Agilent GC, GC-MS User manual

Maintaining your Agilent GC and GC/MS Systems

Our measure is your success.

Table of Contents |

|

Gas Management........................................................................................ |

1 |

Gas Types .................................................................................................................................................................................... |

2 |

Gas Purification Systems............................................................................................................................................................. |

4 |

Gas Traps..................................................................................................................................................................................... |

6 |

Renewable Gas Purification System ......................................................................................................................................... |

12 |

Universal/External Split Vent Trap............................................................................................................................................. |

13 |

Regulators ................................................................................................................................................................................. |

14 |

Tubing........................................................................................................................................................................................ |

15 |

Flowmeters ............................................................................................................................................................................... |

16 |

Gas Leak Detector..................................................................................................................................................................... |

18 |

Sample Introduction .................................................................................. |

19 |

Vials........................................................................................................................................................................................... |

20 |

Electronic Crimpers and Decappers.......................................................................................................................................... |

25 |

Gold Standard Autosampler Syringes ....................................................................................................................................... |

26 |

Headspace Sampler.................................................................................................................................................................. |

34 |

CTC Autosampler Supplies........................................................................................................................................................ |

37 |

Purge and Trap Supplies ........................................................................................................................................................... |

41 |

Markes Thermal Desorption ..................................................................................................................................................... |

43 |

Inlets .......................................................................................................... |

45 |

Premium Non-Stick Septa......................................................................................................................................................... |

46 |

Ferrules ..................................................................................................................................................................................... |

50 |

Capillary Flow Technology Supplies.......................................................................................................................................... |

54 |

Split/Splitless Liners .................................................................................................................................................................. |

55 |

Direct Connect Liners................................................................................................................................................................ |

59 |

Helix Liners................................................................................................................................................................................ |

59 |

Split/Splitless Inlets ................................................................................................................................................................... |

60 |

Cool On-Column Inlets .............................................................................................................................................................. |

69 |

Purged Packed Inlets ................................................................................................................................................................ |

75 |

Programmed Temperature Vaporizer (PTV) Inlets ..................................................................................................................... |

78 |

Detectors ................................................................................................... |

83 |

Flame Ionization Detector (FID)................................................................................................................................................ |

84 |

Electron Capture Detector (ECD).............................................................................................................................................. |

91 |

Thermal Conductivity Detector (TCD) ....................................................................................................................................... |

94 |

Flame Photometric Detector (FPD)........................................................................................................................................... |

99 |

Nitrogen Phosphorus Detector (NPD) .................................................................................................................................... |

106 |

Nitrogen and Sulfur Chemiluminescence Detectors............................................................................................................... |

113 |

GC/MS Systems ...................................................................................... |

115 |

Maintaining Mass Selective Detectors (MSD)....................................................................................................................... |

116 |

MSD Contamination ............................................................................................................................................................... |

118 |

Cleaning and Maintenance Supplies...................................................................................................................................... |

126 |

Ion Source............................................................................................................................................................................... |

128 |

Installing a Capillary Column in the GC/MSD Interface ......................................................................................................... |

134 |

QuickSwap MS Interface Restrictors...................................................................................................................................... |

135 |

MSD Filaments ...................................................................................................................................................................... |

136 |

Vacuum Systems and Pumps ................................................................................................................................................. |

138 |

MSD Electron Multipliers and Replacement Horn ................................................................................................................ |

142 |

MS Test and Performance Samples........................................................................................................................................ |

143 |

Gas Management

Avoid column damage, improve detector life, and achieve reliable, consistent results.

Gas management means more than just selecting the appropriate carrier gas for your needs. It also means taking steps to prevent contaminants like oxygen, moisture, and hydrocarbons from damaging your GC column.

As you read through the following pages, you will find…

•Practical advice about carrier gas types, impurities, leak detection, and flow rates.

•Valuable techniques that can minimize the likelihood of GC system contamination.

•Tips and tools that will help your lab implement gas management protocols.

•The latest details about Agilent-engineered gas purifiers, tubing, regulators, leak detectors, and flowmeters.

Order online at www.agilent.com/chem/store |

1 |

|

|

Gas Types

Carrier Gases

The most frequently used carrier gases are helium and hydrogen, although nitrogen and argon can be used. Purity is essential for these gases since they sweep the sample through the column where it is separated into its component parts and then through the detector for component quantification. Carrier gas purity is also critical to prevent degradation of chromatographic columns and hardware.

The following tables list minimum and maximum pressures in psi for inlets and detectors measured at the bulkhead fitting at the back of the gas chromatograph.

Inlet Pressure Settings (psi)

|

Split/Splitless |

Split/Splitless |

Cool On-Column |

Packed |

PTV |

|

(0-150 psi) |

(0-100 psi) |

|

|

|

|

|

|

|

|

|

Carrier max |

170 |

120 |

120 |

120 |

120 |

(psi) |

|

|

|

|

|

|

|

|

|

||

Carrier min |

Must supply 20 psi greater than pressure used in method |

|

|

||

(psi) |

|

|

|

|

|

|

|

|

|

|

|

Detector Pressure Settings (psi)

|

FID |

NPD |

TCD |

ECD |

FPD |

|

|

|

|

|

|

Hydrogen |

35-100 |

35-100 |

|

|

45-100 |

|

|

|

|

|

|

Air |

55-100 |

55-100 |

|

|

100-120 |

|

|

|

|

|

|

Make up |

55-100 |

55-100 |

55-100 |

55-100 |

55-100 |

|

|

|

|

|

|

Reference |

|

|

55-100 |

|

|

|

|

|

|

|

|

Conversions: 1 psi = 6.8947, kPa = 0.068947, Bar = 0.068 ATM

2 Order online at www.agilent.com/chem/store

Gas Management

Gas Purity and Selection

Agilent recommends that carrier

and detector gases be 99.9995% pure. Air needs to be zero grade or better. Agilent also recommends using traps to remove hydrocarbons, water and oxygen.

When used with capillary columns, GC detectors require a separate makeup gas for optimum sensitivity. For each detector and carrier gas, there is a preferred choice for makeup gas. This table lists gas recommendations for capillary columns.

Detector |

Carrier Gas |

Make up |

Make up |

Purge or |

|

|

|

1st choice |

2nd choice |

Reference |

|

|

|

|

|

|

|

Electron capture |

Hydrogen |

Argon/methane |

Nitrogen |

Anode purge must |

|

|

|

|

|

be same as |

|

|

Helium |

Argon/methane |

Nitrogen |

||

|

makeup |

||||

|

|

|

|

||

|

Nitrogen |

Nitrogen |

Argon/methane |

|

|

|

|

|

|

|

|

|

Argon/methane |

Argon/methane |

Nitrogen |

|

|

|

|

|

|

|

|

Flame ionization |

Hydrogen |

Nitrogen |

Helium |

Hydrogen and air |

|

|

|

|

|

for detector |

|

|

Helium |

Nitrogen |

Helium |

||

|

|

||||

|

|

|

|

|

|

|

Nitrogen |

Nitrogen |

Helium |

|

|

|

|

|

|

|

|

Flame |

Hydrogen |

Nitrogen |

None |

Hydrogen and air |

|

photometric |

|

|

|

for detector |

|

Helium |

Nitrogen |

|

|||

|

|

|

|||

|

|

|

|

|

|

|

Nitrogen |

Nitrogen |

|

|

|

|

|

|

|

|

|

|

Argon |

Nitrogen |

|

|

|

|

|

|

|

|

|

Mass selective |

Hydrogen |

None |

None |

|

|

|

|

|

|

|

|

|

Helium |

None |

None |

|

|

|

|

|

|

|

|

Nitrogen |

Helium |

Nitrogen |

Helium |

Hydrogen and air |

|

phosphorous |

|

|

|

for detector |

|

Nitrogen |

Nitrogen |

Helium |

|||

|

|

||||

|

|

|

|

|

|

Thermal |

Hydrogen |

Must be same as |

Must be same as |

Reference must |

|

conductivity |

|

carrier and |

carrier and |

be same as carrier |

|

Helium |

|||||

|

reference |

reference |

and makeup |

||

|

|

||||

|

Nitrogen |

|

|

|

|

|

|

|

|

|

Order online at www.agilent.com/chem/store |

3 |

|

|

Tips & Tools

Gas purifiers should always be oriented vertically, not horizontally.

Contaminants & Purities

Contaminants in gases are major contributors to capillary column degradation and detector noise, and can interfere with chromatographic results. Concentration of these contaminants vary by the grade of gas.

Hydrocarbons and Halocarbons

•Decrease detector sensitivity by increasing detector background noise.

•Can also cause baseline drift or wander, contaminant peaks, and noisy or high offsets of baselines.

Moisture

•Can be introduced by improper handling and/or installation of plumbing.

•A common cause of column stationary phase degradation.

•Can damage instrument.

Oxygen

•Most common contaminant.

•A common cause of column stationary phase and inlet liner degradation.

•Can cause decomposition of labile analytes.

•Opportunity for introduction at every fitting present in the gas line or during use of gas permeable tubing.

Gas Purification Systems

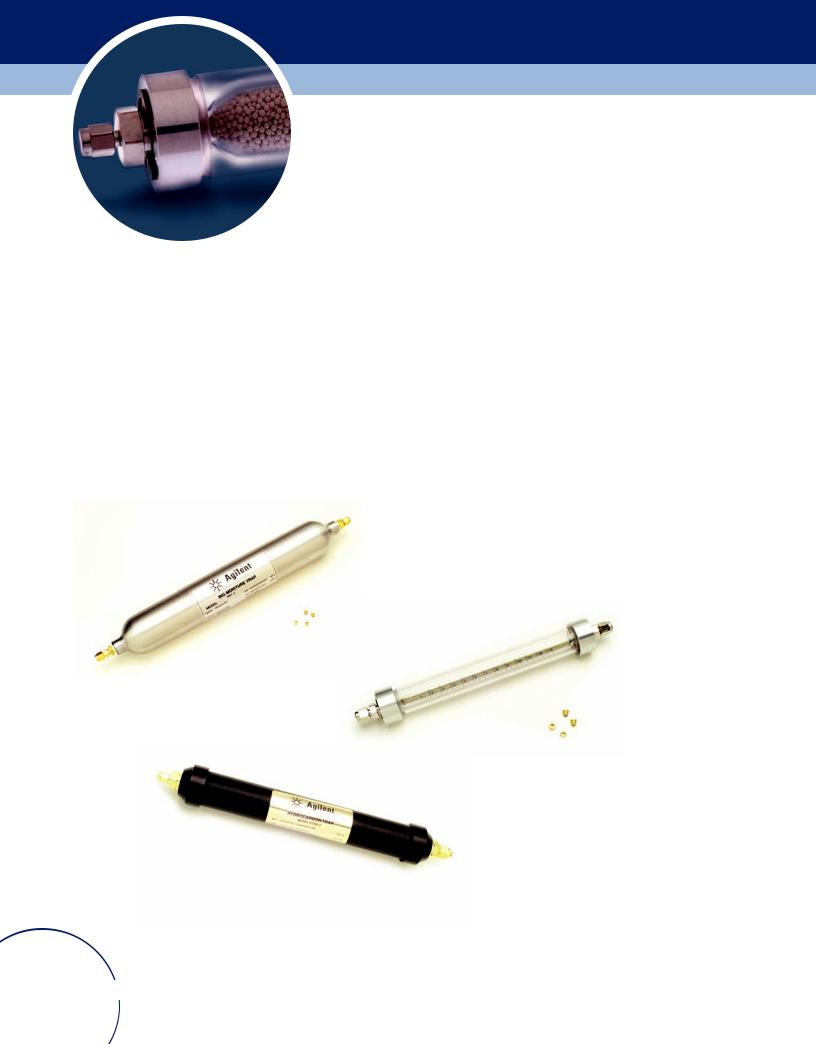

Purifiers are available in a variety of sizes and configurations to remove common contaminants like oxygen, moisture, and hydrocarbons. In-line gas purifiers, including refillable, indicating, S-shaped, and metal body types, are made to remove specific contaminants. Agilent also offers gas purification systems with removable cartridges. These systems provide the ability to design the right combination of filters needed for your application to achieve the proper gas purity.

4 Order online at www.agilent.com/chem/store

Gas Management

Carrier Gas Purification

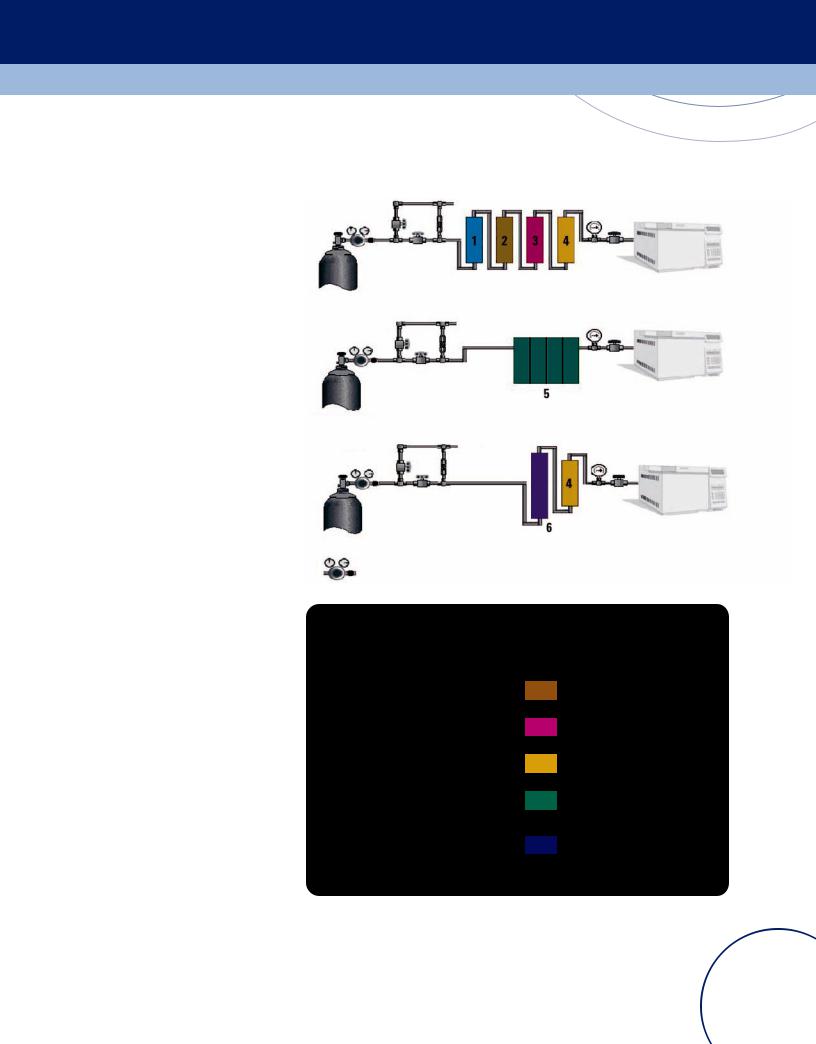

The Carrier Gas Purification illustration shows the most common gas purification configurations used in gas chromatography.

Regardless of which purification system is employed, proper installation and maintenance is required to achieve optimal performance from the purification system(s). A purifier that is not maintained will eventually

expire and become ineffective, or worse, a source of contamination.

•Determine desired purity level.

•Keep number of fittings in gas line to a minimum.

•Install purifiers in a convenient location close to the GC.

•Purifier log books are useful for determining maintenance schedule.

•Use indicating traps closest to the GC so you can determine when to change the traps that are upstream.

In-Line Gas Purifiers

-OR-

Gas supply |

Gas Purification System |

-OR-

Gas supply |

Combination Trap |

Vent

Gas supply = cylinder, in-house line, or gas generator Regulator = brass dual stage regulator

Detector Gas Purification |

Key |

|

|

|

|

FID make-up, air, and H2

ECD make-up

ELCD reaction gas

MS carrier gas

1 = Moisture Trap

2 = Hydrocarbon Trap

3 = Oxygen Trap

4 = Indicating Oxygen Trap

5 = Gas Purification System

6 = Combination Trap for moisture, oxygen, and hydrocarbon removal

Order online at www.agilent.com/chem/store |

5 |

|

|

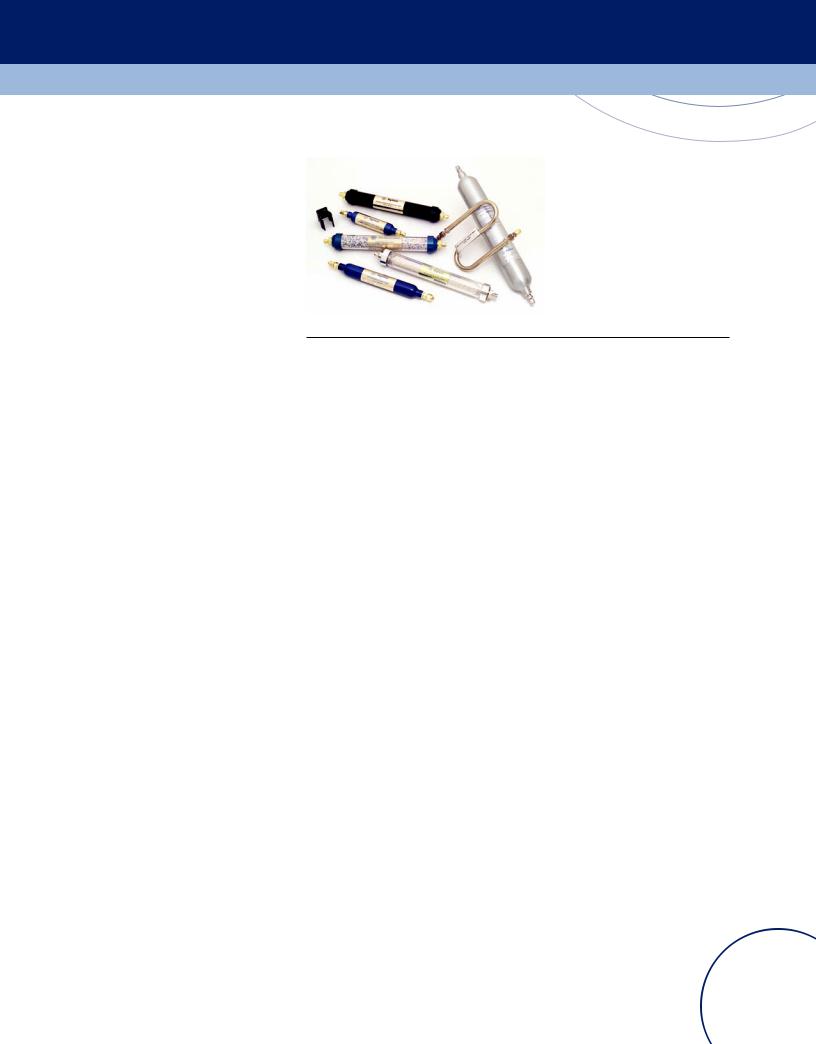

Gas Traps

The purpose of gas traps is to remove detrimental impurities from the carrier and detector gases. Combination traps are available which remove moisture, oxygen and/or organics with a single trap. The effectiveness of the traps depends on the initial quality of the gas.

Constant exposure of capillary columns to oxygen and moisture, especially at high temperatures, results in rapid and severe column damage. The use of oxygen and moisture traps for the carrier gas may extend column life and protect the instrument. Any moisture or oxygen introduced into the gas stream due to a leak will be removed by the trap until it expires.

6 Order online at www.agilent.com/chem/store

Gas Management

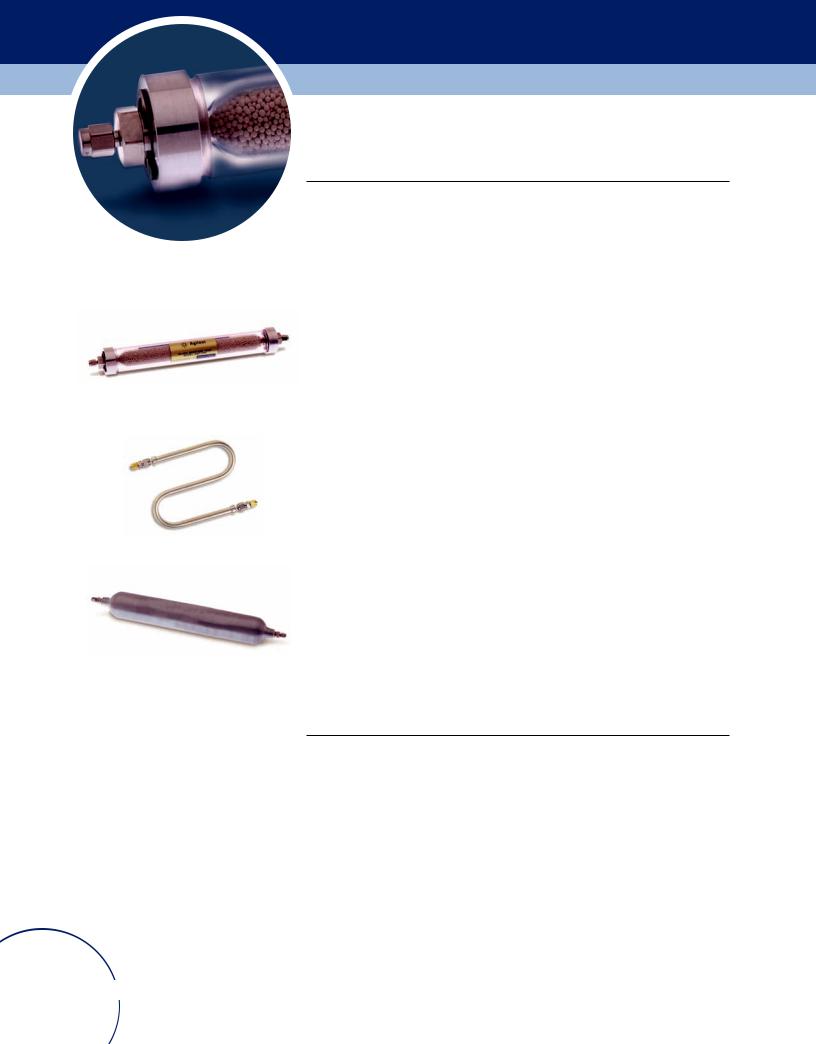

Moisture (Water) Traps

Indicating moisture traps are available in plastic and glass bodies. Glass body traps are used when potential contaminants from plastic trap bodies are a concern. Glass traps are normally encased in a protective, plastic shrink wrap or a high impact plastic shield (outer trap body). Glass and plastic bodied traps are usually pressure tested at 150 psi, thus they are safe for use at the typical pressures required by the GC.

Tips & Tools

Moisture traps are highly recommended for carrier and ECD gases.

Moisture trap

Moisture Traps

Description |

Size |

Removal |

Max. |

1/8 in. |

1/4 in. |

|

(cc) |

Capacity (g) |

Effluent H2O |

Part No. |

Part No. |

|

|

|

Concentration |

|

|

|

|

|

(ppb) |

|

|

|

|

|

|||

Molecular Sieve 13X and Indicating 4A (MT Series) |

|

|

|||

|

|

|

|

|

|

Refillable |

120 |

21.6 |

20 |

MT120-2 |

MT120-4 |

Moisture Trap |

|

|

|

|

|

|

|

|

|

|

|

Refillable |

200 |

36.0 |

18 |

MT200-2 |

MT200-4 |

Moisture Trap |

|

|

|

|

|

|

|

|

|

|

|

Refillable |

400 |

72.0 |

14 |

MT400-2 |

MT400-4 |

Moisture Trap |

|

|

|

|

|

|

|

|

|

||

Adsorbent refill (1 pint) for MT series |

|

MSR-1 |

MSR-1 |

||

|

|

|

|||

Molecular Sieve 5A and Indicating Drierite (MT-D Series) |

|

|

|||

|

|

|

|

|

|

Refillable |

120 |

21.6 |

22 |

MT120-2-D |

MT120-4-D |

Moisture Trap |

|

|

|

|

|

|

|

|

|

|

|

Refillable |

200 |

36.0 |

20 |

MT200-2-D |

MT200-4-D |

Moisture Trap |

|

|

|

|

|

|

|

|

|

|

|

Refillable |

400 |

72.0 |

16 |

MT400-2-D |

MT400-4-D |

Moisture Trap |

|

|

|

|

|

|

|

|

|

||

Adsorbent Refill (1 pint) for MT-D Series |

|

MSR-2 |

MSR-2 |

||

|

|

|

|

|

|

Order online at www.agilent.com/chem/store |

7 |

|

|

Refillable glass moisture trap

Moisture S-trap

Big moisture trap

Moisture Traps

Description |

Size |

Removal |

Max. |

1/8 in. |

1/4 in. |

|

(cc) |

Capacity (g) |

Effluent H2O |

Part No. |

Part No. |

|

|

|

Concentration |

|

|

|

|

|

(ppb) |

|

|

|

|

||||

Silica Gel, Grade 40, and Indicating Silica Gel, Grade 48 (MT-S Series) |

|

||||

|

|

|

|

|

|

Refillable |

120 |

31.5 |

40 |

MT120-2-S |

MT120-4-S |

Moisture Trap |

|

|

|

|

|

|

|

|

|

|

|

Refillable |

200 |

52.5 |

39 |

MT200-2-S |

MT200-4-S |

Moisture Trap |

|

|

|

|

|

|

|

|

|

|

|

Refillable |

400 |

105.0 |

39 |

MT400-2-S |

MT400-4-S |

Moisture Trap |

|

|

|

|

|

|

|

|

|

||

Adsorbent Refill (1 pint) for MT-S series |

|

SGR |

SGR |

||

|

|

|

|||

Glass Indicating Moisture Traps (GMT and LGMT Series) |

|

|

|||

|

|

|

|

|

|

Glass Indicating |

70 |

11.4 |

7 |

GMT-2GC-HP |

GMT-4GC-HP |

Moisture Trap |

|

|

|

|

|

|

|

|

|

|

|

Glass Indicating |

100 |

16.3 |

6 |

GMT-2-HP |

GMT-4-HP |

Moisture Trap |

|

|

|

|

|

|

|

|

|

|

|

Glass Indicating |

250 |

40.09 |

6 |

LGMT-2-HP |

LGMT-4-HP |

Moisture Trap |

|

|

|

|

|

|

|

|

|||

Molecular Sieve Refill for GMT and LGMT series |

GMSR |

GMSR |

|||

|

|

|

|

||

Moisture Removal S-Traps |

|

|

|

||

|

|

|

|

||

Moisture S-trap, preconditioned* |

|

5060-9084 |

|

||

|

|

|

|

||

Moisture S-trap, unconditioned |

|

5060-9077 |

|

||

|

|

|

|

||

Big Moisture Traps (BMT Series) |

|

|

|

||

|

|

|

|

|

|

Big Moisture |

750 |

|

|

BMT-2 |

BMT-4 |

Trap |

|

|

|

|

|

|

|

|

|

||

Refill for Big Moisture Trap (enough for 2 refills) |

|

BMSR-1 |

BMSR-1 |

||

*Traps can be reconditioned by heating at a minimum of 350°C, with flow for 6 hours

8 Order online at www.agilent.com/chem/store

Gas Management

Hydrocarbon Traps

Hydrocarbon traps remove organics, such as hydrocarbons and halocarbons, from the gas stream. The adsorbent is

usually activated carbon or an impregnated carbon filter media. Carbon removes organic solvents from the gas stream, including the typical solvents used

in nearly every lab. Hydrocarbon-moisture combination traps are also available which remove water in addition to organics.

Capillary grade hydrocarbon traps are purged with ultra-high helium and packed with a very efficient activated carbon material. Metal trap bodies are used to prevent any contaminants in plastic trap bodies from contaminating the carbon adsorbent. Most hydrocarbon traps

can be refilled by the end user.

Hydrocarbon trap, HT200-2

Hydrocarbon Traps

Description |

Size |

1/8 in. |

1/4 in. |

|

(cc) |

Part No. |

Part No. |

|

|

|

|

Hydrocarbon Traps (HT Series) |

|

|

|

|

|

|

|

Hydrocarbon Trap |

200 |

HT200-2 |

HT200-4 |

|

|

|

|

Adsorbent Refill (1 pint) |

|

ACR |

ACR |

|

|

|

|

Big Hydrocarbon Traps (BHT Series) |

|

|

|

|

|

|

|

Big Hydrocarbon Trap |

750 |

BHT-2 |

BHT-4 |

|

|

|

|

Refill for Big Hydrocarbon Trap (enough for two refills) |

|

BACR |

BACR |

|

|

|

|

Hydrocarbon Removal S-Traps |

|

|

|

|

|

|

|

Hydrocarbon S-Trap, used for trapping organics from gases |

|

5060-9096 |

|

|

|

|

|

Capillary Grade Hydrocarbon Traps (HT3 Series) |

|

|

|

|

|

|

|

Capillary Grade Hydrocarbon Trap |

100 |

HT3-2 |

HT3-4 |

|

|

|

|

Adsorbent Refill (1 pint) |

|

ACR |

ACR |

|

|

|

|

Tips & Tools

Hydrocarbon traps should be used with carrier, FID and ELCD gases.

Order online at www.agilent.com/chem/store |

9 |

|

|

Indicating oxygen trap, IOT-2-HP

Tips & Tools

Oxygen traps are critical on carrier gas supplies to prevent column bleed. They are also recommended with ECD.

Oxygen Traps

Oxygen traps usually include a metal-containing inert support reagent. Most oxygen traps reduce the oxygen concentration to below 15-20 ppb. The capacity of a standard oxygen trap is approximately 30 mg of oxygen per 100 cc of trap volume. Oxygen traps can also remove some small organic and sulfur compounds from gas streams, but this is not their primary application.

Metal (usually aluminum) trap bodies are recommended for GC analyses. Some plastics are permeable to air and contain contaminants that can degrade gas quality. In addition, many of the metal bodied oxygen traps can withstand high pressures (up to 2000 psi).

Some oxygen traps also remove moisture from the gas stream without affecting the oxygen removal capability.

Indicating oxygen traps change color when oxygen is present in the gas at harmful levels. Indicating traps are not intended to be the primary oxygen removal trap, but should be used in conjunction with a high capacity non-indicating oxygen trap. They are installed after the high capacity oxygen trap in the gas line to indicate when the high capacity trap has expired and needs to be changed. Expired oxygen traps need to be immediately changed since they can contaminate the gas, in addition to failing to remove oxygen.

Oxygen Traps

Description |

Size |

1/8 in. |

1/4 in. |

|

(cc) |

Part No. |

Part No. |

|

|

|

|

Indicating Oxygen Traps (IOT and LIOT Series) |

|

|

|

|

|

|

|

Indicating Oxygen Trap |

30 |

IOT-2-HP |

IOT-4-HP |

|

|

|

|

Large Indicating Oxygen Trap |

150 |

LIOT-2 |

LIOT-4 |

|

|

|

|

Economy Non-Indicating Oxygen Traps (OT1 Series) |

|

|

|

|

|

|

|

Oxygen Trap |

70 |

OT1-2 |

OT1-4 |

|

|

|

|

Big Oxygen Traps (BOT Series) |

|

|

|

|

|

|

|

Big Oxygen Trap |

750 |

BOT-2 |

BOT-4 |

|

|

|

|

10 Order online at www.agilent.com/chem/store

Gas Management

Combination Traps

Agilent carries several Combination Traps that provide multiple contaminant removal in a single trap. These traps offer:

•Optimized adsorbents for maximum surface area and capacity.

•Leak-free, one-piece design to eliminate potential leaks from using multiple traps.

•Efficient design which prevents channeling and promotes efficient scrubbing.

•The ultimate in purification with

the Big Universal Trap, which removes oxygen, moisture, hydrocarbons, carbon monoxide, and carbon dioxide.

Agilent OT3 trap

Combination Traps

Description |

Size |

1/8 in. |

1/4 in. |

|

(cc) |

Part No. |

Part No. |

|

|

|

|

Oxygen/Moisture Traps (OT3 Series) |

|

|

|

|

|

|

|

OT3 Trap |

100 |

OT3-2 |

OT3-4 |

|

|

|

|

Hydrocarbon/Moisture Traps (HMT Series) |

|

|

|

|

|

|

|

Hydrocarbon/Moisture Trap |

200 |

HMT200-2 |

HMT200-4 |

|

|

|

|

Adsorbant Refill (1 pint) |

|

HCRMS |

HCRMS |

|

|

|

|

Combination Traps for Chemical Ionization MS |

|

|

|

|

|

|

|

Chemical Ionization for MS* |

|

G1999-80410 |

|

|

|

|

|

Big Universal Traps (RMS Series) |

|

|

|

|

|

|

|

Hydrogen |

|

RMSHY-2 |

RMSHY-4 |

|

|

|

|

Helium (Ar/Me) |

|

RMSH-2 |

RMSH-4 |

|

|

|

|

Nitrogen |

|

RMSN-2 |

RMSN-4 |

|

|

|

|

*Isobutane or methane applications only |

|

|

|

Order online at www.agilent.com/chem/store |

11 |

|

|

NEW! Renewable Gas Purification System

The Renewable Gas Purification System from Agilent not only traps large quantities of contaminants and lasts a long time, but it is also recyclable. With average use, you'll only have to purchase a replacement cartridge once per year or after approximately 20 cylinders worth of purification. And when you need a replacement, you have the option to purchase a new or recycled cartridge. Recycled cartridges are refilled and certified to the full specification of the new cartridges.

•All cartridges are environmentally friendly and reduce waste.

•High capacity – 850cc or more Oxygen filtration, 12g H2O, and approximately 8g hydrocarbon filtration per cartridge – in a compact footprint.

•Improves 99.995% gas purity to 99.9995% purity.

•Dual indicators make it easy to see the purification results.

•Labeling displays indicator color and shape for accurate reading.

•Simple twist on/off knob and guide rod make cartridge changes quick and easy.

•One Renewable Purifier system can support up to four GC systems.

•Designed with efficiency, safety, and environmental responsibility in mind.

Renewable Gas Purification System

Renewable gas purification system |

|

|

|

Description |

Part No. |

||

|

|||

|

|

|

|

|

Renewable gas purifier system startup kit |

G3440-60004 |

|

|

Includes one G3440-80007 base, one G3440-60003 renewable gas purifier |

|

|

|

cartridge, and wall or bench mount hardware. |

|

|

|

|

|

|

|

Renewable gas purifier system, base only |

G3440-80007 |

|

|

|

|

|

|

Renewable gas purifier cartridge, new |

G3440-60003 |

|

|

|

|

|

|

Renewable gas purifier recycled cartridge |

G3440-69003 |

|

|

|

|

12 Order online at www.agilent.com/chem/store

Gas Management

Split vent trap and cartridges, RDT-1020

Universal/External Split Vent Trap

Split vent traps stop environmental pollution. The split vent trap was designed to protect the lab environment from the contaminants released by split injection systems, which can vent up to 500 times the amount of sample reaching the detector into the laboratory's air. A replaceable, impregnated carbon filter media traps and eliminates a broad range of contaminants. The traps are also easy to change and come with three packs of replacement cartridges each. Replace approximately every six months.

Universal/External Split Vent Trap

Description |

Part No. |

|

|

Universal/external split vent trap with 3 cartridges, 1/8 in. Swagelock fitting |

RDT-1020 |

|

|

Replacement cartridges, 3/pk |

RDT-1023 |

|

|

Split vent trap kit |

G1544-60610 |

|

|

Tips & Tools

Replace split vent traps every six months.

Order online at www.agilent.com/chem/store |

13 |

|

|

Brass body regulator

Tips & Tools

When ordering a regulator, be sure to specify the proper connections. In the US, most gas manufacturers follow CGA connection guidelines. In Europe, there are a number of organizations designating cylinder connections that are specific to individual countries. It is best

to contact your local supplier for the proper connection designation.

Regulators

Agilent recommends using our economical brass body, dual stainless steel diaphragm regulators for most GC applications. These regulators, combined with the proper

gas purification system, provide proper gas pressure control and purity for gas chromatography.

Brass Body, Dual Stainless Steel Diaphragms, 1/8 in., U.S. Only*

Description |

Part No. |

|

|

CGA 346, 125 psig max (8.6 bar), Air |

5183-4641 |

|

|

CGA 350, 125 psig max (8.6 bar), H2, Ar/Me |

5183-4642 |

|

|

CGA 540, 125 psig max (8.6 bar), O2 |

5183-4643 |

|

|

CGA 580, 125 psig max (8.6 bar), He, Ar, N2 |

5183-4644 |

|

|

CGA 590, 125 psig max (8.6 bar), Air |

5183-4645 |

|

|

*For 1/4 in. tubing, purchase a 1/4 in. adapter, U.S. only |

|

Connectors (Swagelok to Female NPT)

Description |

Unit |

Part No. |

|

|

|

1/8 in. (A) x 1/4 in. (B) connector, brass (included with brass regulators) |

1/ea |

0100-0118 |

|

|

|

1/4 in. (A) x 1/4 in. (B) connector, brass* |

1/ea |

0100-0119 |

|

|

|

*Required for plumbing 1/4 in. tubing to regulators |

|

|

14 Order online at www.agilent.com/chem/store

Gas Management

Cleaning Tubing

Before any tubing is placed into service, or if it becomes contaminated with use, it is essential that it be properly cleaned.

Unclean or improperly cleaned tubing can lead to contamination of the system with disastrous results. Never use chlorinated solvents to clean tubing or fittings.

Agilent provides clean, high quality GC grade tubing for large systems as an economical alternative.

Tubing

Agilent recommends using copper tubing for most applications, since it is easy to bend and plumb and is less expensive than stainless steel. Use stainless steel tubing only for crucial applications that require very high purity, or where building codes mandate its use.

Determining Tubing Length

Parameters: 2000 sccm (4.2 scfh); Temperature: 70°F; Pressure 30 psig

Tubing Type |

Diameter |

Recommended |

Pressure Drop |

|

(inches) |

Max. Length (feet) |

(psig) |

|

|

|

|

Copper |

1/8 |

50 |

2 |

|

|

|

|

Copper |

1/4* |

300 |

0.5 |

*Recommended when multiple instruments are connected to the same source

Tubing - Precleaned

Description |

Part No. |

|

|

Copper tubing, 1/8 in., 50 ft |

5180-4196 |

|

|

Copper tubing, 1/8 in., 12 ft |

5021-7107 |

|

|

Fittings

Description |

Part No. |

|

|

Fittings Kit |

5180-4161 |

Includes brass nuts, ferrules, caps, plugs, unions and reducers |

|

|

|

1/8 in. brass nut and ferrule set |

5080-8750 |

|

|

Cylinder wall bracket

Description |

Part No. |

|

|

Cylinder wall bracket with strap & chain |

5183-1941 |

(cylinder size up to 14 in., 35 cm) |

|

|

|

Cylinder wall bracket, 5183-1941

Order online at www.agilent.com/chem/store |

15 |

|

|

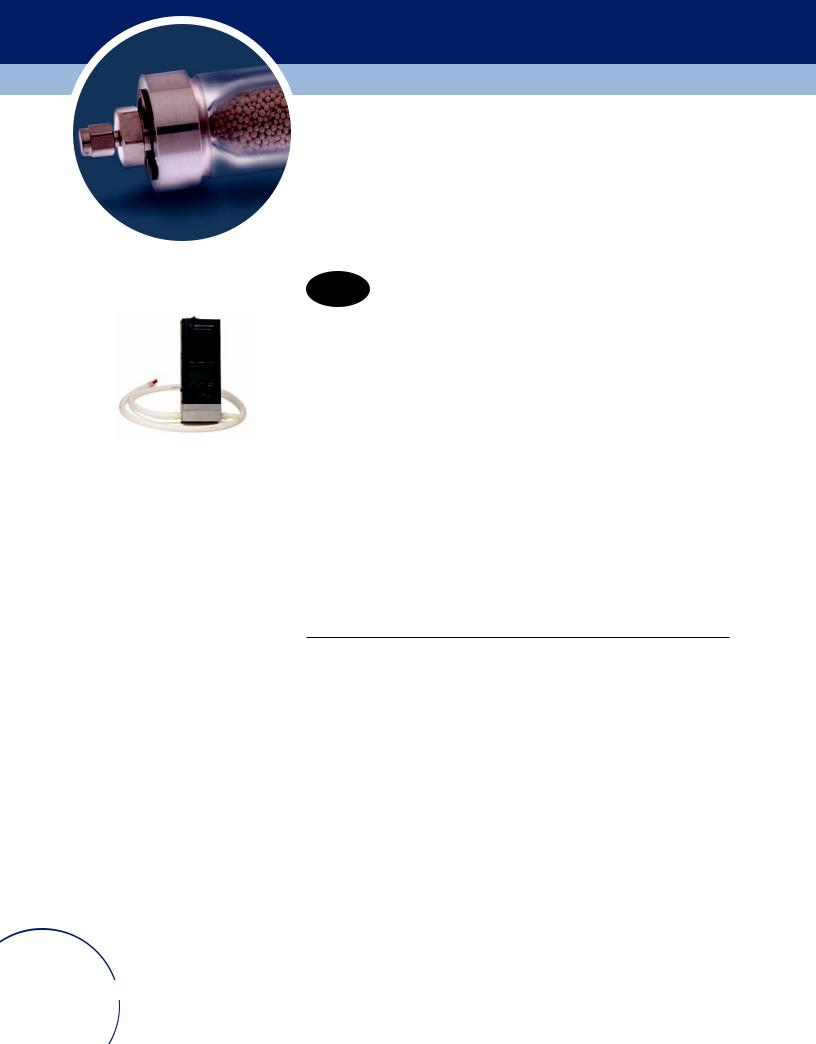

Precision gas flow meter, 5067-0223

Flowmeters

Setting and maintaining GC flow rates greatly affects the instrument accuracy and sensitivity. During maintenance, verify carrier and support gas flows with the proper flowmeter.

NEW! Precision Gas Flow Meter

Agilent's Precision Gas Flow Meter is the ultimate gas flowmeter for chromatography applications. This hand-held flowmeter incorporates industry leading performance and features in a highly accurate and reliable package. The inherent stability of the rugged, solid state components allows us to provide the longest calibration interval on the market, all traceable to NIST standards.

•Highly accurate and reliable measurement of common carrier and fuel gases used in GC, including nitrogen, air, carbon dioxide, hydrogen, helium, and argon/methane.

•Two year guaranteed calibration period traceable to NIST standards.

•Measures flow (0-500 mL/min.) based on gas viscosity properties with an accuracy of ± 0.8% of reading + 0.2% of full scale.

•Flow rate range from 0-500 mL/min (no conversion necessary from SCCM) eliminates the need for two separate meters to measure capillary and standard flows.

•Displays mass flow, volumetric flow, temperature, and pressure readings simultaneously.

•Can be plumbed inline.

Precision Gas Flow Meter

Description |

Part No. |

|

|

Precision gas flow meter |

5067-0223 |

|

|

16 Order online at www.agilent.com/chem/store

Gas Management

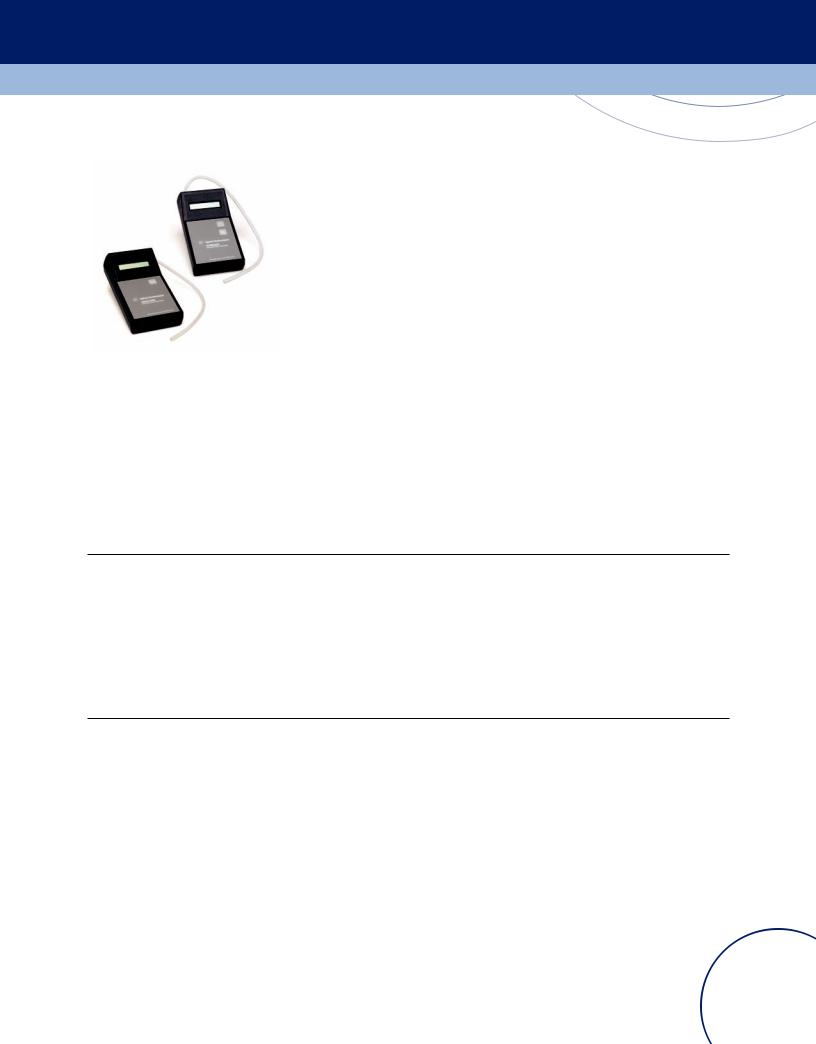

ADM 1000

•Accuracy ± 3%.

•Operating temperature range – 0 to 45ºC for the instrument, -70 to 135ºC for the tubing.

•Calibration – traceable to NIST primary standards.

•Real time, split ratio measurement.

•CE mark certified.

•Measures flow rates from 0.5 to 1000 mL/min.

•Split ratios – compare the ratio from one gas measurement to another (i.e., injection port split ratios).

ADM flowmeters

ADM 2000

In addition to the features of the ADM 1000, the ADM 2000 includes:

•Mass flow measurements – measure flow rate, independent of atmospheric pressure and temperature (calculated).

•Data output through RS-232 port.

•9V battery and AC power adapter (120 or 220 VAC).

ADM Flowmeters

Description |

Flow Rate |

Gases |

Accuracy (%) |

Power |

RS-232 |

Part No. |

|

|

(mL/min) |

Measured* |

|

Supply |

Data Output |

|

|

|

|

|

|

|

|

|

|

|

Low |

High |

|

|

|

|

|

|

|

|

|

|

|

|

|

ADM 1000** |

0.5 |

1000 |

All |

± 3 |

9V Battery |

None |

220-1170 |

|

|

|

|

|

|

|

|

ADM 2000** |

0.5 |

1000 |

All |

± 3 |

Battery or 120V AC |

Yes |

220-1171-U |

|

|

|

|

|

|

|

|

ADM 2000E** |

0.5 |

1000 |

All |

± 3 |

AC Adapter, 220V |

Yes |

220-1171-E |

|

|

|

|

|

|

|

|

Carrying Case for ADM |

|

|

|

|

|

|

907-0056 |

*± 3% or ± 0.2 mL/min, whichever is greater with a flow rate of 0.5 - 1,000 mL/min **Non-corrosive gases only

Order online at www.agilent.com/chem/store |

17 |

|

|

NEW! Gas Leak Detector

Gas leaks can cause detector noise and baseline instability, shorten column life and waste expensive carrier gas. Liquid leak detectors, although inexpensive, can contaminate your system. Agilent's G3388A electronic leak detector is an easy way to quickly identify leaks in your system.

Gas Leak Detector

Description |

Part No. |

|

|

Handheld electronic gas leak detector |

G3388A |

Includes probe, unit, AC power adapter/battery charger, battery, and user manual. |

|

|

|

Gas leak detector

Check valves, fittings, and traps for leaks after every maintenance and thermal cycling, as these can loosen some types of fittings.

Check for leaks at these connections:

• |

Gas supply bulkhead fittings |

|

|

|

• |

Traps |

|||||||||||||||||||||||||||||||||||||||||||||||||

• |

Gas cylinder fitting |

|

|

|

• |

Shut-off valves |

|||||||||||||||||||||||||||||||||||||||||||||||||

• |

Regulator fittings |

|

|

|

• |

T-fittings |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 Order online at www.agilent.com/chem/store

Sample Introduction

Ensure optimal peak shape and reproducibility through accurate sample delivery.

They may be small, but sample introduction supplies can have a profound impact on your results. That is why Agilent vials, septa, and syringes are meticulously engineered to work seamlessly with your GC and GC/MS instruments. They can help you achieve reliable, repeatable results even for your most complex runs.

This section guides you through…

•The selection, use, and maintenance of your essential sample introduction supplies.

•Troubleshooting common and unusual syringe problems.

•Essential procedures, such as vial filling, syringe cleaning, and choosing the right septa material for your application.

Order online at www.agilent.com/chem/store |

19 |

|

|

Agilent Certified Vials

Agilent certified vials undergo stringent testing of critical dimensions to ensure that each vial works flawlessly with your GC and GC/MS systems. Additionally, each certified vial is made from first hydrolytical class, borosilicate glass type 1 then packed in a clean, sealed environment to prevent contamination.

Vials

Agilent's wide opening vials are designed specifically for analyzing samples with your GC. They have specially designed vial neck angles, bottom design, and height to ensure compatibility with Agilent autosamplers with rotating or robotic arm trays. Agilent offers a large variety of autosampler vials in different closures, cap colors, septa choices,

and package options. Agilent also offers convenience packs with 500 vials and caps in a reusable blue storage box.

For small samples sizes, Agilent offers a variety of options. You can use microvolume inserts with the wide opening vials or, for added convenience, use vials with small volume capacity.

Vial Options

Glass - for general purpose |

Silanized - for use with |

use and for use with acids |

samples that bind to glass, |

|

and for trace analysis |

Polypropylene - for use with |

High Recovery Vials - |

alcohols and aqueous solvents |

for use with limited sample vials |

Amber Vials - for use with |

Microvolume Inserts - |

light-sensitive samples |

for use with very small |

|

sample volumes |

20 Order online at www.agilent.com/chem/store

Sample Introduction

Vial Filling

When filling sample vials, keep in mind:

•If you need to test a large amount of sample over repeated injections, divide the sample among several vials to obtain reliable results.

•When sample volume in the vial is low, contaminants from the previous sample injection or solvent washes may have a greater impact on the sample.

The airspace in the vial is necessary to avoid forming a vacuum when sample is withdrawn. This could affect reproducibility.

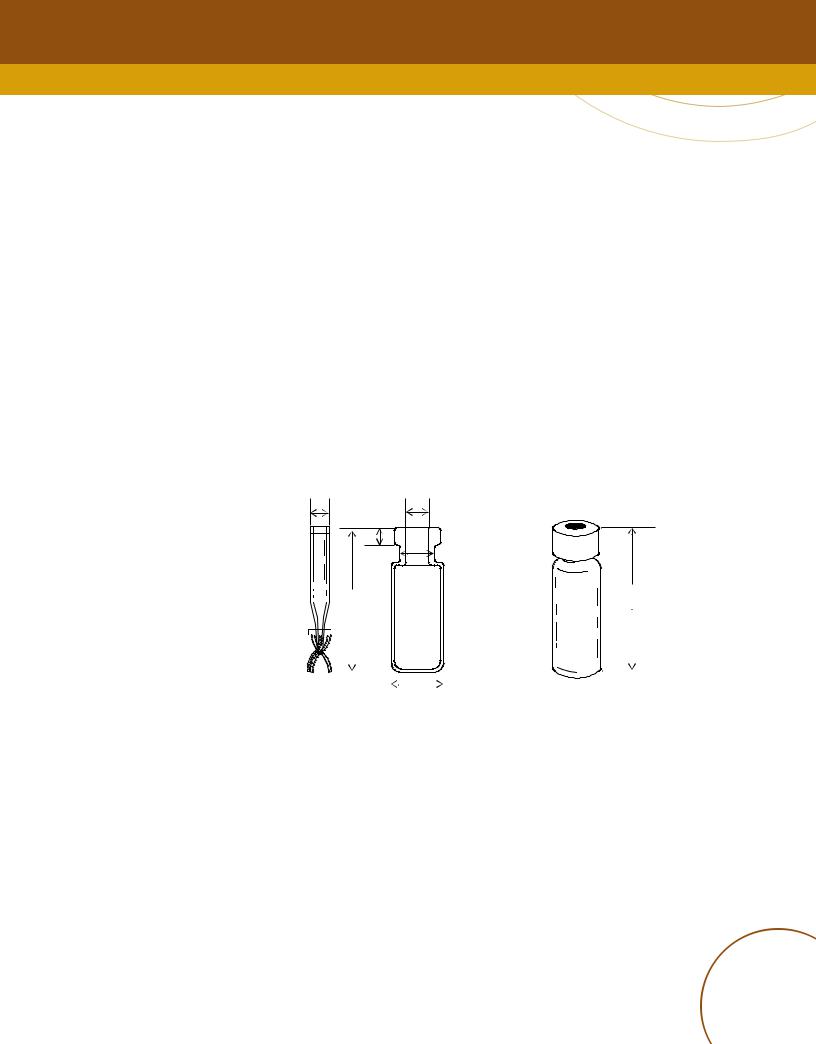

Preparing Sample Vials

The Agilent 7683 Automatic Liquid Sampler Injector and the tray use clear or amber glass sample vials with crimp, snap, or screw top vials. The following diagram shows the critical dimensions for sample vials and microvial inserts to be used with the 7683 Automatic Liquid Sampler. These dimensions do not make up a complete set of specifications. Incompatible sample vials cause tray and turret errors.

5 minimum |

6.25 |

3.7 |

|

|

8.2 |

32 |

34.5 maximum |

|

|

|

|

|

|

|

|

11.7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Microvial insert |

Crimp cap sample vial |

Maximum height of a capped vial |

|||||||||

|

|

|

|

|

|

|

All dimensions in millimeters |

|

|

|

|

Order online at www.agilent.com/chem/store |

21 |

|

|

Selecting Vial Septa Materials

Vial cap septa are critically important to optimal analysis. Each septum complements the overall system and enhances chemical performance. Agilent's vial cap septa are specifically formulated and constructed for optimum system performance, with minimal coring and superior chemical inertness.

|

Type |

Uses |

|

|

|

|

|

|

Red Rubber/PTFE |

• |

Routine analysis |

|

|

• |

Moderate resealing |

|

|

• |

Excellent chemical inertness |

|

|

• |

Not recommended for multiple injections or storage of samples |

|

|

• |

Least expensive |

|

|

|

|

|

Silicone/PTFE |

• |

Excellent resealing |

|

|

• |

Resists coring |

|

|

• |

Good for multiple injections |

|

|

|

|

|

PTFE/Silicone/PTFE |

• |

Used in trace analysis applications |

|

|

• |

Above average resealing |

|

|

• |

Most resistant to coring |

|

|

• |

Least evaporation |

|

|

• |

Use with large diameter, blunt tip syringe needles |

|

|

|

|

|

PTFE Disc |

• |

Good for MS and ECD analysis |

|

|

• |

Good for large-volume injections |

|

|

• |

Chemically inert |

|

|

• |

No resealing |

|

|

• |

Single injection |

|

|

• |

No long-term sampling storage |

Tips & Tools |

|

|

|

Viton |

• |

Chlorinated solvents |

|

To determine potential septa |

|

• |

Organic acids |

|

• |

Limited resealing |

|

quantities, consider: |

|

||

|

• |

Not suitable for 32 guage syringe |

|

•The number of samples run during a day/week.

•If samples are run in small or large batches.

•If samples are run manually or with an autosampler.

•If samples are run overnight, unattended.

22 Order online at www.agilent.com/chem/store

Sample Introduction

Convenience vial and cap pack

Convenience Vial and Cap Packs

Vials |

Caps |

Unit |

Part No. |

|

|

|

|

Certified Screw Top Vial Convenience Packs |

|

|

|

|

|

|

|

Clear |

Blue screw caps, PTFE/red |

500/pk |

5182-0732 |

|

rubber septa |

|

|

|

|

|

|

Clear with write-on spot |

Blue screw caps, PTFE/red |

500/pk |

5182-0867 |

|

rubber septa |

|

|

|

|

|

|

Amber with write-on spot |

Green screw caps, PTFE/red |

500/pk |

5182-0733 |

|

rubber septa |

|

|

|

|

|

|

Clear |

Blue screw caps, |

500/pk |

5182-0736 |

|

PTFE/silicone/PTFE septa |

|

|

|

|

|

|

Clear with write-on spot |

Blue screw caps, |

500/pk |

5182-0869 |

|

PTFE/silicone/PTFE septa |

|

|

|

|

|

|

Amber with write-on spot |

Green screw caps, |

500/pk |

5182-0737 |

|

PTFE/silicone/PTFE septa |

|

|

|

|

|

|

Clear |

Blue screw caps, PTFE/silicone |

500/pk |

5182-0734 |

|

septa |

|

|

|

|

|

|

Clear with write-on spot |

Blue screw caps, PTFE/silicone |

500/pk |

5182-0868 |

|

septa |

|

|

|

|

|

|

Amber with write-on spot |

Green screw caps, PTFE/silicone |

500/pk |

5182-0735 |

|

septa |

|

|

|

|

|

|

Clear |

Blue screw caps, pre-slit |

500/pk |

5183-2079 |

|

PTFE/silicone septa |

|

|

|

|

|

|

Clear with write-on spot |

Blue screw caps, pre-slit |

500/pk |

5183-2080 |

|

PTFE/silicone septa |

|

|

|

|

|

|

Amber with write-on spot |

Green screw caps, pre-slit |

500/pk |

5183-2081 |

|

PTFE/silicone septa |

|

|

|

|

|

|

Clear |

Blue screw caps, pre-slit |

500/pk |

5067-0205 |

|

PTFE/silicone septa |

|

|

|

|

|

|

Order online at www.agilent.com/chem/store |

23 |

|

|

Convenience Vial and Cap Packs

Certified Crimp Top Vial Convenience Packs

Clear |

Silver aluminum crimp caps, |

500/pk |

5181-3400 |

|

PTFE/red rubber septa |

|

|

|

|

|

|

Amber with write-on spot |

Silver aluminum crimp caps, |

500/pk |

5181-8801 |

|

PTFE/red rubber septa |

|

|

|

|

|

|

Snap Top Vial Convenience Packs |

|

|

|

|

|

|

|

Clear |

Clear polypropylene snap caps, |

500/pk |

5182-0547 |

|

PTFE/red rubber septa |

|

|

|

|

|

|

Amber, with write-on spot |

Clear polypropylene snap caps, |

500/pk |

5182-0548 |

|

PTFE/red rubber septa |

|

|

|

|

|

|

Certified crimp top vial convenience pack

24 Order online at www.agilent.com/chem/store

Sample Introduction

Electronic Crimpers and Decappers

Whenever large amounts of crimp vials need to be crimped or decapped,

the electronic crimper or decapper is the right tool. It reduces stress and repetitive motion injury associated with manual plier-style crimpers and decappers. Agilent's newly-designed crimper offers easy, hand-held pushbutton operation and provides the following advantages:

•Stronger and sturdier crimping and decapping.

•Consistent seals.

•Shorter recharging time and a larger number of battery charges.

•Better clearance and more flexibility thanks to improved crimp jaws.

•Individual test certificates.

Electronic crimper, 5062-0207

Electronic Crimpers and Decappers

Description |

Part No. |

|

|

11 mm Electronic Crimper with 4.8v rechargeable battery pack and charger |

5062-0207 |

|

|

20 mm Electronic Crimper with 4.8v rechargeable battery pack and charger |

5062-0208 |

|

|

11 mm Electronic Decapper with 4.8v rechargeable battery pack and charger |

5062-0209 |

|

|

20 mm Electronic Decapper with 4.8v rechargeable battery pack and charger |

5062-0210 |

|

|

4.8v nickel metal hydride replacement battery |

5188-6565 |

|

|

Tips & Tools

For a consistent seal, make sure there are no folds or wrinkles on the part of the cap that wraps under the neck of the vial.

Order online at www.agilent.com/chem/store |

25 |

|

|

Gold Standard Autosampler Syringes

With a broad selection of syringes for auto injection, Agilent has what you need for accurate and effective sampling. Agilent delivers even more value in every autosampler syringe with the introduction of many new features in our line of Gold Standard GC Autosampler Syringes.

Agilent Gold Standard Autosampler syringes are designed:

•For reproducible sample volume delivery.

•Specifically for the Agilent inlet or autosampler.

•To maximize inlet septum lifetime.

Agilent Gold Standard Autosampler syringes feature:

•Lot numbers printed directly on the barrel with a corresponding Certificate of Conformance ensuring certified performance to all specifications.

•Gold protective cap on the fused needle, preventing the glass syringe barrel from chipping as it is pressed against the inlet.

Gold standard autosampler syringes

•Black ink and gold illuminating backing strip, for effortless viewing of the volume scale, which is easily discernible from imitators.

•Environmentally friendly packaging, an improved design that reduces waste.

•Individually sealed packaging, for contaminant-free use right out of the box.

Tips & Tools

Use syringe needles with an Agilent dual-taper needle or a conical tip. Sharptipped needles tend to tear the inlet septum and cause leaks. Also, a sharptipped needle tends to leave residual amounts of sample on the septum as it exits, resulting in a large solvent tail on the chromatogram.

26 Order online at www.agilent.com/chem/store

Sample Introduction

Needle Gauge Selection

•Syringe needles compatible with Agilent Automatic Liquid Samplers are 42 mm long and have an HP style or cone shaped tip.

•The Merlin Microseal requires 23 gauge needles.

•The smaller the gauge, the larger the needle diameter.

Needle Gauge Selection

Inlet |

Needle Gauge |

Column Type |

|

|

|

Packed, split or splitless (including |

23 gauge or 23/26 gauge tapered |

Any |

PTV) |

|

|

|

|

|

Cool on-column |

23/26 gauge tapered or 26 gauge |

530 µm |

|

|

|

Cool on-column |

26/32 gauge tapered |

320 µm |

|

|

|

Cool on-column |

26/32 gauge tapered |

250 µm |

|

|

|

Needle Tip Needle Shape

Needle tips

Tips & Tools

For highest productivity and to minimize coring, use Agilent Premium Non-Stick Inlet Septa with Center Point Guide.

See page 46.

Cone tip |

Tapered needle |

Order online at www.agilent.com/chem/store |

27 |

|

|

Syringe Characteristics and Recommended Uses

Syringe |

Advantage |

Limitations |

Recommended Use |

|||

|

|

|

|

|

|

|

10 µL, PTFE-tipped |

• |

Less plunger binding than fitted |

• |

More expensive than fitted plunger |

• |

High sample throughput |

|

|

plunger |

• |

PTFE-tipped syringes not available |

• |

Samples in polar solvents |

|

• |

Replaceable plunger for reduced |

|

in 5 µL size |

• |

Dirty samples |

|

|

repair cost |

|

|

• |

Gases and volatile samples |

|

• |

Tight seal between plunger and barrel |

|

|

• |

Reactive samples |

|

|

|

|

|

|

|

10 µL, fitted plunger |

• |

Most economical |

• |

Most accurate only for 1 µL and |

• |

General purpose syringe |

|

• |

Most reliable fitted plunger syringe |

|

larger injections |

• |

Clean samples |

|

• |

Less bending |

• |

Plunger not replaceable |

• |

Routine analysis |

|

• |

Better for high viscosity samples |

|

|

|

|

|

|

|

|

|

|

|

5 µL, fitted plunger |

• |

Most accurate for 1 µL injection |

• |

Thinnest plunger, can bend more |

• |

1 µL injections |

|

• |

No hardware modification needed for |

|

easily |

• |

Clean samples |

|

|

0.5 µL |

• |

Not ideal for higher viscosity |

• |

Routine analysis |

|

|

|

|

samples |

|

|

|

|

|

• |

Plunger not replaceable |

|

|

|

|

|

|

|

|

|

28 Order online at www.agilent.com/chem/store

Loading...

Loading...