Page 1

Agilent 34401A

6 ½ Digit Multimeter

User’s Guide

Agilent Technologies

Page 2

Notices

© Agilent Technologies, Inc. 1991 - 2007

No p art o f this manual may be rep roduc ed in

any form or by any means (including electronic storage and retrieval or translation

into a foreign language) without prior agreement and written consent from Agilent

Technologies, Inc. as governed by United

States and international copyright laws.

Manual Part Number

34401-90004

Edition

Seventh Editio n. August 2007

Printed in Malaysia

Agilent Technologies, Inc.

3501 Stevens Creek Blvd.

Santa Clara, CA 95052 USA

Microsoft® and Windows® are U.S. registered trademarks of Microsoft Corporation.

Software Revision

This guide is valid for the firmware that was

installed in the instrument at the time of

manufacture. However, upgrading the firmware may add or change product features.

For the latest firmware and documentation,

go to the product page at:

www.agilent.com/find/34401A

Warranty

The material contained in this document is provided “as is,” and is subject to being changed, without notice,

in future editions. Furt her, to the maximum extent permitted by applicable

law, Agilent disclaims all warranties,

either express or implied, with regard

to this manual and any information

contained herein, including but not

limited to the implied warranties of

merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for incidental or

consequential damages in connection with the furnishing, use, or performance of this document or of any

information contained herein. Should

Agilent and the user have a separate

written agreement with warranty

terms covering the material in this

document that conflict with these

terms, the warranty terms in the separate agreement shall control.

Technology Licenses

The hardware and/or software described in

this document are furnished under a license

and may be used or copied only in accordance with the terms of such license.

Restricted Rights Legend

U.S. Government Restricted Rights. Software and technical data rights granted to

the federal government include only those

rights customarily provided to end user customers. Agilent provides this customary

commercial license in Software and technical data pursuant to FAR 12.211 (Technical

Data) and 12.212 (Computer Software) and,

for the Department of Defense, DFARS

252.227-7015 (Technical Data - Commercial

Items) and DFARS 227.7202-3 (Rights in

Commercial Computer Software or Computer Software Documentation).

Safety Notices

CAUTION

A CAUTION notice denotes a haz-

ard. It calls attention to an operating procedure, practice, or the like

that, if not correctly performed or

adhered to, could result in damage

to the product or loss of important

data. Do not proceed beyond a

CAUTION notice until the indicated

conditions are fully understood and

met.

WARNING

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly performed or adhered to, could result

in personal injury or death. Do not

proceed beyond a WARNING

notice until the indicated conditions are fully understood and

met.

ii 34401A User’s Guide

Page 3

Safety Information

General

Do not use this product in any manner not

specified by the manufacturer. The protective features of this product may be

impaired if it is used in a manner not specified in the operation instructions.

Do not install substitute parts or perform

any unauthorized modification to the product. Return the product to an Agilent Technologi es Sales and S ervice Office for service

and repair to ensure that safety features are

maintained.

Ground the Instrument

If your product is provided with a grounding-type power plug, the instrument chassis

and cover must be connected to an electrical ground to minimize shock hazard. The

ground pin must be firmly connected to an

electrical ground (safety ground) terminal at

the power outlet. Any interruption of the

protective (grounding) conductor or disconnection of the protective earth terminal will

cause a potential shock hazard that could

result in personal injury.

Cleaning

Clean the outside of the instrument with a

soft, lint-free, slightly dampened cloth. Do

not use detergent or chemical solvents.

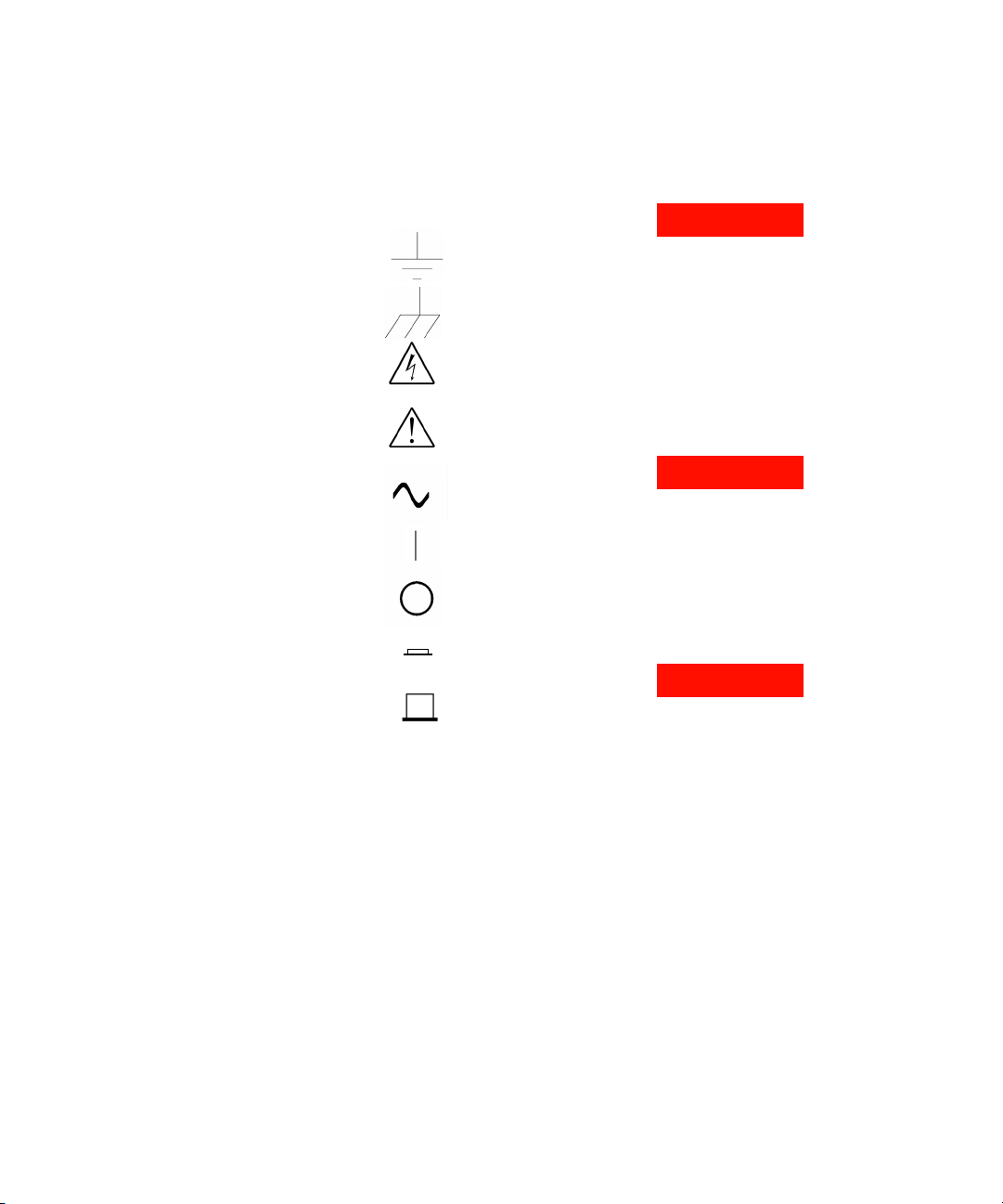

Safety Symbols

Earth Ground

Chassis Ground

Risk of electric shock

Refer to manual for additional safety information

Alternating Current

On supply

Off supply

‘In’ position of bi-stable push

switch

‘Out’ position of bi-stable

push switch

CAT II (300V)

IEC Measurement Category II.

Inputs may be connected to

mains (up to 300 VAC) under

Category II overvoltage conditions.

WARNING

Main Power and Test Input Disconnect: Unplug instrument from

wall outlet, remove power cord,

and remove all probes from all

terminals before servicing. Only

qualified, service-trained personnel should remove the cover from

the instrument.

WARNING

Line and Current Protection

Fuses: For continued protection

against fire, replace the line fuse

and the current-protection fuse

only with fuses of the specified

type and rating.

WARNING

Front/Rear Switch: Do not

change the position of the

Front/Rear switch on the front

panel while signals are present on

either the front or rear set of terminals. The switch is not intended

as an active multiplexer. Switching while high voltages or currents are present may cause

instrument damage and lead to

the risk of electric shock.

34401A User’s Guide iii

Page 4

WARNING

IEC Measurement Category II. The

HI and LO input terminals may be

connected to mains in IEC Category II installations for line voltages up to 300 VAC. To avoid the

danger of electric shock, do not

connect the inputs to mains for

line voltages above 300 VAC. See

"IEC Measurement Category II

Overvoltage Protection" on the

following page for further information.

WARNING

Protection Limits: To avoid instrument damage and the risk of electric shock, do not exceed any of

the Protection Limits defined in

the following section.

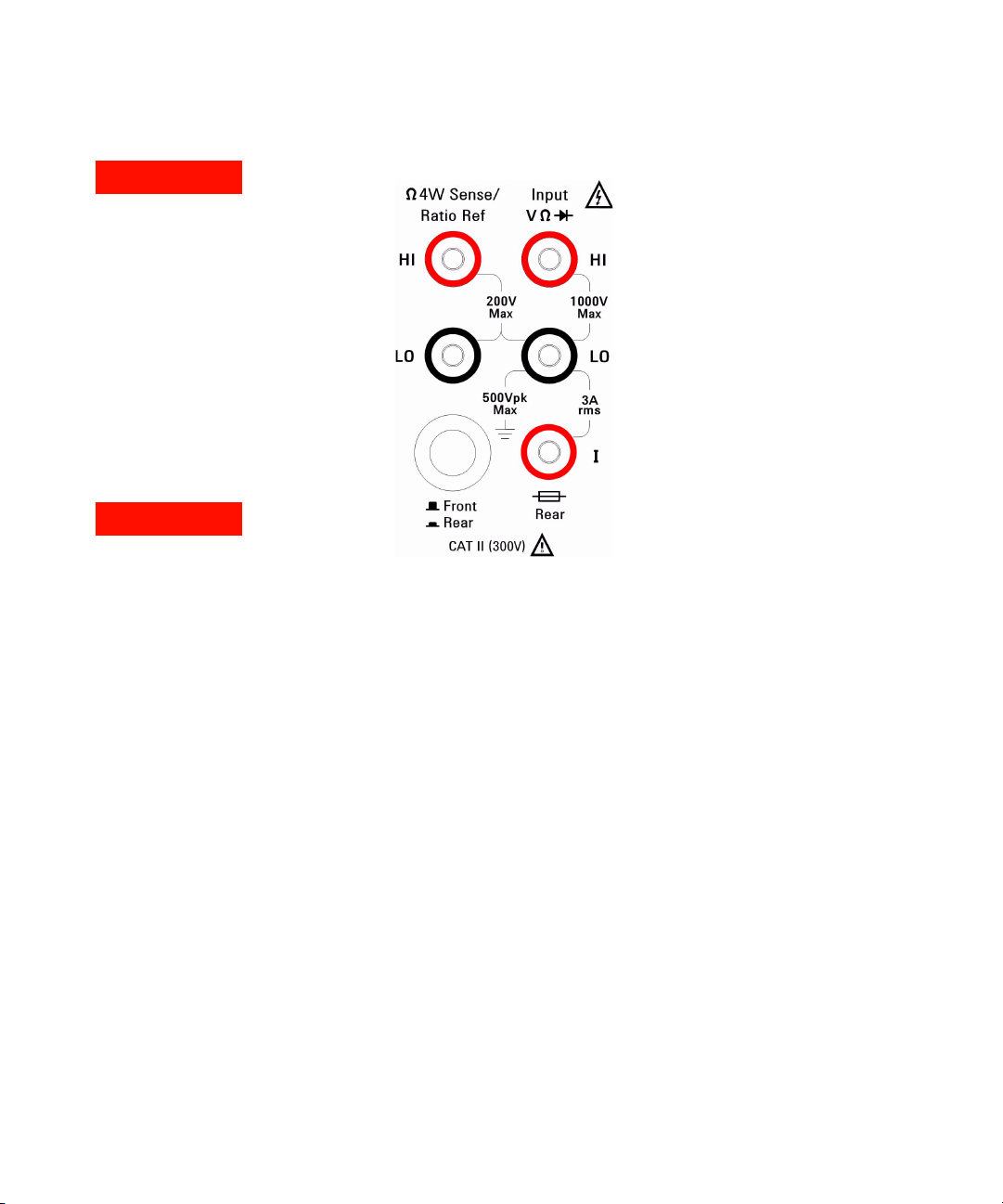

Protection Limits

The Agilent 34401A Digital Multimeter provides protection circuitry to prevent damage

to the instrument and to protect against the

danger of electric shock, provided the Protection Limits are not exceeded. To ensure

safe operation of the instrument, do not

exceed the Protection Limits shown on the

front and rear panel, and defined as follows:

Note: The front-panel terminals are shown

above. The rear-panel terminals are identical. The Front/Rear switch selects the terminal set to be used. Do not operate this

switch while signals are pr esent on the

front or rear terminals. The current-protec-

tion fuse is on the rear panel.

Input Terminal Protection

Limits

Protection Limits are defined for the input

terminals:

Main Input (HI and LO) Terminals. The HI

and LO input terminals are used for voltage,

resistance, frequency (period), an d diode

test measurements. Two Protection Limits

are defined for these terminals:

HI to LO Protection Limit. The Protection

Limit from HI to LO (Input terminals) is

1000 VDC or 750 VAC, which is also the

maximum voltage measurement. This

limit can also be expressed as 1000 Vpk

maximum.

LO to Ground Protection Limit. The LO

input terminal can safely "float" a maximum of 500 Vpk relative to ground.

As is implied by the above limits, the Protection Limit for the HI input terminal is a maximum of 1500 Vpk relative to ground.

Current Input Terminal. The current input

("I") terminal has a Protection Limit of 3A

(rms) maximum current flowing from the LO

input terminal. Note that the current input

terminal will be at approximately the same

voltage as the LO terminal.

Note: The current-protection circuitry

includes a fuse on the rear panel. To maintain protection, replace this fuse only with a

fuse of the specified type and rating.

Sense Terminal Protection

Limits

The HI and LO sense terminals are used

only for four-wire resistance and temperature measurements ("

tion Limit is 200 Vpk for all of the terminal

pairings:

LO sense to LO input

HI sense to LO input

HI sense to LO sense

Note: The 200 Vpk limit on the sense terminals is the Protection Limit. Operational

voltages in resistance measurements are

much lower — less than 10 V in normal

operation.

Ω 4W"). The Protec-

IEC Measurement Category II

Overvoltage Protection

To protect against the danger of electric

shock, the Agilent 34401A Digital Multimeter provides overvoltage protection for

line-voltage mains connections meeting

both of the following conditions:

The HI and LO input terminals are connected to the mains under Measurement

Category II conditions, defined below,

The mains are limited to a maximum line

voltage of 300 VAC.

and

iv 34401A User’s Guide

Page 5

IEC Measurement Category II includes electrical devices connected to mains at an outlet on a branch circuit. Such devices include

most small appliances, test equipment, and

other devices that plug into a branch outlet

or socket. The 34401A may be used to make

measurements with the HI and LO inputs

connected to mains in such devices, or to

the branch outlet itself (up to 300 VAC).

However, the 34401A may not be used with

its HI and LO inputs connected to mains in

permanently installed electrical devices

such as the main circuit-breaker panel,

sub-panel disconnect boxes, or permanently

wired motors. Such devices and circuits are

subject to overvoltages that may exceed the

protection limits of the 34401A.

Note: Voltages above 300 VAC may be measured only in circuits that are isolated from

mains. However, transient overvoltages are

also present on circuits that are isolated

from mains. The A gilent 34401A are

designed to safely withstand occasional

transient overvoltages up to 2500 Vpk. Do

not use this equipment to measure circuits

where transi ent overvoltages could exceed

this level.

Additional Notices

Waste Electrical and

Electronic Equipment (WEEE)

Directive 2002/96/EC

This product complies with the WEEE Directive (2002/96/EC) marking requirement.

The affixed product label (see below) indicates that you must not discard this electrical/electronic product in domestic

household waste.

Product Category: With reference to the

equipment types in the WEEE directive

Annex 1, this product is classified as a

"Monitoring and Contr ol instrumentation"

product.

Do not dispose in domestic household

waste.

To return unwanted products, contact your

local Agilent office, or see

www.agilent.com/environment/product

for more information.

Agilent 34138A Test Lead Set

The Agilent 34401A is compatible with the

Agilent 34138A Test Lead Set described

below.

Test L e a d Ra t i n g s

Test Leads - 1000V, 15A

Fine Tip Probe Attachments - 300V, 3A

Mini Grabber Attachment - 300V, 3A

SMT Grabber Attachments - 300V, 3A

Operation

The Fine Tip, Mini Grabber, and SMT Grabber attachments plug onto the probe end of

the Test Leads.

Maintenance

If any portion of the Test Lead Set is worn or

damaged, do not use. Replace with a new

Agilent 34138A Test Lead Set.

WARNING

If the Test Lead Set is used in a

manner not specified by Agilent

Technologies, the protection provided by the Test Lead Set may be

impaired. Also, do not use a damaged or worn Test Lead Set.

Instrument damage or personal

injury may result.

34401A User’s Guide v

Page 6

DECLARATION OF CONFORMITY

According to ISO/IEC Guide 22 and CEN/CENELEC EN 45014

Manufacturer’s Name:

Manufacturer’s Address:

Agilent Technologies, Incorporated

815 – 14th St. SW

Loveland, Colorado 80537

USA

Declares, that the product

Product Name:

Model Number:

Multimeter

34401A

Product Options: This declaration covers all options of the above product(s).

Conforms with the following European Directives:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC and the EMC Directive 89/336/EEC

(including 93/68/EEC) and carries the CE Marking accordingly.

Conforms with the following product standards:

EMC Standard

IEC 61326-1:1997+A1:1998 / EN 61326-1:1997+A1:1998

CISPR 11:1990 / EN 55011:1991

IEC 61000-4-2:1995+A1:1998 / EN 61000-4-2:1995

IEC 61000-4-3:1995 / EN 61000-4-3:1995

IEC 61000-4-4:1995 / EN 61000-4-4:1995

IEC 61000-4-5:1995 / EN 61000-4-5:1995

IEC 61000-4-6:1996 / EN 61000-4-6:1996

IEC 61000-4-11:1994 / EN 61000-4-11:1994

Canada: ICES-001:1998

Australia/New Zealand: AS/NZS 2064.1

Limit

Group 1 Class A

4kV CD, 8kV AD

3 V/m, 80-1000 MHz

0.5kV signal lines, 1kV power lines

0.5 kV line-line, 1 kV line-ground

3V, 0.15-80 MHz

Dips: 30% 10ms; 60% 100ms

Interrupt > 95%@5000ms

The product was tested in a typical configuration with Agilent Technologies test systems.

Safety

IEC 61010-1:1990+A1:1992+A2:1995 / EN 61010-1:1993+A2:1995

Canada: CSA C22.2 No. 1010.1:1992

UL 3111-1: 1994

18 July 2001

Date

Ray Corson

Product Regulations Program Manager

Authorized EU-representative: Agilent Technologies Deutschland GmbH, Herrenberger Straβe 130, D 71034 Böblingen, Germany

For further information, please contact your local Agilent Technologies sales office, agent or distributor.

Page 7

Note: Unless ot h erwise indicat ed, this manual applies to all Seri al N umbers.

The Agilent Technologies 34401A is a 6

1

⁄

-digit, high-performance

2

digital multimeter. Its co m bination o f bench-to p and syste m featur e s

makes this multimeter a versatile solution for y our m easurement n eeds

now and in the future.

Convenient Bench-Top Features

• Highly visible vacuum-fluorescent display

• Built-in math operations

• Continuity and diode test functions

• Hands-free, Reading Hold fea ture

• Portable, ruggedized case with non-skid feet

Flexible System Features

• GPIB (IEEE-488) interface and RS-232 interface

• Standard programming languages: SCPI, Agilent 3478A, and

Fluke 8840

• Reading rates up to 1000 readings per second

• Storage for up to 512 readings

• Limit testing with pass/fail signals

• Optional 34812A BenchLink/Meter Software for Microsoft

Windows

TM

Agilent 34401A

Multimeter

®

Page 8

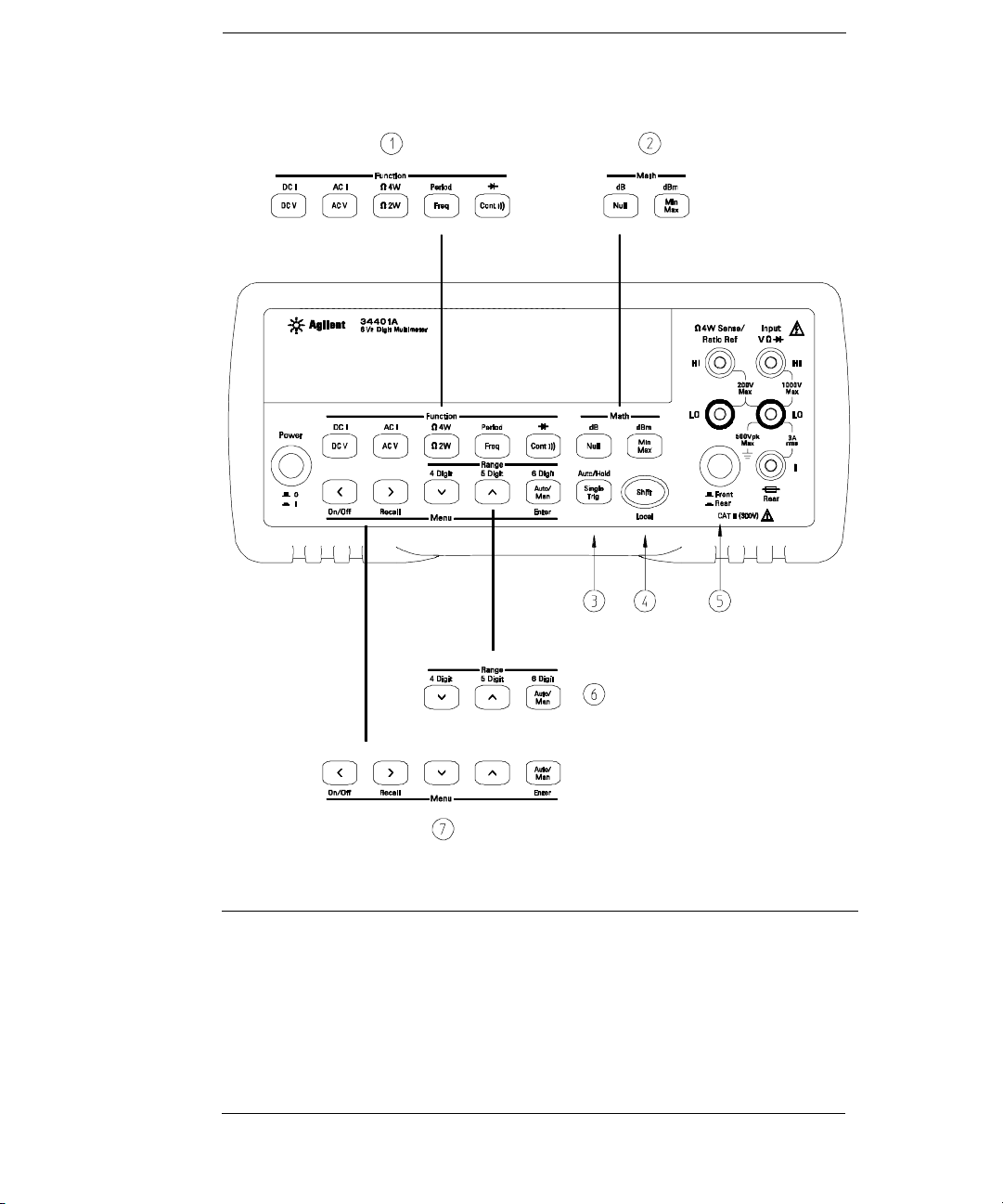

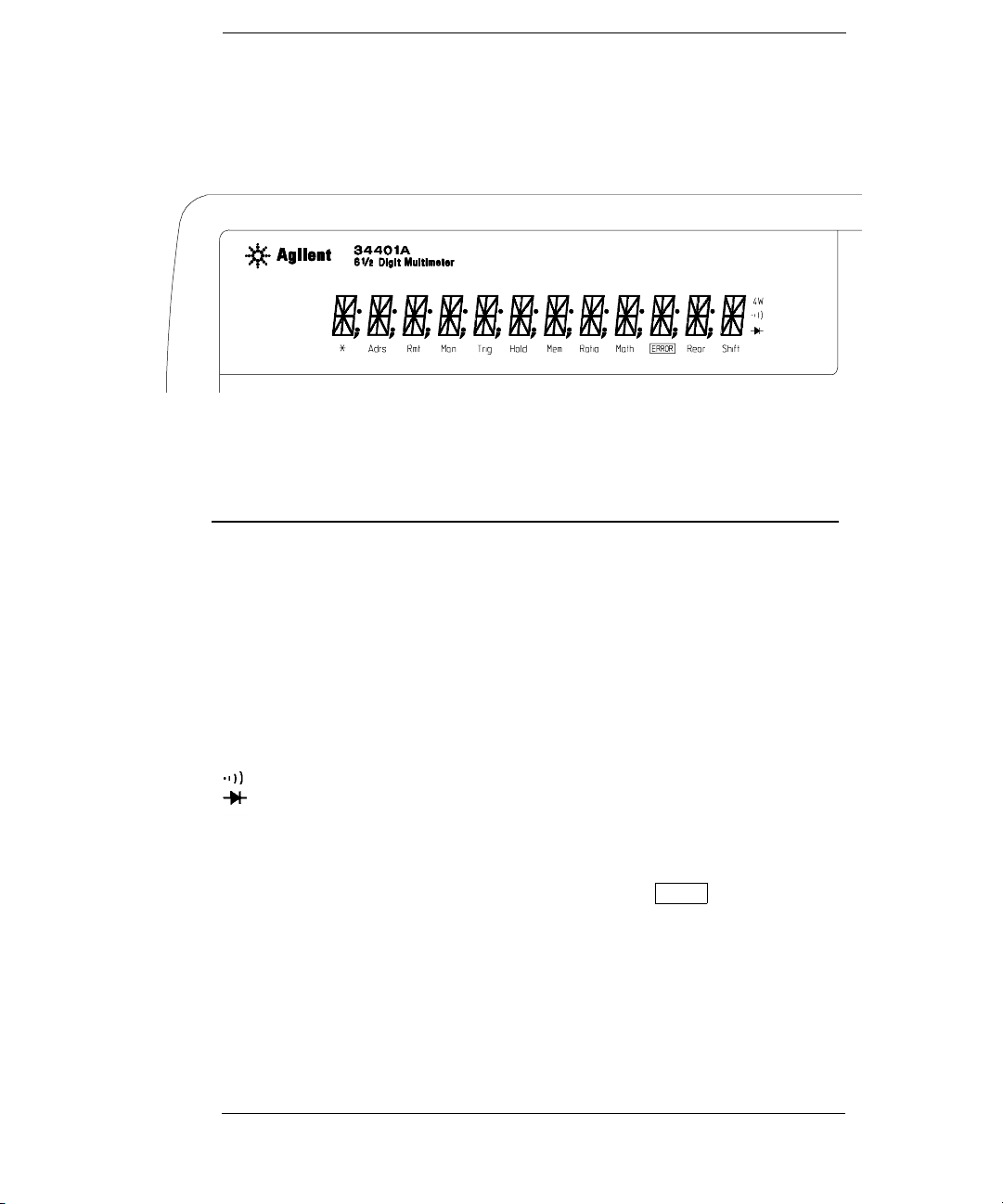

The Front Panel at a Glance

1 Measurement Function keys

2 Math Operation keys

3 Single Trigger / Autotrigger / Reading Hold key

4 Shift / Local key

2

5 Front / Rear Input Terminal Switch

6 Range / Number of Digits Displayed keys

7 Menu Operation keys

Page 9

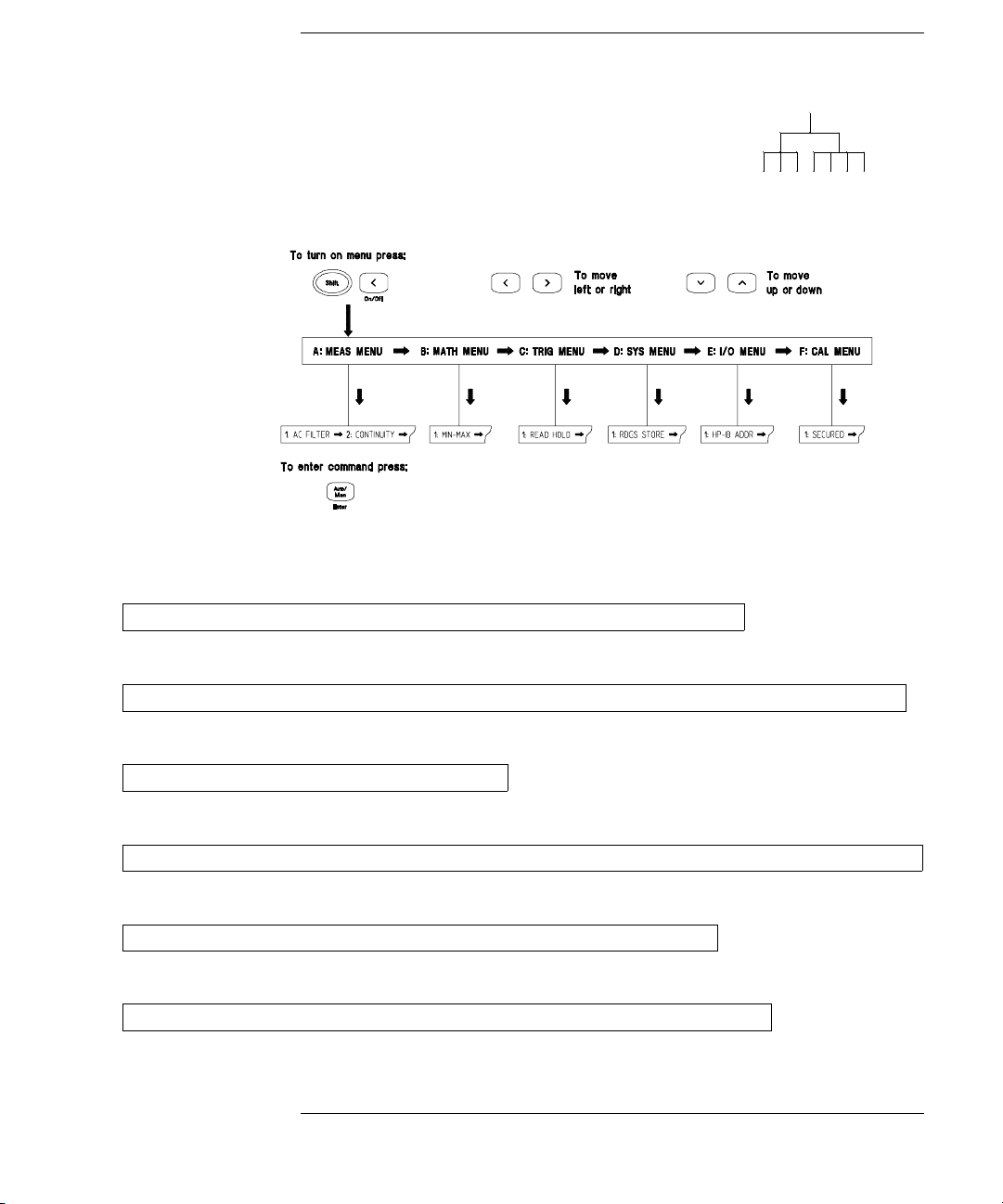

The Front-Panel Menu at a Glance

The menu is organized in a top -d own tree structure with three levels.

A: MEASurement MENU

1: AC FILTER > 2: CONTINUITY > 3: INPUT R > 4: RATIO FUNC > 5: RESOLUTION

B: MATH MENU

1: MIN-MAX > 2: NULL VALUE > 3: dB REL > 4: dBm REF R > 5: LIMIT TEST > 6: HIGH LIMIT > 7: LOW LIMIT

C: TRIGger ME N U

1: READ HOLD > 2: TRIG DELAY > 3: N SAMPLES

D: SYStem MENU

1: RDGS STORE > 2: SAVED RDGS > 3: ERROR > 4: TEST > 5: DISPLAY > 6: BEEP > 7: COMMA > 8: REVISION

E: Input / Output MENU

1: GPIB ADDR > 2: INTERFACE > 3: BAUD RATE > 4: PARITY > 5: LANGUAGE

F: CALibration MENU

1: SECURED > [ 1: UNSECURED ] > [ 2: CALIBRATE ] > 3: CAL COUNT > 4: MESSAGE

The commands enclosed in square brackets ( [ ] ) are “hidden” unless the multimeter

*

is UNSECURED for calibration.

*

3

Page 10

Display Annunciators

∗

Adrs

Rmt

Man

Trig

Hold

Mem

Ratio

Math

ERROR

Rear

Shift

4W

Turns on during a measurement.

Multimeter is addressed to listen or talk over the GPIB interface.

Multimeter is in remote mode (remote interface).

Multimeter is using manual ranging (autorange is disabled).

Multimeter is waiting for a single trigger or external trigger.

Reading Hold is enabled.

Turns on when reading memory is enabled.

Multimeter is in dcv:dcv ratio function.

A math operation is enabled (null, min-max, dB, dBm, or limit test ).

Hardware or remote interface command errors are detected.

Rear input terminals are selected.

“Shift” key has been pressed.

Multimeter is in 4-wire ohms function.

Multimeter is in continuity test function.

Multimeter is in diode test function.

Press “Shif t” again to turn off.

To review the display annunciators, hold down the Shift key as you

turn on the multimeter.

4

Page 11

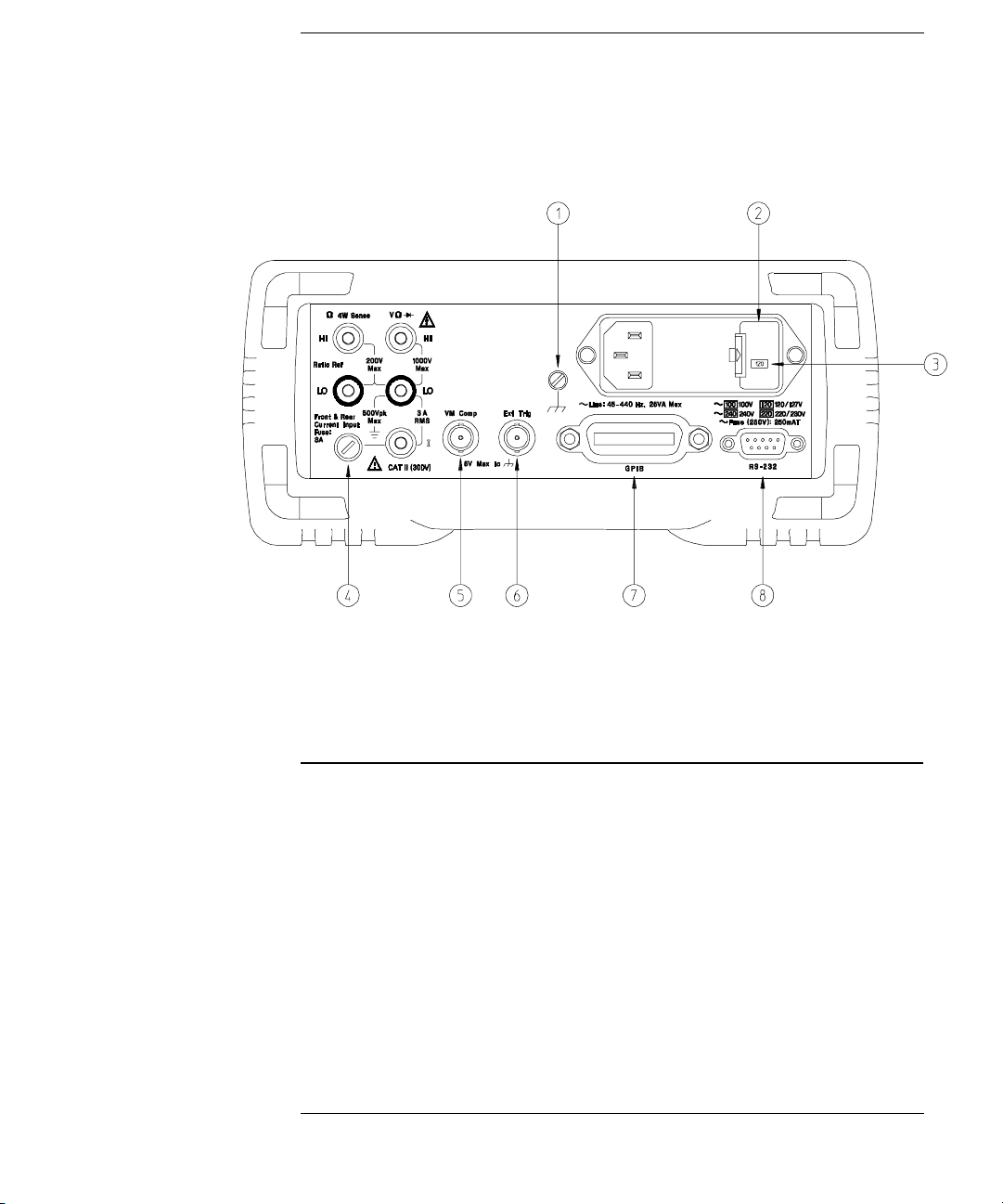

The Rear Panel at a Glance

1 Chassis Ground

2 Power-Line Fuse-Holder Assembly

3 Power-Line Voltage Setting

4 Front and Rear Current Input Fuse

5 Voltmeter Complete Output Terminal

6 External Trigger Input Terminal

7 GPIB (IEEE-488) Interface connector

8 RS-232 interface connector

Use the front-panel Input / Output Menu to:

• Select the GPIB or RS-232 interface (see chapter 4).

• Set the GPIB bus address (see chapter 4).

• Set the RS-232 baud rate and parity (see chapter 4).

5

Page 12

In This Book

Quick Start Chapter 1 prepares the multimeter for use and helps you

get familiar with a few of its front-panel features.

Front-Panel Menu Operation Chapter 2 introduces you to the

front-panel menu and describes some of t he mu ltimeter’s menu fea tur es.

Features and Functions Chapter 3 gives a detailed description of the

multimeter’s capabilities and operation. You will find this chapter

useful whether you are oper ating the multimeter from the front panel or

over the remote in t er fac e.

Remote Interface Reference Chapter 4 contains reference

information to help you program th e m ultimeter over t he rem ote interface.

Error Messages Chapter 5 lists the error messages that may appear

as you are working with the multimeter. Each listing contains enough

information to help you diagnose and solve the problem.

Application Programs Chapter 6 contains several remote interface

application programs to help you develop programs for your

measurement application.

Measurement Tutorial Chapt er 7 discus ses measurement

considera ti ons an d te chn iq u es to hel p you obt ai n the bes t acc u rac ies

and reduce sources of measurement error.

Specifications Chapter 8 lists the multimeter’s specifications and

describes how to interpret these specifications.

If you have questions relating to the operation of the Agilent 34401A,

call 1-800-452-4844 in the United States, or contact your nearest

Agilent Sal es Of fic e .

If your 34401A fails within one year of purchase, Agilent will repair or

replace it free of charge. Call 1-877-444-7278 (“ Agile nt Expr ess”) in th e

United States, or c ontact you r neare st Agilen t Sales O ffice.

6

Page 13

Contents

Chapter 1 Quick Start

To Prepare th e Multimeter for Use 13

If the Multi meter Does Not Turn On 14

To Adjust the Carrying Handle 16

To Measure Volt ag e 17

To Measure Resis tan ce 17

To Measur e Cu rr en t 18

To Measure Frequency (or Period) 18

To Test Continuity 19

To Check Di ode s 19

To Select a Range 20

To Set th e R e s olu t i on 21

Front-Panel Display Formats 22

To Rack Mount the Multimeter 23

Chapter 2 Front-Panel Menu Operation

Front-Panel Menu Reference 27

A Front-Panel Menu Tutorial 29

To Turn Off the Comma Separator 37

To Make Null (Relative) Measurements 38

To Store Mi nimum and Maximum Rea dings 39

To Make dB Measurements 40

To Make dBm Measurements 41

To Trigger the Multimeter 42

To Use Reading Hold 43

To Make dcv :d cv R at io Measurements 44

To Use Reading Memory 46

Chapter 3 Features and Functions

Measurement Configura ti on

AC Signal Filter 51

Continuity Threshold Resistance 52

DC Input Resistance 53

Resolution 54

Integration Time 57

Front / Rear Input Terminal Switching 58

Autozero 59

Ranging 60

Contents

7

Page 14

Contents

Contents

Chapter 3 Features and Functions (continued)

Math Operations

Min-Max Operation 64

Null (Relative) Operation 65

dB Measurements 67

dBm Measurements 68

Limit Testing 69

Triggering

Trigger Source Choices 73

The Wait-for-Trigger State 76

Halting a Measurement in Progress 76

Number of Sample s 77

Number of Trigger s 78

Trigger Delay 79

Automatic Trigger Delays 81

Reading Hold 82

Voltmeter Complete Terminal 83

External Trigger Terminal 83

System-Related Operations

Reading Memory 84

Error Conditions 85

Self-Test 86

Display Control 87

Beeper Control 88

Comma Separators 89

Firmware Revision Query 89

SCPI Language Version Query 9 0

Remote Inte r face Configura tion

GPIB Address 91

Remote Int erf a ce Selection 92

Baud Rate Selection (RS -23 2) 93

Parity Selection (RS-232) 93

Programming Language Selection 94

Calibration

Calibration Security 95

Calibration Count 98

Calibration Message 99

Operator Maintenance

To Replace the Power-Line Fuse 100

To Replace the C urrent Input Fuses 100

Power-On and Reset State 101

8

Page 15

Contents

Chapte r 4 Remote Interface Reference

Command Su mmary 10 5

Simplified Prog r a m m in g O v erview 112

The MEASure? and CONFigure Commands 117

Measurement Conf iguration Commands 121

Math Operat ion Commands 124

Triggering 127

Triggering Commands 130

System-Rel ate d Commands 132

The SCPI Status Model 134

Status Rep orting Commands 144

Calibration C om ma n ds 146

RS-232 Interface Configuration 148

RS-232 Interf ace Commands 153

An Introd uct ion to the SCPI L an gu age 154

Output Data Formats 159

Using Device Clear to Halt Measurements 160

TALK ONLY for Printers 160

To Set the GPIB Addres s 161

To Select the R em ote Interface 162

To Set th e B au d Rate 163

To Set th e P arity 164

To Select the Programming Language 165

Alternate Programming Language Compatibility 166

SCPI Complianc e I nfo rmation 168

IEEE-488 Compliance Information 169

Contents

Chapter 5 Error Messages

Execution Errors 173

Self-Test Errors 179

Calibration E rr ors 180

Chapter 6 Application Programs

Using MEA Sure? for a Single Measur ement 185

Using CONFigure with a Math O p eration 186

Using the S tat us R eg is te rs 188

RS-232 Operation Using Quic kBASIC 192

RS-232 Operation Using Turbo C 193

9

Page 16

Contents

Contents

Chapte r 7 Measurement Tutorial

Thermal EMF Errors 199

Loading Errors (dc volts) 199

Leakage Current Errors 199

Rejecting Power-Line Noise Voltages 200

Common Mode Rejection (CMR) 201

Noise Caused by Magnetic Loops 201

Noise Caused by Ground Loops 202

Resistance Measur ements 20 3

4-Wire Ohms Meas ur em ents 203

Removing Test Lead Res istance Errors 204

Power Dissipat ion Effects 204

Settling T im e E f fec ts 204

Errors in High Resistance Measureme n ts 205

DC Curr en t Measurement Er rors 205

True RMS AC Measurements 206

Crest Fa ct or Errors 207

Loadi ng Errors (ac volts ) 209

Measurem ents Below Full Scale 210

High-Voltage Self-Heating Errors 210

Temperature Coefficient and Overl oad Errors 210

Low-Level Measurement Errors 211

Common Mode Errors 212

AC Current Measurement Errors 212

Frequency and P eri od M easurement Errors 213

Making H ig h- Speed DC and Resistance Measu rem ents 213

Making High - Sp eed AC M eas u r em en t s 214

Chapter 8 Specifications

DC Character is tic s 216

AC Character is tic s 218

Frequency and Peri od Ch aracteristics 220

General Information 222

Product Dimensions 223

To Calcula te Tot a l M eas urement Error 224

Interpreting Multimeter S pec ifications 226

Configur in g f or H ig h est Accuracy Meas u rements 229

Index 231

Declaration of Conformity 237

10

Page 17

1

1

Quick Start

Page 18

Quick Start

One of the first things you will want to do with your multimeter is to

become acquainted with its front panel. We have written the exercises

in this chapter to prepare the multimeter for use and help you g et

familiar with some of its front-panel operations.

The front panel has two rows of keys to select various functions and

operations. Most ke ys have a shifted function printed in blue above

the key. To perform a shifted function, press

annunciator will turn on). Then, press the key that has the desired

label above it. For example, to select the dc current function,

Shift DC V .

press

Shift (the Shift

If you accident a l ly press

Shift annunciato r.

The rear cover of this bo ok is a fold -out Qu ick Re feren ce Gu ide. On t his

cover you will fi nd a quick summary of various multi m eter feature s.

Shift , just press it again to turn off the

12

Page 19

Chapter 1 Quick Start

To Prepare the Multimeter for Use

To Prepare the Multimeter for Use

The following steps help you verify that the multimeter is ready for use.

1 Check the list of supplied ite ms.

Verify that you have received the following items with your multimeter.

If anyt hi ng i s mi s si ng , contact your n e ar e st A gilent Sales Of fi ce .

One test lead kit.

One power cord.

This User’s Guide.

One Service Guide.

One folded Quick Reference card.

Certificate of Calibration.

2 Connect the power cord a nd turn on the multimeter.

1

The front-panel display will light up while the multimeter performs its

power-on self-test. The

multimeter powers up in the dc voltage function with autoranging enabled.

To review the power-on display with all annunciators turned on,

hold down

3Perform a complete self-test.

The complete self-test per for m s a mor e ex ten sive s er ies of tests than

those performed at power-on. Hold down

Power switch to turn on the multimeter; hold down the key for more

than 5 seconds. The self-test will begin when you release the key.

If the self-test is successful, “

not successful, “

See the Service Guide for instructions on returning the multimeter to

Agilent for service.

Shift as you turn on the multi met e r.

FAIL” is displayed and the ERROR annunciator turns on.

GPIB bus address is displayed. Notice that the

Shift as you press the

PASS” is displayed. If the self-test is

13

Page 20

Chapter 1 Quick Start

If the Multimeter Does Not Turn On

If the Multimeter Does Not Turn On

Use the following steps to help solve problems you might encounter

when turning on the multimeter. If you need more help, see the

Service Gui de for instructions on returning the multimeter to Agilent for

service.

1 Verify that there is ac power to the multimeter.

First, verify that the multimeter’s Power switch is in the “On” position.

Also, make sure that the power cord is firmly plugged into the power

module on the rear panel. You shou ld als o mak e sure t hat t h e pow er

source you plugged the multimeter into is energized.

2 Verify the power-line voltage setting.

The line voltage i s set to the pr oper valu e for yo ur co un tr y when the

multimeter is shipped from the factory. Change the volta g e set ti ng if

it is not correct. The settings are: 100, 120, 220, or 240 Vac (for 230 Vac

operation, use the 220 Vac setting).

1

See the next page if you need to change the line-voltage setting.

3 Verify that the power-line fuse is good.

The multimeter is shipped from the factory with a 250 mA fuse

installed. This is the correct fuse for all line voltages.

See the next page if you need to replace the power-line fuse.

To replace the 250 mAT fuse, order Agilent part number 2110-0817.

14

Page 21

Chapter 1 Quick Start

If the Multimeter Does Not Turn On

1

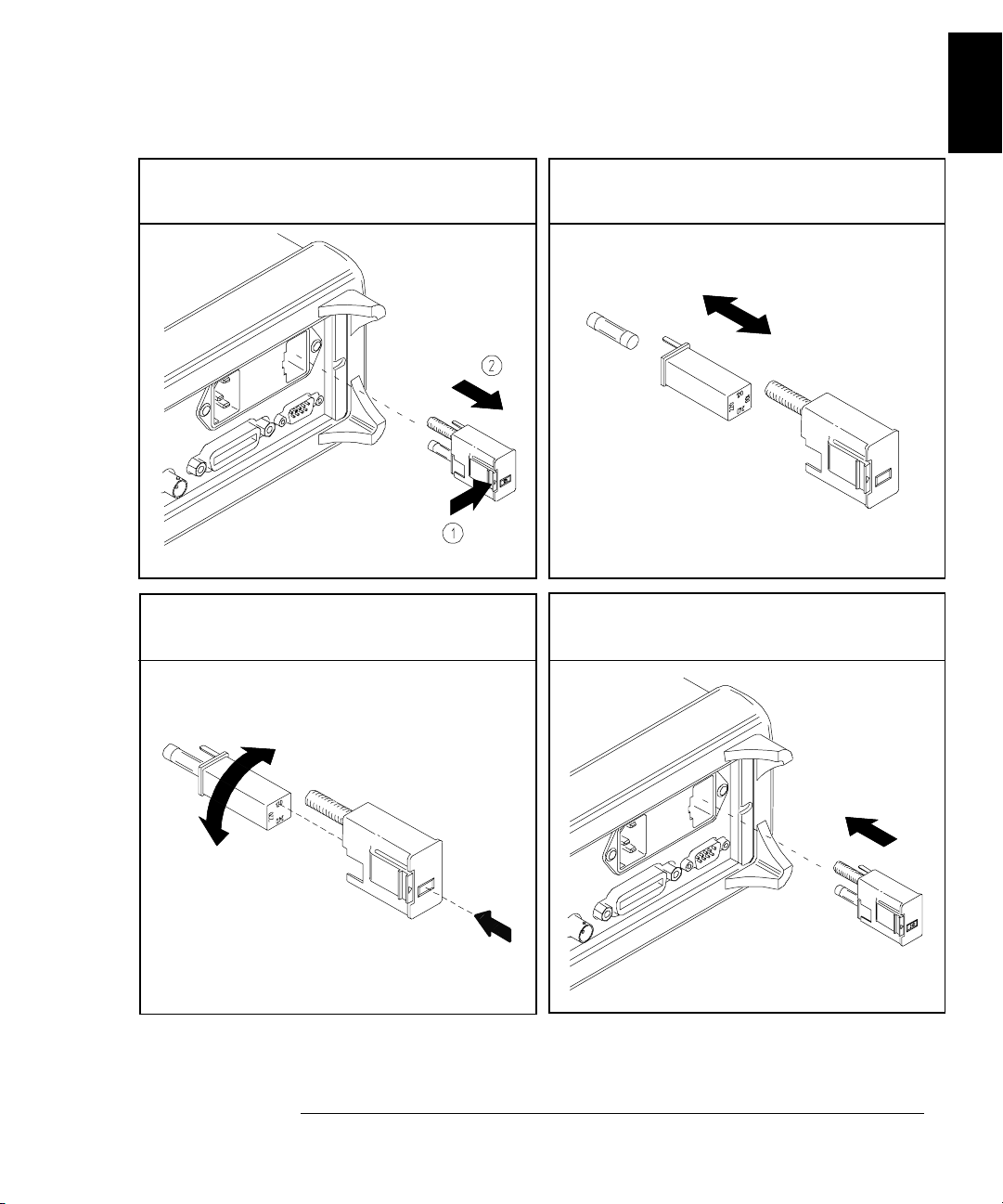

1 Remove the power cord. Remove the

fuse-holder assembly from the rear panel.

3 Rotate the line-voltage selector until the

correct voltage appears in the window.

2 Remove the line-voltage selector from

the assembly.

See rear panel for proper fuse rating.

Agilent Part Number: 2110-0817 (250 mAT)

4 Replace the fuse-h ol de r as sem bly in

the rear panel.

100, 120, 220 (230) or 240 Vac

Verify that the correct line voltage is selected and the power-line fuse is good.

15

Page 22

Chapter 1 Quick Start

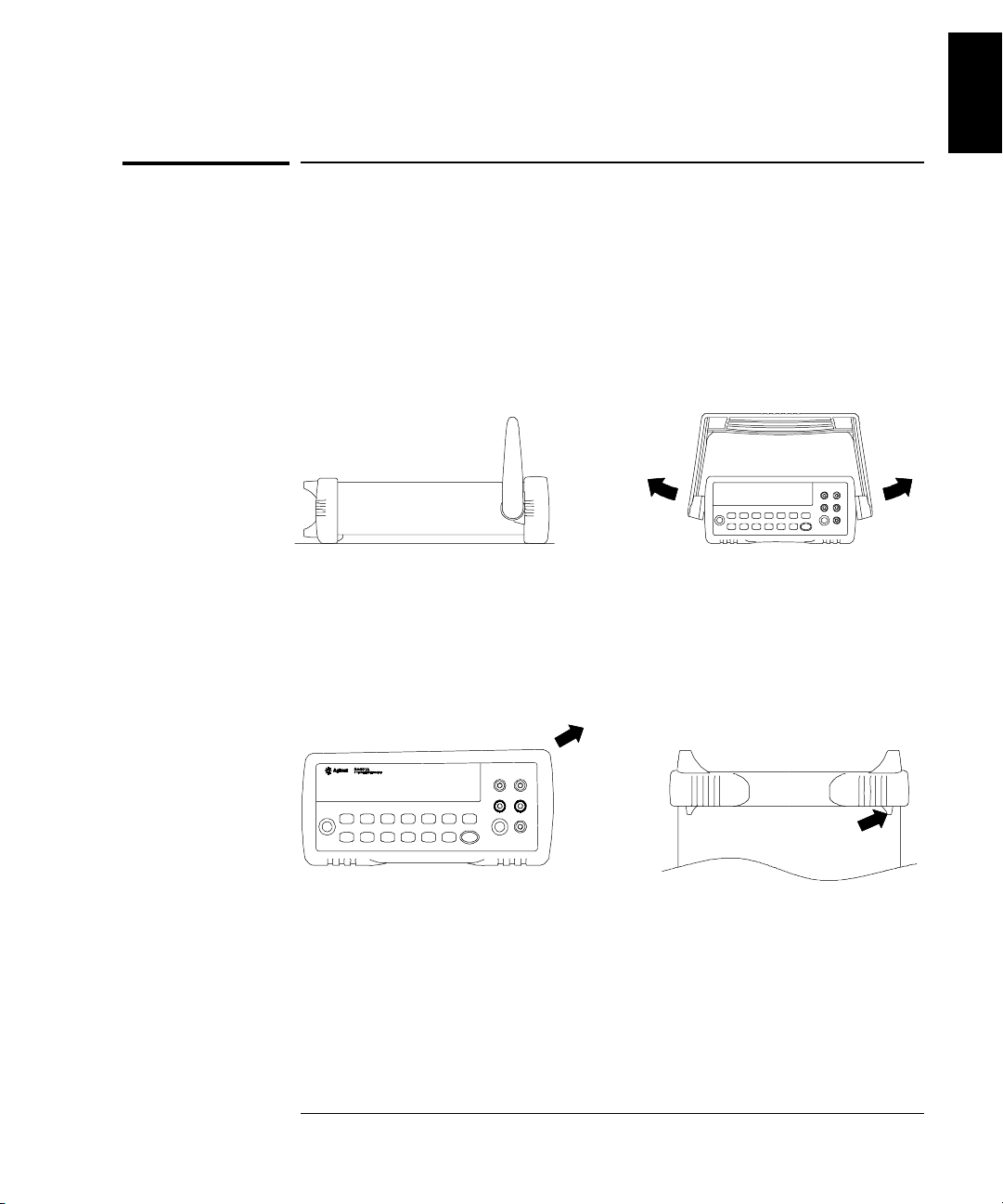

To Adjust the Carrying Handle

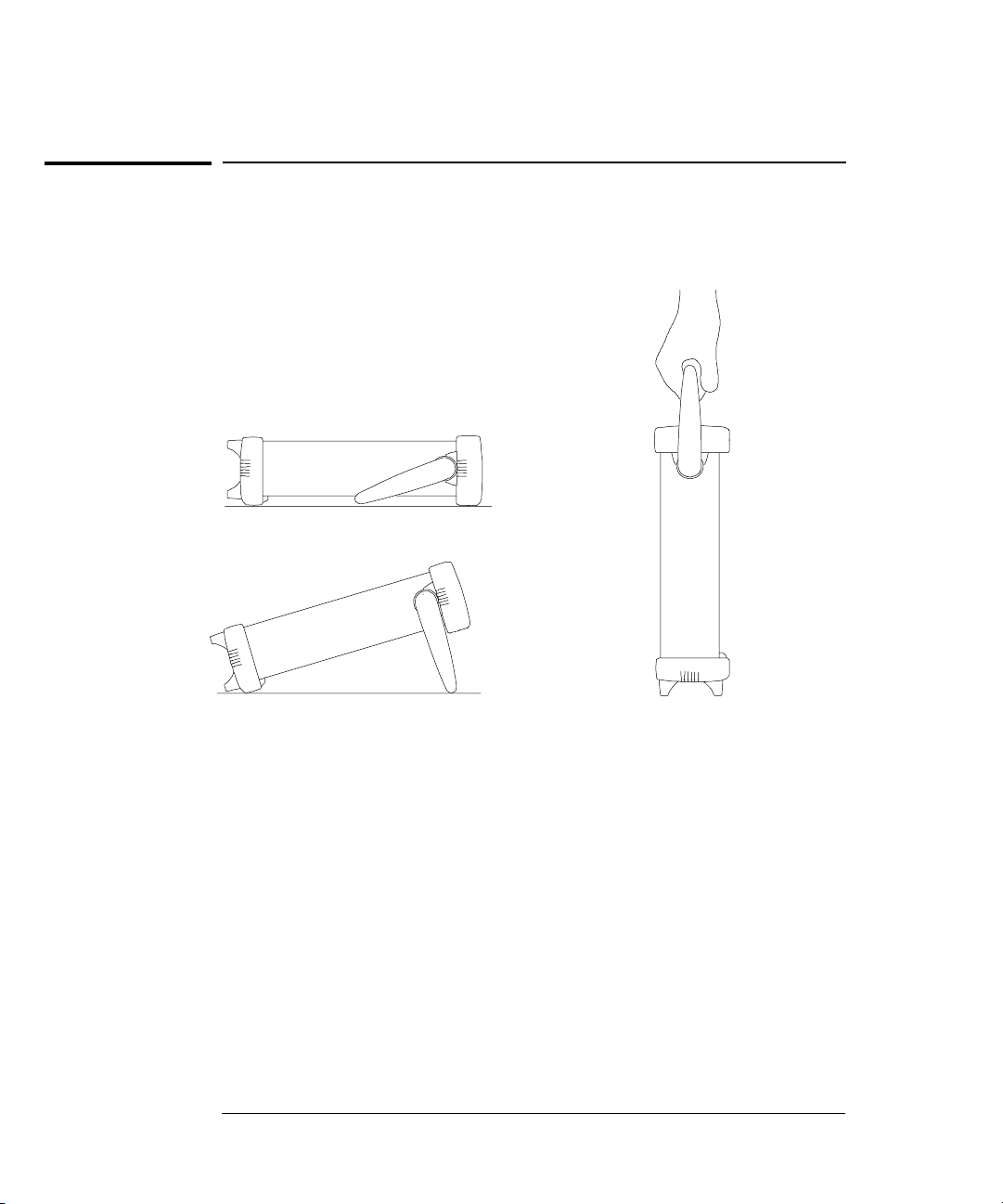

To Adjust the Carrying Handle

To adjust the position, grasp the handle by the sides and pu ll outward.

Then, rotate the handle to the desired position.

Bench-top viewing positions Carrying position

16

Page 23

Chapter 1 Quick Start

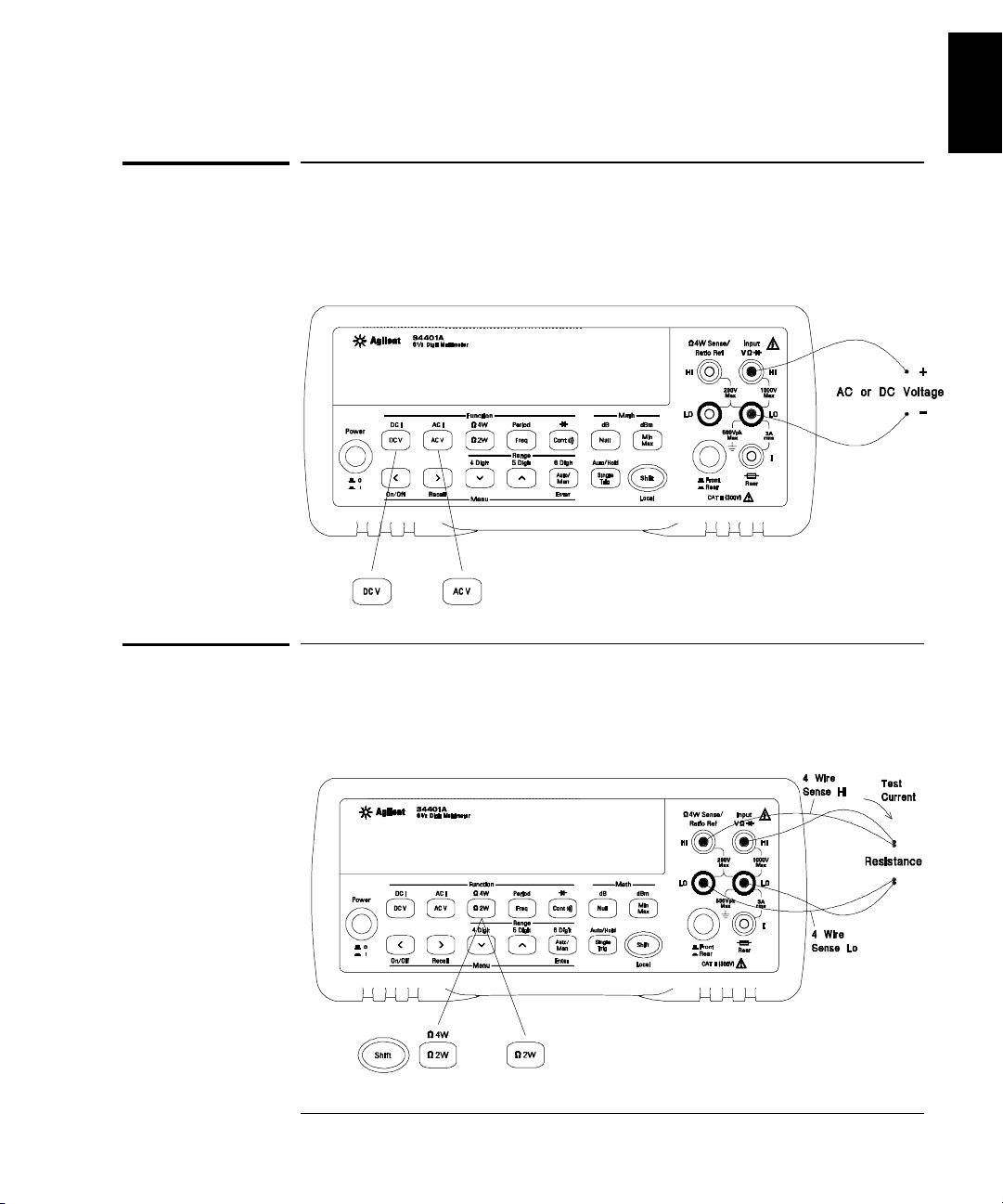

To Measure Voltage

To Measure Voltage

Ranges: 100 mV, 1 V, 10 V, 100 V, 1000 V (750 Vac)

Maximum resolution: 100 nV (on 100 mV range)

AC technique: true

RMS, ac-coupled

1

To Measure Resistance

Ranges: 100 Ω, 1 kΩ, 10 kΩ, 100 kΩ, 1 MΩ, 10 MΩ, 100 MΩ

Maximum resolution: 100 µΩ (on 100 ohm range)

17

Page 24

Chapter 1 Quick Start

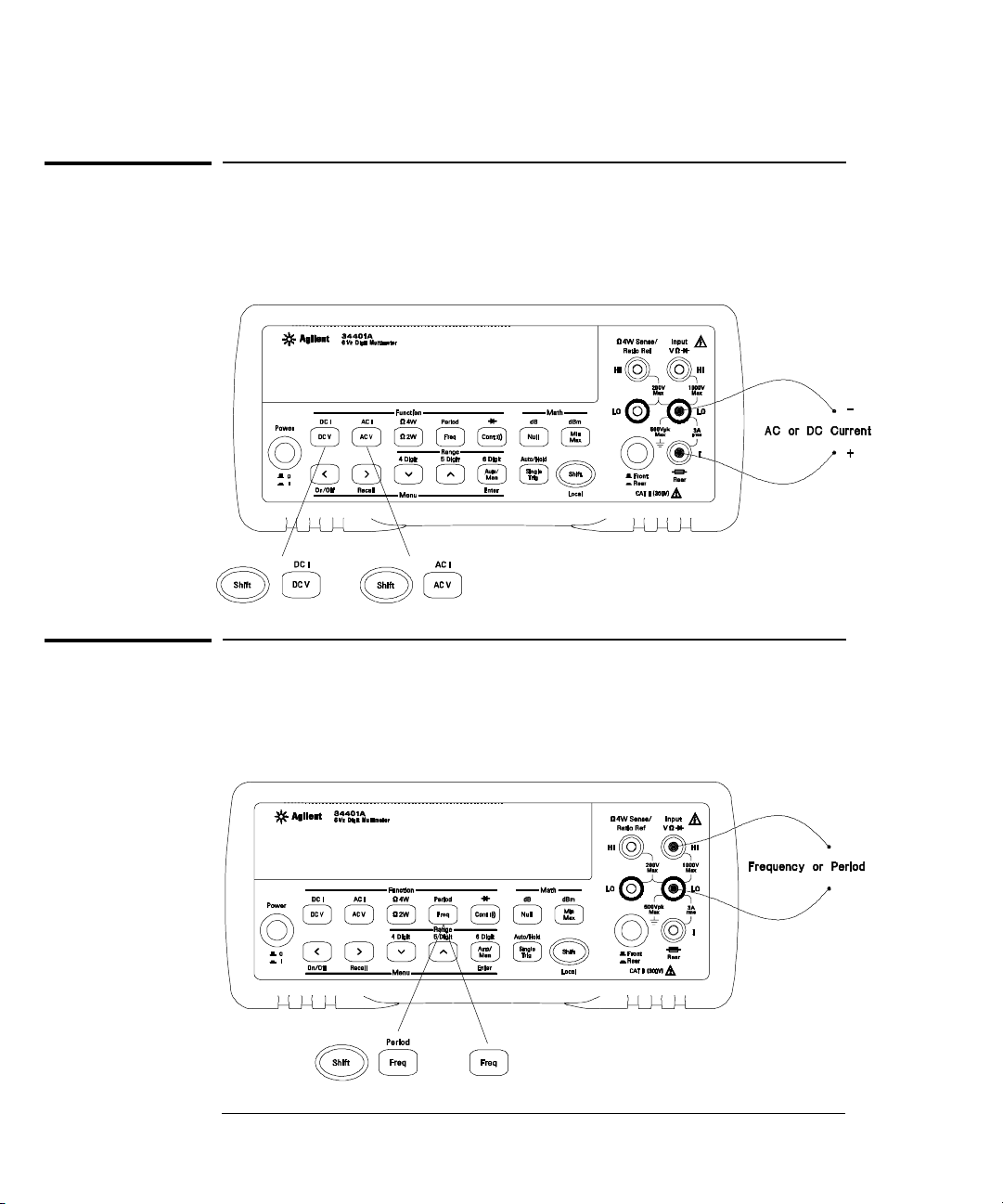

To Measure Current

To Measure Current

Ranges: 10 mA (dc only), 100 mA (dc only), 1 A , 3 A

Maximum resolution: 10 nA (on 10 mA range)

AC technique: true

RMS, ac-coupled

To Measure Frequency (or Period)

Measurement band: 3 Hz to 300 kHz (0.33 sec to 3.3 µsec)

Input signal range: 100 mVac to 750 Vac

Techniqu e: reciprocal co unt ing

18

Page 25

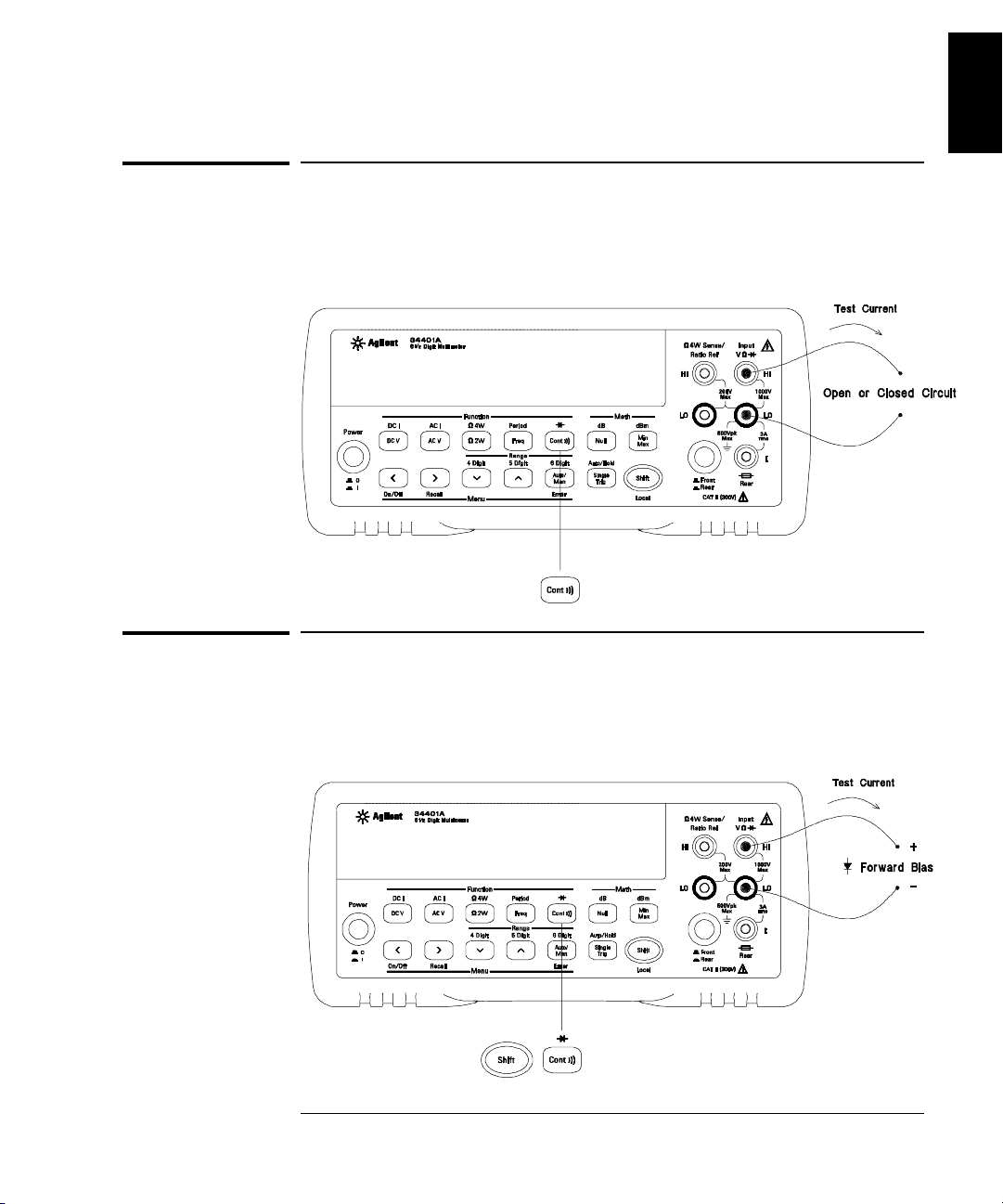

Chapter 1 Quick Start

To Test Continuity

To Test Continuity

Test current source: 1 mA

Maximum resolution: 0.1 Ω (rang e i s fi xed at 1 kohm)

Beeper threshold: 1 Ω to 1000 Ω (beeps below adjustable threshold)

1

To Check Diodes

Test current source: 1 mA

Maximum resolution: 100 µV (range is fix ed at 1 Vdc)

Beeper threshold: 0.3 volts ≤ V

measured

≤ 0.8 volts (not adjus table)

19

Page 26

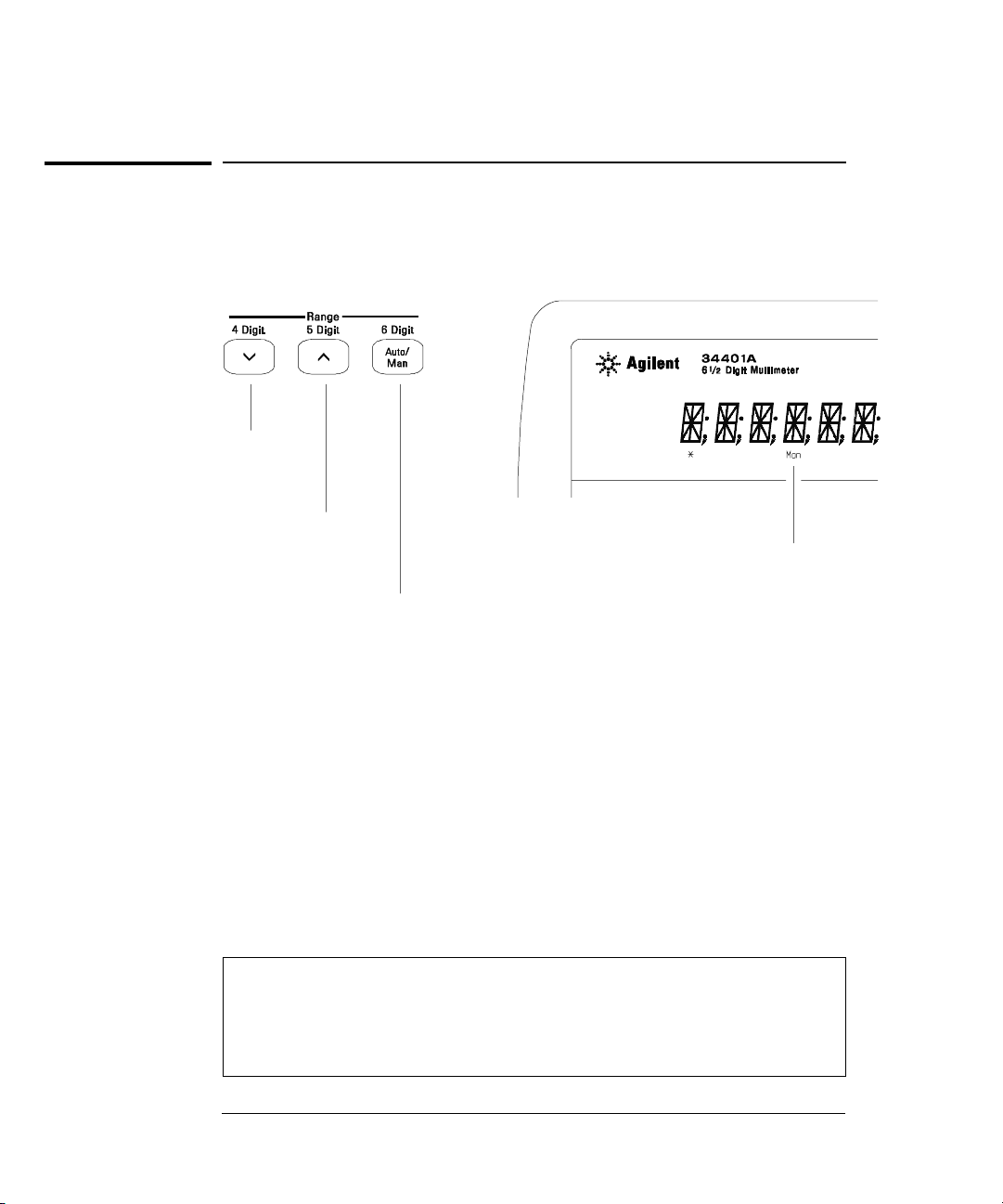

Chapter 1 Quick Start

To Select a Range

To Select a Range

You can let the multimeter automatically select the range using

autoranging or you can select a fixed range using manual ranging.

Selects a lower range and

disables autoranging.

Selects a higher range and

disables autoranging.

Man annu nci ator is on when

manual range is enabl ed.

Toggles betwee n aut or anging

and manual ranging.

• Autoranging is selecte d at power-on a nd a ft e r a re m o t e i nt e rfa ce reset.

• Autorange t h re sholds:

Down range at <1 0 % of range

Up range at >120% of range

• If the input signal is greater than the present range can measure,

the multimeter will give an overload indication (“

• For frequency and period measurements from the front panel,

OVLD”).

ranging applies to the signal’s input voltage, not its frequency.

• The range is fixed for co ntin u it y (1 kΩ range) and diode (1 Vdc rang e).

Ranging is local to the selected function. This means that you can select

the ranging method (auto or manual) for each function independently.

When manually ranging, the selected ran ge is local t o th e fu nction ;

the multimeter remembers the range when you switch between functions.

20

Page 27

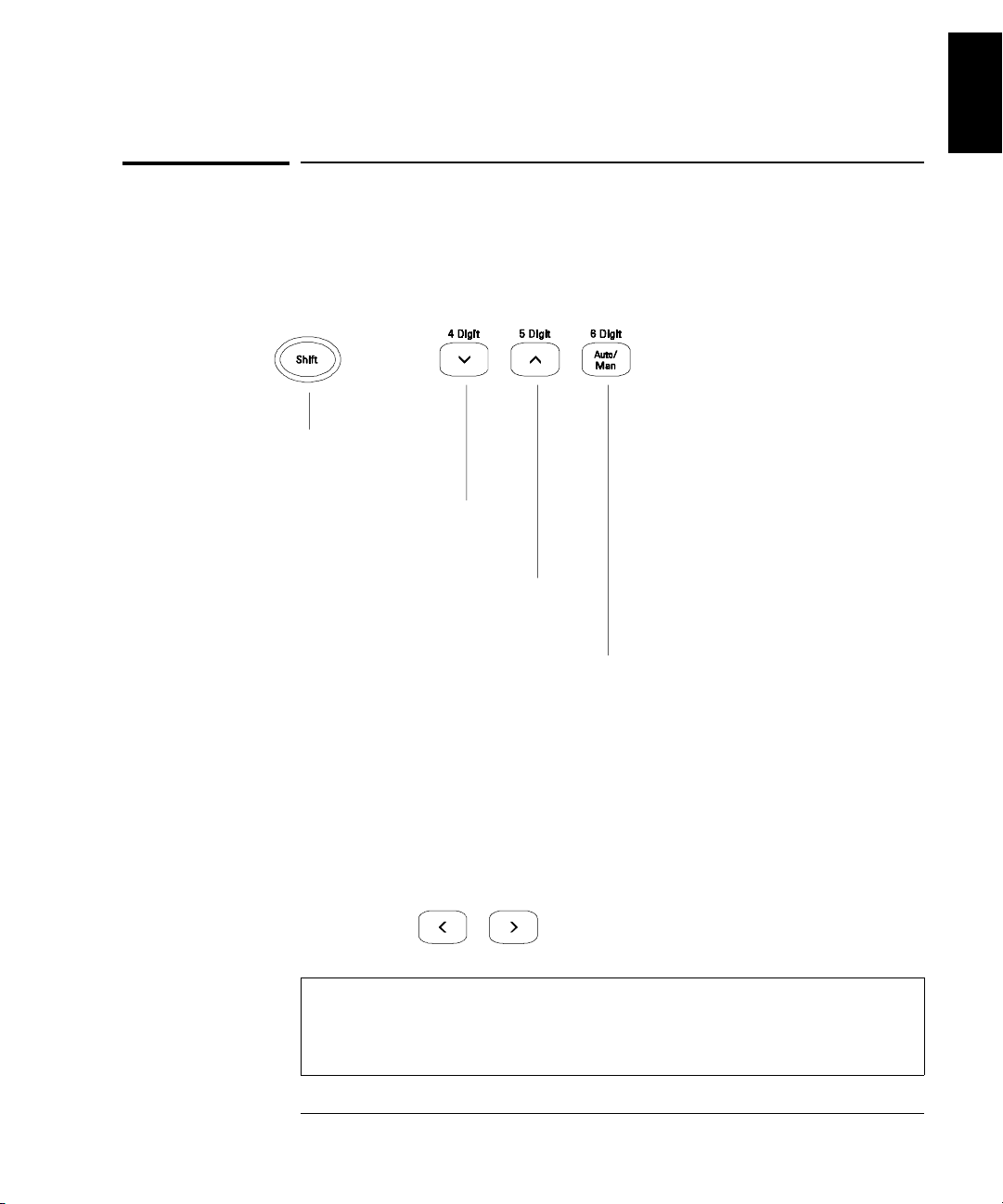

Chapter 1 Quick Start

To Set the Resolution

1

To Set the Resolution

You can set the display resolution to 4

1

1

⁄

, 5

2

⁄

, or 6

2

1

⁄

digits either to

2

optimize measur em ent spe ed or nois e reje ction. In this book, th e most

significant digit (leftmost on the display) is referred to as the “

1

⁄

” digit,

2

since it can only be a “0” or “1.”

Press the Shift key .

1

Sele cts 4

⁄2 digits.

Selects 5

1

⁄2 digits.

Selects 61⁄2 digits (most noise rejection).

• The resolution is set to 5

1

⁄

digits at power-on and after a remote

2

interface reset.

• The resolution is fixed at 5

• You can also vary the number of digits displayed using the arrow keys

1

⁄

digits for continuity and diode tests.

2

(however, the integration time is not changed).

Fewer More

Digits Digits

Resolutio n is local to t he selected func tion. This means t hat you can

select the r esolutio n for each fun ction inde pendently. T he multime ter

remembers the resolution when you switch between functions.

21

Page 28

5 digits

Chapter 1 Quick Start

Front-Panel Display Formats

Front-Pan el Display Formats

– Negative sign or blank (positive)

1

H “

-H.DDD,DDD EFFF

Front-pa ne l display form a t.

10.216,5 VDC

D Numeric digits

E Exponent ( m, k, M )

F Measurement units ( VDC, OHM, HZ, dB )

⁄2 ” digit (0 or 1)

“1⁄2” digi t

“1⁄2” digit

This is the 10 Vdc range, 5

1

⁄

digits are displayed.

2

-045.23 mVDC

This is the 100 mVdc range, 4

1

⁄

digits are displayed.

2

113.325,6 OHM

This is the 100 ohm range, 6

1

⁄

digits are displayed.

2

OVL.D mVDC

This is an overload indication on the 100 mV dc range.

22

Page 29

Chapter 1 Quick Start

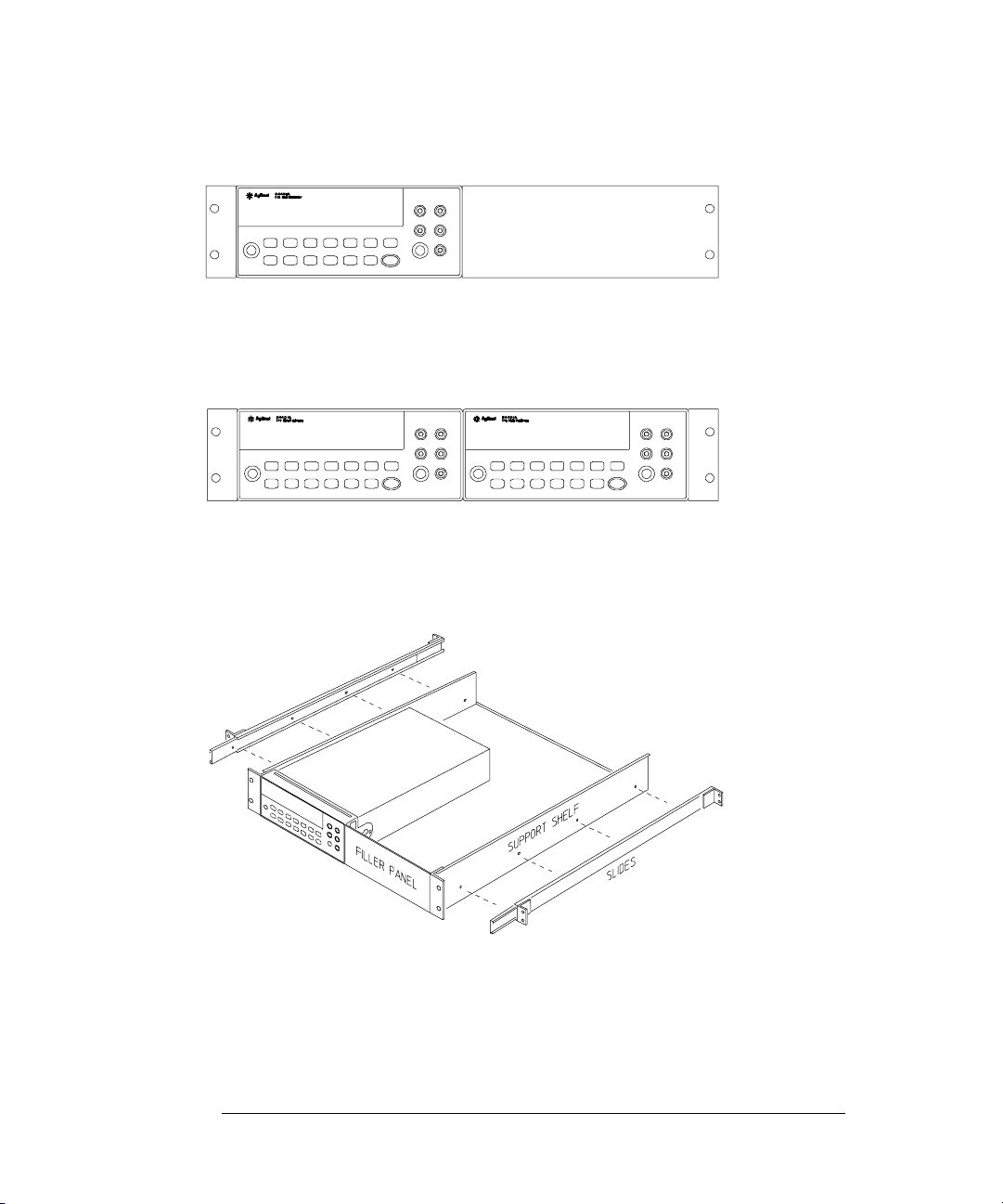

To Rack Mount the Multimeter

To Rack Mount the Multimeter

You can mount the multi m eter in a standard 1 9 -inch rack cabinet using

one of three optional kits available. Instr uction s and m ounting h ardw are

are included with each r ack-mou nting kit . Any

instrument of the same size can be rack-mounted beside the 34401A.

Remove the carrying handle, and the front and rear rubber bumpers,

before rack- m ounting the multi m eter.

Agilent System II

1

To remove the handle, rotate it to the vertical position and pull the ends outward.

Fron t

To remove the rubber bumper, stretch a corner and then slide it off.

Rear (bottom view)

23

Page 30

Chapter 1 Quick Start

To Rack Mount the Multimeter

To rack mount a single instrument, order adapter kit 5063-9240.

To rack mount two instruments side-by-side, order lock-link kit 5061-9694 and

flange kit 5063-9212.

To install one or two instruments in a sliding support shelf, order shelf 5063-9255,

and slide kit 1494-0015 (for a single instrument, also order filler panel 5002-3999).

24

Page 31

2

2

Front-Panel

Menu Operation

Page 32

Front-Panel Menu Operation

By now you should be f amiliar with the FUNCTION and RANGE / DIGITS

groups of fro nt -panel keys . You should als o understand how to ma ke

front-panel connections for the various types of measurements. If you

are not familiar with this information, we recommend that you read

chapter 1, “Quick Start,” starting on page 11.

This chapter introduces you to three new groups of front-panel keys:

MENU, MATH, and TRIG. You will also learn how to use the comma

separator and store readings in memory. This chapter does no t gi ve a

detailed description of every front-panel key or menu operation. It does,

however, give y ou a good ov er vie w of th e fro nt- pan el menu and many

front-panel operations. See chapter 3 “Features and Functions,” starting

on page 49, for a complete discussion of the multimeter’s capabilities

and operation.

26

Page 33

Chapter 2 Front-Panel Menu Operation

Front-Panel Menu Reference

Front-Panel Menu Reference

A: MEASurement MENU

1: AC FILTER > 2: CONTINUITY > 3: INPUT R > 4: RATIO FUNC > 5: RESOLUTION

1: AC FILTER

2: CONTINUITY

3: INPUT R

4: RATIO FUNC

5: RESOLUTION

Selects the slow, medium, or fast ac filter.

Sets the continuity beeper threshold (1 Ω to 1000 Ω).

Sets the input resistance for dc vol tage measurements.

Enables the dcv:dcv r atio functio n.

Selects the measure m ent resolution.

B: MATH MENU

1: MIN-MAX > 2: NULL VALUE > 3: dB REL > 4: dBm REF R > 5: LIMIT TEST > 6: HIGH LIMIT > 7: LOW LIMIT

1: MIN- MAX

2: NULL VALUE

3: dB REL

4: dBm REF R

5: LIMIT TEST

6: HIGH LIMIT

7: LOW LIMIT

Recalls the stored minimum, maximum, average, and reading count.

Recalls or sets the null value stored in the null register.

Recalls or sets the dBm value stored in the dB relative register.

Selects the dBm refer ence resistance value.

Enables or disables limit testing.

Sets the upper limit for limit testing.

Sets the lower limit for li mit testing.

C: TRIGger MENU

1: READ HOLD > 2: TRIG DELAY > 3: N SAMPLES

2

1: READ HOLD

2: TRIG DELAY

3: N SAMPLES

Sets the readin g ho ld se ns itiv ity ban d.

Specifies a time interval which is inserted before a measurement.

Sets the nu mb er of sa mp le s p er tr ig ge r .

27

Page 34

Chapter 2 Front-Panel Menu Operation

Front-Panel Menu Reference

D: SYStem MENU

1: RDGS STORE > 2: SAVED RDGS > 3: ERROR > 4: TEST > 5: DISPLAY > 6: BEEP > 7: COMMA > 8: REVISION

1: RDGS STORE

2: SAVED RDGS

3: ERROR

4: TEST

5: DISPLAY

6: BEEP

7: COMMA

8: REVISION

Enables or disables reading memory.

Recalls readings stored in memory (up to 51 2 readings).

Retrieves errors from the error queue (up to 20 errors).

Performs a complete self-test.

Enables or disables the front-panel display.

Enables or disables the beeper function.

Enables or disables a comma separator between digits on the display.

Displays the multim eter’s firmwa re revision codes.

E: Input / Output MENU

1: GPIB ADDR > 2: INTERFACE > 3: BAUD RATE > 4: PARITY > 5: LANGUAGE

1: HP-IB ADDR

2: INTERFACE

3: BAUD RATE

4: PARITY

5: LANGUAGE

F: CALibra tion MENU

1: SECURED > [ 1: UNSECURED ] > [ 2: CALIBRATE ] > 3: CAL COUNT > 4: MESSAGE

*

1: SECURED

1: UNSECURED

2: CALIBRATE

3: CAL COUNT

4: MESSAGE

Sets the GPIB bus address (0 to 31).

Selects the GPIB or RS-232 interface.

Selects the baud rate for RS-232 operation.

Selects even, odd, or no parity for RS -232 operation.

Selects the interface language: SCPI, Agilent 3478, or Fluke

8840/ 42.

The multimeter is secured against calibration; enter code to unsecure.

The multimeter is unsecured for calibration; enter code to secure.

Performs complete calibration of present function; must be UNSECURED.

Reads the total number of times the multimeter has been calibrated.

Reads the calibration string (up to 12 characters) entered from remote.

The commands enclosed in square brackets ( [ ] ) are “hidden” unless the multimeter is UNSECURED for calibration.

*

28

Page 35

Chapter 2 Front-Panel Menu Operation

A Front-Panel Menu Tutorial

A Front-Pan el Menu Tutorial

This section is a step-by-step tutorial which shows how to use the

front-panel menu. We recommend that you spend a few minutes with this

tutorial to get comfortable with the structure and operation of the menu.

The menu is organized in a top-down tree structure with three

levels (menus, commands, and parameters). You move down

or up

∧ the menu tree to get from one level to the next. Each of the

three levels has several horizontal choices which you can view by

moving left

< or right > .

Menus

Commands

∨

2

Parameters

• To turn on the menu, press Shift Menu On/Off .

• To turn off the menu, press Shift Menu On/Off , or press any of

the function or math keys on the top row of front-panel keys.

• To execute a menu command, press Enter .

• To recall the last menu command that was executed,

Shift Recall .

press

29

Page 36

Chapter 2 Front-Panel Menu Operation

A Front-Panel Menu Tutorial

MESSAGES DISPLAYED DURING MENU USE

TOP OF MENU You pressed while on the “menus” level; this is the top level of

the menu and you cannot go any higher.

To turn off the menu, press (Menu On/Off). To move across the choices

on a level, press or . To move down a level, press .

MENUS You are on the “menus” level. Press or to view the choices.

COMMANDS You are on the “commands” level. Press or to view the

command c hoices within the selected menu group.

PARAMETER You are on the “parameter” level. Press or to view and edit

the parameter for the selected command.

MENU BOTTOM You pressed while on the “parameter” level; this is the bottom

level of the menu and you cannot go any lower.

To turn off the menu, press (Menu On/Off). To move up a level,

press .

∧

CHANGE SAVED The change made on the “parameter” level is saved. This is

displayed after you press (Menu Enter) to execute the command.

MIN VALUE The value you specified on the “parameter” level is too small for th e

selected command. The minimum value allowed is displayed for you to edit.

MAX VALUE The value you specified on the “parameter” level is too large for the

selected command. The maximum value allowed is displayed for you to edit.

EXITING MENU You will see this message if you turn off the menu by pressing

(Menu On/Off) or a front-panel function/math key. You did not edit any values

Shift

<

on the “para meter” level and c hanges were NOT saved.

< >

∧

Shift <

∨

Shift

Auto/Man

<

<

>

<

<

∨

>

>

NOT ENTERED You will see this message if you turn off the menu by pressing

(Menu On/Off) or a front-panel function/math key. You did some editing of

<

Shift

parameters but the changes were NOT saved. Press (Menu Enter)

to save changes made on the “parameter” level.

NOT RELEVANT The selected math operation is NOT valid for the function in use.

Auto/Man

30

Page 37

Chapter 2 Front-Panel Menu Operation

A Front-Panel Menu Tutorial

Menu Example 1 The following steps sh ow you h ow to turn on the men u, mo ve up or

down between l evels, move across the choice s on each level, and turn of f

the menu. In this example, you will turn off the front-panel beeper.

On/Off

Shift <

> >

∨

>

1 Turn on the menu.

You enter the menu on the “menus” level. The

MEAS MENU is your first

choice on this level.

A: MEAS MENU

2 Move across to the

SYS MENU choice on this level.

There are six menu grou p choi c es a vaila bl e on the “menus” level. Eac h

choice has a letter pref ix for easy i dentification (

A: , B: , etc.).

D: SYS MENU

3 Move down to the “commands” level within the

RDGS STORE command is your first choice on this level.

The

SYS MENU.

1: RDGS STORE

2

31

Page 38

Chapter 2 Front-Panel Menu Operation

A Front-Panel Menu Tutorial

> > >

> >

∨

>

4 Move across to the BEEP command on the “commands” level.

There are eight command choices available in the

choice on this level has a n umber pr efix for ea sy identifi cation (

SYS MENU. Each

1: , 2: , etc.).

6: BEEP

5 Move down a level to the BEEP parameter choices.

The first parameter choice is “

setting is stored in non-volatile memory and “

ON” for the BEEP command (the beeper

ON” is the factory setting).

ON

6 Move across to the “OFF” choice.

There are two parameter choice s for

BEEP.

OFF

Auto/Man

ENTER

7 Save the change and turn off the menu.

The multimeter beeps and displays a message to show that the change

is now in effect. You are th en exi ted from the me n u.

CHANGE SAVED

32

Page 39

Chapter 2 Front-Panel Menu Operation

A Front-Panel Menu Tutorial

Menu Example 2 The following exercise demonstr a t es how to use the menu reca ll feature

as a shortcut to set the

BEEP command back to its original setting.

You must perform the steps in Exa m ple 1 before you start this exam pl e.

Shift

∨

>

Recall

>

1 Use menu recall to return to the

This returns you to the

BEEP command, which was the last command

BEEP command.

used before you exi ted t h e menu i n th e Exampl e 1.

6: BEEP

2 Move down to the

The first parameter choice is “

BEEP parameter choices.

OFF” (the current setting from Example 1).

OFF

3 Move across to the “ON” choice.

Set the parameter back to its original value.

ON

2

Auto/Man

ENTER

4 Save the change and turn off the menu.

The multimeter beeps and displays a message to show that the change

is now in effect. You are th en exi ted from the me n u.

CHANGE SAVED

33

Page 40

Chapter 2 Front-Panel Menu Operation

A Front-Panel Menu Tutorial

Menu Example 3 Some commands in the menu require that you enter a numeric

parameter value. The following steps show you how to enter a number

in the menu. For this example, you will set the null value to –2.0 volts.

Make sure the mul timeter is in th e dc voltage funct io n with 5

1

resolution displayed. Disconnect all inputs to the multimeter.

On/Off

Shift <

1 Turn on the menu.

⁄2 digits of

>

∨

>

You enter the menu on the “menus” level. The

MEAS MENU is your first

choice on this level.

A: MEAS MENU

2 Move across to the

MATH MENU choice on this level.

There are six menu grou p choi c es a vaila bl e on this l evel .

B: MATH MENU

3 Move down to the “commands” level within the MATH MENU.

MIN–MAX command is your first choice on this level.

The

1: MIN-MAX

4 Move across to the

NULL VALUE command on this level.

There are seven command choices available within the

2: NULL VALUE

34

MATH ME NU.

Page 41

Chapter 2 Front-Panel Menu Operation

A Front-Panel Menu Tutorial

∨

∨ ∨

>

5 Move down to edit the NULL VALUE parameter.

The null value should be 0.0 Vdc when you come to this point in the

menu for the first time. For this example, you will set the null value

to –2.0 volts.

∧000.000 mVDC

When you see the flashing “∧” on the left side of the displa y, you can

abort the edit and return to the “commands” level by pressing

6 Make the number negative.

The leftmost character on the display toggles between + and – .

-000.000 mVDC

7 Move the flashing cursor over to edit the first digit.

Notice that the leftmost digit is flashing.

∧ .

2

∧

∧

-000.000 mVDC

8 Increment the first digit until “ 2 ” is displayed.

You decrement or increment each digit independently. Neighboring

digits are not affected.

-200.000 mVDC

35

Page 42

Chapter 2 Front-Panel Menu Operation

A Front-Panel Menu Tutorial

< <

∧

Auto/Man

ENTER

9 Move the flashing cursor over to the “units” location.

Notice that the units are flashing on the right side of the display.

-200.000 mVDC

10 Increase the displayed number by a factor of 10.

Notice that the position of the decimal point changes and the displayed

number increases by a factor of 10.

-2.000,00 VDC

11 Save the change and turn off the menu.

The multimeter beeps and displays a message to show that the change

is now in effect. You are th en exi ted from the me n u.

CHANGE SAVED

Keep in mind that math null is turned on and –2.0 volts is used as

the null va lu e for m ea su r e men t s. To cl ear the null value, pres s

Null .

This is the end of the front-panel menu tutorial. The remainder of the

chapter discusses several of the most common front-panel operations.

36

Page 43

Chapter 2 Front-Panel Menu Operation

To Turn Off the Comma Separator

To Turn Off the Comma Separator

The multimet er can display re adi n gs on the fr on t panel w it h or with ou t

a comma separator. The following steps show how to disable the comma.

2

On/Off

Shift <

>

>

<

∨

>

∨

>

<

08.241,53 VDC

With comma separator

(factory setting) Without comma separator

08.24153 VDC

1 Turn on the menu.

A: MEAS MENU

2 Move across to the

SYS MENU choice on the “ menus” level.

D: SYS MENU

3 Move down a level and then across to the

COMMA command.

7: COMMA

4 Move down a level and then move across to the “OFF” choice.

Auto/Man

ENTER

OFF

5 Save the change and turn off the menu.

The comma separator setting is stored in non-volatile memory , and

does not ch ange when pow er has been off or a fter a r em ote int erface res et.

37

Page 44

Chapter 2 Front-Panel Menu Operation

To Make Null (Relative) Measurements

To Make Null (Relative) Measurements

Each null measurement, also called relative, is the difference between a

stored null value a nd the i n put signal.

Result = reading – null value

To read / edit the null value, use the MATH menu.

Enables null ope rati on;

Press again to di sable.

• You can make null m easurements wi t h a ny function exce pt

Math annunciator is on when

null operation is enabl ed.

continuity, diode, or ratio. The null operation is local to the selected

function ; when yo u chan g e fu nct ion s , null i s disab led.

• To null the test lead resistance for more accurate two-wire ohms

measurements, short the ends of the test leads together and then

press

Null .

• The first reading taken after you press Null is stored as the null

value in the Null Register. Any previously stored value is

replaced with the new value.

• After enabling null, you can edit the stored null value by

pressing

“

NULL VAL UE ” command in th e MATH MENU (only if null is

Shift > (Menu Recall). This takes you to the

enabled). Go down to the “paramete r” level, and then edit the

displayed value.

• The null register is c lear ed wh en yo u chan g e fu nct ion s , tu rn nul l off,

turn off the power, or perform a remote interface reset.

38

Page 45

Chapter 2 Front-Panel Menu Operation

To Store Minimum and Maximum Readings

To Store Minimum and Maximum Readings

You can store the minimum and maximum readings during a series

of measurements. The following discussion shows how to read the

minimum, maximum, average, and reading count.

To read the minimum, ma ximu m, average, and count,

use the MATH menu.

2

Enables min-max operation;

Press again to dis able.

• You can use min-max with an y funct ion except c ontinuity or diode test.

Math annunciator is on when

min-max operation is enabled.

The min-max operation is local to the selected function; when you

change functions, min-max is disabled.

•• After enabling min-max, you can read the stored minimum,

maximum, average, and count by pressing

This takes you to the “

MIN–MAX” command in the MATH MENU

Shift > (Menu Recall).

(only if min-m ax is enabled). Go down to the “parameter” level,

and then read the values by pressing

• The stored valu es are c l ear ed wh en yo u tu rn min- m ax off , tur n off the

< or > .

power, or perform a remote interface reset.

• The average is of all rea din gs t aken sin c e mi n-m ax w as en ab led (n ot

just the average of the stored minimum and maximum). The count is

the total number of readings taken since min-max was enabled.

39

Page 46

Chapter 2 Front-Panel Menu Operation

To Make dB Measurements

To Make dB Measurements

Each dB measurement is the difference between the input signal and a

stored relative value, with both values converted to dBm.

dB = reading in dBm – relative value in dBm

To read / edit the dB relativ e value, use the MATH menu .

Enables dB operat ion;

Press again to disa bl e.

• Select DC V or AC V .

• The first reading taken after you enable dB measurements is

Math annunciator is on when

dB operation is enabl ed.

converted to dBm and is stored as the relative value in the

dB Relative Register. Any previously stored value is replace d

with the new value.

• After enabling dB operations, you can edit the relative value by

pressing

command in the

Shift > (Menu Recall). This takes you to the “dB REL”

MATH MENU (only if dB is enabled ). Go down to

the “p a rame t er ” level, and then edit the value display ed.

• The register is cl ear ed when yo u c hang e fu nc tion s , tu rn dB off,

turn off the power, or perform a remote interface reset.

40

Page 47

Chapter 2 Front-Panel Menu Operation

To Make dBm Measurements

To Make dBm Measurements

The dBm operation calculates the power delivered to a resistance

referenced to 1 milliwatt.

dBm = 10 × Log

( reading

10

2

/ reference resistance / 1 mW )

To read / edit the dBm refer enc e res is tance,

use the MATH menu.

2

Enables dBm oper at ion;

Press again to dis able.

• Select DC V or AC V .

• The factory setting for the reference resistance is 600 Ω. To select a

different value, press

operations. This takes you to the “

MATH MENU (only if dBm is enabled).

Shift > (Menu Recall) after enabling dBm

dBm REF R” command in the

Math annunciator is on when

dBm operation is enabled.

Go down to the “ p ar am eter” level, and then selec t a value: 50, 75,

93, 110, 124, 125, 135, 150, 250, 300, 500, 600, 800, 900, 1000,

1200, or 8000 ohms.

• The reference resistance is stored in non-volatile memory, and does no t

change when power has been off or after a remote interface reset.

41

Page 48

Chapter 2 Front-Panel Menu Operation

To Trigger the Multimeter

To Trigger the Multimeter

You can trigger the multimeter from the front panel using single trigger

or auto trigger.

Enables single trigger

and triggers the multimeter.

Toggles betwe en aut o trigger

and reading hold.

• Auto trigger ing is ena bl ed w he n you tur n on the m u lti met er . Notic e

that the ∗ (sample) annunciator turns on during each measurement.

• Single triggering takes one reading each time yo u press Single

and then waits for the next trigger. Continue pressing this key to

trigger the multimeter.

Using an External Trigger

The external trigger mode is also enabled by pressi ng . It is like

the single trigger mode except that you apply a trigger pulse to the re ar-panel

Ext Trig terminal. The mult imet er is trigger ed on t he negative edge of a

TTL pulse.

The front-panel key is disabled when in remote.

Single

(sample) annunciator is on

∗

during each measur ement .

Trig annunciator is on when the

multimeter is waiting f or singl e

trigger (auto trigge r disabled).

Single

42

Page 49

Chapter 2 Front-Panel Menu Operation

To Use Reading Hold

To Use Reading Hold

The reading hold feature allows you to capture and hold a stable

reading on the display. When a stable reading is detected, the

multimeter emits a beep and holds th e value on the display.

To adjust the rea di ng hold sensitivity band,

use the TRIG men u.

2

Toggles between aut o trigger

and reading hold.

• Reading hold has an adjustable sen s iti vit y b an d to allow you to

Hold annunciator is on when

reading hold is enabled.

select which readings are considered stable enough to be displayed.

The band is expres sed as a percen t of re a din g on the s elec ted r a nge.

The multimeter will capture and display a new value only after three

consecutiv e r ea din g s ar e with in the b and .

• The default band is 0.10% of reading. After enabling reading hold,

you can choose a different band by pr essing

Shift >

(Menu Recall). This takes you to the “READ HOLD” command in

TRIG MENU (only if read ing hol d is enable d ).

the

Go down to the “ p ar am eter” level, and then selec t a value:

0.01%, 0.10%, 1.00%, or 10.00% of reading.

• The sensitivity band is stored in volatile memory; the multimeter

sets the band to 0.10% of reading when power has been off or after a

remote interface reset.

43

Page 50

Chapter 2 Front-Panel Menu Operation

To Make dcv:dcv Ratio Measurements

To Make dcv:dcv Ratio Measurements

To calculate a ratio, the multimeter measures a dc reference voltage

applied to the

terminals.

To enable ratio me asurem ent s, use the MEAS menu.

Sens e terminals and the voltage applied to the Input

Ratio =

dc signal voltage

dc reference voltage

Ratio annunciator is on when

• At the Sense te rminals, the reference voltage measurement function

ratio measurem ents ar e enabled.

is always dc voltage and has a maximum measurable input of

±12 Vdc. Autoranging is automatically selected for reference voltage

measurements on the

• The Input LO and Sense LO terminals must have a common reference

and cannot hav e a volta ge di ff er en ce grea ter than

• The specified measurement range applies only to the signal connected

to the

Input terminals. The signal on the Input terminals can be any

Sens e terminals.

±2 volts.

dc voltage up to 1000 volts.

44

Page 51

On/Off

Shift <

<

∨

<

Chapter 2 Front-Panel Menu Operation

To Make dcv:dcv Ratio Measurements

The following steps sh ow you h ow to selec t the ratio function usin g th e

front-panel menu.

1 Turn on the menu.

A: MEAS MENU

2 Move down a level and then across to the

RATIO FUNC command.

4: RATIO FUNC

2

∨

Auto/Man

ENTER

3 Move down to the “parameter” level.

For this command, there is only one choice on this level.

DCV:DCV

4 Select the ratio function and turn off the menu.

Notice that the

Ratio annunciator turns on.

CHANGE SAVED

To disabl e rat io measurements, select a dif ferent measurement functi on

by pressing any front-panel function key.

45

Page 52

Chapter 2 Front-Panel Menu Operation

To Use Reading Memory

To Use Reading Memory

The multimeter can store up to 512 readings in internal memory.

The following steps demonstrate how to store readings and retrieve them.

1 Select the functio n.

Select any measurement functi on. You can also sele ct Nu l l , Mi n–Max,

dB, dBm, or limit test. You can change the function at any time during

reading memory.

Single

On/Off

Shift <

> > >

∨

2 Select the sing le trigger mode.

Notice that the

Tri g annunciator turns on. When reading memory is

enabled, read i ngs are s t ored wh en yo u tr igger the mul tim eter .

For this example, single triggering is used to store readings. You can also

use auto triggering or reading hold.

3 Turn on the menu.

A: MEAS MENU

4 Move across to the

SYS MENU choice on this level.

D: SYS MENU

5 Move down to a level to the

RDGS STORE command.

1: RDGS STORE

46

Page 53

Chapter 2 Front-Panel Menu Operation

To Use Reading Memory

Auto/Man

ENTER

Single

Single

Single

Recall

Shift >

> ∨

6 Move down a level and then across to the “ON” choice.

ON

2

7 Save the change and exit the menu.

Notice that the

multimeter is ready to store readings. Up to 512 readings can be stored

in fir st-i n-f irs t-ou t (

will turn off.

Readings are preserved until you re-enable reading memory at another

time, tur n of f the power, or per fo rm a remote inter face reset.

8 Trigger the multimeter three times.

This stores three readings in memory.

9 Use menu recall to retrieve the stored readings.

This takes you to the “

Mem (memory) annunciator turns on to indicate that t he

FIFO) order. When memory is full, the Mem annunciator

SAVED RDGS” command in the SYS M E NU.

2: SAVED RDGS

47

Page 54

Chapter 2 Front-Panel Menu Operation

To Use Reading Memory

∨

>

>

On/Off

Shift <

10 Move down a level to view the first stored reading.

Reading memory is automa tically tu rned off when you go to the

“parameter” level in the menu .

The first readi ng displayed is the first reading that was stor ed (F I FO).

If no readings are s tor ed in mem ory , “

EMPTY” is displayed. The stored

readings are displayed with their units ( µ, m, k, etc.) when appropriate.

For example:

Reading number

10.31607K: 1

Exponent

11 Move across to view the two remaining stored readings.

The readings a re stored horizontally on the “paramet er ” level.

If you press

< when you get to the “parameter” level, you will see the

last reading and you will know how many readings were stored.

12 Turn off the menu.

EXITING MENU

48

Page 55

3

3

Features and

Functions

Page 56

Features and Functions

You will find that this chapter makes it easy to look up all the details

about a partic ular feat u r e of the mu lt imet er . Whet h er you are oper at ing

the multimeter from the front panel or from the remote interface, this

chapter will be useful. This chapter is divided into the following sections:

• Measurement Configuration, starting on page 51

• Math Operations, starting on page 63

• Triggering, starting on page 71

• System-Rela ted O per a ti ons , star ti ng on page 84

• Remote Interface Configuration, starting on page 91

• Calibration Overview, starting on page 95

• Operator Maintenance, star ti ng on page 10 0

• Power-On and Reset State, on page 101

Some knowledge of the front-panel menu will be helpful before you read

this chapter. If you have not already read chapter 2, “Front-Panel Menu

Operation,” starting on page 25, you may want to read it now. Chapter 4,

“Remote Interface Reference,” starting on page 103, lists the syntax for

the

SCPI commands available to program the multimeter.

Throughout this manual, the following conventions are used for

SCPI command syntax f o r remote interface programming.

• Square brackets ( [ ] ) indicate optional keywords or parameters.

• Braces ( { } ) enclose parameters within a command string.

• Triangle brackets ( < > ) indicate that you must substitute a value

for the enclosed parameter.

• A vertical bar (

|

) separates multiple parameter choices.

50

Page 57

Chapter 3 Features and Functions

Measurement Configuration

Measurement Configuration

This secti on contains information to help you config ure the multimet er

for making measurements. You may never have to change any of the

measurement parameters discussed here, but they are provided to give

you the flexibility you might need.

AC Signal Filter

The multimet er uses thr ee diffe re nt a c filte rs whi c h enabl e you to eith er

optimize low frequency accuracy or achieve faster ac settling times.

The multimeter selects the slow, medium, or fast filter based on the

input freque ncy t ha t you specify.

Applies to ac vo ltage and ac current measurements only.

3

Input Frequency

3 Hz to 300 kHz

20 Hz to 300 kHz

200 Hz to 300 kHz

• The ac filter selection is stored in volatile memory; the multimeter

AC Filter Selected

Slow f ilter

Mediu m filt er (d ef au lt )

Fast filter

Settling Time

7 seconds / reading

1 reading / second

10 readings / second

selects the medium filter (20 Hz ) when pow er has been off or aft er a

remote interface reset.

• Front-Panel Operation: Select from the menu the slo w filter (3 Hz),

medium filter (20 Hz), or fast filter (200 Hz). The default is the

medium filter.

1: AC FILTER (MEAS MENU)

• Remote Interface Operation: Spec ify the lowest fr equ en cy ex pec t ed in

the input signal. The multimeter selects the appropriate filter based

on the frequency you specify (see table above). The CONFigure and

MEASure? commands select the 20 Hz filter.

DETector:BANDwidth {3|20|200|MINimum|MAXimum}

51

Page 58

Chapter 3 Features and Functions

Measurement Configuration

Continuity Threshold R esistance

When measuring continuity, the multimeter emits a continuous tone if

the measured resistance is less than the threshold resistance. You can

set the threshold to any value between 1

The threshold resistance is adjustable only from the fro nt panel.

• The threshold resistance is stored in non-v olatile mem or y, an d does not

change when power has been off or after a remote interface reset.

• The factory setting for the threshold resistance is 10 Ω.

• After enabling the continuity function, you can select a different

threshold resistance by pressing

Ω and 1000 Ω.

Shift > (Menu Recall).

2: CONTINUITY (MEAS MENU)

See also “To Test Conti nuity,” on page 19.

∧0010 OHM

52

Page 59

Chapter 3 Features and Functions

Measurement Configuration

DC Input Resistance

Normally, the multimeter’s input resistance is fixed at 10 MΩ for a ll

dc voltage ranges to mini mize n oi se pi cku p. To r edu ce the effects of

measurement loading errors, you can set the input r esi stance to greater

than 10 G

Applies to dc voltage meas ureme nts an d is d isabled for all oth er fu nc tions.

Fixed Resistance ON

Fixed Resistance OFF

• The input resi stan c e set ting is stor ed i n volatile memory; the

multimeter selects 10 M

has been off or after a remote interface reset.

Ω for the 100 mVdc, 1 Vdc, and 10 Vdc ranges.

Input Resistance Input Resistance

100mV, 1V, 10V ranges 100V, 1000V ranges

(default)

10 MΩ 10 MΩ

> 10 GΩ 10 MΩ

Ω (for all dc voltage ranges) wh en pow er

3

• Front-Panel Operation: Select from the menu the 10 MΩ mode (fixed

resistance fo r all d c volt a ge ranges) or the >10 G

is 10 M

Ω.

Ω mode. The default

3: INPUT R (MEAS MENU)

• Remote Interface Operation: You can enable or disable the automatic

input resistance mode. With

is fixed at 10 M

is set to >10 G

Ω for all ranges. With AUTO ON, t he input resistance

Ω for the three lowest dc voltage ranges. Th e CONFigure

and MEASure? commands automatically turn

AUTO OFF (default), the input resistance

AUTO OFF.

INPut:IMPedance:AUTO {OFF|ON}

53

Page 60

Chapter 3 Features and Functions

Measurement Configuration

Resolution

Resolution is expr es sed in t er ms of number of digits the multimeter can

measure or display. You can set the resolution to 4, 5, or 6 full digits,

plus a “

accuracy and improve noise rejection, select 6

measurement speed, select 4

Applies to all measurement functions. The resolution for the math

operations (null, min-max, dB, dBm, limit test) is the same as the

resolution for the measurement function in use.

The correspondence between the number of digits selected and the

resulting integration time (in power line cycles) is shown below.

The autozero mode is set indirectly when you set the resolution.

See also “Autozero,” on page 59.

1

⁄

” digit which can only be a “0” or “1”. To increase measurement

2

1

⁄

digits.

2

1

⁄

digits. To increase

2

Resolution Choices

Fast 4 Digit

* Slow 4 Digit

Fast 5 Digit

* Slow 5 Digit (default)

* Fast 6 Digit

Slow 6 Digit

* These settings configure the multimeter just as if you had pressed

the corresponding “DIGITS” keys from the front panel.

Integration Time

0.02 PLC

1 PLC

0.2 PLC

10 PLC

10 PLC

100 PLC

Resolutio n is local to t he selected func tion. This means t hat you can

select the r esolutio n for each fun ction inde pendently. T he multime ter

remembers the resolution when you switch between functions.

54

Page 61

5 digits

Chapter 3 Features and Functions

Measurement Configuration

10.216,5 VDC

“1⁄2” digi t

“1⁄2” digit

This is the 10 Vdc range, 5

1

⁄

digits are displayed.

2

-045.23 mVDC

This is the 100 mVdc range, 4

1

⁄

digits are displayed.

2

113.325,6 OHM

This is the 100 ohm range, 6

1

⁄

digits are displayed.

2

• The resolutio n is stor ed in volatile memory; the multimeter sets the

resolution to 5

1

⁄

digits (for all functions) when power has been off or

2

after a remote interface reset.

• The resolution is fixed at 5

• For dc and resistance measurements, changing the number of digits

1

⁄

digits for continuity and diode tests.

2

does more than just change the resolution of the multimeter. It also

changes the integration time, which is the period the multimeter’s

analog-to-digital (A/D) converter samples the input signal for a

measurement. See also “Integration Tim e,” on page 57.

• For ac measurements, the resolution is actually fixed at 6

If you select 4

1

⁄

digits or 5

2

1

⁄

digits, the multimeter “masks” one or

2

1

⁄

digits.

2

two digits. The only way to c ontrol th e reading r ate for ac meas urements

is by setting a trigger delay (see page 79).

3

• For ratio measurements, the specified resolution applies to the signal

connected to the

Input terminals.

55

Page 62

Chapter 3 Features and Functions

Measurement Configuration

Resolution

(continued)

• Front-Panel Operation: Select either the slow or fa st mode for eac h

resolution setting. The default m ode is 5 digits slow.

5: RESOLUTION (MEAS MENU)

See also “To Set the Resolution,” on page 21.

• Remote Interface Operation: You can set the resolution using the

foll owing commands.

CONFigure:<

MEASure:<

<

function>:RESolution {<resolution>|MIN|MAX}

function> {<range>|MIN|MAX|DEF},{<resolution>|MIN|MAX|DEF}

function>? {<range>|MIN|MAX|DEF},{<resolution>|MIN|MAX|DEF}

Specify the resolution in the same units as the measurement

function, not in number of digi ts . For ex ampl e, for dc volts , specify the

resolution in volts. For frequency, specify the resolution in hertz.

1

⁄

CONF:VOLT:DC 10,0.001 4

MEAS:CURR:AC? 1,1E-6 6

digits on the 10 Vdc range

2

1

⁄

digits o n th e 1 A ra n g e

2

CONF:FREQ 1 KHZ,0.1 Hz 1000 Hz input, 0.1 Hz resolution

VOLT:AC:RES 0.05 50 mV resolution on the ac function

56

Page 63

Chapter 3 Features and Functions

Measurement Configuration

Integration Time

Integration time is the period during which the multimeter’s analog-todigital (A/D) converter samples the input signal for a measurement.

Integration time affects the measurement resolution (for better resolution,

use a longer integration time), and measurement speed (for faster

measurements, use a shorter integration time).

Applies to all measurement functions except ac voltage, ac current,

frequency, and period. The integration time for the math operations

(null, min-max, dB, dBm, limit test) is the same as the integration time

for the measurement function in use.

• Integration time is specified in num b er of power line cycles (NPLCs).

The choices are 0.02, 0.2, 1, 10, or 100 power line cycles. The default

is 10 PLCs.

• The integration time is stored in volatile memory; the multimeter

selects 10 PLCs when power has been off or after a remote

interface reset.

3

• Only the integral number of power line cycles (1, 10, or 100 PLCs)

provide normal mode (line frequency noise) rejection.

• The only way to contr ol th e reading rate for ac measurement s is by

setting a trigger delay (see page 79).

• The following table shows the relationship between integration time

and measurement resolution.

Integration Time

0.02 N PLC

0.2 NPLC

1 NPLC

10 NPLC

100 NPLC

Resolution

0.0001 x Full-Scale

0.0000 1 x Full-Scale

0.000003 x Full-Scale

0.000001 x Full-Scale

0.0000 00 3 x F ull -S ca le

57

Page 64

Chapter 3 Features and Functions

Measurement Configuration

Integration Time

(continued)

• Front-Panel Operation: Integration time is set indirectly when you

select the numbe r o f d i gi t s. See the table for resolution on page 54.

• Remote Interface Operation:

<

function>:NPLCy cles {0.02|0.2|1|10|100|M INimum|MAXimum}

For frequenc y an d per iod m eas urem e nts , aperture time (or gate time)

is analogous to integration time. Specify 10 ms ( 4

(default; 5

1

⁄

digits), or 1 second (6

2

1

⁄

digits).

2

1

⁄

digits), 100 ms

2

FREQuency:APERture {0.01|0.1|1|MINimum|MAXimum}

PERiod:APERture {0.01|0.1|1|MINimum|MAXimum}

Front / Rear Input Terminal Switching

Any measurement made using the front terminals can also be made

using the input terminals on the rear panel. See “The Front Panel at

a Glance,” on page 2, for the location of the front / rear switch.