Page 1

Service Guide

Publication Number 33120-90017 (order as 33120-90104 manual set)

Edition 6, March 2002

© Copyright Agilent Technologies, Inc. 1994-2002

For Safety information, Warranties, and Regulatory information,

see the last page in this manual.

Agilent 33120A

15 MHz Function /

Arbitrary Waveform Generator

Page 2

Page 3

Note: Unless otherwise indicated, this manual applies to all Serial Numbers.

The Agilent Technologies 33120A is a high-performance 15 MHz

synthesized function generator with built-in arbitrary waveform

capability. Its combination of bench-top and system features makes this

function generator a versatile solution for your testing requirements now

and in the future.

Convenient bench-top features

10 standard waveforms

Built-in 12-bit 40 MSa/s arbitrary waveform capability

Easy-to-use knob input

Highly visible vacuum-fluorescent display

Instrument state storage

Portable, ruggedized case with non-skid feet

Flexible system features

Warning

Four downloadable 16,000-point arbitrary waveform memories

GPIB (IEEE-488) interface and RS-232 interface are standard

SCPI (Standard Commands for Programmable Instruments) compatibility

Agilent IntuiLink Arb Waveform Generation Software for

Microsoft

The procedures in this manual are intended for use by qualified,

service-trained personnel only.

®

Windows

®

Agilent 33120A

15 MHz Function /

Arbitrary Waveform Generator

Page 4

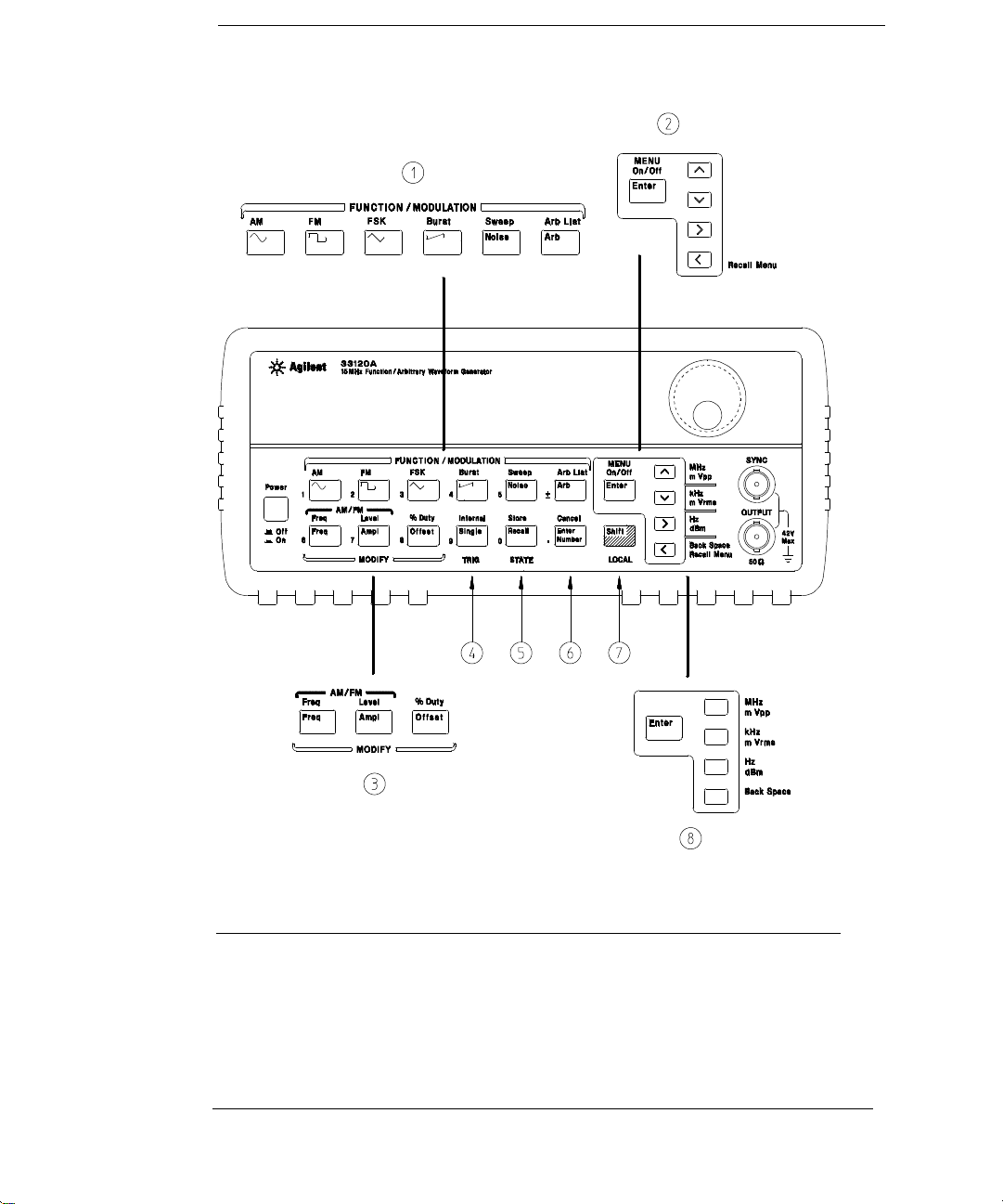

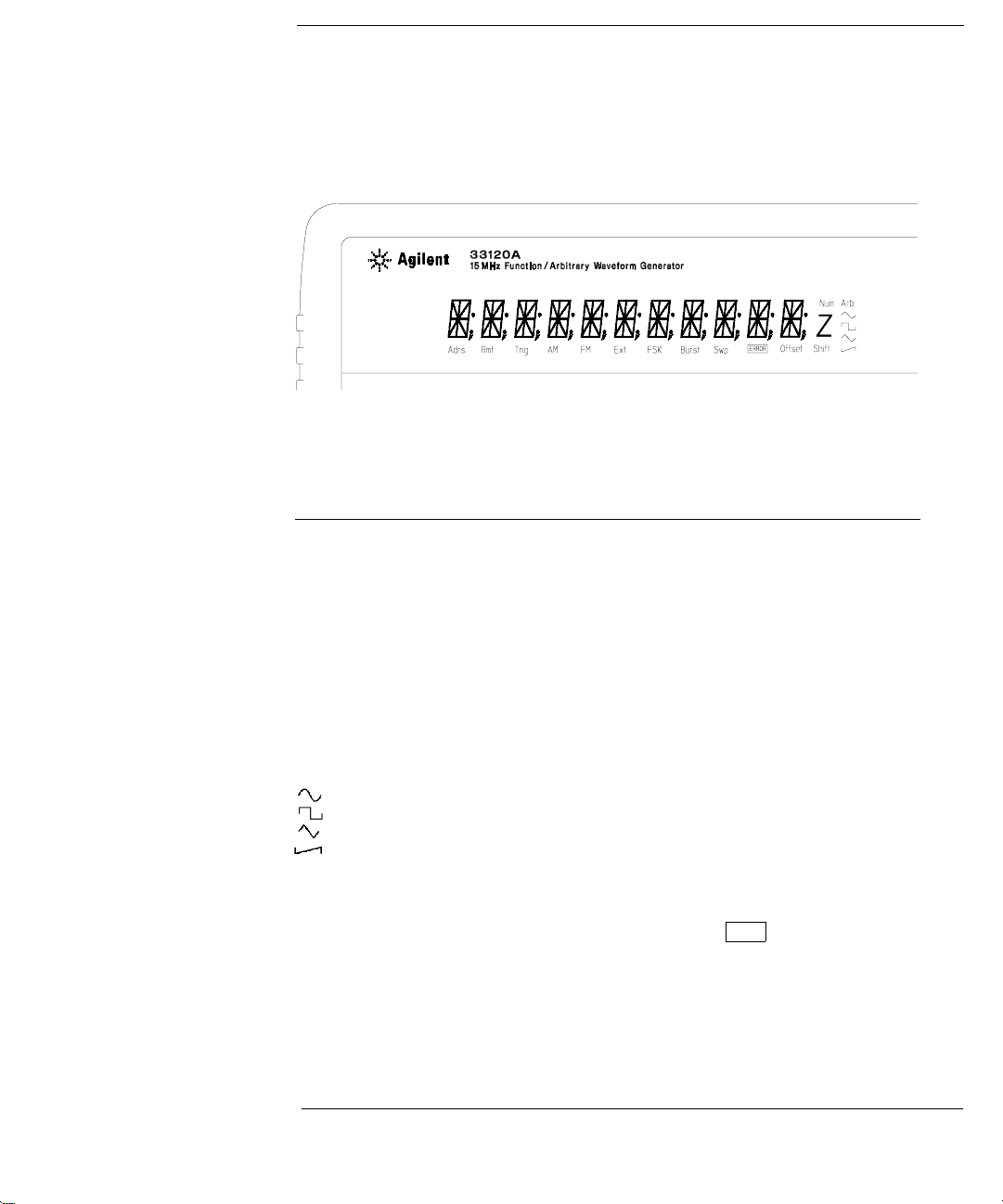

The Front Panel at a Glance

1 Function / Modulation keys

2 Menu operation keys

3 Waveform mod ify keys

4 Single / Internal Trigger key

(Burst and Sweep only)

2

5 Recall / Store instrument state key

6 Enter Number key

7 Shift / Local key

8 Enter Number “units” keys

Page 5

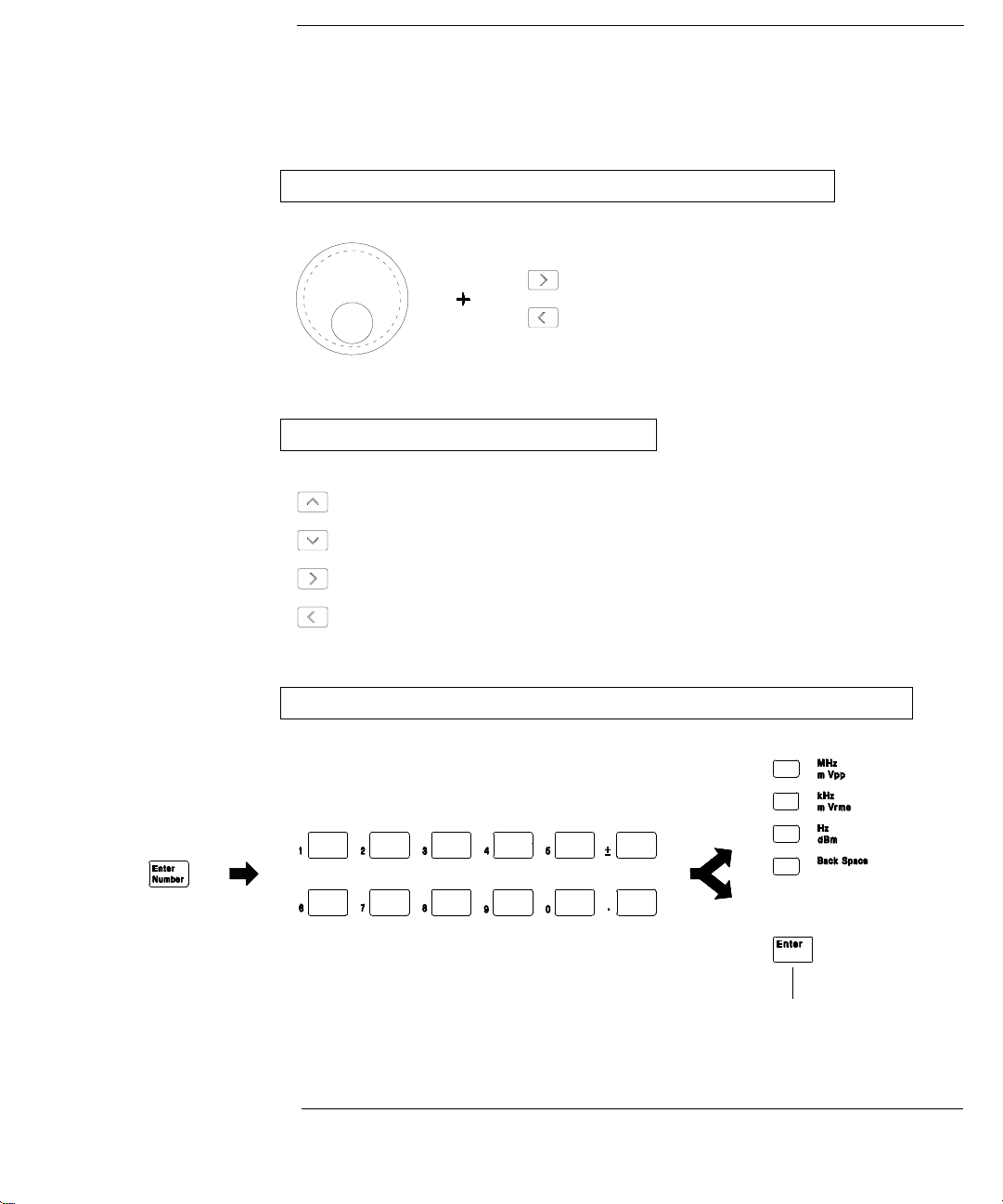

Front-Panel Number Entry

You can enter numbers from the front-panel using one of three methods.

Use the knob and the arrow keys to modify the displayed number.

Use the arrow keys to edit individual digits.

Increments the flashing digit.

Decrements the flashing digit.

Moves the flashing digit

Moves the flashing digit

to the right.

to the left.

Use the “Enter Number” mode to enter a number with the appropriate units.

Use “Enter” for those operations that do not

require units to be specified (AM Level,

Offset, % Duty, and Store/Recall State).

3

Page 6

The Front-Panel Menu at a Glance

The menu is organized in a top-down tree structure with three levels.

A: MODulation MENU

1: AM SHAPE Õ 2: AM SOURCE Õ 3: FM SHAPE Õ 4: BURST CNT Õ 5: BURST RATE Õ

Õ 6: BURST PHAS Õ 7: BURST SRC Õ 8: FSK FREQ Õ 9: FSK RATE Õ 10: FSK SRC

B: SWP (Sweep) MENU

1: START F Õ 2: STOP F Õ 3: SWP TIME Õ 4: SWP MODE

C: EDIT MENU

1: NEW ARB Õ [ 2: POINTS ] Õ [ 3: LINE EDIT ] Õ [ 4: POINT EDIT ] Õ [ 5: INVERT ] Õ [ 6: SAVE AS ] Õ 7: DELETE

The commands enclosed in square brackets ( [ ] ) are “hidden” until you make a selection from the

*

NEW ARB command to initiate a new edit session.

*

D: SYStem MENU

1: OUT TERM Õ 2: POWER ON Õ 3: ERROR Õ 4: TEST Õ 5: COMMA Õ 6: REVISION

E: Input / Output MENU

1: HPIB ADDR Õ 2: INTERFACE Õ 3: BAUD RATE Õ 4: PARITY Õ 5: LANGUAGE

F: CALibration MENU

1: SECURED or [ 1: UNSECURED ] Õ [ 2: CALIBRATE ] Õ 3: CAL COUNT Õ 4: MESSAGE

The commands enclosed in square brackets ( [ ] ) are “hidden” unless the function generator

*

is UNSECURED for calibration.

*

4

Page 7

Display Annunciators

Adrs

Rmt

Trig

AM

FM

Ext

FSK

Burst

Swp

ERROR

Offset

Shift

Num

Arb

Function generator is addressed to listen or talk over a remote interface.

Function generator is in remote mode (remote interface).

Function generator is waiting for a single trigger or external trigger (Burst, Sweep).

AM modulation is enabled.

FM modulation is enabled.

Function generator is set for an external modulation source (AM, FSK, Burst).

FSK (frequency-shift keying) modulation is enabled.

Burst modulation is enabled.

Sweep mode is enabled.

Hardware or remote interface command errors are detected.

The waveform is being output with an offset voltage.

“Shift” key has been pressed. Press “Shift” again to turn off.

“Enter Number” mode is enabled. Press “Shift-Cancel” to disable.

Arbitrary waveform function is enabled.

Sine waveform function is enabled.

Square waveform function is enabled.

Triangle waveform function is enabled.

Ramp waveform function is enabled.

To review the display annunciators, hold down the Shift key as you

turn on the function generator.

5

Page 8

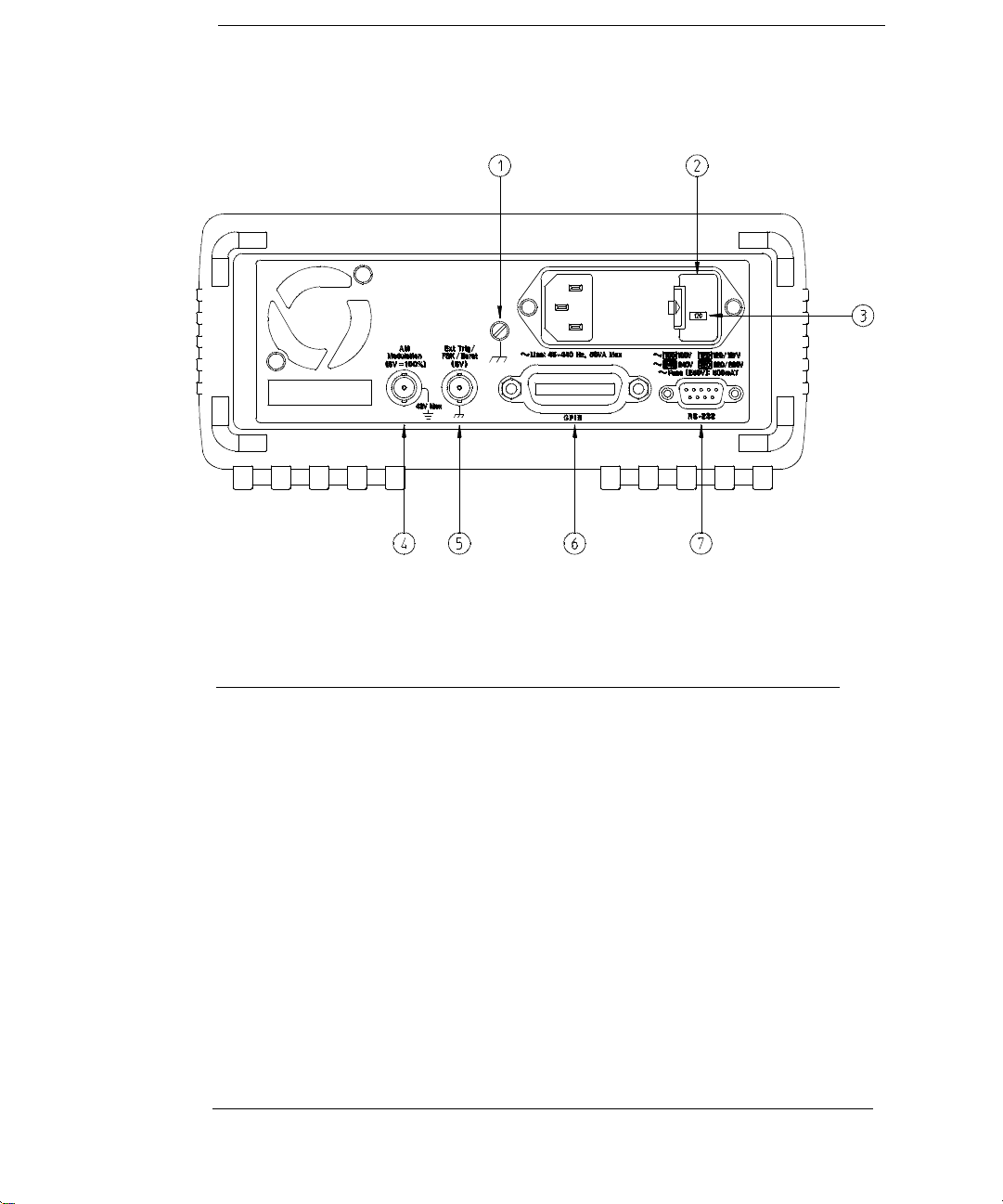

The Rear Panel at a Glance

1 Chassis ground

2 Power-line fuse-holder assembly

3 Power-line voltage setting

4 AM modulation input terminal

Use the front-panel Input / Output Menu to:

5 External Trigger / FSK / Burst modulation

input terminal

6 GPIB (IEEE-488) interface connector

7 RS-232 interface connector

Select the GPIB or RS-232 interface (see chapter 4 in User’s Guide).

Set the GPIB bus address (see chapter 4 in User’s Guide).

Set the RS-232 baud rate and parity (see chapter 4 in User’s Guide).

6

Page 9

In This Book

Specifications Chapter 1 lists the function generator’s specifications

and describes how to interpret these specifications.

Quick Start Chapter 2 prepares the function generator for use and

helps you get familiar with a few of its front-panel features.

Front-Panel Menu Operation Chapter 3 introduces you to the front-panel

menu and describes some of the function generator’s menu features.

Calibration Procedures Chapter 4 provides calibration, verification,

and adjustment procedures for the function generator.

Theory of Operation Chapter 5 describes block and circuit level theory

related to the operation the function generator.

Service Chapter 6 provides guidelines for returning your function

generator to Agilent for servicing, or for servicing it yourself.

Replaceable Parts Chapter 7 contains a detailed parts lists of the

function generator.

Schematics Chapter 8 contains the function generator’s block diagram,

schematics, disassembly drawings, and component locator drawings.

For information on using the Phase-Lock Option for the 33120A, refer to

the User’s and Service Guide included with the Option 001.

If you have questions relating to the operation of the 33120A,

call 1-800-452-4844 in the United States, or contact your nearest

Agilent Technologies Sales Office.

If you believe your 33120A has failed, refer to “Operating Checklist”,

“Types of Service Available”, and “Repackaging for Shipment” at the

beginning of chapter 6.

7

Page 10

8

Page 11

Contents

Chapter 1 Specifications

Chapter 2 Quick Start

To prepare the function generator for use 21

If the function generator does not turn on 22

To adjust the carrying handle 24

To set the output frequency 25

To set the output amplitude 26

To set a dc offset voltage 27

To set the duty cycle 28

To output a stored arbitrary waveform 29

To output a dc voltage 30

To store the instrument state 31

To rack mount the function generator 33

Chapter 3 Front-Panel Menu Operation

Front-panel menu reference 37

A front-panel menu tutorial 39

To select the output termination 44

To output a modulated waveform 45

To unsecure the function generator for calibration 47

Contents

Chapter 4 Calibration Procedures

Agilent Calibration Services 51

Calibration Interval 51

Time Required for Calibration 51

Automating Calibration Procedures 52

Recommended Test Equipment 52

Test Considerations 53

Performance Verification Tests 54

Frequency Verification 56

Function Gain and Linearity Verification 56

DC Function Offset Verification 57

AC Amplitude Verification 57

Amplitude Flatness Verification 60

AM Modulation Depth Verification 61

Optional Performance Verification Tests 62

9

Page 12

Contents

Contents

Chapter 4 Calibration Procedures (continued)

Calibration Security Code 64

Calibration Count 66

Calibration Message 66

General Calibration/Adjustment Procedure 67

Aborting a Calibration in Progress 69

Frequency and Burst Rate Adjustment 69

Function Gain and Linearity Adjustment 70

AC Amplitude Adjustment (High-Z) 70

Modulation Adjustment 72

AC Amplitude Adjustment (50

DC Output Adjustment 76

Duty Cycle Adjustment 77

AC Amplitude Flatness Adjustment 77

Output Amplifier Adjustment (Optional) 80

Error Messages 81

Chapter 5 Theory of Operation

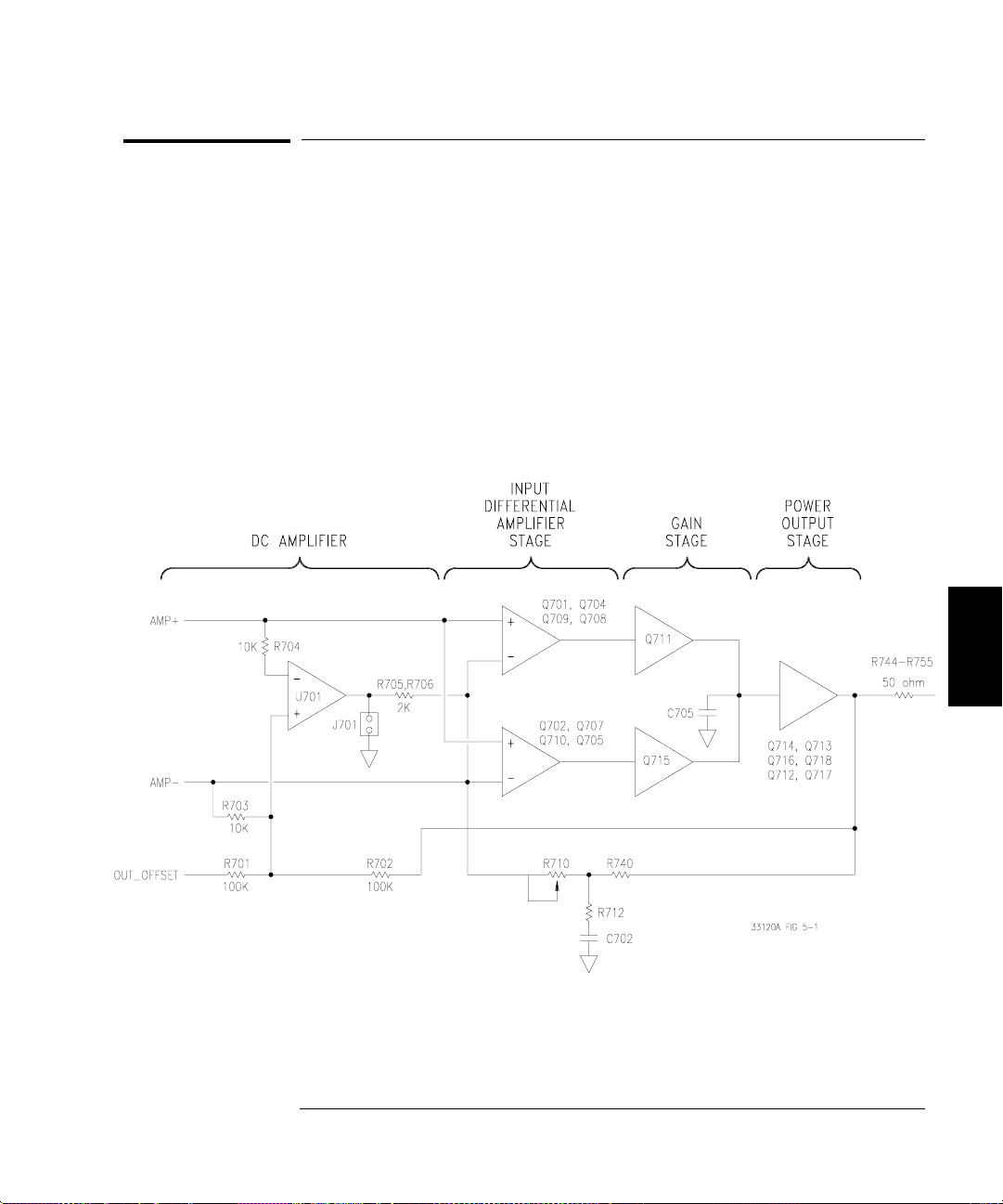

Block Diagram Overview 85

Output Attenuator 86

Output Amplifier 87

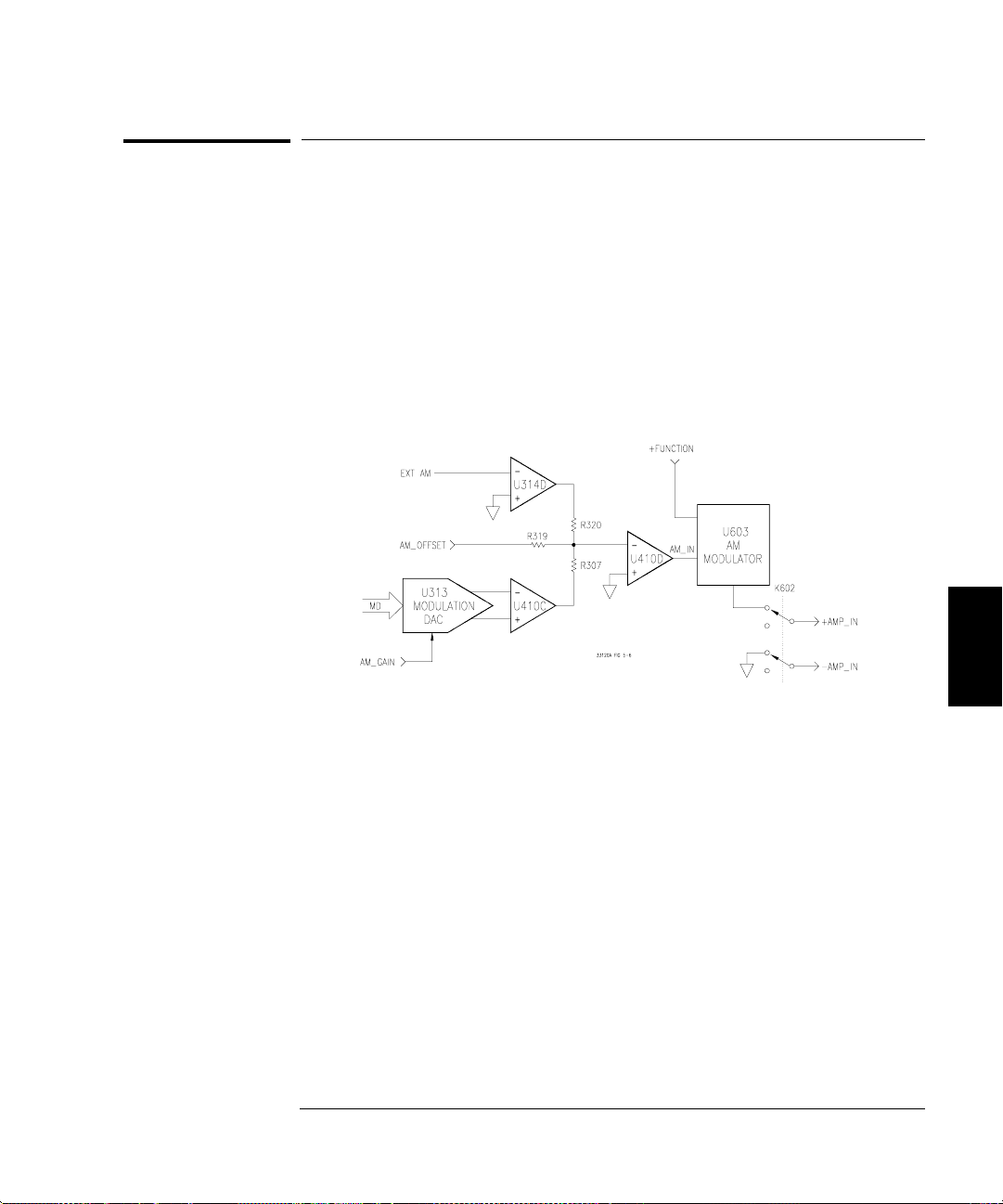

AM Modulation 89

Pre-attenuator 90

Square Wave and Sync 90

Filters 92

Waveform DAC/Amplitude Leveling/Waveform RAM 93

Direct Digital Synthesis (DDS ASIC) 95

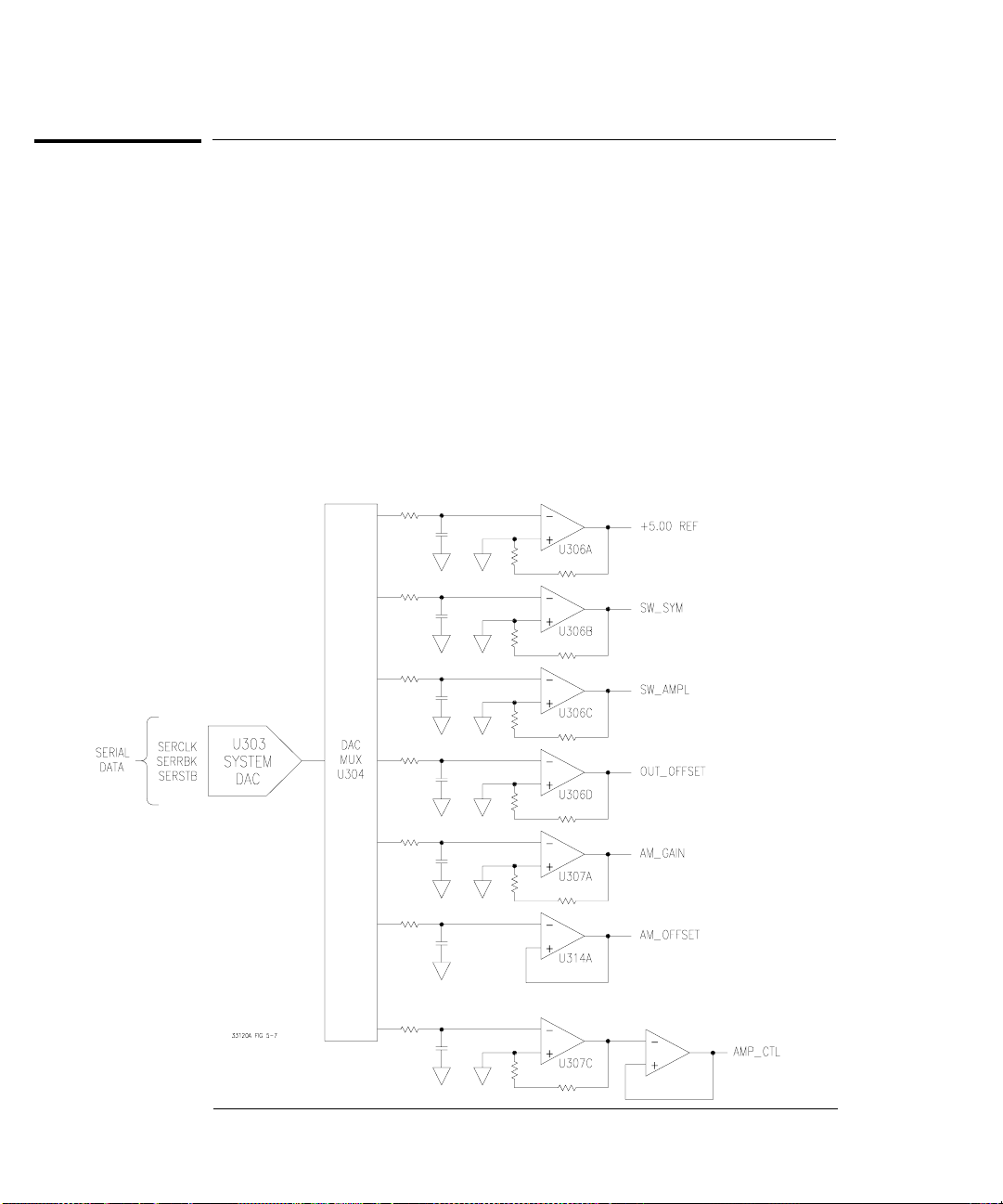

System DACs 96

Floating Logic 97

Earth-Referenced Logic 98

Power Supplies 98

Display and Keyboard 100

W) 73

10

Page 13

Contents

Chapter 6 Service

Operating Checklist 103

Types of Service Available 104

Repackaging for Shipment 105

Cleaning 105

Electrostatic Discharge (ESD) Precautions 106

Surface Mount Repair 106

To Replace the Power-Line Fuse 107

To Replace the Output Protection Fuse (F801) 107

Troubleshooting Hints 108

Self-Test Procedures 110

Chapter 7 Replaceable Parts

Replaceable Parts 113

Chapter 8 Schematics

33120A Block Diagram 129

Mechanical Disassembly 130

Floating Logic Schematic 131

Digital Waveform Data Synthesis 132

System DAC Schematic 133

Waveform DAC Schematic 134

Filters Schematic 135

Sync, Square Wave, and Attenuator Schematic 136

Output Amplifier Schematic 137

Output Attenuator Schematic 138

Earth Reference Logic Schematic 139

Power Supplies Schematic 140

Display and Keyboard Schematic 141

33120-66521 Component Locator Diagram 142

33120-66502 Component Locator Diagram 143

Contents

11

Page 14

Contents

12

Page 15

1

1

Specifications

Page 16

Chapter 1 Specifications

Agilent 33120A Function Generator

WAVEFORMS

Standard Waveforms:

Sine, Square, Triangle,

Ramp, Noise, DC volts,

Sine(x)/x, Negative Ramp,

Exponential Rise,

Exponential Fall, Cardiac

Arbitrary Waveforms:

Waveform Length:

Amplitude Resolution:

Sample Rate:

Non-Volatile Memory:

8 to 16,000 points

12 bits (including sign)

40 MSa / sec

Four 16,000-point waveforms

FREQUENCY CHARACTERISTICS

Sine:

Square:

Triangle:

Ramp:

Noise (Gaussian):

Arbitrary Waveforms:

8 to 8,192 points:

8,193 to 12,287 points:

12,288 to 16,000 points:

Resolution:

Accuracy:

Temperature Coefficient:

Aging:

m

Hz – 15 MHz

100

m

Hz – 15 MHz

100

m

Hz – 100 kHz

100

m

Hz – 100 kHz

100

10 MHz bandwidth

m

Hz – 5 MHz

100

m

Hz – 2.5 MHz

100

m

Hz – 200 kHz

100

10

m

Hz or 10 digits

10 ppm in 90 days,

20 ppm in 1 year,

C – 28C

18

< 2 ppm /

C

< 10 ppm / yr

SINEWAVE SPECTRAL PURITY (into 50

SIGNAL CHARACTERISTICS

Squarewave

Rise/Fall Time:

Overshoot:

Asymmetry:

Duty Cycle:

Triangle, Ramp, Arb

Rise/Fall Time:

Linearity:

Settling Time:

Jitter:

OUTPUT CHARACTERISTICS

(4)

W

(3)

W

):

Amplitude (into 50

Accuracy (at 1 kHz):

Flatness

< 100 kHz:

100 kHz to 1 MHz:

1 MHz to 15 MHz:

1 MHz to 15 MHz:

Offset (into 50

Accuracy:

Output Impedance:

Resolution:

Output Units:

Isolation:

W

)

Protection:

< 20 ns

< 4%

1% + 5 ns

20% to 80% (to 5 MHz)

40% to 60% (to 15 MHz)

40 ns (typical)

< 0.1% of peak output

< 250 ns to 0.5% of final value

< 25 ns

(2)

50 mVpp – 10 Vpp

):

1% of specified output

(sine wave relative to 1 kHz)

1% (0.1 dB)

1.5% (0.15 dB)

2% (0.2 dB) Ampl 3Vrms

3.5% (0.3 dB) Ampl < 3Vrms

5 Vpk ac + dc

2% of setting + 2 mV

50 ohms fixed

3 digits, Amplitude and Offset

Vpp, Vrms, dBm

42 Vpk maximum to earth

Short-circuit protected

15 Vpk overdrive < 1 minute

(1)

Harmonic Distortion

DC to 20 kHz:

20 kHz to 100 kHz:

100 kHz to 1 MHz:

1 MHz to 15 MHz:

Total Harmonic Distortion

DC to 20 kHz:

Spurious (non-harmonic)

Output (DC to 1 MHz):

Output (> 1 MHz):

Phase Noise:

-70 dBc

-60 dBc

-45 dBc

-35 dBc

< 0.04%

< -65 dBc

< -65 dBc + 6 dB/octave

< -55 dBc in a 30 kHz band

14

(1) Add 1/10th of output amplitude and offset specification

C for operation outside of 18C to 28C range

per

(1-year specification).

(2) 100 mVpp – 20 Vpp amplitude into open-circuit load.

(3) Offset

2 X peak-to-peak amplitude.

(4) For square wave outputs, add 2% of output amplitude

additional error.

Page 17

Chapter 1 Specifications

Agilent 33120A Function Generator

1

MODULATION CHARACTERISTICS

AM Modulation

Carrier -3 dB Freq:

Modulation:

Frequency:

Depth:

Source:

FM Modulation

Modulation:

Frequency:

Peak Deviation:

Source:

Burst Modulation

Carrier Frequency:

Count:

Start Phase:

Internal Rate:

Gate Source:

Trigger Source:

FSK Modulation

Frequency Range:

Internal Rate:

Source:

10 MHz (typical)

Any internal waveform plus Arb

10 mHz to 20 kHz (

2.5 kHz, then decreases linearly

0.4% at upper limit)

to

0% to 120%

Internal / External

Any internal waveform plus Arb

10 mHz to 10 kHz (

600 Hz, then decreases linearly

0.8% at upper limit)

to

10 mHz to 15 MHz

Internal Only

5 MHz max.

1 to 50,000 cycles, or Infinite

to +360

-360

10 mHz to 50 kHz 1%

Internal or External Gate

Single, External, or Internal Rate

10 mHz to 15 MHz (

600 Hz, then decreases linearly

4% at upper limit)

to

10 mHz to 50 kHz

Internal / External (1 MHz max.)

0.05% to

0.05% to

0.05% to

(1)

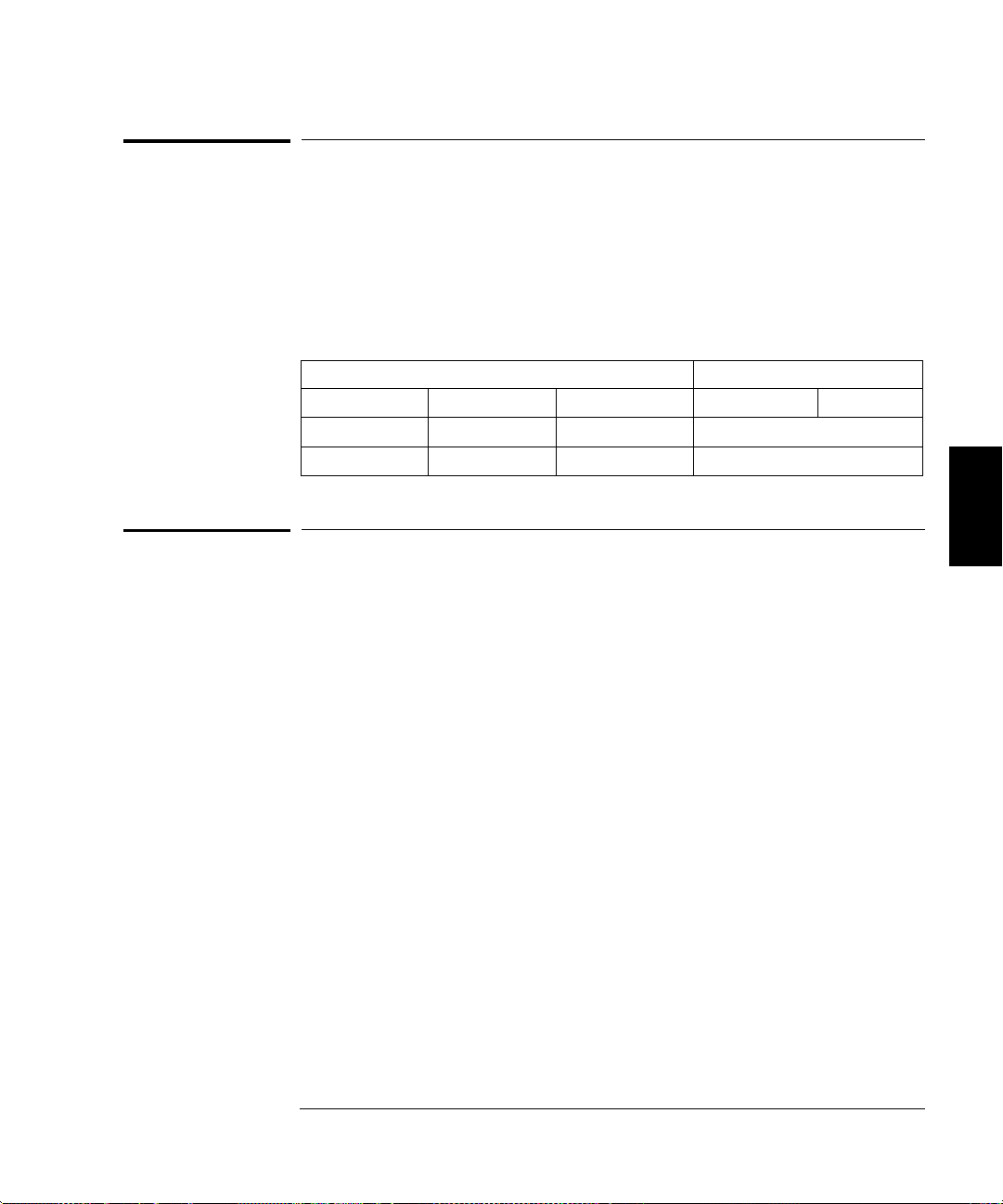

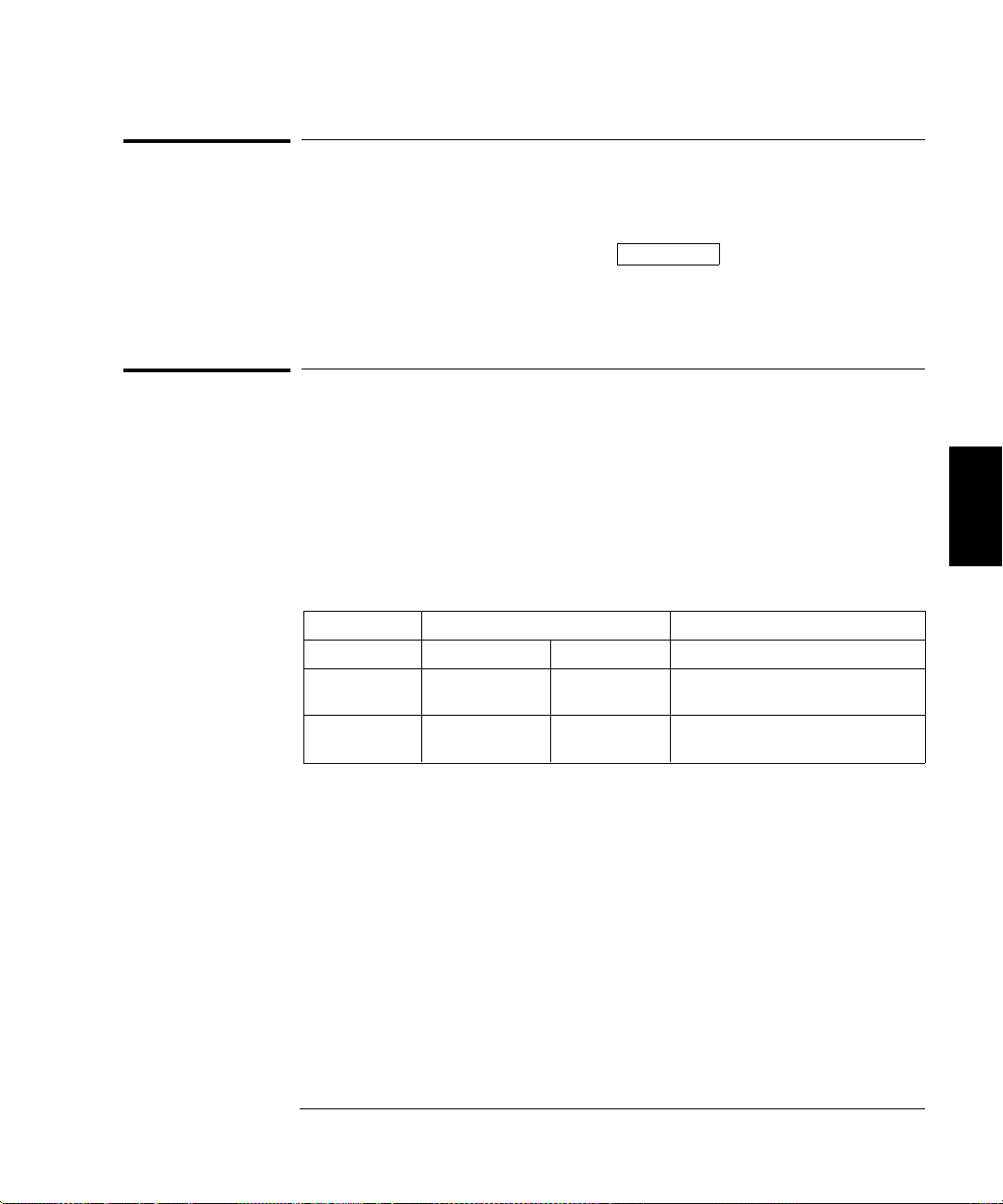

SYSTEM CHARACTERISTICS

Configuration Times

Function Change:

Frequency Change:

Amplitude Change:

Offset Change:

Select User Arb:

Modulation Parameter Change:

Arb Download Times over GPIB:

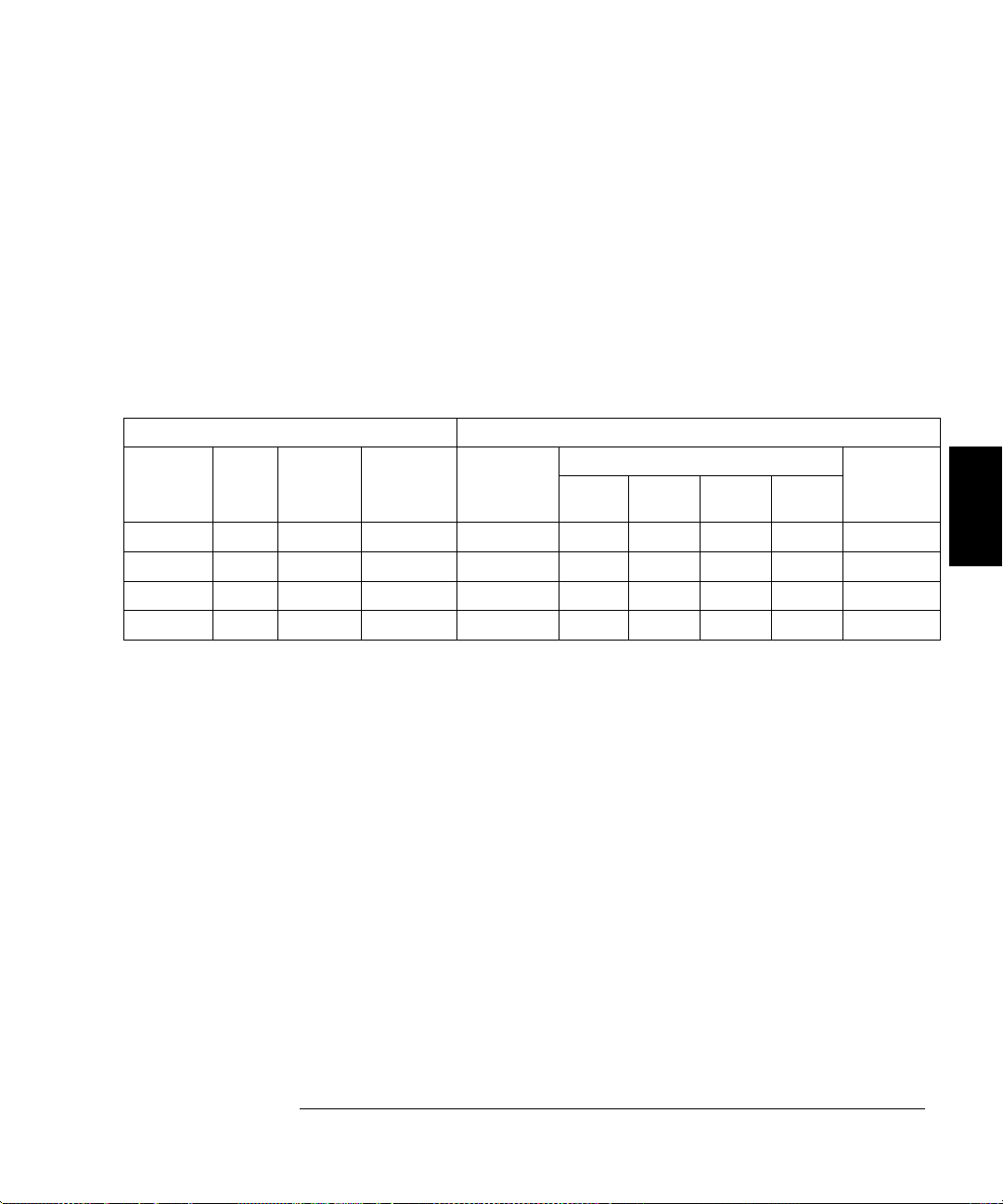

Arb Length Binary ASCII Integer ASCII Real

16,000 points 8 sec 81 sec 100 sec

8,192 points 4 sec 42 sec 51 sec

4,096 points 2.5 sec 21 sec 26 sec

2,048 points 1.5 sec 11 sec 13 sec

Arb Download Times over RS-232 at 9600 Baud:

Arb Length Binary ASCII Integer ASCII Real

16,000 points 35 sec 101 sec 134 sec

8,192 points 18 sec 52 sec 69 sec

4,096 points 10 sec 27 sec 35 sec

2,048 points 6 sec 14 sec 18 sec

(3)

(2)

(3)

80 ms

30 ms

30 ms

10 ms

100 ms

< 350 ms

(4)

(5)

(6)

FREQUENCY SWEEP

Type:

Direction:

Start F / Stop F:

Time:

Source:

Linear or Logarithmic

Up or Down

10 mHz to 15 MHz

1 ms to 500 sec

Single, External, or Internal

REAR-PANEL INPUTS

External AM

Modulation:

External Trigger/FSK

Burst Gate:

Latency:

Jitter:

(1)

5 Vpk = 100% Modulation

W

Input Resistance

5 k

TTL (low true)

m

s

1.3

25 ns

0.1%

(1) Trigger source ignored when External Gate is selected.

(2) Time to change parameter and output the new signal.

(3) Modulation or sweep off.

(4) Times for 5-digit and 12-digit numbers.

(5) For 4800 baud, multiply the download times by two;

For 2400 baud, multiply the download times by four, etc.

(6) Time for 5-digit numbers. For 12-digit numbers,

multiply the 5-digit numbers by two.

15

Page 18

Chapter 1 Specifications

Agilent 33120A Function Generator

GENERAL SPECIFICATIONS

Power Supply:

(1)

Power-Line Frequency:

Power Installation:

Power Consumption:

Operating Environment:

Storage Environment:

State Storage Memory:

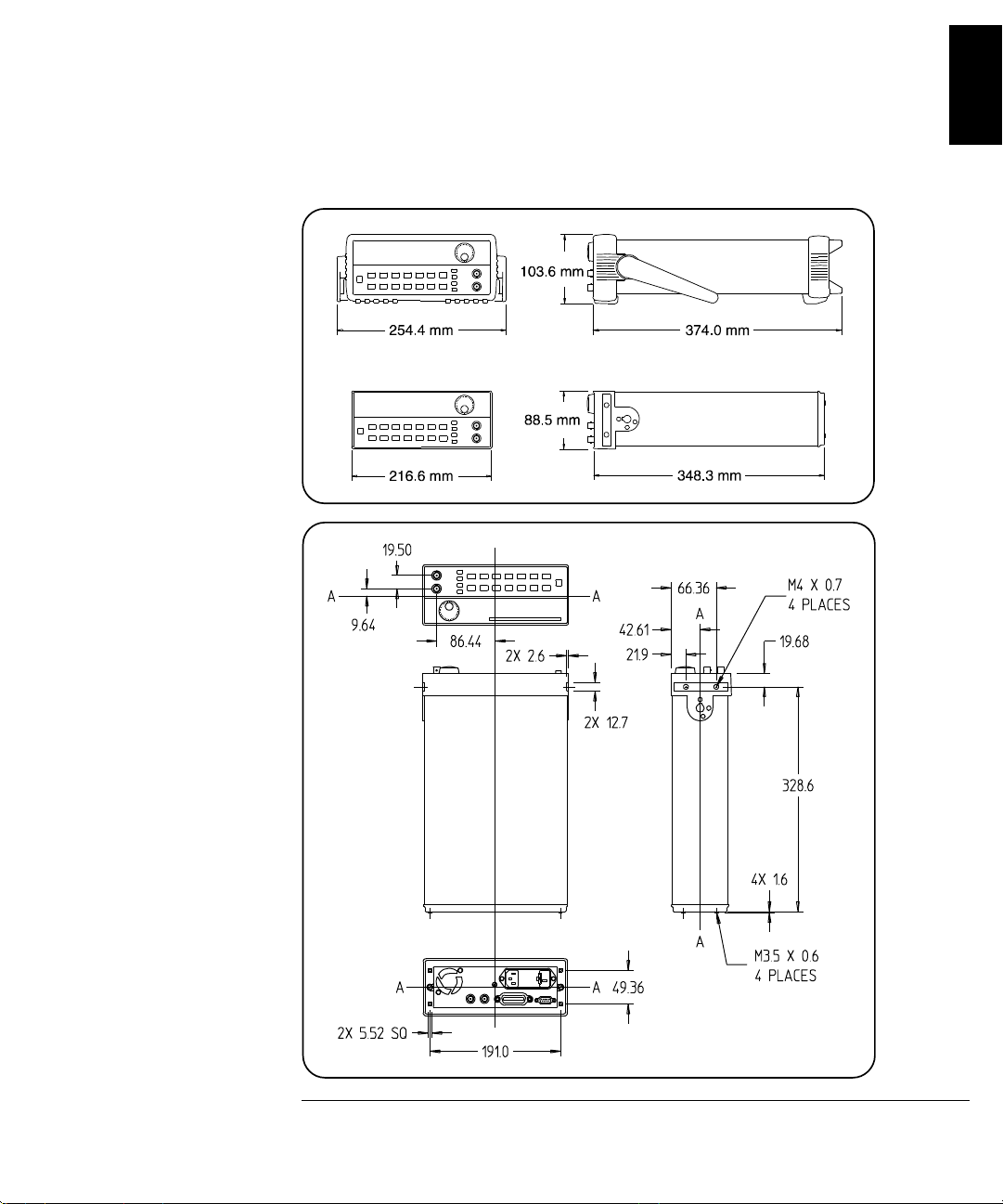

Dimensions (W x H x D)

Bench Top:

Rack Mount:

Weight:

100V / 120V / 220V / 240V

10%

(switch selectable)

50 Hz to 60 Hz

400 Hz

10% and

10%. Automatically

sensed at power-on.

CAT II

50 VA peak (28 W average)

0

C to 55C

80% Relative Humidity to 40

C

Indoor or sheltered location

-40

C to 70C

Power-off state automatically

saved. Three (3) UserConfigurable Stored States,

Arbitrary waveforms stored

separately.

254.4 mm x 103.6 mm x 374 mm

212.6 mm x 88.5 mm x 348.3 mm

4 kg (8.8 lbs)

Safety Designed to:

EMC:

Vibration and Shock:

Acoustic Noise:

Warm-Up Time:

Warranty:

Remote Interface:

Programming Language:

Accessories Included:

N10149

EN61010, CSA1010, UL-1244

EN61326, 1:1997 + 1A:1998

MIL-T-28800E, Type III, Class 5

(data on file)

30 dBa

1 hour

3 years standard

IEEE-488 and RS-232 standard

SCPI-1993, IEEE-488.2

User’s Guide, Service Guide,

Quick Reference Card,

IntuiLink Arb software,

RS-232 cable, Test Report,

and power cord.

(1) For 400 Hz operation at 120 Vac, use the 100 Vac

line-voltage setting.

16

Page 19

Chapter 1 Specifications

Agilent 33120A Function Generator

PRODUCT DIMENSIONS

1

TOP

All dimensions are

shown in millimeters.

17

Page 20

18

Page 21

2

2

Quick Start

Page 22

Quick Start

One of the first things you will want to do with your function generator is

to become acquainted with its front panel. We have written the exercises

in this chapter to prepare the function generator for use and help you get

familiar with some of the front-panel operations.

The front panel has two rows of keys to select various functions and

operations. Most keys have a shifted function printed in blue above the

key. To perform a shifted function, press

turn on). Then, press the key that has the desired label above it. For

example, to select the

Shift AM (the shifted version of the key).

AM (amplitude modulation) function, press

Shift (the Shift annunciator will

If you accidentally press

Shift , just press it again to turn off the Shift

annunciator.

Most keys also have a number printed in green next to the key. To enable

the number mode, press

Enter Number (the Num annunciator will turn on).

Then, press the keys that have the desired numbers printed next to them.

For example, to select the number “10”, press

(next to the

If you accidentally press

off the

and Recall keys).

Enter Number , just press Shift Cancel to turn

Num annunciator.

Enter Number 1 0

20

Page 23

Chapter 2 Quick Start

To prepare the function generator for use

To prepare the function generator for use

The following steps help you verify that the function generator is

ready for use.

1 Check the list of supplied items.

Verify that you have received the following items with your function

generator. If anything is missing, contact your nearest Agilent

Technologies Sales Office.

One power cord.

One RS-232 serial cable.

One User’s Guide.

This Service Guide.

á

One folded Quick Reference card.

Certificate of Calibration.

Agilent IntuiLink Arb Waveform Generation Software.

2

2 Connect the power cord and turn on the function generator.

If the function generator does not turn on, see chapter 6 for troubleshooting

information. The front-panel display will light up while the function

generator performs its power-on self-test. The

displayed. Notice that the function generator powers up in the sine wave

function at 1 kHz with an amplitude of 100 mV peak-to-peak (into a 50

termination).

To review the power-on display with all annunciators turned on,

hold down

3Perform a complete self test.

The complete self-test performs a more extensive series of tests than

those performed at power-on. Hold down

switch to turn on the function generator; hold down the key for more than

5 seconds. The self-test will begin when you release the key.

If the self-test is successful, “

If the self-test is not successful, “

annunciator turns on. See chapter 6 for instructions on returning the

function generator to Agilent for service.

Shift as you turn on the function generator.

PASS” is displayed on the front panel.

FAIL” is displayed and the ERROR

GPIB bus address is

Shift as you press the Power

W

21

Page 24

Chapter 2 Quick Start

If the function generator does not turn on

If the function generator does not turn on

Use the following steps to help solve problems you might experience

when turning on the function generator. If you need more help,

see chapter 6 for instructions on returning the function generator to

Agilent for service.

1 Verify that there is ac power to the function generator.

First, verify that the function generator’s Power switch is in the

“On” position. Also, make sure that the power cord is firmly plugged into

to the power module on the rear panel. You should also make sure that

the power source you plugged the function generator into is energized.

2 Verify the power-line voltage setting.

The line voltage is set to the proper value for your country when the

function generator is shipped from the factory. Change the voltage

setting if it is not correct. The settings are: 100, 120, 220, or 240 Vac

(for 230 Vac operation, use the 220 Vac setting).

See the next page if you need to change the line-voltage setting.

3 Verify that the power-line fuse is good.

The function generator is shipped from the factory with a 500 mAT fuse

installed. This is the correct fuse for all line voltages.

See the next page if you need to change the power-line fuse.

To replace the 500 mAT fuse, order Agilent part number 2110-0458.

22

Page 25

Chapter 2 Quick Start

If the function generator does not turn on

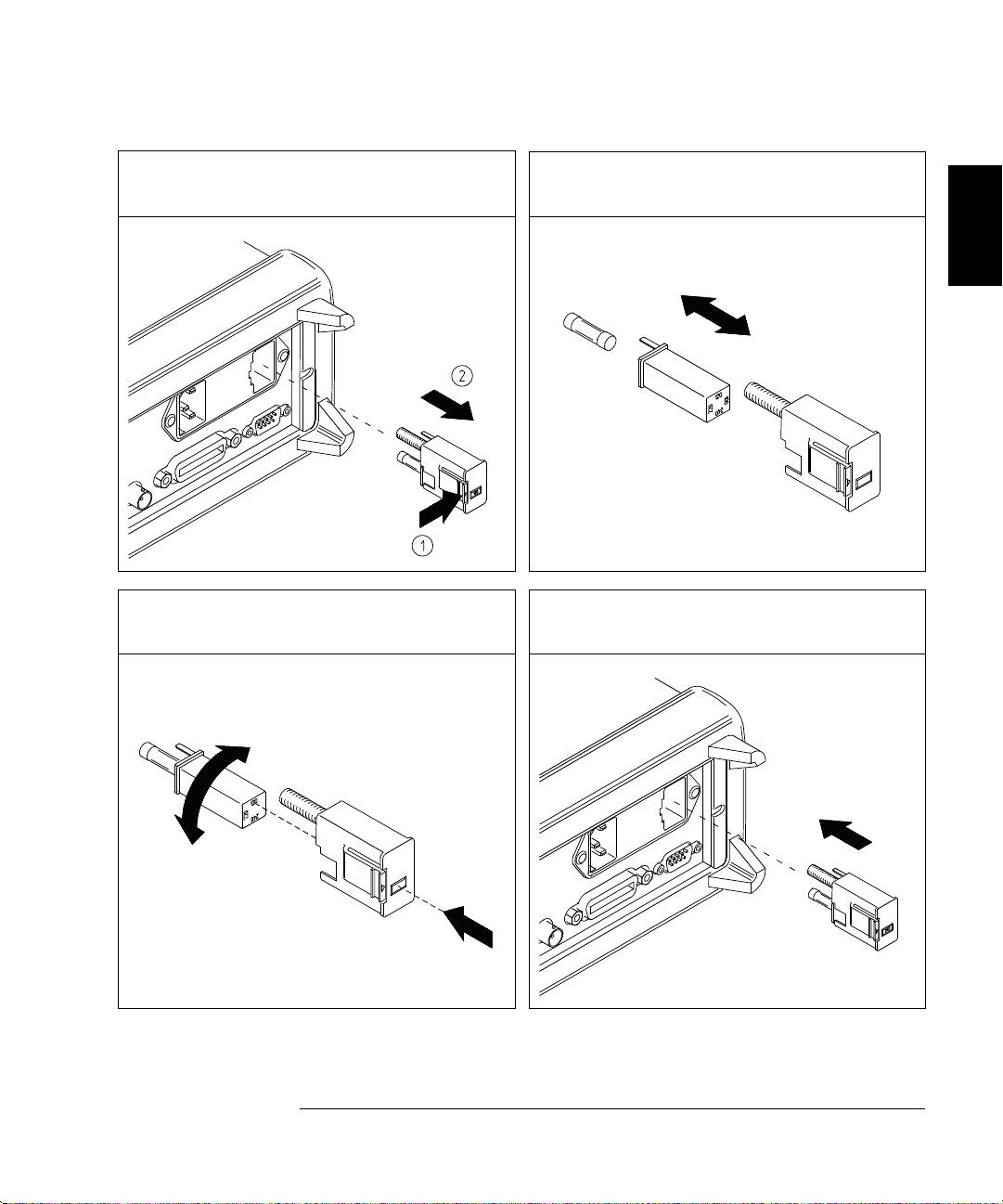

1 Remove the power cord. Remove the

fuse-holder assembly from the rear panel.

3 Rotate the line-voltage selector until the

correct voltage appears in the window.

2 Remove the line-voltage selector from

the assembly.

Fuse: 500 mAT (for all line voltages)

Part Number: 2110-0458

4 Replace the fuse-holder assembly in

the rear panel.

2

100, 120, 220 (230), or 240 Vac

Verify that the correct line voltage is selected and the power-line fuse is good.

23

Page 26

Chapter 2 Quick Start

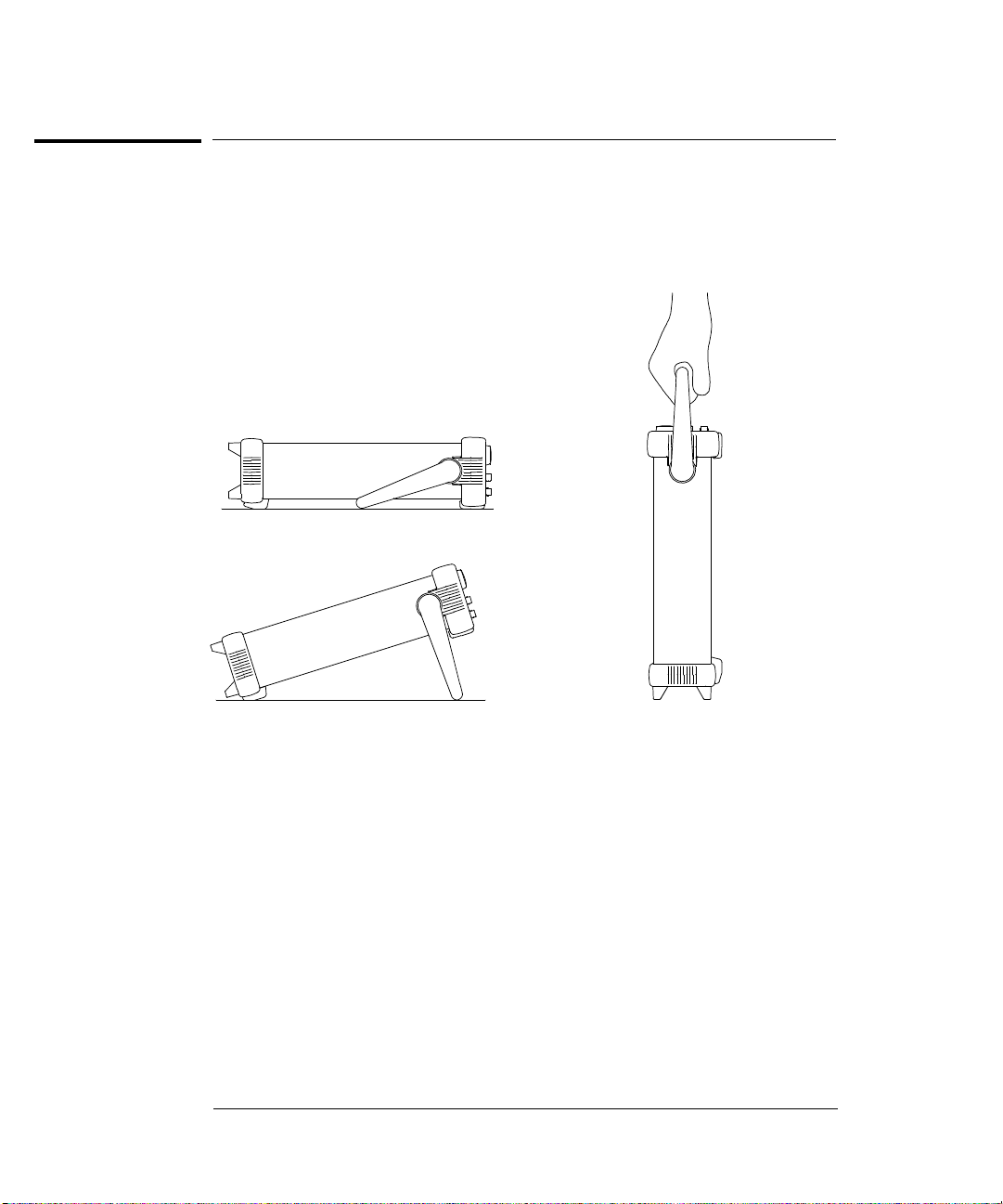

To adjust the carrying handle

To adjust the carrying handle

To adjust the position, grasp the handle by the sides and pull outward.

Then, rotate the handle to the desired position.

Bench-top viewing positions Carrying position

24

Page 27

Chapter 2 Quick Start

To set the output frequency

To set the output frequency

At power-on, the function generator outputs a sine wave at 1 kHz with

an amplitude of 100 mV peak-to-peak (into a 50

The following steps show you how to change the frequency to 1.2 MHz.

Freq 1 Enable the frequency modify mode.

The displayed frequency is either the power-on value or the previous

frequency selected. When you change functions, the same frequency is

used if the present value is valid for the new function.

1.000,000,0 KHz

W termination).

2

Enter Number 2 Enter the magnitude of the desired frequency.

1 2 . Notice that the Num annunciator turns on and “ENTER NUM” flashes on

1

the display, indicating that the number mode is enabled.

1.2

¾

MHz

m Vpp

To cancel the number mode, press

3 Set the units to the desired value.

Shift Cancel .

The units are selected using the arrow keys on the right side of the front

panel. As soon as you select the units, the function generator outputs the

waveform with the displayed frequency. To turn off the flashing digit,

move the cursor to the left of the display using the arrow keys.

1.200,000,0 MHz

1

You can also use the knob and arrow keys to enter a number.

25

Page 28

Chapter 2 Quick Start

To set the output amplitude

To set the output amplitude

At power-on, the function generator outputs a sine wave with an

amplitude of 100 mV peak-to-peak (into a 50

The following steps show you how to change the amplitude to 50 mVrms.

Ampl 1 Enable the amplitude modify mode.

The displayed amplitude is either the power-on value or the previous

amplitude selected. When you change functions, the same amplitude is

used if the present value is valid for the new function.

100.0 mVPP

W termination).

Enter Number 2 Enter the magnitude of the desired amplitude.

5 0 Notice that the Num annunciator turns on and “ENTER NUM” flashes on

1

the display, indicating that the number mode is enabled.

50

To cancel the number mode, press

Shift 3 Set the units to the desired value.

¿

kHz

m Vrms

The units are selected using the arrow keys on the right side of the front

panel. As soon as you select the units, the function generator outputs the

Shift Cancel .

waveform with the displayed amplitude. To turn off the flashing digit,

move the cursor to the left of the display using the arrow keys.

50.00 mVRMS

1

You can also use the knob and arrow keys to enter a number.

26

Page 29

Chapter 2 Quick Start

To set a dc offset voltage

To set a dc offset voltage

At power-on, the function generator outputs a sine wave with a dc offset

voltage of 0 volts (into a 50

how to change the offset to –1.5 mVdc.

Offset 1 Enable the offset modify mode.

The displayed offset voltage is either the power-on value or the previous

offset selected. When you change functions, the same offset is used if the

present value is valid for the new function.

+0.000 VDC

W termination). The following steps show you

2

Enter Number 2 Enter the magnitude of the desired offset.

1 . 5 Notice that the Num annunciator turns on and “ENTER NUM” flashes on

1

the display, indicating that the number mode is enabled. Notice that

toggles the displayed value between + and – .

-1.5

To cancel the number mode, press

Shift 3 Set the units to the desired value.

¿

kHz

m Vrms

At this point, the function generator outputs the waveform with the

displayed offset. Notice that the

Shift Cancel .

Offset annunciator turns on, indicating

that the waveform is being output with an offset. The annunciator will

turn on when the offset is any value other than 0 volts. To turn off the

flashing digit, move the cursor to the left of the display using the arrow keys.

-01.50 mVDC

1

You can also use the knob and arrow keys to enter a number.

27

Page 30

Chapter 2 Quick Start

To set the duty cycle

To set the duty cycle

Applies only to square waves. At power-on, the duty cycle for square waves

is 50%. You can adjust the duty cycle for a square waveform from 20%

to 80%, in increments of 1% (for frequencies above 5 MHz, the range is 40%

to 60%). The following steps show you how to change the duty cycle to 45%.

1 Select the square wave function.

Notice that the annunciator turns on, indicating that the square

wave function is enabled.

Shift % Duty 2 Enable the duty cycle modify mode.

The displayed duty cycle is either the power-on value or the previous

value selected.

50 % DUTY

This message appears on the display for approximately 10 seconds.

Repeat this step as needed.

Enter Number

4 5 Notice that the Num annunciator turns on and “ENTER NUM” flashes on

3 Enter the desired duty cycle.

1

the display, indicating that the number mode is enabled.

45

To cancel the number mode, press

Enter 4 Output the waveform with the displayed duty cycle.

Shift Cancel .

45 % DUTY

1

You can also use the knob and arrow keys to enter a number.

28

Page 31

Chapter 2 Quick Start

To output a stored arbitrary waveform

To output a stored arbitrary waveform

There are five built-in arbitrary waveforms stored in non-volatile memory

for your use. You can output these waveforms directly from non-volatile

memory. The following steps show you how to output an “exponential rise”

waveform from memory.

Shift Arb List 1 Display the list of arbitrary waveforms.

The list contains the five built-in arbitrary waveforms (sinc, negative

ramp, exponential rise, exponential fall, and cardiac). The list may also

contain up to four user-defined arbitrary waveform names. The first

choice on this level is “

SINC

This message appears on the display for approximately 10 seconds.

Repeat this step as needed.

> 2 Move across to the EXP_RISE choice.

>

SINC”.

2

1

EXP_RISE

Enter 3 Select and output the displayed arbitrary waveform.

Notice that the

Arb annunciator turns on, indicating that the output is an

arbitrary waveform. The waveform is output using the present settings

for frequency, amplitude, and offset unless you change them.

The selected waveform is now assigned to the

Arb key. Whenever you

press this key, the selected arbitrary waveform is output.

1

You can also use the knob to scroll left or right through the choices in the list.

29

Page 32

Chapter 2 Quick Start

To output a dc voltage

To output a dc voltage

In addition to generating waveforms, you can also output a dc voltage in

the range

how to output +155 mVdc.

5 Vdc (into a 50W termination). The following steps show you

1 Press the key and hold it down for more than 2 seconds.

To enter the dc voltage mode, press the

of function keys and

Offset

Offset key or any key in the top row

hold it down for more than 2 seconds. The displayed

voltage is either the power-on value or the previous offset voltage selected.

DCV

+0.000 VDC

Enter Number

1 5 5 Notice that the Num annunciator turns on and “ENTER NUM” flashes on

2 Enter the magnitude of the desired voltage.

1

the display, indicating that the number mode is enabled.

155

To cancel the number mode, press

Shift 3 Set the units to the desired value.

Shift Cancel .

¿

kHz

m Vrms

At this point, the function generator outputs the displayed dc voltage.

Notice that the

Offset annunciator turns on (all other annunciators are

off), indicating that a dc voltage is being output. The annunciator will

turn on when the offset is any value other than 0 volts.

+155.0 mVDC

1

You can also use the knob and arrow keys to enter a number.

30

Page 33

Chapter 2 Quick Start

To store the instrument state

To store the instrument state

You can store up to three different instrument states in non-volatile

memory. This enables you to recall the entire instrument configuration

with just a few key presses from the front panel. The following steps show

you how to store and recall a state.

1 Set up the function generator to the desired configuration.

The state storage feature “remembers” the function, frequency,

amplitude, dc offset, duty cycle, as well as any modulation parameters.

Shift Store 2 Turn on the state storage mode.

Three memory locations (numbered 1, 2, and 3) are available to store

instrument configurations. The instrument configuration is stored in

non-volatile memory and is remembered when power has been off.

STORE 1

2

This message appears on the display for approximately 10 seconds.

Repeat this step as needed.

¾

3 Store the instrument state in memory location “2”.

Use the up and down arrow keys to select the memory location.

STORE 2

To cancel the store operation, press

time-out after 10 seconds.

Enter 4 Save the instrument state.

The instrument state is now stored. To recall the stored state, turn to the

next page.

1

You can also use the knob or “enter number” mode to enter a memory location.

1

Shift Store again or let the display

31

Page 34

Chapter 2 Quick Start

To store the instrument state

To verify that the state was stored properly, you can turn the power off

before recalling the state.

Recall 5 Recall the stored instrument state.

To recall the stored state, you must use the same memory location used

previously to store the state. Use the up and down arrow keys to change

the displayed storage location.

RECALL 2

To cancel the restore operation, press

This message appears on the display for approximately 10 seconds.

Repeat this step as needed.

Enter 6 Restore the instrument state.

The function generator should now be configured in the same state as

when you stored the setup on the previous page.

When power is turned off, the function generator automatically stores

its state in memory location “0”. You can recall the power-down state,

but you cannot store the state to location “0” from the front panel.

Use the POWER ON ENABLE command in the SYS MENU to

automatically recall the power-down state when power is turned on.

See chapter 3 for more information on using the front-panel menus.

Recall again.

32

Page 35

Chapter 2 Quick Start

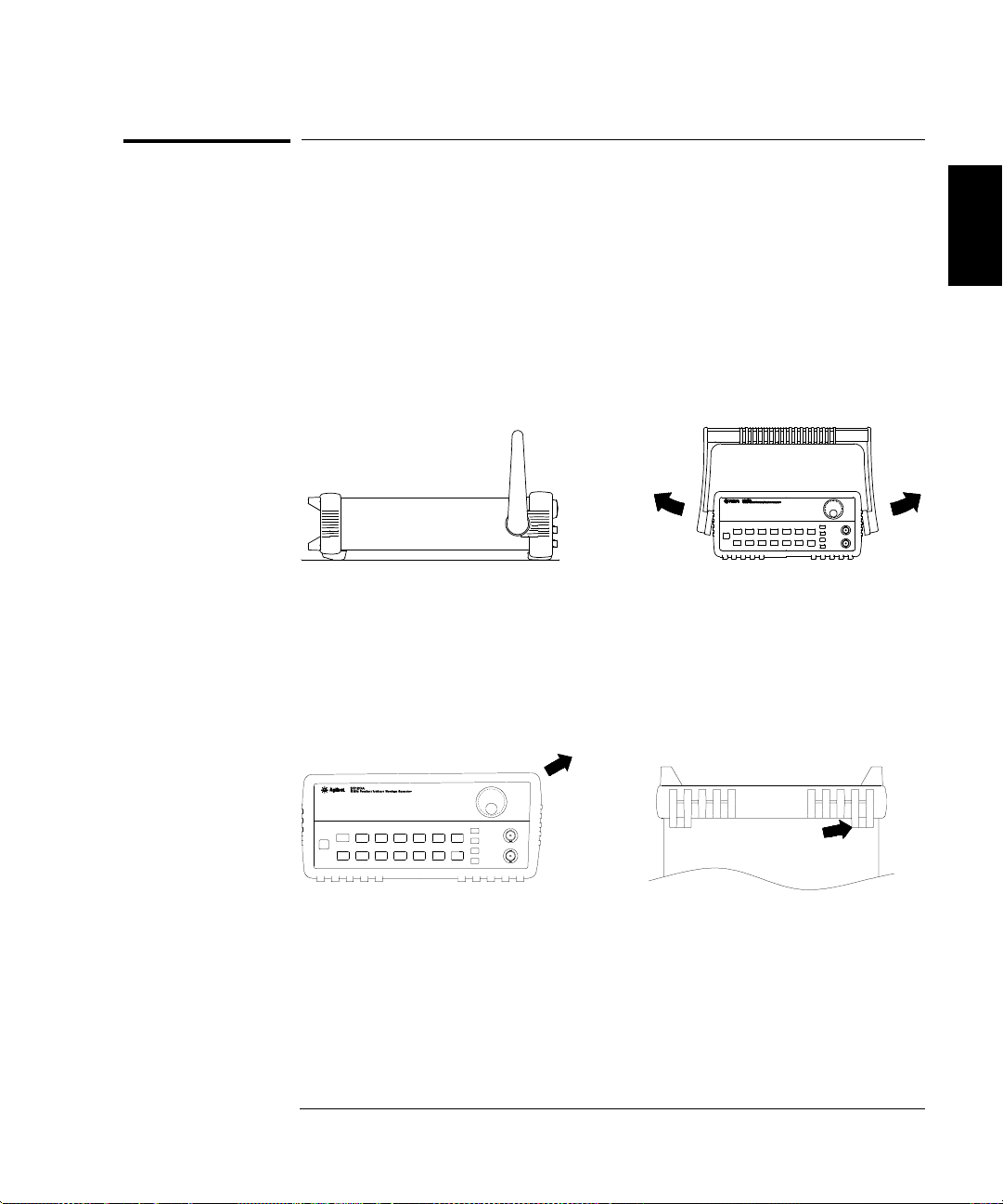

To rack mount the function generator

To rack mount the function generator

You can mount the function generator in a standard 19-inch rack

cabinet using one of three optional kits available. Instructions and

mounting hardware are included with each rack-mounting kit.

Any Agilent System II instrument of the same size can be rack-mounted

beside the 33120A Function Generator.

Remove the carrying handle, and the front and rear rubber bumpers,

before rack-mounting the function generator.

2

To remove the handle, rotate it to the vertical position and pull the ends outward.

Front Rear (bottom view)

To remove the rubber bumper, stretch a corner and then slide it off.

33

Page 36

Chapter 2 Quick Start

To rack mount the function generator

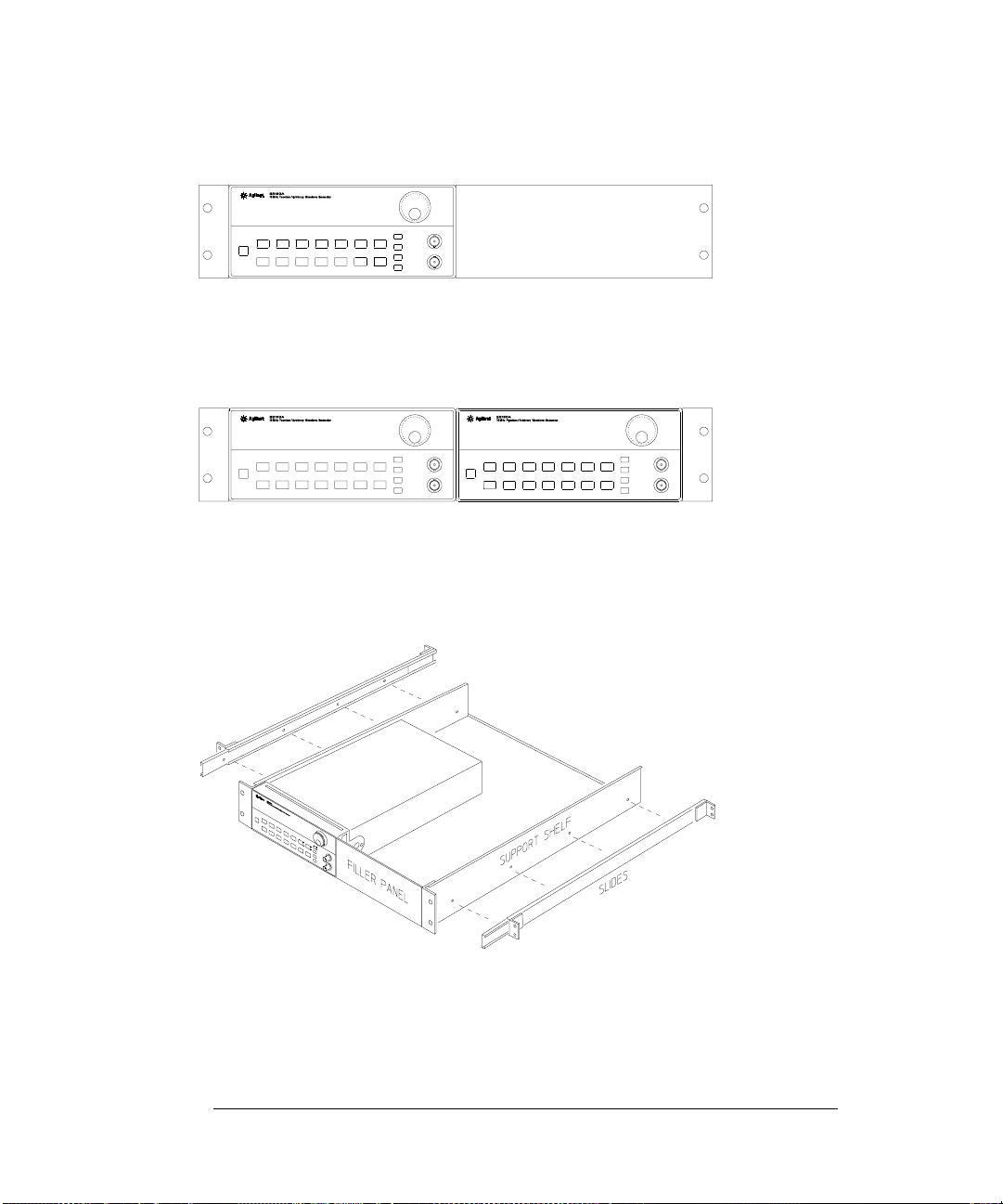

To rack mount a single instrument, order adapter kit 5063-9240.

To rack mount two instruments side-by-side, order lock-link kit 5061-9694

and flange kit 5063-9212.

To install one or two instruments in a sliding support shelf, order shelf 5063-9255,

and slide kit 1494-0015 (for a single instrument, also order filler panel 5002-3999).

34

Page 37

3

3

Front-Panel

Menu Operation

Page 38

Front-Panel Menu Operation

By now you should be familiar with some of the basic features of the front

panel. Chapter 2 shows you how to prepare the function generator for use

and describes a few of the front-panel features. If you are not familiar

with this information, we recommend that you read chapter 2, “Quick Start,”

starting on page 19.

Chapter 3 introduces you to the use of the front-panel menu. This chapter

does not give a detailed description of every front-panel key or menu

operation. It does, however, give you an overview of front-panel menu

operations related to verification, adjustment and service. See chapter 3

“Features and Functions” in the User’s Guide for a complete discussion of

the function generator’s capabilities and operation.

If you purchased the Phase-Lock Option for the 33120A, an additional

menu

(G: PHASE MENU) is available from the front panel. For inform-

ation on using the Phase-Lock Option, refer to the User’s and Service

Guide included with Option 001.

36

Page 39

Chapter 3 Front-Panel Menu Operation

Front-panel menu reference

Front-panel menu reference

A: MODulation MENU

1: AM SHAPE Õ 2: AM SOURCE Õ 3: FM SHAPE Õ 4: BURST CNT Õ 5: BURST RATE Õ

Õ 6: BURST PHAS Õ 7: BURST SRC Õ 8: FSK FREQ Õ 9: FSK RATE Õ 10: FSK SRC

1: AM SHAPE Selects the shape of the AM modulating waveform.

2: AM SOURCE Enables or disables the internal AM modulating source.

3: FM SHAPE Selects the shape of the FM modulating waveform.

4: BURST CNT Sets the number of cycles per burst (1 to 50,000 cycles).

5: BURST RATE Sets the burst rate in Hz for an internal burst source.

6: BURST PHAS Sets the starting phase angle of a burst (-360 to +360 degrees).

7: BURST SRQ Selects an internal or external gate source for burst modulation.

8: FSK FREQ Sets the FSK “hop” frequency.

9: FSK RATE Selects the internal FSK rate between the carrier and FSK frequency.

10: FSK SRC Selects an internal or external source for the FSK rate.

B: SWP (Sweep) MENU

3

1: START F Õ 2: STOP F Õ 3: SWP TIME Õ 4: SWP MODE

1: START F Sets the start frequency in Hz for sweeping.

2: STOP F Sets the stop frequency in Hz for sweeping.

3: SWP TIME Sets the repetition rate in seconds for sweeping.

4: SWP MODE Selects linear or logarithmic sweeping.

C: EDIT MENU *

1: NEW ARB Õ 2: POINTS Õ [3: LINE EDIT] Õ [4: POINT EDIT] Õ [5: INVERT] Õ [6: SAVE AS] Õ 7:DELETE

1: NEW ARB Initiates a new arb waveform or loads the selected arb waveform.

2: POINTS Sets the number of points in a new arb waveform (8 to 16,000 points).

3: LINE EDIT Performs a linear interpolation between two points in the arb waveform.

4: POINT EDIT Edits the individual points of the selected arb waveform.

5: INVERT Inverts the selected arb waveform by changing the sign of each point.

6: SAVE AS Saves the current arb waveform in non-volatile memory.

7: DELETE Deletes the selected arb waveform from non-volatile memory.

* The commands enclosed in square brackets ( [ ] ) are “hidden” until you make a selection from the NEW ARB

command to initiate a new edit session.

37

Page 40

Chapter 3 Front-Panel Menu Operation

Front-panel menu reference

D: SYStem MENU

1: OUT TERM Õ 2: POWER ON Õ 3: ERROR Õ 4: TEST Õ 5: COMMA Õ 6:REVISION

1: OUT TERM Selects the output termination (50

2: POWER ON Enables or disables automatic power-up in power-down state “0”.

3: ERROR Retrieves errors from the error queue (up to 20 errors).

4: TEST Performs a complete self-test.

5: COMMA Enables or disables a comma separator between digits on the display.

6: REVISION Displays the function generator’s firmware revision codes.

W

or high impedance).

E: Input / Output MENU

1: HPIB ADDR Õ 2: INTERFACE Õ 3: BAUD RATE Õ 4: PARITY Õ 5: LANGUAGE

1: HPIB ADDR Sets the GPIB bus address (0 to 30).

2: INTERFACE Selects the GPIB or RS-232 interface.

3: BAUD RATE Selects the baud rate for RS-232 operation.

4: PARITY Selects even, odd, or no parity for RS-232 operation.

5: LANGUAGE Verifies the interface language: SCPI.

F: CALibration MENU *

1: SECURED Õ [1: UNSECURED] Õ [2: CALIBRATE] Õ 3: CAL COUNT Õ 4: MESSAGE

1: SECURED The function generator is secured against calibration; enter code to unsecure.

1: UNSECURED The function generator is unsecured for calibration; enter code to secure.

2: CALIBRATE Performs individual calibrations; must be UNSECURED.

3: CAL COUNT Reads the total number of times the function generator has been calibrated.

4: MESSAGE Reads the calibration string (up to 11 characters) entered from remote.

* The commands enclosed in square brackets ( [ ] ) are “hidden” unless the function generator is UNSECURED for

calibration.

38

Page 41

Chapter 3 Front-Panel Menu Operation

A front-panel menu tutorial

A front-panel menu tutorial

This section is a step-by-step tutorial which shows you how to use the

front-panel menu. We recommend that you spend a few minutes with this

tutorial to get comfortable with the structure and operation of the menu

before attempting verification, calibration, or adjustments.

The menu is organized in a top-down tree structure with three levels

(menus, commands, and parameters). You move down

the menu tree to get from one level to the next. Each of the three levels

has several horizontal choices which you can view by moving left

or right

> .

Menus

Commands

¿

or up

¾

<

3

Parameters

The menu is organized in a top-down tree structure with three levels.

To turn on the menu, press Shift Menu On/Off .

To turn off the menu, press Shift Menu On/Off .

To execute a menu command, press Enter .

To recall the last menu command that was executed,

press

Shift Recall Menu .

To turn off the menu at any time without saving changes,

press

Shift Cancel .

39

Page 42

Chapter 3 Front-Panel Menu Operation

A front-panel menu tutorial

Messages Displayed During Menu Use

TOP OF MENU You pressed

¾ while on the “MENUS” level; this is the top

level of the menu and you cannot go any higher.

To turn off the menu, press

a level, press

MENUS

COMMANDS

< or > . To move down a level, press

You are on the “MENUS” level. Press < or > to view the choices.

You are on the “COMMANDS” level. Press < or > to view the

Shift Menu On/Off . To move across the choices on

¿ .

command choices within the selected menu group.

PARAMETER You are on the “

PARAMETER” level. Press < or > to view

and edit the parameter for the selected command.

MENU BOTTOM You pressed

¿ while on the “PARAMETER” level; this is the

bottom level of the menu and you cannot go any lower.

To turn off the menu, press

ENTERED The change made on the “

displayed after you press

MIN VALUE The value you specified on the “

Shift Menu On/Off . To move up a level, press

PARAMETER” level is saved. This is

Enter (Menu Enter) to execute the command.

PARAMETER” level is too small for

¾ .

the selected command. The minimum value allowed is displayed for you to edit.

MAX VALUE The value you specified on the “

PARAMETER” level is too large for

the selected command. The maximum value allowed is displayed for you to edit.

EXITING You will see this message if you turn off the menu by pressing

Shift Menu On/Off or Shift Cancel . You did not edit any values on the

“

PARAMETER” level and changes were NOT saved.

NOT ENTERED You will see this message if you turn off the menu by pressing

Shift Menu On/Off or Shift Cancel . You did some editing of parameters but

the changes were

made on the “

NOT saved. Press Enter (Menu Enter) to save changes

PARAMETER” level.

40

Page 43

Chapter 3 Front-Panel Menu Operation

A front-panel menu tutorial

Menu Example 1 The following steps show you how to turn on the menu, move up and

down between levels, move across the choices on each level, and turn off

the menu. In this example, you will restore the function generator to the

power-on default state. This procedure is recommended before performing

the verification procedures in chapter 4.

Shift 1 Turn on the menu.

Menu On/Off You enter the menu on the “MENUS” level. The MOD MENU is your first

choice on this level.

A: MOD MENU

> > > 2 Move across to the SYS MENU choice on this level.

1

There are six menu group choices available on the “MENUS” level. Each

choice has a letter prefix for easy identification (

A: , B: , etc.).

D: SYS MENU

¿ 3 Move down to the “COMMANDS” level within the SYS MENU.

The

OUT TERM command is your first choice on this level.

1: OUT TERM

> 4 Move across to the POWER ON command on this level.

1

There are six command choices available in the SYS MENU. Each choice

on this level has a number prefix for easy identification (

1: , 2: , etc.).

3

2: POWER ON

1

You can also use the knob to scroll left or right through the choices on each

level of the menu.

41

Page 44

Chapter 3 Front-Panel Menu Operation

A front-panel menu tutorial

¿ 5 Move down a level to the “PARAMETER” choices.

The first parameter choice is “

(“

DEFAULT” is the factory setting and is stored in non-volatile memory).

DEFAULT” for the POWER ON command

DEFAULT

> 6 Move across to the “LAST STATE” choice.

There are two parameter choices for POWER ON.

LAST STATE

Enter 7 Save the change and turn off the menu.

The function generator beeps and displays a message to show that the

change is now in effect. You are then exited from the menu.

ENTERED

8 Cycle the power to restore the default values.

Turn the function generator OFF and then ON. The default output

state will now be in effect (1 kHz sine wave, 100 mV peak-to-peak,

50

W termination).

1

1

You can also use the knob to scroll left or right through the choices on each

level of the menu.

42

Page 45

Chapter 3 Front-Panel Menu Operation

A front-panel menu tutorial

Menu Example 2 Some commands in the menu require that you enter a numeric

parameter value. The following steps show you how to enter a number in

the menu. For this example, you will change the output amplitude.

Ampl 1 Select amplitude adjustment

The function generator displays the current output amplitude.

100.0 mVPP

< 2 Move the flashing cursor over to edit the first digit.

The cursor movement wraps around.

100.0 mVPP

3

^ ^ ^ 3 Increment the first digit until 300.0 mVPP is displayed.

The output amplitude of the function changes as you adjust the

displayed value.

300.0 mVPP

1

You can also use the knob and arrow keys to enter a number.

1

43

Page 46

Chapter 3 Front-Panel Menu Operation

To select the output termination

To select the output termination

The function generator has a fixed output impedance of 50 ohms on the

OUTPUT terminal. You can specify whether you are terminating the

output into a 50

between the source and load will result in an output amplitude or dc offset

which does not match the specified value.

Shift 1 Turn on the menu.

Menu On/Off A: MOD MENU

W load or an open circuit. Incorrect impedance matching

> > > 2 Move across to the SYS MENU choice on this level.

D: SYS MENU

¿ 3 Move down a level to the OUT TERM command.

1: OUT TERM

> 4 Move down a level and then across to the HIGH Z choice.

¿

With the output termination set to “HIGH Z”, the function generator

allows you to set the unloaded (open circuit) output voltage.

HIGH Z

Enter 5 Save the change and turn off the menu.

The function generator beeps and displays a message to show that the

change is now in effect. You are then exited from the menu.

1

1

1

You can also use the knob to scroll left or right through the choices on each

level of the menu.

44

Page 47

Chapter 3 Front-Panel Menu Operation

To output a modulated waveform

To output a modulated waveform

A modulated waveform consists of a carrier and a modulating waveform.

In

AM (amplitude modulation), the amplitude of the carrier is varied by

the amplitude of the modulating waveform. For this example, you will

output an AM waveform with 80% modulation depth. The carrier will be a

5 kHz sine wave and the modulating waveform will be a 200 Hz sine wave.

3

1 Select the function, frequency, and amplitude of the carrier.

For the carrier waveform, you can select a sine, square, triangle, ramp,

or arbitrary waveform. For this example, select a

an amplitude of

Shift AM 2Select AM.

Notice that the

Shift 3 Use the menu to select the shape of the modulating waveform.

< Recall Menu After you enable the AM function, the “recall menu” key will

automatically take you to the

1: AM SHAPE

5 Vpp.

AM annunciator turns on.

AM SHAPE command in the MOD MENU.

5 kHz sine wave with

45

Page 48

Chapter 3 Front-Panel Menu Operation

To output a modulated waveform

¿ 4 Move down a level verify that “SINE” is selected.

For the modulating waveform, you can select a sine, square, triangle,

ramp, noise, or arbitrary waveform. For this example, you will modulate

the carrier with a sine waveform. Notice that the

indicating that the displayed parameter is for

AM annunciator flashes,

AM.

SINE

Enter 5 Save the change and turn off the menu.

The modulating waveform is now a sine waveform.

ENTERED

Shift Freq 6 Set the modulating frequency to 200 Hz.

Notice that the

AM annunciator flashes, indicating that the displayed

frequency is the modulating frequency. Also notice that the modulating

frequency is displayed with fewer digits than the carrier frequency.

MOD 200.0 Hz

This message appears on the display for approximately 10 seconds.

Repeat this step as needed.

Shift Level 7 Set the modulation depth to 80%.

Notice that the

percentage is the

AM annunciator flashes, indicating that the displayed

AM depth (also called percent modulation).

080 % DEPTH

This message appears on the display for approximately 10 seconds.

Repeat this step as needed.

At this point, the function generator outputs the

specified modulation parameters.

AM waveform with the

46

Page 49

Chapter 3 Front-Panel Menu Operation

To unsecure the function generator for calibration

To unsecure the function generator for calibration

The function generator can use a calibration security code to prevent

unauthorized or accidental calibration. This procedure shows you how to

unsecure the function generator for calibration.

Shift 1 Turn on the menu.

Menu On/Off A: MOD MENU

< 2 Move across to the CAL MENU choice on this level.

F: CAL MENU

¿ 3 Move down a level to the SECURED command.

3

1: SECURED

If the display shows UNSECURED, you do not need to perform this

procedure to execute a calibration.

47

Page 50

Chapter 3 Front-Panel Menu Operation

To unsecure the function generator for calibration

¿ 4 Move down to the “parameters” level.

^000000:CODE

0 3 3

1 2 0 5 Unsecure the function generator by entering the security code.

ENTER

^033120:CODE

The security code is set to “HP33120” when the function generator is

shipped from the factory. The security code is stored in non-volatile

memory and does not change when the power has been off or after a

remote interface reset.

To enter the security code from the front panel, enter only the six digits.

To enter the security code from the remote interface, you may enter up to

12 characters. Use the knob or arrow keys to move left or right between

digits. Use the up or down arrow keys to change the digits.

To re-secure the function generator following a calibration, perform this

procedure again.

Additional information about the calibration security feature is given

on page 64.

48

Page 51

4

4

Calibration

Procedures

Page 52

Calibration Procedures

This chapter contains procedures for verification of the function

generator’s performance and adjustment (calibration). The chapter is

divided into the following sections:

Agilent Calibration Services . . . . . . . . . . . . . . 51

Calibration Interval . . . . . . . . . . . . . . . . . . . 51

Time Required for Calibration . . . . . . . . . . . . . 51

Automating Calibration Procedures . . . . . . . . . . 52

Recommended Test Equipment . . . . . . . . . . . . . 52

Test Considerations . . . . . . . . . . . . . . . . . . . 53

Performance Verification Tests . . . . . . . . . . . . . 54

Frequency Verification . . . . . . . . . . . . . . . . . 56

Function Gain and Linearity Verification . . . . . . . 56

DC Function Offset Verification . . . . . . . . . . . . 57

AC Amplitude Verification . . . . . . . . . . . . . . . 57

Amplitude Flatness Verification . . . . . . . . . . . . 60

AM Modulation Depth Verification . . . . . . . . . . . 61

Optional Performance Verification Tests . . . . . . . . 62

Calibration Security Code . . . . . . . . . . . . . . . . 64

Calibration Count . . . . . . . . . . . . . . . . . . . . 66

Calibration Message . . . . . . . . . . . . . . . . . . . 66

General Calibration/Adjustment Procedure . . . . . . 67

Aborting a Calibration in Progress . . . . . . . . . . . 69

Frequency and Burst Rate Adjustment . . . . . . . . 69

Function Gain and Linearity Adjustment . . . . . . . 70

AC Amplitude Adjustment (High-Z) . . . . . . . . . . 70

Modulation Adjustment . . . . . . . . . . . . . . . . . 72

AC Amplitude Adjustment (50W) . . . . . . . . . . . . 73

DC Output Adjustment . . . . . . . . . . . . . . . . . 76

Duty Cycle Adjustment . . . . . . . . . . . . . . . . . 77

AC Amplitude Flatness Adjustment . . . . . . . . . . 77

Output Amplifier Adjustment (Optional) . . . . . . . 80

Error Messages . . . . . . . . . . . . . . . . . . . . . 81

50

Page 53

Chapter 4 Calibration Procedures

Agilent Calibration Services

Closed-Case Electronic Calibration The function generator features

closed-case electronic calibration since no internal mechanical

adjustments are required for normal calibration. The function generator

calculates correction factors based upon the input reference value you set.

The new correction factors are stored in non-volatile memory until the

next calibration adjustment is performed (non-volatile memory does not

change when power has been off or after a remote interface reset).

Agilent Calibration Services

When your function generator is due for calibration, contact your local

Agilent Service Center for a low-cost recalibration. The 33120A Function

Generator is supported on automated calibration systems which allow

Agilent to provide this service at competitive prices. Calibrations to

MIL-STD-45662 are also available at competitive prices.

Calibration Interval

4

The function generator should be calibrated on a regular interval

determined by the measurement accuracy requirements of your

application. A 1- or 2-year interval is adequate for most applications.

Agilent does not recommend extending calibration intervals beyond

two years for any application.

Whatever calibration interval you select, Agilent recommends that complete

re-adjustment should always be performed at the calibration interval.

This will increase your confidence that the 33120A will remain within

specification for the next calibration interval. This criteria for re-adjustment

provides the best long-term stability. Performance data measured using this

method can be used to extend future calibration intervals.

Time Required for Calibration

The 33120A can be automatically calibrated under computer control.

With computer control you can perform the complete calibration

procedure and performance verification tests in less than 15 minutes.

Manual calibrations using the recommended test equipment will take

approximately 45 minutes.

51

Page 54

Chapter 4 Calibration Procedures

Automating Calibration Procedures

Automating Calibration Procedures

You can automate the complete verification and adjustment procedures

outlined in this chapter if you have access to programmable test

equipment. You can program the instrument configurations specified for

each test over the remote interface. You can then enter readback

verification data into a test program and compare the results to the

appropriate test limit values.

You can also enter calibration constants from the remote interface.

Remote operation is similar to the local front-panel procedure. You can

use a computer to perform the adjustment by first selecting the required

setup. The calibration value is sent to the function generator and then

the calibration is initiated over the remote interface. The function

generator must be unsecured prior to initiating the calibration procedure.

For further detailing on programming the function generator, see

chapters 3 and 4 in the Agilent 33120A User’s Guide.

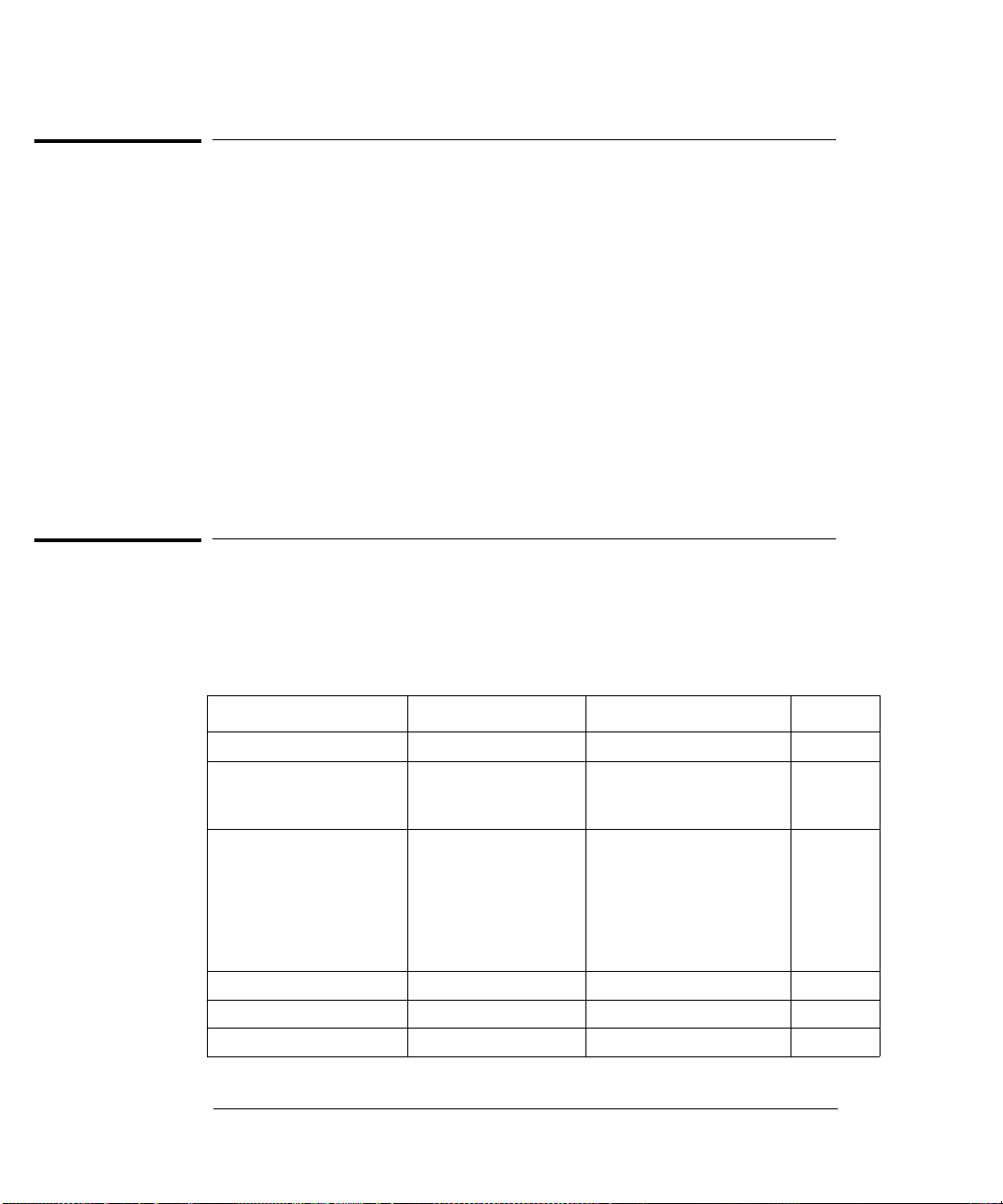

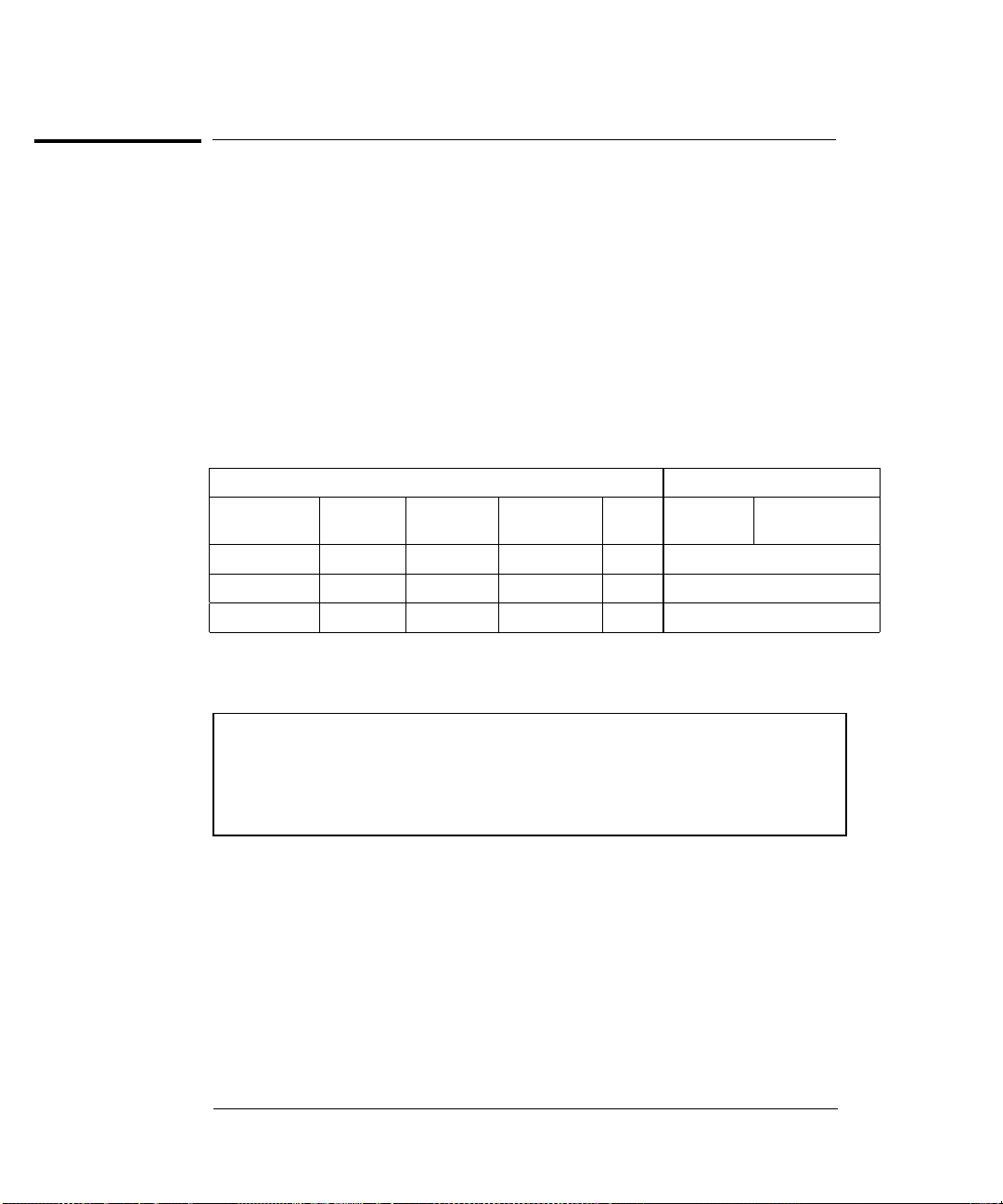

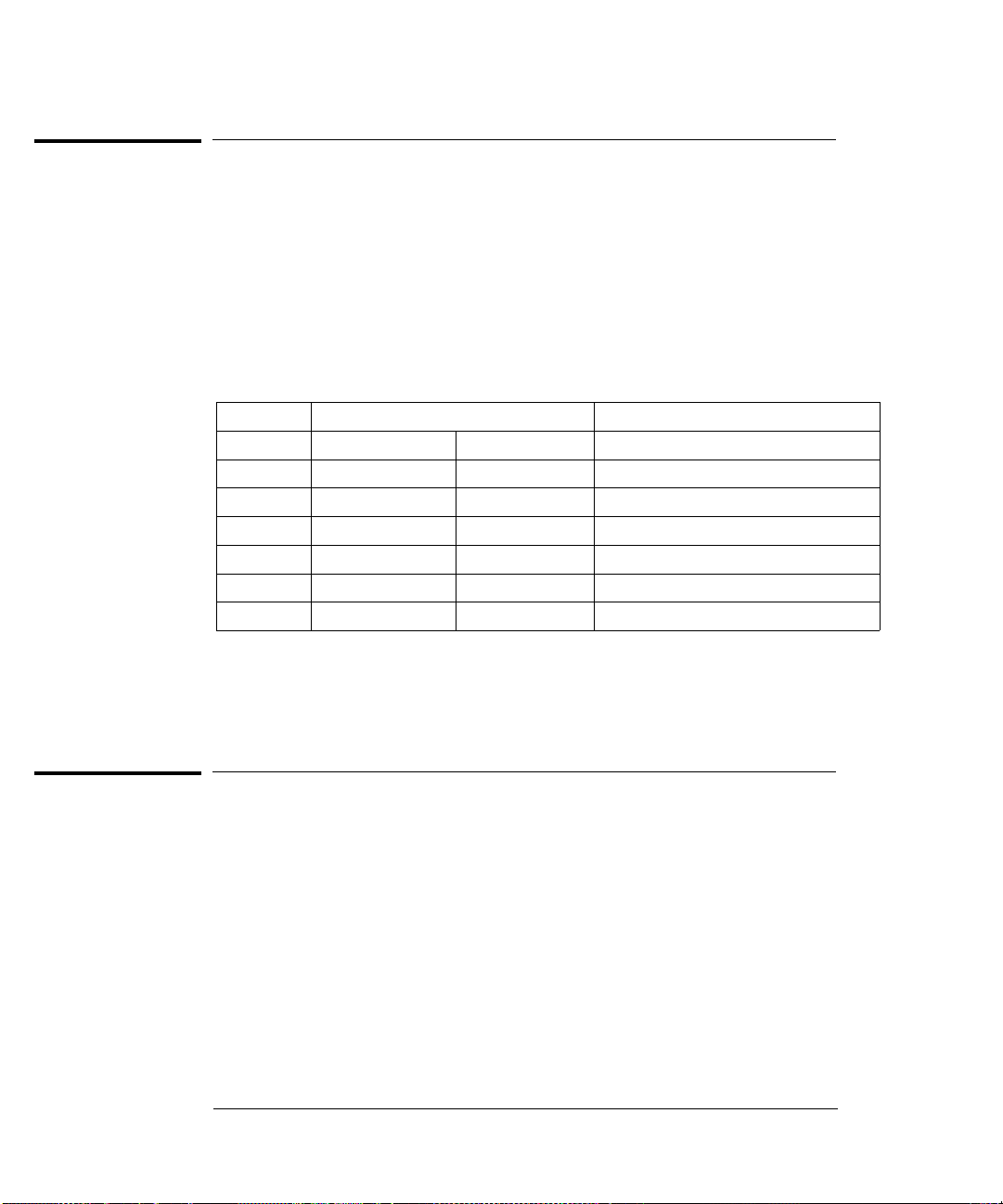

Recommended Test Equipment

The test equipment recommended for the performance verification and

adjustment procedures is listed below. If the exact instrument is not

available, use the accuracy requirements shown to select substitute

calibration standards.

Instrument Requirements Recommended Model Use*

50 W feedthrough load 50 W 0.1 W

6 1/2 digit Digital

Multimeter (DMM)

Thermal Voltage Converter

(50 W termination type)

or

Power Meter

or

Wideband ACrms Meter

Frequency Meter 1 ppm accuracy Agilent 53131A Q,P,T

Oscilloscope 100 MHz Agilent 54624A T

Spectrum Analyzer Response to 90 MHz Agilent 8560EC O

* Q = Quick Verification O= Optional Verification Tests

P = Performance Verification Tests T = Troubleshooting

20 Vdc 0.01%

Integrating ACrms

10 Vacrms 0.1%

1kHz to 15 MHz

100 kHz to 15 MHz

1 VAC rms 0.5%

1 kHz to 20 MHz

Agilent 34401A Q,P,T

3 Volt

Agilent E4418A with

Agilent 8482A

and 20 dB attenuator

—

Q,P,O,T

Q,P

52

Page 55

Chapter 4 Calibration Procedures

Test Considerations

Test Considerations

To ensure proper instrument operation, verify that you have selected the

correct power line voltage prior to attempting any test procedure in this

chapter. See page 22 in chapter 2 for more information.

For optimum performance, all test procedures should comply with the

following recommendations:

Verify the function generator is set to the default power on state

(power on default). A procedure is given on page 41.

Make sure that the calibration ambient temperature is stable and

between 18

Make sure ambient relative humidity is less than 80%.

C and 28 C.

Allow a 1-hour warm-up period before verification or adjustment.

Use only RG-58 or equivalent 50W cable.

Keep cables as short as possible, consistent with the impedance

requirements.

4

53

Page 56

Chapter 4 Calibration Procedures

Performance Verification Tests

Performance Verification Tests

The performance verification tests use the function generator’s

specifications listed in chapter 1, “Specifications,” starting on page 13.

You can perform four different levels of performance verification tests:

Self-Test A series of internal verification tests that give a high

confidence that the function generator is operational.

Quick Verification A combination of the internal self-tests and

Q

selected verification tests.

Performance Verification Tests An extensive set of tests that are

P

recommended as an acceptance test when you first receive the function

generator or after performing adjustments.

Optional Verification Tests Tests not performed with every

O

calibration. These tests can can be used to verify additional instrument

specifications following repairs to specific circuits.

Self-Test

A brief power-on self-test occurs automatically whenever you turn on the

function generator. This limited test assures that the function generator

is capable of operation.

To perform a complete self-test hold down the

Power switch to turn on the function generator; hold down the key for

more than 5 seconds (a complete description of these tests can be found in

chapter 6). The function generator will automatically perform the

complete self-test procedure when you release the key. The self-test will

complete in approximately 5 seconds.

You can perform many tests individually (or all tests at once) using the

TEST command in the SYS MENU. You can also perform a self-test from

the remote interface (see chapter 3 in the Agilent 33120A User’s Guide).

If the self-test is successful, “PASS” is displayed on the front panel.

If the self-test fails, “FAIL” is displayed and the ERROR annunciator

turns on. If repair is required, see chapter 6, “Service,” for further details.

If all tests pass, you have a high confidence (90%) that the function

generator is operational.

54

Shift key as you press the

Page 57

Chapter 4 Calibration Procedures

Performance Verification Tests

Quick Performance Check

The quick performance check is a combination of internal self-test and an

abbreviated performance test (specified by the letter Q in the performance

verification tests). This test provides a simple method to achieve high

confidence in the function generator’s ability to functionally operate and

meet specifications. These tests represent the absolute minimum set of

performance checks recommended following any service activity.

Auditing the function generator’s performance for the quick check points

(designated by a Q) verifies performance for “normal” accuracy drift

mechanisms. This test does not check for abnormal component failures.

To perform the quick performance check, do the following:

Set the function generator to the default power on state (power on default).

A procedure is given on page 41.

Perform a complete self-test. A procedure is given on page 21.

Perform only the performance verification tests indicated with

the letter Q.

If the function generator fails the quick performance check, adjustment or

repair is required.

Performance Verification Tests

The performance verification tests are recommended as acceptance tests

when you first receive the function generator. The acceptance test results

should be compared against the 1 year test limits. After acceptance, you

should repeat the performance verification tests at every calibration interval.

If the function generator fails performance verification, adjustment or

repair is required.

4

55

Page 58

Chapter 4 Calibration Procedures

Frequency Verification

Frequency Verification

This test verifies the frequency accuracy of the two sources in the

function generator. All output frequencies are derived from a single

generated frequency, and only one frequency point is checked.

The second test verifies the burst rate frequency.

Set the function generator for each output indicated in the table below.

Use a frequency meter to measure the output frequency. Compare the

measured results to the test limits shown in the table. This is a 50

output termination test.

Agilent 33120A Measurement

Function

Q Sine wave

Q Square wave

OUT

TERM

50 W

50 W

1

Ampl Freq

3.5 Vrms 1.00 kHz — — 1.00 kHz

3.5 Vrms 1.00 kHz 500 Hz 1 CYC 500 Hz

BURST

RATE

BURST

CNT

Nominal Error

W

0.02 Hz

5 Hz

Function Gain and Linearity Verification

This test verifies the output amplitude accuracy specification for

sine wave, triangle wave, ramp, and square wave outputs.

Set the function generator for each output indicated in the table below.

Use a DMM to measure the function generator ACrms output voltage.

Compare the measured results to the test limits shown in the table.

This is a HIGH Z output termination test.

Agilent 33120A Measurement

1

Function OUT TERM

Q Sine wave HIGH Z 7.0 Vrms 1.0 kHz 7.0 Vrms

Sine wave HIGH Z 5.7 Vrms 1.0 kHz 5.7 Vrms

Triangle wave HIGH Z 5.7 Vrms 100 Hz 5.7 Vrms

Ramp wave HIGH Z 5.7 Vrms 100 Hz 5.7 Vrms

Q Square wave HIGH Z 10.0 Vrms 100 Hz 10.0 Vrms

Square wave HIGH Z 8.0 Vrms 100 Hz 8.0 Vrms

1

Output termination set using front panel controls. HIGH Z assumes no load on

output. 50W assumes a 50W 0.1W load on output.

56

Ampl Freq Nominal Error

0.07 Vrms

0.057 Vrms

0.057 Vrms

0.057 Vrms

0.1 Vrms

0.08 Vrms

Page 59

Chapter 4 Calibration Procedures

DC Function Offset Verification

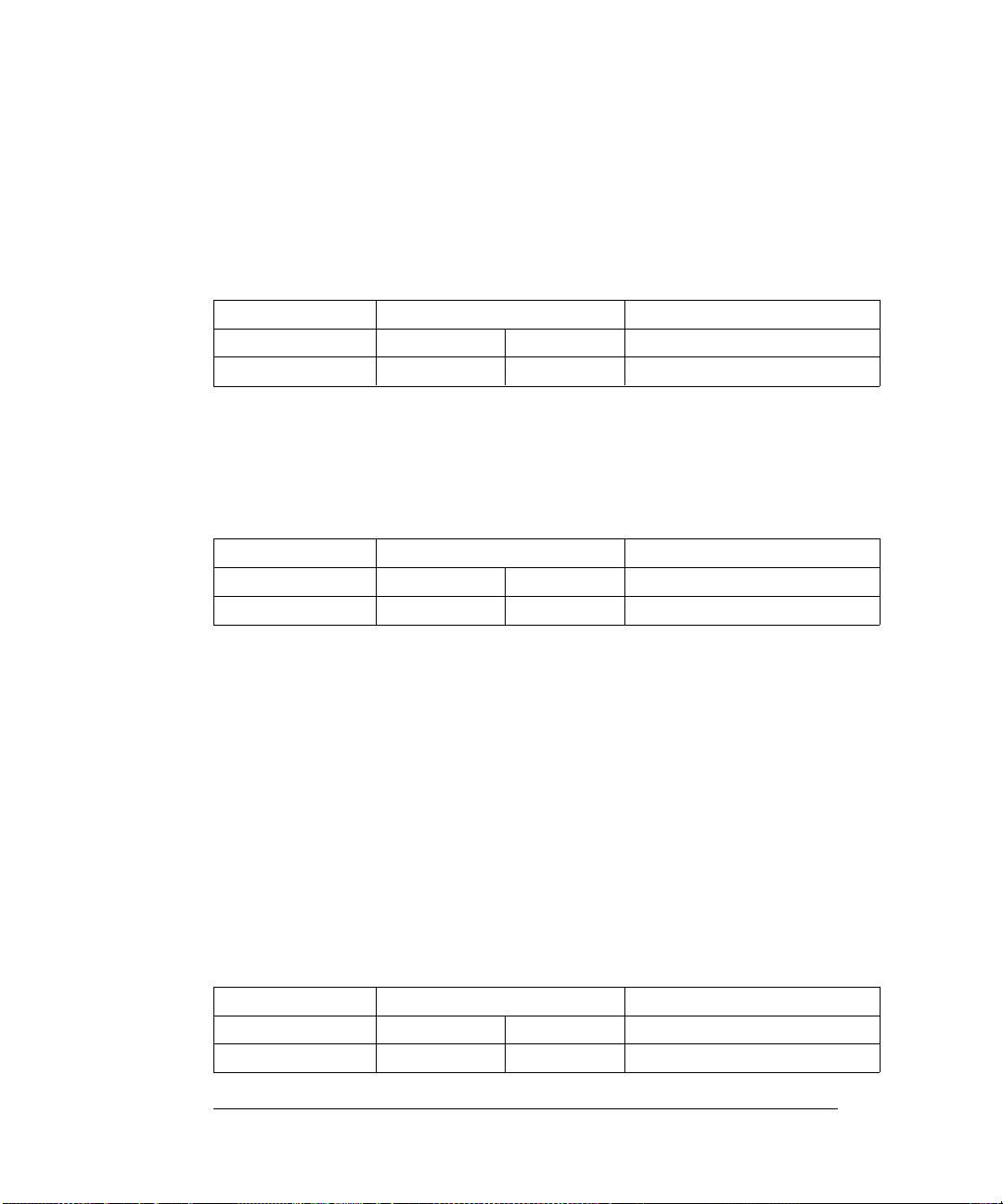

DC Function Offset Verification

This test verifies the DC offset and DC output specifications.

Set the function generator for each output indicated in the table below.

Use a DMM to measure the function generator dcV output. Compare the

measured results to the test limits shown in the table. This is a HIGH Z

output termination test.

Agilent 33120A Measurement

Function OUT TERM

Q DC Volts HIGH Z 10.0 Vdc 10.0 Vdc

DC Volts HIGH Z -10.0 Vdc -10.0 Vdc

1

Ampl Nominal Error

0.20 Vdc

0.20 Vdc

AC Amplitude Verification

4

This procedure is used to check the output amplitude calibration of the

function generator. Verification checks are performed to check the

accuracy of the pre-attenuator and post attenuator. Make sure you have

read “Test Considerations” on page 53.

Set the function generator for each output indicated in the table on the

next page. Use a DMM to measure the ACrms output voltage of the

function generator. Compare the measured results to the test limits

shown in the table. This is a HIGH Z output termination test.

1

Output termination set using front panel controls. HIGH Z assumes no load on

output. 50W assumes a 50W 0.1W load on output.

57

Page 60

Chapter 4 Calibration Procedures

AC Amplitude Verification

Agilent 33120A Measurement

Function OUT TERM

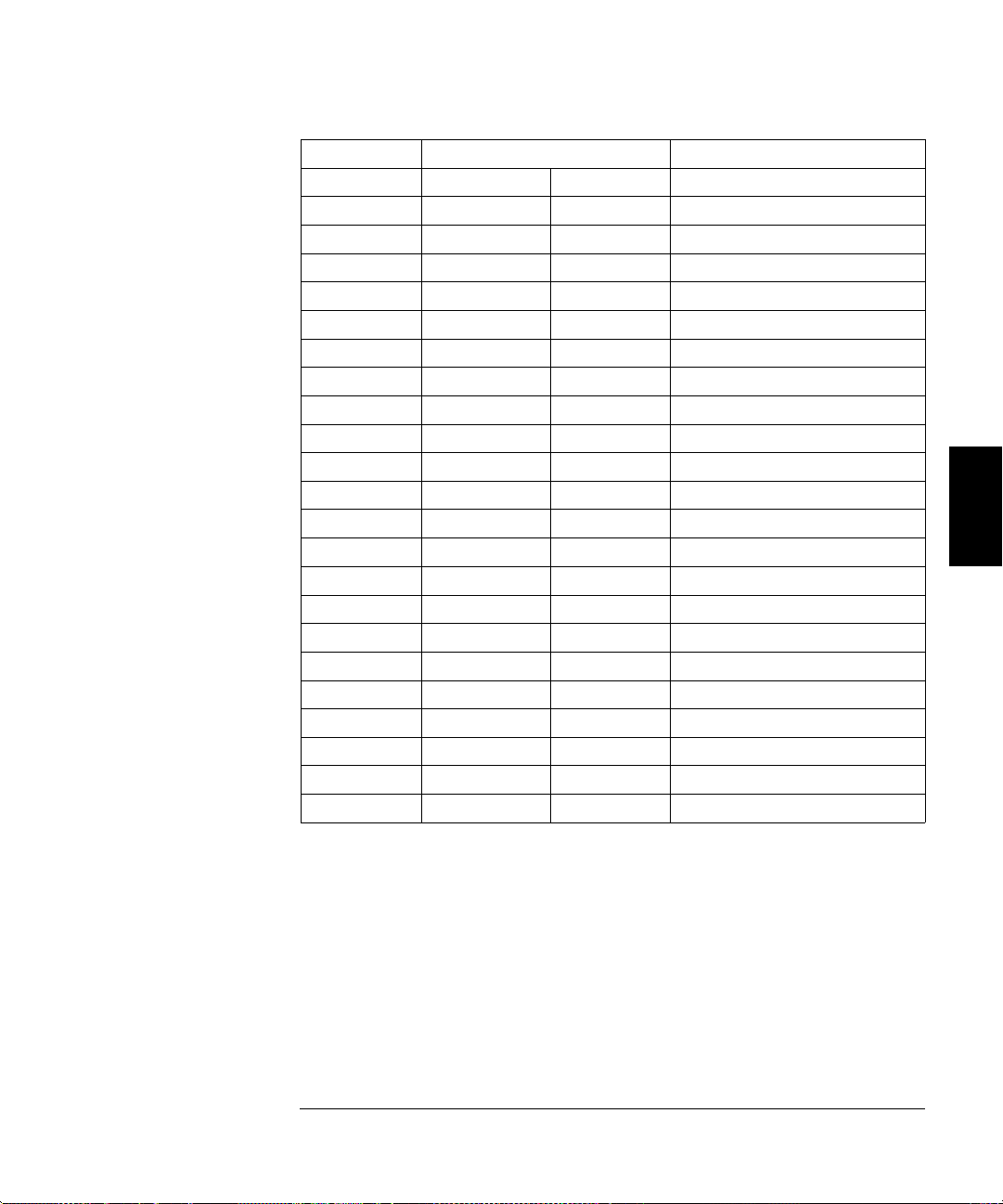

Q Sine wave HIGH Z 7.0 Vrms 1.00 kHz 7.0 Vrms

Sine wave HIGH Z 5.7 Vrms 1.00 kHz 5.7 Vrms

Sine wave HIGH Z 5.5 Vrms 1.00 kHz 5.5 Vrms

Sine wave HIGH Z 4.4 Vrms 1.00 kHz 4.4 Vrms

Sine wave HIGH Z 3.5 Vrms 1.00 kHz 3.5 Vrms

Sine wave HIGH Z 2.8 Vrms 1.00 kHz 2.8 Vrms

Sine wave HIGH Z 2.2 Vrms 1.00 kHz 2.2 Vrms

Sine wave HIGH Z 1.7 Vrms 1.00 kHz 1.7 Vrms

Sine wave HIGH Z 1.4 Vrms 1.00 kHz 1.4Vrms

Sine wave HIGH Z 1.1 Vrms 1.00 kHz 1.1 Vrms

Q Sine wave HIGH Z 0.88 Vrms 1.00 kHz 0.88 Vrms

Sine wave HIGH Z 0.70 Vrms 1.00 kHz 0.70 Vrms

Sine wave HIGH Z 0.55 Vrms 1.00 kHz 0.55 Vrms

Sine wave HIGH Z 0.44 Vrms 1.00 kHz 0.44 Vrms

Sine wave HIGH Z 0.35 Vrms 1.00 kHz 0.35 Vrms

Sine wave HIGH Z 0.28 Vrms 1.00 kHz 0.28 Vrms

Sine wave HIGH Z 0.22 Vrms 1.00 kHz 0.22 Vrms

Sine wave HIGH Z 0.17 Vrms 1.00 kHz 0.17 Vrms

Sine wave HIGH Z 0.14 Vrms 1.00 kHz 0.14 Vrms

Sine wave HIGH Z 0.11 Vrms 1.00 kHz 0.11 Vrms

Q Sine wave HIGH Z 0.088 Vrms 1.00 kHz 0.088Vrms

Sine wave HIGH Z 0.070 Vrms 1.00 kHz 0.070 Vrms

Sine wave HIGH Z 0.055 Vrms 1.00 kHz 0.055 Vrms

Sine wave HIGH Z 0.044 Vrms 1.00 kHz 0.044 Vrms

Q Sine wave HIGH Z 0.036 Vrms 1.00 kHz 0.036 Vrms

1

Ampl Freq Nominal Error

0.070 Vrms

0.057 Vrms

0.055 Vrms

0.044 Vrms

0.035 Vrms

0.028 Vrms

0.022 Vrms

0.017 Vrms

0.014 Vrms

0.011 Vrms

0.0088 Vrms

0.0070 Vrms

0.0055 Vrms

0.0044 Vrms

0.0035 Vrms

0.0028 Vrms

0.0022 Vrms

0.0017 Vrms

0.0014 Vrms

0.0011 Vrms

0.00088 Vrms

0.00070 Vrms

0.00055 Vrms

0.00044 Vrms

0.00036 Vrms

1

Output termination set using front panel controls. HIGH Z assumes no load on

output. 50W assumes a 50W 0.1W load on output.

58

Page 61

Chapter 4 Calibration Procedures

AC Amplitude Verification

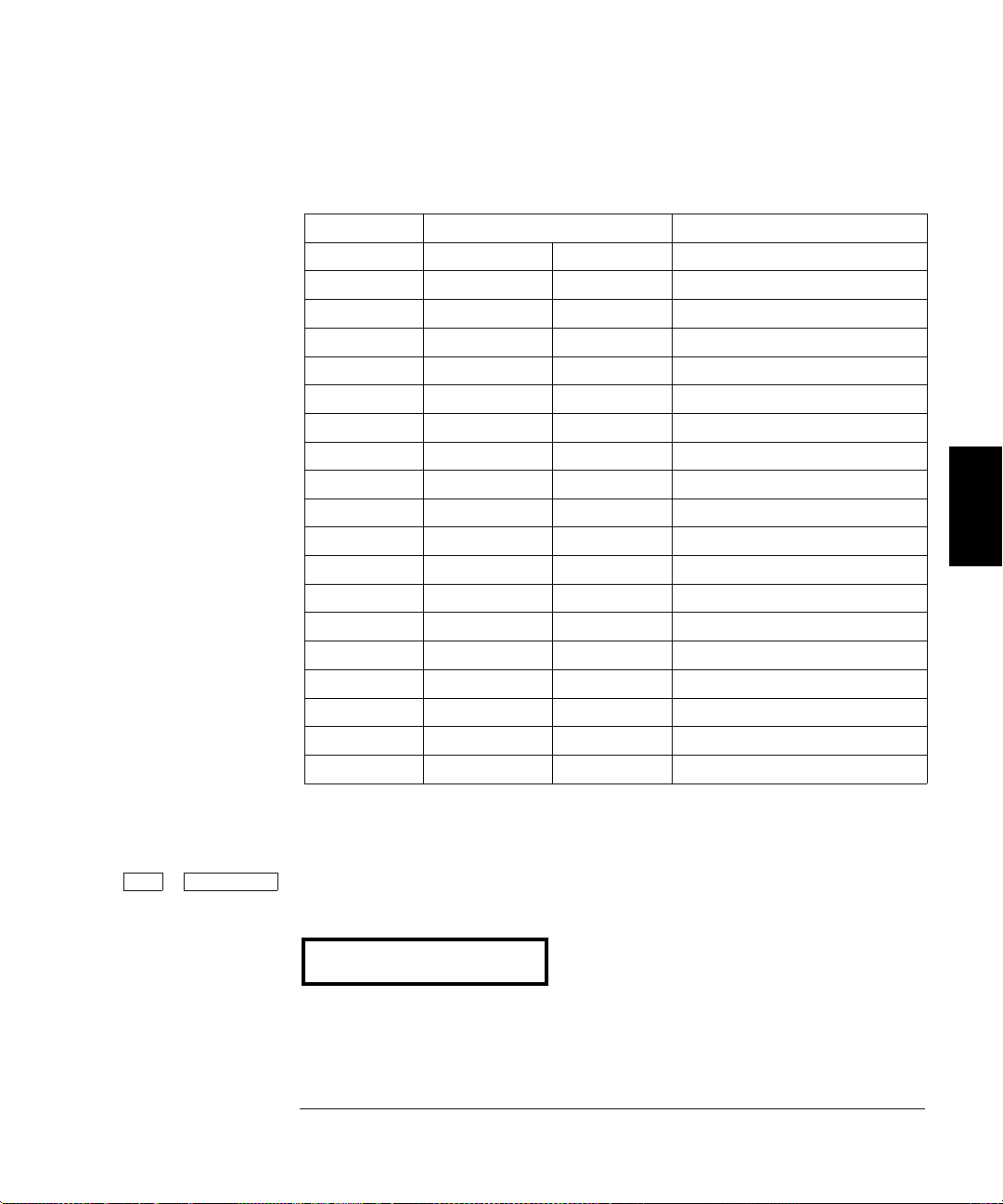

Install the 50W feedthrough load between the DMM and the function

generator output. Set the function generator for each output indicated in

the table on the next page. Use a DMM to measure the ACrms output

voltage of the function generator. Compare the measured results to the

test limits shown in the table. This is a 50

Function OUT TERM

Q Sine wave

Sine wave

Sine wave

Sine wave

Sine wave

Sine wave

Q Sine wave

Sine wave

Sine wave

Sine wave

Sine wave

Sine wave

Sine wave

Sine wave

Sine wave

Sine wave

Sine wave

Sine wave

Sine wave

Sine wave

Q Sine wave

Sine wave

Sine wave

Sine wave

W output termination test.

Agilent 33120A Measurement

1

Ampl Freq Nominal Error

50 W

50 W

50 W

50 W

50 W

50 W

50 W

50 W

50 W

50 W

50 W

50 W

50 W

50 W

50 W

50 W

50 W

50 W

50 W

50 W

50 W

50 W

50 W

50 W

3.5 Vrms 1.0000 kHz 3.5 Vrms

2.8 Vrms 1.0000 kHz 2.8 Vrms

2.2 Vrms 1.0000 kHz 2.2 Vrms

1.7 Vrms 1.0000 kHz 1.7 Vrms

1.4Vrms 1.0000 kHz 1.4Vrms

1.1 Vrms 1.0000 kHz 1.1 Vrms

0.88 Vrms 1.0000 kHz 0.88 Vrms

0.70 Vrms 1.0000 kHz 0.70 Vrms

0.55 Vrms 1.0000 kHz 0.55 Vrms

0.44 Vrms 1.0000 kHz 0.44 Vrms

0.35 Vrms 1.0000 kHz 0.35 Vrms

0.28 Vrms 1.0000 kHz 0.28 Vrms

0.22 Vrms 1.0000 kHz 0.22 Vrms

0.17 Vrms 1.0000 kHz 0.17 Vrms

0.14 Vrms 1.0000 kHz 0.14 Vrms

0.11 Vrms 1.0000 kHz 0.11 Vrms

0.088Vrms 1.0000 kHz 0.088Vrms

0.070 Vrms 1.0000 kHz 0.070 Vrms

0.055 Vrms 1.0000 kHz 0.055 Vrms

0.044 Vrms 1.0000 kHz 0.044 Vrms

0.035 Vrms 1.0000 kHz 0.035 Vrms

0.028 Vrms 1.0000 kHz 0.028 Vrms

0.022 Vrms 1.0000 kHz 0.022 Vrms

0.018 Vrms 1.0000 kHz 0.018 Vrms

0.035 Vrms

0.028 Vrms

0.022 Vrms

0.017 Vrms

0.014 Vrms

0.011 Vrms

0.0088 Vrms

0.0070 Vrms

0.0055 Vrms

0.0044 Vrms

0.0035 Vrms

0.0028 Vrms

0.0022 Vrms

0.0017 Vrms

0.0014 Vrms

0.0011 Vrms

0.00088 Vrms

0.00070 Vrms

0.00055 Vrms

0.00044 Vrms

0.00035 Vrms

0.00028 Vrms

0.00022 Vrms

0.00018 Vrms

4

1

Output termination set using front panel controls. HIGH Z assumes no load on

output. 50W assumes a 50W 0.1W load on output.

59

Page 62

Chapter 4 Calibration Procedures

Amplitude Flatness Verification

Amplitude Flatness Verification

This test verifies the output amplitude flatness specification at selected

frequencies. If you use a TVC (recommended) or a wide band ACrms

voltmeter (with a 50

described. If you are using a measurement device that requires a transfer

measurement (for example, a power meter), make the transfer in the

reference measurement at 100 kHz.

Set the function generator to the first output indicated in the table below

and make a reference measurement. Select each function generator output

in the table below and adjust the function generator output amplitude until

the measured output is at the reference measurement. Compare the

amplitude level set on the front panel to the test limits shown in the table.

This test is a 50

Function

Q Sine wave

Sine wave

Sine wave

Q Sine wave

Sine wave

Sine wave

Sine wave

Sine wave

Sine wave

Sine wave

Q Sine wave

OUT

TERM

W feed through load), perform this procedure as

W output termination test.

Agilent 33120A Measurement

1

50 W

50 W

50 W

50 W

50 W

50 W

50 W

50 W

50 W

50 W

50 W

Ampl Freq Nominal Error

3.0 Vrms 1.00 kHz <reference>

3.0 Vrms 100.00 kHz <reference>

3.0 Vrms 500.00 kHz <reference>

3.0 Vrms 1.00 MHz <reference>

3.0 Vrms 3.00 MHz <reference>

3.0 Vrms 5.00 MHz <reference>

3.0 Vrms 7.00 MHz <reference>

3.0 Vrms 9.00 MHz <reference>

3.0 Vrms 11.00 MHz <reference>

3.0 Vrms 13.00 MHz <reference>

3.0 Vrms 15.00 MHz <reference>

0.03 Vrms

0.045 Vrms

0.045 Vrms

0.06 Vrms

0.06 Vrms

0.06 Vrms

0.06 Vrms

0.06 Vrms

0.06 Vrms

0.06 Vrms

1

Output termination set using front panel controls. HIGH Z assumes no load on

output. 50W assumes a 50W 0.1W load on output.

60

Page 63

Chapter 4 Calibration Procedures

AM Modulation Depth Verification

AM Modulation Depth Verification

This test verifies the modulation depth specification.

Select each function generator output in the table below. Use a DMM to

measure the function generator ACrms output voltage. Compare the

measured results to the test limits shown in the table. This is a HIGH Z

output termination test.

Agilent 33120A Measurement

AM Modulation

1

Function

Q Sine wave HIGH Z 1.0 Vrms 1.00 kHz Sinewave 100 Hz 0% 0.50 Vrms

Sine wave HIGH Z 1.0 Vrms 1.00 kHz Sinewave 100 Hz 100% 0.61 Vrms

OUT

TERM

Ampl Freq Shape Freq Depth Nominal Error

0.005 Vrms

0.0061 Vrms

4

1

Output termination set using front panel controls. HIGH Z assumes no load on

output. 50W assumes a 50W 0.1W load on output.

61

Page 64

Chapter 4 Calibration Procedures

Optional Performance Verification Tests

Optional Performance Verification Tests

These tests are not intended to be performed with every calibration.

They are provided as an aid for verifying additional instrument specifications.

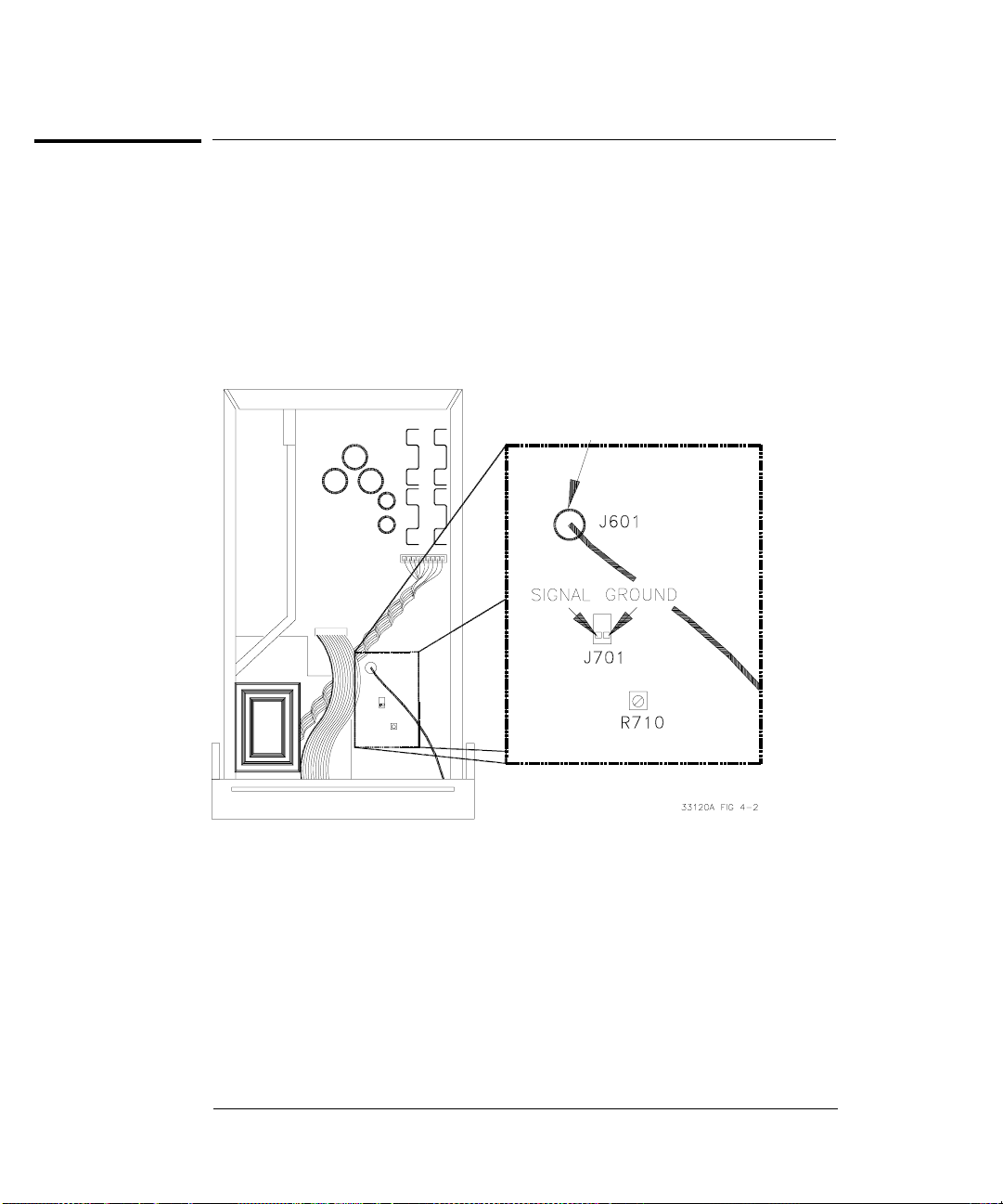

Square Wave Duty Cycle Verification

This test verifies the duty cycle specification of the squarewave output.

Select each function generator output in the table below. Use an integrating

DMM to measure the Vdc output of the function generator. Compare the

measured results to the test limits shown in the table. This is a HIGH Z

output termination test.

Agilent 33120A Measurement

1

Function

Square wave HIGH Z 1.0 Vrms 300.00 Hz 50% 0.00 Vdc

Square wave HIGH Z 1.0 Vrms 300.00 Hz 25% - 0.50 Vdc

Square wave HIGH Z 1.0 Vrms 300.00 Hz 75% + 0.50 Vdc

OUT

TERM

Ampl Freq