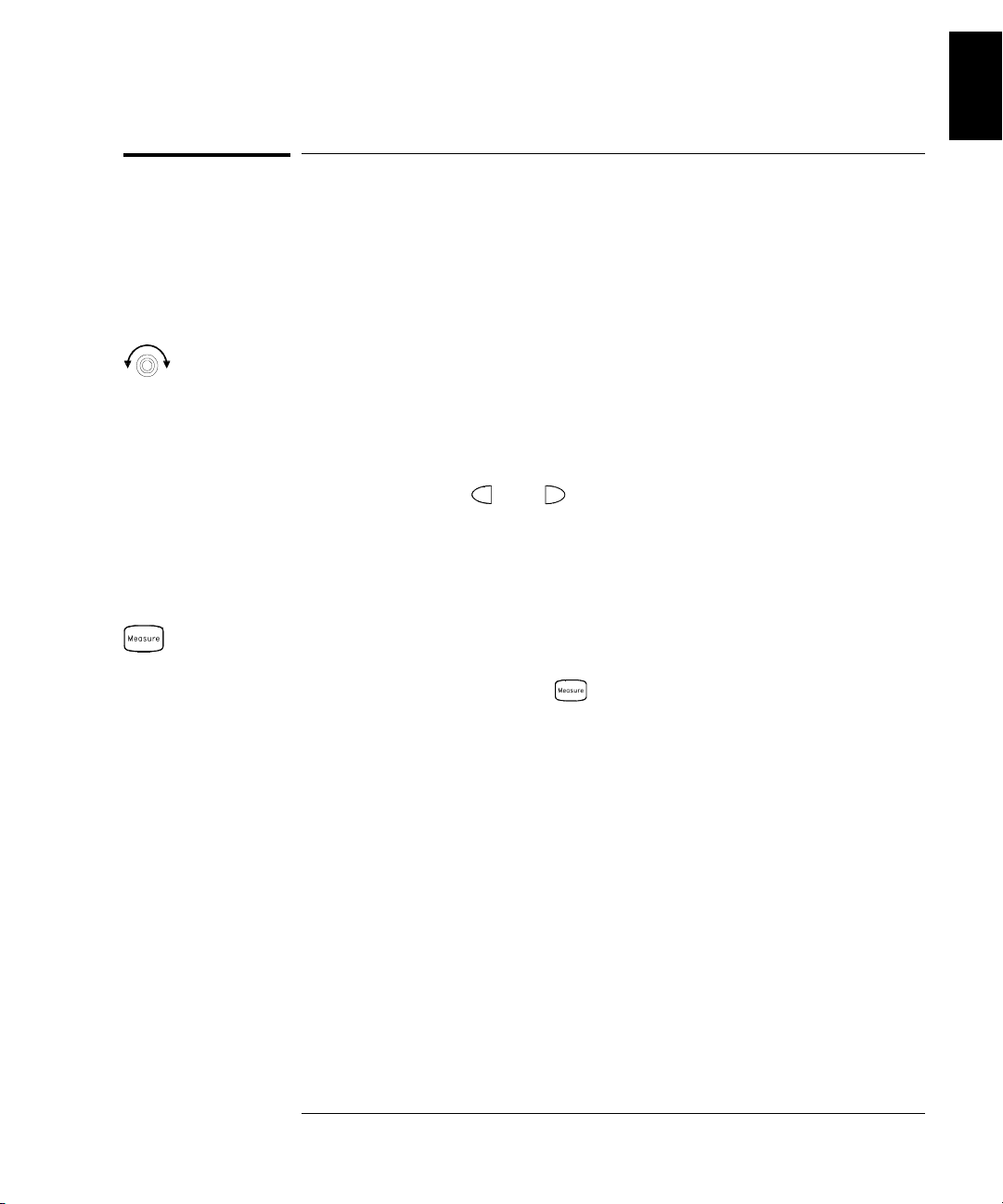

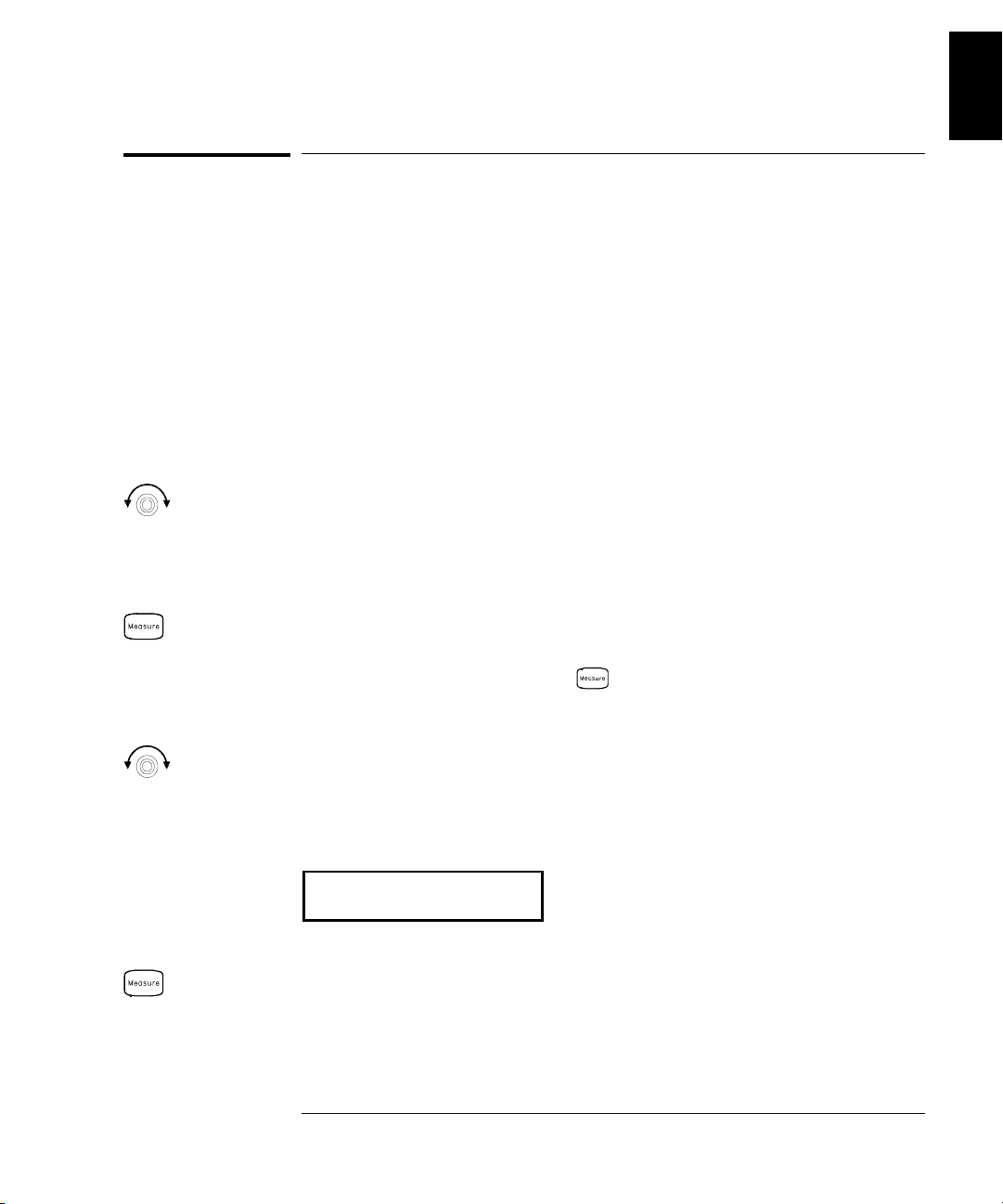

You can use the Monitor function to continuously take readings on a si ngle

channel, even during a scan. This feature is useful for troubleshooting your

system before a test or for watching an important signal.

1 Select the channel to be monitored.

Only one channel can be monitored at a time but you can change the

channel being monitored at any time by turning the knob.

2 Enable monitoring on the selected cha nnel.

Any channel that can be “read” by the instrument can be monitored

(the

MON annunciator turns on). This includes any combination of

temperature, voltage, resistance, current, frequency, or period

measurements on multiplexer channels. You can also monitor a digital

input port or the totalizer count on the multifunction module.

2

To disable monitoring, press again.

37

Page 40

Chapter 2 Front-Panel Overview

To Set a Scan Interval

To Set a Scan Interval

You can set the instrument’s internal timer to automatically scan at a

specific interval (e.g., start a new scan sweep every 10 seconds) or when

an external

instrument to scan continuously or to stop after sweeping through the

scan list a specified number of tim es.

1 Select the interv al s c an mo de .

For this example, select the Interval Scan mode which allows you to set

the time from the start of one scan sweep to the start of the next scan

sweep. Set the interval to any value between 0 and 99 hours.

,17(59$/6&$1

2 Select the scan count.

TTL trigger pulse is received. You can configure the

You can specify the number of times that the instrument will sweep

through the scan list (the default is continuous). When the specified

number of sweeps have occurred, the scan stops. Set the scan count to

any number between 1 and 50,000 scans (or continuous).

6&$16

3 Run the scan and sto re t he r e ad ing s i n memo ry.

38

Page 41

Chapter 2 Front-Panel Overview

To Apply Mx+B Scaling to Measurements

To Apply Mx+B S caling to Measu re ments

The scaling function allows you to apply a gain and offset to all readings

on a specified multiplexer channel during a scan. In addition to setting

the gain (“M”) and offset (“B”) values, you can also specify a custom

measurement label for your scaled readings (

1 Configure the channel.

You must configure the channel (function, tra nsducer type, etc.) before

applying any scaling values. If you change the measurement

configuration, scaling is turned off on that channel and the gain and

offset values are reset (M=1 and B=0).

2 Set the gain and of f s et va l ues .

The scaling values are stored in non-volatile memory for the specified

channels. A Factory Reset turns off scaling and clears the scaling values

on all channels. An Instrument Preset or Card Reset does not clear the

scaling values and does not turn off scaling.

RPM, PSI, etc.).

2

,

,9'&

3 Select the custom label.

You can specify an optional three-character label for your scaled

readings (

unit for the selected function (

RPM, PSI, etc.). The default label is the standard engineering

Set Gain

Set Offset

VDC, OHM, etc.).

/$%(/$6/%6

4 Run the scan and stor e the s c ale d re ad ing s i n memo ry.

39

Page 42

Chapter 2 Front-Panel Overview

To Configure Alarm Limits

To Configure Alarm Limits

The instrument has four alarms which you can configure to alert you

when a reading exceeds specified limits on a channel during a scan.

You can assign a high limit, a low limit, or both to any configured

channel in the scan list. You can assign multiple channels to any of the

four available alarms (numbered 1 through 4).

1 Configure the channel.

You must configure the channel (function, tra nsducer type, etc.) before

setting any alarm limits. If you change the measurement configuration,

alarms are turned off and the limit values are cleared. If you plan to use

Mx+B scaling on a channel which will also use alarms, be sure to

configure the scaling values first.

2 Select which of the four al arms yo u want to use .

86($/$50

3 Select the alarm mode on the selected channel.

You can configure the instrument to generate an alarm when a

measurement exceeds the specified HI or LO limits (or both) on a

measurement channel.

+,$/$5021/<

40

Page 43

Chapter 2 Front-Panel Overview

To Configure Alarm Limits

4 Set the limit value.

The alarm limit values are stored in non-volatile memory for the

specified channels. The def ault val ues for the high an d low limi ts are “0”.

The low limit must always be less than or equal to the high limit, even if

you are using only one of the limits. A Factory Reset clears all alarm

limits and turns off all alarms. An Instrument Preset or Card Reset does

not clear the alarm limits and does not turn off alarms.

,°&

5 Run the scan and sto re t he r e ad ing s i n memo ry.

If an alarm occurs on a channel as it is being scanned, then that

channel’s alarm status is stored in reading memory as the readings are

taken. Each time you start a new scan, the instrument clears all

readings (including alarm data) stored in reading memory from the

previous scan. As alarms are generated, they are also logged in an

alarm queue, which is separate from reading memory. Up to 20 alarms

can be logged in the alarm queue. Reading the alarm queue using the

View menu clears the alarms in the queue.

2

41

Page 44

Chapter 2 Front-Panel Overview

To Read a Digital Input Port

To Read a Digital Input Port

The multifunction module (34907A) has two non-isolated 8-bit

input/output ports which you can use for reading digital patterns.

You can read the live status of the bits on the port or you can configure

a scan to include a digital read.

1 Select the Digital Input port.

Select the slot containing the multifunction module and continue

turning the knob until

2 Read the specified port.

You can specify whether you want to use binary or decimal format.

Once you have selected the number base, it is used for all input or

output operations on the same port. To change the number base,

press the key and select

DIN is displayed (channel 01 or 02).

USE BINARY or USE DECIMAL.

',1

Bit 7 Bit 0

The bit pattern read from the port will be displayed until you press

another key, turn the knob, or until the display times out.

Note: To add a digital input channel to a scan list, press and select

the

DIO READ choice.

42

Binary Display Shown

Page 45

Chapter 2 Front-Panel Overview

To Write to a Digital Output Port

To Write to a Digital Output Port

The multifunction module (34907A) has two non-isolated 8-bit

input/output ports which you can use for outputting digital patterns.

1 Select the Digital Output port.

Select the slot containing the multifunction module and continue

turning the knob until

2 Enter the bit pattern editor.

DIN is displayed (channel 01 or 02).

2

Notice that the port is now converted to an output port (

'287

Bit 7 Bit 0

3 Edit the bit pattern.

Use the knob and or keys to edit the individual bit values.

You can specify whether you want to use binary or decimal format.

Once you have selected the number base, it is used for all input or

output operations on the same port. To change the number base,

press the key and select

'287

4 Output the bit pattern to the specified port.

The specified bit pattern is latched on the specified port. To cancel an

output operation in progress, wait for the display to time out.

Binary Display Shown

USE BINARY or USE DECIMAL.

Decimal Display Shown

DOUT).

43

Page 46

Chapter 2 Front-Panel Overview

To Read the Totalizer Count

To Read the Totalizer Count

The multifunction module (34907A) has a 26-bit totalizer which can

count pulses at a 100 kHz rate. You can manually read the totalizer

count or you can configure a scan to read the count.

1 Select th e totalizer ch a n ne l .

Select the slot containing the multifunction module and continue

turning the knob until

2 Configure the totalize mode.

The internal count starts as soon as you turn on the instrument.

You can configure the totalizer to reset the count to “0” after being read

or it can count continuously and be manually reset.

5($'5(6(7

TOTALIZE is displayed (channel 03).

3 Read the count.

The count is read once each time you press ; the count does not

update automatically on the display. As configured in this example,

the count is automatically reset to “0” each time you read it.

727

The count will be displayed until you press another key, turn the knob,

or until the display times out. To manually reset the totalizer count,

press .

Note: To add a totalizer channel to a scan list , press and select the

TOT READ choice.

44

Page 47

Chapter 2 Front-Panel Overview

To Output a DC Volta ge

To Output a DC Voltage

The multifunction module (34907A) has two analog outputs capable of

outputting calibrated voltages between

±12 volts.

2

1Select a

Select the slot containing the multifunction module and continue

turning the knob until

2 Enter the output vo lta ge ed it or.

DAC Output channel.

DAC is displayed (channel 04 or 05).

9'$&

3 Set the desired output voltage.

Use the knob a nd or keys to edit the individual digits.

9'$&

4 Output the vol t ag e f r o m the se l ec t ed DAC.

The output voltage will be displayed until you press another key or turn

the knob. To manually reset the output voltage to 0 volts, press .

45

Page 48

Chapter 2 Front-Panel Overview

To Configure the Remote Interface

To Configure the Remote Interface

The instrument is shipped with both an GPIB (IEEE-488) interface

and an

The

the factory.

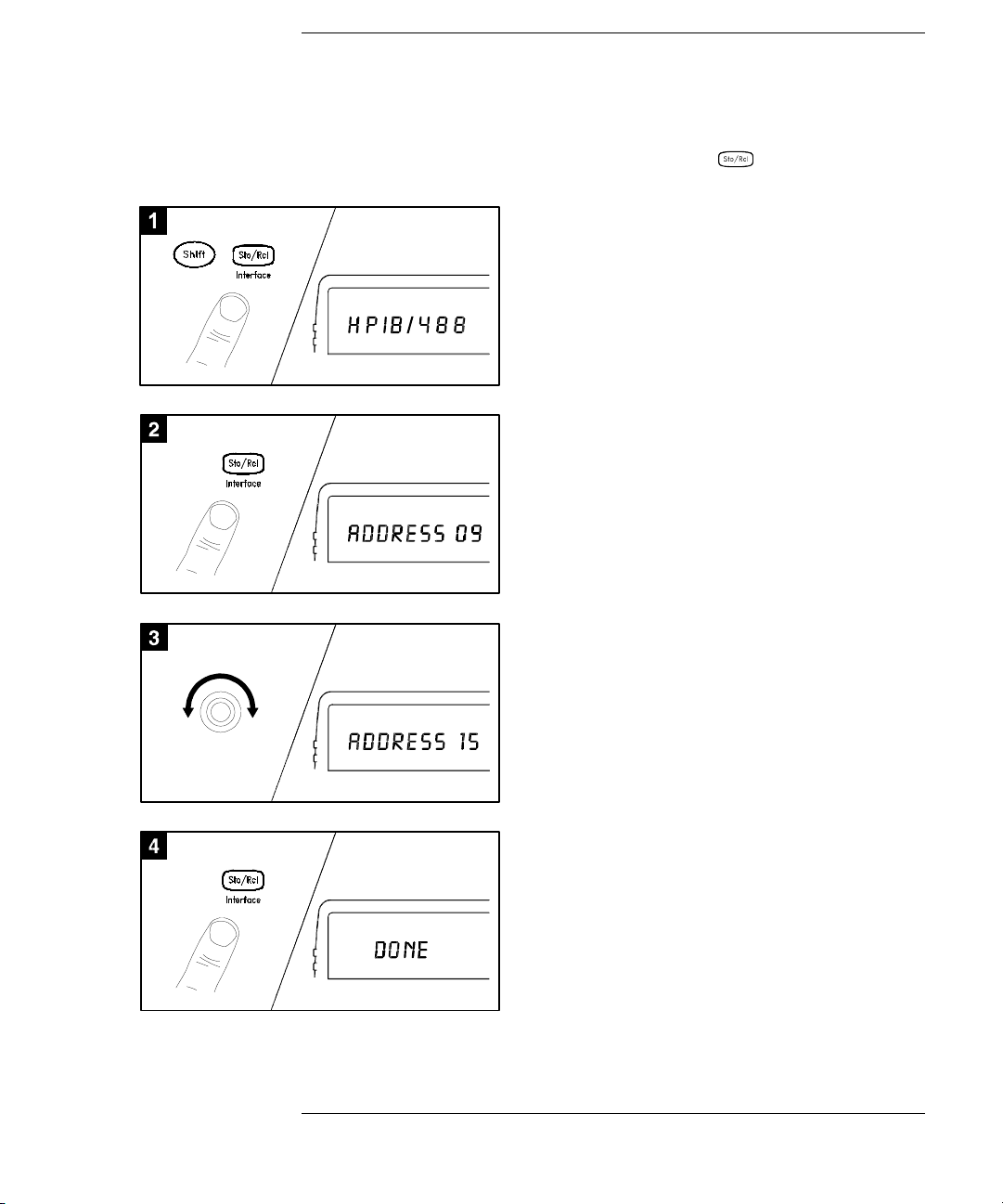

GPIB Configuration

RS-232 interface. Only one interface can be enabled at a time.

GPIB interface is selected when the instrument is shipped from

Interface

Interface

1 Select the

GPIB (HPIB) interface.

+3,%

2 Select the GPIB address.

You can set the instrument’s address to any value between 0 and 30.

The factory setting is address “9”.

$''5(66

3 Save the change and exit the menu.

Note: Your computer’s GPIB interface card has its own address.

Be sure to avoid using the computer’s address for any instrument on the

interface bus. Agilent’s GPIB interface cards generally use address “21”.

46

Page 49

Chapter 2 Front-Panel Overview

To Configure the Remote Interface

RS-232 Configuration

Interface

Interface

1 Select the RS -2 32 int erf a c e.

2

56

2 Select the baud rate.

Select one of the following: 1200, 2400, 4800, 9600, 19200, 38400,

57600 (factory setting), or 115200 baud.

%$8'

3 Select the parity and number of data bits.

Select one of the following: None (8 data bits, factory setting),

Even (7 data bits), or Odd (7 data bits). When you set the parity,

you are also indirectly setting the number of data bits.

(9(1,%,76

Interface

Interface

4 Select the flow control method.

Select one of the following: None (no flow control),

XON/XOFF (factory setting), or Modem.

)/2:'75'65

5 Save the changes and ex it the menu.

RTS/CTS, DTR/DSR,

47

Page 50

Chapter 2 Front-Panel Overview

To Store the Instrument State

To Store the Instrument State

You can store the instrument state in one o f five non-volatile storage

locations. A sixth storage location automatically holds the power-down

configuration of the instrument. When power is restored, the instrument

can automatically return to its state before power-down (a scan in

progress before power-down will also be resumed).

1 Select the storage location.

From the front panel, you have the ability to assign names (up to 12

characters) to each of the five stored states.

1$0(67$7(

7(67BUDFNB

The storage locations are numbered 1 through 5. The power-down

state is automatically stored and can be recalled from the front panel

(the state is named

LAST PWR DOWN).

6725(67$7(

67$7(

2 Store the instrument state.

The instrument stores all channel configurations, alarm values, scaling

values, scan interval setups, and advanced measurement configurations.

&+$1*(6$9('

48

Page 51

3

3

System Overview

Page 52

System Overview

This chapter provides an overview of a computer-based system and

describes the parts of a data acquisition system. This chapter is divided

into the following sections:

• Data Acquisition System Overview, see below

• Signal Routing and Switching, starting on page 57

• Measurement Input, starting on page 60

• Control Output, starting on page 67

Data Acquisition System Overview

You can use the Agilent 34970A as a stand-alone instrument but there are

many applications where you will want to take advantage of t he built-i n

connectivity features. A typical data acquisition system is shown below.

PC

Computer

and Software Interface Cable 34970A

50

Plug-in

Modules

System

Cabling

Transducers,

Sensors,

and Events

Page 53

Chapter 3 System Overview

Data Acquisition System Overview

The system configuration shown on the previous page offers the

following advantages:

• You can use the 34970A to perform data storage, data reduction,

mathematical calculations, and conversion to engineering units.

You can use the

PC to provide easy configuration and data presentati on.

• You can remove the analog signals and measurement sensors from

the noisy

PC environment and electrically isolate them from both the

PC and earth ground.

• You can use a single PC to monitor multiple instruments and

The Computer and Interface Cable

Since computers and operating systems are the subject of many books

and periodicals, they are not discussed in this chapter. In addition to the

computer and operating system, you will need a serial port (

GPIB port (IEEE-488) and an interface cable.

Serial (RS-232) GPIB (IEEE-488)

Advantages Disadvantages Advantages Disadvantages

Often built into the computer;

no additional hardware is

required.

Drivers usually included in

the operating system.

Cables readily available

and inexpensive.

The 34970A is

shipped with a serial cable

(if internal DMM is ordered).

measurement points while performing other

Cable length is limited

to 45 ft (15 m). *

Only one instrument or

device can be connected

per serial port.

Cabling is susceptible to

noise, causing slow or

lost communications.

Varying connector pinouts

and styles.

Data transfers up to

85,000 characters/sec.

Speed; faster data and

command transfers.

Additional system flexibility,

multiple instruments can

be connected to the

same GPIB port.

Direct Memory Transfers

are possible.

Data transfe r s up to

750,000 characters/sec.

PC-based tasks.

RS-232) or

Cable length is limited

to 60 ft (20 m). *

Requires an expansion

slot plug-in card in PC

and associated drivers.

Requires special cable.

3

* You can overcome these cable length limitations using spe cia l communications hardware.

For example, you can use the Agilent E5810A LAN-to-GPIB Gateway interface or a serial modem.

51

Page 54

Chapter 3 System Overview

Data Acquisition System Overview

Measurement Software

A variety of software is available to configure your data acquisition

hardware and manipulate and display your measurement data.

Data Logging and Monitoring

®

Agilent BenchLink Data Logger is a Windows

designed to make it easy to use the 34970A with your

and analyzing measurements. The software is included with the 34970A

when you order the internal

DMM. Use this software to set up your test,

acquire and archive measurement data, and perform real-time display

and analysis of your incoming measurements.

-based application

PC for gathering

Agilent BenchLink Data Logger

Automated Testing with Multiple Instrumen ts

• Agilent VEE

• TransEra HTBASIC

• National Instruments LabVIEW

• Microsoft

®

Visual Basic or Visual C++

52

®

for Windows

Page 55

Chapter 3 System Overview

Data Acquisition System Overview

The 34970A Data Acquisition / Switch Unit

As shown below, the logic circuitry for the 34970A is divided into two

sections: earth-referenced and floating. These two sections are isolated

from each other in order to maintain measurement accuracy and

repeatability (for more information on ground loops, see page 341).

External Trigger

OUT

IN

Alarms

To Computer

Optional

Digital

Bus

Internal

DMM

Analog Bus

100

200

300

Control

GPIB

RS-232

AC Power

Floating

Logic

Earth

Referenced

Logic

= Optical Isolators

The earth-referenced and floating circuitry communicate with each

other via an optically-isolated data link. The earth-referenced section

communicates with the floating section to provide

The instrument is shipped with both an

GPIB (IEEE-488) interface

PC connectivity.

and an RS-232 interface. Only one interface can be enabled at a time.

The earth-referenced section also provides four hardware alarm outputs

and external trigger lines. You can use the alarm output lines to trigger

external alarm lights, sirens, or send a

TTL pulse to your control system.

3

Plug-In

Slots

The floating section contains the main system processor and controls all

of the basic functionality of the instrument. Thi s is where the instrument

communicates with the plug-in modules, scans the keyboard, controls the

front-panel display, and controls the internal

DMM. The floating section

also performs Mx+B scaling, monitors alarm conditions, converts

transducer measurements to engineering units, time stamps scanned

measurements, and stores data in non-volatile memory.

53

Page 56

Chapter 3 System Overview

Data Acquisition System Overview

Plug-In Modules

The 34970A offers a complete selection of plug-in modules to give you

high-quality measurement, switching, and control capabilities.

The plug-in modules communicate with the floating logic via the internal

isolated digital bus. The multiplexer modules also connect to the

internal

microprocessor to offload the mainframe processor and minimize

backplane communications for faster throughput. The table below shows

some common uses for eac h plug-in module.

For more information on each module, refer to the module sections in

chapter 4, starting on page 163.

Model Number Module Name Common Uses

34901A 20-Channel Mux with T/C

34902A 16-Channel Reed Mux with T/C

34908A 40-Channel Single-Ended Mux

34907A Multifunction Module Digital Input, Event Counting.

34901A 20-Channel Mux with T/C

34902A 16-Channel Reed Mux with T/C

34908A 40-Channel Single-Ended Mux

34904A 4x8 Matrix Switch 32 Crosspoint Matrix switching.

34905A

34906A

34903A 20-Channel Actuator General-purpose switching and control

34907A Multifunction Module Digital Output, Voltage (DAC) Outputs.

DMM via the internal analog bus. Each module has its own

Measurement Input

Compensation

Compensation

with T/C Compensation

Signal Routing

Compensation

Compensation

with T/C Compensation

Dual 4-Channel RF Mux (50

Dual 4-Channel RF Mux (75

Control Output

Scanning and direct measurement of

temperature, voltage, resistance, frequency,

and current (34901A only) using the

internal DMM.

Scanning and direct measurement of

temperature, voltage, and resistance using

the internal DMM.

Multiplexing of signals to or from external

instruments.

50

Ω)

Ω)

Ω high-frequency applications (< 2 GHz).

75

Ω high-frequency applications (< 2 GHz).

using Form C (SPDT) switches.

54

Page 57

Chapter 3 System Overview

Data Acquisition System Overview

System Cabling

The plug-in modules have screw-terminal connectors to make it easy to

connect your system cabling. The type of cabling that you use to connect

your signals, transducers, and sensors to the module is critical to

measurement success. Some types of transducer s, such a s th ermocouples,

have very specific requirements for the type of cable that can be used to

make connections. Be sure to consider the usage environment when

choosing wire gauge and insulation qualities. Wire insulation typically

consists of materials such as

PVC or Teflon

several common cable types and describes their typical uses.

Note: Wiring insulation and usage is described in more detail in

“System Cabling and Connections” starting on page 335.

Cable Type Common Uses Comments

Thermocouple

Extension Wire

Twisted Pair,

Shielded Twisted Pair

Shielded Coaxial,

Double-Shielded

Coaxial

Flat Ribbon,

Twisted Pair Ribbon

Thermocouple measurements. Av ail a ble in s p ec ific th er mo couple types.

Measurement inputs, voltage

outputs, switching, counting.

VHF signal switching. Most common cable for high-frequency

Digital Input/Output Often used with mass termination

®

. The table below lists

Also available in a shielded cable for

added noise immunity.

Most common cable for low-frequency

measurement inputs. Twisted pair

reduces common mode noise.

Shielded-twisted pair provides additional

noise immunity.

signal routing. Available in specific

impedance values (50

Provides excellent noise immunity.

Double-shielded cable improves

isolation between channels. Requires

special connectors.

connectors. These cables provide little

noise immunity.

3

Ω or 75Ω).

Teflon is a registered trademark of E.I. duPont deNemours and Company.

55

Page 58

Chapter 3 System Overview

Data Acquisition System Overview

Transducers and Sensors

Transducers and sensors convert a physical quantity into an electrical

quantity. The electrical quantity is measured and the result is then

converted to engineering units. For example, when measuring a

thermocouple, the instrument measures a dc voltage and ma themat icall y

converts it to a corresponding temperature in

Measurement Typical Transducer Types Typical Transducer Output

Temperature Thermocouple 0 mV to 80 mV

RTD 2-wire or 4-wire resistance

Thermistor 2-wire resistance from

Pressure Solid State ±10 Vdc

Flow Rotary Type

Thermal Type

Strain Resistive Elements 4-wire resistance from

Events Limit Switches

Optical Counters

Rotary Encoder

Digital System Status TTL Levels

°C, °F, or K.

Ω to 500Ω

from 5

Ω to 1 MΩ

10

4 mA to 20 mA

Ω to 10 kΩ

10

0V or 5V Pulse Train

Alarm Limits

The 34970A has four alarm outputs which you can configure to alert you

when a reading exceeds specified limits on a channel during a scan.

You can assign a high limit, a low limit, or both to any configured

channel in the scan list. You can assign multiple channels to any of the

four available alarms (numbered 1 through 4). For example, you can

configure the instrument to generate an alarm on Alarm 1 when a limit

is exceeded on any of channels 103, 205, or 320.

You can also assign alarms to channels on the multifunction module.

For example, you can generate an alarm when a specific bit pattern or

bit pattern change is detec ted on a digi tal i np u t c h a nn e l or w he n a sp e ci fi c

count is reached on a tota lizer c hannel . With th e multifu nct ion modul e,

the channels do not have to be part of the scan list to generate an alarm.

56

Page 59

Chapter 3 System Overview

Signal Routing and Switching

Signal Routing and Switching

The switching capabilities of the plug-in modules available with the

34970A provide test system flexibility and expandability. You can use

the switching plug-in modules to route signals to and from your test

system or multiplex signals to the internal

Relays are electromechanical devices which are subject to wear-out

failure modes . The life of a relay, or the number of actual operations

before failure, is dependent upon how it is used – applied load, switching

frequency, and environment. The 34970A Relay Maintenance System

automatically counts the cycles of each relay in the instrument and

stores the total count in non-volatile memory on each switch module.

Use this feature to track relay fai lures and to p redict system main tenan ce

requirements. For more information on using this feature, refer to

“Relay Cycle Count” on page 147.

Switching Topologies

DMM or external instruments.

3

Several switching plug-in modules are available with different

topologies for various applications. The following switching topologies

are available:

• Multiplexer (34901A, 34902A, 34905A, 34906A, 34908A)

• Matrix (34904A)

• Form C – Single Pole, Double Throw (34903A)

The following sections describe each of these switching topologies.

57

Page 60

Chapter 3 System Overview

Signal Routing and Switching

Multiplexer Switching Multiplexers allow you to connect one of

multiple channels to a common channel, one at a time. A simple 4-to-1

multiplexer is shown below. When you combine a multiplexer with a

measurement device, like the internal

DMM, you create a scanner.

For more information on scanning, see page 62.

Channel 1

Common

Channel 2

Channel 3

Channel 4

Multiplexers are available in several types:

• One-Wire (Single-Ended) Multiplexers for common LO measurements.

For more information, see page 379.

• Two-Wire Multiplexers for floating measurements. For more

information, see page 379.

• Four-Wire Multiplexers for resistance and RTD measurements.

For more information, see page 380.

• Very High Frequency (VHF) Multiplexers for switching frequencies

up to 2.8 GHz. For more information, see page 390.

58

Page 61

Chapter 3 System Overview

Signal Routing and Switching

Matrix Switching A matrix switch connects multiple inputs to

multiple outputs and therefore offers more switching flexibility than a

multiplexer. Use a ma trix for switc hing low- freq uenc y (less than 10 MHz)

signals only. A matrix is arranged in rows and columns. For example,

a simple 3x3 matrix could be used to connect three sources to three test

points as shown below.

Source 1

NO = Normally Open

NC = Normally Closed

Source 2

Source 3

Test 1 Test 2 Test 3

Any one of the signal sources can be connected to any one of the test

inputs. Be aware that with a matrix, it is possible to connect more than

one source at the same time. It is important t o make sure tha t dangerous

or unwanted conditions are not created by these conn ections.

Form C (SPDT) Switching The 34903A Actuator contains 20 Form C

switches (also called single-pole, double-throw). You can use Form C

switches to route signals but they are typically used to control external

devices.

Channel Open

(NC Contact Connected)

NO

NC

Channel Closed

(NO Contact Connected)

NO

NC

3

COM

COM

59

Page 62

Chapter 3 System Overview

Measurement Input

Measurement Input

The 34970A allows you to combine a DMM (either internal or external)

with multiplexe r c ha n nels to c reat e a scan. During a scan, the instrument

connects the

and makes a measurement on each channel.

Any channel that can be “read” by the instrument can also be included

in a scan. This includes any combination of temperature, voltage,

resistance, current, frequency, or period measurements on multiplexer

channels. A scan can also include a read of a digital port or a read of the

totalizer count on the multifunction module.

The Internal DMM

A transducer or sensor converts a physical quantity being measured

into an electrical signal which can be measured by the internal

To make these measurements, the internal

following functions:

DMM to the configured multiplexer channels one at a time

DMM.

DMM incorporates the

• Temperature (thermocouple, RTD, and thermistor)

• Voltage (dc and ac up to 300V)

• Resistance (2-wire and 4-wire up to 100 MΩ)

• Current (dc and ac up to 1A)

• Frequency and Period (up to 300 kHz)

The internal

DMM provides a universal input front-end for measuring

a variety of transducer types without the need for additional external

signal conditioning. The internal

DMM includes signal conditioning,

amplification (or attenuation), and a high resolution (up to 22 bits)

analog-to-digital converter. A simplified diagram of the internal

DMM is

shown below.

Analog

Input

Signal

Signal

Conditioning

Amp

Analog to

Digital

Converter

Main

Processor

To / F rom

Earth

Referenced

Section

= Optical Isolators

60

Page 63

Chapter 3 System Overview

Measurement Input

Signal Conditioning, Ranging, and Amplification Analog input

signals are multiplexed into the internal

section – typically comprising switch ing , ranging, and amplification

circuitry. If the input signal is a dc voltage, the signal conditioner

is composed of an attenuator for the higher input voltages and a

dc amplifier for the lower input voltages. If the input signal is an

ac voltage, a converter is used to convert the ac signal to its equivalent

dc value (true

supplying a known dc current to an unknown resistance and measuring

the dc voltage drop across the resistor. The input signal switching and

ranging circuitry, together with the amplifier circuitry, convert the

input to a dc voltage which is within the measuring range of the

internal

You can allow the instrument to automatically select the measurement

range using autoranging or you ca n select a fixed measurement range

using manual ranging. Autoranging is convenient because the instrument

automatically decides which range to use for each measurement based

on the input signal. For fastest scanning operation, use manual ranging

for each measurement (some additional time is required for autoranging

since the instrument has to make a range selection).

RMS value). Resistance measurements are performed by

DMM’s analog-to-digital converter (ADC).

DMM’s signal-conditioning

3

Analog-to-Digi t al Conv er sion (ADC) The

dc voltage from the signal-conditioning circuitry and converts it to digital

data for output and display on the front panel. The

the most basic measurement characteristics. These include measur eme nt

resolution, reading speed , and the ab ilit y to reject spuriou s noise. There

are several analog-to-digital conversion techniques but they can be

divided into two types: integrating and non-integrating. The integrating

techniques measure the average input value over a defined time

interval, thus rejecting many noise sources. The non-integrating